Patents

Literature

37results about How to "Easy desorption and regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

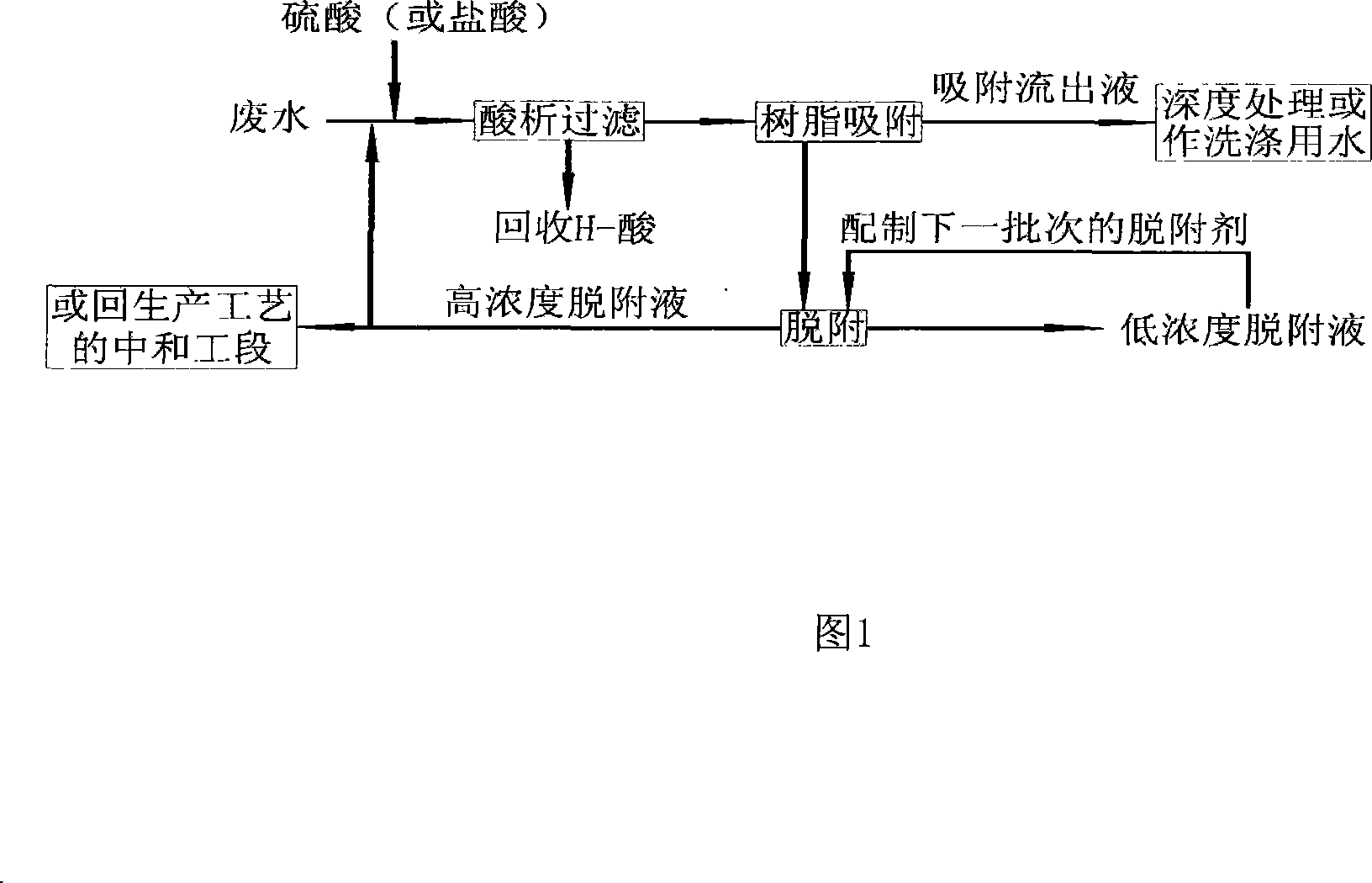

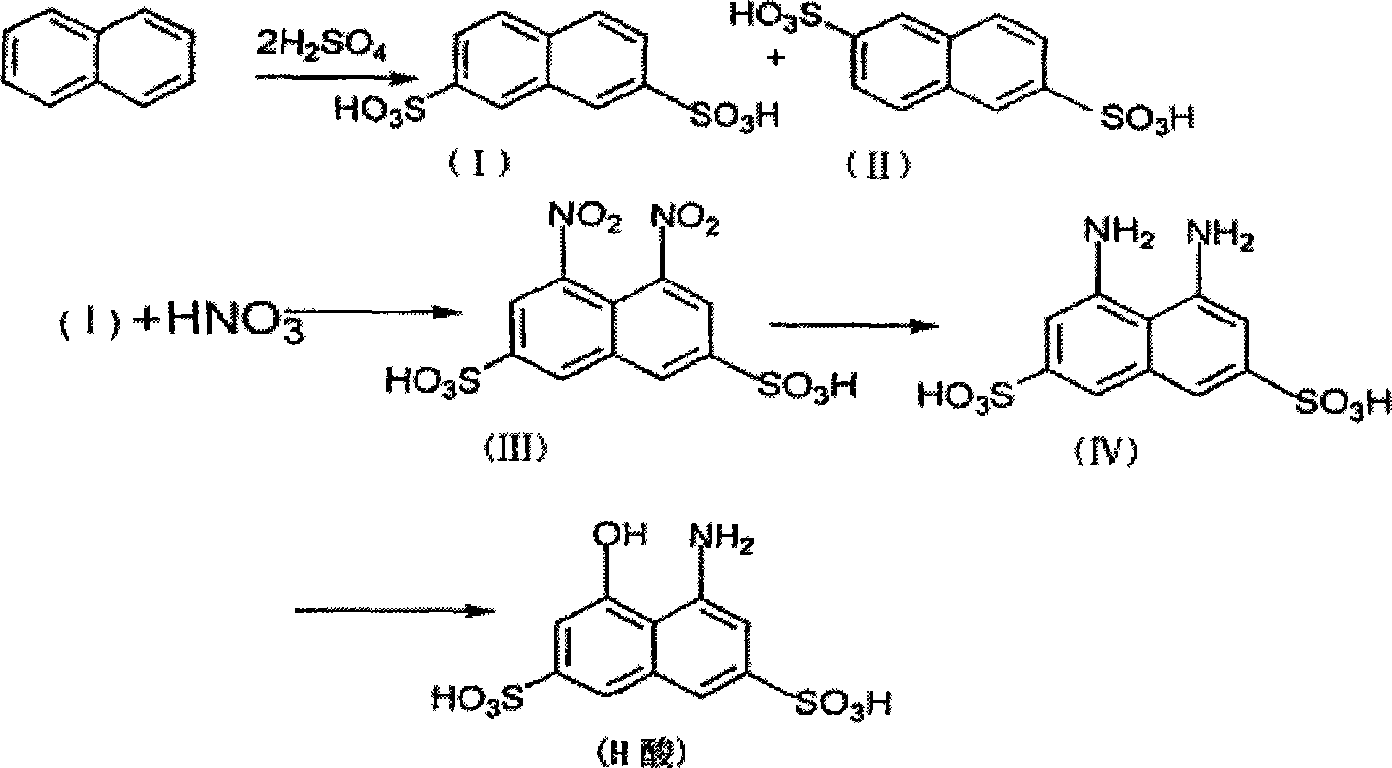

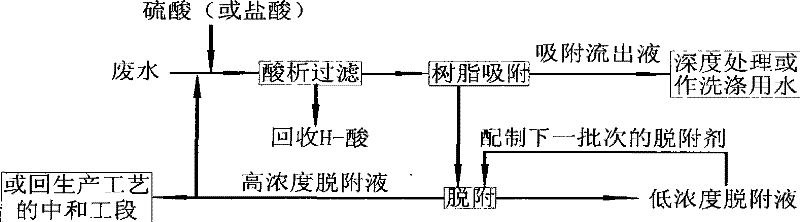

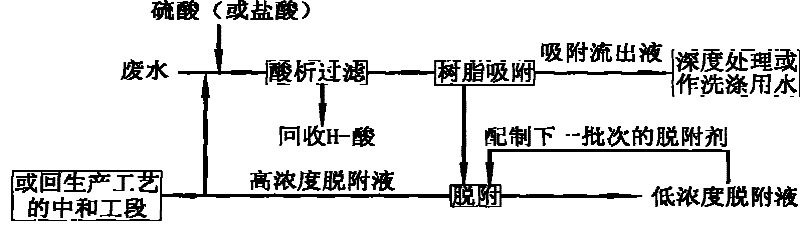

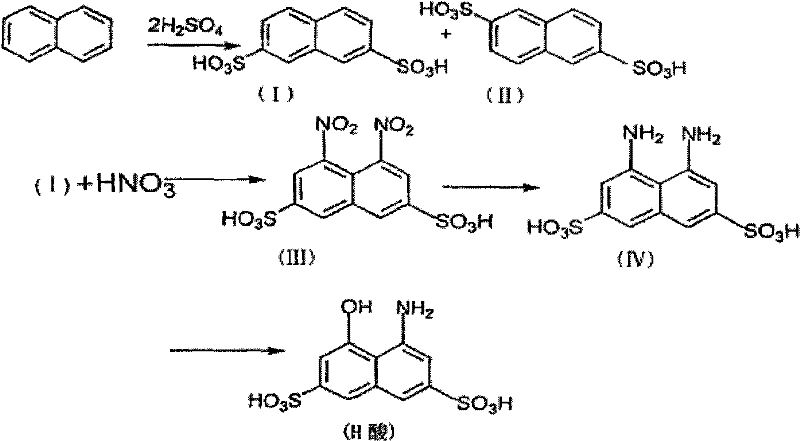

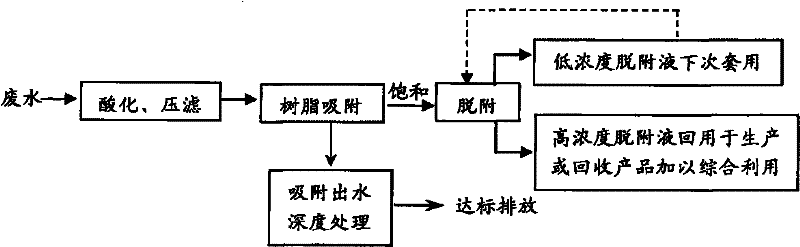

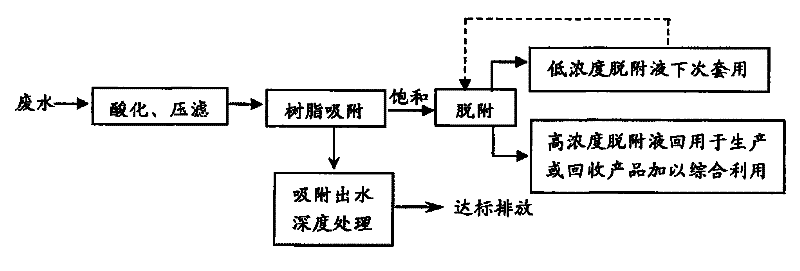

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

Method for refining byproduct hydrogen chloride during production process of organochlorine products

InactiveCN101200286AHigh economic valueLarge adsorption capacityChlorine/hydrogen-chloride purificationDispersed particle separationBenzeneDesorption

The utility model relates to a refining method of by-product HCl gas in organic chlorine production process, the by-product HCl gas passes by the absorption post filled with absorption resin at flow speed of 0.1-0.5m / s under constant-temperature constant-pressure, the removal ratio of the organic in the HCl gas can reach 99.8 percent, afterwards the absorption resin that absorbs the organic is desorbed by 110-160 DEG C saturation vapor, the desorption ratio can exceed more than 99 percent, the desorption liquid is condensed, oil-gas separated, recycled to obtain the organic mixture containing benzene or chlorobezene, the mixture is furthermore distilled and separated to obtain the benzene or chlorobezene, finally the absorption resin after desorbed by the vapor is dried by 110-140 DEG C hot air, and then cooled to room temperature for next stage absorption. The absorption resin can be reused after desorption and regeneration.

