Ultrasonic bubble column rectification device and method

An ultrasonic and bubble-cap tower technology, applied in the field of ultrasonic bubble-cap tower rectification devices, can solve the problems of loss of economic benefits, increase of investment in equipment transformation and equipment, increase of start-up and parking costs, material consumption and energy consumption, etc., and achieve the elimination of laminar flow Effect, good social benefit, effect of simple equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

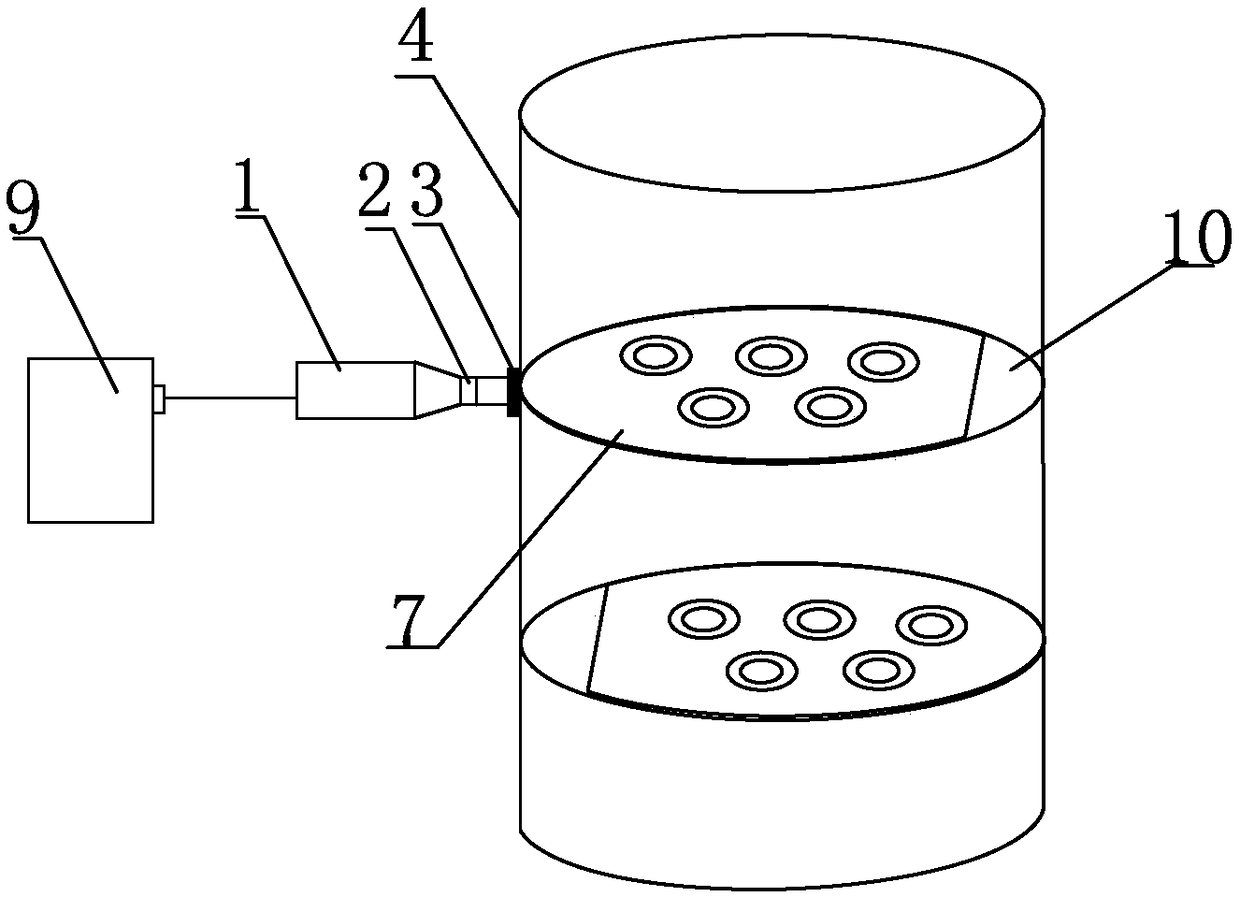

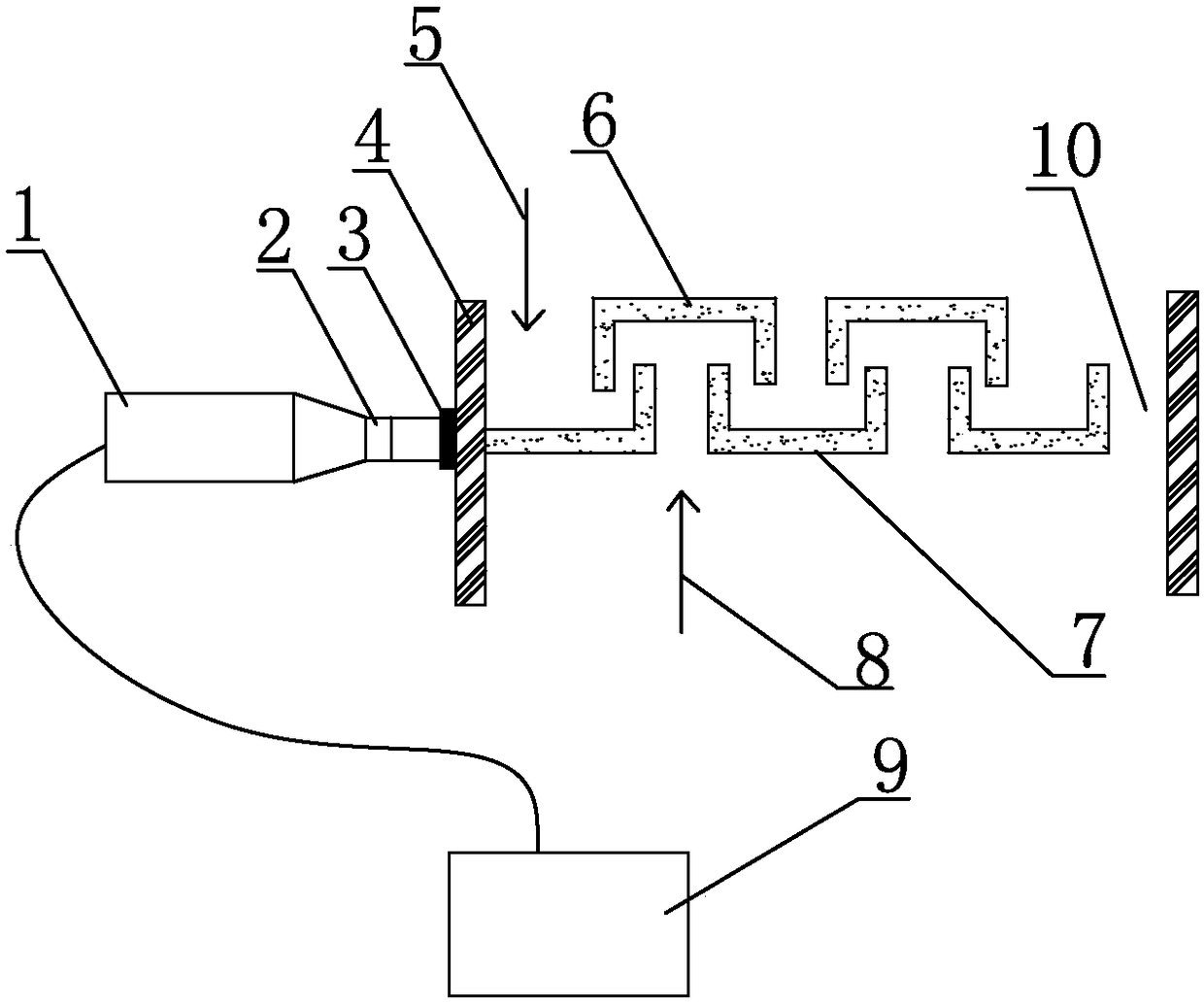

[0040] An ultrasonic bubble column rectification device, such as figure 1 with figure 2 Shown, comprise bubble cap column, comprise a plurality of trays 7 and bubble cap 6 in the bubble cap column, also comprise supersonic generator 9, a distributor 3 is arranged on the position corresponding to one of the trays 7 on the bubble cap column outer wall 4 , the distributor 3 is connected to the ultrasonic generator 9 through the ultrasonic transducer 1; the angle between the ultrasonic transducer 1 and the distributor 3 is 45°-135°. A cooler 2 is provided between each distributor 3 and its corresponding ultrasonic transducer 1 .

[0041] In the distillation method using an ultrasonic distillation device, the raw materials are sent into the bubble tower for distillation and separation, and the liquid phase material 5 descending in the tower and the gas phase material 8 rising in the tower are contacted on the tray 7 for reverse heat and mass transfer, At the same time, one of th...

Embodiment 2

