Patents

Literature

839results about How to "Not easy to scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

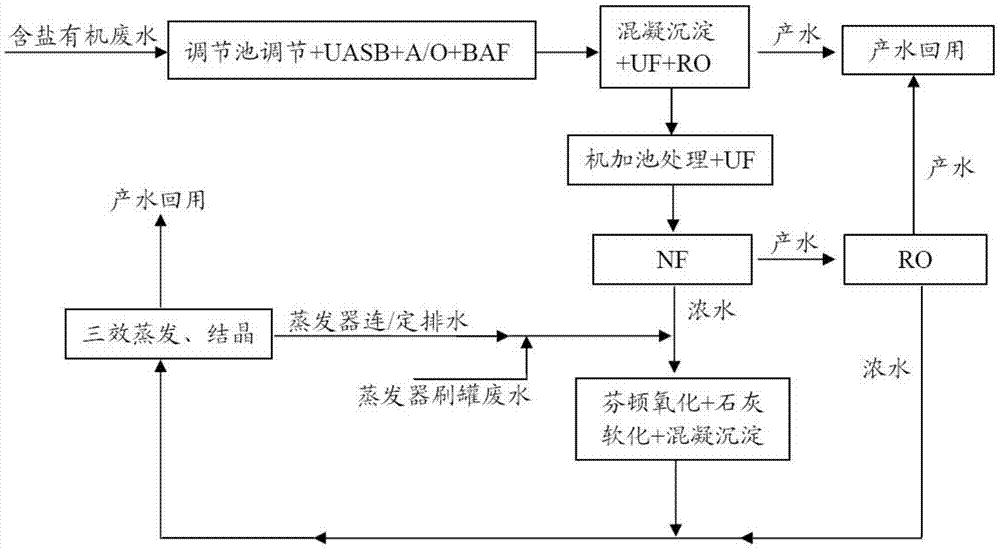

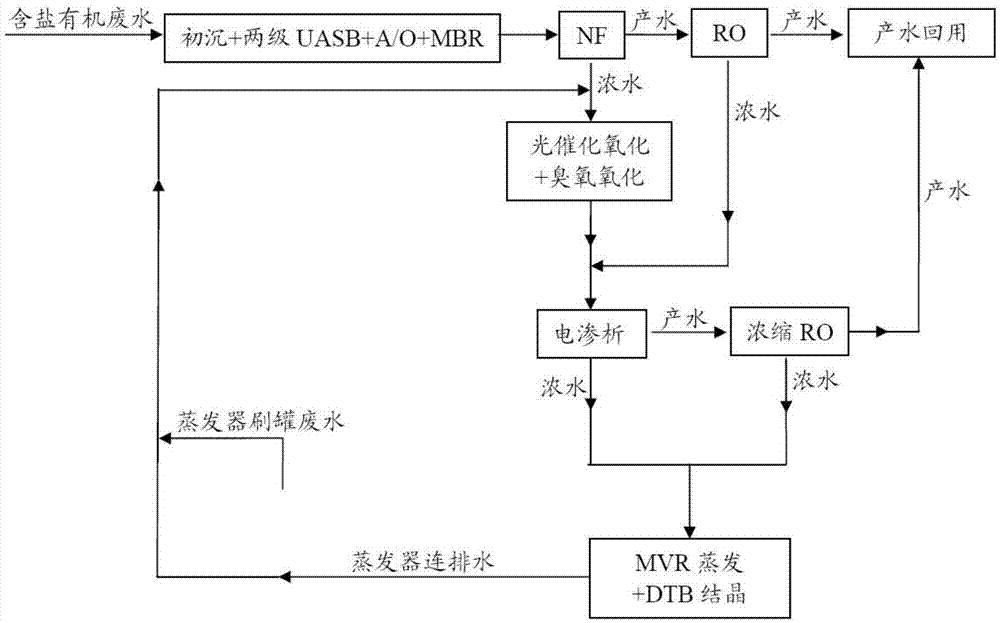

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

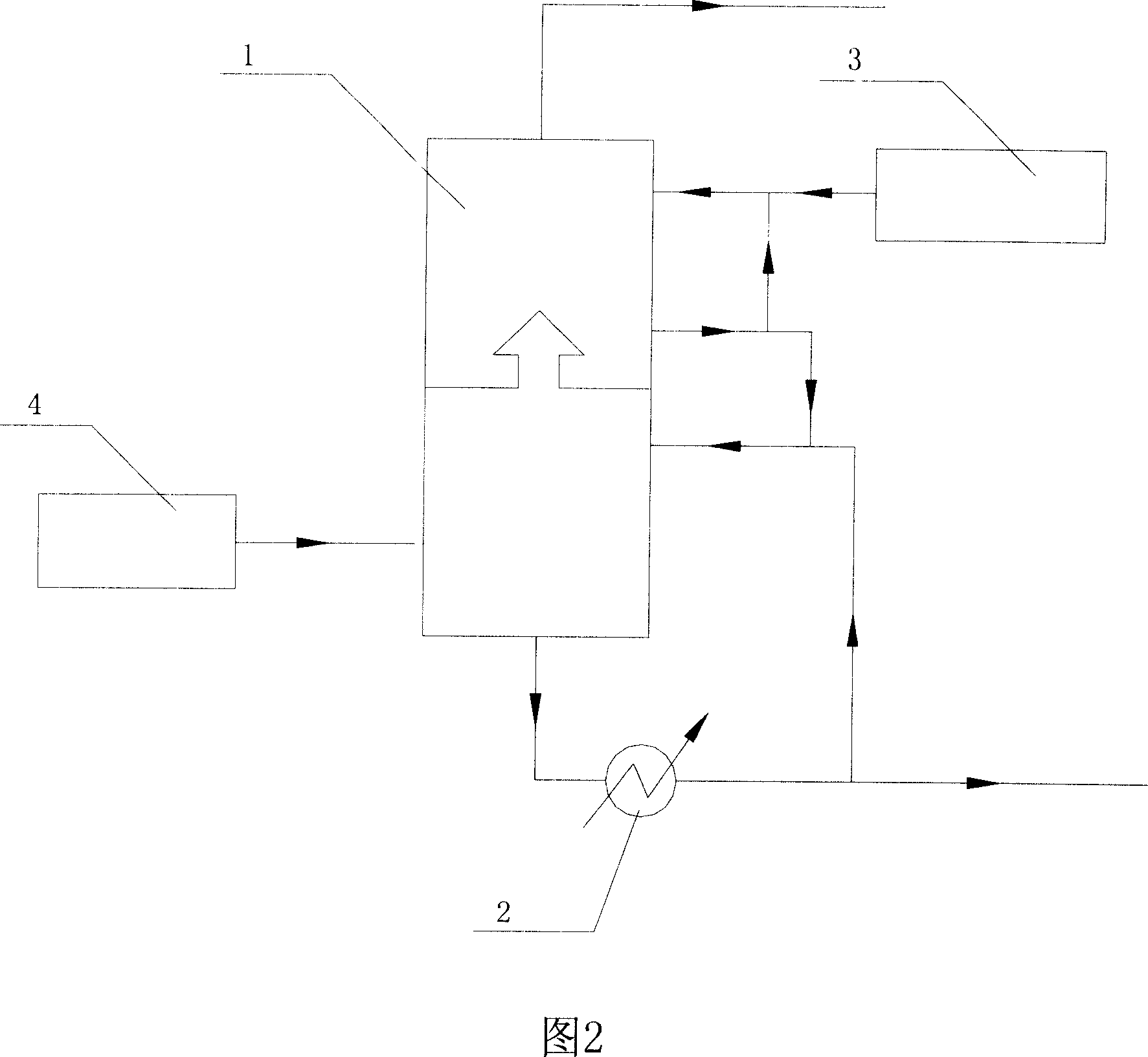

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

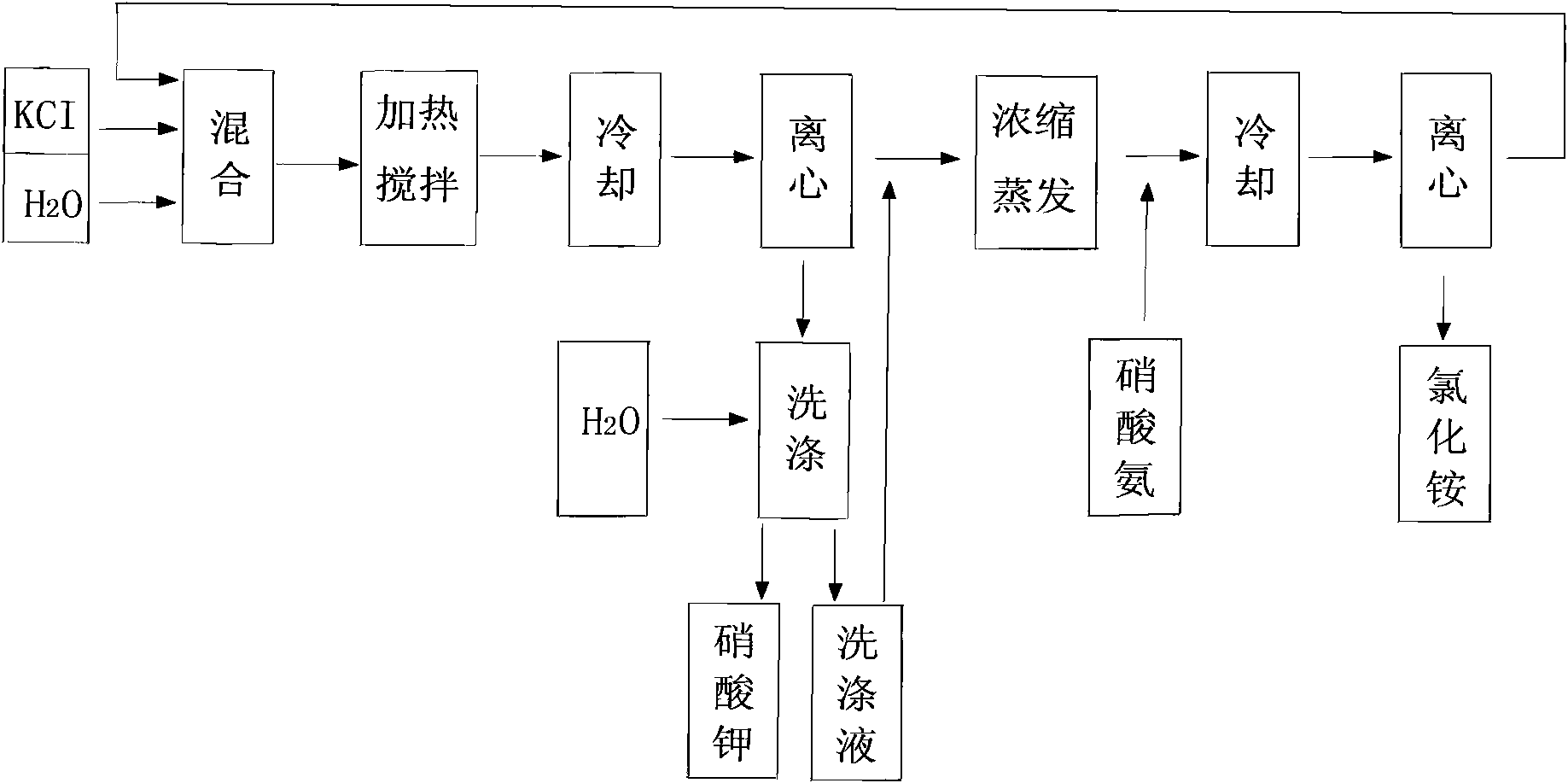

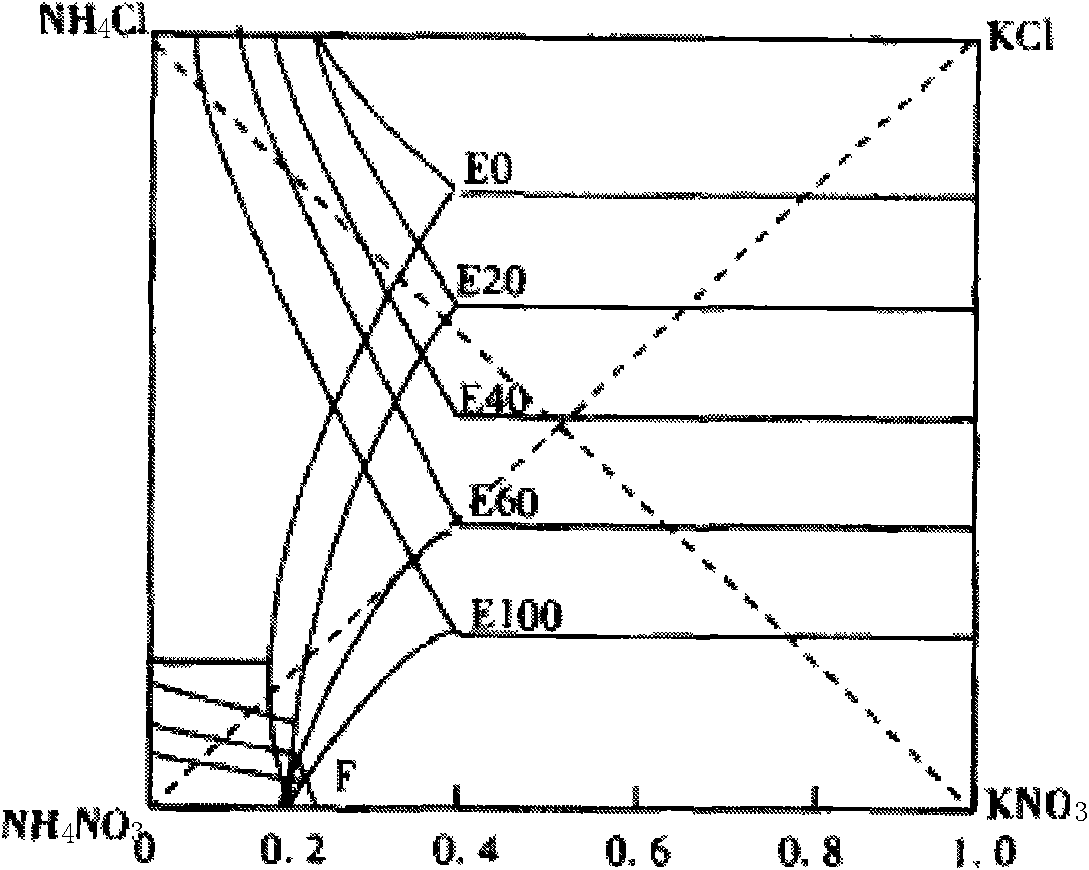

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

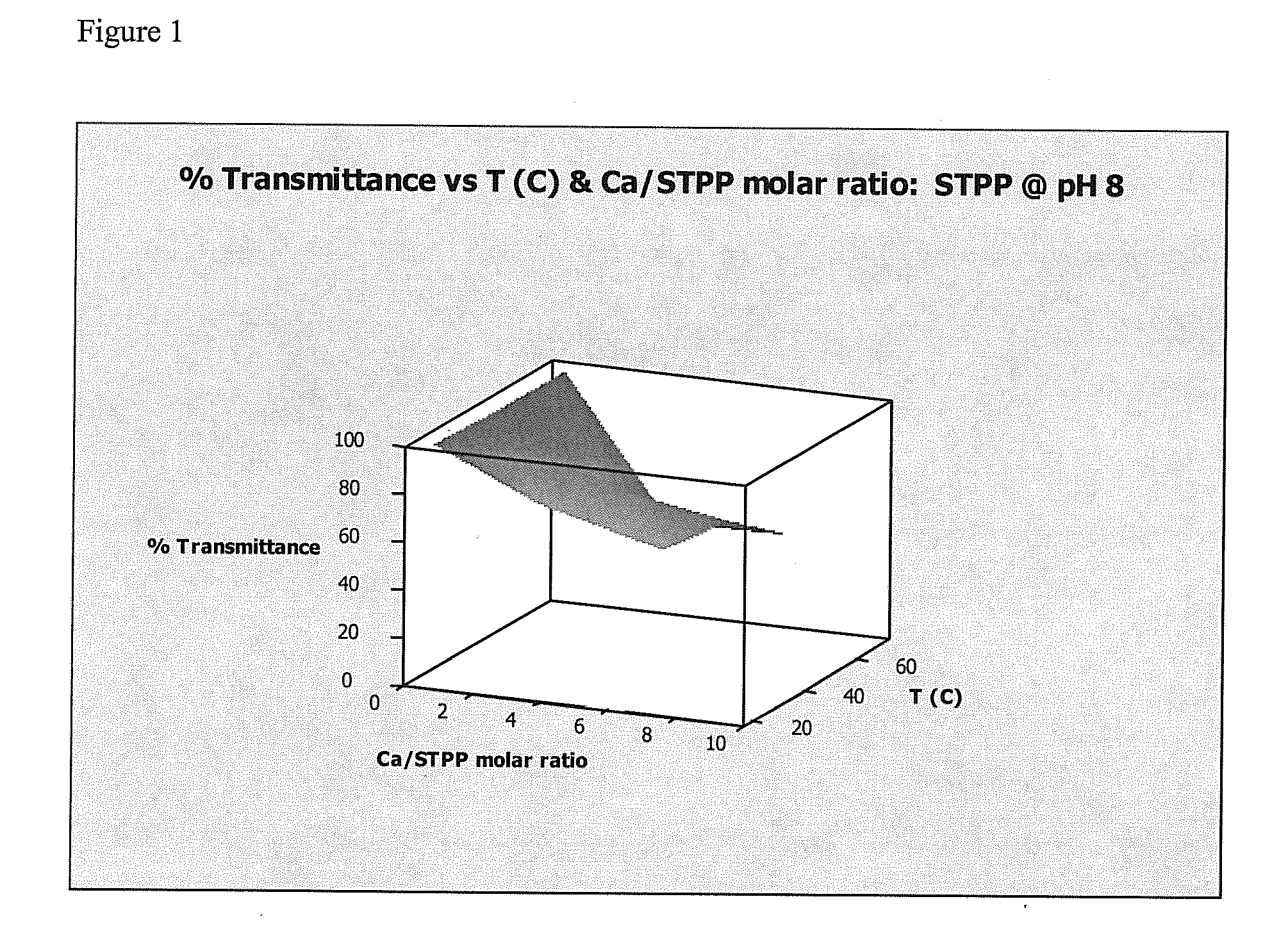

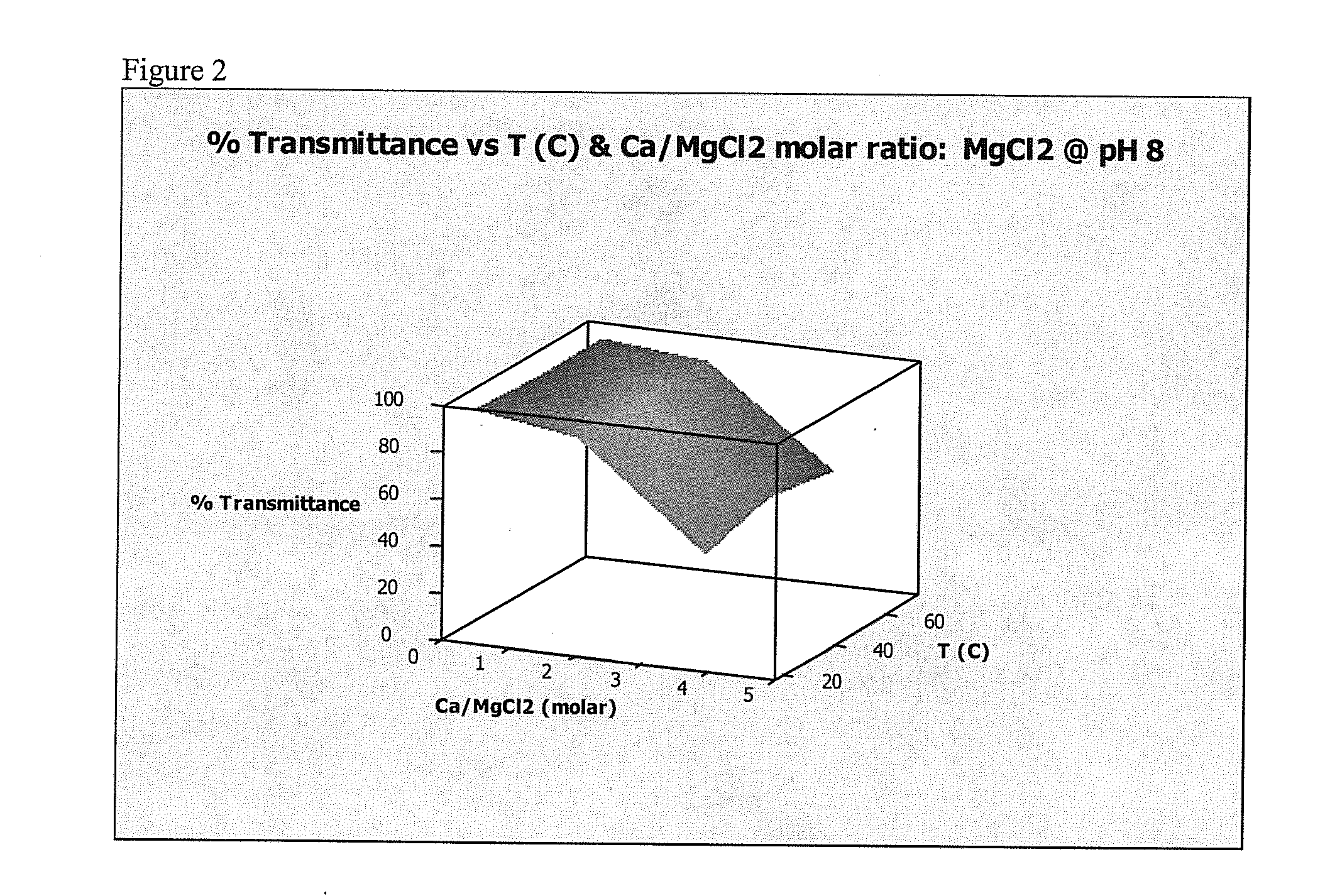

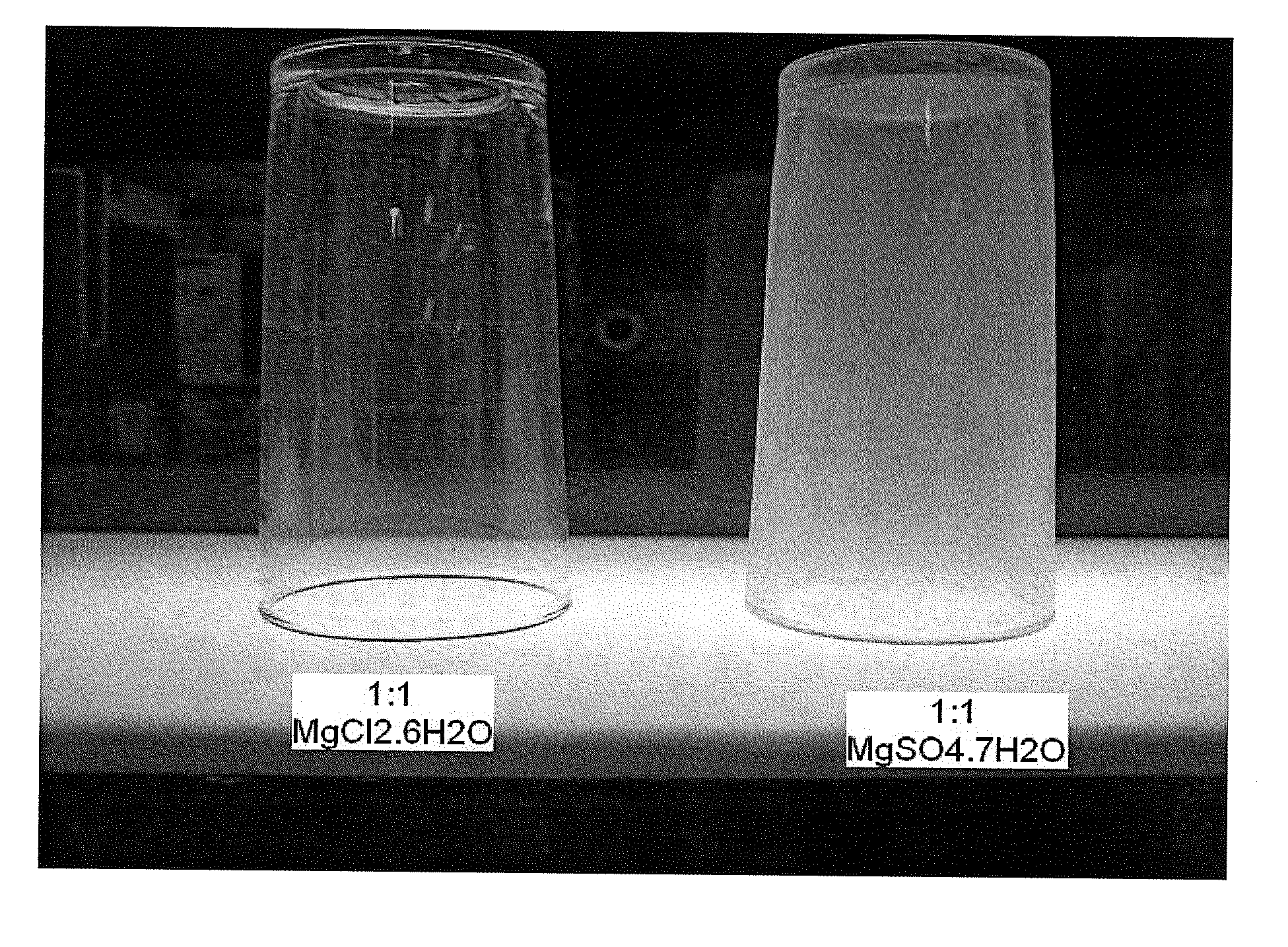

Water soluble magnesium compounds as cleaning agents and methods of using them

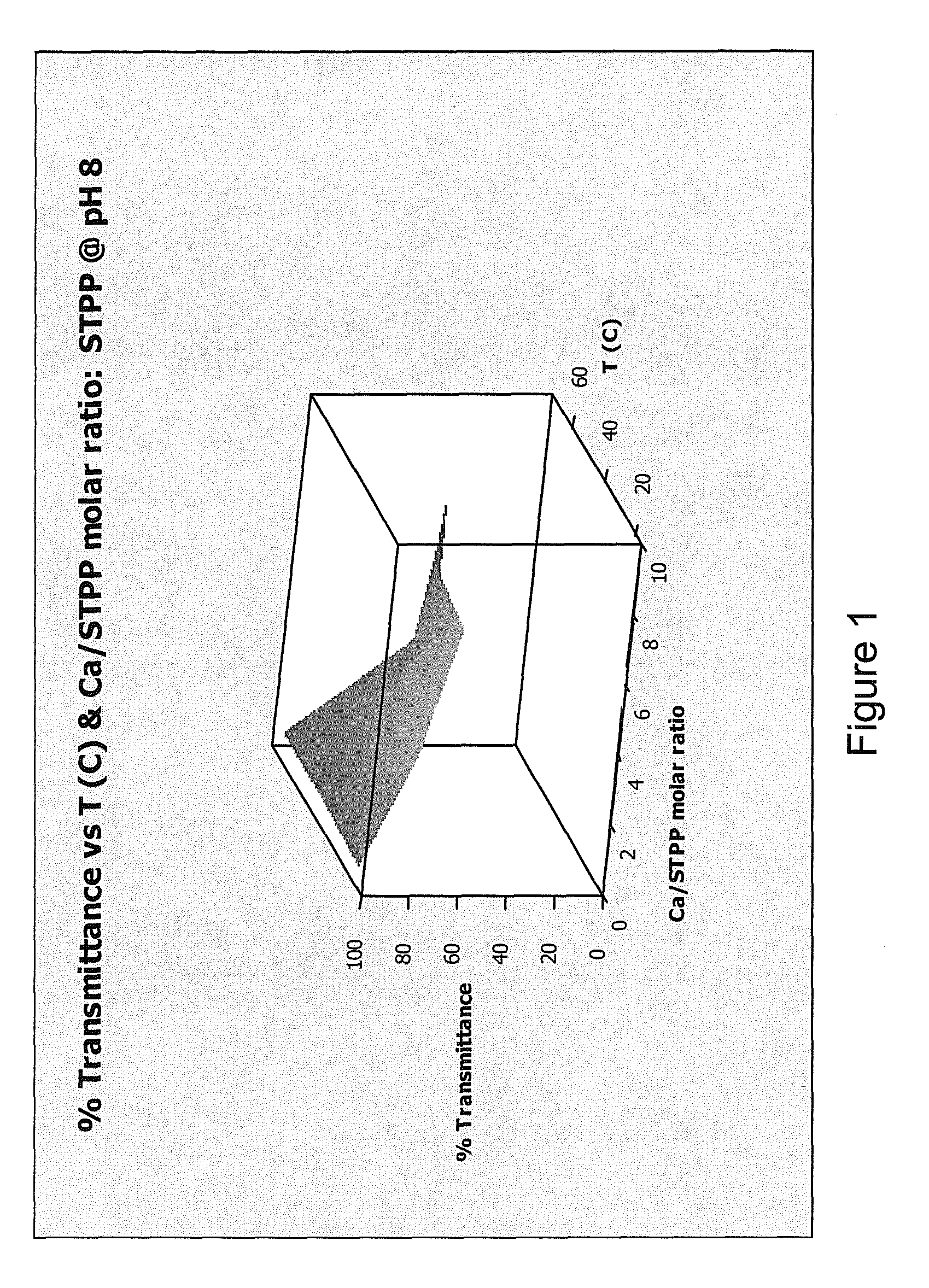

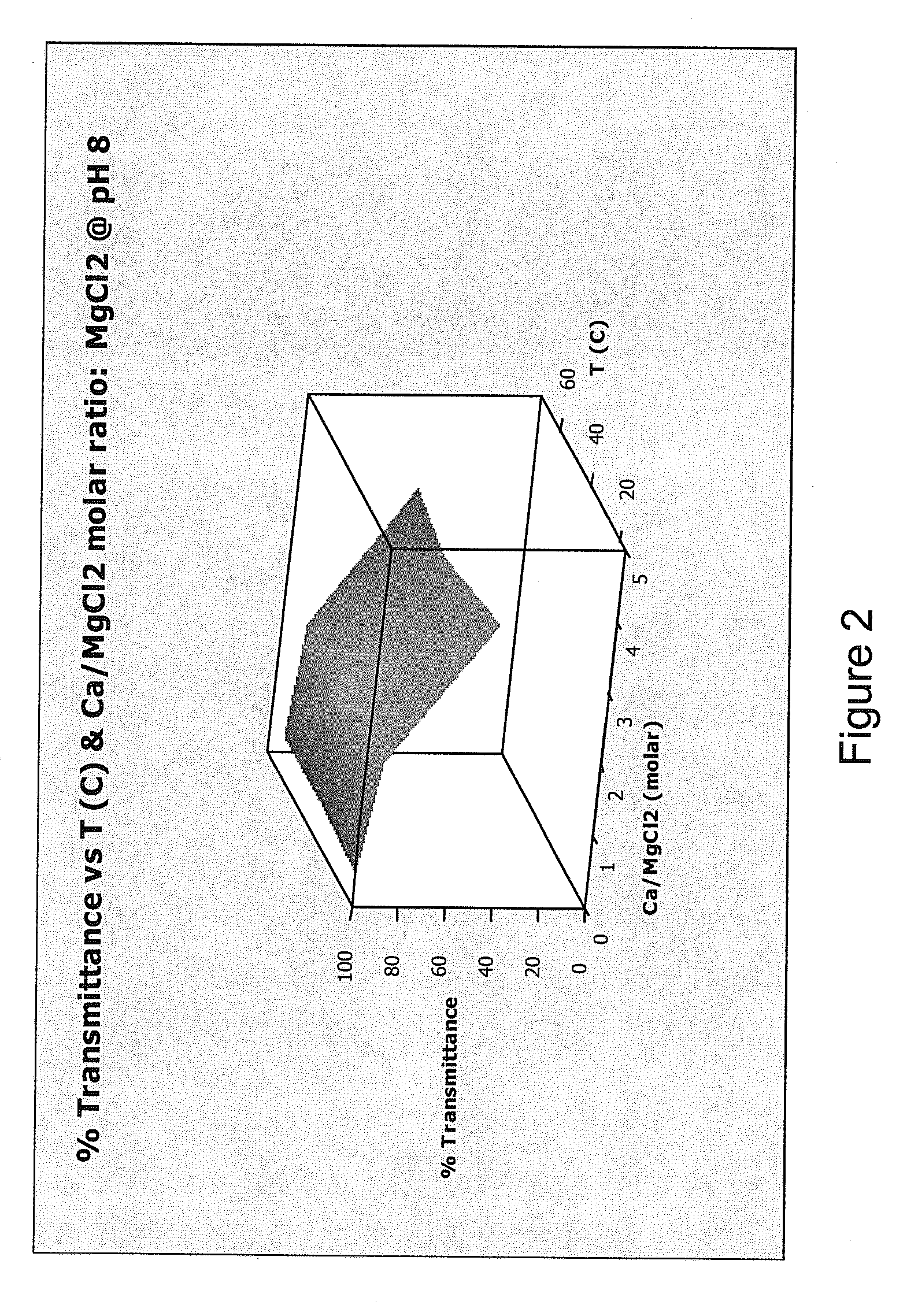

InactiveUS20080274928A1Reduce and prevent formationImprove solubilityInorganic/elemental detergent compounding agentsSpecific water treatment objectivesMagnesium saltWater insoluble

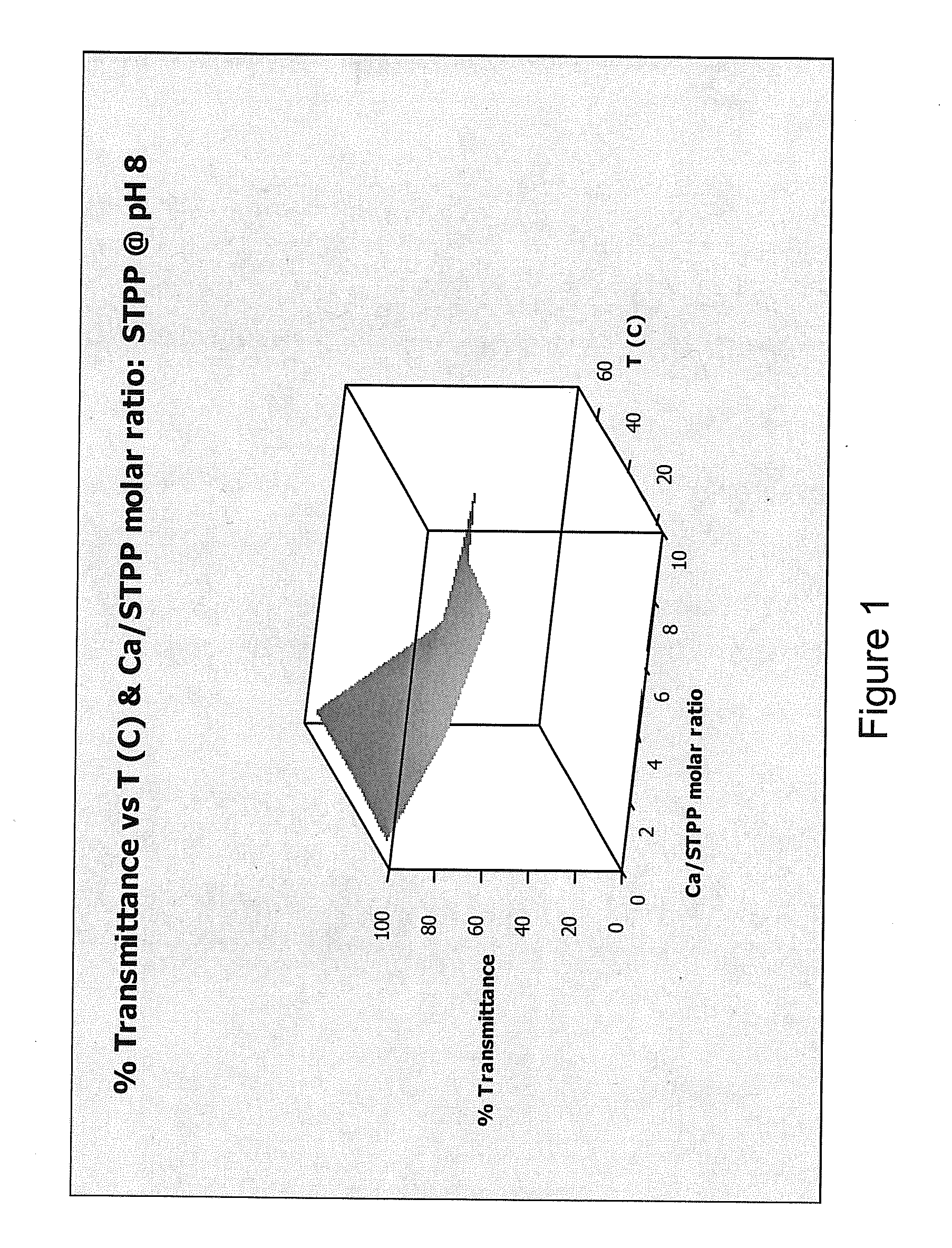