Owner:NANJING UNIV +1

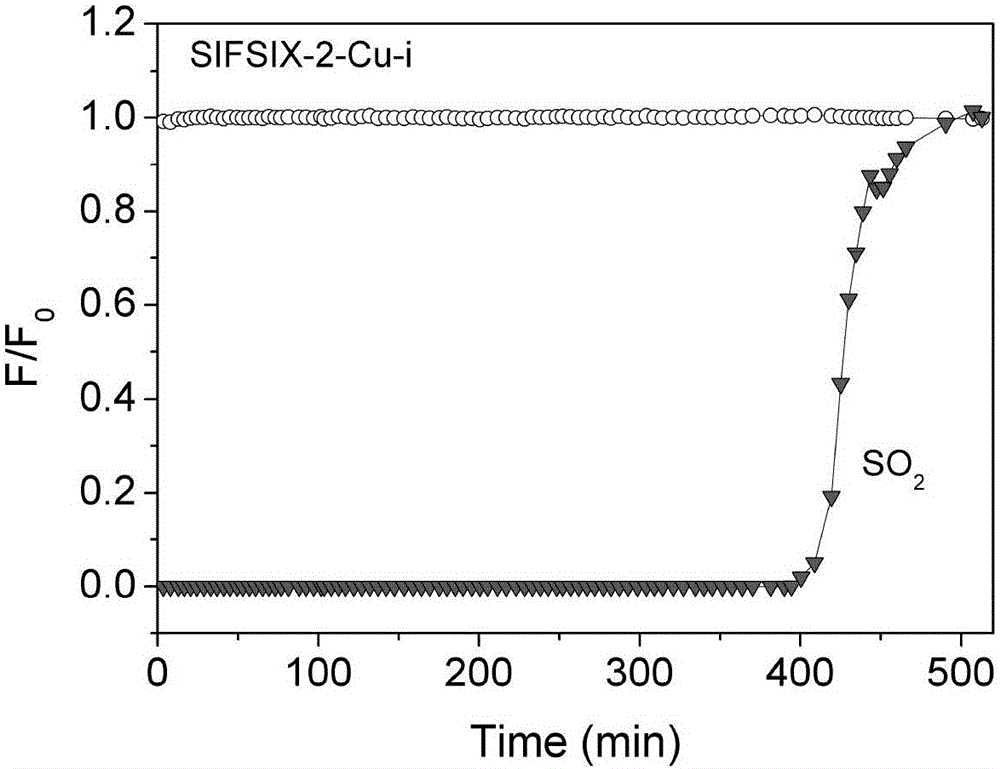

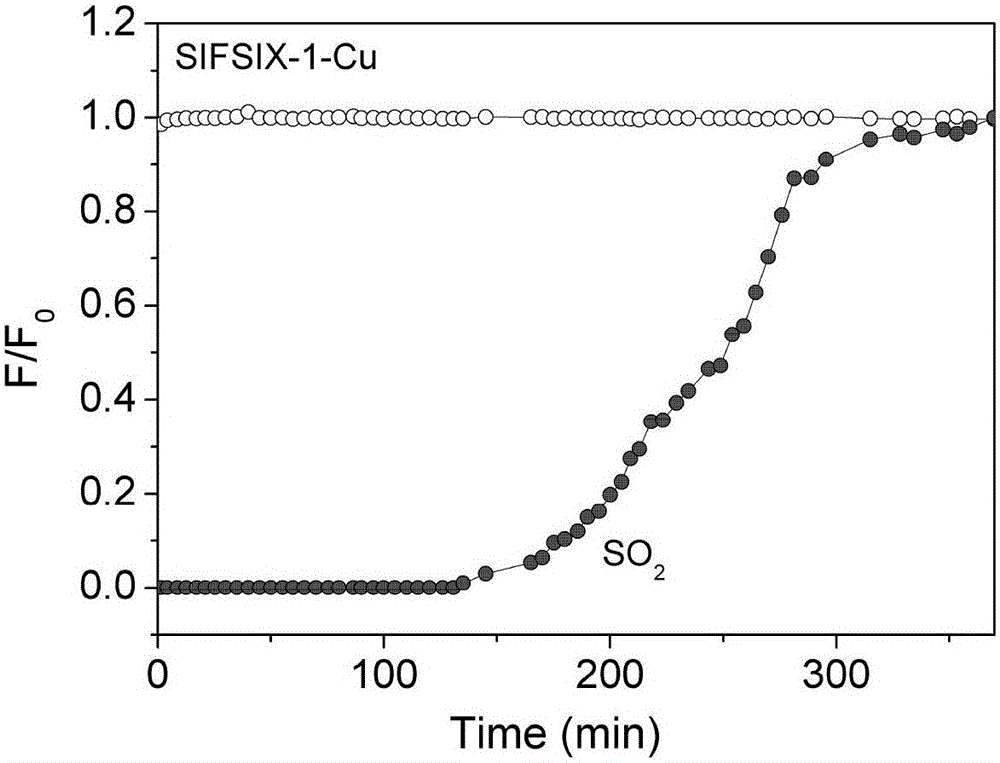

Method for adsorbing and separating sulfur-containing acid gas

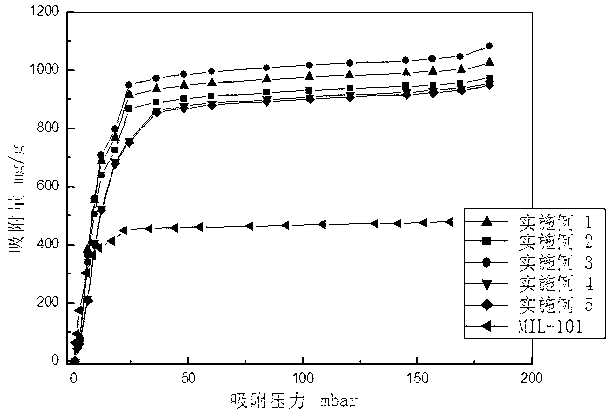

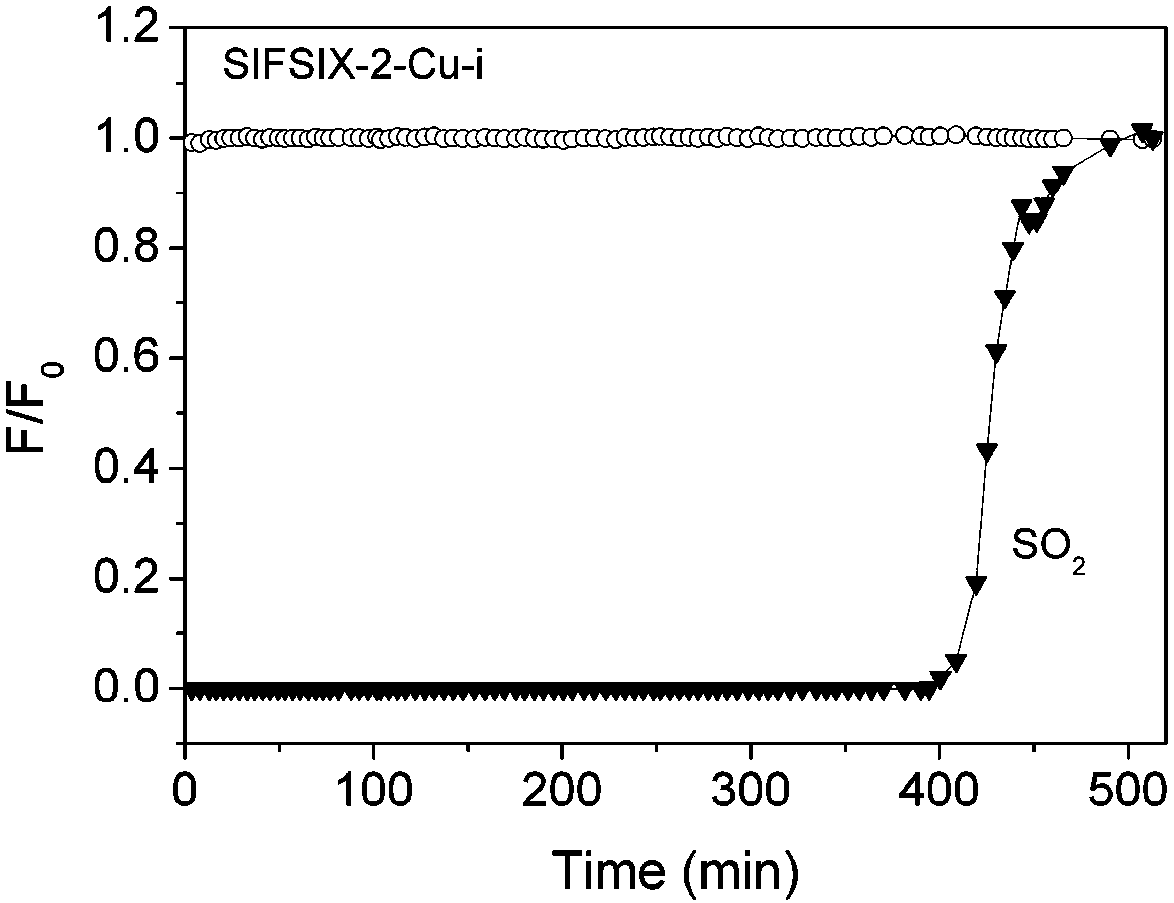

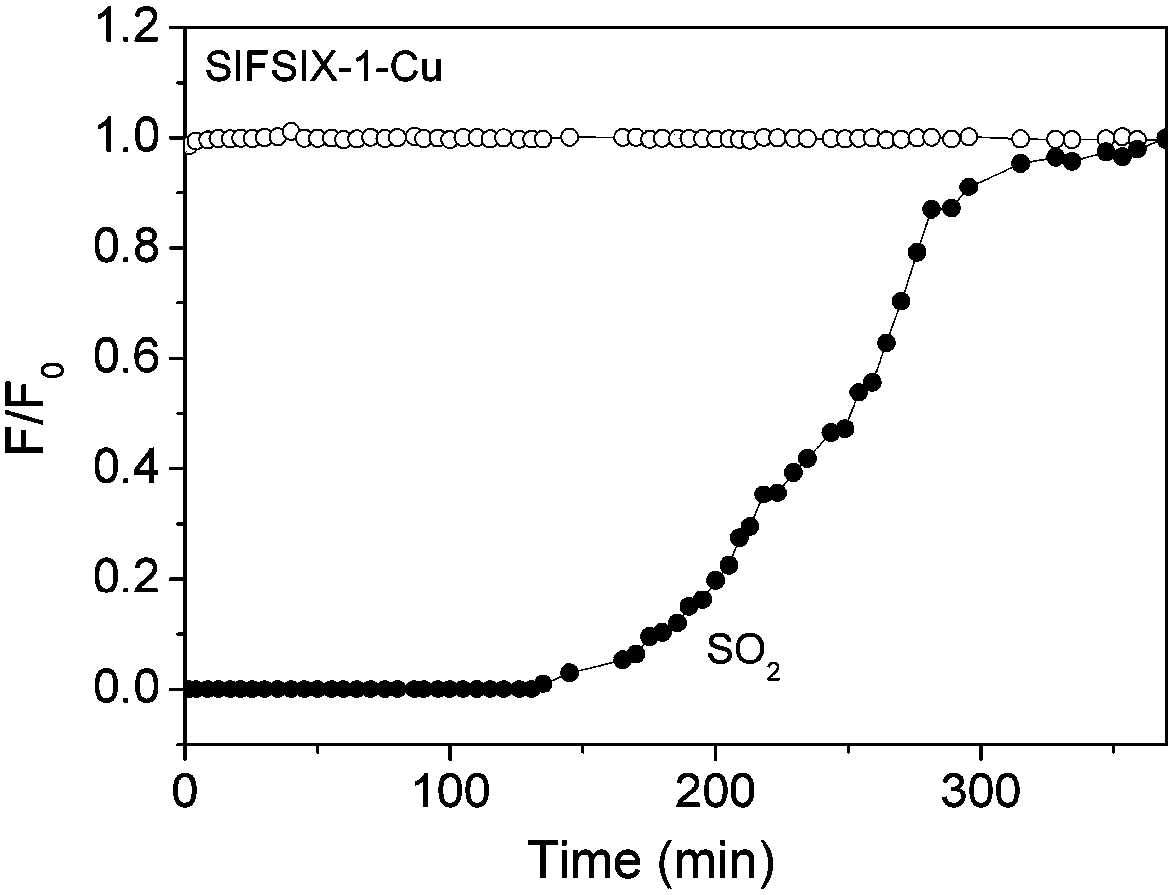

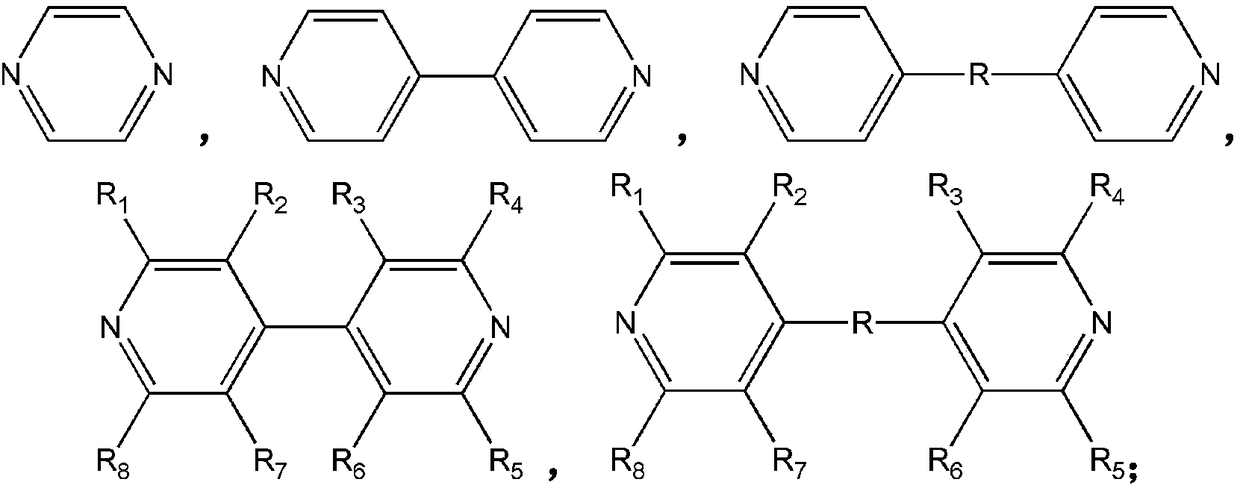

ActiveCN105833662AEasy desorption and regenerationLow costGas treatmentOther chemical processesElectricitySorbent

The invention discloses a method for adsorbing and separating a sulfur-containing acid gas. The method comprises the following step: by taking an anion-containing metal-organic frame material as an adsorbent, selectively adsorbing the sulfur-containing acid gas in a gas mixture so as to obtain a purified gas, wherein the sulfur-containing acid gas comprises one or more of sulfur dioxide, sulfur trioxide and hydrogen sulfide. The anion-containing metal-organic frame material used in the method has a great number of regularly arranged inorganic anion functional groups with negative electricity, the size of the aperture of an MOF material can be adjusted in a controllable manner by adjusting the size of organic ligand, or a three-dimensional channel spatial structure can be adjusted through an interpenetration structure. The inorganic anions with negative electricity can form an electrostatic environment in a limited space of the MOF material, sulfur-containing acid gas molecules can be selectively adsorbed by virtue of an electrostatic effect of the electrostatic environment and lacked electron atoms of the acid gas, and thus high-capacity high-selectivity separation of the sulfur-containing acid gas can be achieved.

Owner:ZHEJIANG UNIV

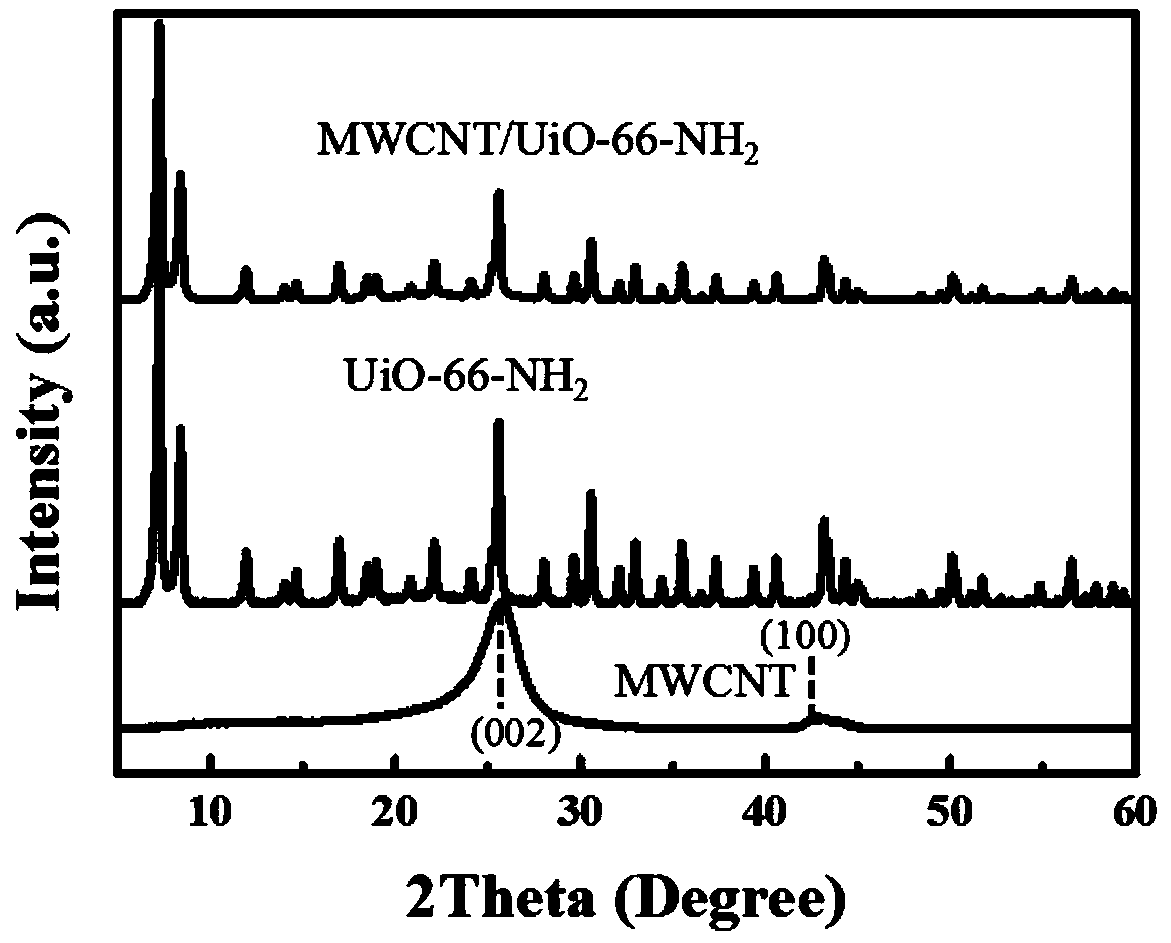

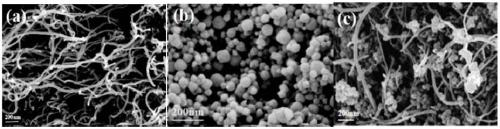

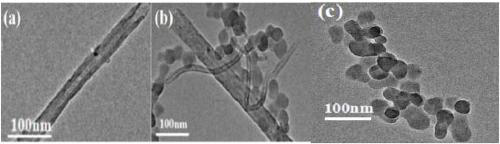

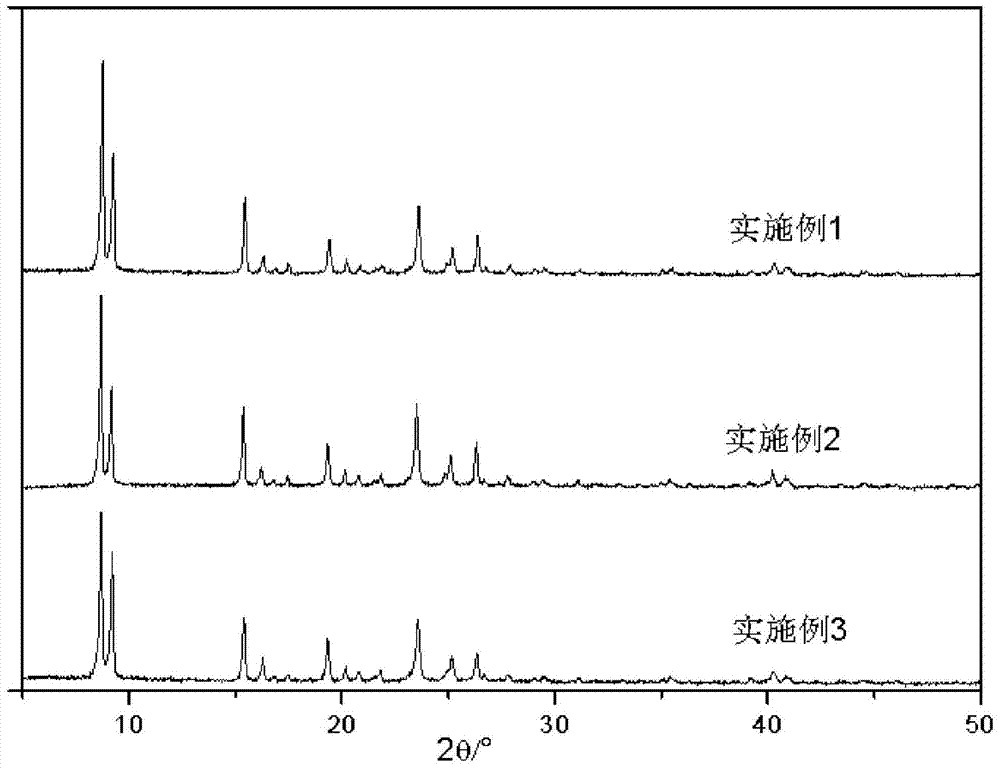

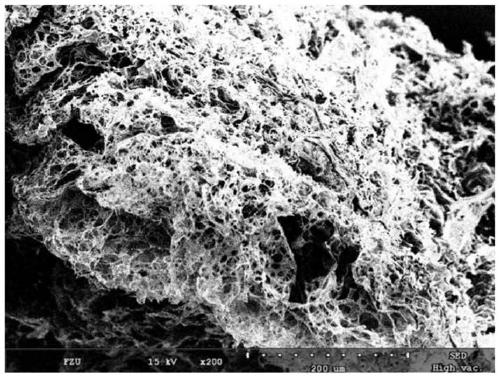

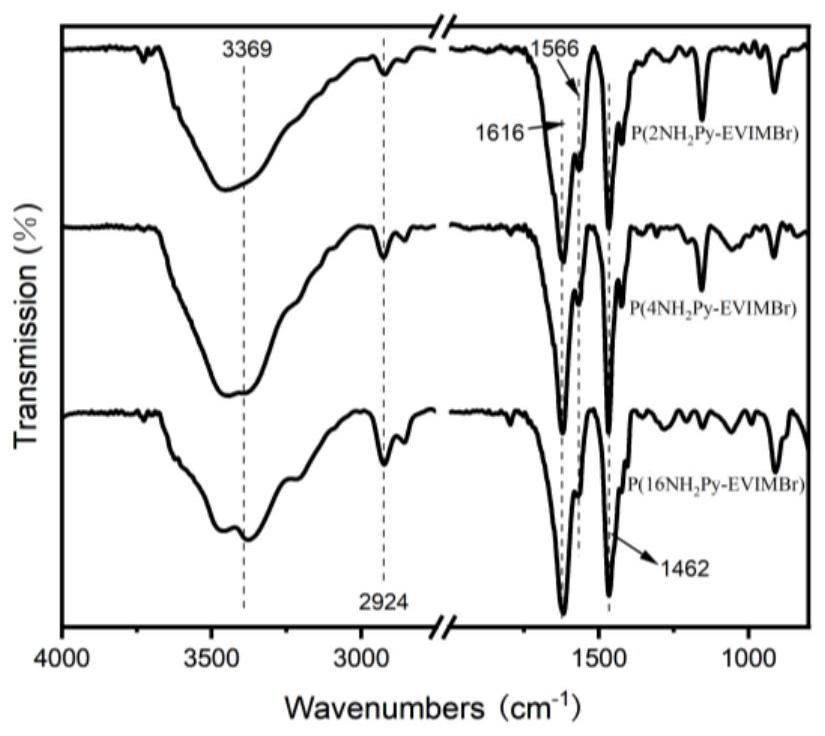

Preparation method of carbon nanotube/UiO-66-NH2 nano-composite material

ActiveCN109589932AReduce degradationImprove adsorption capacityOther chemical processesWater contaminantsMetal-organic frameworkCarbon nanotube

