Patents

Literature

107results about How to "Stable mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

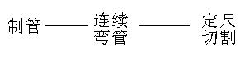

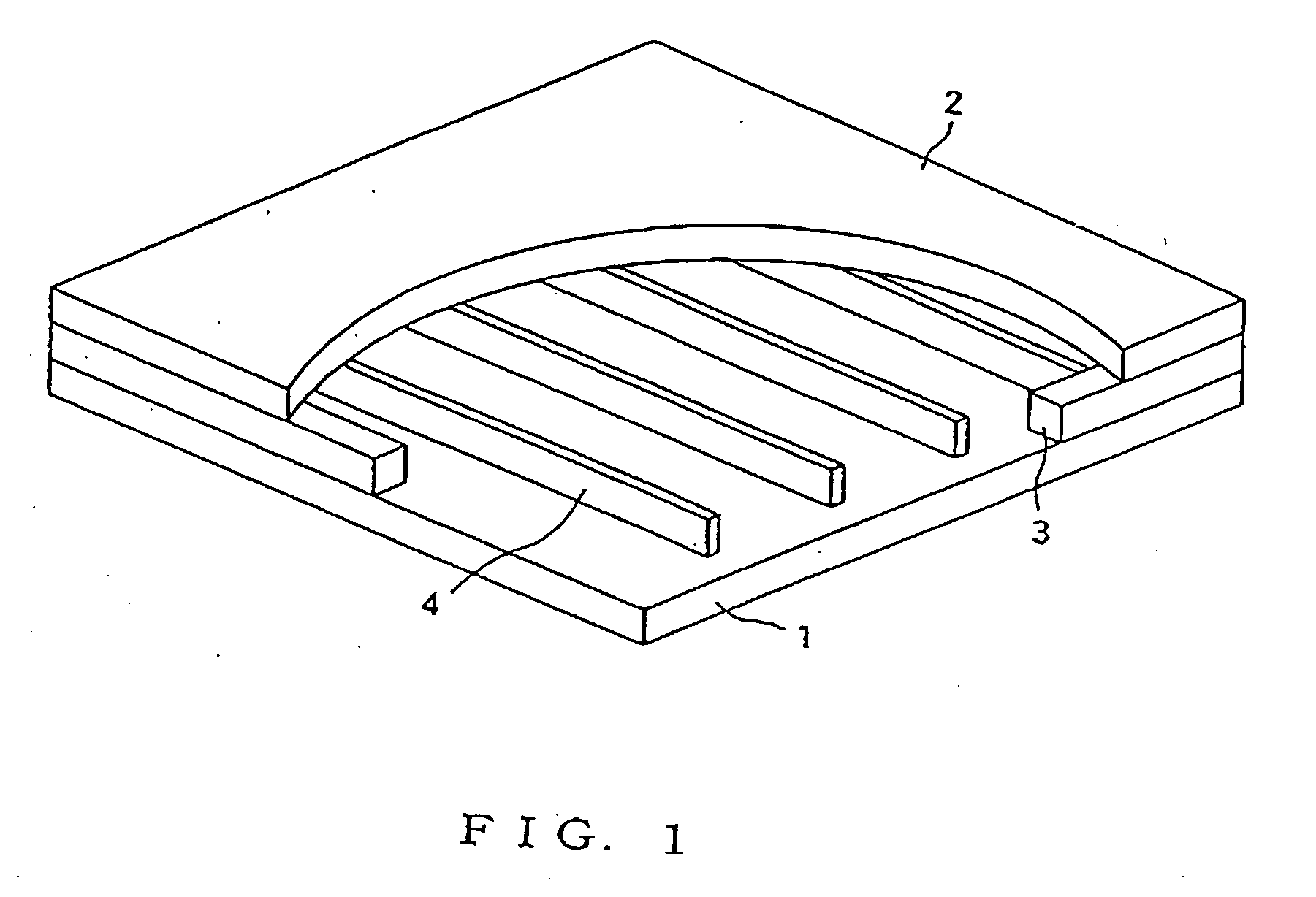

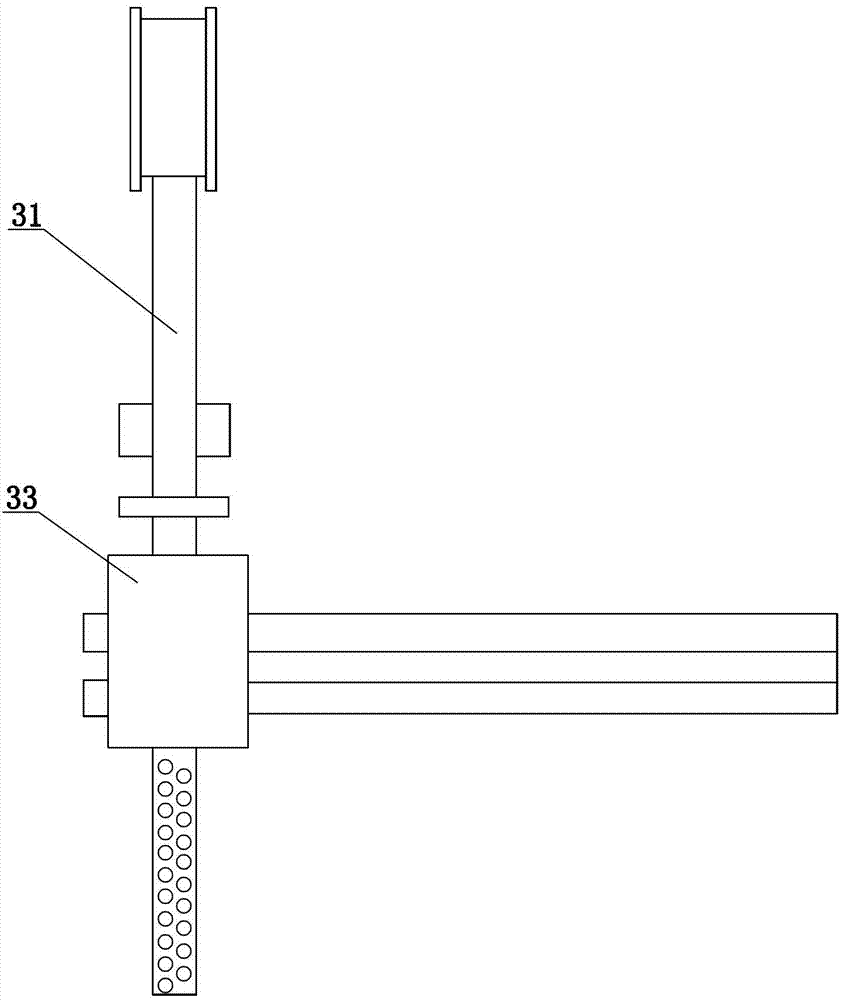

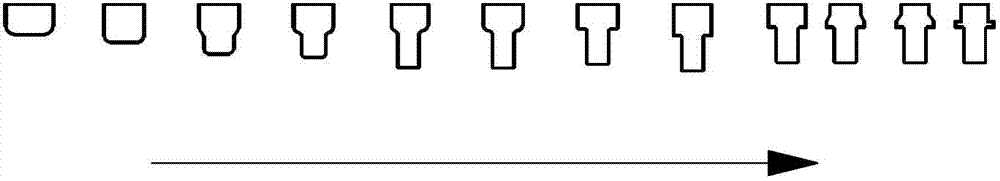

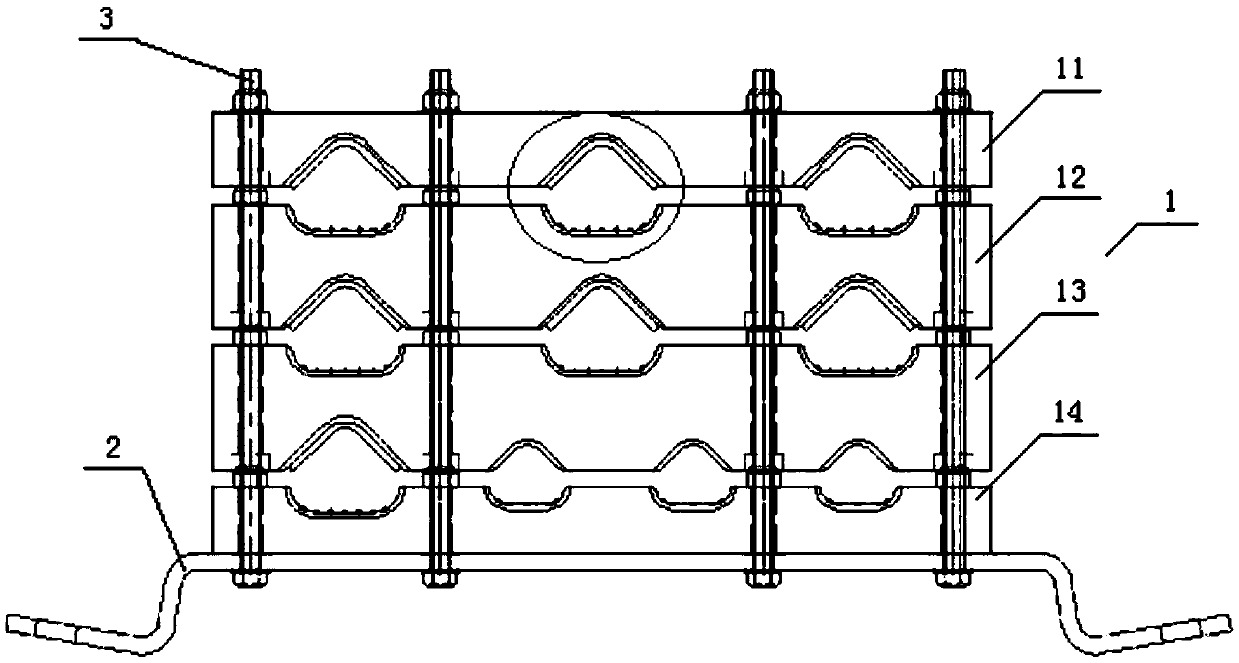

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

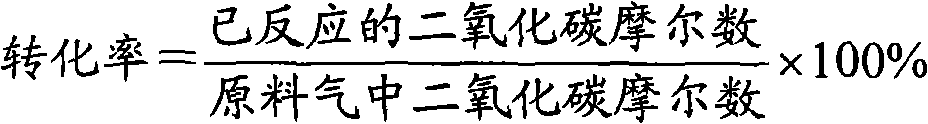

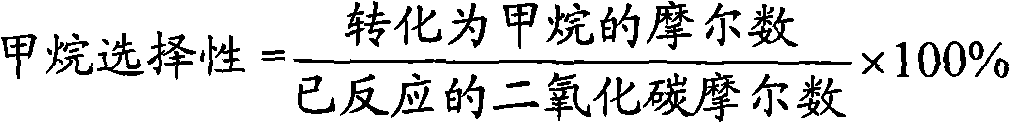

Catalyst for methanation of carbon dioxide

InactiveCN102091629AImprove structural stabilityImprove heat stabilityHydrocarbon from carbon oxidesHydrogen separation using solid contactMethanationActive component

The invention discloses a catalyst for the methanation of carbon dioxide. The carrier of the catalyst is composite oxide of rare earth and other metals, and the composition of the catalyst is represented by a general formula of AxByOz, wherein in the formula, A is a rare metal, B is one or two metals from groups IIB, IIIA, VIA, IVB, VB and VIB, x is 0 to 1, y is 0 to 2, and z is 2 to 4; and the active component of the catalyst is nickel, and the nickel loaded on the carrier accounts for 1 to 15 percent of the total weight of the catalyst. Compared with the conventional carbon dioxide methanation technique, the catalyst technique disclosed by the invention, under the similar reaction conditions, can achieve a carbon dioxide conversion rate of 100 percent, a methane selectivity of 100 percent and a methane time space yield of more than 1,000g / kg.h.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

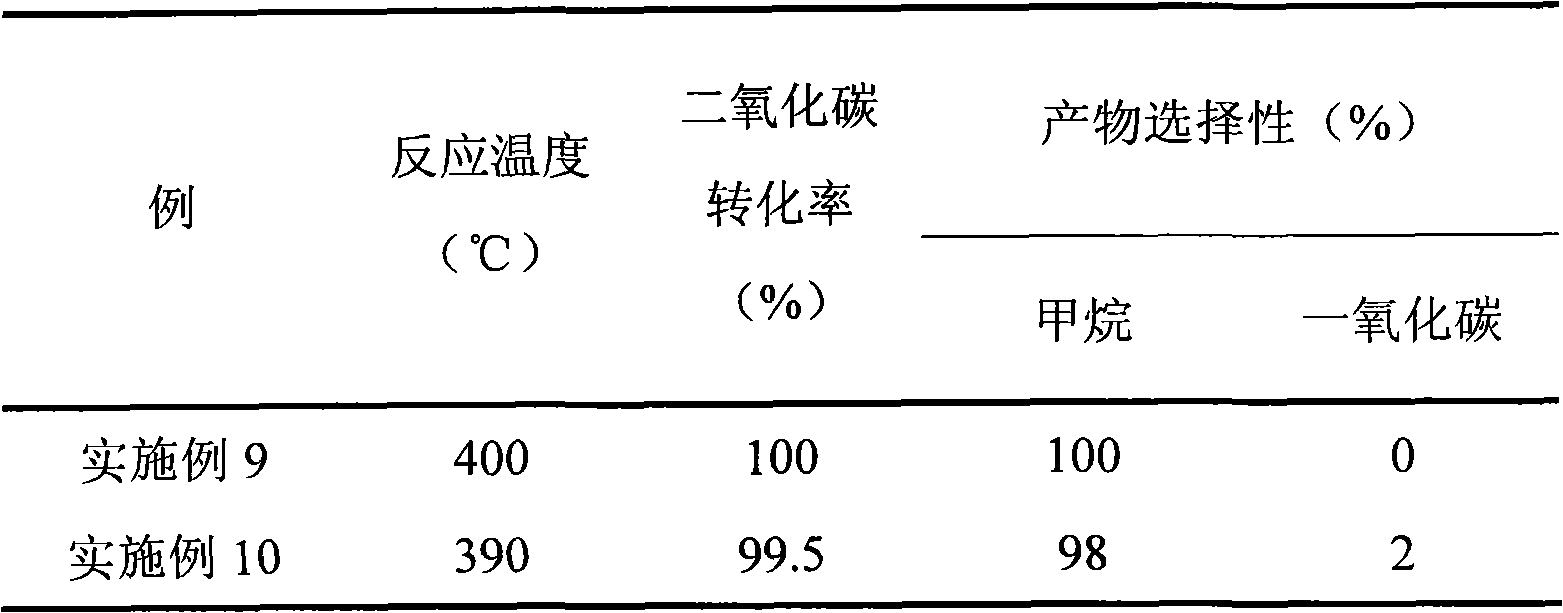

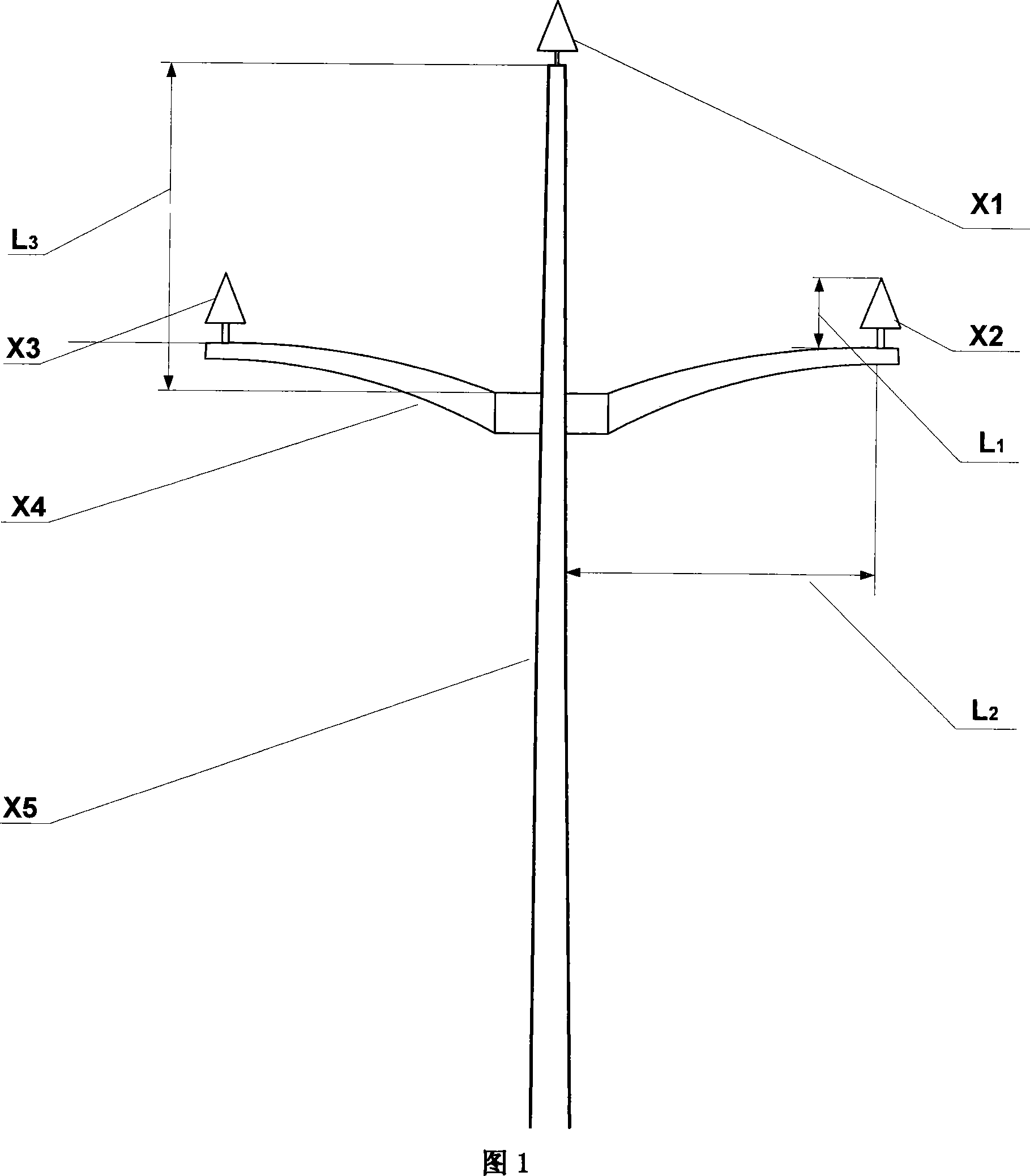

10 kV distribution line insulation tower head

ActiveCN101227071APreventing Lightning Disconnection AccidentsImprove the insulation levelOverhead installationInsulatorsEngineeringLine Break

A 10kV power distribution circuit insulation tower head is disclosed, which is characterized in that: adopting hydrophobic high-strength insulation bar to be assembled with needle-typed insulator by gold tool and form an insulation tower head entity, or adopting hydrophobic high-strength insulation bar to be assembled with gold tool directly and form an insulation tower head. By using the invention, the insulation level of the power distribution circuit can be greatly improved, the thunder discharge air gap can be obviously enlarged, the lightning stroke and line break accidents can be effectively prevented and the climbing distance can be expanded, further, the structure type is easy to improve self-cleaning ability and the occurrence of pollution flashover can be basically and completely precluded, which is beneficial in charged operation, simple in operation process and improves the operation security.

Owner:STATE GRID ELECTRIC POWER RES INST

Solar cell back plate and preparation method thereof

ActiveCN102420264AExtended service lifeNo pollutionFinal product manufactureSynthetic resin layered productsWeather resistanceEngineering

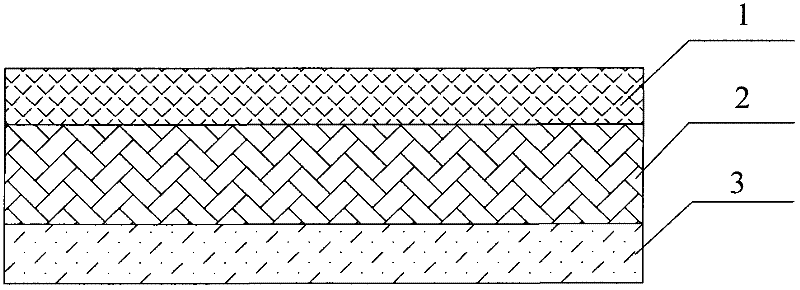

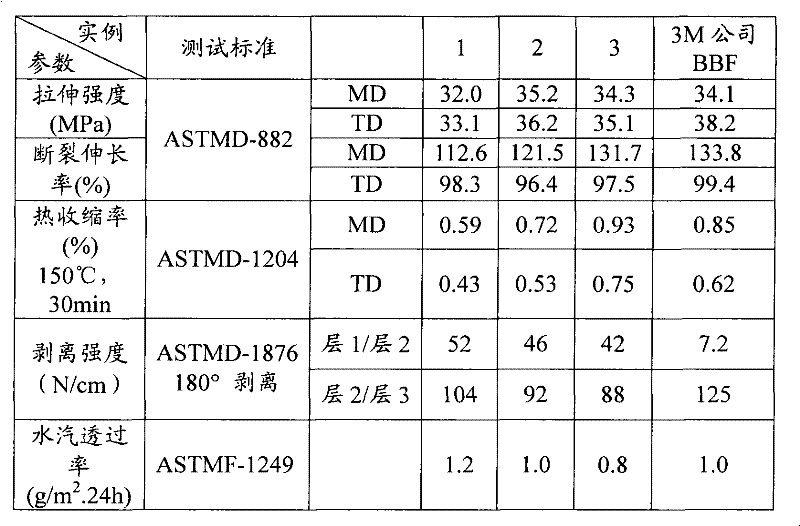

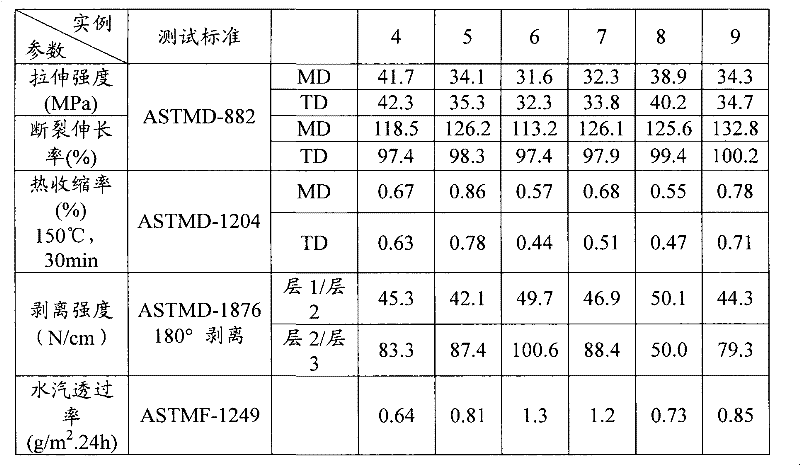

The invention relates to the technical field of solar photovoltaic cells, in particular to a solar cell back plate and a preparation method thereof. In order to overcome the defects of higher production cost and complicated production process of the existing solar cell back plate, the invention provides the solar cell back plate and the preparation method thereof. The solar cell back plate provided by the invention structurally and sequentially comprises a weather resistance layer, a structure reinforcing layer and a blocking layer, only the three-layer structure is adopted, but the weather resistance and the blocking performance are better, the production cost is lower, the fluorine element is not contained, and the environment pollution cannot be caused. The preparation method of the solar cell back plate provided by the invention comprises three-layer coextrusion and two-way stretch process, the production process of the method is simple, and the implementation is easy.

