Novel guide solid valve tower plate

A oriented and new type of technology, which is applied in chemical equipment and gas-liquid mass transfer fields, can solve the problems of restricting the opening height of the valve plate and the small side clearance area of the solid valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

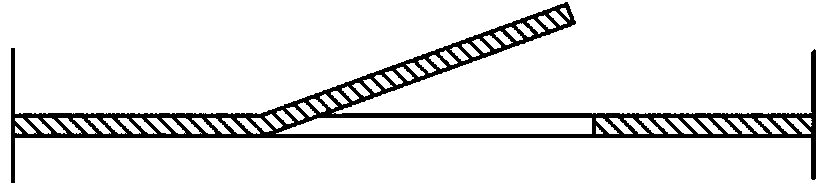

[0050] When the liquid flow intensity on the valve orifice 2 (that is, the liquid flow rate per meter of weir length) L Figure 6 As shown, the liquid on the upper tray flows into the open area of the valve orifice plate 2 through the liquid tray 1, and carries out gas-liquid contact with the gas phase flowing out from the first guide solid valve 4 and the second guide solid valve 5 on the tray, and then The gas rises and the liquid flows into the downcomer 3. The structural features of the first guiding solid valve 4 are as Figure 4a and 4b As shown, the valve plate 6 is directly punched out from the valve orifice plate 2, forming a valve hole 7 and a side gap 8 for gas circulation. The length of the valve hole 7 is 75mm, the width is 26mm, and the opening height of the valve plate 6 is 8-14mm. On the horizontal section of the valve plate 6, there is a small-sized fixed valve 10 of arch bridge type, and its valve hole 11 has a length of 24 mm and a width of 10 mm. At the ...

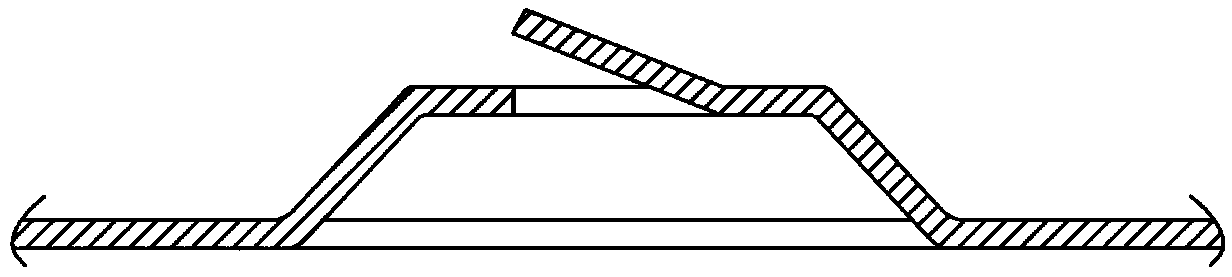

Embodiment 2

[0052] When the liquid flow intensity L=25~50m3 / m.h, the arrangement of the trays is as follows: Figure 7 shown. The structural features of the first guide valve 4 are as follows: Figure 4a and 4b As shown, the length of the valve hole 7 is 75mm, the width is 26mm, and the opening height of the valve plate 6 is 8-14mm. On the horizontal section of valve plate 6, be provided with the small solid valve 10 of arch bridge type, its valve hole 11 length is 24mm, and width is 10mm. The front end of the first guiding solid valve 4 is provided with a support plate 9 with a length of 16 mm and a thickness of 3 mm, which is only welded with the orifice plate 2 . Figure 7 The structural features of the second guiding valve 5 in Figure 5a and 5b As shown, the length of the valve hole 7 is 76mm, the width of the rear end of the valve hole is 30mm, the width of the front end is 22mm, and the opening height of the valve plate 6 is 8-14mm. The small solid valve 10 and the support pl...

Embodiment 3

[0054] When the liquid flow intensity L on the tray is >50m3 / m.h, the arrangement of the tray is as follows Figure 8 shown.

[0055] Its structural features of the first guiding solid valve 4 among the figure are as Figure 4a and 4b As shown, the length of the valve hole 7 is 75mm, the width is 26mm, and the opening height of the valve plate 6 is 8-14mm. The front end of the valve plate 7 is provided with a support plate 9 with a length of 16 mm and a thickness of 3 mm. The support plate 9 is only welded to the valve orifice plate 2 . Figure 8 The structural features of the second guiding solid valve 5 in Figure 5a and 5b As shown, the length of the valve hole 7 is 76mm, the rear end width is 30mm, the front end width is 22mm, and the opening height of the valve plate 6 is 8-14mm. The rest are basically the same as those of the above-mentioned first guiding valve 4 . Such as Figure 8 As shown, the second guide solid valve 5 is mainly arranged at the liquid inlet po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com