Patents

Literature

54results about How to "Does not affect flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

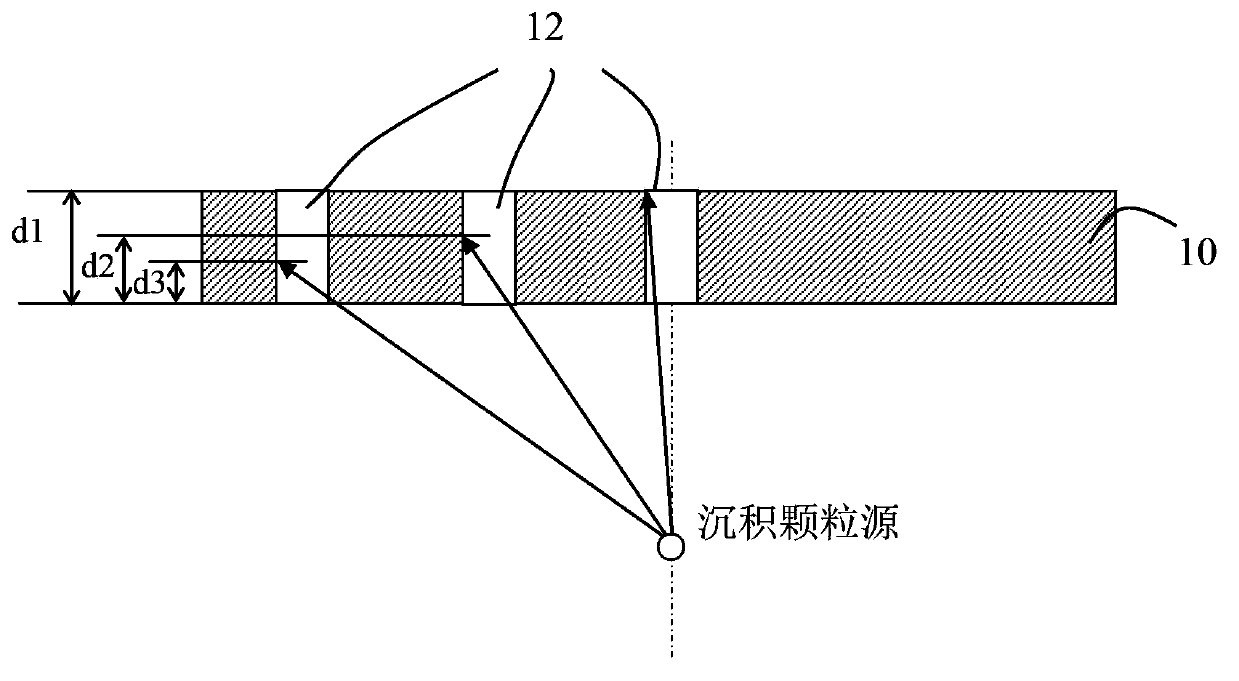

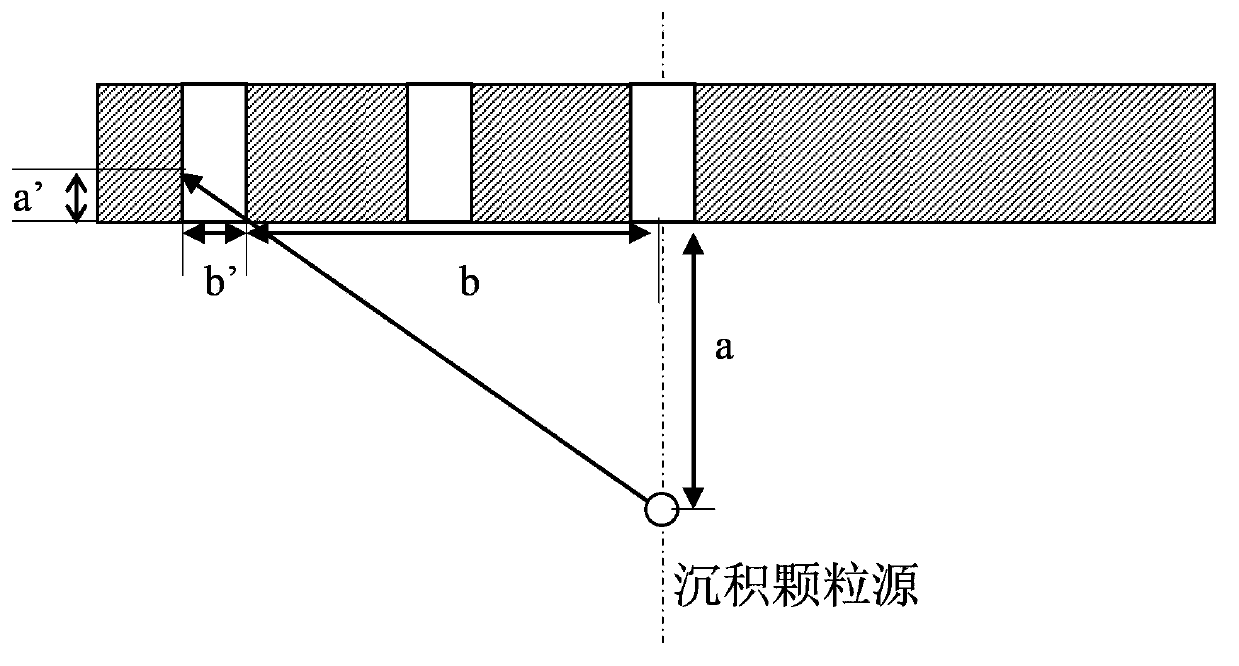

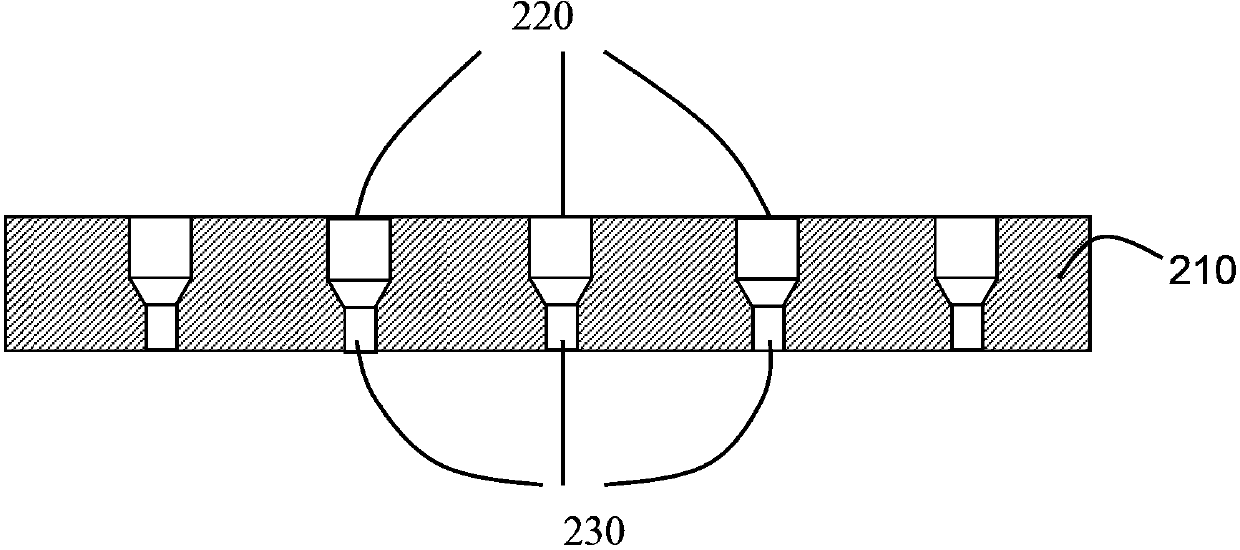

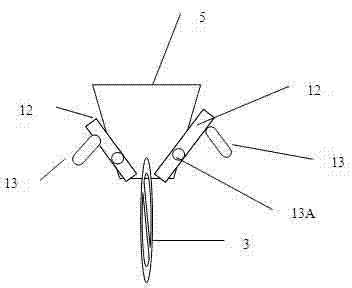

Corrosion-resistant pneumatic spray head and manufacture method thereof

ActiveCN103866291AExtended service lifeSpeed up entryChemical vapor deposition coatingSuperimposed coating processCeramic coatingShielding gas

The invention discloses a corrosion-resistant pneumatic spray head and a manufacture method thereof. The manufacture method of the corrosion-resistant pneumatic spray head is characterized in that an air through hole of the traditional pneumatic spray head is divided into two sections with different diameters, and thus the depth of a coating entering the air through hole can be increased without influencing the flow rate of gas; both the upper surface and the lower surface of the pneumatic spray head are coated with ceramic coatings, so that the inner surface of the air through hole is completely coated with the corrosion-resistant ceramic coating, so as to prevent the sidewall of the air through hole from being impacted by energy-carrying particles, and as a result, the service life of the pneumatic spray head is prolonged.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

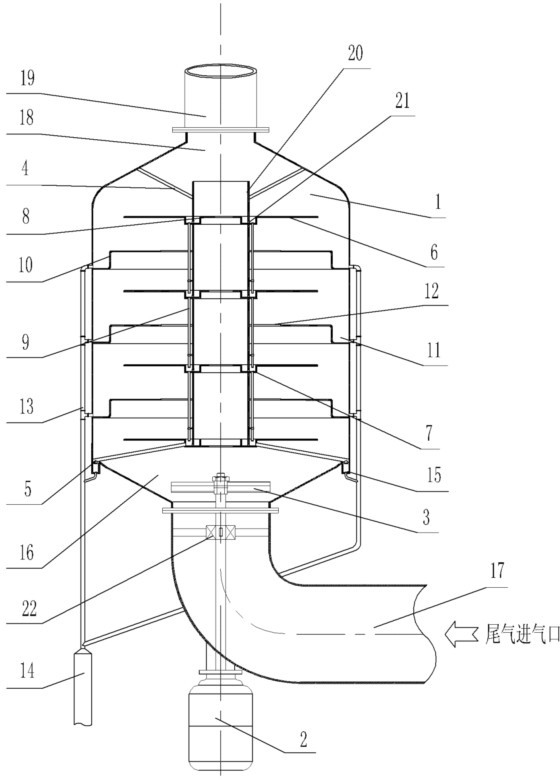

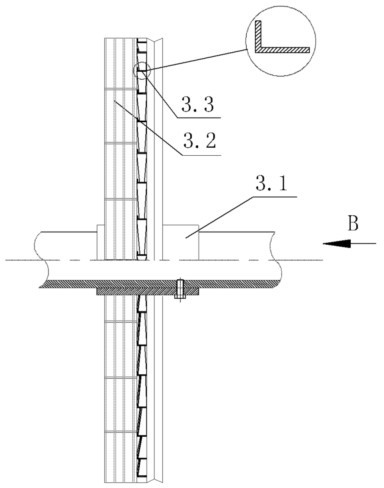

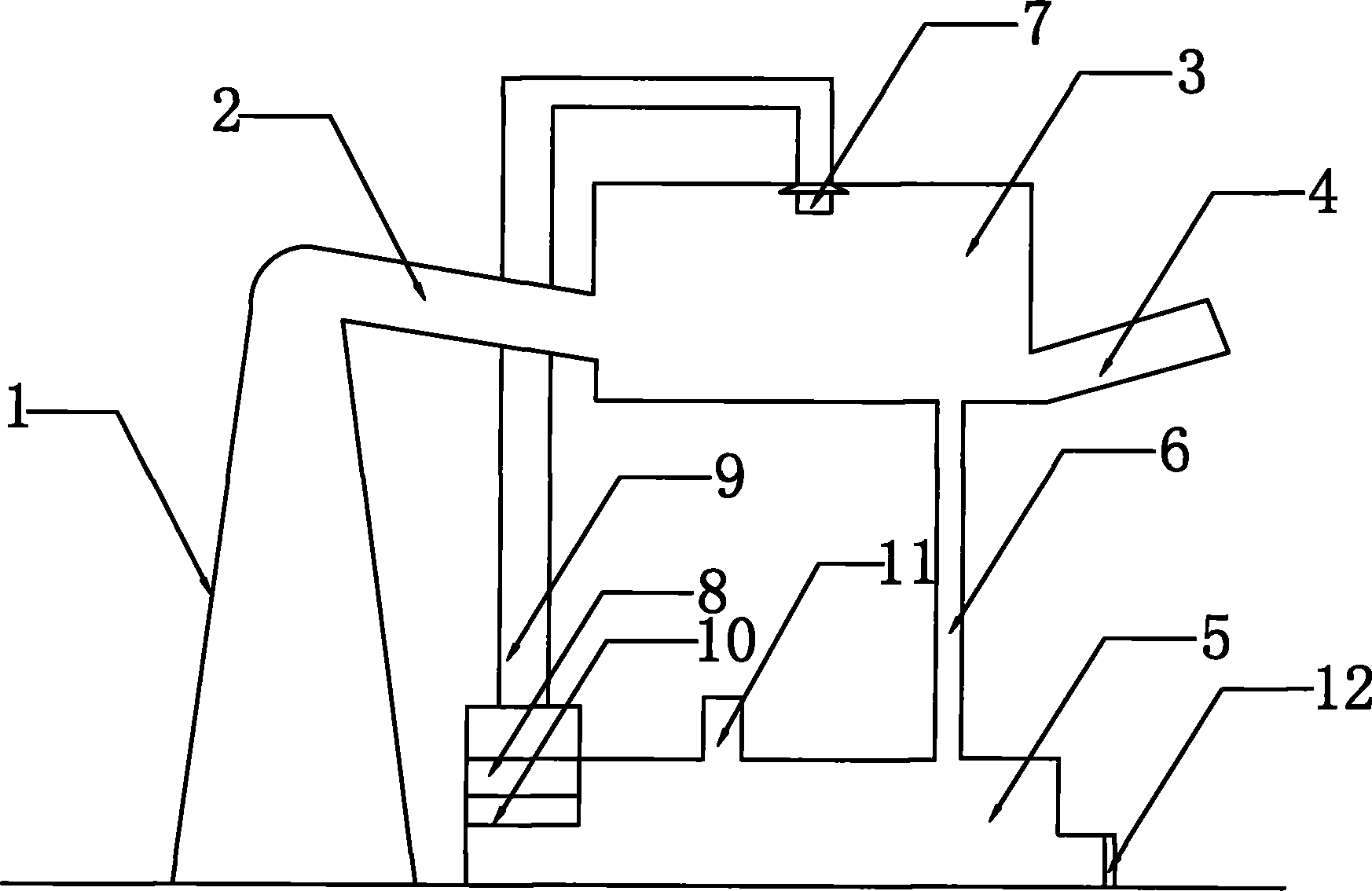

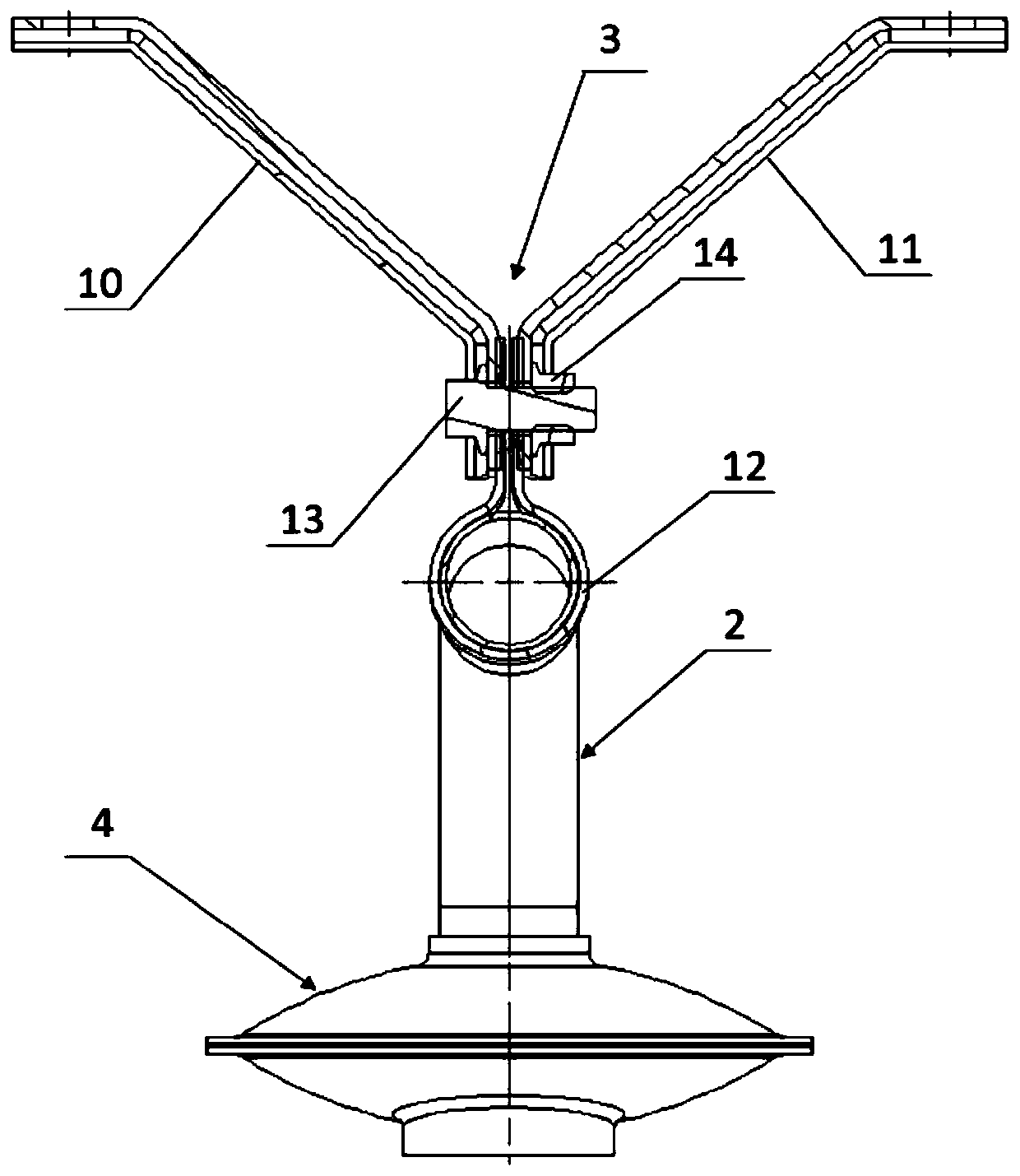

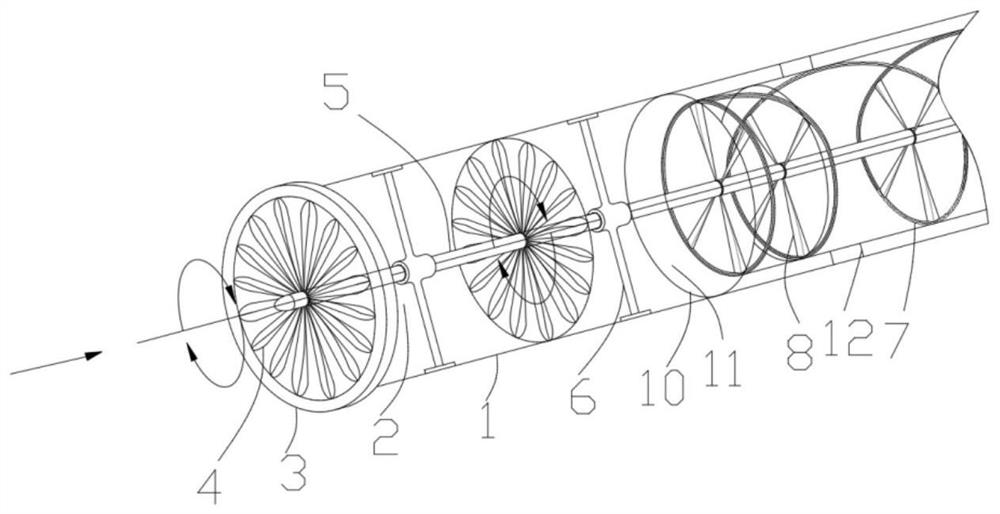

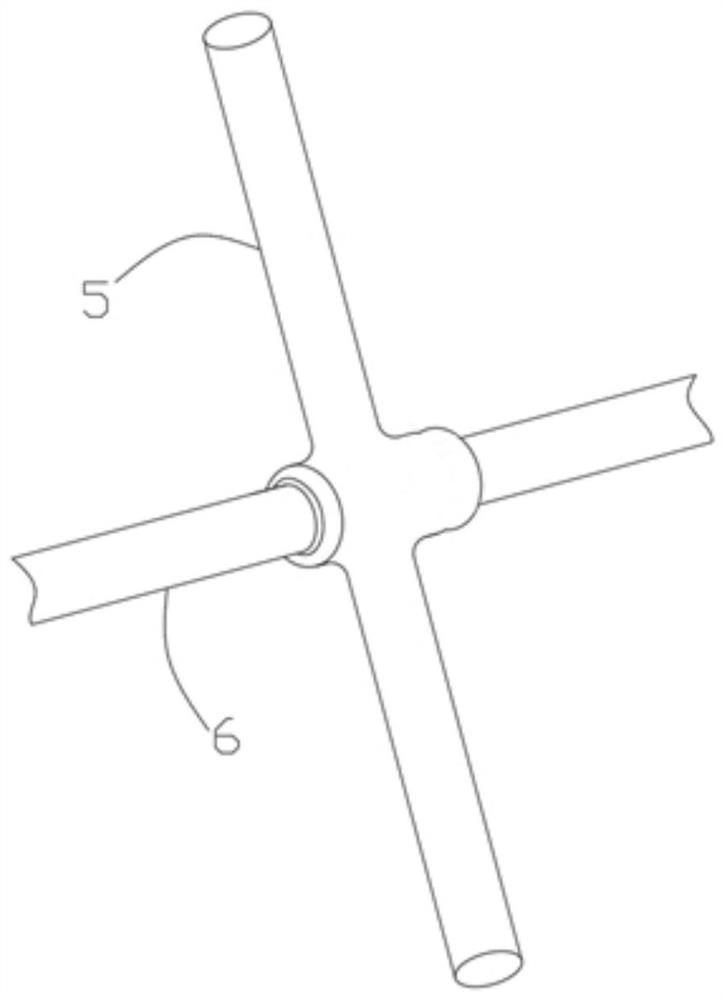

Vertical mist eliminator

ActiveCN102423579ADoes not affect flow rateGood anti-fog effectDispersed particle separationCentrifugationGas passing

The invention relates to a vertical mist eliminator. The vertical mist eliminator comprises a vertically-arranged cylinder, wherein the vertically-arranged cylinder is connected with a gas entering pipeline and a gas exhaust pipeline. A mist eliminating motor is arranged on the bending position of the gas entering pipeline. A mist eliminating fan blade is arranged on an output shaft of the mist eliminating motor. An outer drainage pipe is arranged on the outer side of the cylinder. A plurality of inner damping plates and a plurality of outer damping plates are arranged inside the cylinder, wherein the inner damping plates and the outer damping plates are intervally arranged. The inner damping plates are provided with circular inner backwater tanks, wherein the circular inner backwater tanks recess downward. Outer backwater tanks are arranged between the side edges of the outer damping plates and the inner wall of the cylinder, wherein the outer backwater tanks recess downward. With the present invention, the induced draft fan is adopted to absorb the water mist and the tail gas purified by the water mist from the gas entering pipeline; with the mist eliminating fan blade, the water mist hits the high speed centrifugation shunt blades and is coagulated into the water; the water and the gas are subjected to rechanneling and multiple friction rolling on the positions tightly close to the inner wall of the cylinder, and then hit the inner damping plates, the outer damping plates and the inner wall of the cylinder, the water is discharged by the drainage pipe after coagulating, and the gas is discharged by the gas exhaust pipeline. According to the vertical mist eliminator, the mist eliminating effect is significant, and the flow rate of the air flow is not affected.

