Patents

Literature

219results about How to "Smooth inner wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

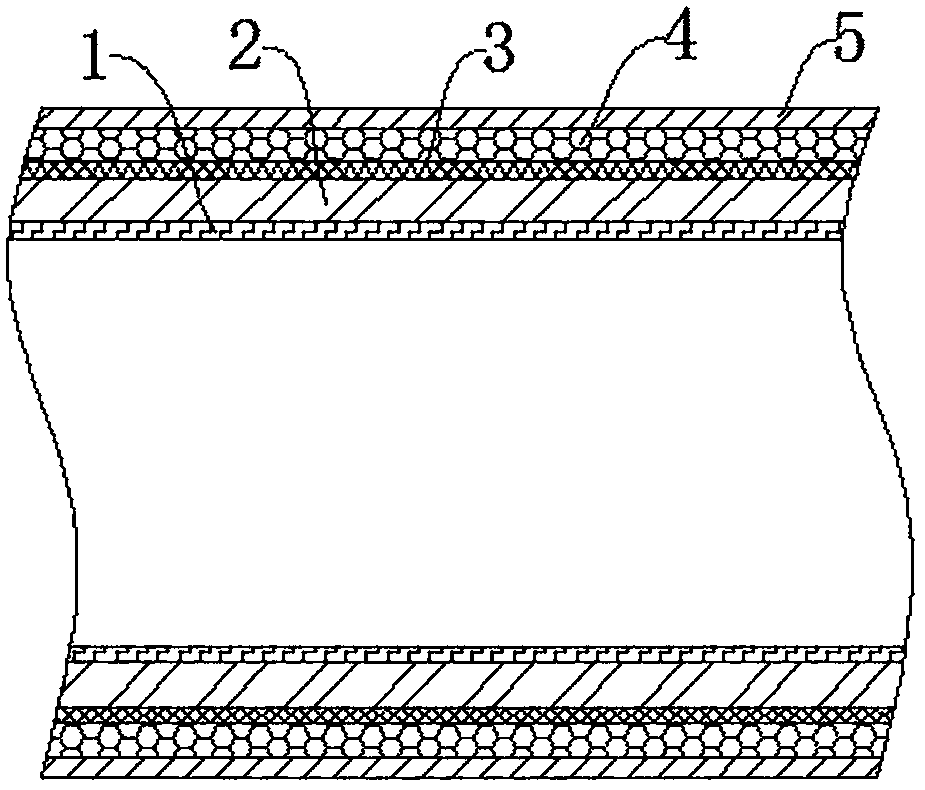

High-strength glass fiber-reinforced plastic pipeline and production method thereof

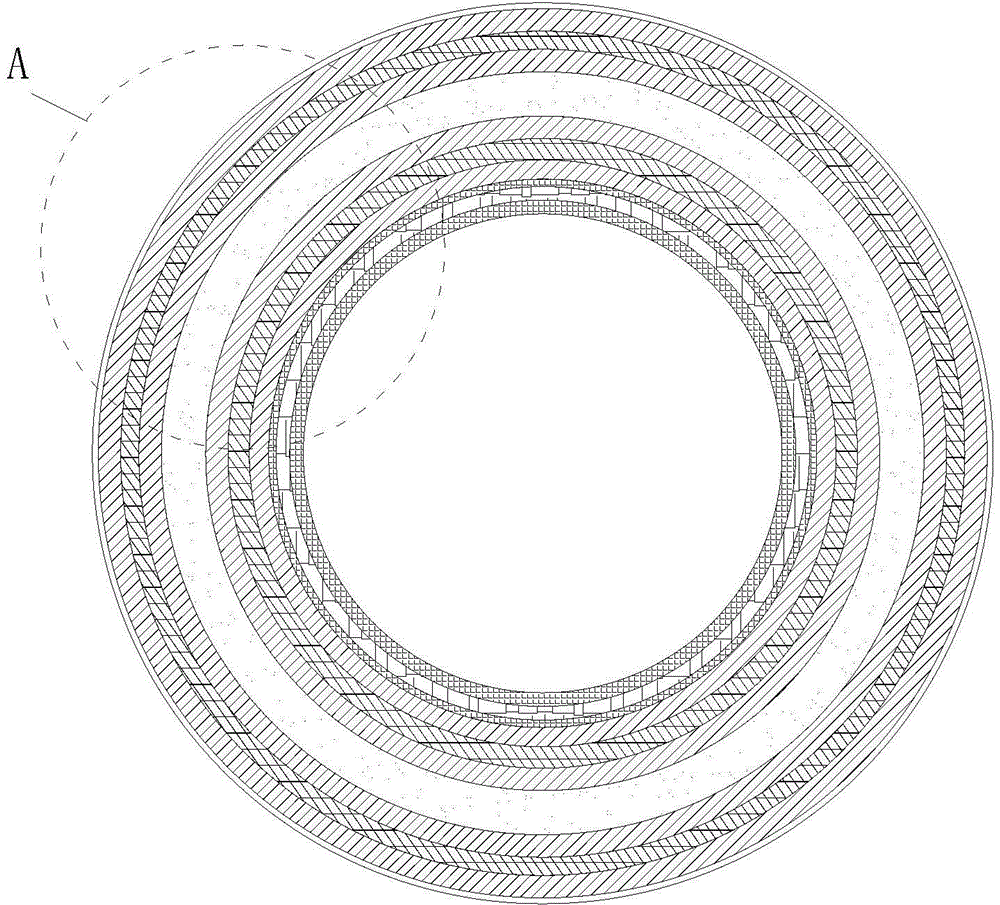

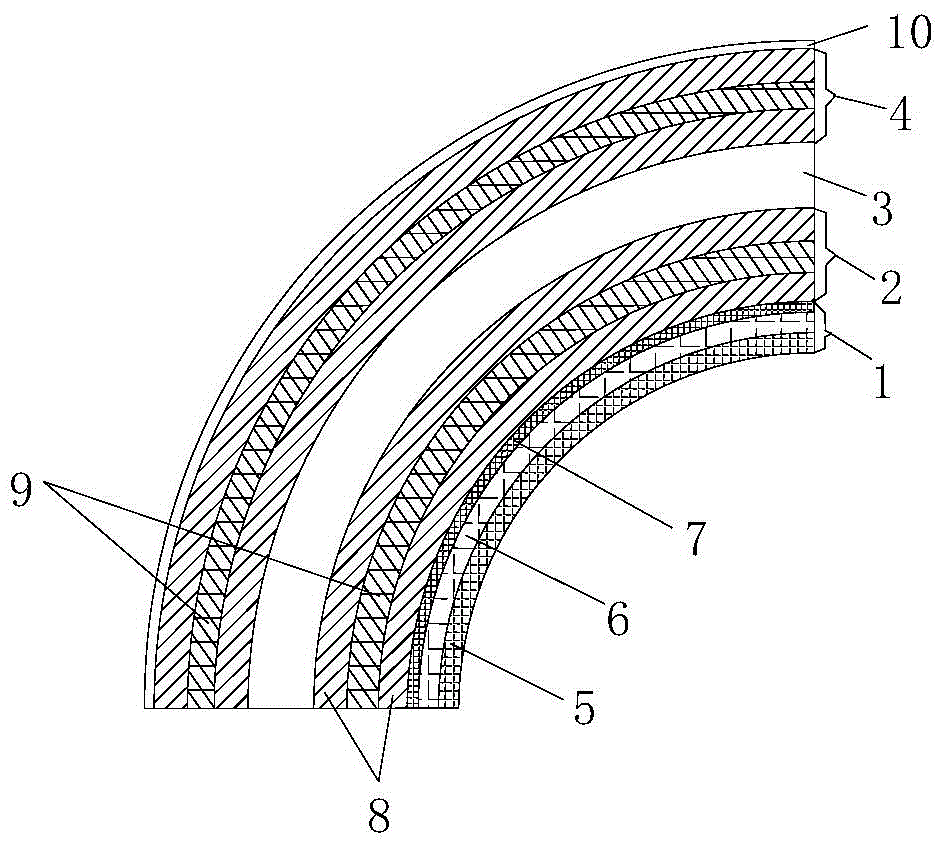

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

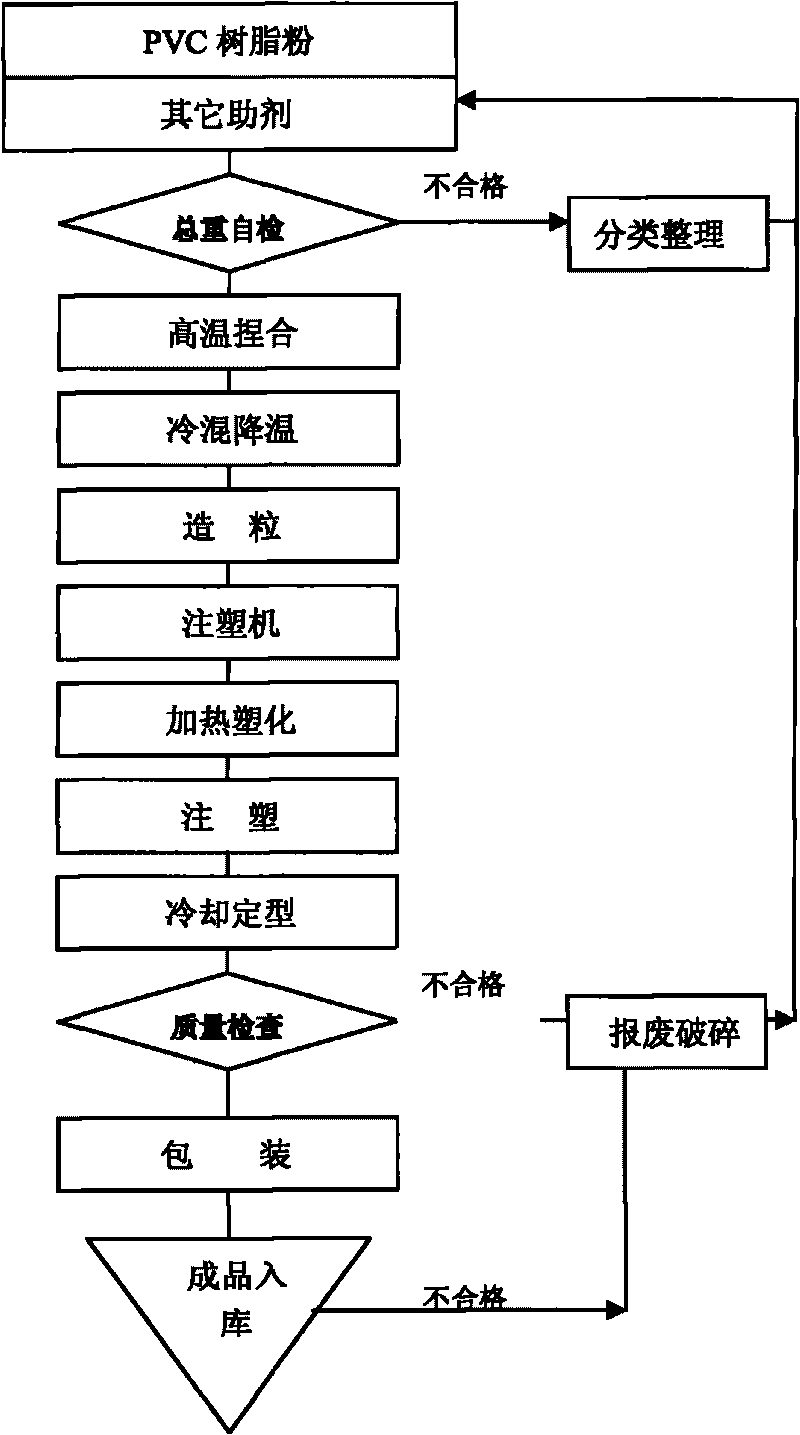

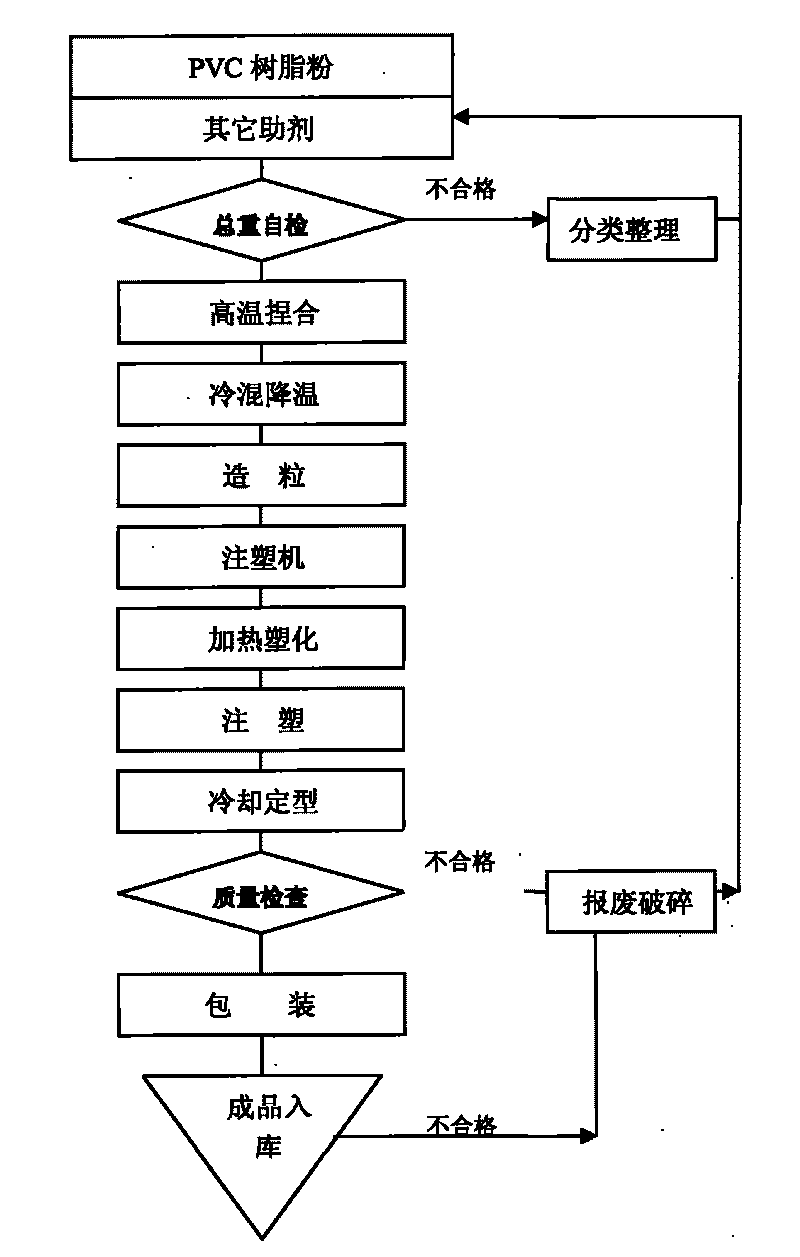

Polyvinyl chloride composition and transparent pipe thereof

The invention discloses a polyvinyl chloride composition and a transparent pipe thereof. The polyvinyl chloride composition consists of the following components in part by weight: 100 parts of PVC resin, 1.0 to 5.0 parts of heat stabilizer, 0.2 to 2 parts of lubricating additive, 1 to 3 parts of processing modification aid, 2 to 5 parts of impact modifier, 0.01 to 0.08 part of decolorizing agent, 0.2 to 0.6 part of age resister and 0 to 10 parts of plasticizer. The polyvinyl chloride composition is subjected to high-speed hot mixing and low-speed cold mixing, and then is extruded to prepare the polyvinyl chloride transparent pipe; and the pipe is homogenous and transparent, has smooth inner wall, is not easy to scale, can be sleeved outside a pipeline for delivering important or dangerous chemicals, has monitoring and protecting functions, has good ageing resistance, and can be used for outdoor occasions. The preparation method for the polyvinyl chloride transparent pipe is simple, convenient and quick, does not require special tools and professional staff, and is favorable for large-scale industrial production.

Owner:GUANGDONG LIANSU TECH INDAL

Glass-lined anti-corrosion steel pipe producing and welding processes

InactiveCN103822031AGood chemical stabilitySmooth inner wallLiquid surface applicatorsArc welding apparatusChemical industryGlass corrosion

The invention relates to a glass-lined anti-corrosion steel pipe producing and welding processes. The producing process includes pre-overlaying a nickel-based corrosion resistant alloy layer from 1.5 to 2 mm in inner holes with depth of 30 to 50 mm to the end face of a steel pipe, allowing the nickel-based corrosion resistant alloy layer to fuse on the base material; beveling the overlaid-preprocessed end face of the steel pipe, and smoothly polishing the surface of the nickel-based overlaying layer; performing rust removal and dust treatment on the inner wall of the steel pipe; coating glass powder on the inner wall of the steel pipe in a hot spraying manner to melt and form an inner glass corrosion resistant layer. By coating the inner glass corrosion resistant layer on the inner wall of a metal pipe in a hot melting manner, a glass and metal composite corrosion resistant structure is formed, chemical stability is high, the inner wall is smooth, and fluid resistance is small; the glass-lined anti-corrosion steel pipe has special advantages of corrosion resistance, waxing resistance, wear resistance, resistance reduction and energy efficiency, and can be widely applied in various fields of petroleum, chemical industry, natural gas, tap water, sewage, municipal construction and the like.

