Gasoline desulfurization adsorbent and preparation and application thereof

An adsorbent and gasoline technology, which is applied in the field of gasoline desulfurization adsorbent and its preparation and application, can solve the problems of low adsorption selectivity and adsorption capacity, harsh operating conditions and high operating cost, and achieves low production cost, low operating cost and raw material. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

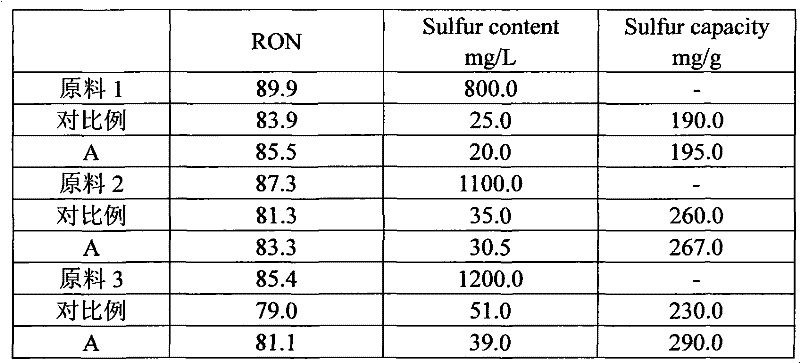

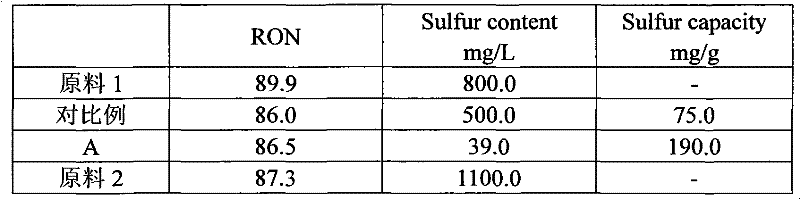

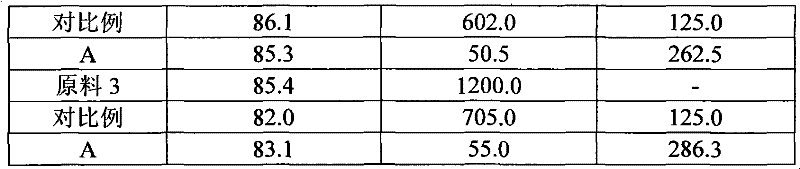

Examples

Embodiment 1

[0018] Preparation of desulfurization adsorbent in the present invention.

[0019] As an illustrative example, the sulfur storage agent is prepared as follows: Weigh 3.20 g of nickel nitrate hexahydrate, 3.20 g of aluminum nitrate hexahydrate, and 7.35 g of zinc nitrate hexahydrate and dissolve them in 200 ml of distilled water, add 8.10 g of urea and stir fully at 90°C for 24 hours to make The precipitating agent was completely hydrolyzed, filtered and washed with deionized water to obtain a wet filter cake, which was then vacuum-dried to obtain a green solid, which was calcined at 500°C for 4 hours, and the sample number was A.

Embodiment 2

[0021] The preparation of octane recovery agent in the present invention.

[0022] As an illustrative example, the octane recovery agent is prepared as follows: weigh 32.5g Hβ, 17.5g pseudo-boehmite, grind and mix them evenly, add 1mL 63% concentrated HNO 3 and 37mL of distilled water, and grind into a moderately suitable powder cake. Extrude on a extruder into rods with a diameter of 2 mm. After air drying at room temperature, it was dried at 120° C. for 10 hours, and calcined at 500° C. for 4 hours to prepare a catalyst carrier. Weigh 0.8227 g of ammonium molybdate and add 4 mL of distilled water to dissolve it, and add 3 mL of distilled water containing 0.5 mL of 85% phosphoric acid into the ammonium molybdate solution. Add 10 grams of catalyst carrier into the above mixed solution, soak for 24 hours, dry at 120°C for 12 hours, and then bake at 500°C for 4 hours. The sample number is B.

Embodiment 3

[0024] The invention prepares the mixed adsorbent containing sulfur storage agent and octane recovery agent.

[0025] Mix the wet filter cake obtained in Example 1 with 2g Hβ and 1g pseudo-boehmite evenly, put it in an oven and dry it at 60°C for 1 hour, then add 3ml of 3% nitric acid aqueous solution and knead it and extrude it; After drying, it was dried at 120° C. and calcined at 500° C. to obtain a calcined sample; and then carried molybdenum and phosphorus on the above calcined sample in the same manner as in Example 2 to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com