Method for capturing carbon dioxide from flue gas

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problem of low adsorption capacity, achieve high removal depth, easy regeneration, and high selectivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In a 50 mL round bottom flask, 241.6 mg (1 mmol) of Cu(NO 3 ) 2 ·3H 2 O and 197.9 mg (1 mmol) of (NH 4 ) 2 TiF 6 Dissolve in 14mL of water. In another 50 mL round bottom flask, 331.05 mg (1.3 mmol) of tris(4-pyridyl)amine (L1) was dissolved in 30 mL methanol. The methanol solution was added dropwise to the aqueous solution and stirred at 30°C for 48 hours to obtain a purple solid precipitate, which was filtered and washed with methanol. The above-mentioned solid was immersed in anhydrous methanol, and the anhydrous methanol was replaced every six hours for more than 3 times in total to remove the water molecules in the pores of the material, and the column cage metal organic framework material (CuTiF) was obtained. 6 ) 3 (L1) 4 .

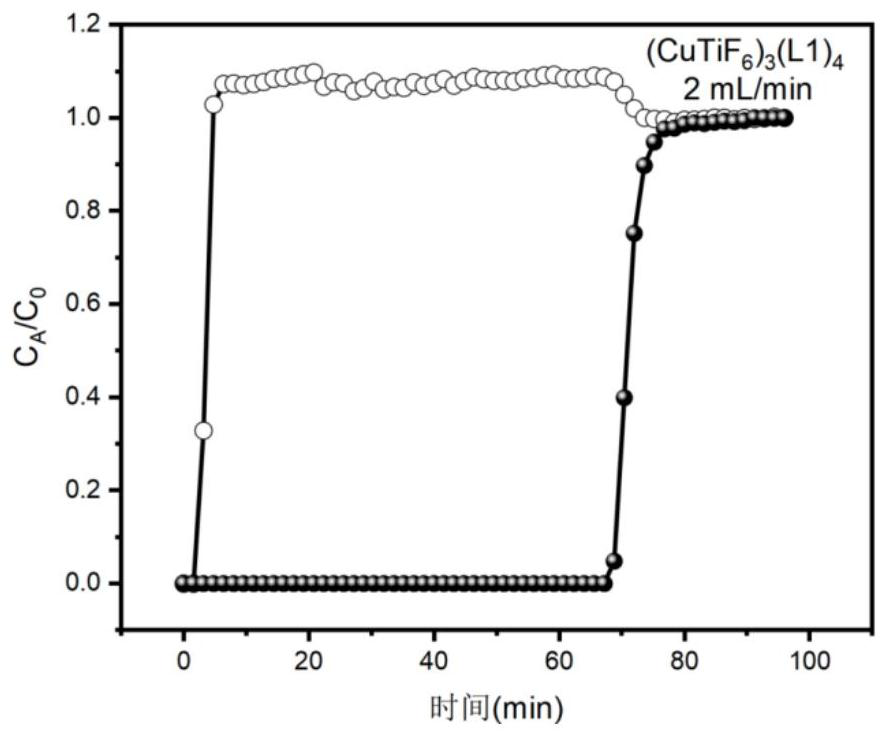

[0045] (CuTiF 6 ) 3 (L1) 4 Grind into fine powder of uniform size, put it into an adsorption column with an inner diameter of 0.5 cm and a length of 5 cm, activate it at 120 °C for 10 hours, and at room temperature of 25 °C, pass ...

