Patents

Literature

153results about "Evaporators with heating coils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

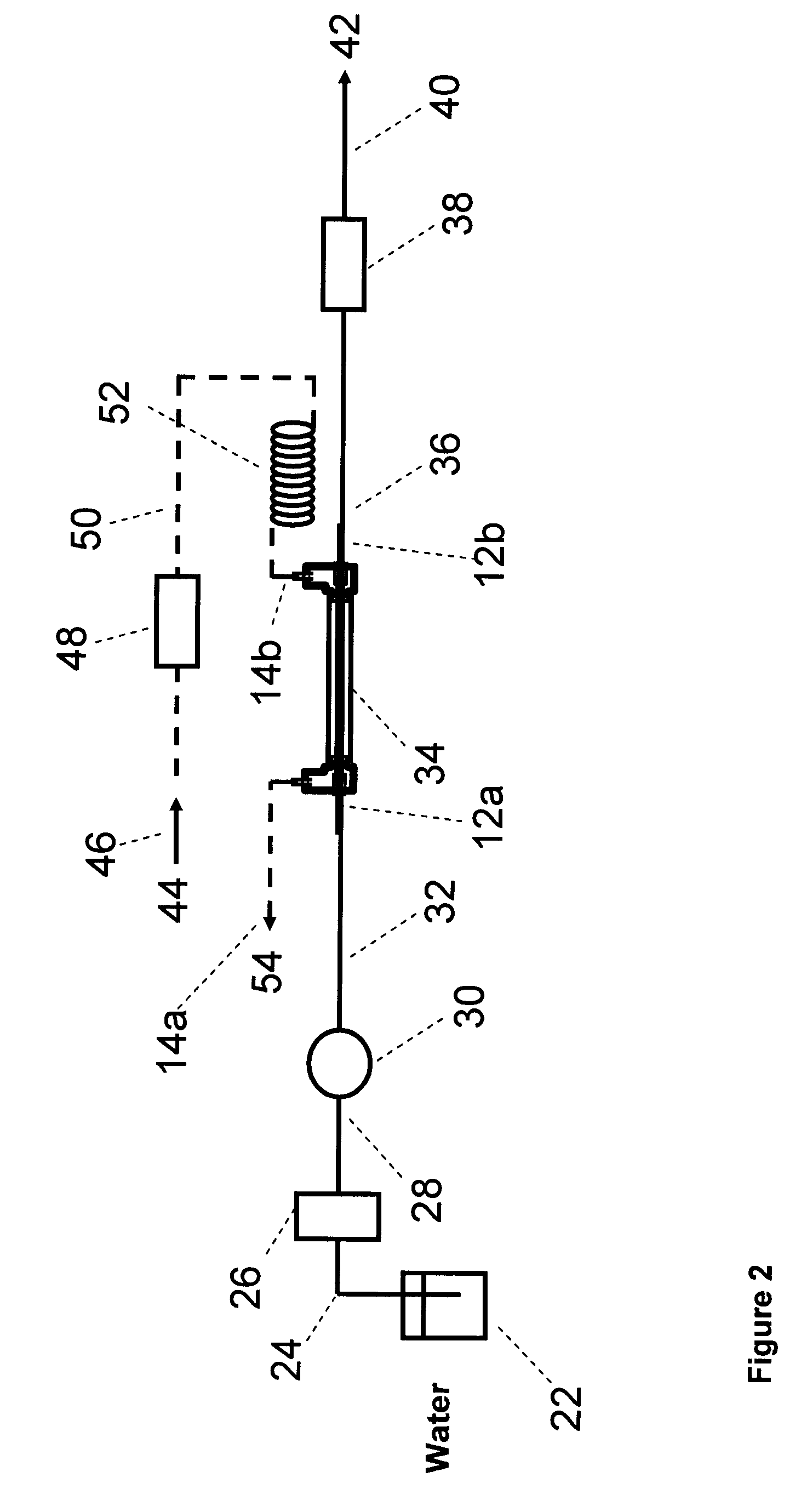

Water producing method and apparatus

InactiveUS20090077992A1Water/sewage treatment by irradiationLighting and heating apparatusFilter systemEnvironmental engineering

A water producing system adapted to condense water from the air and collected in a storage tank were the water is purified and bacteria is killed. One form of killing the bacteria is utilizing a circulation line with a filter system to remove the ozone before the water is dispensed. A circulation line is to prevent dead legs in the system which can lead to bacteria production.