Owner:ANHUI SAFE ELECTRONICS

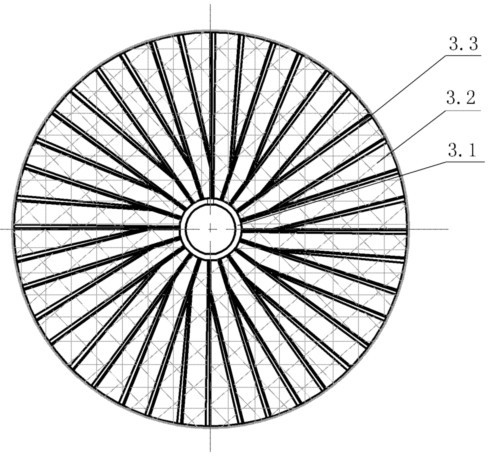

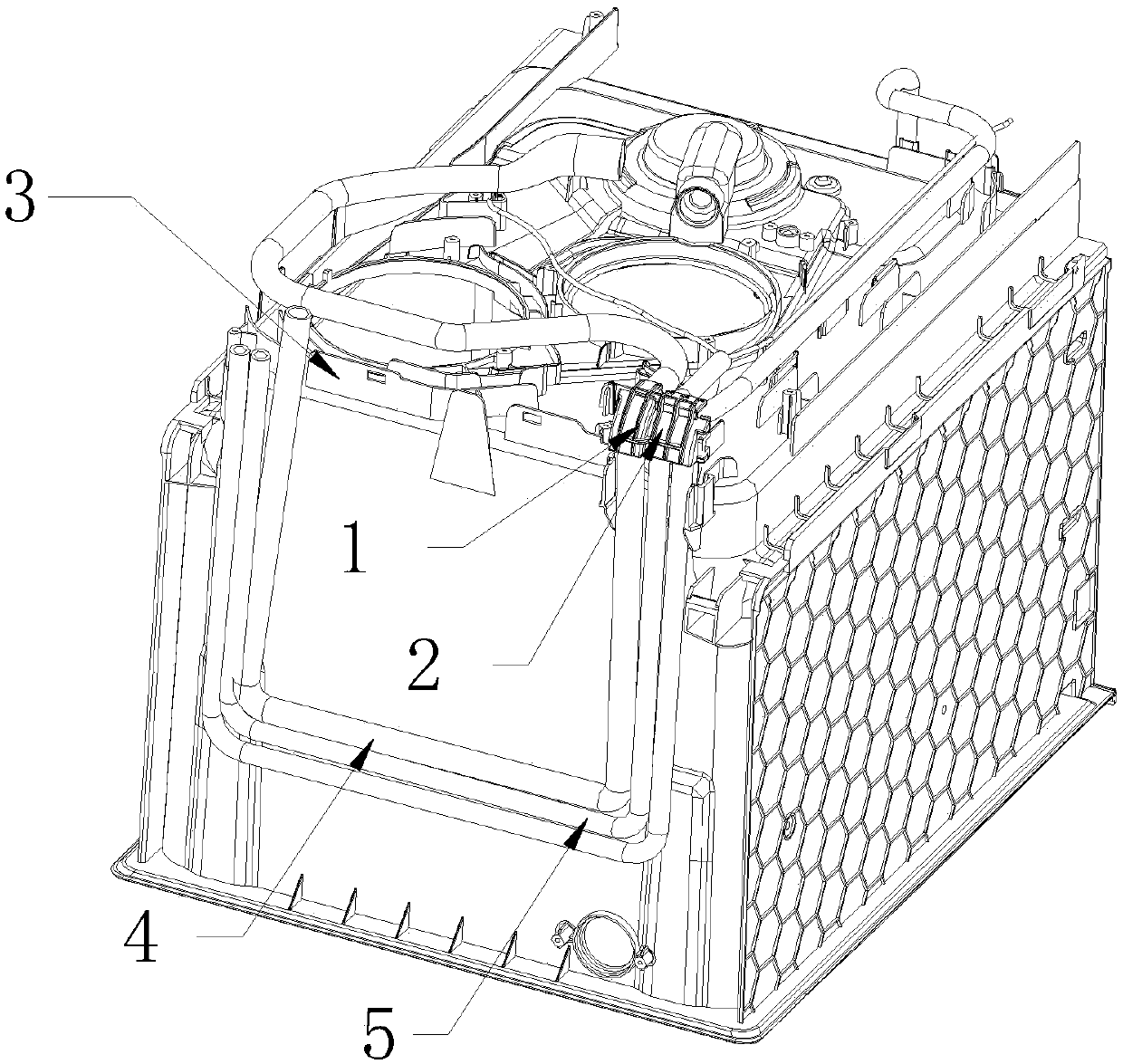

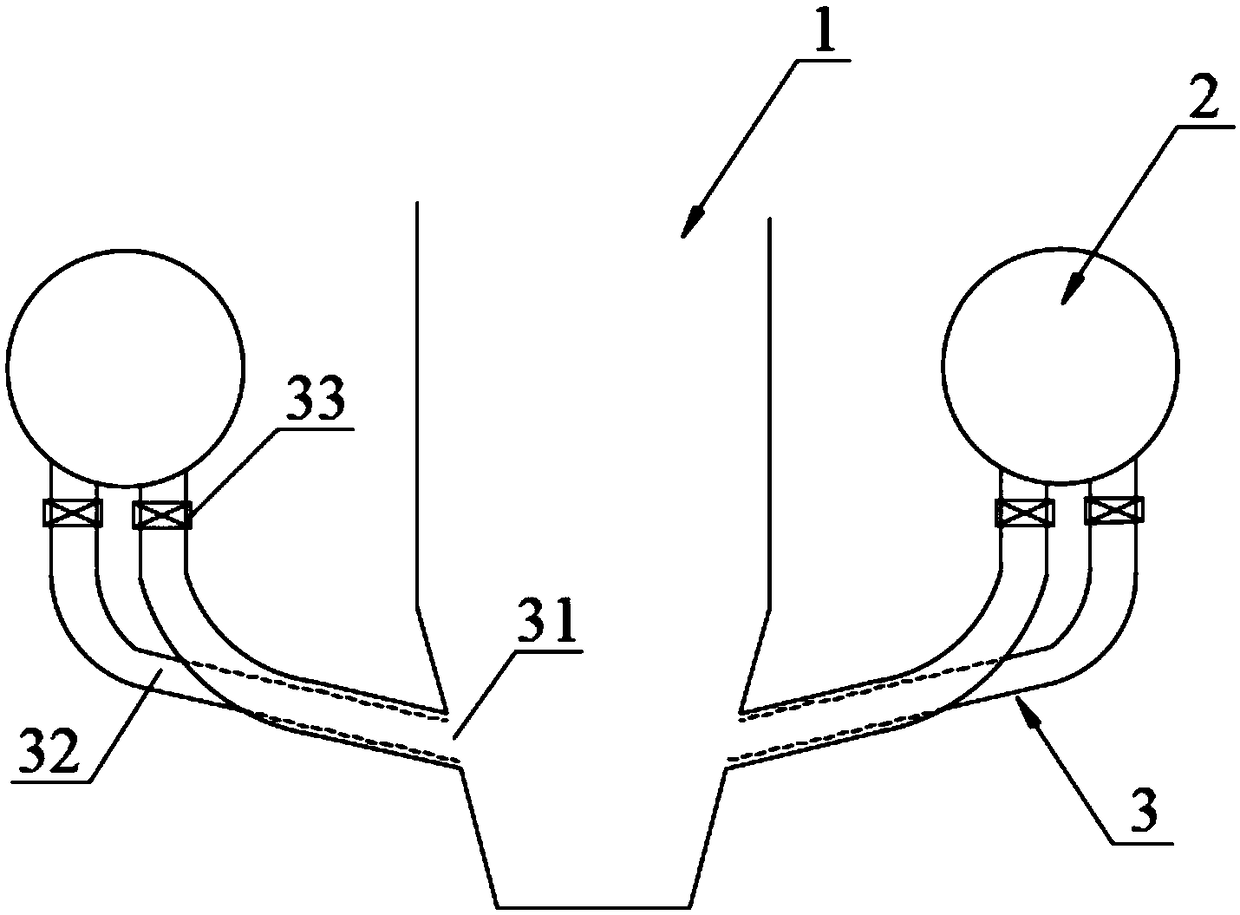

Shoe washing machine

PendingCN110384459ADo not squeeze each otherAvoid Mutual WearPipe protection against damage/wearFootwear cleanersFatigue damageWater leakage

The present invention belongs to the technical field of the shoe washing machine, in order to solve the problems of water seepage / water leakage of the inlet pipe and the drainage pipe due to fatigue damage of the inlet pipe and the drainage pipe caused by that the inlet pipe and the drainage pipe of the existing drawer type shoe washing machine are repeatedly bent when moving with the drawer. Thepresent invention provides a shoe washing machine. The shoe washing machine comprises a box body and a drawer slidably arranged in the box body; the drawer is provided with a fixing member for fixingpipes and / or a wire harness of the shoe washing machine; and at least part of the fixing member is designed as an arcuate configuration to limit the bending angle of the pipes and / or the wire harnessof the shoe washing machine. According to the technical scheme of the present invention, the pipes and / or the wire harness are fixed to the bottom of the drawer by using the fixing member, the pipes and / or the wire harness cannot be excessively bent to damage the pipes and / or the wire harness, and the flow of the medium inside the pipes cannot be affected by the bent pipes, so that the normal operation of the shoe washing machine can be ensured, and the safety of the shoe washing machine can be improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

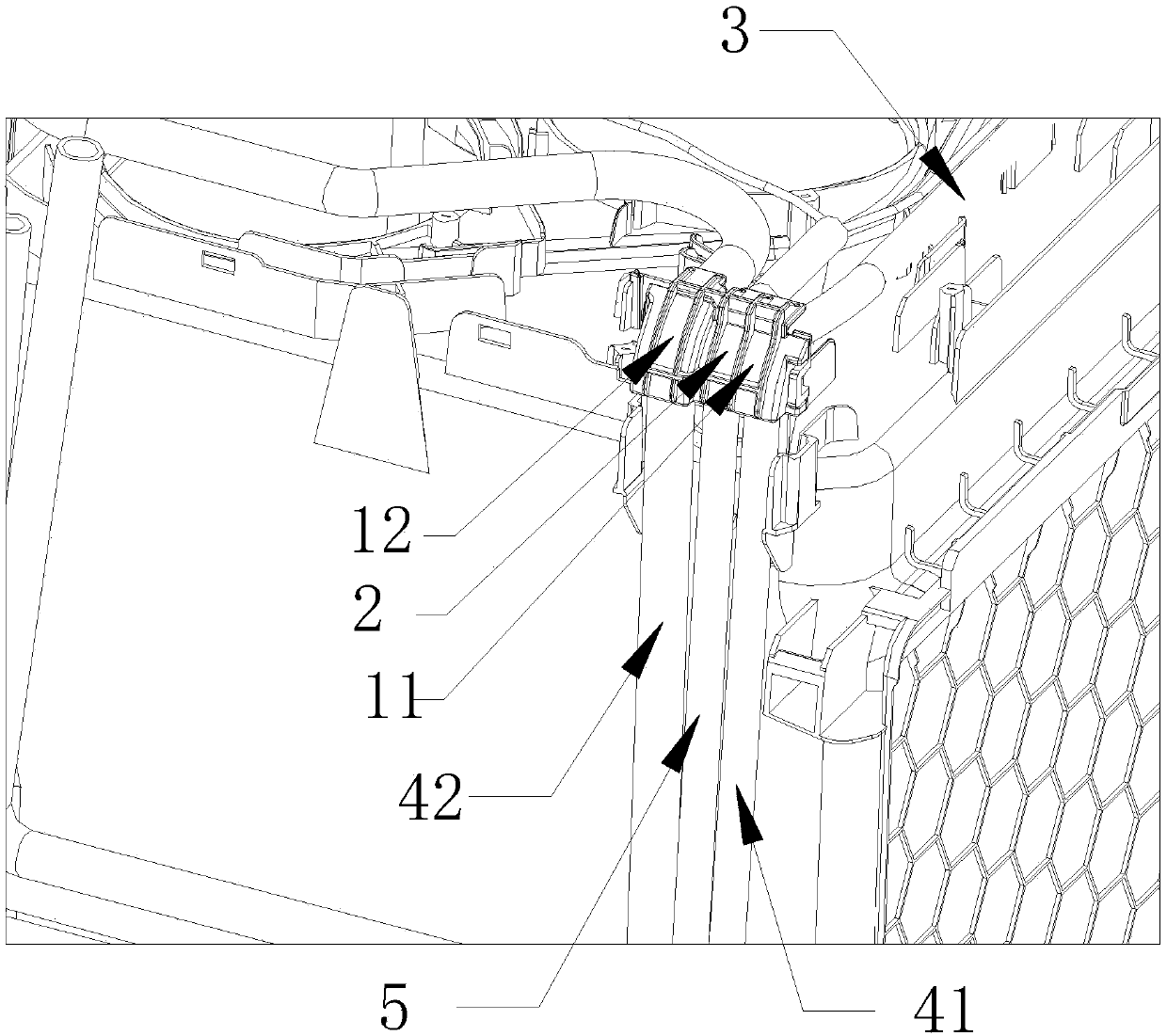

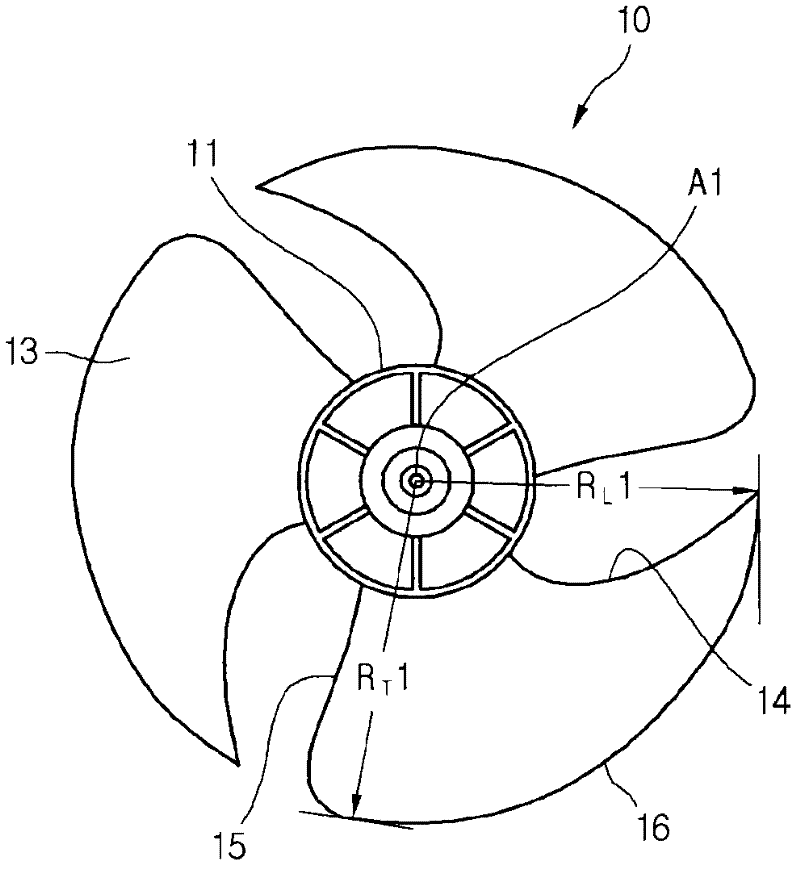

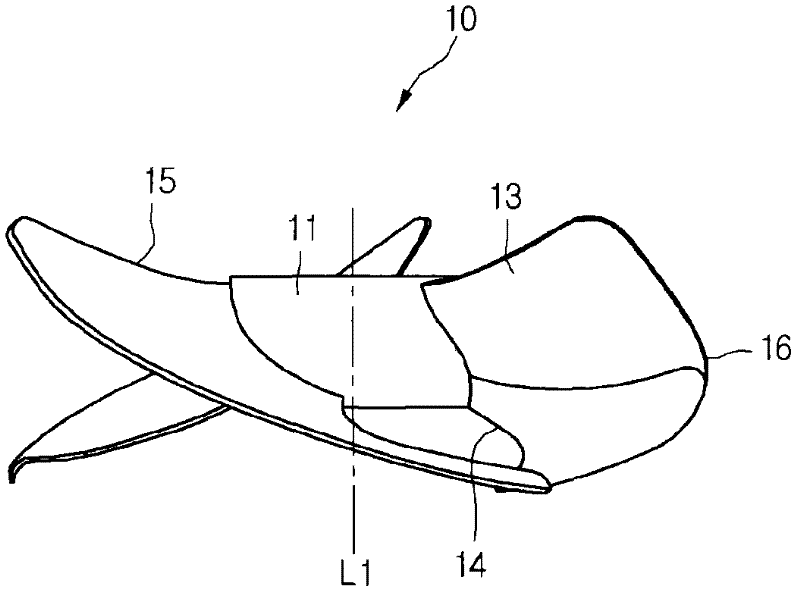

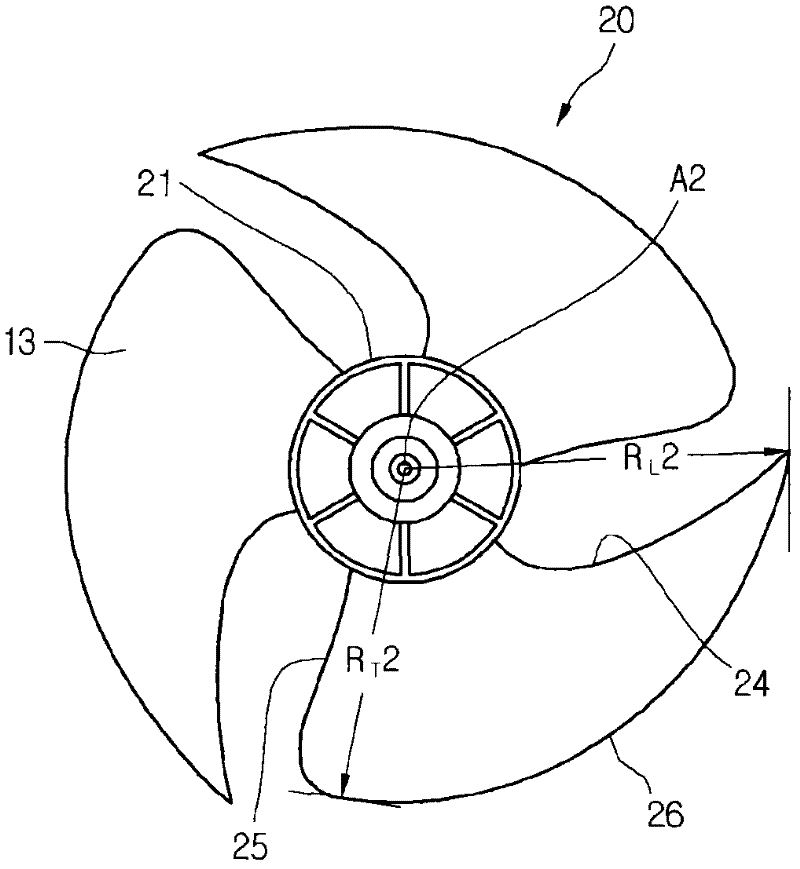

Axial flow fan and outdoor unit for air conditioner

ActiveCN102536899AReduce noiseIncrease flow ratePump componentsLighting and heating apparatusEngineeringMechanical engineering

Provided are an axial flow fan and an air conditioner outdoor unit including the axial flow fan. The axial flow fan includes a hub and blades disposed on an outer surface of the hub. Each of the blades satisfies that a shortest distance measured from an imaginary line (L2) passing through a center of the hub to a front end of an outer edge of the blade is greater than a shortest distance measured from the imaginary line (L2) to a rear end of the outer edge of the blade. The front end of the outer edge of the blade is a leading end in a rotation direction of the blade, and the rear end of the outer edge of the blade is a trailing end in the rotation direction of the blade. Owing to the shape of the blade, noise can be reduced while increasing the flowrate of air.

