MXene silicon-carbon composite material, preparation method thereof, negative electrode and lithium ion battery

A technology of silicon-carbon composite materials and silicon-carbon, which is applied in nanotechnology for materials and surface science, negative electrodes, battery electrodes, etc., can solve the problems of amorphous carbon with large irreversible capacity, unstable structure, and poor processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of MXene silicon-carbon composite material, comprises the following steps:

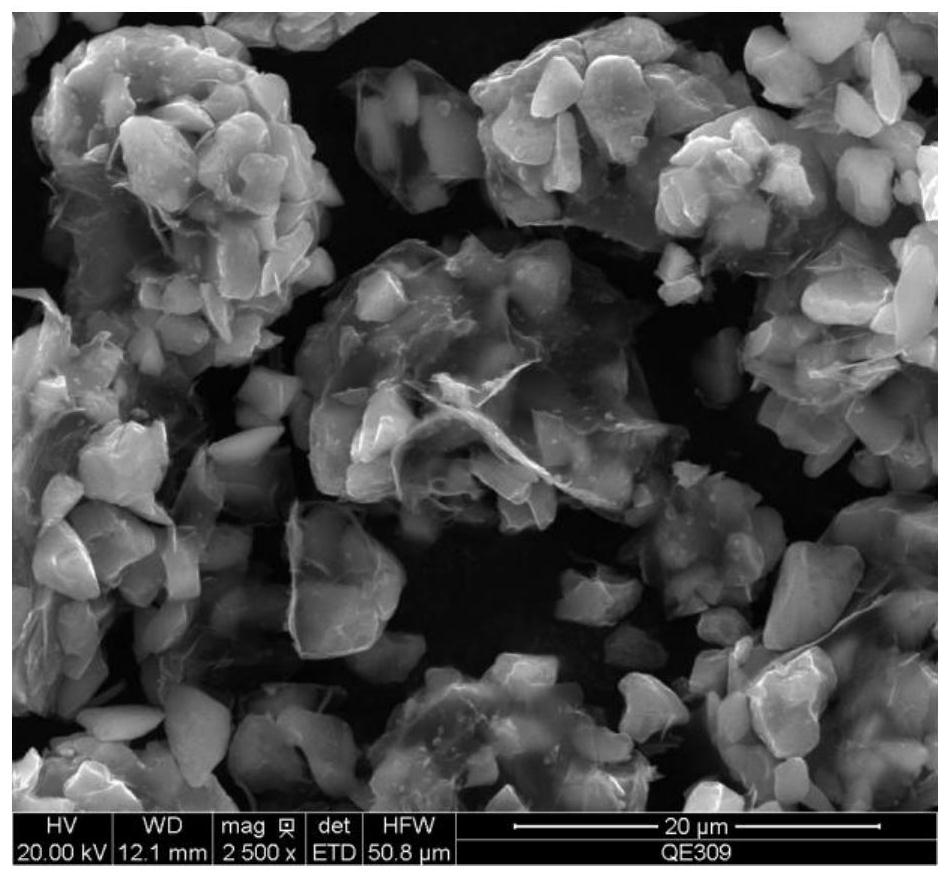

[0036] A) mixing the silicon-carbon precursor solution and the MXene slurry, and spray-drying the resulting mixed solution to obtain intermediate particles;

[0037] The silicon carbon precursor solution includes SiOx, nano-carbon source, additive and water, 0.6<x<1.4, and the additive is one of stearic acid, Tween, silane coupling agent, fatty acid sorbitan, fatty acid glyceride species or several;

[0038] Described MXene slurry comprises MXene, dispersion agent and solvent;

[0039] B) Calcining the intermediate particles at a high temperature under an inert atmosphere or a reducing atmosphere to obtain an MXene silicon-carbon composite material.

[0040] In the present invention, first, the silicon carbon precursor solution and the MXene slurry are prepared respectively.

[0041] The silicon carbon precursor solution is preferably prepa...

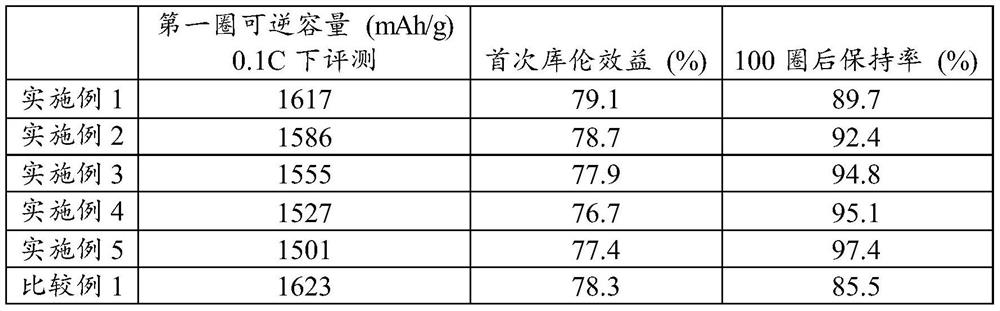

Embodiment 1

[0080] by SiO 0.95 : Nano carbon = 94:6 Weigh SiOx and polyvinylpyrrolidone, add 0.2% silane coupling agent, disperse in water, prepare a slurry with a solid content of 50%, and then carry out high-energy ball milling, the ratio of material to ball is 1:10, milling The ratio of the ball diameter is 0.5, 1, 5cm is 1:2:3, the ball milling speed is 450r / min, and the ball milling time is 1h.

[0081] MXene was added to water, and 2.5% polyvinylpyrrolidone and 2.5% hydroxymethylcellulose were added as dispersants for high-speed dispersion at a speed of 1200r / min, and finally an MXene solution with a solid content of 3% was prepared.

[0082] Mix A and B solutions evenly, add MXene to 5% of SiOx, add water to adjust the solid content to 20%, disperse at a speed of 300r / min for 2h, and then spray dry at a drying temperature of 220°C and an atomizer at a speed of 22000r / min min, drying speed 10L / h.

[0083] Then it was sintered at 800°C for 8h under argon atmosphere.

Embodiment 2

[0085] by SiO 0.95 : Nano carbon = 94:6 Weigh SiOx and polyvinylpyrrolidone, add 0.2% silane coupling agent, disperse in water, prepare a slurry with a solid content of 50%, and then carry out high-energy ball milling, the ratio of material to ball is 1:10, milling The ratio of the ball diameter is 0.5, 1, 5cm is 1:2:3, the ball milling speed is 450r / min, and the ball milling time is 1h.

[0086] MXene was added to water, and 2.5% polyvinylpyrrolidone and 2.5% hydroxymethylcellulose were added as dispersants for high-speed dispersion at a speed of 1200r / min, and finally an MXene solution with a solid content of 3% was prepared.

[0087] Mix A and B solutions evenly, add MXene to 10% of SiOx, add water to adjust the solid content to 15%, disperse at a speed of 300r / min for 2h, and then spray dry at a drying temperature of 220°C and an atomizer at a speed of 22000r / min min, drying speed 10L / h.

[0088] Then it was sintered at 800°C for 8h under argon atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com