Temperature-sensitive metal organic skeleton material, preparation method, and applications thereof

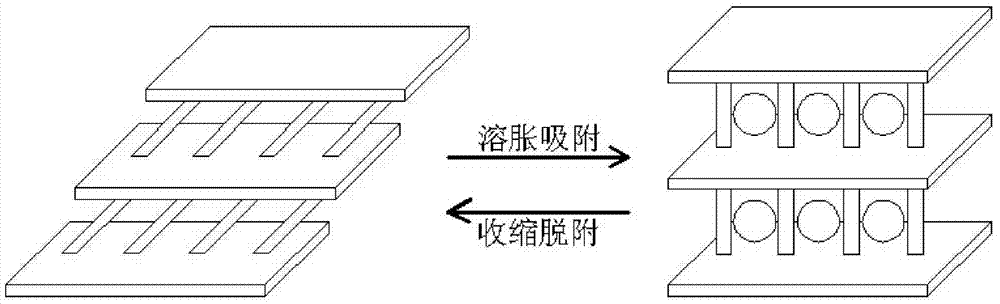

A metal-organic framework and temperature-sensitive technology, applied in the field of metal-organic framework porous materials and their preparation, can solve problems such as multiple energy consumption, achieve fast reaction, reversible and repeatable adsorption/desorption process, and easy desorption and regeneration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 0.3716g Cu(ClO 4 ) 2 ·6H 2 O and 1.0012g pyrazine are dissolved in the aqueous solution of 20mL ethanol (ethanol: H 2 (2 volume ratio 1:1), 0.1682g organic ligand 2,3-pyrazine dicarboxylic acid is dissolved in the aqueous solution of 20mL ethanol (ethanol: H 2 O volume ratio 1:1), then slowly add the ethanol aqueous solution of 2,3-pyrazine dicarboxylic acid into Cu(ClO 4 ) 2 ·6H 2 In the ethanol aqueous solution of O and pyrazine; Continue to stir 5h after dropwise addition, obtain blue solid; Then blue solid powder is washed 3 times with the aqueous solution of ethanol, soaked in methanol three times, replace a new methanol every 10h, finally use Centrifuge at 7000r / min for 8min, and vacuum dry at 100°C for 6h to obtain the temperature-sensitive metal-organic framework material.

Embodiment 2

[0046] 0.3604g Cu(ClO 4 ) 2 ·6H 2 O and 0.8041g pyrazine are dissolved in the aqueous solution of 15mL ethanol (ethanol: H 2 (2 volume ratio 5:1), 0.1576g organic ligand 2,3-pyrazine dicarboxylic acid is dissolved in the aqueous solution of 15mL ethanol (ethanol: H 2 (2 volume ratio 5:1), then slowly add the ethanol aqueous solution of 2,3-pyrazine dicarboxylic acid into Cu(ClO 4 ) 2 ·6H 2 In the ethanol aqueous solution of O and pyrazine; Continue to stir 2h after dropwise addition, obtain blue solid; Then blue solid powder is washed 2 times with the aqueous solution of ethanol, chloroform soaks 3 times, every 8h replaces a new chloroform, finally Centrifuge at 8000r / min for 5min, and vacuum dry at 80°C for 8h to obtain the temperature-sensitive metal-organic framework.

Embodiment 3

[0048] 0.3821g Cu(ClO 4 ) 2 ·6H 2 O and 1.2096g pyrazine are dissolved in the aqueous solution of 25mL ethanol (ethanol: H 2 (2 volume ratio 2:1), 0.1690g organic ligand 2,3-pyrazine dicarboxylic acid is dissolved in the aqueous solution of 25mL ethanol (ethanol: H 2 (2 volume ratio 2:1), then under stirring at room temperature, the ethanol aqueous solution of 2,3-pyrazine dicarboxylic acid was slowly added dropwise to Cu(ClO 4 ) 2 ·6H 2 O and pyrazine in an aqueous ethanol solution; after the dropwise addition, continue to stir for 8 hours to obtain a blue solid; then wash the blue solid powder with an aqueous solution of ethanol for 3 times, soak in DMF (N,N-dimethylformamide) for 2 time, replace with new DMF every 12 hours, and finally centrifuge at 6000r / min for 10 minutes, and vacuum dry at 150°C for 5 hours to obtain the temperature-sensitive metal-organic framework material.