Owner:合肥长阳新材料科技有限公司

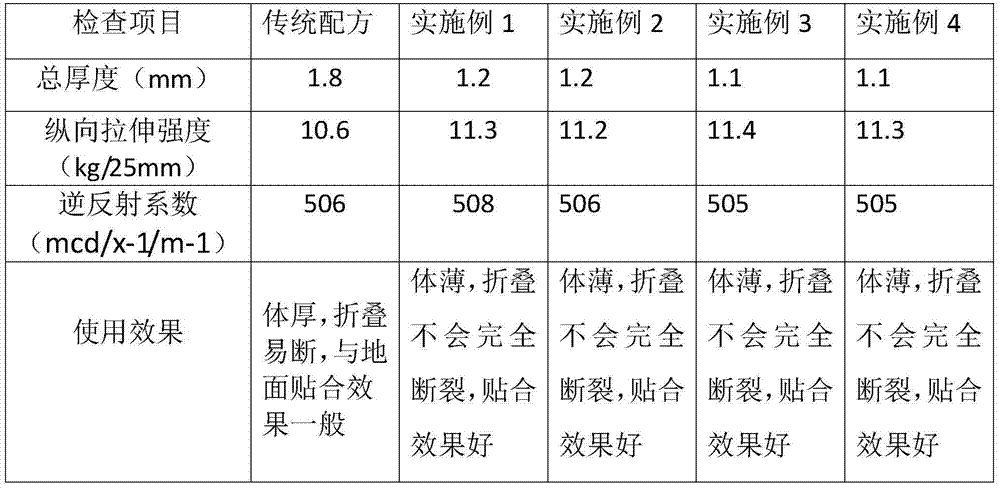

Reflective marking belt base material, base material and method for manufacturing reflective marking belt

The invention discloses a reflective marking belt base material which comprises the following components: 8-15 parts of SBS, 2-6 parts of EVA, 5-10 parts of quartz sand 7-12 parts of rosin, 3-6 parts of a petroleum resin, 30-50 parts of wollastonite powder, 20-40 parts of calcium carbonate, 1-8 pats of pigments, 2-5 parts of a plasticizer, 1-2 parts of paraffin and 8-15 parts of glass beads. In addition, the invention also discloses a base material and a method for manufacturing a reflective marking belt. The reflective marking belt base material disclosed by the invention has the advantages of high compatibility with the ground and asphalt and high strength and toughness.

Owner:SICHUAN JIANGYOU YUSHU YESHILI REFLECTIVE MATERIAL

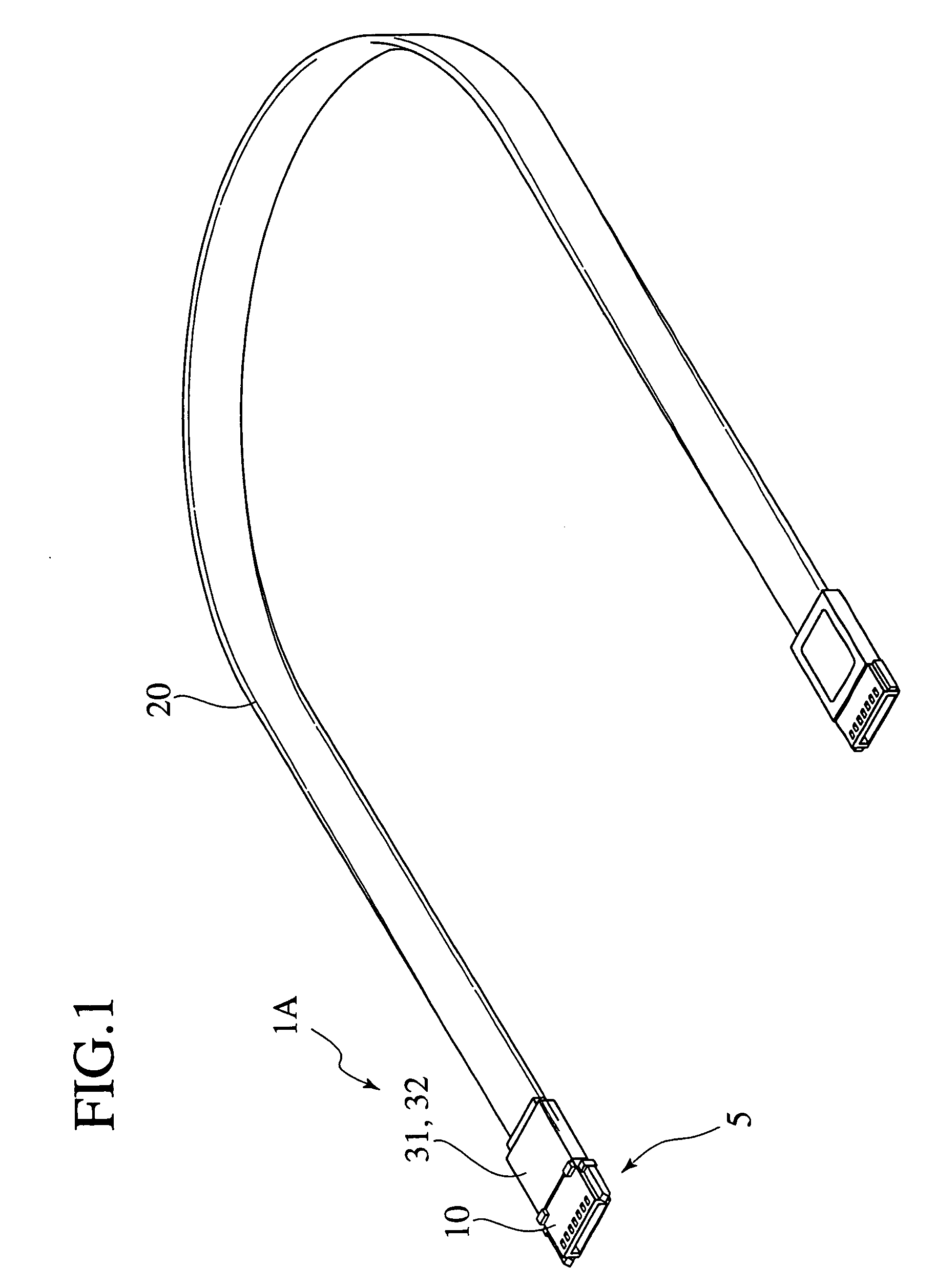

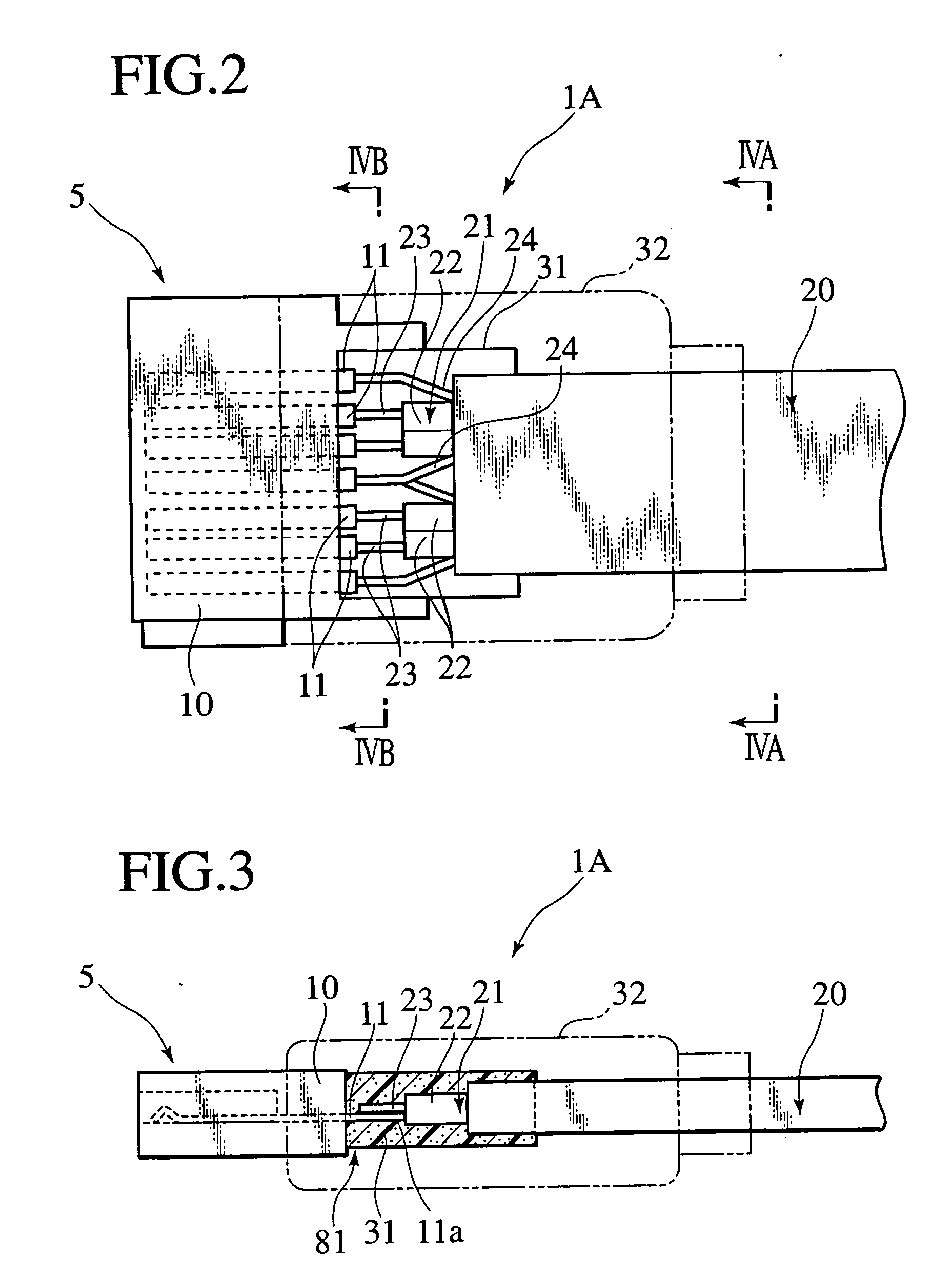

Electric connector and cable

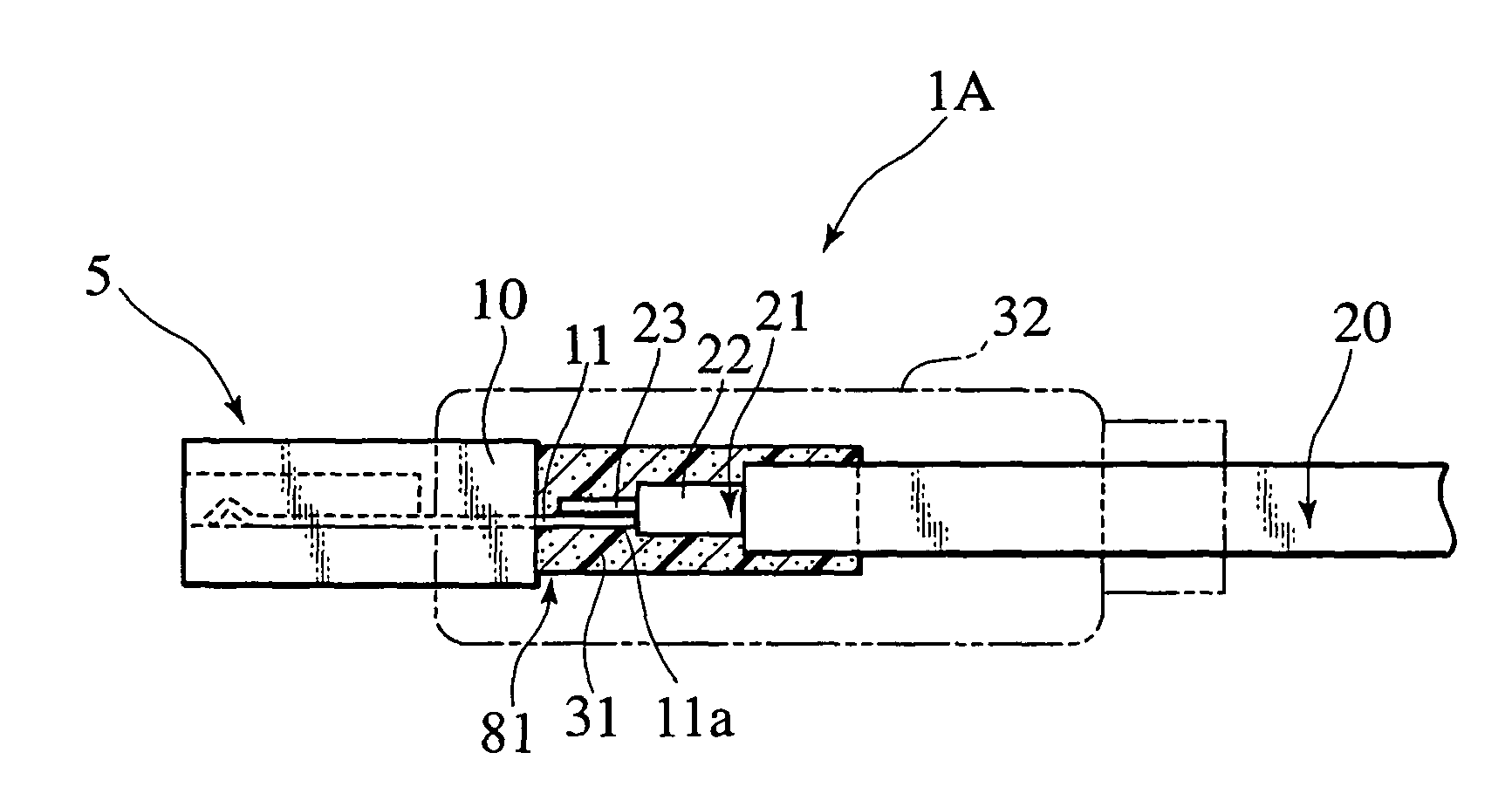

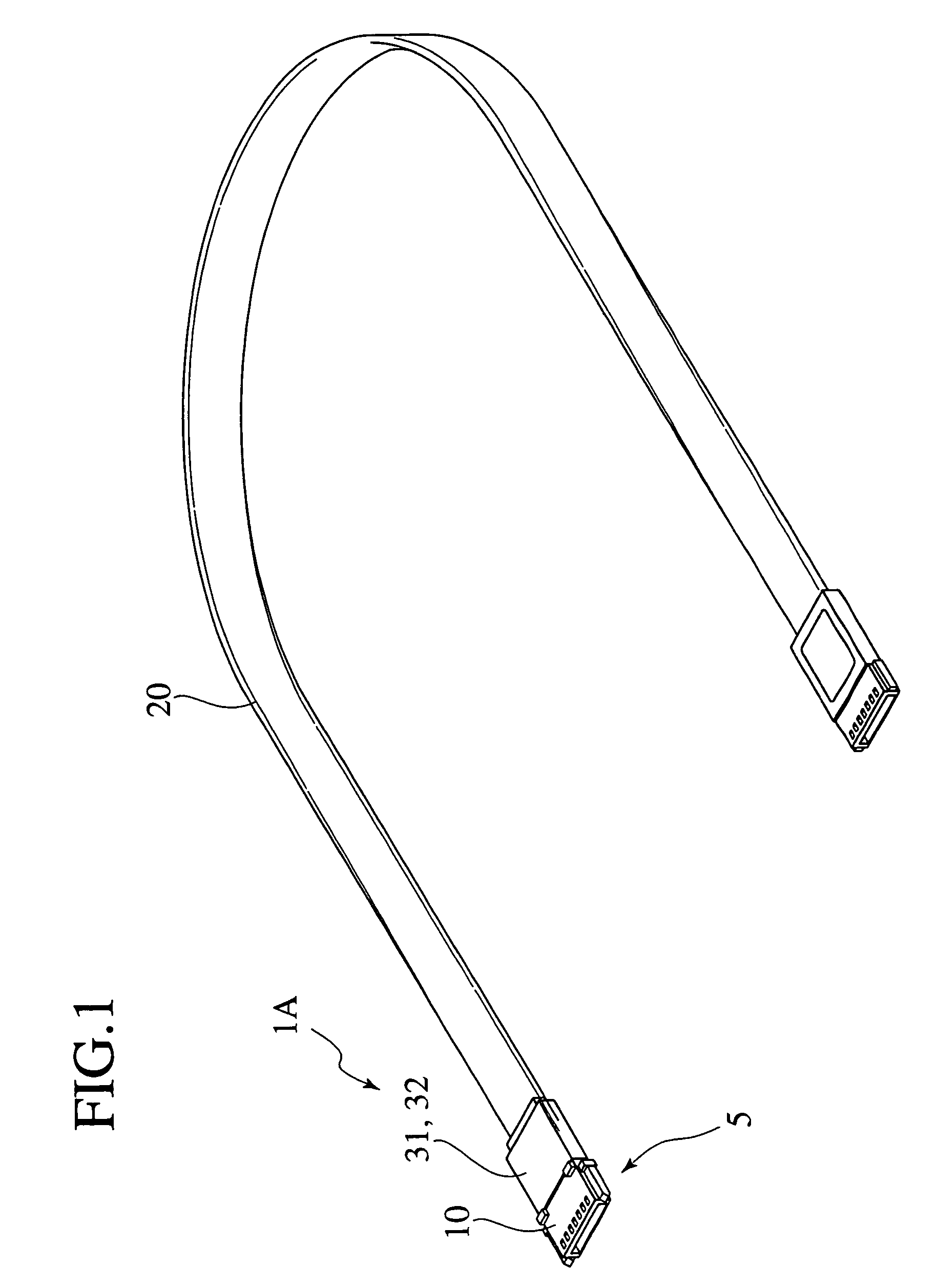

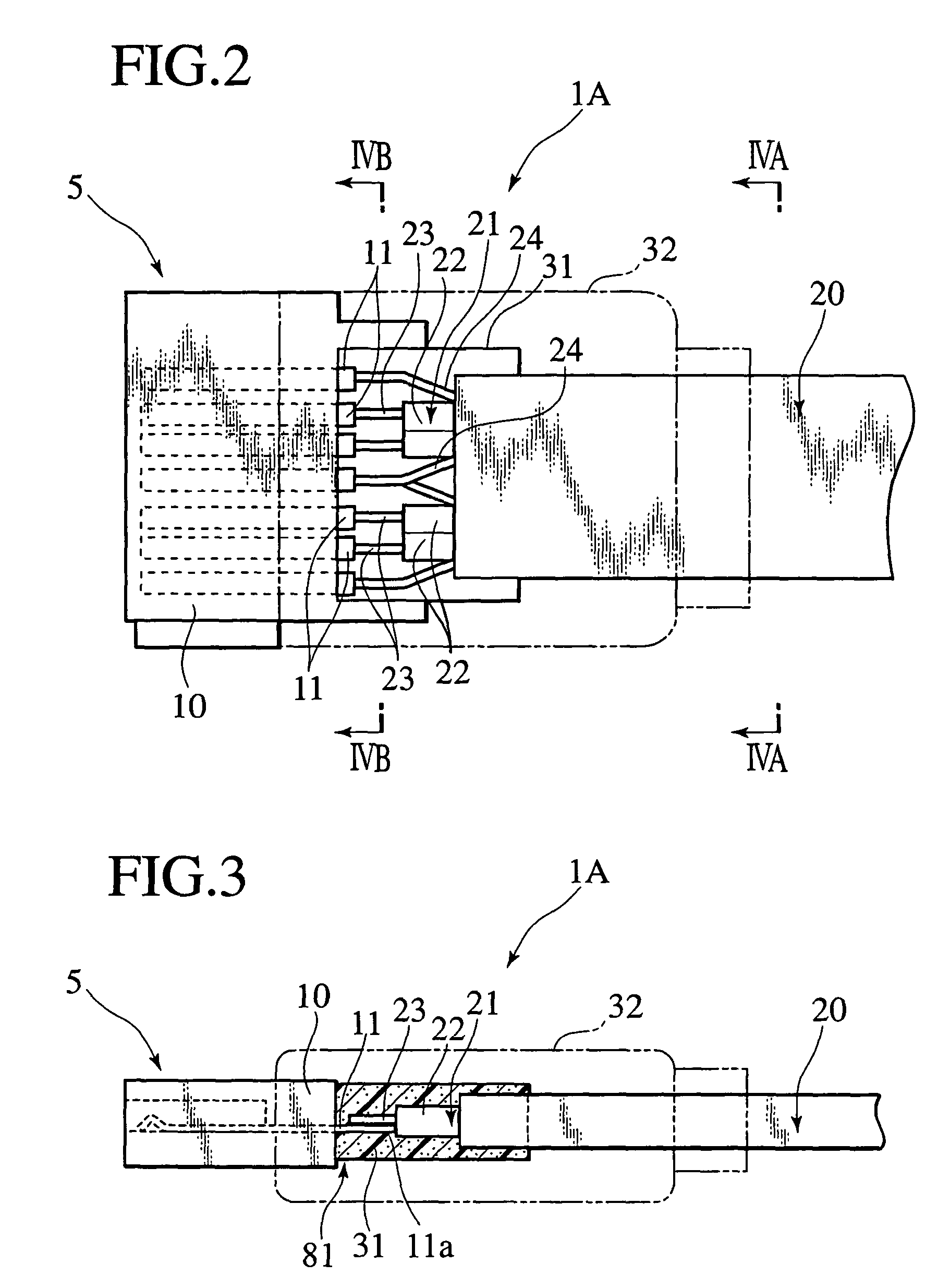

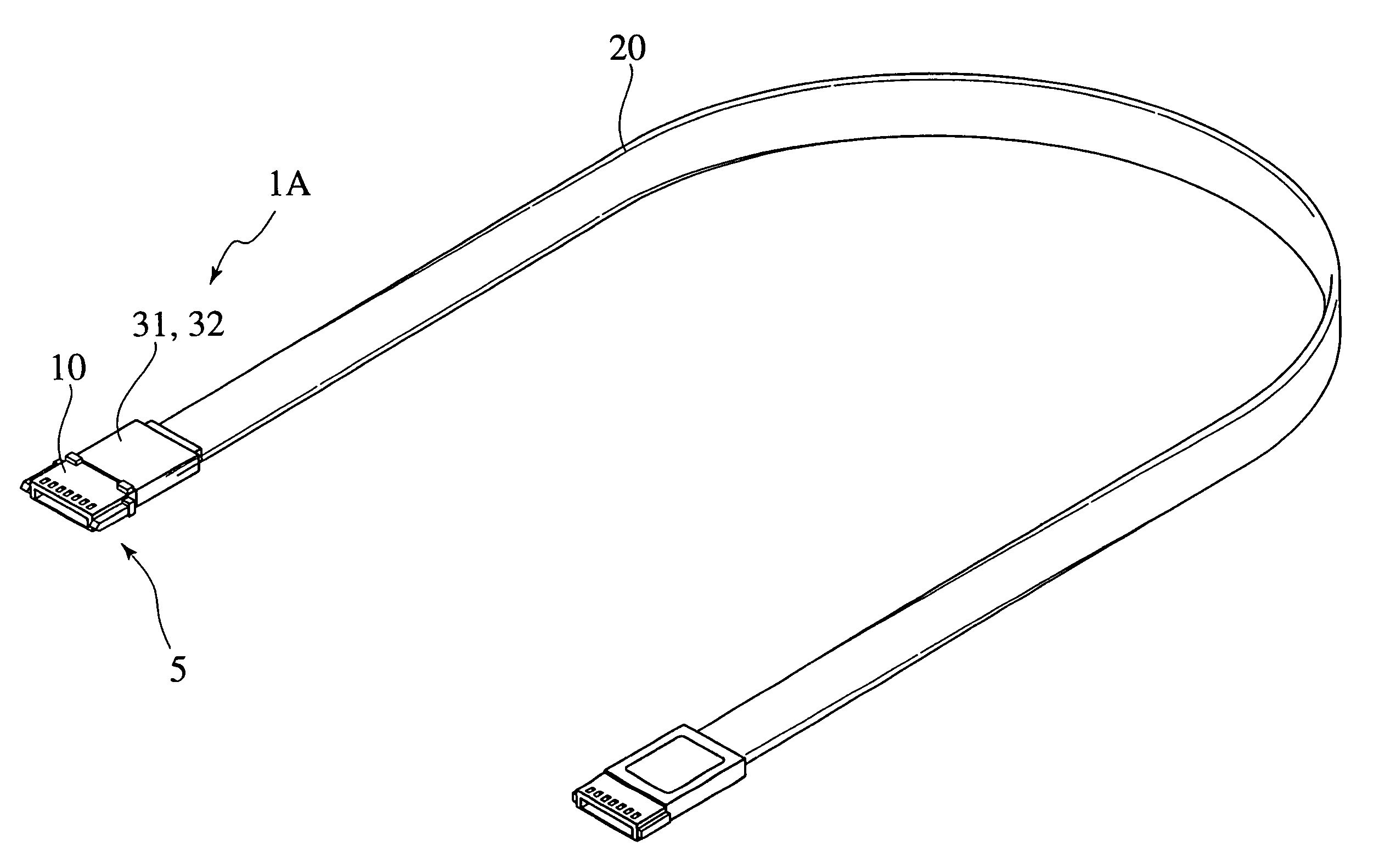

InactiveUS8039746B2Electrical characteristicStable mechanical strengthElectrically conductive connectionsContact member assembly/disassemblyElectricityElectrical conductor

Owner:FUJIKURA LTD

Electric connector and cable

InactiveUS20050255741A1Electrical characteristicStable mechanical strengthContact member assembly/disassemblyCouplings bases/casesElectrical conductorEngineering

An electrical connector includes a terminal (11) fixed to a connector housing (10). The electrical connector includes a conductor (23) exposed from a covering (22) and having a connection portion connected to a connection portion of the terminal (11). The electrical connector includes a foam element (31) at a predetermined foam ratio located around respective connection portions of the conductor (23) and the terminal (11).

