Semi-carbon wastewater treatment method

A technology of semi-charcoal wastewater and treatment methods, which is applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of non-recyclability and achieve the effect of improving biochemical ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

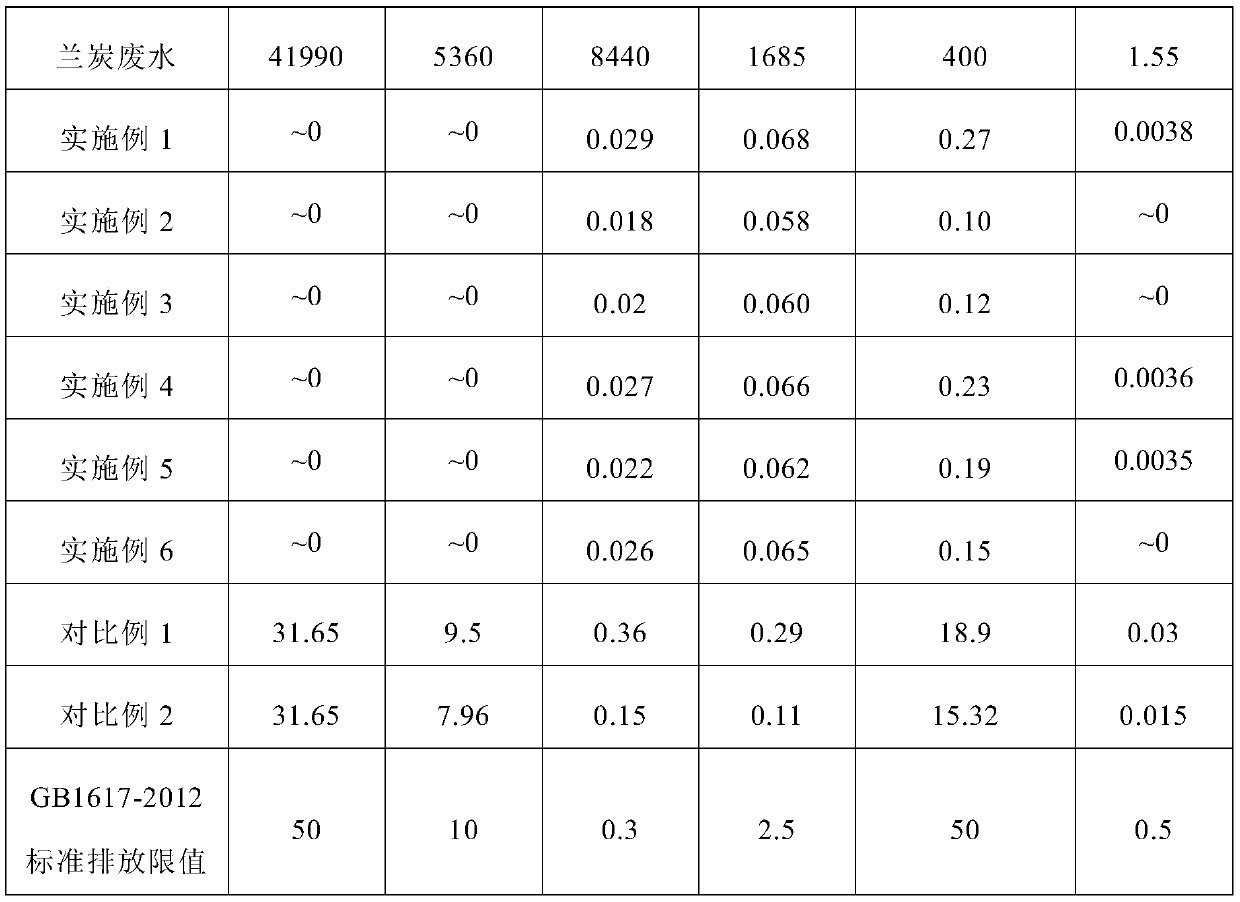

Embodiment 1

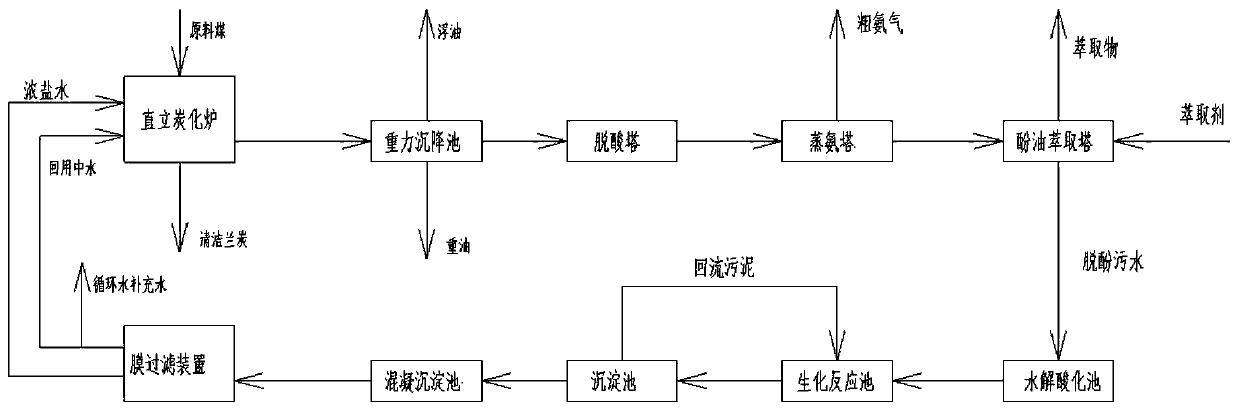

[0030] figure 1It is a process flow diagram of a specific example of the blue charcoal wastewater treatment method in Embodiment 1 of the present invention. The raw material lump coal enters the carbonization chamber from the upper part of the vertical carbonization furnace 9 at a speed of 16 t / h, and the temperature in the preheating section of the vertical carbonization furnace 9 is 350 ℃, the carbonization temperature is 750℃, the temperature in the upper part of the cooling section is 180℃, and the temperature in the lower part of the cooling section is 70℃. The factory carries out screening, obtains semi-coke product after screening, and the semi-coke waste water produced by vertical carbonization furnace 9 passes through steel concrete structure grease trap 10, obtains oil slick in the upper part, obtains heavy oil in the lower part, removes the sewage of heavy oil and oil slick from The middle part of the steel concrete structure grease trap 10 enters the entrance of th...

Embodiment 2

[0032] The semi-coke waste water treatment process that vertical carbonization furnace 9 produces is the same as embodiment 1, and the difference is that the process parameters of deacidification tower 1, deamination tower 2, and phenol oil extraction tower 3 are different, and