Owner:胜利油田金岛工程安装有限责任公司

Method of cryogenic surface activation direct bonding for preparation of quartz glass capillary tube

InactiveCN105016632ARequirements for lower machining accuracySmooth inner wallPlasma treatmentMicrometer

The present invention discloses a method of cryogenic surface activation direct bonding for preparation of a quartz glass capillary tube. According to the method, a wet chemical method is used to activate a quartz glass surface, and the manner of direct bonding of a stack of multiple layers of glass is applied, so as to prepare the quartz glass capillary tube at a lower temperature with a proper pressure. A steel needle of a specific size is added to a model and used to define a size and location of the capillary tube. The minimum diameter of the capillary tube prepared can reach as small as 200 micrometers ,and the bonding strength can reach 5 MPa. According to the method, the operation of cryogenic surface activation bonding is simple, the requirement on the glass sheet surface roughness is low, and no clean room or expensive ultra-high vacuum plasma treatment device is required. The method overcomes the problems of the pipe collapse, the device superficial devitrification and the inner wall roughness that may be caused by the conventionally prepared capillary tubes. The capillary tube produced has the smooth inner wall, increases the viewable region of the sample in the capillary tube, and dramatically improves chip performance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

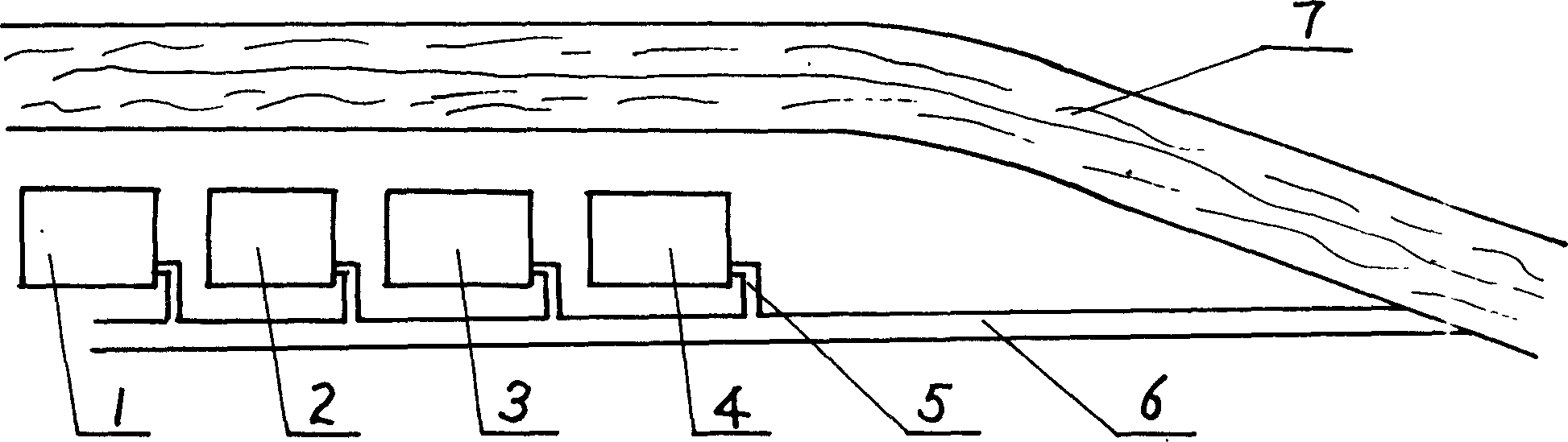

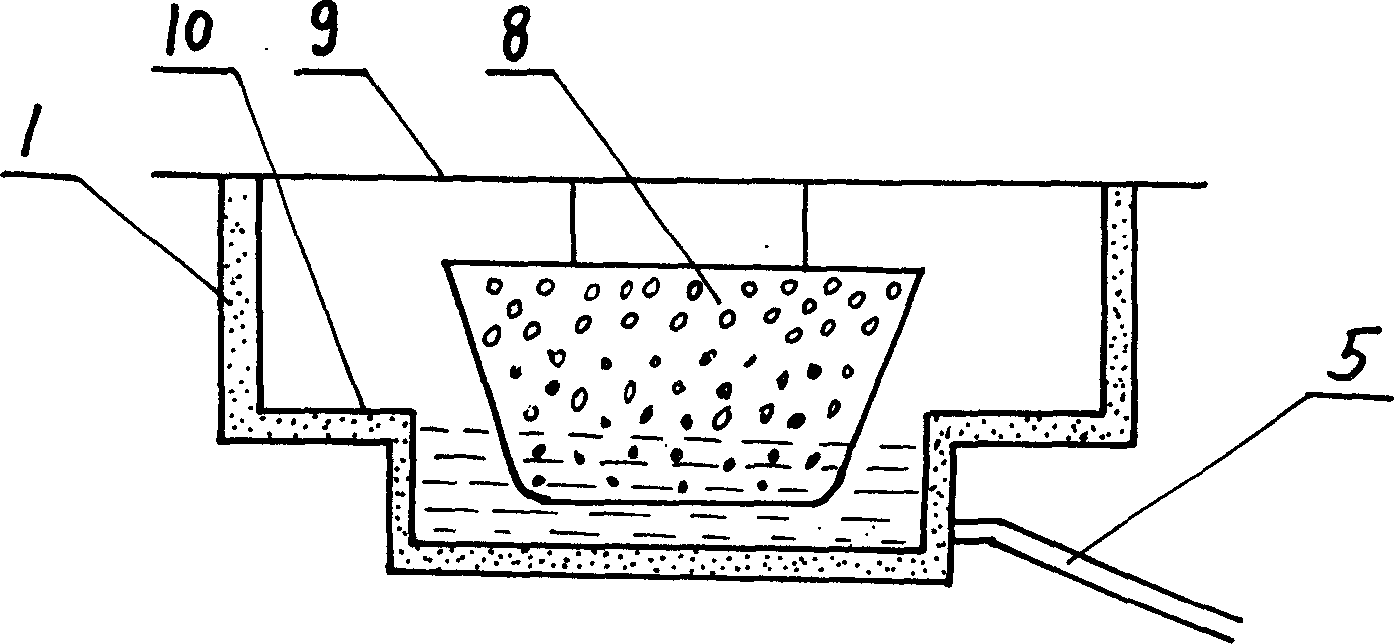

Emulated ecological environment breeding method and device for giant salamander

InactiveCN1788696ASmooth inner wallImprove hatchabilityAnimal reproductionClimate change adaptationEcological environmentWater flow

The present invention relates to giant salamander aquiculture method and apparatus in simulated habitat. Giant salamander is hatched and cultured in a simulated habitat with proper natural geographic condition, overshadowed and water flowing environment established according to the characteristics of giant salamander in different growth stages, including oviposition, hatching, infant giant salamander, adult giant salamander, etc. During oviposition and hatching, spawning inducing medicine and hatching liquid in proper amount are adopted separately. The present invention is favorable to raising the propagation rate of giant salamander and promoting the growth of giant salamander.

Owner:张丙彦

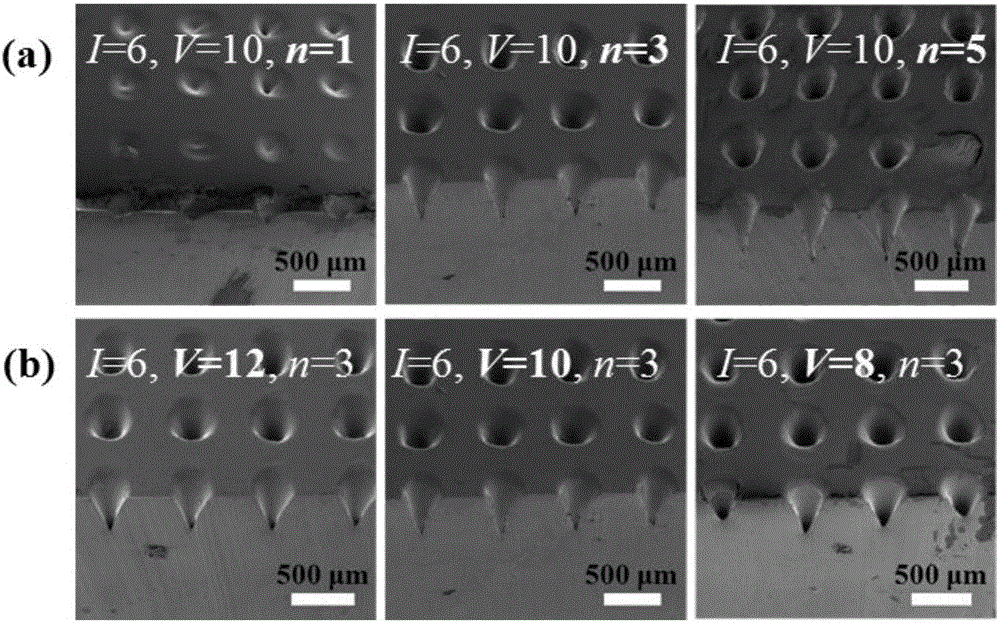

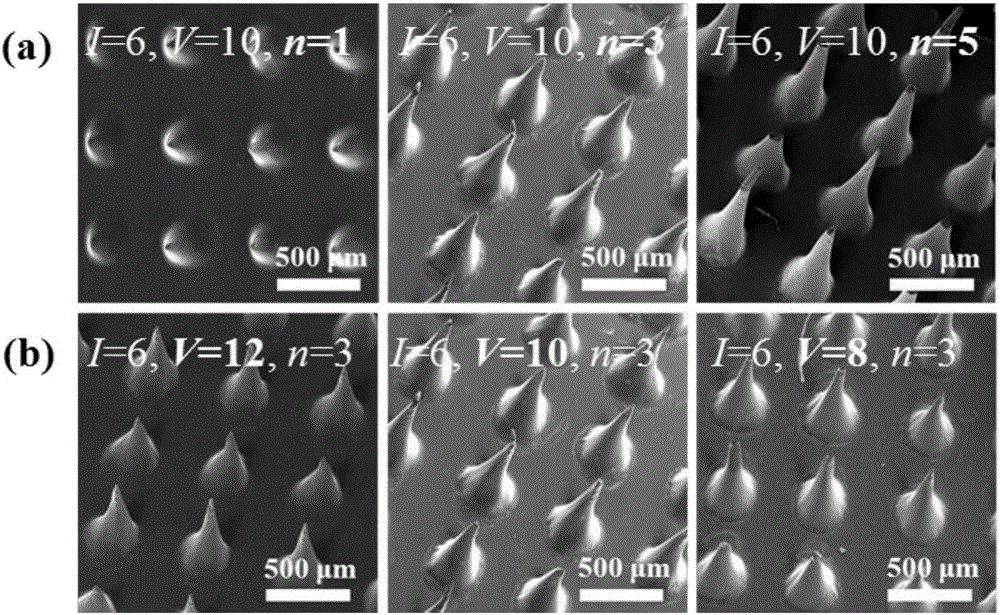

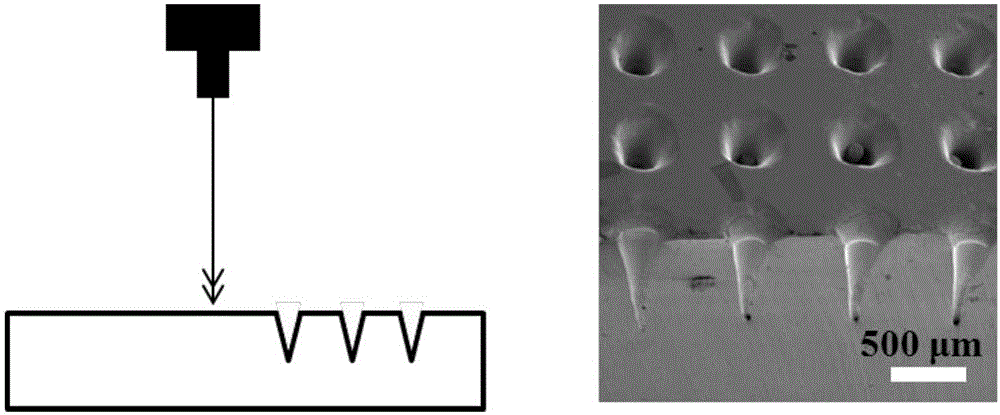

Method for producing micro-needle array templates based on laser etching technology as well as products and application thereof

InactiveCN106511257AImprove skin permeabilityImprove the effect of transdermal treatmentSurgeryPharmaceutical delivery mechanismOptoelectronicsTemplate based

The invention discloses a method for producing micro-needle array templates based on a laser etching technology as well as products and application thereof. The method comprises the following steps: (1) curing and cooling PDMS and a curing agent to obtain a PDMS substrate; (2) designing a laser etching mask plate pattern and enabling the pattern to be a concentric circle array; and (3) placing the PDMS substrate in an engraving area of a laser engraving machine and setting condition parameters of laser processing technology, subsequently carrying out laser treatment on the PDMS substrate with reference to the laser etching mask plate pattern so as to obtain the PDMS substrate etched by laser, wherein the PDMS substrate is the micro-needle array template. According to the method, the key laser etching process conditions are improved, so that the problems that the micro-needle array templates are complex in production process, high in cost and poor in structural design, and large-scale production and application of the micro-needle array templates are difficult can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

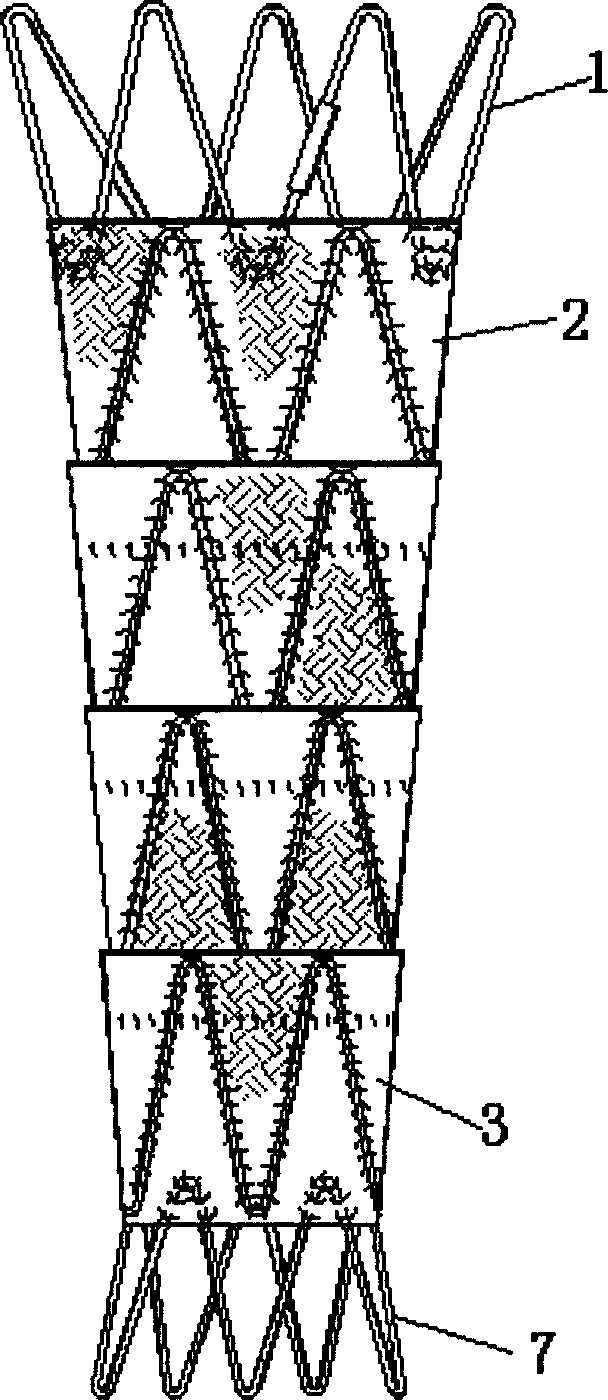

Combined membrane-covered stent capable of being bent in any direction

The invention discloses a composite tectorial support of random orientation bending for intracavity insulating therapy of human pathology vessel, which consists of several intermediate tectorial support units and a tail tectorial support unit, wherein each tectorial support unit contains tubular tectorial unit and support unit fixed on the tectorial unit by suture, wherein the support unit concludes several sealing column structure of alloying filament fabrication. There is an overlapping part between adjacent tectorial support units, which stitches by the suture. The invention overcomes the directional defect of congeneric product with the advantages of the following: steady structure, random orientation bending, smooth inwall and so on, which is applied in the human pathology therapy of artery, vein or other lumen, especially in the pathology therapy of aorta-vessel.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