Owner:LG ELECTRONICS INC

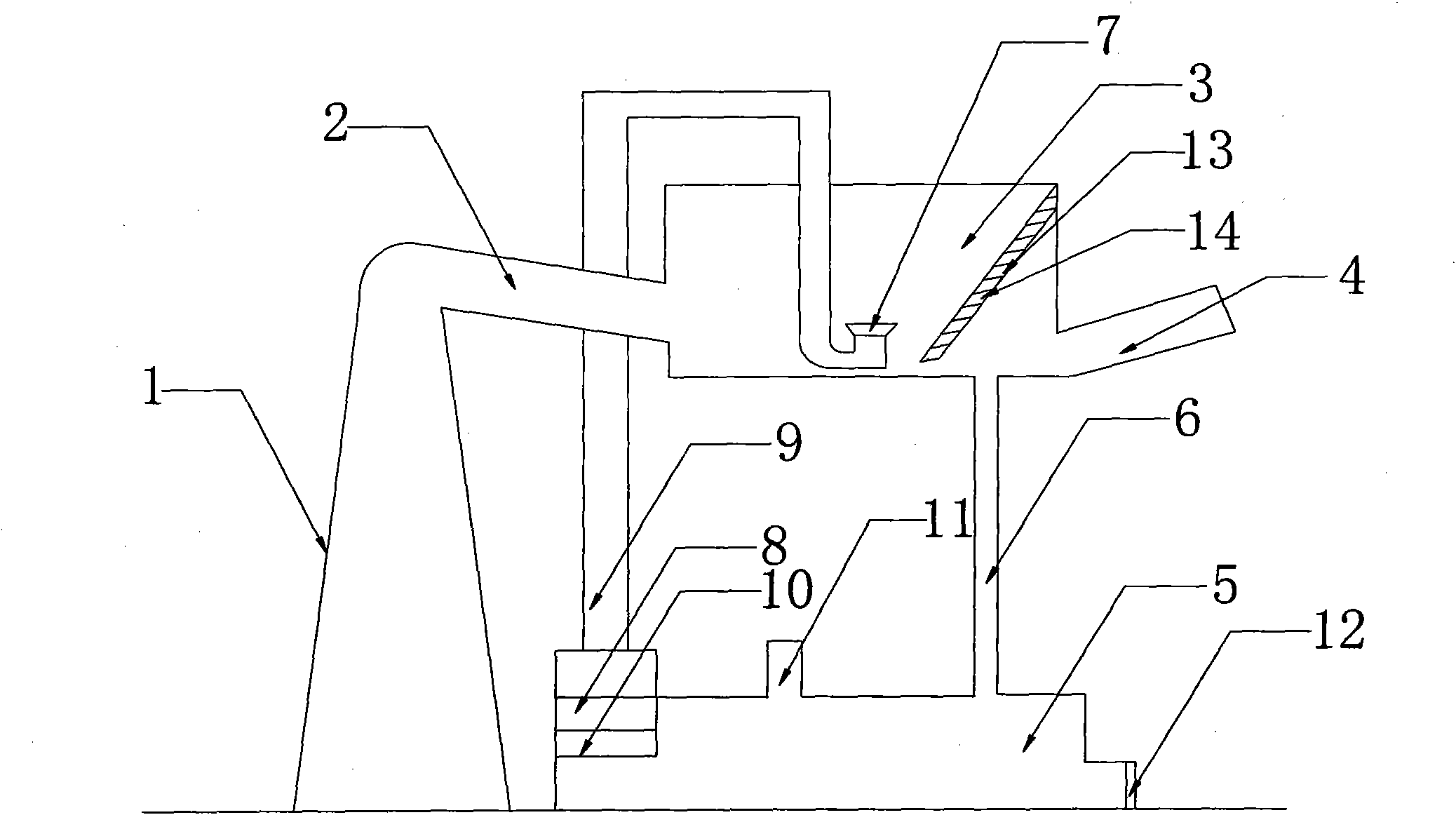

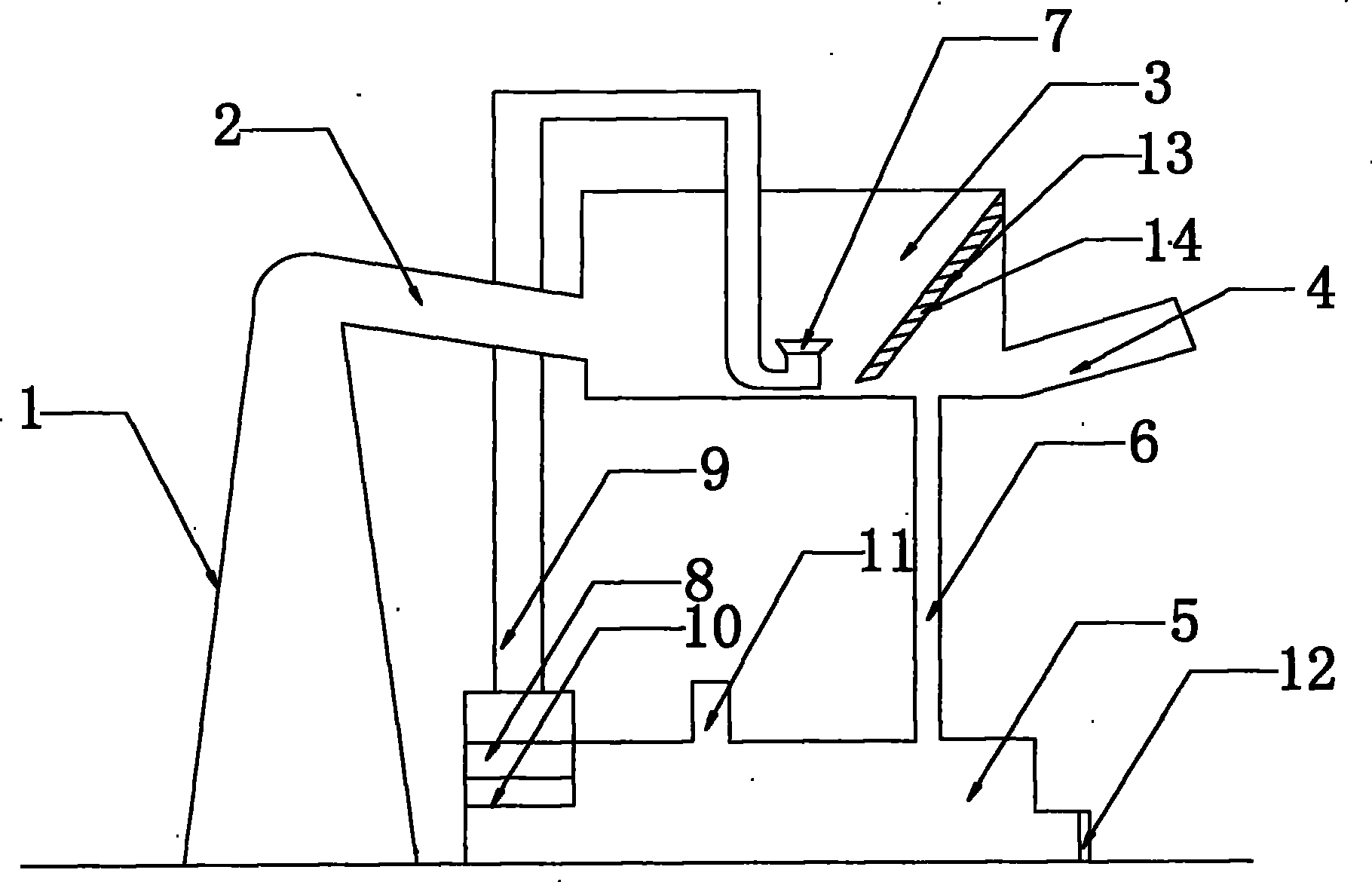

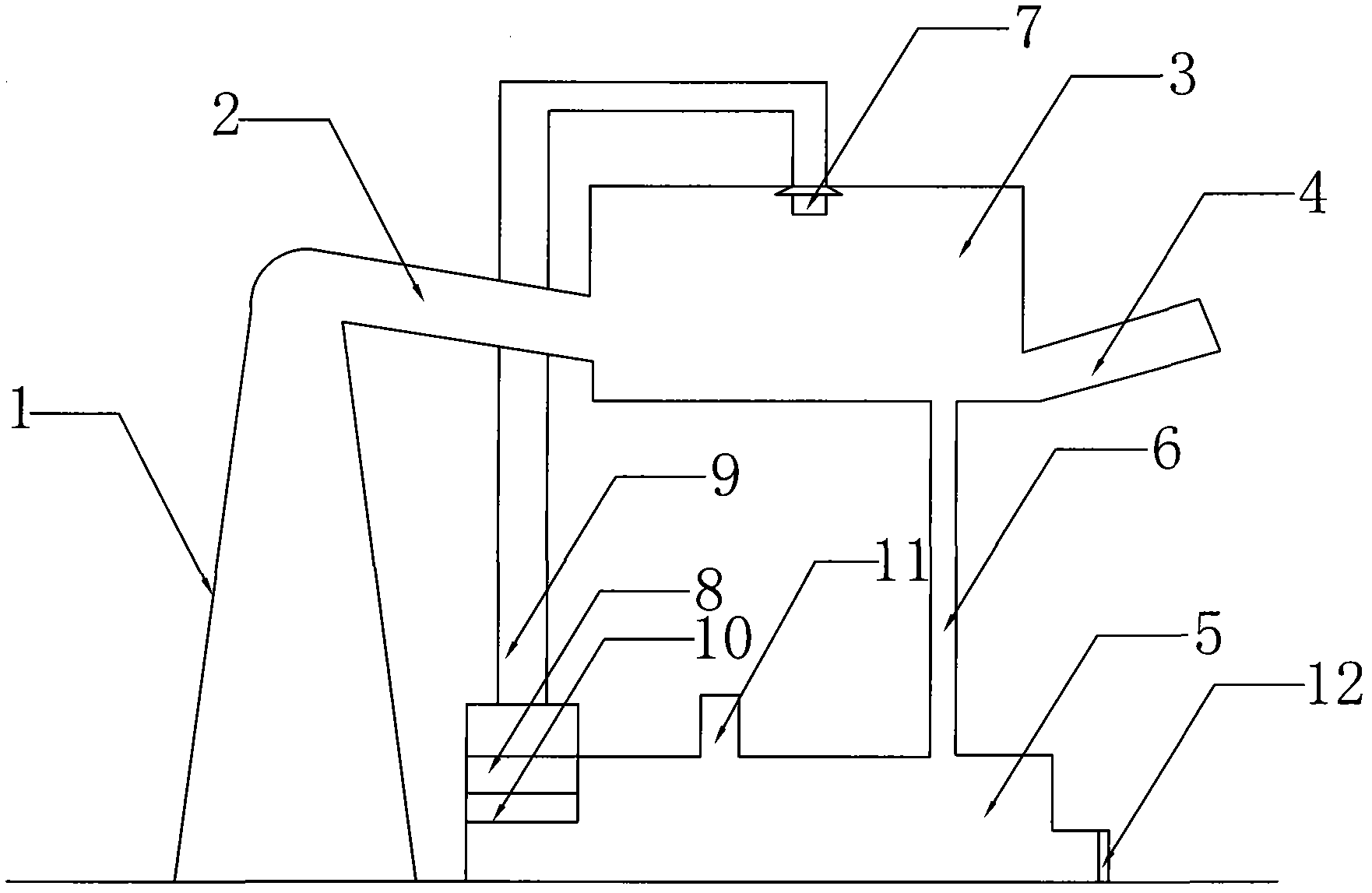

Chimney deduster

InactiveCN102688643ADoes not affect flow rateImprove dust removal effectCombination devicesUsing liquid separation agentSprayerEngineering

The invention relates to a chimney deduster which comprises a smoke-transporting channel communicated with a chimney outlet; an outlet of the smoke-transporting channel is connected with a dust chamber; a smoke outlet is disposed above the dust chamber; a water pool is disposed at the bottom of the dust chamber; the water pool is communicated with the dust chamber through a water pipe I; the invention is characterized in that: the outlet of the smoke-transporting channel is lower than the chimney outlet; a sprayer is disposed at the bottom of the dust chamber; the sprayer is communicated with the water poor through a water pump and a water pipe II; a filter screen is disposed at the joint of the water pipe II and the water pool; a water inlet is disposed at the top of the water pool; a baffle plate is disposed in the dust chamber; a plurality of air vents are disposed on the baffle plate. The advantages of the invention are that: the dedusting effect is good; the smoke flow velocity is not affected; the smoke is not only dedusted but also cooled.

Owner:胡建生

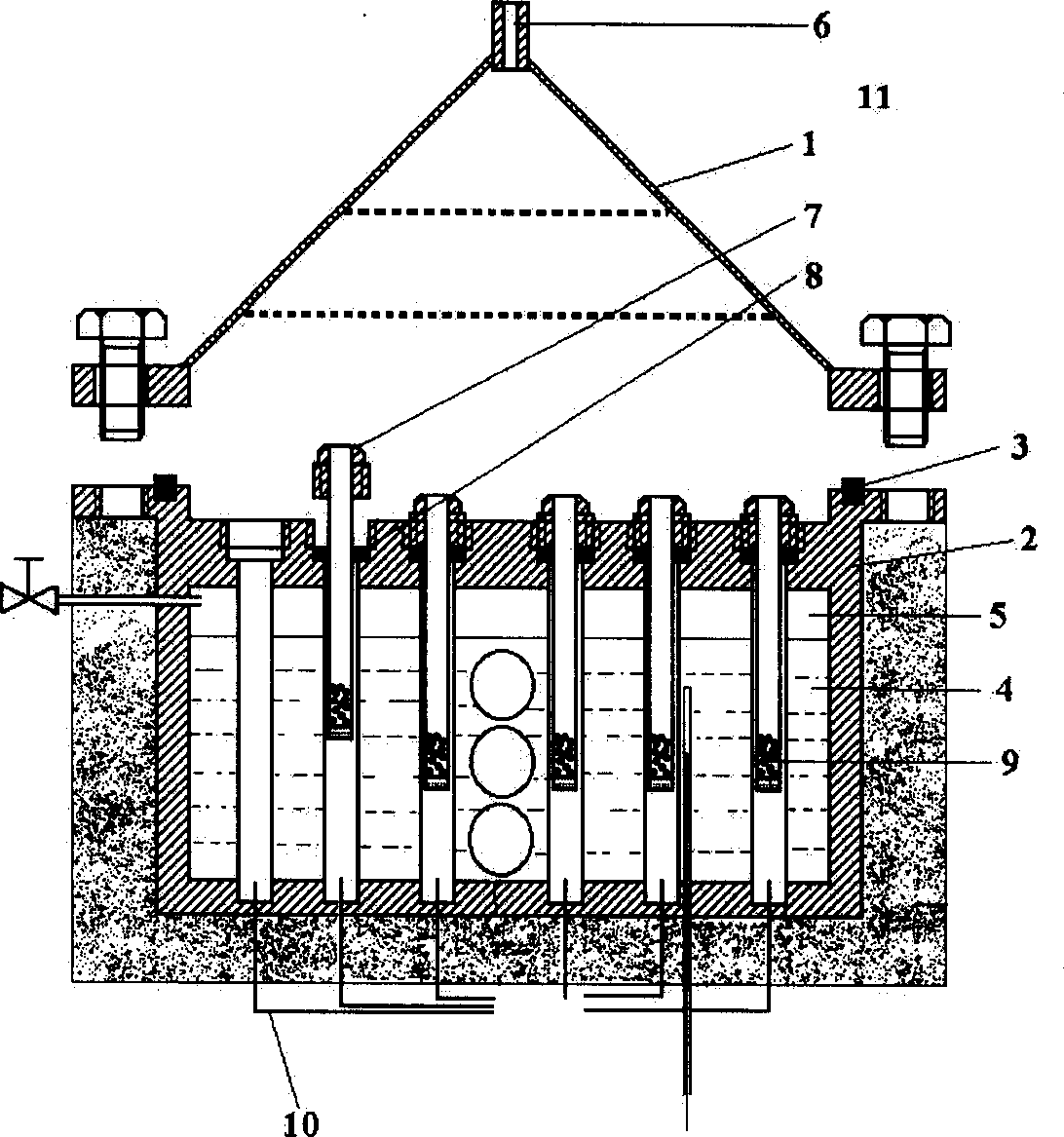

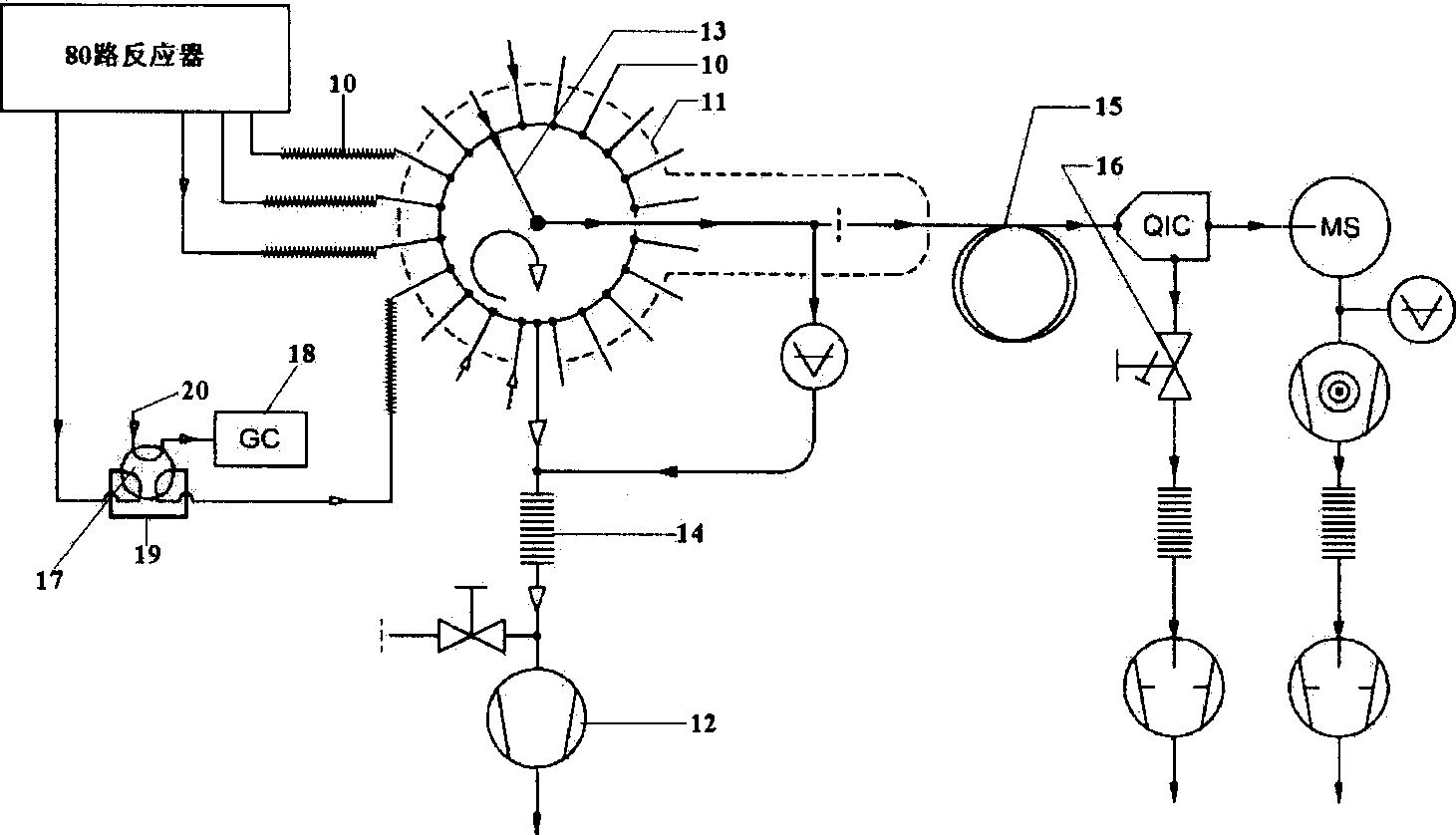

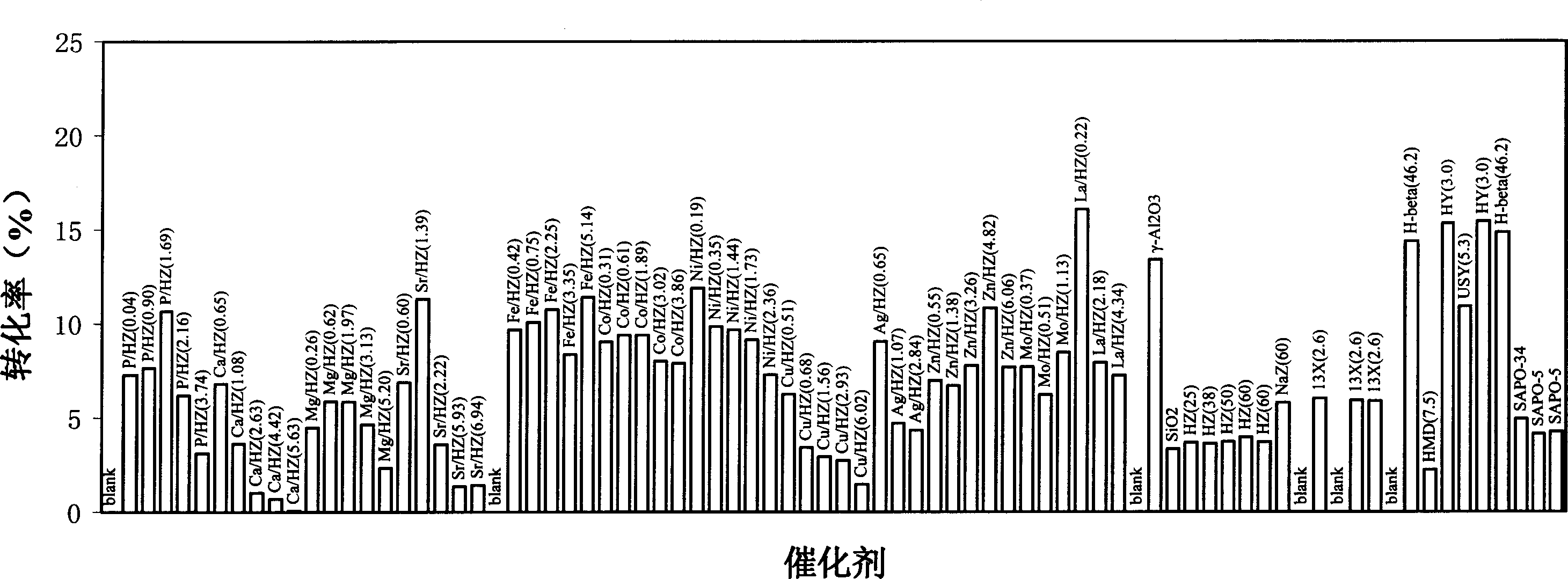

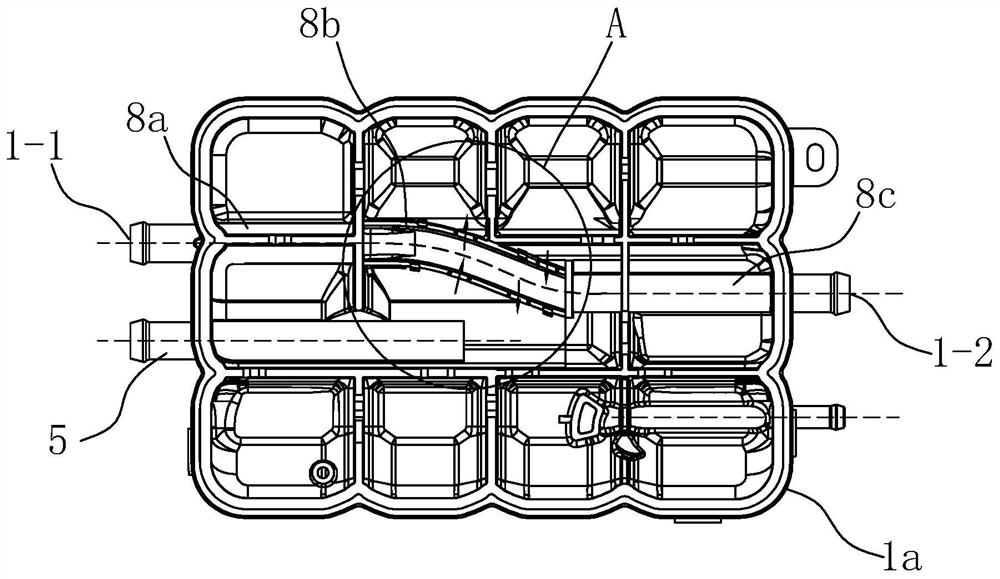

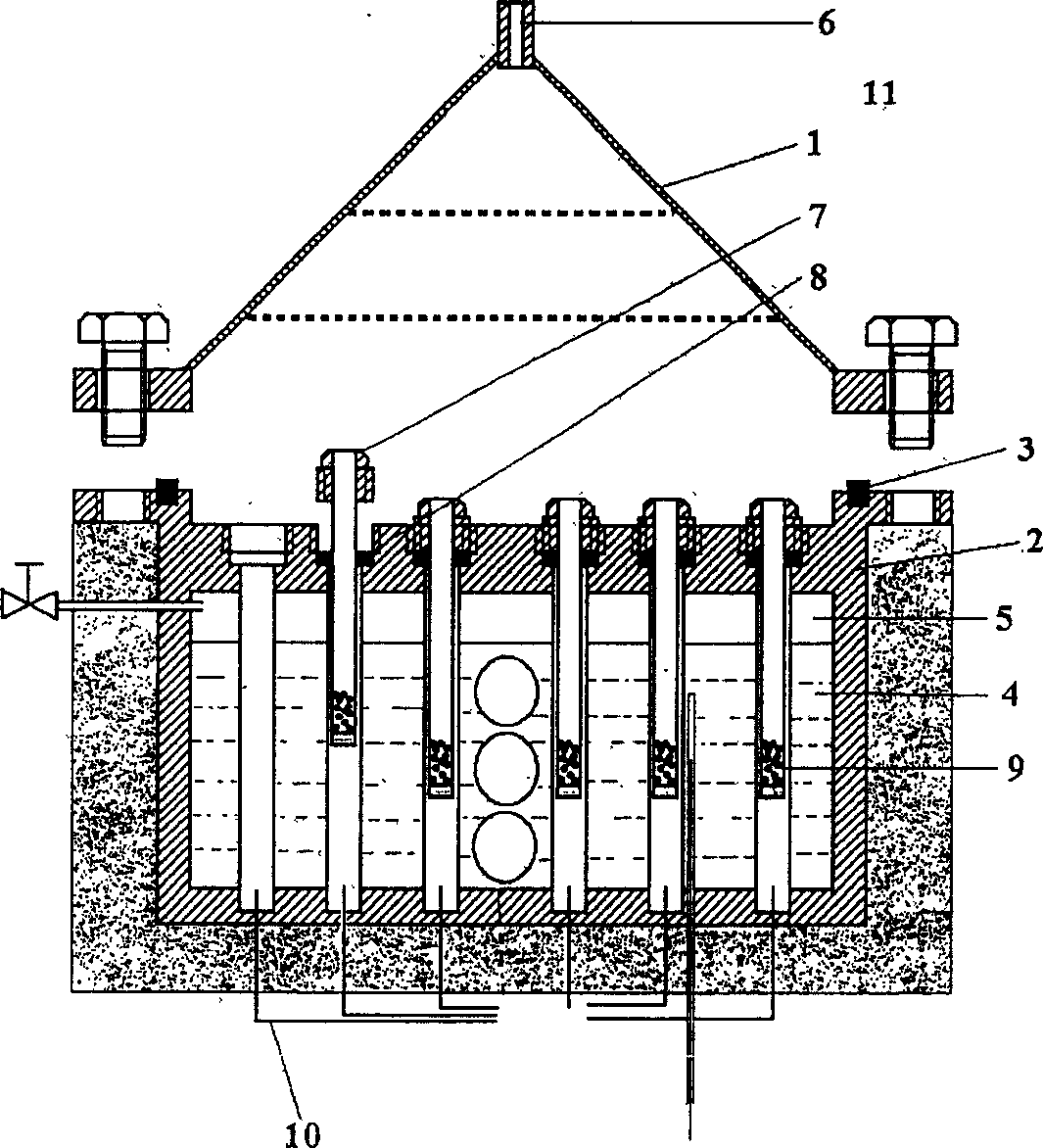

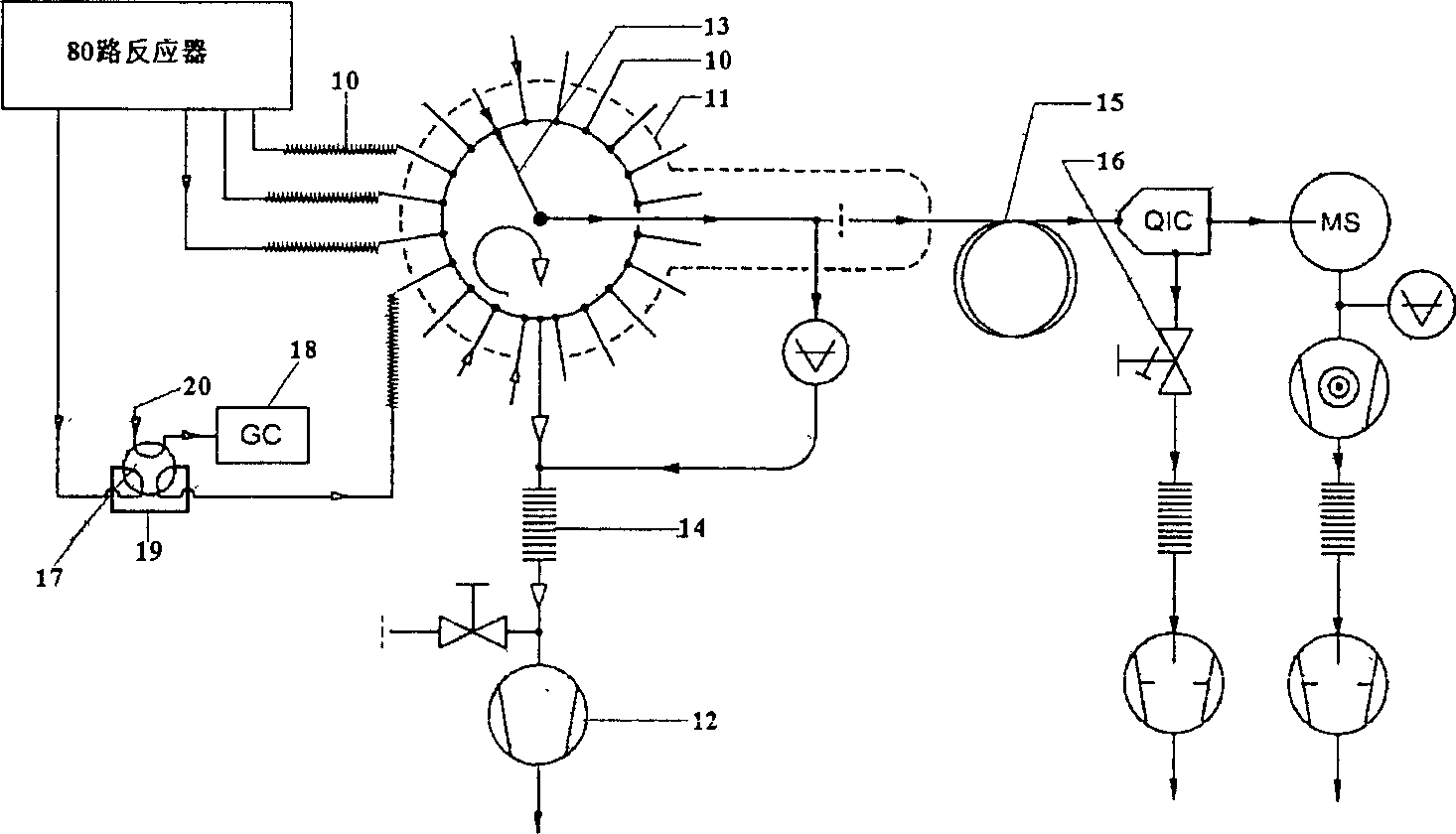

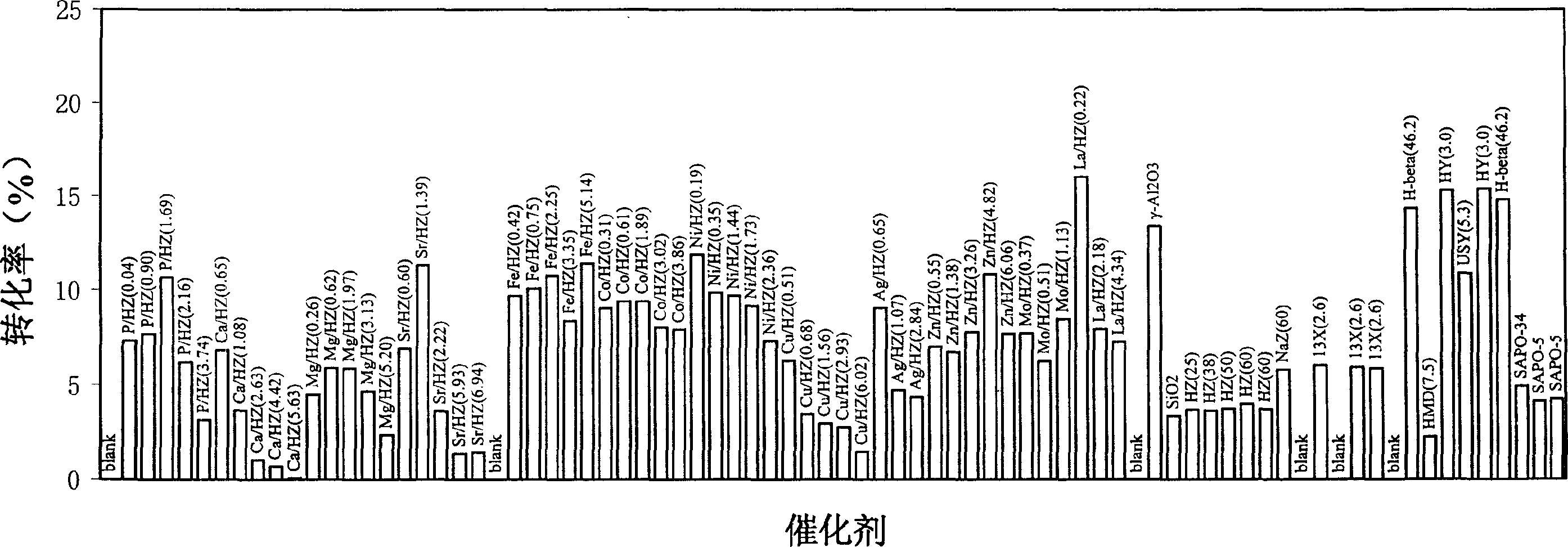

High-flux filter method of composite polyphase catalysis materials

InactiveCN1504262ADoes not affect flow rateAchieving Parallel ReactionsRadiation pyrometrySamplingHigh fluxMass spectrometry detector