Owner:ANDERSON RAE RAY T +1

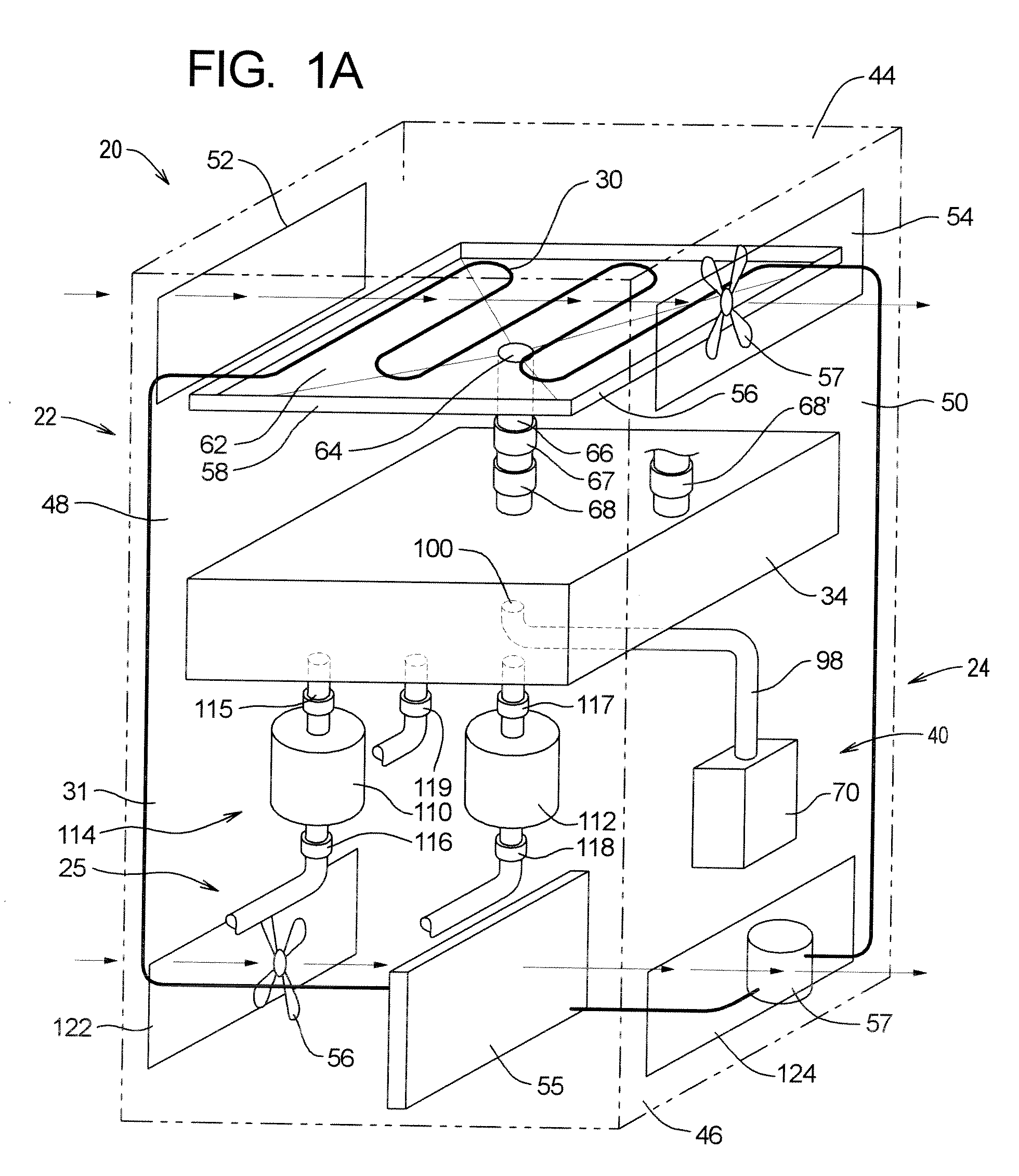

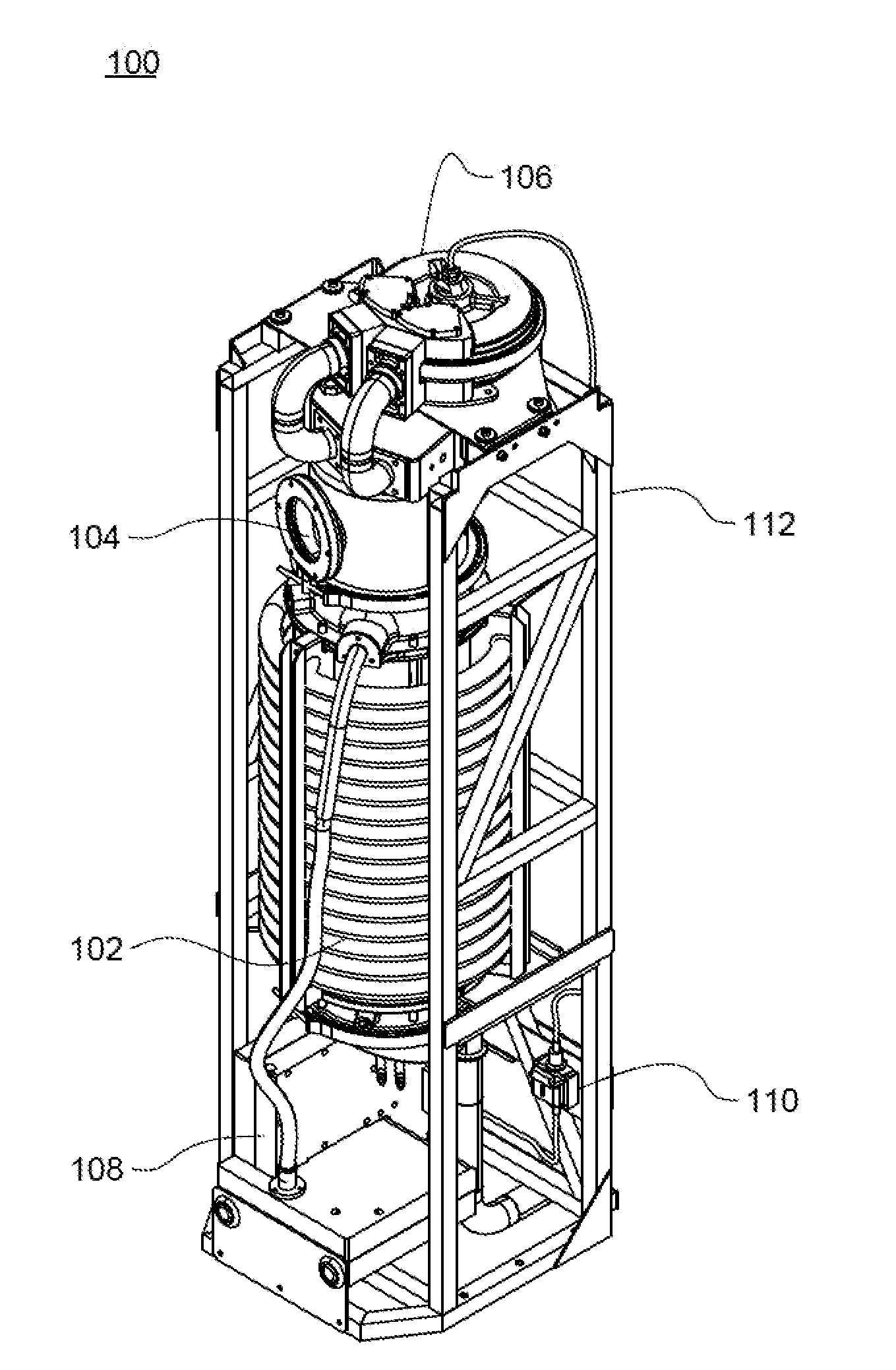

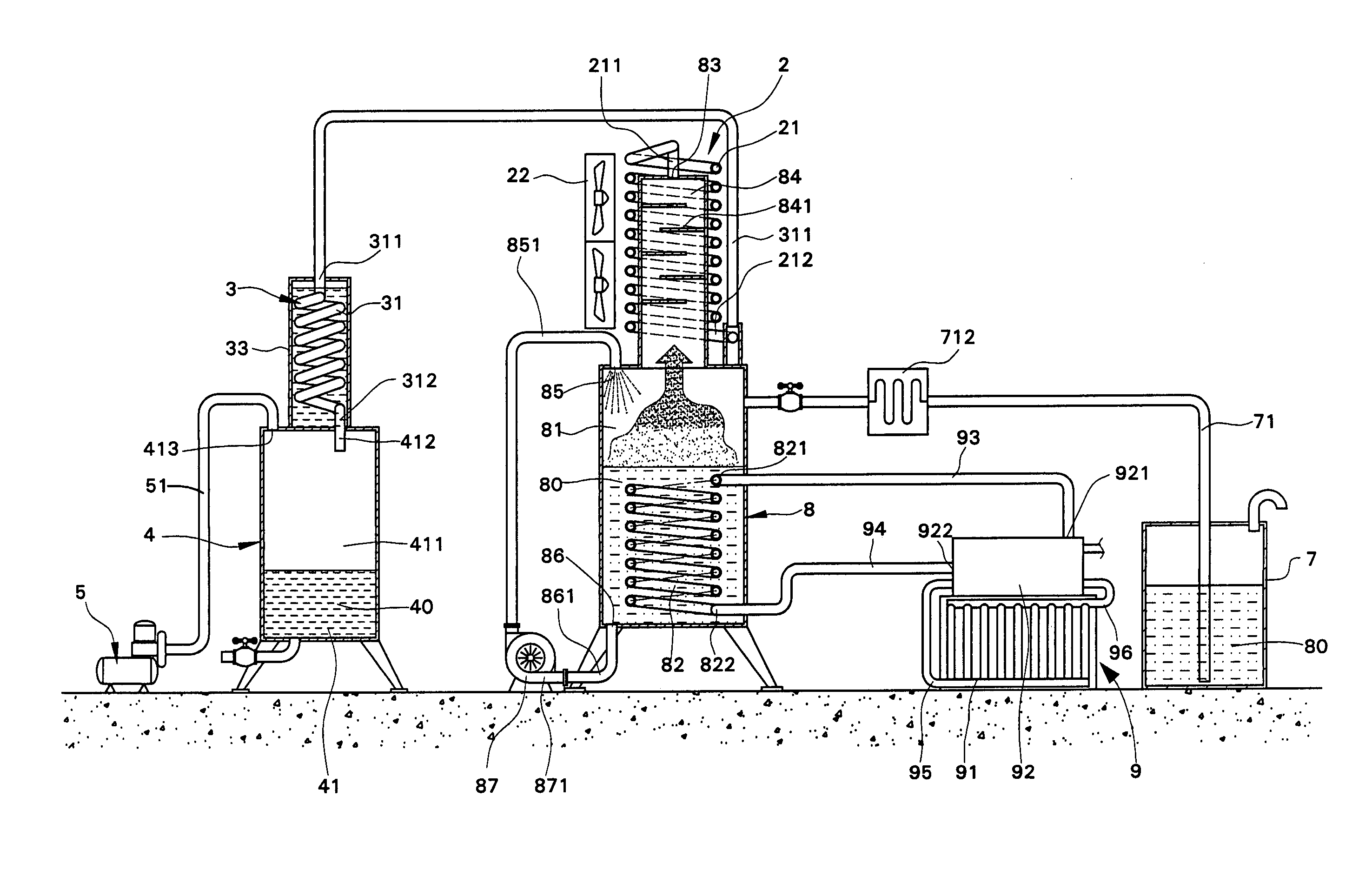

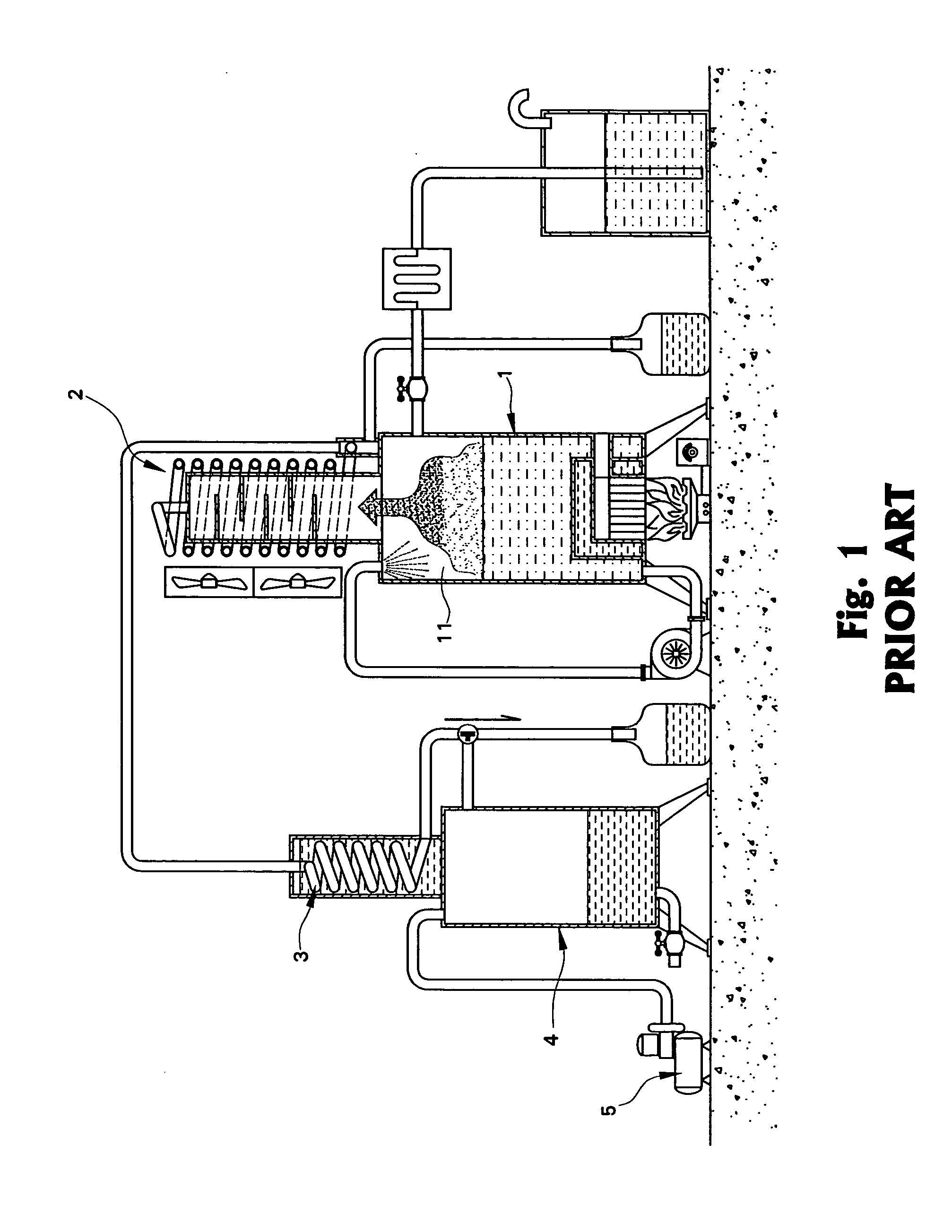

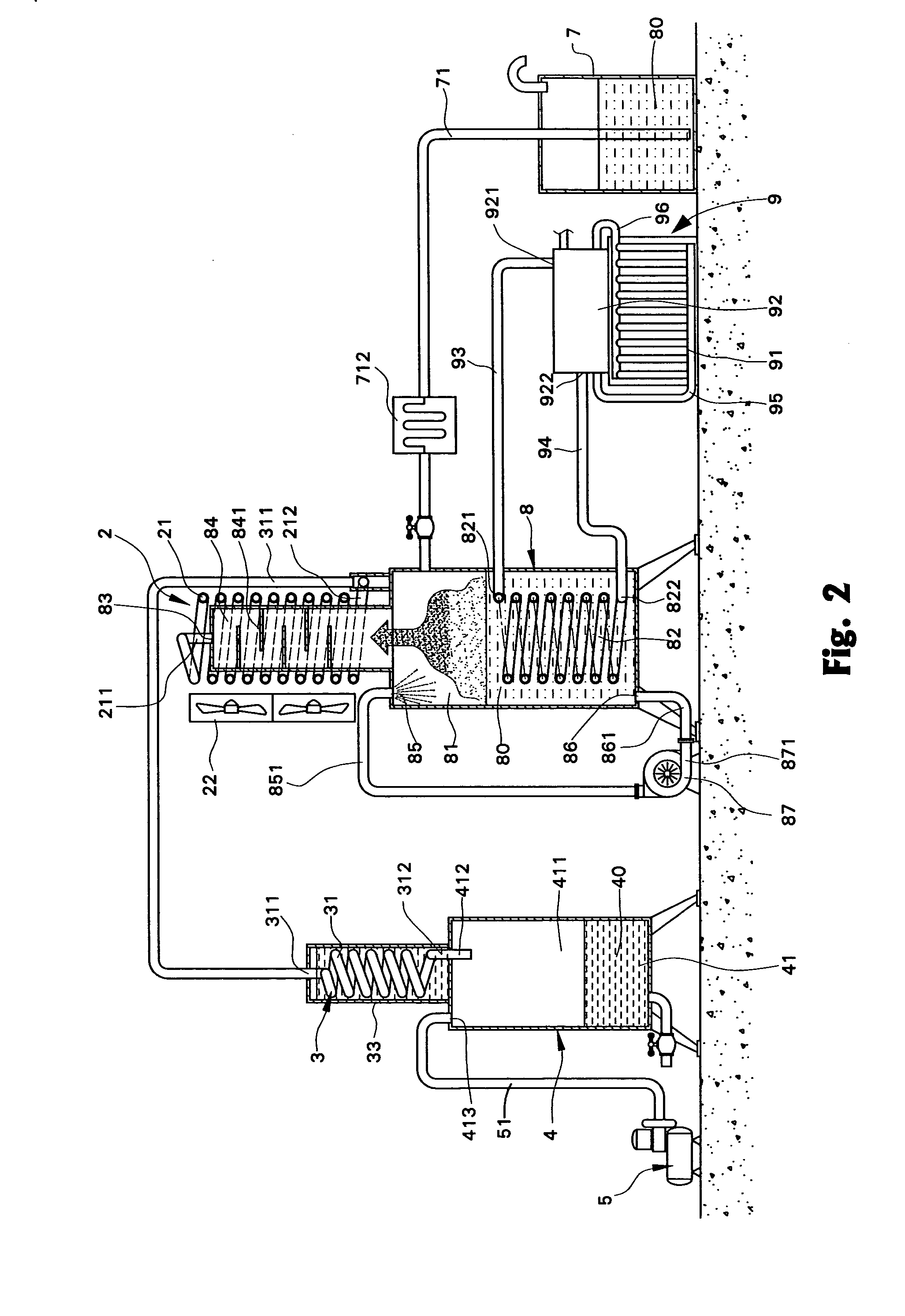

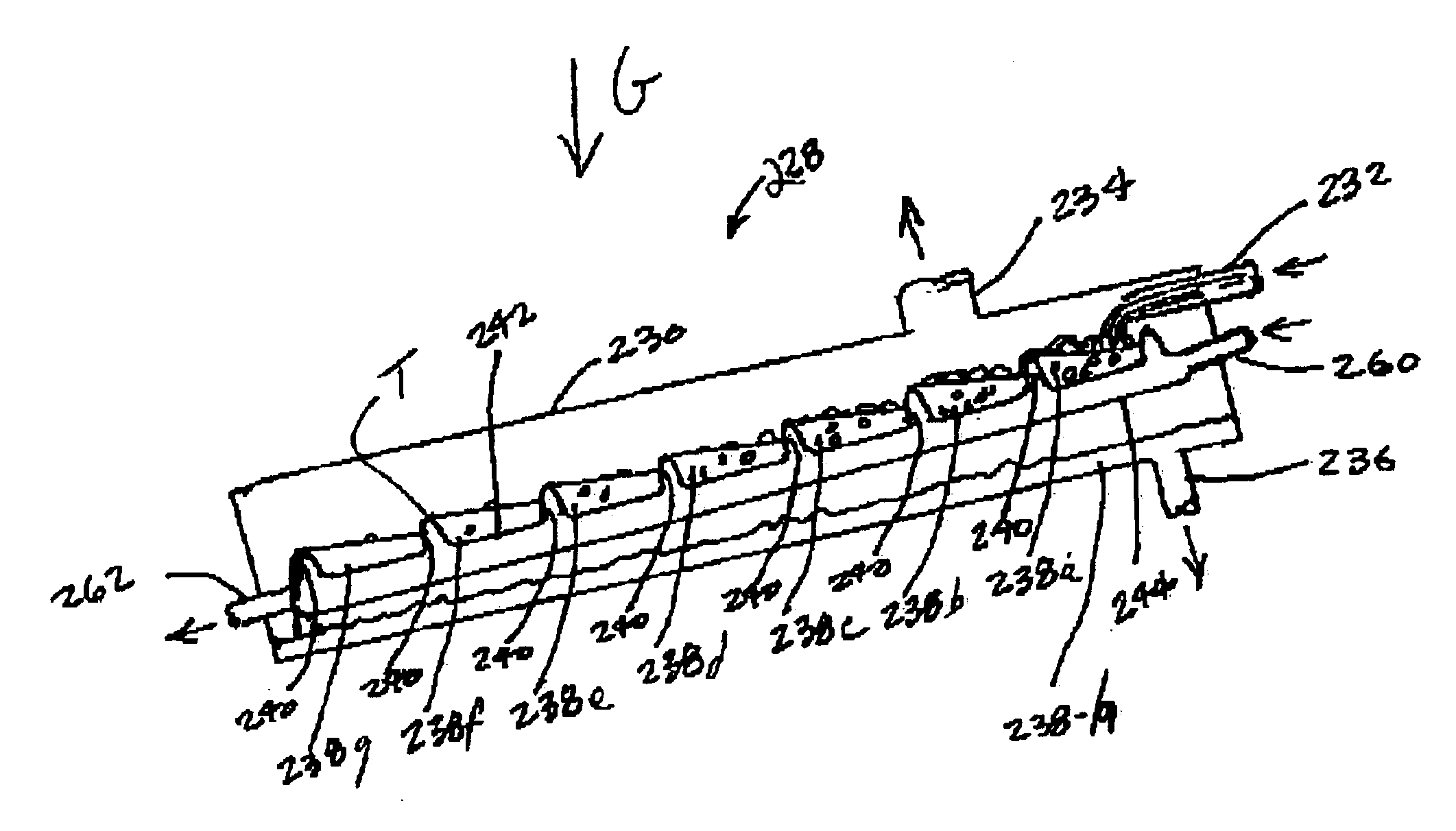

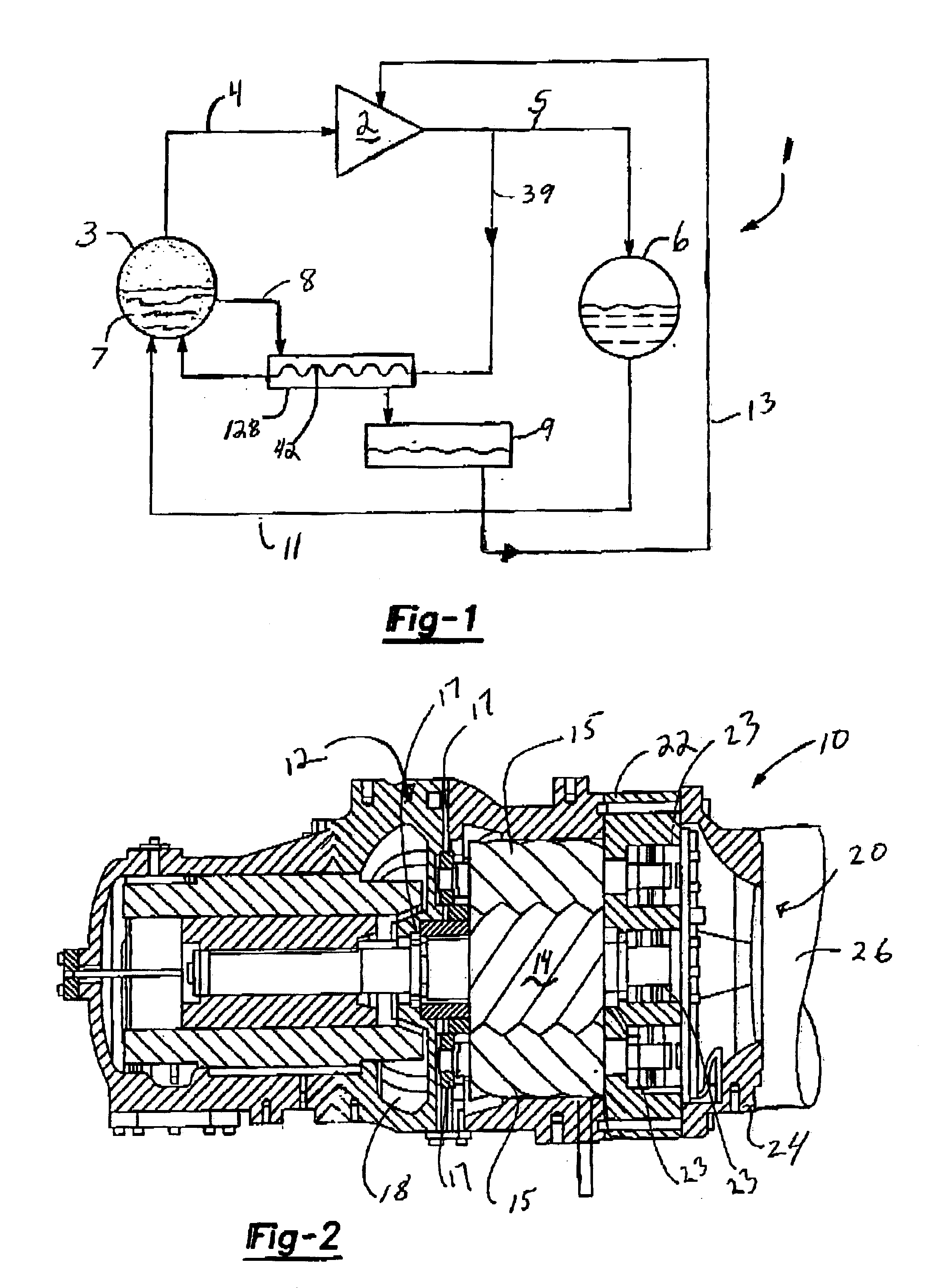

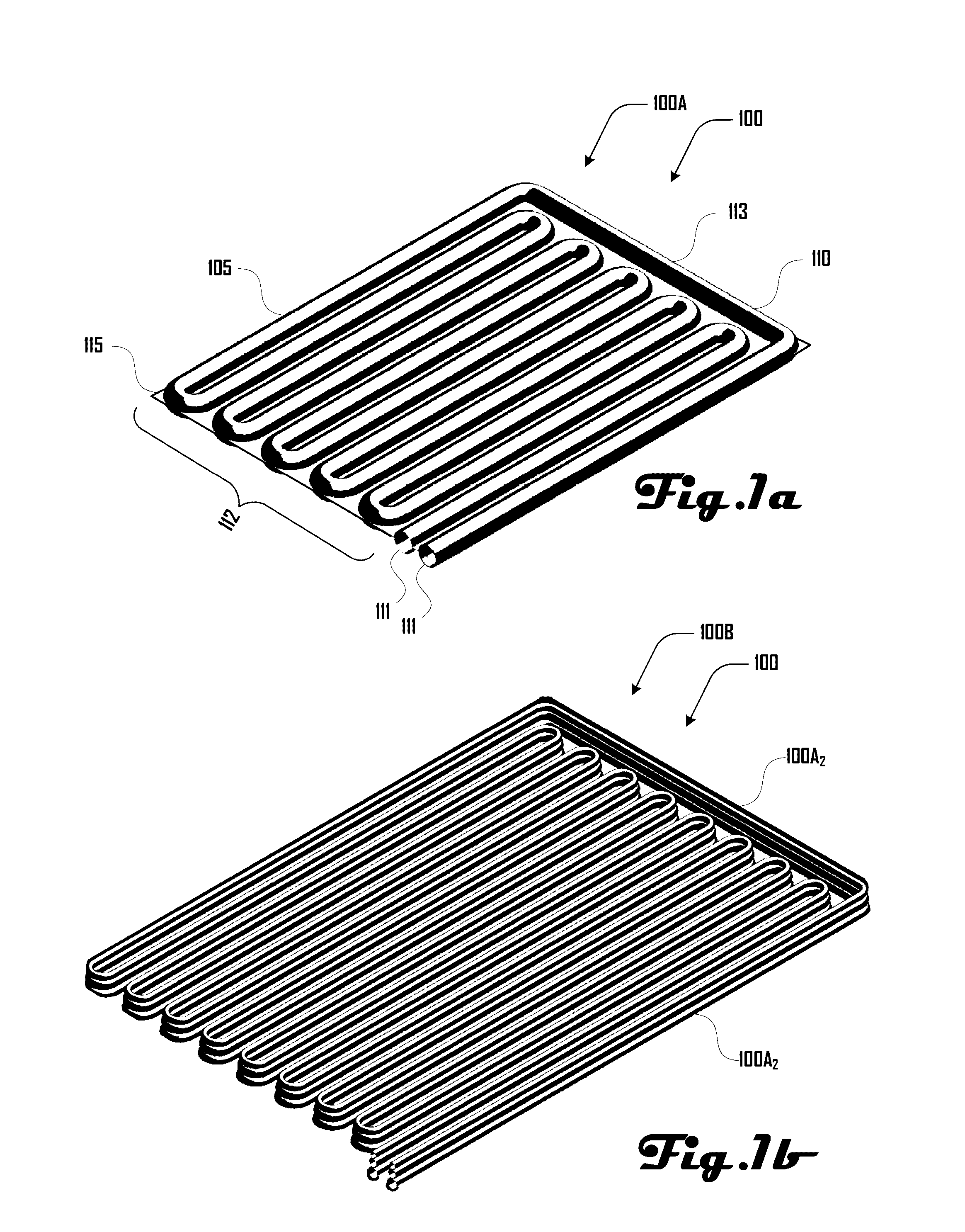

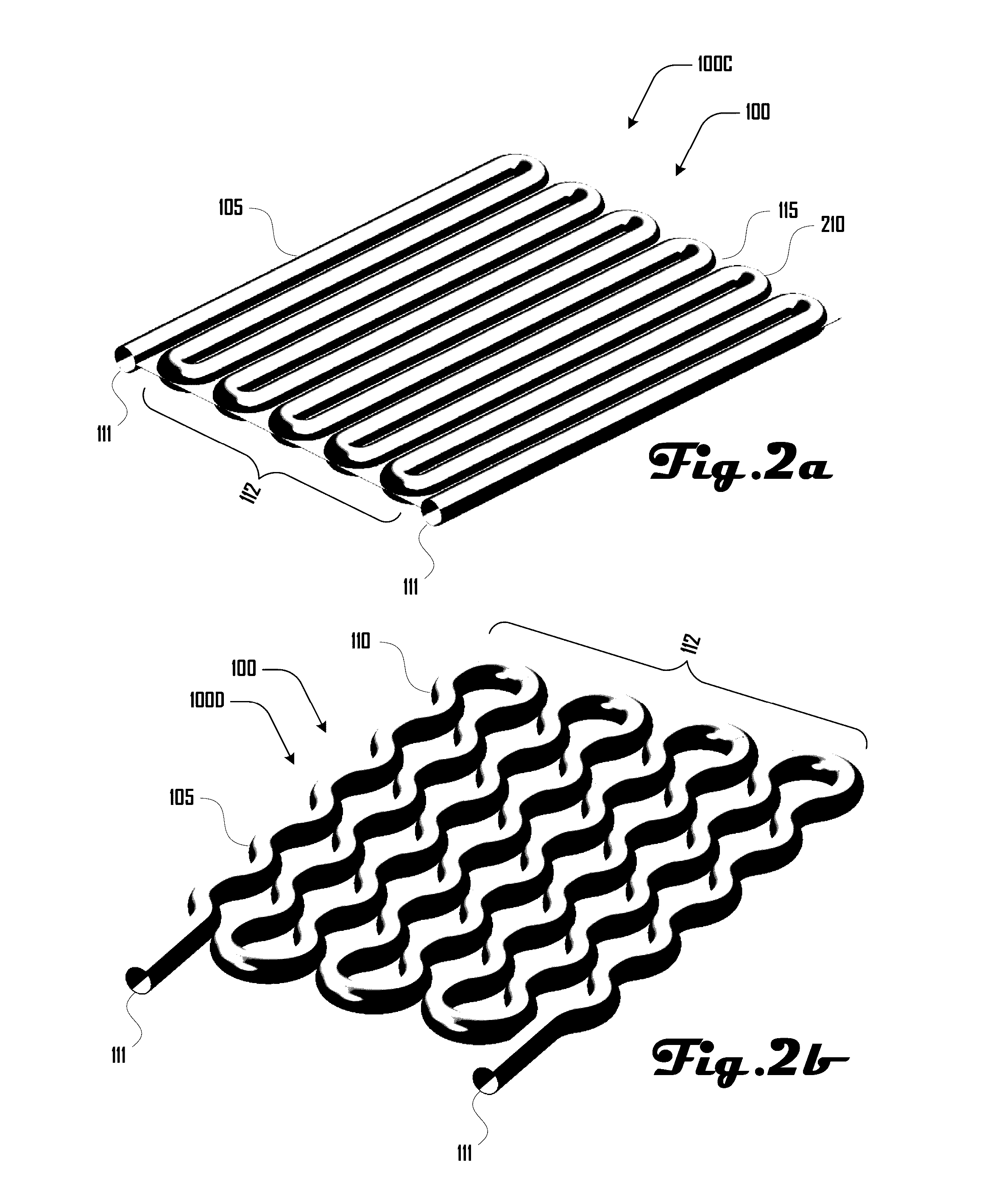

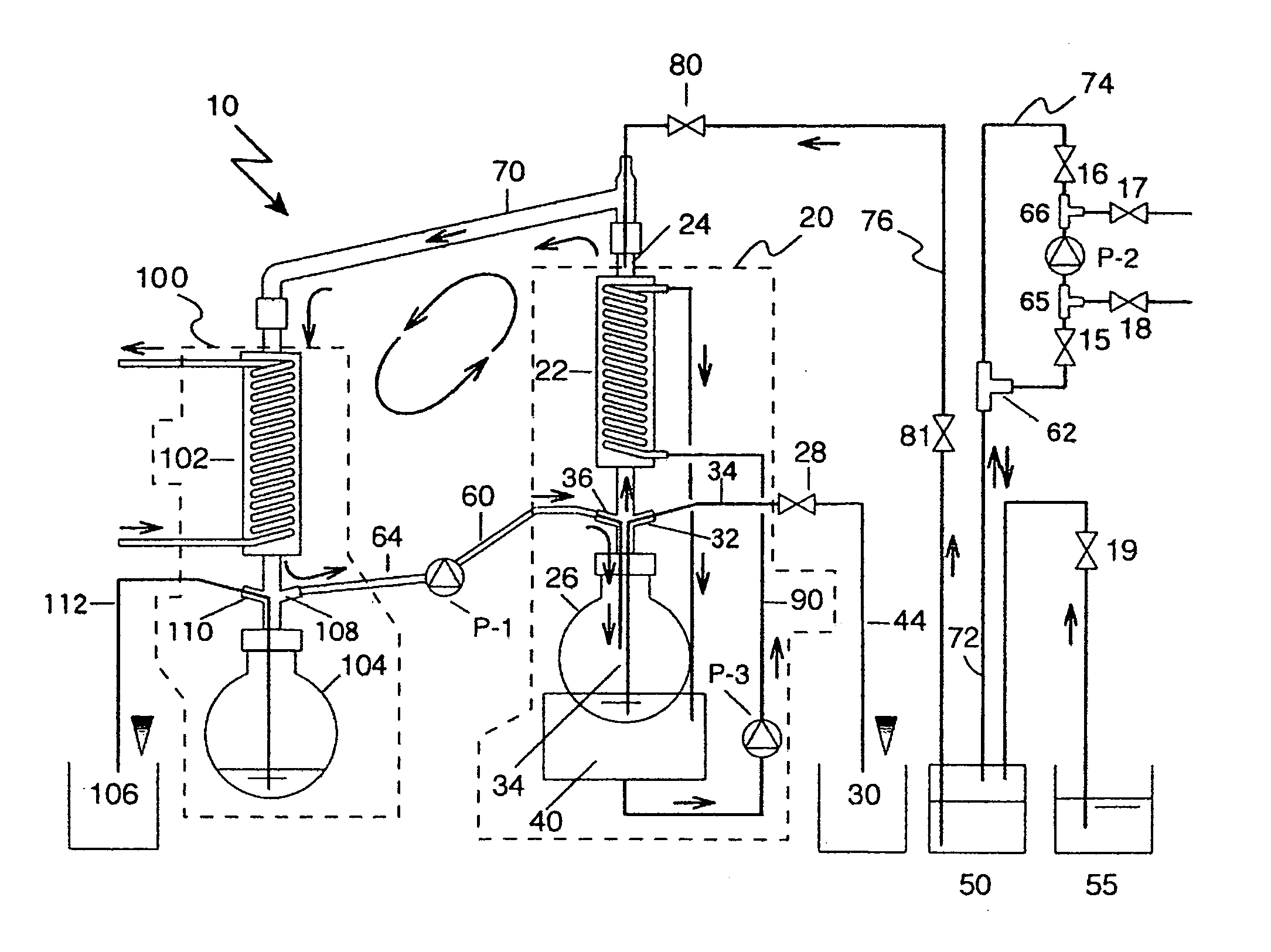

Water Vapor Distillation Apparatus, Method and System

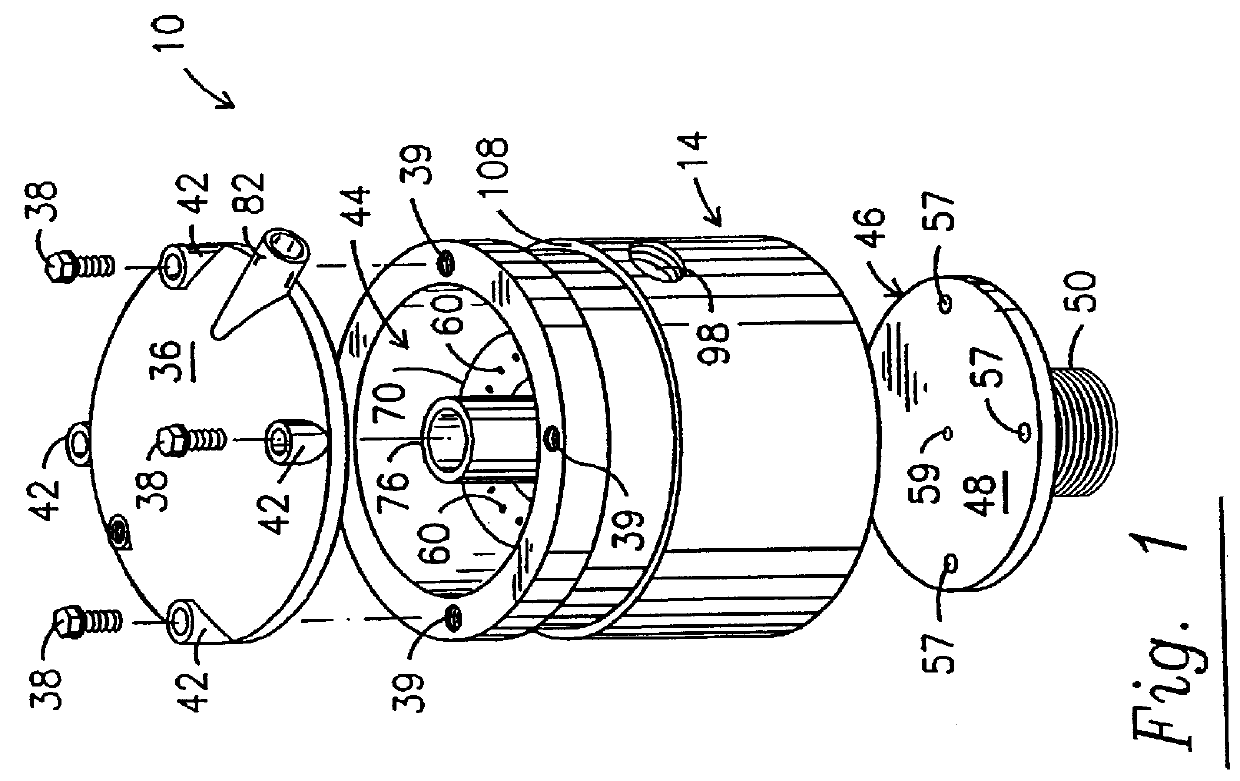

ActiveUS20090025399A1Semiconductor/solid-state device detailsSolid-state devicesWater vaporEngineering

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

Fuel processor for fuel cell systems

A fuel processor assembly for producing a hydrogen rich stream for a fuel cell includes a reformer, a vaporizer adjacent the reformer, a heat transfer block around at least a portion of the reformer and the vaporizer and a heating element coupled to the heat transfer block for providing heat to the block during start up. To cold start the fuel processor, the heating element is activated to heat the heat transfer block. When a temperature of the heat transfer block reaches operational for the reformer, the heating element is turned off and an alternative source of heat is utilized for the endothermic reaction.

Owner:SILICON VALLEY BANK

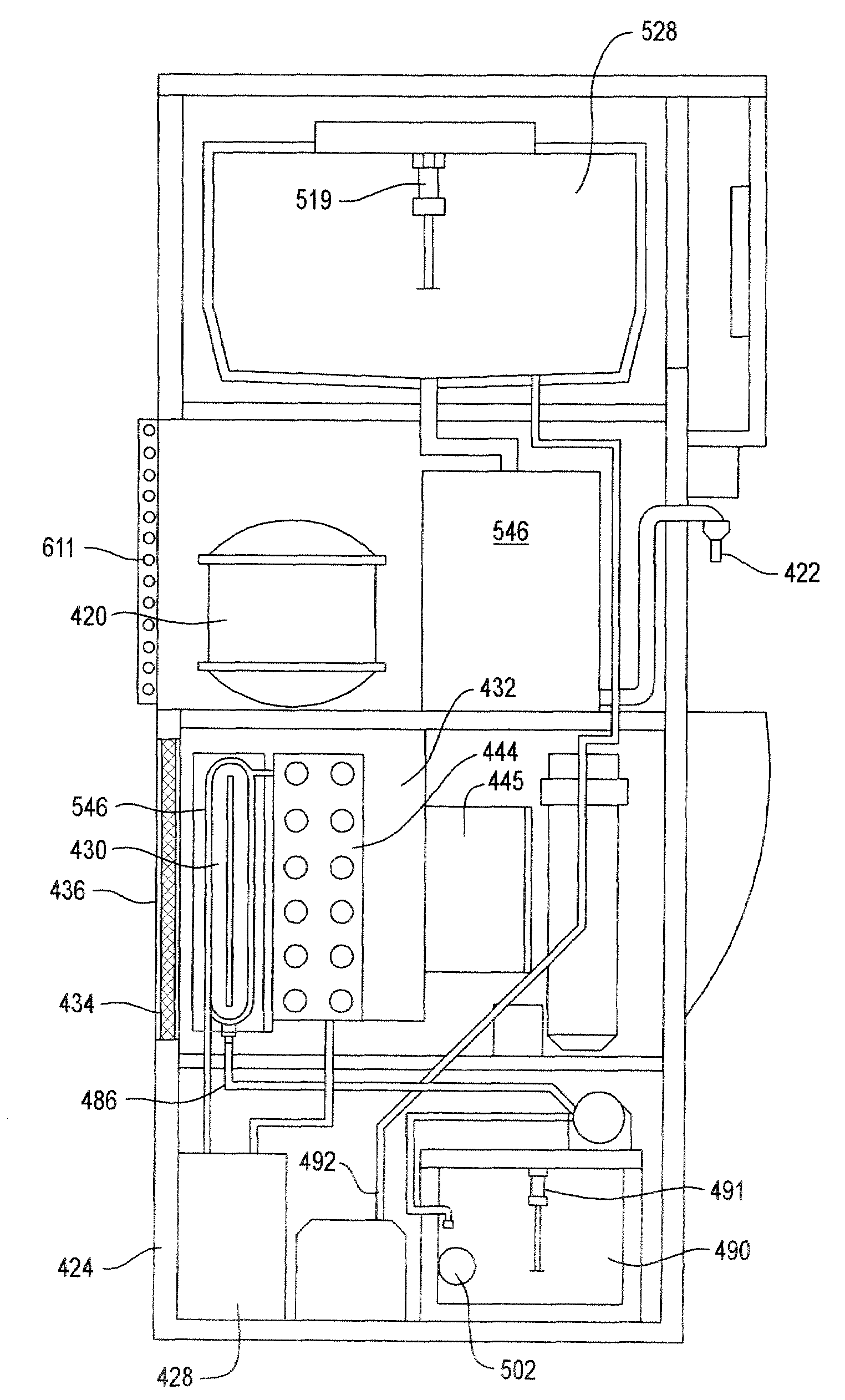

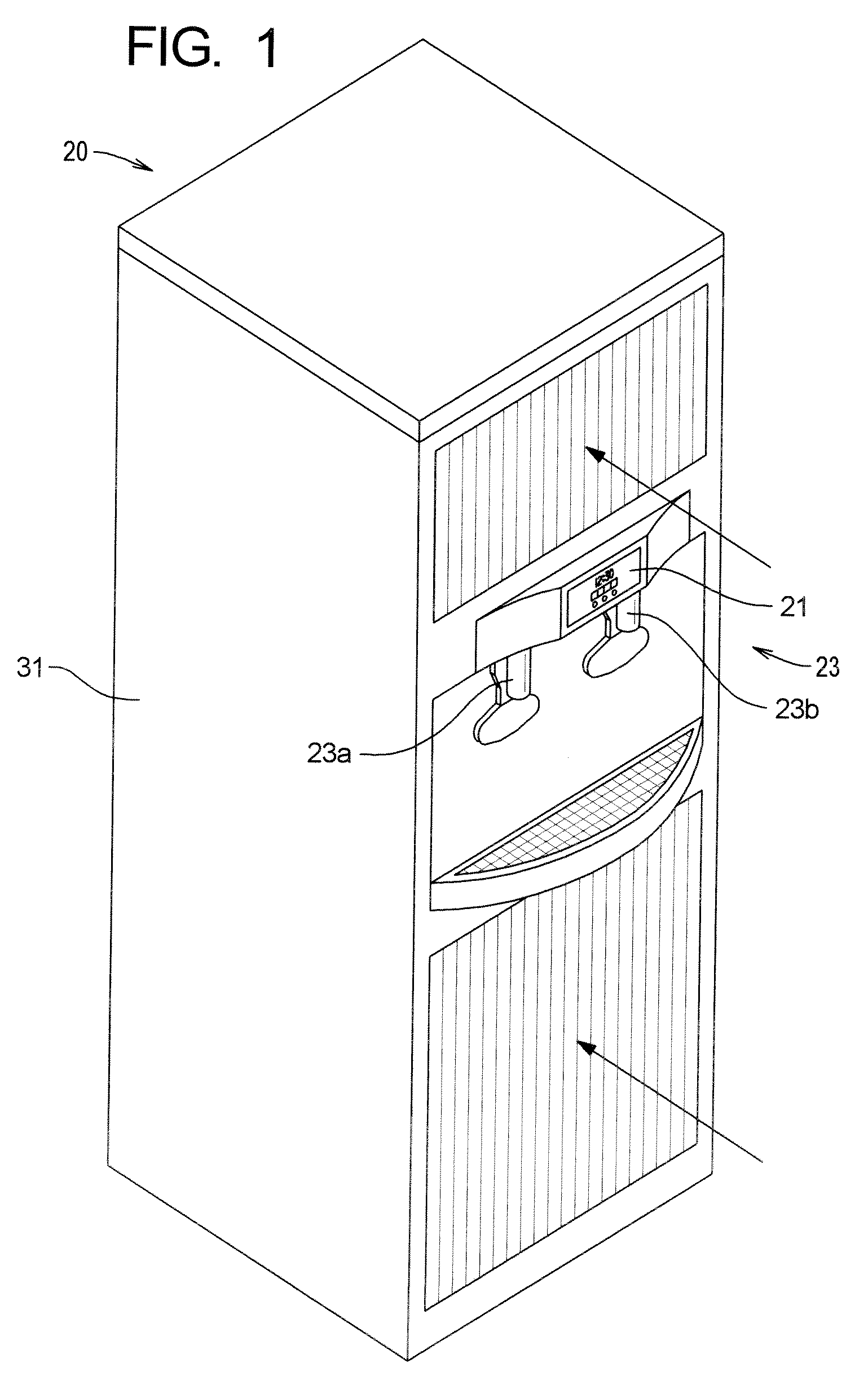

Water vending apparatus

ActiveUS8359877B2Prevents sediment buildupLesser rateEvaporation with vapour compressionLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Phosphate beneficiation process using methyl or ethyl esters as float oils

ActiveUS20050269248A1Fatty/oily/floating substances removal devicesSewerage structuresPhosphoriteEthyl ester

A process for use in a phosphate ore beneficiation process to minimize the long-term environmental impact of the use of petroleum based hydrocarbon materials mixed with fatty acid based primary floatation reagents for froth flotation in the flotation of phosphate ores, wherein the process comprises substituting the petroleum based hydrocarbon materials with methyl and / or ethyl esters of fatty acids.

Owner:ARRMAZ PROD INC

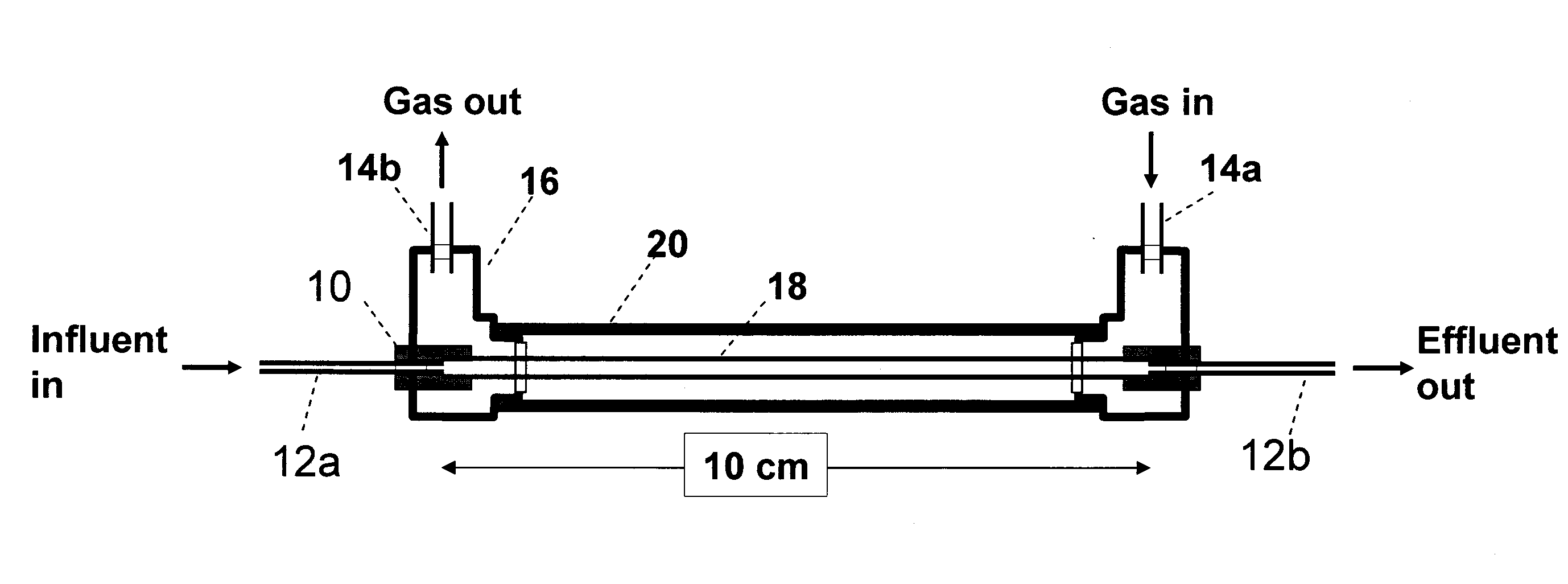

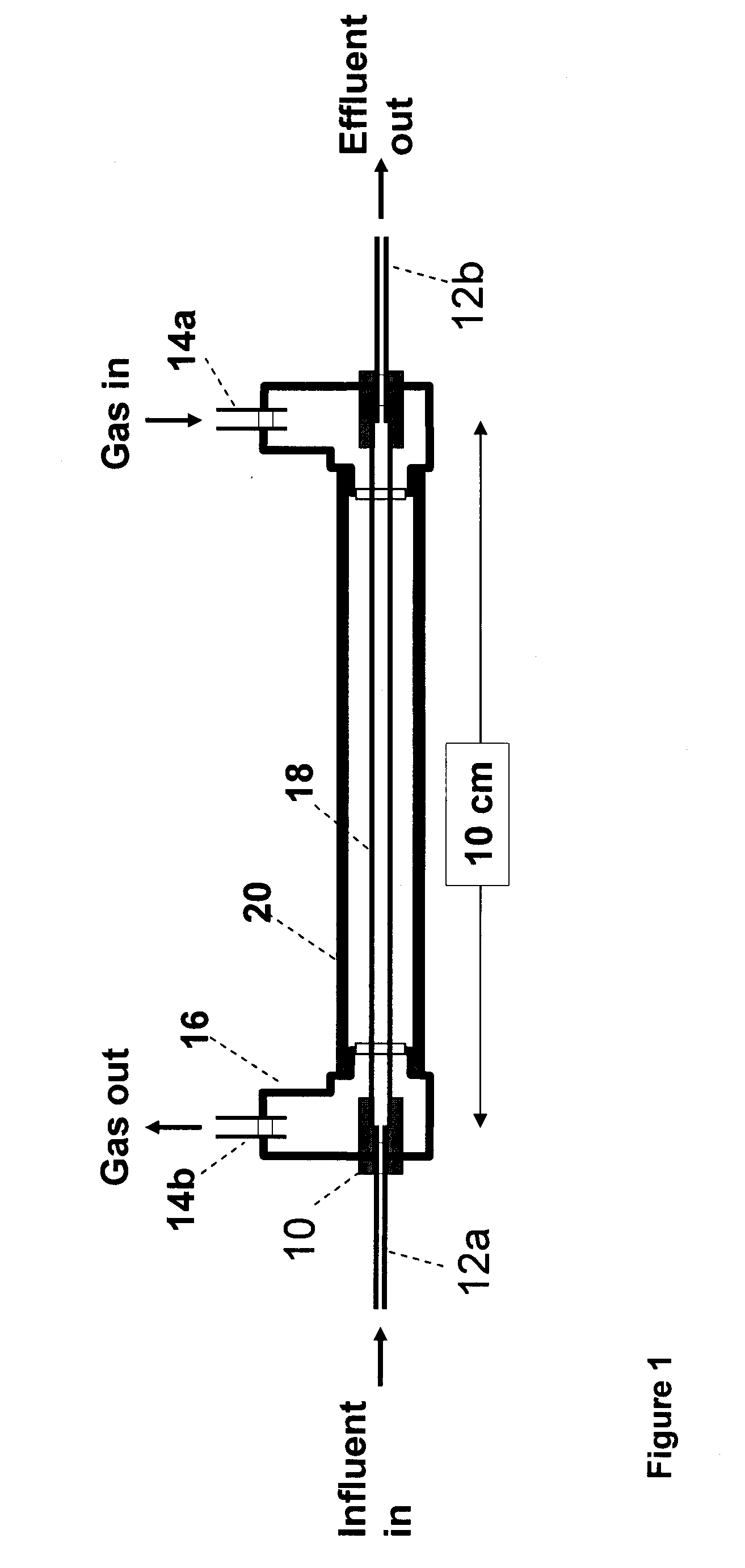

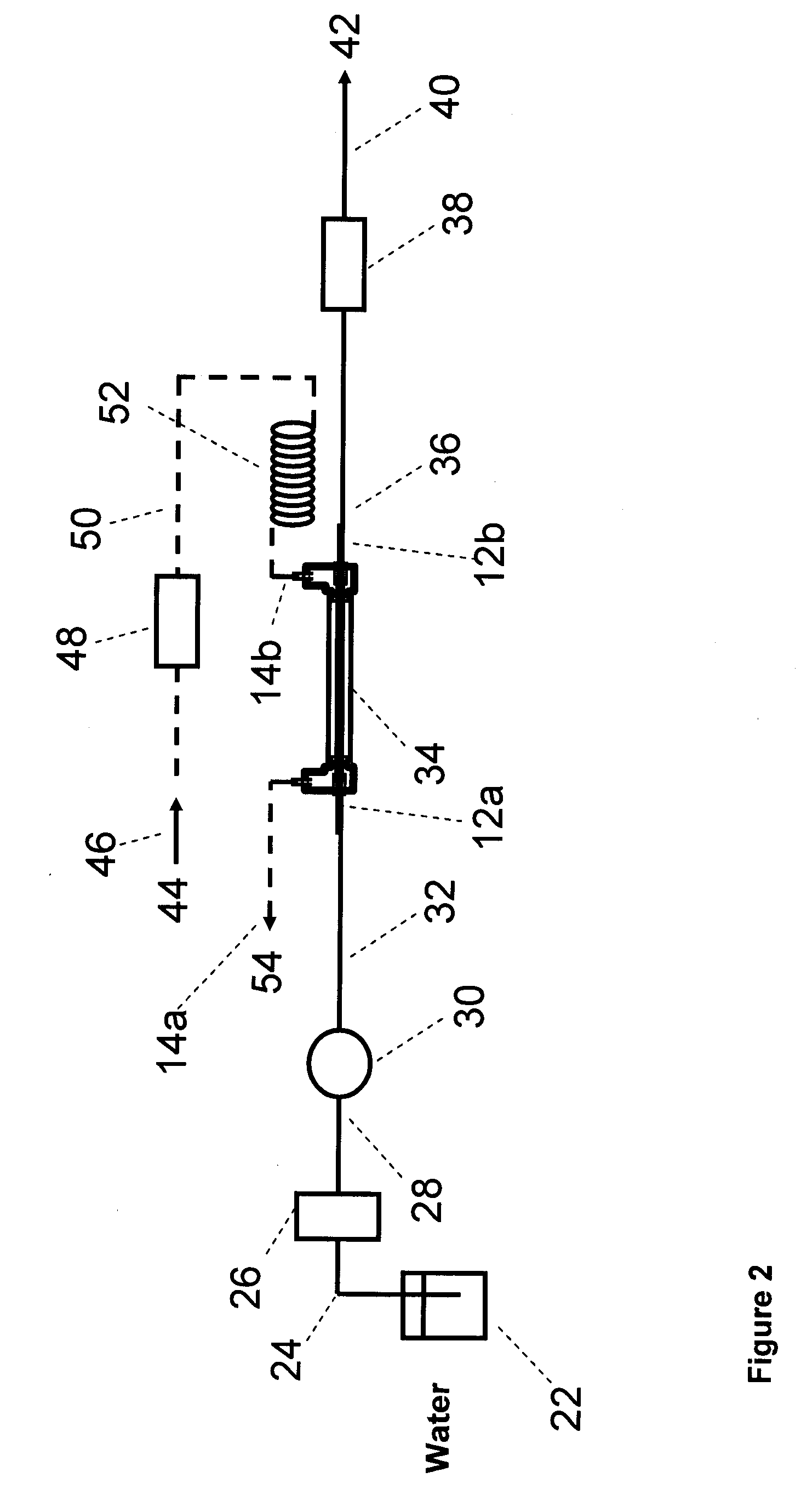

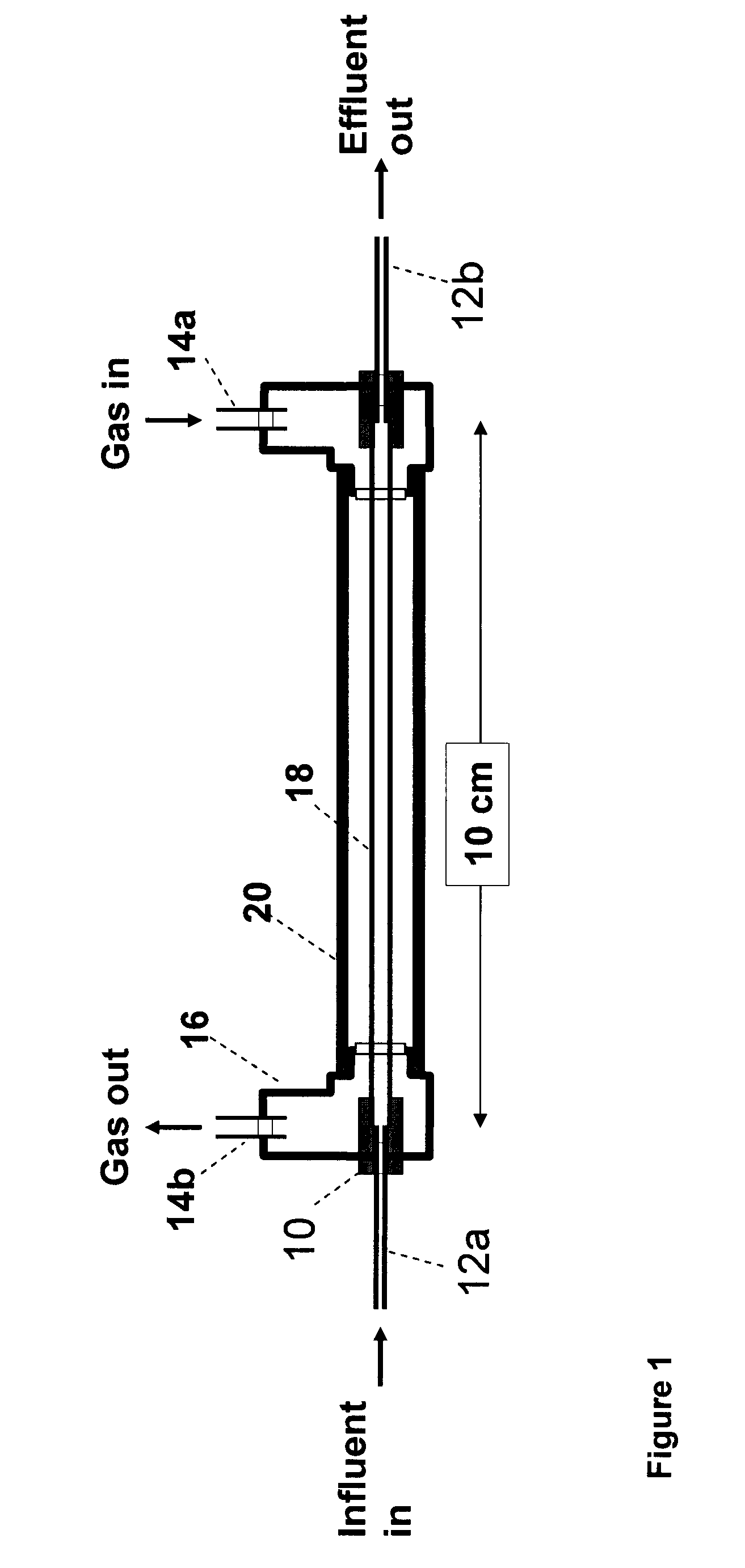

Membrane based concentrators

A sample concentrator for concentrating analytes in a solvent-containing liquid sample stream, including concentrator housing having a sample stream flow channel and a gas stream flow channel having an inlet and an outlet, a heater for gas in the gas stream conduit, and a hydrophilic ion exchange or non-ionic membrane barrier separating said gas stream flow channel and said sample stream flow channel. Solvent is evaporated from the liquid sample stream in said sample stream flow channel in or at the interface with said membrane, when the gas stream is at an elevated temperature. A regeneration step is used to regenerate the ion exchange membrane barrier.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Water vapor distillation apparatus, method and system

ActiveUS20120006670A1Distillation regulation/controlSpecific water treatment objectivesWater vaporControl system