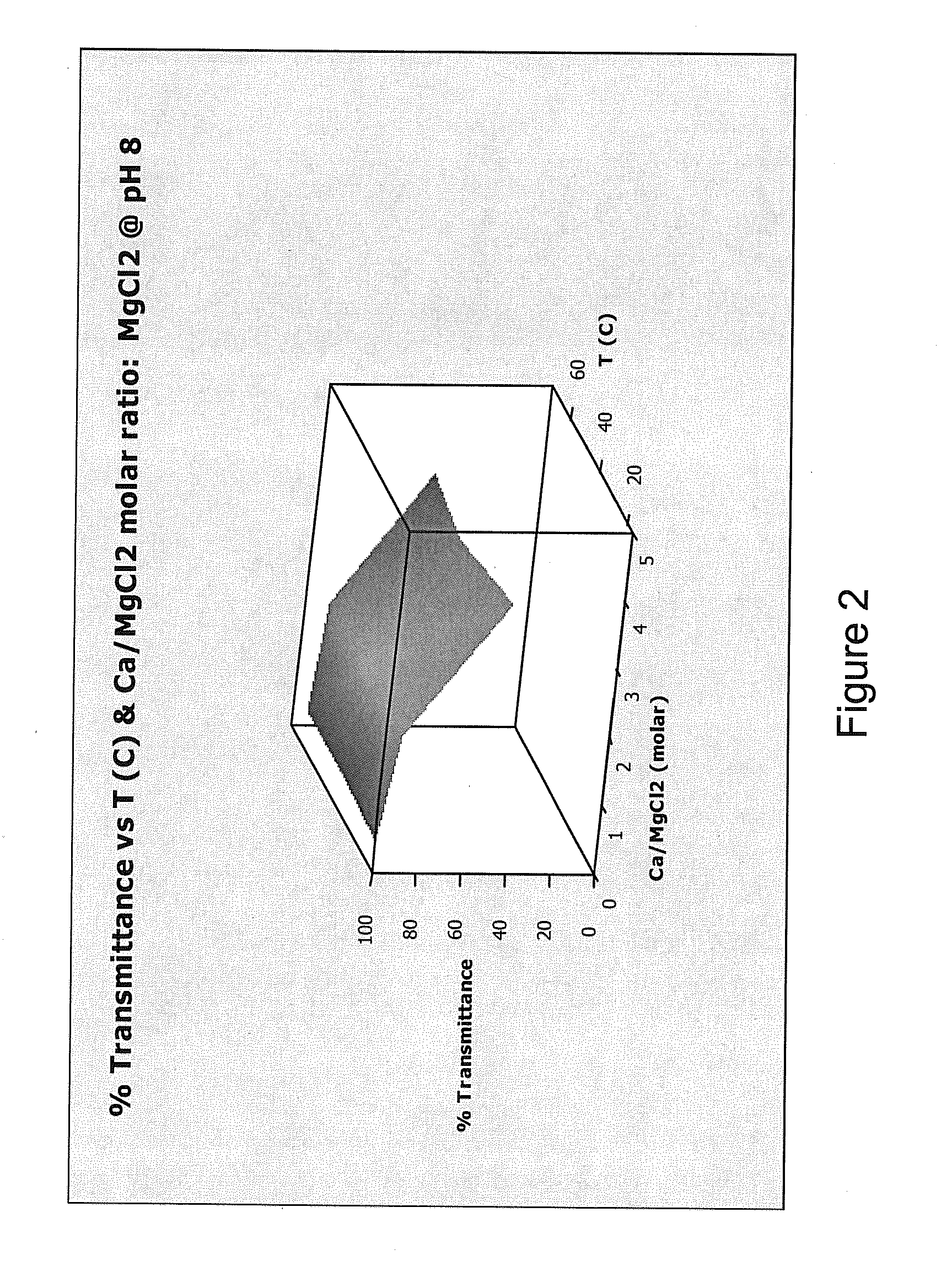

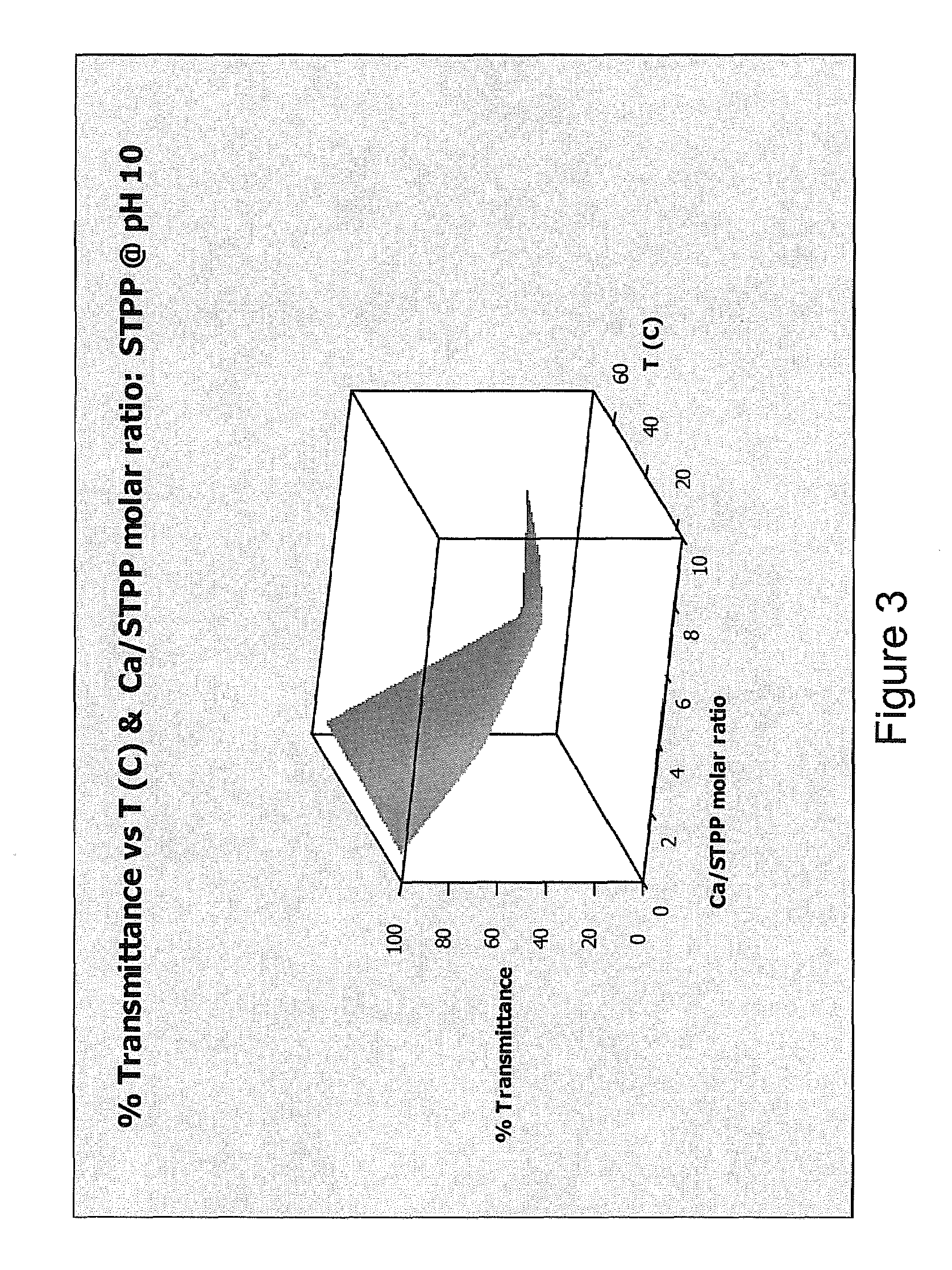

The present invention relates to compositions and methods employing a water soluble magnesium compound. In certain embodiments, the composition includes water and water soluble magnesium compound, but lacks other materials commonly used in cleaning compositions. The methods and compositions can provide magnesium ion at predefined ratios to calcium ion in water, such as magnesium ion in a molar amount equal to or in excess over a molar amount of calcium ion. A water soluble magnesium salt including an anion of a water soluble calcium salt is more effective than a magnesium salt with an anion of a water insoluble calcium salt. These compositions can be used for reducing lime scale or precipitate formation from hard water, removing soap scum, or the like.

Owner:ECOLAB USA INC

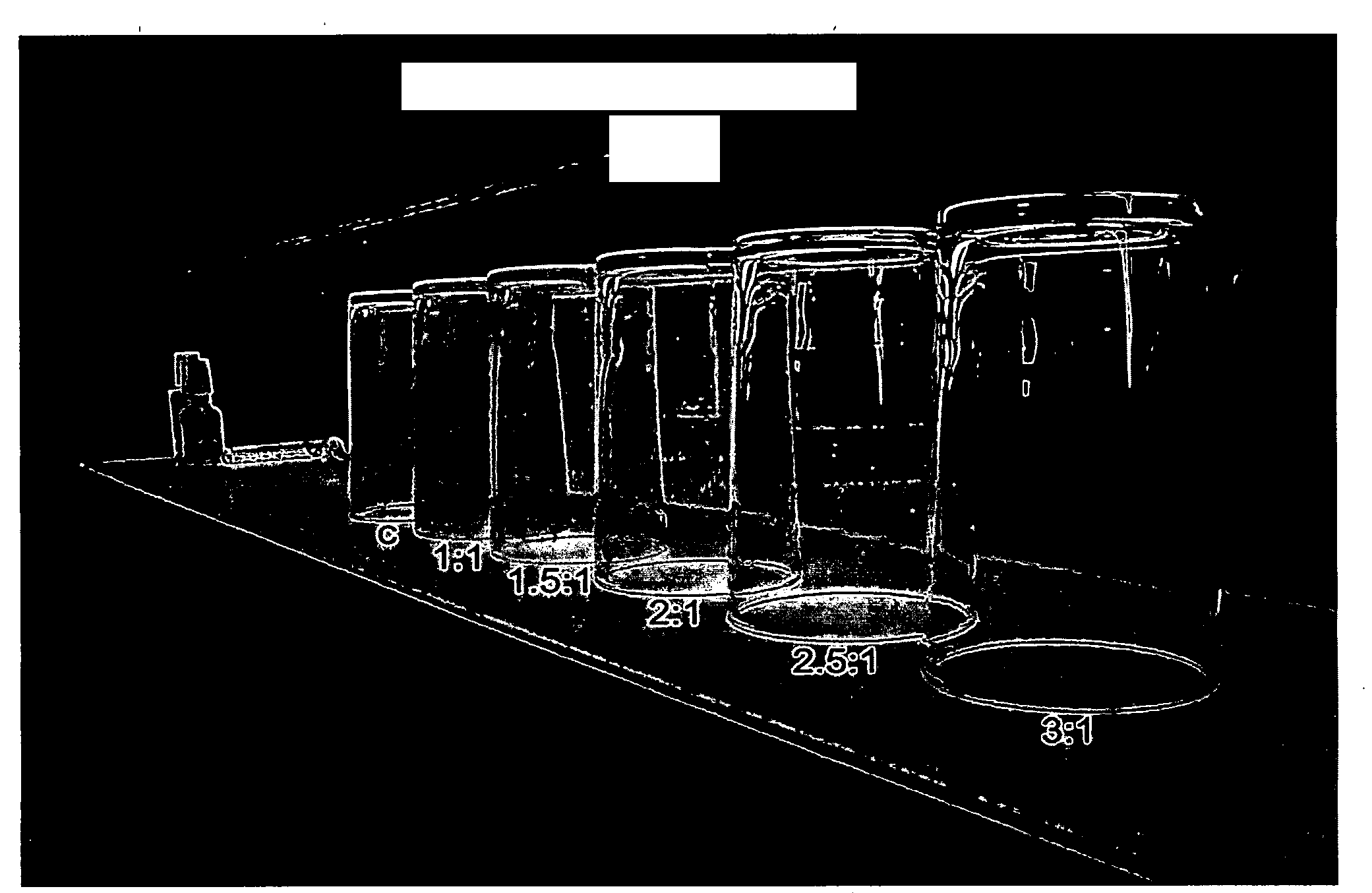

Cleaning compositions containing water soluble magnesium compounds and methods of using them