Owner:THE FUJIKURA CABLE WORKS LTD

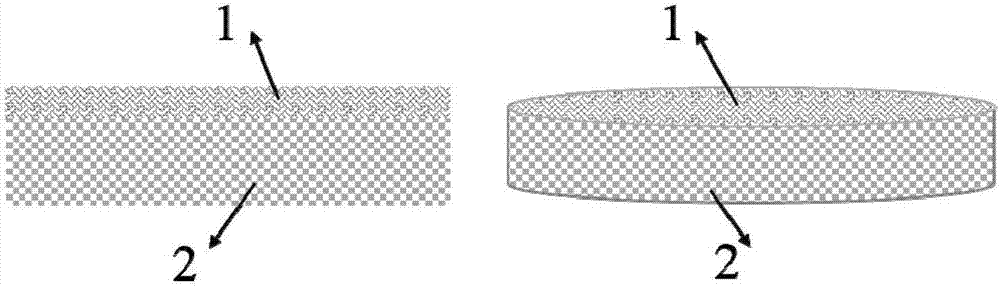

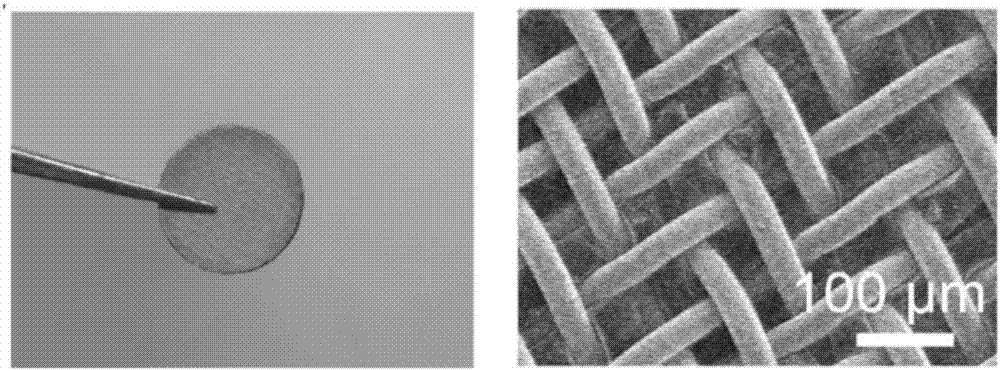

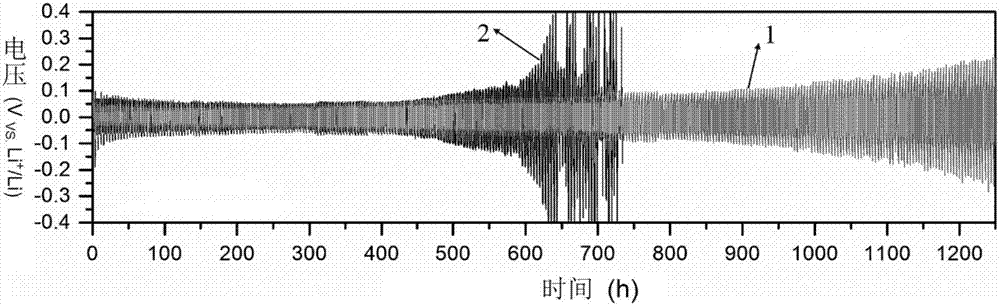

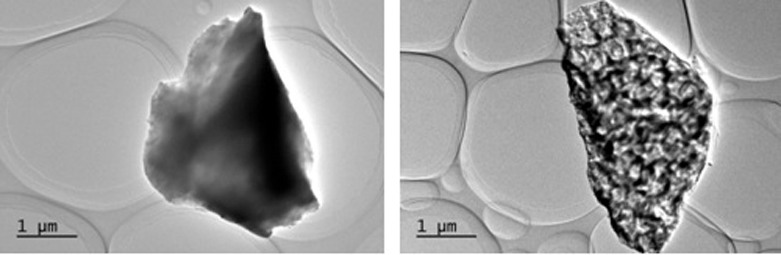

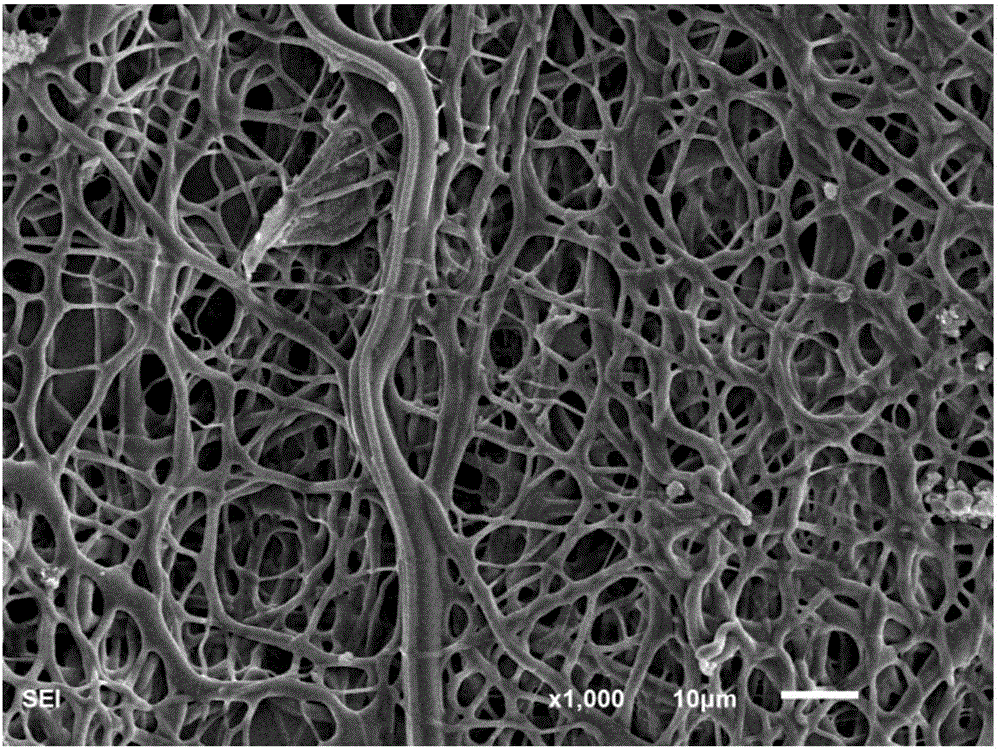

Metal electrode with three-dimensional structure

The invention discloses a metal electrode with a three-dimensional structure. The metal electrode comprises a substrate, wherein at least one surface of the substrate is provided with an embedded layer with a netlike structure; the substrate is selected from metal lithium, sodium, magnesium or aluminum, or an alloy consisting of at least two of the metal lithium, sodium, magnesium and aluminum; the embedded layer with the netlike structure is of a single-layer or multi-layer structure, and is selected from at least one of a metal layer, a polymer layer, a semiconductor layer and an insulator layer; the netlike structure is a planar netlike structure or a three-dimensional netlike structure; and the embedded layer is made of a material different from the material of the substrate. Through adoption of the metal electrode with the three-dimensional structure provided by the invention, the aims of restraining dendritic crystal growth and reducing volume expansion can be fulfilled, thereby increasing the coulombic efficiency of a battery and prolonging the service life the battery.

Owner:ZHEJIANG UNIV

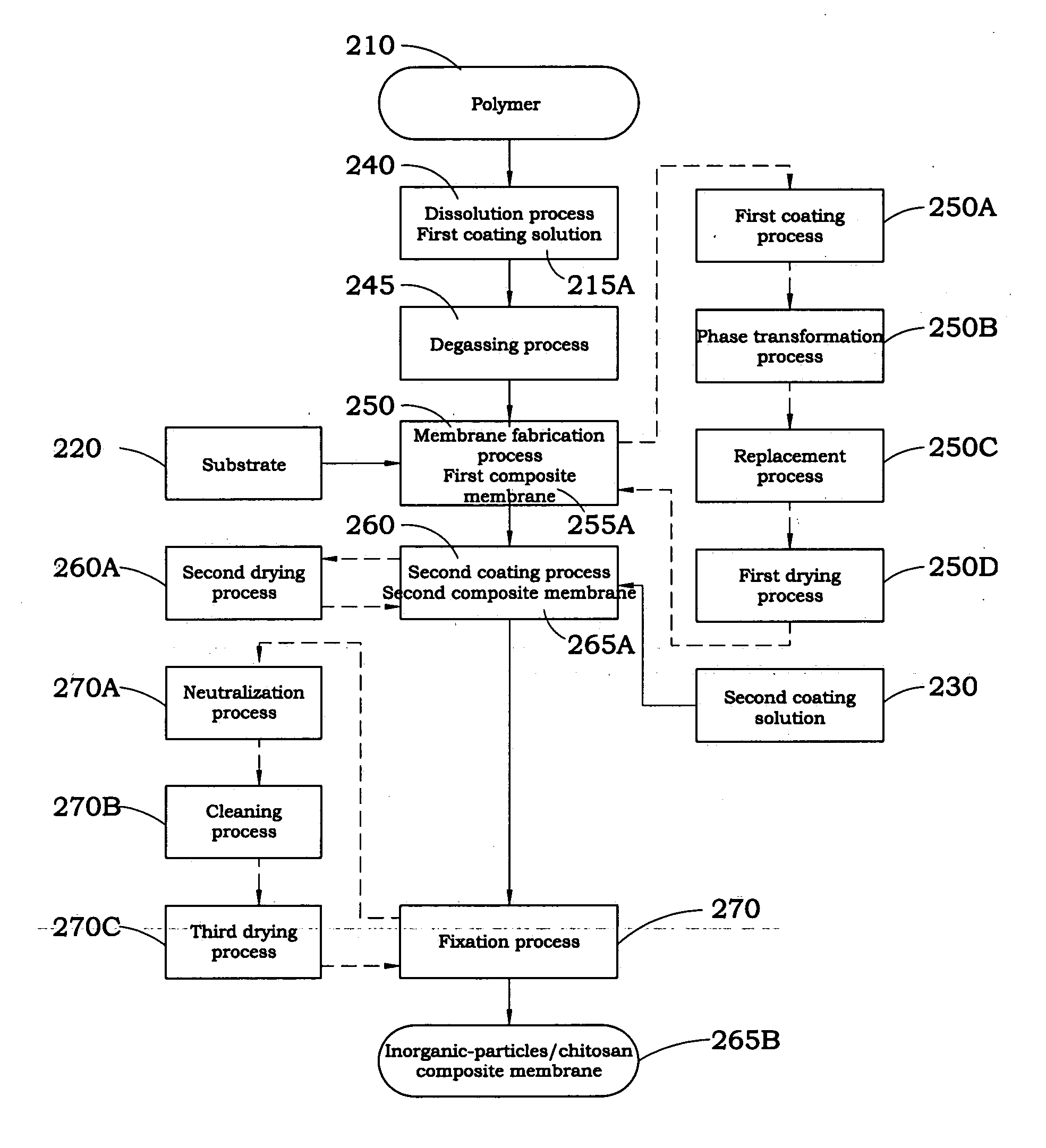

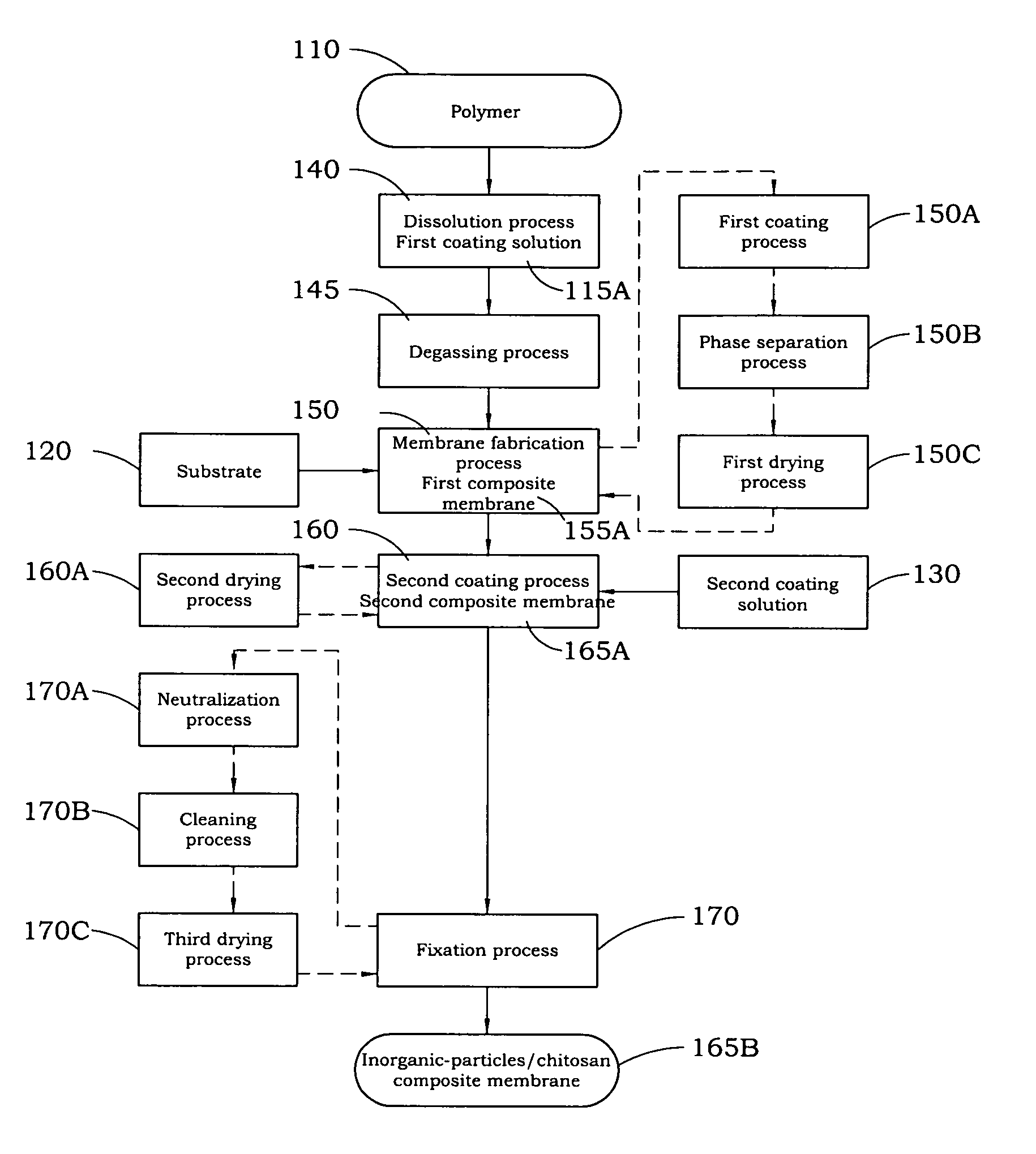

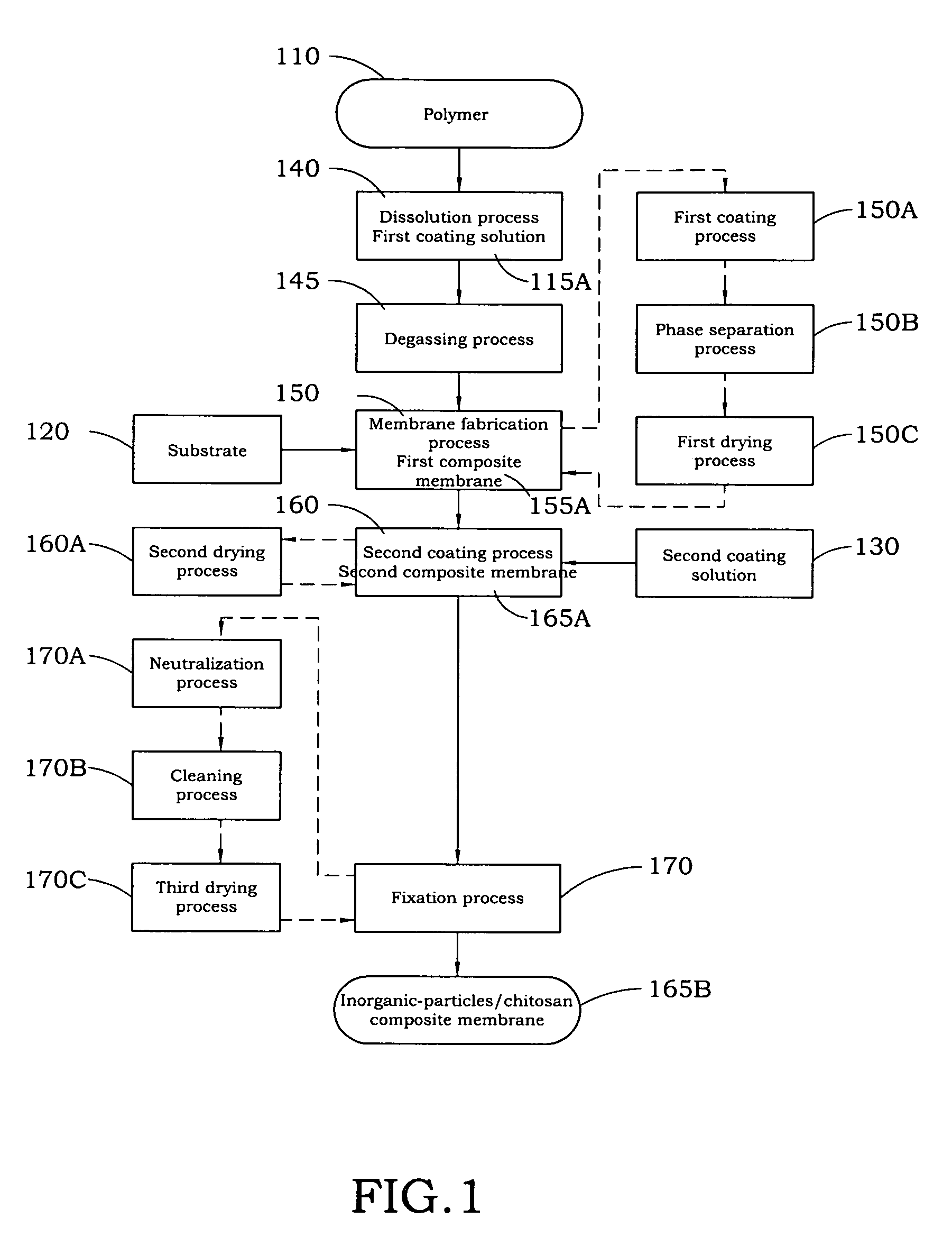

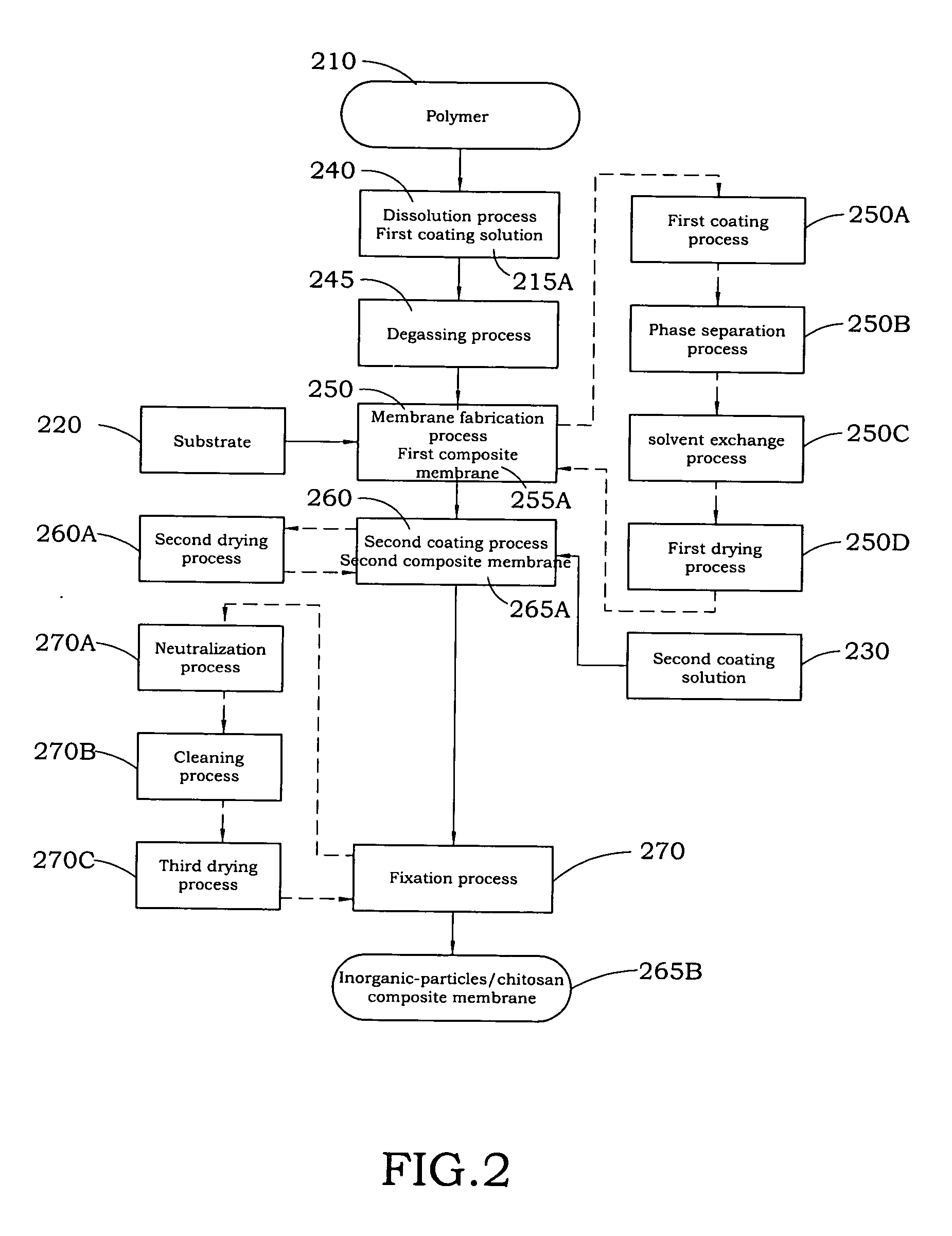

Composite membrane for separating organic solvents and the method for fabricating the same

InactiveUS20050077232A1High selectivityHigh fluxMembranesLoose filtering material filtersNanometreInorganic particle

This invention discloses a composite membrane for separating organic solvents that comprises a carrier layer, a support layer and a separation layer. The material of the separation layer is chitosan containing nano-inorganic particles, wherein the nano-inorganic particles are uniformly embedded in the the chitosan separation layer. This invention also discloses a method for fabricating a composite membrane for separating organic solvents. Moreover, the method comprises a dissolution process, a degassing process, a membrane fabrication process, a coating process and a fixation process.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

