Parallelly-distributed ultrasonic bubble column rectification device and method

An ultrasonic and bubble column technology is applied in the field of parallel distributed ultrasonic bubble column rectification devices, which can solve the problems of increased investment in device renovation and equipment investment, loss of economic benefits, increased start-up and parking costs, material consumption and energy consumption, etc. The effect of operation and management mode, prolonging service life and reducing labor intensity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

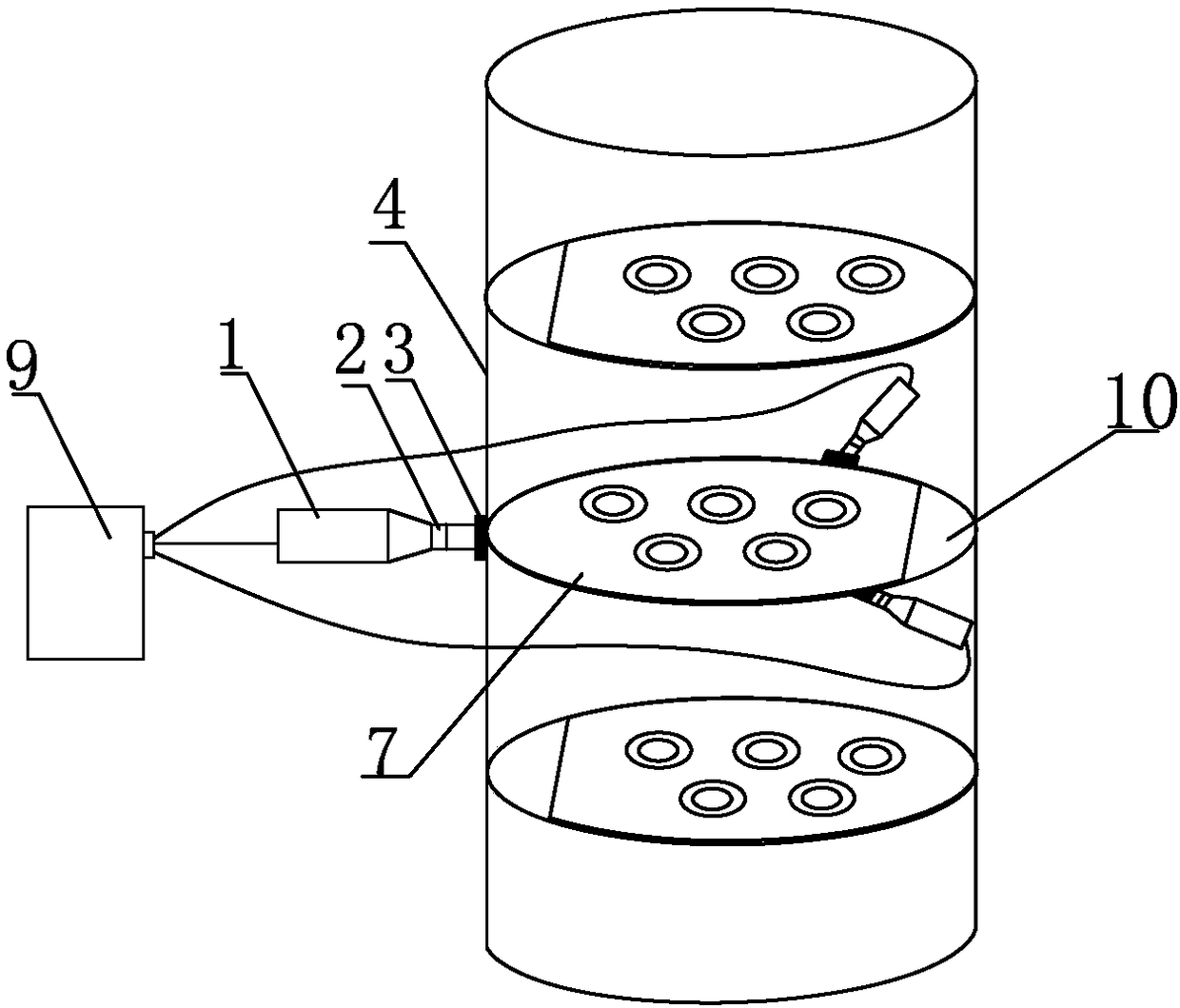

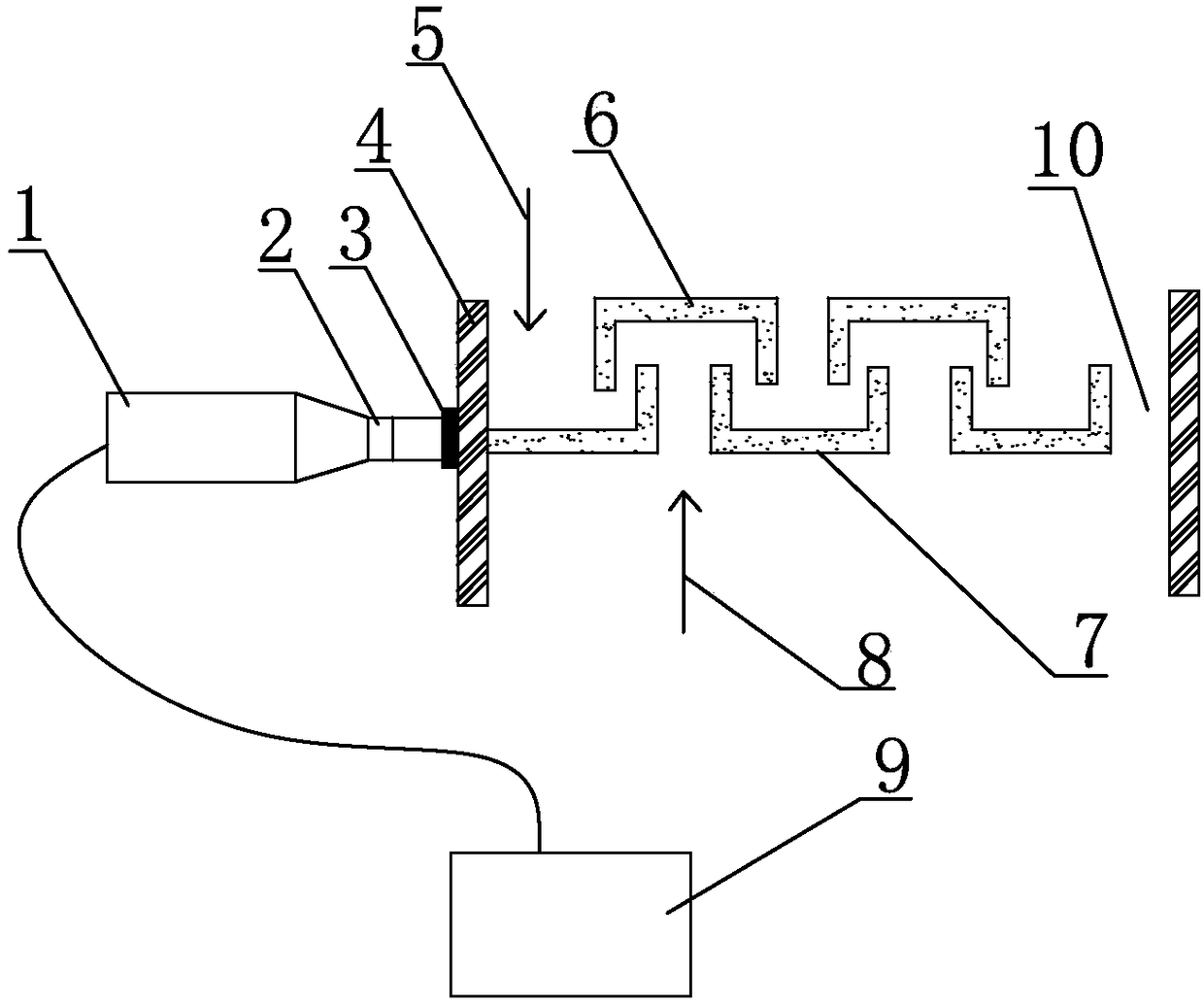

[0044] A parallel distributed ultrasonic bubble column rectification device, such as figure 1 and figure 2 Shown, comprise bubble cap column, comprise a plurality of trays 7 and bubble cap 6 in the bubble cap column, also comprise supersonic generator 9, on the position corresponding to one of the trays 7 on the outer wall of bubble cap column, three distributors are set 3. Each distributor 3 is connected to the ultrasonic transducer 1, one distributor 3 corresponds to one ultrasonic transducer 1, the angle between the ultrasonic transducer 1 and the distributor 3 is 45°-135°, the ultrasonic transducer 1 is connected with ultrasonic generator 9 again. The connection mode between the ultrasonic transducer 1 and the ultrasonic generator 9 is welding or flange connection. A cooler 2 is provided between each distributor 3 and its corresponding ultrasonic transducer 1 . The distributor 3 is made of metal, and the outer surface of the distributor 3 is a curved structure.

[004...

Embodiment 2

[0048] The present invention is an implementation of parallel ultrasonic bubble cap towers in an 800kt / a heavy oil catalytic cracking unit.