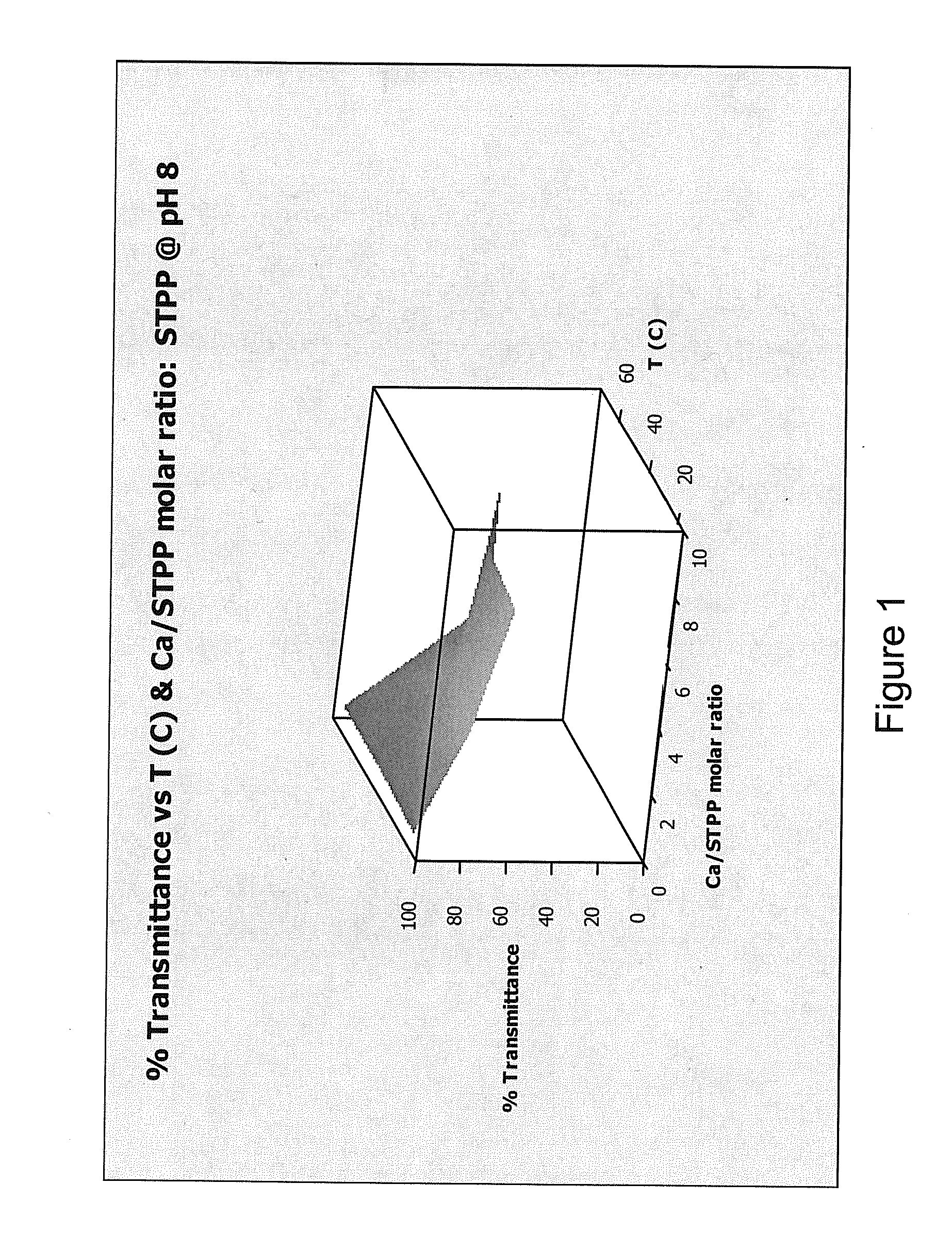

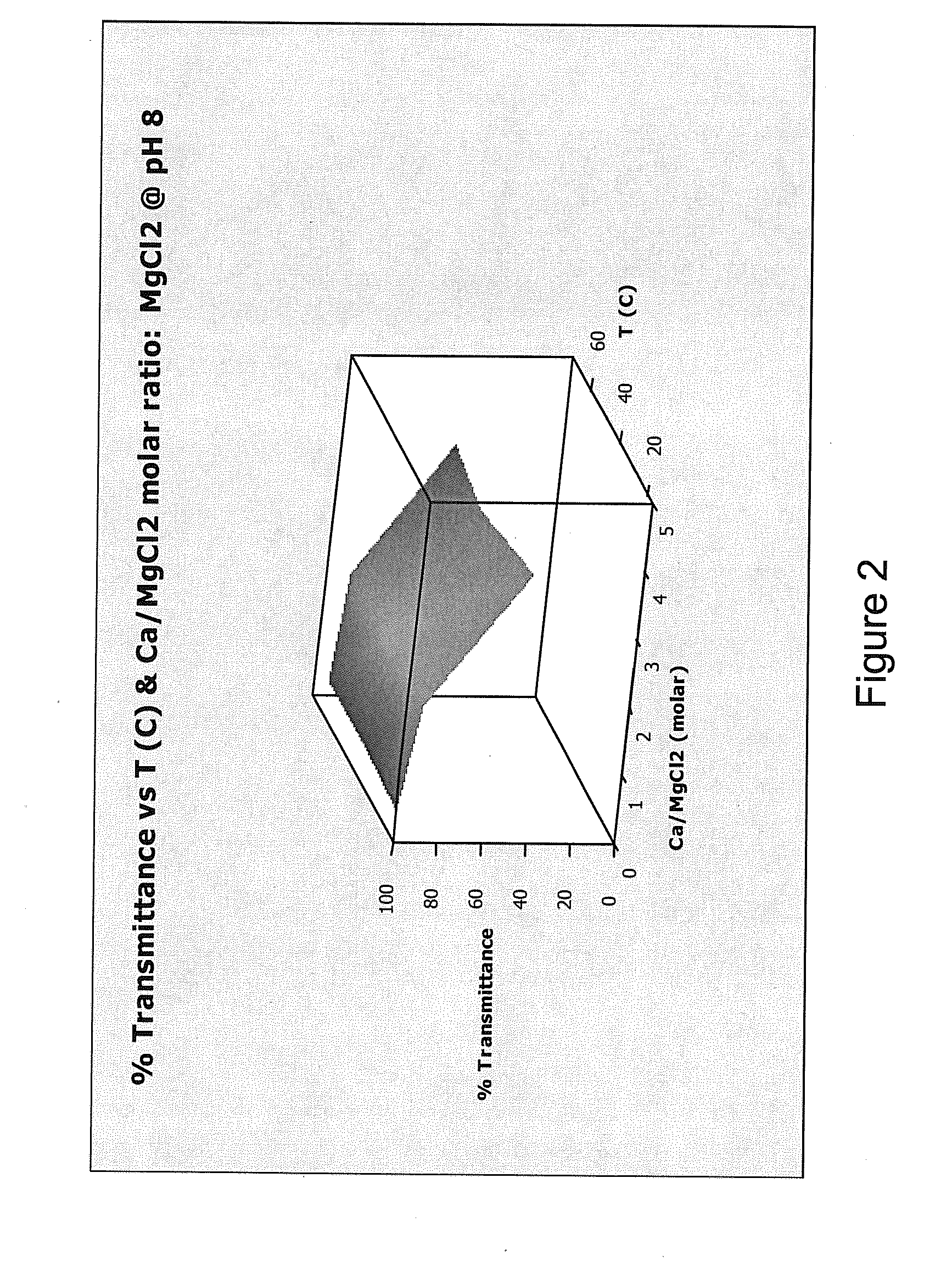

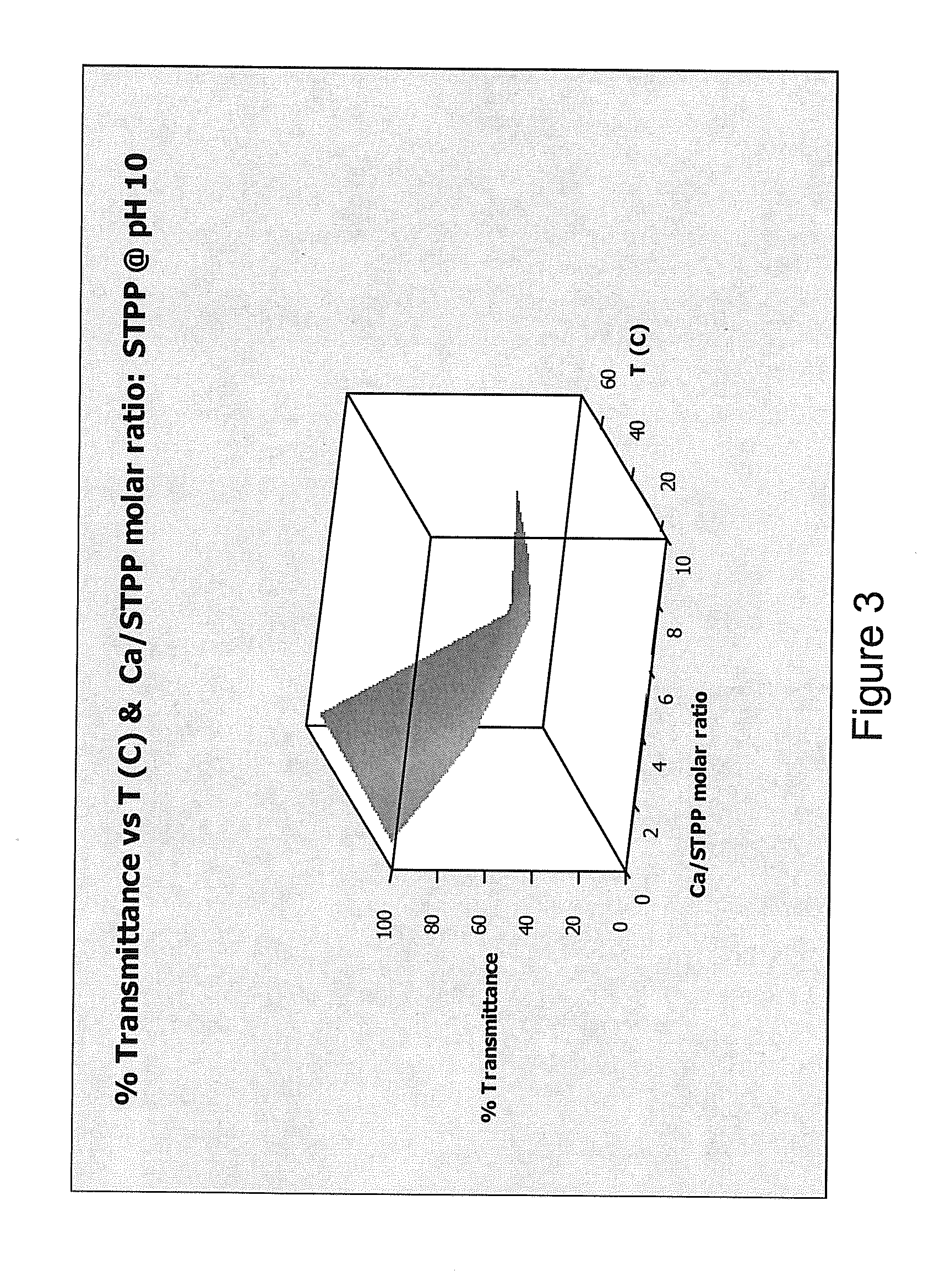

ActiveUS20090165818A1Difficult to buildNot easy to scaleInorganic/elemental detergent compounding agentsHollow article cleaningNuclear chemistryCorrosion

The present invention relates to cleaning compositions and methods employing a water soluble magnesium compound. Such compositions can be used for reducing scale, rinsing, hard surface cleaning, ware washing, and corrosion inhibition.

Owner:ECOLAB USA INC

Cleaning compositions containing water soluble magnesium compounds and methods of using them

InactiveUS7922828B2Difficult to buildNot easy to scaleInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSurface cleaningCompound (substance)

The present invention relates to cleaning compositions and methods employing a water soluble magnesium compound. Such compositions can be used for reducing scale, rinsing, hard surface cleaning, ware washing, and corrosion inhibition.

Owner:ECOLAB USA INC

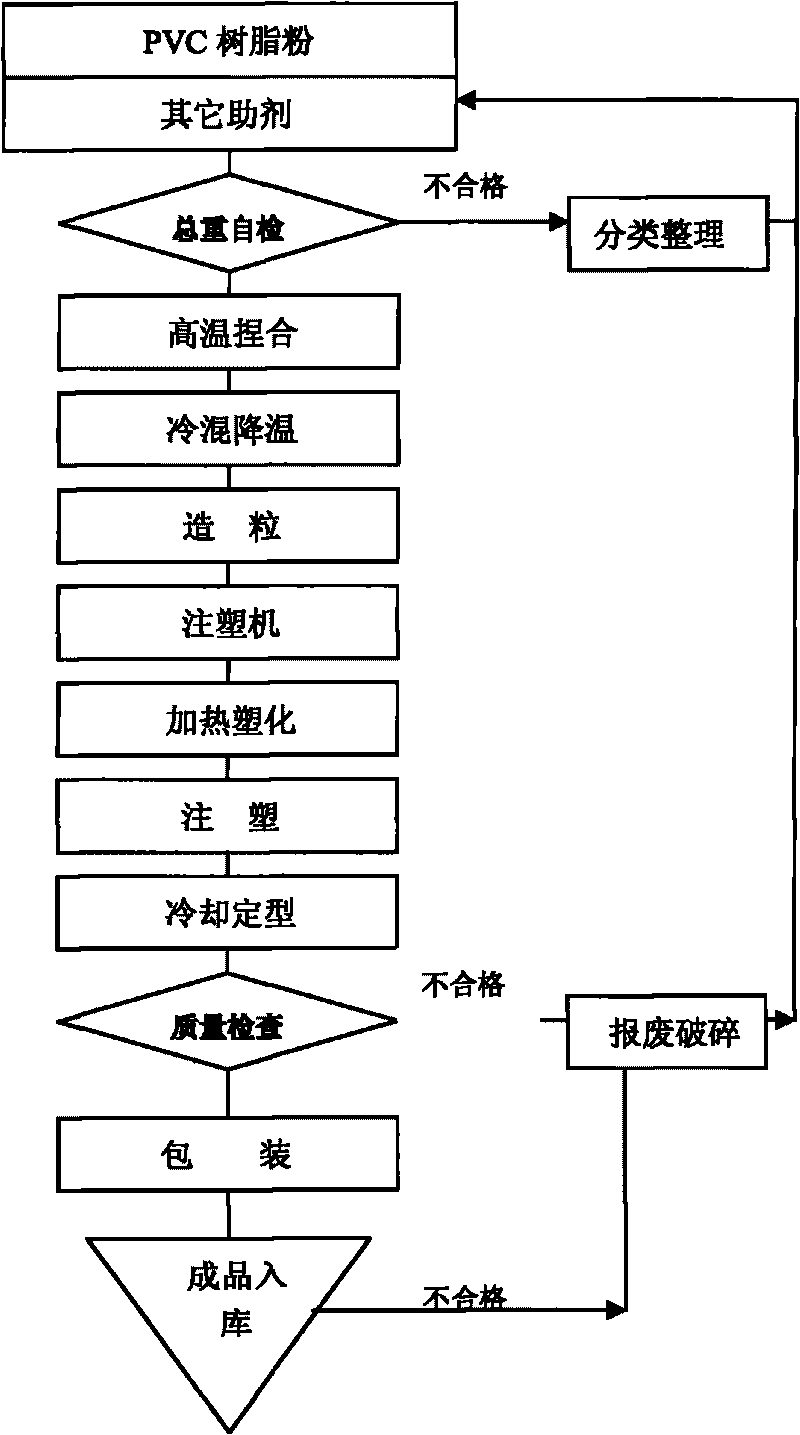

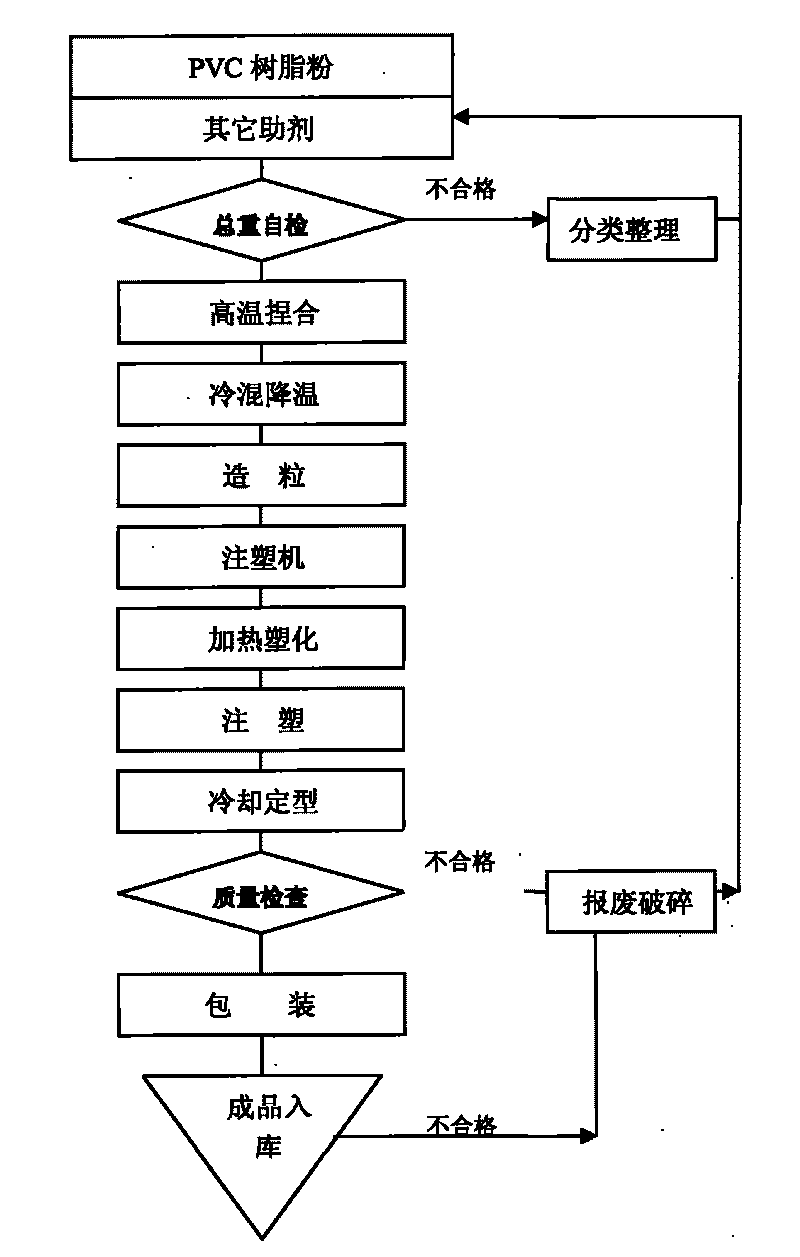

Polyvinyl chloride composition and transparent pipe thereof

The invention discloses a polyvinyl chloride composition and a transparent pipe thereof. The polyvinyl chloride composition consists of the following components in part by weight: 100 parts of PVC resin, 1.0 to 5.0 parts of heat stabilizer, 0.2 to 2 parts of lubricating additive, 1 to 3 parts of processing modification aid, 2 to 5 parts of impact modifier, 0.01 to 0.08 part of decolorizing agent, 0.2 to 0.6 part of age resister and 0 to 10 parts of plasticizer. The polyvinyl chloride composition is subjected to high-speed hot mixing and low-speed cold mixing, and then is extruded to prepare the polyvinyl chloride transparent pipe; and the pipe is homogenous and transparent, has smooth inner wall, is not easy to scale, can be sleeved outside a pipeline for delivering important or dangerous chemicals, has monitoring and protecting functions, has good ageing resistance, and can be used for outdoor occasions. The preparation method for the polyvinyl chloride transparent pipe is simple, convenient and quick, does not require special tools and professional staff, and is favorable for large-scale industrial production.

Owner:GUANGDONG LIANSU TECH INDAL

Cleaning compositions containing water soluble magnesium compounds and methods of using them

InactiveUS20080276967A1Difficult to buildNot easy to scaleInorganic/elemental detergent compounding agentsSpecific water treatment objectivesSurface cleaningWater soluble

The present invention relates to cleaning compositions and methods employing a water soluble magnesium compound. Such compositions can be used for reducing scale, rinsing, hard surface cleaning, ware washing, and corrosion inhibition.

Owner:ECOLAB USA INC

Discharge-enhanced atmospheric pressure chemical vapor deposition

InactiveUS20060040067A1Increase depositionNot easy to scaleChemical vapor deposition coatingPlasma techniqueElectricityNoble gas

A discharge-enhanced CVD apparatus and method utilizes a nozzle containing electrodes to generate a high voltage electrical discharge at or near atmospheric pressure in the absence of a stabilizing or arc-suppressing noble gas. Reactants are passed directly through or / and under the discharge before being directed to the surface of a substrate to be coated.

Owner:ARKEMA INC

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

Modified polyphenylene sulfide coating and application thereof

ActiveCN102676048AImprove corrosion resistanceSelf-lubricatingAnti-corrosive paintsWear resistantCorrosion

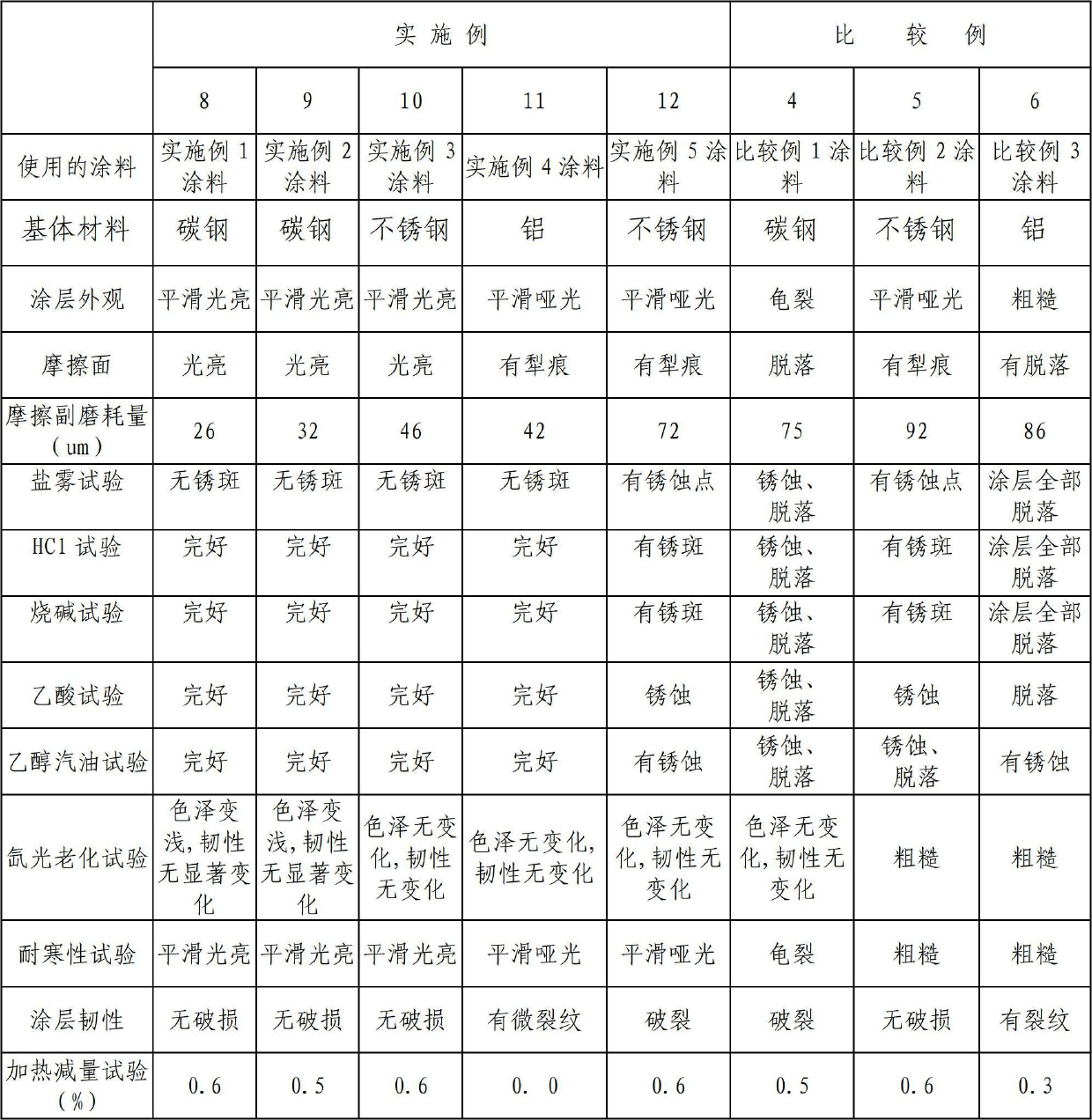

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Owner:CHENGDU LETIAN PLASTICS

