Mould and method for preparing ultra-high performance concrete pipeline

An ultra-high-performance, concrete technology, applied in the direction of molds, ceramic forming cores, etc., can solve the problems of ultra-high-performance concrete delamination, difficulty in forming a pipe body, and no way to adapt to ultra-high-performance concrete pipe forming, and achieves good durability. , The inner wall is smooth, which is conducive to the effect of water flow through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] A method for preparing ultra-high performance concrete pipelines using the mold, comprising the steps of:

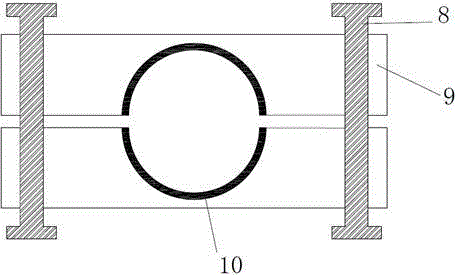

[0052] 1) Assemble the mould, fix it with clamp 9, connect the pumping machine with the mould, and ensure the tightness of the mould;

[0053] 2) Prepare ultra-high performance concrete mixture;

[0054] 3) Put the ultra-high-performance concrete mixture into the pumping machine, and use the pumping jacking process to form the pipeline;

[0055] 4) After the pumping is completed, close the grouting port of the mold in time;

[0056] 5) The overall maintenance of the pipeline and the mold, until the ultra-high performance concrete has the strength to remove the mold, the mold can be disassembled;

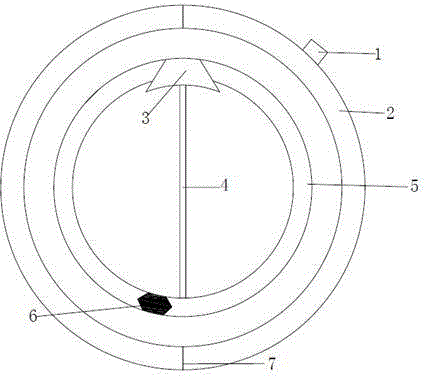

[0057] 6) When disassembling the mold, remove the wedge support 4 first, take out the steel wedge 3, and then disassemble the steel inner mold 5 and the steel outer mold 2, until the mold is completely disassembled;

[0058] Specifically, in this embodiment, specifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com