Embodiment 2

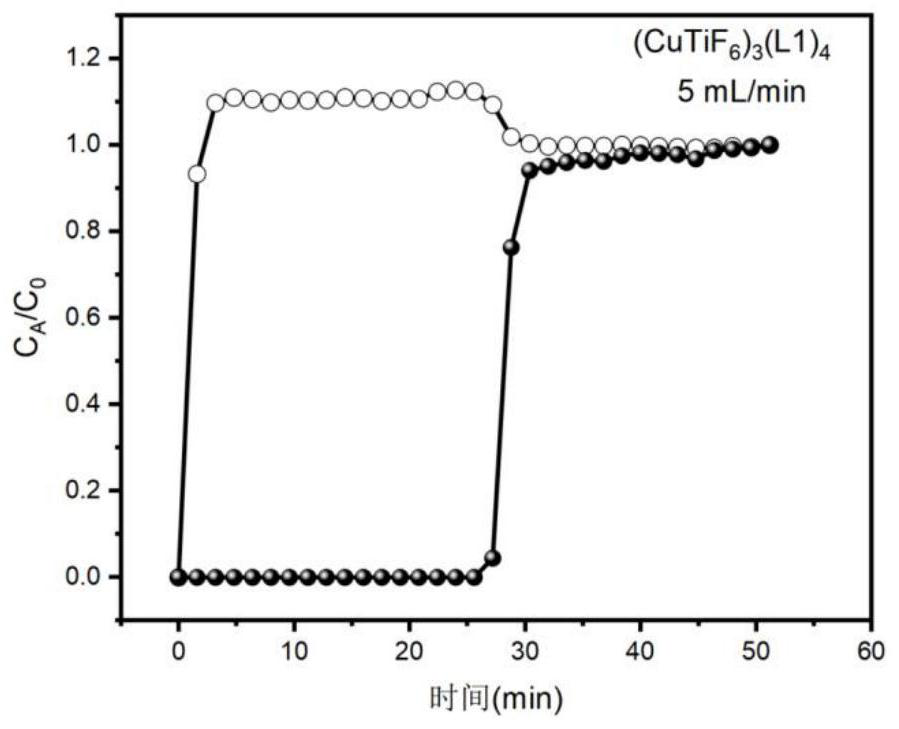

[0047] The adsorption column (inner diameter 0.5cm, length 5cm) of embodiment 1, at room temperature 25 ℃, the nitrogen / carbon dioxide gas mixture is passed into the adsorption column at 5mL / min, the nitrogen with extremely low carbon dioxide content is obtained in the first 26min, and the adsorption is stopped. At 50°C, the carbon dioxide gas was desorbed under vacuum. N 2 / CO 2 (v:v=85:15) mixture in (CuTiF 6 ) 3 (L1) 4 The penetration curve on the figure 2 shown.

Embodiment 3

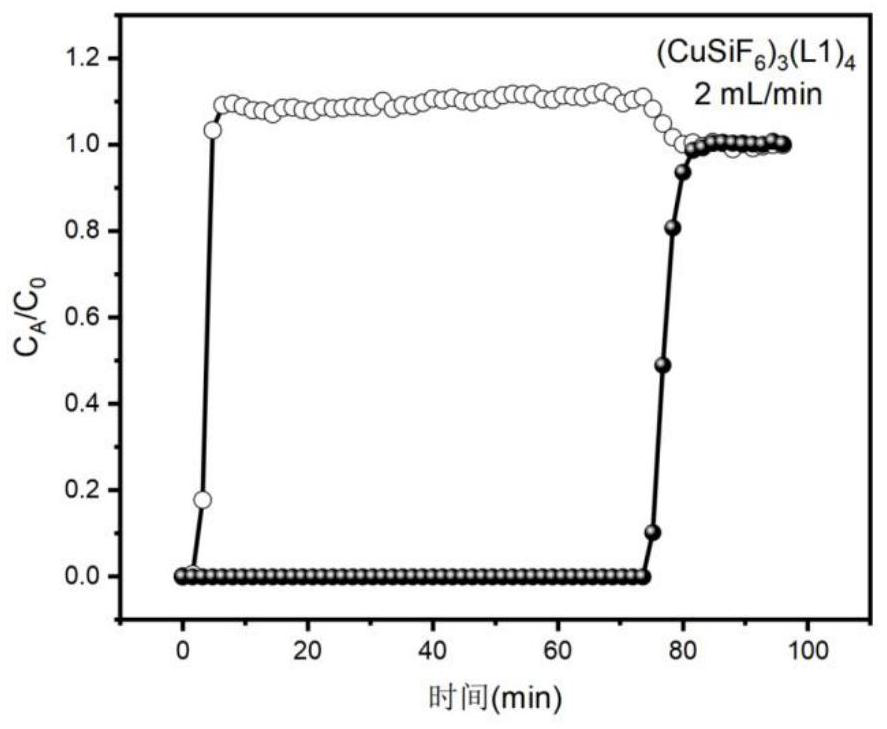

[0049] In a 50 mL round bottom flask, 277.7 mg (1 mmol) of CuSiF 6 Dissolve in 14mL of water. In another 50 mL round bottom flask, 331.05 mg (1.3 mmol) of tris(4-pyridyl)amine (L1) was dissolved in 30 mL methanol. The methanol solution was added dropwise to the aqueous solution, and stirred at 30° C. for 48 hours to obtain a purple-red solid precipitate, which was filtered and washed with methanol. The above-mentioned solid was immersed in anhydrous methanol, and the anhydrous methanol was replaced every six hours for more than 3 times in total to remove the water molecules in the material holes to obtain a column cage-type metal organic framework material (CuSiF). 6 ) 3 (L1) 4 .

[0050] Grind the adsorbent into fine powder of uniform size, put it into an adsorption column with an inner diameter of 0.5 cm and a length of 5 cm, activate it at 120°C for 10 hours, and mix nitrogen / carbon dioxide (v:v=85:15) at room temperature of 25°C The gas was passed into the adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com