Device for separating droplets

A separation liquid and droplet separator technology, which is applied in the field of droplet separation devices, can solve the problems of increased manufacturing costs, expensive equipment, and difficulty in managing the flow conditions of plate components, so as to achieve high evaporation efficiency, reduce droplet formation, and promote The effect of gravity droplet separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] For the sake of clarity, the same reference numerals have been used for corresponding parts in the different embodiments. The direction of travel of liquid and vapor is shown with arrows.

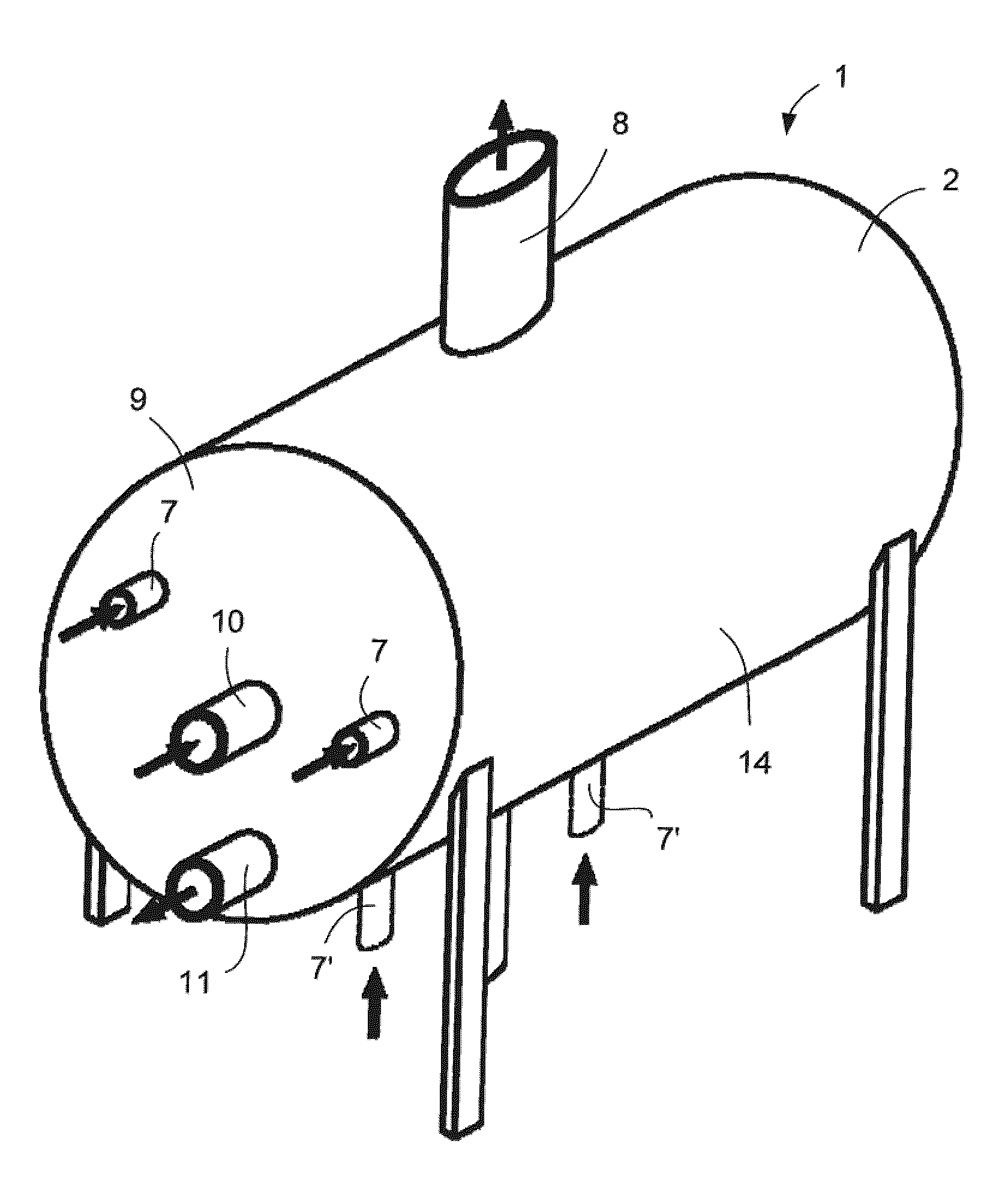

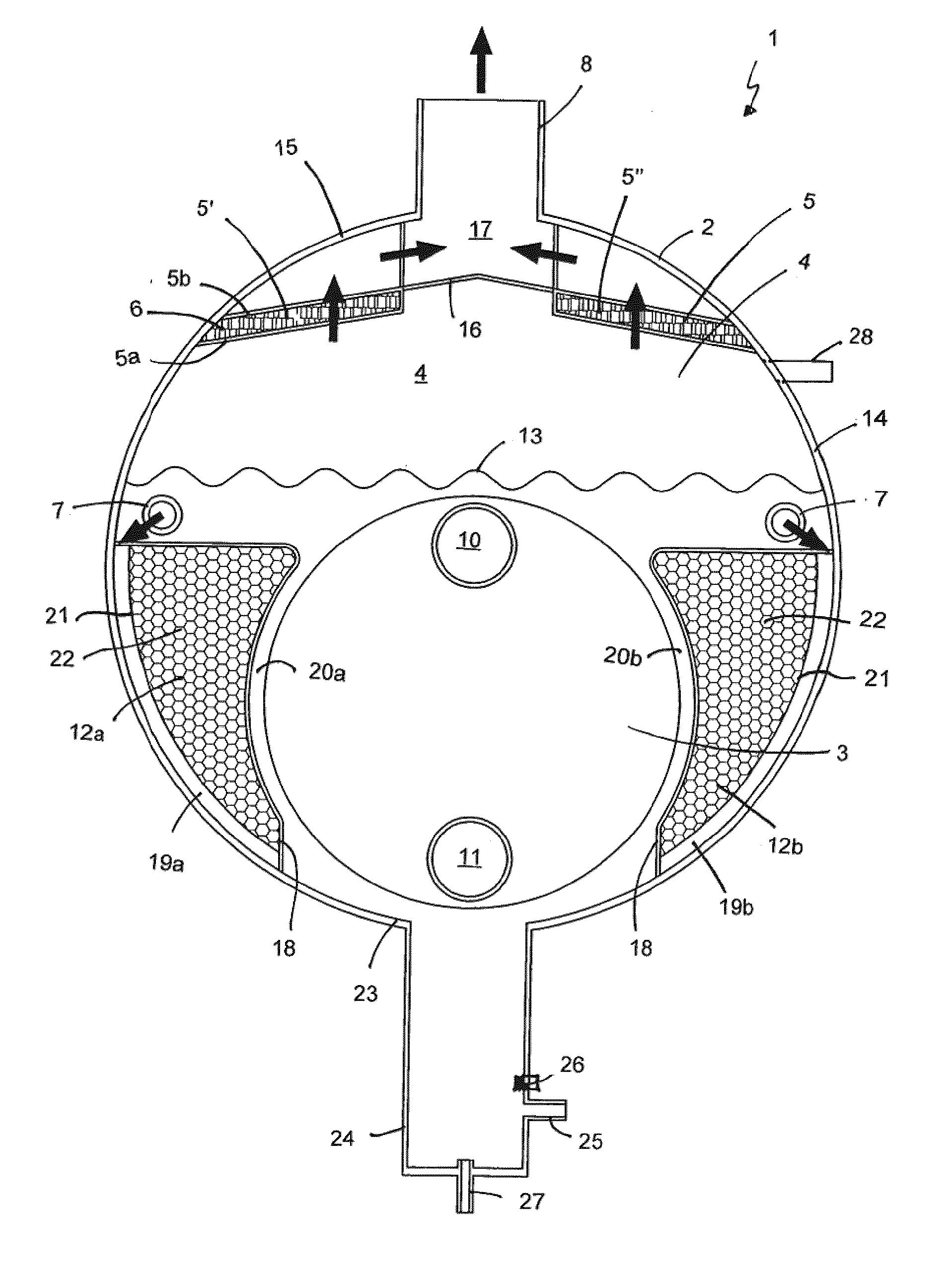

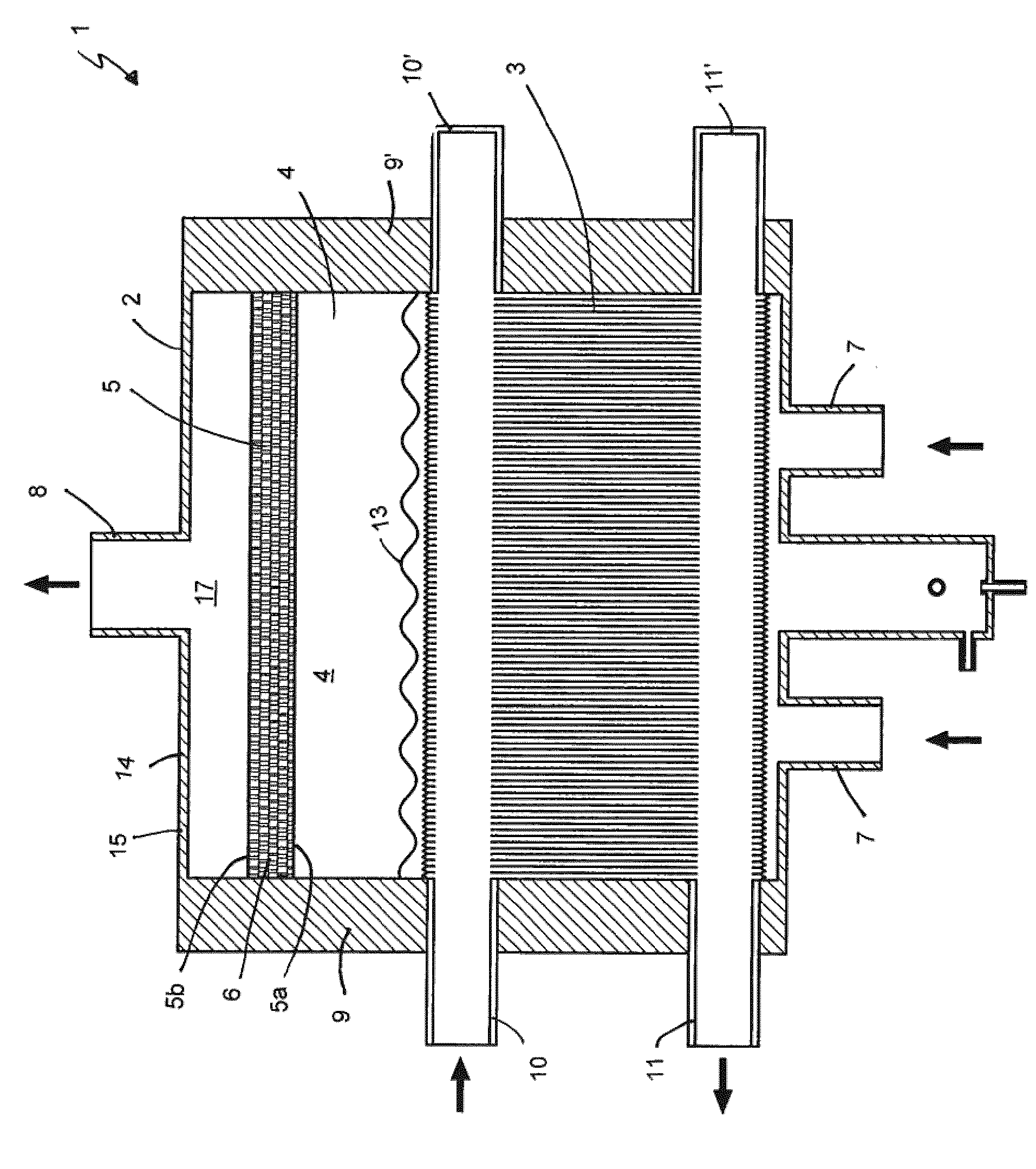

[0049] Figure 1 to Figure 3 Shown is an evaporator droplet separator device 1 having a centrifugal / eccentric fit into an outer housing 2 acting as a frame, i.e. for example into a figure 1 Inside the flat-ended cylinder shown in for example in figure 2 with image 3 Plate&Shell shown in TM A template assembly 3, and a gravity droplet separator 4 and a mist eliminator 5. The demister 5 has two perforated or mesh panels 5a, 5b with steel wool 6 fitted between them. The substance to be vaporized, for example refrigerant, is introduced from the inlet connection 7 into the outer housing 2 . The vaporized substance exits / discharges from the outlet connection 8 in the upper part of the outer housing. With the inlet connection 10 a heating substance is introduced into the plate asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com