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

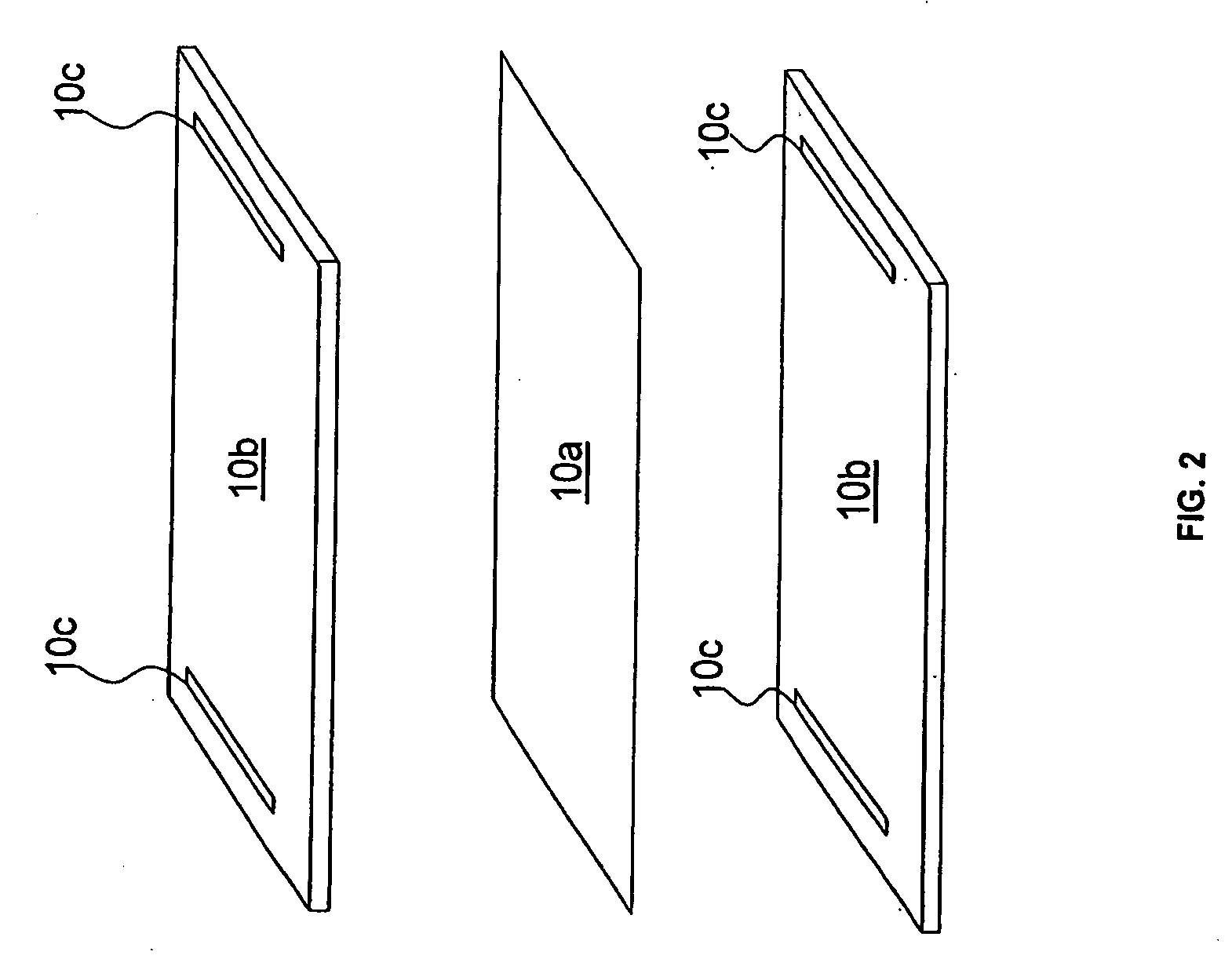

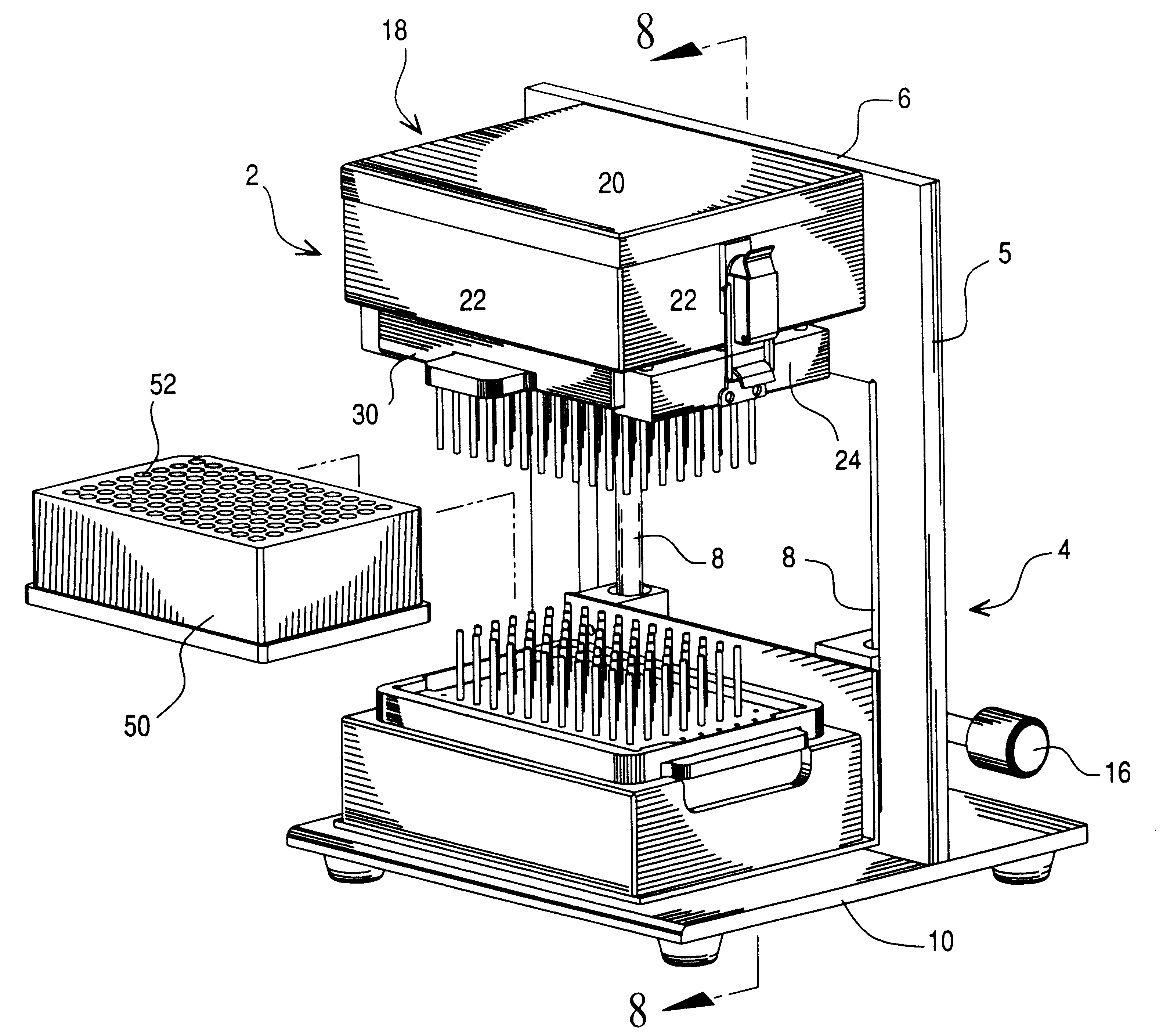

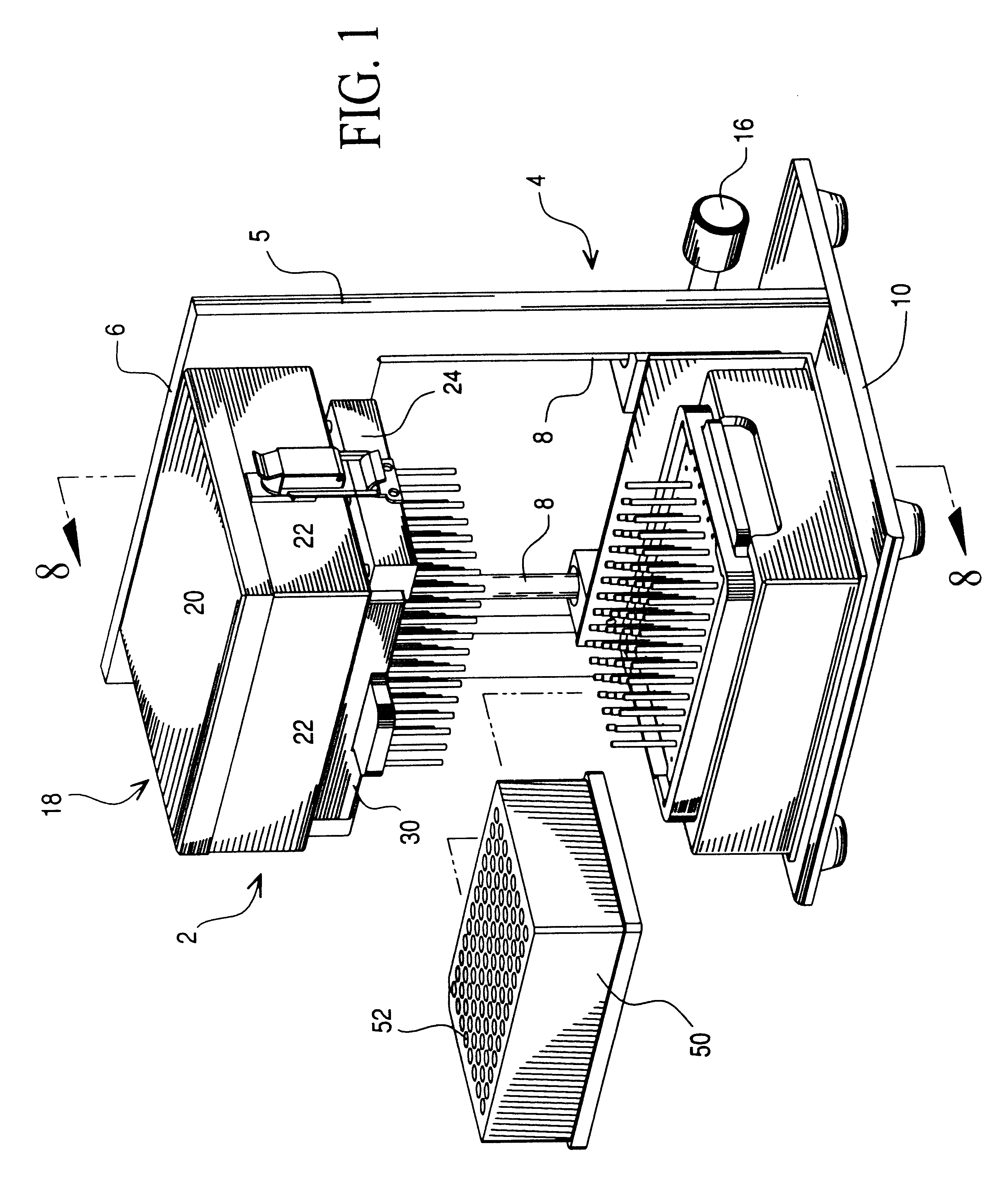

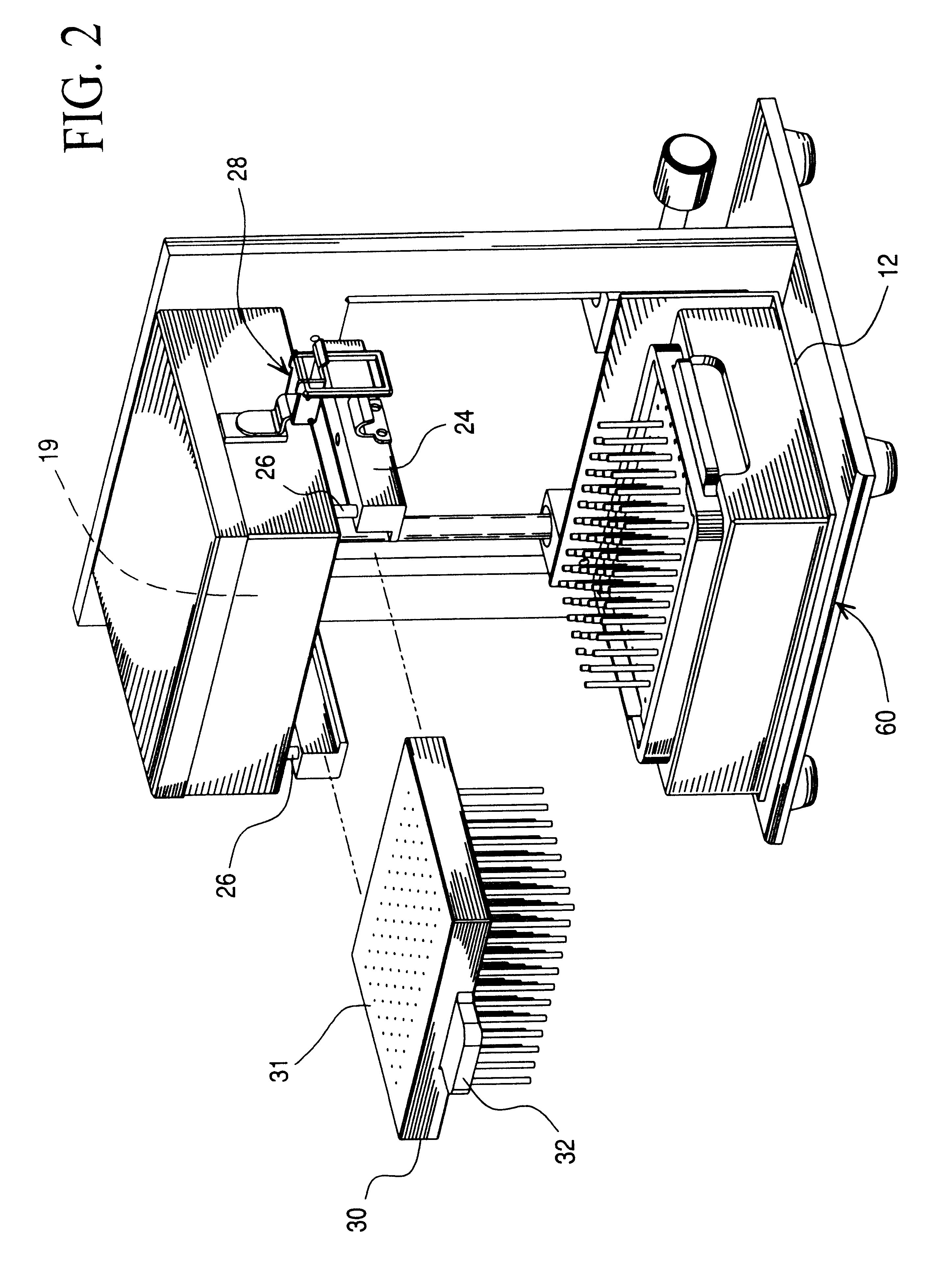

Solid phase evaporator device

InactiveUS6464943B1Easy to useReduce processWithdrawing sample devicesPreparing sample for investigationLaboratory deviceModularity

A laboratory evaporator device is disclosed which is modular in form so that the modular member supporting depending, upraised hollow needles or tubes through which evaporating fluid is conducted, may be individually sterilized and cleansed to thereby forestall cross-contamination. The laboratory device is simple in use, of relatively low cost and is of rugged construction.

Owner:YIU FELIX H

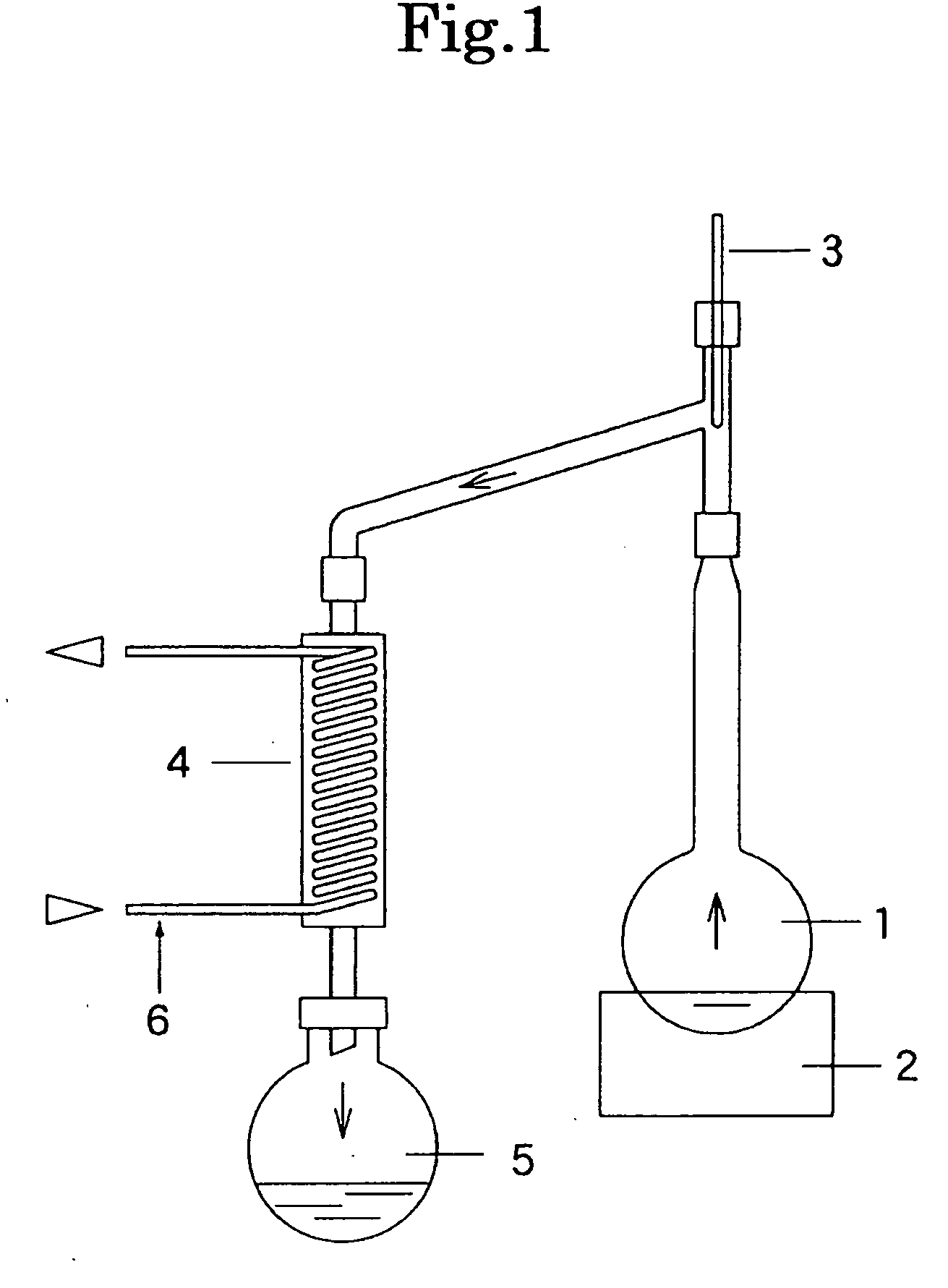

Solar distilling apparatus for alcohol

InactiveUS20060037853A1Reduce the temperatureFermented solutions distillation/rectificationGeneral water supply conservationAlcoholSteam condensation

A distilling apparatus for alcohol includes an evaporation tank having a compartment for receiving fermented alcoholic liquid. A heating tube is mounted in the compartment for heating the fermented liquid into steam. A condensing device is communicated with the evaporation tank for receiving and condensing steam from the evaporation tank. A collecting tank is communicated with the condensing device for collecting condensed liquid from the condensing device. A negative pressure creating device creates a negative pressure in the evaporation tank, allowing the fermented alcoholic liquid in the evaporation tank to evaporate at a low temperature. A solar energy collecting device includes a solar energy collector and a water tank containing water heated by the solar energy collector. Hot water in the water tank flows into the heating tube for heating the fermented alcoholic liquid in the evaporation tank.