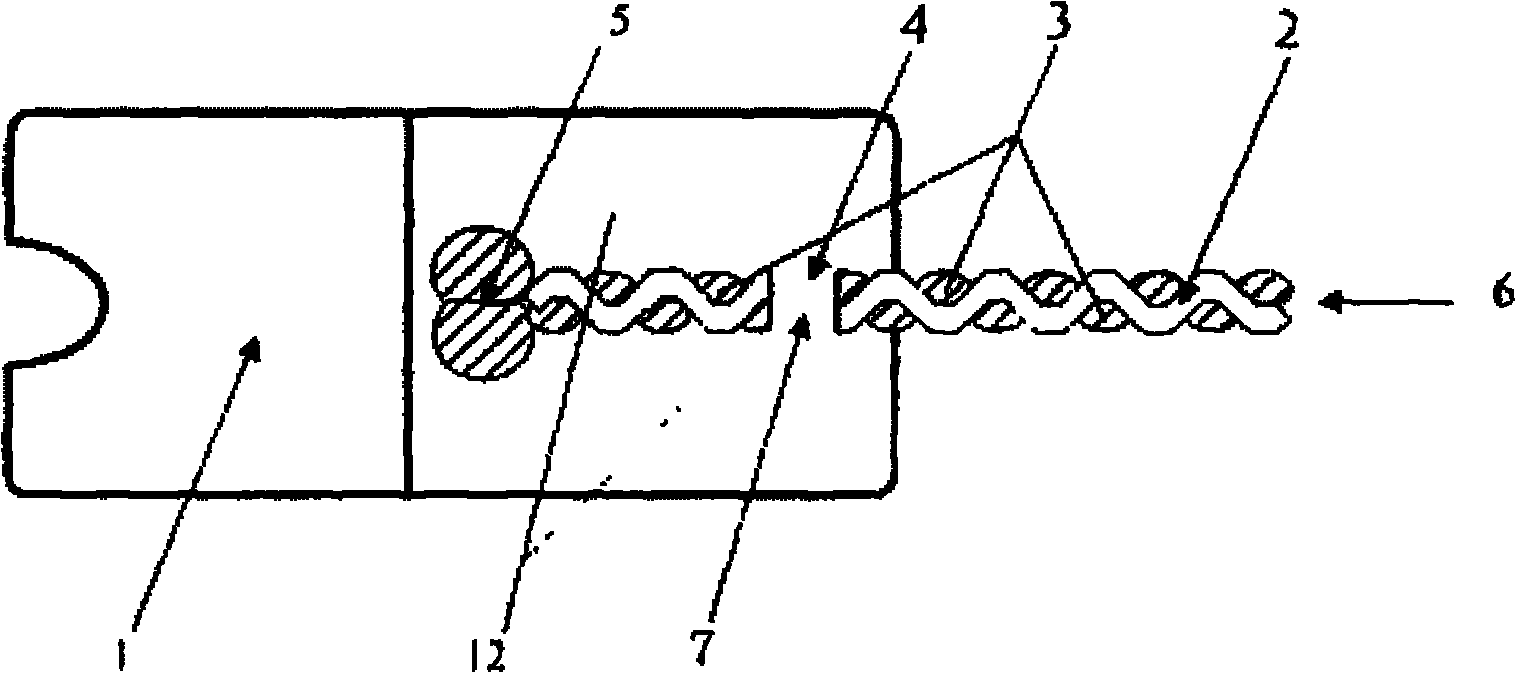

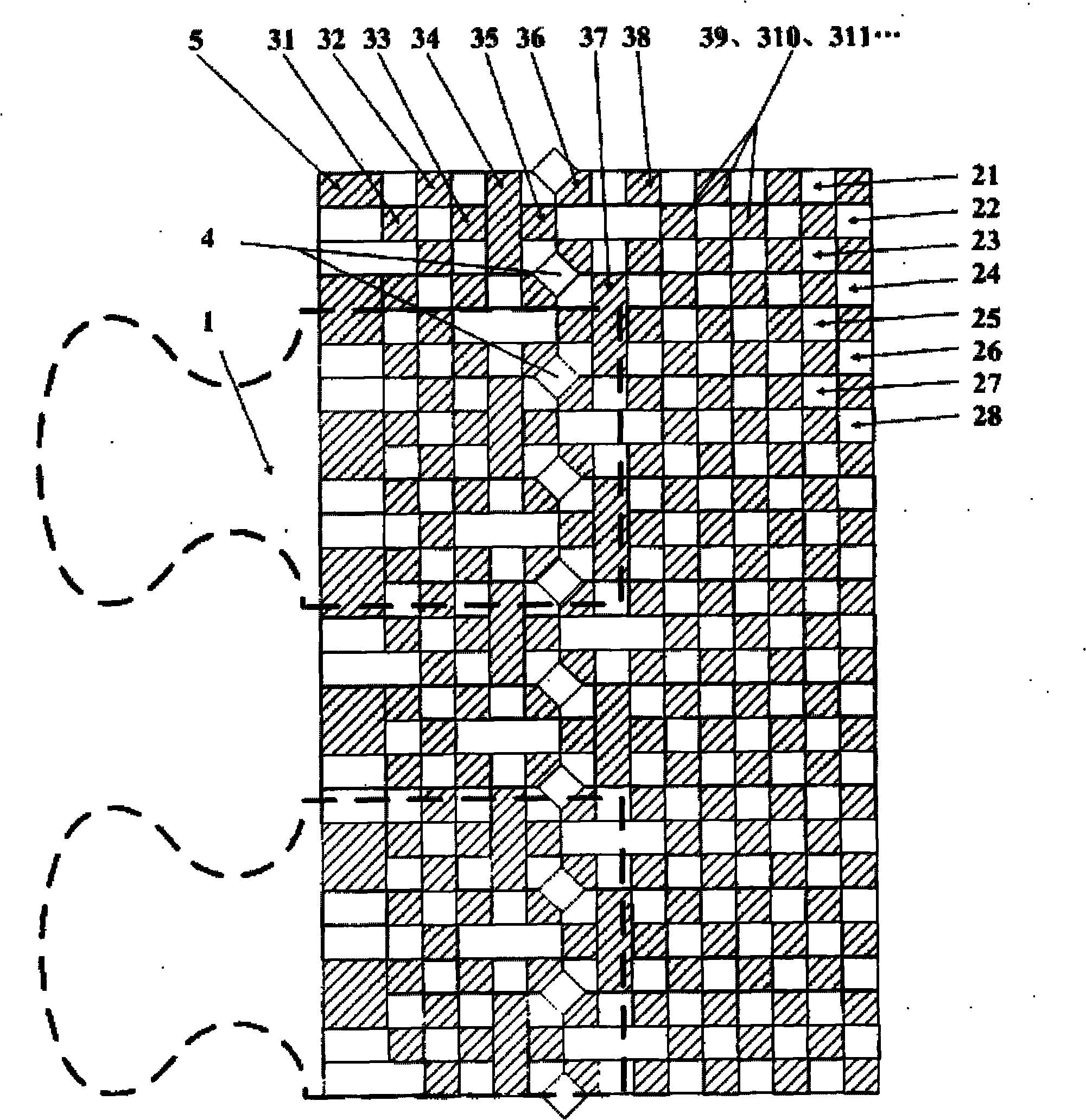

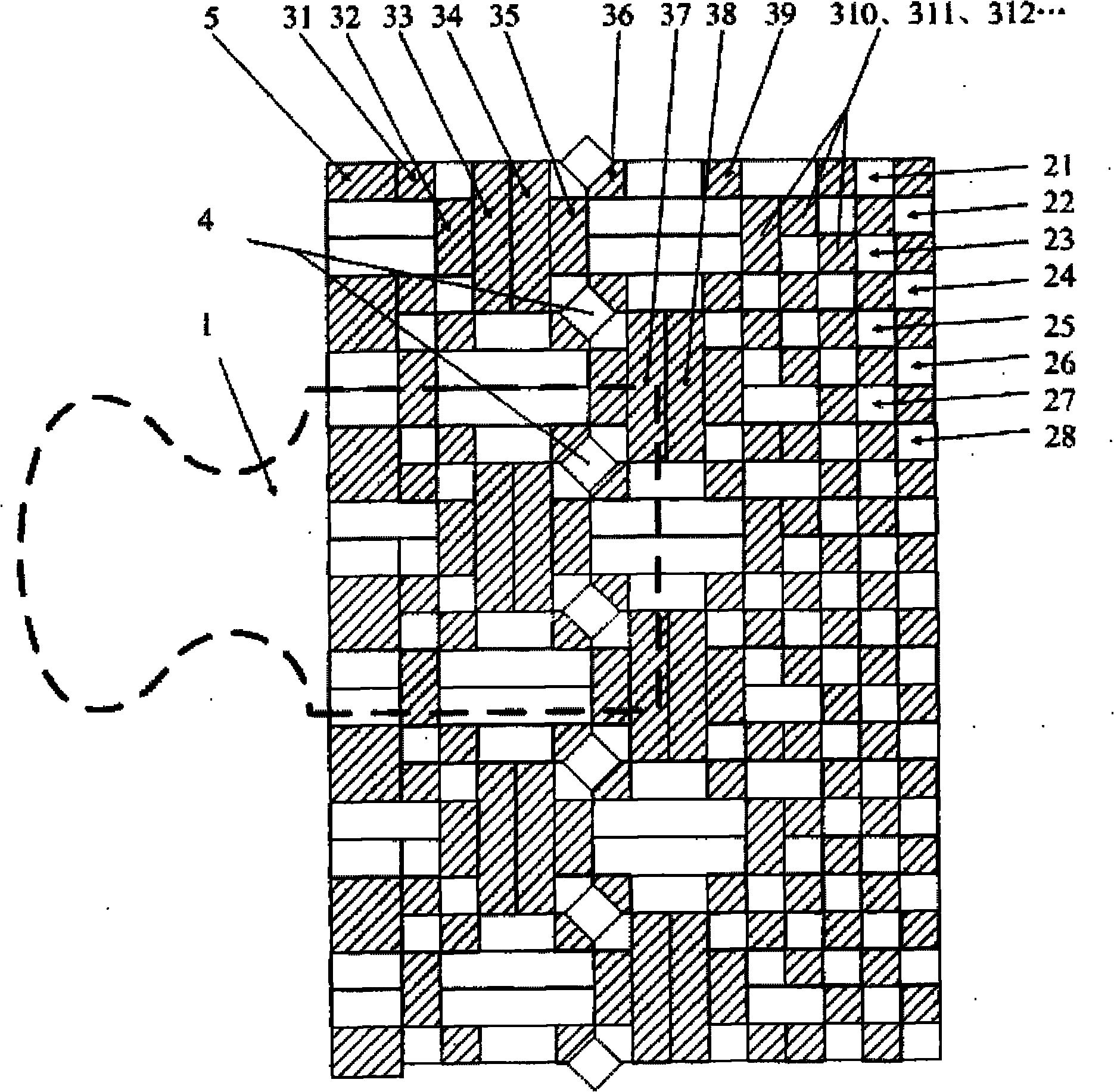

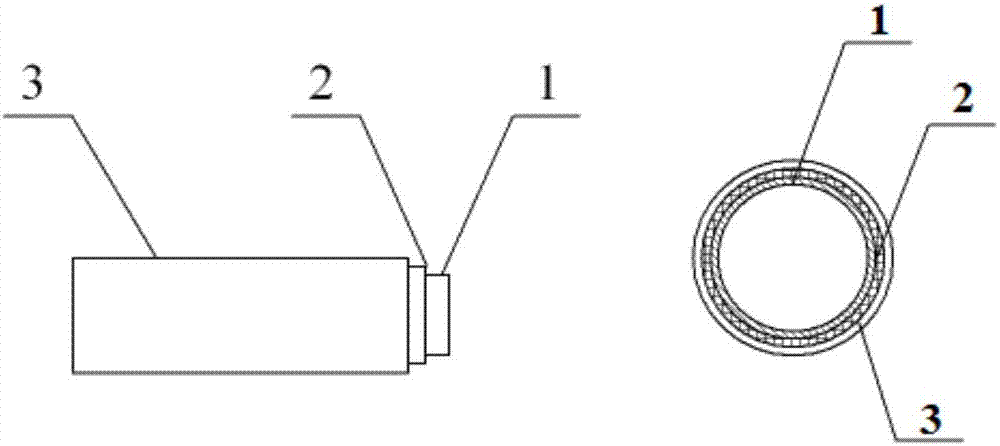

Cloth strap

InactiveCN101933692AImprove bindingPrecise positioningSlide fastenersWoven fabricsEngineeringUltimate tensile strength

The invention discloses a novel injection zipper cloth strap comprising a central line (5) at the edge of the cloth strap, a group of warp (3) and continuous wept (2). Continuous and alternately-arranged small holes (4) are arranged in a joint surface zone of the cloth strap and the injection zipper teeth and formed by setting the structural tissue of the warp of the cloth strap through the mutual influence of tension between the warp and the wept while braiding. The holes in the injection zipper cloth strap are formed without special tools, special procedures or special materials, and the warp and the wept of the cloth strap are kept to be integral with uninfluenced appearance and strength. The invention has the advantages of convenient and simple production and can enhance the binding force between the zipper cloth strap and the zipper teeth, and the like.

Owner:SHANGHAI ZEPU ZIPPER TECH SERVICES

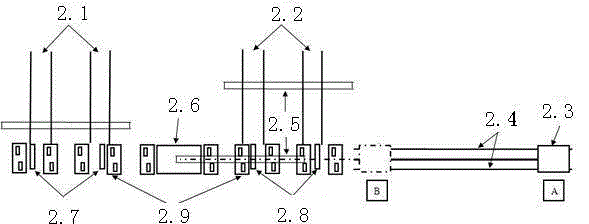

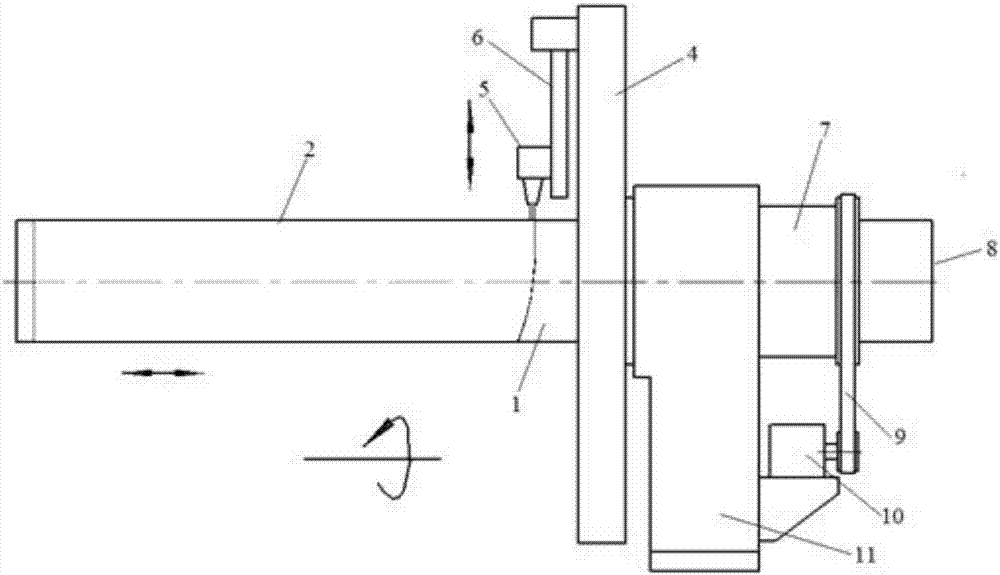

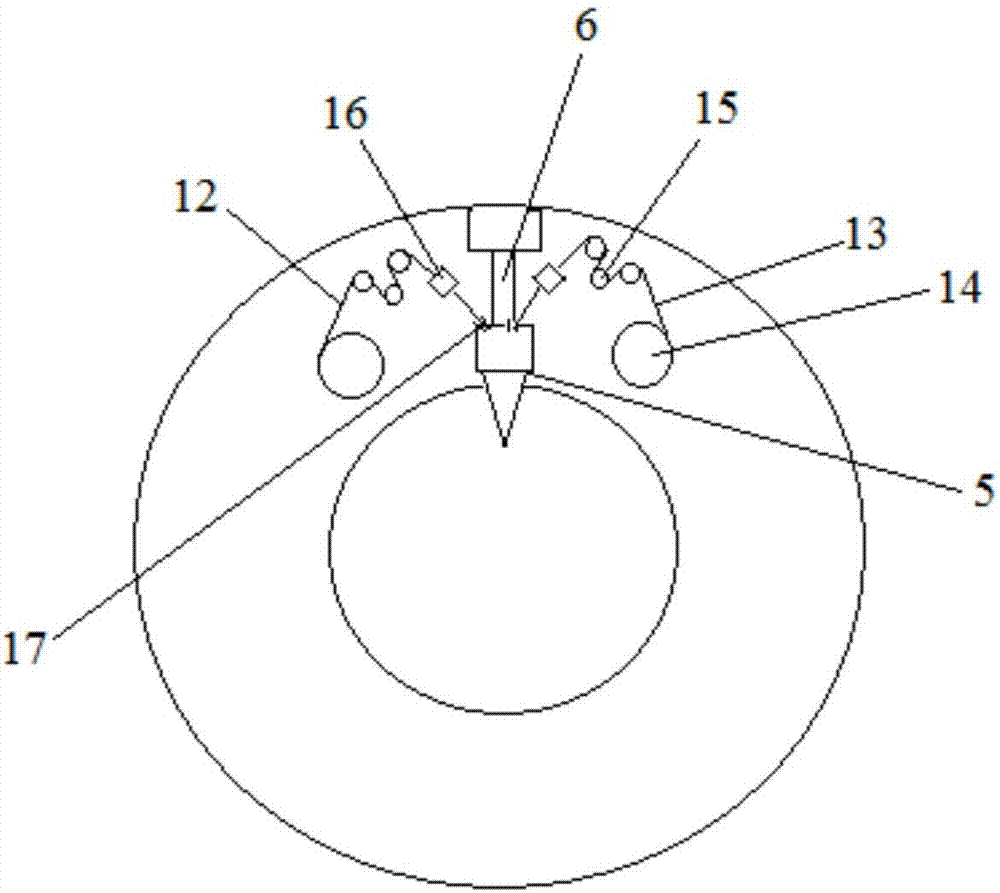

Large-caliber thermoplastic composite long-distance transportation pipe and manufacturing method and device thereof

ActiveCN107081922AHigh precisionAchieve constant tension3D object support structuresRigid pipesManufacturing technologyEngineering

The invention relates to the technical field of manufacturing of thermoplastic composite pipelines, in particular to a large-caliber thermoplastic composite long-distance transportation pipe manufactured through a 3D printing forming technology and a manufacturing method and device of the large-caliber thermoplastic composite long-distance transportation pipe. The large-caliber thermoplastic composite long-distance transportation pipe structurally and sequentially comprises a lining layer, a fiber reinforced layer and an outer protective layer from inside to outside. The length of the thermoplastic composite long-distance transportation pipe is 8-10 m, the pipe diameter of the thermoplastic composite long-distance transportation pipe is 1000-1500 mm, the lining layer is 10-50 mm thick, the reinforced layer is 50-200 mm thick and the outer protective layer is 10-50 mm thick. The large-caliber thermoplastic composite long-distance transportation pipe has the outstanding advantages of being light in weight, resistant to high temperature, resistant to corrosion, good in flexibility and air impermeability, high in internal and external pressure rating, convenient to install and the like. Because of the smooth inner wall, the large caliber and the high internal and external pressure rating, the large-caliber thermoplastic composite long-distance transportation pipe can obtain a higher fluid speed and a higher fluid flow and is particularly suitable for being applied on the aspect of long-distance oil and gas transportation pipelines.

Owner:WEIHAI NACHUAN PIPE FITTINGS

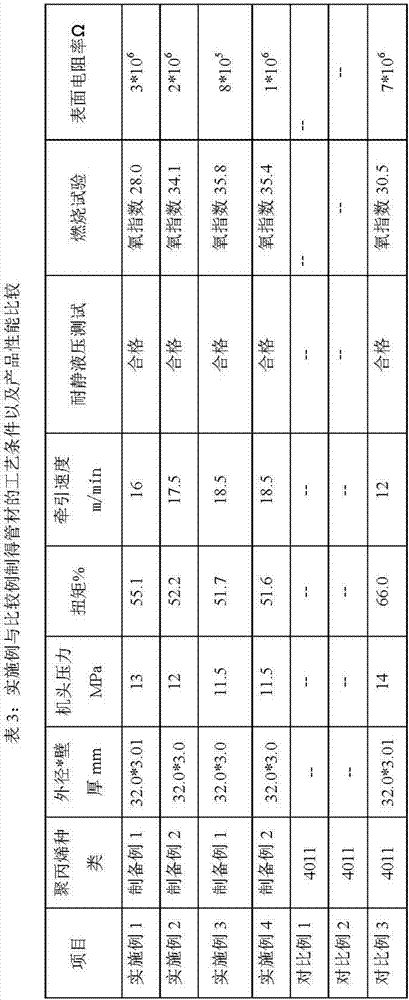

Processing process of large-diameter anti-static fiber glass epoxy plastic pipeline

ActiveCN102490369ANo decline in physical strength indexAnti-static performance does not decreaseYarnEpoxy

The invention provides a processing process of a large-diameter anti-static fiber glass epoxy plastic pipeline. The process is characterized in that a carbon fiber felt is uniformly wound on a pipeline die, so that the carbon fiber felt is flatly coated on the outer wall of the pipeline die; after the carbon fiber felt is immersed by epoxy resin, fiber glass high-strength yarns and carbon fiber yarns are spirally wound on the pipeline die, and an anti-static high-strength fiber glass epoxy plastic pipeline produced by high-temperature cure heating after the winding is completed; and in the processing process, the carbon fiber inner felt, the high-strength carbon fiber, the fiber glass and imported epoxy resin are used as raw materials, and wounding formation, steam heating by stages and high-temperature inner die curing formation are adopted. The process comprises the following specific steps: preparing materials; winding the carbon fiber felt; adding carbon fibers; heating with steam by stages; curing and forming; and processing and finishing, thus obtaining a finished product pipeline. The pipeline provided by the invention has the advantages that the anti-static performance, the physical strength index of the material and the anti-corrosion index are not reduced at an environmental temperature of minus 40-120 DEG C, and the anti-static, anti-aging and anti-fatigue service life is not lower than 30 years under the condition that the pipeline is exposed in the sea.

Owner:山东欧森管道科技有限公司

Flame-retardant antistatic polyethylene pipe and making method thereof

InactiveCN104277279AImprove antistatic performanceImprove flame retardant performanceFlexible pipesCorrosionErosion

The invention discloses a flame-retardant antistatic polyethylene pipe and a making method thereof. The pipe comprises the following raw materials by weight: 40%-60% of high density polyethylene (HDPE), 10%-20% of zinc borate, 20%-40% of special nanometer conductive carbon black, 1%-5% of a coupling agent, and 1%-5% of auxiliary agents. The flame-retardant antistatic polyethylene pipe provided by the invention has good antistatic and flame-retardant synergistic effect, excellent antistatic properties and flame retardance, light weight, soft texture, good toughness, coilability, corrosion resistance, resistance to erosion of various chemical media, smooth inner wall, and small resistance. Difficult to scale in use, the pipe has better wear resistance than rubber tubes and pure polyethylene pipes, and has simple ingredients and is easy to prepare. The pipe provided by the invention can completely replace steel pipes to be widely used in drainage, water supply, air compression and gas drainage, and has the advantages of no toxicity and sanitation, light weight, and convenient construction.

