Ore used in core tube of water treatment device

A water treatment device and ore technology, applied in the fields of adsorption water/sewage treatment, ion exchange water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. , to achieve the effect of not affecting the flow rate and low filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

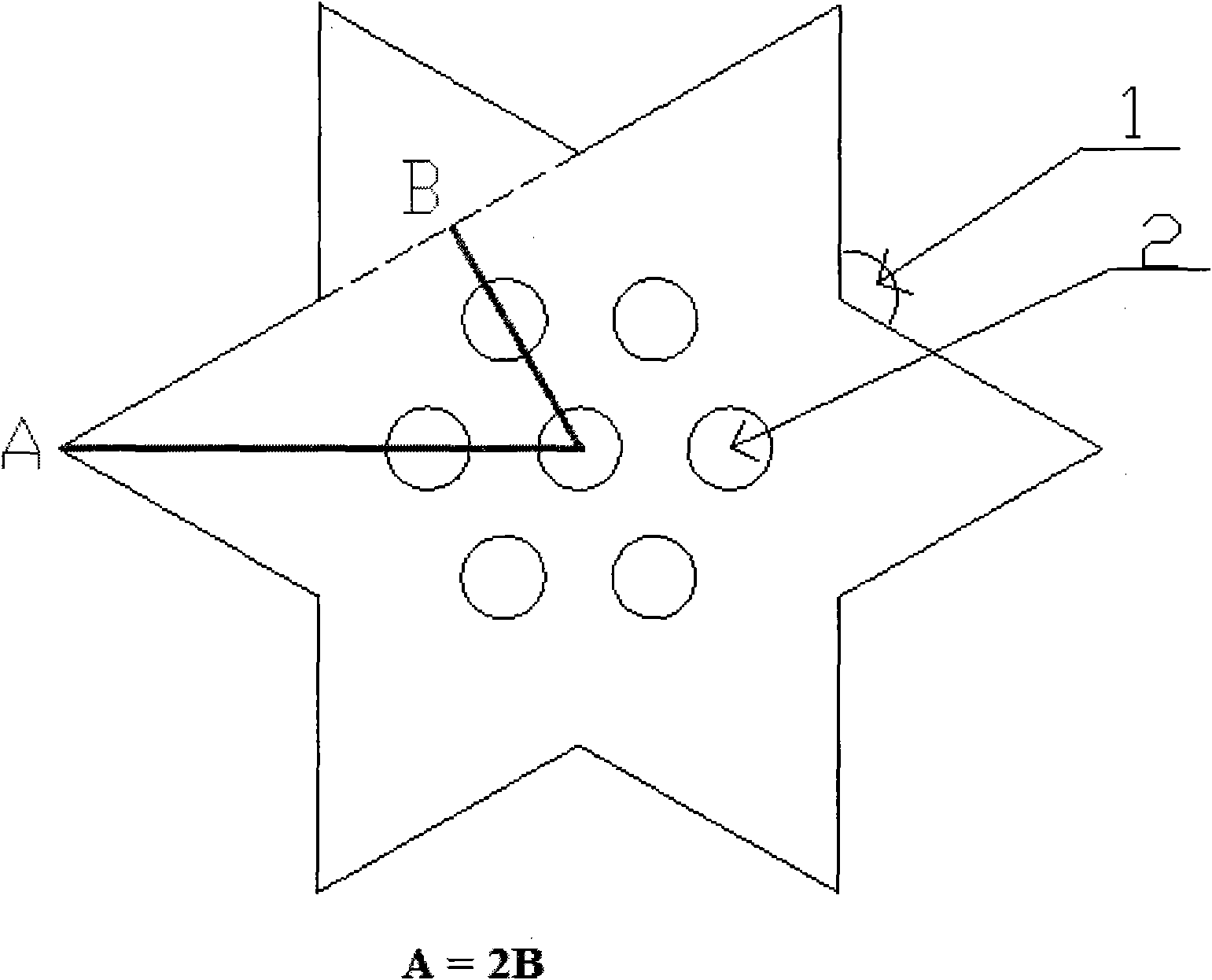

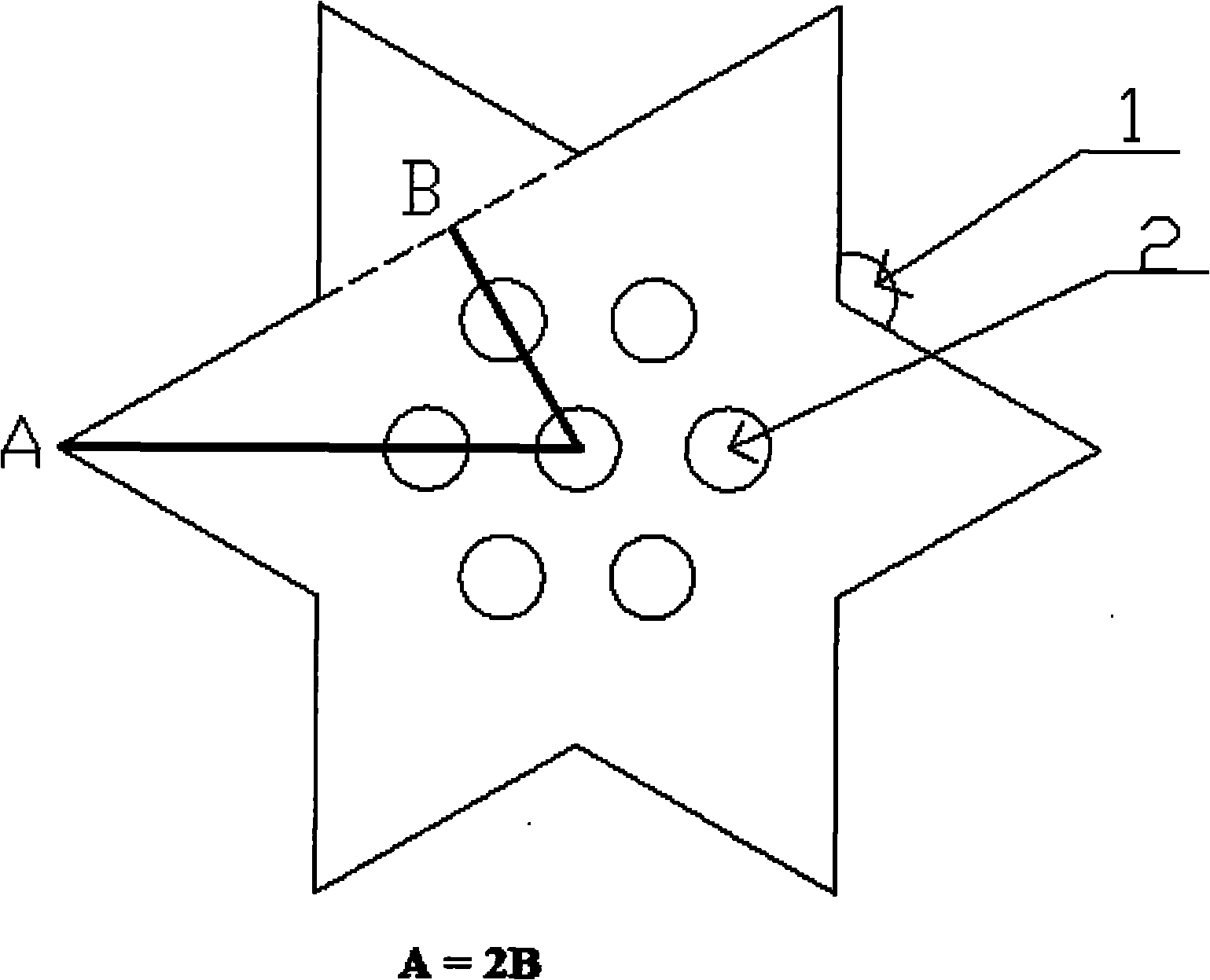

[0013] Such as figure 1 The ore in the core tube of a water treatment device is shown. The ore has hexagons and is evenly distributed on the periphery. A concave is formed between the two corners. The distance A from the center to the top of the corner is twice the distance B from the bottom corner; The inner recess is an obtuse angle 1; the angle of the obtuse angle 1 is 120°; there are 7 through holes 2 on the ore surface.

[0014] The composition of the ore includes: medical stone as the matrix, 10-15% tourmaline, 50-68% rare earth material Nd 2 Fe 14 B. 18-30% granite, 1-2% magnetite, 3-4% zeolite and 1-0.5% silver; the ore also includes 2-3% charcoal; rare earth materials also contain La, SiO 2 、Al 2 o 3 . It has the functions of activation, deodorization and sterilization.

[0015] For ores of the same weight and shape, their size is inversely proportional to the total surface area. When water molecules are impacted by ores, the larger the impact area, the greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com