the plate number of deacidification tower 1 in the present embodiment is 30. The operating pressure at the top of the tower is 0.4Mpa, the operating pressure at the bottom of the tower is 0.42Mpa, the temperature at the top of the tower is 43°C, the temperature at the bottom of the tower is 136°C, the reflux ratio is 4, and the number of plates of the deamination tower 2 is 40. The operating pressure is 0.5Mpa, the operating pressure at the bottom of the tower is 0.53Mpa, the temperature at the top of the tower is 142°C, the temperature at the bottom of the tower is 154°C, the reflux ratio is 6, the number of plates of the phenol oil extraction tower 3 is 75, and the operating pressure at the top of the t...

Embodiment 3

[0034] The semi-coke waste water treatment process that vertical carbonization furnace 9 produces is the same as embodiment 1, and the difference is that the process parameters of deacidification tower 1, deamination tower 2, and phenol oil extraction tower 3 are different, and the plate number of deacidification tower 1 in the present embodiment is 35, the operating pressure is 0.45Mpa, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 135°C. The reflux ratio is 5; 0.58Mpa, the temperature at the top of the tower is 140°C, the temperature at the bottom of the tower is 148°C, and the reflux ratio is 4; the number of plates in the phenol oil extraction tower 3 is 80, the operating pressure at the top of the tower is 200Kpa, and the operating pressure at the bottom of the tower is 210Kpa. The temperature is 55°C, the bottom temperature is 60°C, and the solvent ratio is 8:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com