Owner:东港市远东节水灌溉设备有限公司

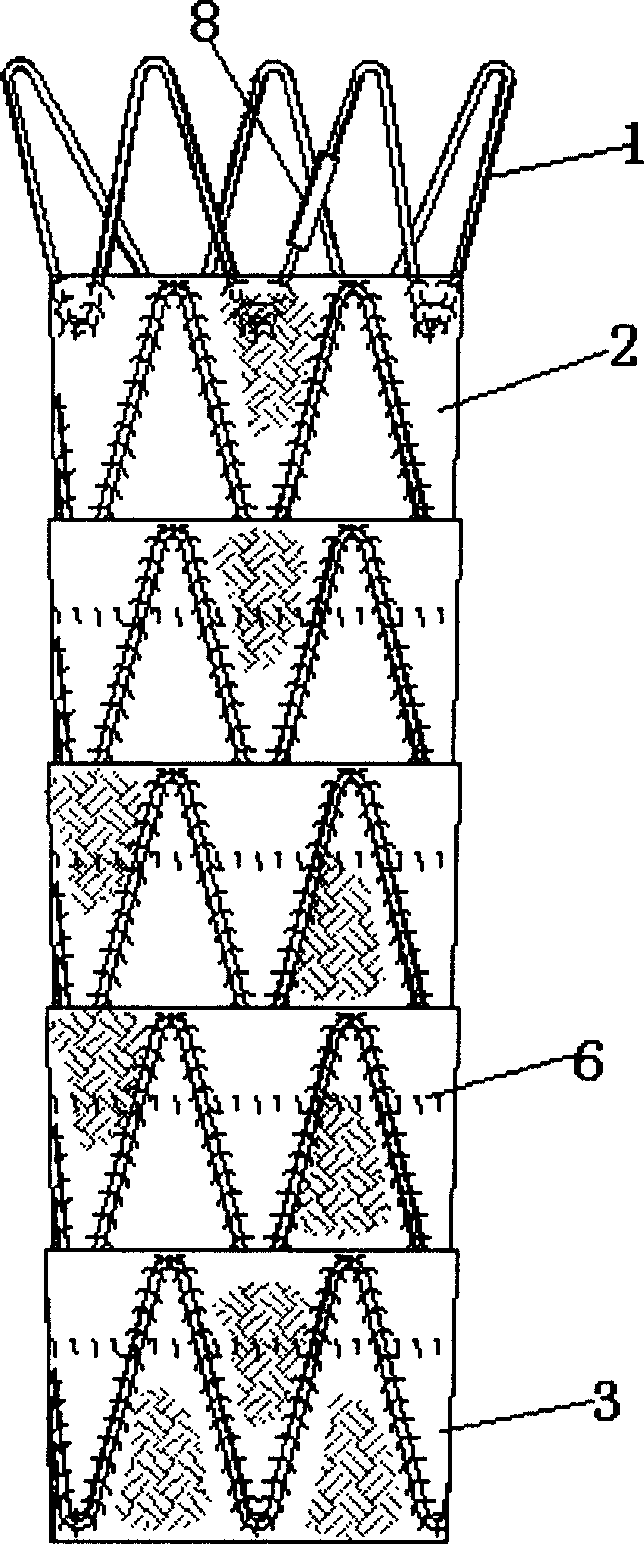

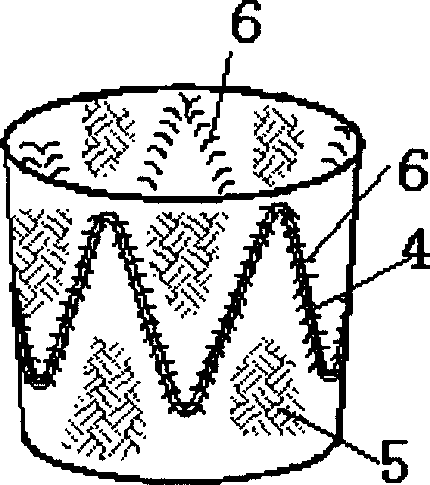

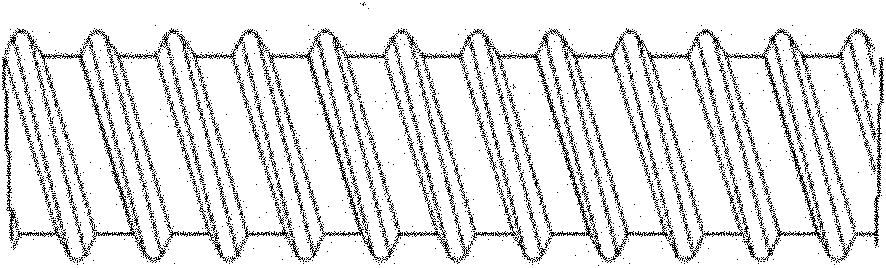

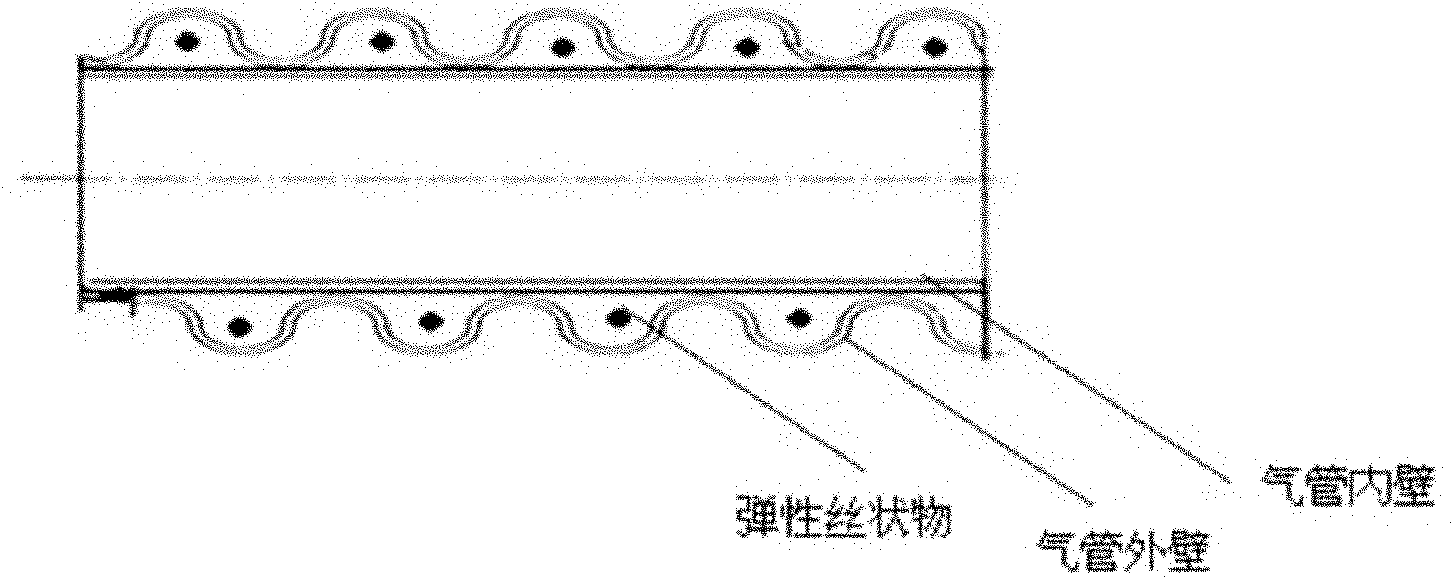

Woven artificial trachea and preparation method thereof

InactiveCN101972175AImprove radial supportSolve the problem of insufficient radial support forceTubular organ implantsWoven fabricsEngineeringSingle filament

The invention relates to a woven artificial trachea and a preparation method thereof, the woven artificial trachea comprises a tube blank and elastic filaments, the tube wall structure of the tube blank is a two-layer woven structure which comprises an inner wall structure and an outer wall structure, a spiral cavity is formed between the inner wall and the outer wall by using a tying and a separating organizational structure at an interval along the axial direction of the tube blank, and then the elastic filaments are inserted into the spiral cavity; and the preparation comprises the following steps: adopting multifilaments and / or single filaments as raw materials, adopting a double-layer tubular organization constituted by a base organization with not more than 6 warp threads according to different motion rules in organization cycles, using the tying and the separating organization at the interval along the axial direction, weaving the tube blank which forms the spiral cavity between the inner wall and the outer wall and penetrating the elastic filaments into the spiral cavity. The woven artificial trachea can improve the radial support performance of the woven artificial trachea, increase the closeness, lead the post-finishing process step to be simple, lead the inner wall to be smooth and be conductive to discharge wastes in the trachea; and the preparation method is simple and applicable to industrial production.

Owner:DONGHUA UNIV

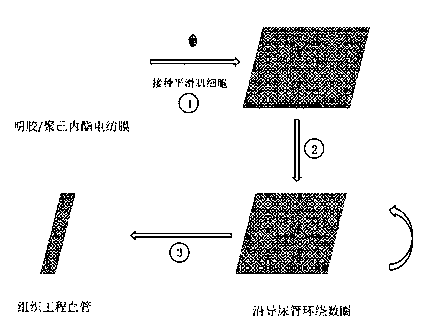

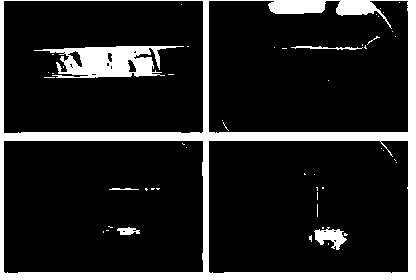

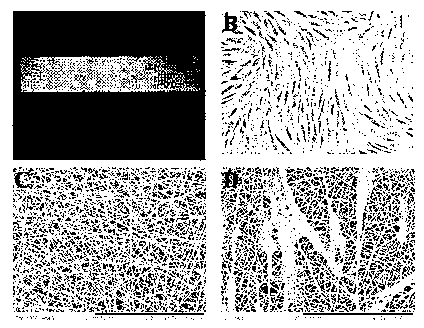

Tissue engineering vessel and preparation method and application thereof

The invention relates to a tissue engineering vessel and a preparation method and an application thereof. The tissue engineering vessel uses a tubular gelatin / polycaprolactone electricity texture membrane as a support, and smooth muscle cells are evenly distributed in the support. The preparation method includes: a) spreading disinfected gelatin / polycaprolactone materials in a culture dish; b) collecting umbilical artery smooth muscle cells, evenly inoculating the umbilical artery smooth muscle cells on the surface of the gelatin / polycaprolactone electricity texture membrane to culture over the night, and forming a cell material composite electricity texture membrane; and c) twisting the cell material composite electricity texture membrane on a polyvinyl chloride (PVC) tube for culturing, and finally forming the tubular tissue engineering vessel. Cells of the tissue engineering vessel prepared by the method are evenly distributed, simultaneously the tissue engineering vessel has the advantages of being good in elasticity, moderate in hardness and compact in tissue structure, having smooth inner walls and abundant collagenous fibers, and being clear in self tissue boundary and the like. The characteristics of the tissue engineering vessel are close to that of living body vessels.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

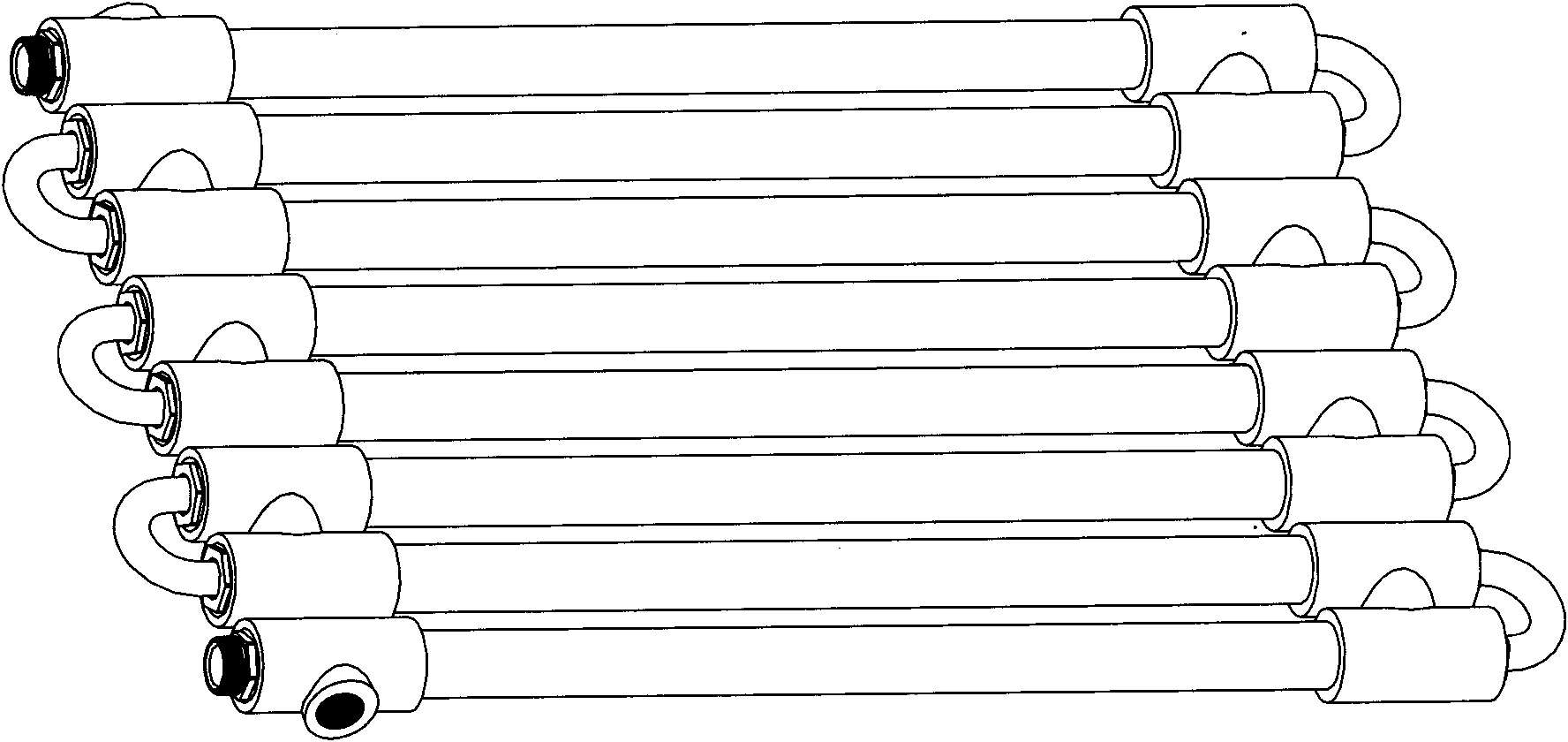

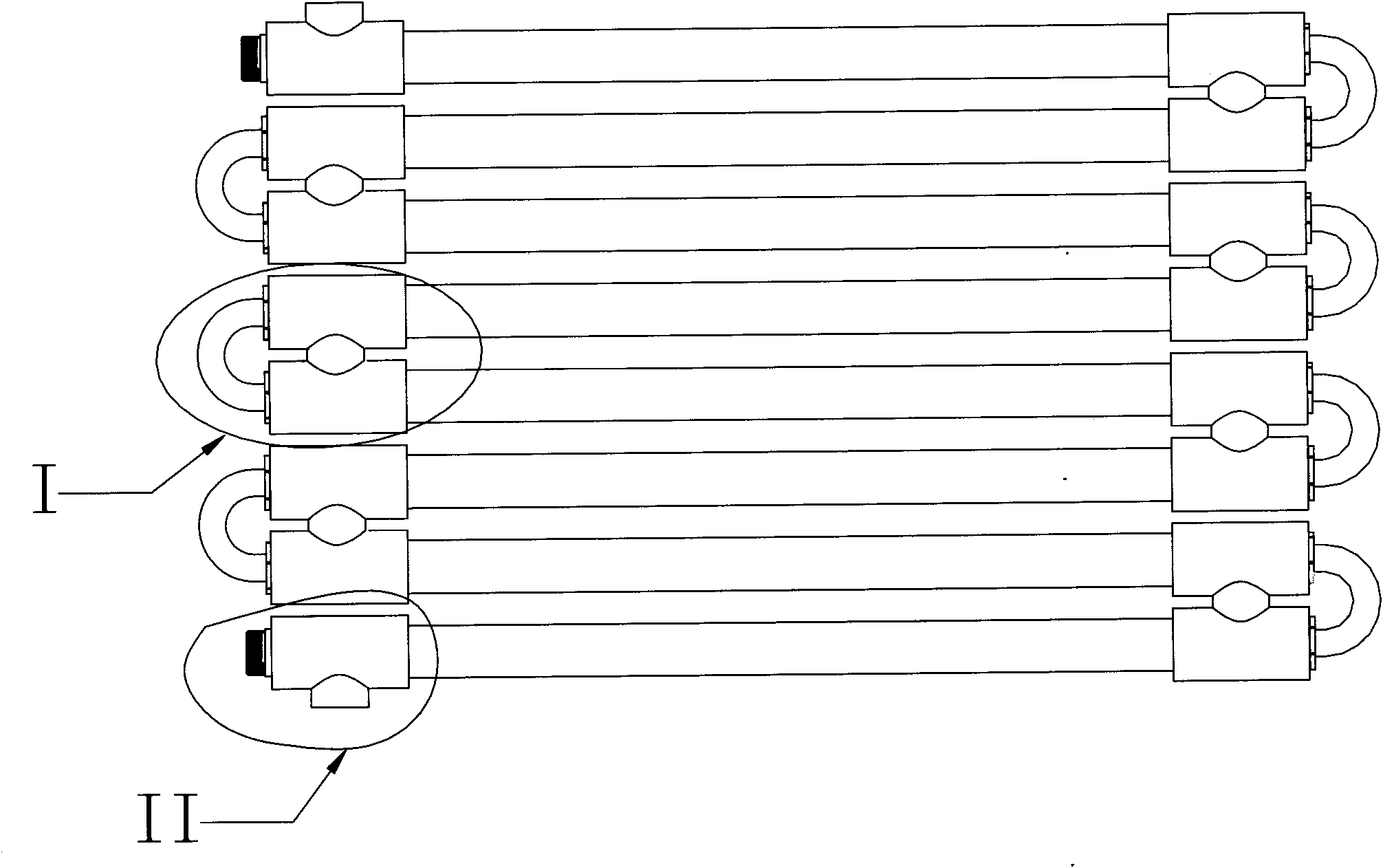

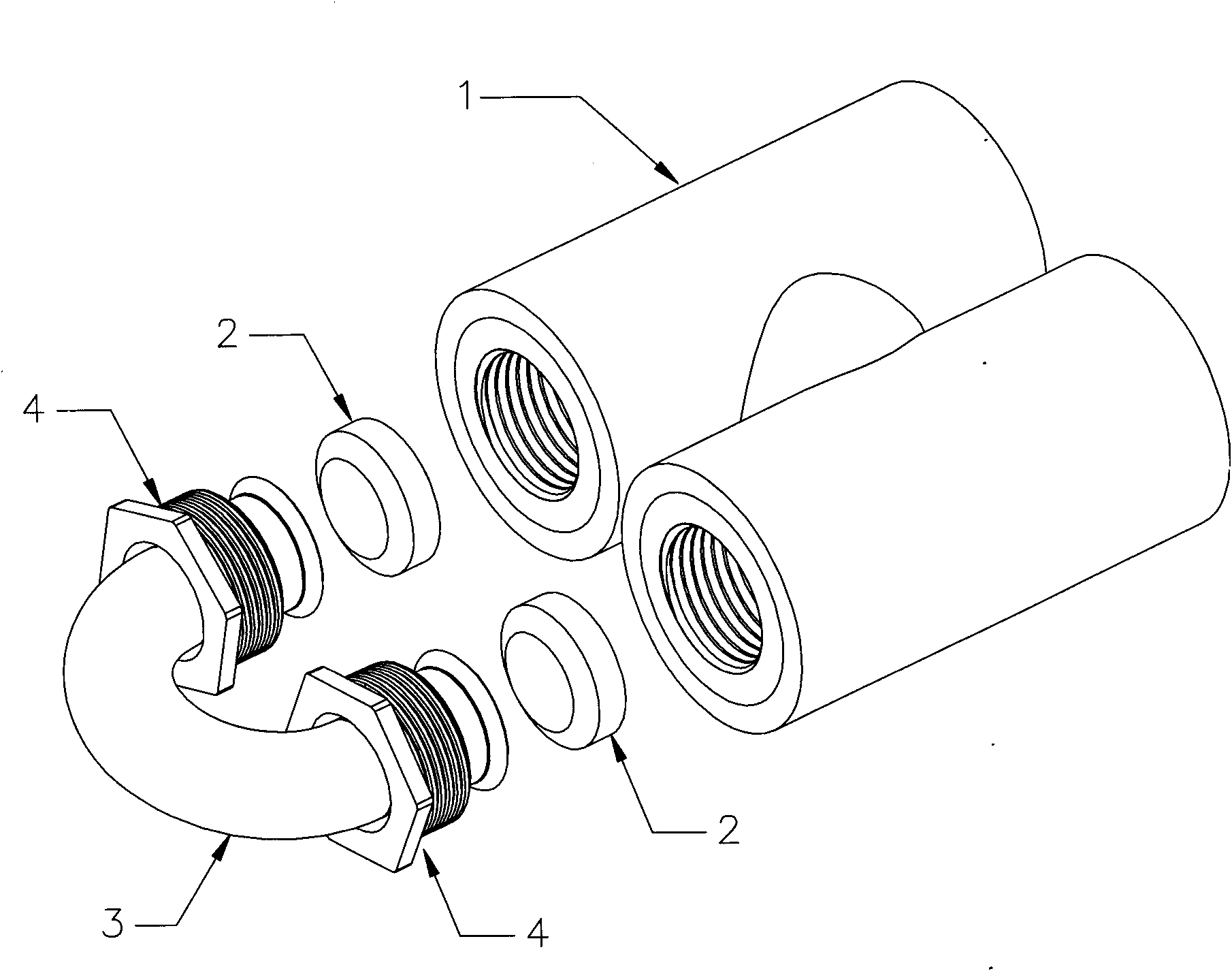

Double-pipe heat exchanger

InactiveCN101776405AReduce lossesImprove heat transfer effectHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerScrew thread