A flux screening process of combination heterogeneous catalysis material, wherein the multi-path reacting gas produced in the reaction furnace enters the multi-port valve of the mass spectrum detecting system through the capillary tube, which selects any path of the gas to enter the mass spectrum detector for analysis, each of the capillary tube is connected to each path of the multi-port valve through a six-way valve, and the six-way valve connects to a gas chromatograph simultaneously, the calculation of reaction conversion rate is realized through the comparison of the mass-spectrometric data of each path of reacting gas and margin reaction tube.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

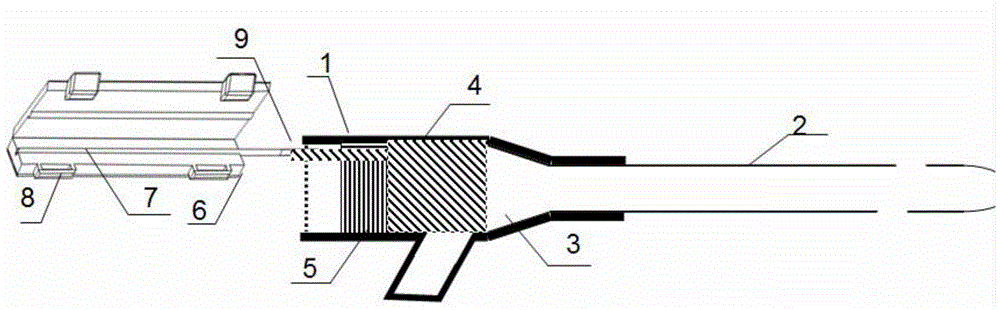

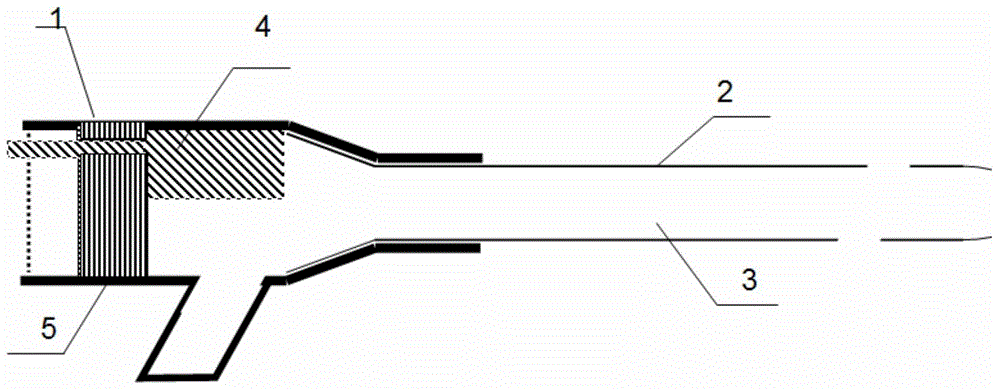

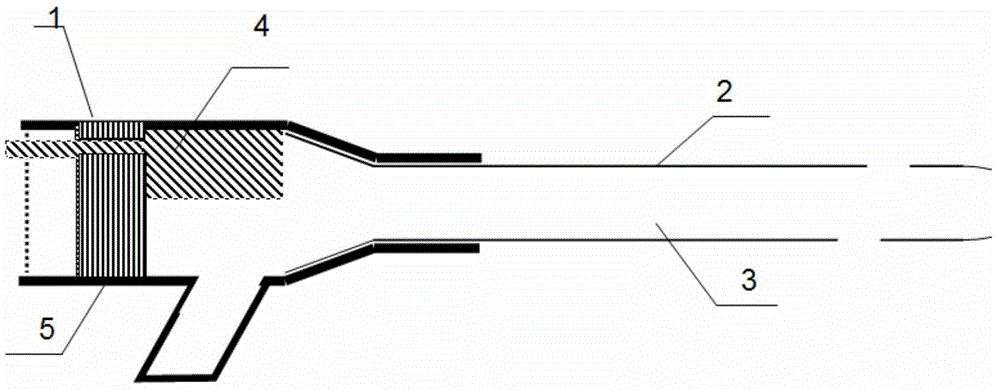

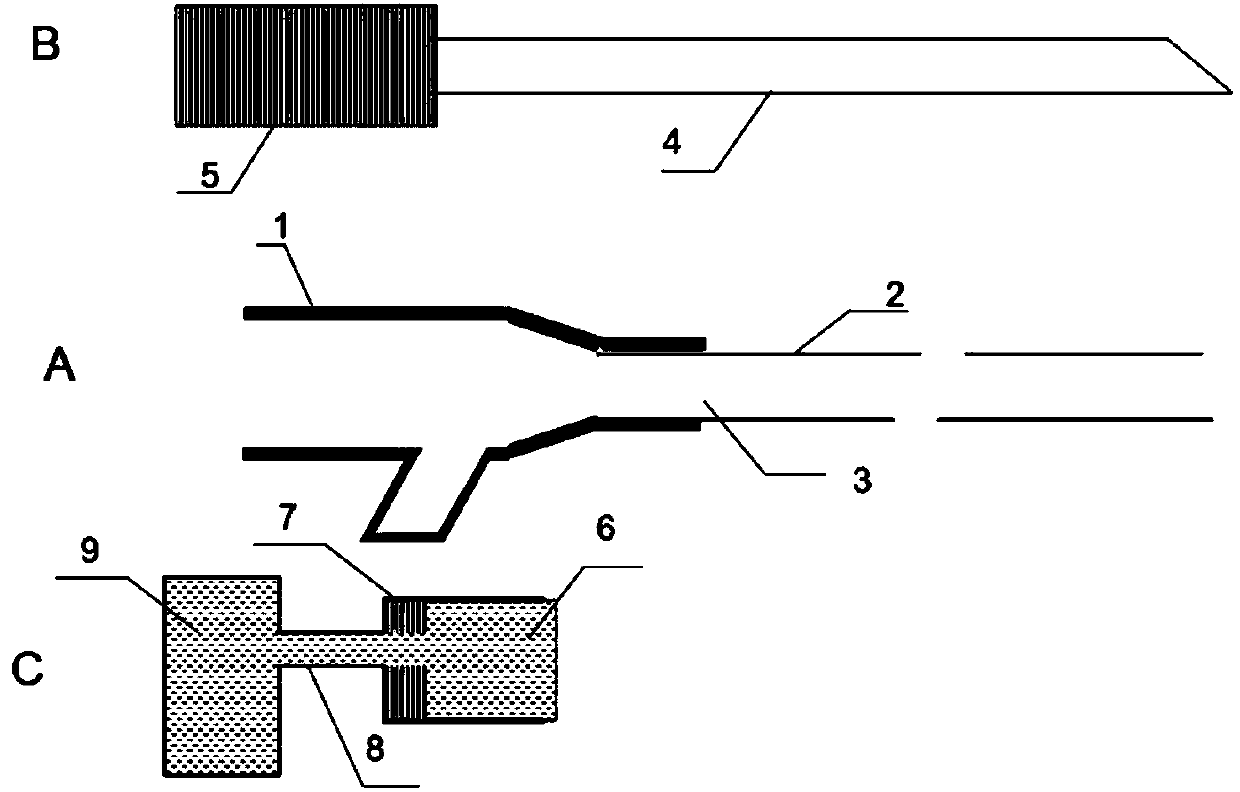

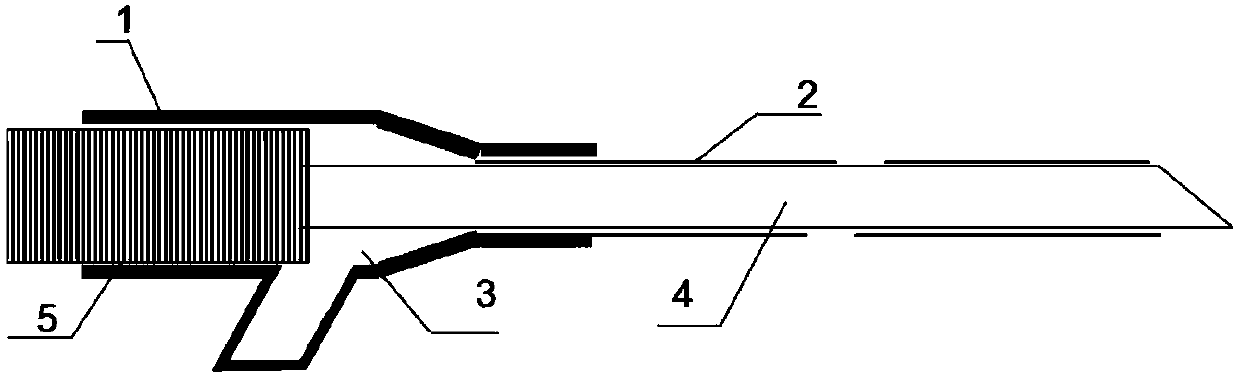

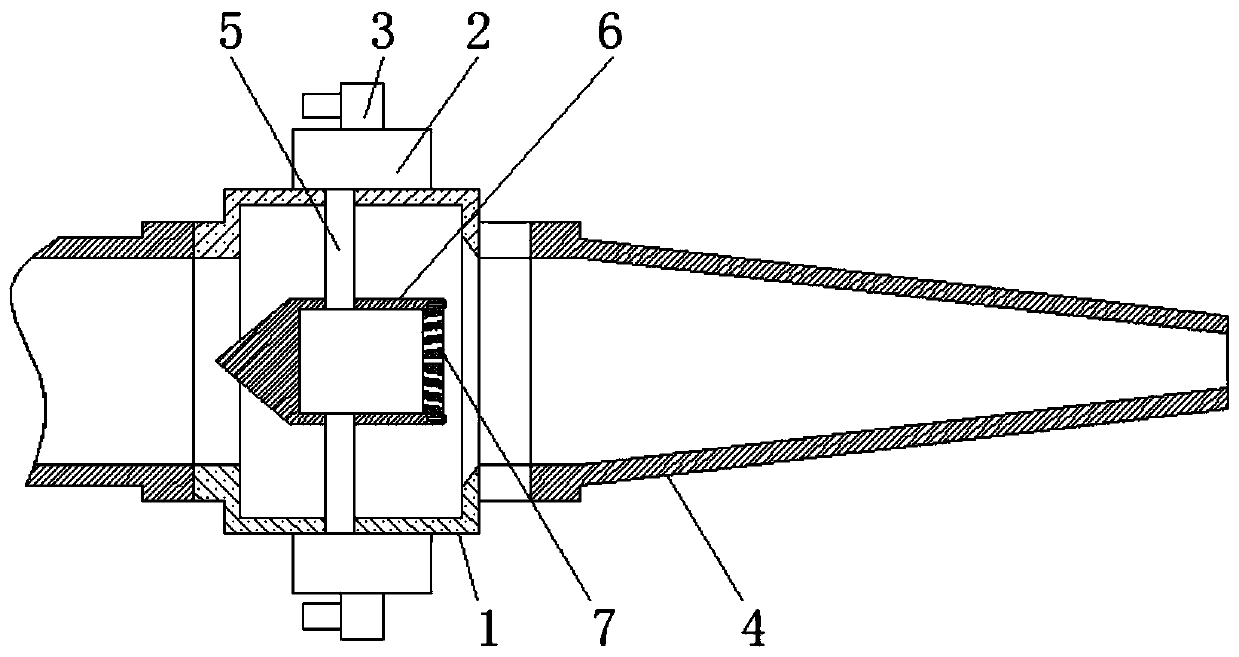

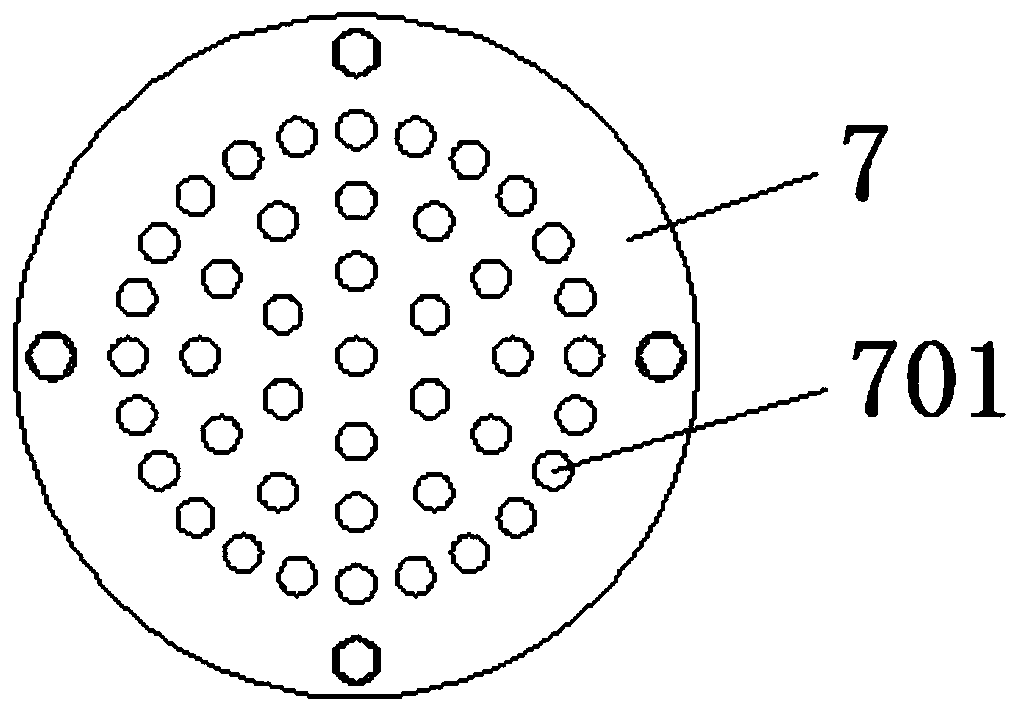

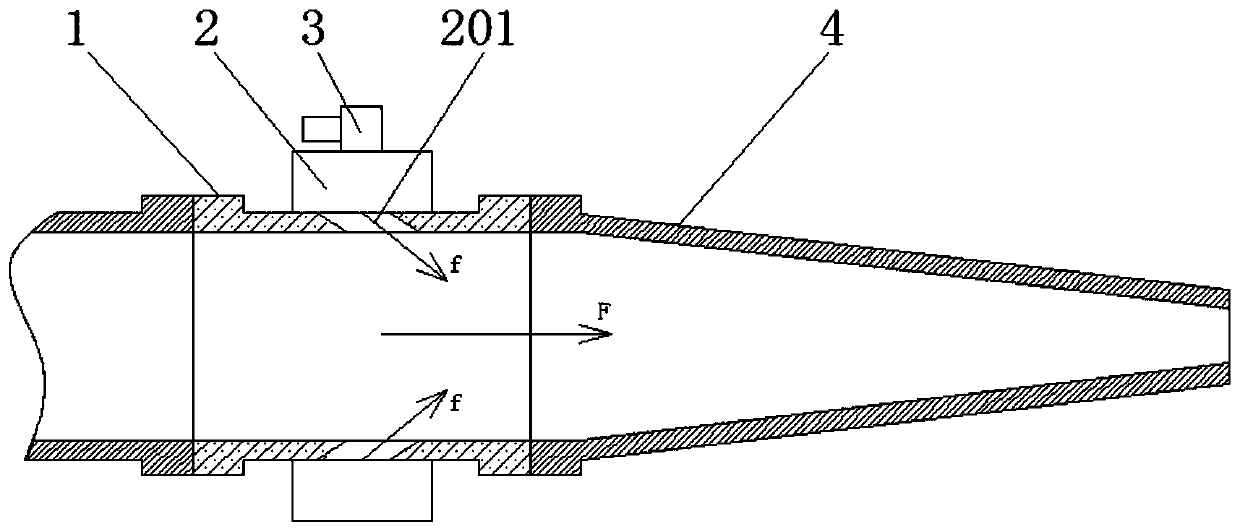

Self-sealing type venous indwelling needle with liquid bag in needle holder

The invention relates to a self-sealing type venous indwelling needle with a liquid bag in a needle holder. The self-sealing type venous indwelling needle with the liquid bag in the needle holder is composed of the needle holder 1, an indwelling catheter 2, an infusion channel 3, a working medium liquid bag tube 4, a steel needle isolation plug 5, a pressurization block 6, a pressure-resisting liquid bag 7, a lock catch 8, a flexible connecting tube 9 and the like. According to the self-sealing type venous indwelling needle with the liquid bag in the needle holder, the working medium liquid bag is located in the needle holder, the infusion channel is large, the requirement for large-flow-speed infusion can be met, no rubber impurity or pollutant flows in, and the service time of the indwelling needle is prolonged; on the condition that the working liquid medium is completely closed, tube sealing can be achieved by pressing the pressurization block, and complex nursing operation is simplified.