The invention belongs to the field of preparation of a metal organic framework material, and relates to a preparation method of a novel adsorption material carbon nano-tube / UiO-66-NH2. The preparationmethod comprises the following steps: firstly, performing acidizing treatment on a multi-wall carbon nano-tube to ensure that carboxyl located at the defect sites of the carbon nano-tube is functionalized and then a coordinate bond is formed by simultaneously an organic ligand and metal ions, and performing self-assembly to form a nano-composite material. The carbon nano-tube participates in theUiO-66-NH2 material in a form of physical blending, and the carbon nano-tube / UiO-66-NH2 composite material is also formed in a form of chemical bond. Because addition of the carbon nano-tube, the water stability of the metal organic framework material is obviously improved, and the heat stability, the specific surface area and the pore volume aperture of the composite material are all improved toa certain extent, and thus, the composite material has more excellent adsorption performance. The preparation method is simple and effective, and a new way is provided for preparing the nano-tube / MOFscomposite material.

Owner:CHANGZHOU UNIV

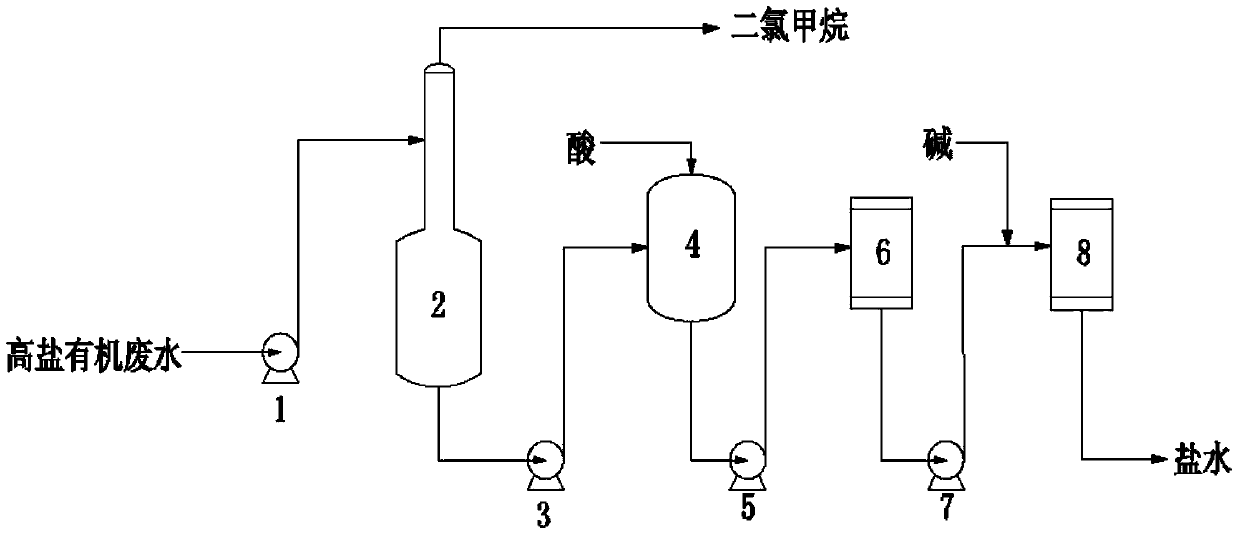

Method for processing hyper-saline organic wastewater

ActiveCN103739136AIncrease profitReduce consumptionWater contaminantsMultistage water/sewage treatmentGranularityWastewater

The invention discloses a method for processing hyper-saline organic wastewater. The method comprises the steps of gas stripping, resin absorption and active carbon absorption. The step of gas stripping comprises the steps of feeding wastewater into a polycarbonate producing process into a gas stripping tower, feeding a heating medium into the gas stripping tower to heat the wastewater, vaporizing a dichloromethane in the wastewater to condense and enter a solvent recycling system; the resin absorption step adopts macroporous resin; the active carbon absorption step adopts particle active carbon with a granularity of 10-24 meshes; before the resin absorption step, inorganic acid is added for adjusting pH value of the organic wastewater at 1-6; before the active carbon absorption step, alkaline liquid is added for adjusting pH value of the hyper-saline organic wastewater at 5-9. The method has the characteristics that operation is convenient and reliable and investment cost is low.

Owner:甘肃北方三泰化工有限公司

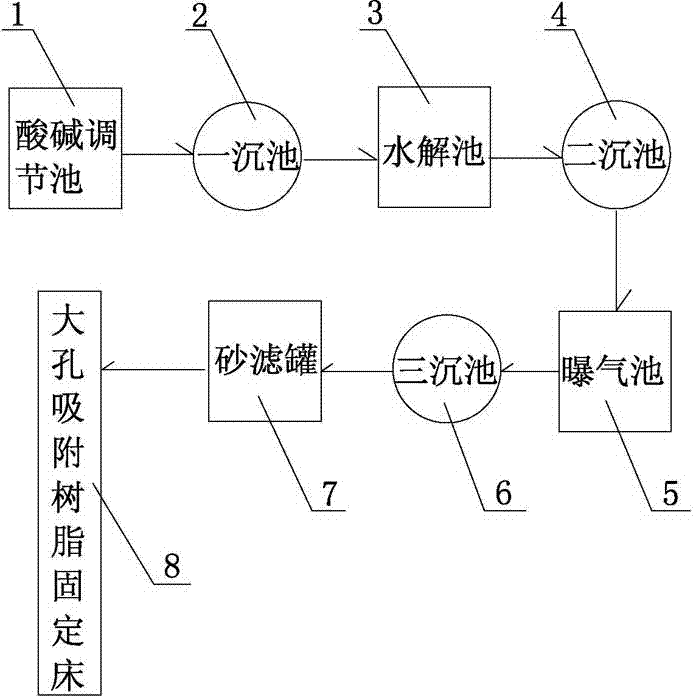

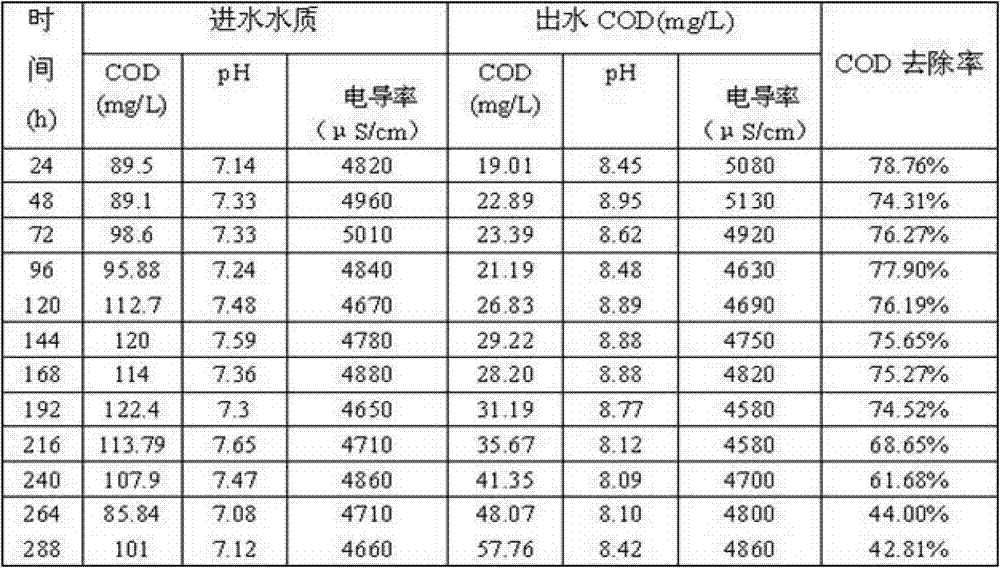

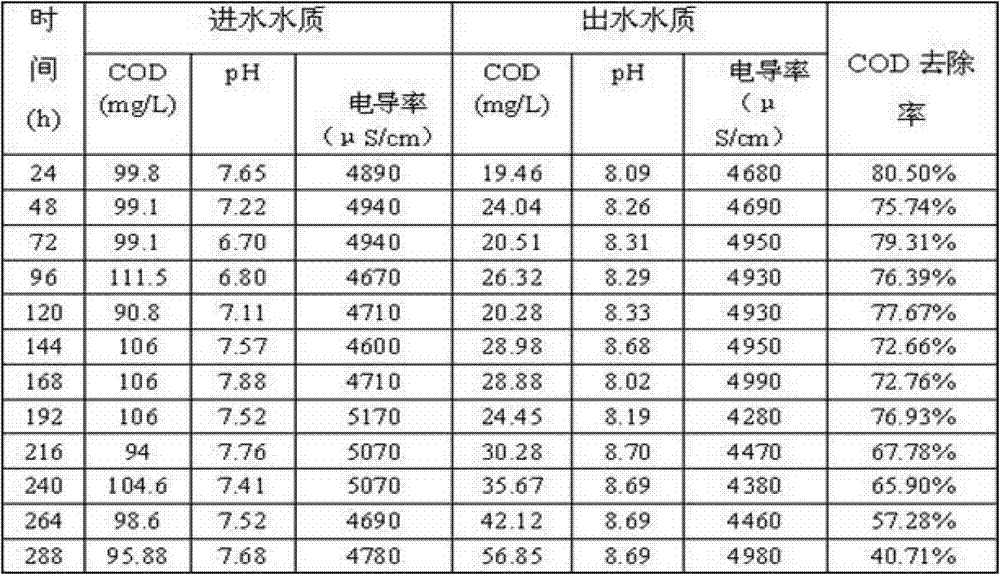

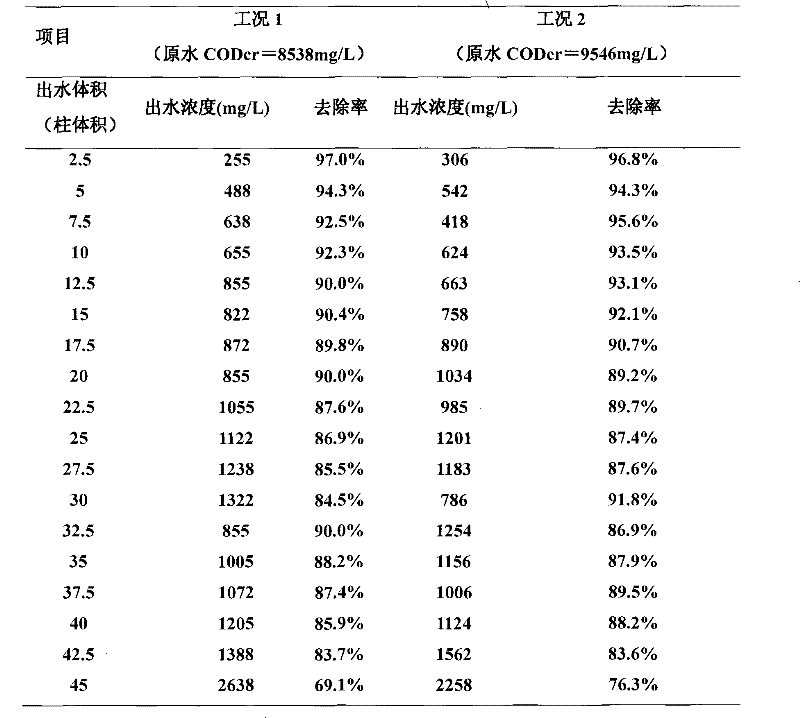

Method and device for treating printing and dyeing wastewater by using macroporous adsorption resin

InactiveCN103043857ALarge specific surface areaSmall sizeMultistage water/sewage treatmentWaste water treatment from textile industryFixed bedDyeing wastewater

The invention relates to a method and a device for treating printing and dyeing wastewater by using a macroporous adsorption resin. The method comprises the following technical steps: (1) adding a sodium hydroxide solution to an acidity and alkalinity regulating pond, regulating the pH value of the printing and dyeing wastewater to be more than 8.5, and then discharging the printing and dyeing wastewater into a primary precipitation pond, charging 25% of ferrous sulfate into the primary precipitation pond so as to carry out coagulating precipitation on the printing and dyeing wastewater, discharging the coagulated and precipitated printing and dyeing wastewater into a hydrolyzation pond so as to carry out anaerobic hydrolysis on the printing and dyeing wastewater, precipitating the printing and dyeing wastewater in a secondary precipitation pond, and discharging the printing and dyeing wastewater into an aeration pond so as to carry out aerobic aeration biological treatment on the printing and dyeing wastewater; (2) discharging the aerated wastewater into a tertiary precipitation pond and then filtering suspended solids in the wastewater through a sand filter tank; and (3) enabling sand filtered water to enter a macroporous adsorption resin fixed bed, adsorbing the sand filtered water through the macroporous adsorption resin fixed bed and discharging out the adsorbed water. The wastewater treatment method provided by the invention has the advantages as follows: through the adoption of the macroporous adsorption resin with large specific surface area, high adsorbing efficiency, low cost and simple regeneration, the treatment is efficient, economic, stable, reliable, low-carbon and environment-friendly and adapts to time development; and the wastewater treatment method can be promoted and used in printing and dyeing wastewater treatment.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

Modified macroporous resin and method for treating butyl acrylate waste water by using same

ActiveCN106732452AImprove adsorption capacityEasy desorption and regenerationOther chemical processesWater/sewage treatment by ion-exchangeEnvironmental resistanceWater discharge

The invention discloses modified macroporous resin and a method for treating butyl acrylate production waste water by using the same. The modified macroporous resin is macroporous resin modified by amino; compared with the common macroporous resin, due to the special intermolecular action of the amino on carboxyl and hydroxyl, the modified macroporous resin is better in effect of absorbing acrylic acid, n-butyl alcohol, a polymerization inhibitor and the like, and is easy in desorption regeneration and stable in performance. The modified macroporous resin can be used for recovering the components such as the acrylic acid, the n-butyl alcohol and the polymerization inhibitor in butyl ester waste water, and is taken as a raw material of a butyl ester esterification reaction, thus realizing waste resource utilization and producing obvious economic benefit; furthermore, the waste water treated by using the modified macroporous resin can reach the requirement for the indexes of waste water discharged into the sea in China, so that the waste water can be directly discharged into the sea, the subsequent waste water treatment pressure is relieved, and a great environmental protection benefit is obtained.

