Oxygen-resistant geothermal pipe with high thermal conducting function and scale preventing function

A floor heating pipe and functional technology, applied in hot water central heating systems, heating methods, tubular objects, etc., can solve the problems of low heat conduction efficiency, roughness, and non-high temperature resistant pipe inner wall surface of oxygen barrier pipes, etc., and achieve thermal conductivity The effect of improving, not easy to scale, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

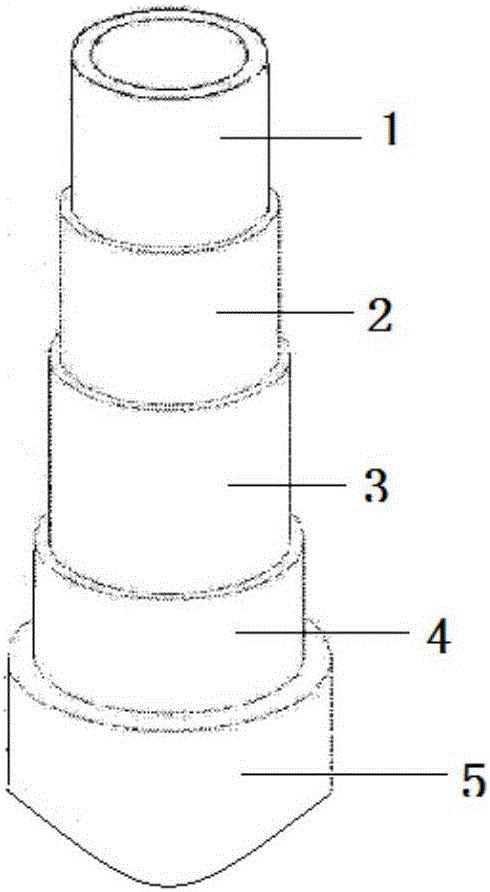

[0023] The inner layer 1, the outer layer 5, the first adhesive layer 2 and the second adhesive layer 4 of the five-layer high thermal conductivity and anti-scaling functional oxygen-resistant floor heating pipe all use surface-modified graphene oxide, The graphene oxide is prepared by the following steps: disperse graphene oxide in DMF and ultrasonically disperse for 1 hour to obtain graphene oxide colloid, add organic amine to graphene oxide under mechanical stirring, and react at 90°C for 4 hours , and then washed with deionized water for 2-3 times, dried, ground and sieved to obtain modified graphene oxide.

[0024] Wherein: the inner layer 1 includes the following components by weight: modified graphene oxide: 0.5 parts, ethylene-tetrafluoroethylene copolymer: 5 parts, PERT: 100 parts; the outer layer 5 includes the following parts by weight Components: modified graphene oxide: 1 part, PERT: 100 parts; the first adhesive layer 2 and the second adhesive layer 4 include the...

Embodiment 2

[0028] The preparation of the modified graphene used in this example is the same as that in Example 1.

[0029] Wherein: the inner layer 1 includes the following components by weight: modified graphene oxide: 1 part, ethylene-tetrafluoroethylene copolymer: 10 parts, PERT: 100 parts; the outer layer 5 includes the following parts by weight Components: modified graphene oxide: 5 parts, PERT: 100 parts; the first adhesive layer 2 and the second adhesive layer 4 include the following components in parts by weight: modified graphene oxide : 0.8 parts, hot melt adhesive: 100 parts.

[0030] The oxygen-resistant floor heating pipe adopts a five-layer co-extrusion process to prepare a pipe with a specification of D20S4.0, and its temperature control and speed control are similar to the existing technology.

[0031] The thermal conductivity of the prepared five-layer high thermal conductivity and anti-scaling functional oxygen-resistant floor heating pipe is 0.98 W / m·K, and the inner ...

Embodiment 3

[0033] The inner layer 1, the outer layer 5, the first adhesive layer 2 and the second adhesive layer 4 of the five-layer high thermal conductivity and anti-scaling functional oxygen-resistant floor heating pipe all use surface-modified graphene oxide, The graphene oxide is prepared by the following steps: disperse graphene oxide in absolute ethanol and disperse ultrasonically for 1 hour to obtain graphene oxide colloid, add silane coupling agent KH560 to graphene oxide under mechanical stirring, and heat at 60°C After reacting for 4 hours, wash with deionized water for 2-3 times, dry, grind and sieve to obtain modified graphene oxide.

[0034] Wherein: the inner layer 1 includes the following components by weight: modified graphene oxide: 0.5 parts, ethylene-tetrafluoroethylene copolymer: 5 parts, PERT: 100 parts; the outer layer 5 includes the following parts by weight Components: modified graphene oxide: 1 part, PERT: 100 parts; the first adhesive layer 2 and the second adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com