Owner:ROAN TONY +1

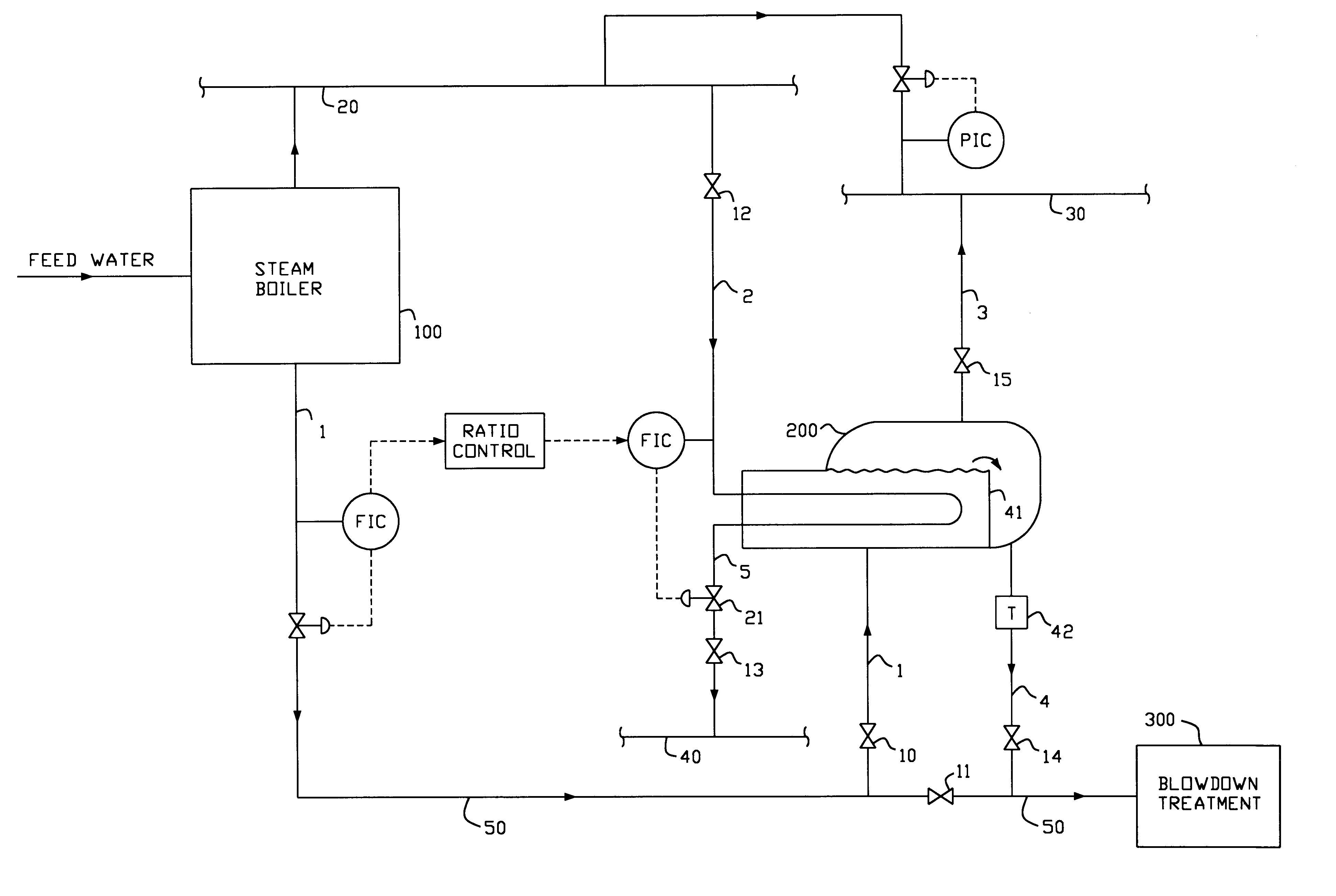

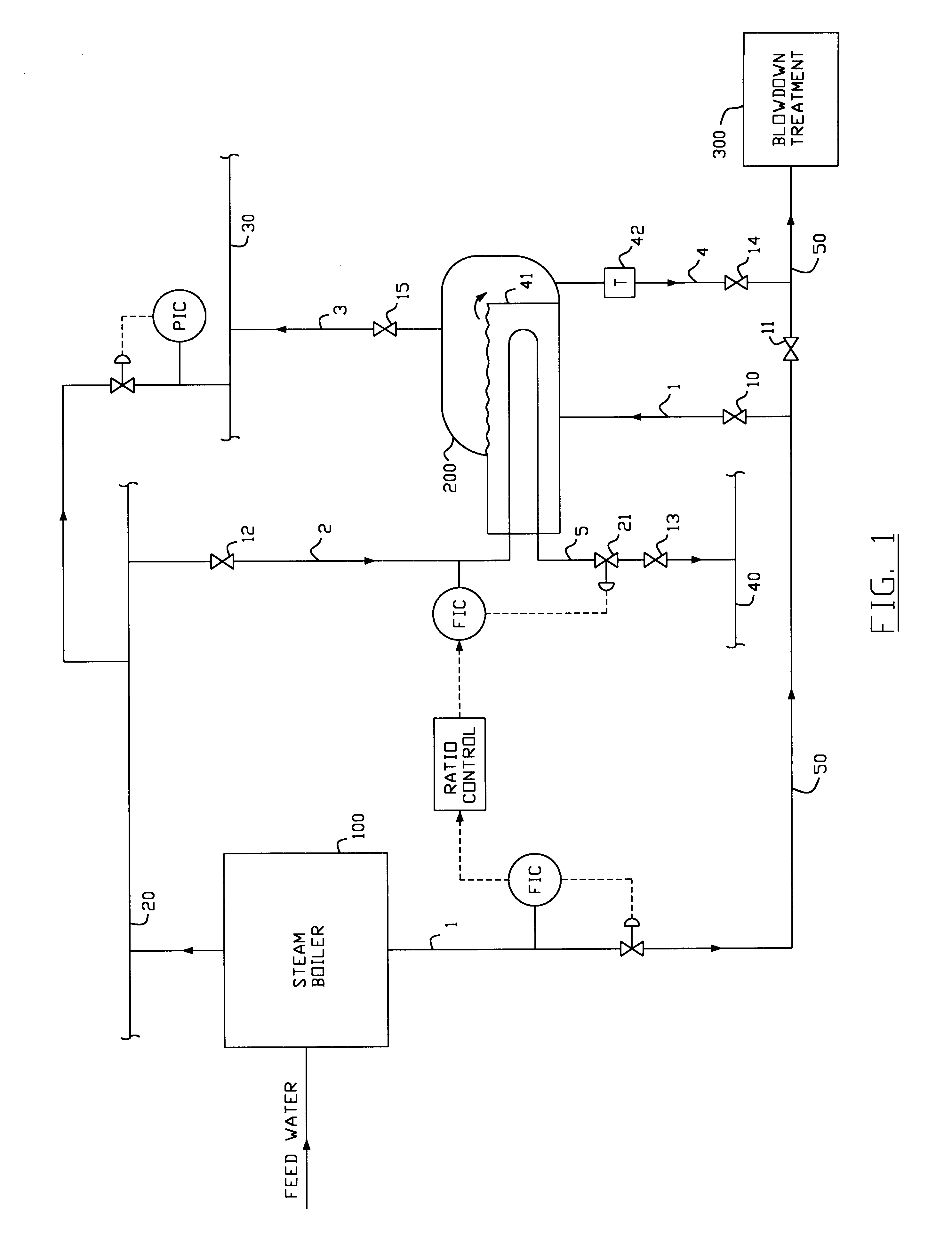

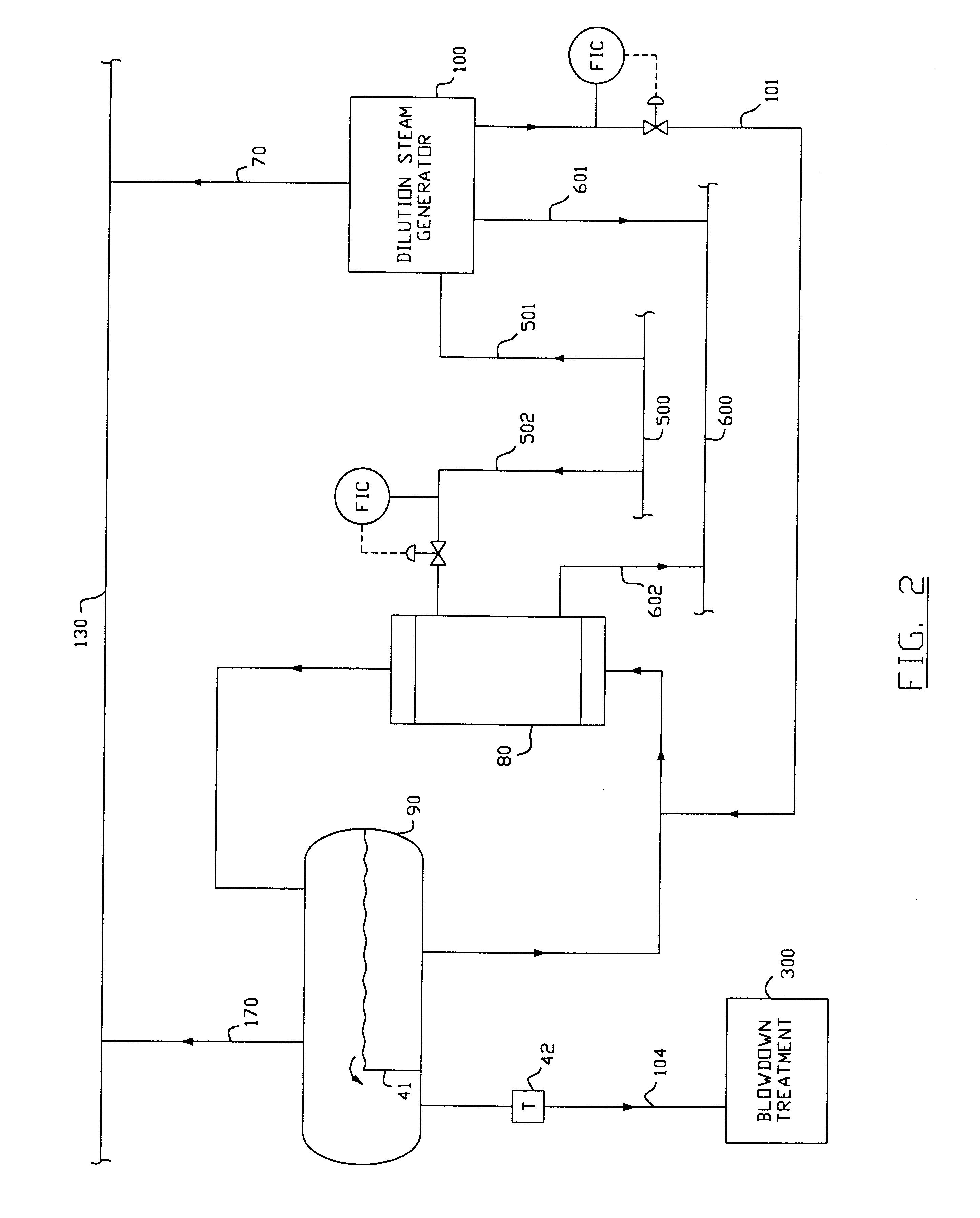

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

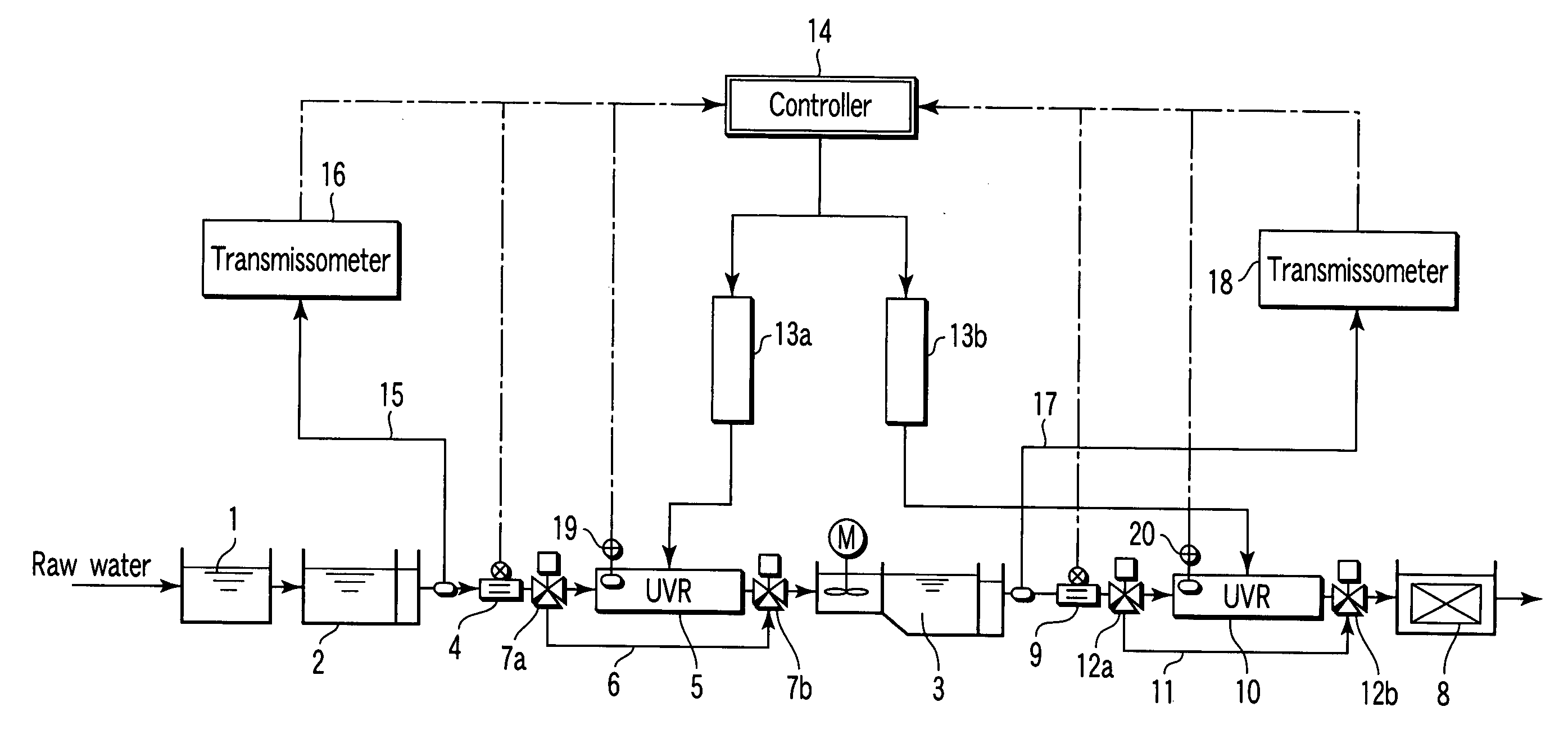

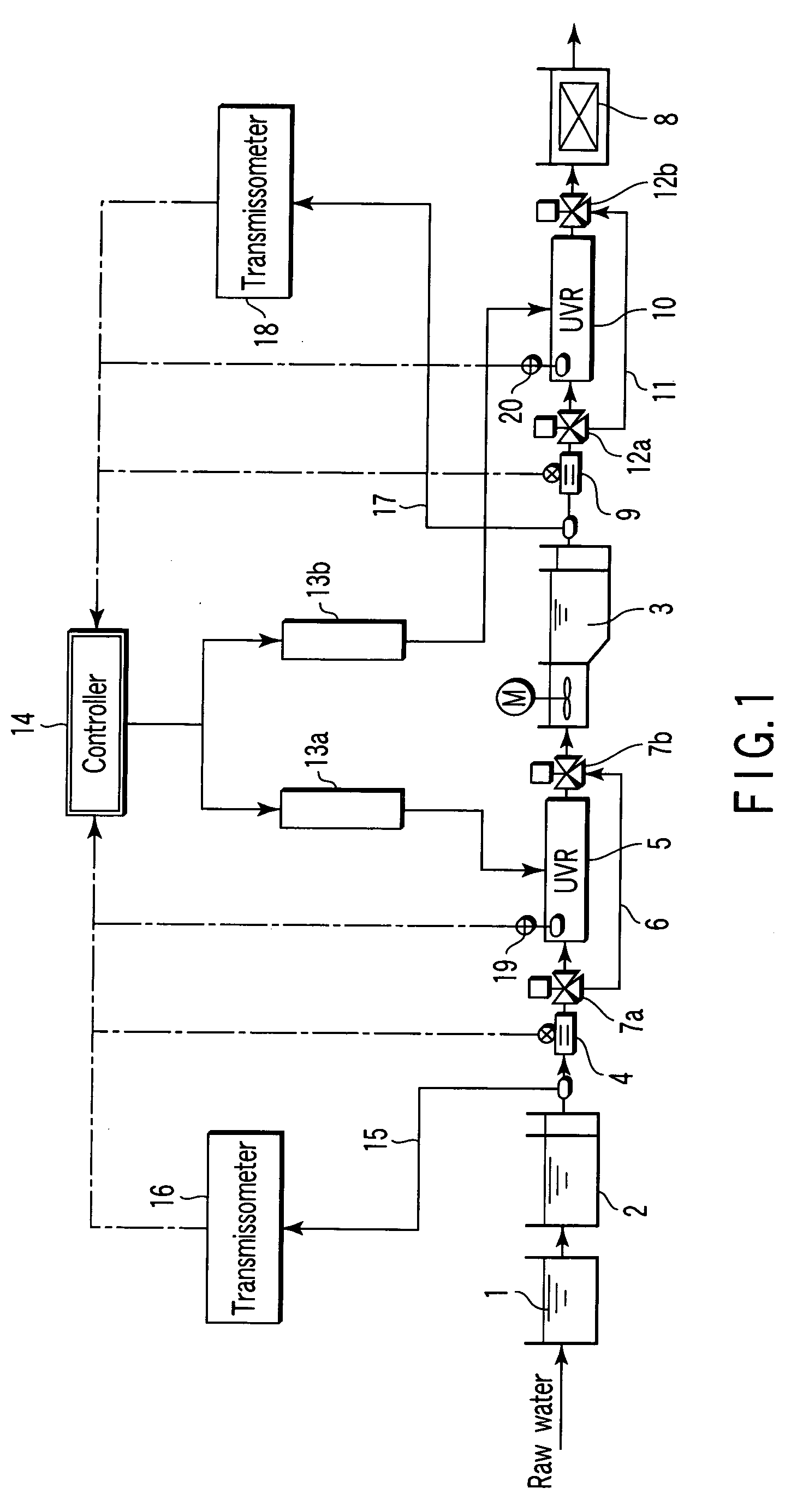

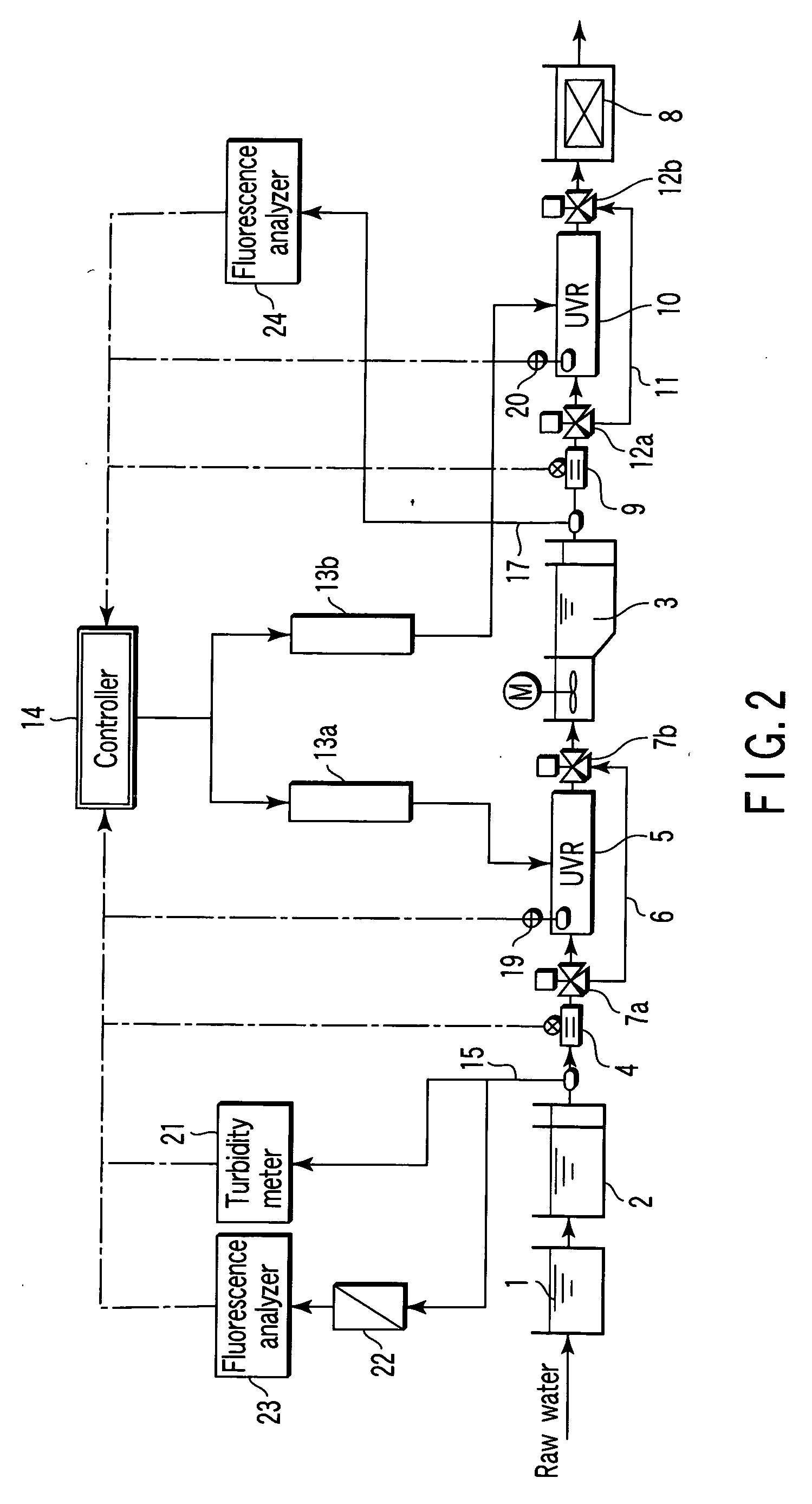

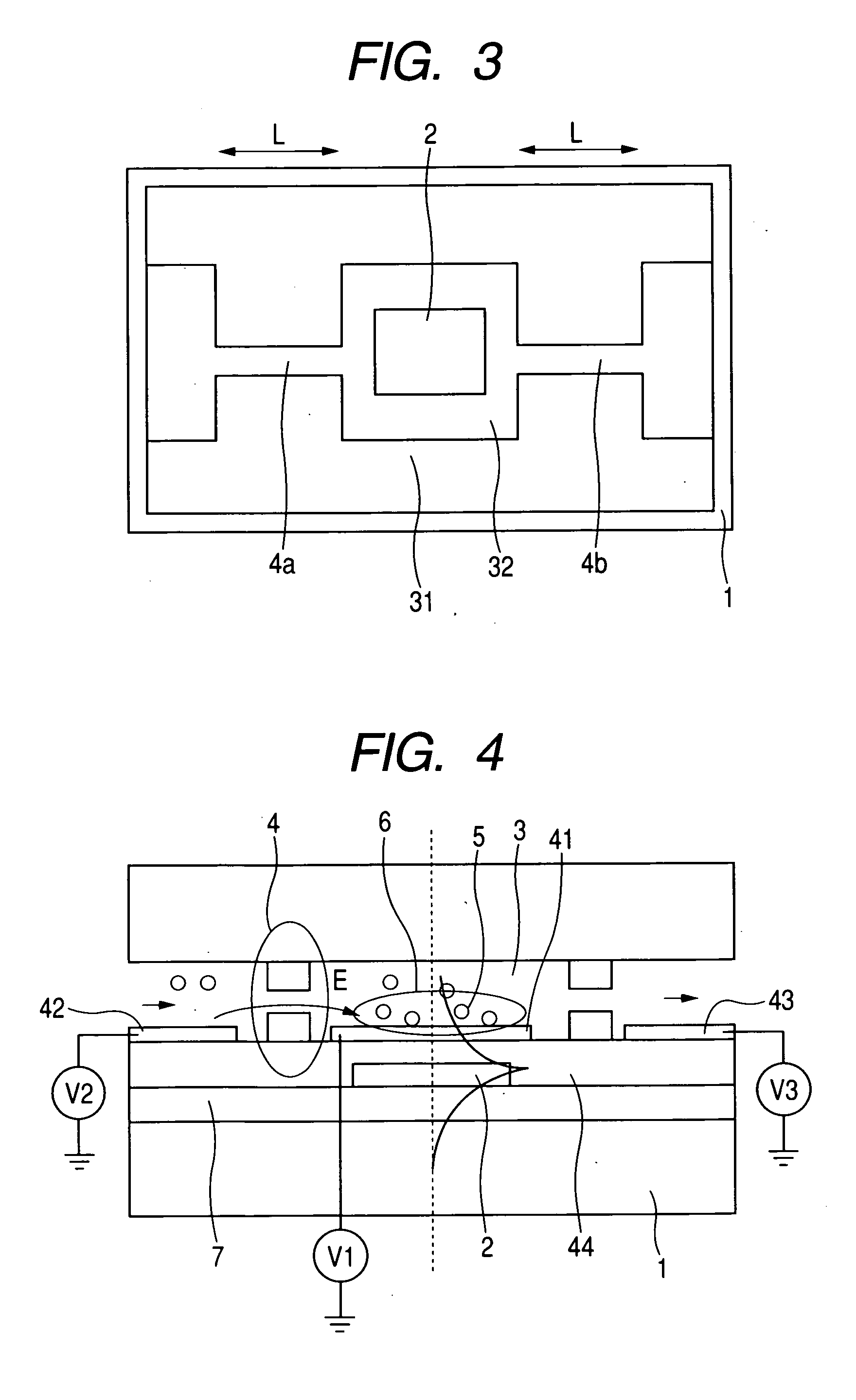

Ultraviolet radiation water treatment system

ActiveUS20060219630A1Ion-exchanger regenerationExhaust apparatusWater treatment systemUltraviolet radiation

A water treatment system that performs a water purifying treatment by use of ultraviolet radiation, comprises a front stage ultraviolet radiation device for radiating ultraviolet light in a front stage process in a water purifying treatment process, a rear stage ultraviolet radiation device for radiating ultraviolet light in a rear stage process, and a controller for controlling these ultraviolet radiation devices.

Owner:KK TOSHIBA

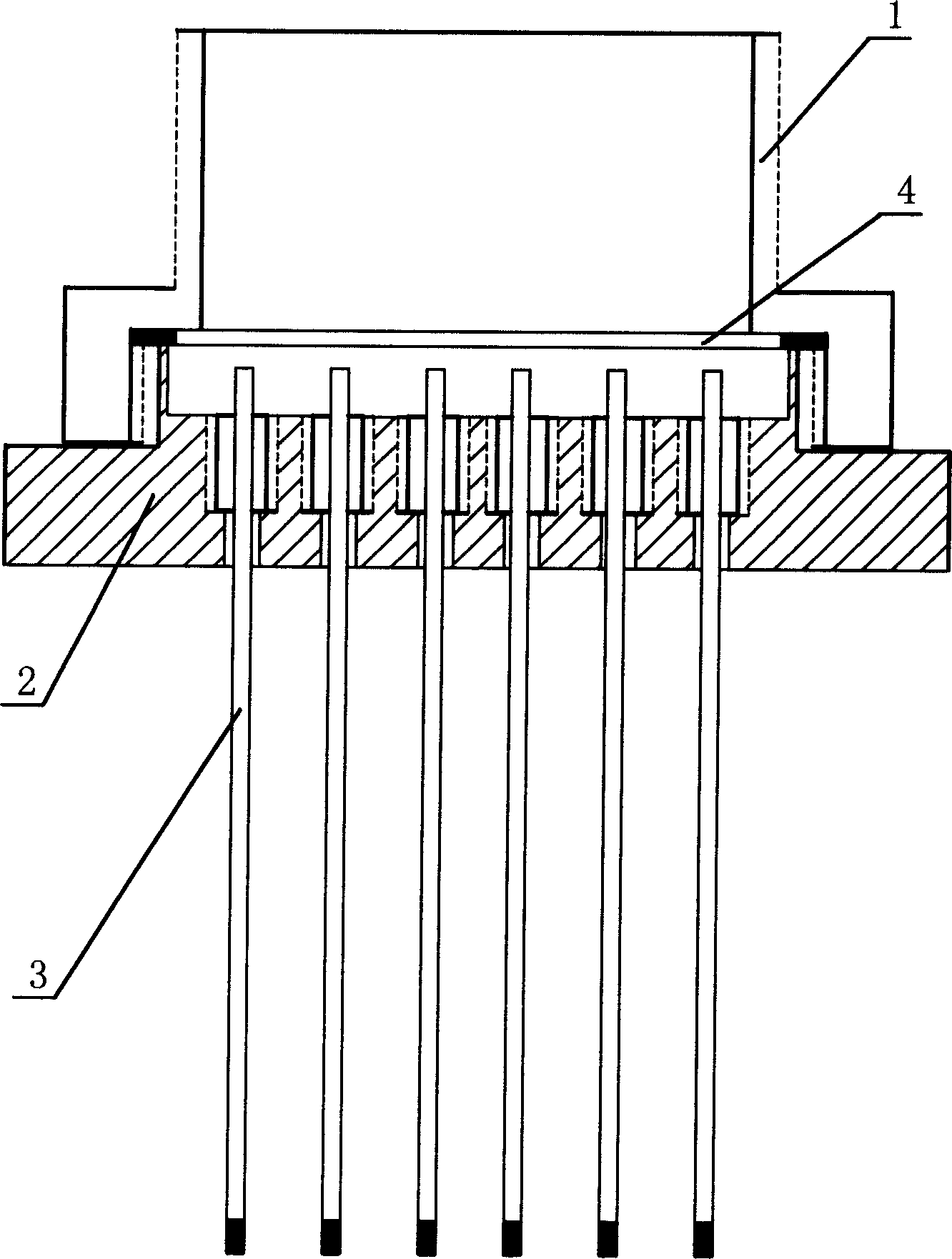

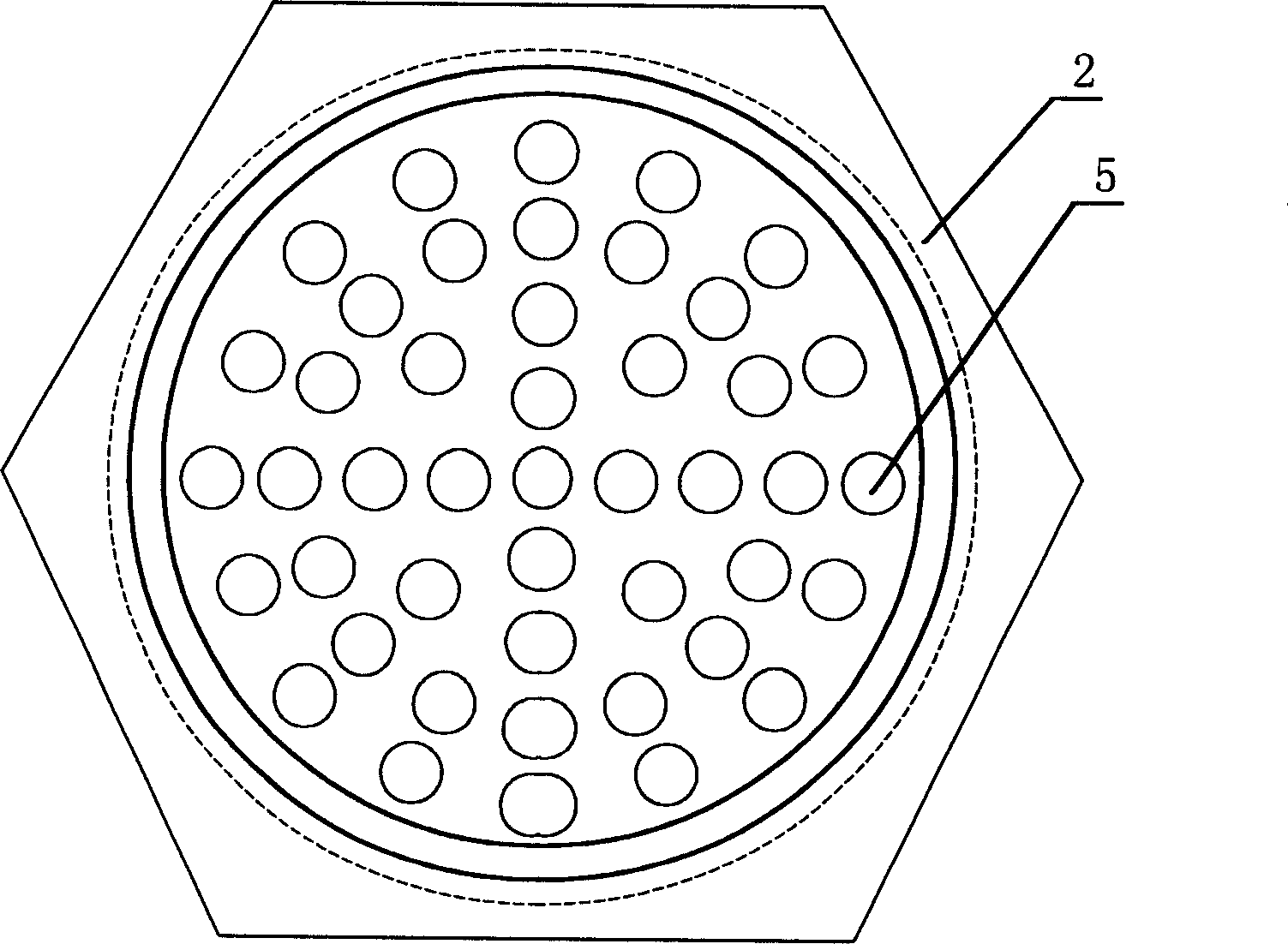

Ceramic hollow fiber membrane reactor for making oxygen by air separation, and its preparing method and use

ActiveCN1676198AReduce manufacturing costSimple processSemi-permeable membranesDispersed particle separationFiberHollow fibre membrane

The present invention belongs to a ceramic hollow fibre film reactor for making oxygen by means of air separation, its preparation method and application. The ceramic hollow fibre film can be made into the form of tube, the parallel tubes can be formed into tube bundle; and said invented reactor is formed from tube bundle, placing disk and sealing head which are successively insert-connected together. Besides, said invention also provides the connection mode of the said all the components and concrete structure of every component. Said invention is convenient for application, and can reduce cost for making oxygen by means of air separation.

Owner:上海穗杉实业股份有限公司

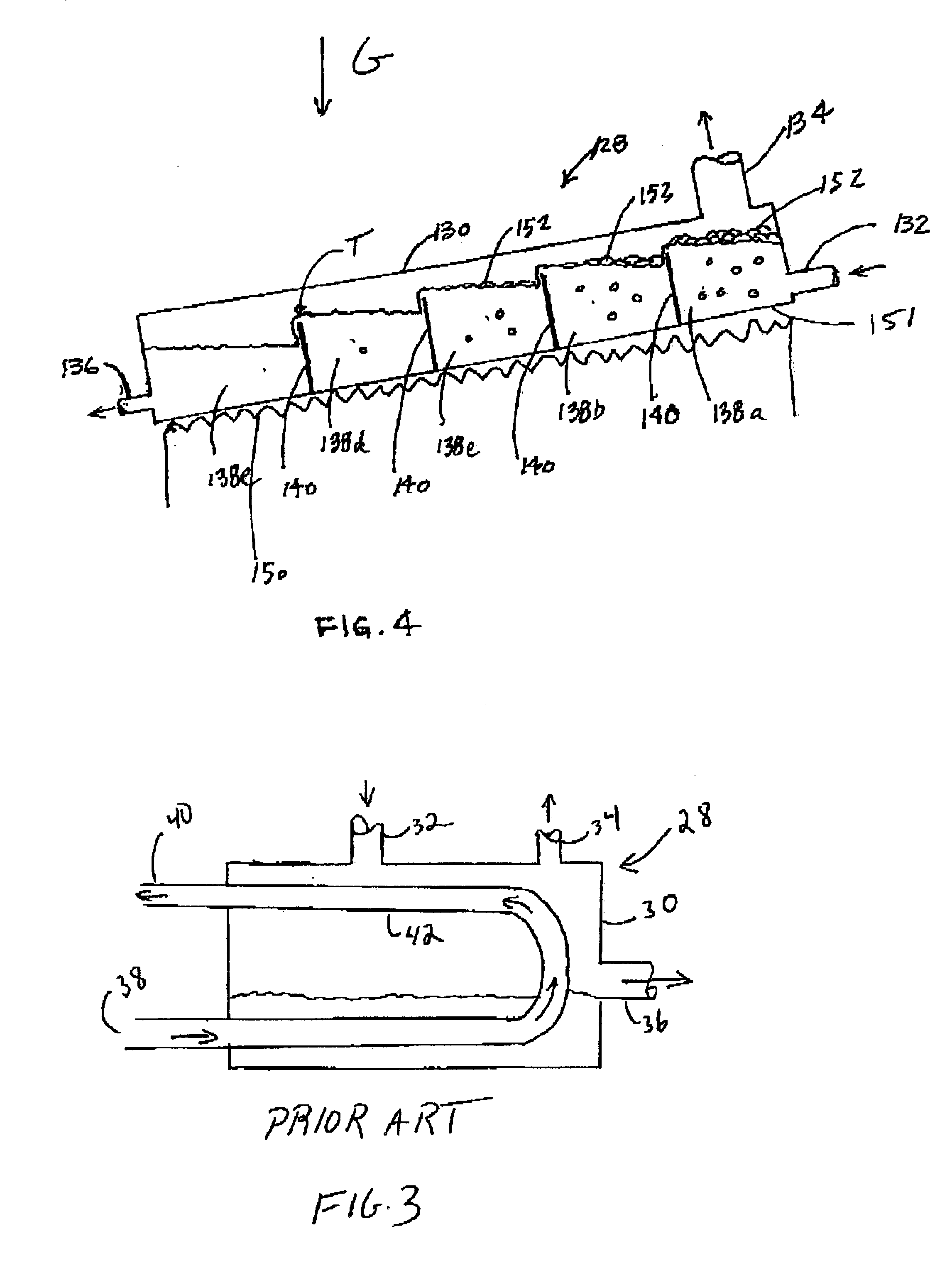

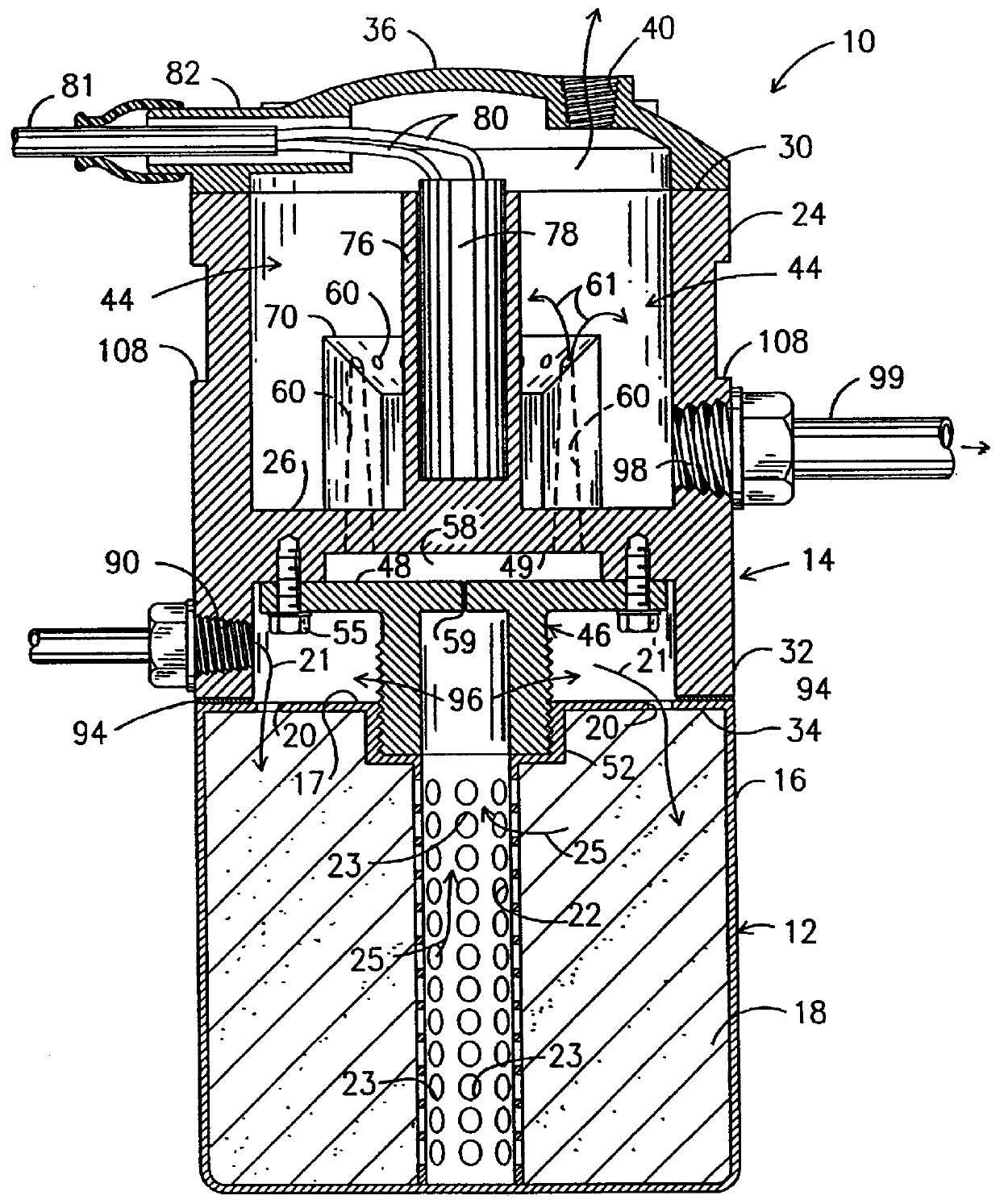

Lubricant still and reservoir for refrigeration system

InactiveUS6904759B2High viscosityHigh trafficStationary conduit assembliesEvaporators with heating coilsRefrigerationRefrigerant

A lubricant still for use in a compressor for separating oil from refrigerant, includes a vessel having an inlet for incoming oil laden refrigerant, an outlet for gaseous refrigerant, and an outlet for refrigerant laden oil. A separating structure is provided for separating transitioning oil laden refrigerant from the incoming oil-laden refrigerant, wherein the oil laden refrigerant progressively changes to the refrigerant laden oil closer to the outlet for refrigerant laden oil. A heating device is used for heating the incoming oil laden refrigerant and transitioning oil laden refrigerant, for facilitating the formation of the gaseous refrigerant and the refrigerant laden oil.

Owner:CARRIER CORP

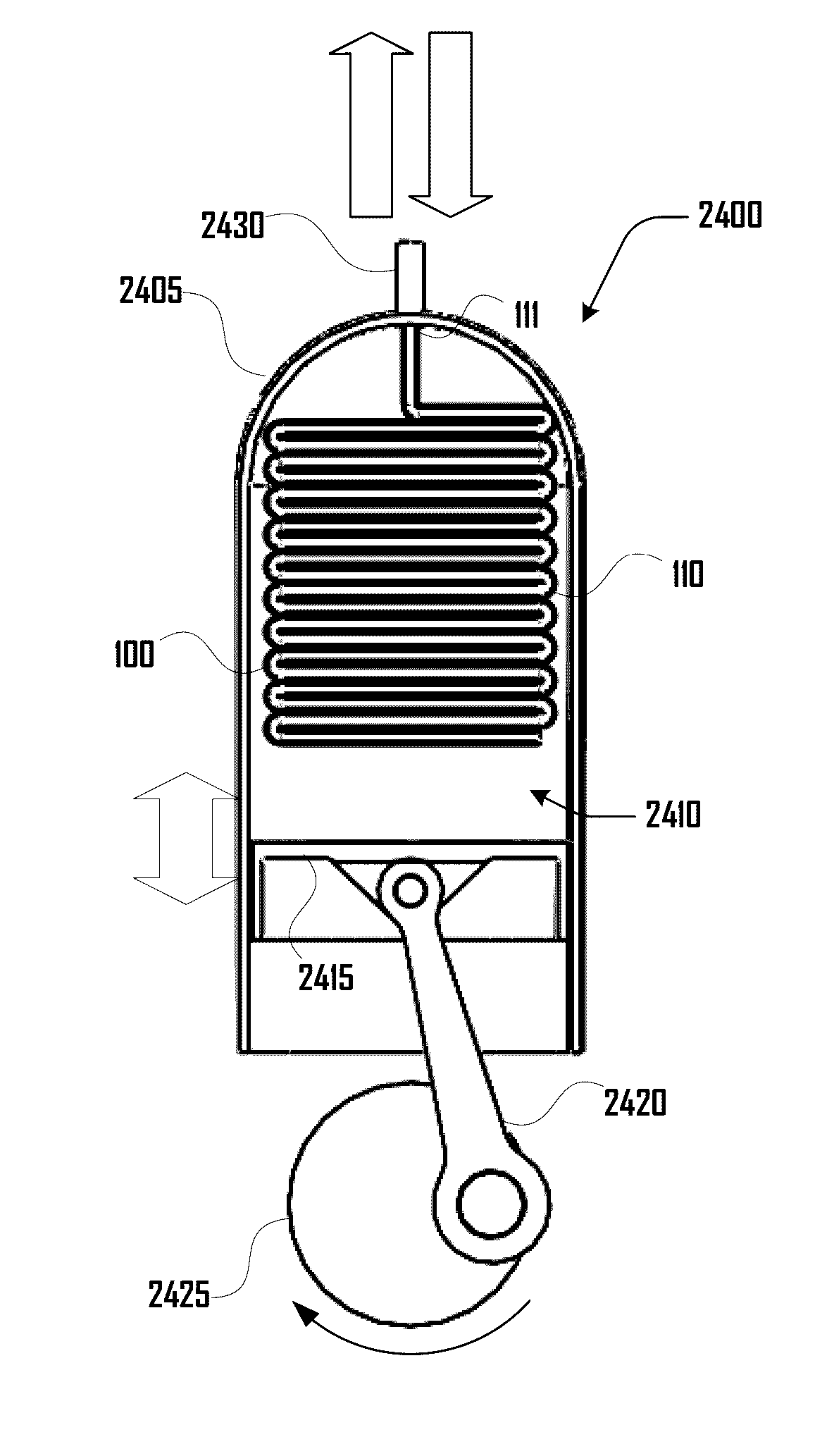

Near-isothermal compressor/expander

One aspect includes an isothermal compressor that includes an isothermal body, an isothermal cavity defined by the isothermal body, a compressible membrane heat exchanger disposed within the isothermal cavity that defines at least one first fluid chamber, and an actuating assembly configured to compress the membrane heat exchanger. A further aspect includes an isothermal engine that includes the isothermal compressor.