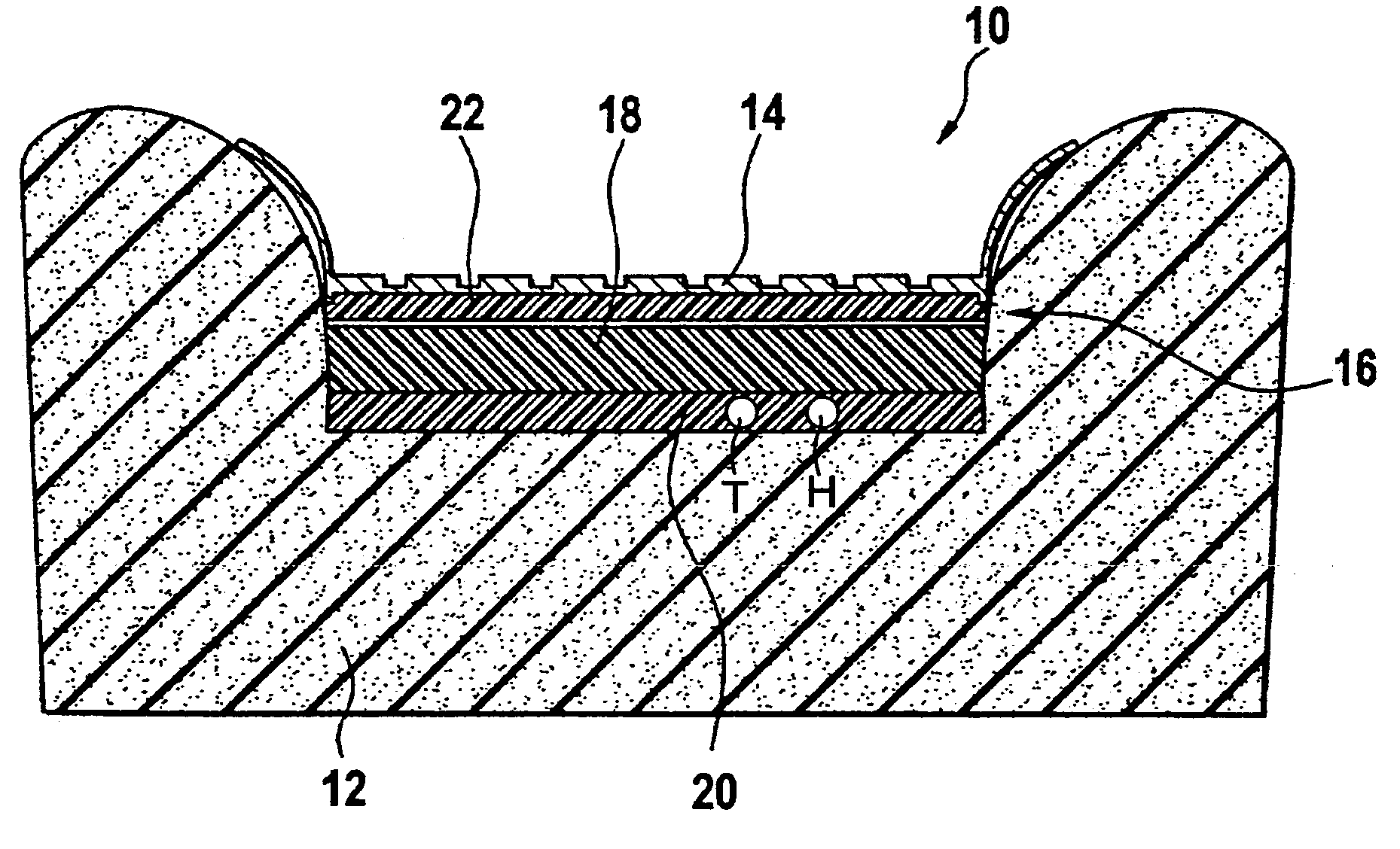

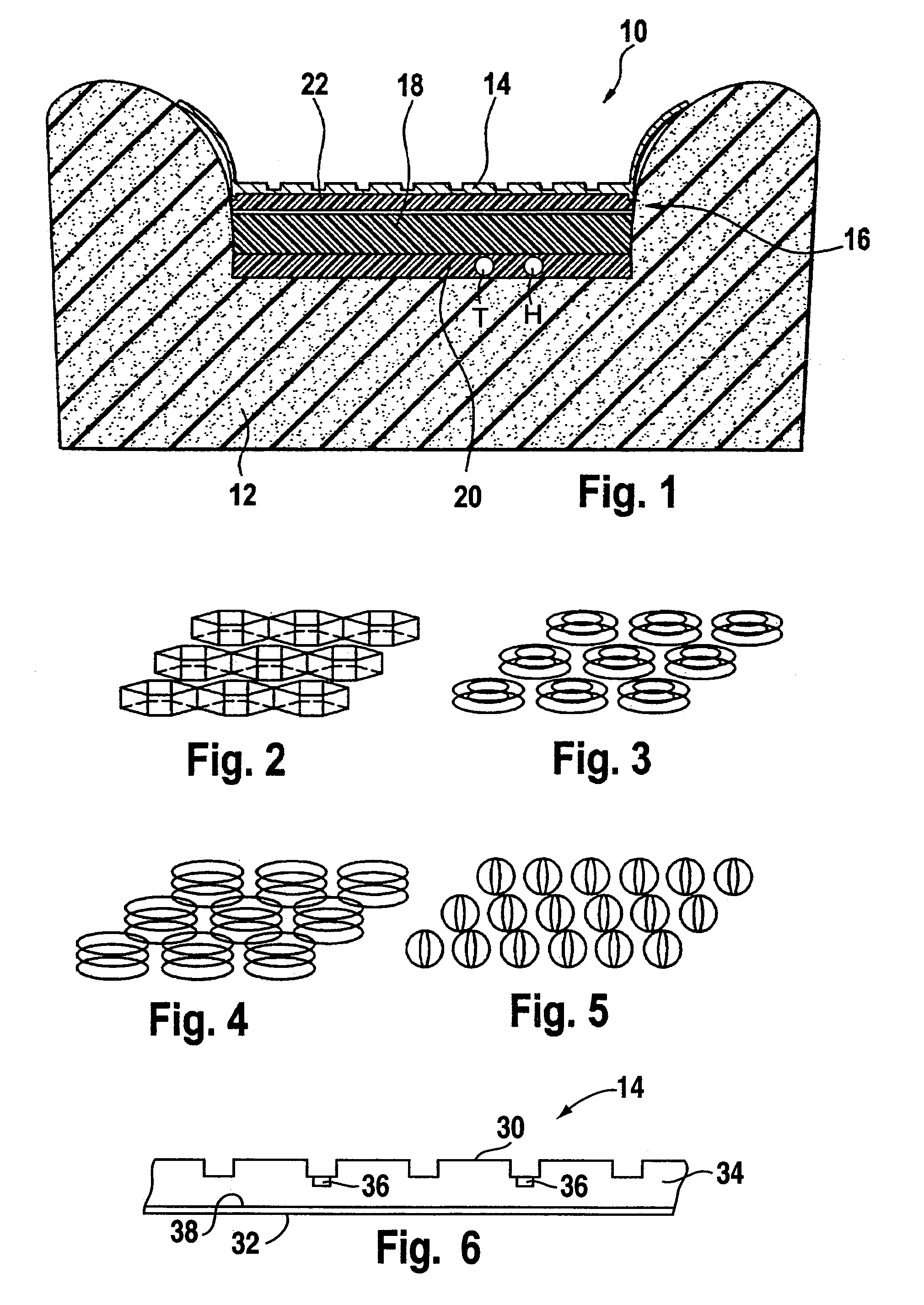

Device for detecting passengers of a vehicle

InactiveUS6977592B2Easy to installInterference minimizationVehicle seatsPedestrian/occupant safety arrangementElastic modulusEngineering

A detection device for an automobile seat includes a flexible pressure sensor having an upper face and a lower face, as well as a decoupling layer fixed on the lower face of the pressure sensor. The decoupling layer has a constant modulus of elasticity.

Owner:IEE INT ELECTRONICS & ENG SA

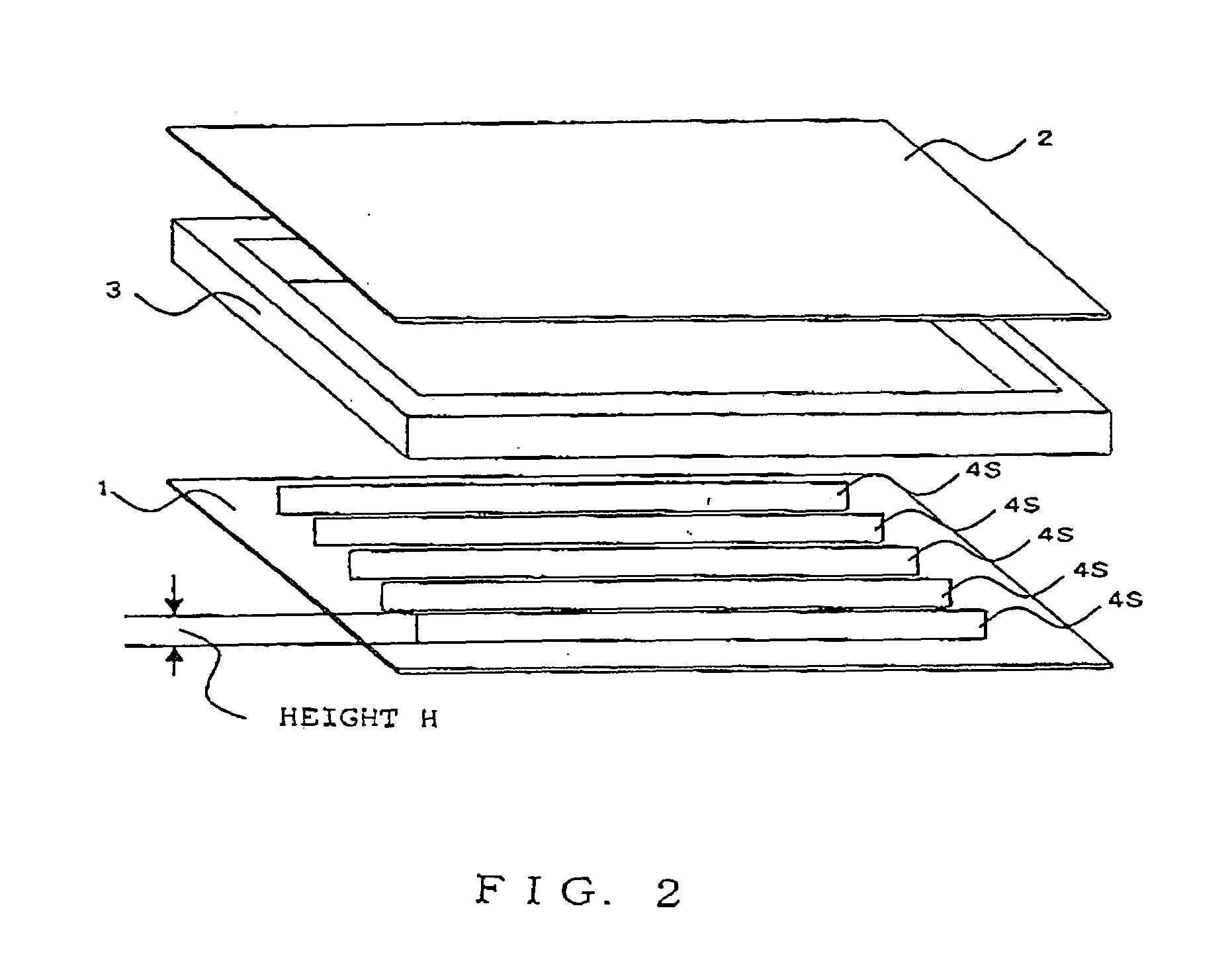

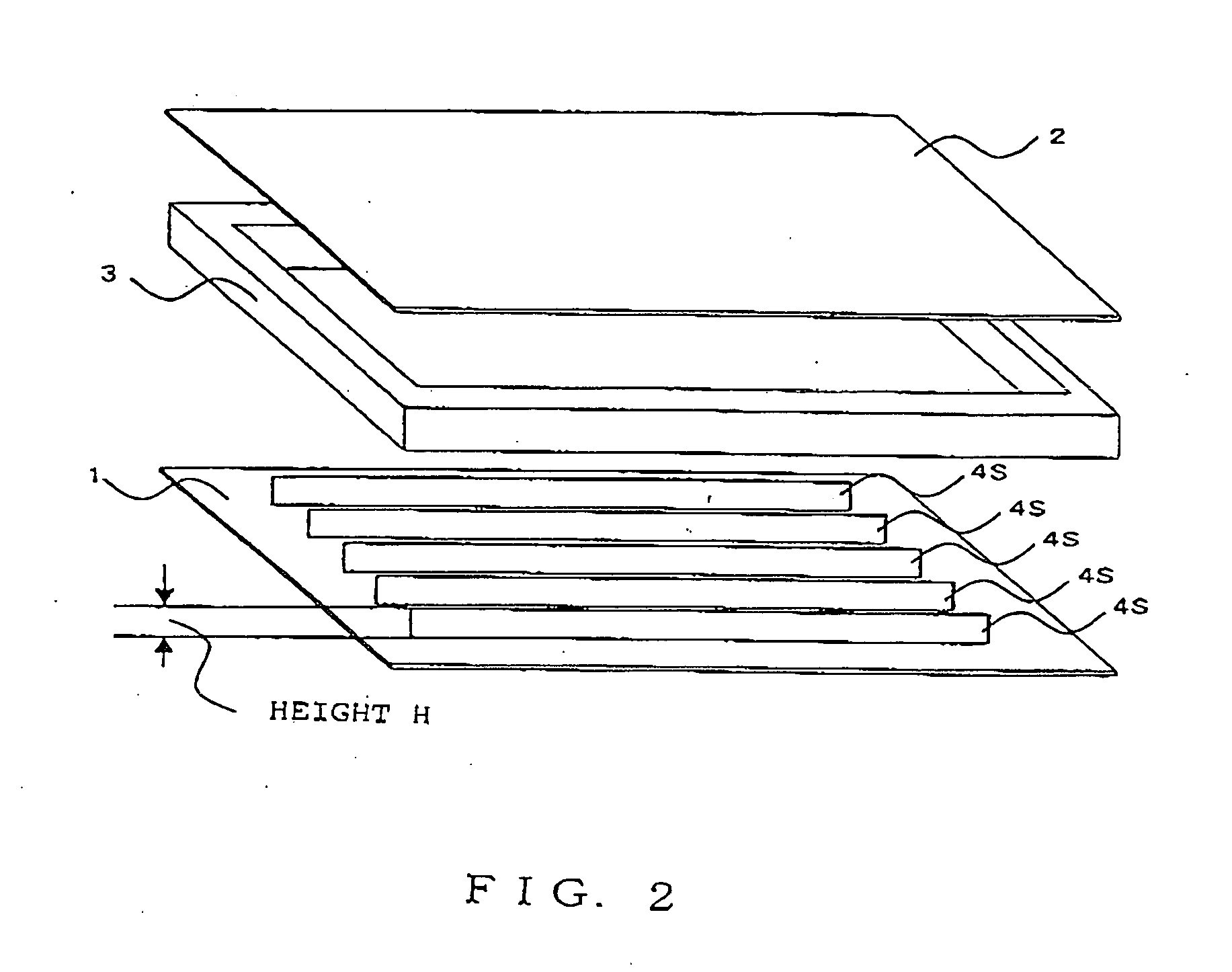

Method for manufacturing image display device, image display device, and TV apparatus

InactiveUS7088036B2Stable mechanical strengthHigh mechanical precisionCathode-ray/electron-beam tube vessels/containersStatic indicating devicesDisplay deviceComputer science

Owner:CANON KK

Method of preparing nonstoichiometry doping rare earth element nano SiO2 composite particles

InactiveCN101054480AHigh mechanical strengthStable mechanical strengthInorganic pigment treatmentRare-earth elementOrganic film

The invention discloses a preparing method for non-stoichiometric doped rare-earth element nano SiO2 compound particle belonging to SiO2 compound material. The method comprises following steps: having the organic silane and disposed rare-earth element inorganic salt before drying as monomer, respectively dissolving in the absolute ethyl alcohol and distilled water to produce respective precursor, uniformly mixing under the mechanical agitation, hydrolyzing under the ultrasonic environment having the ammonia as buffer in the alkaline condition, forming equal, stable, transparent sol, aging to obtain gel, gel dehydration by azeotropic distillation, then sintering in the retort furnace to get doped rare-earth element nano SiO2 compound particle without group lump. The invention has a simple process. The obtained doped rare-earth element nano SiO2 compound particle has a high mechanical strength, a strong hydrophilicity and a wide universality which is mainly used to produce filling material of the organic film, super strong sorbent, photoluminescence material.

Owner:TIANJIN UNIV

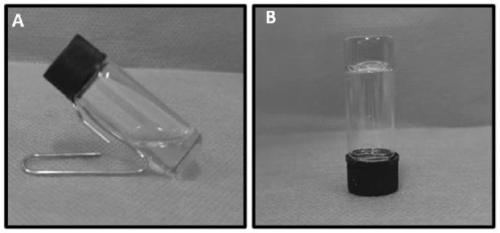

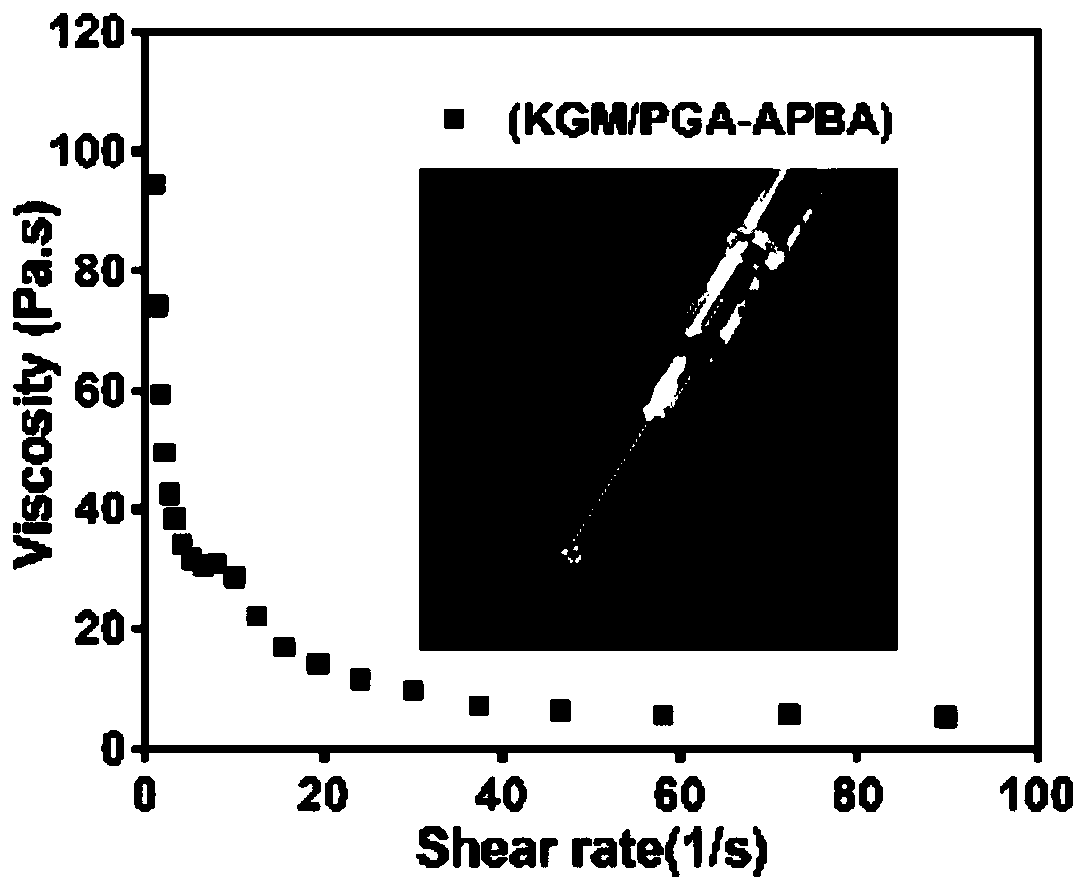

Thiol/boronic group modified polymer, glucose-sensitive hydrogel composition, glucose-sensitive drug-loaded hydrogel, and preparation method thereof

ActiveCN110256669AStable mechanical strengthAdjust the release speedMetabolism disorderAerosol deliveryGlucose sensitivityConcentrations glucose

The invention relates to the field of macromolecules, in particular to a thiol / boronic group modified polymer, a glucose-sensitive hydrogel composition, glucose-sensitive drug-loaded hydrogel and a preparation method thereof. The thiol / phenylboronic group modified polymer is dispersed in a polysaccharide aqueous solution with an o-diol structure, and is stirred to swell under a near-neutral condition, so that the glucose sensitive hydrogel is obtained by utilizing spontaneous oxidation of the thiol group and condensation crosslinking of the boronic acid groups and the o-diol in the molecules. The preparation method of the glucose-sensitive hydrogel is simple, a condensing agent or a free radical initiator does not need to be added, and the glucose-sensitive hydrogel has good injectability, biocompatibility and glucose sensitivity. When the hydrogel is used as a drug carrier, only the drug needs to be added into the glucose sensitive hydrogel to be dissolved or uniformly dispersed. According to the prepared glucose-sensitive drug-loaded hydrogel, the release speed and release behavior of the drug can be adjusted by responding to the change of the glucose concentration, so that the drug can be quickly released when the glucose concentration is high.

