Porous plum-blossom-shaped pipe and preparation method thereof

A plum-blossom tube and resin powder technology, applied in the field of porous plum-blossom tubes and polymer materials, can solve the problem of pipe acid and alkali resistance, salt-alkali resistance, poor corrosion resistance, unreasonable ratio of plum-blossom tube raw materials, poor oxidation resistance, and poor aging ability and other problems, to achieve the effect of reducing construction difficulties, light weight, high temperature resistance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

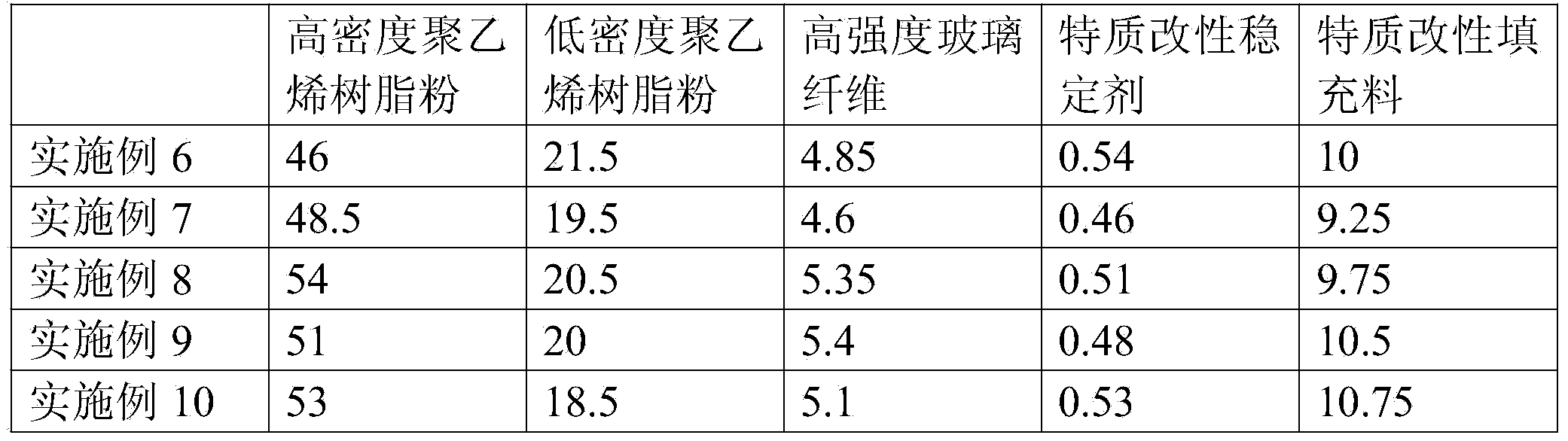

Examples

Embodiment 1

[0041] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 50 parts of high-density polyethylene resin powder, 20 parts of low-density polyethylene resin powder, 5 parts of high-strength glass fiber, 0.5 parts of special modified stabilizer, special modified filler 10 servings.

[0042] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0043] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0044] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0045] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0046] The composition of the base materia...

Embodiment 2

[0060] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 52.5 parts of high-density polyethylene resin powder, 19 parts of low-density polyethylene resin powder, 5.5 parts of high-strength glass fiber, 0.55 parts of special modified stabilizer, special modified filler 9.5 servings.

[0061] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0062] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0063] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0064] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0065] The composition of the base m...

Embodiment 3

[0068] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 45 parts of high-density polyethylene resin powder, 22 parts of low-density polyethylene resin powder, 4.75 parts of high-strength glass fiber, 0.525 parts of special modified stabilizer, special modified filler Ingredients 11 servings.

[0069] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0070] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0071] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0072] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0073] The composition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com