Decorative tail pipe for automobile exhaust pipe

A technology for decorating tailpipes and automobile exhaust. It is applied in the direction of exhaust devices, power devices, and noise reduction devices. It can solve problems such as high cost, abnormal vibration, and unsightly appearance, and achieve reasonable structural design, stable mechanical strength, and Avoid the effect of abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

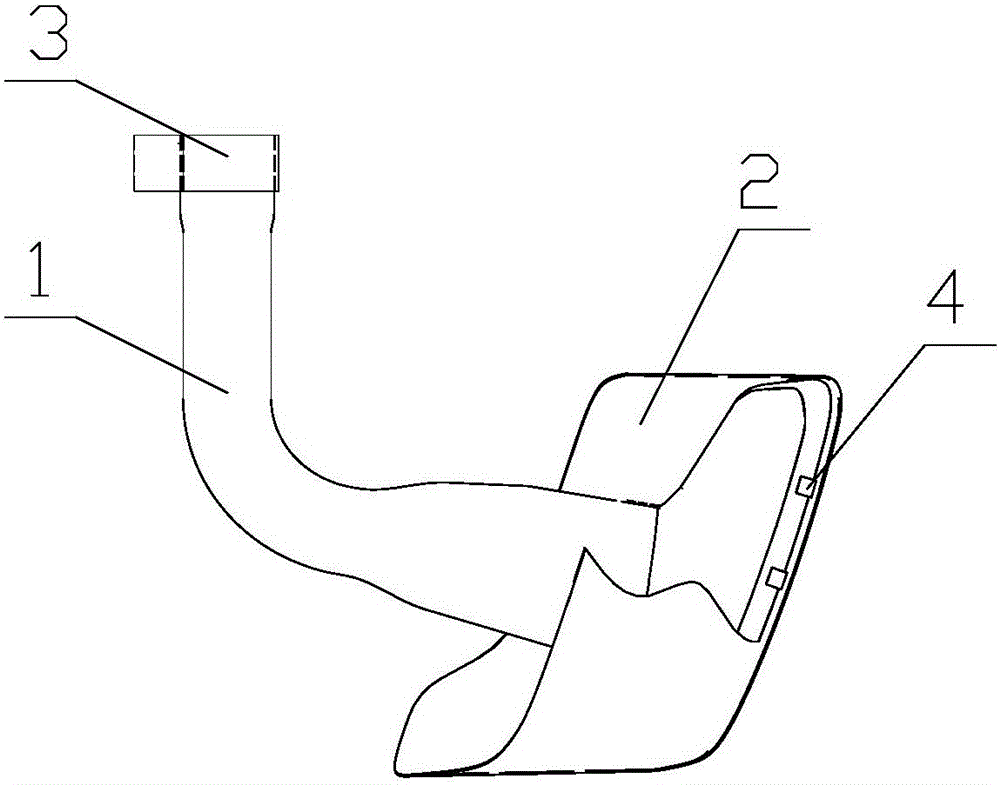

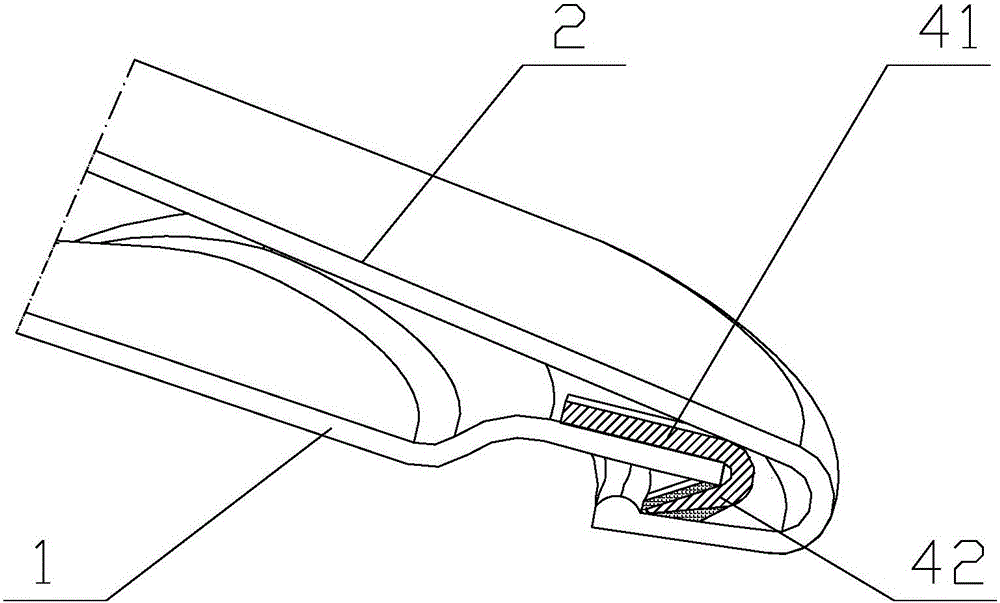

[0020] like figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a decorative tailpipe of an automobile exhaust pipe proposed by the present invention, figure 2 for figure 1 Schematic diagram of the partial enlarged structure of the decorative tailpipe of the automobile exhaust pipe.

[0021] refer to figure 1 and 2 , a kind of decorative tailpipe of automobile exhaust pipe that the present invention proposes, comprises: inner pipe 1 and outer pipe 2;

[0022] The inner tube 1 includes a first tube part and a second tube part connected in sequence. The end of the first tube part far away from the second tube part is provided with a clamp 3 outside, and the end of the second tube part away from the first tube part is gradually increased in the direction of the radial opening of the tube. Large, the end of the second pipe part away from the opening of the first pipe part is provided with a clamping part, and the outer periphery of the clamping part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com