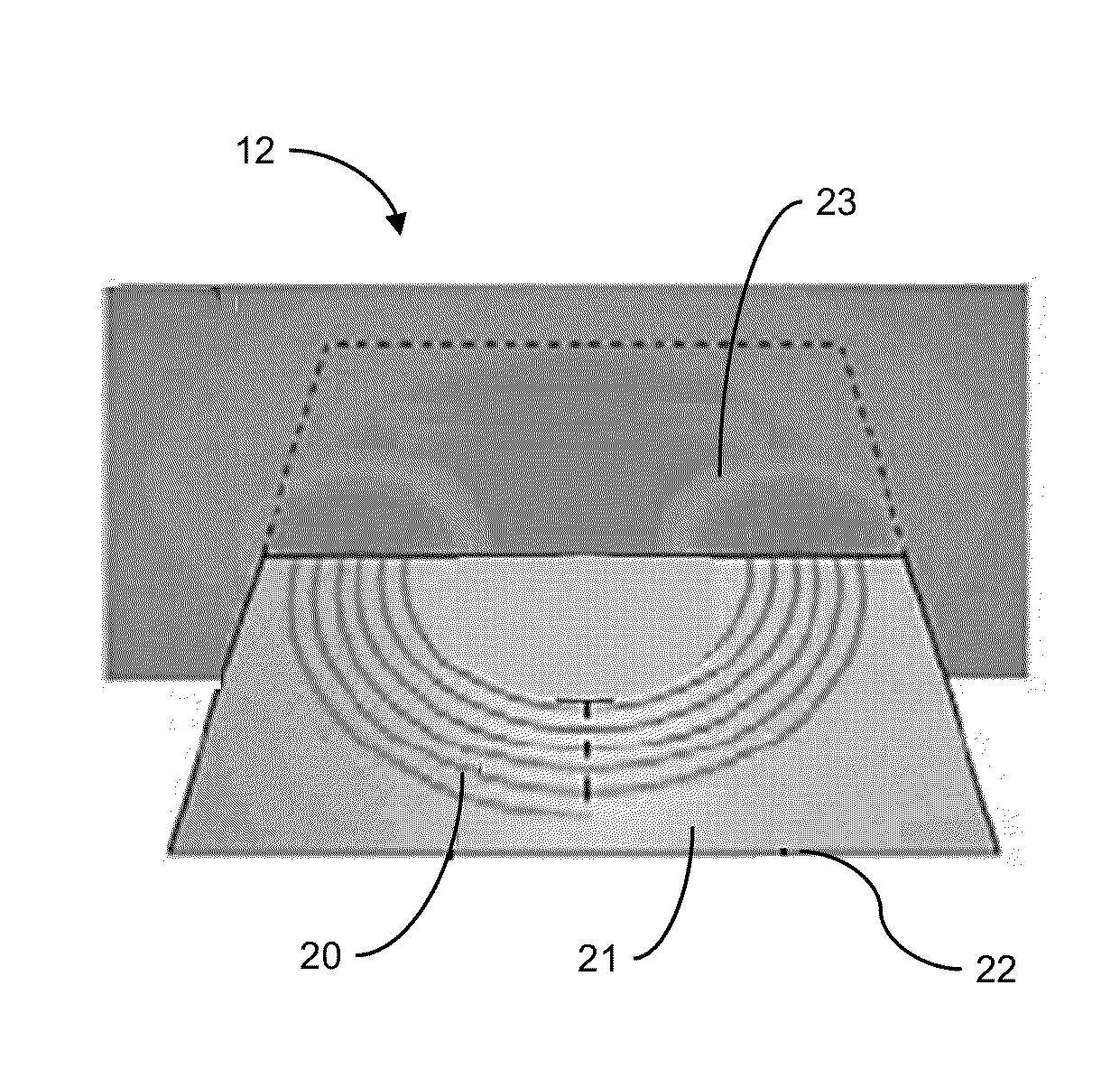

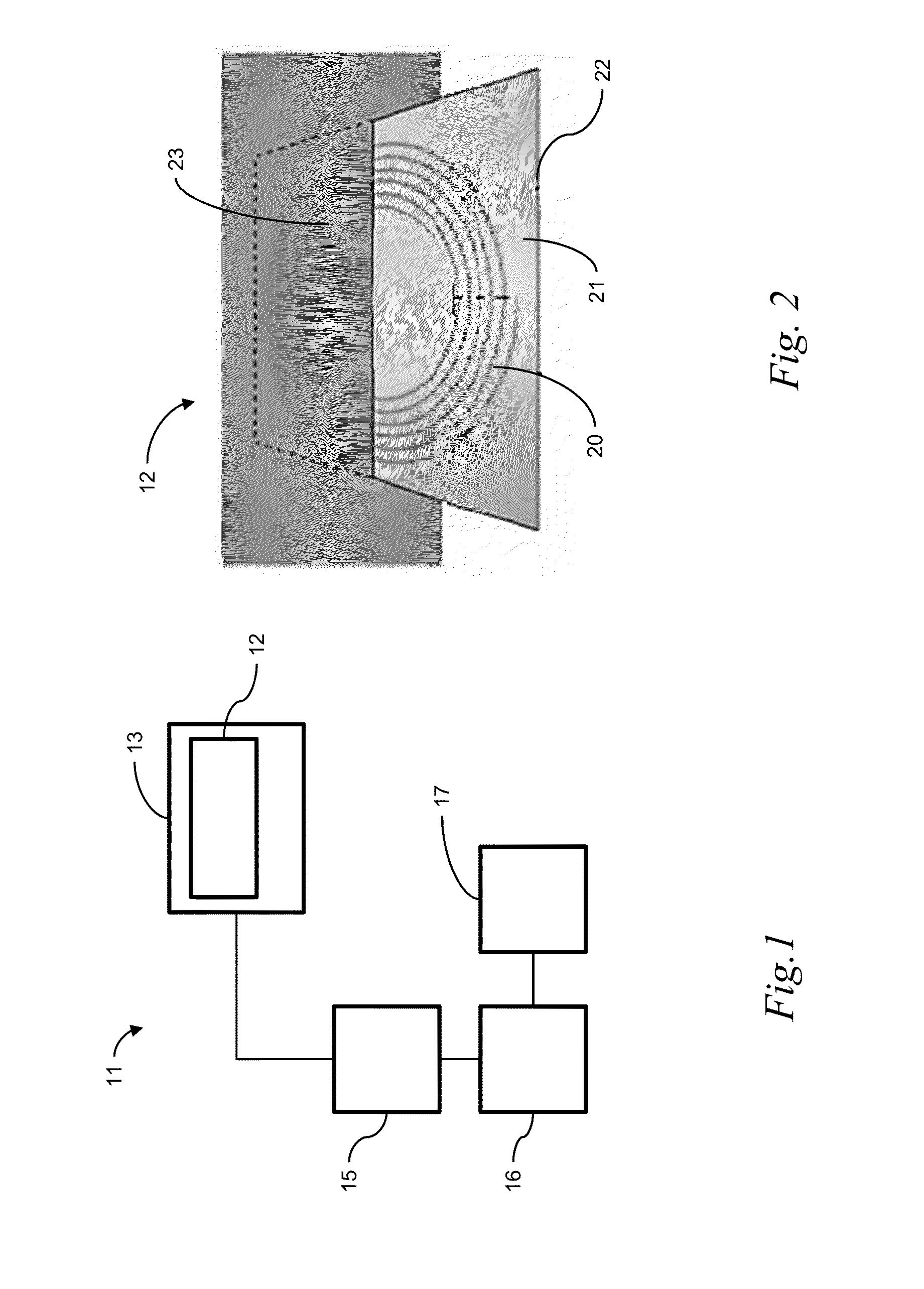

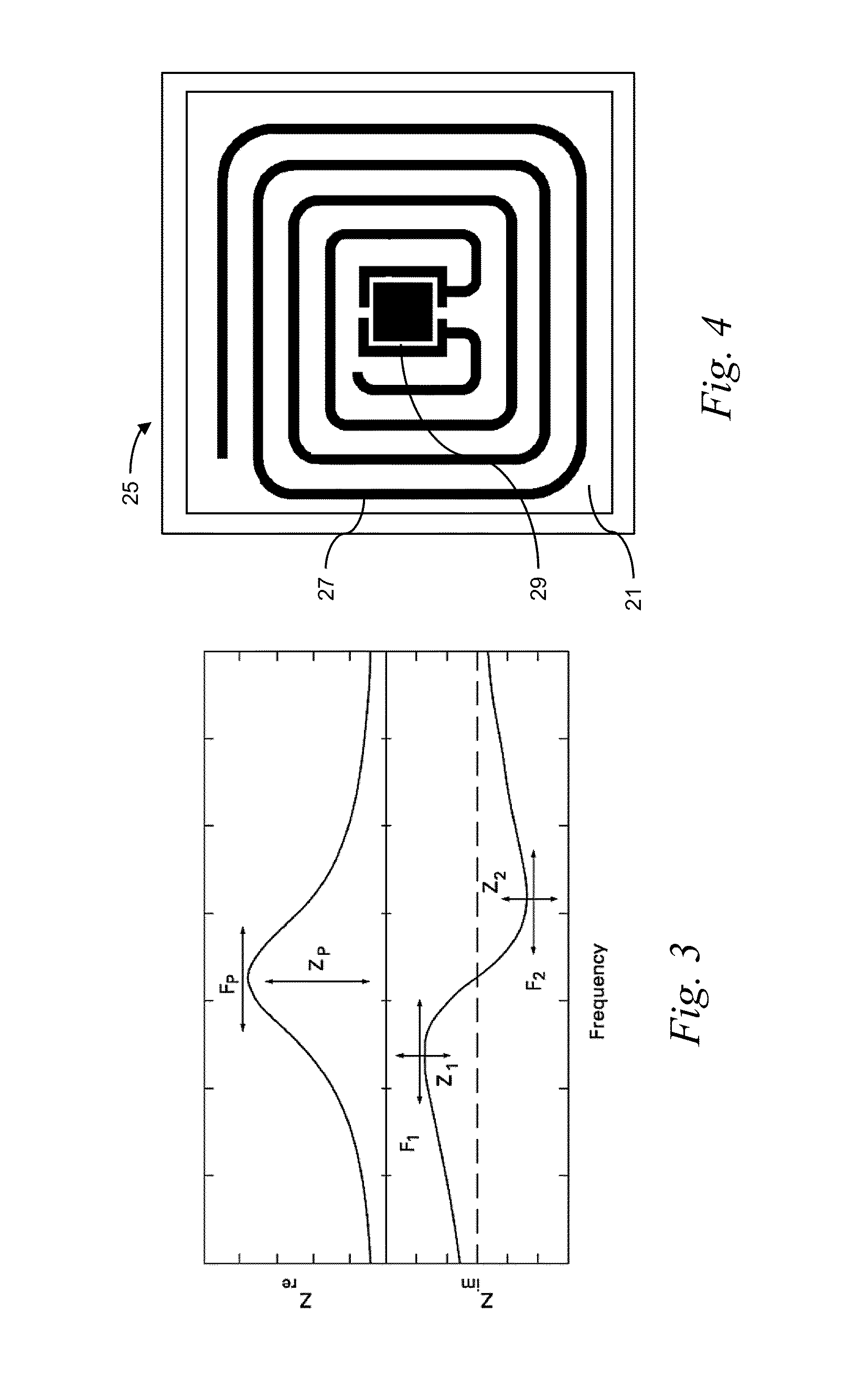

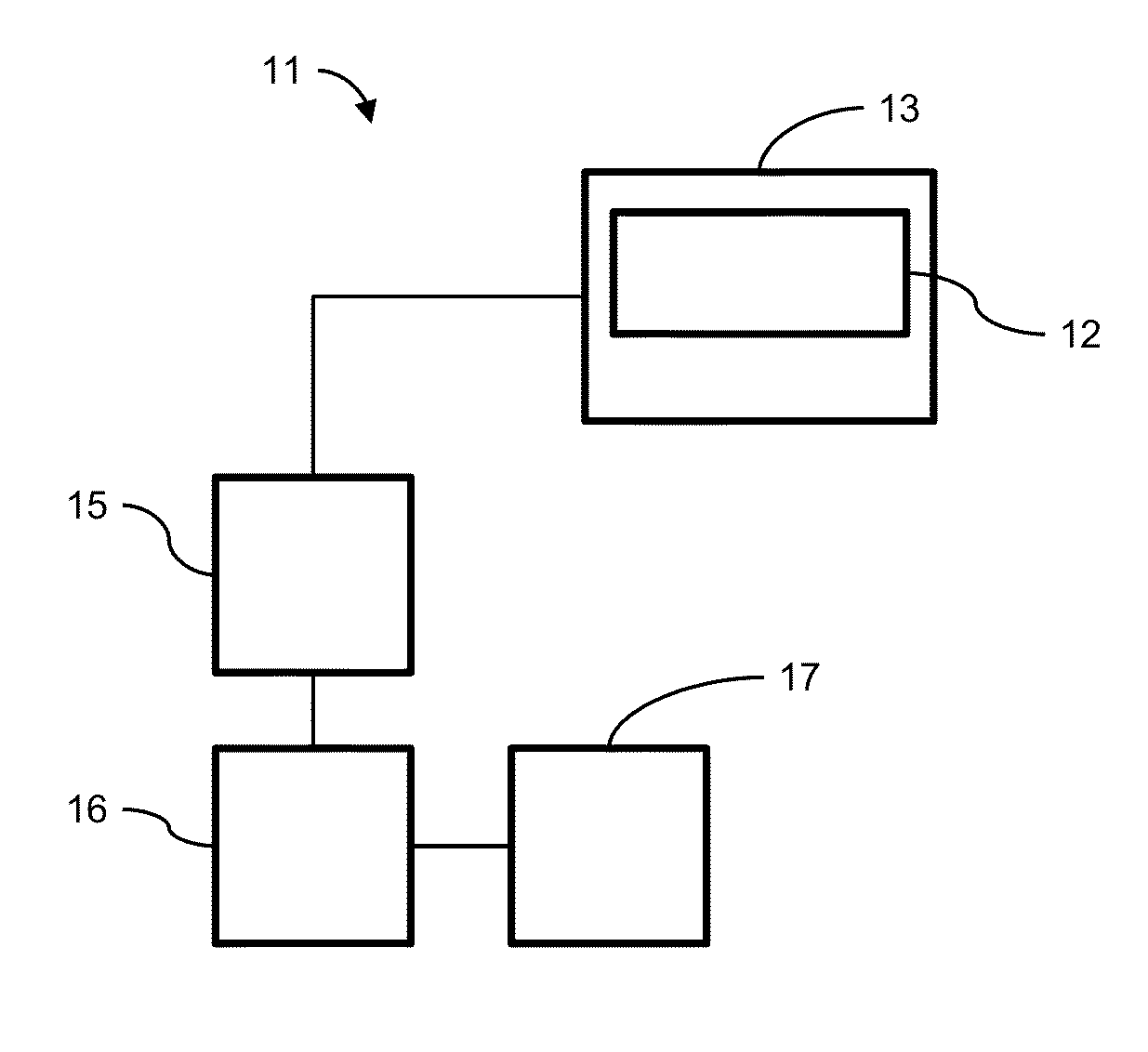

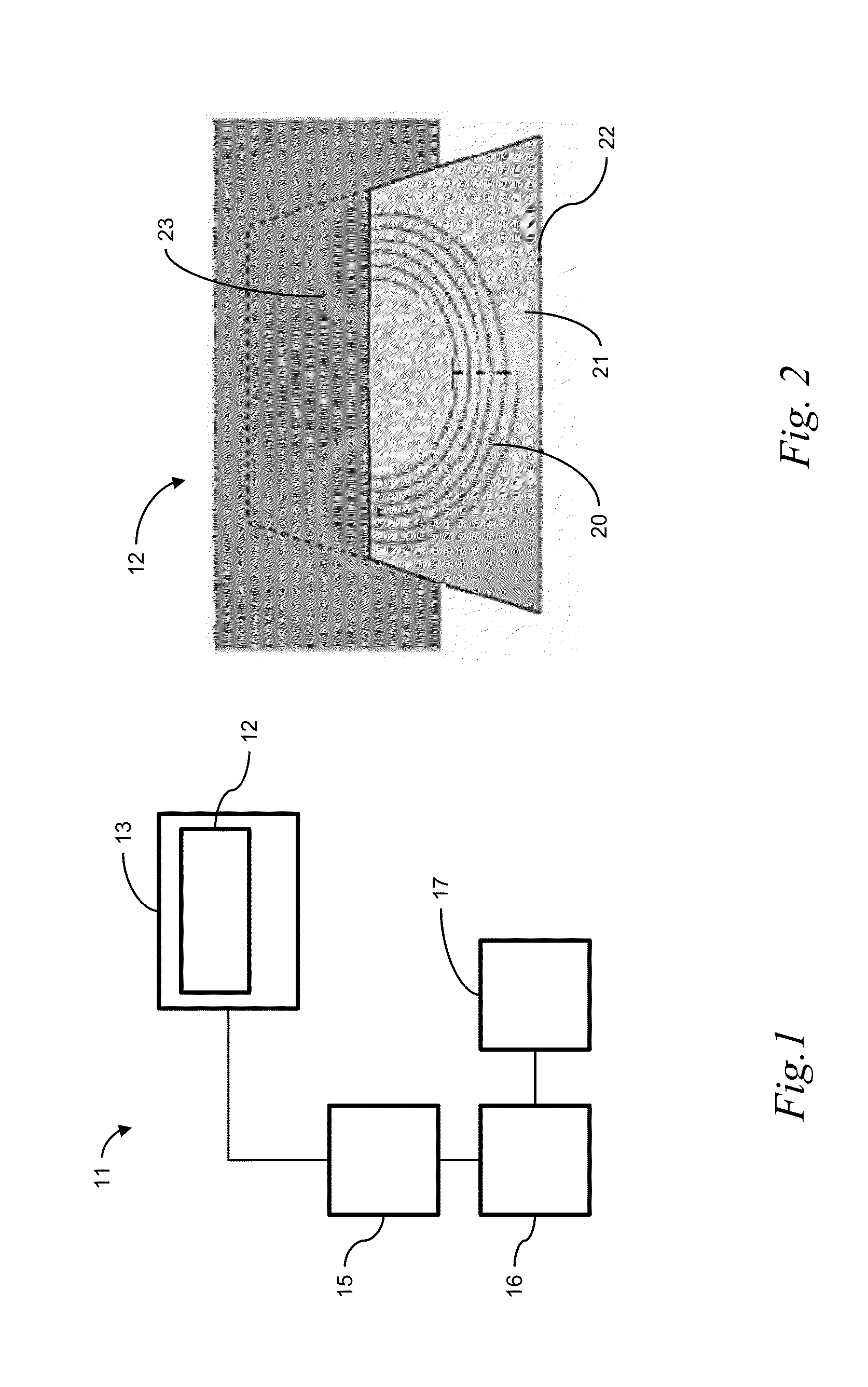

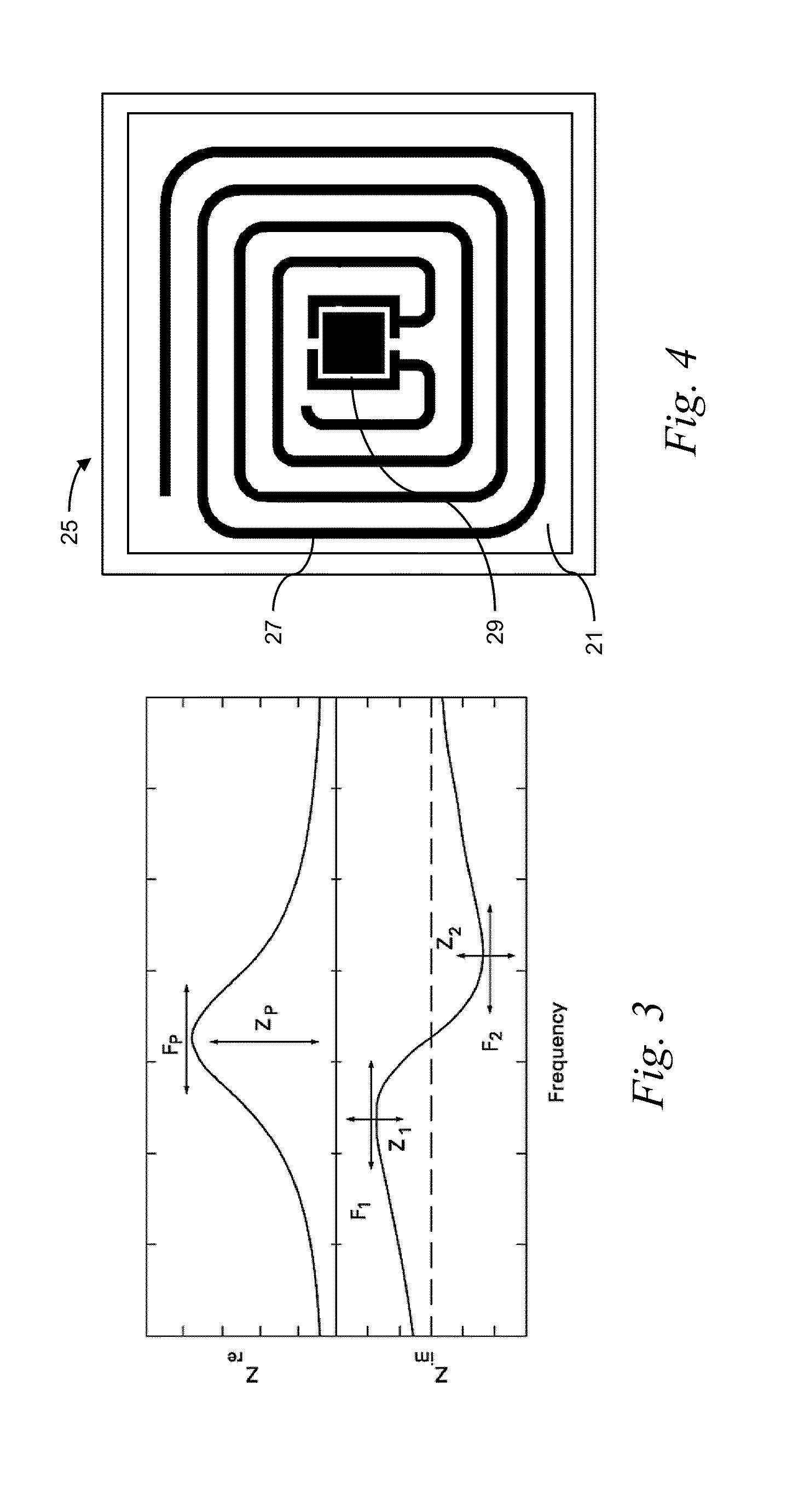

Systems and Methods for Measuring an Interface Level in a Multi-Phase Fluid Composition

ActiveUS20140090451A1Not easy to scaleLow costVolume measurement apparatus/methodsMachines/enginesComplex impedance spectraFluid phase

A system includes a vessel system for a fluid, a sampling assembly and a resonant sensor system coupled to the sampling assembly. The resonant sensor system may include a subsystem that detects a set of signals from a resonant sensor system at a plurality of locations in the vessel. The resonant sensor system may also include a subsystem that converts the set of signals to values of a complex impedance spectrum for the plurality of locations and stores the values of the complex impedance spectrum and frequency values. A subsystem determines a fluid phase inversion point from the values of the complex impedance spectrum.

Owner:BL TECH INC

Sensor Systems for Measuring an Interface Level in a Multi-Phase Fluid Composition

ActiveUS20140090454A1Low costHigh sensitivityComponent separationMaterial impedanceComplex impedance spectraEmulsion

A sensor includes a resonant transducer, the resonant transducer being configured to determine the composition of an emulsion. The composition of the emulsion is determined by measuring the complex impedance spectrum values of the mixture of the emulsion and applying multivariate data analysis to the values.

Owner:BL TECH INC

Coal powder injection catalytic combustion burning-rate accelerator of blast furnace

InactiveCN101220312AIncrease coal injection ratioImprove effective utilizationSolid fuelsRare earthCarbonate

The invention discloses an additive which can reduce pollution emission and improve combustion efficiency when in the combustion of bunker coal, which more particularly relates to a blast furnace coal injection catalyzing oxidant. The invention consists of soft manganese ore, fluorite powder, magnesium carbonate and rare earth metal oxide, the production method is that the raw materials are respectively smashed into the granules below 80 meshes, mixed evenly and directly added into the bunker coal for even mixing according to the weight proportion of 0.2 to 5 percent; or the raw materials are fed on a conveying raw coal belt by a spiral feeding machine, sprayed and blown into a blast furnace; the invention can also be taken as the bunker coal additive of a powder coal boiler or a boiling furnace.

Owner:GUANGXI QINGRONG REFRACTORIES

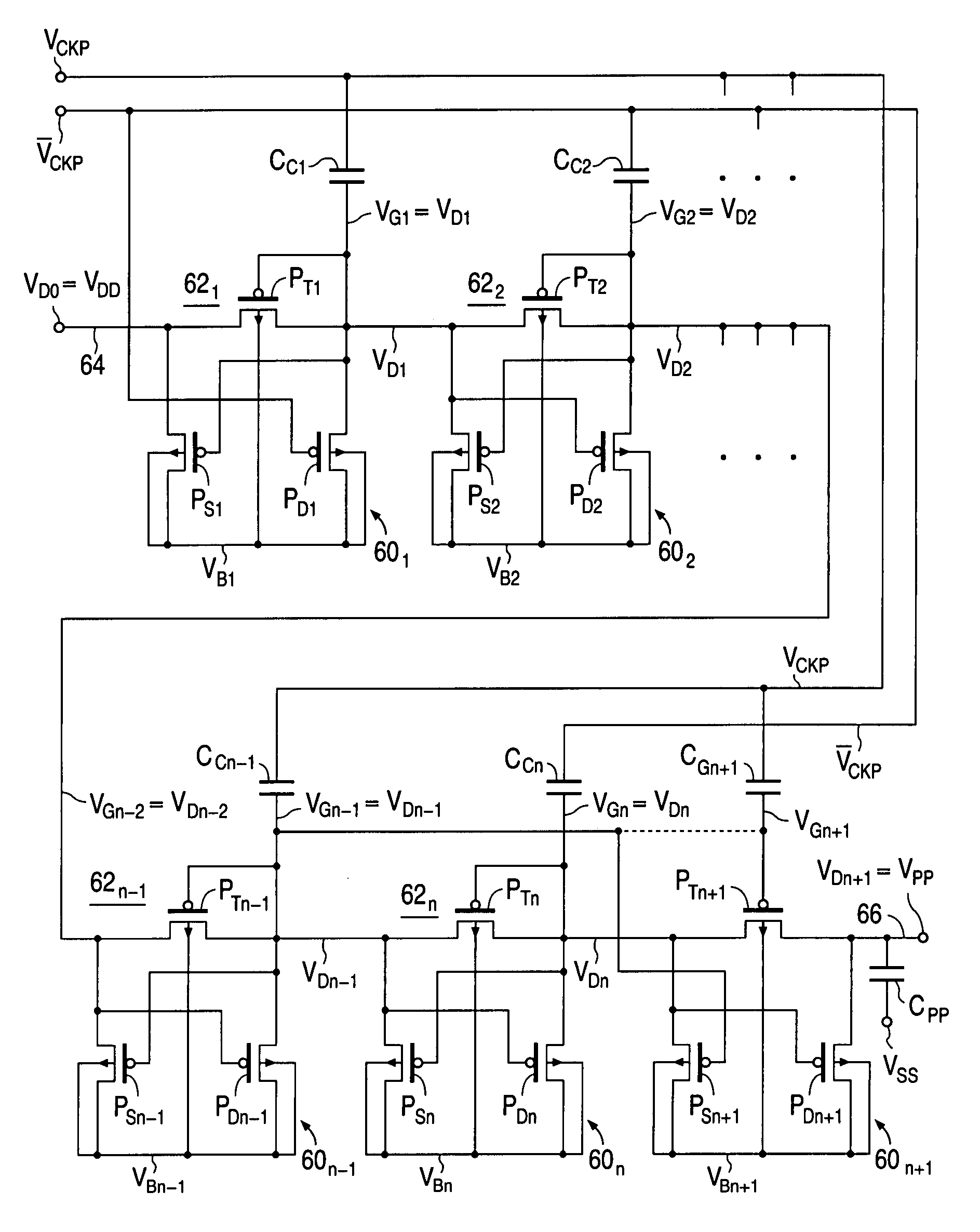

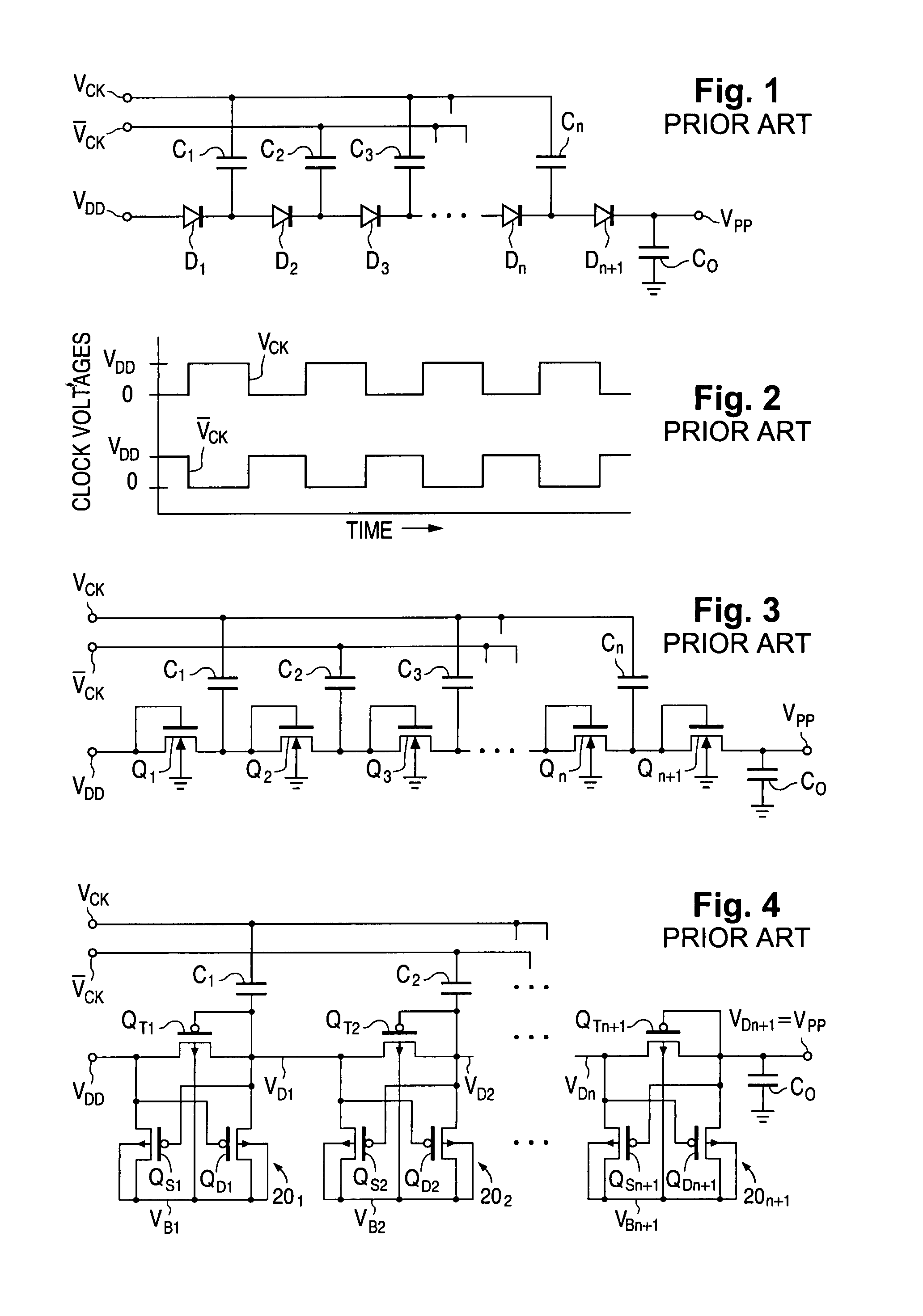

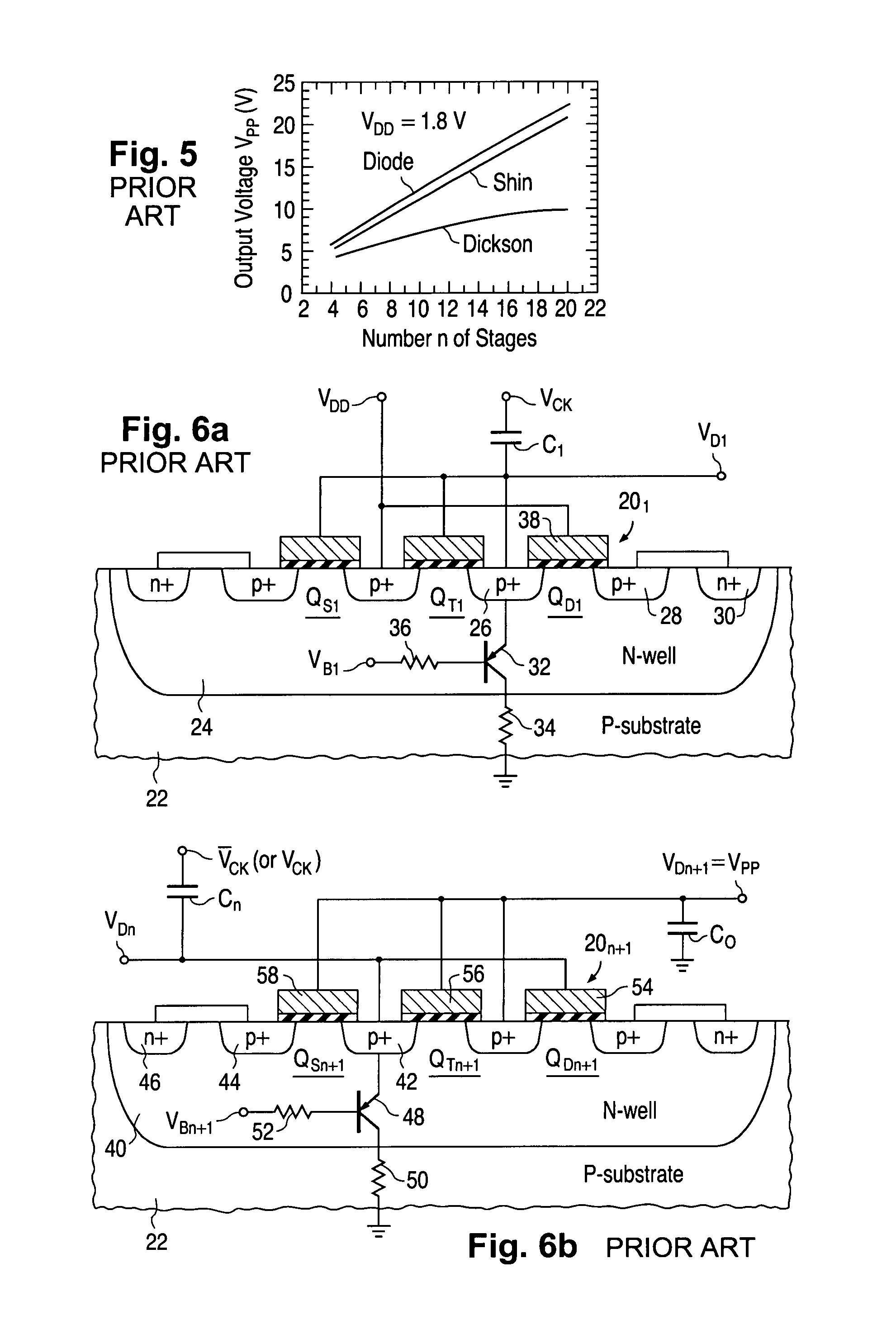

Charge pump with ensured pumping capability

InactiveUS7301388B2Prevents undesired bipolar actionAvoids loss in the pump's overall voltage gainAc-dc conversionApparatus without intermediate ac conversionEngineeringCharge pump

An n-stage charge pump contains n primary capacitive elements (CC1-CCn or CD1-CDn), n+1 charge-transfer cells (601-60n+1, 1101-110n+1, 1201-120n+1, or 1301-130n+1) respectively sequentially designated as the first through (n+1)th cells, and sources of first and second clock signals (VCKP and VCK P or VCKP1 and VCKP2) approximately inverse to each other. Each pump stage (62i, 112i, 122i, or 132i) includes one (CCi or CDi) of the capacitive elements and a corresponding one (60i, 110i, 120i, or 130i) of the first through nth charge-transfer cells. Each cell contains a charge-transfer FET (PTi or NTi). A pair of side FETs (PSi and PDi or NSi and NDi) are provided in the first cell, in the (n+1)th cell, and normally in each remaining cell. The side FETs in the first cell or / and the (n+1) cell are connected in such a manner as to avoid undesired bipolar action that could cause degradation in the pump's voltage gain.