The invention discloses a double-pipe heat exchanger which is characterized in that an outer pipe is a plastic pipe and an inner pipe is a metal pipe; the two pipes are spliced through a U-shaped pipe with movable adapters, a rubber sealing ring and a plastic H-shaped four-way joint; and the two ports of the heat exchanger are separated and led out through a plastic T-shaped tee joint, an annular rubber sealing ring and a metal straight-through joint. Both the plastic T-shaped tee joint and the plastic H-shaped four-way joint are provided with ports which are provided with metal inserts, and round holes just for the inner pipe to pass through are arranged at the bottoms of the inserts. Two parallel straight pipe sections with equal length are respectively arranged at the two ends of the U-shaped pipe, two tubular threaded moveable adapters are respectively sleeved at the outsides of the two ends of the U-shaped pipe, and trumpet-shaped flarings are arranged at the ports of the two ends of the U-shape pipe. The heat exchanger is convenient to install, can be dismantled for cleaning and is low in cost.

Owner:SHANGHAI CHUNHUA ELECTRONICS

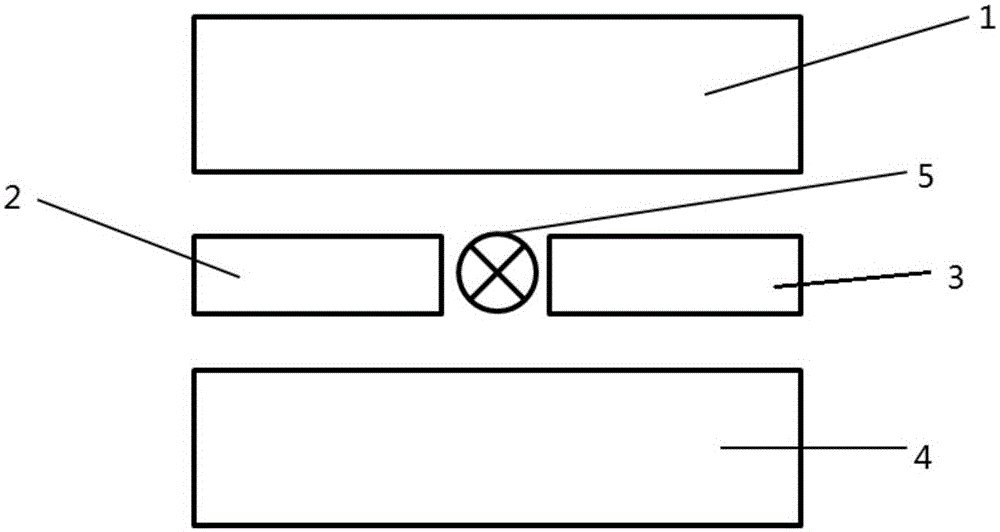

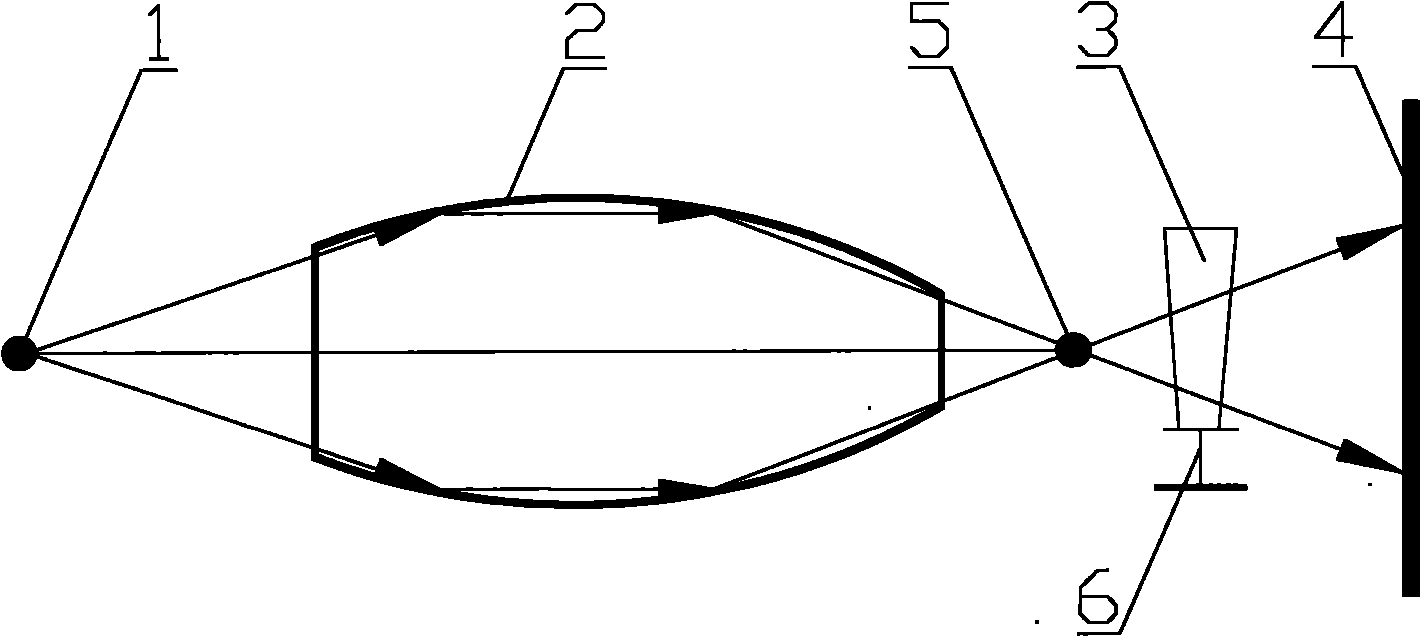

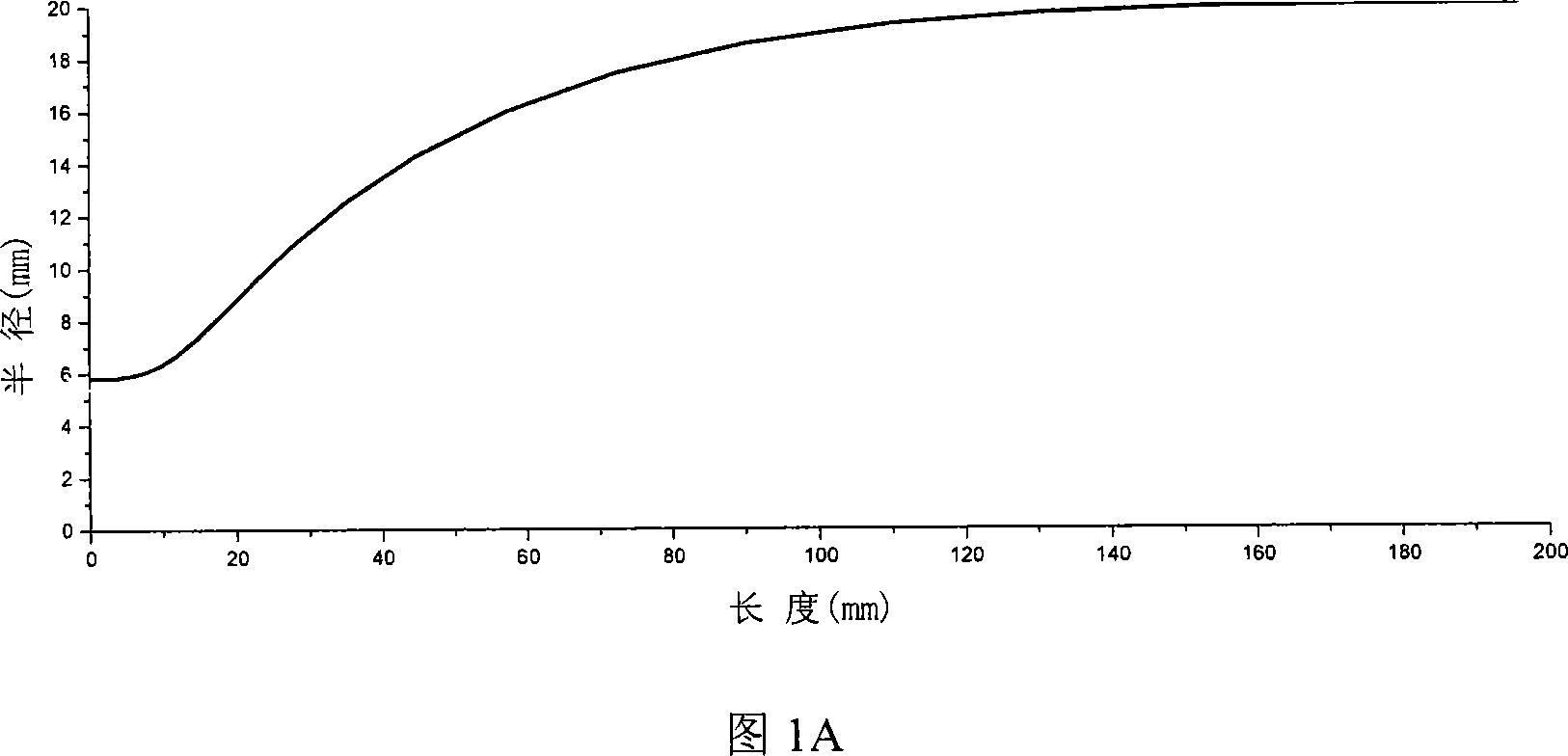

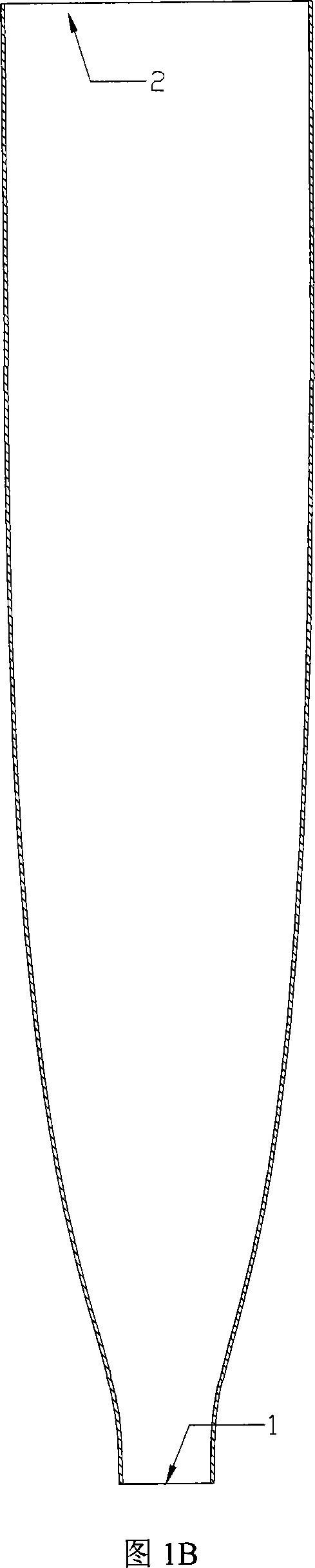

X-ray phase imaging device

ActiveCN101833233AMeet spatial coherence requirementsSimple processing technologyRadiation/particle handlingMaterial analysis by transmitting radiationX-rayX ray photons

The invention discloses an X-ray phase imaging device comprising an X-ray photon source (1), an optical device (2) and an X-ray detector (4) which are sequentially arrayed. An X ray emitted by the X-ray photon source (1) is transmitted from one end of the optical device (2) to the other end of the optical device (2) to form a micro focal spot (5), and after the X ray passes through an imaged sample (3), an image is formed on the X-ray detector (4), and the optical device (2) is a single capillary, the outlet diameter is in the range of 1mum to 30mum. The imaging device can form a smaller micro focal spot in order to increase the spatial resolution of X-ray phase image, the X-ray phase image is clearer, and the X-ray phase imaging device has low cost and is convenient to popularize.

Owner:BEIJING NORMAL UNIVERSITY

Anti-electrostatic flame-retardant polyvinyl material

InactiveCN1418907AExtended service lifeImprove teleportation effectOther chemical processesAntistatic agentMechanical property

The composition of said antistatic fire-resisting polyethylene material is formed from (by weight portion) 100 portions of high-density polyethylene, 5-24 portions of composite fire-resisting agent and 3-7 portions of composite antistatic agent. It possesses excellent antistatic property, fire-resisting property, and toughness and high strength, corrosion resistance and other chemical property and mechanical property, and can be made into pipe material with extensive application range instead of steel pipe in various engineerings.

Owner:山东方大工程有限责任公司

Insulated oil pipe and preparation method thereof

PendingCN107131393AReduce frictionSmooth inner wallThermal insulationCorrosion preventionInsulation layerEngineering

The invention discloses an insulated oil pipe. The insulated oil pipe comprises an oil pipe base body. A ceramic glaze is arranged on the inner surface of the oil pipe base body. An insulating layer is arranged on the outer surface of the oil pipe base body. A protective layer is arranged on the outer surface of the insulating layer. An anticorrosion layer is arranged on the surface of the protective layer. The insulated oil pipe has the beneficial effects that the inner wall is smooth, the friction force generated when oil flows can be greatly reduced, the weight is low, the insulating effect and the anticorrosion effect are both good, the service life is long, no energy needs to be additionally consumed during use, and the cost performance is high.