Owner:西藏多欣健康科技有限公司

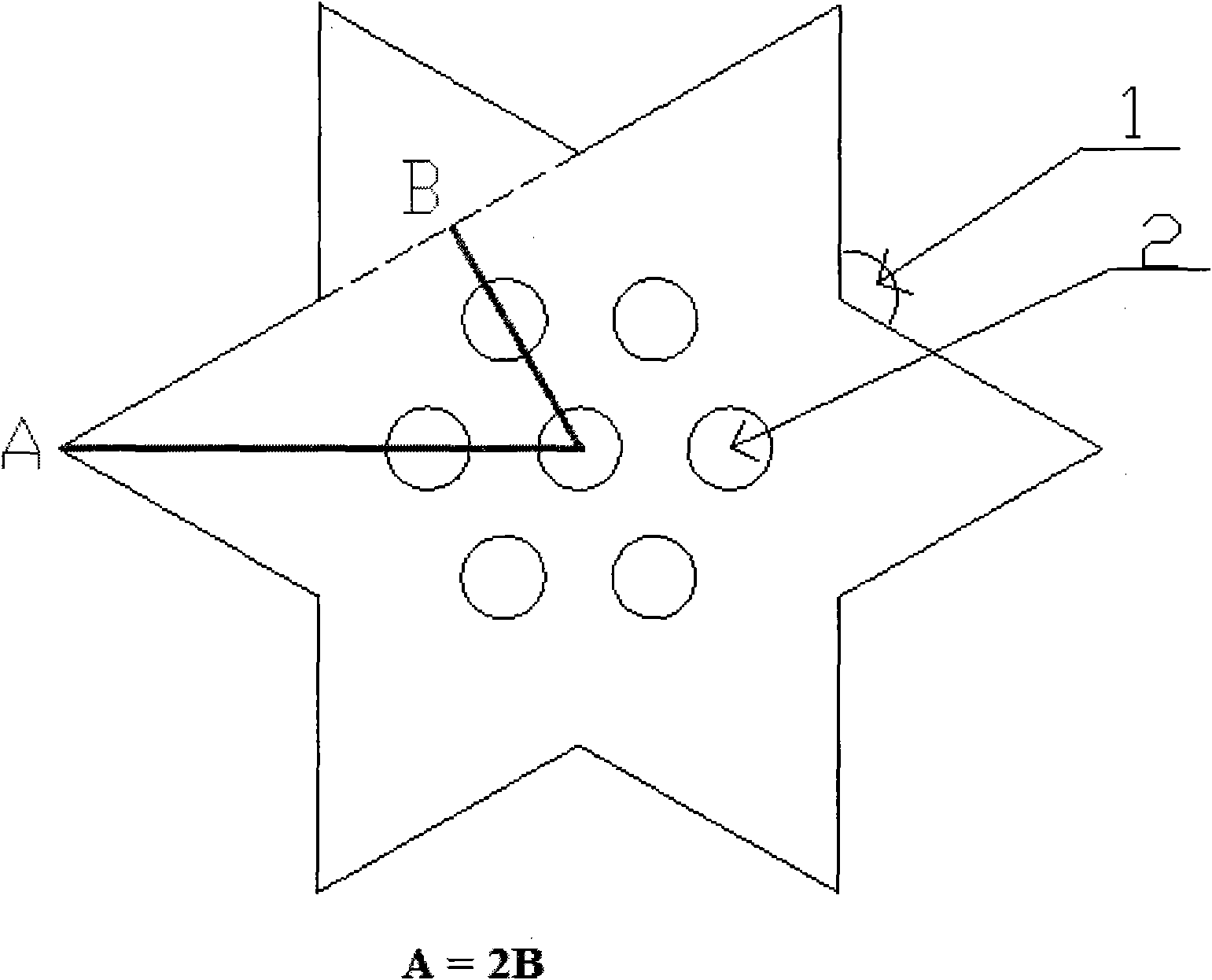

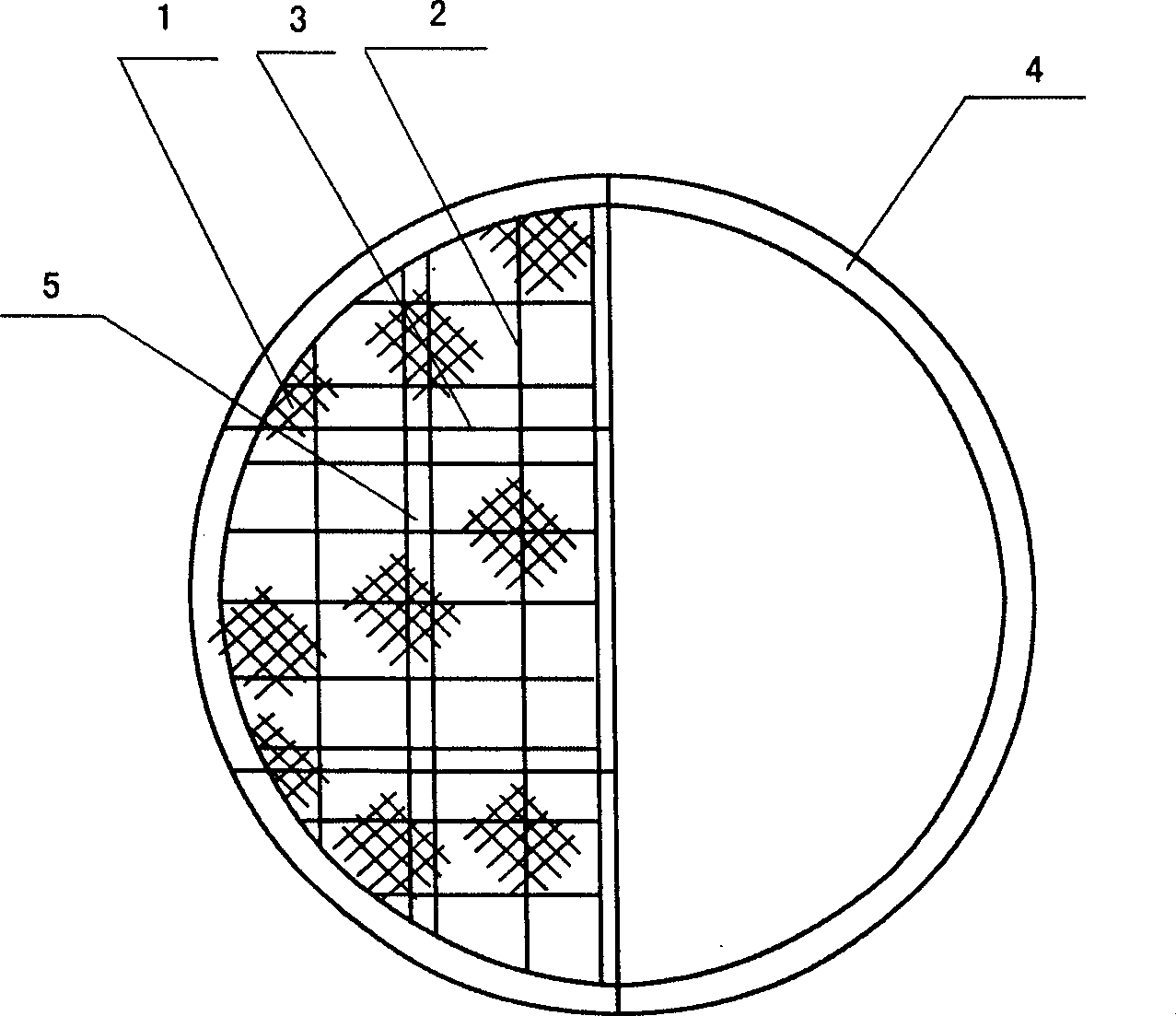

Ore used in core tube of water treatment device

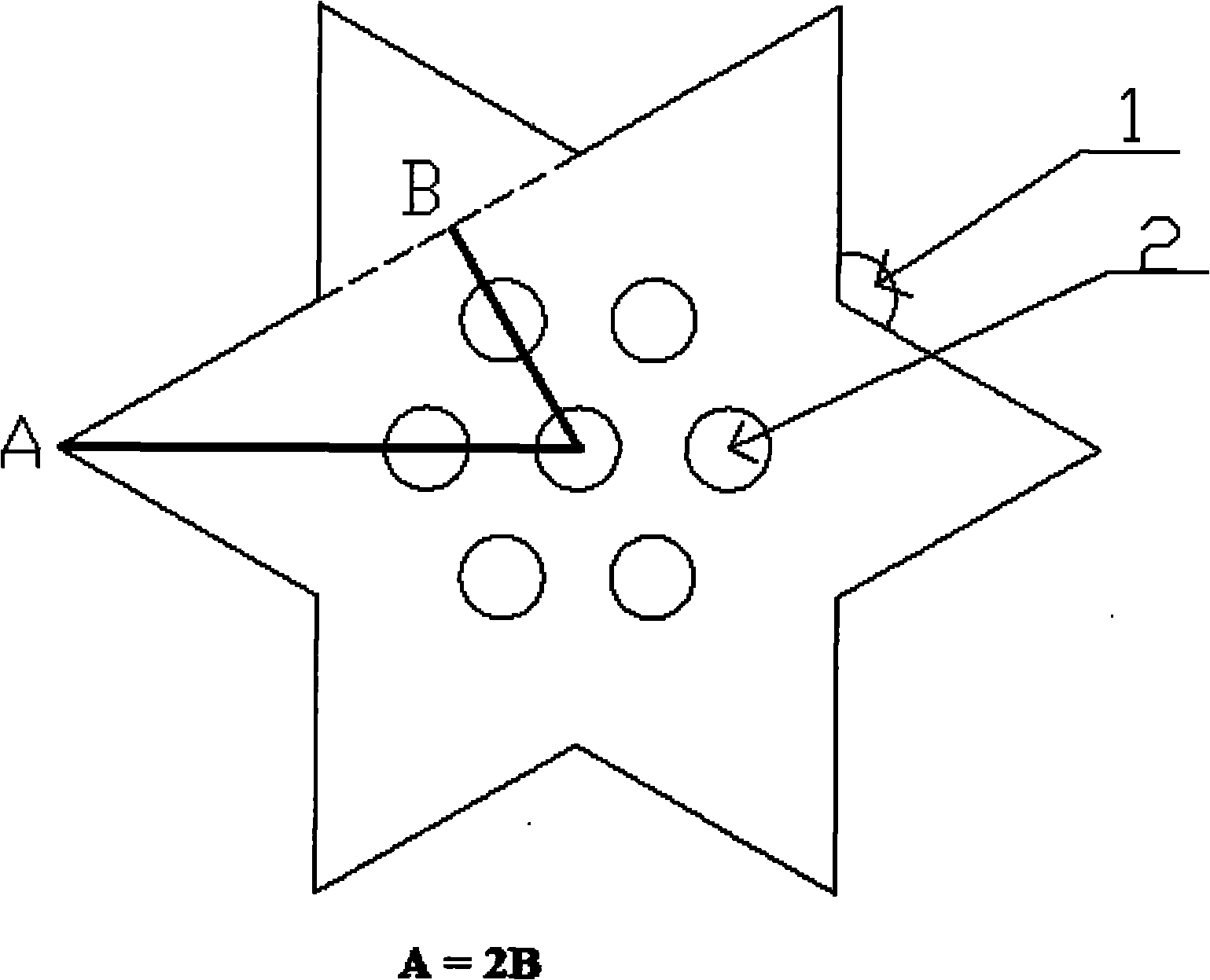

ActiveCN101913682AIncreased energy fieldLow filling rateFatty/oily/floating substances removal devicesWater/sewage treatment by ion-exchangeIon densityRare earth

The invention relates to an ore used in a core tube of a water treatment device. The ore has six angles which are uniformly distributed at the periphery of the hexagonal ore. A concave part is formed between every two angles. A distance A from the center to the angle top is twice a distance B from the center to the angle bottom. The concave part is at an obtuse angle. The surface of the ore is provided with at least one through hole. The ore comprises the following components: medical stone used as a matrix, 10 to 15 percent of tourmaline, 50 to 68 percent of rare earth materials Nd2Fe14B, 18 to 30 percent of granite, 1 to 2 percent of magnetite, 3 to 4 percent of zeolite and 1 to 0.5 percent of silver. The ore has an irregular shape, so the filling ratio is lower, the flow rate is not influenced, the impact direction of a water column is irregular and the water molecule energy field is naturally increased. Compared with the surface area of a spherical ore with the same density and weight as the hexagonal ore, the surface area of the hexagonal ore is nearly 20 percent larger than that of the spherical ore. Therefore, the impact area of water and the hexagonal ore is relatively superior to that of the water and the spherical ore. The impact area is larger, more water molecules are fragmentated and correspondingly the water molecule energy and the negative ion density can be higher.

Owner:PRO REACH BIOTECH SUZHOU

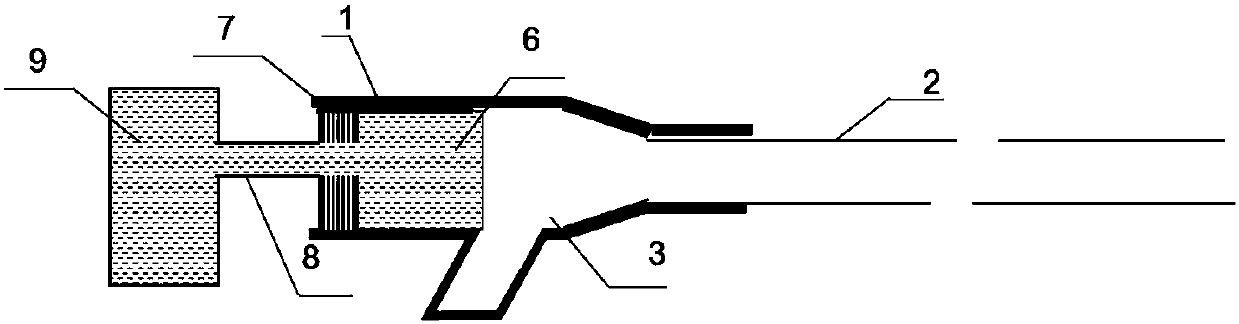

Positive-pressure liquid bag self-sealing type intravascular indwelling needle

PendingCN107890595AEasy to operateEasy to masterInfusion needlesOther medical devicesThrombusNursing care

The invention provides a positive-pressure liquid bag self-sealing type intravascular indwelling needle. The positive-pressure liquid bag self-sealing type intravascular indwelling needle is mainly composed of a main body part A, a part I B and a part II C. For the positive-pressure liquid bag self-sealing type intravascular indwelling needle, the operation is extremely simple, a working medium liquid bag seals an infusion channel and provides continuous positive pressure, and the effects in sealing a tube, preventing backflow and resisting thrombus are reliable; the operation is easy to master when the indwelling needle is placed through puncture, during the nursing operation, the operations of pumping liquid medicine and preparing tube sealing liquid are not needed, the operation can becompleted through one movement of one hand, a disposable syringe and a flusher do not need to be consumed, thus the step of the nursing operation is saved, and the nursing efficiency and quality are improved.

Owner:西藏多欣健康科技有限公司

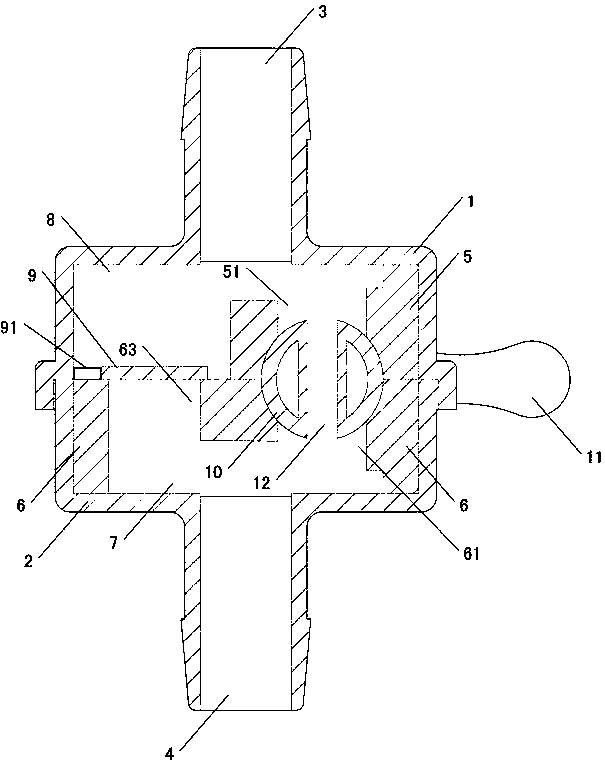

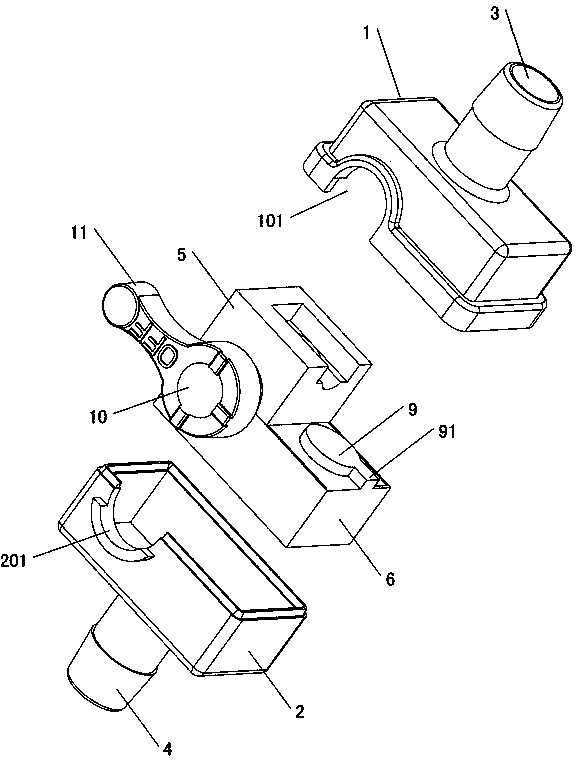

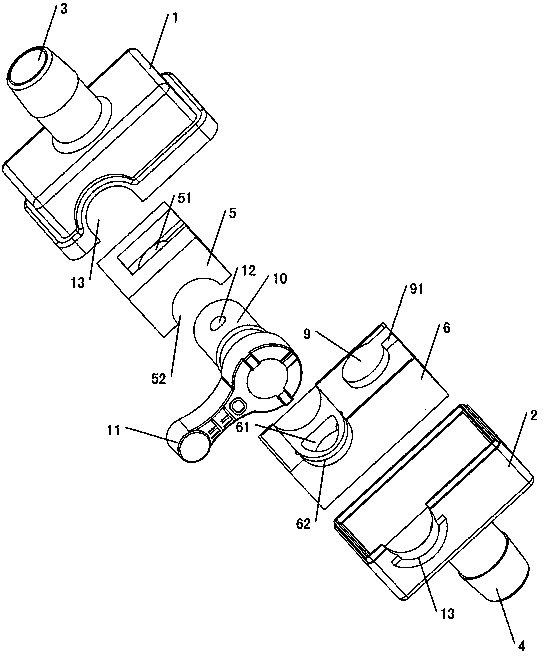

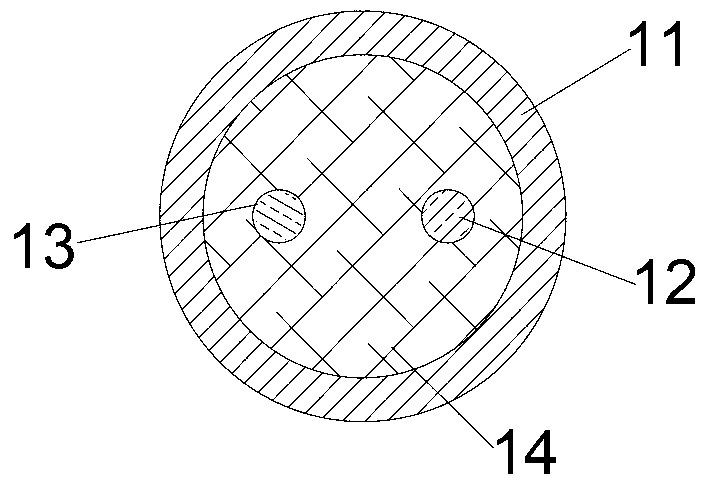

Improved one-way and two-way integrated valve for medical treatment

InactiveCN103463735ADoes not affect flow rateEasy injection moldingValvesMechanical engineeringMedical treatment

The invention provides an improved one-way and two-way integrated valve for medical treatment. The valve comprises a valve body and a valve element, wherein a lead-in pipe joint and a lead-out pipe joint are arranged on the valve body. The integrated valve is characterized in that the valve body comprises an upper shell and a lower shell; the valve element comprises an upper valve element, a lower valve element, a third through hole communicated with an upper transition passage and a lower transition passage, and a one-way valve which is formed in the third through hole and comprises a diaphragm; a valve rotating shaft in the valve element is used for controlling the communication of the upper transition passage and the lower transition passage. Compared with the prior art, the one-way and two-way integrated valve works reliably, the flowing speed of drainage liquid cannot be influenced, the working state is independent of position, and the die is simple, convenient to assemble and low in cost.

