A device for reducing the fluctuation range of the liquid level on the tray

A technology of liquid level fluctuations and trays, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve liquid level fluctuations on trays, manufacturing cost constraints, and reduced tray efficiency and other problems, to achieve the effect of increasing turbulence, increasing weight, and increasing liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

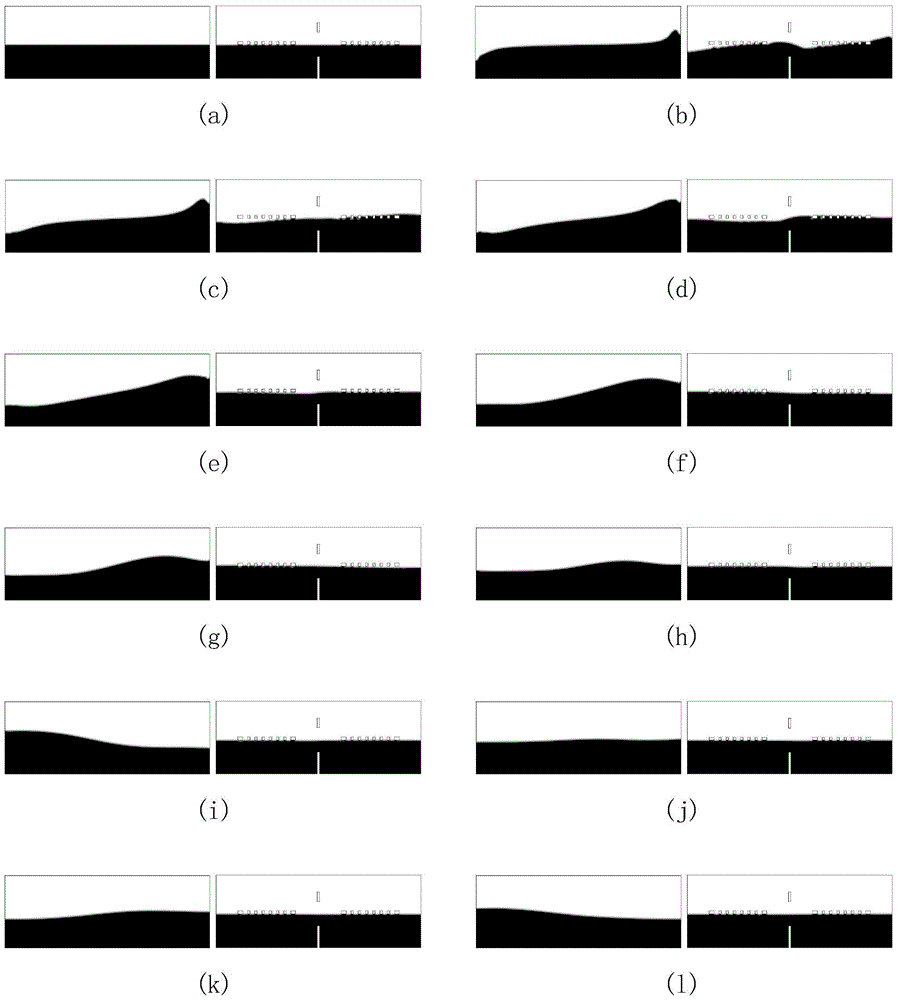

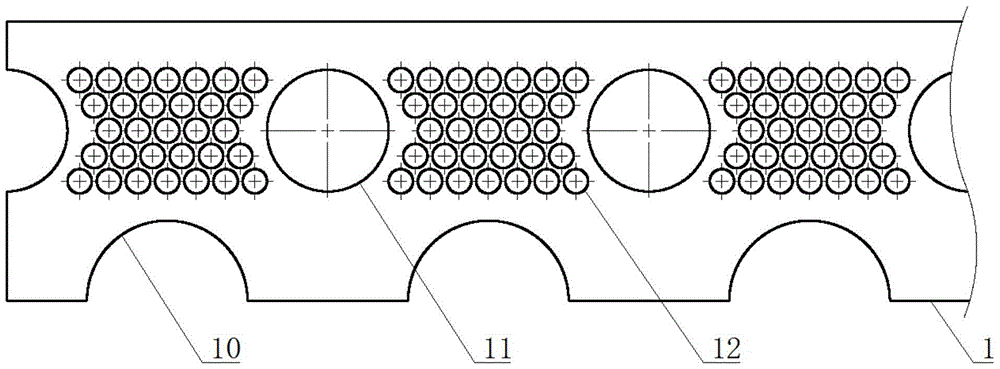

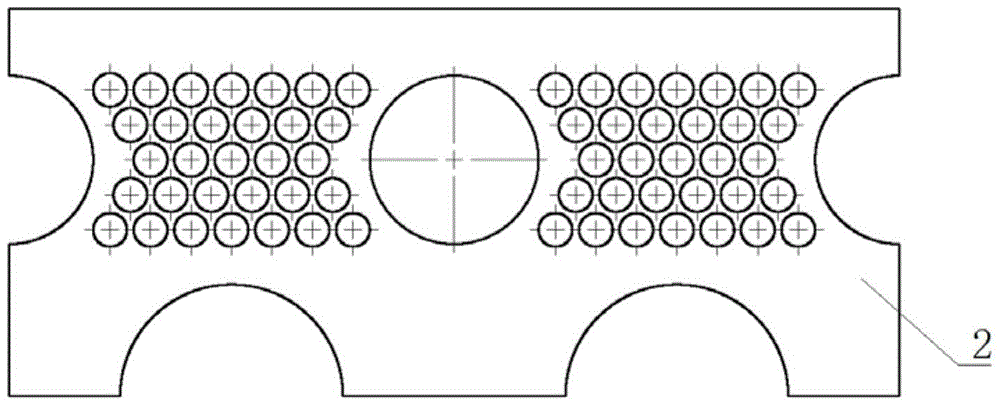

[0032] exist figure 1 In the schematic diagram of the front view of the device for reducing the fluctuation of the liquid level on the tray, the vertical liquid separator has a plate-shaped base, the height of which is 40 mm greater than the height of the liquid layer on the tray, and its length is There are two specifications, the length of the longer plate-shaped substrate is equal to the width of the gas-liquid contact area on the tray, and the length of the shorter plate-shaped substrate is twice the diameter of the semicircular slot hole than the length of the longer plate-shaped substrate. The lower edge of the strip-shaped substrate is provided with several semicircular slots, and the distance between two adjacent semicircular slots is equal to the diameter of the semicircular slots. There is a large-diameter circular through hole with a radius equal to twice the height of the liquid layer on the overflow weir. The center of the large-diameter circular through-hole is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com