Metal organic skeleton-graphite oxide nano composite adsorption material and preparing method thereof

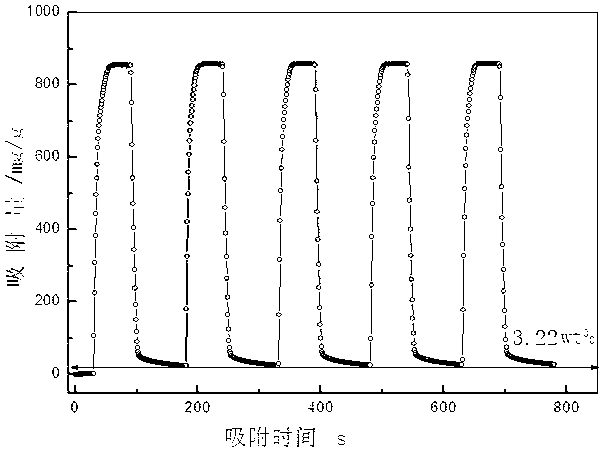

A metal-organic framework and nanocomposite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low physical adsorption force of alkane molecules and low atomic arrangement density, and achieve easy desorption regeneration and excellent cycle performance. , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

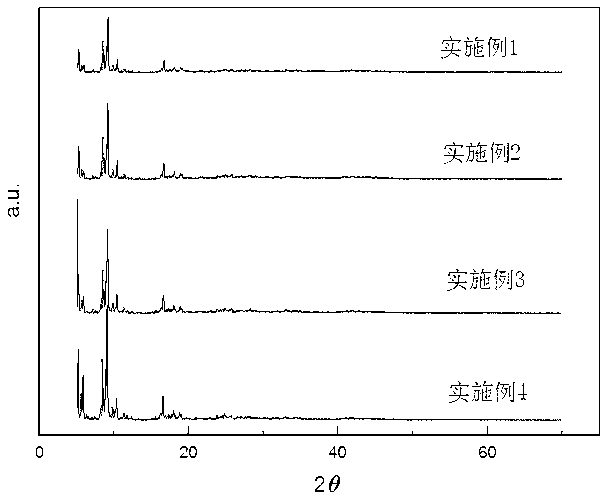

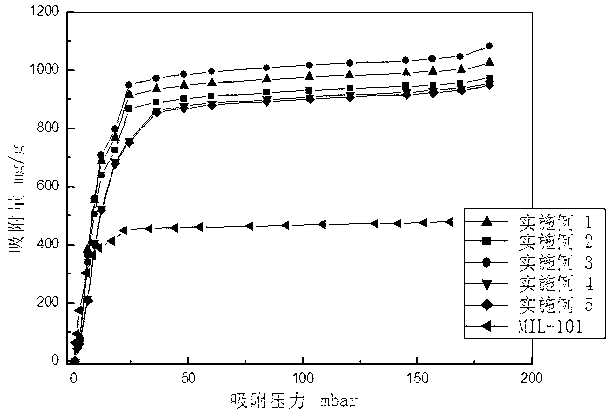

Embodiment 1

[0029] 2.395g Cr(NO 3 ) 3 9H 2 O and 1.988g of terephthalic acid were dissolved in 43mL of deionized water; while stirring, 0.26mL of hydrofluoric acid with a mass concentration of 40% was added dropwise, then 0.2192g of graphite oxide was added, and placed on a magnetic stirrer and stirred for 30min to obtain a reaction Then pour the reaction solution into a stainless steel high-pressure reaction kettle, seal it, and put it into a temperature-programmed furnace for hydrothermal reaction. After constant temperature for 8 hours, the solution was lowered to 25°C at a cooling rate of 0.4°C / min; after the reaction was completed, the precipitates were washed with water and ethanol in turn, centrifuged at 5000r / min for 40min, and the lower layer was dried in an oven at 100°C After 10 hours, the metal-organic framework-graphite oxide nanocomposite adsorption material was obtained.

Embodiment 2

[0031] 2.395g Cr(NO 3 ) 3 9H 2 O and 0.994g of terephthalic acid were dissolved in 30mL of deionized water; while stirring, 0.13mL of hydrofluoric acid with a mass concentration of 40% was added dropwise, then 0.3389g of graphite oxide was added, and placed on a magnetic stirrer and stirred for 35min to obtain a reaction Then pour the reaction solution into a stainless steel high-pressure reaction kettle, seal it and put it into a temperature-programmed furnace for hydrothermal reaction. After constant temperature for 8 hours, the solution was lowered to 35°C at a cooling rate of 1°C / min; after the reaction was completed, the precipitates were washed with water and ethanol in turn, centrifuged at 7000r / min for 30min, and the lower layer was dried in an oven at 130°C 8h, the metal-organic framework-graphite oxide nanocomposite adsorption material was obtained.

Embodiment 3

[0033] 2.395g Cr(NO 3 ) 3 9H 2 O and 0.994g of terephthalic acid were dissolved in 30mL of deionized water; while stirring, 0.13mL of hydrofluoric acid with a mass concentration of 40% was added dropwise, then 0.5084g of graphite oxide was added, and placed on a magnetic stirrer and stirred for 30min to obtain a reaction Then pour the reaction solution into a stainless steel high-pressure reaction kettle, seal it and put it into a temperature-programmed furnace for hydrothermal reaction. After constant temperature for 9 hours, the solution was lowered to 35°C at a cooling rate of 0.4°C / min; after the reaction was completed, the precipitates were washed with water and ethanol in sequence, centrifuged at 5000r / min for 40min, and the lower layer was dried in an oven at 130°C 8h, the metal-organic framework-graphite oxide nanocomposite adsorption material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com