Segmental-evaporation buried gravity-assisted heat pipe with large length-diameter ratio

A gravity heat pipe, large aspect ratio technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of affecting heat transfer effect, limiting the length of gravity heat pipe, uneven flow of condensing liquid, etc., to achieve efficient evaporation and heat transfer. The effect of heat and low filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

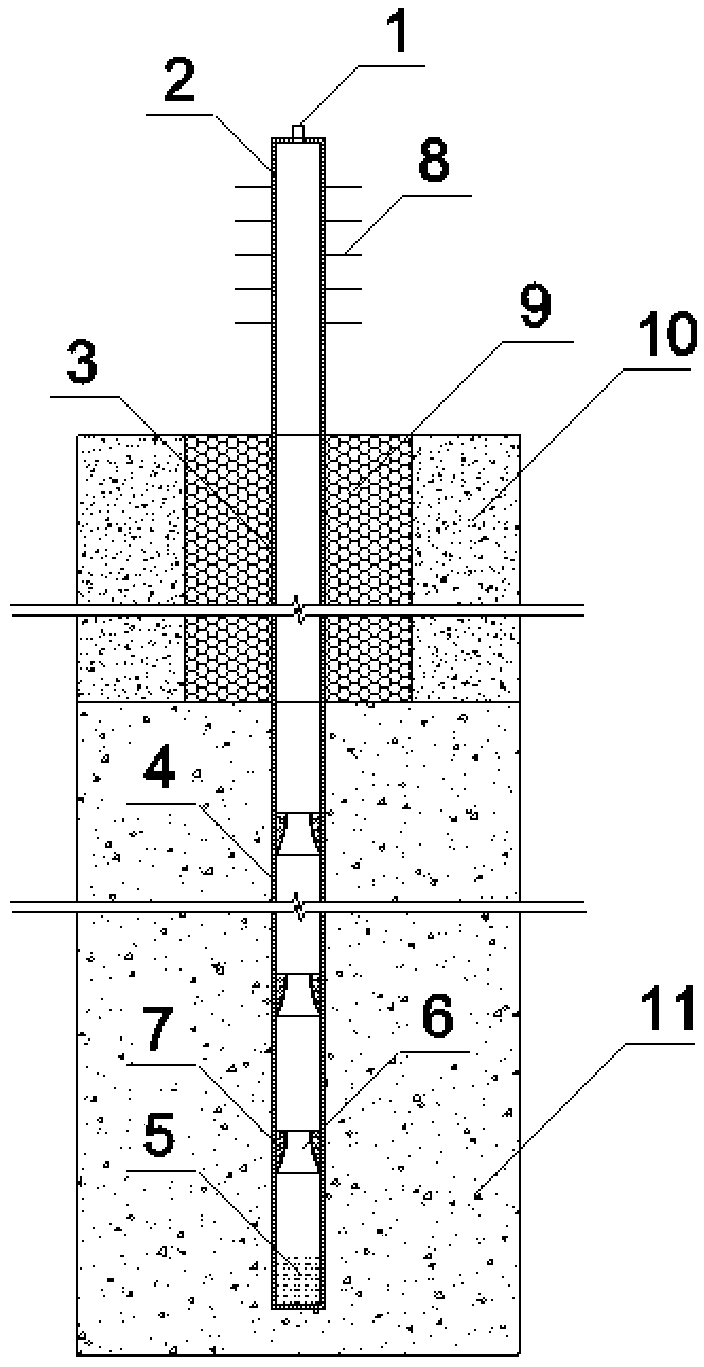

[0018] A large length-to-diameter ratio segmental evaporation type ground buried gravity heat pipe of the patent of the present invention will be described in detail below in conjunction with the accompanying drawings.

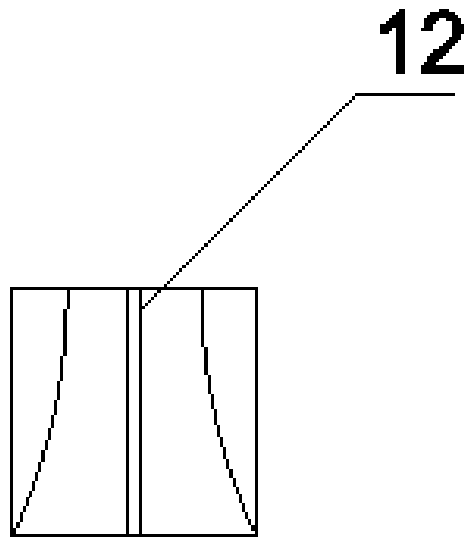

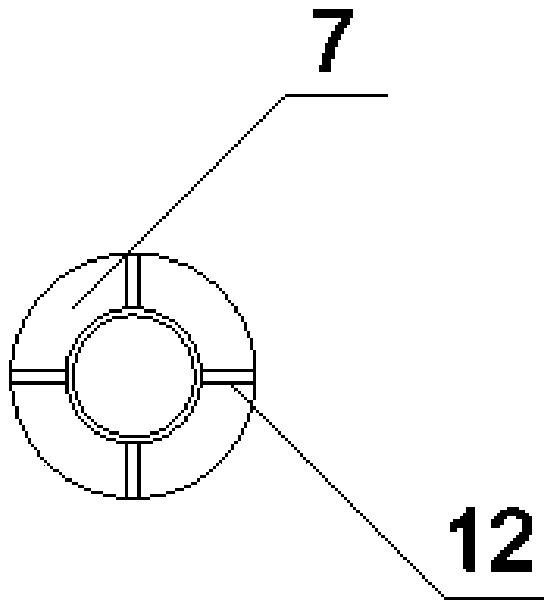

[0019] Such as Figures 1 to 5 As shown, a large length-to-diameter ratio segmental evaporation type underground gravity heat pipe includes a condensation cooling section 2, an adiabatic section 3, and an evaporation section 4. The three are integrated, and a liquid injection hole 1 is welded on the top of the heat pipe. The liquid hole 1 fills the inside of the heat pipe with a phase-change working fluid 5. There are multiple segmented evaporation components 6 in the evaporation section 4. The evaporation components 6 are hollow truncated cones. The connected multiple ribs are installed in the evaporation section 4 by means of expansion joints, and the distance between adjacent segmented evaporation components 6 is generally 10-30 times the inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com