Large-caliber glass fiber-reinforced plastic ribbed pipe

A fiberglass and reinforced pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy damage, heavy weight, low external load rigidity, etc., and achieve long service life, enhanced comprehensive force, The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

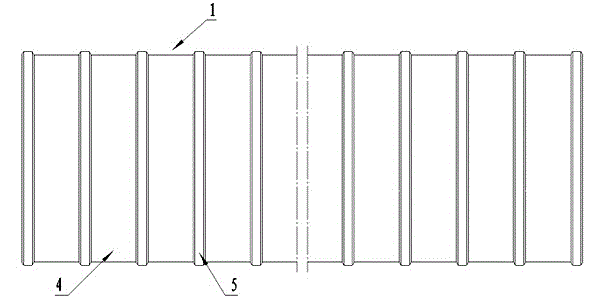

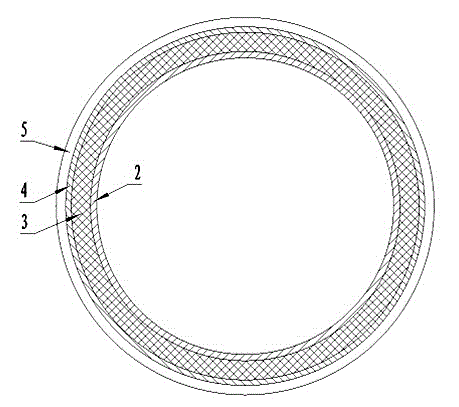

[0023] Such as Figure 1-3 As shown, in the large-diameter FRP reinforced pipe 1 described in the embodiment of the present invention, the pipe wall of the main body sequentially includes a lining layer 2, a continuous glass fiber reinforced structure layer 3, and a ring-to-out protection layer 4 from the inside to the outside. The exterior of the outer protective layer 4 is provided with several glass fiber fabric reinforcing rib rings 5 arranged at intervals.

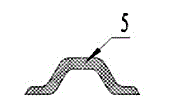

[0024] Further, several glass fiber fabric reinforcing rib rings 5 are evenly distributed on the circumference of the pipe wall of the body, the size of the rib ring and the reinforcing density can be designed according to the rigidity requirements, and the center of the section of the glass fiber fabric reinforcing rib ring 5 is raised A trapezoid with sides extending horizontally.

[0025] The lining layer 2 adopts a glass fiber fabric reinforced dense structure;

[0026] The continuous glass fiber-reinforced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com