Owner:丘奂阳 +2

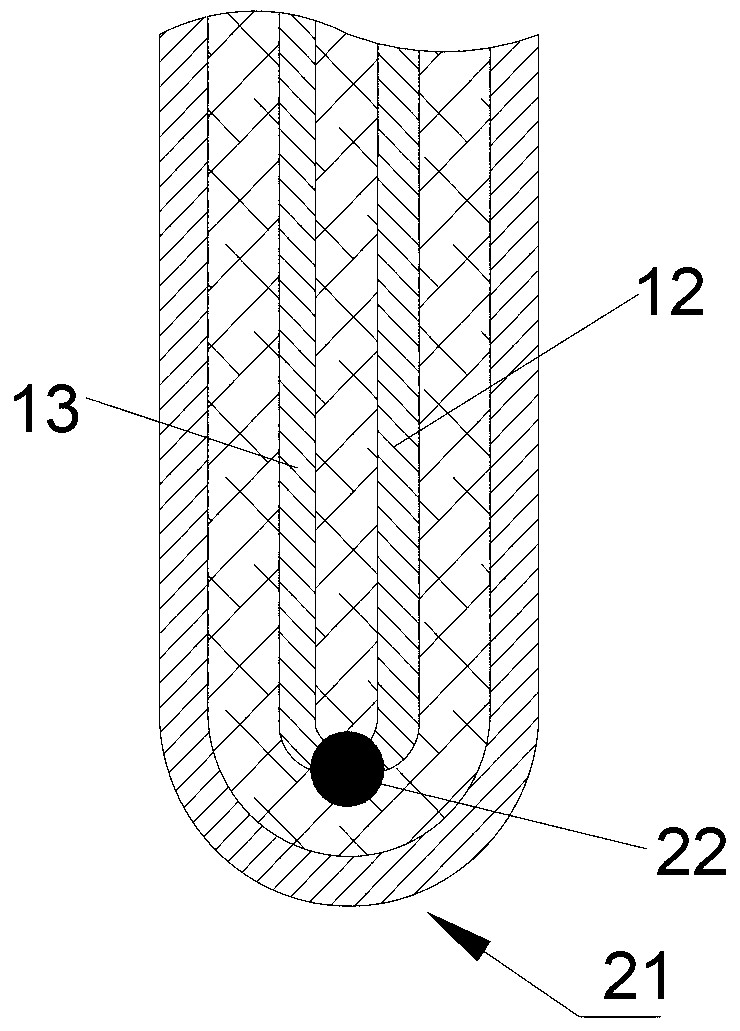

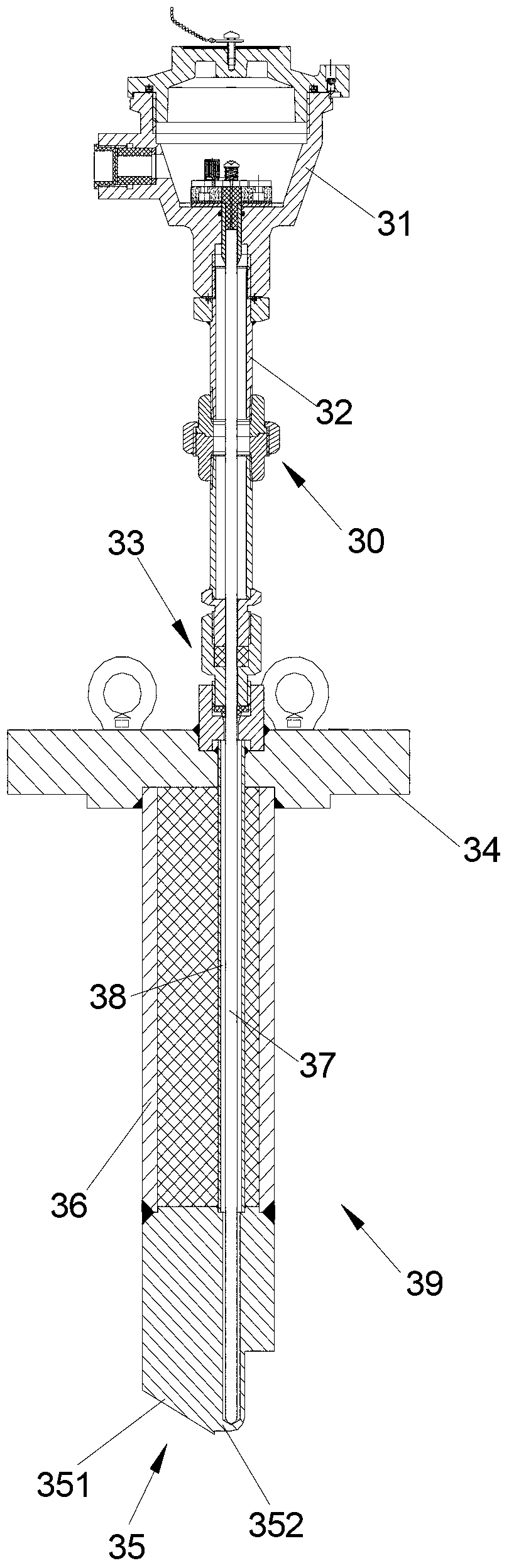

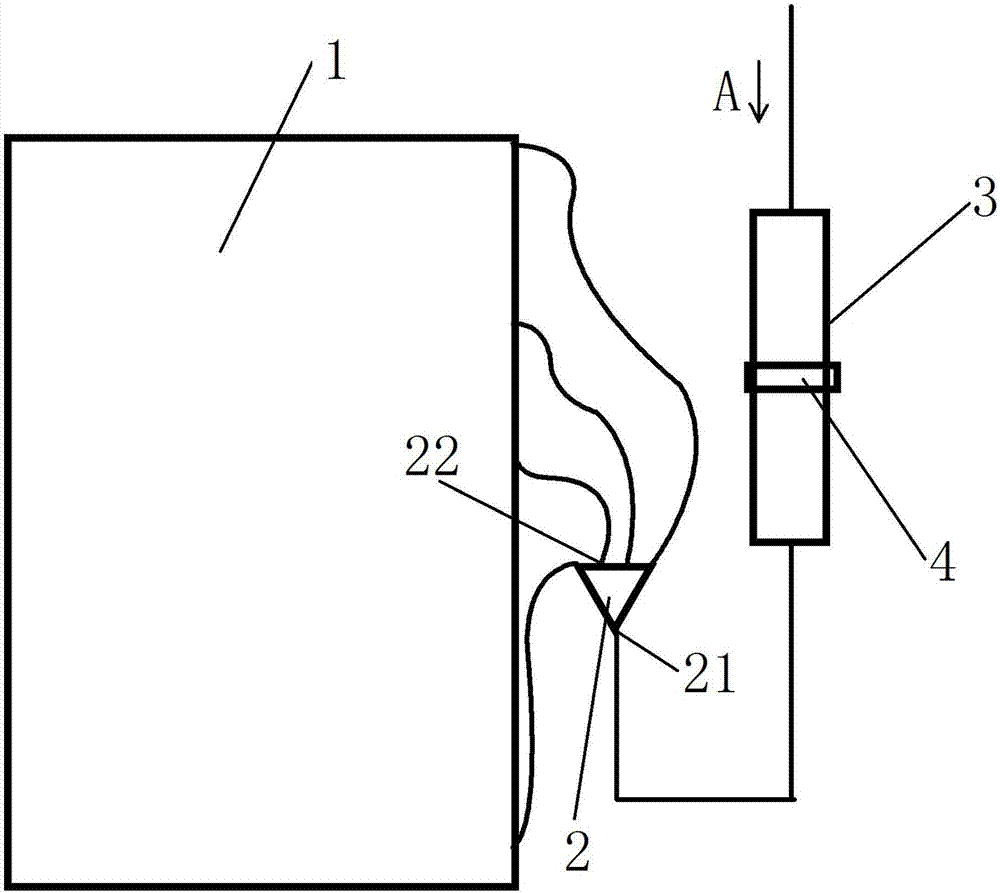

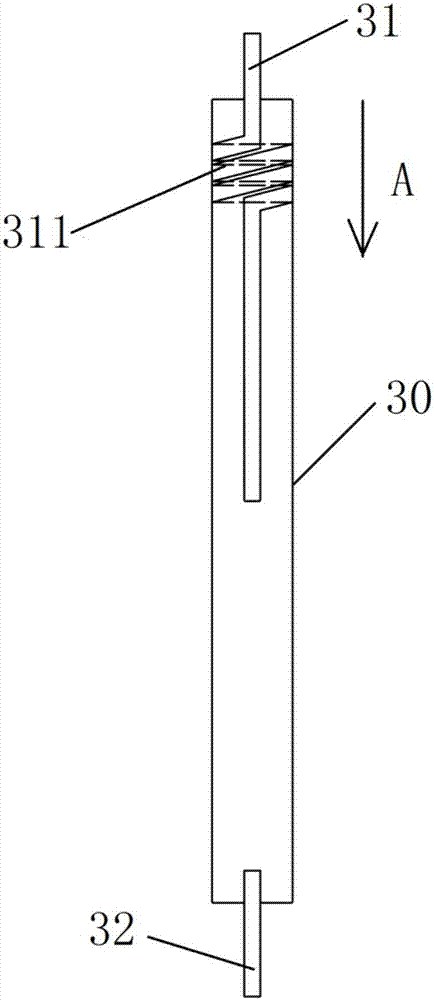

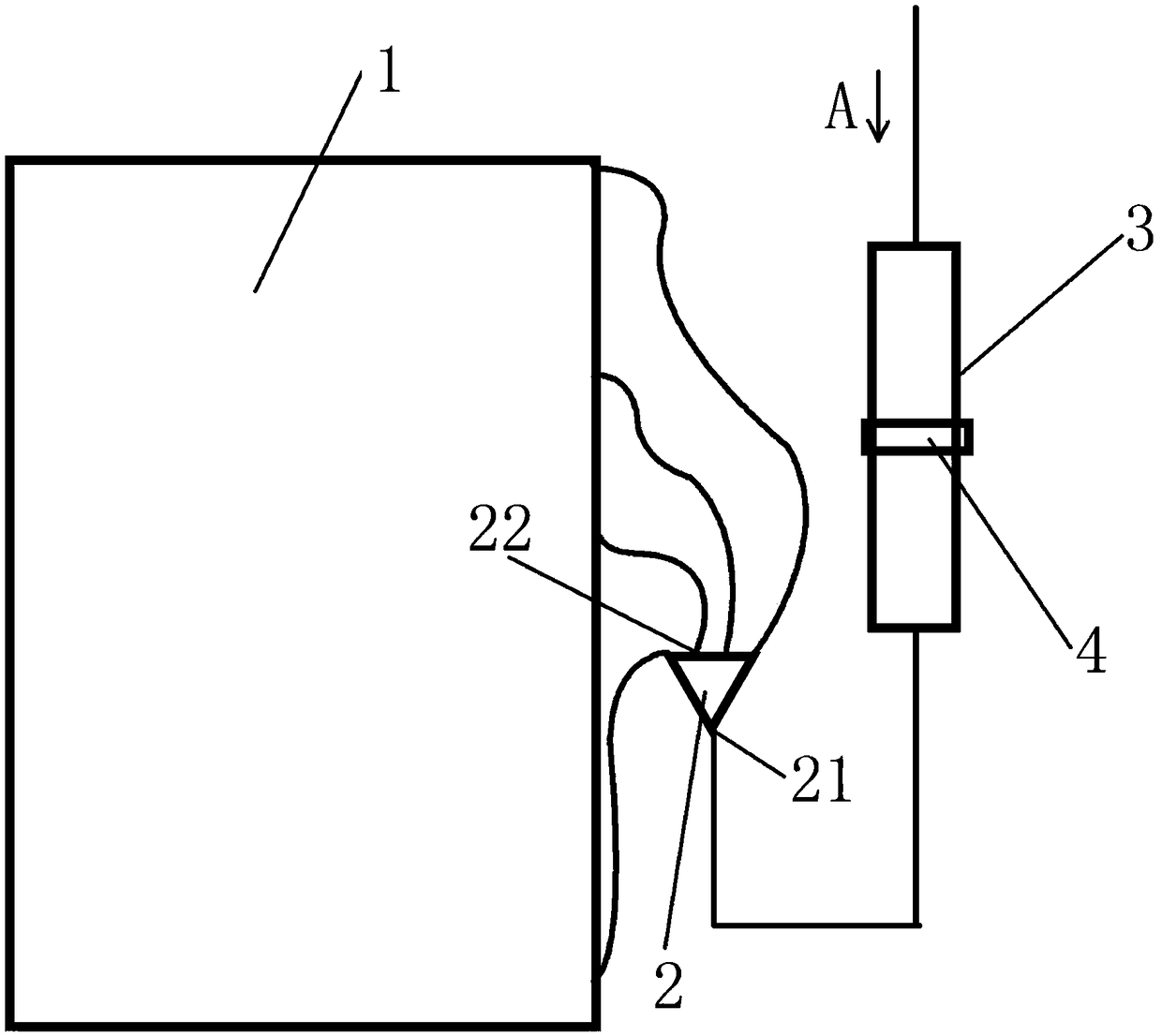

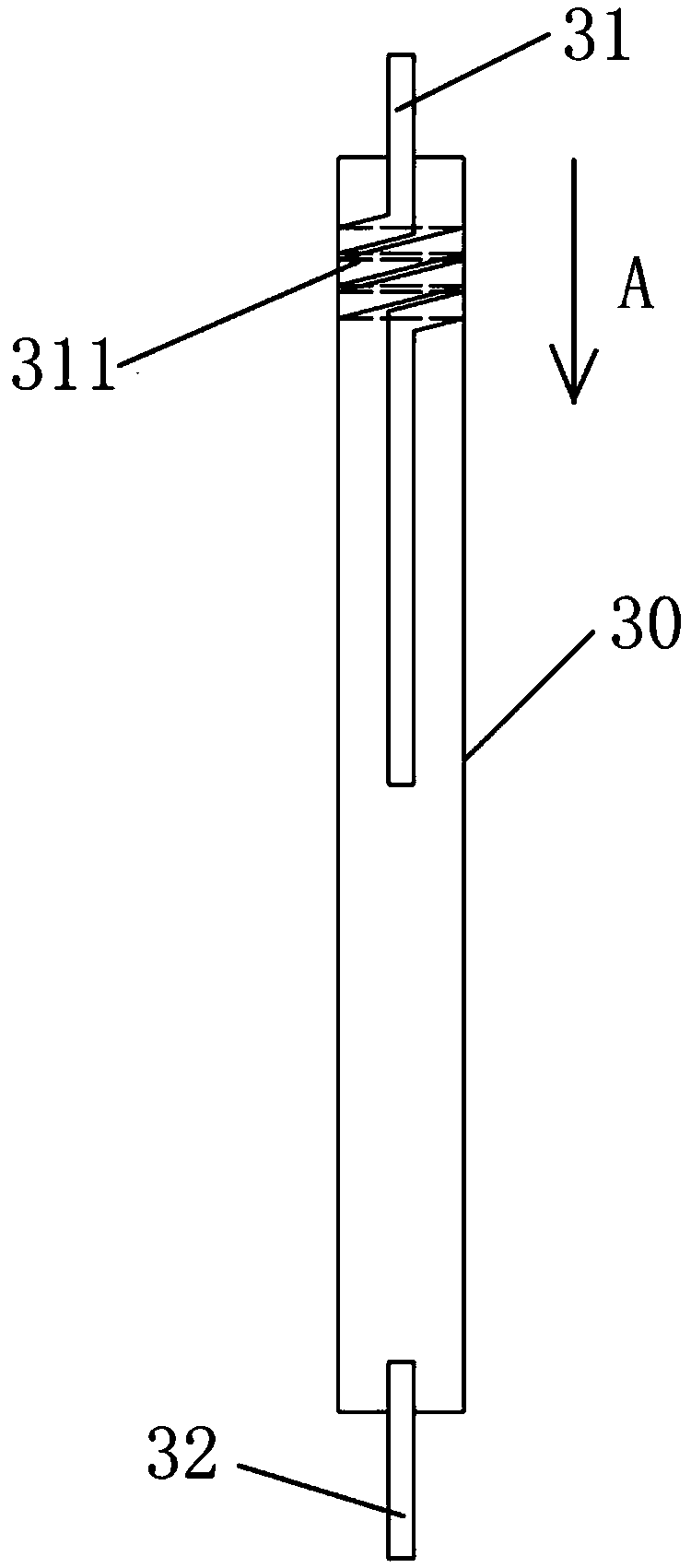

Cracking furnace COT thermocouple and mounting method thereof

InactiveCN103278256AExtended service lifeDoes not affect flow rateThermometer detailsThermometers using electric/magnetic elementsWear resistantThermocouple

The invention discloses a cracking furnace COT thermocouple, which comprises a junction box, an upper protective tube, a leakproof sealing device, a connecting flange and a measuring end which are connected sequentially, wherein the parts are connected sequentially to form an inner cavity; a sheathed thermocouple is arranged in the inner cavity; the measuring end comprises a wear-resistant washing connecting sleeve and an induction end; the induction end comprises a protective body and a measuring head; the cracking furnace COT thermocouple is arranged in a mounting tube at the outlet of an ethylene cracking furnace; and a temperature measuring area is formed between the induction end and the inner wall of the mounting tube. Compared with the prior art, the cracking furnace COT has the characteristics of stable temperature measuring results of the thermocouple, high temperature measuring accuracy and long service life.

Owner:吴方立

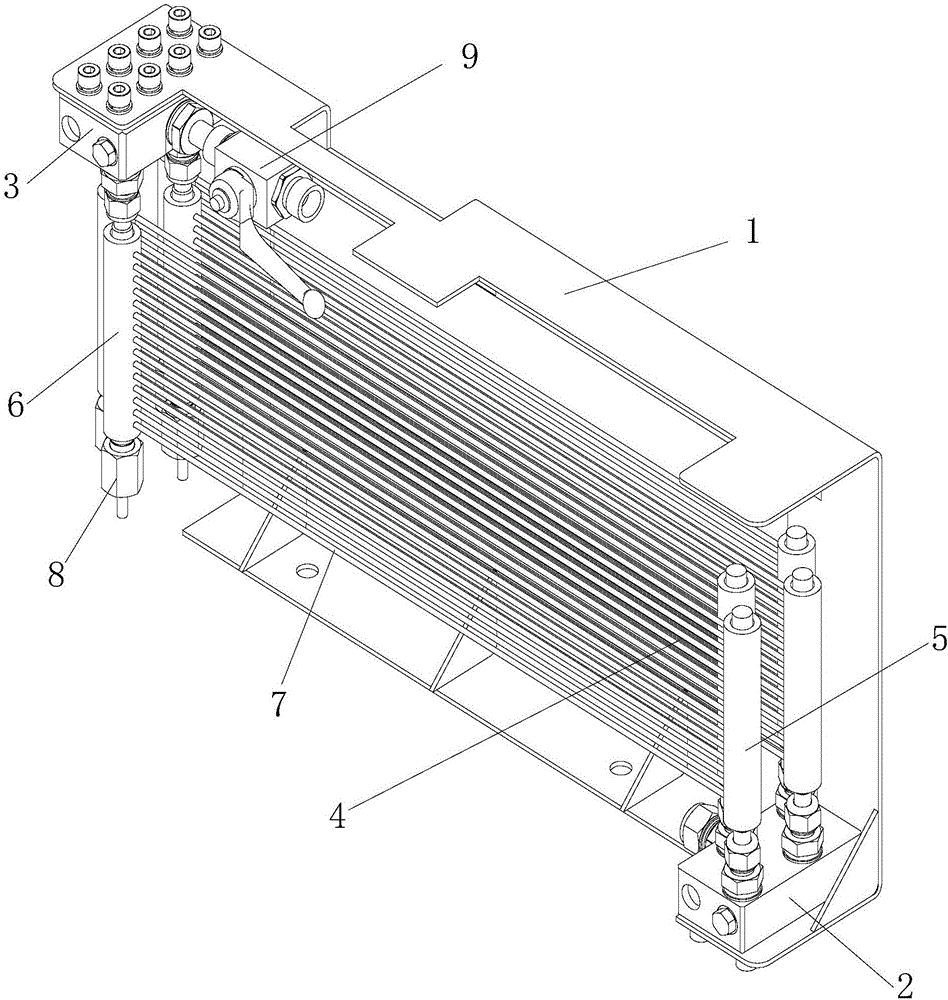

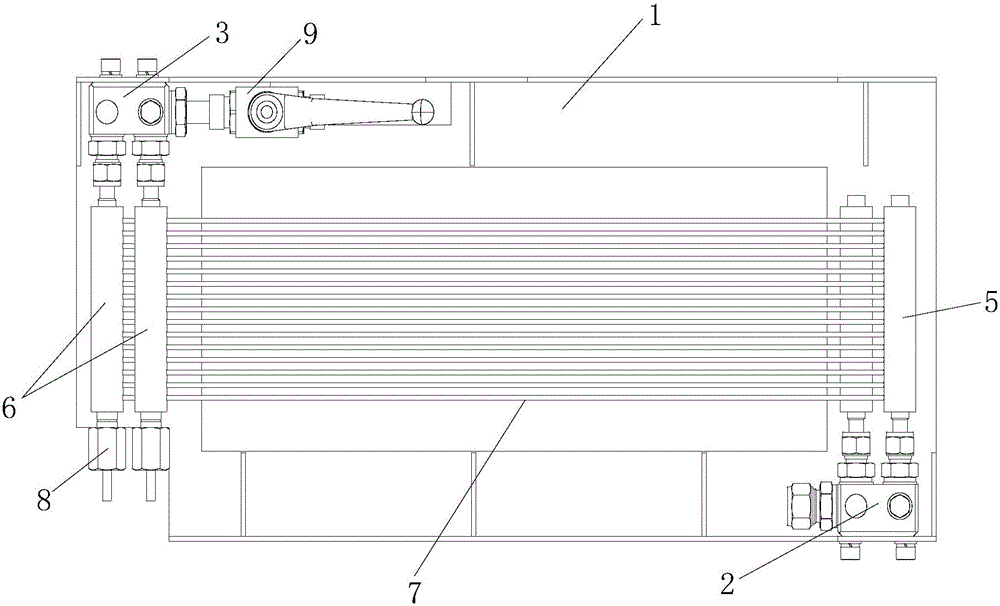

Liquid distributor assembly and air conditioner comprising same

ActiveCN107062713AFrosting evenlyEven defrostingMechanical apparatusFluid circulation arrangementVapor–liquid separatorHeating effect

The invention relates to the field of air conditioners, in particular to a liquid distributor assembly and an air conditioner comprising same. The liquid distributor assembly comprises a liquid distributing head, wherein a liquid collecting hole is formed in one end of the liquid distributing head; a plurality of liquid distributing holes are formed in the other end of the liquid distributing head; the liquid distributing holes communicate with a liquid distributing tube of a heat exchanger; a gas-liquid separator with a refrigerant outflow hole is arranged at the upstream side of the liquid collecting hole; and the refrigerant outflow hole communicates with the liquid collecting hole. In order to solve the technical problems that a liquid distributor in the prior art is uneven in frosting and defrosting and is not good in heating effect as a gas-liquid mixture entering each liquid distributing tube of a heat exchanger is inconsistent in proportion, the invention provides the liquid distributor assembly which is more even in frosting and defrosting and is better in heating effect as well as the air conditioner comprising the liquid distributor assembly.

Owner:GREE ELECTRIC APPLIANCES INC

Chimney dust collector

InactiveCN102384481ADoes not affect flow rateImprove dust removal effectLighting and heating apparatusFlue gasWater pipe

The invention relates to a chimney dust collector which comprises a flue gas output channel communicated with a chimney outlet. An outlet of the flue gas output channel is connected with a dust collection chamber; a flue gas outlet is arranged on the dust collection chamber; and a pool is arranged at the bottom part of the dust collection chamber and is communicated with the dust collection chamber through a water pipe I. The chimney dust collector is characterized in that the outlet of the flue gas output channel is lower than that of the chimney; a sprayer is arranged at the top part of the dust collection chamber and is communicated with the pool through a water pump and a water pipe II; a filter screen is arranged at the connection of the water pipe II and the pool; and a water inlet is arranged at the top part of the pool. The chimney dust collector has the advantages that the dust collection effect is good; the flow rate of flue gas is not affected; and while being subjected to dust collection, the flue gas can also be cooled.

Owner:陈晓花

A liquid separator assembly and its air conditioner

ActiveCN107062713BFrosting evenlyEven defrostingMechanical apparatusFluid circulation arrangementVapor–liquid separatorHeating effect

The invention relates to the field of air conditioners. Specifically relates to a liquid distributor assembly and its air conditioner, wherein a liquid distributor assembly includes a liquid distribution head, one end of the liquid distribution head has a liquid collection port, the other end has a number of liquid distribution ports, the liquid distribution head The port is used to communicate with the liquid distribution pipe of the heat exchanger; a gas-liquid separator with a refrigerant outlet is arranged on the upstream side of the liquid collection port, and the refrigerant outlet communicates with the liquid collection port. The technical problem to be solved by the present invention is that in the prior art, the ratio of the gas-liquid mixture entering the liquid pipes of the heat exchanger from the liquid separator is inconsistent, resulting in uneven frosting and defrosting, and poor heating effect. The liquid separator assembly and its air conditioner with more uniform frost and defrost and better heating effect.

Owner:GREE ELECTRIC APPLIANCES INC

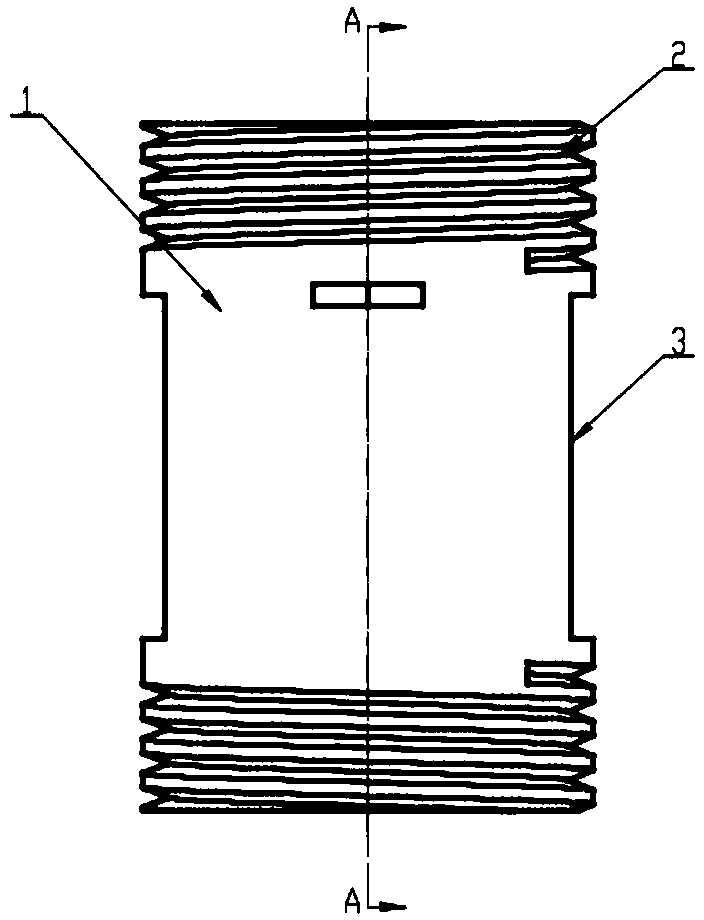

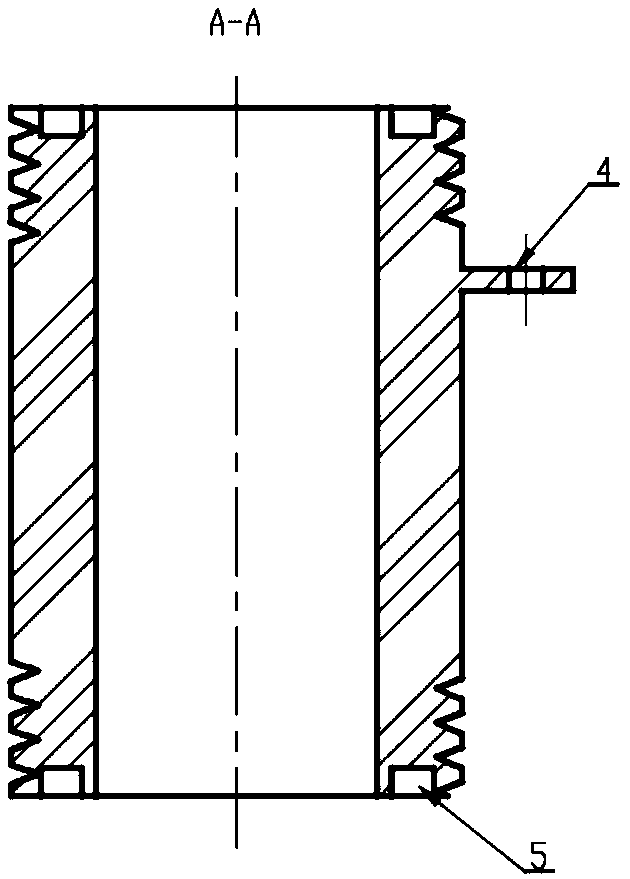

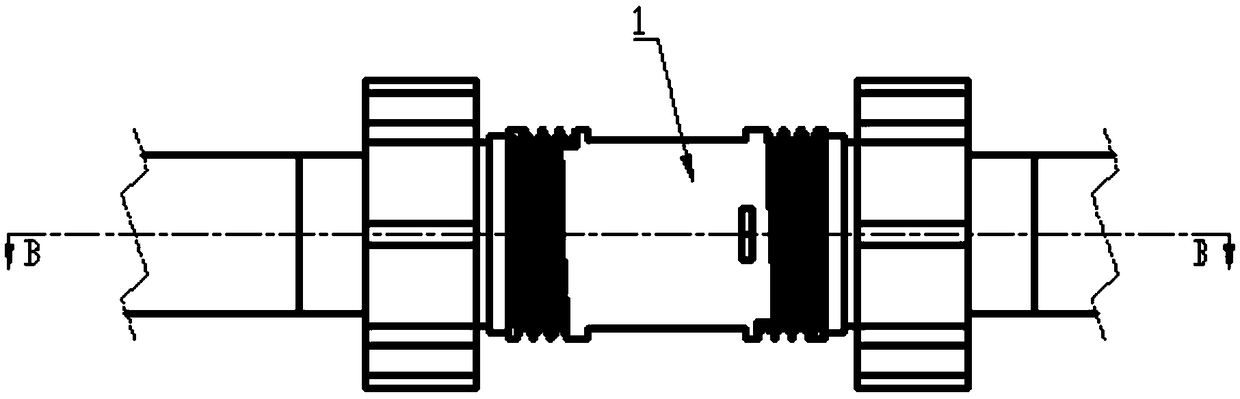

A tubular equipotential electrode for a converter valve

PendingCN109039104ASolve corrosiveAvoid badSemiconductor/solid-state device detailsConversion constructional detailsPower flowWater flow

A tubular equipotential electrode for converter valve is composed of a circular tube with threads at both ends of outer wall, an annular groove on the end face of said circular tube, an O-shaped sealing ring in said annular groove, and an equipotential electrode connecting plate fixed on outer wall of said circular tube. The equipotential electrode is arranged at both ends of the transverse waterpipe of the valve section of the converter valve and arranged along the axial direction of the water pipe diameter. The utility model has the advantages of simple structure, high reliability, large contact area with cooling medium and obvious anti-electrolytic corrosion effect. The equipotential electrode is arranged along the axial direction of the water pipe and parallel to the flow of water andcurrent, which reduces the leakage point and the current density on the electrode surface, and effectively solves the corrosion and fouling problems of the equipotential electrode. At the same time,the sealing ring does not contact with the cooling medium, which effectively prevents the sealing ring from corrosion and improves the sealing reliability of the waterway system.

Owner:BEIJING RONGXIN HUIKE TECH

Secondary air system of boiler

ActiveCN109185872AStrong penetrating powerDoes not affect flow rateFluidized bed combustionNon-combustible gases/liquids supplyNozzleBellows

The invention belongs to the technical field of boiler modification, and discloses a secondary air system of a boiler. The secondary air system of the boiler comprises a hearth and a secondary air bellow connected with the hearth, wherein the secondary air box is connected with a plurality of groups of secondary air pipes, and each group of secondary air pipes and the hearth are correspondence with one nozzle, and each group of secondary air pipes comprise at least two secondary air branch pipes; and in each group of secondary air pipes, each secondary air branch pipe is located at one end ofthe secondary air bellow in a separating mode, and the other end of each secondary air branch pipe located in one side of the hearth is connected with the corresponding nozzle of the secondary air pipes. According to the boiler, by arranging the mode that each secondary air branch pipe is arranged at one end of the secondary air bellow in the separating mode, and one end of each secondary air branch pipe located in one end of the hearth communicates with the corresponding nozzle of each secondary air pipe, so that when a load is reduced, one of secondary air branch pipes can be turned down orturned off, the flow speed of other secondary air branch pipes in the group of secondary air pipes is not influenced, so that the momentum of secondary air passing through the nozzle is maintained, and the problem that the secondary air permeability is poor due to the fact that the load is reduced is solved.

