Polyvinyl chloride composition and transparent pipe thereof

A technology of polyvinyl chloride and composition, applied in the field of polyvinyl chloride composition and its transparent pipes, can solve the problems of complex technology in the processing process, large workload, complex formula, etc. Smooth, non-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

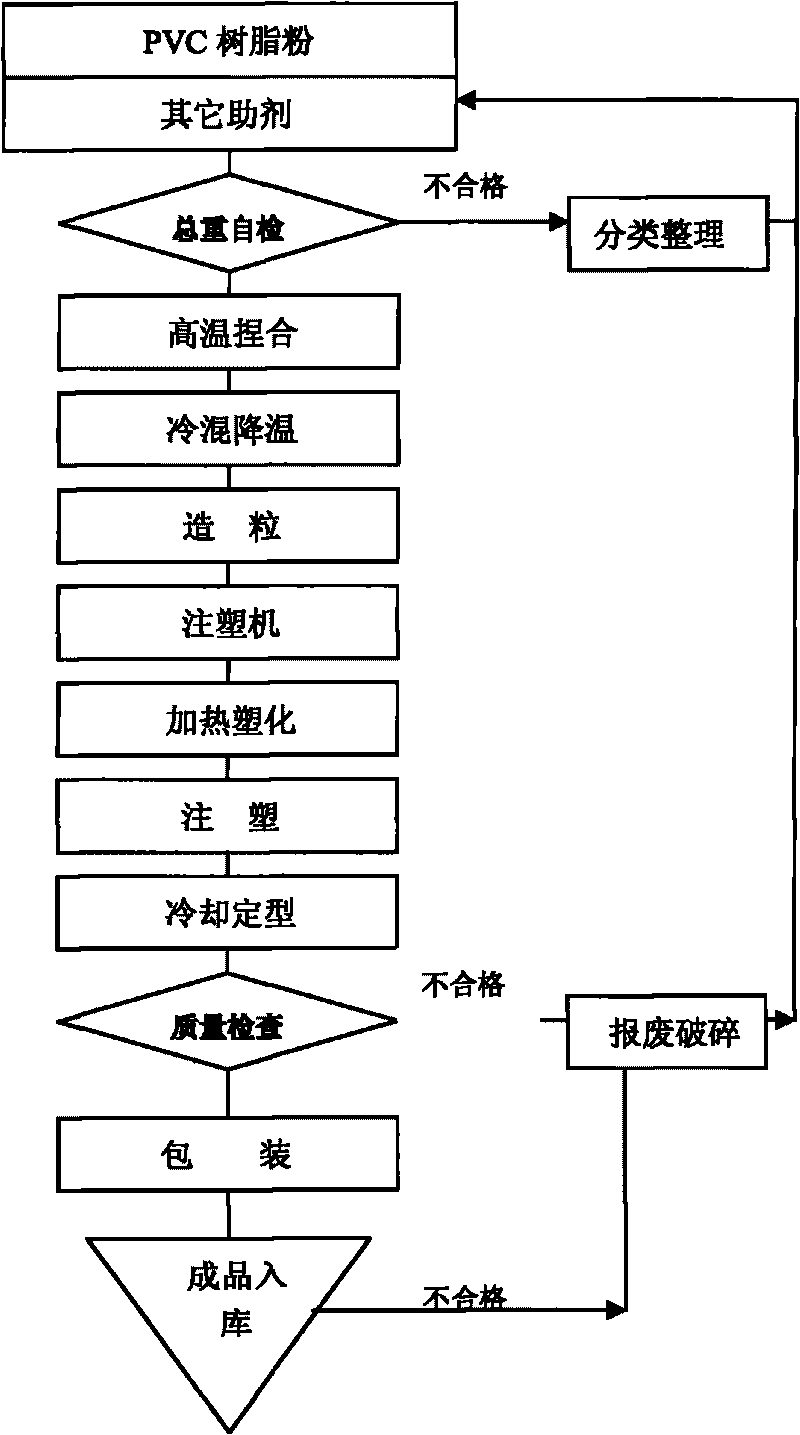

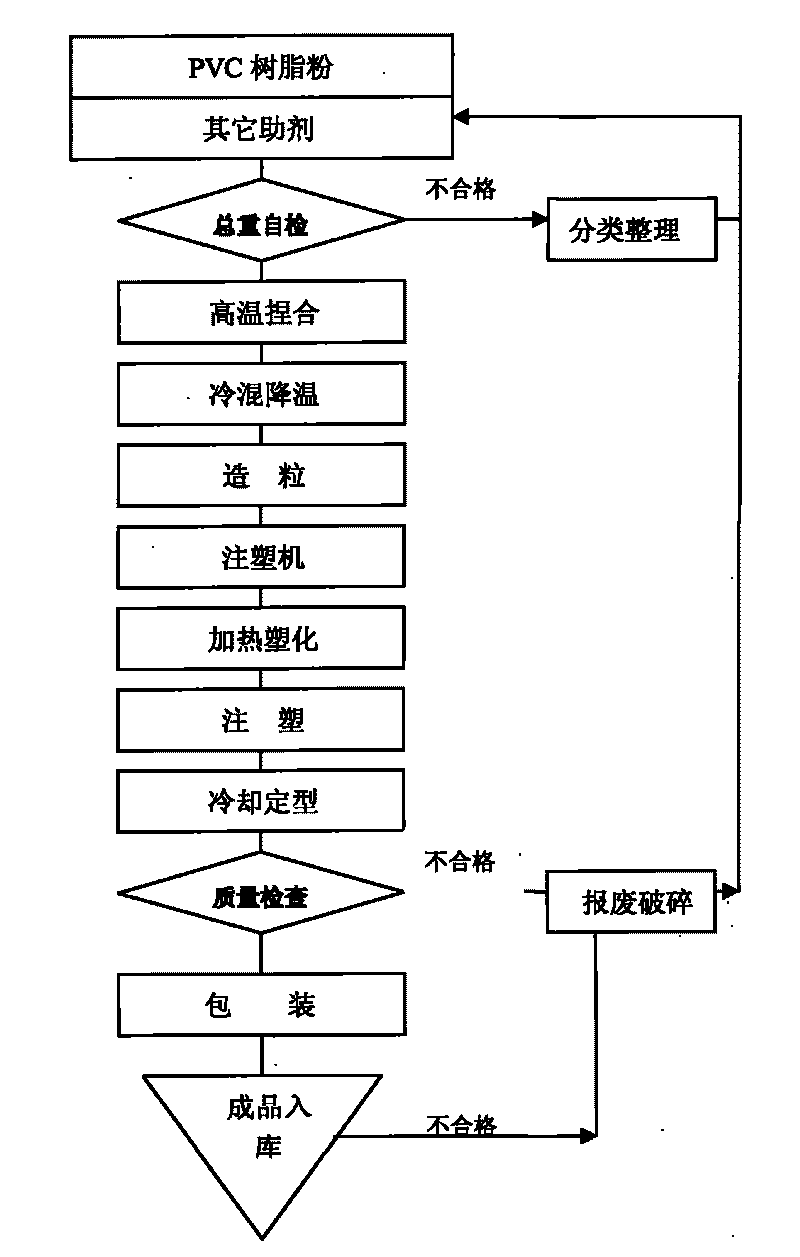

Method used

Image

Examples

Embodiment 1

[0040] The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0041] PVC resin 100;

[0042] Organotin T-178A (heat stabilizer) 1.8;

[0043] G60 (internal lubricant) 0.6;

[0044] Polyethylene wax (lubrication aid) 0.8;

[0045] PA-40 (processing modifier) 2.0;

[0046] B610 (impact modifier) 3;

[0047] Ultramarine (decolorizer) 0.01;

[0048] UV531 (ultraviolet absorber) 0.3;

[0049] Antioxidant 1010 0.2;

[0050] DOP (plasticizer) 5.

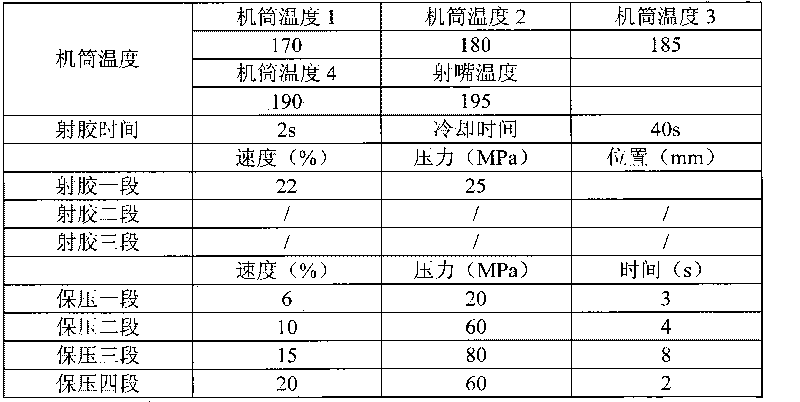

[0051] Weigh the above-mentioned components and add them into the heat mixer, turn to cold mixing when the temperature is about 110°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then granulate the obtained compound The transparent pellets were obtained, and the transparent PVC pipe fittings were injection-molded by an injection molding machine. The specific injection molding parameters are shown in Table 1...

Embodiment 2

[0055] The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0056] PVC resin 100;

[0057] Organotin T-178A (heat stabilizer) 2.2;

[0058] G60 (internal lubricant) 0.5;