Owner:WANHUA CHEM GRP CO LTD

Acetoacetanilide wastewater recycling process

InactiveCN105036234AImprove adsorption efficiencyEasy desorption and regenerationWater contaminantsWater/sewage treatment by sorptionDesorptionFiltration

The invention relates to the technical field of industrial wastewater treatment process, in particular to an acetoacetanilide wastewater recycling process. Acetoacetanilide wastewater is firstly subjected to preliminary filtration and then is recycled by means of the adsorption action of resin; afterwards the resin is subjected to desorption treatment, and finally recycling is realized and waste is reduced. The treatment process is simple, operation and management are convenient, a device is simple and small in occupied area, and NDA-150 resin has a property of selectively adsorbing naphthalene type organic matters, is high in adsorption efficiency and easy for desorption regeneration. In a whole wastewater treatment process, any new pollutant is not introduced, and secondary pollution is not generated. The NDA-150 resin is high in acid and alkali resistant capacity, high in mechanical strength and good in temperature resistance and has the service life of at least 4 years.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

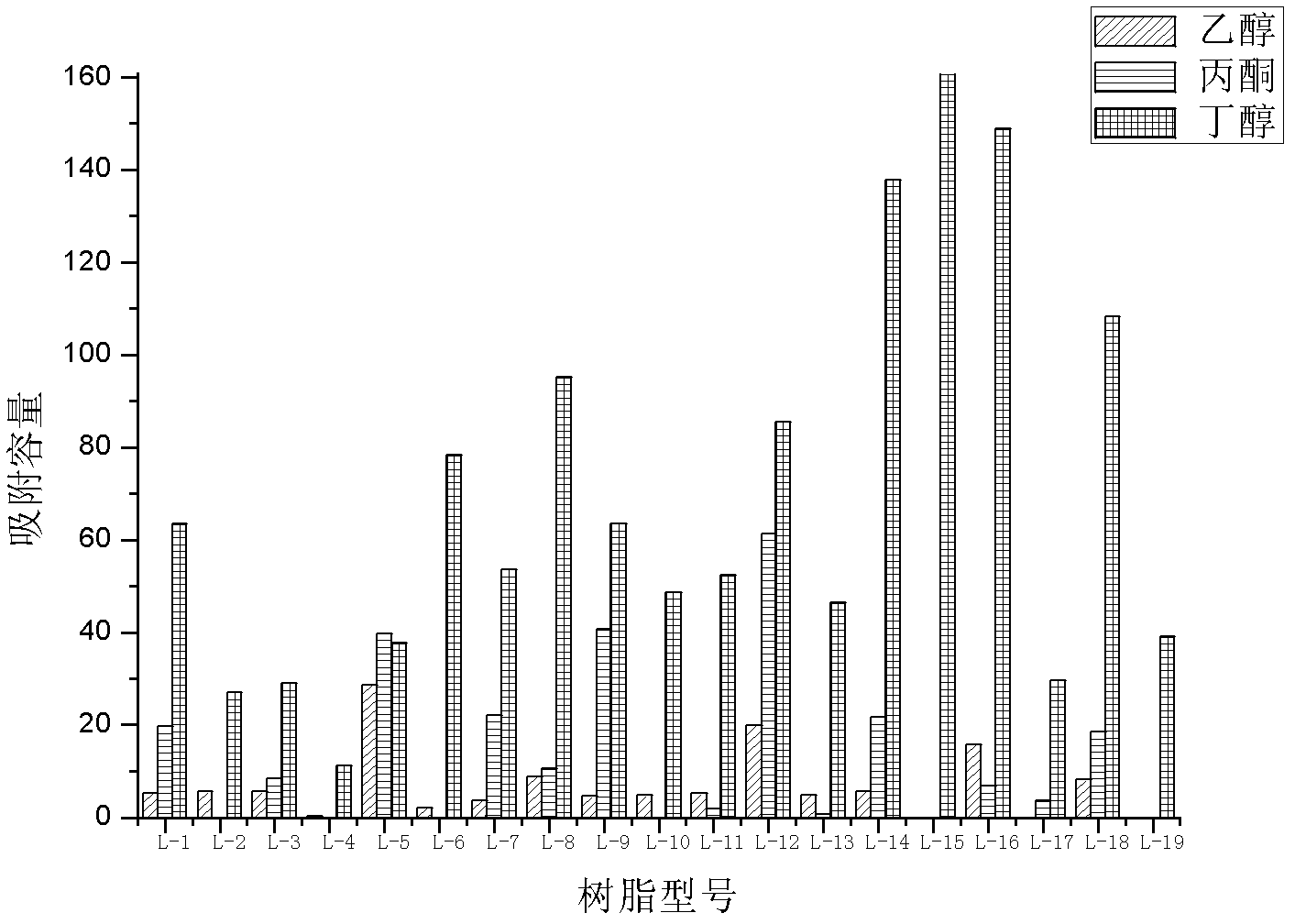

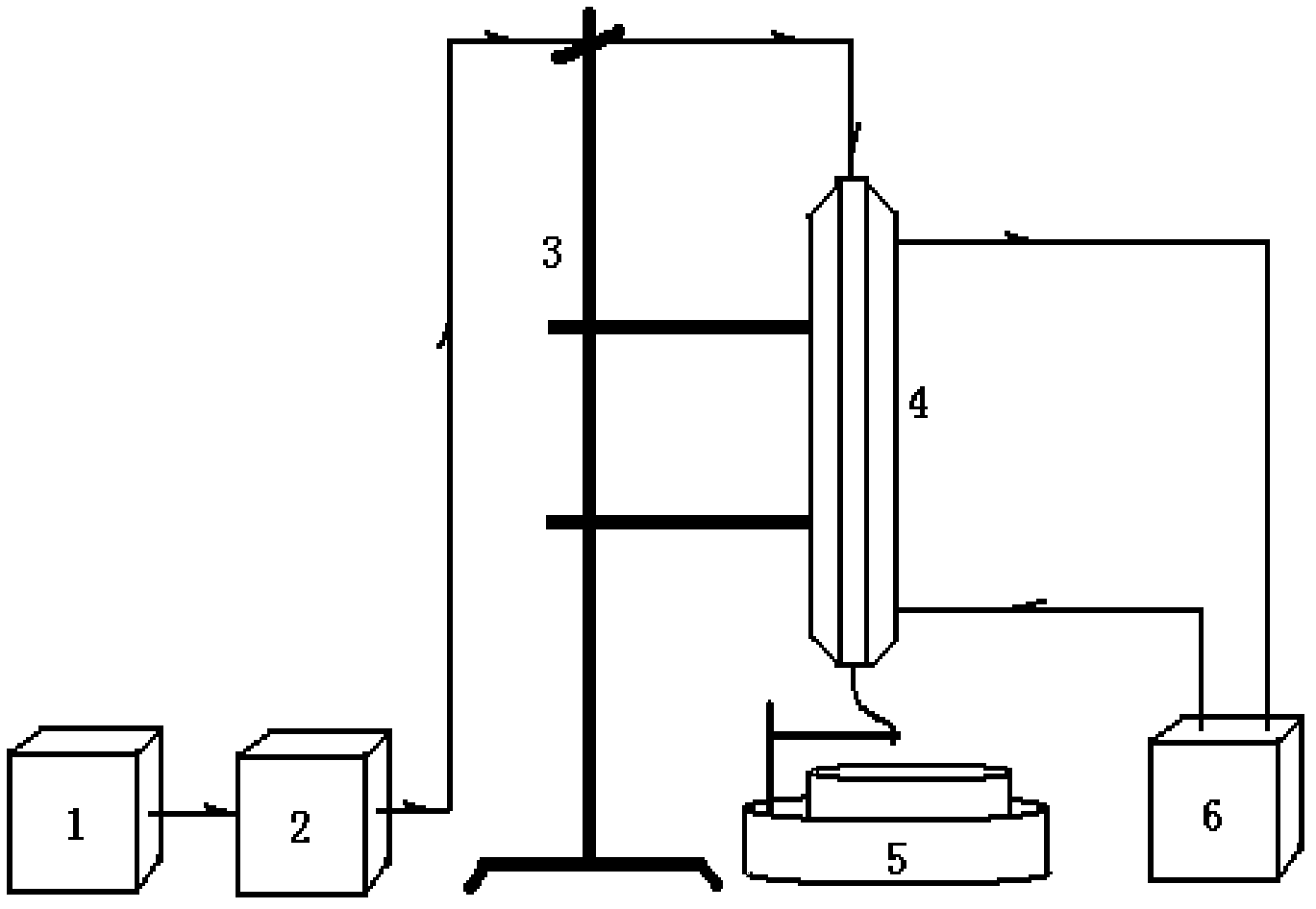

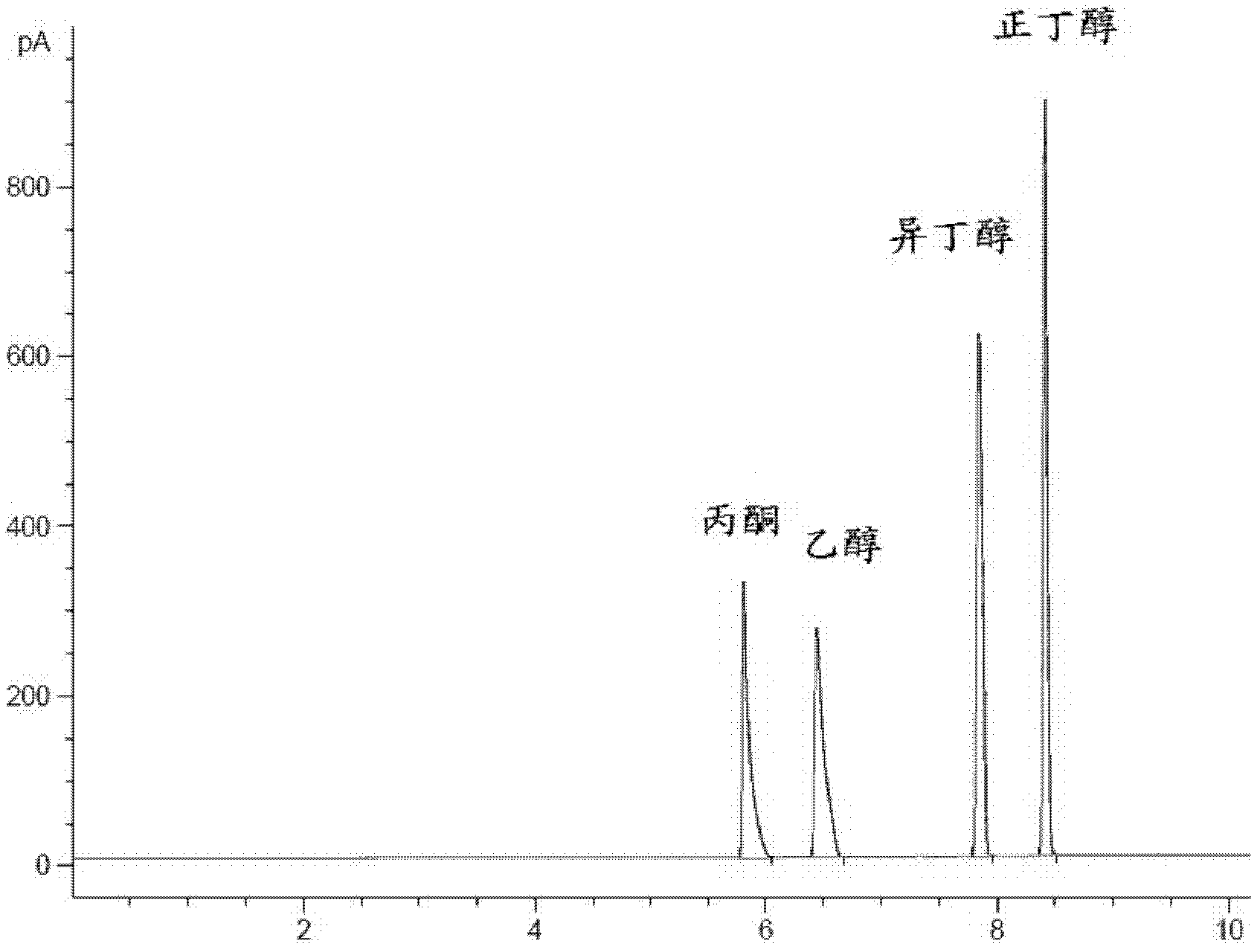

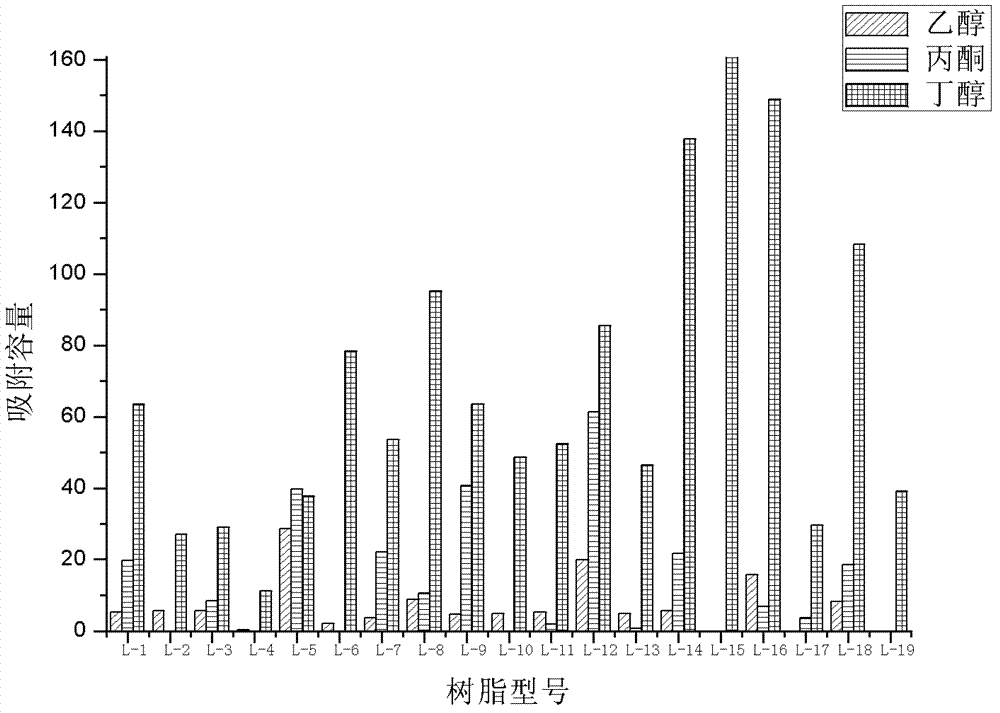

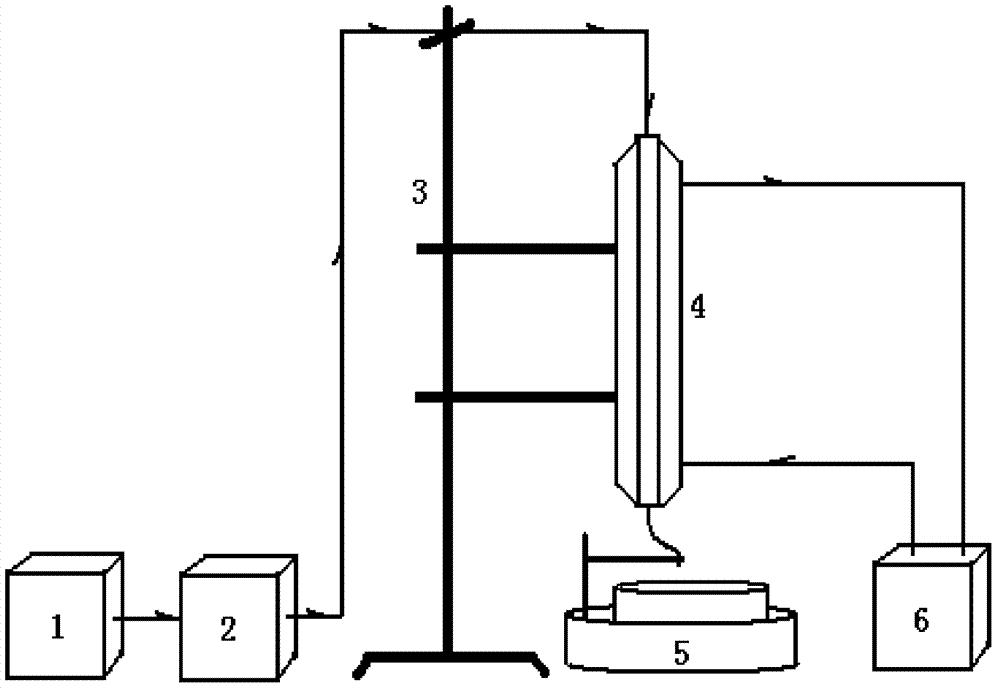

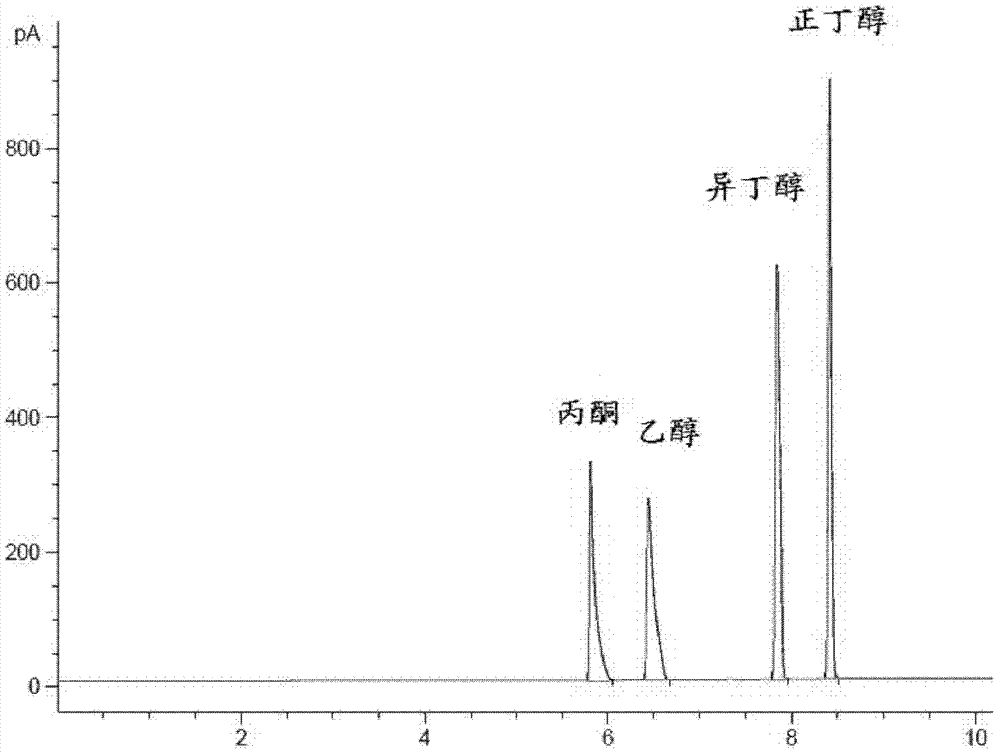

Desorption regeneration method of hydrophobic macroporous polymer adsorbent adsorbed with butanol

ActiveCN102861561AImprove adsorption capacityRealize processingOther chemical processesCombustible gas purificationSorbentDesorption

The invention provides a desorption regeneration method of a hydrophobic macroporous polymer adsorbent adsorbed with butanol. The method disclosed herein comprises the steps of using water-soluble low-boiling polar solvent and water to successively elute the hydrophobic macroporous polymer adsorbent adsorbed with butanol. According to the invention, after a solution containing butanol (e.g. butanol fermentation liquor) is adsorbed by the hydrophobic macroporous polymer adsorbent, by using the desorption regeneration method disclosed herein, the full dissolution and desorption of the adsorbed butanol in the adsorbent can be realized; in addition, the regeneration treatment can be directly carried out on the adsorbent on a fixed bed where the butanol fermentation liquor is adsorbed, and the adsorption process of the next stage can be directly conducted without taking out the adsorbent from the fixed bed, thus a lot of time is saved, and the regeneration efficiency is raised. The method disclosed herein has the advantages of simple process, short separation time, easy, rapid and complete desorption and regeneration, low investment of devices, low pollution, and low energy consumption, and is easy for large scale production.