Owner:MOSEL VITELIC CORP

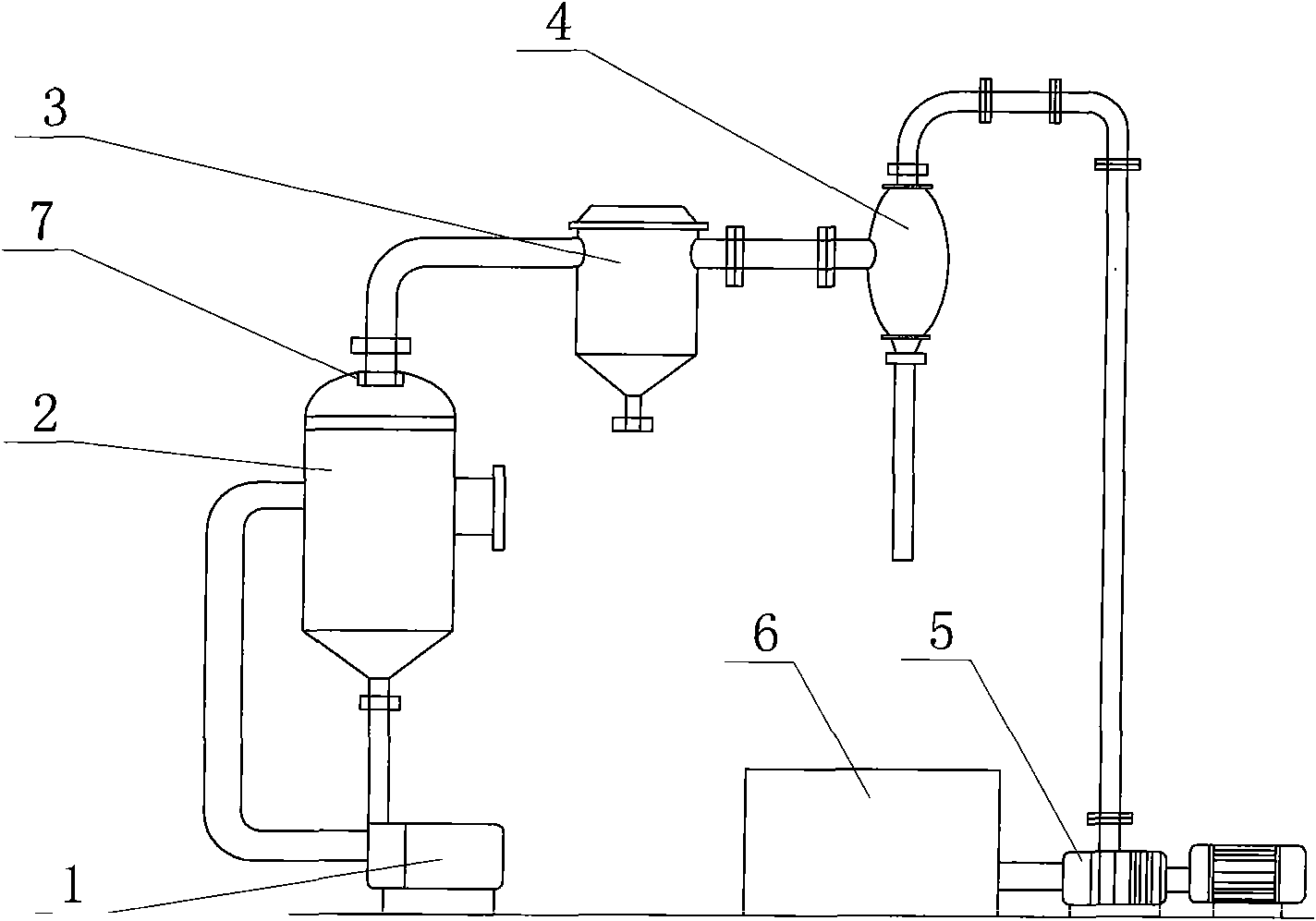

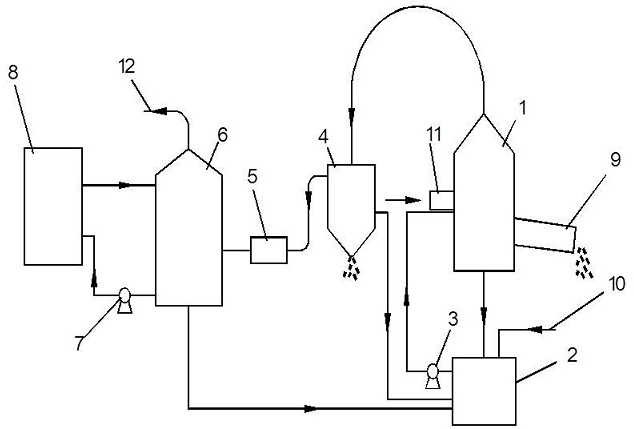

Blast furnace smelting slag water quenching waste steam waste heat recovery system

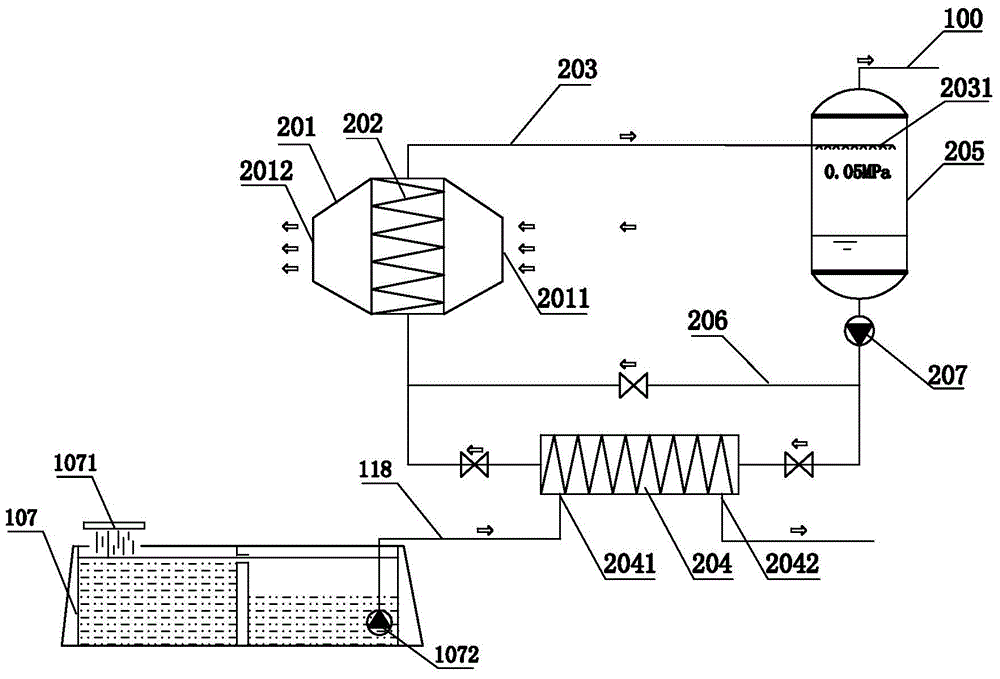

InactiveCN102424868AImprove waste heat utilization efficiencyIncrease waste heat recoveryLighting and heating apparatusProcess efficiency improvementBlast furnace smeltingWastewater

The present invention provides a blast furnace smelting slag water quenching waste steam waste heat recovery system. The system comprises a blast furnace slag water quenching apparatus, a slag quenching water circulation apparatus and a waste steam waste heat recovery apparatus. The blast furnace slag water quenching apparatus comprises a smelting slag groove, a water quenching apparatus and a slag discharging and conveying belt. The slag quenching water circulation apparatus comprises the water quenching apparatus, a water circulating tank, a water quenching pump and a water supplying pipe. The waste steam waste heat recovery apparatus comprises the water quenching apparatus, a three-phase separator, a fan, a heat exchanger, a hot water pump and a low-temperature user. The method of the present invention is different from the method in the prior art, wherein the recovery of the slag quenching waste water waste heat is adopted to recover the smelting slag waste heat by the method in the prior art, and the waste heat in the waste steam generated from the smelting slag quenching by the recovered water is adopted to recover the smelting slag waste heat by the method of the present invention, the water quality of the waste steam is better than the water quality of the waste water, such that the disadvantages of high hardness of the waste water, equipment scaling, equipment blocking and the like in the prior art are overcome. According to the present invention, the slag quenching waste steam waste heat is effectively recovered; the system has advantages of energy saving and emission reduction, and environmental protection; the collected waste heat can be used to meet the requirements of the low-temperature user.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

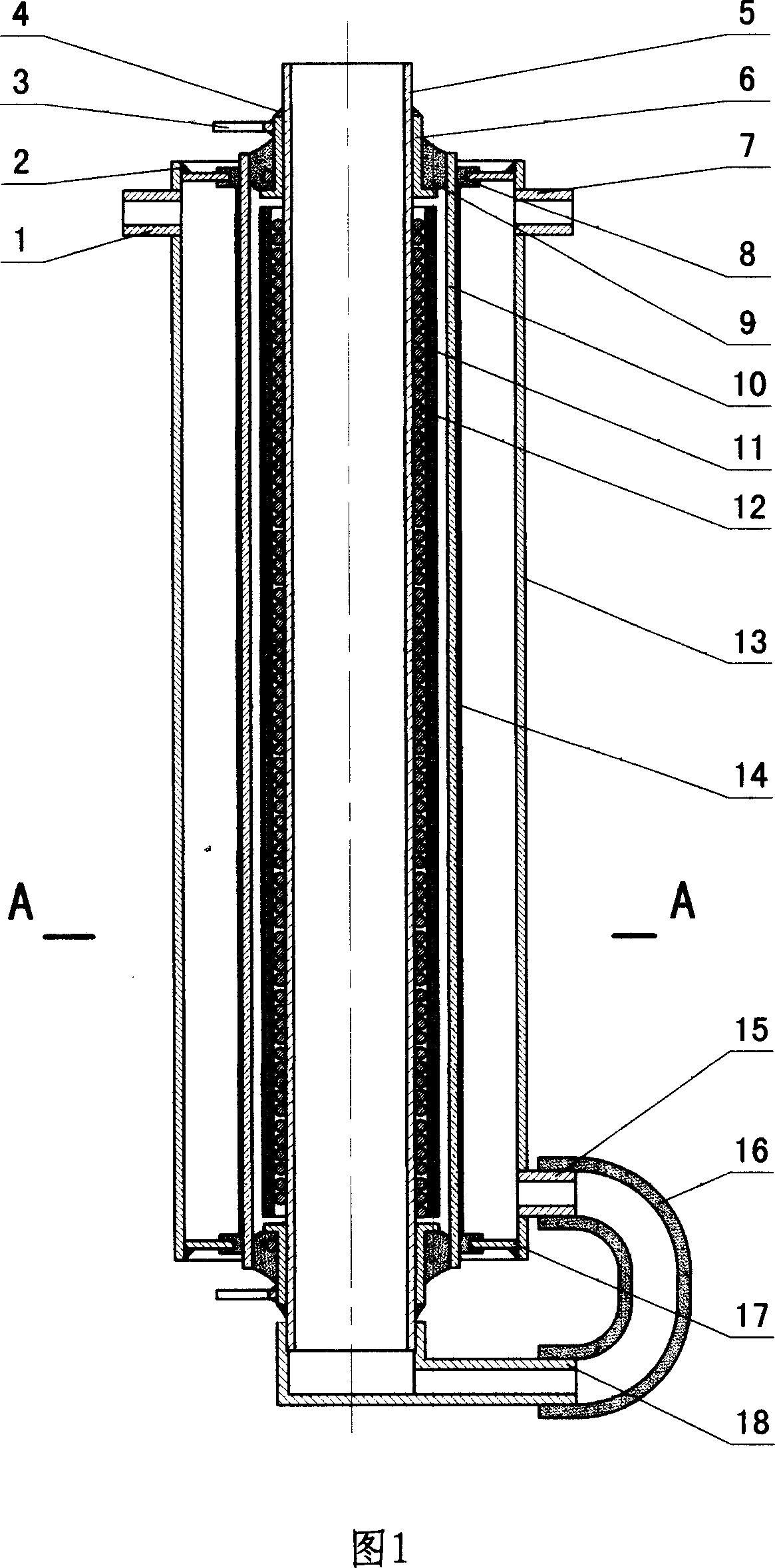

Energy-saving instantaneously heated type electric heater unit

The invention relates to an energy-saving instant heating electric-heat device, comprising a non-metal water pipe, an electric-heat wire twisted on the non-metal water pipe and a water leg could absorb heat. When the device is operated, the normal temperature water firstly flows inside the water leg, the water is gradually preheated by the heat leaked via the electric-heat wire, the water preheated go to the water pipe, the water is gradually reheated by the electrical-heat wire when the water is flowing, when the water flows to the outlet of the heat device, the water temperature reaches the needed temperature. The distinctive character is that the heat speed is high, energy-saving, and safe and deposition would not be easy to form. The device is mainly applied in the instant heating drinking machine, to heat the water flows inside. The invention can be used in the devices that need to instantaneously heat the flowing liquids.