Owner:WENZHOU MEDICAL UNIV

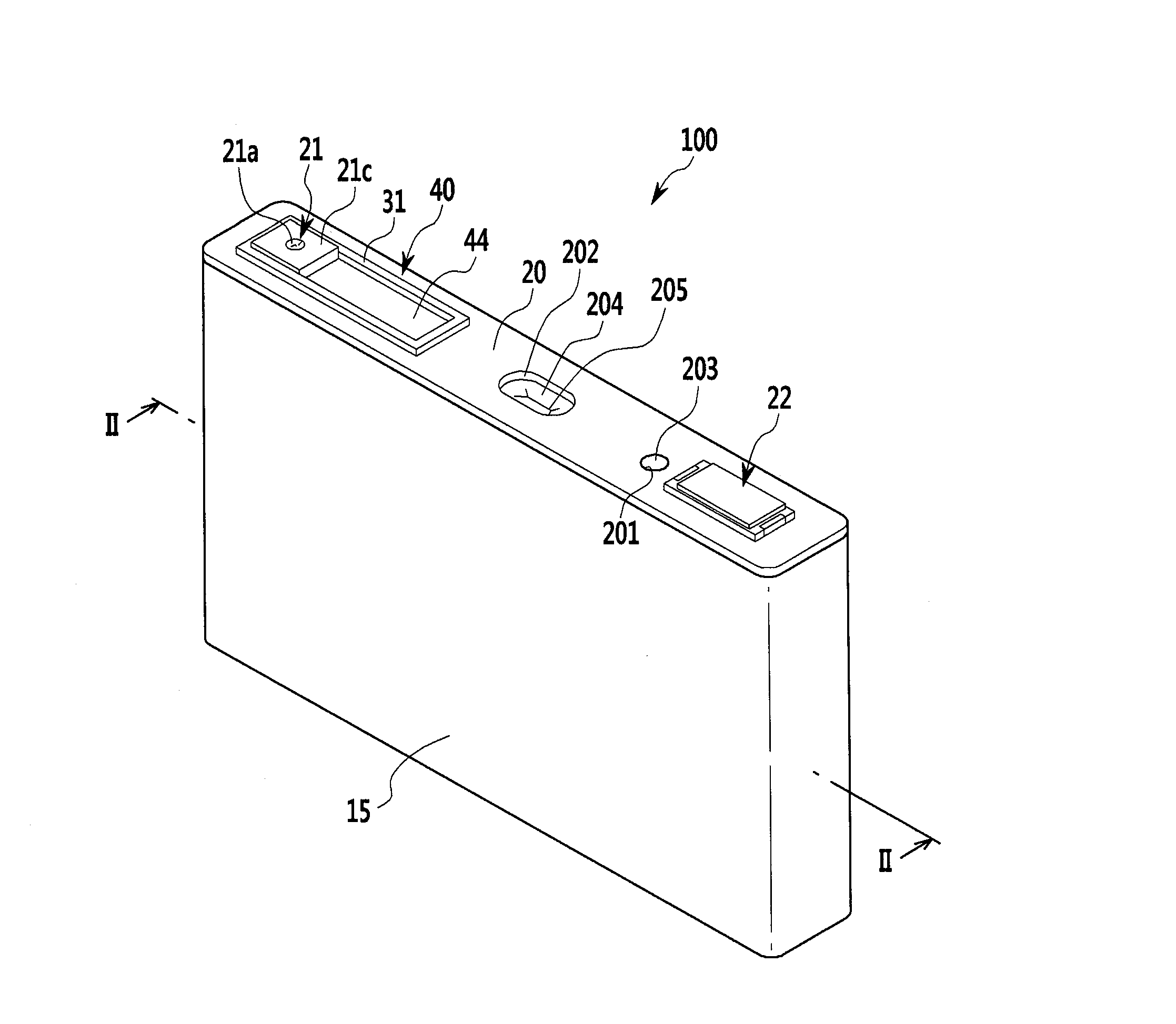

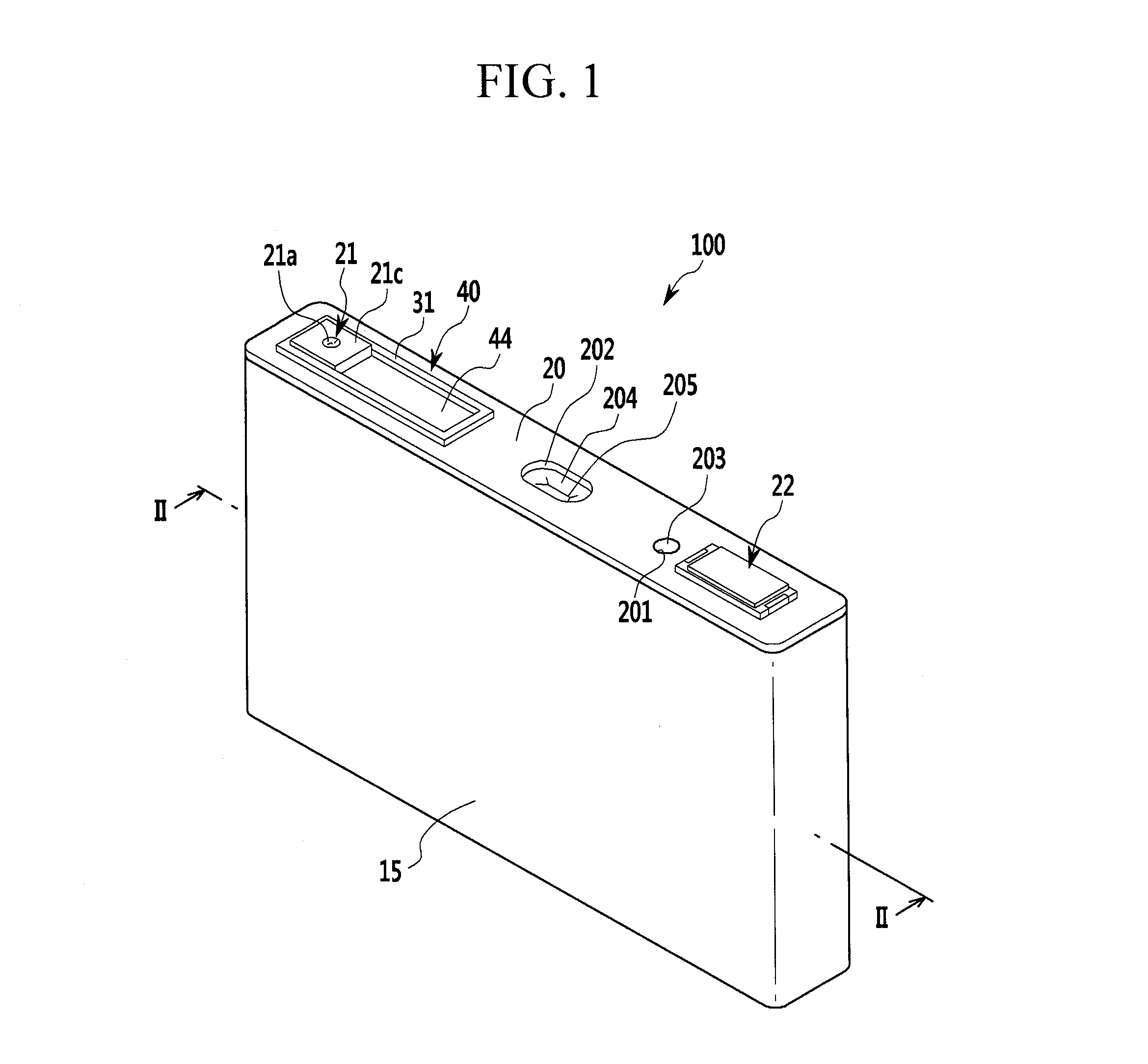

Rechargeable battery

ActiveUS20160293908A1Stable mechanical strengthLower resistanceSmall-sized cells cases/jacketsElectric connector introductionRechargeable cellElectrical and Electronics engineering

A rechargeable battery includes an electrode assembly having a first electrode and a second electrode on either side of a separator, a case accommodating the electrode assembly, a cap plate sealing the case and electrically connected to the second electrode, a first terminal electrically connected to the first electrode and located with a terminal hole of the cap plate, and a second terminal directly connected to the cap plate, wherein the second terminal includes a spacing part spaced from the cap plate and configured to be connected to a bus bar, and a connection part connected to the spacing part through a round part and connected to the cap plate, wherein a curvature radius of an outer surface of the round part is less than a first thickness of the connection part.

Owner:SAMSUNG SDI CO LTD

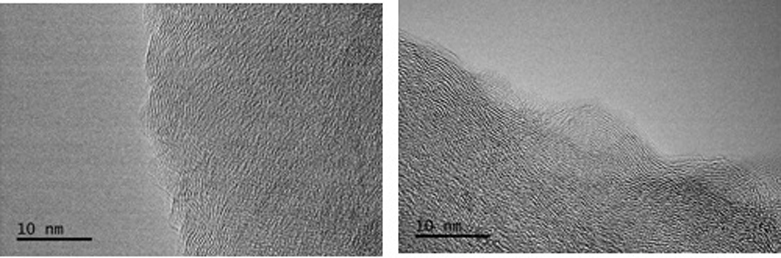

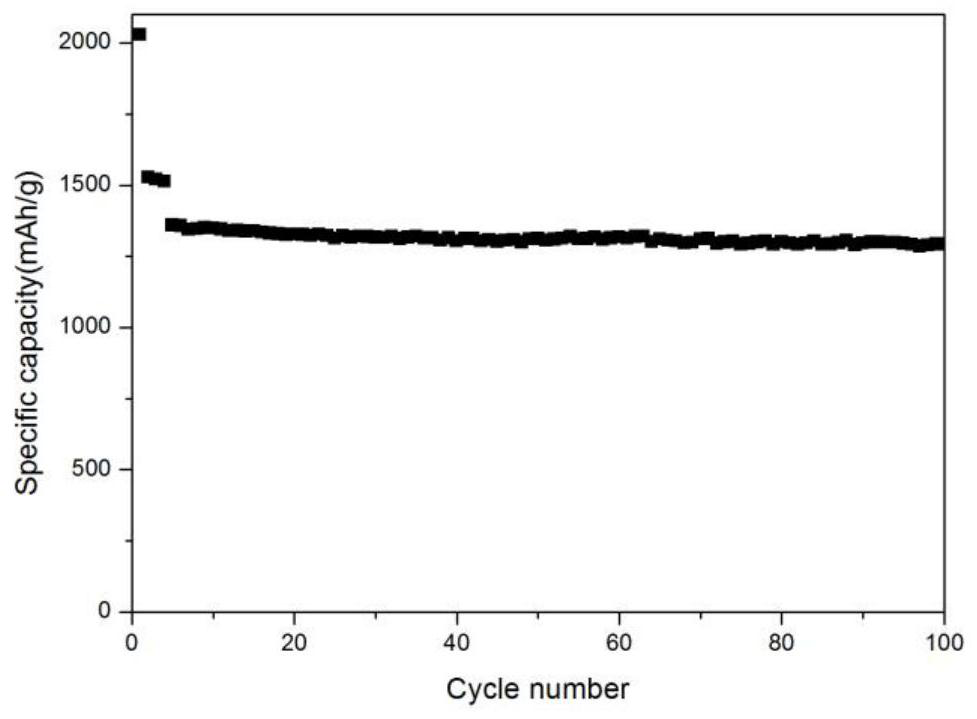

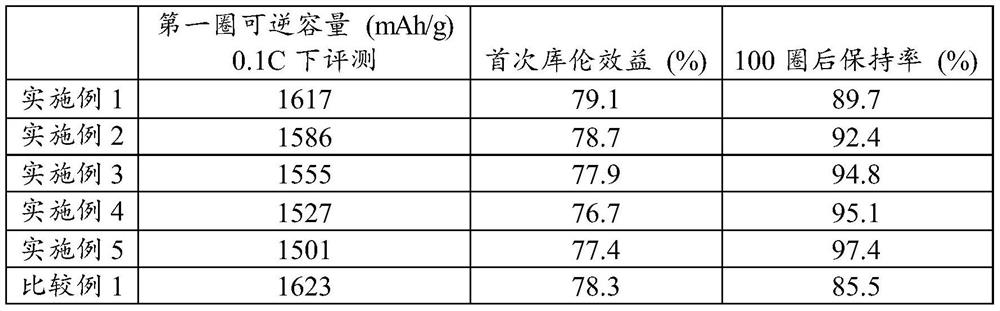

Preparation method and application of high-stability silicon-based composite material constructed by in-situ fluorination

InactiveCN113270587AReduce damageImprove Interface StabilitySecondary cellsNegative electrodesLithium electrodeSilicon based

The invention discloses a preparation method and application of a high-stability silicon-based composite material constructed through in-situ fluorination, the silicon-based composite material comprises an inner core silicon-based material and an outer fluorine-containing coating layer, and the thickness of the fluorine-containing coating layer is 1-10 nm; the fluorine-containing coating layer is lithium fluoride (Li2CO3-LiF) doped with lithium carbonate, and the fluorine-containing coating layer is obtained by carrying out an in-situ fluorination reaction on the surface of the silicon-based material through a fluorination reagent. The fluorine-containing coating layer is a stable coating layer constructed by performing in-situ fluorination on the surface of the silicon-based material through a fluorination reagent. Through an in-situ fluorination method, surface residual salt is directly converted into lithium fluoride, and a stable coating layer structure is constructed while the alkalinity of the material is reduced. The silicon-based composite material provided by the invention has high slurry stability when being used as a lithium ion battery negative electrode material, shows excellent interface stability in an electrochemical cycle process, and prolongs the cycle life of a battery.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

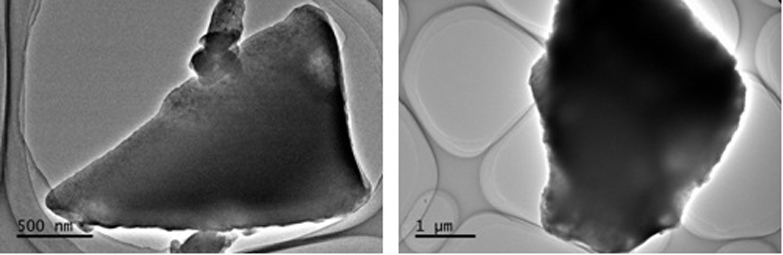

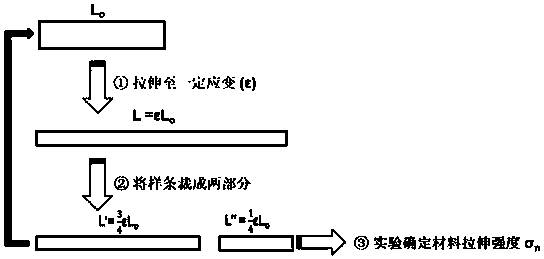

High polymer material capable of realizing self-healing of chemical bond damage under humid and stressed conditions and preparation method of high polymer material

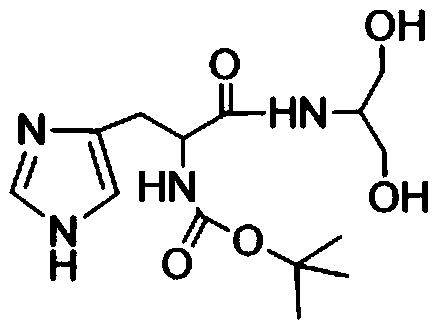

ActiveCN111423599AStrong mechanical propertiesStable mechanical strengthSoft segmentPolymer chemistry

The invention discloses a polymer material capable of realizing self-healing of chemical bond damage under humid and stressed conditions and a preparation method of the polymer material. The polymer material is prepared from linear polymers through crosslinking via reversible bonds, wherein the reversible bonds comprise a divalent metal ion-histidine coordination bond and a Fe<3+>-dopamine coordination bond; when the high polymer material is not stressed, the coordination number of Fe<3+> in the Fe<3+>-dopamine coordination bond is 4; the linear polymers comprise soft segments and hard segments; histidine groups in the divalent metal ion-histidine coordination bond comes from side groups of the soft segments, and dopamine groups in the Fe<3+>-dopamine coordination bond comes from side groups of the hard segments. The polymer material provided by the invention can perform self-healing of chemical bond damage under humid and stressed conditions, can realize self-repairing at an initial stage of micro-damage generation, eliminates micro-damage generated during stress in time, prevents the micro-damage from expanding, stabilizes the mechanical strength of the material, and maintains long-term stability in the aspect of mechanical properties.

Owner:SUN YAT SEN UNIV

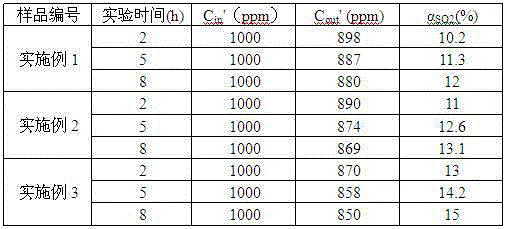

Honeycombed catalyst for low-temperature denitration and preparation method

InactiveCN105195171AHigh activityImprove acid and sulfur corrosion resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTunnel kilnPtru catalyst

The invention belongs to the technical field of catalyst preparation, discloses a honeycombed catalyst for low-temperature denitration and a preparation method. The honeycombed catalyst for low-temperature denitration comprises components in percentage by weight as follows: 82.29%-88.64% of a catalyst primary material, 3.29%-6.16% of a surfactant, 2.24%-5.08% of a crosslinking agent and 4.28%-6.96% of a reinforcing agent. The catalyst primary material, the surfactant, the crosslinking agent and the reinforcing agent are added to deionized water, and a muddy mixture is formed; the muddy mixture is subjected to mud smelting in vacuum, a product is aged, molded and dried under constant temperature and humidity conditions and calcined in a tunnel kiln until the product is dried sufficiently, and the honeycombed catalyst for low-temperature denitration is prepared. The honeycombed catalyst for low-temperature denitration has higher catalytic activity at the temperature of 180-300 DEG C and has the characteristics of good water resistance, acid and sulfur corrosion resistance capacity, high thermal stability, high catalytic activity, high mechanical strength and large specific surface area.

Owner:海南海控特玻科技有限公司

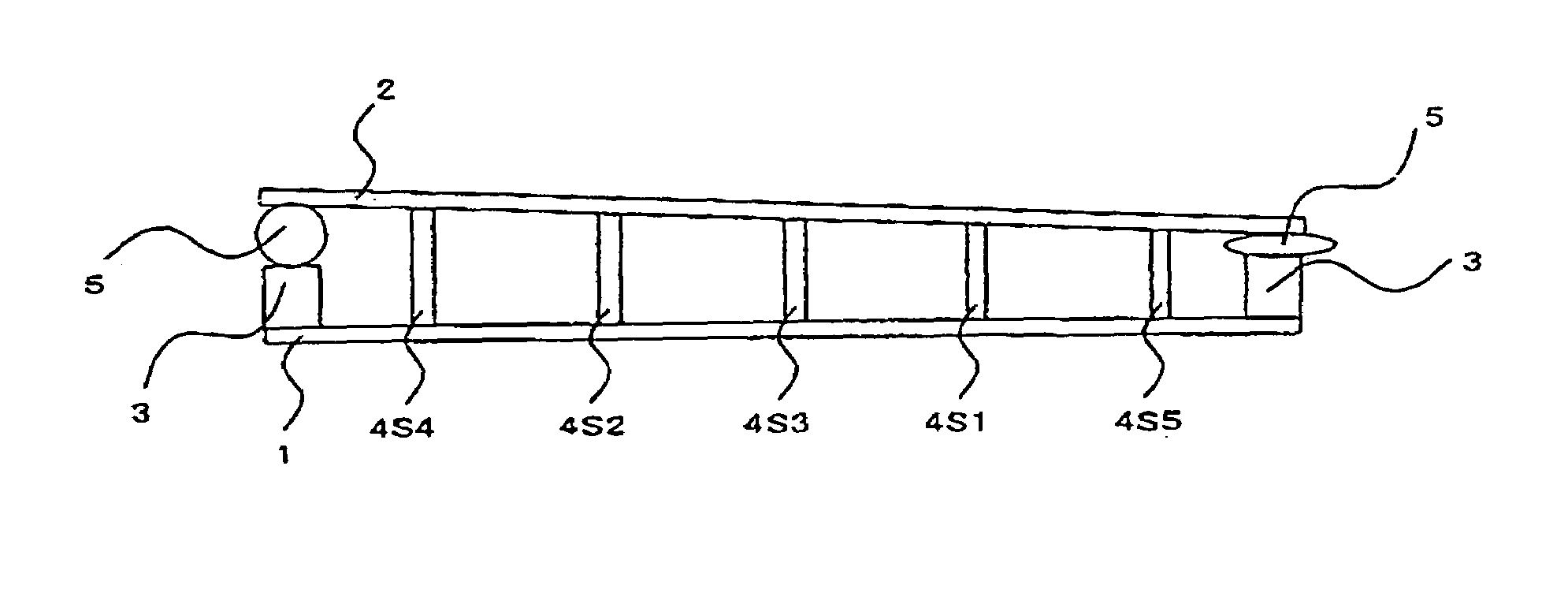

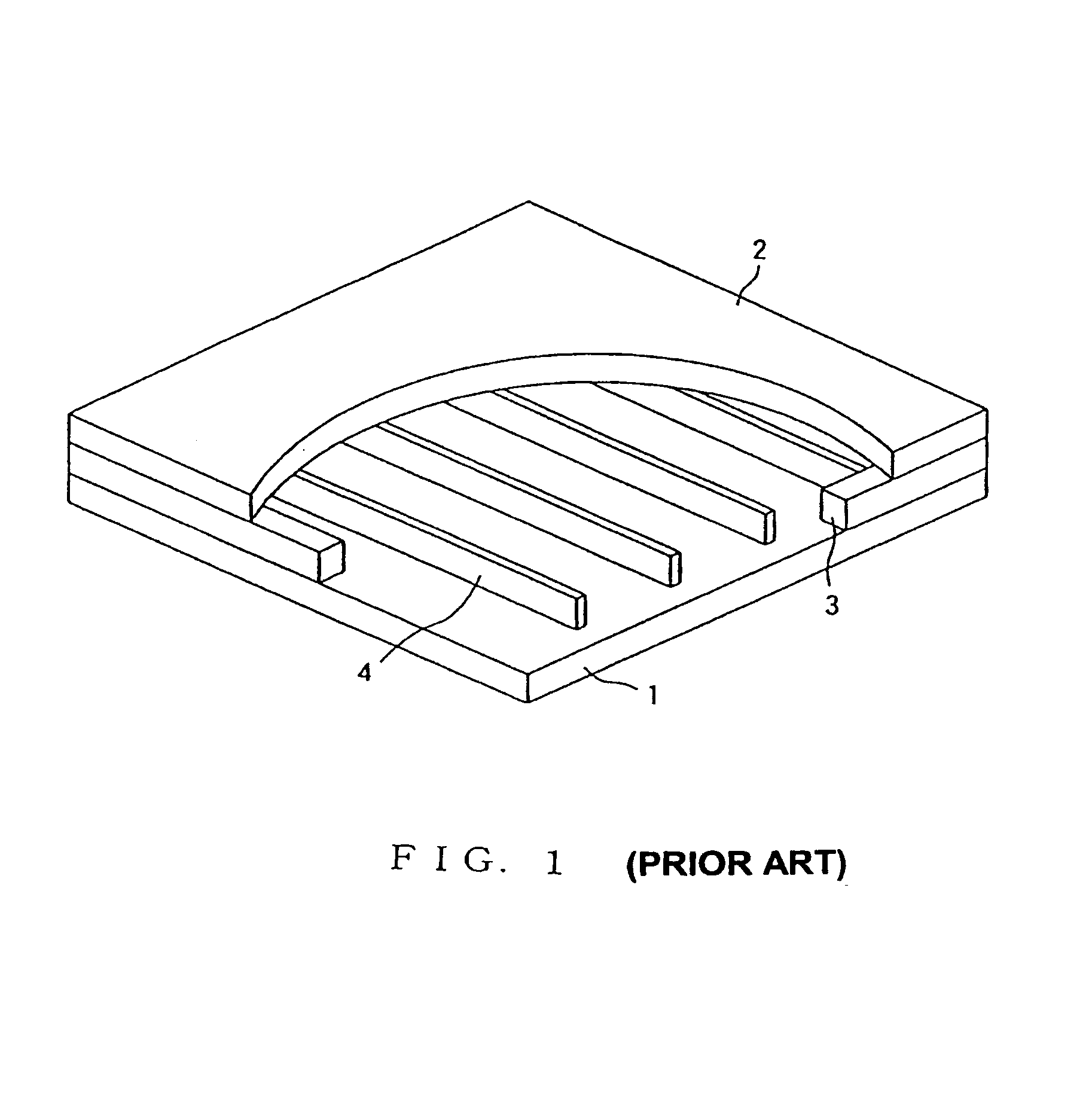

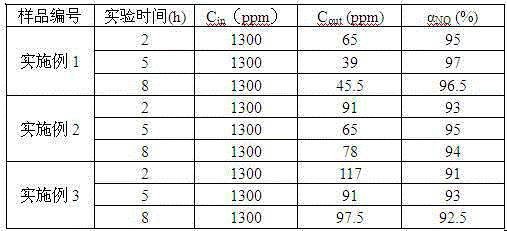

Method for manufacturing image display device, image display device, and TV apparatus

InactiveUS20050009434A1Stable mechanical strengthHigh mechanical precisionCathode-ray/electron-beam tube vessels/containersStatic indicating devicesComputer scienceCable television

An image display device of a high quality, in which the variation of heights between adjoining spacers is reduced by measuring the heights of spacers to arrange the spacers from the end in the sequential order of heights so that the mechanical precision of the spacers need not be strictly managed.