Owner:NANJING UNIV OF TECH

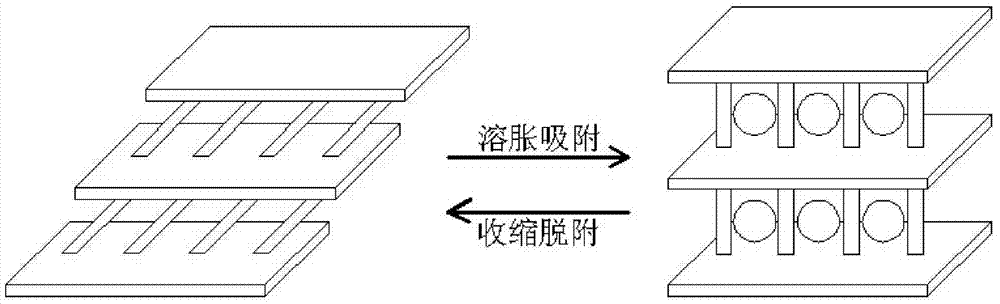

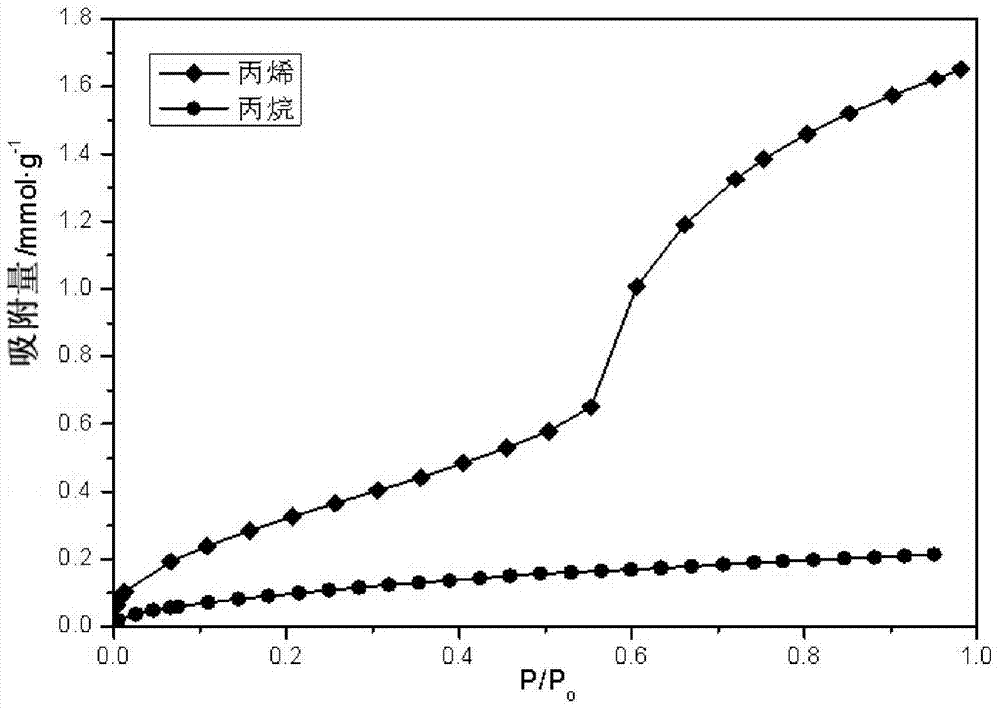

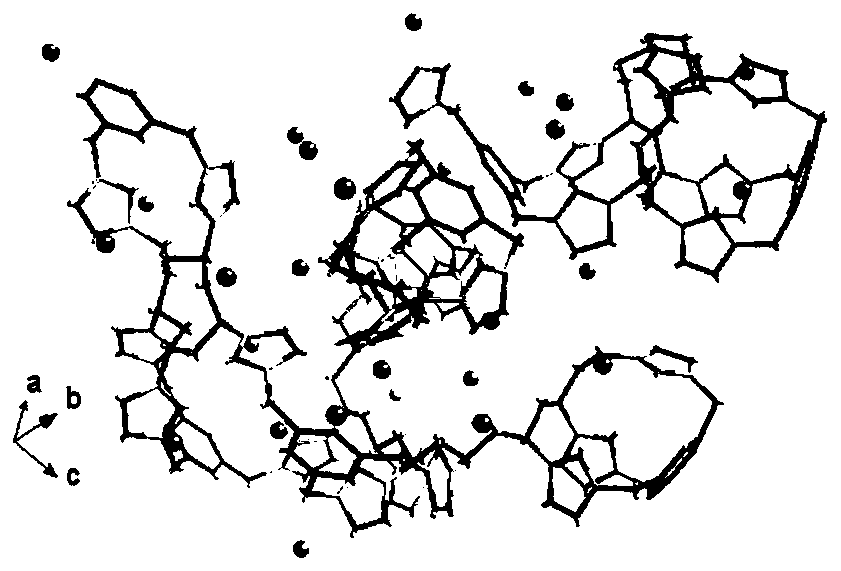

Temperature-sensitive metal organic skeleton material, preparation method, and applications thereof

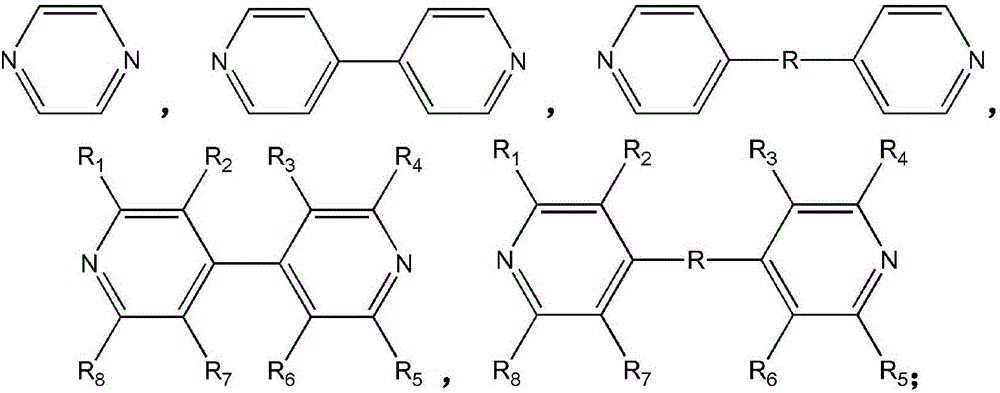

InactiveCN104772119AFlexible Skeleton StructureHigh adsorption selectivityOther chemical processesChemical industryPyrazineDesorption

The invention belongs to the technical field of metal organic skeleton materials, and discloses a temperature-sensitive metal organic skeleton material, a preparation method, and applications thereof. In the preparation method, copper perchlorate, pyrazine, and pyrazine-2,3-dicarboxylic acid (double organic ligands) are stirred in a solvent at a room temperature to prepare the temperature-sensitive metal organic skeleton material. The temperature-sensitive metal organic skeleton material has a flexible skeleton structure, which can generate skeleton swelling absorption. The temperature-sensitive metal organic skeleton material has different swelling conversion pressures on alkene and alkane, so the temperature-sensitive metal organic skeleton material has a high selectivity on alkene and alkane, can carry out skeleton structure swelling absorption on alkene at the temperature of 273 K, and carry out skeleton structure contraction desorption at the temperature of 298 K, and thus desorption regeneration is easy for the skeleton material. The temperature-sensitive metal organic skeleton material can be used as an efficient energy-saving absorption separating material in the field of alkene / alkane separation and has a vast application prospect.

Owner:SOUTH CHINA UNIV OF TECH

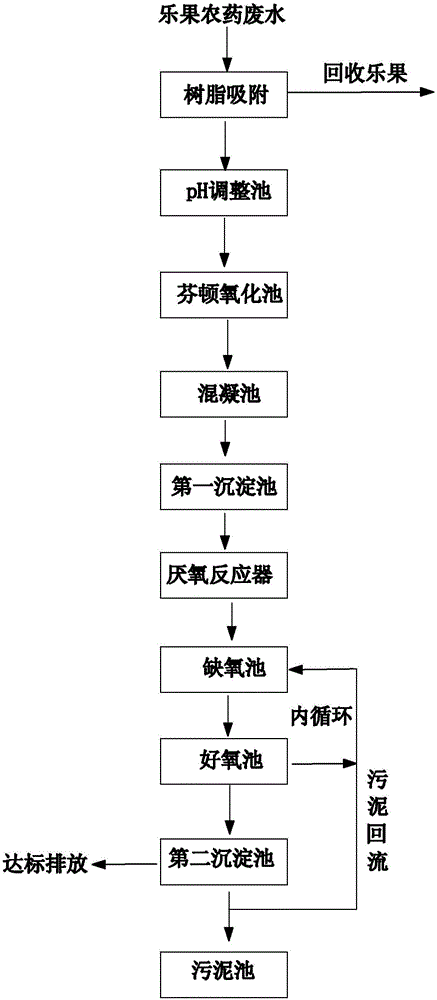

Resource recycling handling method of dimethoate pesticide wastewater

InactiveCN106335962AImprove adsorption efficiencyEasy desorption and regenerationWater treatment compoundsWater contaminantsDimethoateBoiling point

The invention discloses a resource recycling handling method of dimethoate pesticide wastewater, and the method comprises the steps of (1) adsorbing dimethoate pesticide wastewater through an adsorber which is provided with a macro-porous resin to obtain wastewater effluent and the macro-porous resin adsorbed with the dimethoate; (2) conducting desorption and regeneration of the macro-porous resin adsorbed with the dimethoate through a desorption agent to obtain desorption liquid contained with the dimethoate, wherein the boiling point of the adopted desorption agent is lower than that of the dimethoate and can dissolve the dimethoate; (3) disposing the desorption liquid by adopting one or the combination of two of method a and method b, wherein method a is that by distilling the desorption liquid to separate the dimethoate and the desorption agent, desorption agent component and dimethoate component are obtained, then the dimethoate component is used for preparing dimethoate pesticide; method b is to use the desorption liquid in the step (2) as a desorption agent. The resource recycling handling method of dimethoate pesticide wastewater can not only adsorb the dimethoate from the dimethoate pesticide wastewater, but also recycle the dimethoate in the wastewater.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

Metal organic skeleton-graphite oxide nano composite adsorption material and preparing method thereof

ActiveCN102335592BLarge specific surface areaHigh porosityOther chemical processesMetal-organic frameworkChromium nitrate

The invention discloses a metal organic skeleton-graphite oxide nano composite adsorption material and a preparing method thereof. The material is composed of graphite oxide and chromium-based metal organic skeleton. The preparing method of the material comprises the following steps of: dissolving chromium nitrate and terephthalic acid in deionized water, stirring and simultaneously adding hydrofluoric acid dropwise, then adding graphite oxide and uniformly stirring to obtain reaction liquid, and conducting hydro-thermal reaction under program temperature controlling; and after sequentially conducting washing with water and washing with ethanol for the decomposed materials, centrifuging, drying and obtaining the metal organic skeleton-graphite oxide nano composite adsorption material. Theadsorption capacity of the adsorption material for hydrocarbon volatile organic matters is greatly increased, and the adsorption material is easy for desorption and regeneration. The preparing methodhas simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

