Solar cell back plate and preparation method thereof

A technology for solar cells and back sheets, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of complex production processes and high production costs of solar cell back sheets, and achieve simple production processes, stable mechanical strength, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

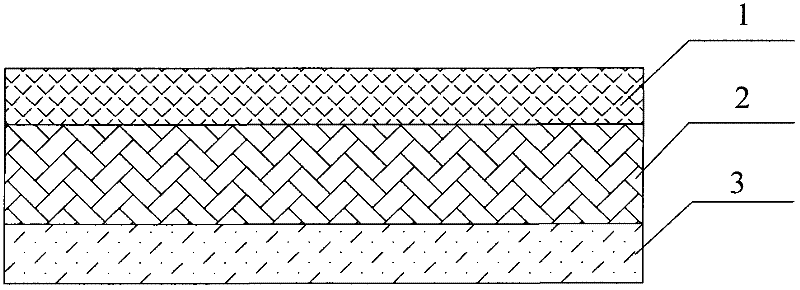

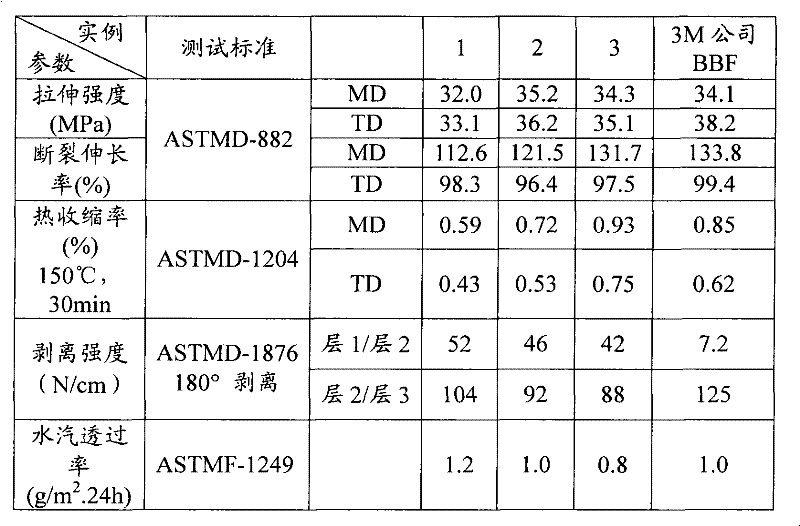

[0046] Such as figure 1 As shown, the weather-resistant layer 1 has a thickness of 20 microns, wherein the addition of the antioxidant diphenylamine is 1%, the addition of the anti-ultraviolet stabilizer UV-P is 0.5%, and the rest is PETG; the structural reinforcement layer 2 has a thickness of 150 Micron, the addition of titanium dioxide white pigment is 10%, the addition of antioxidant diphenylamine is 1%, the addition of anti-ultraviolet stabilizer UV-P is 0.5%, and the rest is PET; barrier layer 3, the thickness is 10 microns, vinyl The content is 20%, the addition of antioxidant diphenylamine is 1%, the addition of anti-ultraviolet stabilizer UV-P is 0.5%, and the rest is EVOH. The particle size of the titanium dioxide is 0.2um. The relevant parameters are shown in Table 1.

[0047] The specific preparation method is as follows:

[0048] (1), the components of the weather-resistant layer are uniformly mixed by a 100L high-mixer to make a mixed plastic A; the components...

Embodiment 2

[0053] Such as figure 1 As shown, the weather-resistant layer 1 has a thickness of 30 microns, wherein the addition of the antioxidant diphenylamine is 2%, the addition of the anti-ultraviolet stabilizer UV-P is 1%, and the rest is PETG; the structural reinforcement layer 2 has a thickness of 200 microns Micron, the addition of titanium dioxide white pigment is 20%, the addition of antioxidant diphenylamine is 2%, the addition of anti-ultraviolet stabilizer UV-P is 1%, and the rest is PET; the barrier layer 3, the thickness is 20 microns, vinyl The content is 30%, the addition of antioxidant diphenylamine is 2%, the addition of anti-ultraviolet stabilizer UV-P is 1%, and the rest is EVOH. The particle size of the titanium dioxide is 0.3um. The relevant parameters are shown in Table 1.

[0054] The specific preparation method is as follows:

[0055] The stretching temperature of the static stretching machine is 85° C., and other steps are the same as in Example 1.

Embodiment 3

[0057] Such as figure 1 As shown, the weather-resistant layer 1 has a thickness of 50 microns, wherein the addition of the antioxidant diphenylamine is 3%, the addition of the anti-ultraviolet stabilizer UV-P is 1.5%, and the rest is PETG; the structural reinforcement layer 2 has a thickness of 250 Micron, the addition of titanium dioxide white pigment is 30%, the addition of antioxidant diphenylamine is 3%, the addition of anti-ultraviolet stabilizer UV-P is 1.5%, and the rest is PET; barrier layer 3, thickness 50 microns, vinyl The content is 40%, the added amount of antioxidant p-phenylenediamine is 3%, the added amount of anti-ultraviolet stabilizer UV-531 is 1.5%, and the rest is EVOH. The particle size of the titanium dioxide may be 0.25um. The relevant parameters are shown in Table 1.

[0058] The specific preparation method is as follows:

[0059] The preparation method is the same as in Example 1, wherein the stretching temperature of the static stretching machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com