Owner:CANON KK

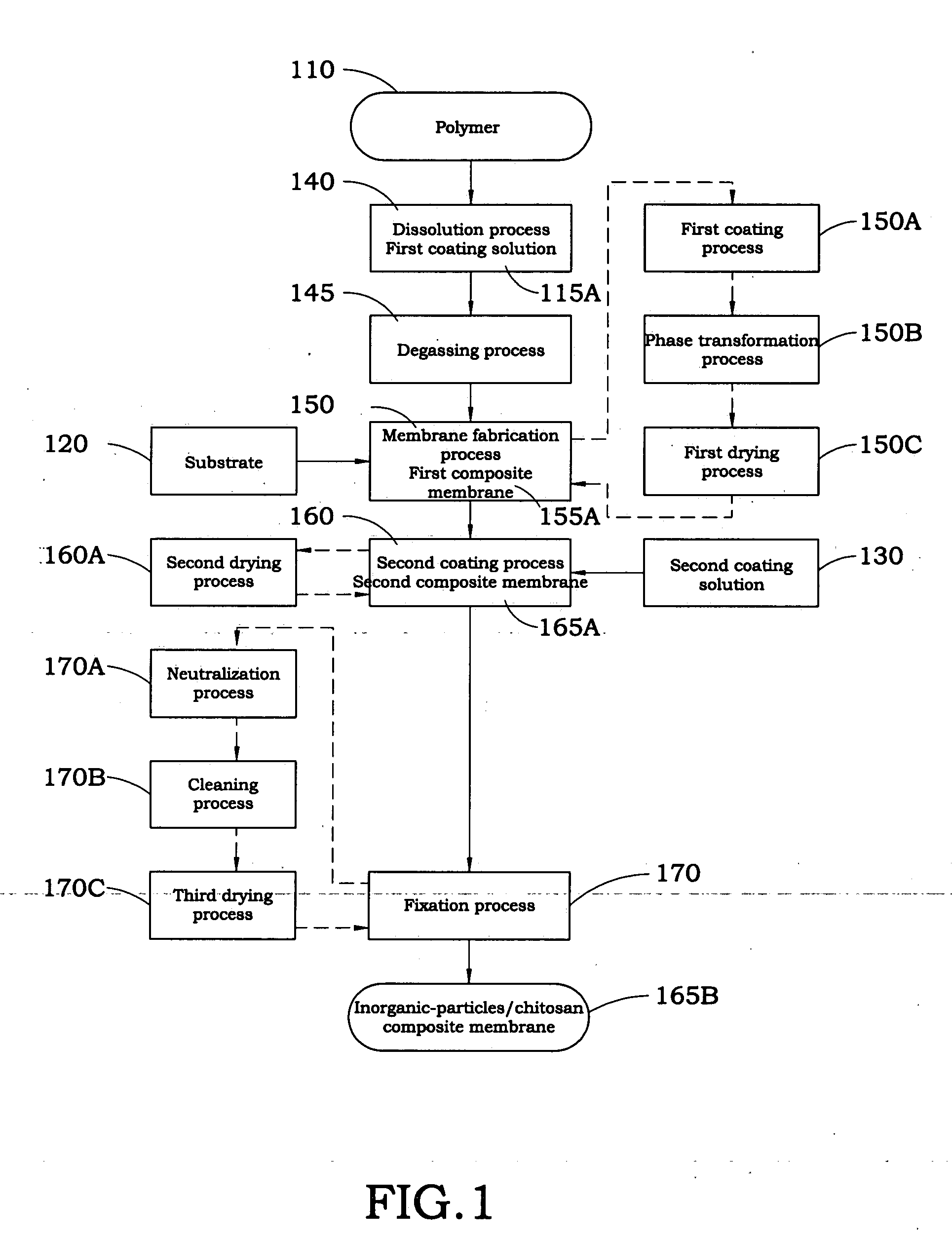

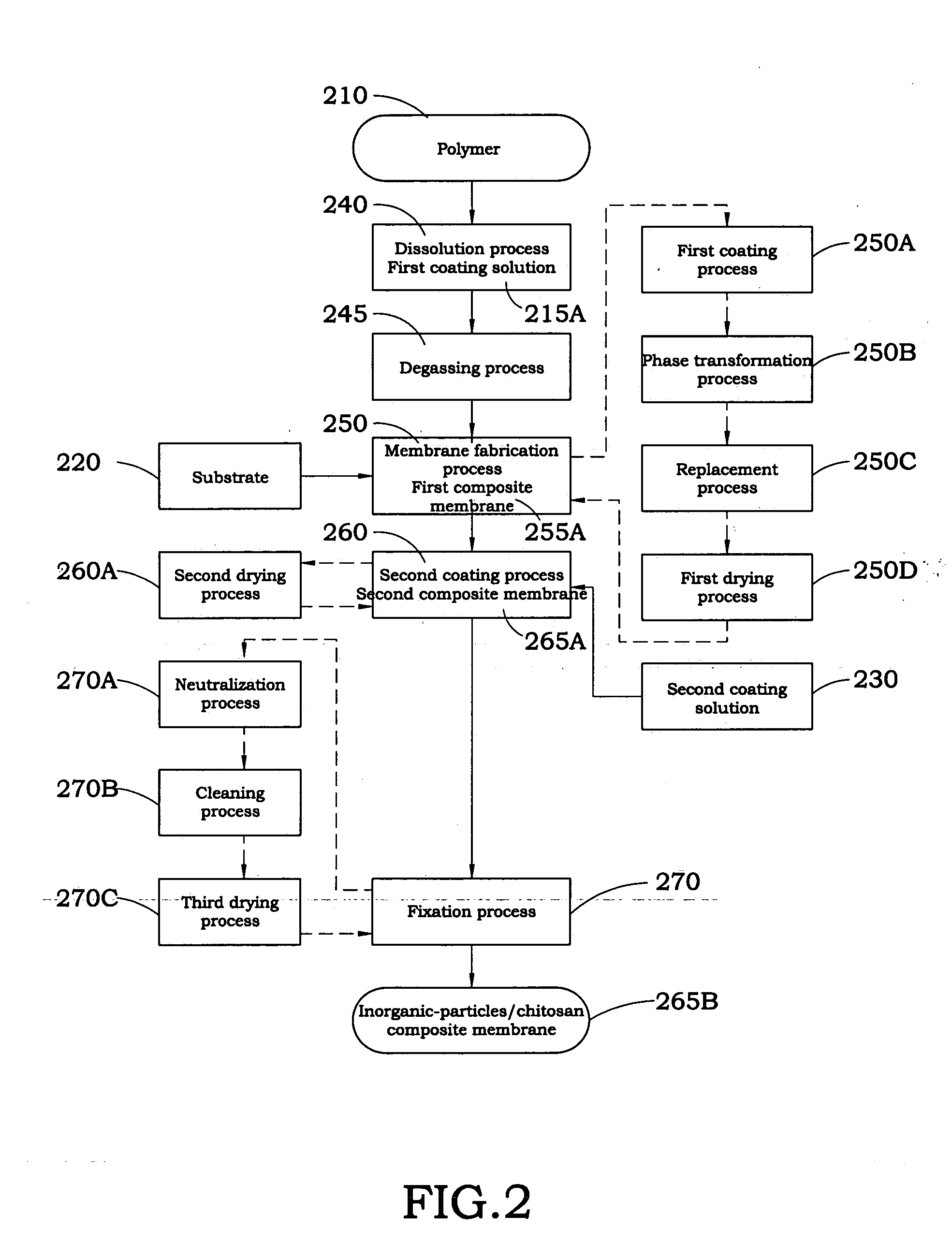

Composite membrane for separating organic solvents and the method for fabricating the same

InactiveUS20070082141A1High selectivityImprove throughputMembranesLiquid surface applicatorsOrganic solventInorganic particle

This invention discloses a composite membrane for separating organic solvents that comprises a carrier layer, a support layer and a separation layer. The material of the separation layer is chitosan containing nano-inorganic particles, wherein the nano-inorganic particles are uniformly embedded in the the chitosan separation layer. This invention also discloses a method for fabricating a composite membrane for separating organic solvents. Moreover, the method comprises a dissolution process, a degassing process, a membrane fabrication process, a coating process and a fixation process.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

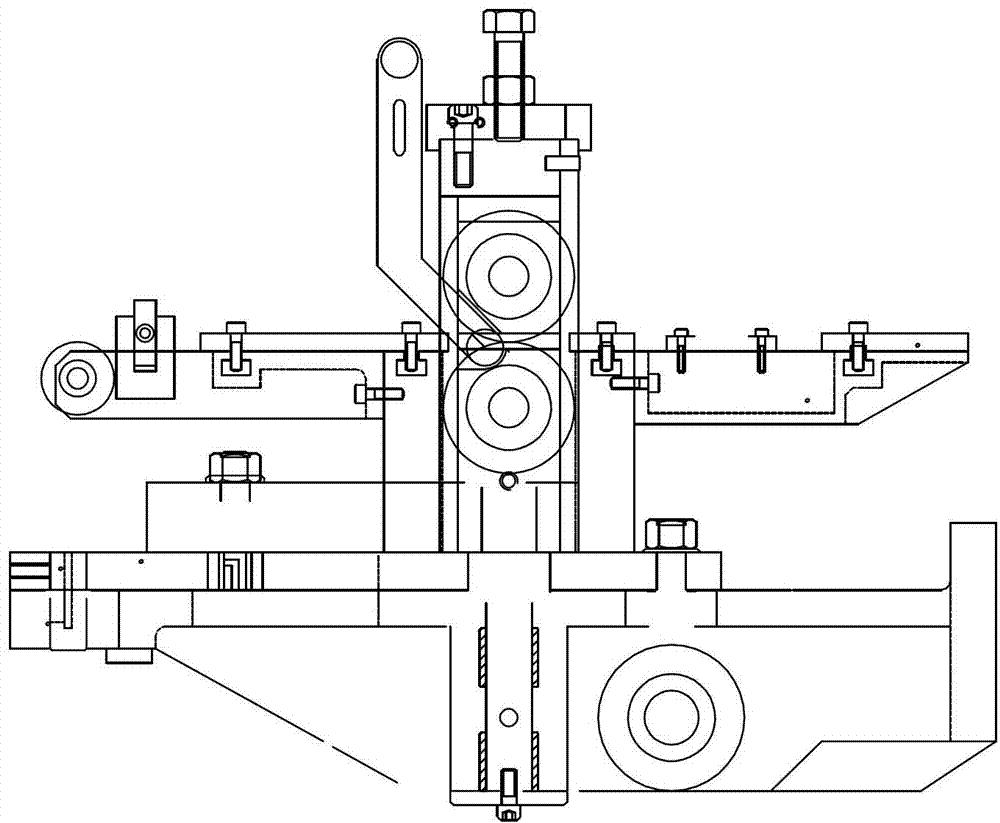

Novel making process of cylindrical pin piece of digital transmission connection pin

ActiveCN102761046BHigh precisionIncrease productivityContact member manufacturingStampingUltimate tensile strength

The invention relates to the field of pin piece manufacturing, in particular to a novel making process of a cylindrical pin piece of a digital transmission connection pin. The process comprises the following steps of: (a) selecting materials: selecting a copper strip with width of 18-27.5 mm and thickness of 0.16-0.22 mm, and placing the copper strip on a swinging feeding device; and (b) high speed precision stamping and deep drawing: feeding the copper strip meeting specifications to a deep drawing progressive die by the swinging feeding device; carrying out continuous deep drawing on the copper strip until an outer pipe finished product meeting the specifications are deeply drawn by a multi-station continuous die. The novel making process provided by the invention has the advantages as follows: the production efficiency is greatly increased, the direct production cost is reduced and high accuracy and stable quality of a product are guaranteed; good mechanical strength and transmission performance are also achieved; it is proved by test that parameters of the product, such as mechanical strength, anti-interference property and the like, all meet specifications and standards in the industry, and compared with a copper rod turned piece, the product has the advantages of more stable performance and strong signal transmission effect.

Owner:CIXI LVLV ELECTRONICS

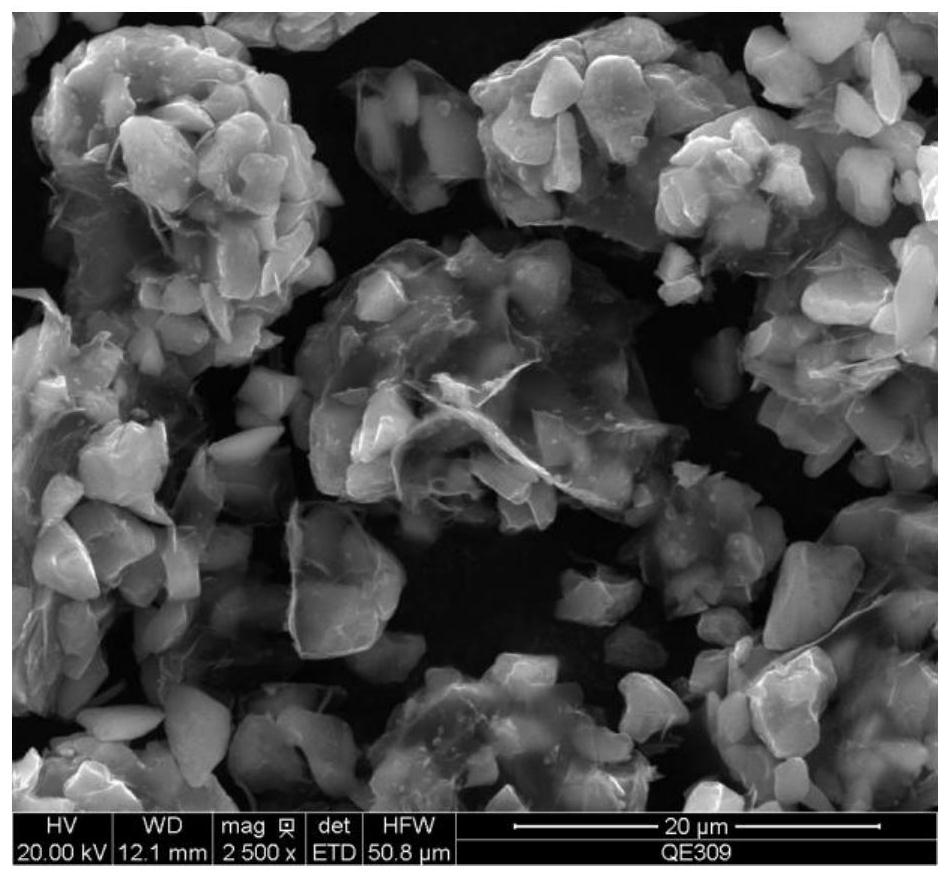

MXene silicon-carbon composite material, preparation method thereof, negative electrode and lithium ion battery

ActiveCN112038641AImprove hydrophilicityStable mechanical strengthMaterial nanotechnologySecondary cellsCarbon compositesNanostructured carbon

The invention provides an MXene silicon-carbon composite material. The MXene silicon-carbon composite material comprises a SiOx substrate material, nano carbon coating the surface of the SiOx substrate material and MXene coating the surface of the nano carbon, and 0.6<x<1.4. The MXene material is innovatively adopted as a coating layer to reconstruct a secondary structure, the stable mechanical strength and good conductivity of the MXene material are utilized to effectively inhibit the expansion of a silicon carbon material and enhance the conductivity of the silicon carbon material, and the good hydrophilicity of the MXene material enables the preparation process to be simpler and the compounding effect to be better. The invention further provides a preparation method of the MXene silicon-carbon composite material, and the preparation method provided by the invention can reduce MXene overlapping inactivation, is adjustable and controllable in particle size and pore structure characteristics, and can be more effectively matched with a battery negative electrode.

Owner:宁波富理电池材料科技有限公司

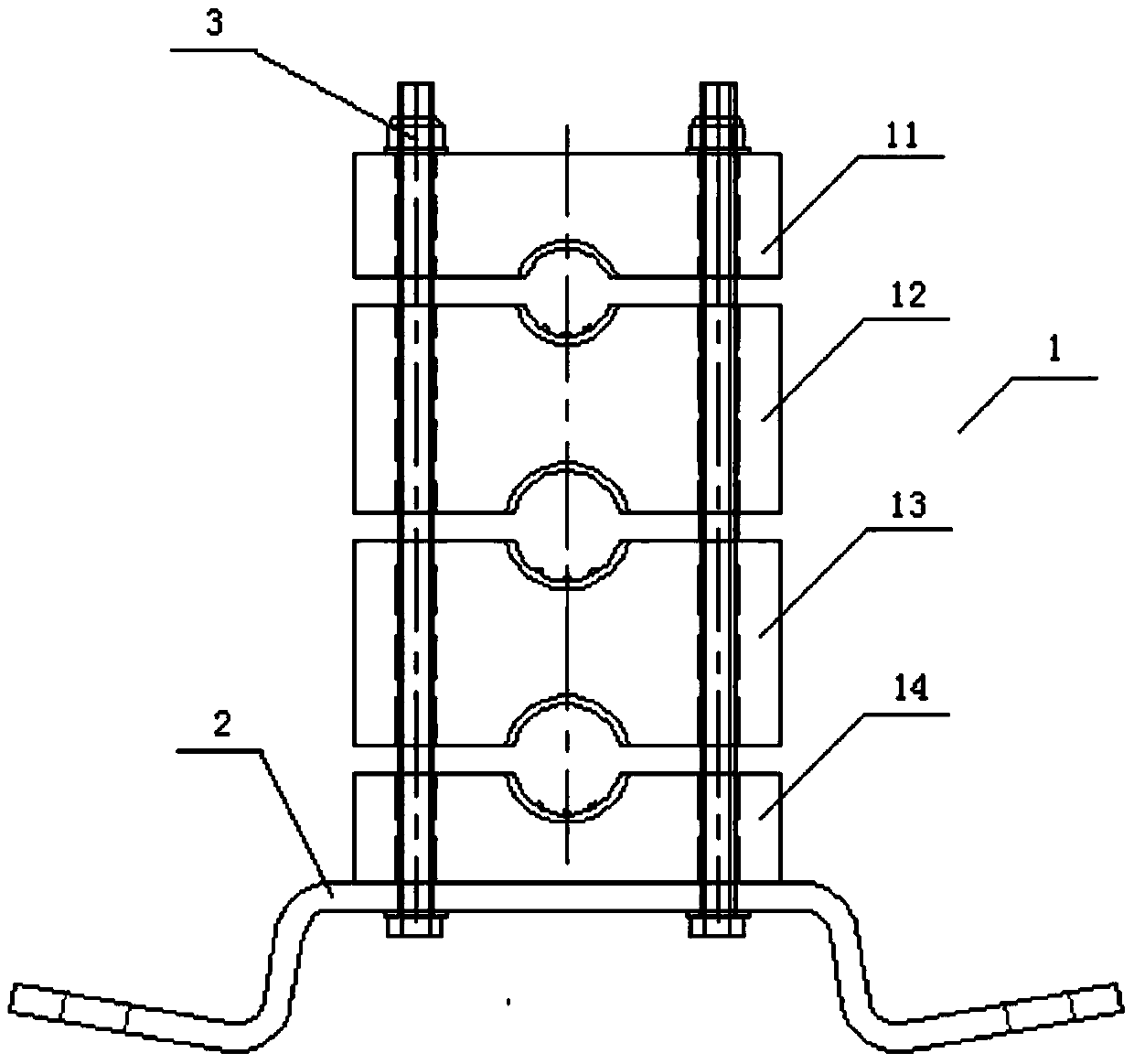

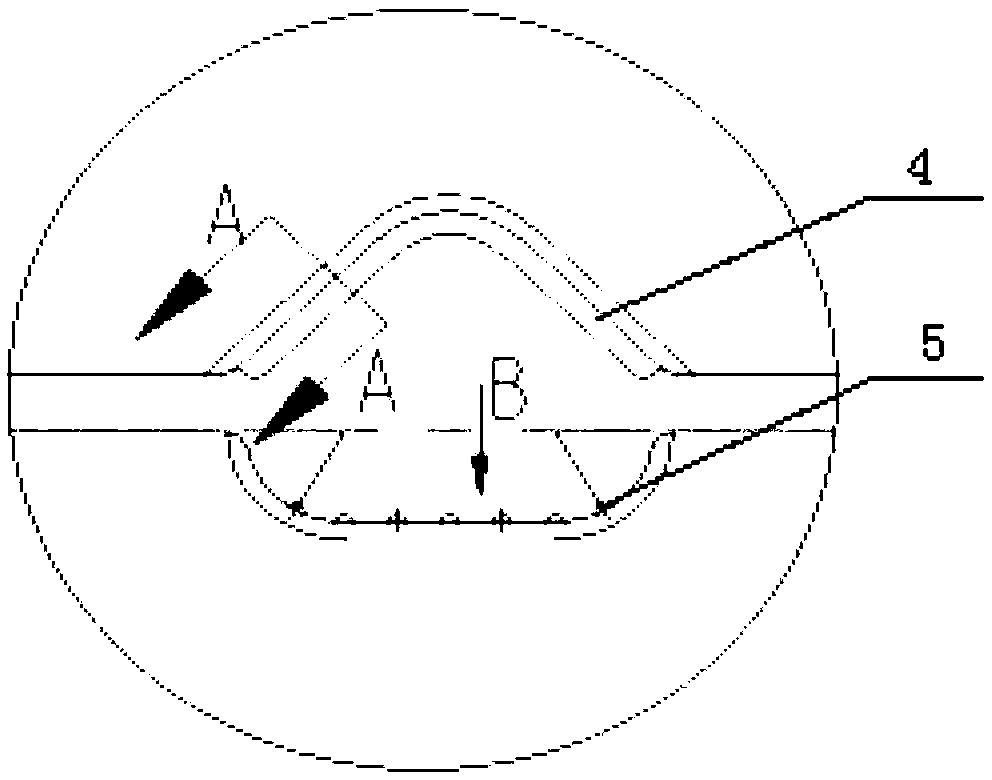

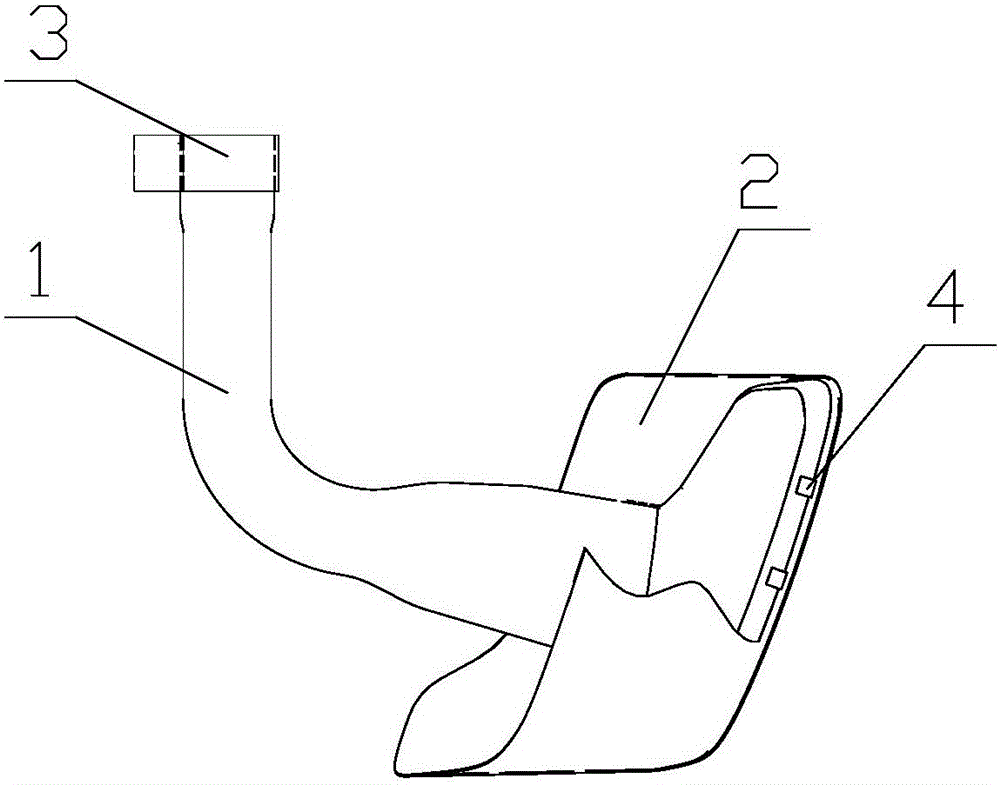

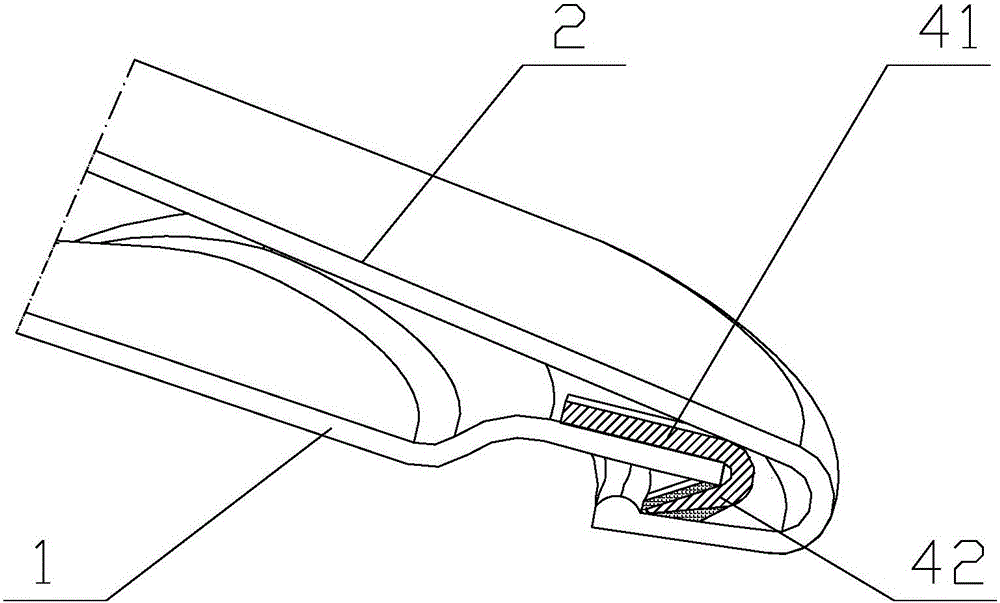

Composite cable clamping plate special for wind power generation tower barrel

InactiveCN105508151AHigh mechanical strengthStable mechanical strengthEngine fuctionsMachines/enginesFiberAlkali free

A composite cable clamping plate special for a wind power generation tower barrel comprises a clamping plate body (1), a clamping plate support (2) and tightening bolts (3). The clamping plate body is fixed to the clamping plate support through the tightening bolts, and the clamping plate body is made of resin, a low-shrinkage additive, an initiator, pigment paste, zinc stearate, magnesium oxide, styrene, alkali-free glass fibers and aluminum hydroxide. The composite cable clamping plate special for the wind power generation tower barrel has the advantages of being high in mechanical strength and bend resistance performance, free of distortion and brittle failures, resistant to acid-base, good in corrosion resistance, aging resistance, insulation performance and frame retardant property and the like. According to the composite, the high-strength alkali-free glass fibers serve as a reinforcing material, and the high-performance unsaturated polyester resin serves as a base material, so that the product has excellent physical and chemical performance, and the cable clamping plate is novel, can replace existing cable clamping plates made of various other materials, and has good application and popularization value.

