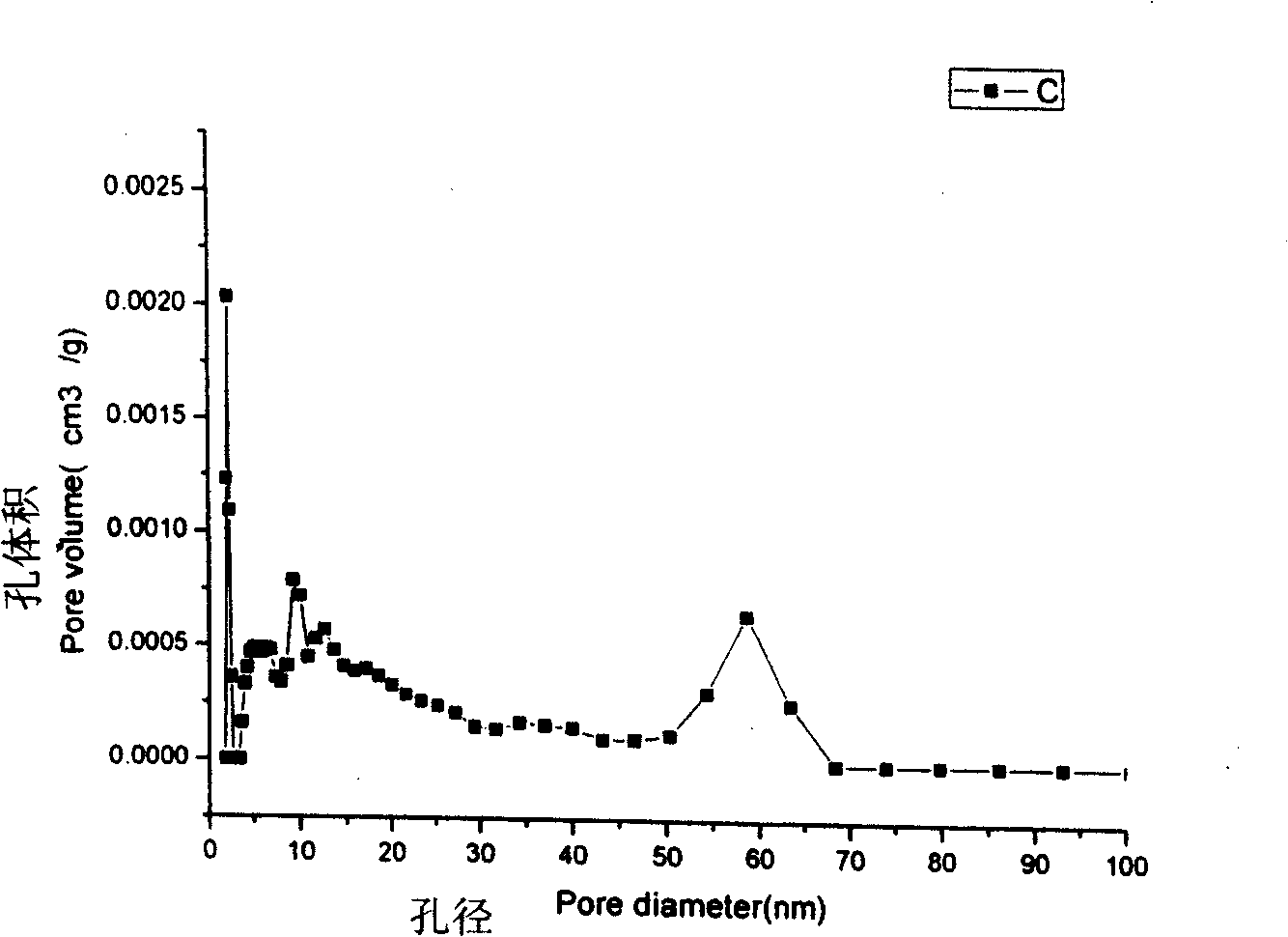

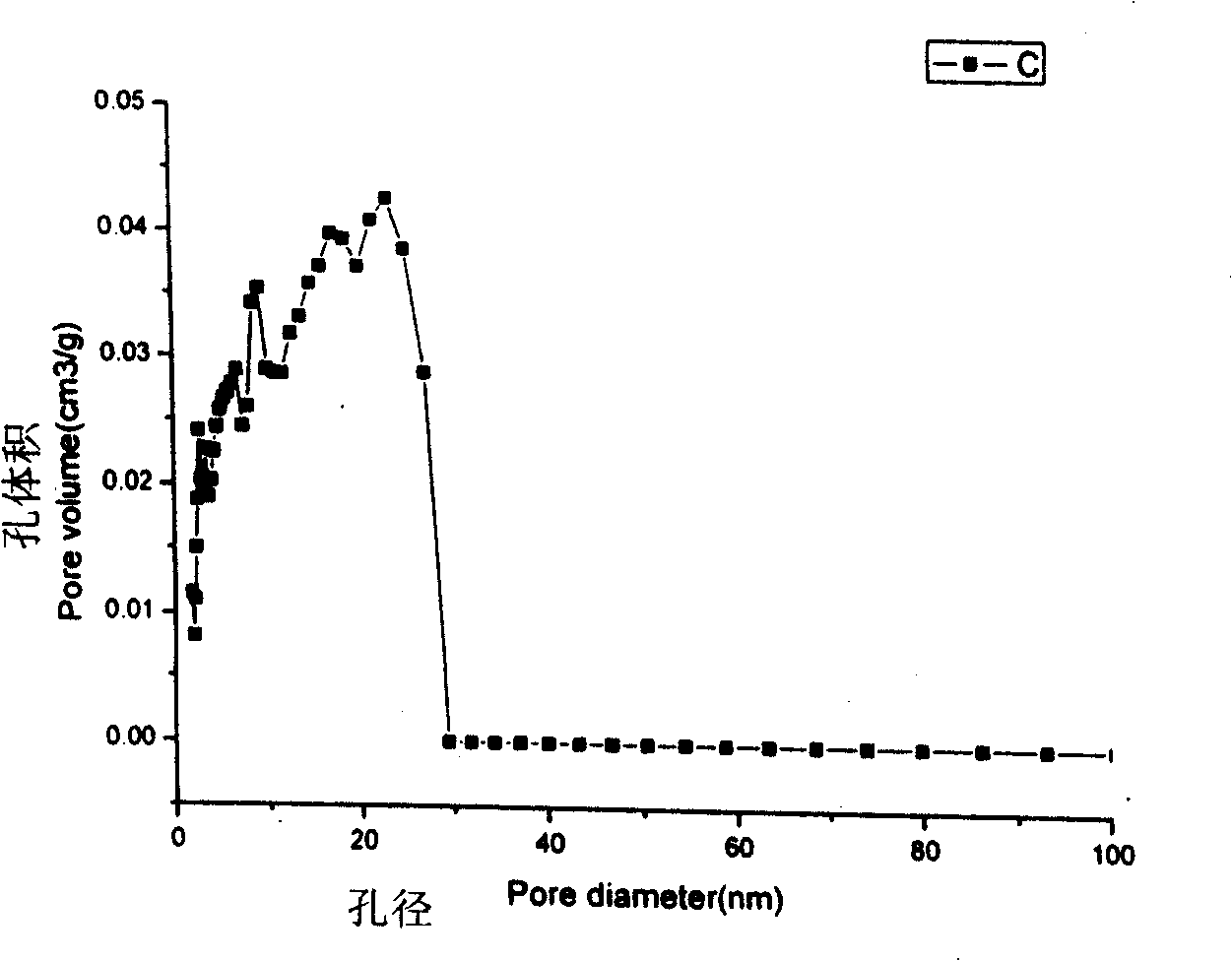

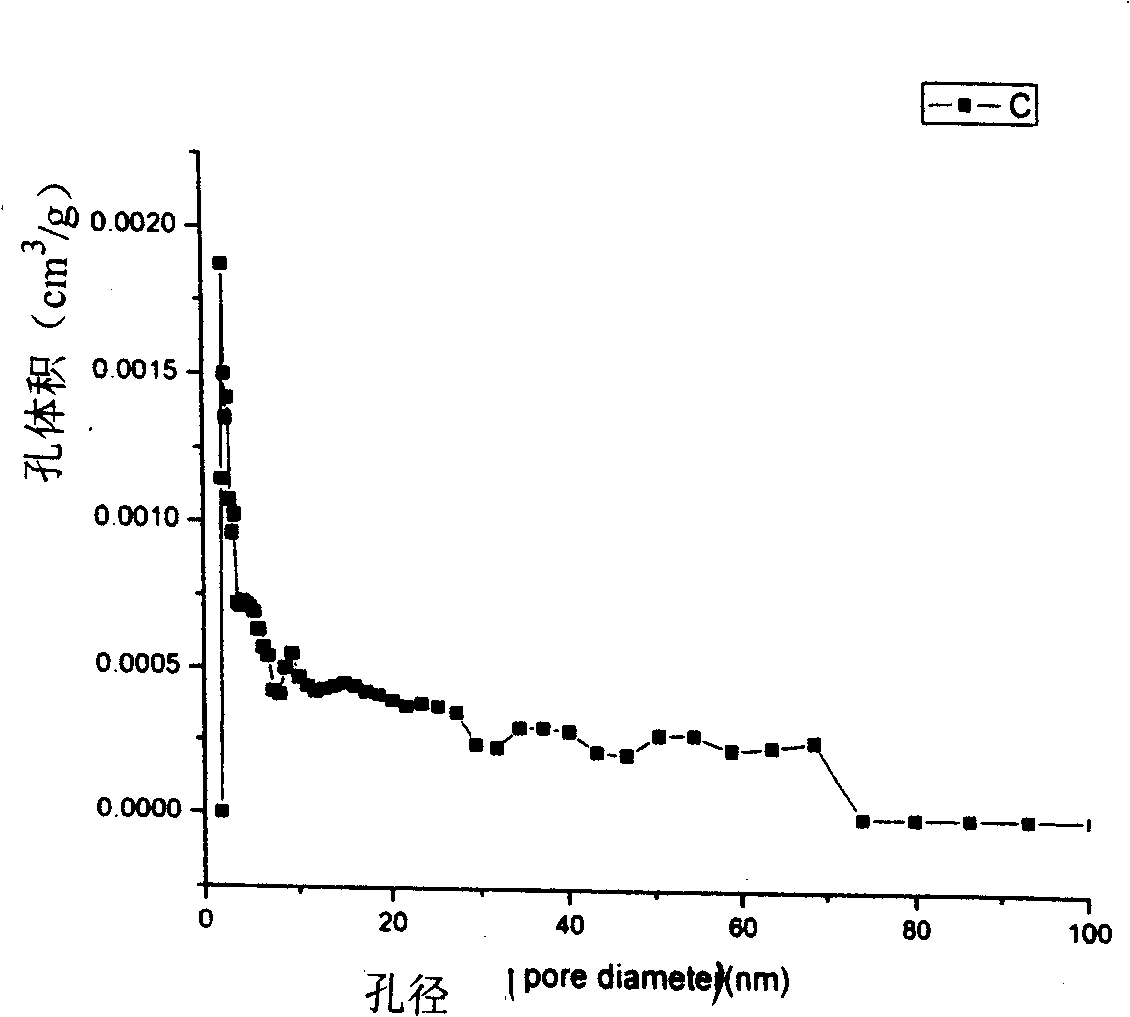

Adsorption resin with centralized pore diameter and large Micropore specific surface area and method for producing the same

A technology with large specific surface area and adsorption resin, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problem of uneven pore size distribution of ultra-high cross-linked adsorption resin, and achieve simple equipment, good adsorption selectivity, and uniform pore distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The low cross-linked polymer with styrene-divinylbenzene skeleton was synthesized by suspension polymerization. The water phase (500g) contained 1g of hydroxyethyl cellulose, 2g of sodium carbonate, 30g of magnesium sulfate, and 100g of table salt. The oil phase (300 g) contained: 176.5 g of styrene monomer, 23.5 g of divinylbenzene (purity: 55.1%), and 100 g of ethylene glycol monomethyl ether. Add 3 g of initiator benzoyl peroxide in addition. The polymerization reaction is carried out in a three-necked flask of 1000 milliliters, first add the pre-configured water phase, add the oil phase containing the initiator under