Owner:OTHER LAB

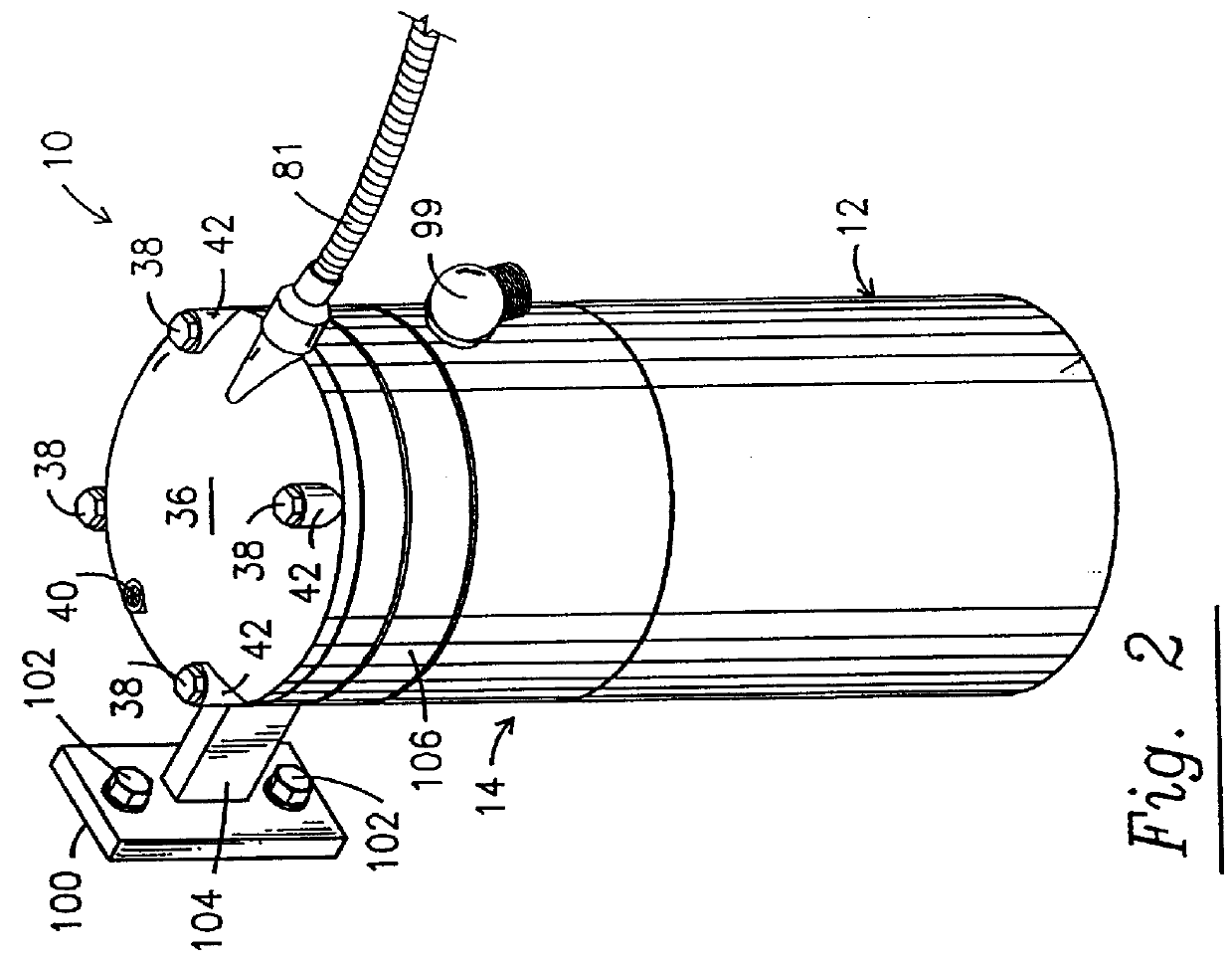

Water vapor distillation apparatus, method and system

ActiveUS8505323B2Lighting and heating apparatusDistillation regulation/controlControl systemDistillation

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

Membrane based concentrators

A sample concentrator for concentrating analytes in a solvent-containing liquid sample stream, including concentrator housing having a sample stream flow channel and a gas stream flow channel having an inlet and an outlet, a heater for gas in the gas stream conduit, and a hydrophilic ion exchange or non-ionic membrane barrier separating said gas stream flow channel and said sample stream flow channel. Solvent is evaporated from the liquid sample stream in said sample stream flow channel in or at the interface with said membrane, when the gas stream is at an elevated temperature. A regeneration step is used to regenerate the ion exchange membrane barrier.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

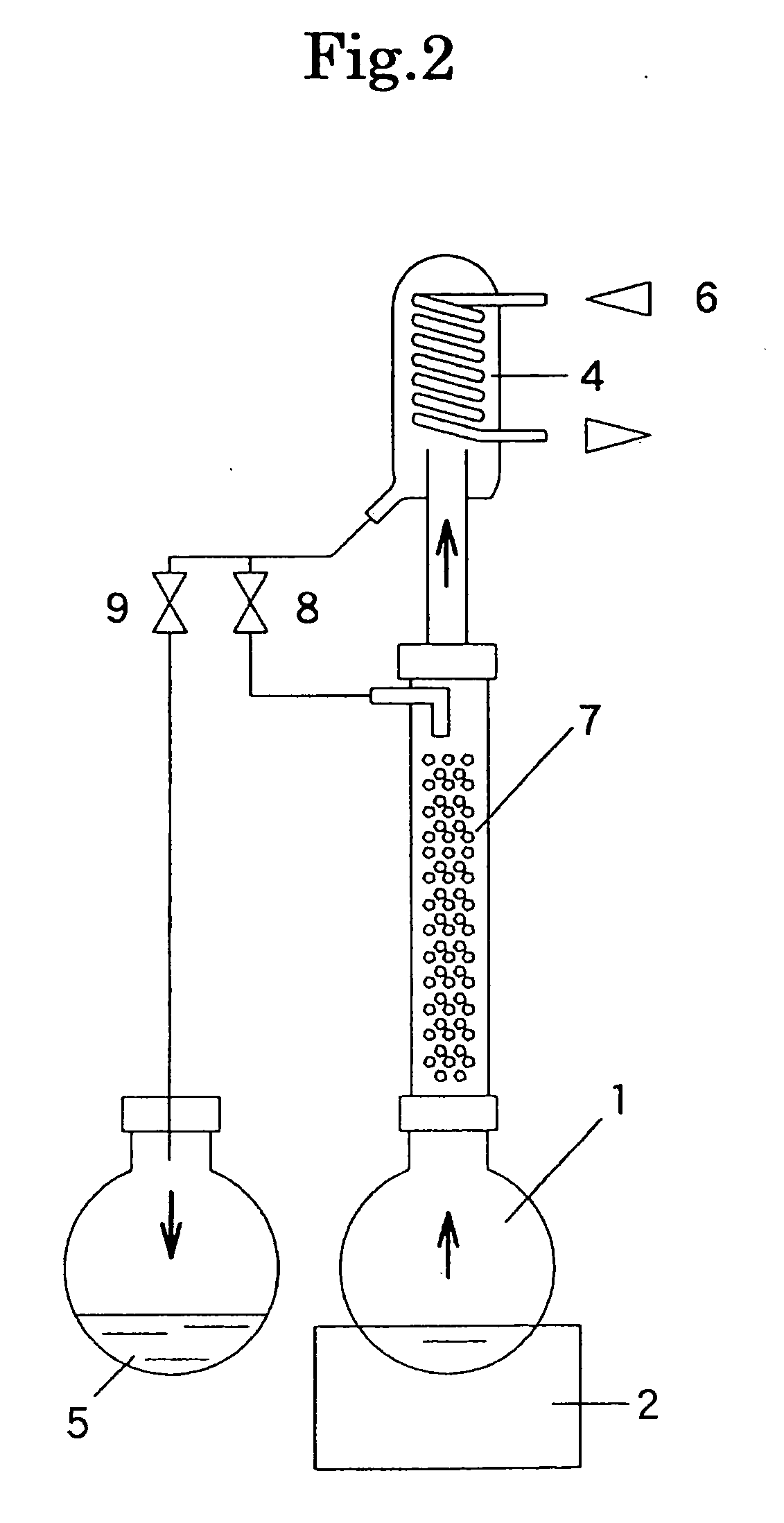

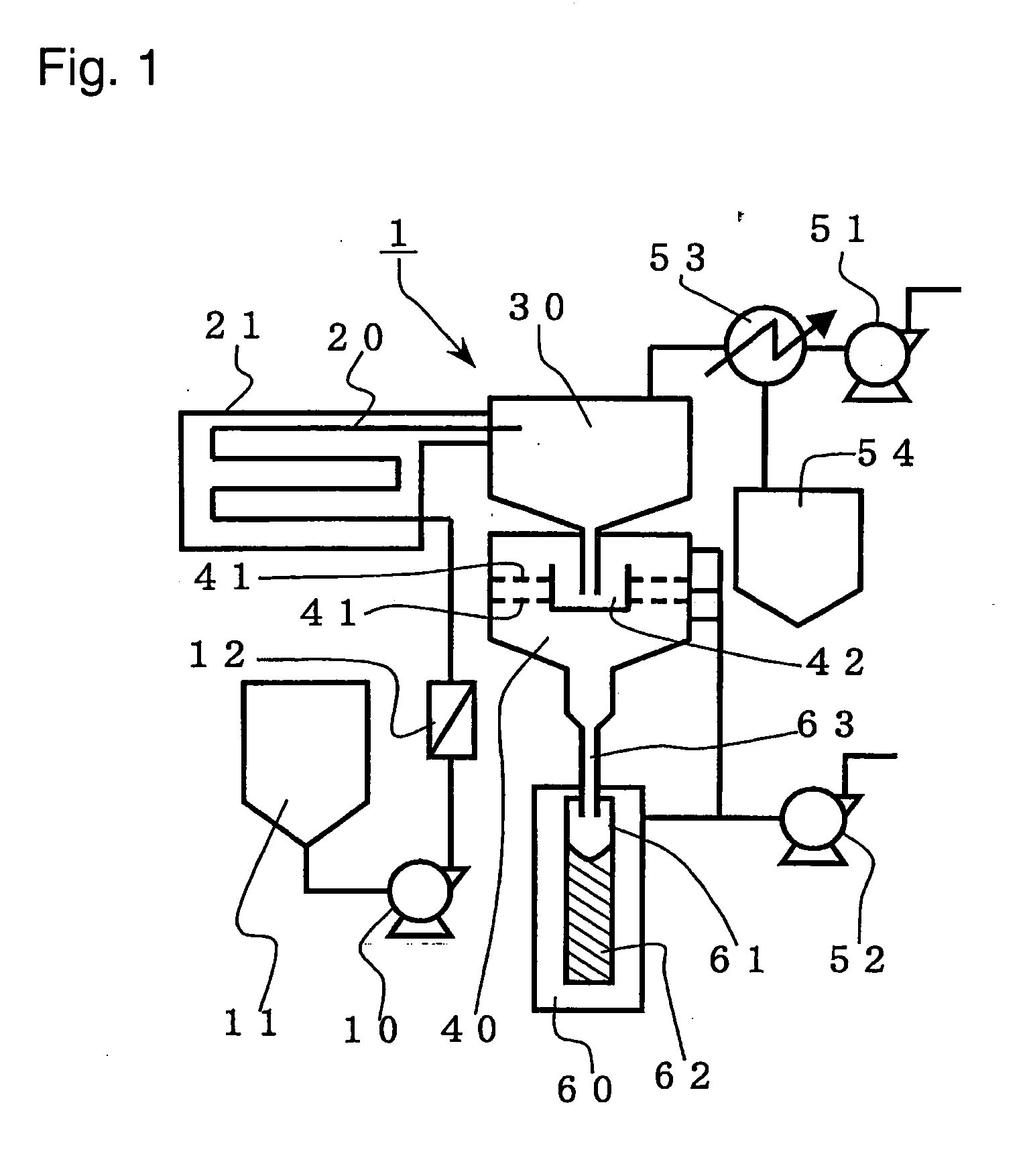

Method for Recovering a Liquid Medium and System for Recover a Liquid Medium

ActiveUS20080035467A1Drying using combination processesDistillation regulation/controlLiquid mediumProduct gas

A method for recovering a liquid medium, comprising gas to be compulsorily contacted with the liquid medium to gasify the liquid medium, and condensing the gasified medium, and a device for recovering a liquid medium. Further, the present invention is directed to a device for recovering a liquid medium, wherein the device comprises: a gasifying means for bringing gas into contact with a mixed liquid comprising a liquid medium and a nonvolatile substance to gasify the liquid medium; a condensing-separating means for cooling the gas and the gasified medium fed from the gasifying means to separate the condensed medium from the separated gas; and a gas feeding means for feeding the separated gas as the gas to the gasifying means.

Owner:INST OF CREATIVE CHEM

Water vapor distillation apparatus, method and system

Owner:DEKA PROD LLP

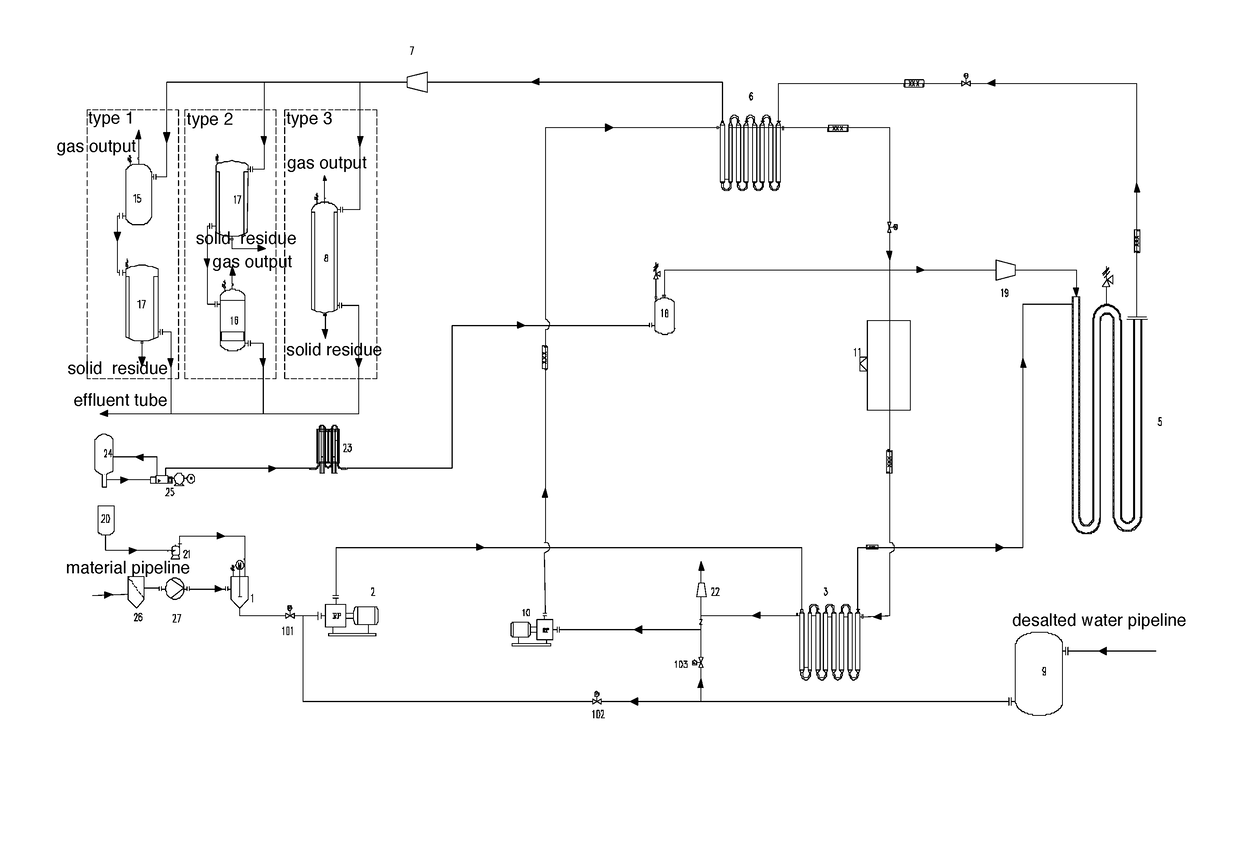

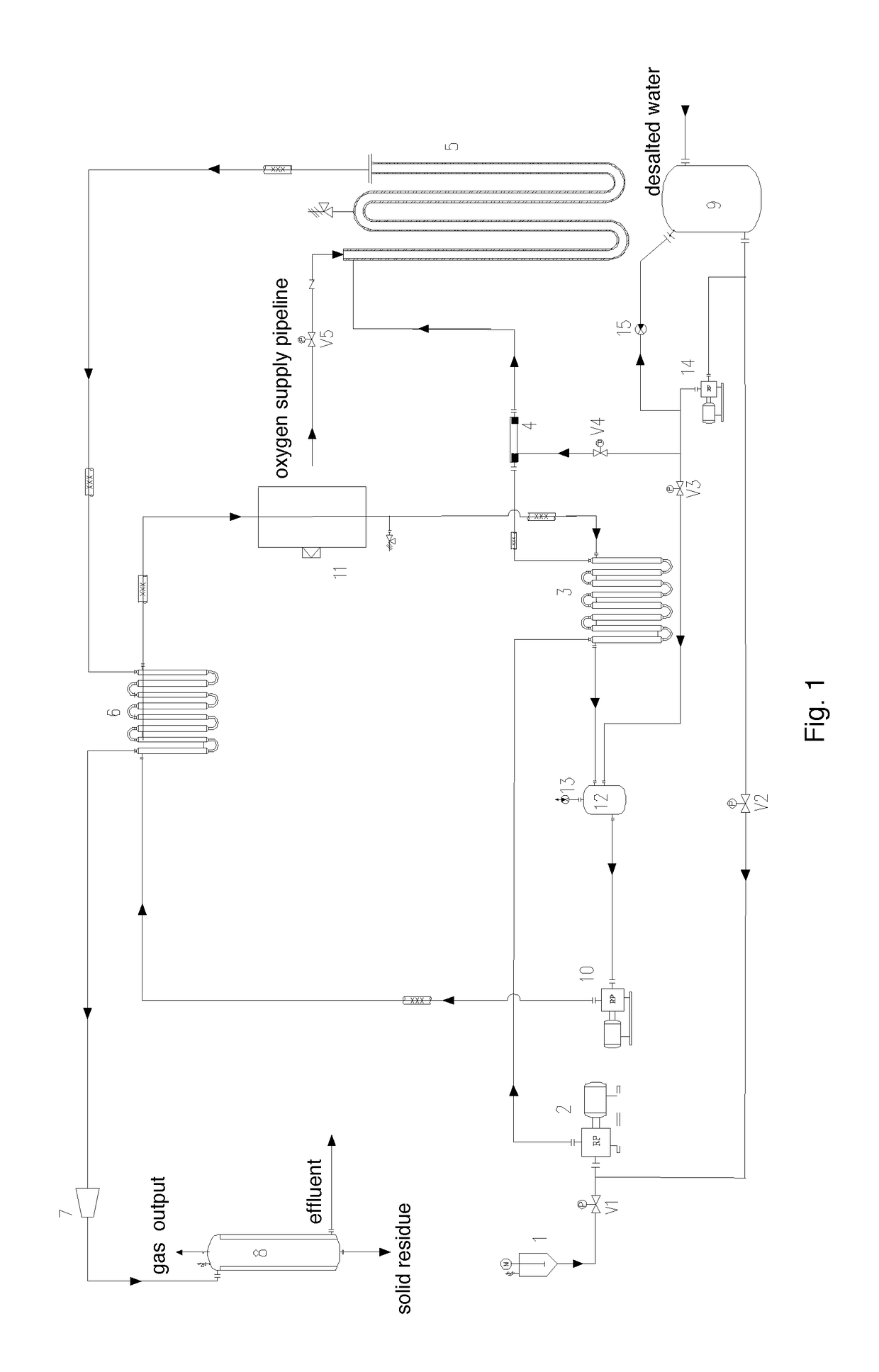

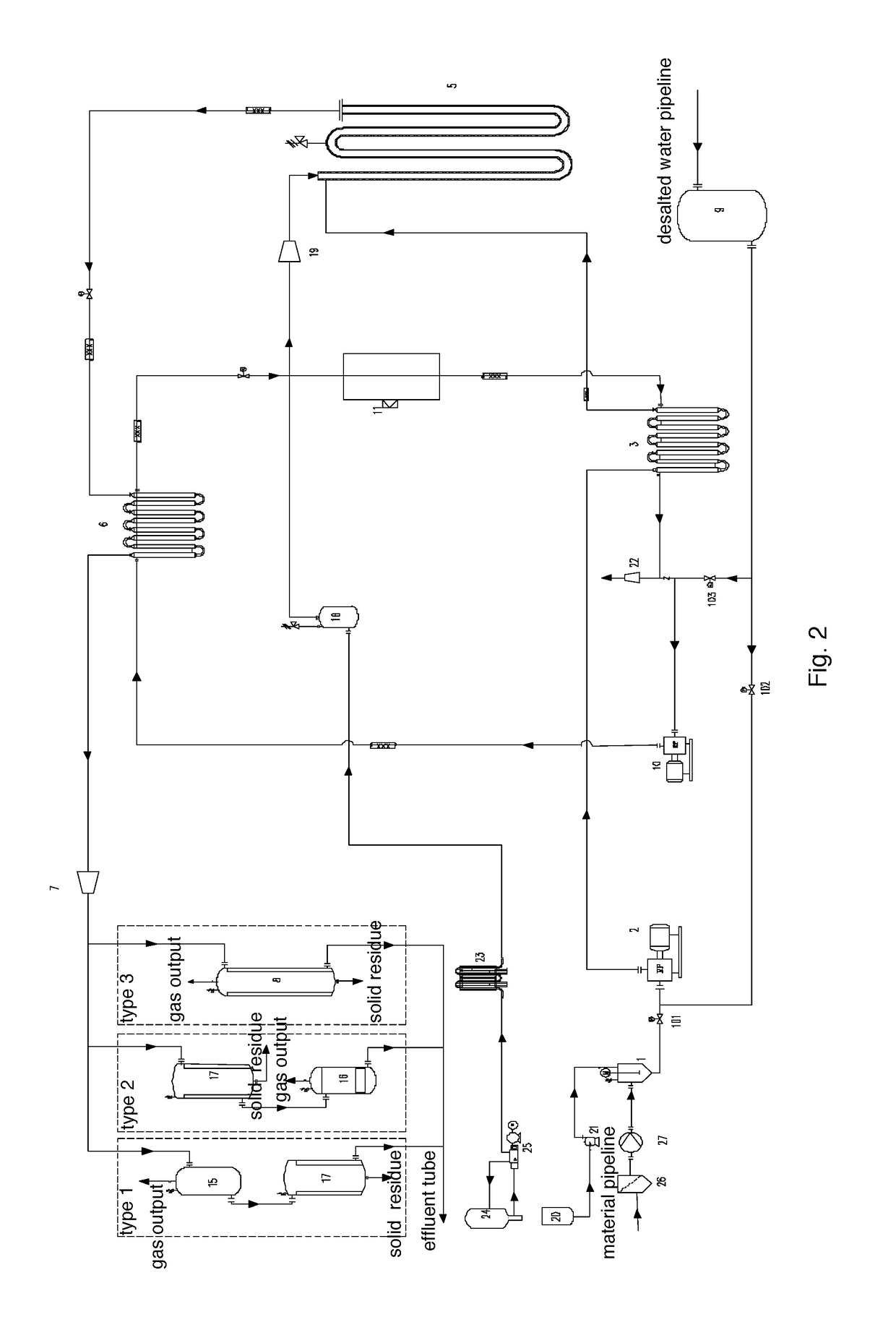

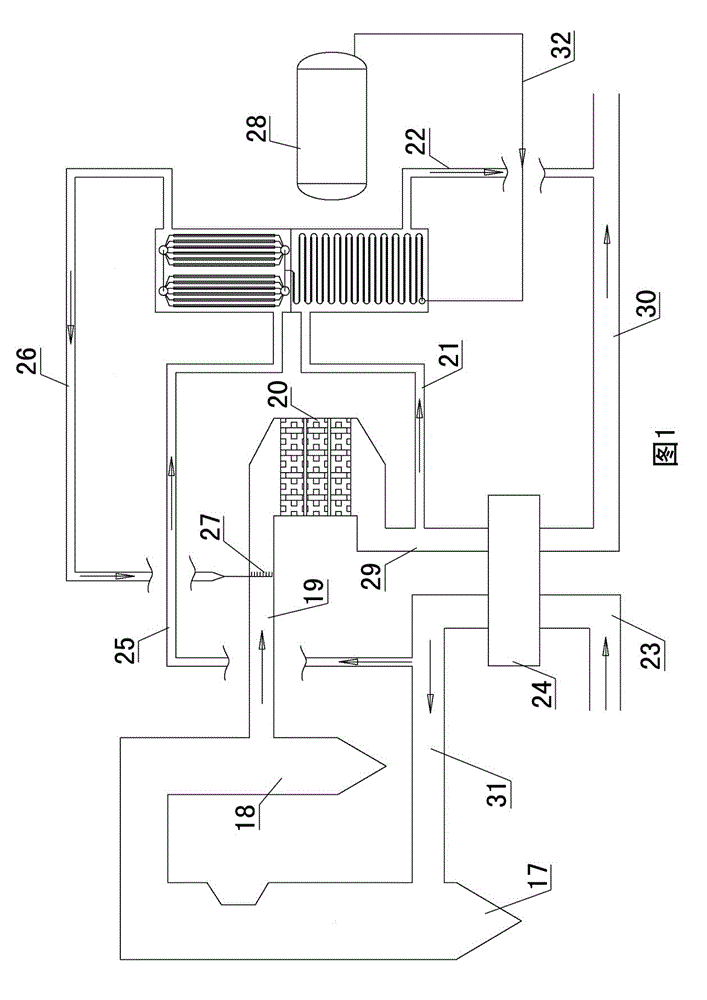

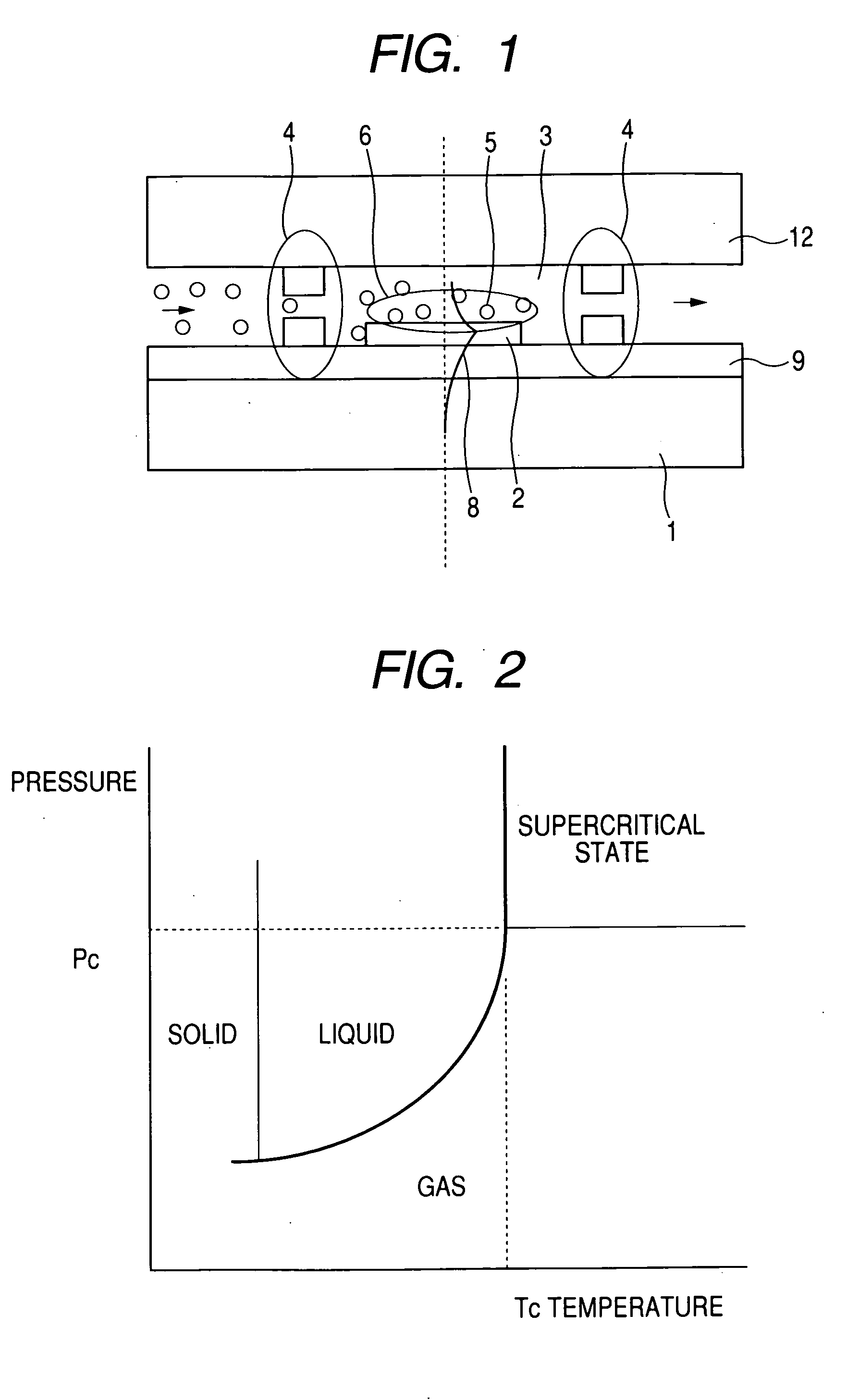

Indirect heat transfer supercritical water oxidation system and control method thereof

InactiveUS20170297941A1Low investment costAvoid risk of cloggingWater treatment parameter controlSludge treatment by oxidationAutomatic controlWorking pressure

An indirect heat transfer supercritical water oxidation system includes a supercritical water oxidation reactant system and an intermediate medium circuit. A control method thereof includes controlling two-process pressure and temperature increase, controlling pressure and temperature decrease and controlling normal operation. The present invention focuses on automatic control strategy of engineering practice of the indirect heat transfer supercritical water oxidation system. The system heating process adopts the idea of circulating heating, which effectively reduces the investment of the heating equipment avoids the mismatch between the working pressure of the two processes, and ensures effectiveness of the heat transfer between supercritical pressure fluid in the inner tube and the outer tube of the preheater / heat exchanger during subsequent heating process. The effective control of a reaction temperature and overpressure protection of critical equipment ensure a process effect and system safety.

Owner:XI AN JIAOTONG UNIV +1

Apparatus for removing solid and volatile contaminants

InactiveUSRE36527E1Reduce heat lossEasy constructionHydrocarbon distillationMachines/enginesFilter mediaEngineering

A combination filter and evaporator unit for use in small engine applications includes a filter member that is screw threadedly engaged to the evaporator unit to facilitate replacement of filter media as needed. The design of the unit constrains incoming oil to flow first through the filter media and then to an evaporation chamber. A central hub and a bottom wall of the evaporation chamber are directly heated by a heating element, and the evaporation chamber is closed by an imperforate lid so that heat loss is inhibited.