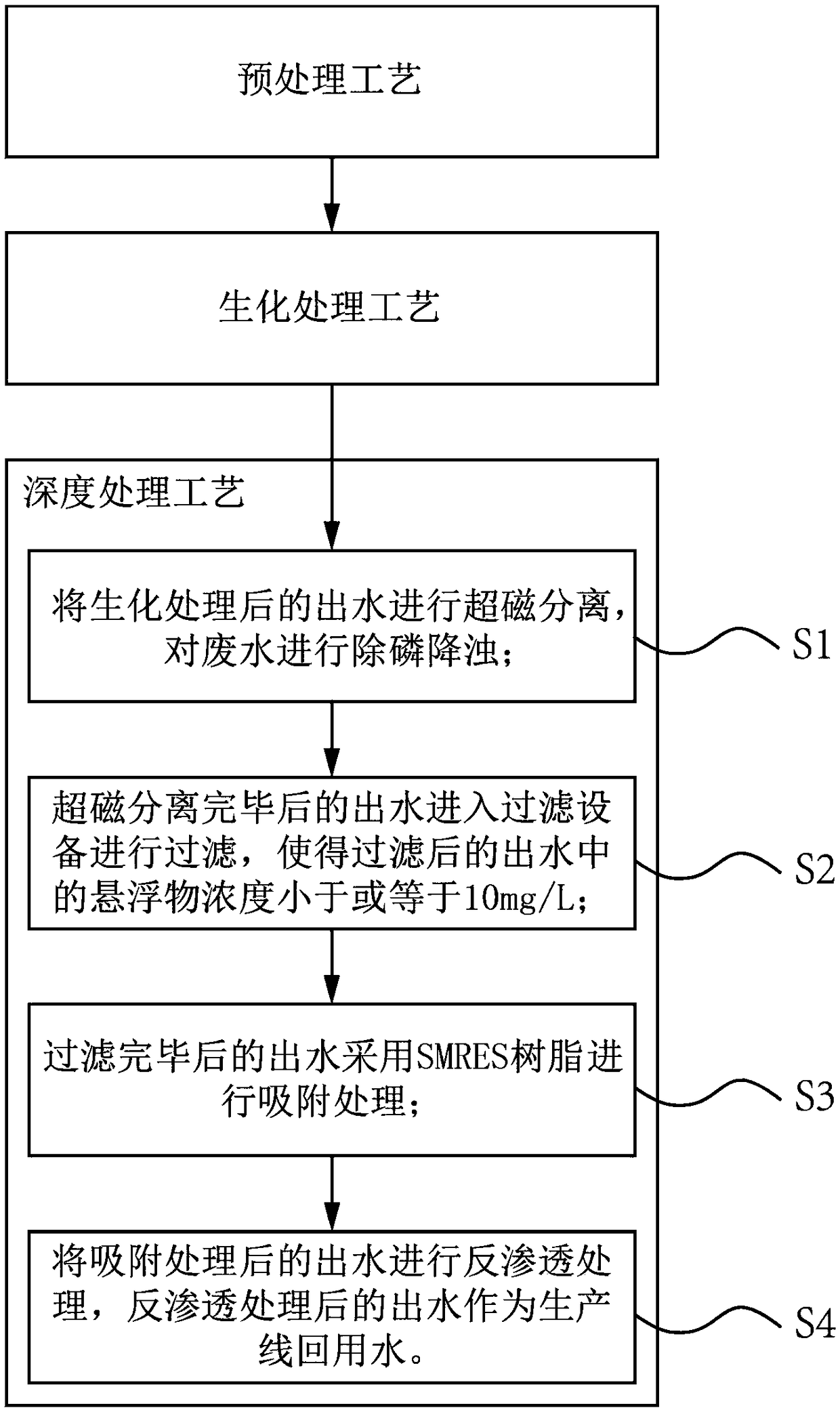

Treatment technology and system of organic waste water with high concentration

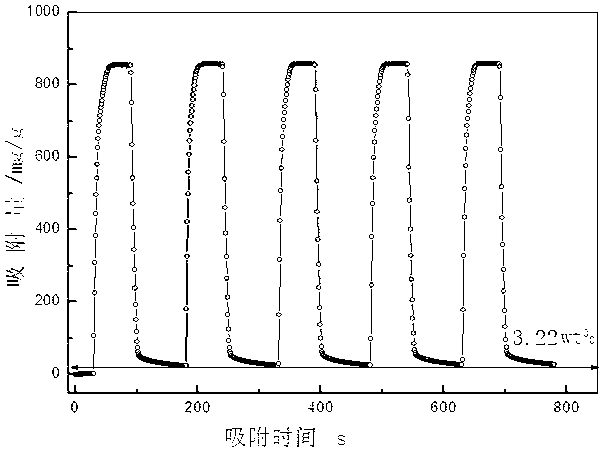

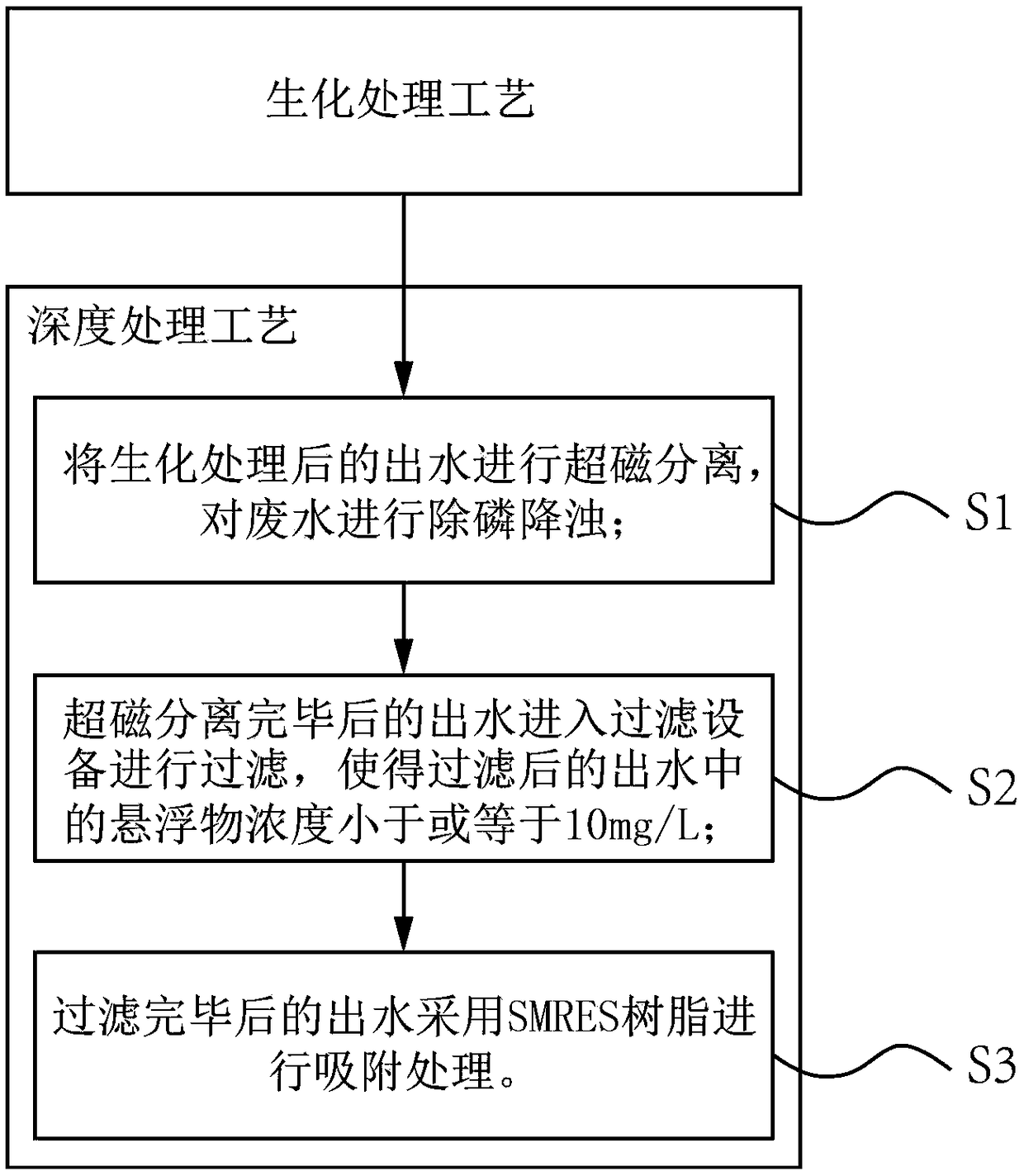

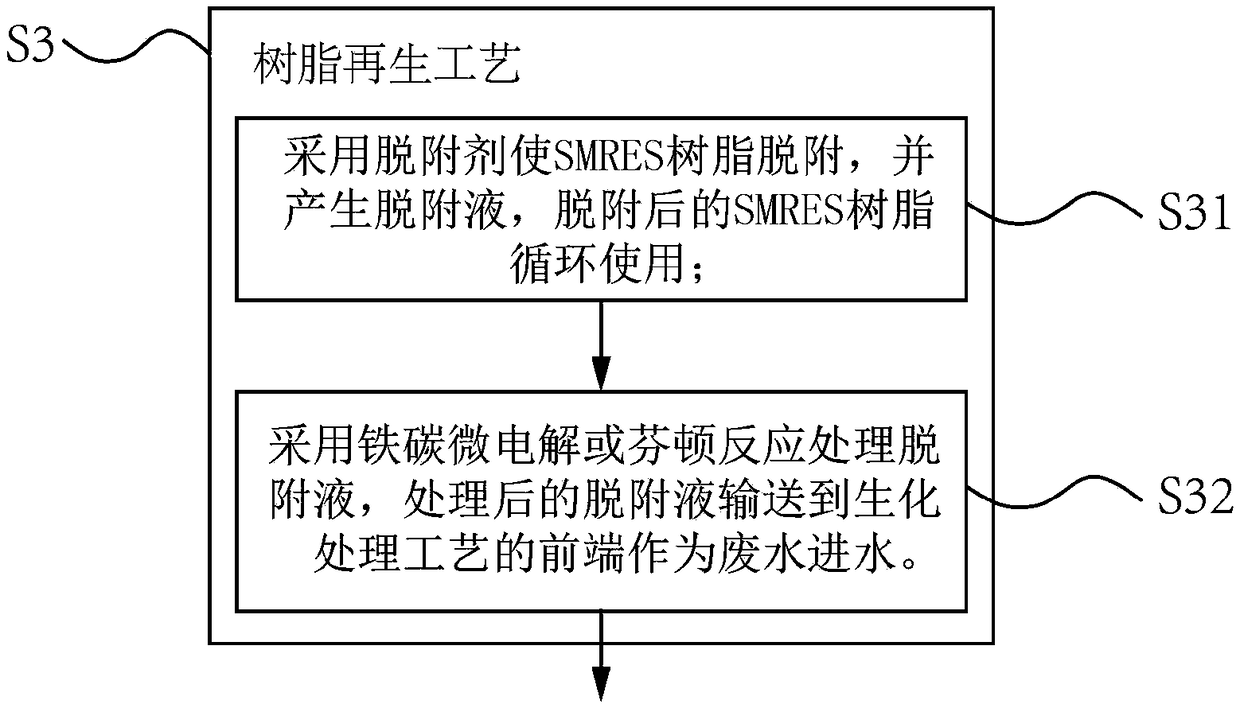

PendingCN108892333AEasy to handleGood processing effectFatty/oily/floating substances removal devicesTreatment using aerobic processesHigh concentrationWater flow

The invention relates to a treatment technology and system of organic waste water with high concentration. The technology comprises a biochemical treatment process and an advanced treatment process, and the biochemical treatment process is set before the advanced treatment process, wherein the biochemical treatment process is used for conducting biodegradation on the waste water; the advanced treatment process comprises the following steps that S1, the discharged water after the biochemical treatment process is subjected to super magnetic separation, and dephosphorization and turbid descendingare conducted on the waste water; S2, after super magnetic separation is completed, the discharged water flows into filtering equipment for filtering, so that the concentration of suspended matters in the discharged water after filtering is less than or equal to 10 mg / L; S3, after filtering, SMRES resin is adopted for adsorbing the discharged water. The technology adopts the method which combinesthe biochemical treatment process and the advanced treatment process for treating the organic waste water with the high concentration, not only can the removal rate of COD and NH3-N in the waste water be effectively increased to strengthen the effect of treating the waste water, but also the technology is applicable to printing and dyeing waste water, papermaking feedwater, electroplating wastewater and other high-concentration organic waste water of different types, and the effect of treating coking waste water is especially significant.

Owner:SCIMEE TECH & SCI CO LTD

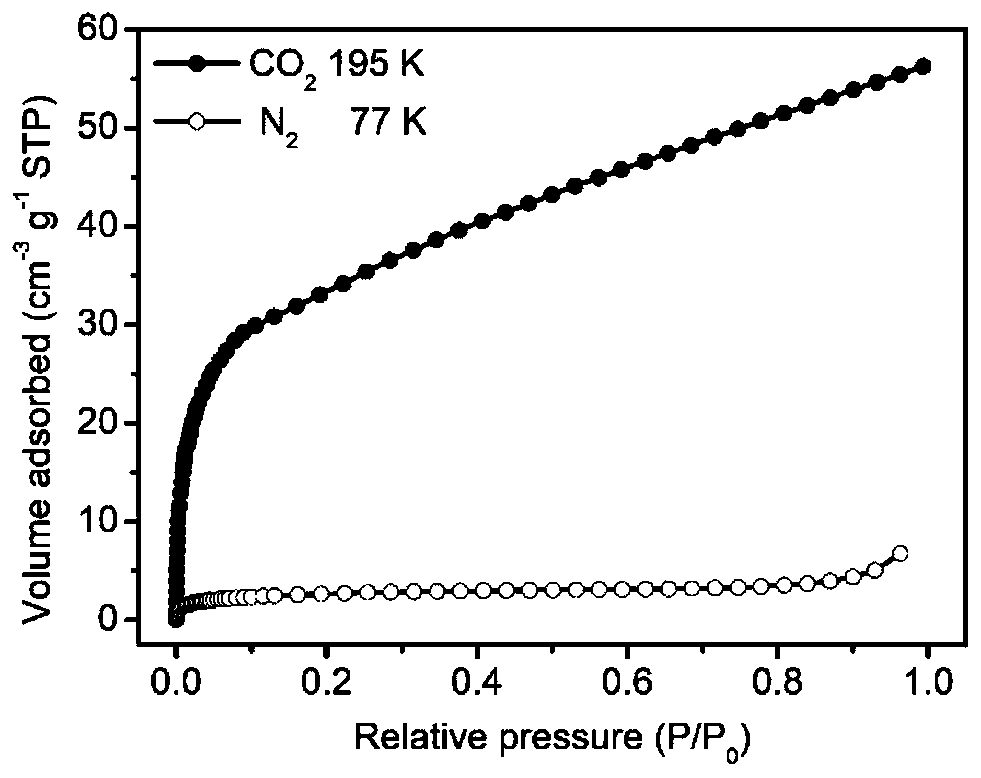

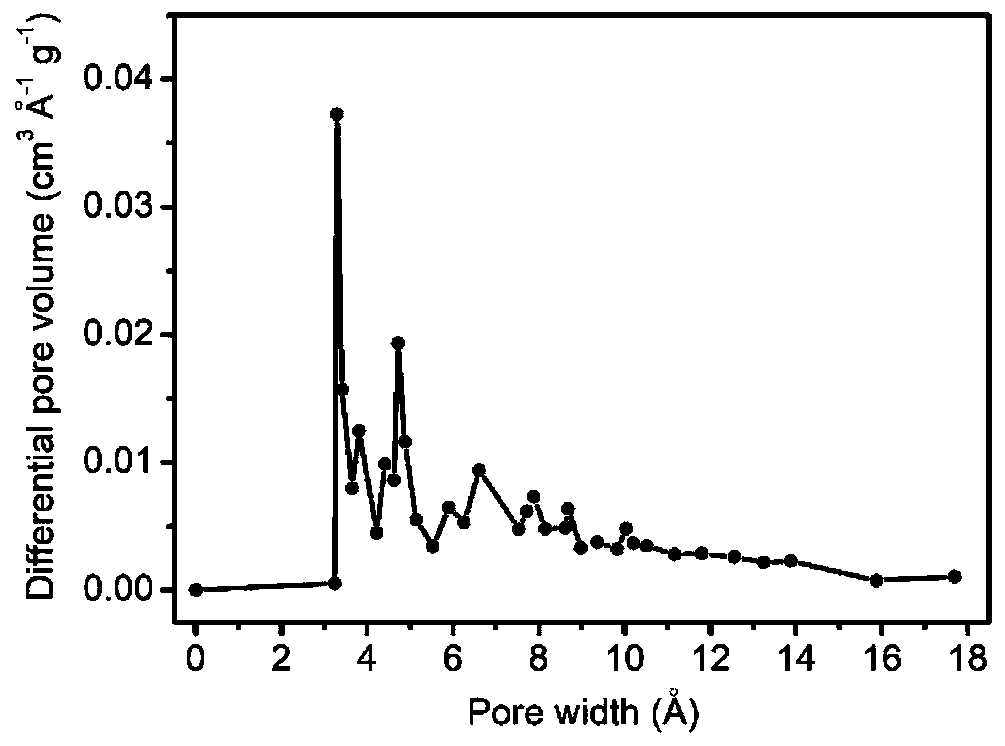

Ultra-microporous ionic polymer material and preparation method and application thereof

ActiveCN111375390AImprove stabilityAir is freshOther chemical processesDispersed particle separationPolymer scienceAlkyne

The invention discloses an ultra-microporous ionic polymer material based on hyperbranched ionic liquid and preparation and alkyne / olefin separation application thereof. The ultra-microporous ionic polymer material has the characteristics of high anion density and narrow pore size distribution, and the structural properties are regulated and controlled by changing a hyperbranched structure and anion and cation types. High-selectivity separation of acetylene and propyne is realized by utilizing a strong hydrogen bond environment constructed by high anion density and a size screening effect, sothat alkyne in alkyne and olefin mixed gas is removed to a very low degree, and olefin gas with extremely low alkyne content is obtained. The material prepared by the method has the advantages of highstability, simple preparation, strong controllability of material structural properties, good adsorption performance, easy desorption, greenness, environmental protection, and good industrial application prospect.

Owner:ZHEJIANG UNIV

Efficient desulfurization material and preparation method thereof

InactiveCN111774032AImprove desulfurization efficiencyExtend the life cycleGas treatmentOther chemical processesAdhesiveCarbonization

The invention belongs to the technical field of desulfurization, and particularly relates to an efficient desulfurization material and a preparation method thereof. The high-efficiency desulfurizationmaterial is prepared from industrial carbon-based solid waste, an adhesive, a pore-forming agent and an activating agent. The method comprises the following steps: (1) adjusting the industrial carbon-based solid waste to be alkaline, dehydrating, adding the adhesive, the pore-forming agent and the activating agent, uniformly mixing, adding water, reacting, and granulating and forming after the reaction is finished; and (2) drying the molded material, and carrying out secondary carbonization and water vapor reactivation treatment to obtain the finished product of the carbon-based composite adsorption material. According to the method, the industrial carbon-based solid waste is recycled; carrying out modification and pore size adjustment; after being impregnated with the active components,the desulfurization material is more suitable for gas-phase removal of hydrogen sulfide in the industries of coal chemical industry, petrochemical industry and the like, the sulfur capacity of the desulfurization material can reach 35% or above, and meanwhile, through reasonable pore size distribution, the converted elemental sulfur is deposited in a semi-firm state, is easier to desorb and regenerate, has high working capacity, can be recycled, and is energy-saving and environment-friendly.