Owner:大连辉华新材料有限公司

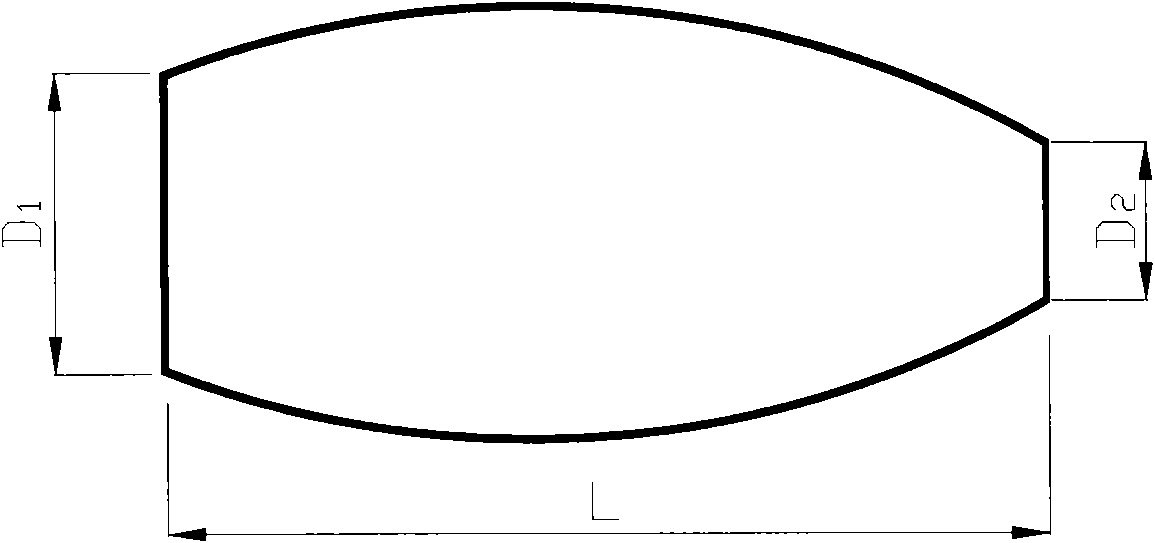

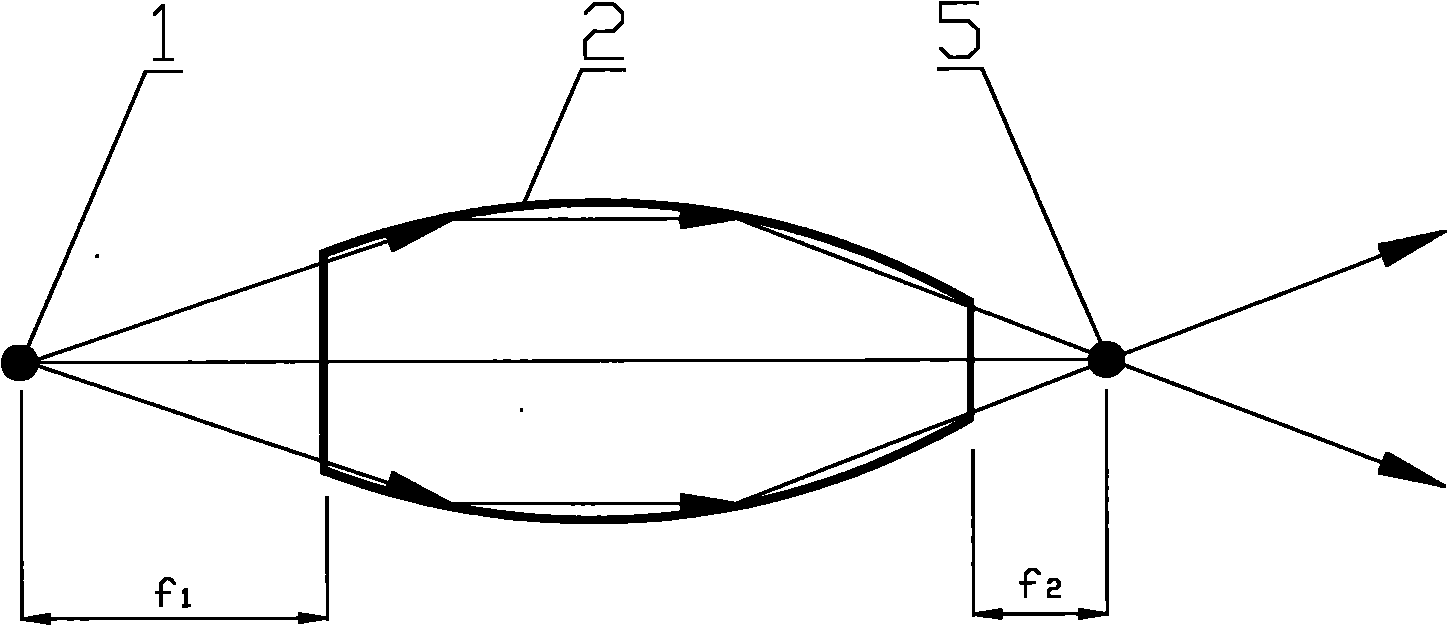

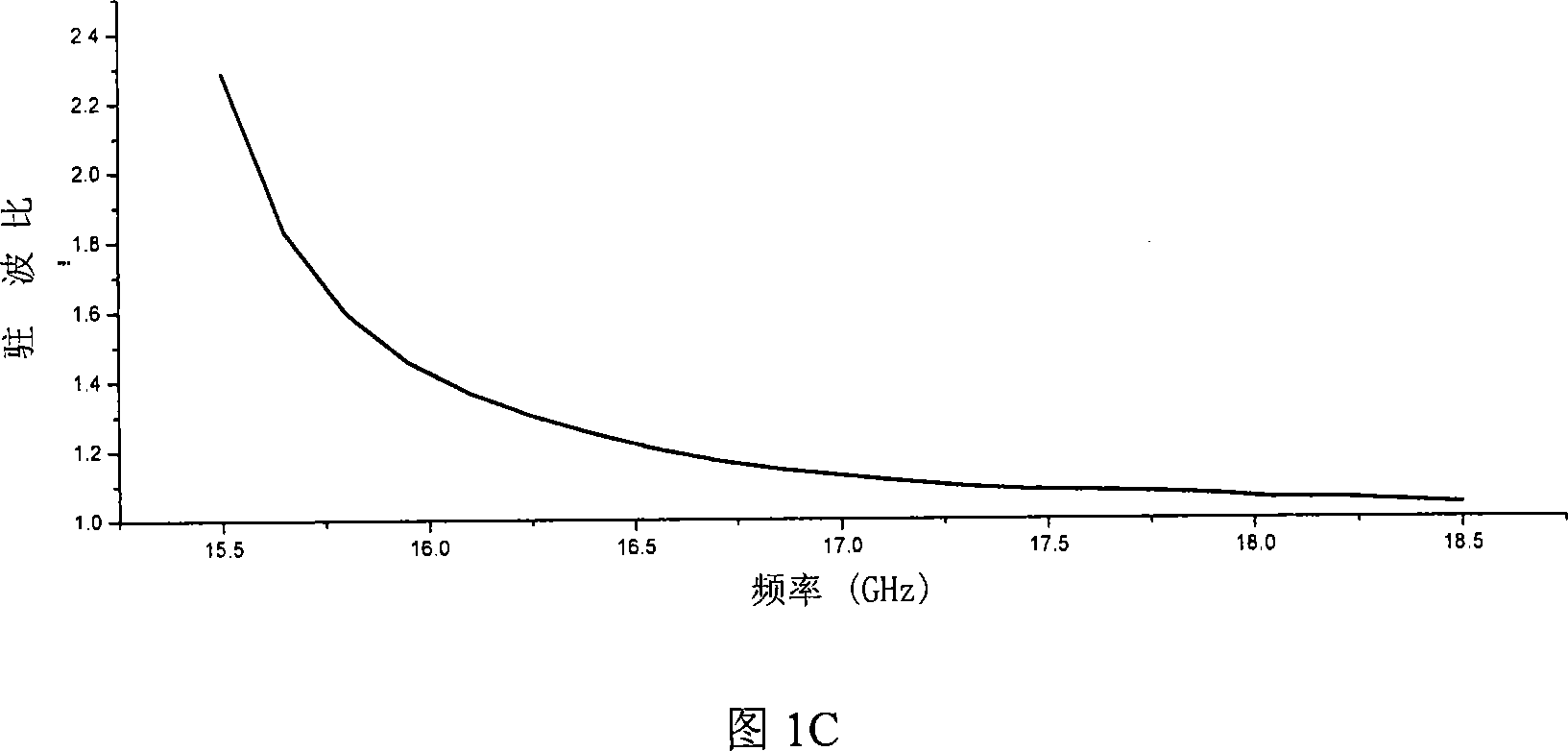

A coupling output structure for gyrotron traveling wave amplifier

InactiveCN101127412AMeet the assembly requirements of the whole tubeSmall VSWRCoupling devicesAudio power amplifierMicrowave

The utility model has discloses a coupling output structure for traveling wave tube amplifiers, which comprises an input port and an output port; wherein, the radius of the output port is bigger than that of the input port, a first grade gradually variable circle waveguide and an Nth rank gradually variable circle waveguide are cascaded between the input port and the output port. The utility model adopts the double-segment correcting Duelfer-Chebyshev gradually variable circle waveguide cascade connection or a transition circle waveguide cascaded in the central section of the double-segment correcting duelfer-chebyshev gradually variable circle waveguide. The utility model has the advantages of resolving the problems in prior art , such as large size, high reflection coefficient of the input port and weak capacity of parasitic mode restraint; when the coupling output structure is applied to traveling wave tube amplifiers, positive effects can be obtained, , which are of great practical significance for developing the high power microwave sources applied in long ranged radars and electronic warfare technology.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

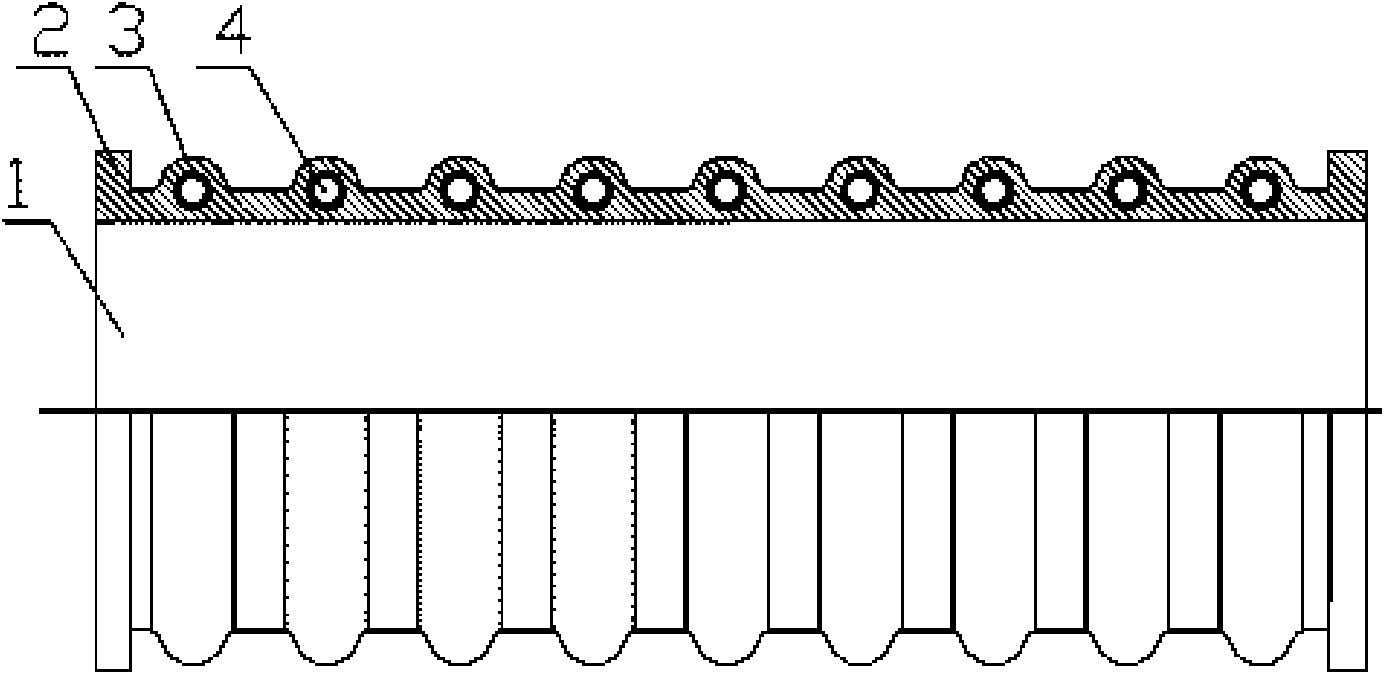

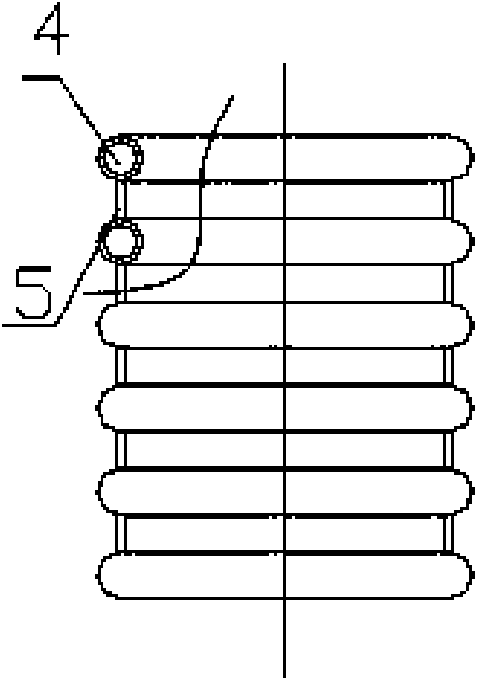

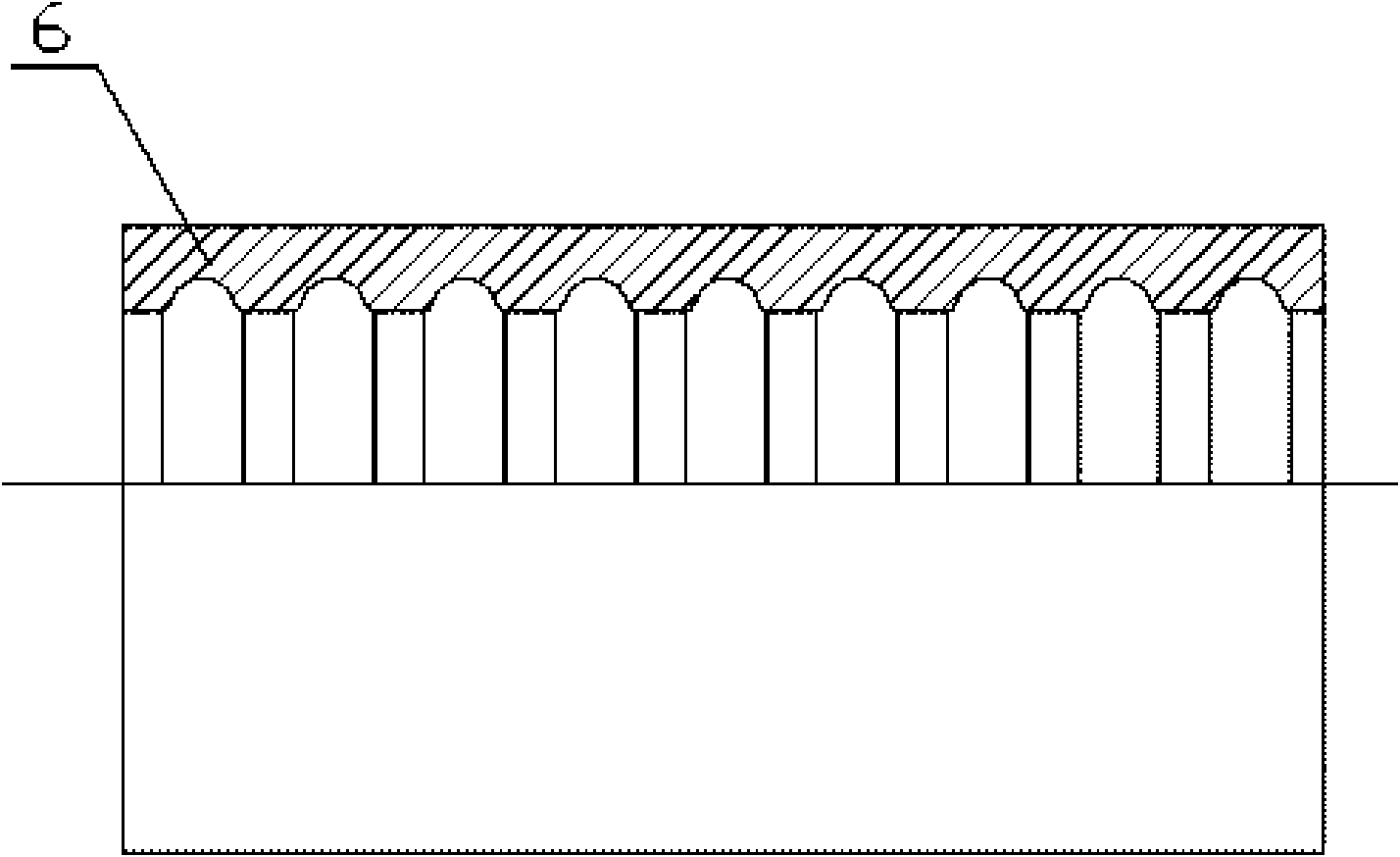

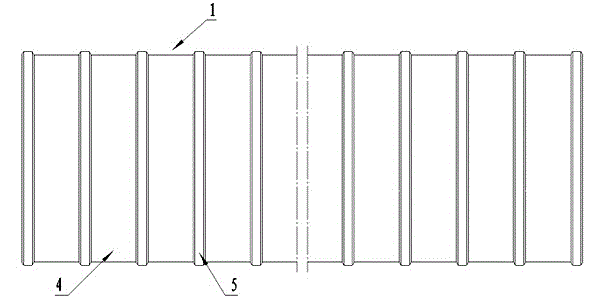

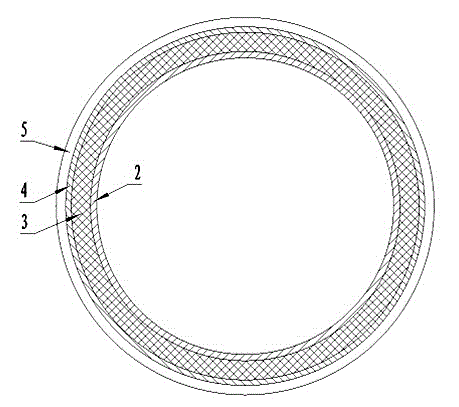

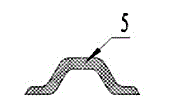

Enhanced plastic double-walled corrugated pipe and manufacturing method thereof

The invention discloses an enhanced plastic double-walled corrugated pipe, comprising a pipe wall with an outer wall to be corrugated and convex. The enhanced plastic double-walled corrugated pipe ischaracterized in that an annular and hollow inner pipe is packed in the corrugated and convex inside. The invention has the advantages that the plastic double-walled corrugated pipe with the structurehas high ring stiffness, high yield, simple operation, high production efficiency, smother inner wall and little water flow friction, the manufacturable pipe has a diameter as large as 3,000 or more,and the structure can be made into the flanged connection. The manufacturing method of the invention uses the flame for heating the molds, thereby saving the electric energy and lowering the manufacturing cost.

Owner:谢志树

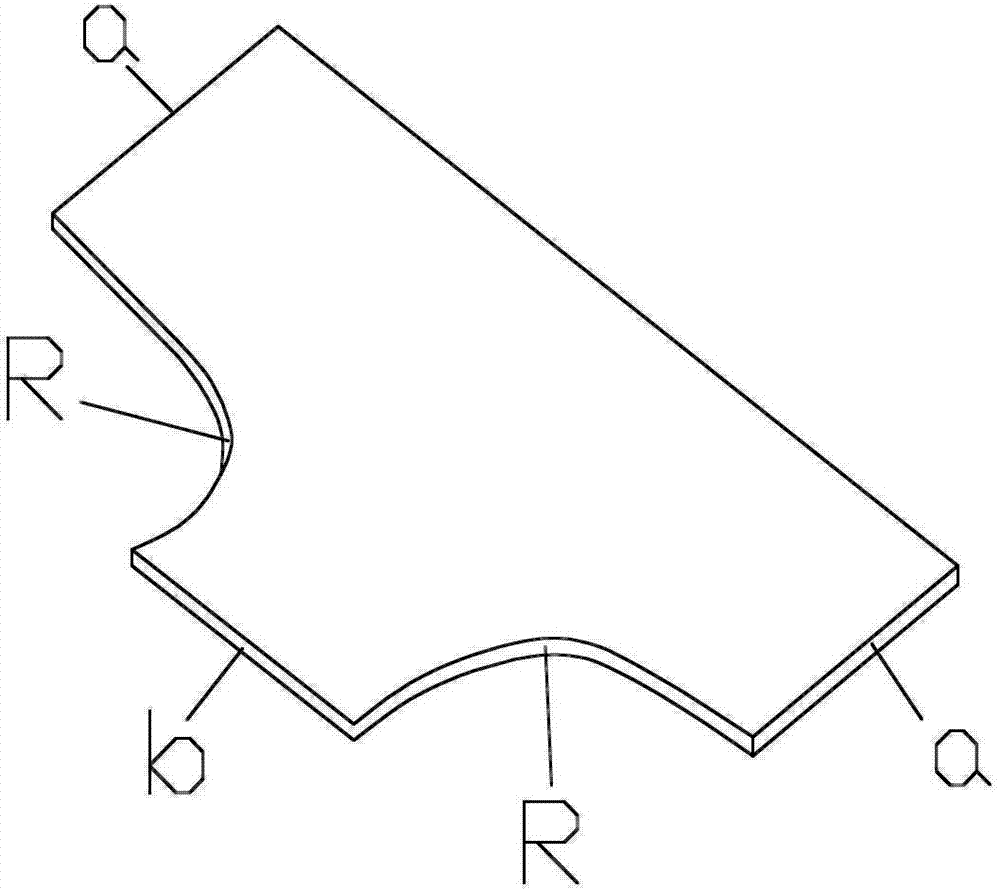

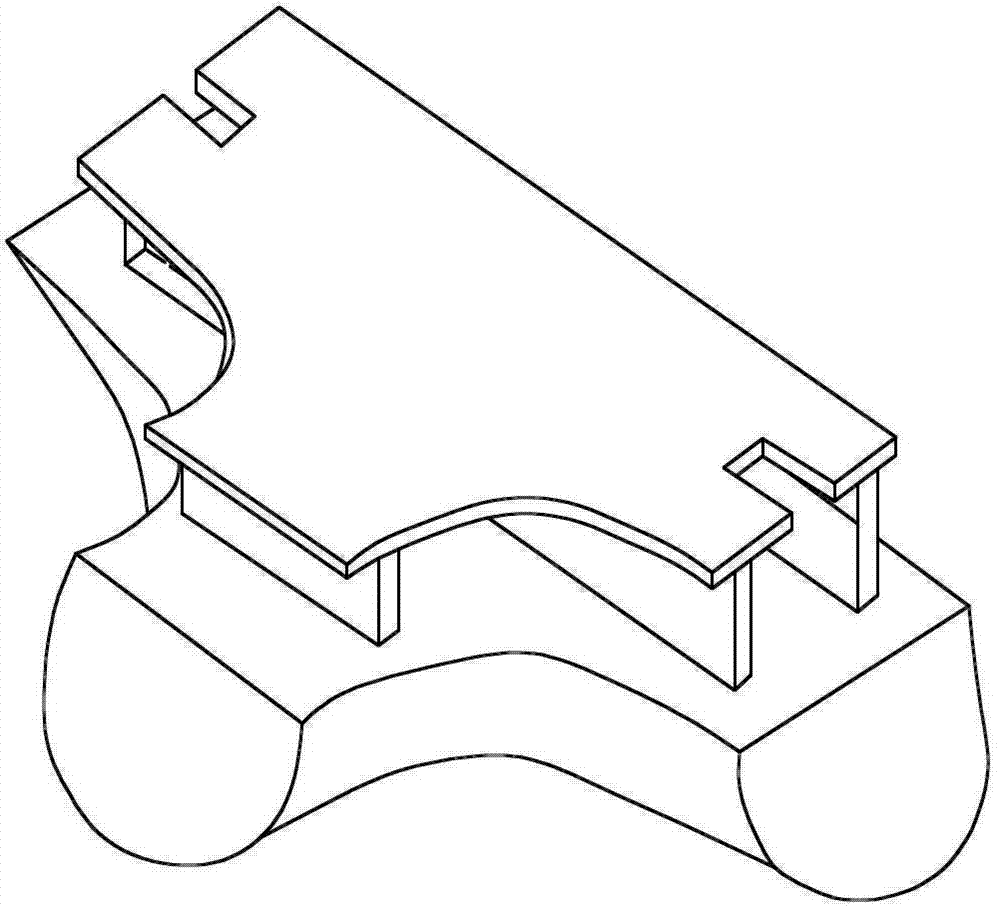

Method for manufacturing a large-outside-diameter equal-diameter titanium tee joint

The invention provides a method for manufacturing a large-outside-diameter equal-diameter titanium tee joint. The method comprises the following steps: feeding, high-temperature pressing, cutting into molding material, welding and forming, and trimming or beveling. According to the invention, rough material is pressed through an upper die and a lower die and is welded and formed into a titanium tee joint, so that the technical defects in cutting and welding of an equal-diameter titanium tee joint with a outside diameter of 168.3 mm can be made up; and the titanium tee joint produced is beautiful, the inside wall is very smooth and unimpeded, the operation is simple and convenient, and the titanium tee joint is conveniently grasped by an operator, so that the work efficiency is greatly improved.