Owner:PREMO LUBRICATION TECH

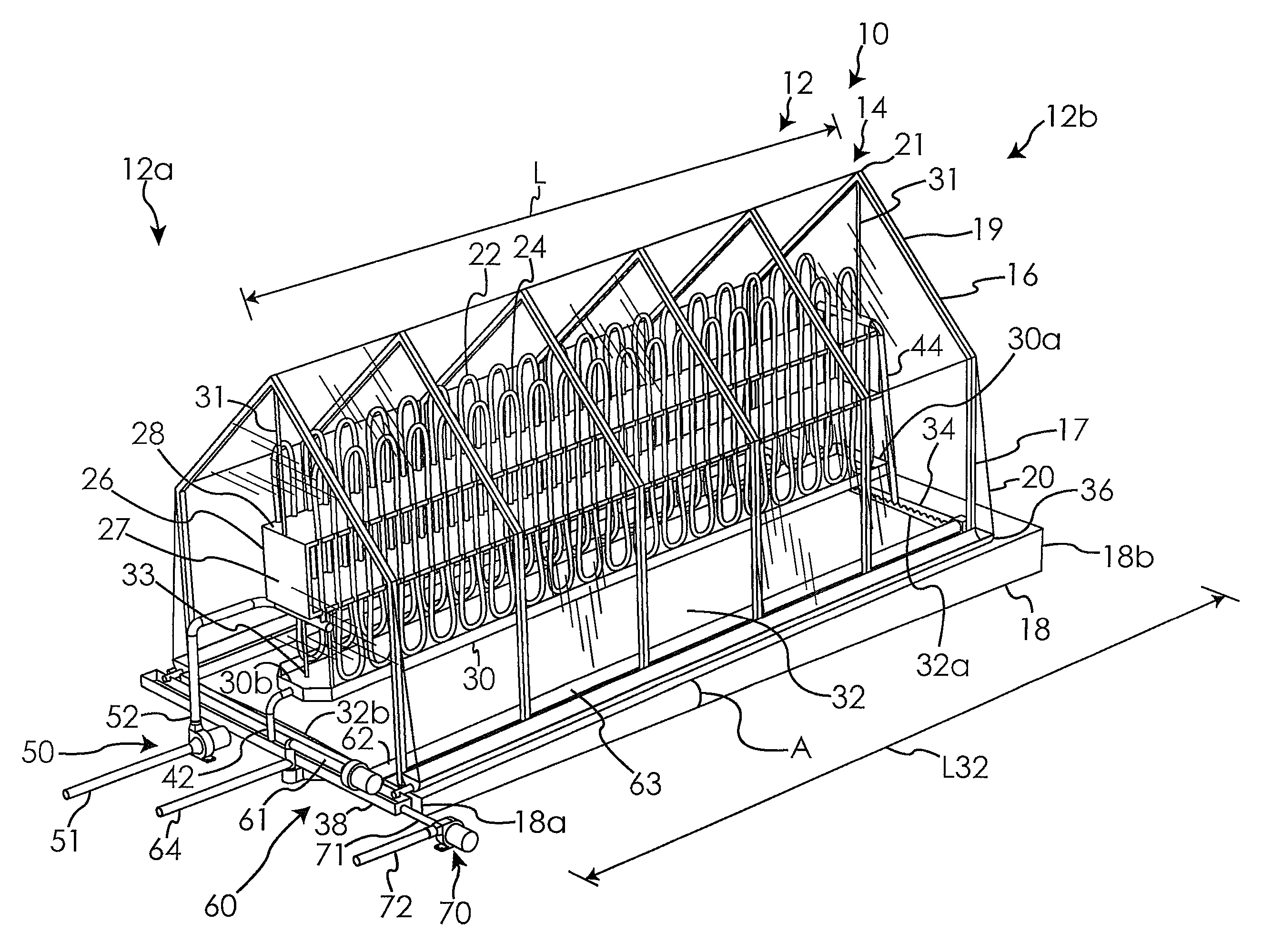

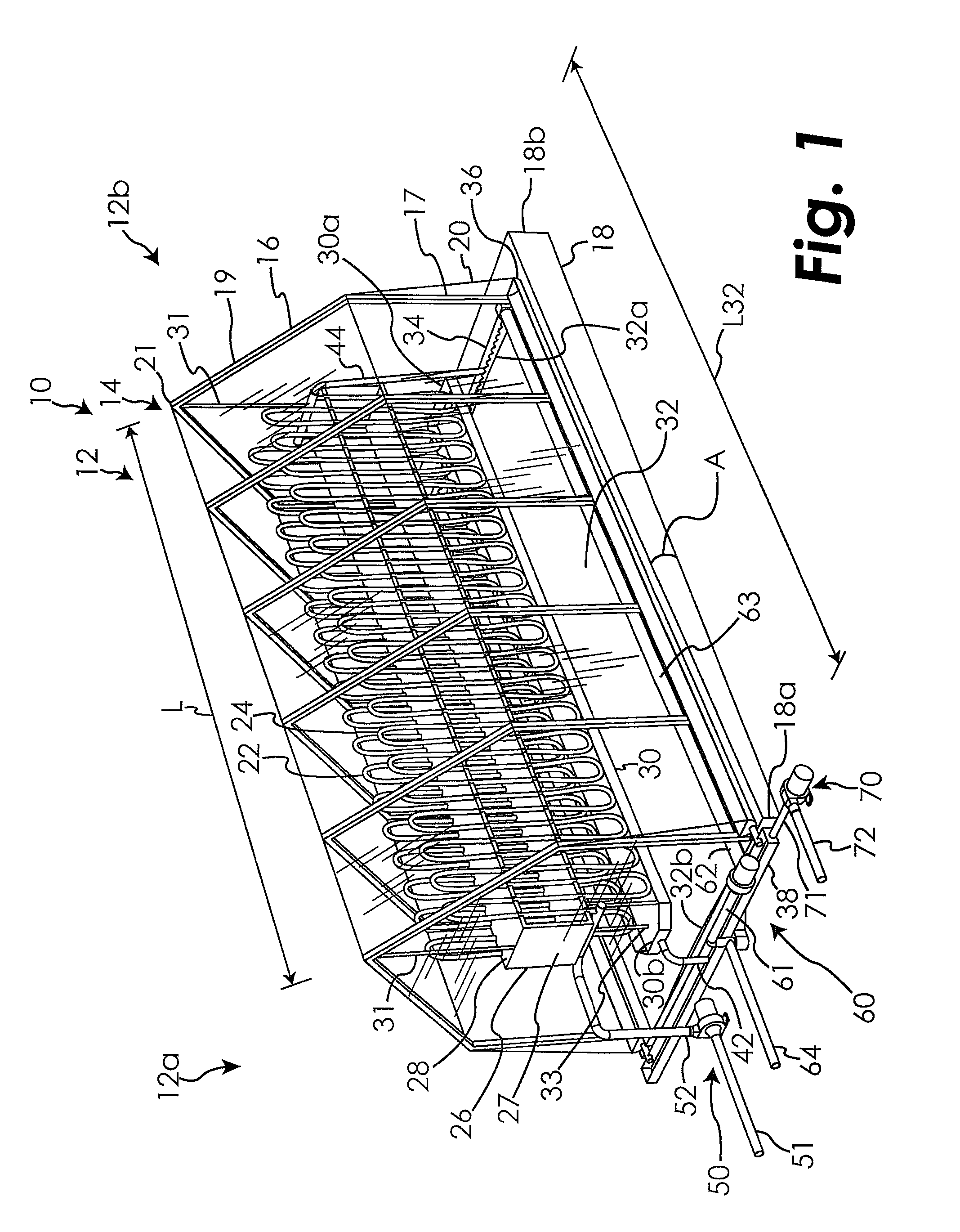

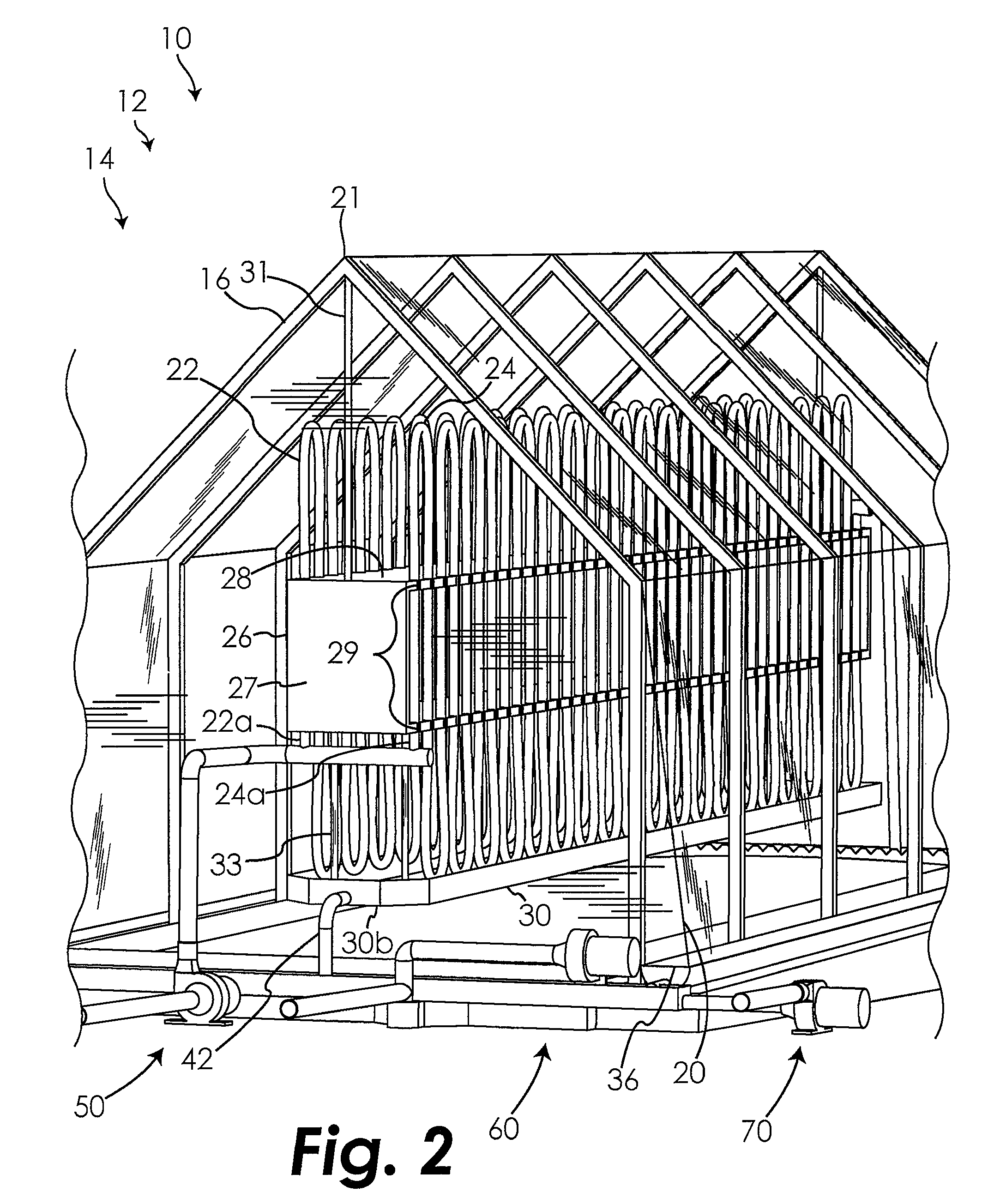

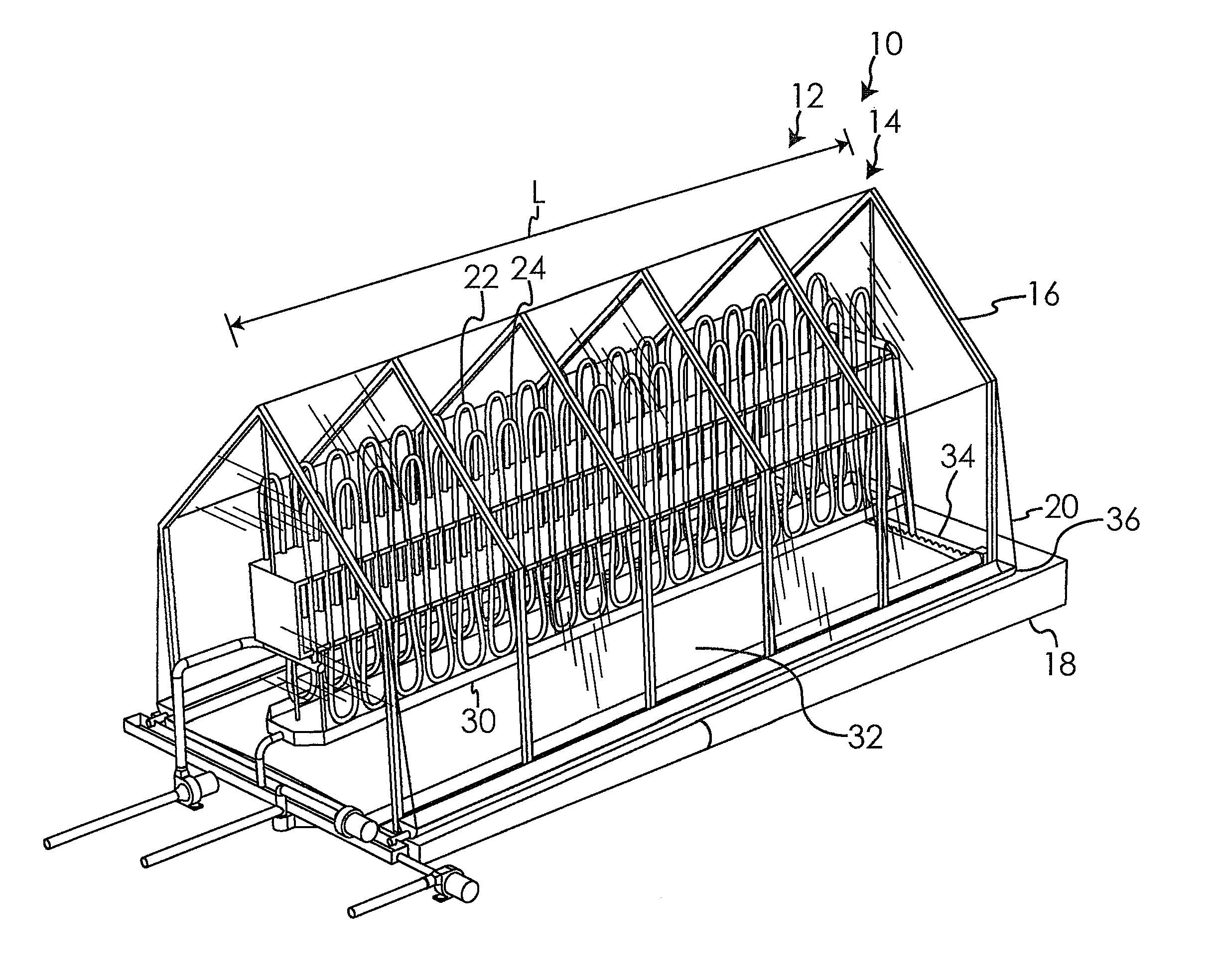

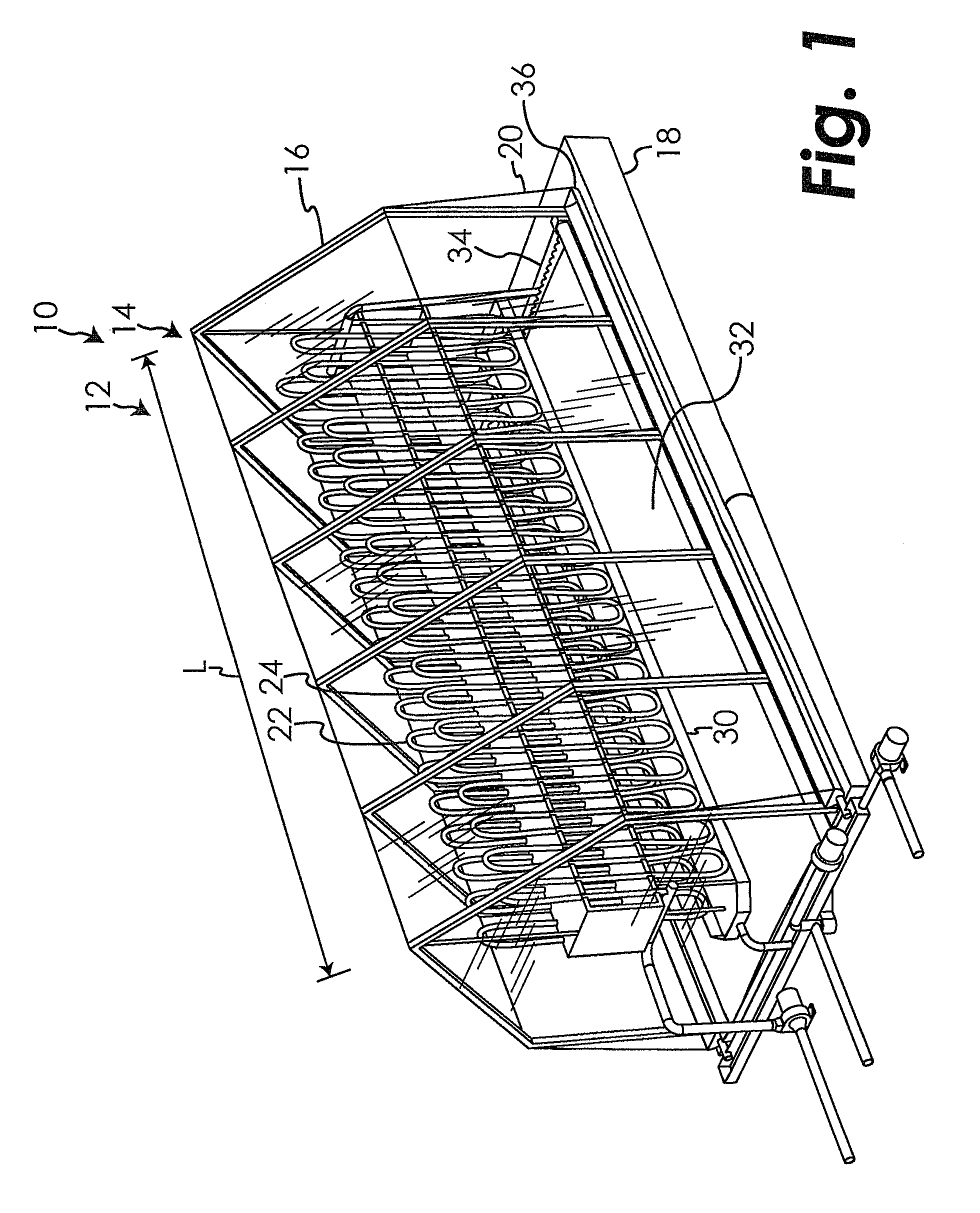

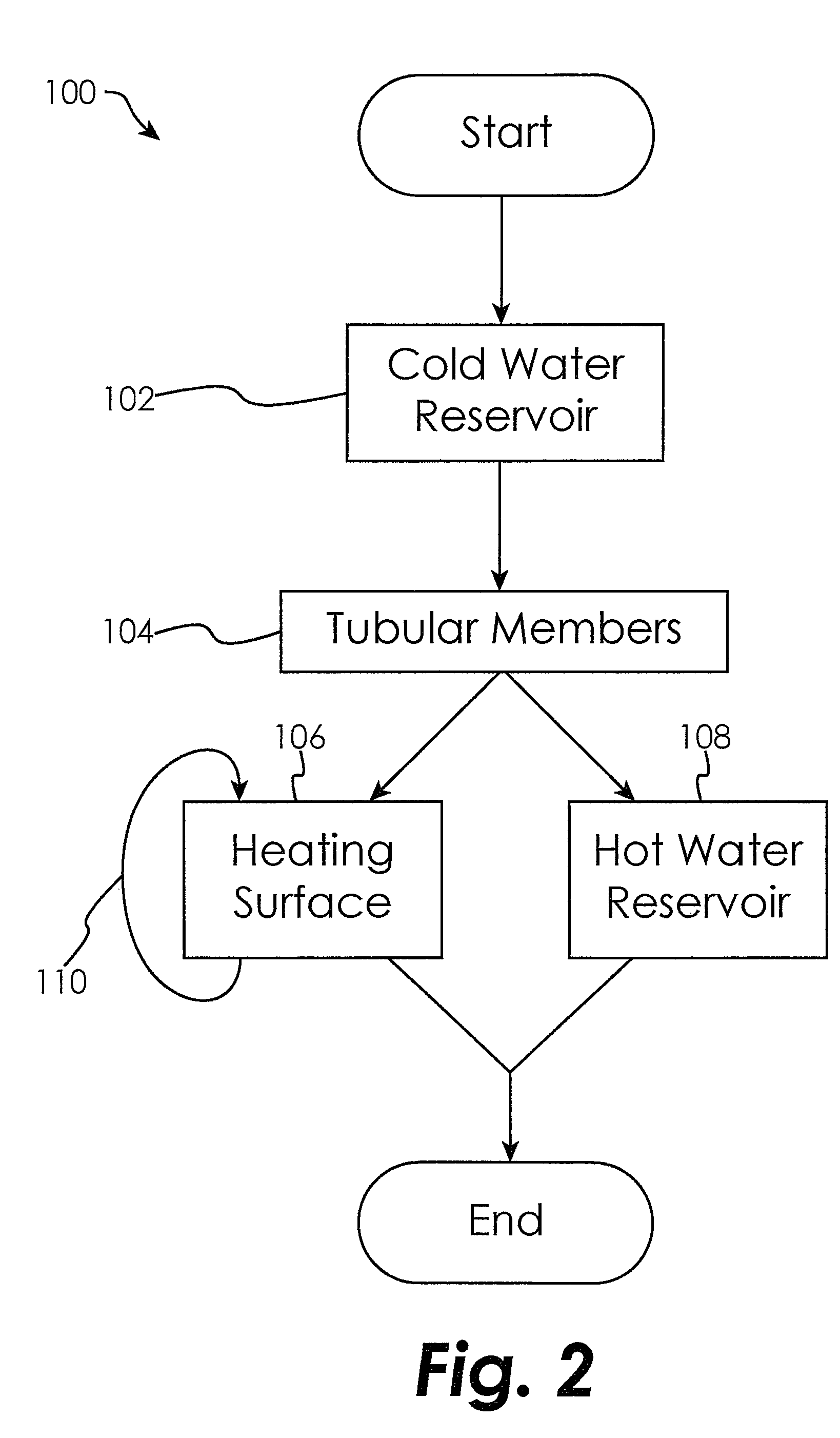

Solar distillation system

The present disclosure is generally directed to a solar distillation system capable of recovering potable water from non-potable water. In certain embodiments, the system includes a substantially air tight solar still having a roof top composed of a solar light-transmitting material. The solar still includes a tube positioned below and running underneath the roof top, the tube having an exit end. Additionally, the solar still includes a heating surface positioned below the roof top and adapted for receiving at least a portion of the non-potable water exiting the tube at the exit end. Non-potable water on the heating surface is solar heated and a portion of the non-potable water evaporates and condenses on the outside of the tube to be collected as potable water.

Owner:KII

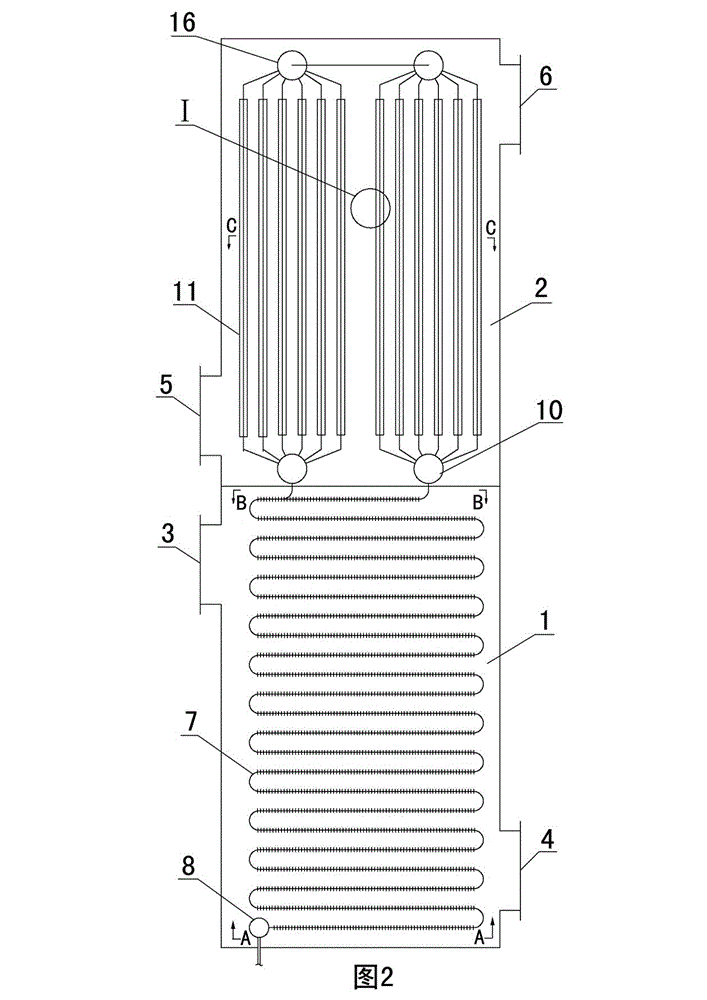

Liquid ammonia evaporator and liquid ammonia evaporation system for flue gas denitration

InactiveCN102743889AImprove heat transfer efficiencySimplify the evaporation supply systemEvaporator accessoriesDispersed particle separationFlue gasEvaporation

The invention discloses a liquid ammonia evaporator and a liquid ammonia evaporation system for flue gas denitration, wherein the liquid ammonia evaporator comprises a heat exchange chamber and a stainless steel heat exchange pipe which is arranged in the heat exchange chamber; the heat exchange chamber consists of a lower heat exchange chamber and an upper heat exchange chamber; a denitrated flue gas inlet is arranged at the top of the lower heat exchange chamber and a denitrated flue gas outlet is arranged at the bottom of the lower heat exchange chamber; a hot air inlet is arranged at the bottom of the upper heat exchange chamber and a hot air outlet is arranged at the top of the upper heat exchange chamber; the stainless steel heat exchange pipe comprises a primary heat exchange pipe which is arranged in the lower heat exchange chamber and a secondary evaporator heat exchange pipe which is arranged in the upper heat exchange chamber; the pipe wall of the secondary evaporator heat exchange pipe consists of an inner wall and an outer wall; evenly distributed millimeter-level small holes are arranged on the inner wall; and evenly distributed micron-level micro holes are arranged on the outer wall, according to the liquid ammonia evaporator, the heat exchange efficiency of liquid ammonia is greatly improved and an ammonia evaporation supply system is simplified; and the liquid ammonia evaporation system has a compact structure and is capable of fully utilizing the waste heat of flue gas and the heat of preheated air.

Owner:北京中新国能环保科技有限公司

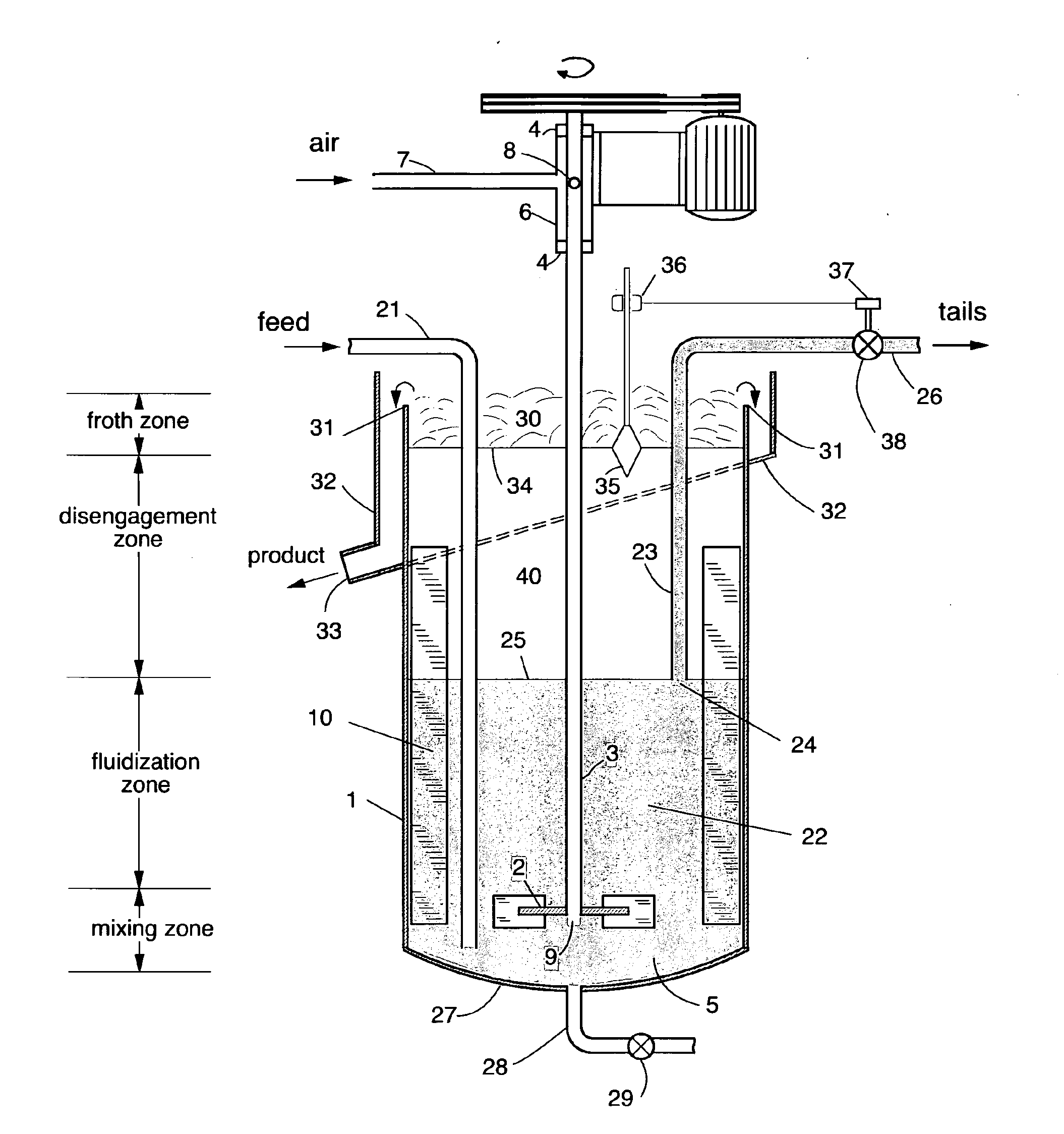

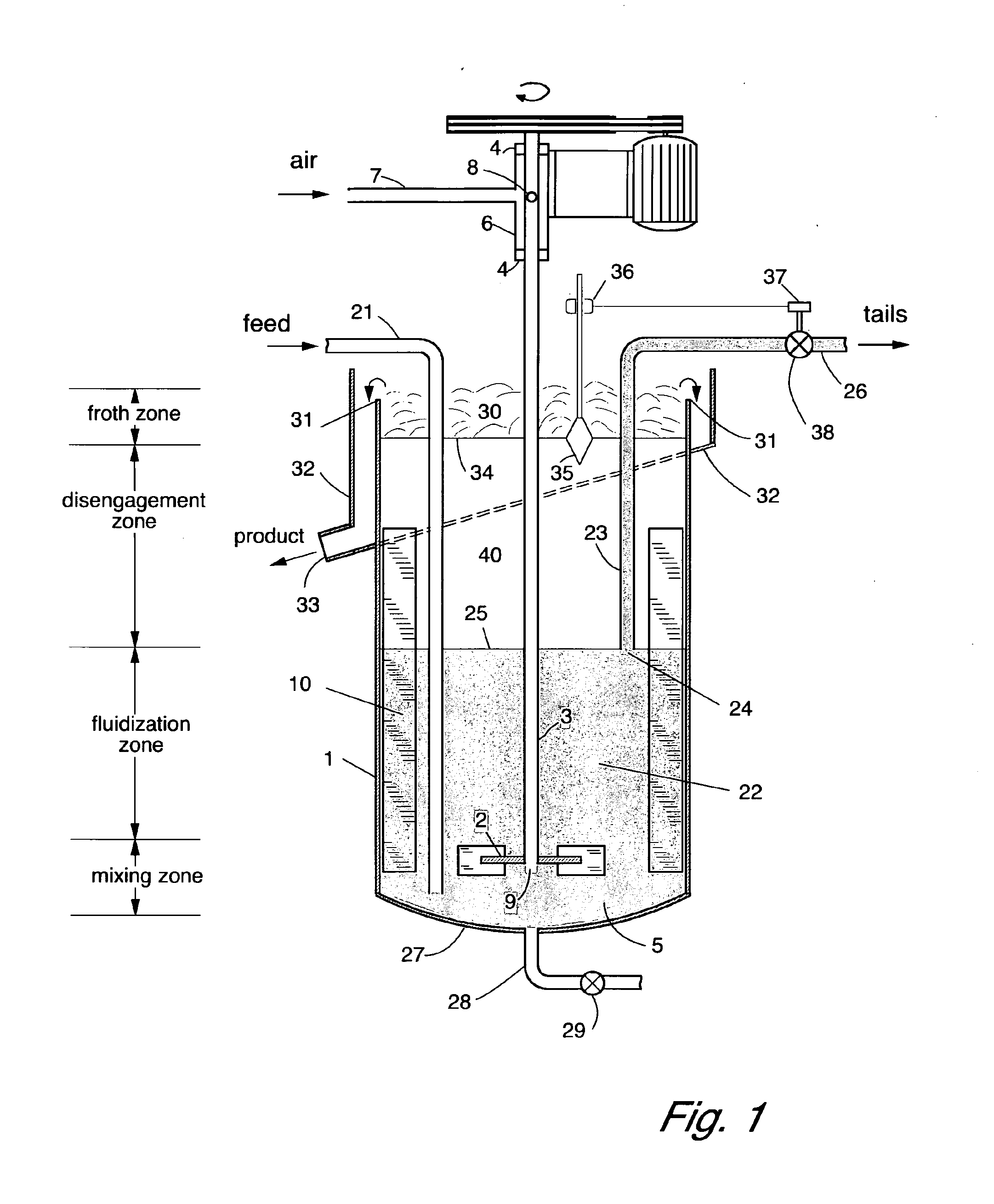

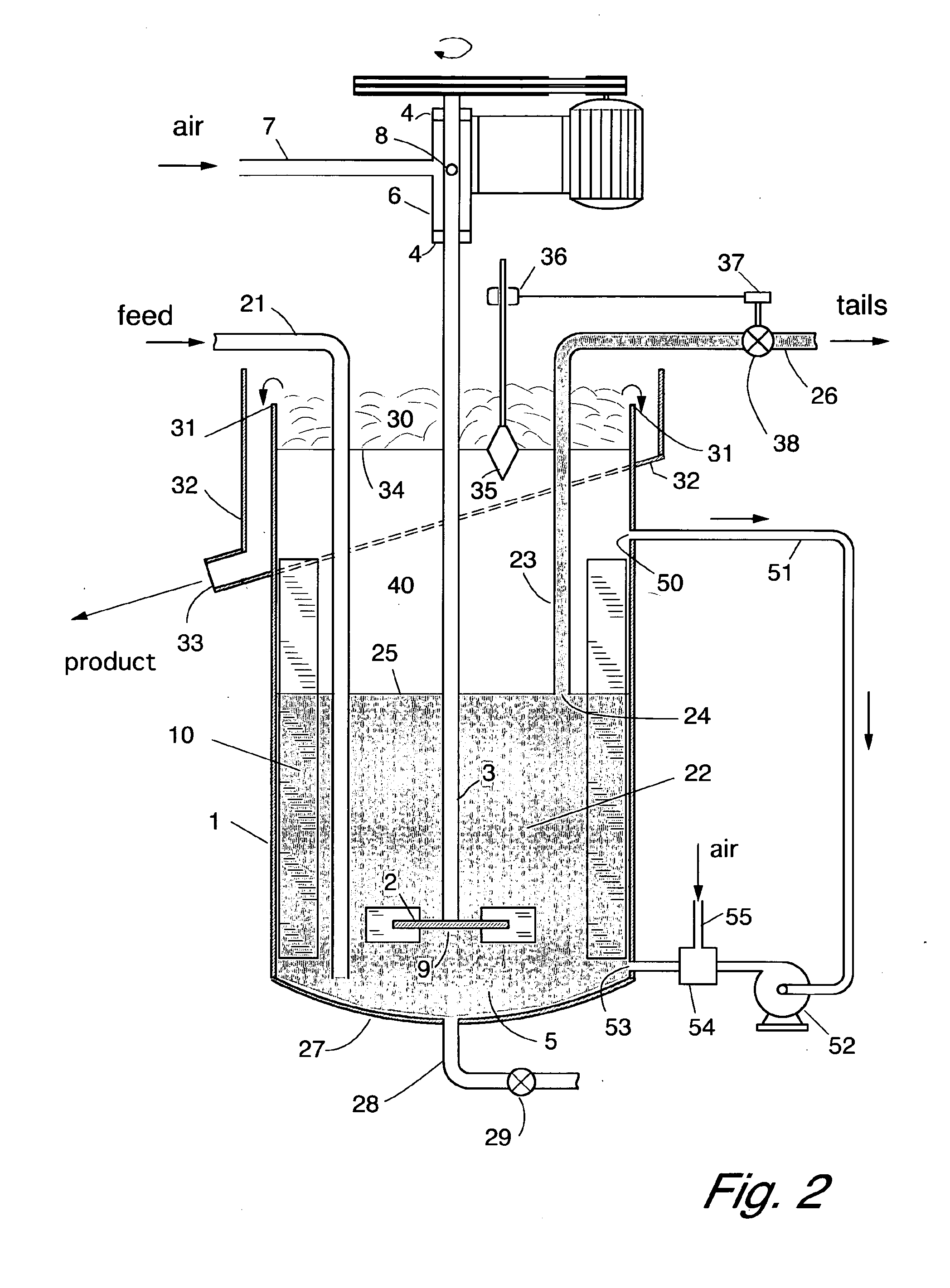

Improved method and apparatus for froth flotation in a vessel with agitation

InactiveUS20120061298A1Reduce volume fractionReduce hydraulic resistanceEvaporators with heating coilsFlotationImpellerFluidized bed

A method of separating mixed particles in a flotation cell uses a fluidized bed within the cell where particles are fluidized in a quiescent zone by liquid moving upwardly through the fluidized bed. The fluidizing liquid may be provided by the feed or by recycling liquid from upper parts of the cell such as from the disengagement zone. Bubbles are introduced into the lower part of the cell through a mechanical impeller which also breaks up any channels in the mixing zone, or by separate aeration in the bottom of the cell or by introduction through a recycle pipe.