Owner:YANTAI LONGYUAN POWER TECH

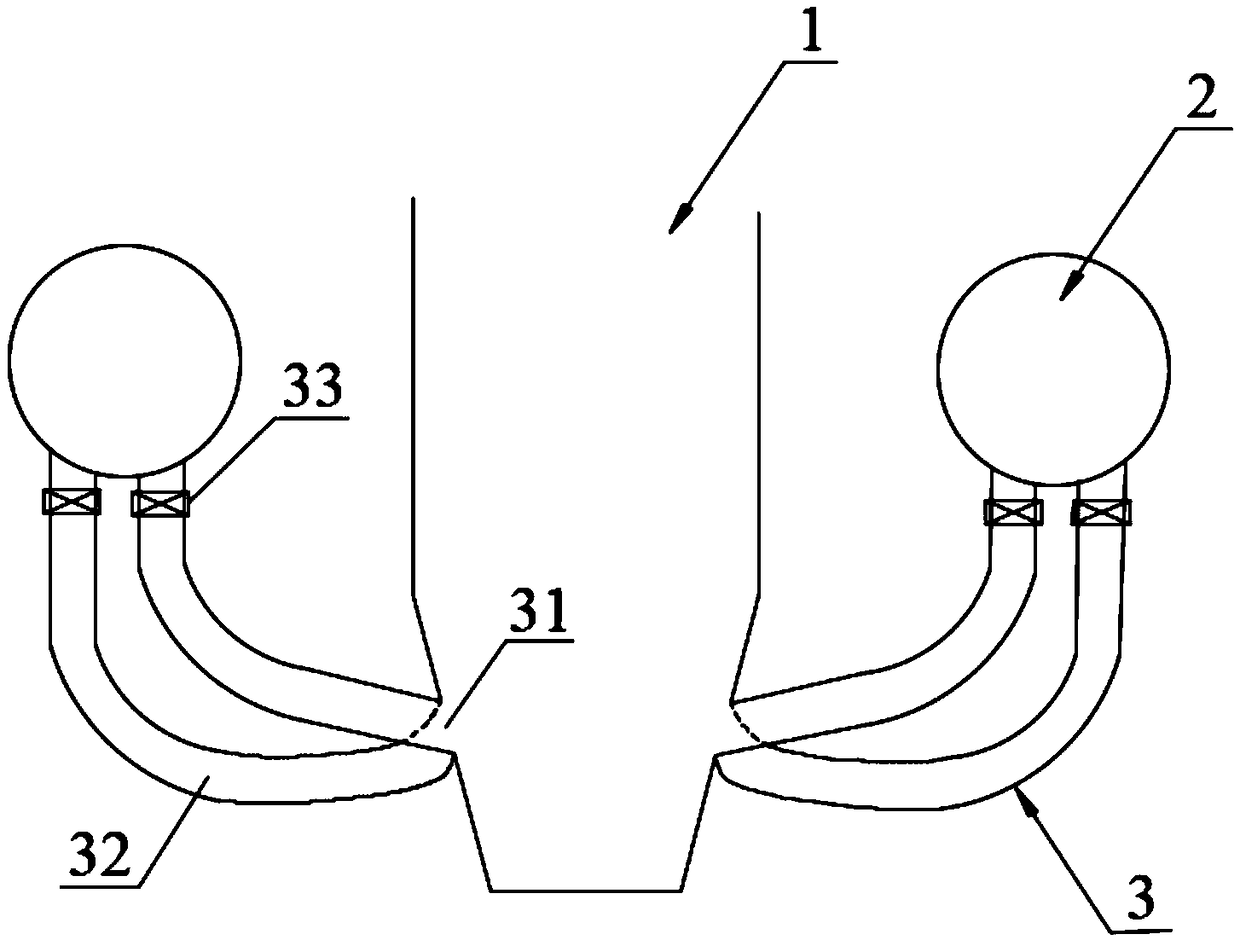

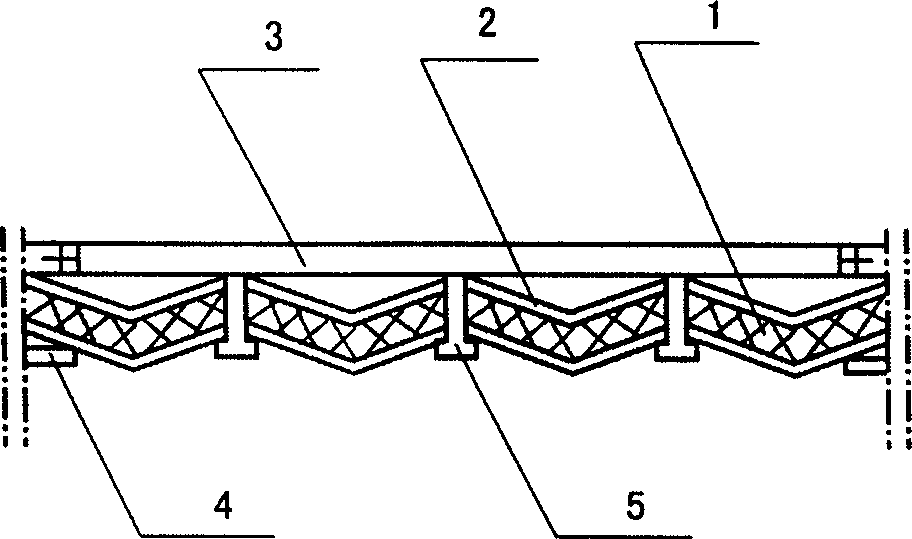

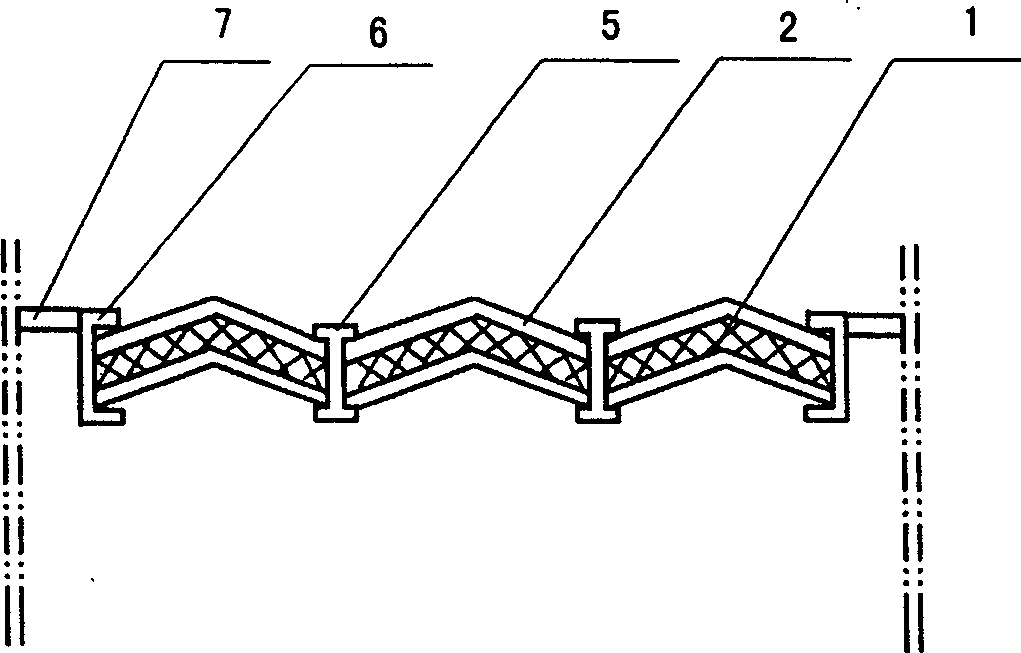

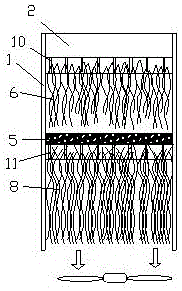

Plastic ripple silk net scum skimmer and the manufacturing method thereof

InactiveCN1485117ASmall bulk densityReduce resistanceLiquid degasificationEngineeringVolumetric Mass Density

The invention provides a plastic corrugated wire-mesh defoamer and its manufacturing method. The defoamer mainly comprise wire mesh(1),wire-mesh block composed of mesh grids, a supporting unit to fixthe wire-mesh block. The wire mesh is formed by superposing a plurality of corrugated plastic meshes. When manufacturing, wire mesh (1) and the mesh grids compose a wire-mesh block. The defoamer is formed by fixing a plurality of wire-mesh blocks onto the wall by the supporting unit. When manufacturing the wire mesh, heating and softening the plane-like plastic mesh, the mesh is corrugated by a pair of rollers with corrugated grooves in circumferences, then the mesh is shaped after cooling by water. The defoamer of the invention could increase the chances of gaseous fluid impacting wire meshes, eliminate foams effectively. Corrugated mesh has a small density and can't influence the flowing rate of gaseous fluids.

Owner:陈长林

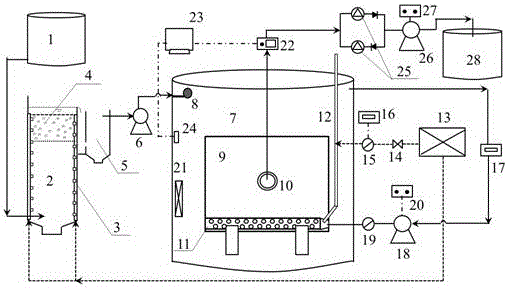

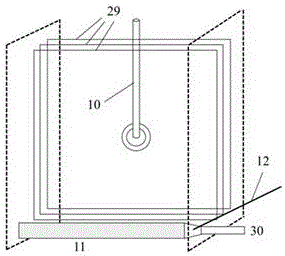

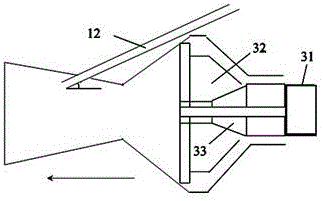

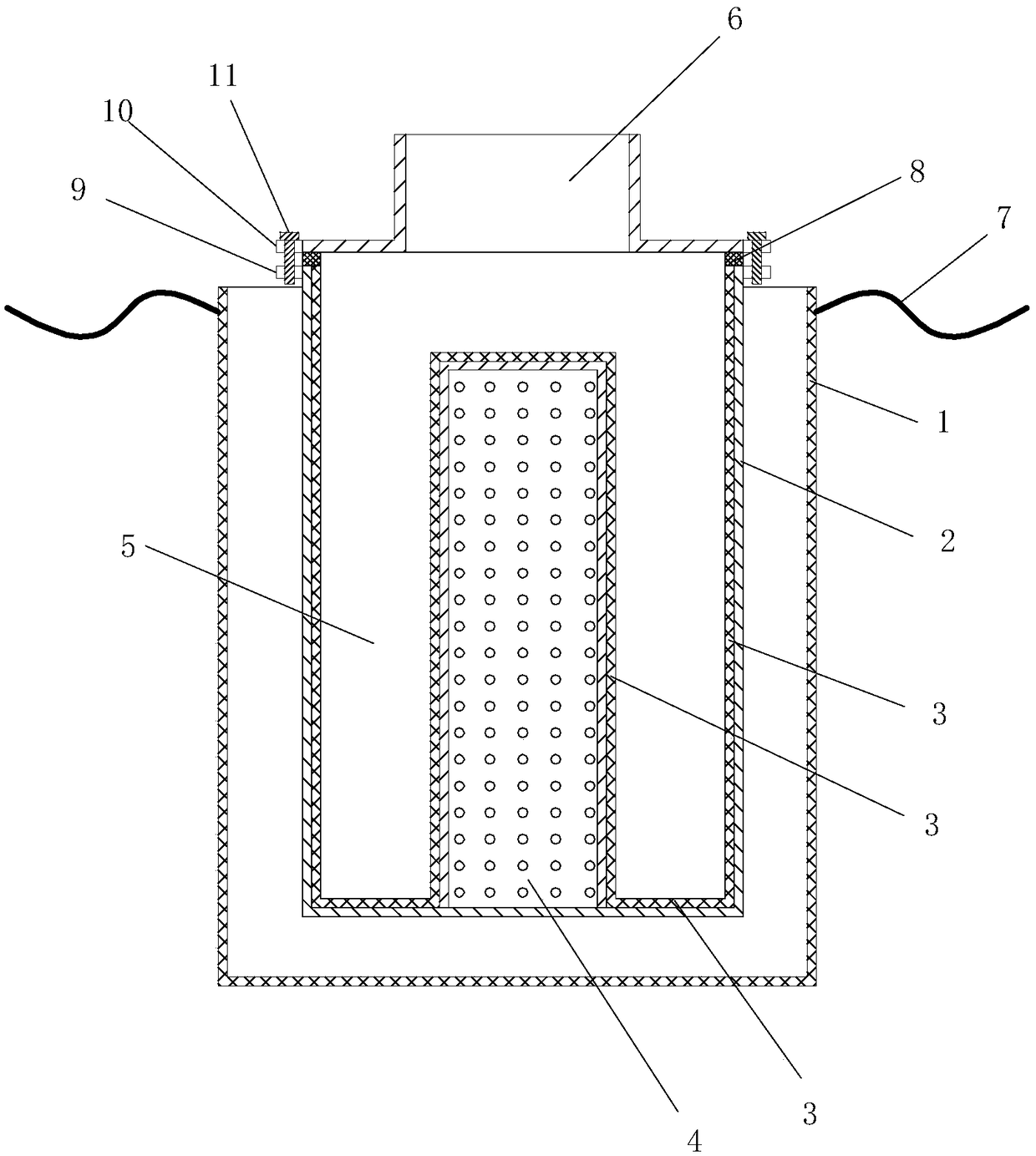

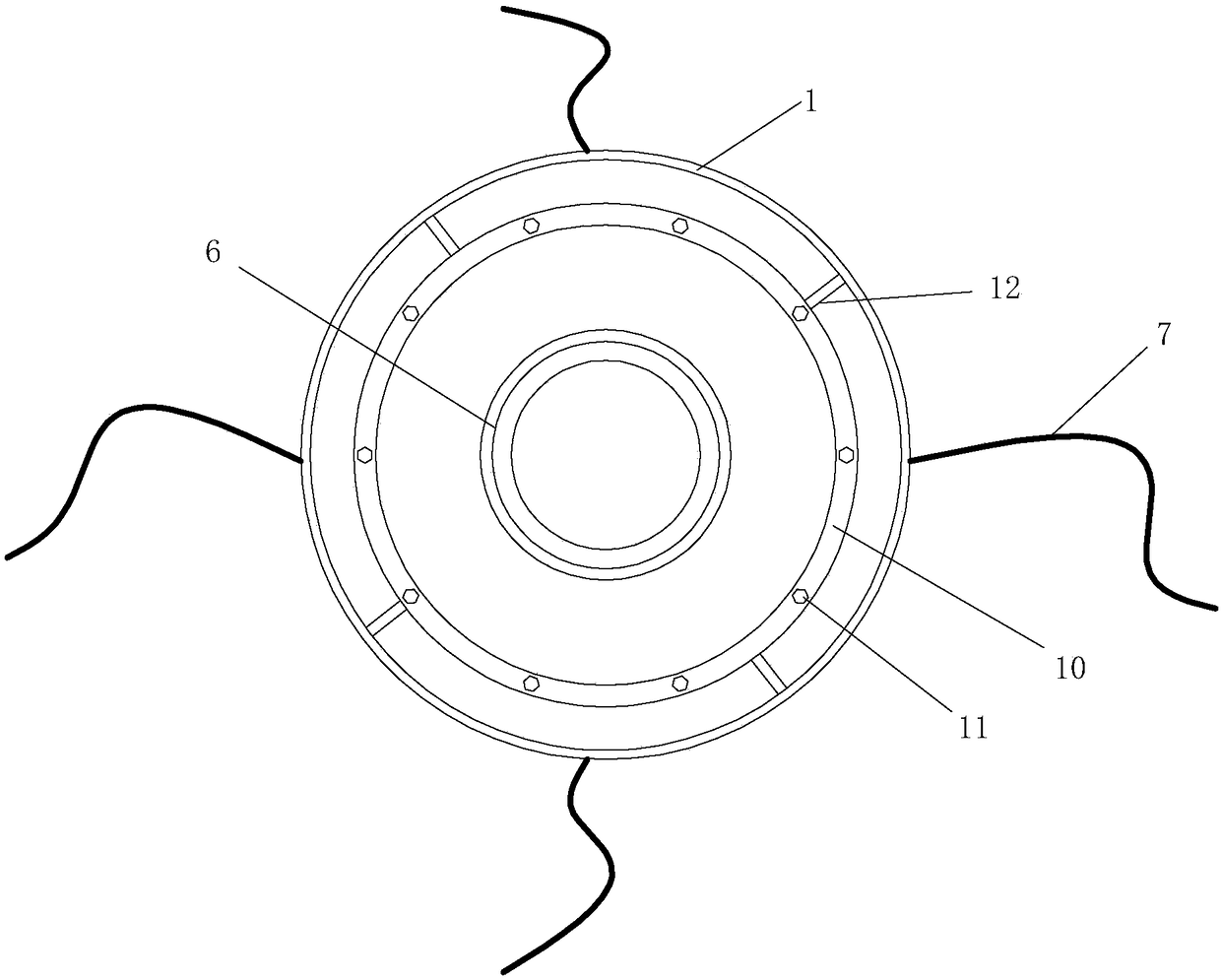

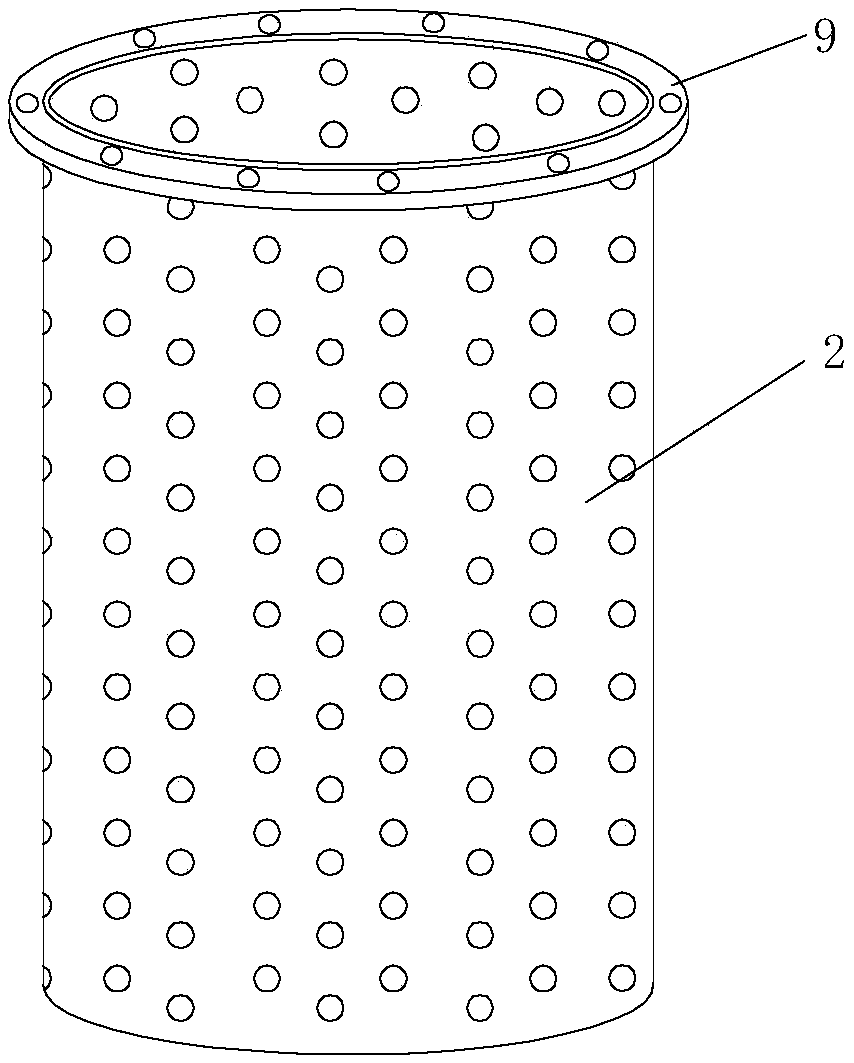

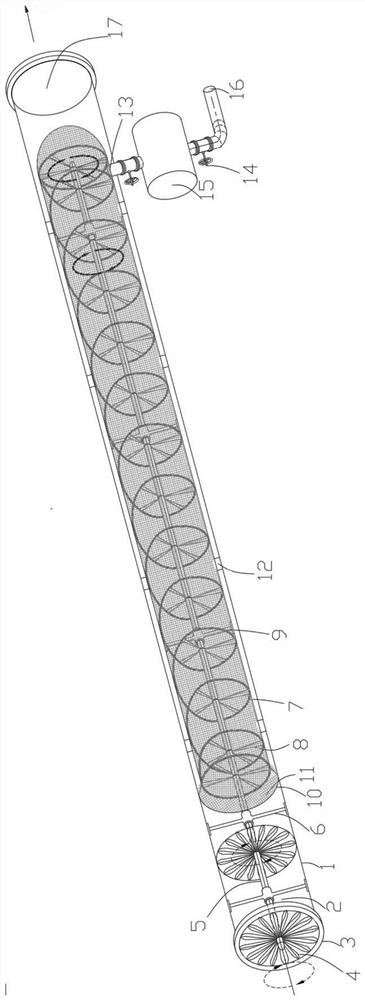

Injection pipe type membrane biological reaction device

ActiveCN106242196AGuaranteed uptimeReduce shear forceTreatment using aerobic processesMultistage water/sewage treatmentPeristaltic pumpWater quality

The invention discloses an injection pipe type membrane biological reaction device. A stock solution supply tank is communicated with the bottom of the side wall of an up-flow type biological fluidized bed reactor through a pipeline, and wastewater flows in the up-flow type biological fluidized bed reactor from bottom to top and overflows to enter an overflow sedimentation tank through a granular active carbon interlayer. The overflow sedimentation tank is communicated with a membrane bioreactor through a pipeline, a suction pump is mounted on the pipeline between the overflow sedimentation tank and the membrane bioreactor, and a permeation water outlet pipeline extends out of the membrane bioreactor to connect with a permeation storage tank through a peristaltic pump. A membrane biological component adopting an ejector for aeration is provided to make efficient use of natural air so as to reduce operation energy consumption, water speed is increased for lowering nearby air pressure of water flow, then air is sucked in to form air-liquid mixed flow, the air-liquid mixed flow is ejected to form a highly-mixed high-disturbance environment so as to retard internal membrane pollution, water quality is effectively improved, and the service life of the membrane component is prolonged. In addition, low energy consumption in operation is guaranteed, and environment friendliness and cost reduction are realized.

Owner:江苏安邦环保科技有限公司

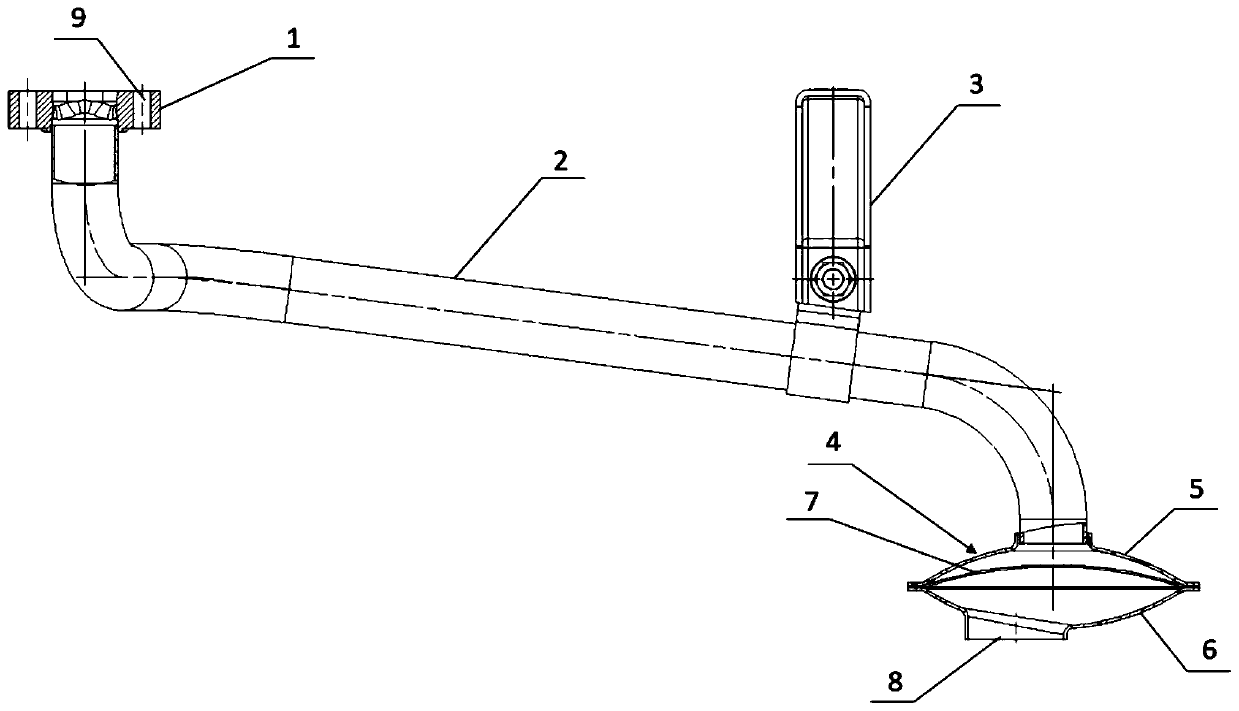

Oil suction pipe part

PendingCN111350562AEliminate assembly errorsReduce assembly stressLubricant conduit arrangementsPressure lubricationStructural engineeringMechanical engineering

The invention provides an oil suction pipe part, comprising a pipeline flange, an oil suction bent pipe, a fixing frame and an oil suction cover. The front end of the oil suction bent pipe and the oilsuction cover are solidified, the tail end of the oil suction bent pipe and the pipeline flange are solidified, and the fixing frame is arranged at the tail end of the oil suction bent pipe; and theoil suction cover comprises an arc-shaped upper cover, an arc-shaped lower cover and an arc-shaped filter net, the arc-shaped upper cover and the front end of the oil suction bent pipe communicate andare solidified, the arc-shaped upper cover and the arc-shaped lower cover are in clamping fit and solidified, the arc-shaped filter net is arranged between the arc-shaped upper cover and the arc-shaped lower cover, and an oil suction opening is further formed in the arc-shaped lower cover. According to the oil suction pipe part provided by the invention, an assembly-type oil suction pipe part isadopted as the fixing frame so that the assembly error within a certain range can be eliminated, assembly stress is reduced, reliability is improved, and a breakage failure caused by long-term usage is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

Spray gun for concrete wet spraying machine

ActiveCN111119937AGood quick setting effectReduce rebound rateUnderground chambersTunnel liningMixed flowStructural engineering

The invention relates to the field of wet spraying machine equipment, and discloses a spray gun for a concrete wet spraying machine. The spray gun comprises a flow mixer pipe, an annular pipe, a compressed air joint and a nozzle; the outer surface of the flow mixer pipe is fixedly sleeved with the annular pipe, the compressed air joint is fixedly mounted at the top of the annular pipe, and the nozzle is fixedly mounted on the side surface of the flow mixer pipe; and the top and the bottom of the inner side of the annular pipe are fixedly sleeved with fixing pipes, one ends of the two fixing pipes extend into the flow mixer pipe and are fixedly sleeved with a flow guide block, and the flow guide block communicates with inner cavities of the fixing pipes and an inner cavity of the annular pipe. According to the spray gun for the concrete wet spraying machine, through the design of the flow guide block and an exhaust plate in the flow mixer pipe, compressed air which is sprayed out of exhaust holes in the exhaust plate and contains an accelerating agent can completely act on concrete in the nozzle, and it is guaranteed that the accelerating agent and the concrete are evenly mixed, sothat the accelerating effect of the sprayed concrete is improved, and the rebound rate of the concrete is effectively reduced.