stirring, add 2ml of 15% (w / w) methylene blue aqueous solution, and stir the oil phase Disperse, the speed of stirrer is controlled at 300rpm, then add the sodium lignosulfonate aqueous solution of 8ml10% (w / w); Polymerization reaction temperature is 78 ℃, after reacting for 10 hours, keep warm at 85 ℃ for 6 hours, then be warming up to 90 ℃ boil ball...

Embodiment 2

[0038] The low cross-linked polymer with styrene-divinylbenzene skeleton was synthesized by suspension polymerization. The aqueous phase (400 g) contained 0.8 g of hydroxyethyl cellulose, 1.6 g of sodium carbonate, and 24 g of magnesium sulfate. The oil phase (240 g) contained 89.8 g of monomeric styrene, 43.2 g of divinylbenzene (80% purity), and 107 g of ethylene glycol monomethyl ether. In addition, 1 g of benzoyl peroxide and 1.4 g of azobisisobutyronitrile (AIBN) were added. The polymerization reaction was carried out in a 1000 ml three-necked flask. First add the pre-configured water phase, add the oil phase containing the initiator under stirring, add 1ml of 30% (w / w) methylene blue aqueous solution, stir and disperse the oil phase, control the speed of the stirrer at 300rpm, and then Add 4ml of 20% (w / w) sodium lignosulfonate aqueous solution; the polymerization temperature is 75°C, and after 10 hours of reaction, keep the temperature at 80°C for 6 hours, then heat u...

Embodiment 3

[0040] The low cross-linked polymer with styrene-divinylbenzene skeleton was synthesized by suspension polymerization. The aqueous phase (500 g) contained 3 g of hydroxyethyl cellulose, 0.5 g of sodium lignosulfonate, 2 g of sodium carbonate, 30 g of magnesium sulfate, and 100 g of table salt. The oil phase (300 g) contained 229.3 g of monomeric styrene, 23.5 g of divinylbenzene (purity: 55.1%), and 47.2 g of tetraethylene glycol monomethyl ether. Add 3 g of initiator benzoyl peroxide in addition. The polymerization reaction is carried out in a three-necked flask of 1000 milliliters, first add the pre-configured water phase, add the oil phase containing the initiator under stirring, add 6ml of 5% (w / w) methylene blue aqueous solution, and stir the oil phase Disperse, the speed of the stirrer is controlled at 300rpm, and then add 2.5ml of 20% (w / w) sodium lignosulfonate aqueous solution; the polymerization temperature is 78 ° C, after 10 hours of reaction, keep it at 85 ° C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com