Metal electrode with three-dimensional structure

A technology of metal electrodes and three-dimensional structures, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of low ionic conductivity at room temperature, inability to provide "cages", and difficult control of metal forms, so as to improve Coulombic efficiency and reduce local Current density, effect of reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

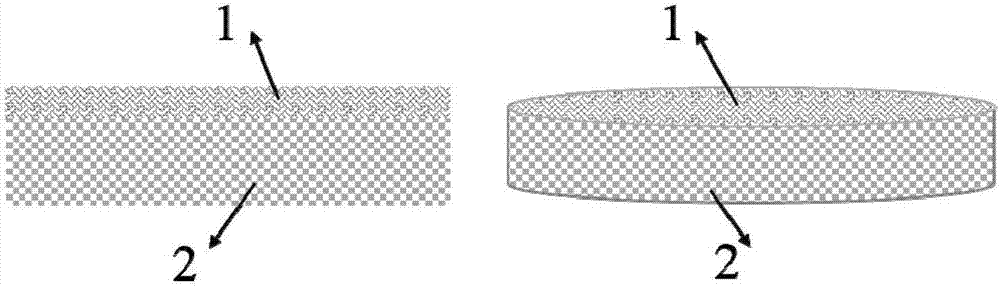

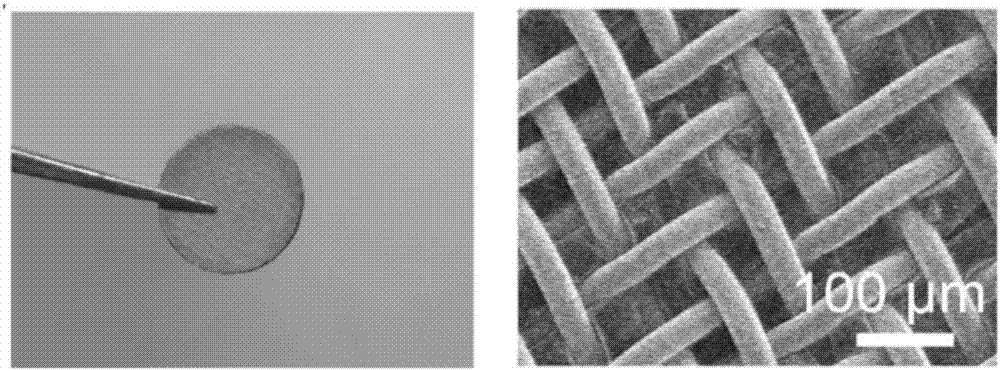

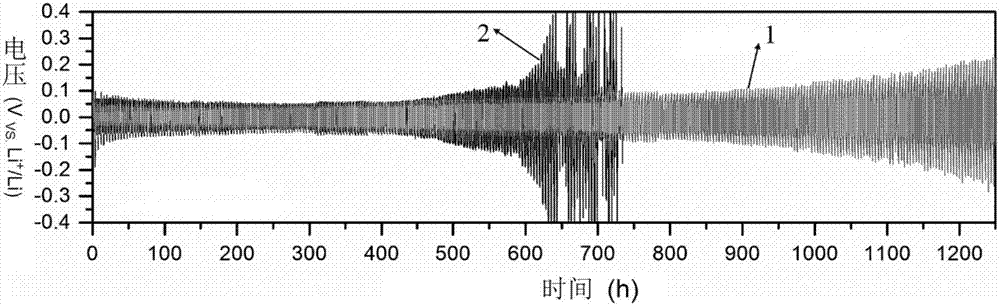

[0041] A 62 μm thick copper mesh with a pore size of 60 μm is placed on a 450 μm thick lithium metal sheet, and then through physical extrusion, the copper mesh is just embedded in the lithium metal surface to form a lithium metal negative electrode with a three-dimensional structure. Assemble a symmetrical battery, the electrolyte is 1M LiPF 6 / EC:DEC(1:1, volume ratio).

[0042] The test conditions of the assembled symmetrical battery are: the current density is 0.5mA cm -2 , with a capacity of 1mAhcm -2, after at least 1280 h, no short-circuit phenomenon appears in the lithium metal anode with three-dimensional structure. However, the battery using common lithium metal negative electrode short-circuited after 640h.

Embodiment 2

[0044] A 96 μm thick copper mesh with a pore size of 100 μm is placed on a 450 μm thick lithium metal sheet, and then the copper mesh is just embedded in the lithium metal surface by physical extrusion to form a lithium metal negative electrode with a three-dimensional structure. Assemble a symmetrical battery, the electrolyte is 1M LiPF 6 / EC:DEC(1:1, volume ratio).

[0045] The test conditions of the assembled symmetrical battery are: the current density is 0.5mA cm -2 , with a capacity of 1mAh cm -2 , after at least 1100 h, no short-circuit phenomenon occurs in the lithium metal anode with a three-dimensional structure. However, the battery using common lithium metal negative electrode short-circuited after 640h.

Embodiment 3

[0047] A 62 μm thick copper mesh with a pore size of 60 μm is placed on a 450 μm thick lithium metal sheet, and then through physical extrusion, the copper mesh is just embedded in the lithium metal surface to form a lithium metal negative electrode with a three-dimensional structure. with lithium titanate (Li 4 Ti 5 o 12 ) to assemble the half-cell, the electrolyte is 1M LiPF 6 / EC:DEC(1:1, volume ratio).

[0048] Under the condition of 4C high rate, after 500 cycles, the measured discharge capacity can still maintain 80% of the initial discharge capacity, while the battery using ordinary lithium metal anodes under the same conditions, the discharge capacity is only 60% of the initial discharge capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com