[0049] In a refining heavy oil catalytic cracking unit, the dry point of diesel products in the first half of 2015 was 365°C, which can meet the national V standard (diesel standard 2 , the sparger is connected to the tray by welding, the test process uses an ultrasonic frequency of 20Khz, the angle between the transducer and the sparger is 90°, and the ultrasonic sound intensity is 0.24w / cm 2 .

[0050] The bubble column device without ultrasonic waves, the product in the bubble column: the distillation range dry point of diesel oil is 368°C, there are many heavy components in the product, and the efficiency of the bubble cap tray is not enough, so the product cannot meet the factory quality requirements (diesel oil dry point <365°C); under the same process conditions, the efficiency of the ultrasonic bubble-cap tray is increased, and t...

Embodiment 3

[0052] The present invention is an implementation of parallel ultrasonic bubble cap towers in a 1400kt / a heavy oil catalytic cracking unit.

[0053] For a heavy oil catalytic cracking unit in a refinery, the designed feed rate is 170 tons / hour. In the first half of 2016, the content of polycyclic aromatic hydrocarbons in diesel products was 10.5%. PAHs are an important type of environmental and food pollutants , a considerable part is carcinogenic, the national standard V diesel oil standard stipulates that the content of polycyclic aromatic hydrocarbons is less than 11%. In August 2016, the feed capacity of the device was increased by 15 tons per hour. The polycyclic aromatic hydrocarbons in diesel oil increased, and the content of polycyclic aromatic hydrocarbons increased to 11.2%, which failed to meet the national V diesel polycyclic aromatic hydrocarbon content 2 , the sparger is connected to the tray by welding, the test process uses an ultrasonic frequency of 20Khz, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com