Composite carbon dioxide adsorption material, preparation method and application thereof

A carbon dioxide, adsorption material technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve problems such as weak adsorption and separation capabilities, achieve high selectivity, overcome volatile, and large porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

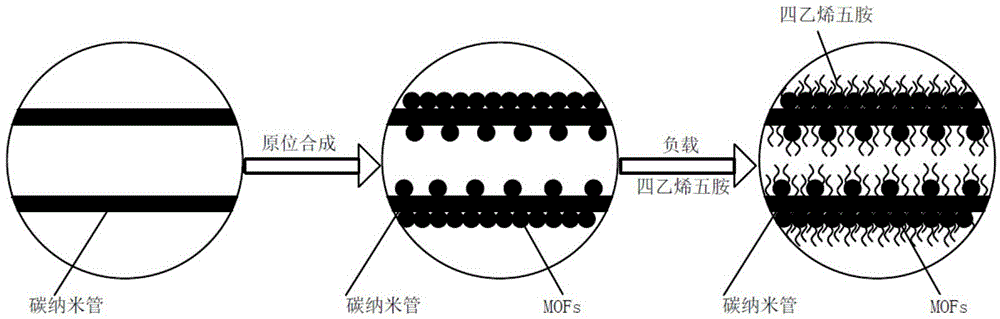

Embodiment 1

[0052] Dissolve 3.28g of terephthalic acid, 8g of chromium nitrate, and 0.25ml of hydrofluoric acid in a 200ml autoclave filled with 140ml of water, add 10g of carbon nanotubes, ultrasonicate for 0.5h, and react at 220°C for 8h. Cool naturally to room temperature, filter, wash, and dry to obtain MOFs-carbon nanotube composite material, referred to as (M-C)1.

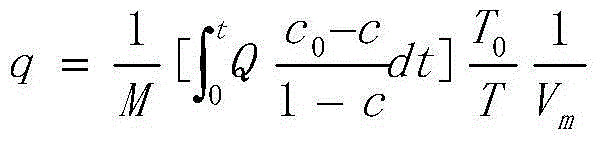

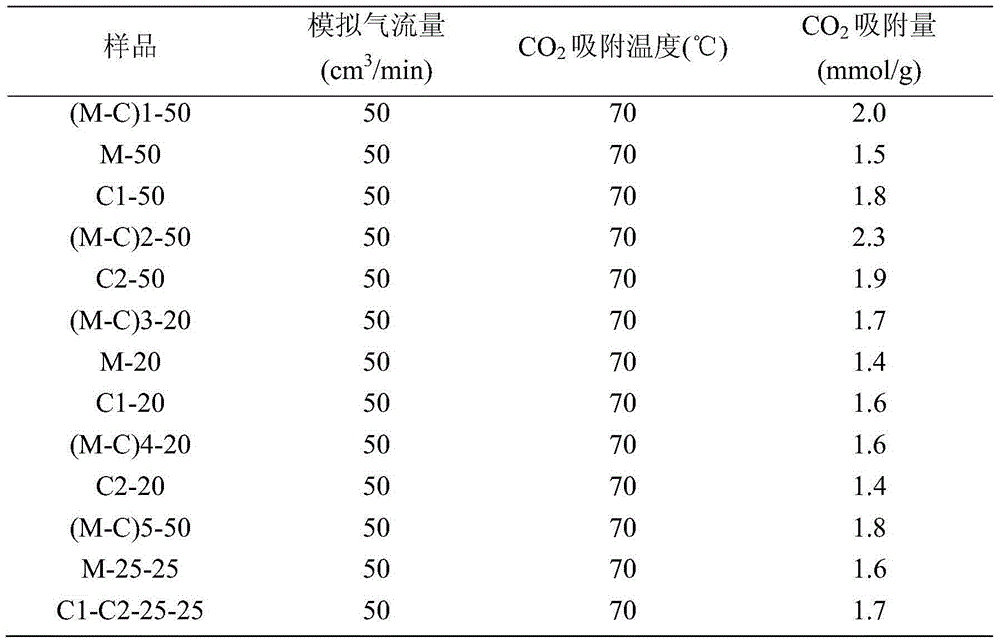

[0053] Dissolve 1g of tetraethylenepentamine in 100ml of absolute ethanol, add 1g of (M-C)1 after stirring for 0.5h, stir for 4h, put the sample in an oven, dry at 80°C to remove ethanol, and then dry at 105°C. In the obtained sample, the content of organic amine is 50wt%, which is recorded as (M-C)1-50. The adsorption data was measured by using a fixed bed. The adsorption temperatures were 20, 30, 40, 50, 60, 70, and 80°C, and the simulated gas flow was 50ml / min. The results are shown in Table 1.

Embodiment 2

[0060] Same as Example 1, except that carbon nanotubes are replaced by graphene, which is recorded as (M-C)2-50. CO 2 The test conditions of adsorption performance are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0064] Dissolve 3.28g of terephthalic acid, 8g of chromium nitrate, and 0.25ml of hydrofluoric acid in a 200ml autoclave filled with 140ml of water, add 15g of carbon nanotubes, ultrasonicate for 0.5h, and react at 220°C for 8h. Cool naturally to room temperature, filter, wash, and dry to obtain MOFs-carbon nanotube composite material, referred to as (M-C)3.

[0065] Dissolve 1g of polyethyleneimine in 100ml of absolute ethanol, stir for 0.5h, add 4g of (M-C)3, stir for 4h, put the sample in an oven, dry at 80°C to remove ethanol, and then dry at 105°C. In the obtained sample, the content of organic amine is 20wt%, which is recorded as (M-C)3-20. The adsorption data was measured by using a fixed bed, the adsorption temperature was 70°C, and the simulated gas flow rate was 50ml / min. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon dioxide adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com