Owner:黄樟焱

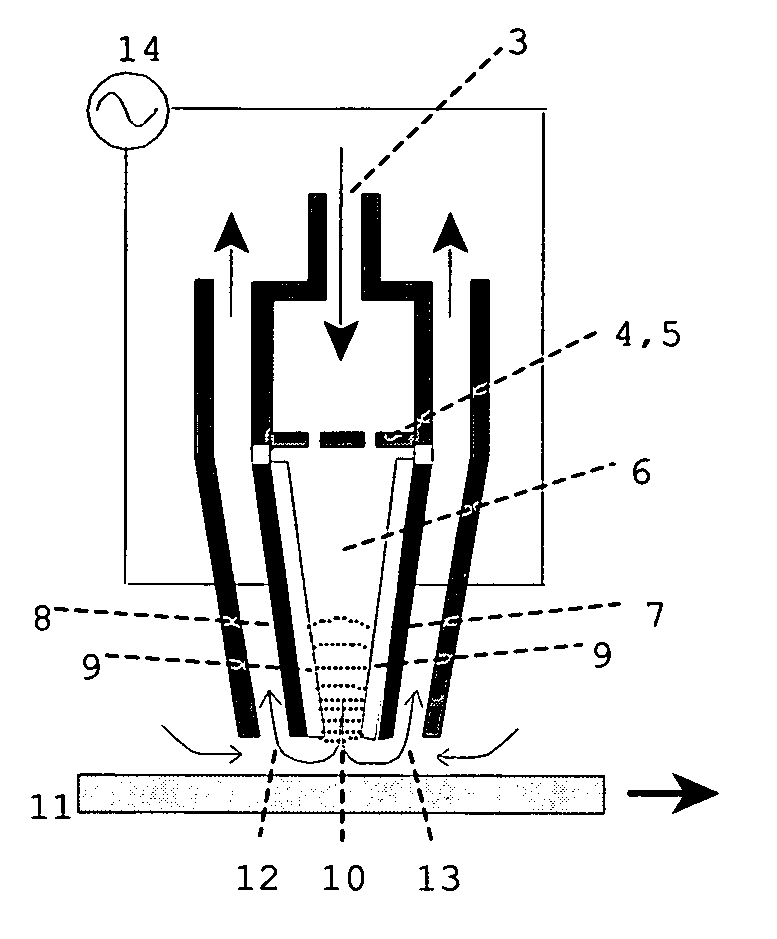

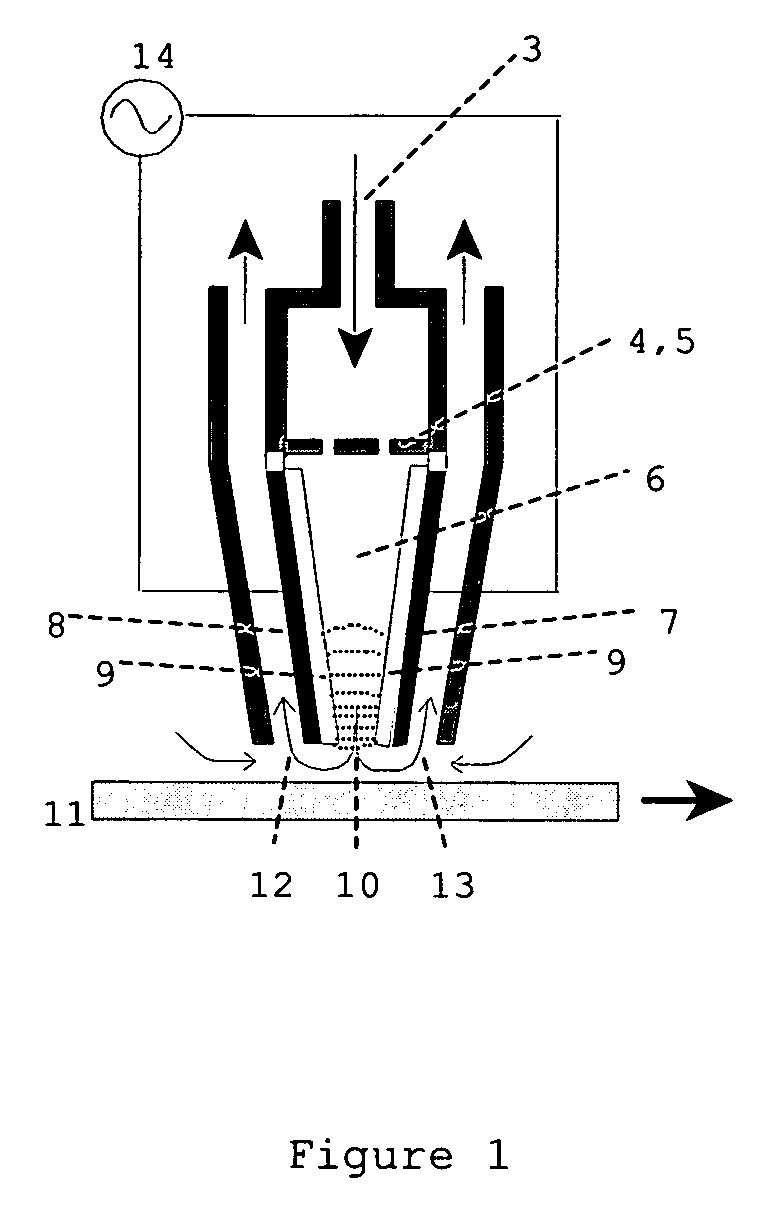

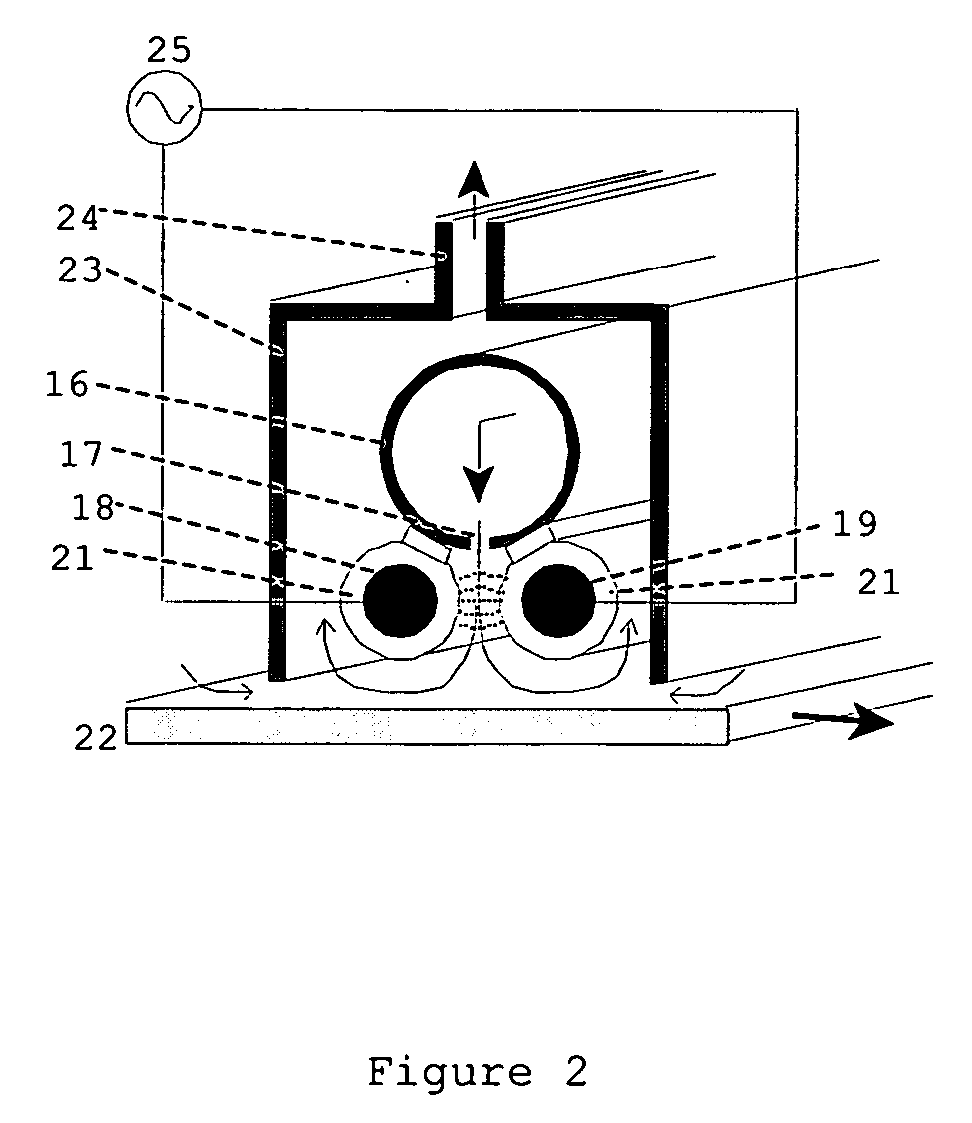

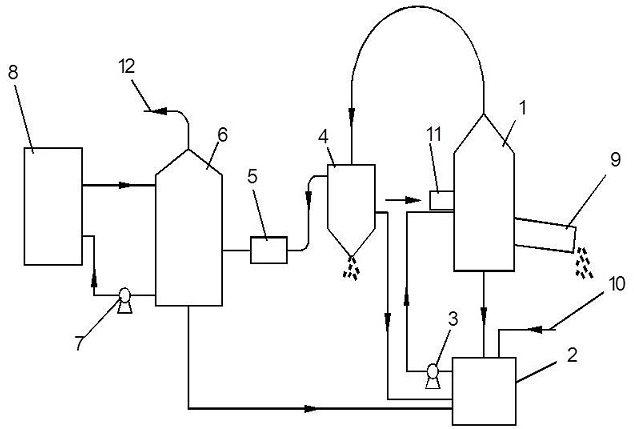

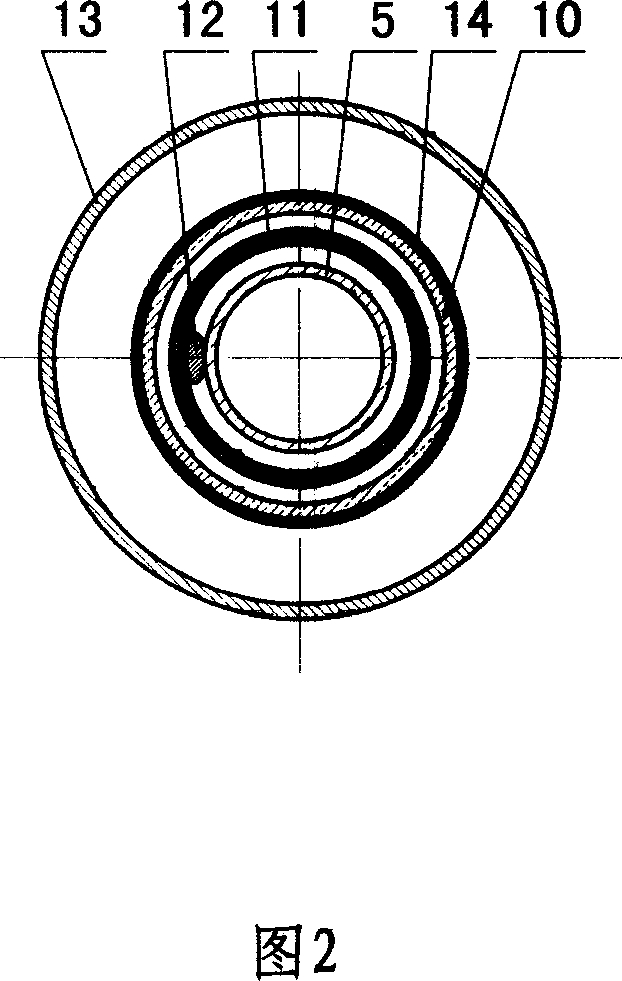

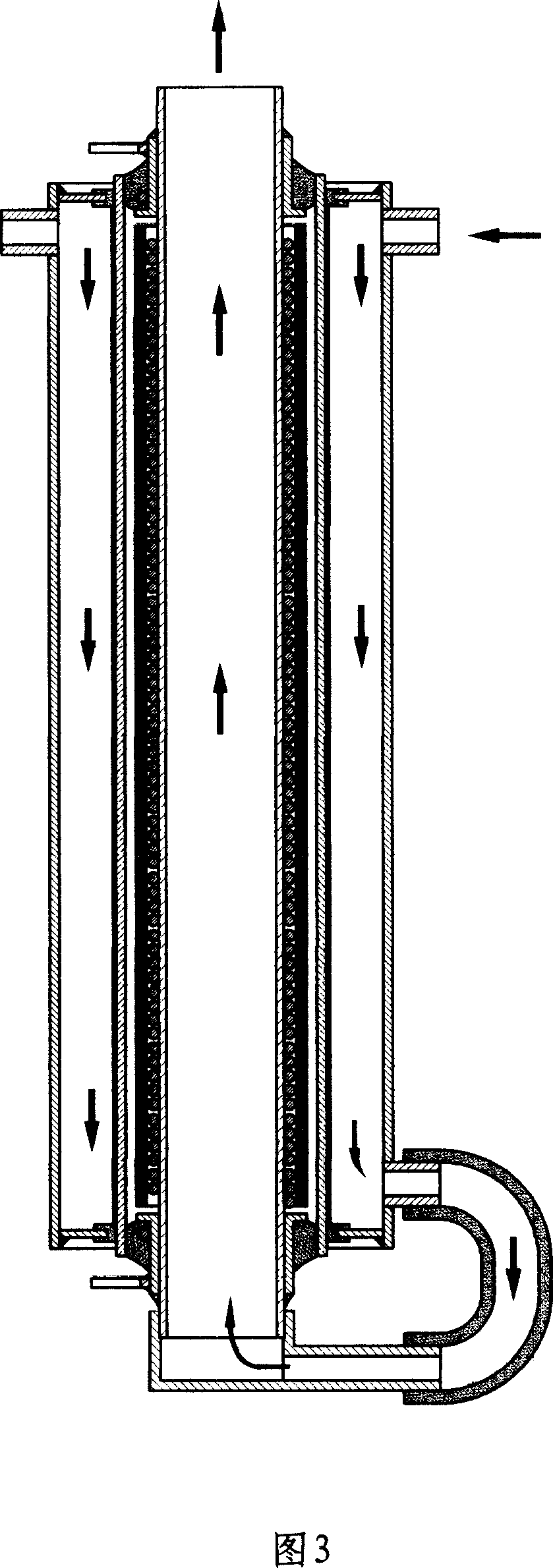

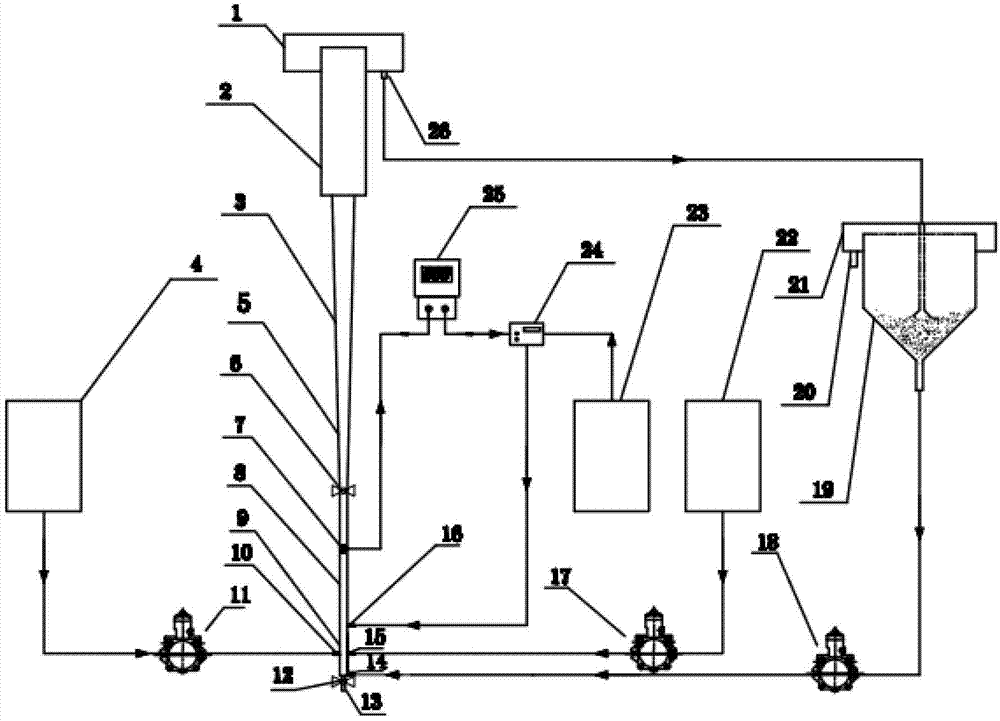

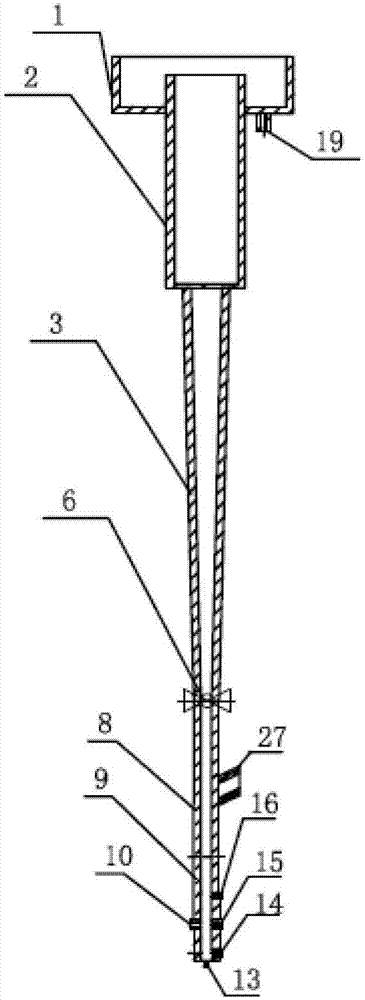

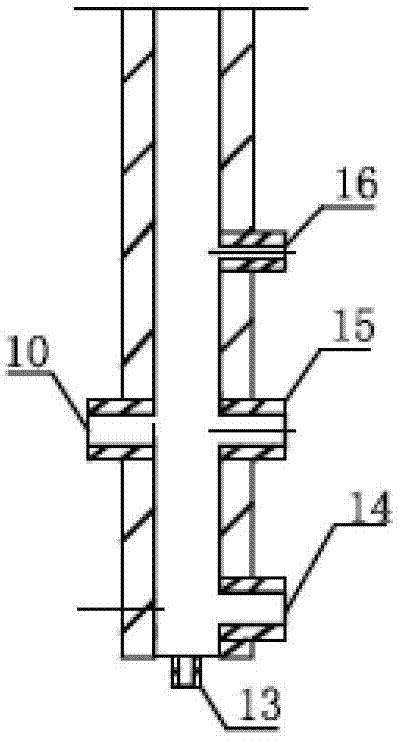

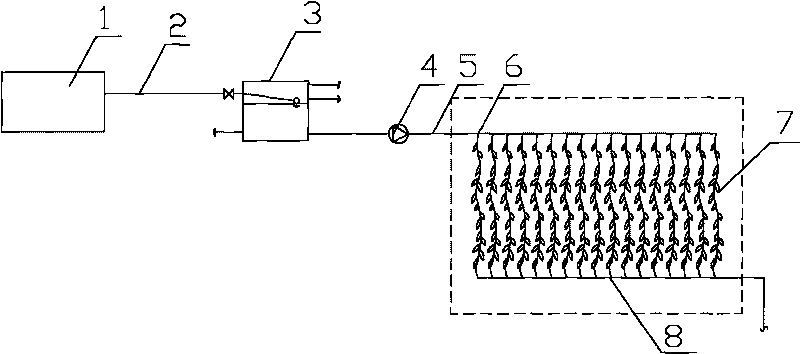

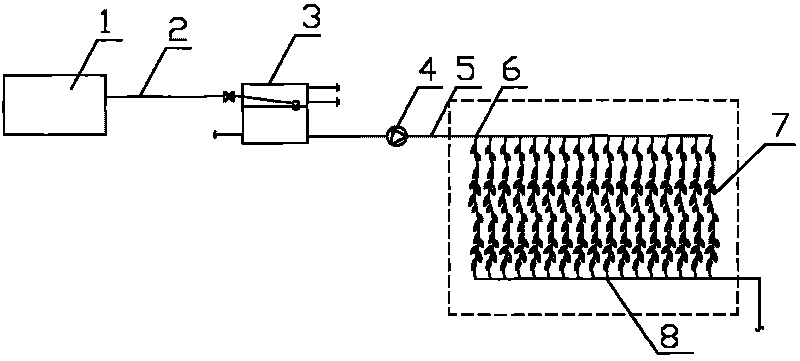

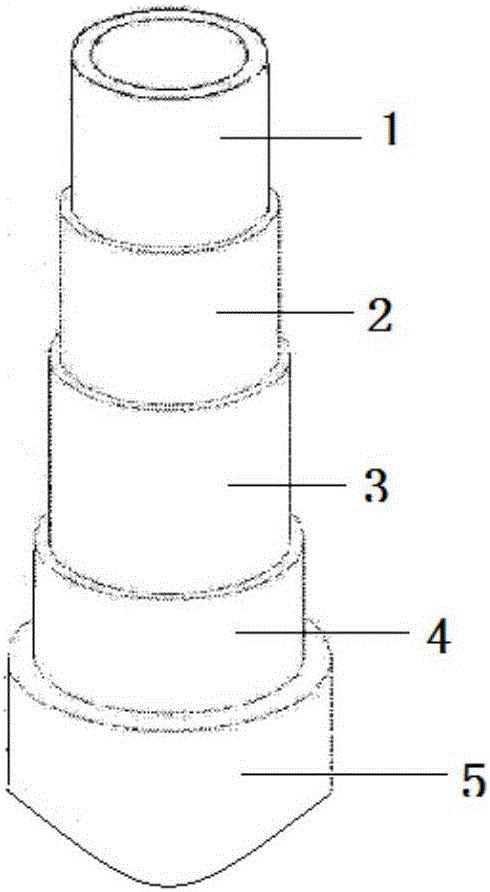

Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

InactiveCN102963970AIncreased turbulence intensityCompact structureWater/sewage treatment by flocculation/precipitationPhosphorus compoundsStruvite CrystalsSmall footprint

The invention relates to a device and a process for preparing struvite crystals from nitrogen and phosphorus in sewage. The device comprises a reactor (5), a pH (potential of Hydrogen) controller (25), a pH regulating pump (24), an alkali liquor tank (23), a nitrogen and phosphorus containing waste water tank (22) and a secondary sedimentation tank (19), wherein the reactor (5) is composed of a reactor feed pipe (9), a reactor crystal collecting pipe (8), a reactor growth tube (3) and a reactor sediment tube (2) from bottom to top. The process comprises the steps of pumping nitrogen and phosphorus containing wastewater into the reactor (5) and pumping a magnesium chloride solution into the reactor (5) to ensure that the molar ratio of NH3-N to PO43-P to Mg <2+> in the reactor (5) is (1:1:1)-(1:1:1.3); controlling the reflux ratio between 14 and 28 and the pH equal to 6.4-9.2; and forming the struvite crystals in the reactor (5) by using the nitrogen, phosphorus and magnesium containing solution. The device disclosed by the invention has the advantages of simple structure and small floor space, is simple and easy to operate and difficult to scale, can be widely applied to preparation of the struvite crystals from the nitrogen and phosphorus containing wastewater such as coking wastewater, pig manure wastewater or sludge fermentation liquor, and is capable of realizing the resource recycling of nitrogen and phosphorus.

Owner:TONGJI UNIV

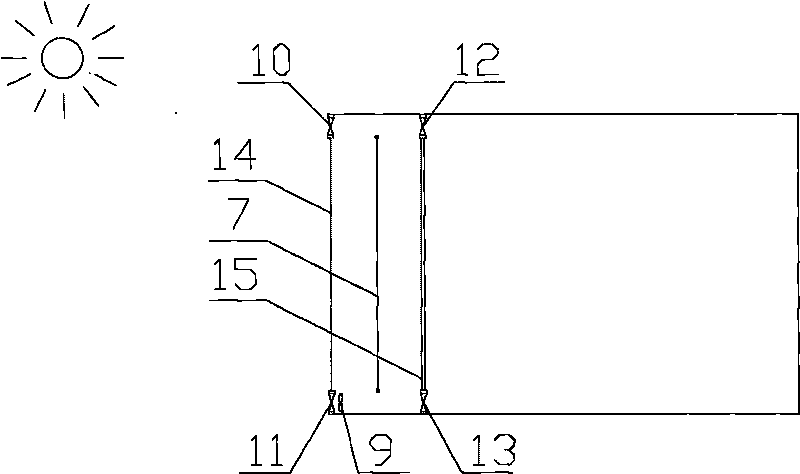

Ventilating glass curtain wall and working method thereof

InactiveCN101701479AGood energy saving effectNot easy to scaleCondensate preventionWallsNew energyWater storage tank

The invention relates to a ventilating glass curtain wall and a working method thereof, belonging to the technical fields of building energy conservation and new energy utilization. The ventilating glass curtain wall is provided with a plant curtain between an outer layer glass curtain wall and an inner layer glass curtain wall; the lower end of the outer layer glass curtain wall is provided with a first ventilating regulator, the lower end of the inner layer glass curtain wall is provided with a second ventilating regulator, and the first ventilating regulator and the second ventilating regulator are respectively connected with a fan; the lower end of the plant curtain is connected with a drain tank, and the upper end thereof is connected with a micro-sprinkling irrigation spray head which is connected with an electronic water pump by a main water supply pipe of a micro-sprinkling irrigation system; and the electronic water pump is connected with a water storage tank which is connected with a condensate water outlet arranged at the end of an air conditioner by a condensate pipe. The ventilating glass curtain wall utilizes the photosynthesis and the transpiration straggling effect of the plant curtain to consume solar radiation, and is simultaneously assisted by ventilation strategy, so that the heat inside a hot channel can be taken away, the temperature inside an air cavity of the ventilating double-layer curtain wall is reduced, and the aim of saving the energy consumption can be achieved.