[0059] Polyethylene wax (lubricating aid) 1.0;

[0060] PA-40 (processing modifier) 1.5;

[0061] B610 (impact modifier) 5;

[0062] Ultramarine (decolorizer) 0.015;

[0063] UV531 (ultraviolet absorber) 0.4;

[0064] Antioxidant 1010 0.2;

[0065] Epoxidized soybean oil 7.

[0066] Weigh the above-mentioned components and add them into the heat mixer, turn to cold mixing when the temperature reaches about 115°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then granulate the obtained compound The transparent pellets were obtained, and the transparent PVC pipe fittings were injection-molded by an injection molding machine. The specific injection molding parameters are sho...

Embodiment 3

[0070] The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0071] PVC resin 100;

[0072] Organotin T-178A (heat stabilizer) 2.5;

[0073] G60 (internal lubricant) 0.8;

[0074] Polyethylene wax (lubricant) 1.0;

[0075] PA-40 (processing modifier) 1.0;

[0076] B610 (impact modifier) 4;

[0077] Ultramarine (decolorizer) 0.01;

[0078] UV531 (ultraviolet absorber) 0.4;

[0079] Antioxidant 1010 0.2;

[0080] Epoxidized soybean oil (plasticizer) 4.

[0081] Weigh the above-mentioned components and add them into the heat mixer, turn to cold mixing when the temperature reaches about 115°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then granulate the obtained compound The transparent pellets were obtained, and the transparent PVC pipe fittings were injection molded by an injection molding machine. The specific injection molding parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com