Owner:NEWCASTE INNOVATION LTD

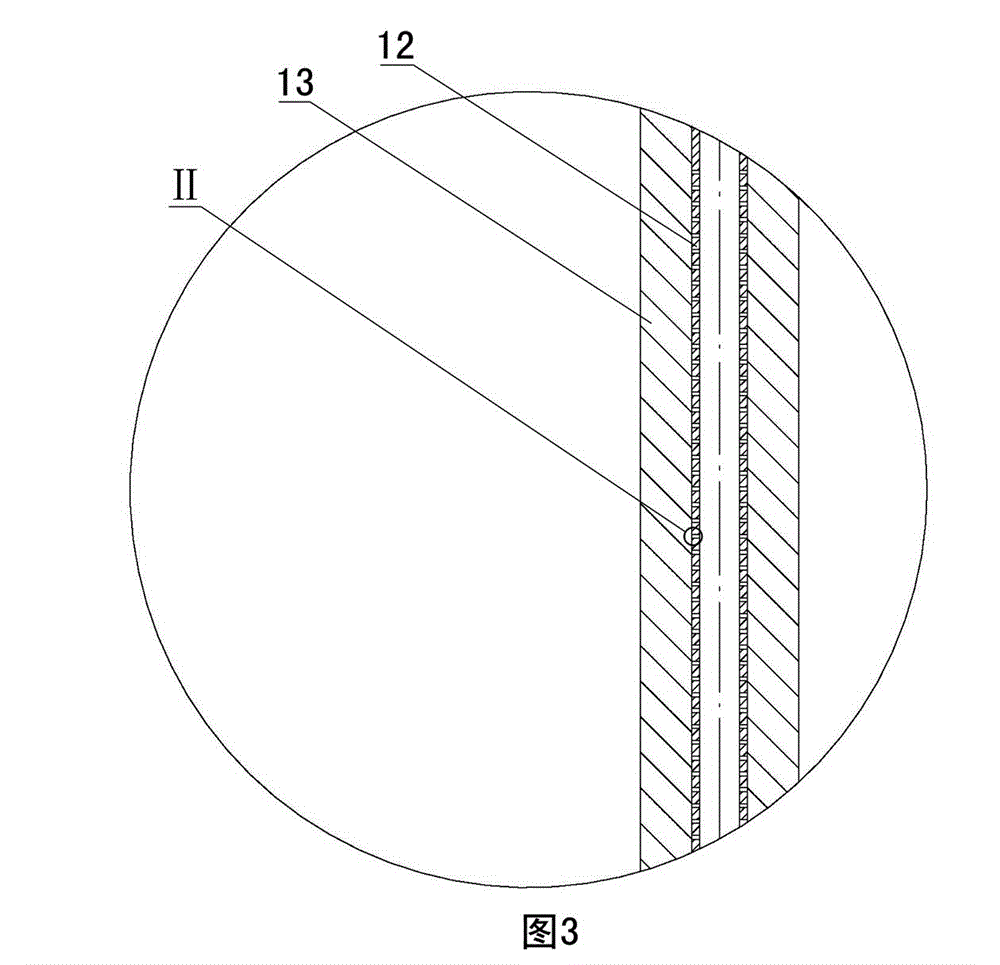

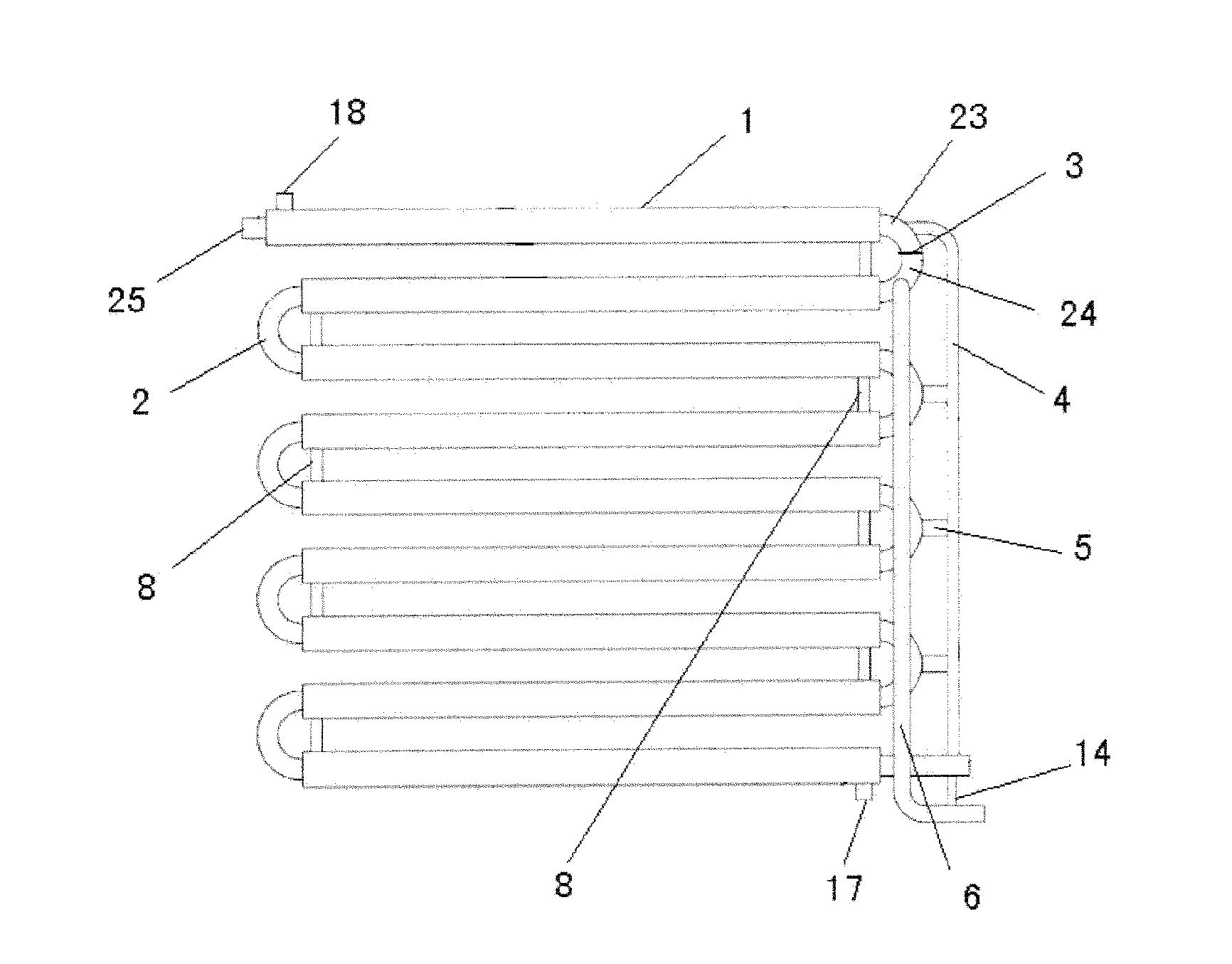

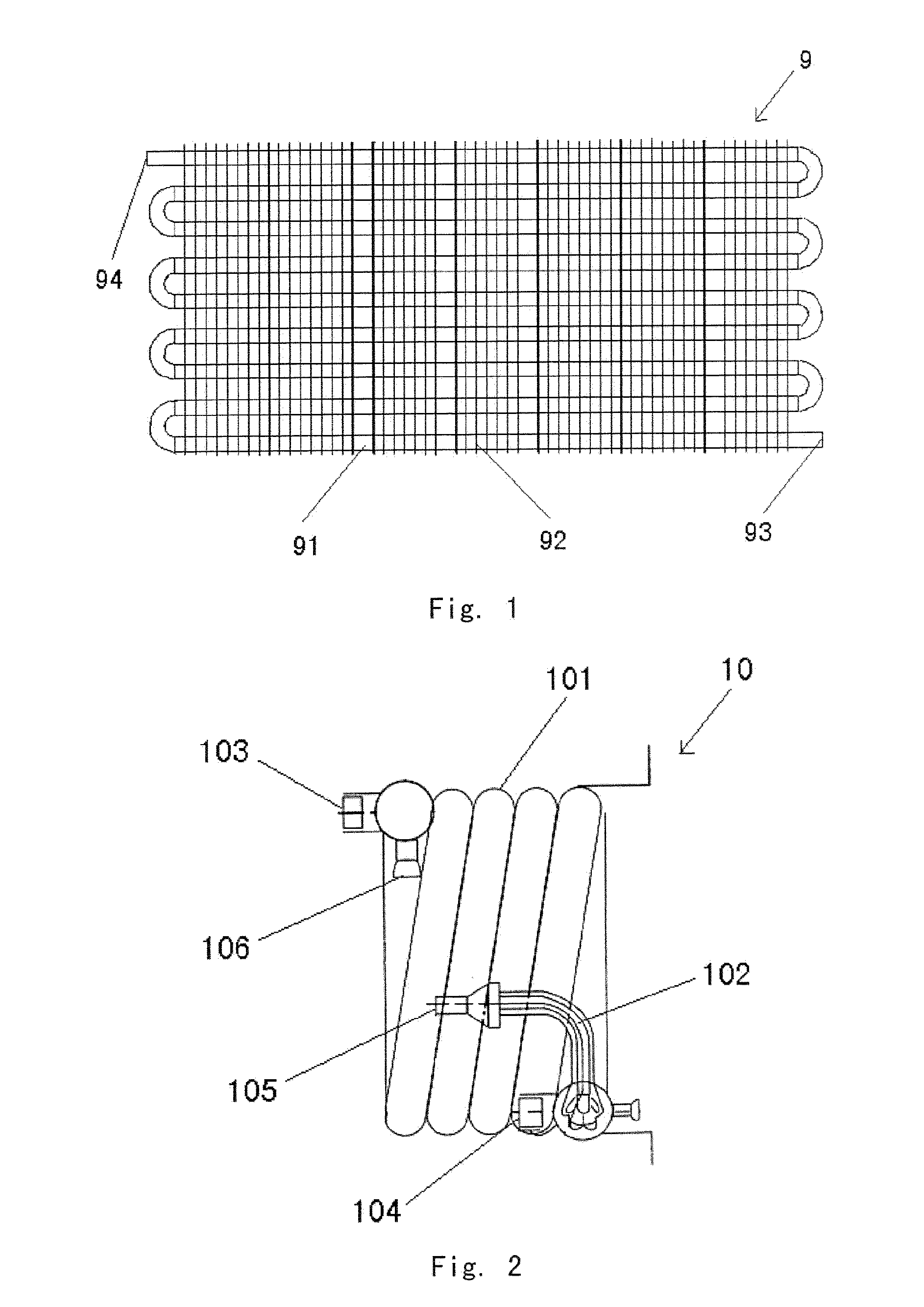

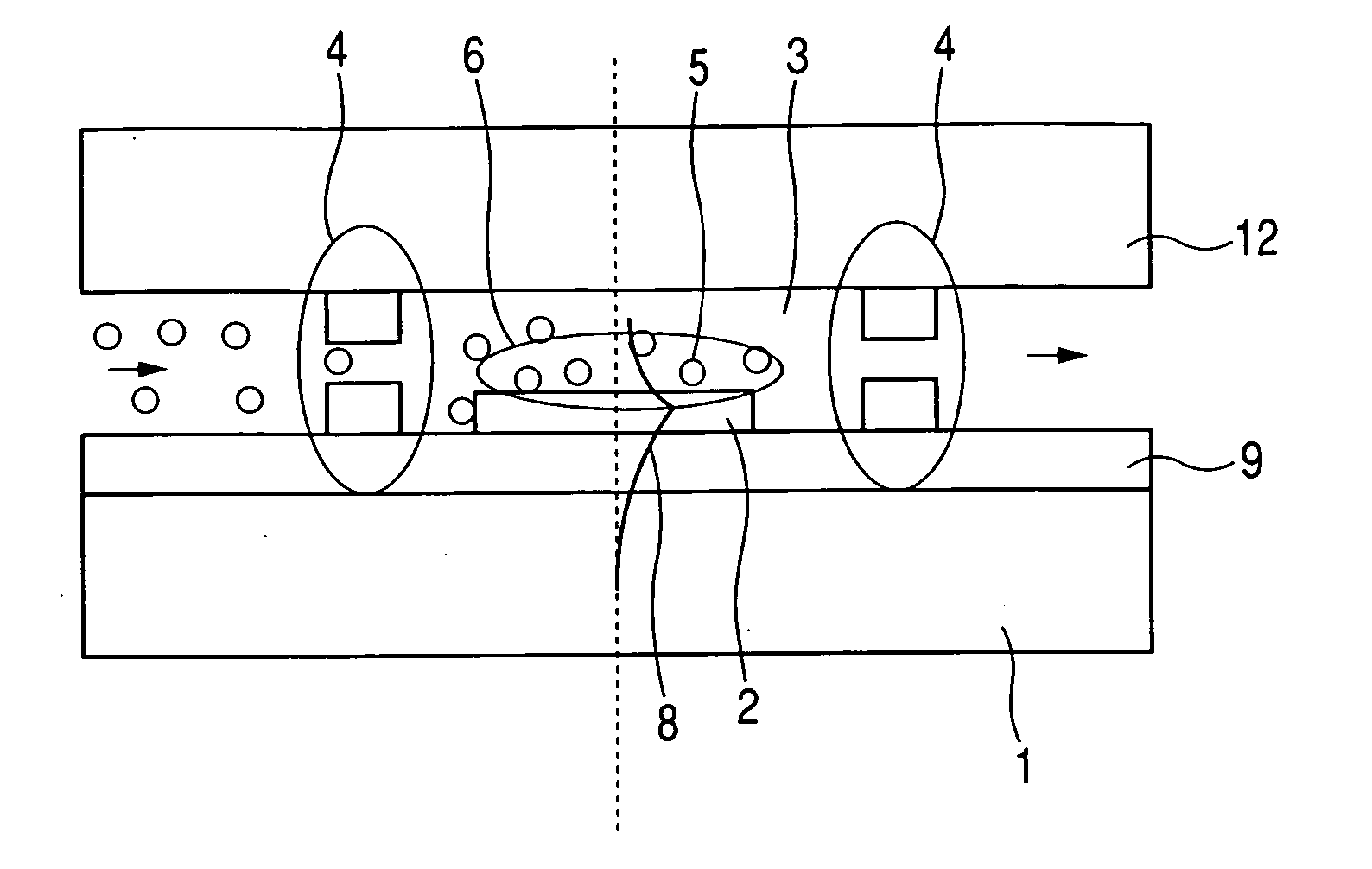

Liquid-Vapor Separating Method and a Liquid-Vapor Separating Type Evaporator

InactiveUS20100126213A1Reduce consumptionImprove efficiencyCompression machines with non-reversible cycleEvaporators/condensersEngineeringSuperheated steam

A liquid-vapor separating method and a liquid-vapor separating type evaporator, the method includes the following steps: (i) provide a partition device (3) in the upper portion of the evaporated liquid pipe, the partition device (3) divides the evaporated liquid pipe into a superheating section (12) and an evaporating section (13); (ii) a liquid-vapor separating pipe (4) is connected to the superheating section (12) near the partition device (3), an evaporated liquid feeding pipe (6) is connected to the evaporating section (13) near the partition device (3), several vapor guiding pipes (5) are respectively provided in the pipe of the evaporating section (13), the vapor guiding pipes (5) are respectively connected with the liquid-vapor separating pipe (4); vapor inside the pipe can flow out, and is separated into vapor and liquid in the liquid-vapor separating pipe (4), then the vapor enters the superheating section (12) and is superheated; the superheated vapor is discharged from a vapor outlet (11); (iii) the residual liquid separated from the liquid-vapor separating pipe (4) and the residual liquid in evaporating section (13) are together sent to the evaporated liquid feeding pipe (6) through a return pipe (14), and back to the evaporating and heat-exchanging process of evaporated liquid.

Owner:TSINGHUA UNIV

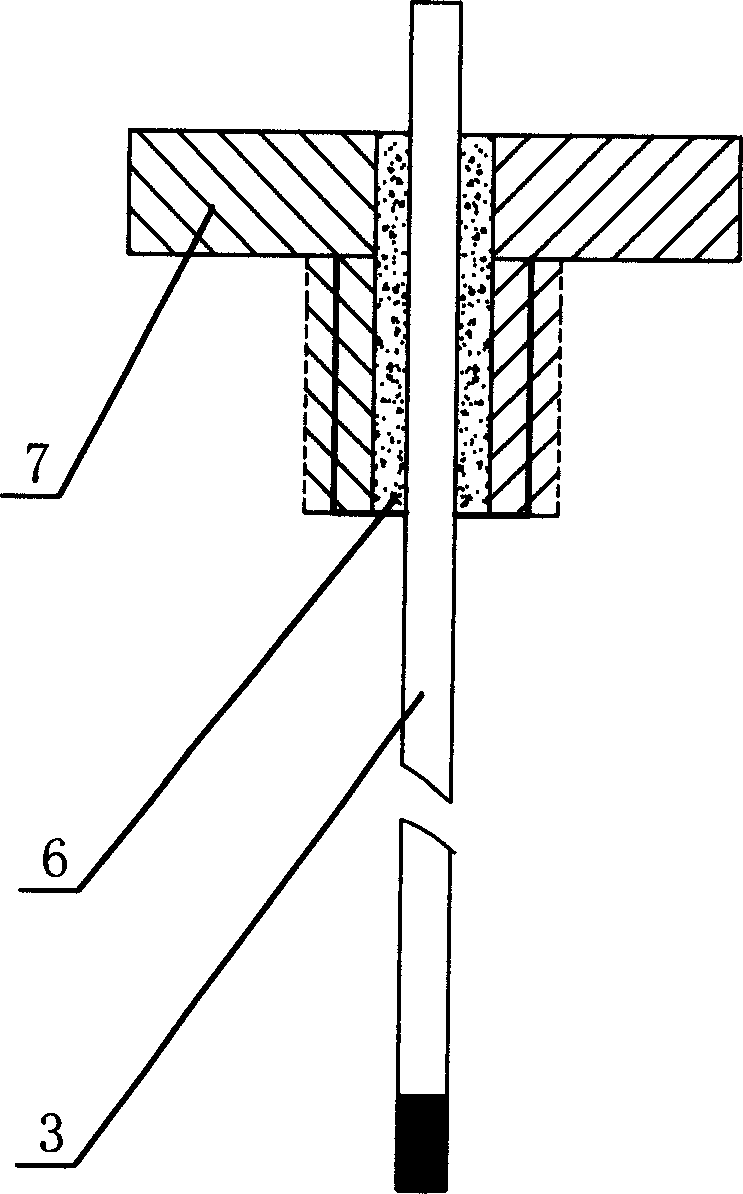

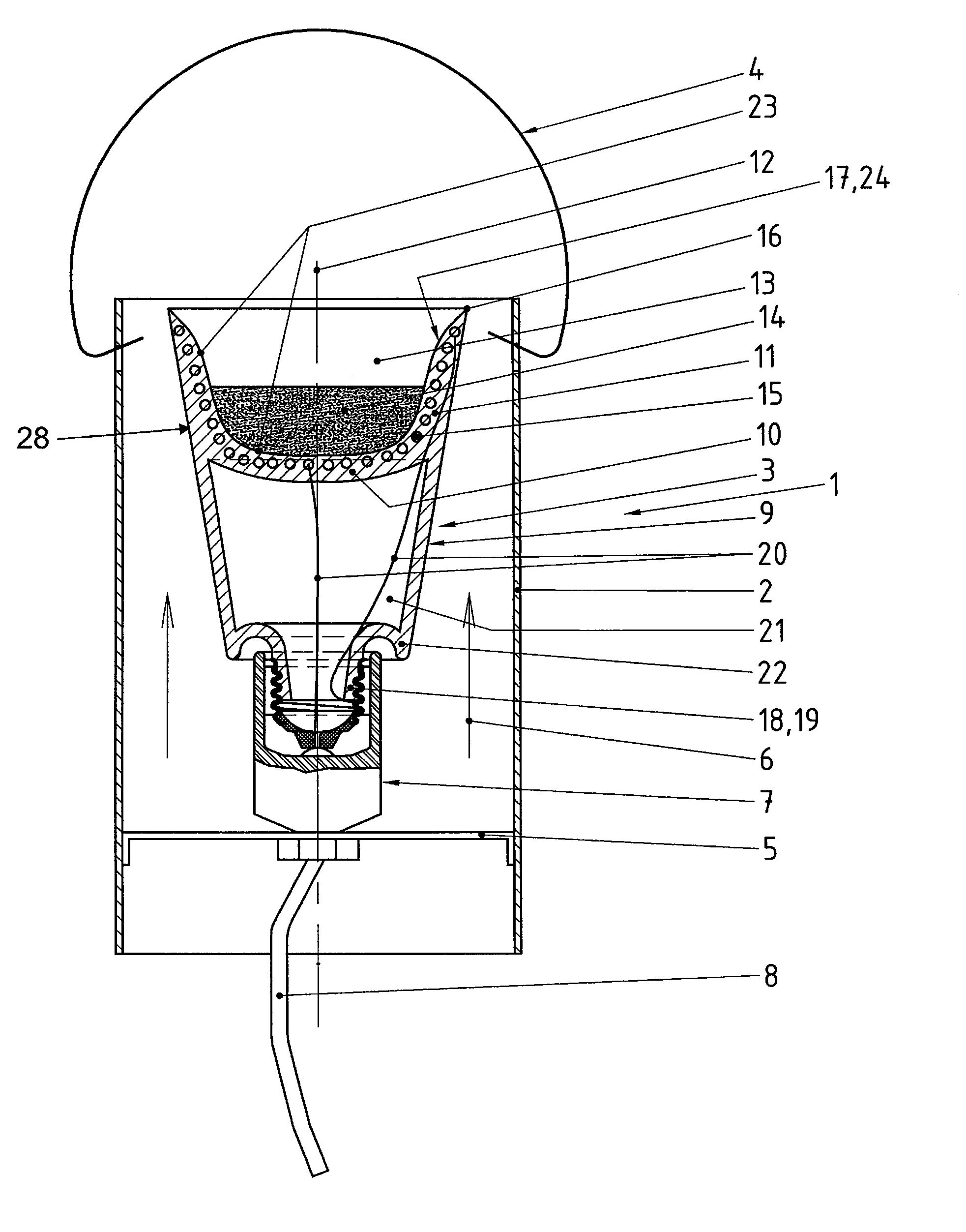

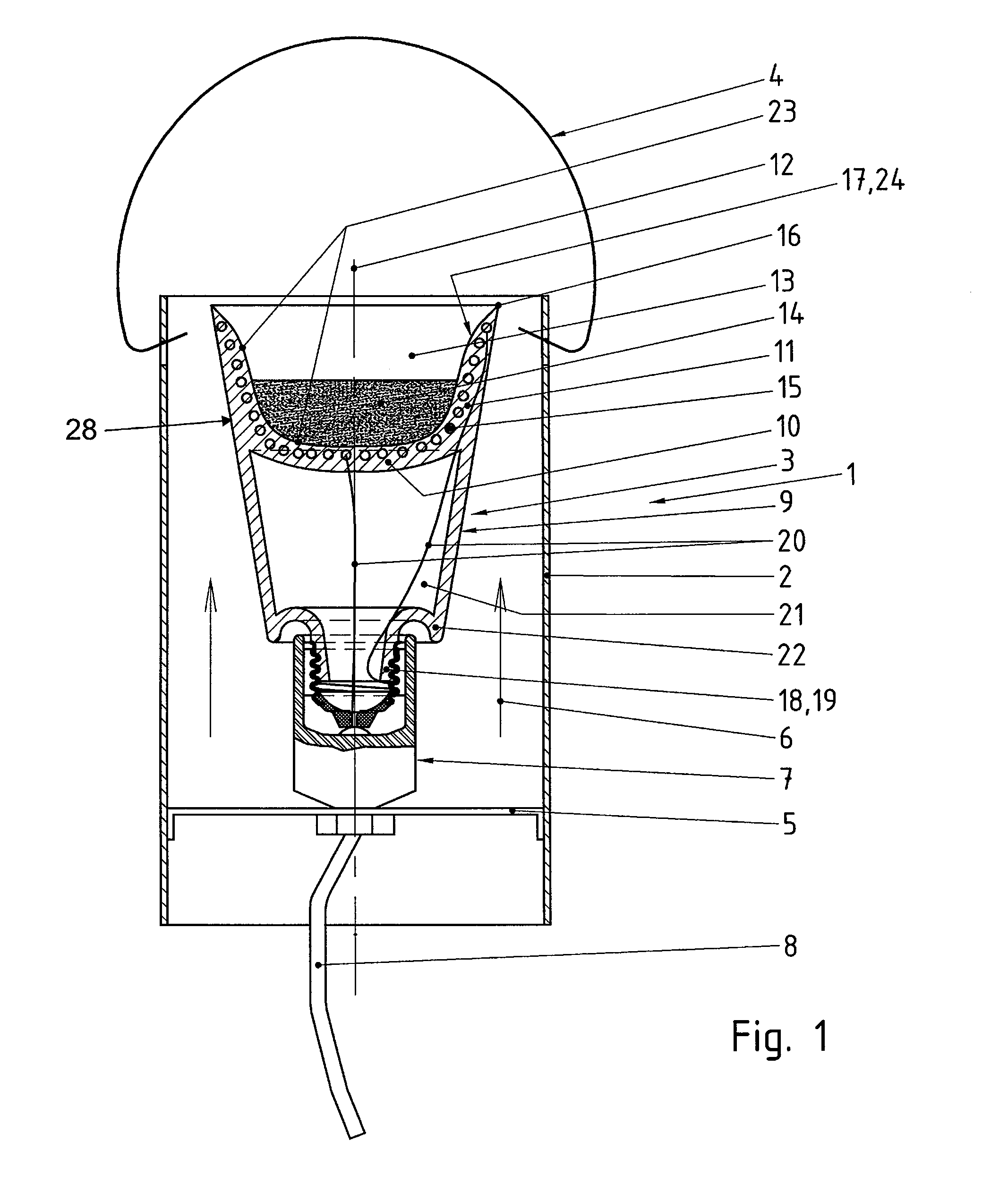

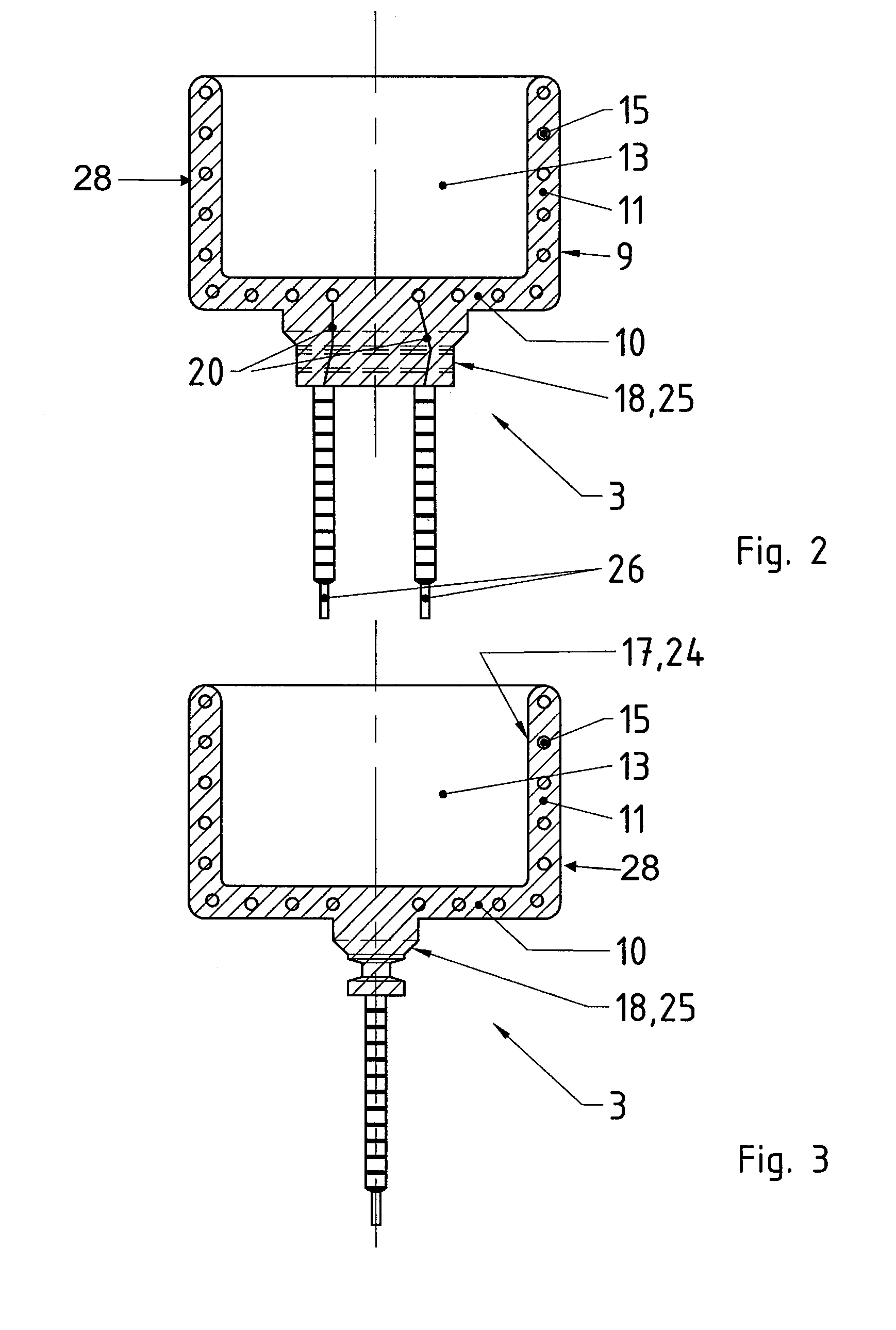

Sulfur Evaporator

InactiveUS20090007482A1Avoid enteringProtect the surfaceMachines/enginesGaseous substancesSulfurProcess engineering

A fumigation apparatus (1) includes a sulfur evaporator (3) including a heat source (28) and a container (9). The heat source (28) includes an electrically operated heating coil (15). The container (9) includes a wall (11) and an inner space (13). The inner space (13) is designed and arranged to store sulfur (14) to be evaporated therein. The container (9) substantially is made of ceramic material. The heat source (28) and the container (9) are designed as one common structural unit. The heating coil (15) at least partly is arranged in the wall (11) of the container (9) such that it is embedded in the ceramic material.

