Method for processing hyper-saline organic wastewater

A technology of organic waste water and treatment method, which is applied in the field of industrial waste brine treatment and high-salt organic waste water treatment, can solve environmental pollution and other problems, and achieve the effects of low industrial investment cost, reduced raw material consumption, and reduced organic matter content in waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

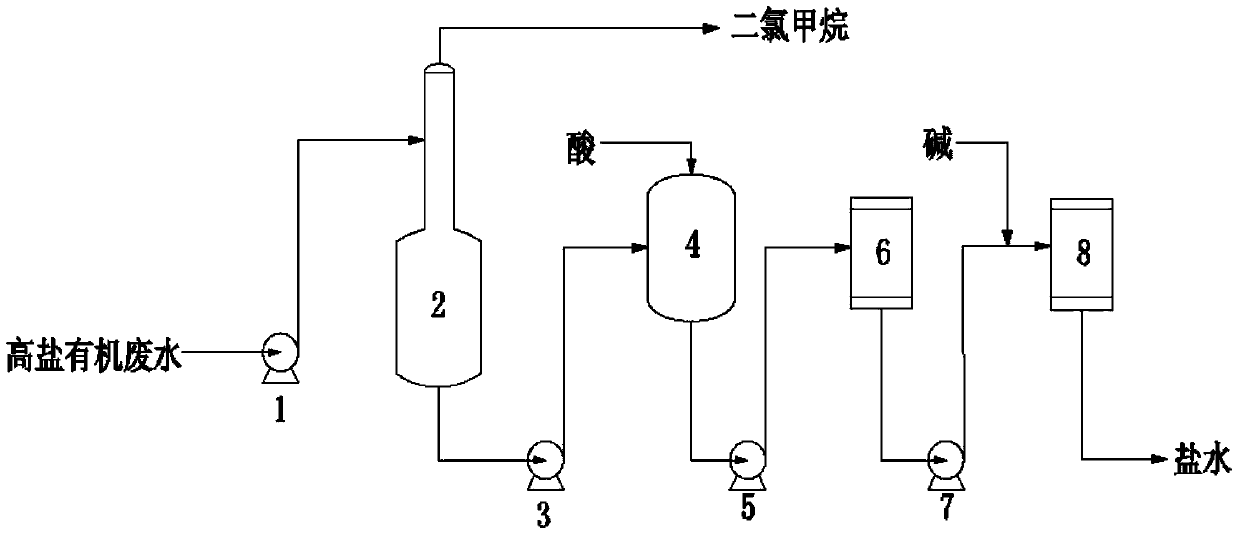

[0029] The waste water produced in the production process is 1~3m 3 / h, wherein the dichloromethane content is 1-10%, and the salt content is 5-15%. After the first delivery pump 1, it enters the stripping tower for dichloromethane stripping. The stripping tower is a packed tower, and the filling material is ceramic abalone Pall ring or 316L Pall ring, the thickness of the packing layer is 2-5m, and the spray density is 1-5L / m 3, wherein the gas introduced is water vapor, which enters from the bottom of the tower, and the waste water is sprayed from the top of the tower, and the two are in countercurrent contact, and the water vapor is low-pressure saturated steam. 0.5~0.2MPa, the vaporized dichloromethane enters the condensation recovery system through the gas phase outlet at the top of the tower, and 64kg / h of dichloromethane can be stripped with 200kg / h steam; the dichloromethane solvent is separated statically and returned to the production process to improve The utilizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com