[0043] In order to compare the effect of the sparger, an experimental verification was carried out on a gasoline rectification pilot plant to remove heavy components in a certain gasoline, using an ordinary bubble cap column (not loaded with ultrasonic waves), loaded with ultrasonic waves but not connected to a sparger, and Experimental evaluation was carried out using the device and process of Example 1 of the present invention. The test was carried out for 2 hours, and the process conditions were: the number of distillation column trays was 40, the reflux ratio was 3.5, the sparger used in the test process was a carbon steel structure, the thickness was 10mm, the sparger was a curved surface, and the sparger area was 0.2m 2 , the distributor is connected to the tray by flange compression, the ultrasonic frequency is 20Khz, the angle between the transducer and the distributor is 90°, and the ultrasonic sound intensity is 0.2w / cm 2 .

[0044] Adopt ordinary bubble cap tower (...

Embodiment 3

[0049] In order to compare the effect of different angles between the ultrasonic transducer and the distributor on the separation effect of the rectification tower, an experiment was carried out on a gasoline rectification pilot plant to remove heavy components in a certain gasoline, and ordinary bubble cap towers were used respectively. (unloaded ultrasonic wave), 45 ° of ultrasonic loading angle (using the device of embodiment 1 of the present invention, the only difference is that the angle between the ultrasonic transducer and the distributor is 45 °) and 90 ° of ultrasonic loading angle (using the present invention In the device of embodiment 1, the only difference is that the angle between the ultrasonic transducer and the distributor is 90°) and the experimental evaluation was carried out under the process. The test was carried out for 2 hours, and the process conditions were: the number of distillation column trays was 40, the reflux ratio was 3.5, the sparger used in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com