Imidazole modified high-crosslinked resin as well as preparation method and application thereof

A high cross-linking, resin technology, used in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Complex process and other problems, to achieve the effect of good reuse performance, improved raw material utilization and yield, and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method of imidazole modified highly cross-linked resin, comprising the following steps:

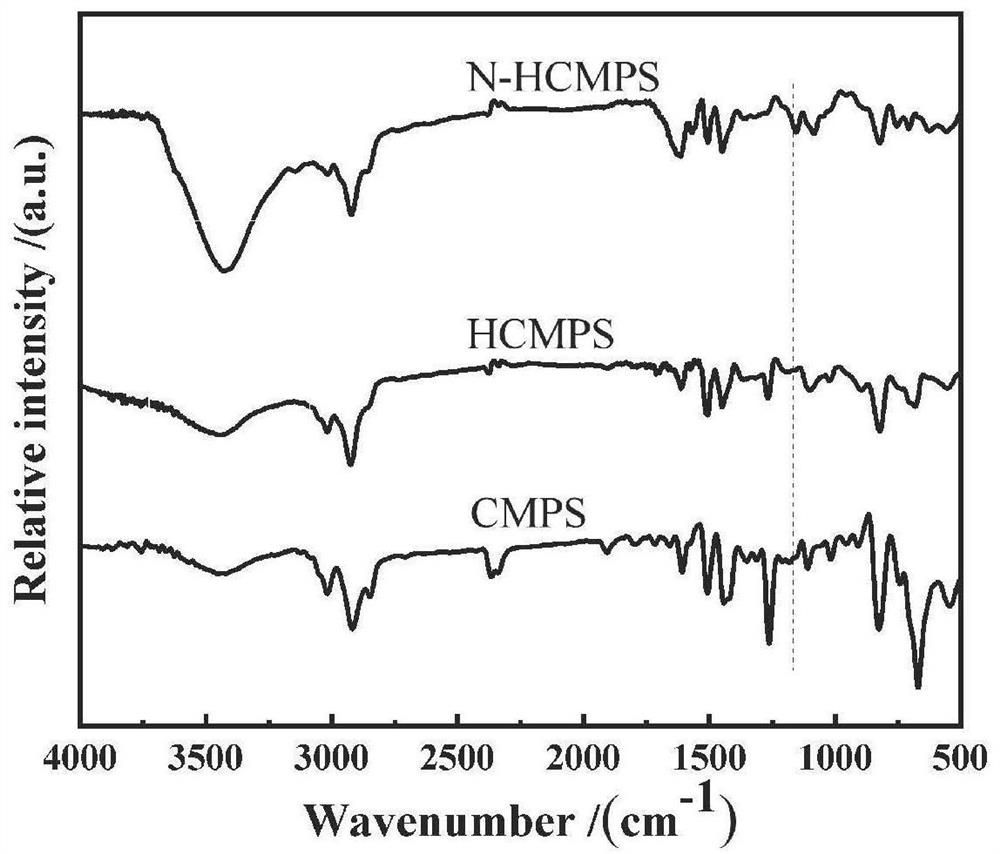

[0032] S1. 20 g of macroporous chloromethylated polystyrene (CMPs, Cl%: 17.3 wt.%) was swelled in 120 mL of 1,2-dichloroethane (DCE) at room temperature overnight, and 4.0 g of anhydrous FeCl was added 3 as a catalyst. The reaction was carried out at 80°C for 30 min. After the polymer was filtered, it was washed sequentially with hot water, absolute ethanol, 1% dilute hydrochloric acid, and absolute ethanol, dried at low temperature, extracted with ethanol Soxhlet for 12 h, and vacuum-dried at 50°C for 12 h. , to obtain medium and high cross-linked resins, called HCMPs (Cl%: 4.5 wt.%, specific surface area 700cm 2 / g), standby.

[0033]S2. Swell 10 g of HCMPs in 120 mL of DCE overnight at room temperature, add 8 g of imidazole and 10 g of 5% sodium hydroxide solution into the reactor, react at 80 °C for 12 h under nitrogen protection, and fi...

Embodiment 2

[0038] S1. 20 g CMPs were swelled overnight at room temperature in 120 mL dichloromethane, and 2.0 g anhydrous AlCl was added 3 as a catalyst. The reaction was carried out at 70°C for 40 min. After the polymer was filtered, it was washed sequentially with hot water, absolute ethanol, 1% dilute hydrochloric acid, and absolute ethanol, dried at low temperature, extracted with ethanol Soxhlet for 12 h, and vacuum-dried at 50°C for 12 h. , to obtain medium and high cross-linked resins, called HCMPs, for later use.

[0039] S2. Swell 10 g HCMPs in 120 mL of dichloromethane overnight at room temperature, add 5 g of imidazole and 10 g of 5% potassium hydroxide solution to the reactor, and react at 70 °C for 12 h under nitrogen protection, Filter, wash with hot water, absolute ethanol, 1% dilute hydrochloric acid, and absolute ethanol sequentially, dry at low temperature, extract with ethanol Soxhlet for 12 h, and dry in vacuum at 50°C for 12 h to obtain 10.4 g of imidazole-modified ...

Embodiment 3

[0041] S1. 20 g CMPs were swollen overnight at room temperature in 120 mL carbon tetrachloride, and 6.0 g anhydrous ZnCl was added 2 as a catalyst. The reaction was carried out at 90°C for 30 min. After the polymer was filtered, it was washed sequentially with hot water, absolute ethanol, 1% dilute hydrochloric acid, and absolute ethanol, dried at low temperature, extracted with ethanol Soxhlet for 12 h, and vacuum-dried at 50°C for 12 h. , to obtain medium and high cross-linked resins, called HCMPs, for later use.

[0042] S2. Swell 10 g HCMPs in 120 mL of DCE overnight at room temperature, add 9 g of imidazole and 10 g of 5% potassium carbonate solution into the reactor, react at 80 °C for 12 h under nitrogen protection, filter, and use Wash with hot water, absolute ethanol, 1% dilute hydrochloric acid, and absolute ethanol in sequence, dry at low temperature, extract with ethanol Soxhlet for 12 h, and dry in vacuum at 50°C for 12 h to obtain 10.5 g imidazole-modified highl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com