Owner:ZIBO PENGDA ENVIRONMENTAL PROTECTION TECH

A method for adsorbing and separating sulfuric acid-containing gas

ActiveCN105833662BImprove adsorption capacityGood removal depthGas treatmentOther chemical processesElectricitySorbent

Owner:ZHEJIANG UNIV

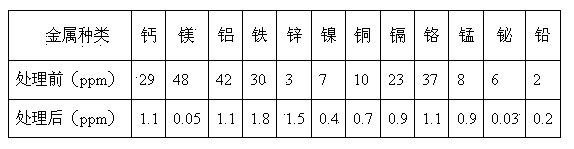

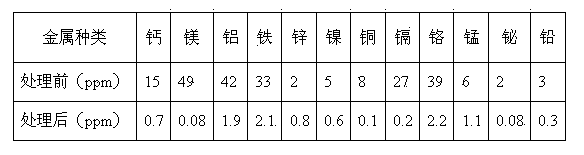

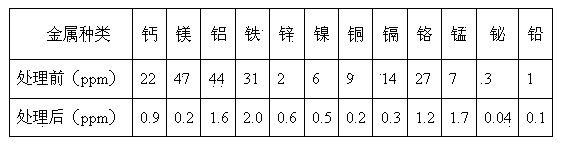

Method for reducing and removing metal impurities from ammonium molybdate solution by using ion exchange resin

InactiveCN102730758BImprove exchange capacityAvoid introducingMolybdeum compoundsIon exchangeMetal impurities

The invention discloses a method for reducing and removing metal impurities from ammonium molybdate solution by using ion exchange resin, relating to the deep purification technology of the ammonium molybdate solution in chemical industry field. The method comprises the following steps: firstly selecting three suitable cationic exchange resins according to the kinds and contents of the impurities metal ions in a molybdenic acid solution; adopting ammonium water to implement transamination treatment for the resins, and putting the resins in the ion exchange columns which are serially connected according to a certain order; regulating the to-be-treated ammonium molybdate solution to be weakly acidic with nitric acid, and leading the treated ammonium molybdate solution through serially connected ion exchange columns in turnat a certain speed for implementing ion exchange treatment; and adopting the ammonium water to adjust the ammonium molybdate exchange processing liquid subjected to columns treatment to alkalescence after the exchange treatment is finished. The method can uniformly reduce the concentration of the impurities metal ions in the ammonium molybdate solution to be lower than 3 ppm, and the metal ions comprise calcium, magnesium, aluminum, zinc, ferrum, nickel, copper, cadmium, chromium, manganese, bismuth and plumbum; and the method cannot change the components and the concentration of the ammonium molybdate solution. The ion exchange resins can be reused, so that the operation cost can be efficiency reduced, and the continuous impurity removing production in large-scale can be realized.

Owner:HENAN UNIV OF SCI & TECH

Method for treating waste water of H-acid production

InactiveCN101104533BNot affected by the adsorption effectImprove practicalityIon-exchange column/bed processesOrganic chemistryResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

Bisphenol S high-concentration waste water pre-treatment technology

InactiveCN105236509AImprove adsorption capacityEasy desorption and regenerationOrganic chemistryOrganic compound preparationHigh concentrationEnvironmental engineering

The invention relates to a bisphenol S high-concentration waste water pre-treatment technology. The technology specifically comprises the steps of 1, preparing a macroporous resin column; 2, placing bisphenol S waste water containing impurities in a dropping funnel through slow dropping at room temperature to enable bisphenol S waste water to pass through the prepared macroporous resin column, and detecting column passing liquid with a quick tester; 3, conducting adsorption saturation on bisphenol S waste water containing impurities in resin multiple times, and then conducting dropwise adding elution with solution the amount of which is twice that of the resin; 4, eluting the solution with the same amount of clear water after elution, then post-treating obtained eluent, and recovering phenol. The technology has the advantages that adsorption is conducted on waste water by means of the macroporous resin, the adopted macroporous resin is characterized by being good in adsorption effect, capable of achieving desorption regeneration easily, stable in performance, wide in application range, high in practicality, capable of achieving comprehensive utilization and the like, and then waste water treatment cost is low and treatment effect is good.

Owner:NANTONG BOTAO CHEM

Method for refining byproduct hydrogen chloride during production process of organochlorine products

InactiveCN101200286BHigh economic valueLarge adsorption capacityChlorine/hydrogen-chloride purificationDispersed particle separationBenzeneDesorption

Owner:NANJING UNIV +1

Desorption regeneration method of hydrophobic macroporous polymer adsorbent adsorbed with butanol

ActiveCN102861561BImprove adsorption capacityRealize processingOther chemical processesCombustible gas purificationDesorptionSorbent

The invention provides a desorption regeneration method of a hydrophobic macroporous polymer adsorbent adsorbed with butanol. The method disclosed herein comprises the steps of using water-soluble low-boiling polar solvent and water to successively elute the hydrophobic macroporous polymer adsorbent adsorbed with butanol. According to the invention, after a solution containing butanol (e.g. butanol fermentation liquor) is adsorbed by the hydrophobic macroporous polymer adsorbent, by using the desorption regeneration method disclosed herein, the full dissolution and desorption of the adsorbed butanol in the adsorbent can be realized; in addition, the regeneration treatment can be directly carried out on the adsorbent on a fixed bed where the butanol fermentation liquor is adsorbed, and the adsorption process of the next stage can be directly conducted without taking out the adsorbent from the fixed bed, thus a lot of time is saved, and the regeneration efficiency is raised. The method disclosed herein has the advantages of simple process, short separation time, easy, rapid and complete desorption and regeneration, low investment of devices, low pollution, and low energy consumption, and is easy for large scale production.

Owner:NANJING TECH UNIV

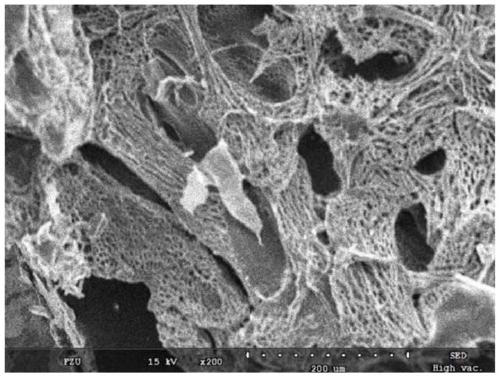

A kind of porous heavy metal ion adsorbent and preparation method thereof

ActiveCN107511139BWell-developed pore structureUniform distribution of poresOther chemical processesWater contaminantsCross-linkLiquid waste

The invention discloses a porous heavy metal ion adsorbent and a preparation method thereof. The method comprises the following steps: uniformly mixing a titanium dioxide solution with acrylic acid; preparing a stable uniform titanium dioxide / polyacrylic acid hybridized gel in the manner of cross-linking polymerization; and using an acid solution for eluting titanium dioxide, thereby acquiring the porous heavy metal ion adsorbent. The porous heavy metal ion adsorbent disclosed by the invention has a developed porous structure and uniform pore distribution, is capable of quickly adsorbing heavy metal ions and is ultrahigh in adsorbing capacity; the adsorbing capacity is free from obvious change after the repeated recycling; the preparation process is simple and efficient; the performance is excellent; and the porous heavy metal ion adsorbent is widely applied to the treatment for the wastewater and effluent containing heavy metal ions, has high industrial application potential and is wide in development prospect.

Owner:FUZHOU UNIV

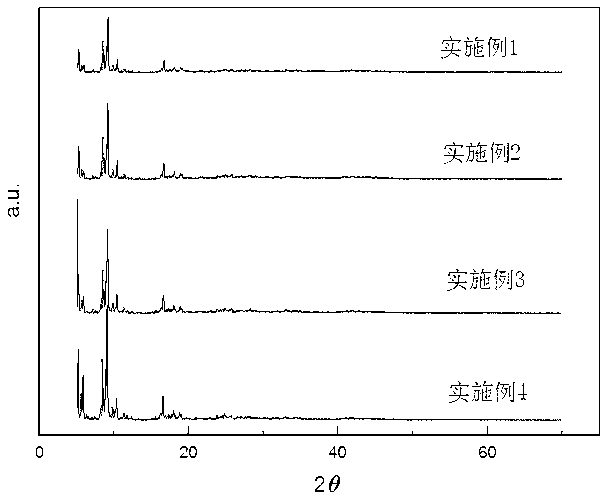

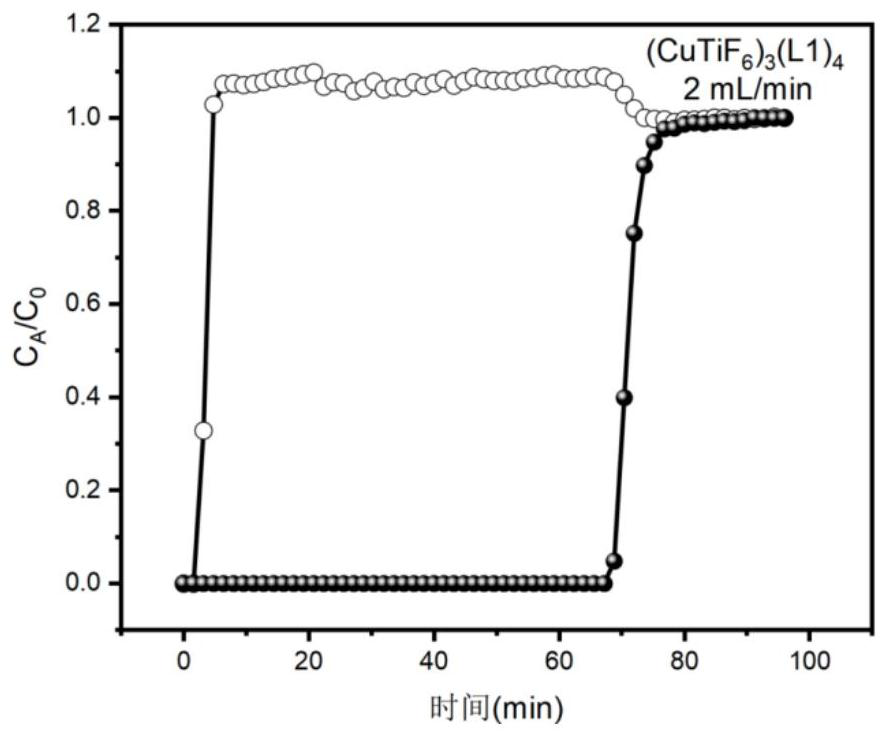

Method for capturing carbon dioxide from flue gas

ActiveCN114669163AReduce energy consumptionEasy desorption and regenerationGas treatmentOther chemical processesFlue gasSorbent

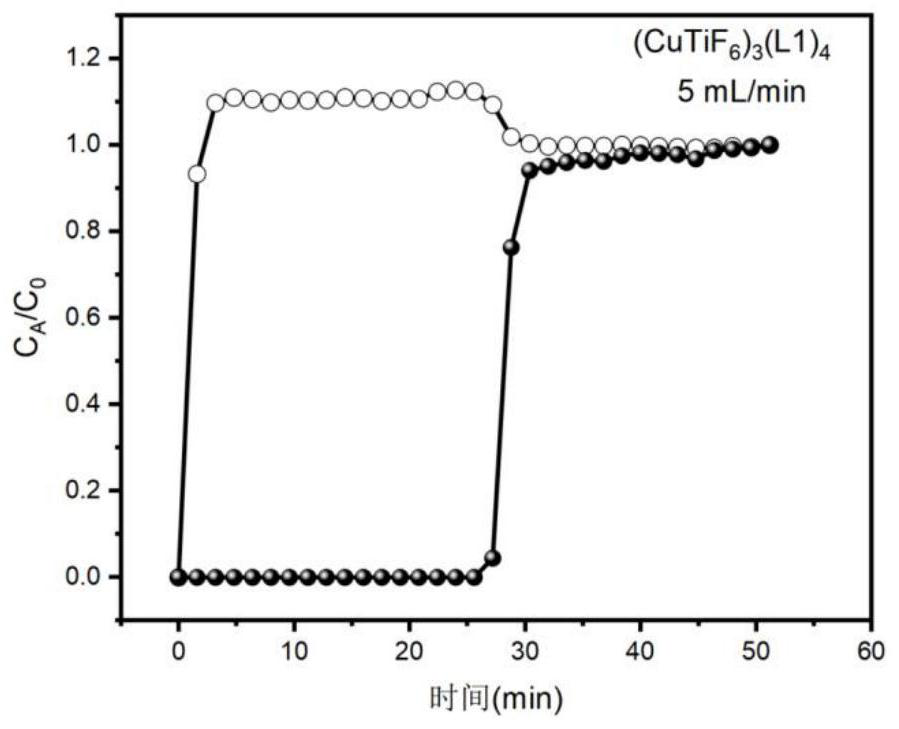

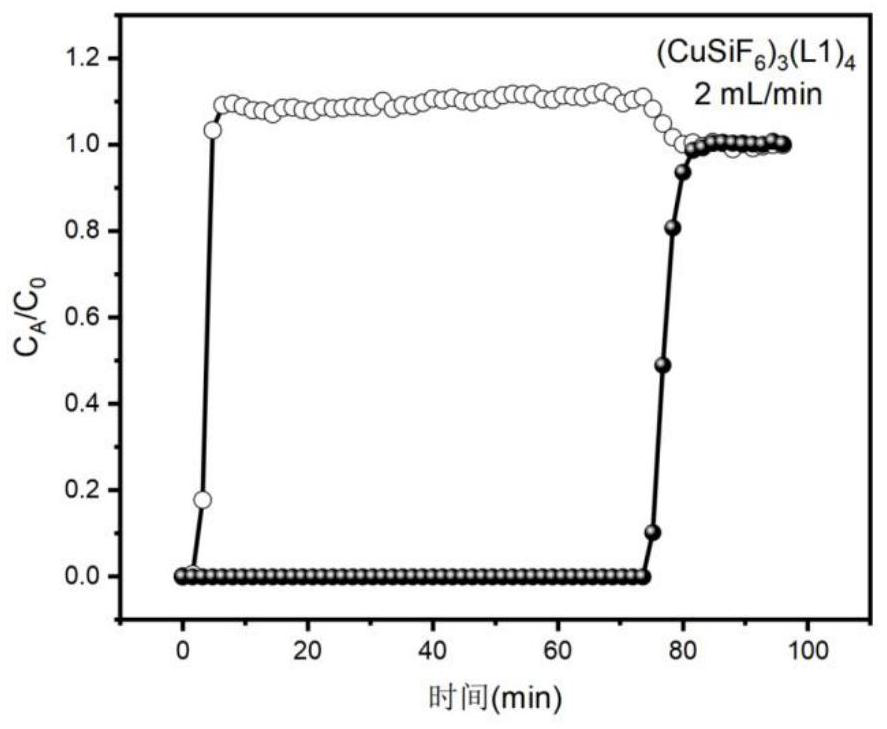

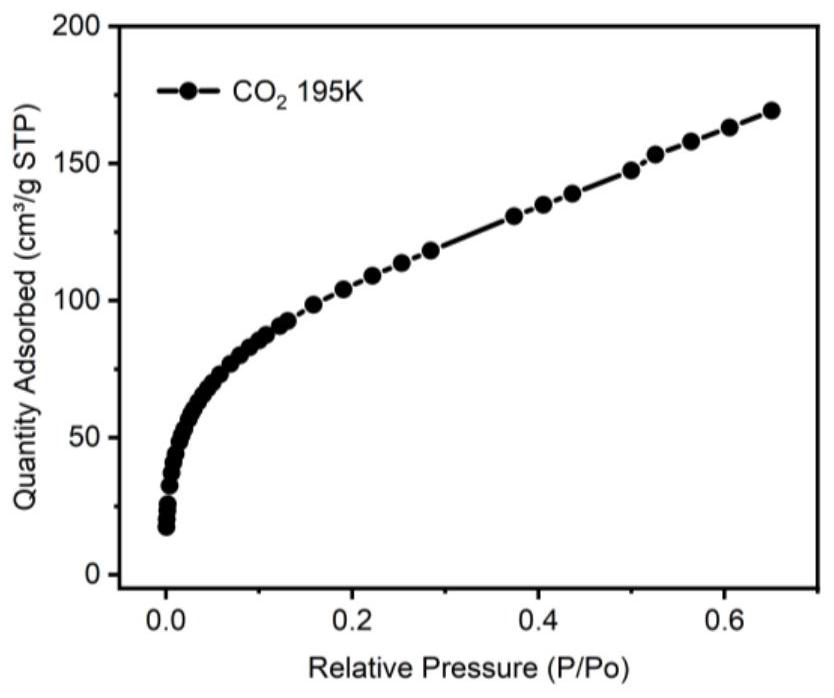

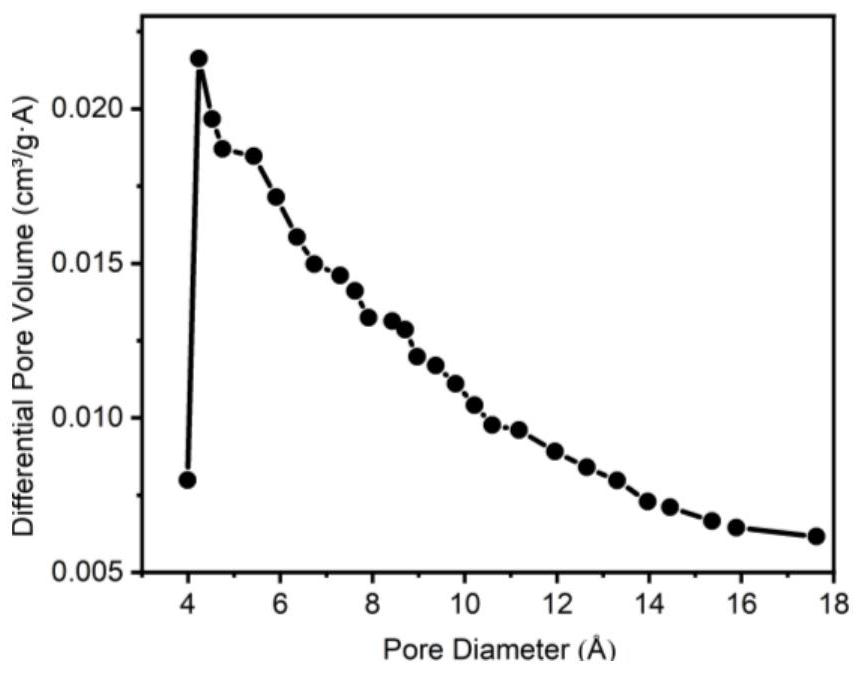

The invention discloses a method for capturing carbon dioxide from flue gas, which comprises the following step of: selectively adsorbing carbon dioxide in the flue gas by using an anion-containing hydrothermal stable column cage type metal-organic framework material as an adsorbent. The structure of the anion-containing hydrothermal stable column cage type metal-organic framework material is that hexa-coordinated metal ions M and a tridentate nitrogen-containing ligand L are coordinated to form a cage type structure, and then the cage type structure is connected through inorganic anions A to form a cross-linked column cage type structure. According to the method provided by the invention, carbon dioxide can be captured from the flue gas in a high-capacity and high-selectivity manner, the removal depth is high, the adsorbent is easy to regenerate, and the hydrothermal stability is good.