Owner:浙江天石建材有限公司

A kind of method that urea ammonium nitrate solution carries out turbidity removal and filling simultaneously

The invention relates to a method for simultaneous turbidity removing and filling of a urea ammonium nitrate solution. According to the method, a urea ammonium nitrate solution filling system is adopted. The system comprises a turbidity removing device, a storage tank, a filtering tank, a conveying pump and a filling hose, wherein the storage tank, the filtering tank, the conveying pump and the filling hose communicate in sequence through pipelines. The filling hose is connected to an inlet short pipe of the turbidity removing device; a filling valve and a flow meter are further installed on the pipeline between the conveying pump and the filling hose; the conveying pump and the filtering tank further communicate through a backflow pipeline; and a pressure gauge and a backflow valve are installed on the backflow pipeline. In the filling process, the flow-integrating value of the flow meter is set, the flow meter is interlocked with a power source switch of the conveying pump, and when the flow-integrating value of the flow meter reaches the set flow-integrating value, the switch of the conveying pump is switched off, so that the accident of filled-tank overflowing caused by desertion of an operator is prevented; and the high-limit pressure value of the pressure gauge is set, the pressure gauge is interlocked with the power source switch of the conveying pump, and when the pressure of the pressure gauge reaches the set high-limit pressure value, the switch of the conveying pump is switched off, so that the burst-open accident of a filter bag due to the large resistance is prevented.

Owner:柳州化工股份有限公司

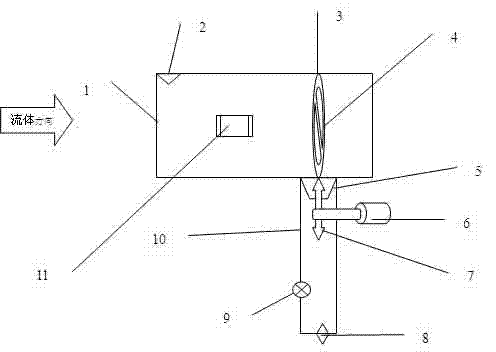

Hydrodynamic filter for micro-irrigation

PendingCN113041687ADoes not affect flow rateDoes not affect fluidityStationary filtering element filtersWater useFiltration

The invention discloses a hydrodynamic filter for micro-irrigation. The hydrodynamic filter comprises a central transmission shaft, one end of the central transmission shaft is fixedly provided with a transmission part used for driving the central transmission shaft to rotate, and the other end of the central transmission shaft penetrates into a filtering and cleaning part and is fixedly connected with the filtering and cleaning part. A power assembly of the filter can utilize water flow to provide rotating power, so that a reliable source of the power is ensured, and energy is saved; meanwhile, the filter is based on the Archimedes spiral theorem, and impurities are pushed towards the water outlet direction along the central transmission shaft through a spiral brush and then discharged out of the filter; and meanwhile, water flow and impurities are separated through a filter assembly, and the impurities are separated in a filter screen to ensure effective filtration, so that the device has the advantages of few accessories, small abrasion, durability, low manufacturing cost, convenience in operation and management, difficulty in blockage, energy conservation, emission reduction, rapidness and high efficiency.

Owner:新疆新水科美环保科技有限公司

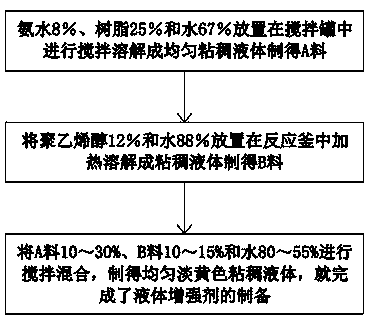

Liquid reinforcing agent

The invention provides a liquid reinforcing agent. The liquid reinforcing agent comprises the following raw materials in percentage by mass: 10-30% of a material A, 10-15% of a material B and 80-55% of water, wherein the material A is prepared from the following raw materials in percentage by mass: 8% of ammonia water, 25% of resin and 67% of water; and the material B is prepared from the following raw materials: 12% of polyvinyl alcohol and 88% of water. The preparation method comprises the following steps: S1, adding 8% of ammonia water, 25% of resin and 67% of water into a stirring tank, and stirring and dissolving to obtain a uniform viscous liquid namely a material A; S2, adding 12% of polyvinyl alcohol and 88% of water into a reaction kettle, and heating and dissolving to obtain a viscous liquid namely a material B; S3, stirring and mixing 10-30% of the material A, 10-15% of the material B and 80-55% of water to obtain a uniform light-yellow viscous liquid. The liquid reinforcingagent has the advantages that the preparation method is simple and convenient, the molecular groups are stable, the breaking strength of a ceramic production green body can be effectively improved, the suspension property of slurry is improved, and the flow rate of the slurry is not influenced.

Owner:四会市奥耳新材料有限公司

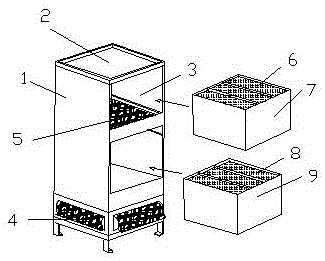

Air filtering device

ActiveCN106694228AEfficient Clean FiltrationDoes not affect flow rateExternal electric electrostatic seperatorElectrodes cleaningFiber layerAlternating current

The invention belongs to the field of air purification, and particularly relates to an air filtering device. The air filtering device comprises an air channel, a fan and a first air filter detachably installed in the air channel; the first air filter comprises a first air filter frame and a first filter body layer containing a first electrostatic fiber layer; and the fan is arranged in the air channel and located in the downstream positions of all air filters. The air filtering device further comprises a second air filter; the second air filter is connected to an alternating current generating device through a power switch and comprises a second filter frame; the second air filter further comprises a second filter body layer containing a second electrostatic fiber layer; and the length of the second electrostatic fiber layer is two to three times of the length of the first electrostatic fiber layer. By means of the air filtering device, air hyperfiltration can be achieved, filter recycling can be achieved, and the air filtering cost is effectively reduced.

Owner:JIANGSU ZHISHI TECH CO LTD

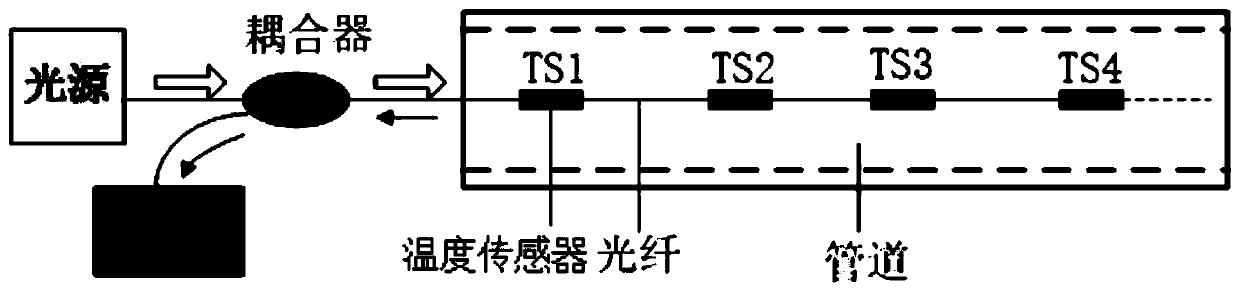

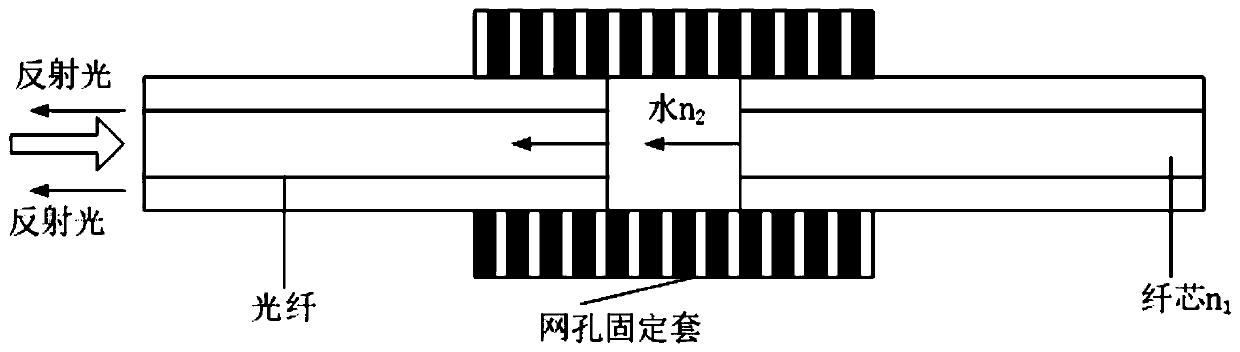

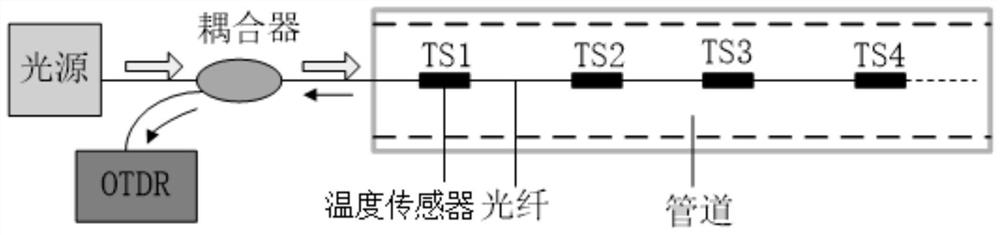

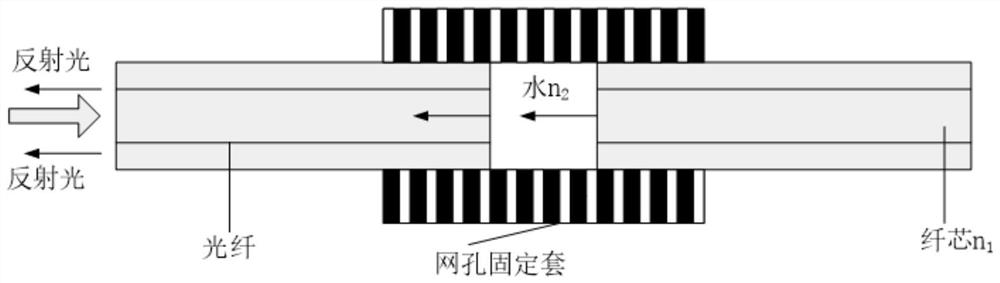

Device of measuring distributed water temperature in pipeline

ActiveCN110296768AAvoid WaterproofingReduce volumeThermometers using physical/chemical changesUnderwaterOptoelectronics

The invention discloses a device of measuring distributed water temperature in a pipeline. The device comprises a light source, a coupler, an OTDR and a plurality of temperature sensors, wherein the light source is used for emitting a light signal, the coupler is used for receiving and transmitting the light signal, the temperature sensors are distributed in the pipeline and have a fiber structurewith a gap, when the light signal transmitted in the fiber structure passes a plane gap, the intensity of transmitted light is changed due to changing water temperature in the gap, light intensity changes so as to detect changing of water temperature, the OTDR is used for detecting different light intensity of the temperature sensors along with temperature changing, and forming a distance-light intensity curve to reflect changing of water temperature. The fiber transmits the light signal in water, thereby avoiding high waterproof requirement of the electronic device underwater; the small fiber can be used in small-size pipelines (such as floor heating pipelines) without affecting flowing speed of liquid in the pipeline.

Owner:NANJING INST OF TECH

Device for automatically removing fluid impurities in pipelines

InactiveCN102225266BAuto clearImprove arresting efficiencyFiltration separationProgrammable logic controllerImpurity

The invention discloses a device for automatically removing fluid impurities in pipelines. The device comprises a cylinder housing and a rectangle housing connected to and communicated with the cylinder housing. The device is characterized in that: an impurity and floater sensor is installed on the left inner wall of the cylinder housing and is connected to a PLC (programmable logic controller); a sealed card mechanism is positioned within the rectangle housing; an arresting net traverses the sealed card mechanism and the lower part of the arresting net is connected with a driving rod that is provided with a tooth bar along a longitudinal direction; a sensor attached to the arresting net is arranged on the arresting net and is connected with the PLC; a motor is positioned outside the rectangle housing and a rotating shaft of the motor is inserted into the rectangle housing; a gear that is cooperatively connected on the rotating shaft of the motor is engaged with the tooth bar of the driving rod, and the motor is controlled by the PLC. The invention has the following advantages that: the arresting net is unfolded when needed and is retracted when having no use, so that the arresting efficiency is improved and the flow rate is not influenced; impurities and floaters in the fluid can be removed automatically, and impurities and floaters on the arresting net can also be removed automatically.

Owner:SOUTHWEST UNIV

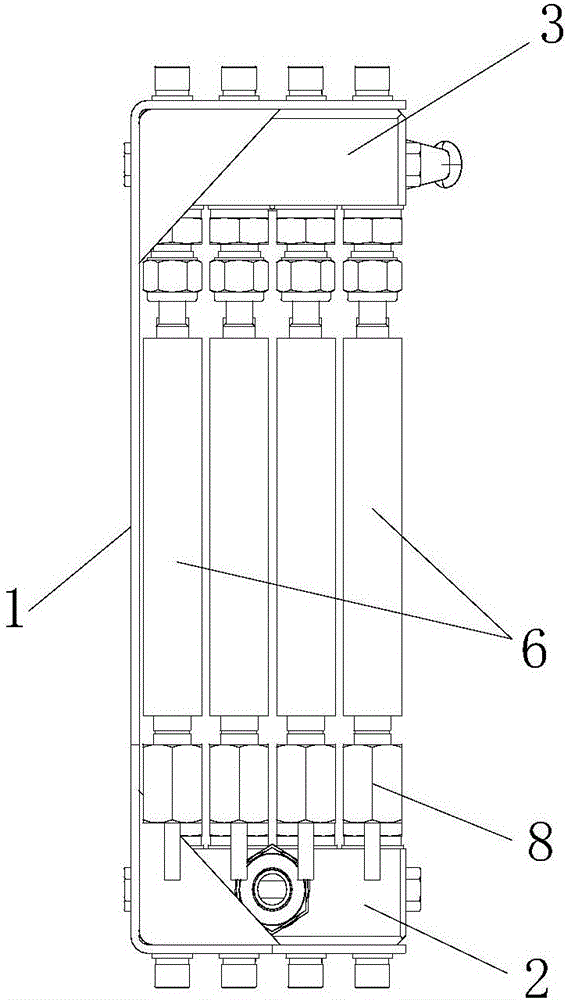

Gas purifying and water removing device used in CNG dispenser

InactiveCN106753639AGuaranteed heat exchange effectReduce volumeGaseous fuelsProcess engineeringInlet valve

The invention discloses a gas purifying and water removing device used in a CNG dispenser. The gas purifying and water removing device comprises an outer frame, a gas inlet valve, a gas outlet valve and multiple condensating gas purifying assemblies, wherein the gas inlet valve and the gas outlet valve are installed on the outer frame; each condensating gas purifying assembly comprises a gas inlet pipe, a gas outlet pipe and multiple heat dissipating capillary tubes, wherein the lower end of the gas inlet pipe is connected with the gas inlet valve, the upper end of the gas outlet pipe is connected with the gas outlet valve, the heat dissipating capillary tubes are arrayed from top to bottom in a row, one end of each heat dissipating capillary tube is connected with the corresponding gas inlet pipe, and the other end of each heat dissipating capillary tube is connected with the corresponding gas outlet pipe; a blow-down valve is arranged at the lower end of each gas outlet pipe, and the upper end of each gas inlet pipe is closed. The condensating gas purifying assemblies do not need to be replaced frequently and are convenient to maintain; the condensating gas purifying assemblies formed by the gas inlet pipes, the gas outlet pipes and the multiple heat dissipating capillary tubes are low in manufacturing cost and high in working efficiency.

Owner:TOKHEIM HENGSHAN TECH GUANGZHOU

A distributed water temperature measuring device in a pipeline

ActiveCN110296768BAvoid waterproofingReduce volumeThermometers using physical/chemical changesEngineeringAtmospheric sciences

The invention discloses a distributed water temperature measuring device in a pipeline, which includes a light source, a coupler, an OTDR and several temperature sensors; the light source is used to emit light signals; the coupler is used to receive and transmit light signals; the temperature sensors are distributed in the pipeline, and the temperature The sensor is an optical fiber structure with a gap. When the optical signal transmitted in the optical fiber structure passes through the plane gap, the change of water temperature in the gap changes the light intensity of the transmitted light, and the change of light intensity is used to detect the change of water temperature; OTDR is used to detect the temperature The different light intensities reflected by the sensor as the temperature changes, and at the same time form a graph of the relationship between distance and light intensity to reflect changes in water temperature. The invention uses optical fiber to transmit optical signals in water, avoiding the high-demand waterproof treatment of electronic equipment underwater; the optical fiber is small in size, and can also be applied in small-sized pipelines (such as ground heating water pipelines), without affecting the liquid in the pipeline flow rate.

Owner:NANJING INST OF TECH

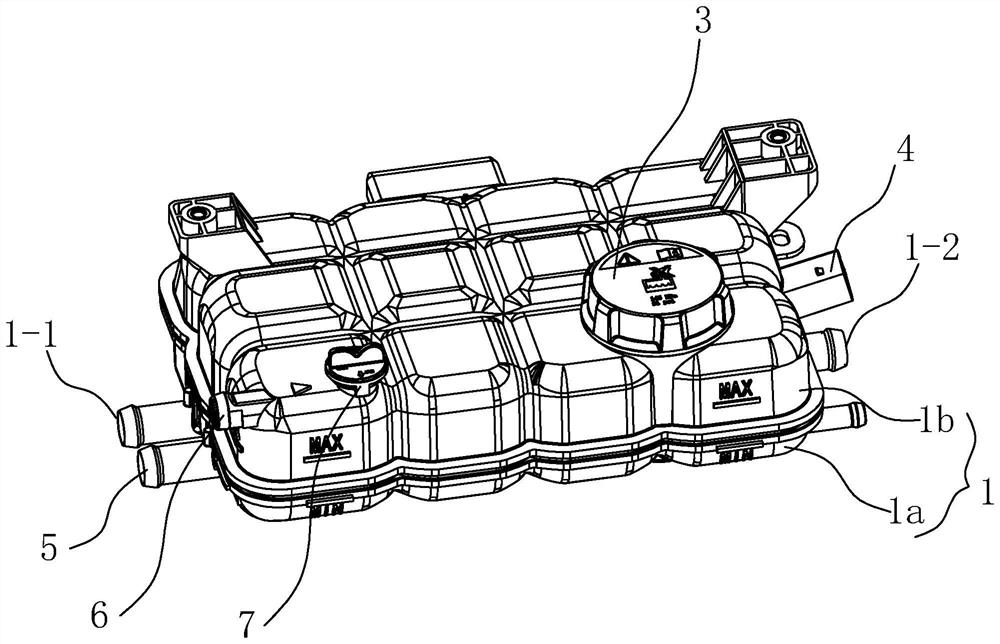

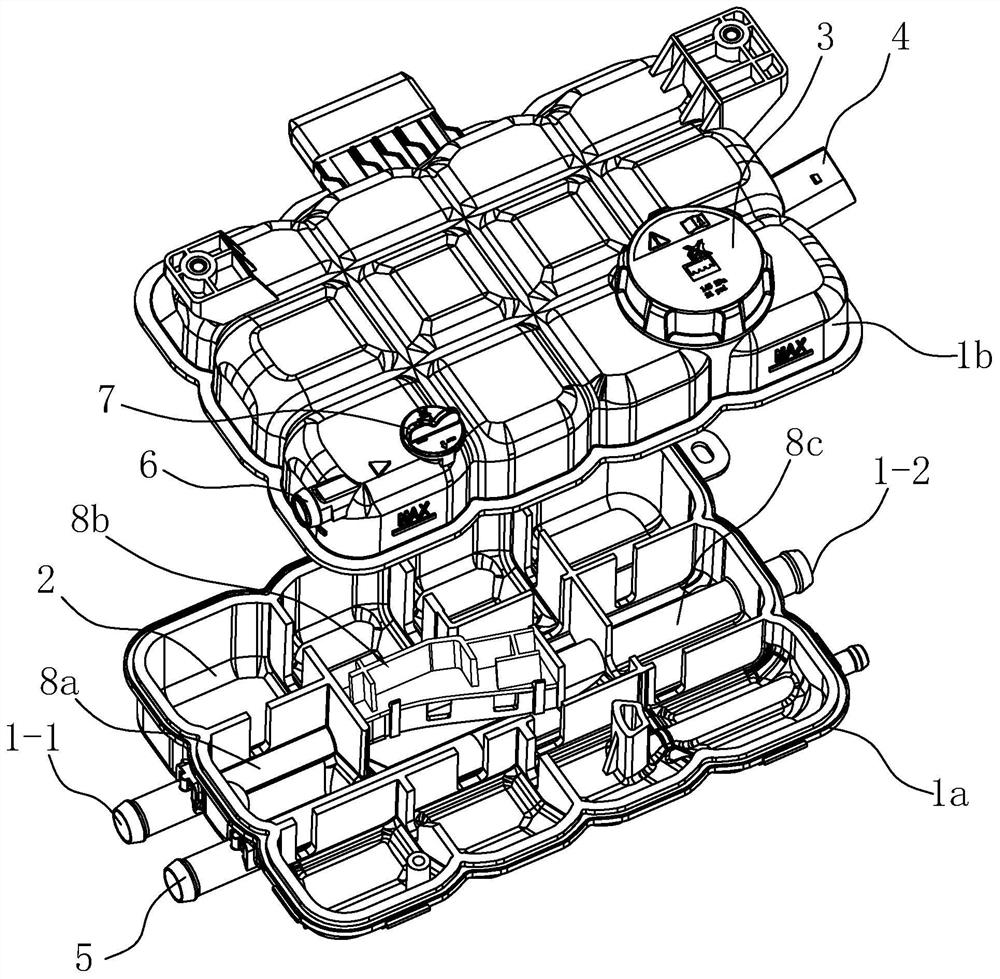

Integrated expansion kettle, cooling system and automobile

ActiveCN114837796AAchieve a separationDoes not affect flow rateMachines/enginesEngine cooling apparatusThermodynamicsElectrical battery

The invention provides an integrated expansion kettle which comprises a kettle body, a cooling liquid flow channel penetrating through a cavity is formed in the kettle body, and at least one gas-liquid separation structure is arranged on the cooling liquid flow channel. Each gas-liquid separation structure comprises a first opening and a second opening, wherein the first opening is formed in the cooling liquid flow channel and used for allowing liquid in the cavity to flow into the cooling liquid flow channel, the second opening is used for allowing the liquid in the cooling liquid flow channel to flow into the cavity, and the pressure intensity of the first opening is larger than that of the second opening. The cooling system comprises a motor cooling loop, a battery cooling loop and the expansion kettle. The automobile comprises the cooling system. According to the gas-liquid separator, separation is conducted in two sections, the gas-liquid separation efficiency is guaranteed, abnormal sound is eliminated, the degassing time of gas-liquid separation is shortened on the whole, heat leakage is reduced, and the temperature difference between a liquid inlet and a liquid outlet can be greatly reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

High-flux filter method of composite polyphase catalysis materials

InactiveCN1232812CAchieving Parallel ReactionsDoes not affect flow rateRadiation pyrometrySamplingHigh-Throughput Screening MethodsMass spectrometry detector

A high-throughput screening method for combined heterogeneous catalytic materials, in which each reaction tube in a parallel combined heterogeneous catalytic reactor is connected to a multi-valve mass spectrometry detection system through a capillary tube. The multi-channel reaction gas generated in the reaction furnace enters the multi-way valve of the mass spectrometry detection system through the capillary, and any part of the gas is selected by the multi-way valve to enter the mass spectrometer detector for analysis. Any one of the capillary tubes is connected to any one of the multi-way valves through a six-way valve, and the six-way valve is connected to a gas chromatograph at the same time. Switch the six-way valve to control the gas in the capillary to enter the gas chromatograph or enter the multi-way valve through the quantitative tube; when the reaction gas in the capillary enters the gas chromatograph and the multi-way valve, a chromatographic result and a mass spectrometry result are obtained , using the coefficient relationship between the two sets of values to correct the mass spectrometry results of all gases to obtain the selectivity of each product in the reaction gas. The calculation of the reaction conversion rate is realized by comparing the mass spectrometry data of each reaction gas with the blank reaction tube.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com