Owner:宝鸡市守善管件有限公司

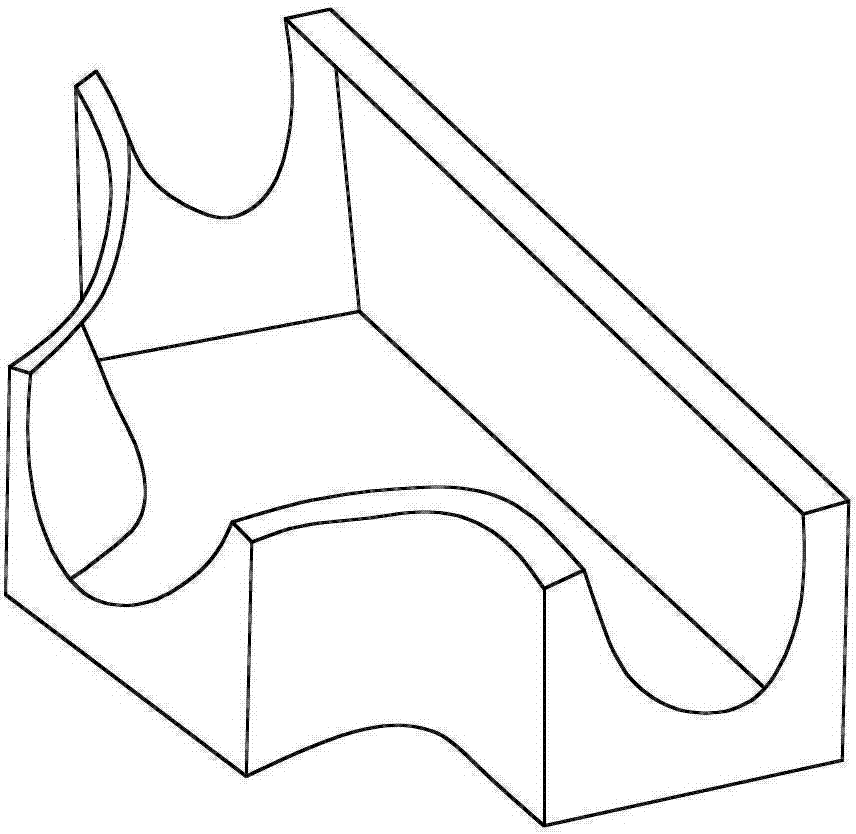

Ceramic shell filtering device integrated with filters

ActiveCN104028698AEasy to installNo need to increase thicknessFoundry mouldsFoundry coresFiltrationCasting mold

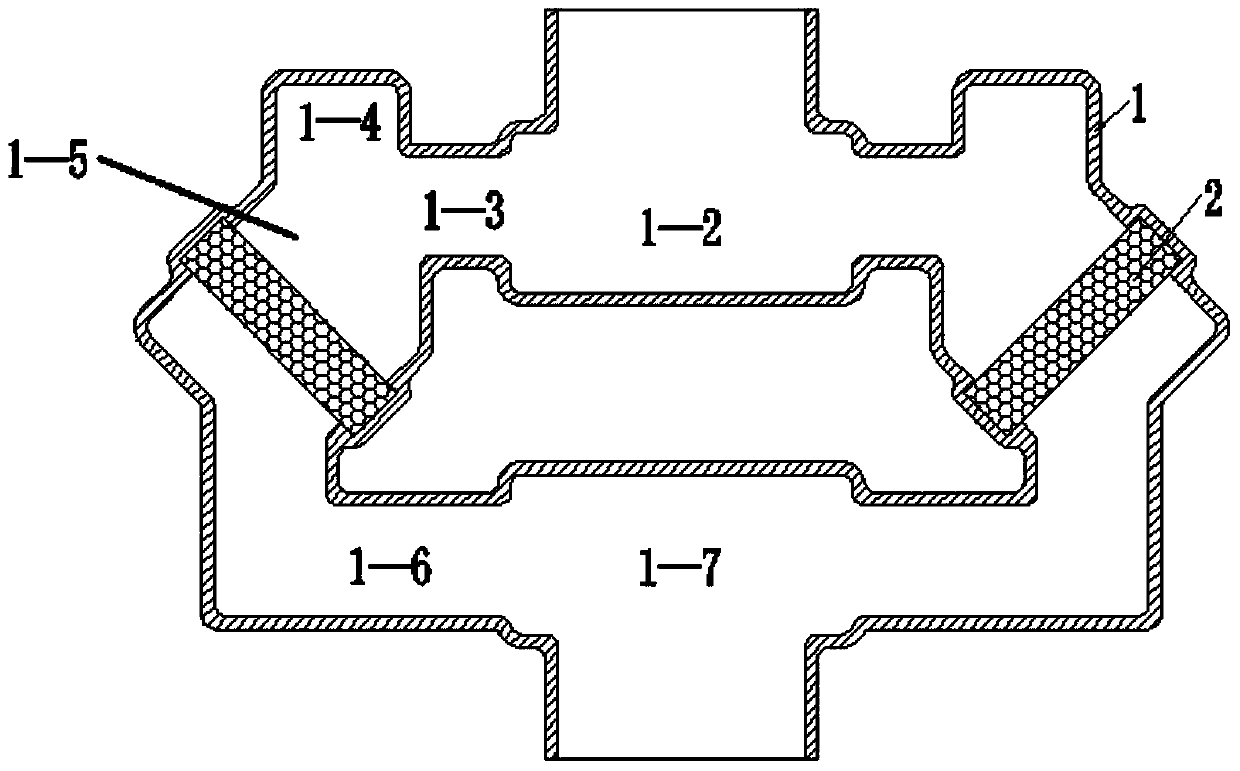

The invention relates to a ceramic shell filtering device. A ceramic shell (1) forms a cavity; the cavity comprises a shunt part (1-2) positioned at the upper part of the shell, a converging part (1-7) positioned at the lower part of the shell, and C-shaped pouring gates in the middle, wherein the upper end of the shunt part (1-2) is an inlet of the filtering device; the lower end of the converging part (1-7) is an outlet of the filtering device; the C-shaped pouring gates are connected in parallel, and are respectively communicated between the shunt part and the converging part; and each of the C-shaped pouring gates is provided with a filter (2). The ceramic shell filtering device realizes the overall filtration of high-flow molten metal outside a casting mold through the design of shunting, filtering and converging, and satisfies the overall filtering requirements of molten metal of a large cast steel piece and an ultra-large cast iron piece outside the casting mold.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Drilling method on sheet metal

The present invention provides a drilling method on a sheet metal. The drilling method comprises the following steps that: the sheet metal and an auxiliary processing piece are provided, the sheet metal includes an area to be drilled, the area to be drilled include a first surface and a second surface relative to the first surface, and the hardness number of the auxiliary processing piece is 0.7 times larger than that of the sheet metal. The auxiliary processing piece fit on the first surface of the area to be drilled. Holes are drilled between the auxiliary processing piece and auxiliary processing piece through a drill head, and the rotate speed of the drill head is larger than 8000 r / min during the drilling course. The auxiliary processing piece is taken down from the area to be drilled. The drilling method on the sheet metal has the advantage that qualities of the holes are improved.

Owner:文霞

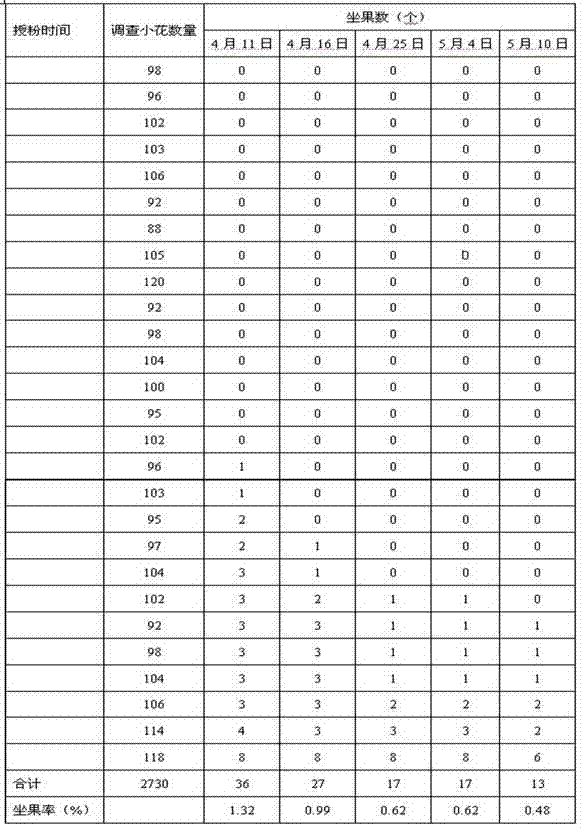

Artificial pollination method for macadamia nut

The invention relates to an artificial pollination method for macadamia nut, and particularly relates to an application method for artificial pollination of macadamia nut, pollen collecting time of macadamia nut, appropriate time of pollination and a pollination tube. The artificial pollination method comprises the following steps: selecting spica bloomed on the same day; opening the pollination tube to wrap the to-be-collected spica; closing the pollination tube and lightly rotating the pollination tube; when a layer of thin pollen can be seen on the inner wall of the pollination tube, gently opening the pollination tube; then wrapping the to-be-pollinated spica by using the pollination tube collecting the pollen, gently closing the pollination tube, gently rotating for 4-5 circles; and opening and taking down the pollination tube to complete the pollination. The pollination tube is used to collect pollen and pollinate, so the style of macadamia nut is little influenced; the fruit setting rate is greatly increased to 4-5% 0.1-0.5% which is the fruit setting rate of natural pollination. By virtue of the method to pollinate, the purpose that the flowers can be used to improve the setting rate can be achieved; and the fruit setting amount can be determined according to the load of the tree. The method is simple to operate, low in cost and easy to promote.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