Owner:ZHEJIANG NORMAL UNIVERSITY

Alkaline functionalized porous polyion liquid material as well as preparation method and application thereof

ActiveCN114573750ARich in basic sitesHigh densityOther chemical processesDispersed particle separationIonic liquidMixed gas

The invention discloses an alkaline functionalized porous polyion liquid material, a preparation method thereof and application of the alkaline functionalized porous polyion liquid material in selective adsorption and separation of sulfur dioxide. The alkaline functionalized porous polyionic liquid material has the characteristics of rich alkaline functionalized sites, high ionic liquid content and developed pore structure. Through strong interaction between alkaline sites and sulfur dioxide guest molecules, deep removal of sulfur dioxide in mixed gas is realized. The material is high in stability, simple to prepare, good in adsorption performance, capable of being recycled, environmentally friendly and good in industrial application prospect.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

A modified polyamino macroporous resin and its preparation method and a method for treating waste gas from acrylic acid production

ActiveCN109134733BHigh affinityImprove adsorption capacityGas treatmentDispersed particle separationHydrogen moleculeMacroporous resin

The invention discloses a modified polyamino macroporous resin, a preparation method and a waste gas treatment method for acrylic acid production. The modified resin is an amino-modified macroporous resin. Compared with the ordinary macroporous resin, due to the special interaction between the amino group and the carbonyl hydrogen molecule, it has a better adsorption effect on acrolein and under alkaline conditions. Easy to desorb and regenerate, with stable performance. The resin of the invention can realize the recovery of toluene in the waste gas of acrylic acid, return it to the acrylic acid refining process and use it as an azeotroping agent for recycling, and realize the resource utilization of waste gas. At the same time, the exhaust gas after adsorption treatment meets the national emission index requirements, reducing the waste gas incineration treatment and further reducing energy consumption, resulting in great environmental protection and obvious economic benefits.

Owner:WANHUA CHEM GRP CO LTD

Treatment method of waste water in hydroxybenzoic acid production

InactiveCN101560044BReduce dosageImprove performanceWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentDesorptionWastewater

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

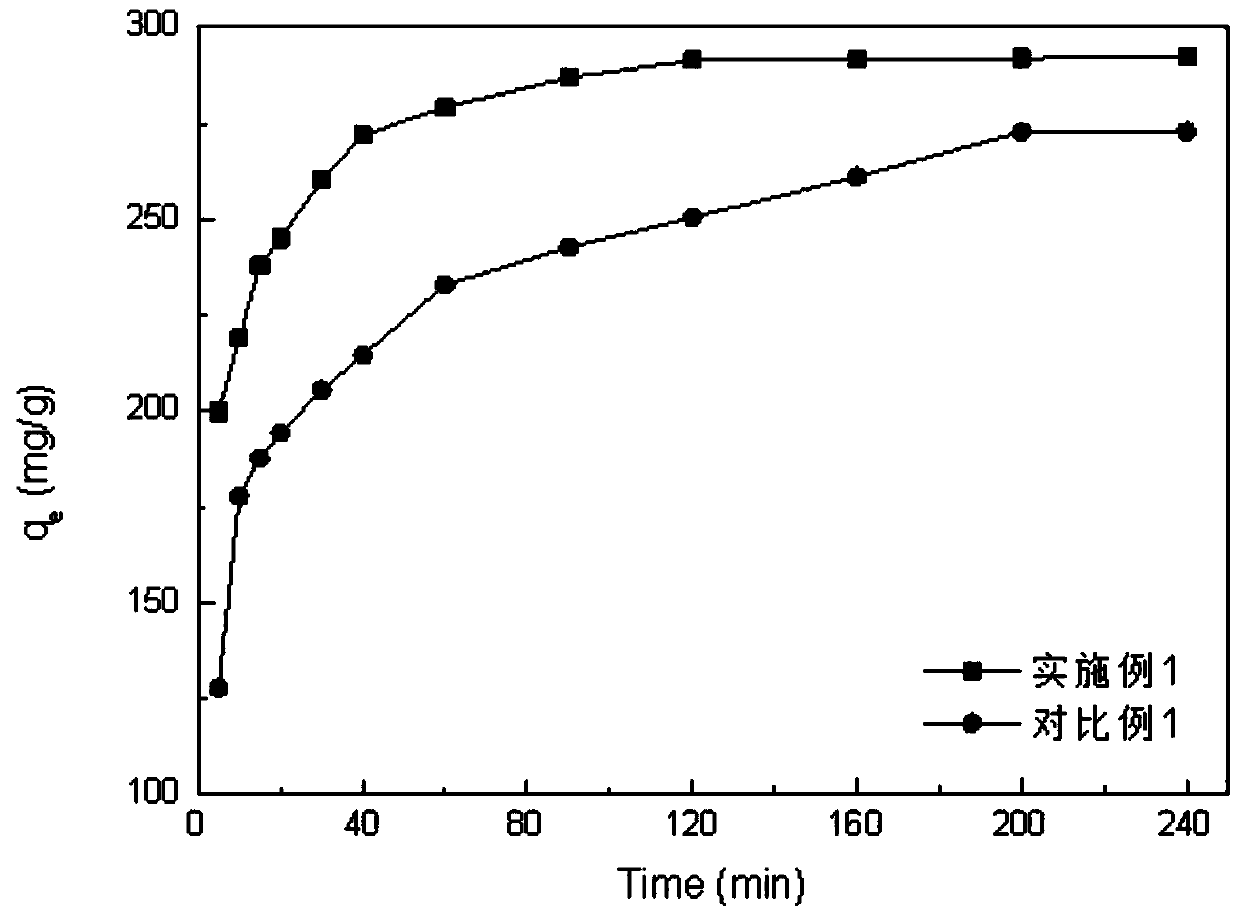

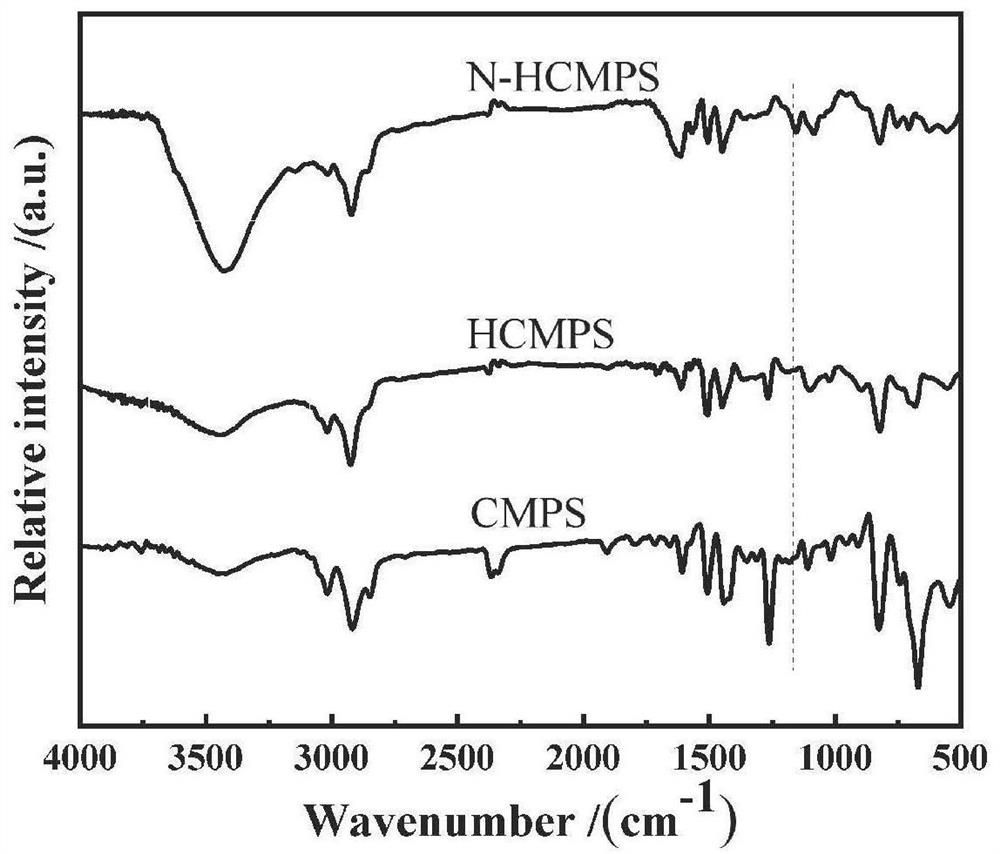

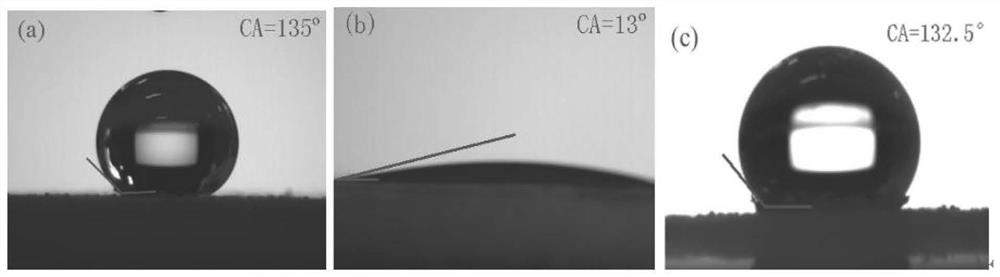

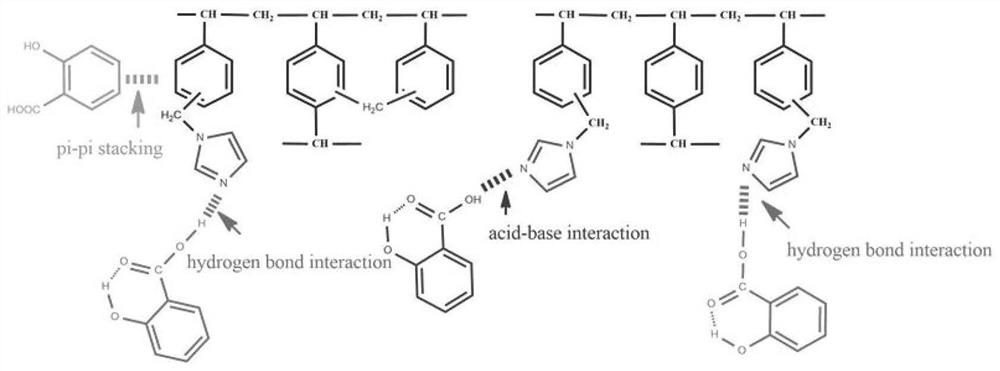

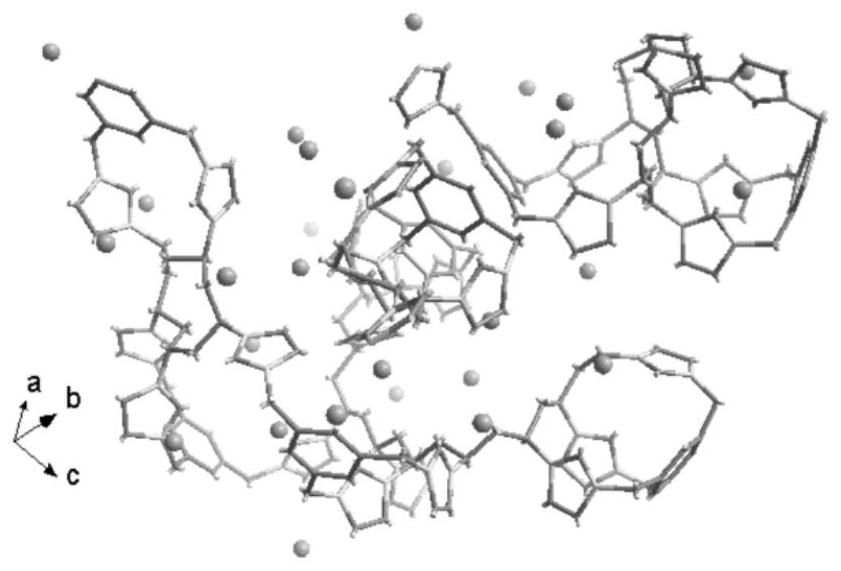

Imidazole modified high-crosslinked resin as well as preparation method and application thereof

PendingCN113912757AImprove adsorption efficiencyImprove hydrophilicityOther chemical processesWater contaminantsPolymer sciencePtru catalyst

The invention provides imidazole modified high-crosslinked resin and a preparation method and application thereof, and belongs to the technical field of macroporous resin. The preparation method comprises the steps of: after macroporous chloromethylated polystyrene is swelled, adding a catalyst to enable chloromethyl of a macroporous chloromethylated polystyrene skeleton to be subjected to a partial self-crosslinking reaction to obtain medium- / high-crosslinked resin; and further swelling the medium- / high-crosslinked resin, adding imidazole and alkali liquor for reaction, and enabling the residual part of chloromethyl of the medium- / high-crosslinked resin skeleton to be subjected to a nucleophilic substitution reaction with the imidazole to obtain imidazole modified high-crosslinked resin. The invention develops a novel adsorption resin material which is mainly used for treating organic wastewater, especially salicylic acid-containing wastewater. The salicylic acid adsorption rate of the novel adsorption resin material reaches 97.4%, the adsorption capacity reaches up to 263.2 mg / g, wastewater can be effectively treated, and the treatment cost is saved.

Owner:HUAIHUA UNIV

Process of treating and reusing effluent from 1-amino-8-naphthol-3, 6-disulfonic acid production

InactiveCN101066824BNot affected by the adsorption effectImprove practicalityOrganic chemistryTreatment using aerobic processesAlpha-naphtholEnvironmental engineering

The present invention is process of treating effluent from the production of dye intermediate 1-amino-8-naphthol-3, 6-disulfonic acid and recovering resource. The process includes: distilling pre-treatment of the effluent; adsorbing 1-amino-8-naphthol-3, 6-disulfonic acid, intermediate product and other organic matter from the effluent with macroporous weak alkaline resin ND900 in serially connected three column; neutralizing the adsorbed columns treated water with alkali and decompression distilling; and final aerobic biochemical treatment for the water to reach exhaust standard. The processcan reduce CODcr in the effluent from 16,700 mg / l to below 100 mg / l. The used resin may be desorbed with NaOH+H2O desorbing agent for reuse, and the desorbed liquid may be distilled for recovery.

Owner:NANKAI UNIV

A class of ultramicroporous ionic polymer material and its preparation method and application

ActiveCN111375390BImprove stabilityAir is freshOther chemical processesDispersed particle separationAlkyneAlkene

The invention discloses an ultra-microporous ionic polymer material based on hyperbranched ionic liquid and preparation and alkyne / olefin separation application thereof. The ultra-microporous ionic polymer material has the characteristics of high anion density and narrow pore size distribution, and the structural properties are regulated and controlled by changing a hyperbranched structure and anion and cation types. High-selectivity separation of acetylene and propyne is realized by utilizing a strong hydrogen bond environment constructed by high anion density and a size screening effect, sothat alkyne in alkyne and olefin mixed gas is removed to a very low degree, and olefin gas with extremely low alkyne content is obtained. The material prepared by the method has the advantages of highstability, simple preparation, strong controllability of material structural properties, good adsorption performance, easy desorption, greenness, environmental protection, and good industrial application prospect.

Owner:ZHEJIANG UNIV

A kind of modified macroporous resin and its method for treating butyl acrylate waste water

ActiveCN106732452BImprove adsorption capacityEasy desorption and regenerationOther chemical processesWater/sewage treatment by ion-exchangeDesorptionResource utilization

The invention discloses a modified macroporous resin and a method for treating wastewater produced by butyl acrylate. The modified macroporous resin is a macroporous resin modified by amino groups. Compared with ordinary macroporous resins, due to the special intermolecular effect of amino groups on carboxyl groups and hydroxyl groups, it is effective against acrylic acid, n-butanol, and polymerization inhibitors. Better adsorption effect, easy desorption and regeneration, stable performance. The present invention can recycle components such as acrylic acid, n-butanol, and polymerization inhibitor in butyl ester wastewater, and use them as raw materials for butyl ester esterification reaction to realize resource utilization of waste materials and produce obvious economic benefits; moreover, the treated wastewater can reach national According to the requirements of the wastewater discharge index, it can be directly discharged into the sea, which can reduce the pressure of subsequent wastewater treatment and produce great environmental benefits.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com