[0049] Performance testing and analysis:

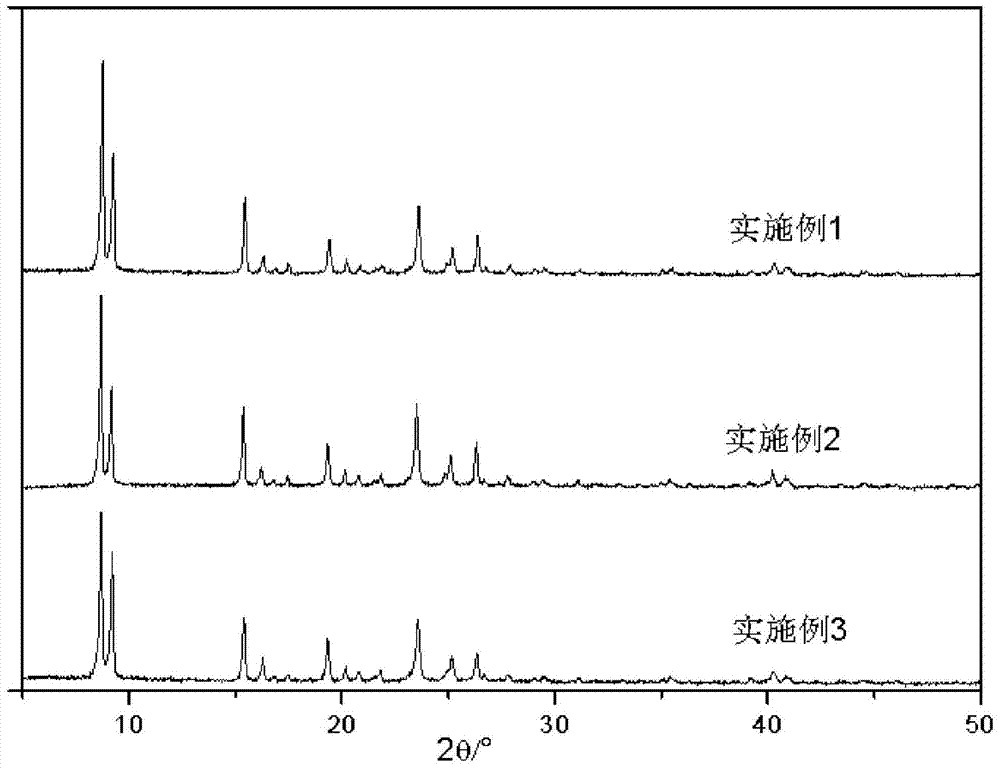

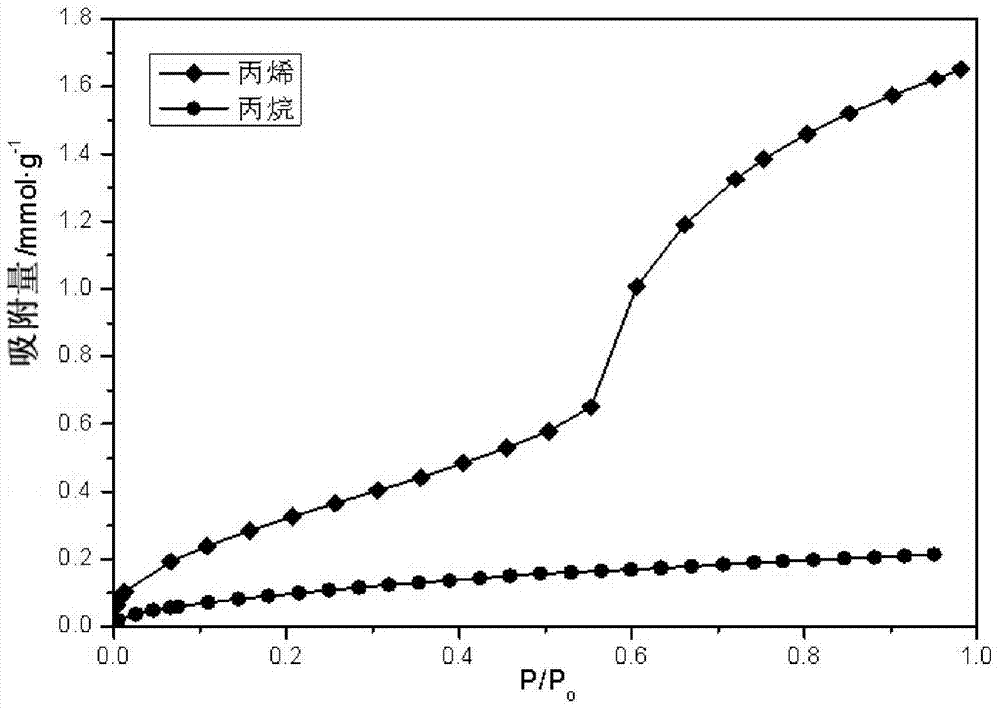

[0050] (1) Crystal structure properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com