Owner:SOUTHEAST UNIV

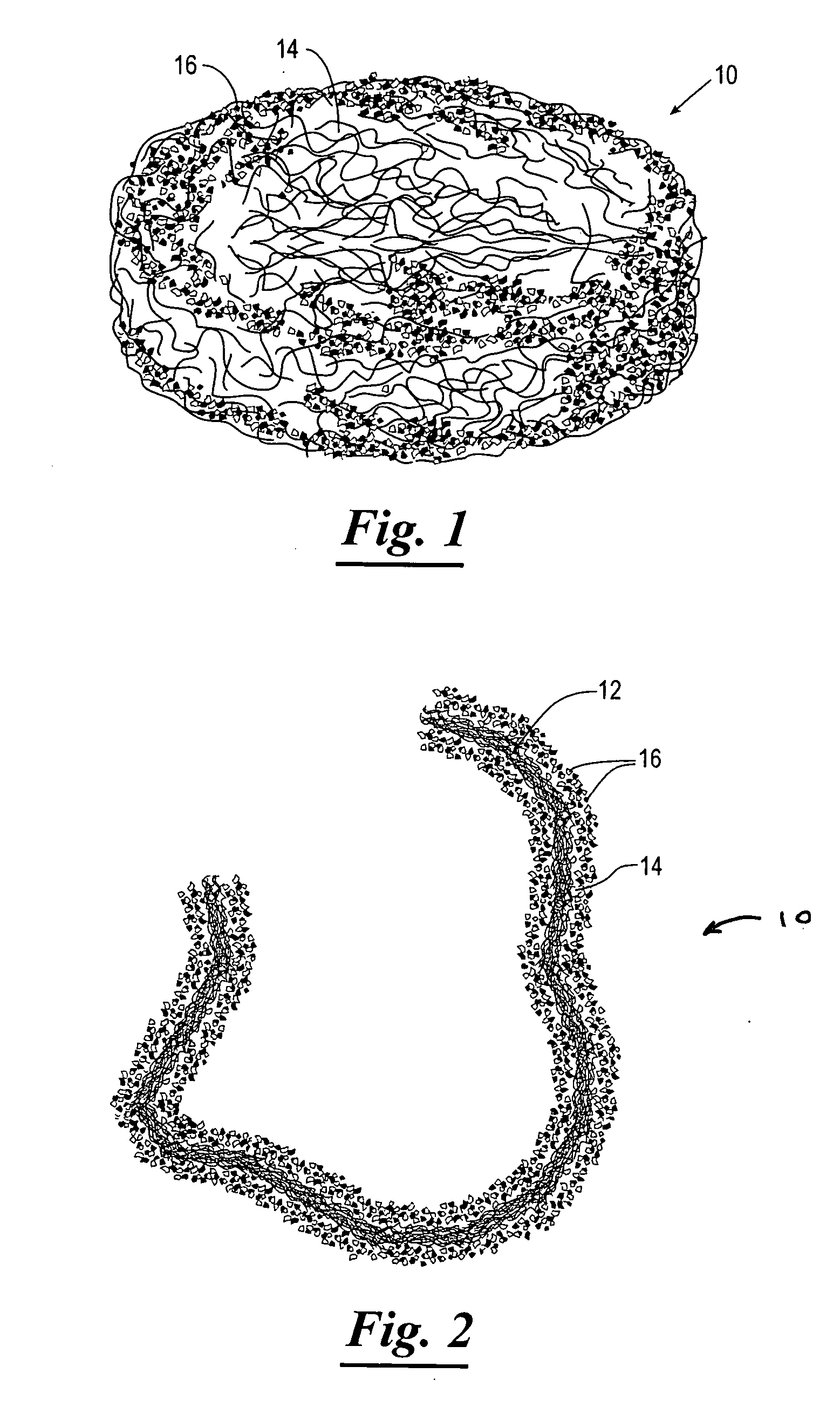

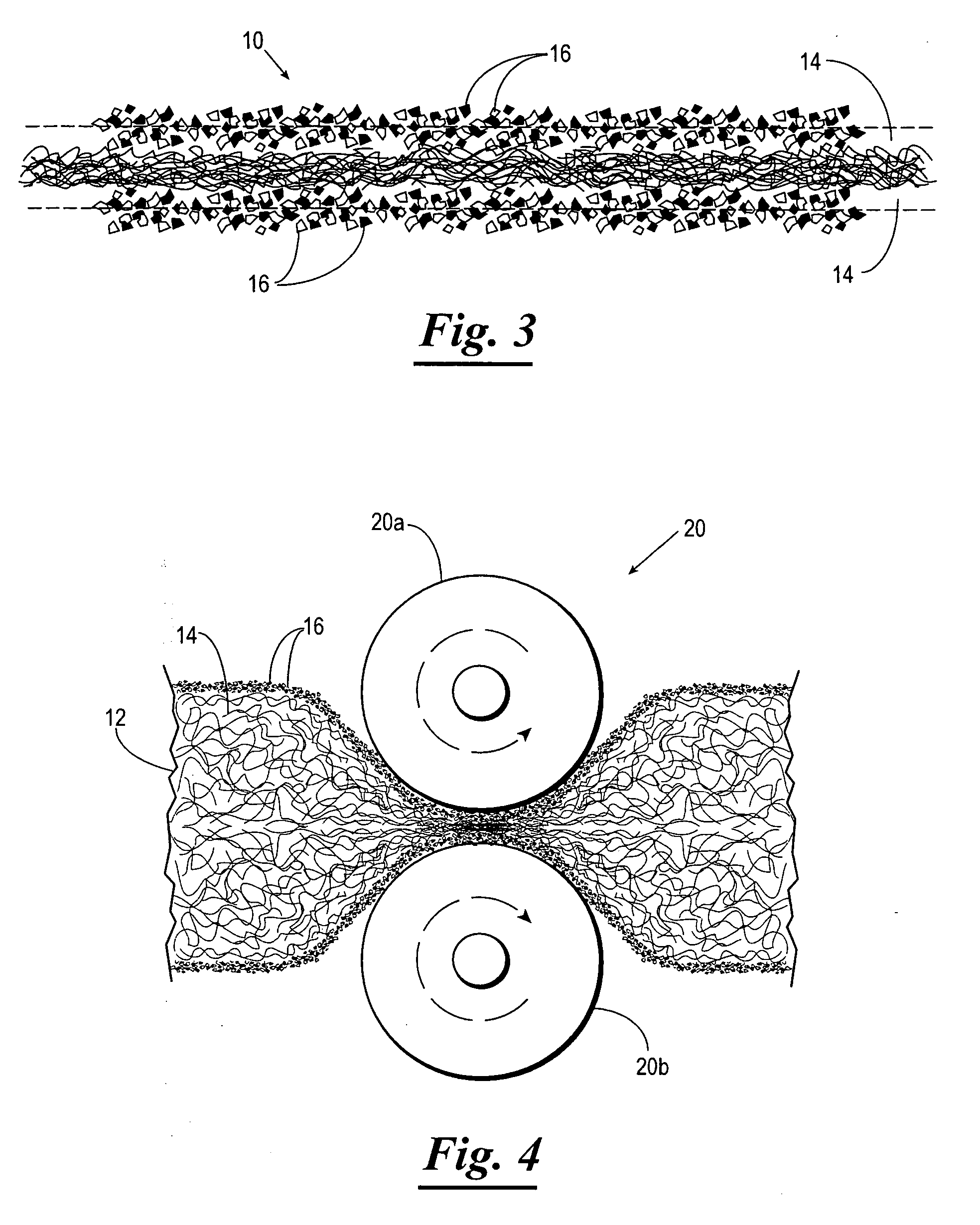

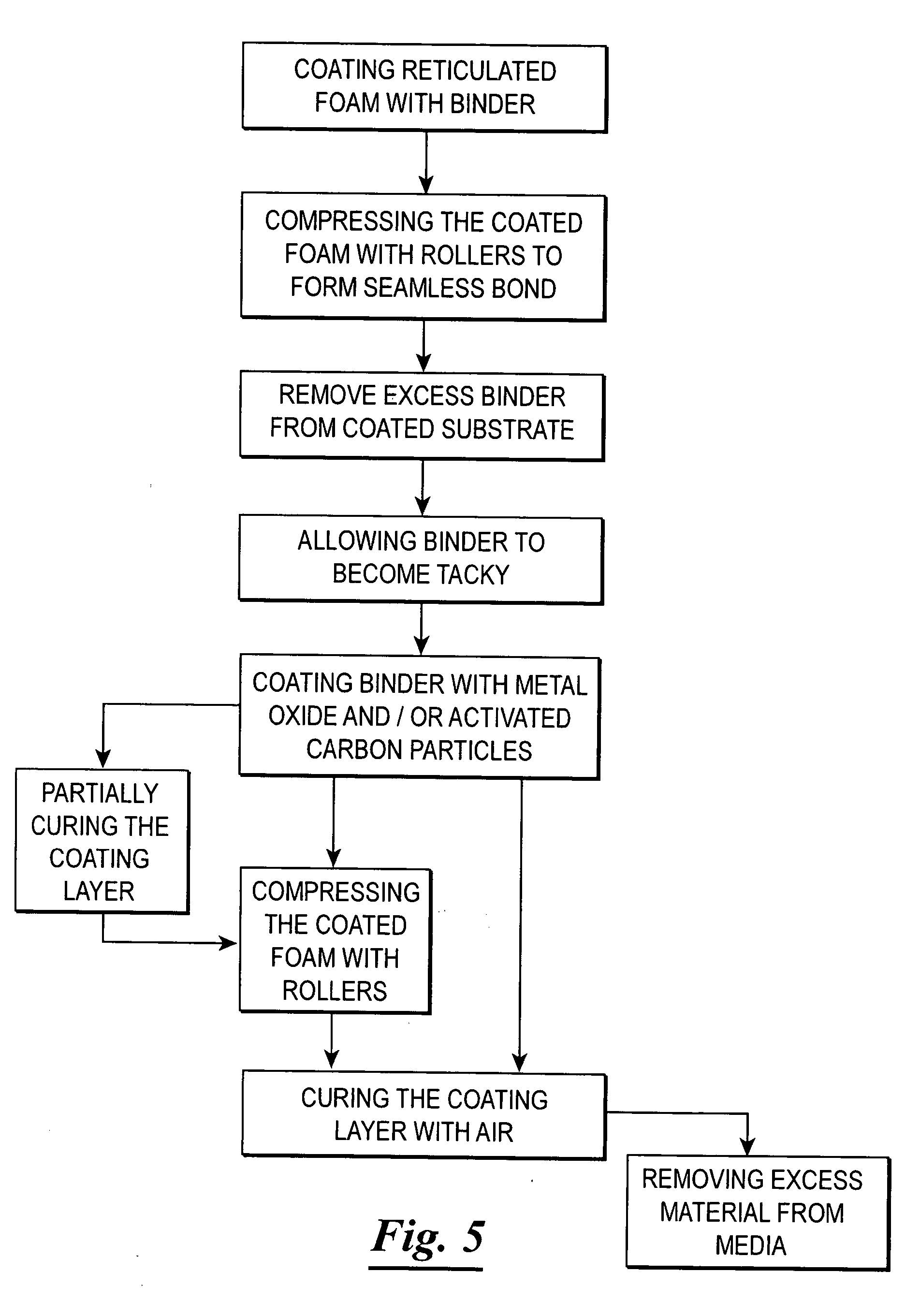

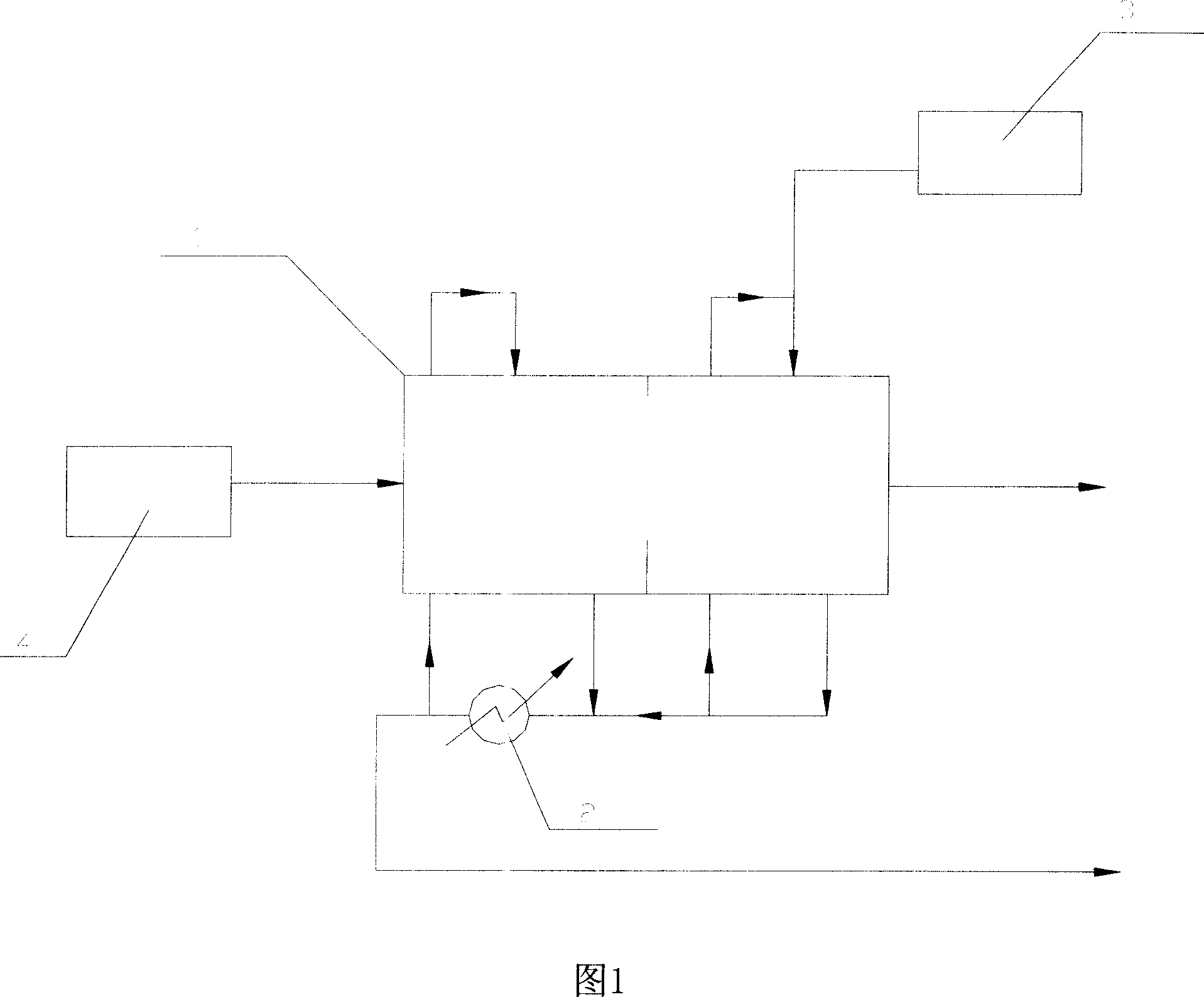

Flexible reticulated foam fluid treatment media and method of preparation

InactiveUS20060182944A1Reduce porositySmall surface areaLayered productsWater/sewage treatmentActivated carbonReticulated foam

Flexible reticulated foam fluid treatment media and a method of making same. The flexible fluid treatment media includes a flexible reticulated foam substrate, a binder coating the flexible reticulated foam substrate and a plurality of particles compressed into the binder to form a durable interconnected layer of particles that are bound together and collectively fixed to the substrate. The flexible reticulated foam fluid treatment media is flexible and easily cut and shaped without damaging the particle layer to form a wide variety of shapes and sizes that lend themselves to use within an equally wide variety of pipes, conduits, ducts, skimmers, filter housings and fluid treatment devices. The method used to create the fluid treatment reticulated foam media includes the steps of coating a soft reticulated foam substrate with a binder, subjecting the coated substrate to compression forces, allowing the coated substrate surface to become tacky, coating the binder with a plurality of metal particles or metal oxides or activated carbon particles or intimate mixtures of these particles combined together, subjecting the coated substrate to compression forces using a roller or by passing the coated substrate between a pair of adjacent rollers, removing any excess metal particles, and curing the binder by air drying using ambient air or heated air, and removing any excess particles.

Owner:FLUID TREATMENT SYST

Deodorant waste lye absorbing treating smoke method

ActiveCN101143293ASolve the problems of low heat transfer efficiency and high equipment costThe method is efficient and stableDispersed particle separationAir quality improvementNitrogen oxidesDeodorant

The invention relates to a method of absorbing and treating gases by using deodorization waste lye. The invention uses deodorization waste lye processed wet air oxidation treatment to absorb sulfur dioxide, dust and nitrogen oxides in the gas. The invention uses two-stage absorption mode, and the forepart uses the absorption liquid discharged in posterior part to contact directly with the gas to reduce gas temperature, and at the same time to remove part of the pollutants in the gas. The posterior part uses deodorization waste lye as absorption liquid to contact with the cooled gas in the forepart, and the absorption pollutants in this stage contains sulfoxides or nitrogen oxides, and the purified gas can be released. The removal efficiency of sulfur dioxide and dust processed treatment by the invention can be achieved above 90 percent, and the removal efficiency of nitrogen oxides can be achieved above 40 percent. The method not only can effectively purify the gas, but also can effectively utilize waste lye. The invention has the advantages of that the method is extremely stable, is not easy to scale, has low investment, simple operation, low operation cost and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

Industrial waste heat type low-temperature multi-effect sea water desaltation system and sea water desaltation method thereof

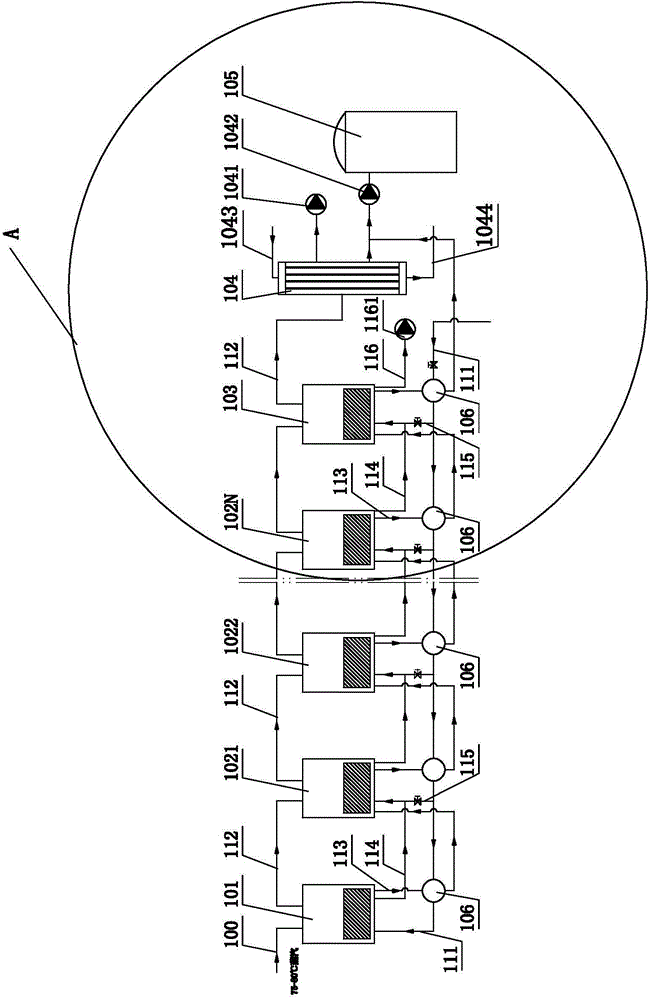

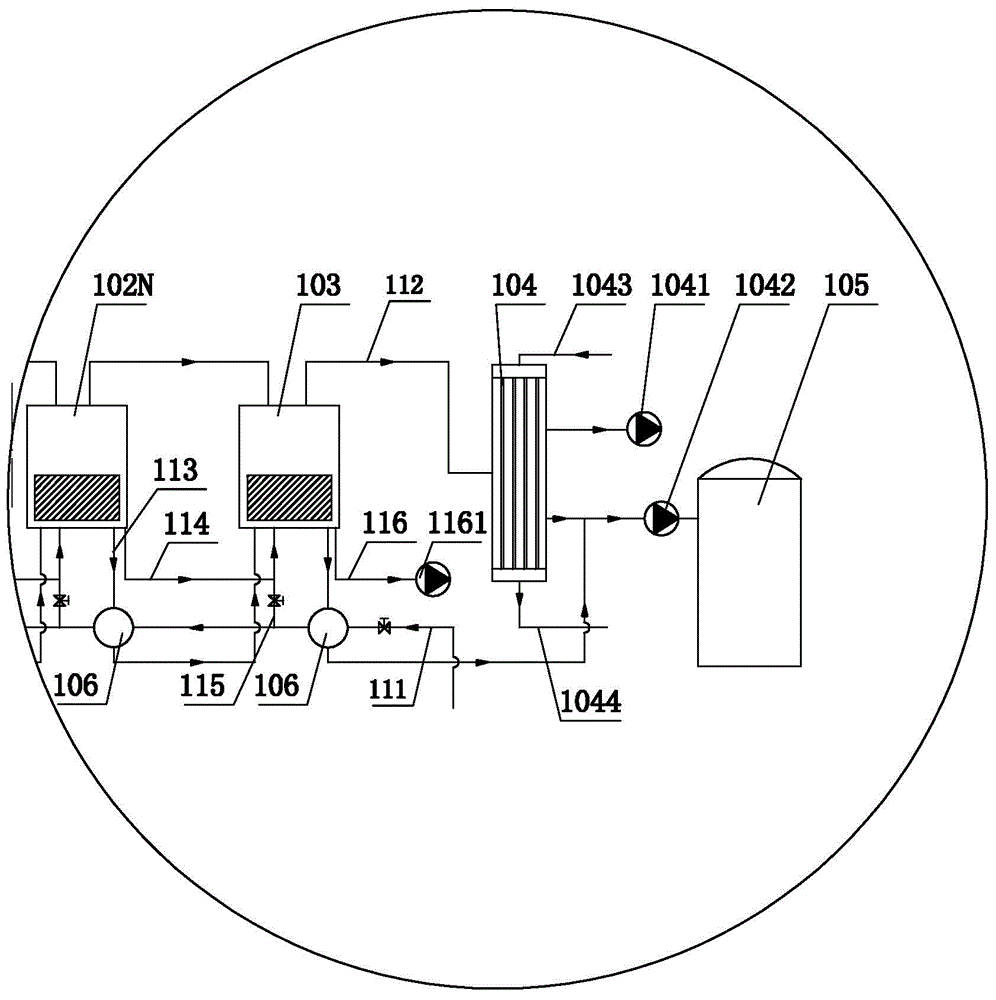

ActiveCN104402079ALower discharge temperatureEmission reductionGeneral water supply conservationSeawater treatmentResource utilizationEngineering

The invention discloses an industrial waste heat type low-temperature multi-effect sea water desaltation system and a sea water desaltation method. The system comprises a flue gas waste heat recovery device used for preparing heat source steam and preheating seawater and a low-temperature multi-effect sea water desaltation device which utilizes the heat source steam to realize sea water desaltation treatment; the low-temperature multi-effect sea water desaltation device comprises a first-effect evaporator, a plurality of intermediate-effect evaporator, a final-effect evaporator and a condenser; the condenser is connected with a vacuum-pumping device; the first-effect evaporator is connected with a feeding seawater pipe on which a plurality of preheaters are serially arranged; a fresh water pipe between every two adjacent evaporators penetrates the preheaters. According to the invention, in-order water supply is adopted, so that the scaling and corrosion problems are solved, equipment cleaning and maintenance are reduced, and therefore the sea water desaltation cost is low; the low-temperature multi-effect sea water desaltation device is combined with exhaust heat utilization, so that comprehensive resource utilization is realized, the flue gas discharge temperature is lowered, the desulphurization efficiency is favorably improved and emission of pollutants is reduced.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

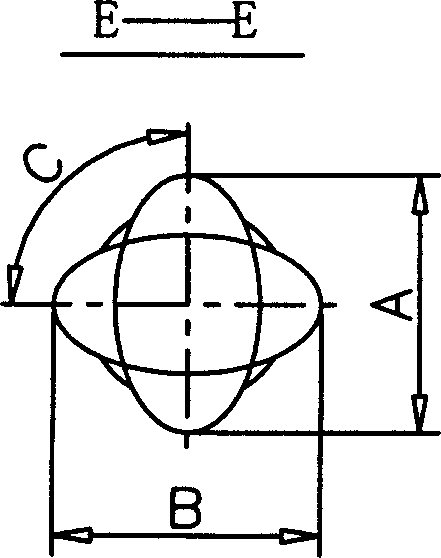

Tubulation and/or sepcial-section tubulation reforced heat exchange tube

InactiveCN1455220AGood heat exchange enhancement effectSmall flow resistanceTubular elementsEllipseEngineering

Owner:TSINGHUA UNIV

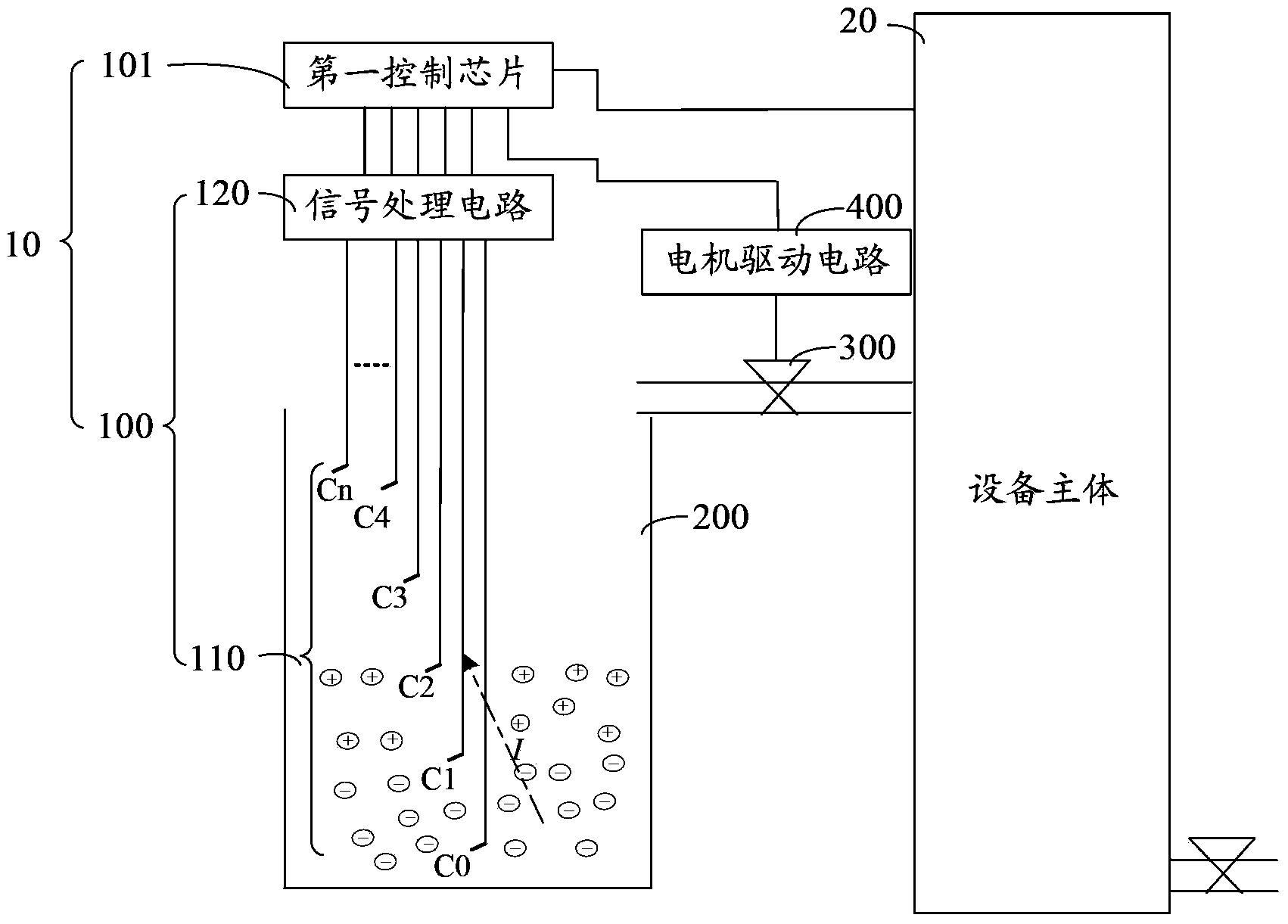

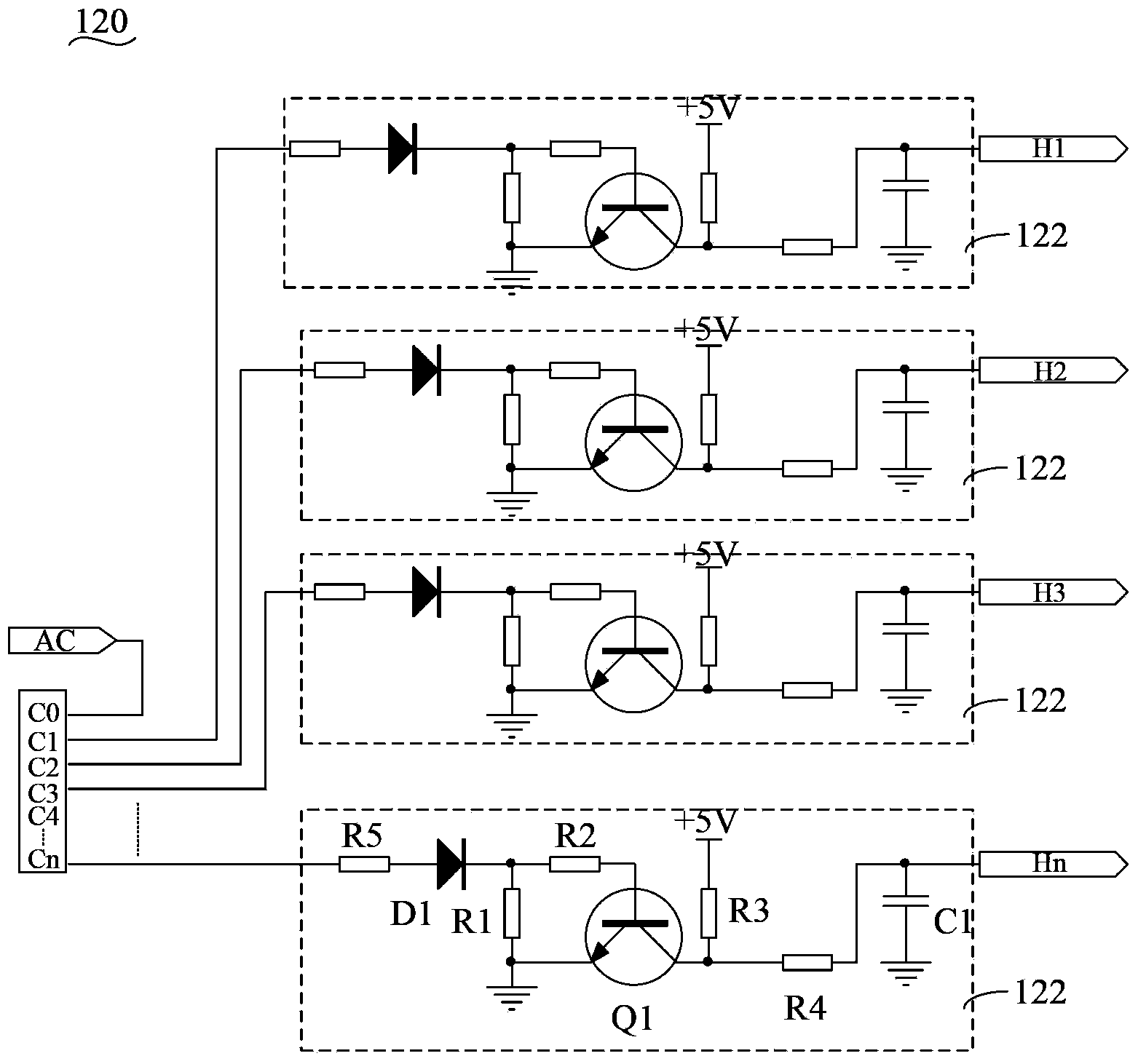

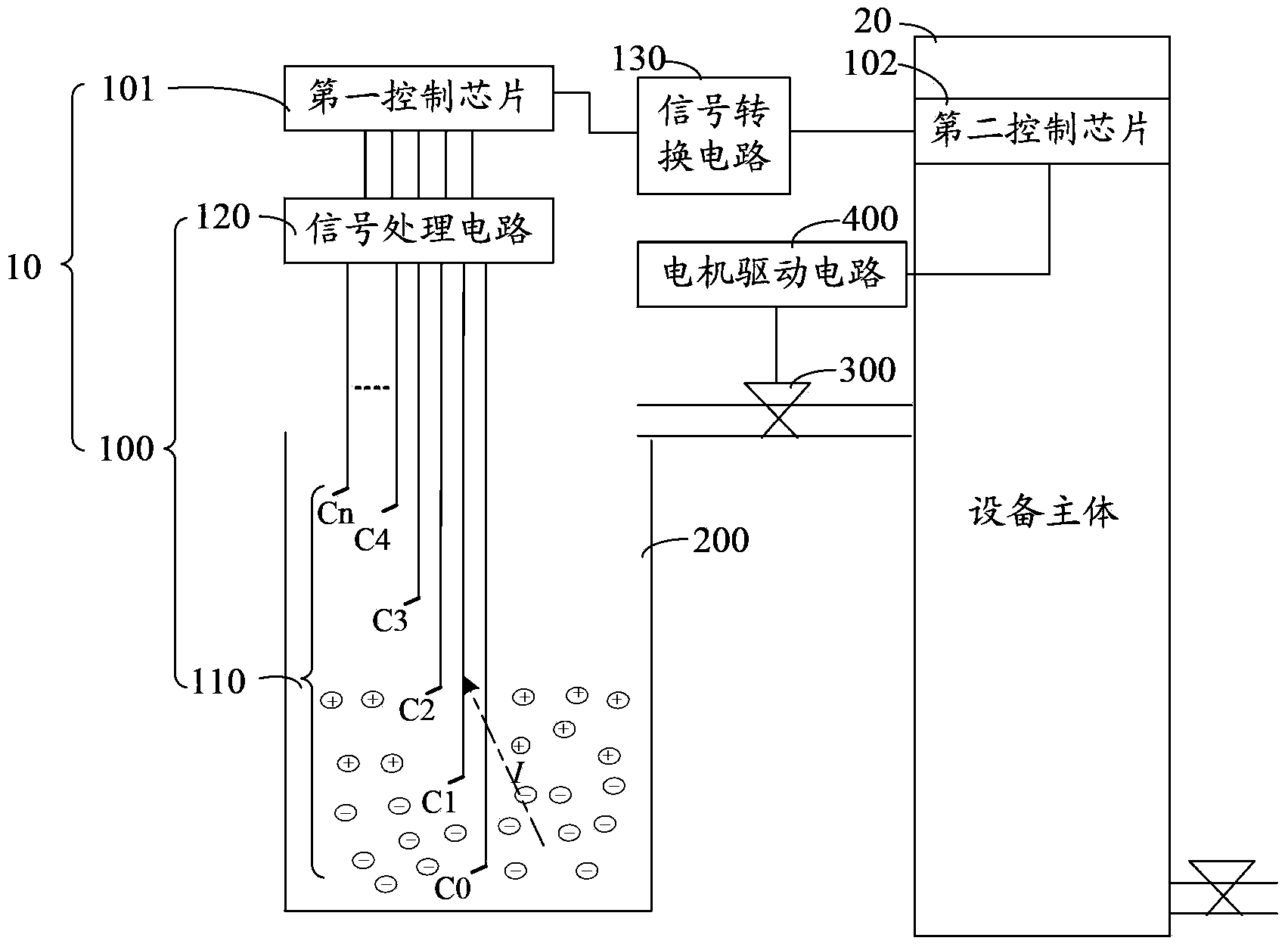

Liquid level detecting circuit, controller and water heater

InactiveCN104215296AAvoid detecting unusual conditionsAccurate outputFluid heatersLevel indicators by physical variable measurementAutomatic controlCorrosion

The invention applies to automatic control over air conditioners and provides a liquid level detection circuit used for detecting the liquid level in a liquid container and outputting detected liquid level signals to a corresponding control device for controlling water pouring or discharging. The liquid level detection circuit comprises a detection electrode and a signal processing circuit. The detection electrode comprises a common terminal arranged on the bottom of the liquid container and a plurality of detection terminals arranged from the bottom to the top of the liquid container, and safe ultra-low alternating current voltage is connected into the common terminal. The signal processing circuit is connected with the detection terminals and comprises a plurality of output terminals corresponding to the detection terminals, and the signal processing circuit is used for outputting detection waveforms serving as liquid level signals at the corresponding output terminal after receiving the information that detection signals are available at the corresponding detection terminal. Due to the fact that the safe ultra-low alternating current voltage is connected into the detection electrode, the detection electrode is not prone to electrolysis, corrosion and scales, and liquid level error judgment and control failures caused by influences of impurities in a water tank can be avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Oxygen-resistant geothermal pipe with high thermal conducting function and scale preventing function

ActiveCN106633302AReduce dosageImprove thermal conductivityNon-macromolecular adhesive additivesLighting and heating apparatusHot meltFluoropolymer

The invention provides an oxygen-resistant geothermal pipe with a high thermal conducting function and a scale preventing function. The oxygen-resistant geothermal pipe comprises an inner layer, an outer layer, a bonding glue layer and an oxygen-resistant layer, wherein the inner layer comprises, by weight, 0-1 part of modified oxidized graphene, 5-10 parts of fluoropolymers and 100 parts of polymer matrixes, the outer layer comprises, by weight, 1-10 parts of the modified oxidized graphene and 100 parts of the polymer matrixes, and the bonding glue layer comprises, by weight, 0.5-0.8 part of modified oxidized graphene and 100 parts of hot-melt glue. The oxygen-resistant geothermal pipe with the high thermal conducting function and the scale preventing function have the advantages that a thermal conducting coefficient is increased largely, thermostability of the bonding glue layer is enhanced, and by means of adding the fluoropolymers in the inner layer, the inner wall of the pipe is enabled to be smooth and less prone to scaling.