Owner:宁夏顺和电工有限公司

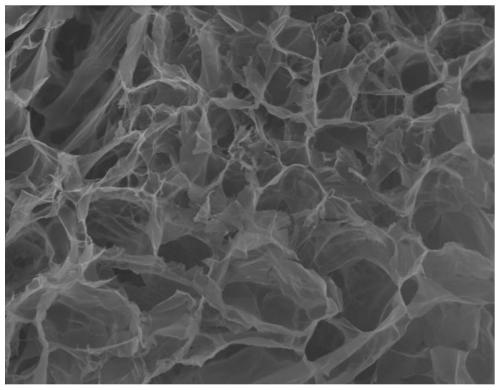

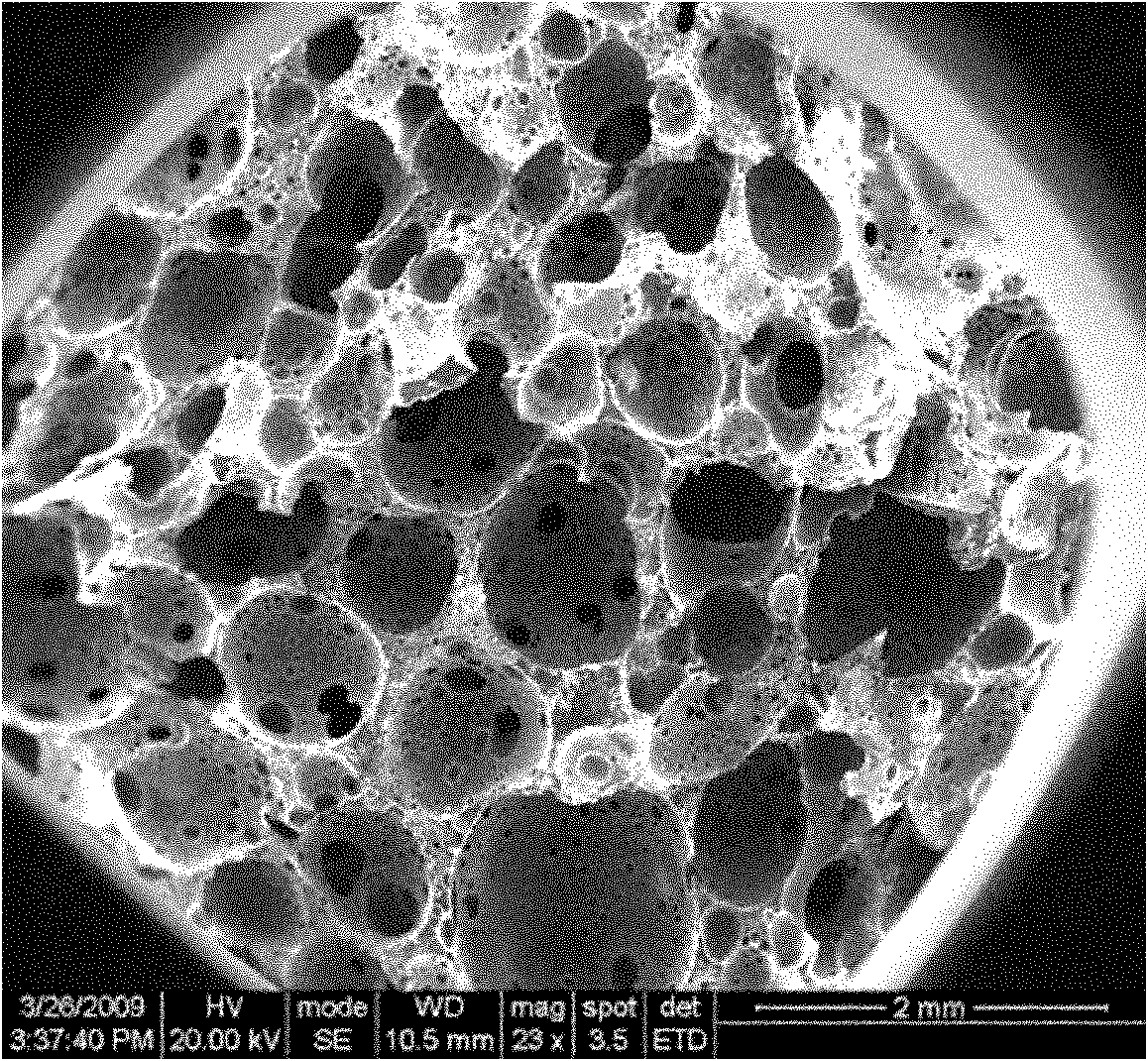

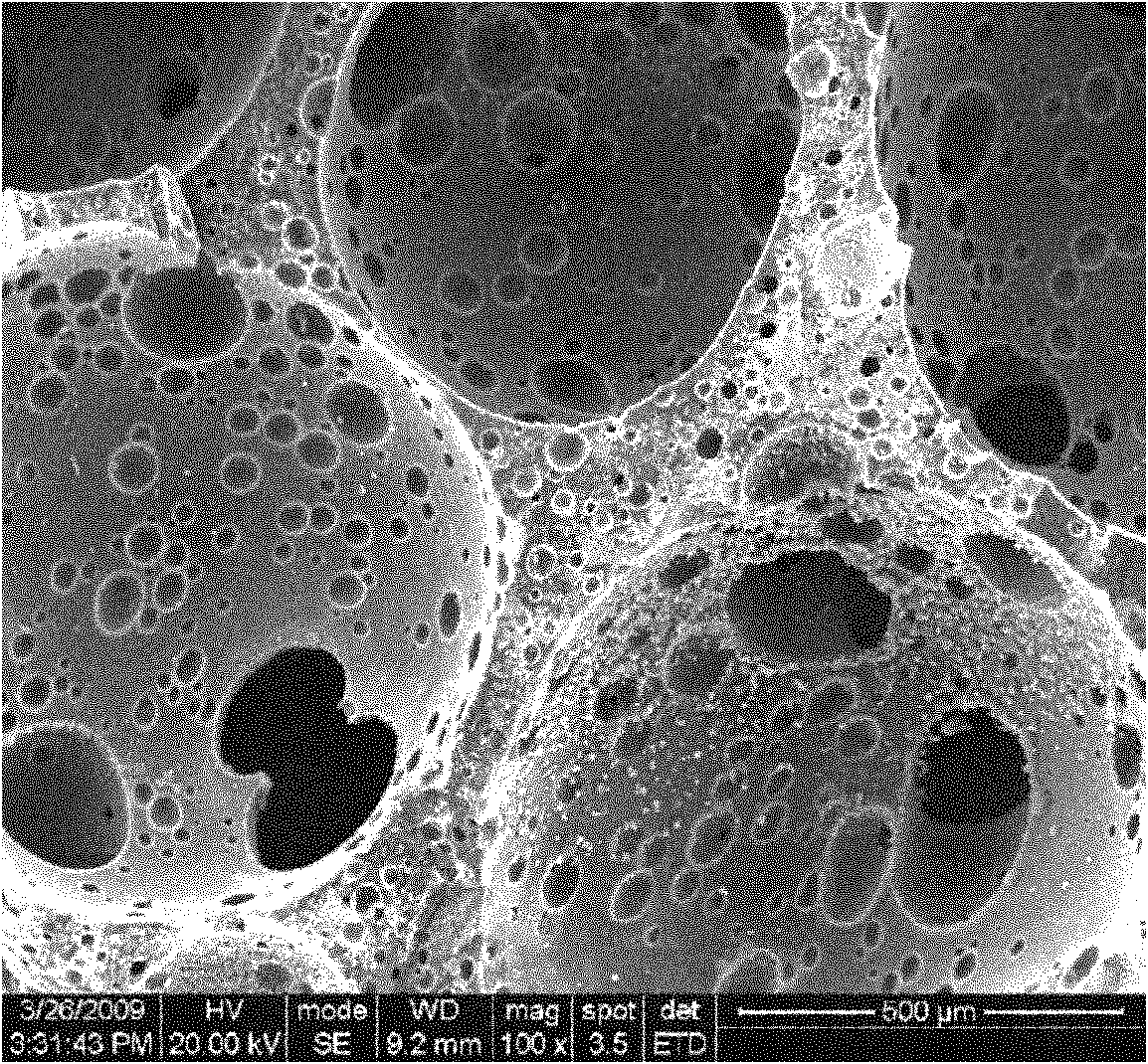

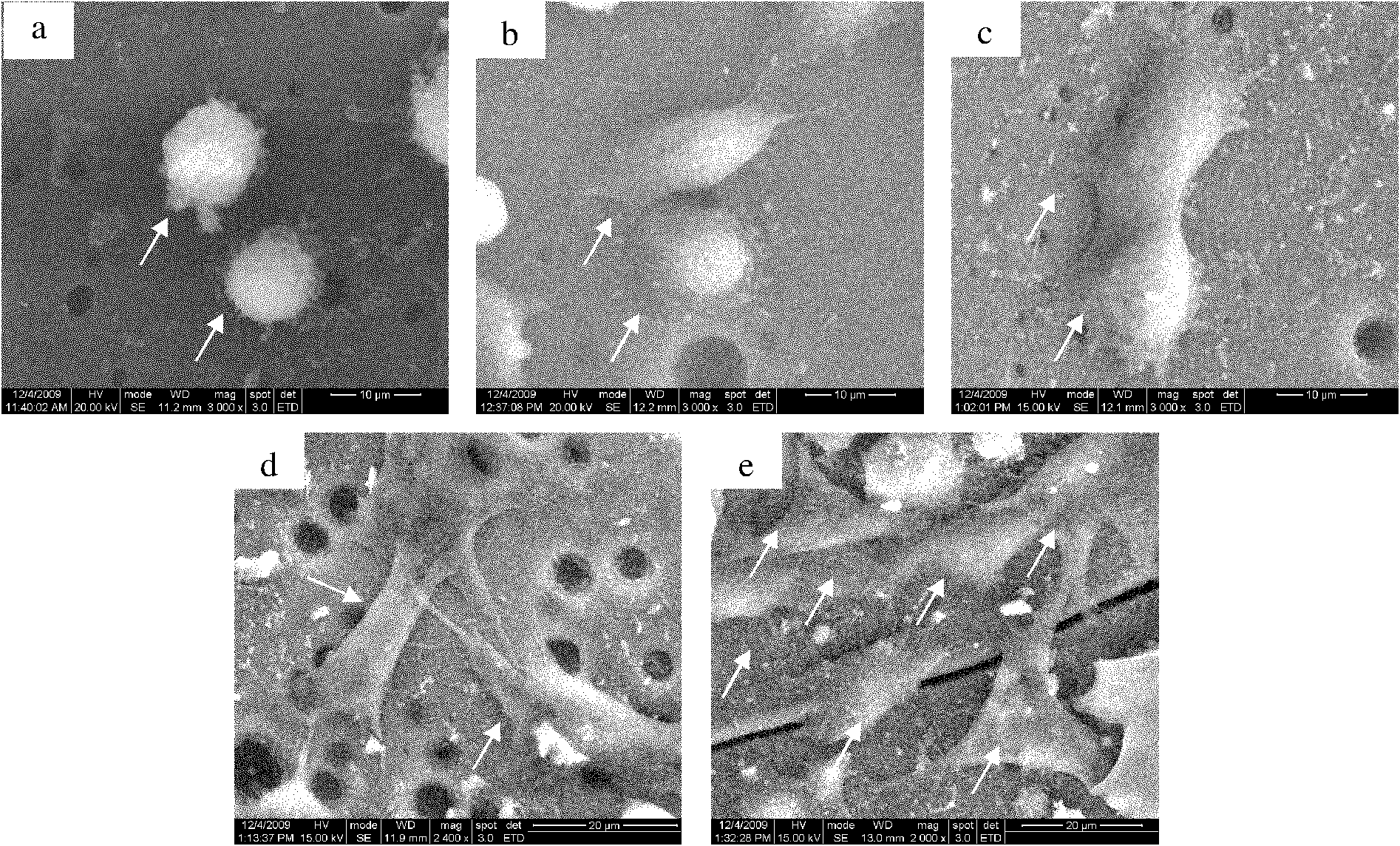

Foam carbon biological support, and preparation method and application thereof

ActiveCN102008747AReduce the cost of trainingMaintain functionalityVertebrate cellsArtificial cell constructsBiocompatibilityAperture ratio

The invention discloses a foam carbon biological support, and a preparation method and an application thereof. The foam carbon biological support is prepared by carbonizing a precursor formed by the foaming and solidification of phenolic resin under ordinary pressure. The method comprises the following steps: when preparation, firstly preparing materials; and then arranging into water bath for foaming and solidifying; drying and solidifying to acquire the precursor; carbonizing the precursor to obtain the foam carbon biological support. When the foam carbon biological support is used for exo-cell culture, the foam carbon biological support planted with cells is arranged in a static or dynamic circulating culture system for culturing according to the demands in different cell types. The foam carbon biological support has good aperture ratio and biocompatibility and high mechanical strength, and can be widely used for exo-cell culture.

Owner:湖南中科要素生物科技有限公司

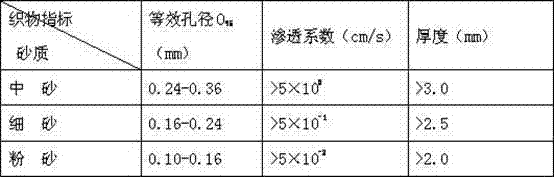

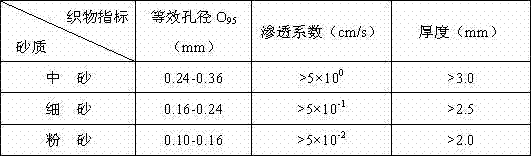

Method and equipment for rescuing dike downstream slope water seepage dangerous case by using three-dimensional composite filtering pads

ActiveCN102535397ALow costQuick implementationCoastlines protectionSoil scienceStructural engineering

The invention discloses a method and equipment for rescuing dike downstream slope water seepage dangerous case by using three-dimensional composite filtering pads. The method comprises the steps of: pre-making the three-dimensional composite filtering pads and connectors like bolts; transporting the three-dimensional composite filtering pads and the connectors to the site after detecting the dangerous case; cleaning the site of the dike downstream slope water seepage dangerous case; placing a plurality of three-dimensional composite filtering pads at a dike downstream slope water seepage place and adding cover weight; and connecting the three-dimensional composite filtering pads which are placed at the dike downstream slope water seepage place into a whole by using the connectors. The used three-dimensional composite filtering pads respectively are composed of three layers of materials and are characterized in that: the upper layer and the lower layer of the three layers of materials are filtering layers; the middle layer is a filter core layer; and the three layers of materials are composited into a whole. According to the invention, by means of a method for changing the earthwork for rescuing the dike downstream slope water seepage dangerous case in flood prevention work into special equipment, the traditional materials are changed into new materials which are batch-produced by utilizing factorization, the three-dimensional composite filtering pads can be paved at the water seepage places in a short time, so that precious time is saved for flood fighting.

