Apparatus for removing solid and volatile contaminants

a technology for removing solid and volatile contaminants, applied in the direction of lubricant mounting/connection, multi-stage water/sewage treatment, separation process, etc., to achieve the effect of improving the construction of the device and its efficiency, reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

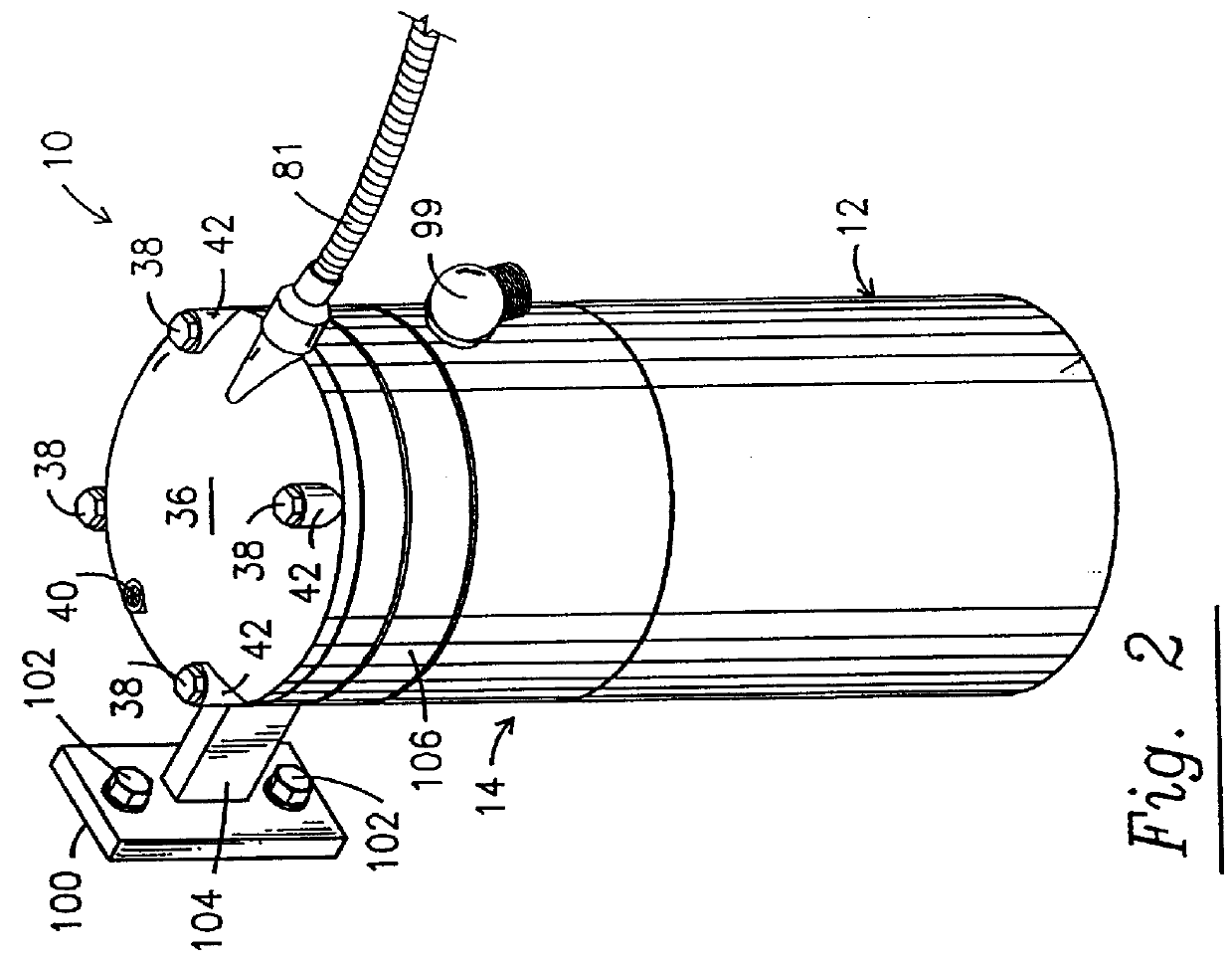

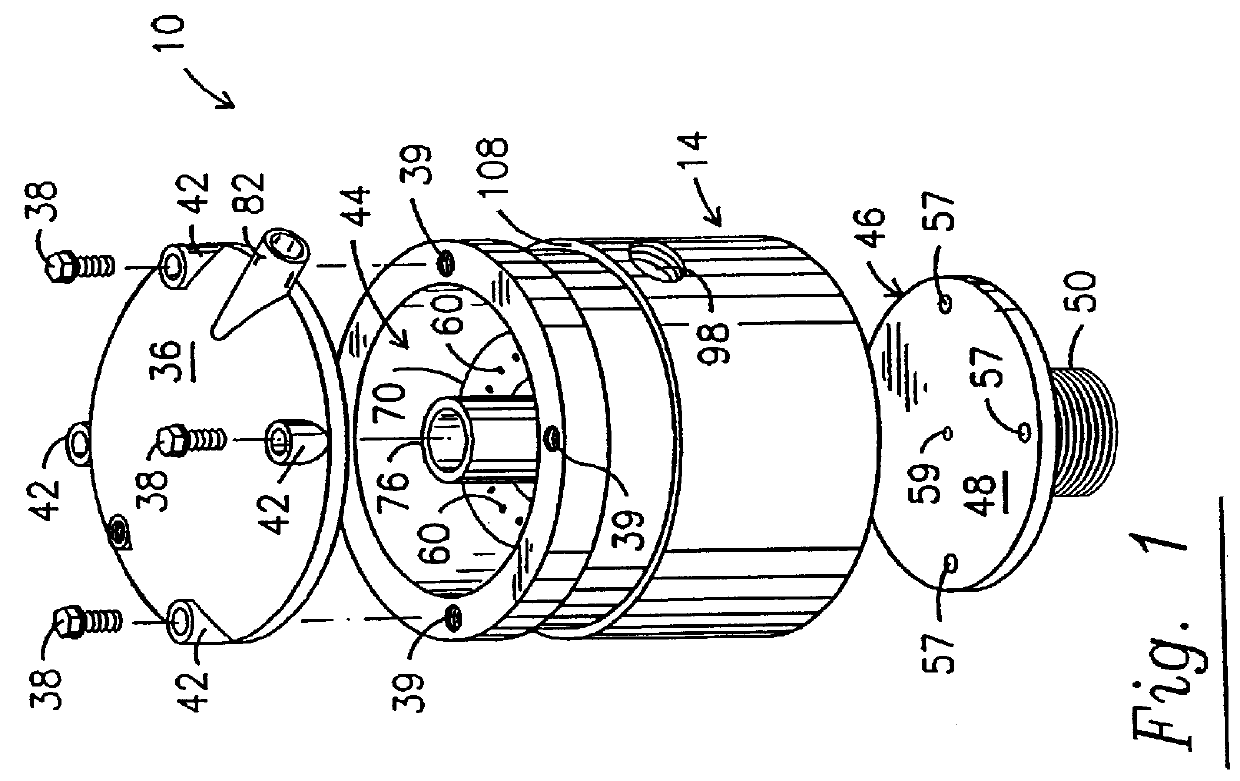

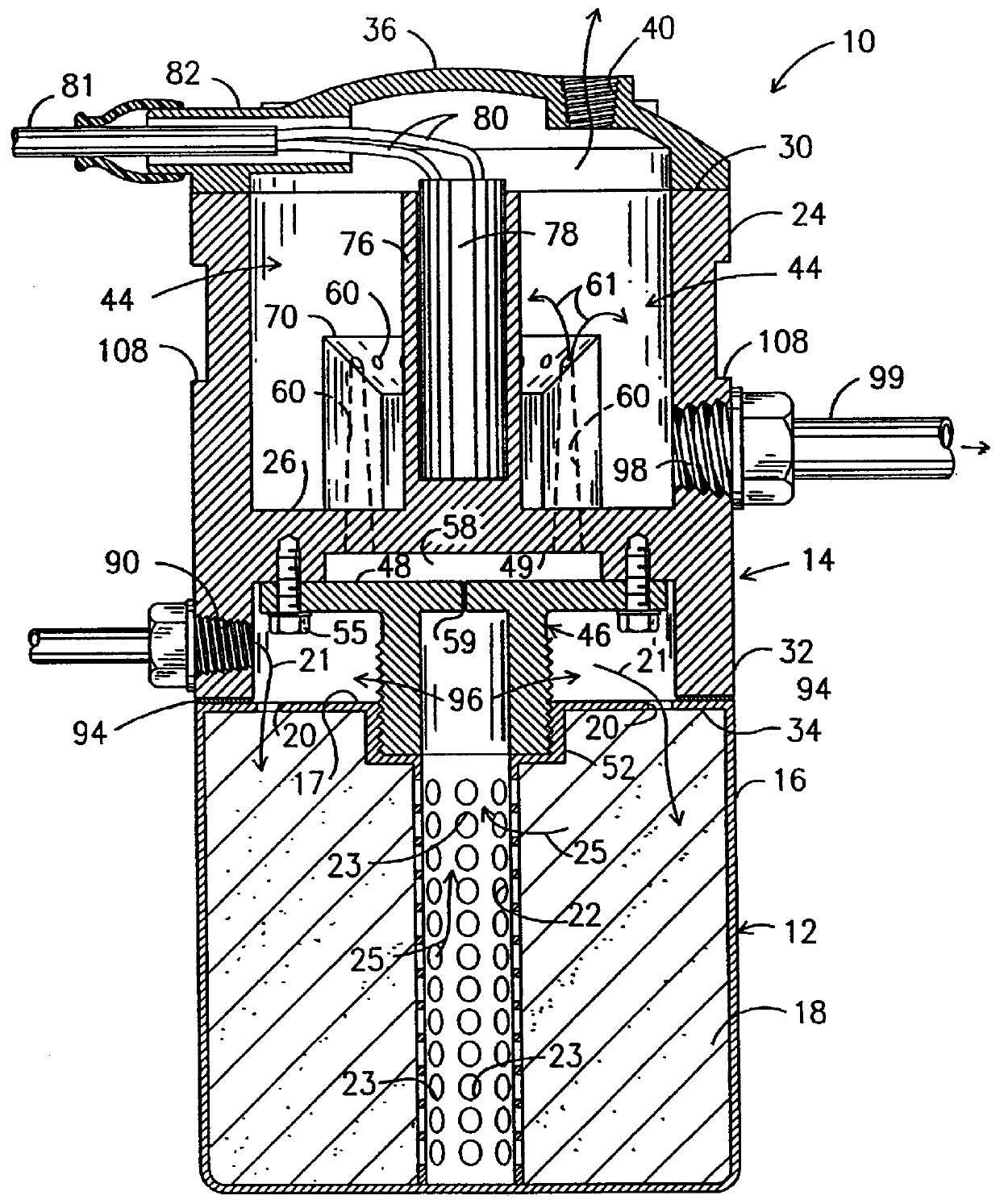

Referring now to FIGS. 1-3, it will there be seen that an exemplary embodiment of the invention is denoted as a whole by the reference numeral 10.

Fluid reclamation apparatus 10 includes a filter means, generally denoted 12, (FIGS. 2 and 3) and an evaporator means, generally denoted 14. In a preferred embodiment, both the filter means 12 and the evaporator means 14 are of cylindrical configuration and share a common diameter, but differing shapes and sizes for both of said parts are within the scope of this invention. Solids are removed from the fluid to be reclaimed by filter means 12, and volatiles are removed therefrom by evaporator means 14. It should be observed from the outset that filter means 12 is readily detachable from evaporator means 14 and that no disassembly of evaporator means 14 is required when filter means 12 is changed.

Filter means 12 has a hollow main body 16, a filter media 18 positioned within said hollow main body, a plurality of openings 20 formed in top wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| volatile | aaaaa | aaaaa |

| electrical power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com