Owner:TIANJIN ZHONGCAI PROFILES

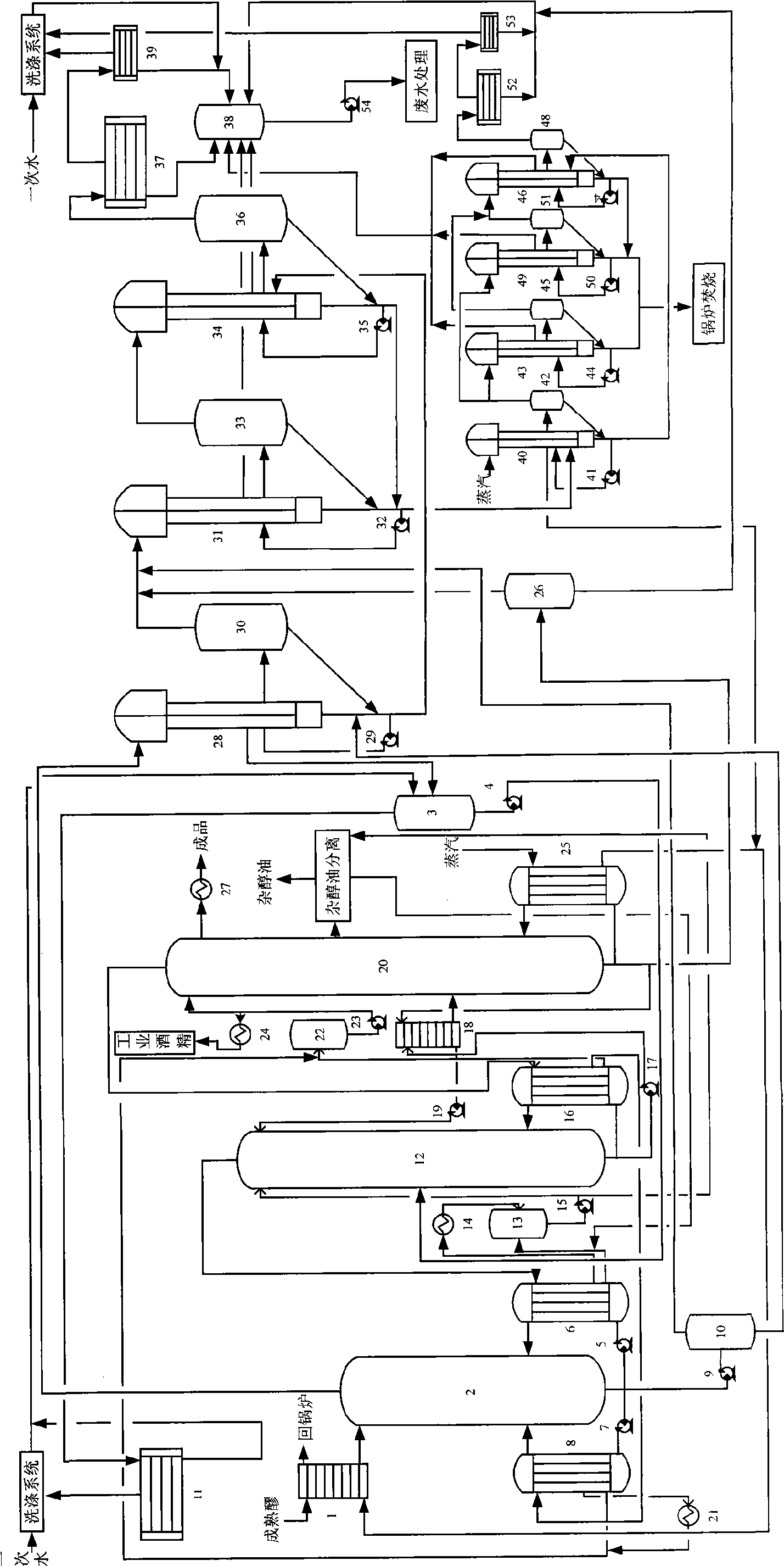

Thermal coupling apparatus and process for alcohol differential pressure distillation and waste liquor concentrate of molasses raw material

ActiveCN101475899AIncrease concentrationReduce concentrationAlcoholic beverage preparationLiquid wasteDifferential pressure

The invention discloses an alcohol differential pressure distillation and waste solution concentration thermal-coupling device and technology thereof for syrup raw materials. The device comprises a set of differential pressure distillation device which is provided with a coarse distillation tower, a washing tower and a rectification tower, and a two-stage multi-effect vacuum evaporation and concentration device. The technology comprises: fermenting mash from the fermentation procedure is subjected to differential pressure distillatory refining of the coarse distillation tower, the washing tower and the rectification tower, and common edible alcohol can be obtained; a waste solution is subjected to two-stage multi-effect vacuum evaporation and concentration in turn; and wine vapor on the top of the coarse distillation tower is introduced into a first stage of the multi-effect vacuum evaporation and concentration device and taken as a heat source for evaporation. The device adopts the differential pressure thermal-coupling technology to realize mutual matching and utilization of energy in the evaporation procedure and the waste solution evaporation and concentration procedure so as to reduce the total vapor consumption of distillation during production of the common edible alcohol through the syrup raw materials, and concentration treatment of the waste solution to be between 3.0 and 3.6 tons per ton of finished alcohol, and saves approximately 30 to 40 percent of vapor, and approximately 25 tons of cooling water consumption per ton of the finished alcohol; and two-stage multi-effect vacuum evaporation and concentration can prolong the fouling period of the device which is then easy to overhaul.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Composite forward osmosis membrane and preparation method thereof

The present invention relates to a composite forward osmosis membrane and a preparation method thereof. The composite forward osmosis membrane comprises an ion exchange resin doped polymer support layer and a polyamide active layer compounded on the polymer support layer surface, wherein a mass ratio of the ion exchange resin to the polymer in the polymer support layer is (0.1-25):(5-40). The preparation method comprises: doping ion exchange resin micro-particles in a polymer solution, preparing a composite forward osmosis membrane support layer containing the ion exchange resin by using a non-solvent induction phase separation method, and compounding an active layer adopting polyamine and poly acyl chloride on the surface of the composite forward osmosis membrane support layer containing the ion exchange resin by using an interfacial polymerization method so as to prepare the composite forward osmosis membrane, wherein the prepared composite forward osmosis membrane can be adopted as the osmosis membrane for seawater desalination and other processes. Compared with the method in the prior art, the method of the present invention has advantages of economy, high efficiency, high water flux, high salt trapping rate, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of olefin-olefin alcohol copolymer

The invention discloses a preparation method of an olefin-olefin alcohol copolymer. The method comprises: in the presence of an alkane solvent, carrying out a contact reaction on olefin, olefin alcohol represented by a formula I, a catalyst and an optional chain transfer agent to generate the olefin-olefin alcohol copolymer, wherein in the formula I, L1-L3 are respectively and independently selected from H and C1-C30 alkyl, L4 is C1-C30 alkylene with a side group, and the C1-C30 alkyl is optionally substituted by a substituent. The prepared copolymer is good in form and has a good prospect inindustrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

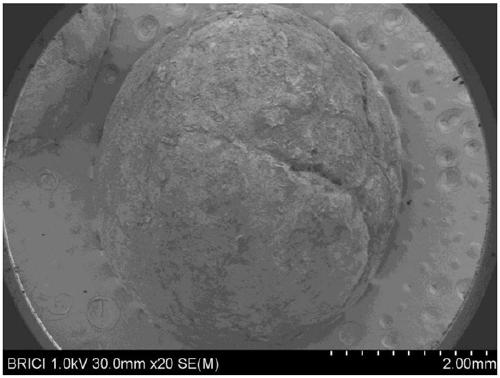

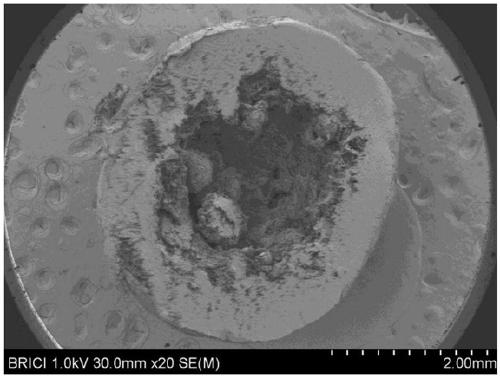

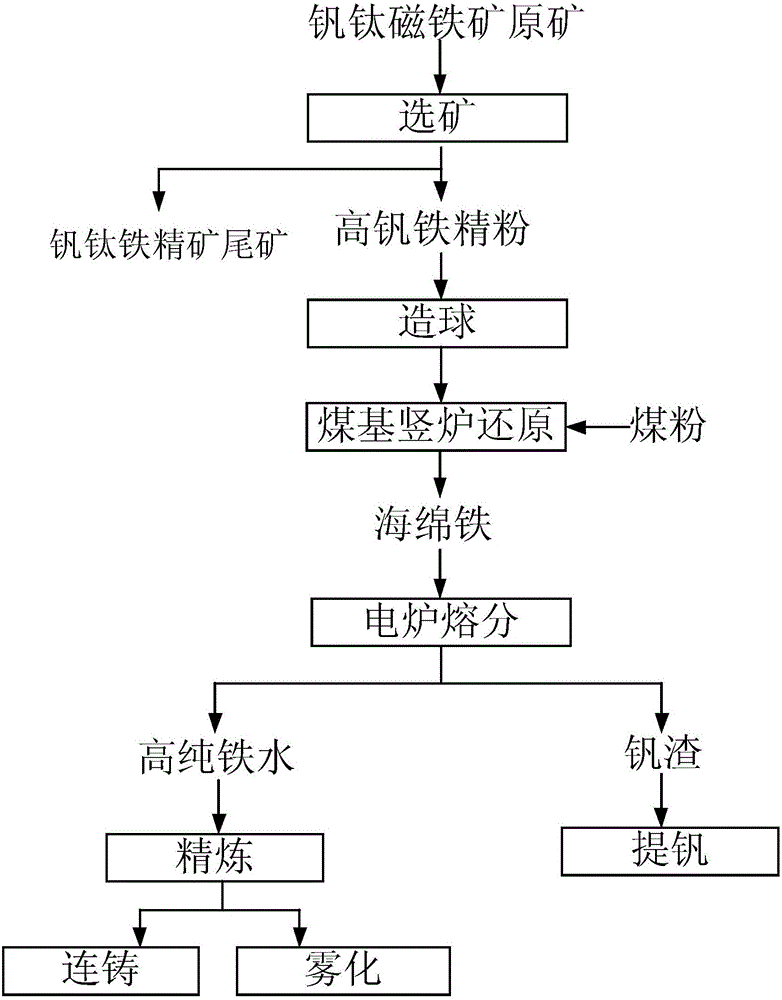

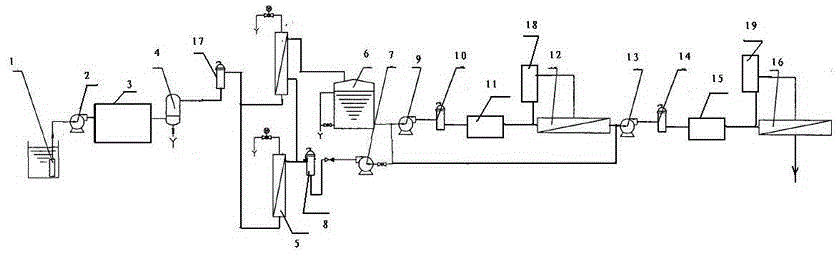

Process for comprehensively utilizing vanadium-titanium magnetite

The invention relates to a process for treating and comprehensively utilizing a vanadium-titanium magnetite. The process is characterized by comprising the following steps: (1) treating a raw vanadium-titanium magnetite by crushing, tailings discarding, fine grinding, low-intensity magnetic separating, high-intensity magnetic separating, and separating by a shaking table, so as to obtain a titanium concentrate and a high-vanadium-ferrum concentrate; (2) adding an adhesive to the high-vanadium-ferrum concentrate; uniformly mixing and pelletizing; drying; uniformly mixing with pulverized coal or coke powder; distributing; performing controlled reduction that V is not reduced through a coal based shaft furnace so as to obtain sponge iron, wherein the amount of used reducing agents such as the pulverized coal is 30 to 70% of the weight of high-vanadium-ferrum concentrate powder, and the reduction is performed for 10 to 18 hours at the temperature of 850 to 1060 DEG C; (3) heating the obtained sponge iron for 0.5 to 1.0 hour at the temperature less than 1050 DEG C through an intermediate frequency / main frequency furnace under a weak reduction atmosphere; then heating until the temperature is more than 1500 DEG C; performing melt separation to enable vanadium to enter slag, thus obtaining high-grade vanadium slag and high-purity molten iron. With the adoption of the process, a plurality of valuable elements in the vanadium-titanium magnetite can be effectively separated and utilized with high additional value.

Owner:WUHAN COSRED SCI & TECH LTD

Water processing method and device thereof of seawater desalination system

ActiveCN103601310ANot easy to scaleReduce the burden onGeneral water supply conservationSeawater treatmentEnergy recoverySodium bisulfite

The invention relates to a water processing method and a device thereof, and especially relates to a water processing method and a device thereof of a seawater desalination system. The method comprises the following steps: adding an alkaline agent into seawater to carry out a preset coagulating and clarifying treatment, then pumping the seawater into a cleaning and washing device through a raw water pump; carrying out a pretreatment for the produced water by adopting an external pressure type ultrafiltration membrane component; adding sodium hypochlorite during the ultrafiltration process and / or the backwashing process; pumping the produced water, which has been subjected to the ultrafiltration process, to orderly go through a safeguard filter, a primary high-pressure pump, a scale inhibitor feeding device, and a primary reverse osmosis device, wherein a scale inhibitor is added into the water in the primary reverse osmosis device to carry out a primary reverse osmosis treatment, and acid and sodium bisulfite are added at the same time in order to protect the reverse osmosis membrane; adjusting the pH value of the primary reverse osmosis produced water, making the produced water orderly go through a secondary safeguard filter, a secondary high-pressure pump, and a secondary reverse osmosis device to carry out a secondary reverse osmosis treatment, subjecting the reverse osmosis condensed water to an energy recovery treatment; and finally subjecting the secondary reverse osmosis produced water to subsequent treatments. The reverse osmosis membrane provided by the invention has the advantages of difficulty in scaling and high seawater desalination recovery rate.

Owner:ZHEJIANG THINK ENERGY TECH

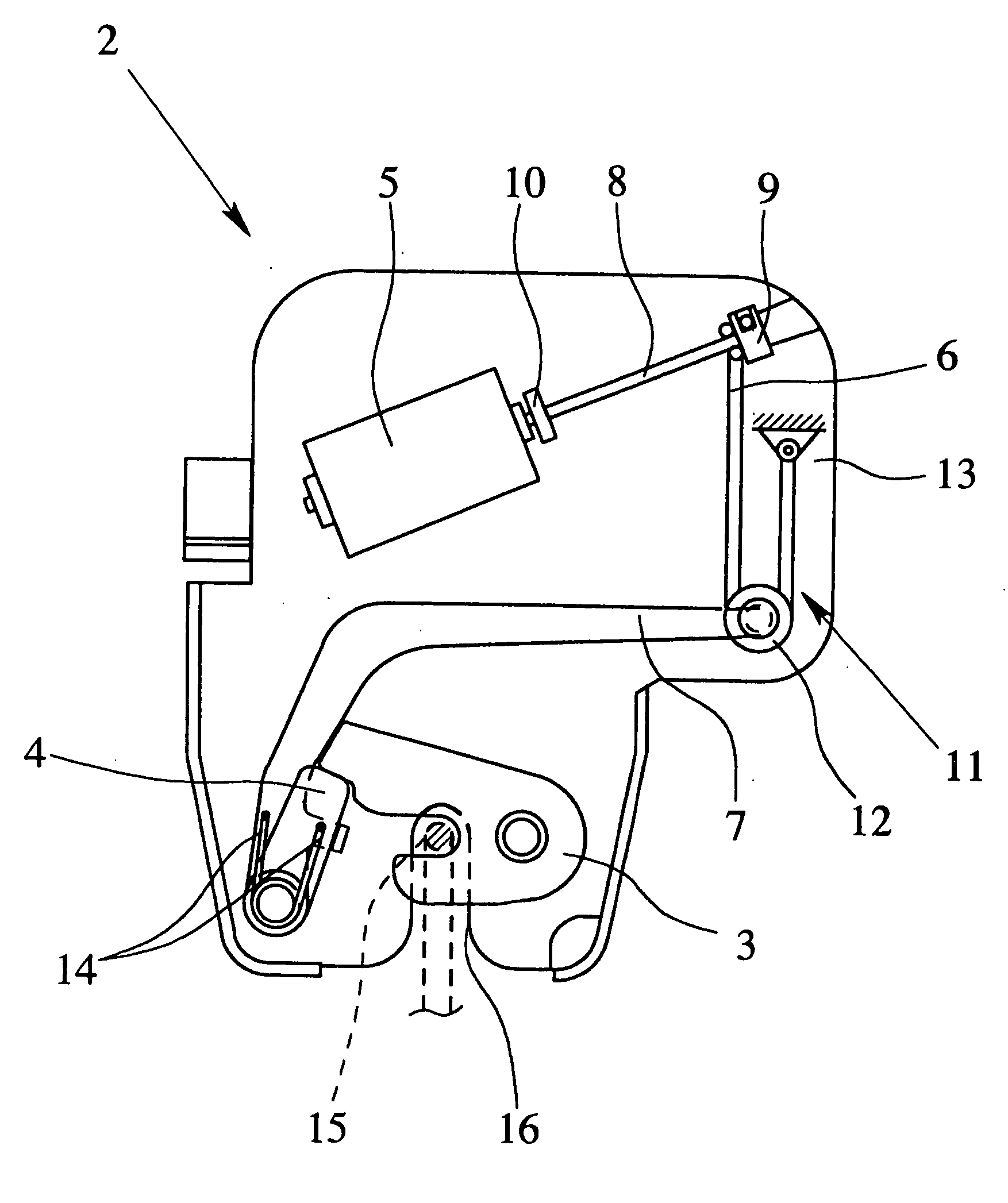

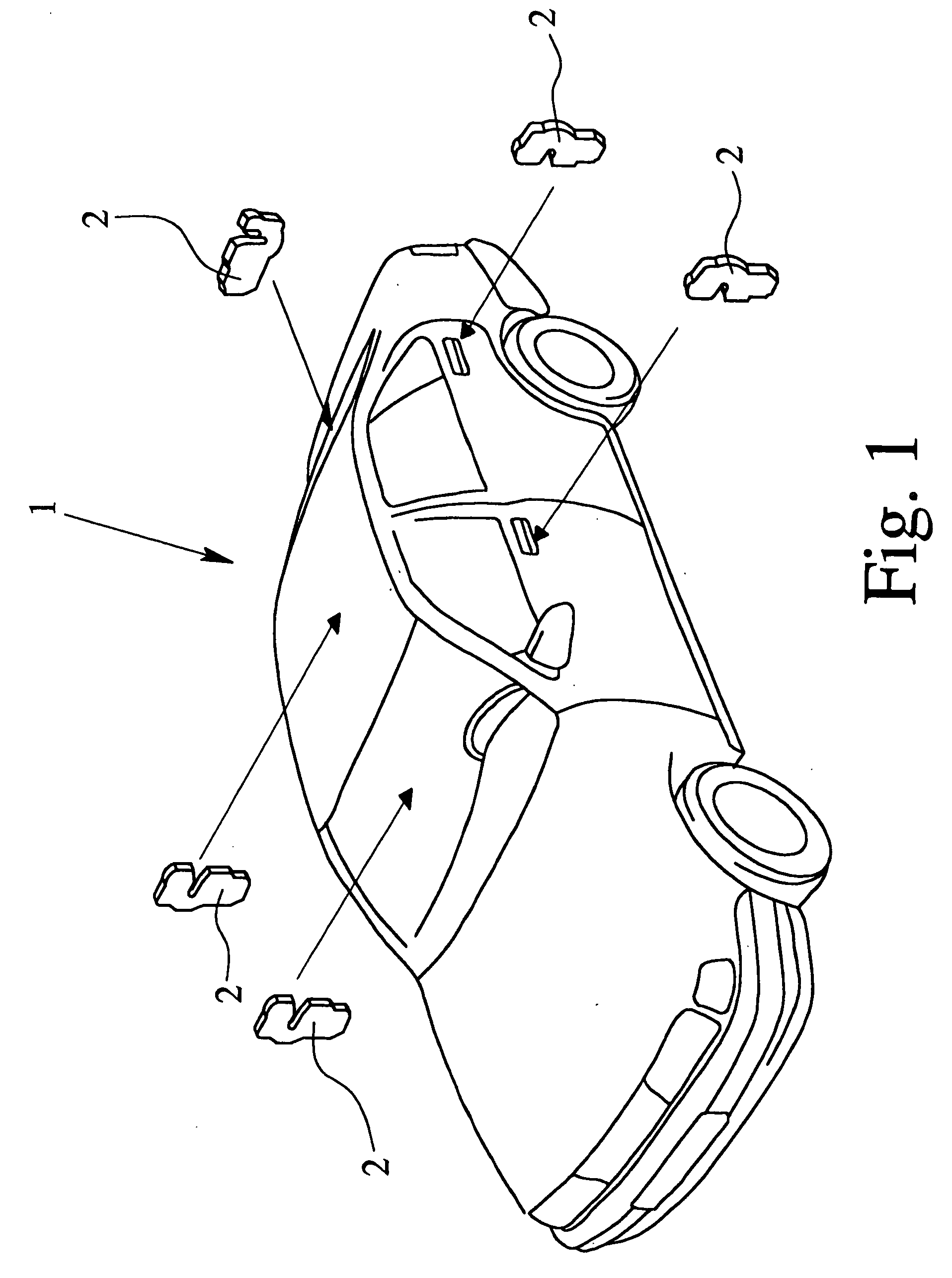

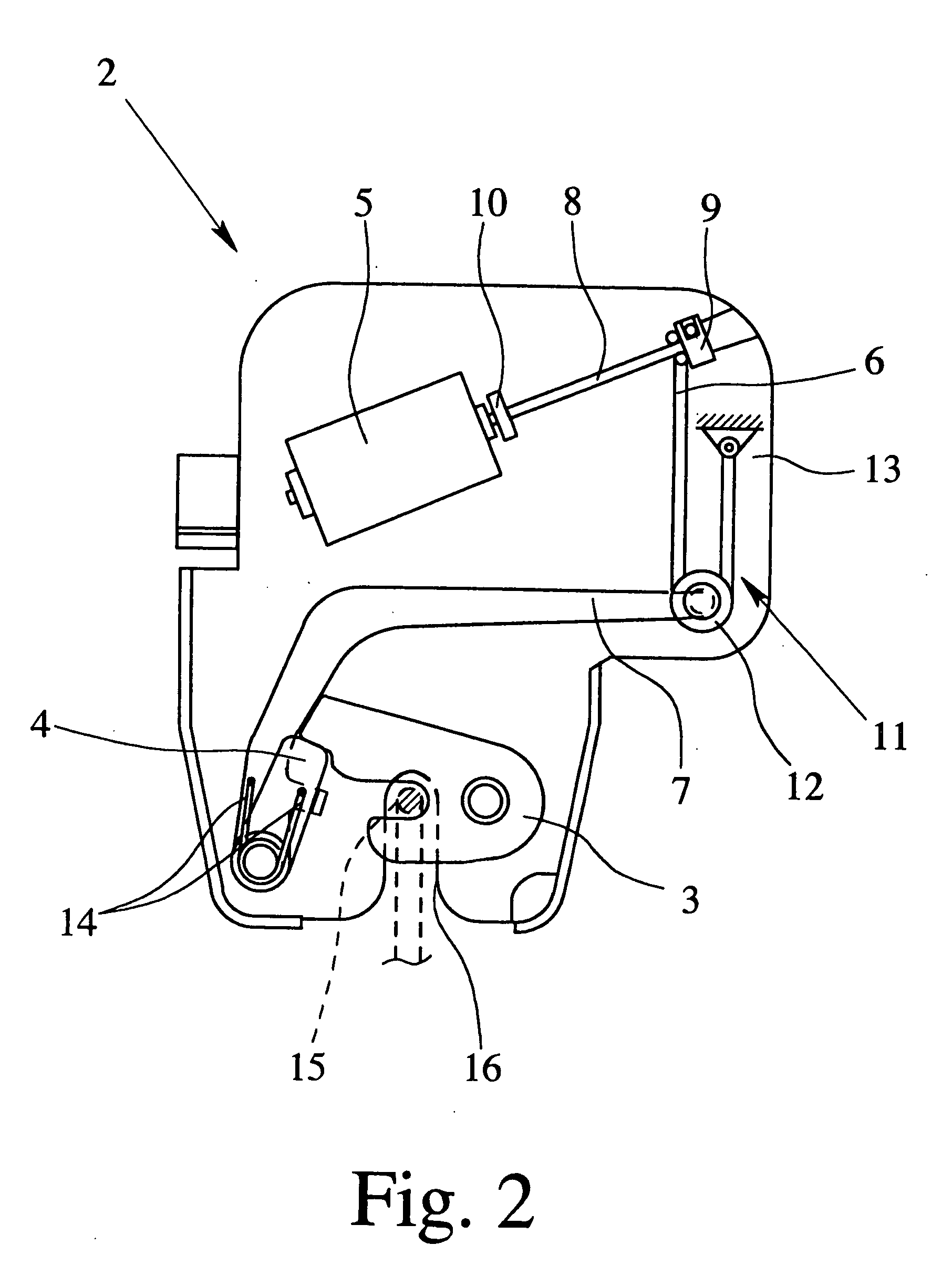

Motor vehicle lock

ActiveUS20050134054A1Low self-lockingSimple triggerNon-mechanical controlsConstruction fastening devicesSpring forceControl theory

A motor vehicle lock with a latch and an associated ratchet and a motor for opening the ratchet. The motor vehicle lock has a flexible traction means which directly or indirectly connects the motor to the ratchet and which is wound up by the motor for opening the ratchet and which can be unwound by spring force when the motor is turned off.

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com