Owner:NANJING HYDRAULIC RES INST

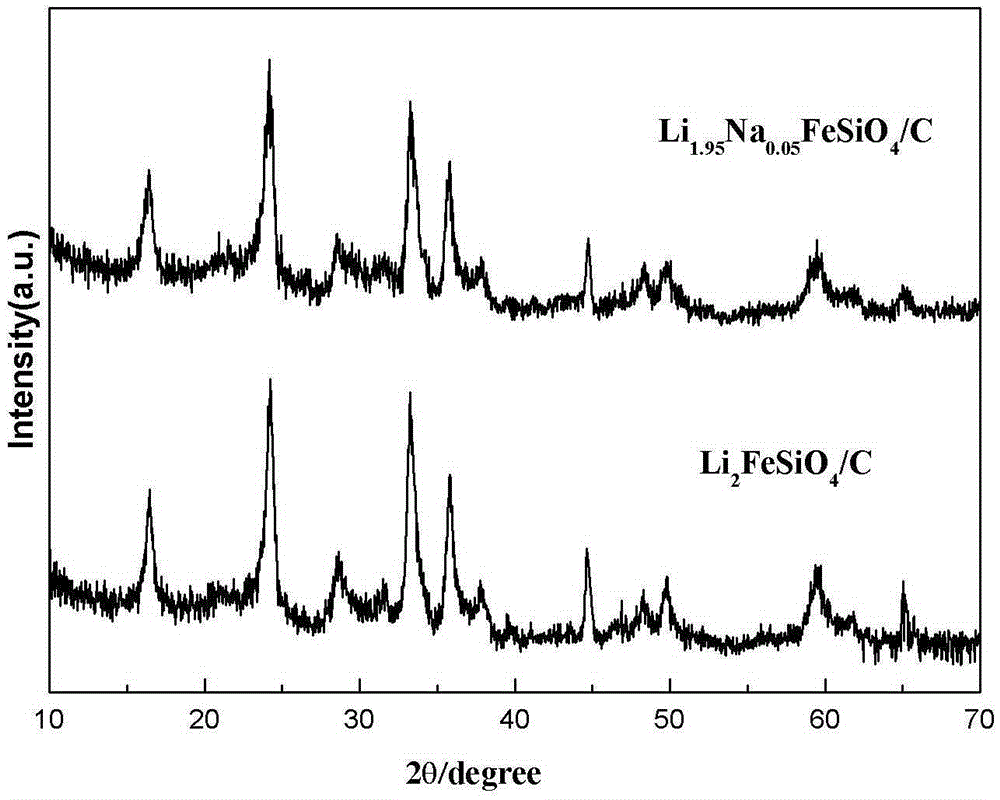

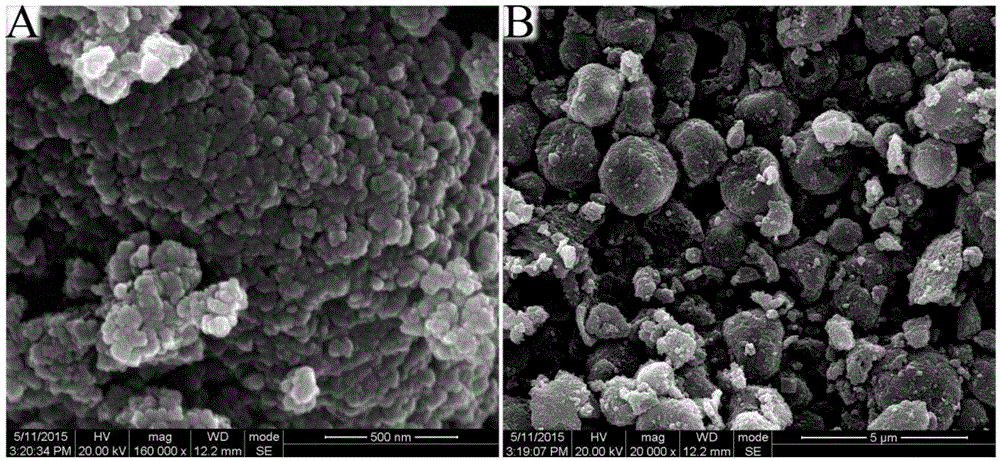

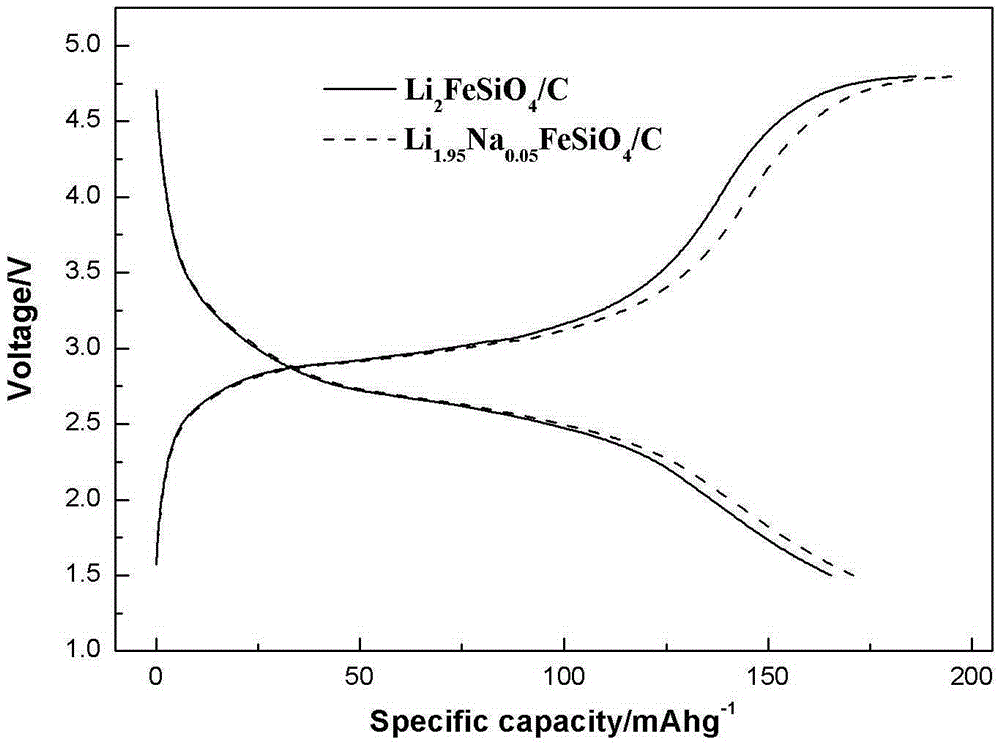

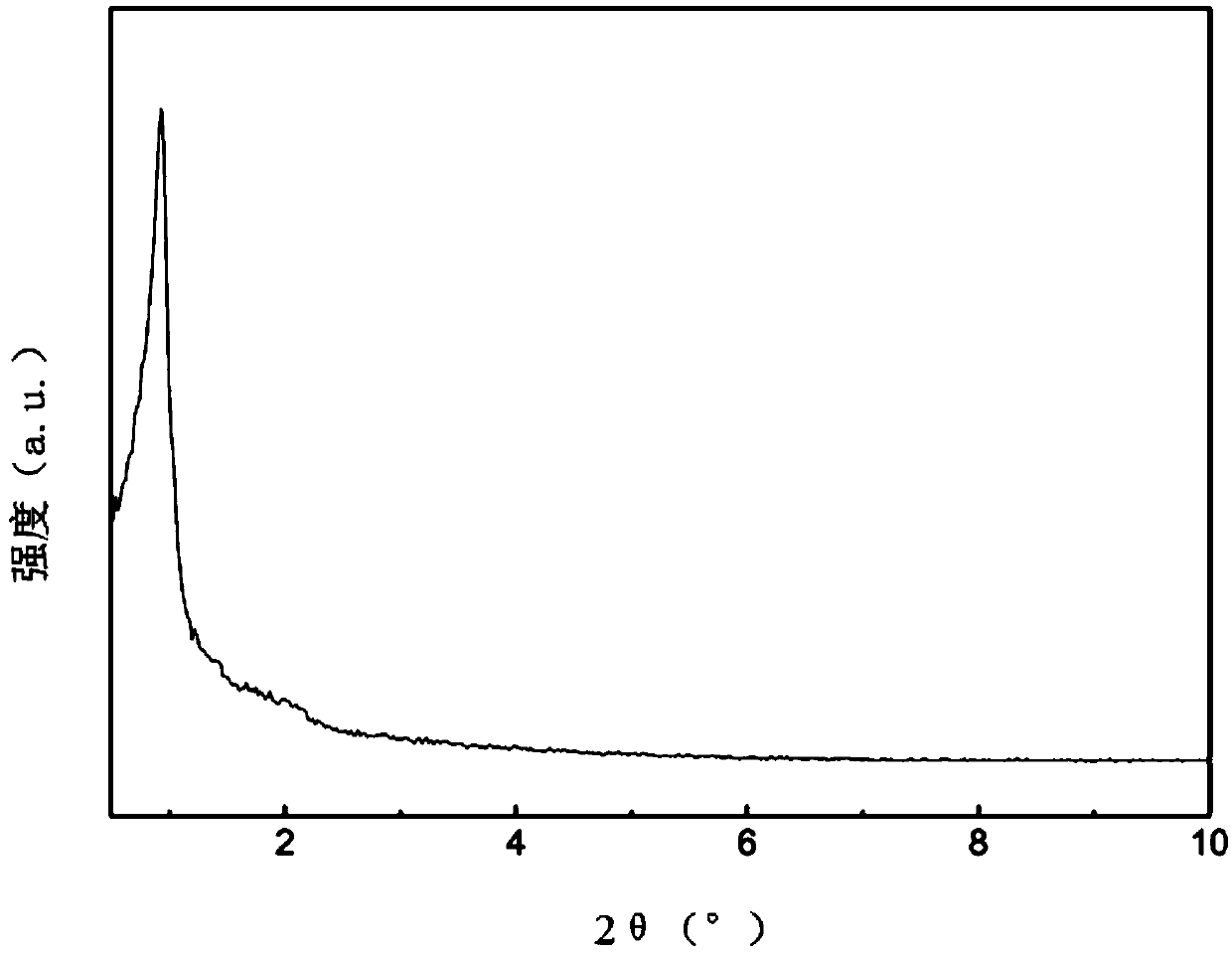

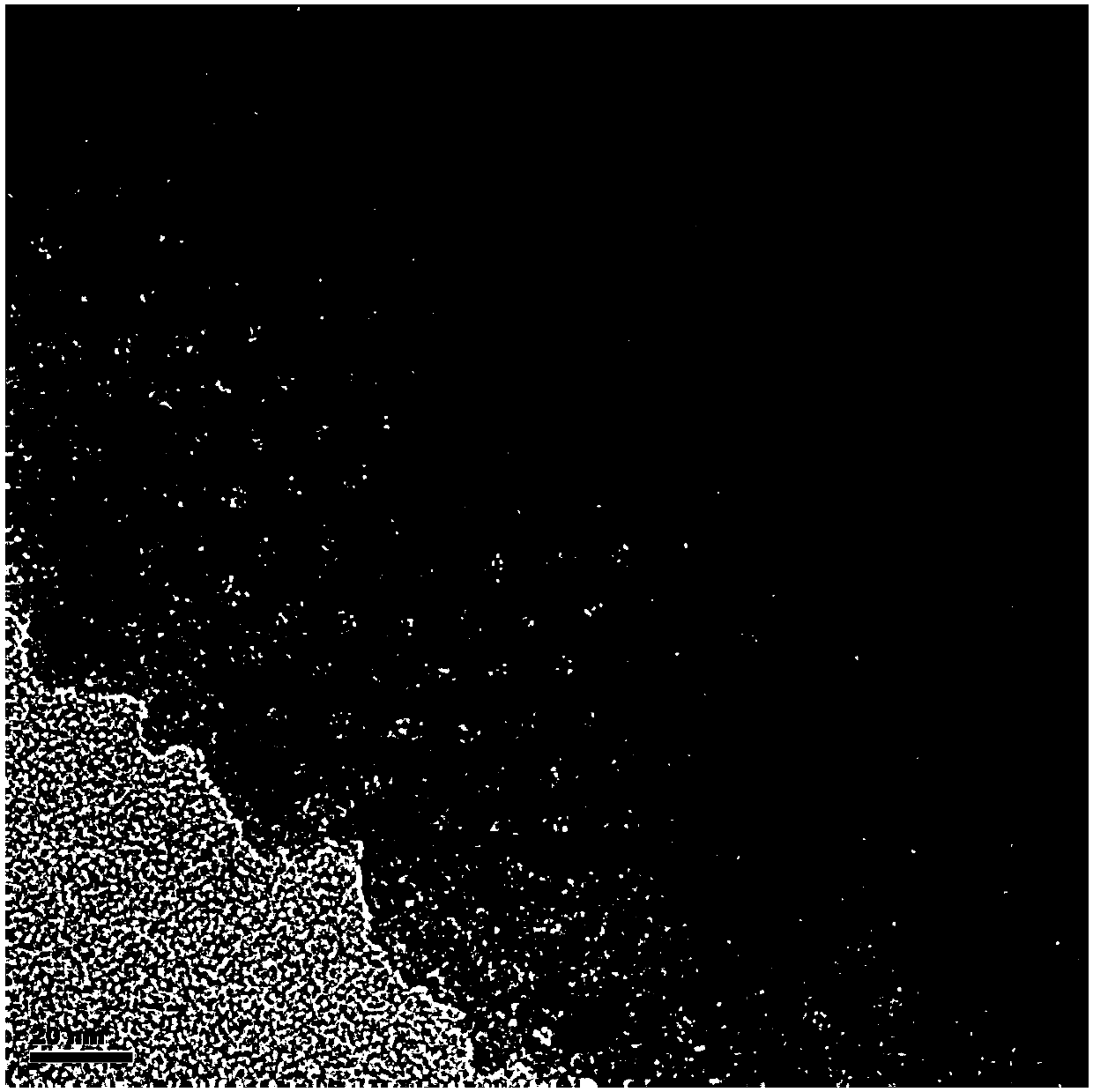

Method for preparing sodium-doped lithium ferrous silicate/carbon nano-micro structure composite cathode material

InactiveCN105375013AImprove Li+ migrationImprove electrochemical performanceCell electrodesSecondary cellsComposite cathodeLithium electrode

The invention relates to the technical field of lithium ion battery manufacturing, and especially a method for preparing a sodium-doped lithium ferrous silicate / carbon nano-micro structure composite cathode material. The method comprises the following steps: adding citric acid, lithium hydroxide, sodium hydroxide and ferrous oxalate into water, stirring and dissolving, performing oil bath and forming a deep green solution; and adding nanosilicon dioxide to obtain a sol, spray drying to obtain a precursor of the sodium-doped lithium ferrous silicate / carbon nano-micro structure composite cathode material, and calcinating in argon to obtain the sodium-doped lithium ferrous silicate / carbon nano-micro structure composite cathode material. The method for preparing the sodium-doped lithium ferrous silicate / carbon nano-micro structure composite cathode material provided by the invention is simple and safe in process, low in cost, and the obtained sodium-doped lithium ferrous silicate / carbon nano-micro structure composite cathode material is uniform in particle distribution and excellent in electrochemical performance.

Owner:CHANGZHOU UNIV

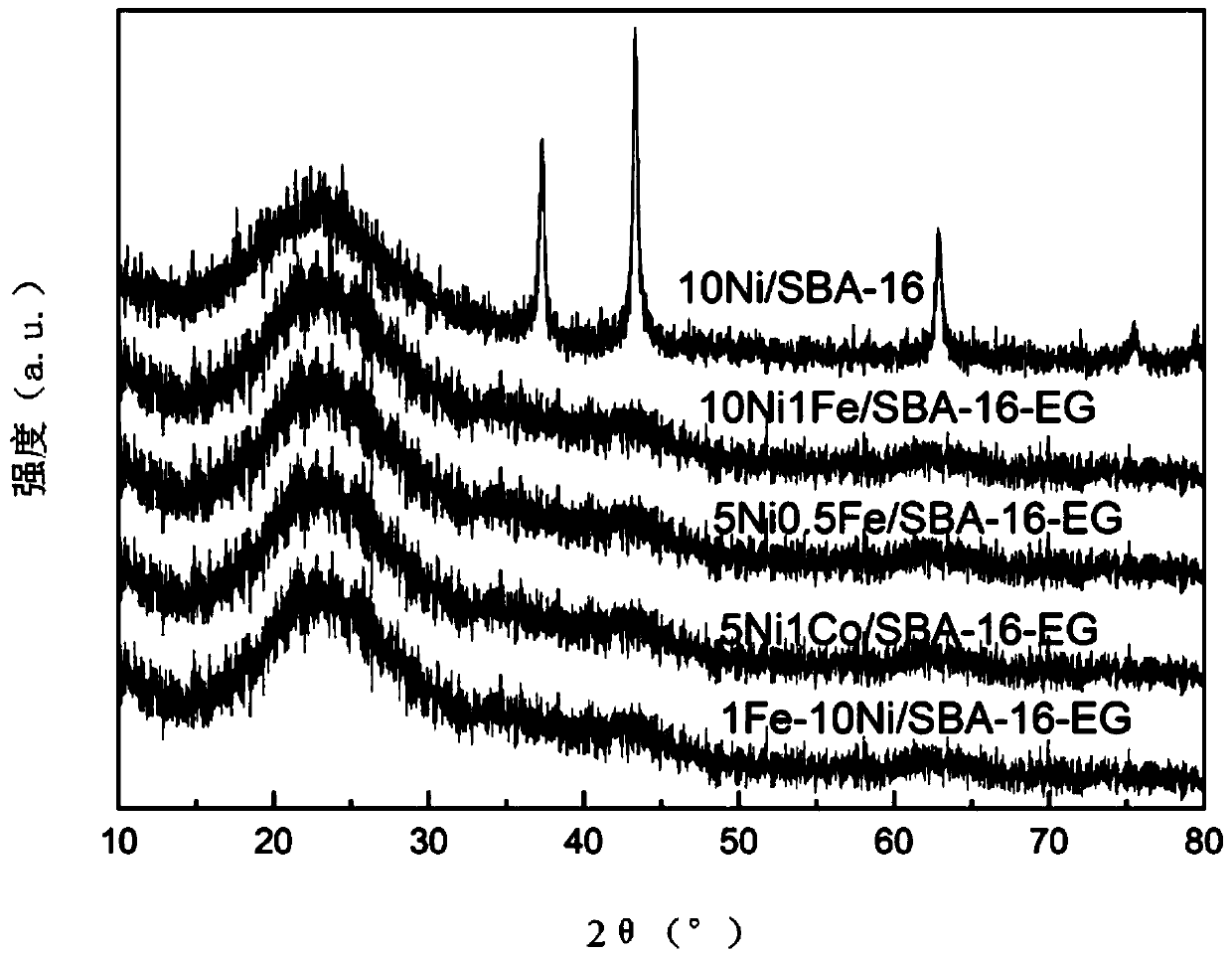

Low-temperature high-activity nickel-based bimetallic methanation catalyst, preparation method and applications thereof

InactiveCN110893347AHigh catalytic activityHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a low-temperature high-activity nickel-based bimetallic methanation catalyst, which uses a mesoporous molecular sieve SBA-16-EG as a carrier, uses metal Ni as a first active component and uses a second active metal M as a second active component, wherein the second active metal M is at least one selected from Fe, Co, La and Mo, and based on 100 parts by weight of the catalyst (calculated as metal elements), the content of nickel is 5-30 parts by weight, the content of the second active metal M is 0.1-10 parts by weight, and the balance is the mesoporous molecular sieveSBA-16-EG. The low-temperature high-activity nickel-based bimetallic methanation catalyst provided by the invention does not contain precious metal components, the preparation method is simple and easy to implement, the precursor is not wasted, the performance is relatively high, and the catalyst has great advantages in performance price ratio.

Owner:EAST CHINA UNIV OF SCI & TECH

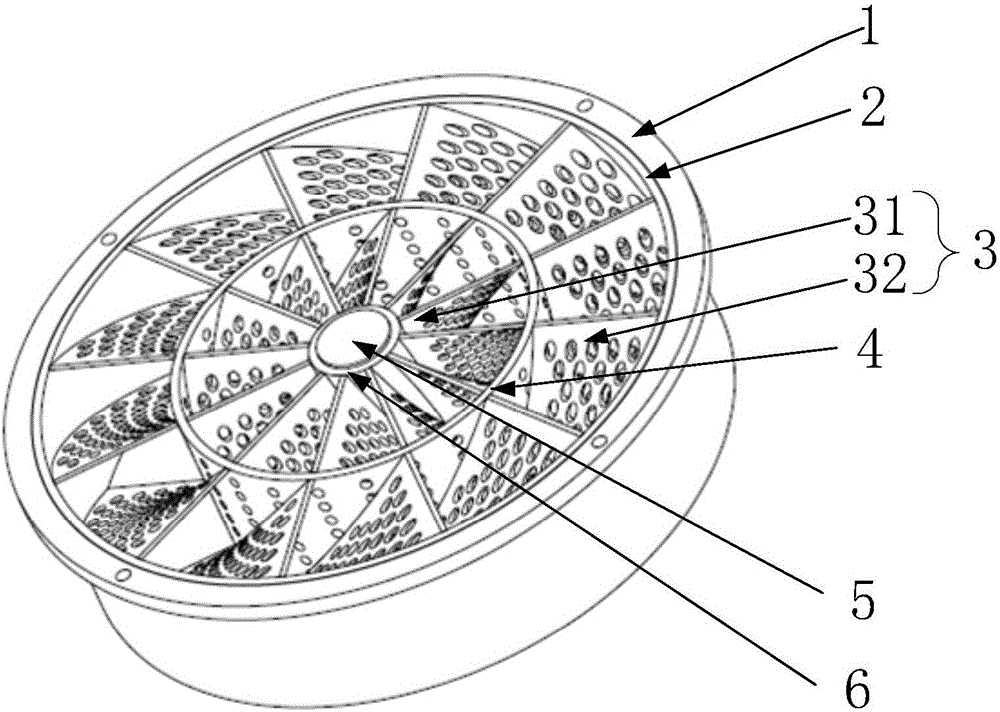

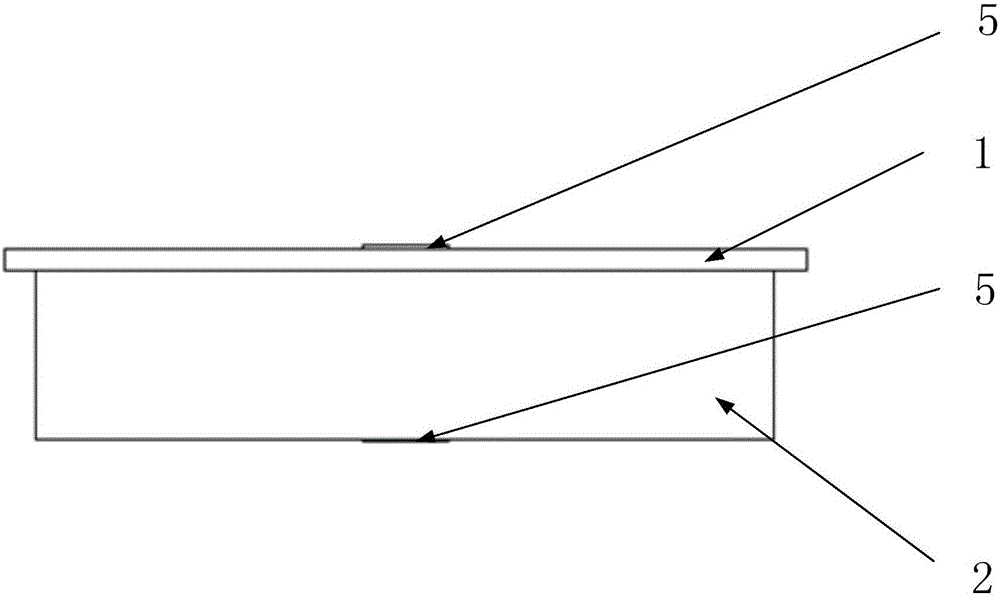

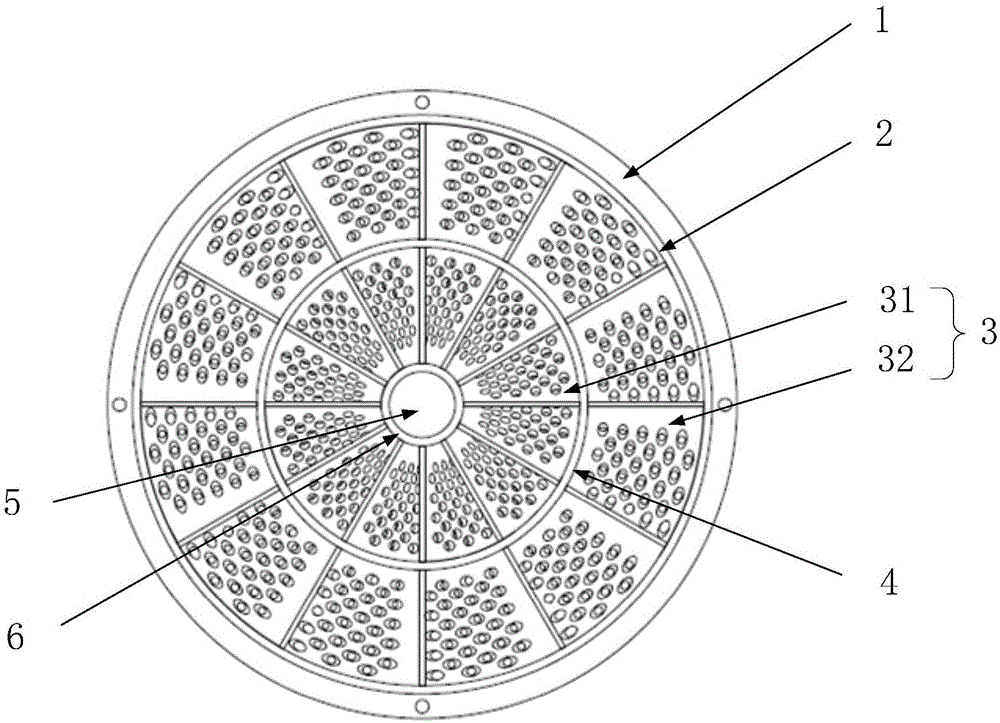

Multilayer three-dimensional rotational flow sieve plate and multilayer rotational flow sieve plate tower

ActiveCN106377919AIncrease the degree of mixingIncrease contact timeUsing liquid separation agentDistillation separationEngineeringTower

The invention provides a multilayer three-dimensional rotational flow sieve plate and a multilayer rotational flow sieve plate tower, and relates to the technical field of tower equipment. The multilayer three-dimensional rotational flow sieve plate comprises an inner tube, a middle tube, an outer tube and a rotational flow sieve plate, wherein the inner tube, the middle tube and the outer tube are sequentially arranged together from inside to outside in a sleeving way; the rotational flow sieve plate comprises an inner rotational flow sieve plate and an outer rotational flow sieve plate; the inner tube and the middle tube are connected through the inner rotational flow sieve plate; the middle tube and the outer tube are connected through an outer rotational flow sieve plate; holes are formed in the rotational flow sieve plate. The multilayer three-dimensional rotational flow sieve plate has the advantages that when the multilayer three-dimensional rotational flow sieve plates are combined, the mass transfer efficiency of the multilayer three-dimensional rotational flow sieve plate is high. Compared with other kinds of tower plates, the multilayer three-dimensional rotational flow sieve plate has the beneficial effects that on the premise of reaching the identical mass transfer effect, the installation quantity of the tower plate can be reduced; the press drop is low; the energy consumption of a water pump, a fan and the like can be effectively reduced; the flux of the multilayer three-dimensional rotational flow sieve plate is greater; the multilayer three-dimensional rotational flow sieve plate can adapt to the selection of larger tower diameter adsorption tower; the mechanical intensity is stable; safety and reliability are realized; the anti-blockage performance is excellent; the obvious advantage is realized in an aspect of dust containing gas treatment.

Owner:HEBEI UNIV OF TECH

Method for simultaneously extracting icariin and baohuoside I and II from herba epimedii

InactiveCN103910772AStable physical and chemical propertiesIncrease surface areaSugar derivativesSugar derivatives preparationHydrolysateSimulated moving bed

The invention discloses a method for simultaneously extracting icariin and baohuoside I and II from herba epimedii. The method comprises the following steps of: crushing herba epimedii plant and then passing the crushed herba epimedii plant through a screen mesh, adding alcohol liquor, heating for reflux extraction, and filtering to obtain filtrate B, concentrating under reduced pressure to recycle alcohol to obtain initial extract; extracting the initial extract by pure water, regulating PH, stewing and carrying out suction filtration to obtain icariin extract; carrying out elution on the icariin extract by adopting macroporous adsorption resin, carrying out elution by using alcohol and collecting eluant; adding medical active carbon into the eluant, heating and refluxing, cooling, and filtering to obtain filtrate C; separating, purifying and crystallizing the filtrate C by simulated moving bed chromatography to obtain herba epimedii crystal, and collecting filtrate D; drying the herba epimedii crystal to obtain a pure icariin finished product; adding tween into the filtrate D, carrying out enzymolysis by glucosaccharase or cellulose, and separating and purifying the enzymatic hydrolysate by a chromatographic column mixed and filled by the macroporous resin to obtain products baohuoside I and II.

Owner:成都合盛生物技术有限公司

Reinforced ligament tissue engineering scaffold and preparation method for same

ActiveCN106474543AStable mechanical strengthGuaranteed stabilityFilament/thread formingTissue regenerationFiberMass ratio

The invention relates to a reinforced ligament tissue engineering scaffold and a preparation method for the same, and belongs to the technical field of medical equipment. The reinforced ligament tissue engineering scaffold consists of a reinforcement skeleton nested between adjacent electrospun nanofiber felt layers, the number of the electrospun nanofiber felt layers is at least three, a material for the electrospun nanofiber felt layers is a composite of silk fibroin and polyvinyl alcohol according to the mass ratio of 1 / 9 to 1 / 1, and the reinforcement skeleton is formed by at least two silk threads or absorbable sutures which are arranged in parallel along the length direction of the electrospun nanofiber felt layers. The scaffold is of a uniform and stable microstructure, and has high biocompatibility, a matrix condition is provided for growth of ligament tissues, and the requirements of keeping slow reduction in mechanical strength of the scaffold in a process of ingrowth of neonatal ligament tissues and slow degradation of nanofibers and stability of a connected joint are met. The preparation method for the scaffold is simple, convenient to operate and adapted to preparation of reinforced ligament tissue engineering scaffolds meeting different mechanical performance requirements.

Owner:WUHAN TEXTILE UNIV

Decorative tail pipe for automobile exhaust pipe

InactiveCN105156194AReasonable structural designStable mechanical strengthExhaust apparatusSilencing apparatusIn vehicleExhaust pipe

The invention discloses a decorative tail pipe for an automobile exhaust pipe. The decorative tail pipe comprises an inner pipe and an outer sleeve, one end of the inner pipe is provided with a clamping part, the periphery of the clamping part is provided with a plurality of spring clamping pieces, the shape of the inner wall of the outer sleeve is matched with the inner pipe, one end of the outer sleeve is provided with an edge folding part which is bent towards the inside of an opening, and a clamping groove is formed between the edge folding part and the inner wall of the outer sleeve. One end of the clamping part of the inner pipe can be inserted into the outer sleeve from the opening at one end of the outer sleeve far away from the edge folding part, so that the clamping part is located in the clamping groove and fixedly clamped to the clamping groove through the spring clamping pieces. The decorative tail pipe for the automobile exhaust pipe is simple in process and rational in structural design. By arranging the spring clamping pieces, the inner pipe is fixedly clamped to the outer sleeve, the visual surface of the tail pipe is free of weld joint, and the mechanical strength of the tail pipe is stable. Due to the spring clamping pieces, the inner pipe is in close fit with the outer sleeve, and abnormal sounds generated between the inner pipe and the outer sleeve due to vibration in vehicle running can be effectively avoided.

Owner:BAOLONG ANHUI AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com