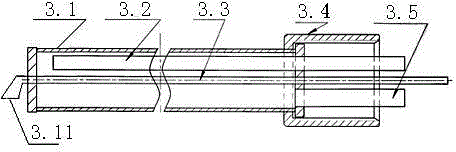

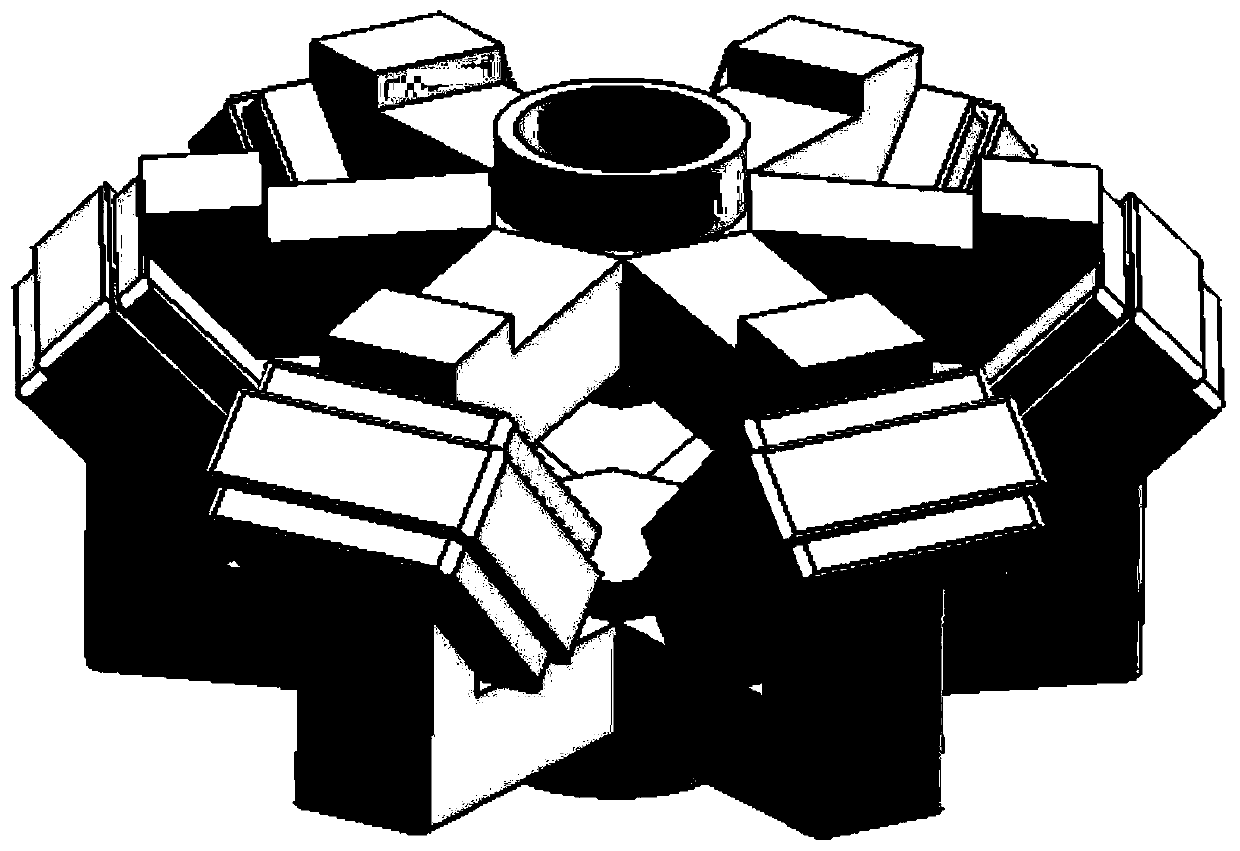

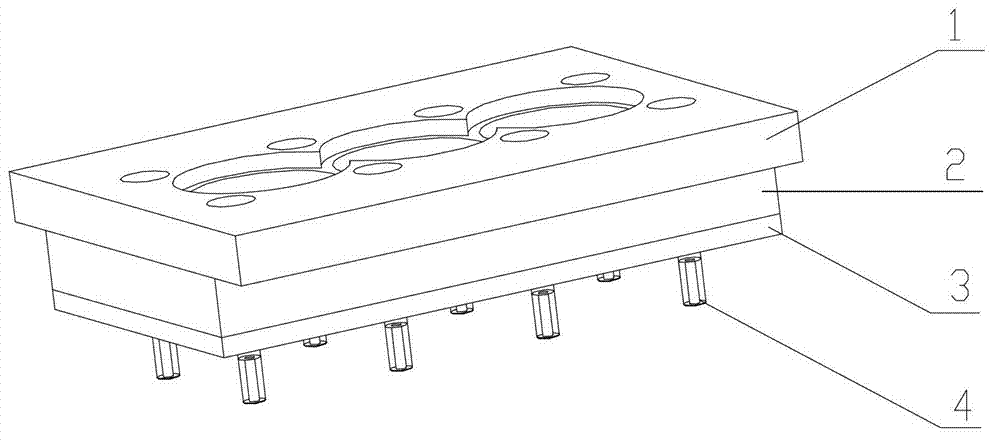

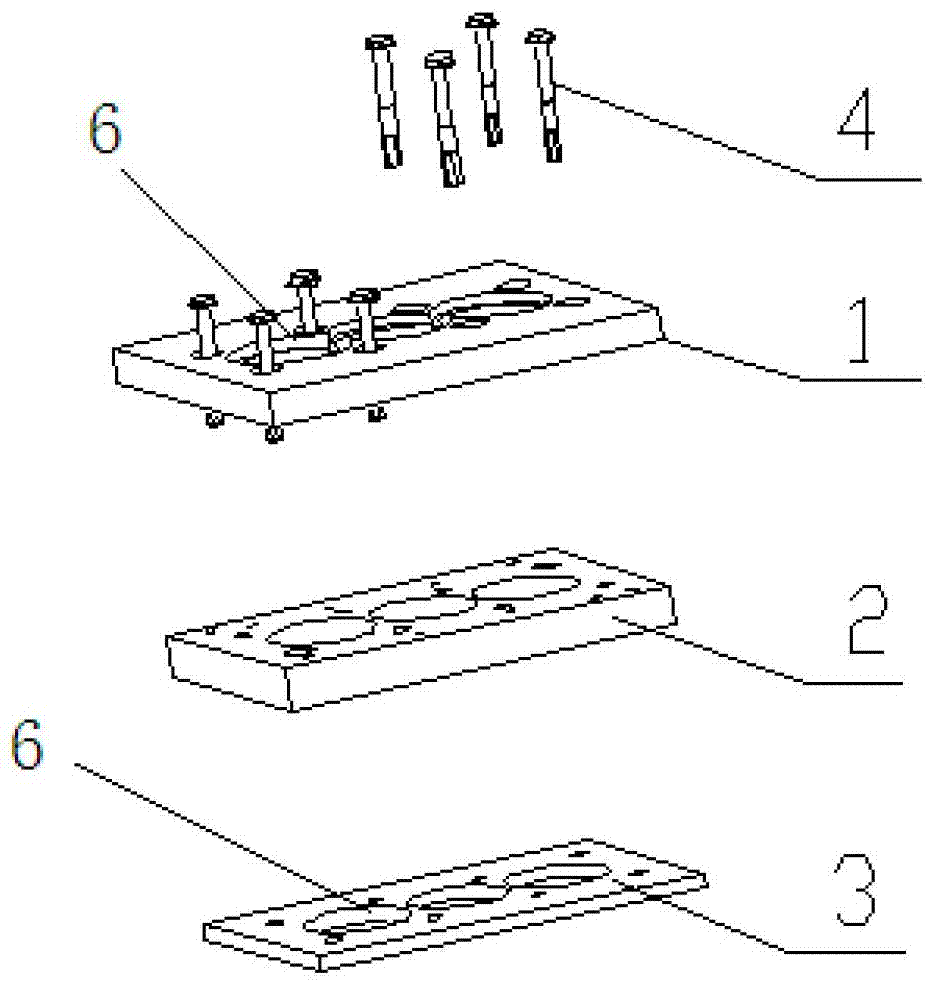

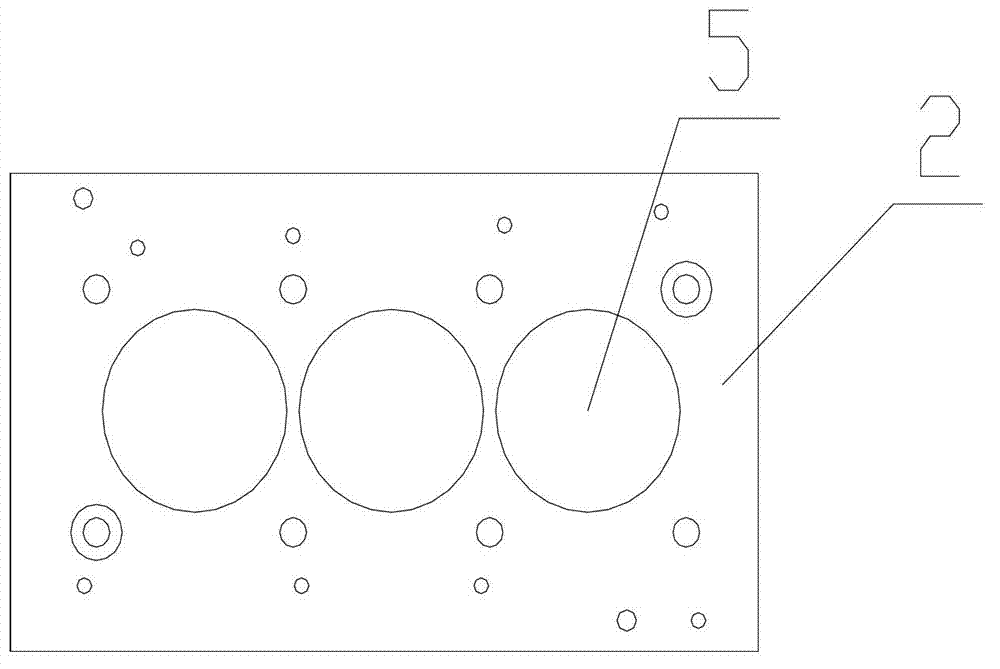

Technological cylinder cover for machining cylinder holes of engine cylinder body and machining method therefor

ActiveCN103920913AReduce distortionSmooth inner wallBoring/drilling componentsSteel platesCylinder block

The invention provides a technological cylinder cover for machining cylinder holes of an engine cylinder body; the technological cylinder cover is composed of an upper layer, a middle layer and a bottom layer connected through bolts, wherein the middle layer of the technological cylinder cover is made of aluminum alloy plates which have same texture with a cylinder cover to be simulated, holes of which the diameters are the same as these of the cylinder holes to be machined in the cylinder body are formed in the middle layer of the technological cylinder cover, the cylinder cover deformation can be simulated by CAE computation, and thus the actual cylinder cover can be simulated. The upper layer and the bottom layer of the technological cylinder cover are made of steel plates so as to reduce accumulated deformation and wearing of the technological cylinder cover caused by repeated use, technological holes corresponding to the cylinder holes in the middle layer of the technological cylinder cover are formed in the upper layer and the bottom layer of the technological cylinder cover. By using the technological cylinder to machine the cylinder holes, the cylinder holes distort as less as possible or hardly distort after the engine cylinder cover is installed, and thus the friction resistance between a piston ring and the cylinder hole wall is reduced, the run-in wear and oil consumption are decreased, the sealing property is improved, and the service life of the engine is prolonged.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

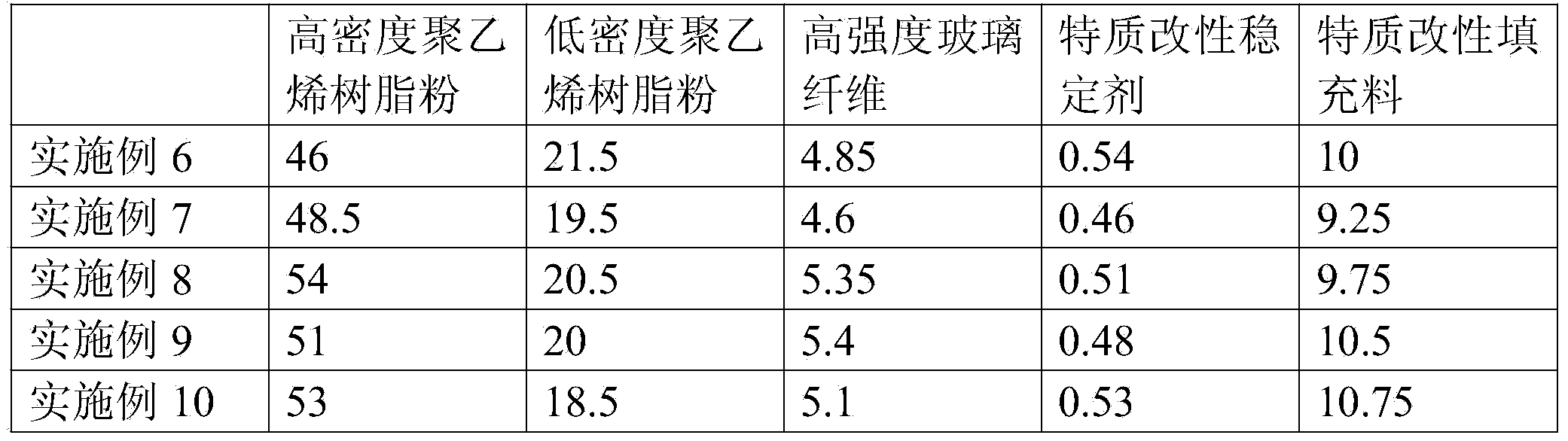

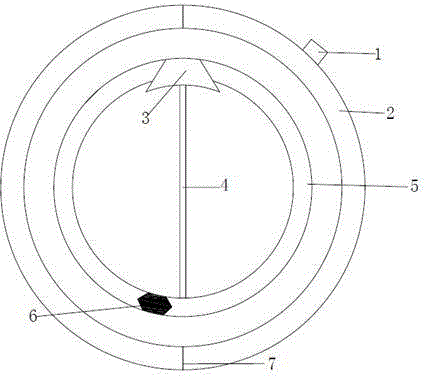

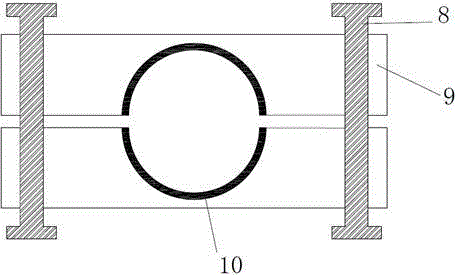

Porous plum-blossom-shaped pipe and preparation method thereof

ActiveCN104212046ANo pollution in the processSave labor costsLow-density polyethyleneEnvironmental resistance

The invention discloses a porous plum-blossom-shaped pipe, and belongs to the technical field of high-molecular materials. The raw materials comprises the following substances in parts by weight: 45-55 parts of high-density polyethylene resin powder, 18-22 parts of low-density polyethylene resin powder, 4.5-5.5 parts of high-strength glass fiber, 0.45-0.55 parts of a property modification stabilizer, and 9-11 parts of a property modification filling material. The plum-blossom-shaped pipe is relatively smooth in inner wall, cables can directly pass through the pipe without using other utensils, and time and labor are saved; the plum-blossom-shaped pipe is resistant to acids and bases, resistant to salts and alkalis, resistant to corrosion, resistant to oxidation, resistant to ageing, suitable in structure, high in usage value, long in service life, green and environment-friendly, and helps to improve the construction speed and substantially reduce the construction cost of an engineering unit.

Owner:陕西中昌科技有限公司

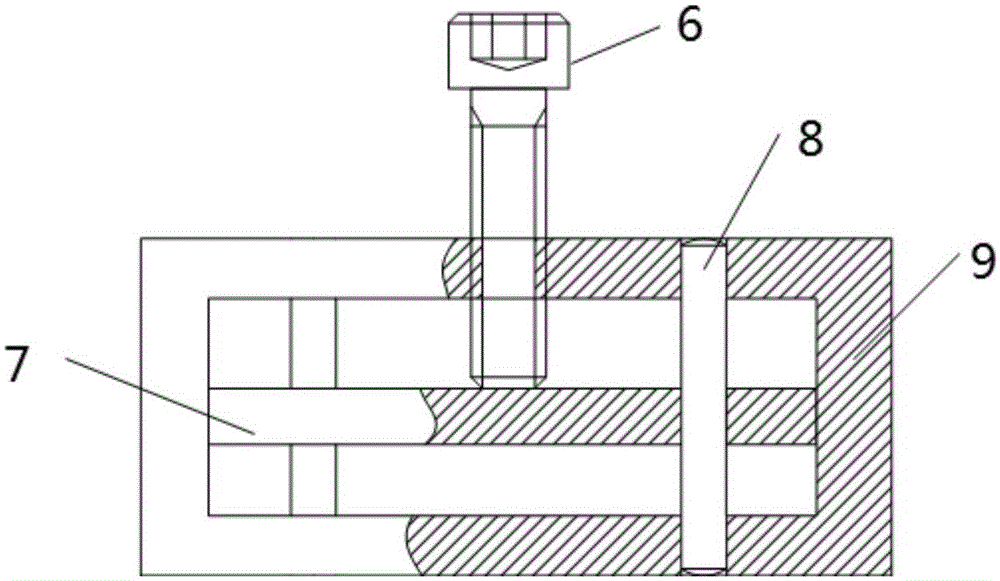

Mould and method for preparing ultra-high performance concrete pipeline

InactiveCN104802301AReduce crackingHigh strengthMouldsCeramic shaping coresShrinkage crackingStructural engineering

The invention discloses a mould for preparing an ultra-high performance concrete pipeline. The mould comprises an outer steel mould and an inner steel mould with grouting holes, wherein a steel wedge block is arranged at a joint of the inner steel mould; the steel wedge block is supported on an inner wall of the inner steel mould through a wedge block; the inner steel mould is formed by splicing two steel components and a rubber part which is connected between the two steel components; fixing devices for clamping and fastening the inner steel mould are arranged at the two ends of the inner steel mould. The invention also discloses a method for preparing the ultra-high performance concrete pipeline by adopting the mould. According to the mould, the steel mould is combined with the rubber, so that the advantages of high rigidity and capability of bearing higher pumping pressure of the steel mould are utilized, the excellent deformability of the rubber is also utilized, and the shrinkage crack phenomenon of the pipeline is effectively eliminated.

Owner:SOUTH CHINA UNIV OF TECH

Processing method for main pipe of stainless steel water collecting and distributing device with plane lug boss

The invention relates to a processing method for a main pipe of a stainless steel water collecting and distributing device with a plane lug boss. The production process of the main pipe comprises the steps such as material preparation, pipe coiling, welding and reshaping, lug boss forming, punching, inner side flanging, necking, outer side flanging, turning, grinding and polishing. In the work procedure of punching, plugged inner dies are at least three overlapped steel plates and aim at bringing convenience to the taking-out of a mould after the punching is carried out; lug bosses matched with the inner wall of a pipe lug boss in shape are arranged on the steel plates on two sides of the main pipe; and punching holes are formed in the central positions of the steel plates, which are positioned on the lug bosses. According to the main pipe of the stainless steel water collecting and distributing device, which is produced by using the processing method, stainless steel is fully utilized and interface threads are not required to be additionally welded; the whole production process is finished at one step; and products can be produced by a semi-mechanical or full-automatic way so as to facilitate the serialization formation of the products. The formed main pipe of the stainless steel water collecting and distributing device has the advantages of smooth inner wall, small viscosityresistance of fluid, attractiveness and elegance in appearance, firmness for mounting of a control valve and no limit to the number of branches.

Owner:NINGBO HRALE PLATE HEAT EXCHANGER

Processing method for supra-macromolecule polyethylene composite pipe

ActiveCN103587121AImprove wear resistanceGood self-lubricating performanceAntioxidantAging resistance

The invention discloses a processing method for a supra-macromolecule polyethylene composite pipe. The processing method comprises the following steps of (1) uniformly mixing supra-macromolecule polyethylene resin, graphite, polyethylene wax and an antioxidant which serve as raw materials, adding the uniformly mixed raw materials into a material barrel of a screw extruder, and manufacturing a pipe with the same shape as that of a neck mold with a certain shape through the neck mold on the screw extruder under the rotary extrusion action of a screw, wherein the pipe passes through a sizing device and a cooling device and is cooled to be hardened and sized by a water-oil cooling mode; continuously and uniformly leading out a product during cooling after a product plastic piece is extruded from the neck mold, cutting the cooled and sized product through a cutting device, and inspecting the cut product, wherein the qualified product is a supra-macromolecule polyethylene pipe; (2) cutting and posttreating the supra-macromolecule polyethylene pipe, and putting the post-treated supra-macromolecule polyethylene pipe into a steel pipe to obtain the supra-macromolecule polyethylene composite pipe. According to the processing method, the technology is simple; the supra-macromolecule polyethylene composite pipe is easy to produce and manufacture; the manufactured pipe is high in abrasion resistance, self-lubrication property and intensity, stable in chemical property and high in aging resistance.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

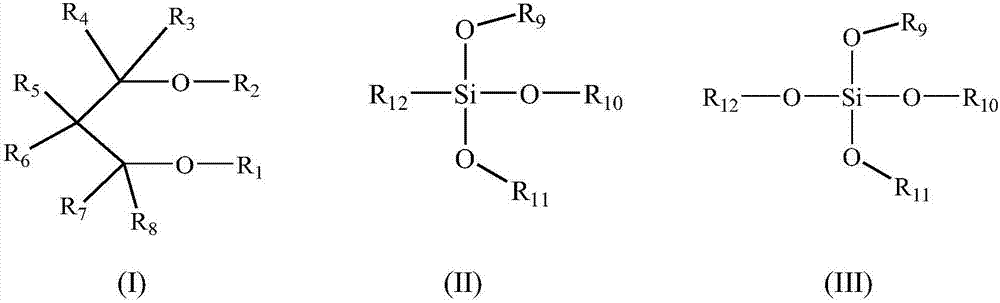

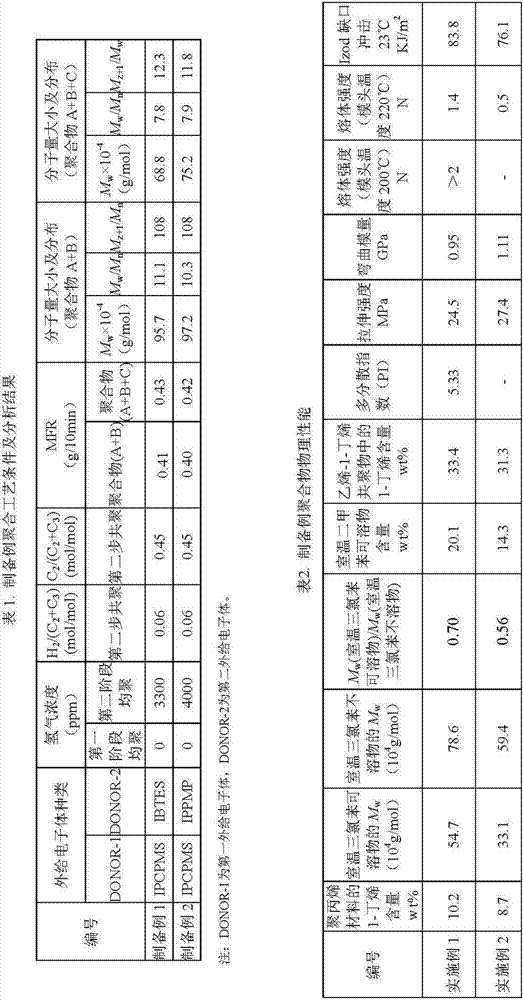

Polypropylene composition and high performance flame retardant antistatic polypropylene pipe

ActiveCN107325394AExcellent flame retardant, antistatic and impact resistanceSmooth inner wallRoom temperatureEthylene Homopolymers

The invention relates to a flame retardant antistatic polypropylene composition and a pipe prepared therefrom. The composition comprises basic polypropylene resin, a fire retardant, and a conductive filling material. The basic polypropylene resin comprises a propylene homopolymer component and ethylene-1-butene copolymer; wherein the propylene homopolymer component at least comprises first propylene homopolymer and second propylene homopolymer. In the basic polypropylene resin, the ratio of the Mw of a substance, which is soluble in trichlorobenzene at a room temperature, to the Mw of a substance, which is insoluble in trichlorobenzene at a room temperature, is greater than 0.5 and less than 1; preferably in a range of 0.5 to 0.8. At a room temperature, the content of a substance, which is soluble in xylene at a room temperature, is in a range of 10 wt% to 30 wt%. The content of 1-butene is 5 to 20 wt%. The provided pipe has a good antistatic and flame retardant performance, moreover, the melt strength is high, and the impact resistant property is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Large-caliber glass fiber-reinforced plastic ribbed pipe

The invention discloses a large-caliber glass fiber-reinforced plastic ribbed pipe. The wall of the body comprises a liner layer, a continuous glass fiber-reinforced structure layer and a circumferential outer protective layer, and the outside of the circumferential outer protective layer is provided with a plurality of glass fiber fabric reinforcing rib rings which are arranged at intervals. The comprehensive internal pressure-resisting and external load-resisting capability of the large-caliber glass fiber-reinforced plastic ribbed pipe provided by the invention is greatly enhanced. The inner wall of the large-caliber glass fiber-reinforced plastic ribbed pipe is smooth, the rigidity of the large-caliber glass fiber-reinforced plastic ribbed pipe is high, and the size of the rib ring and the rib density can be designed according to rigidity requirement; compared with the rigidity of the pure glass fiber-reinforced plastic smooth pipe, the rigidity of the large-caliber glass fiber-reinforced plastic ribbed pipe is higher, and the large-caliber glass fiber-reinforced plastic ribbed pipe is lighter and stronger than the glass fiber-reinforced plastic mortar pipe; and as a novel delivery pipe, the large-caliber glass fiber-reinforced plastic ribbed pipe has the advantages of corrosion resistance, low fluid resistance, long service life and the like, is easy to maintain, and is particularly applicable to the fields of deeply buried large-caliber drainage pipelines, seawater delivery, seawater desalination and the like.

Owner:新疆鹏远复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com