Owner:ELSTEIN WERK M STEINMETZ

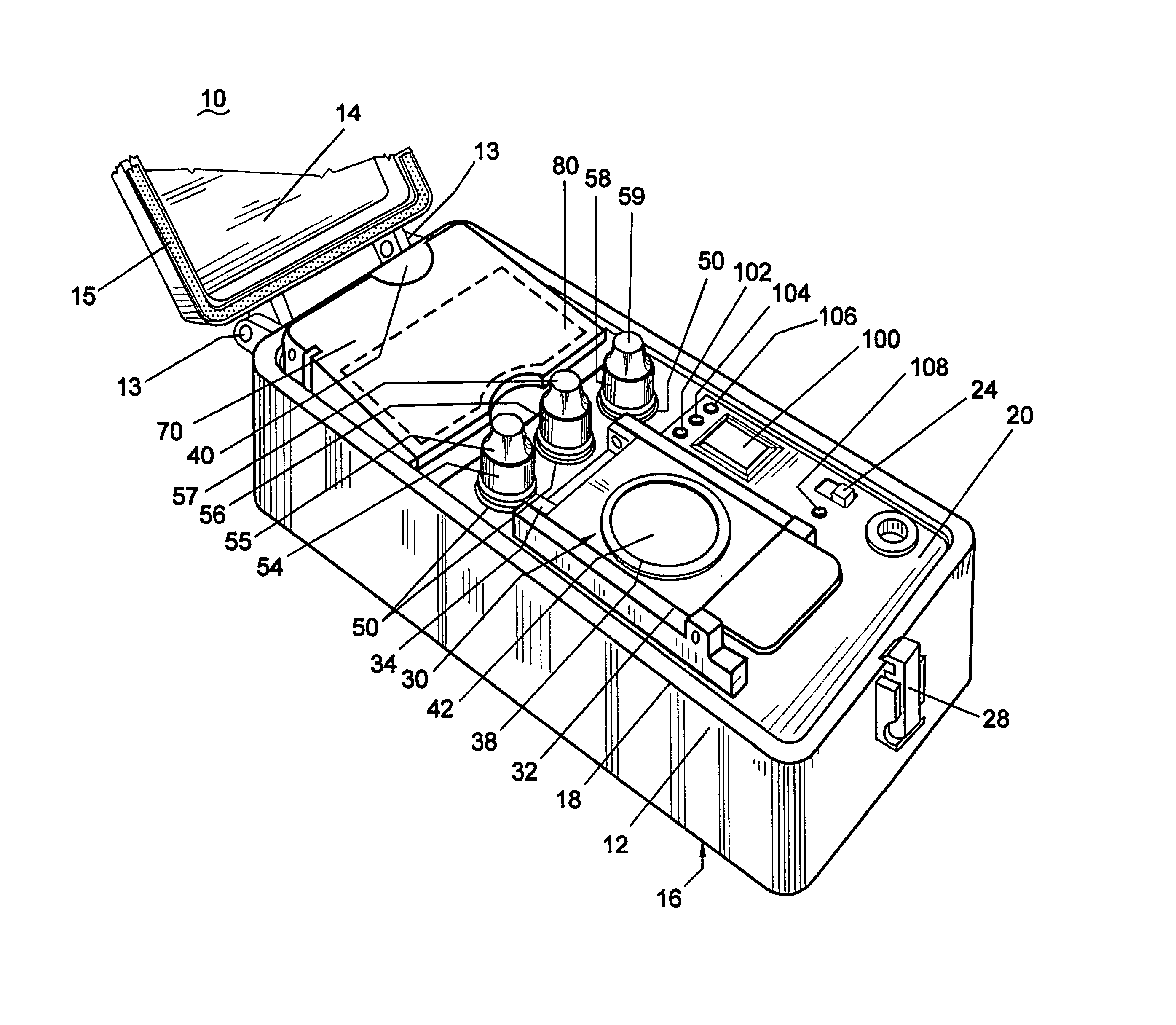

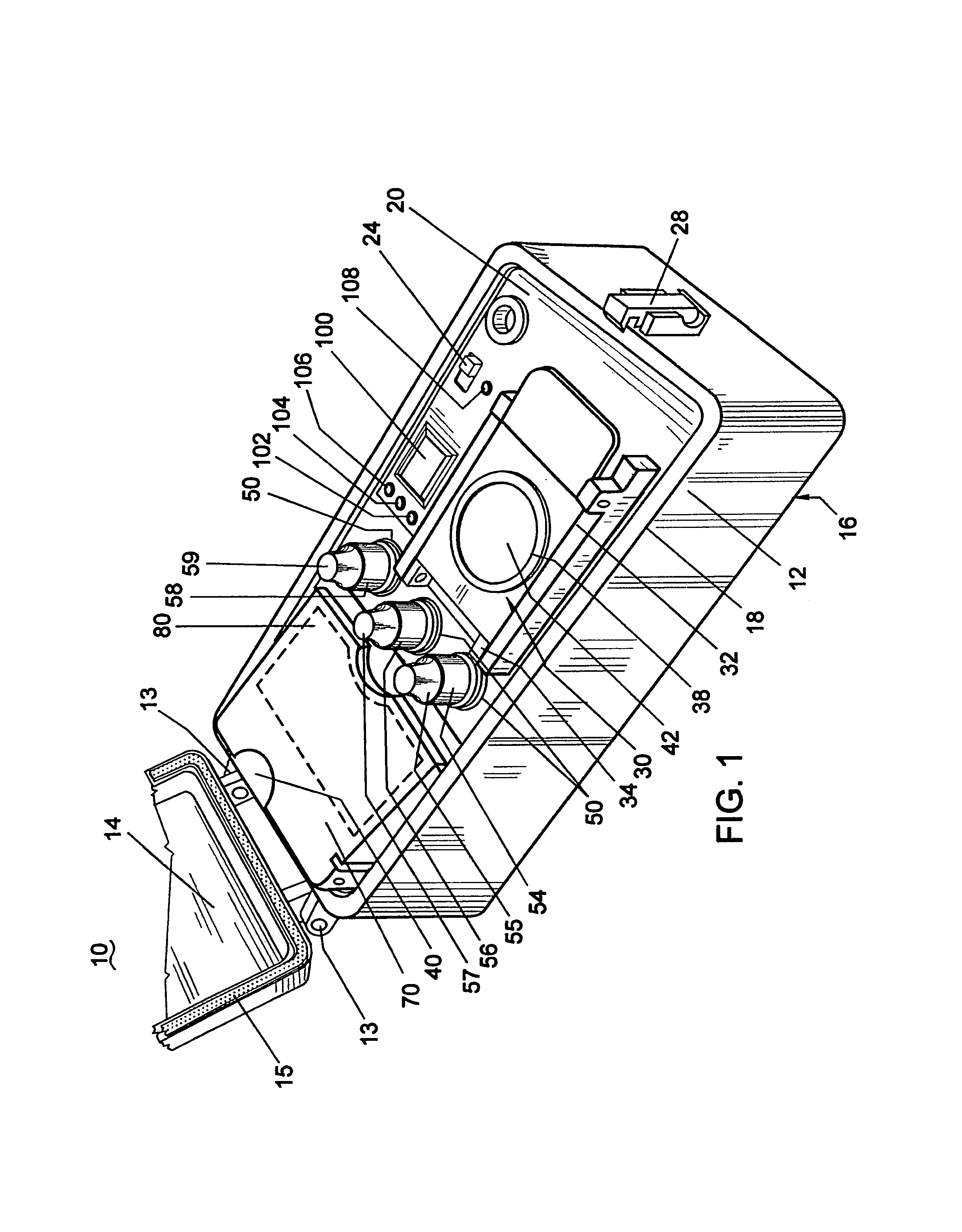

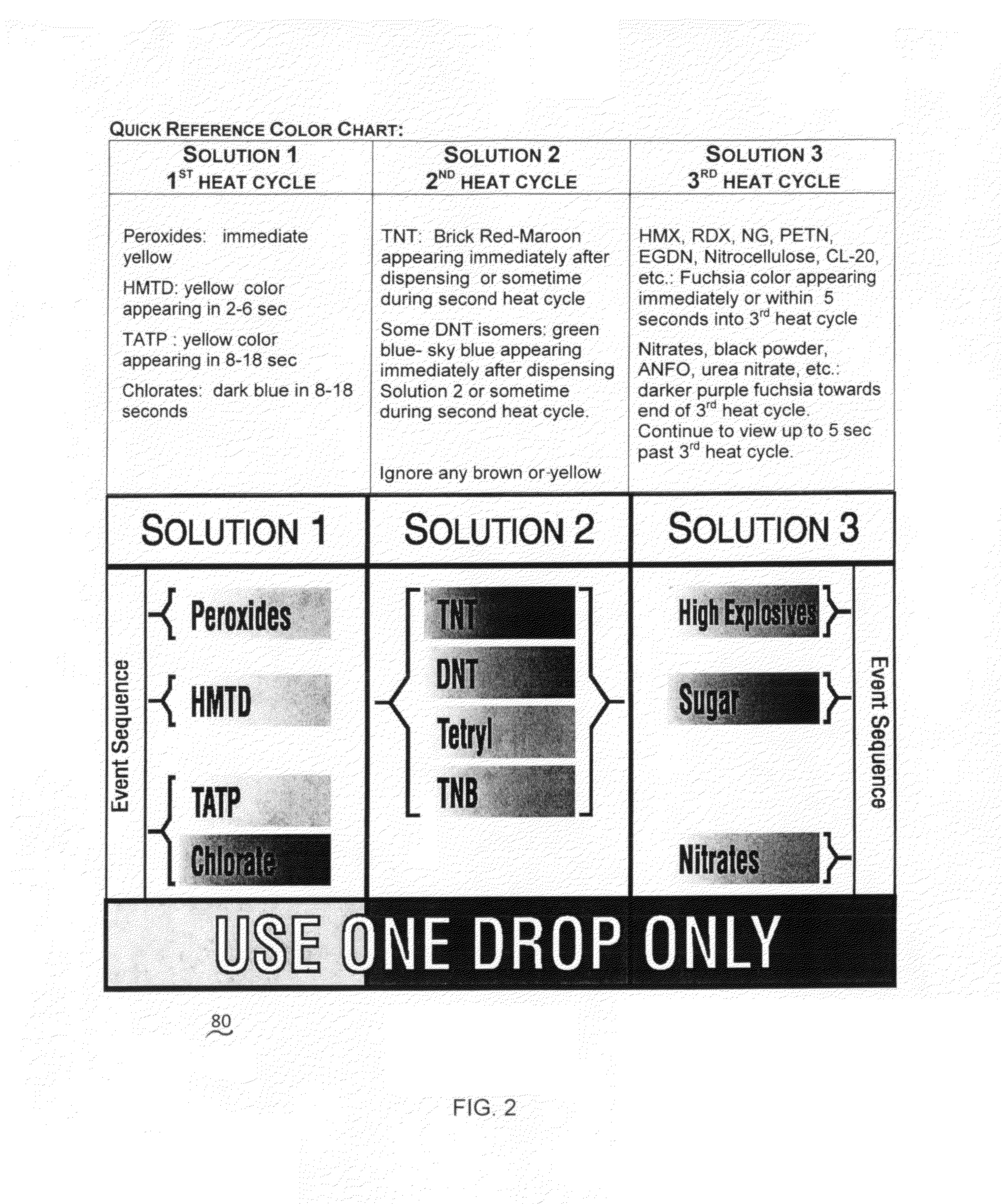

Method and system for explosive detection

InactiveUS8969095B1Optical radiation measurementMicrobiological testing/measurementControl mannerTest sample

The present invention is directed to methods and systems for detecting the presence of explosive elements. A sample element may be used to swipe an object for a test sample. The sample element may be positioned in a sample holder of a testing device having a heater. The heater may be programmed to heat the sample element and sample in a controlled manner through two or three temperature increases from approximately 35 degrees to 165 degrees centigrade in approximately 40 seconds. Prior to each temperature increase a first, second and third reagent fluid is applied to the sample holder, and during the temperature rise the sample holder is observed for the presence of various explosive elements by detecting colors as compared to a color chart. The color observations may be based on time and temperature variations using a testing device.

Owner:HAAS JEFFERY S

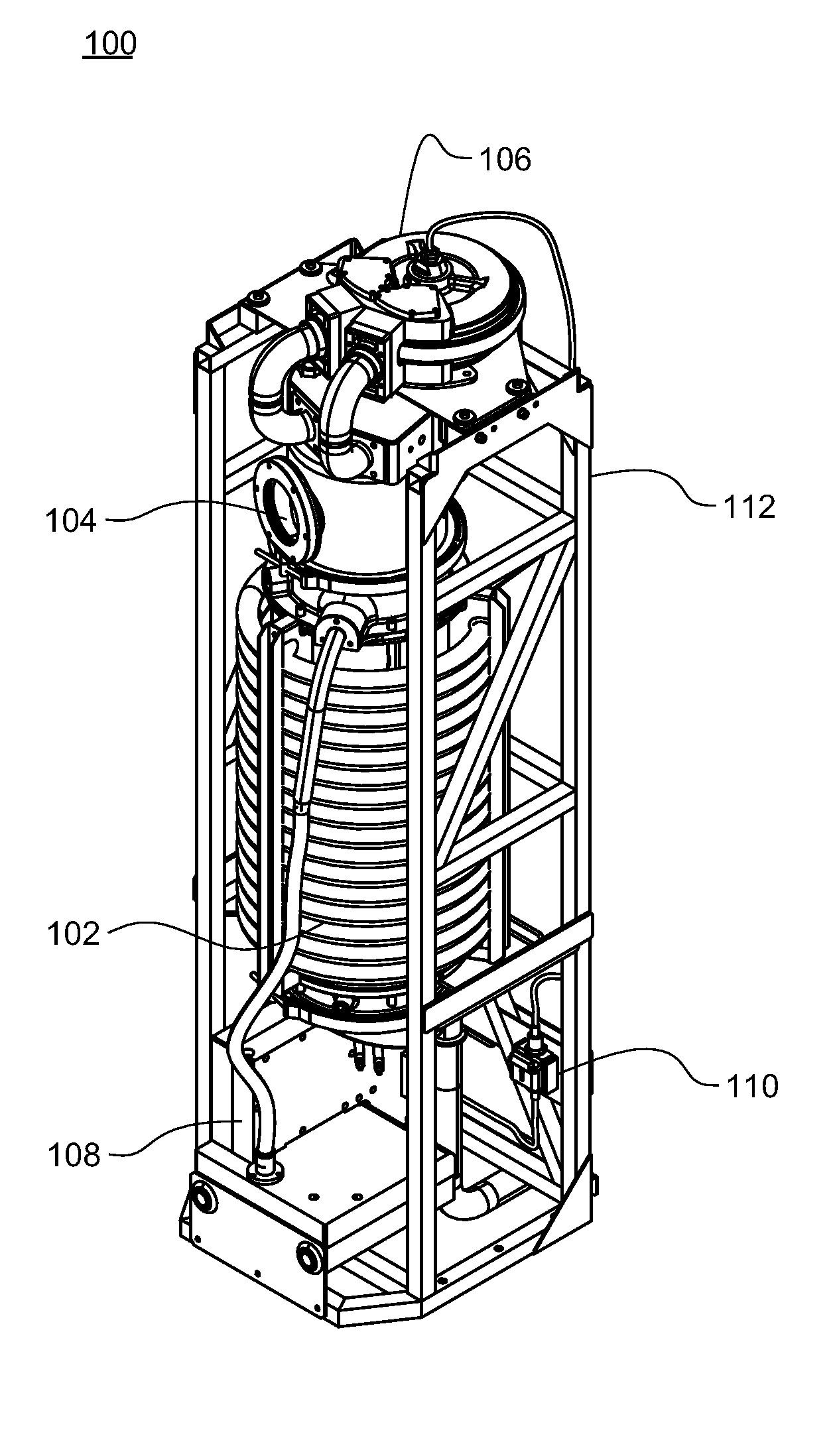

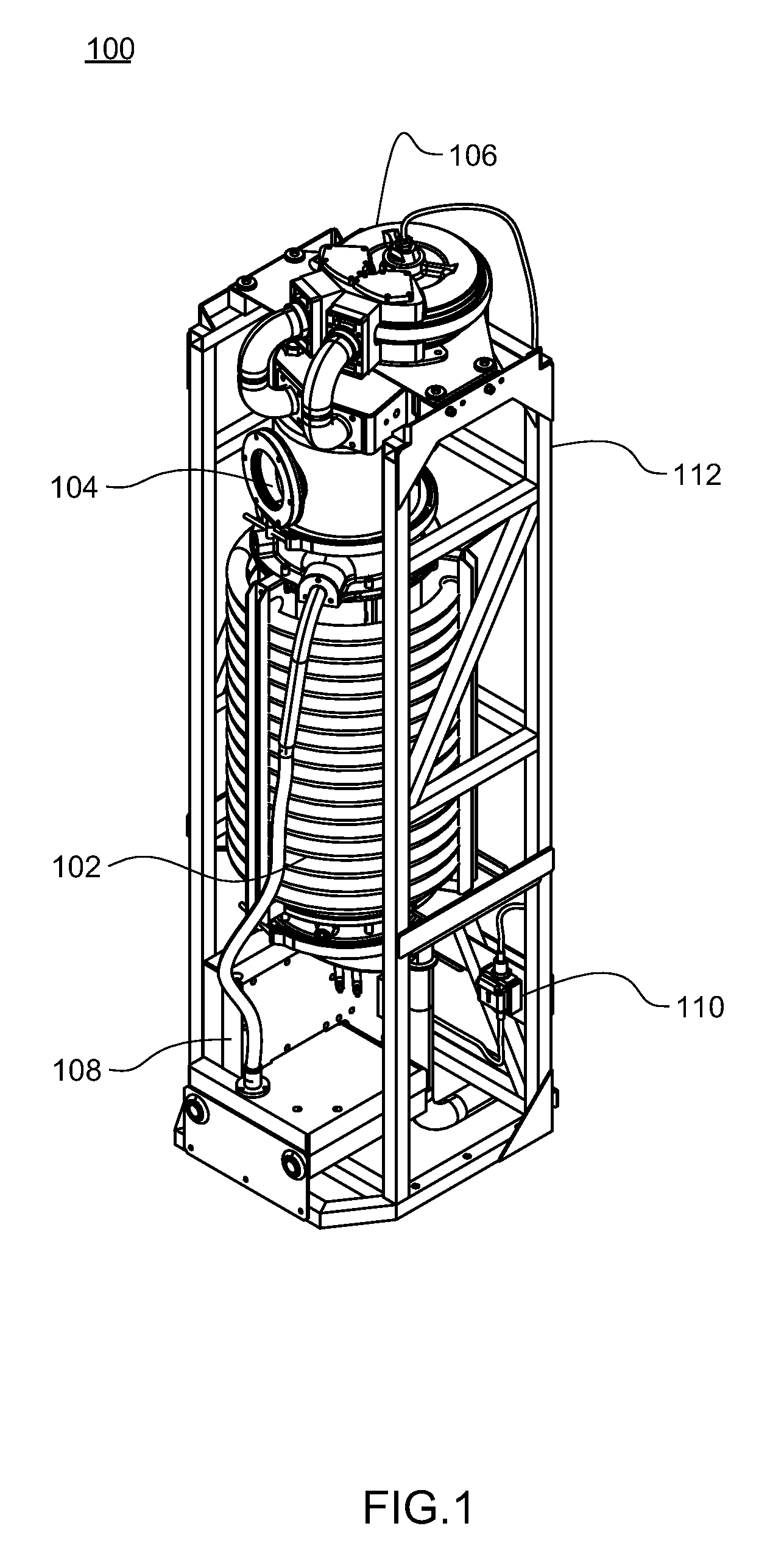

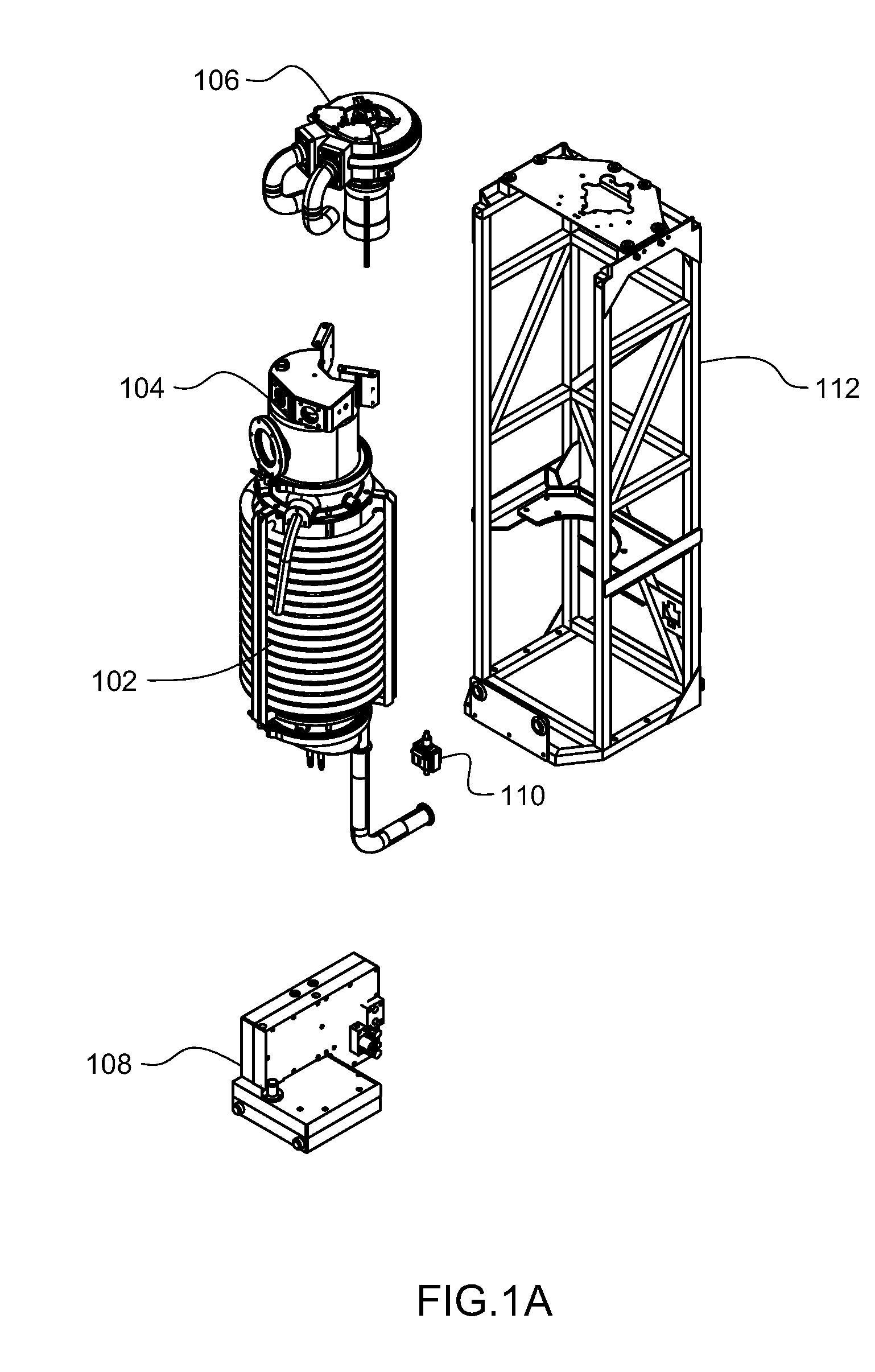

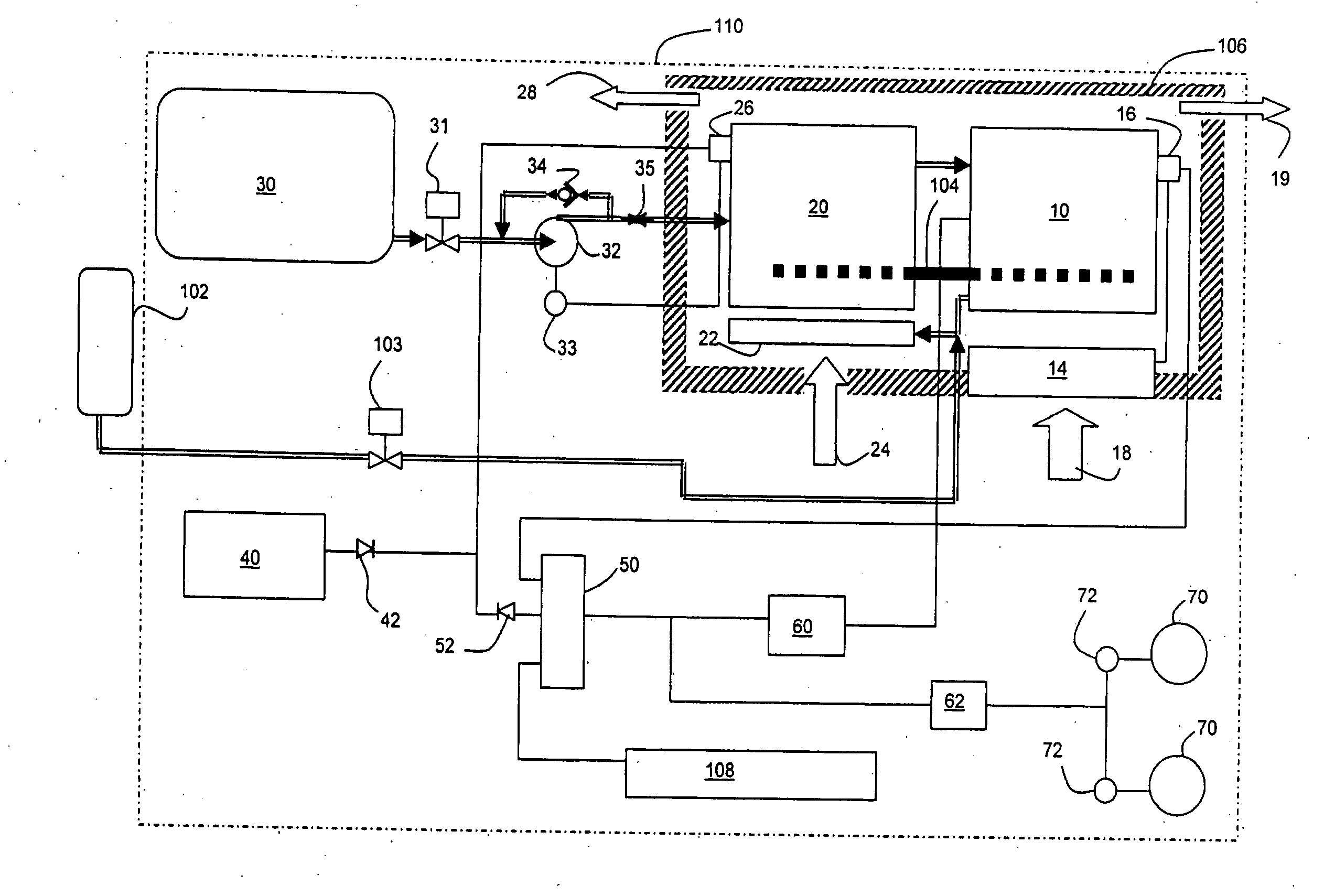

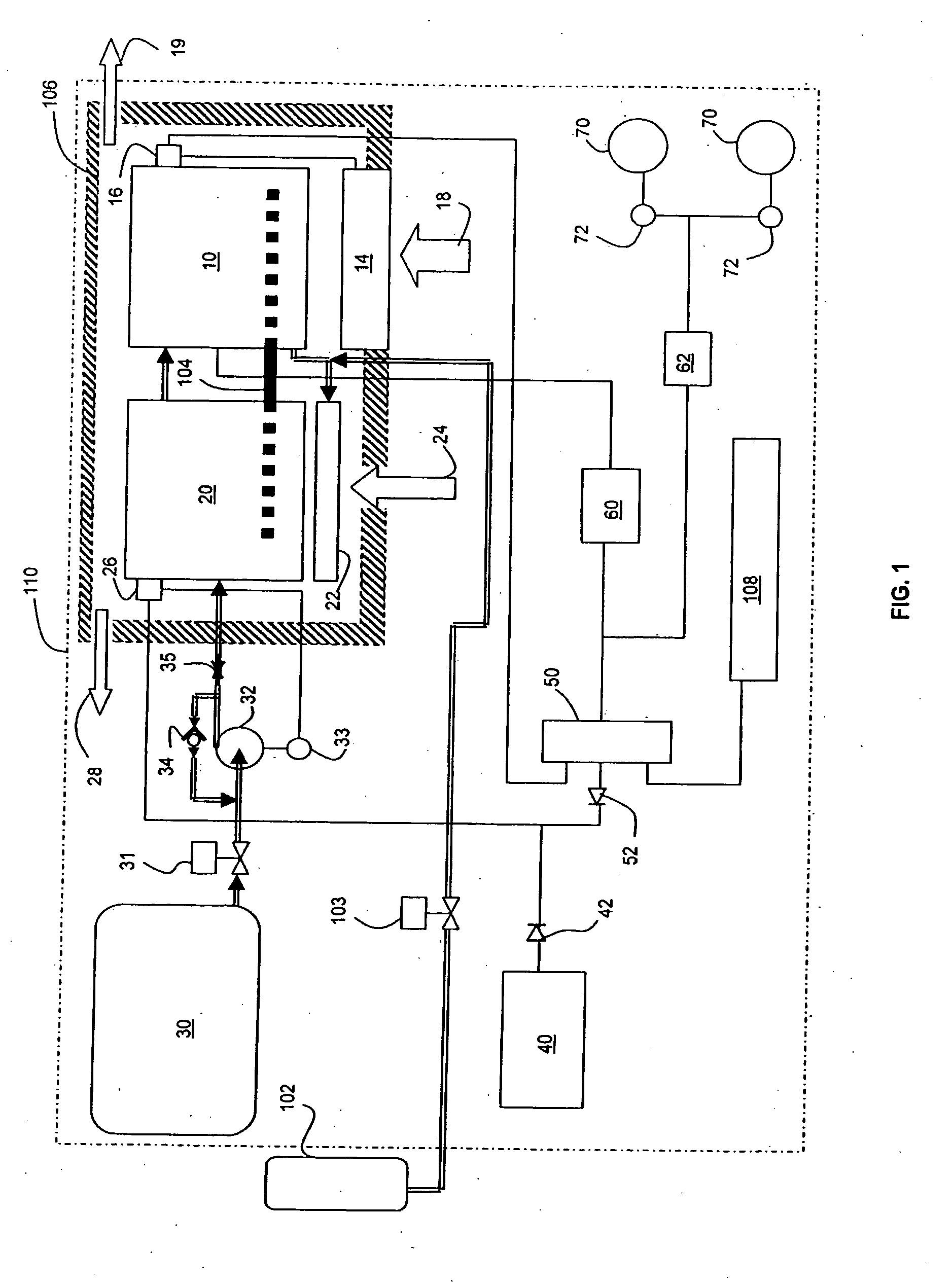

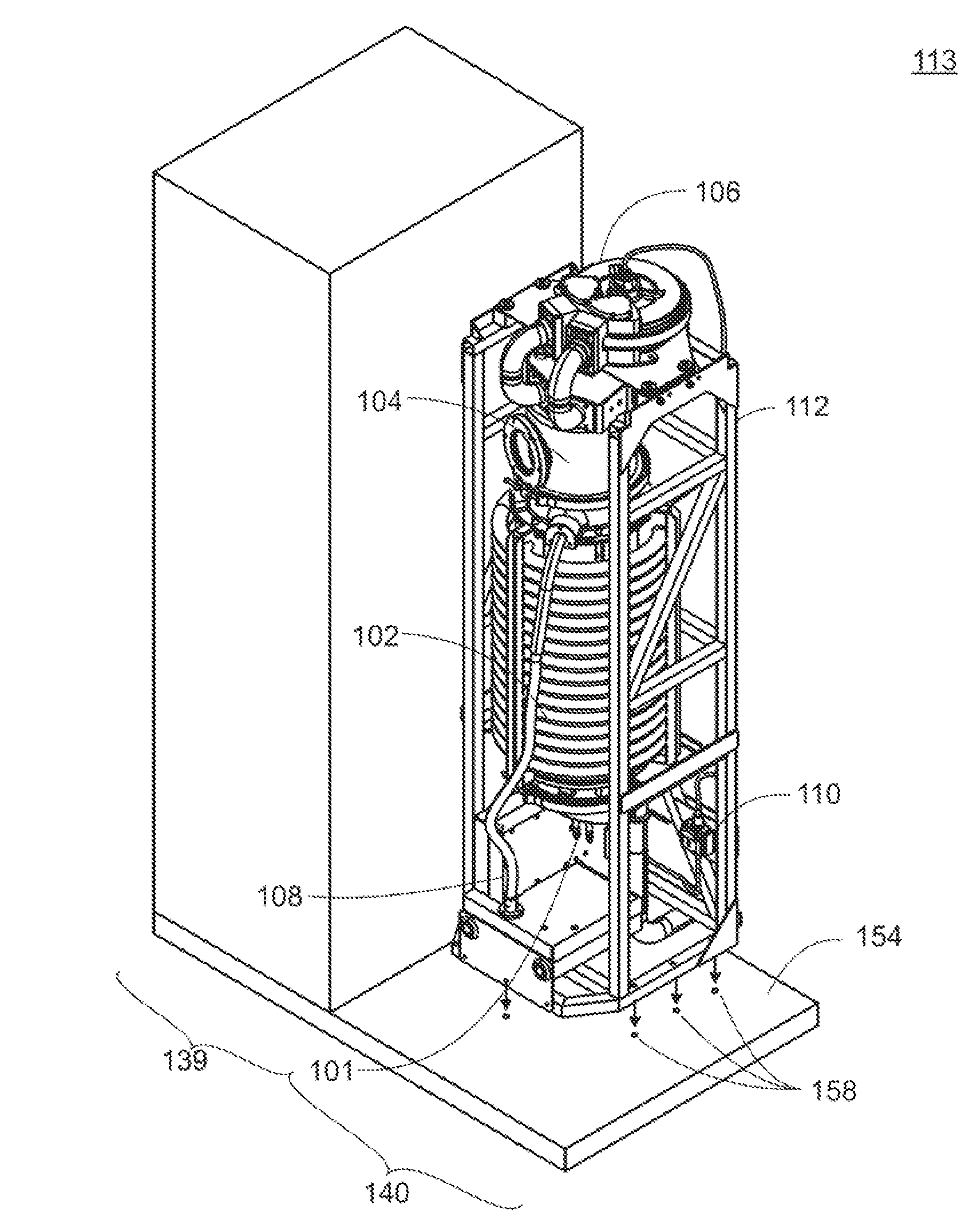

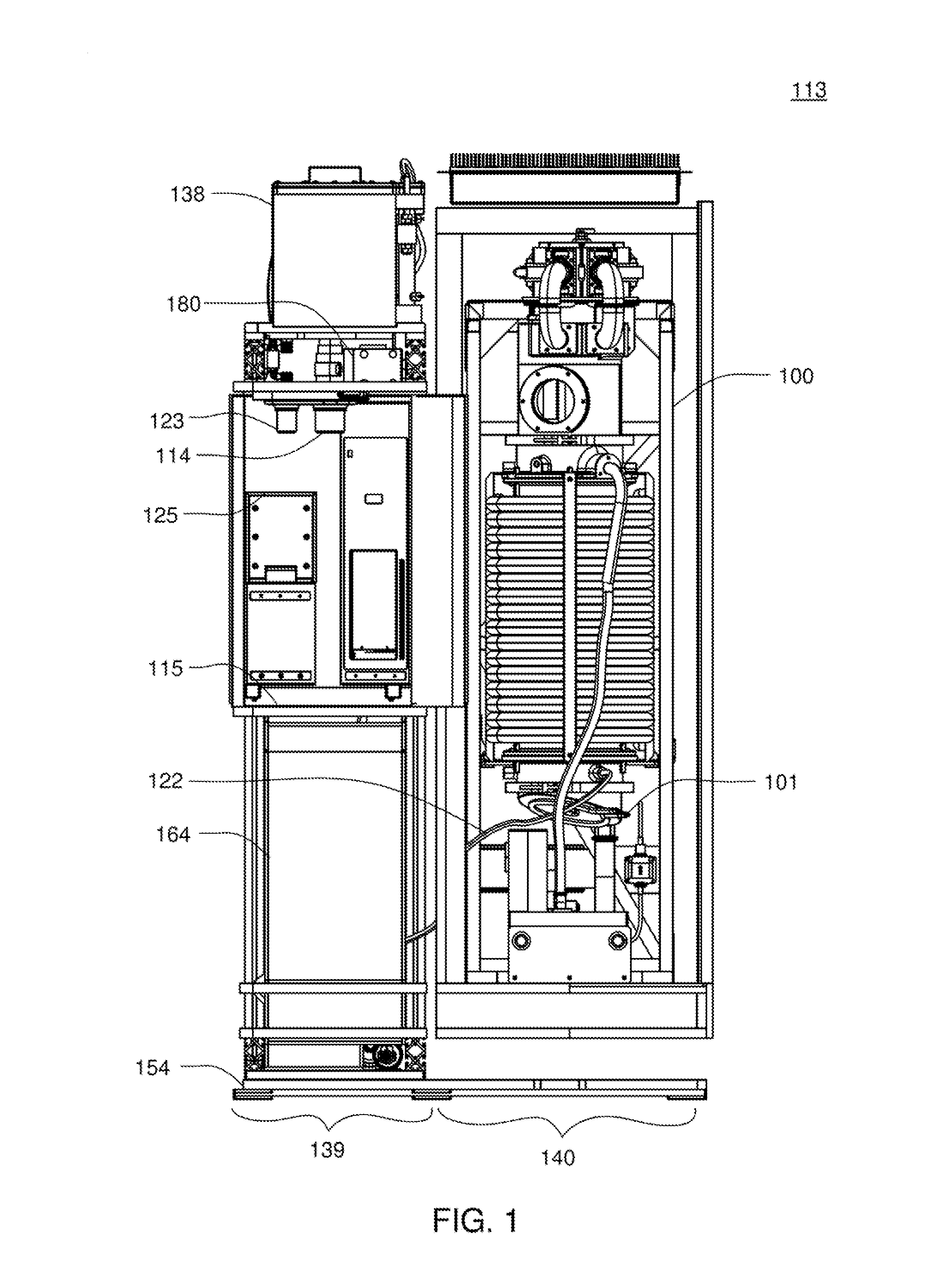

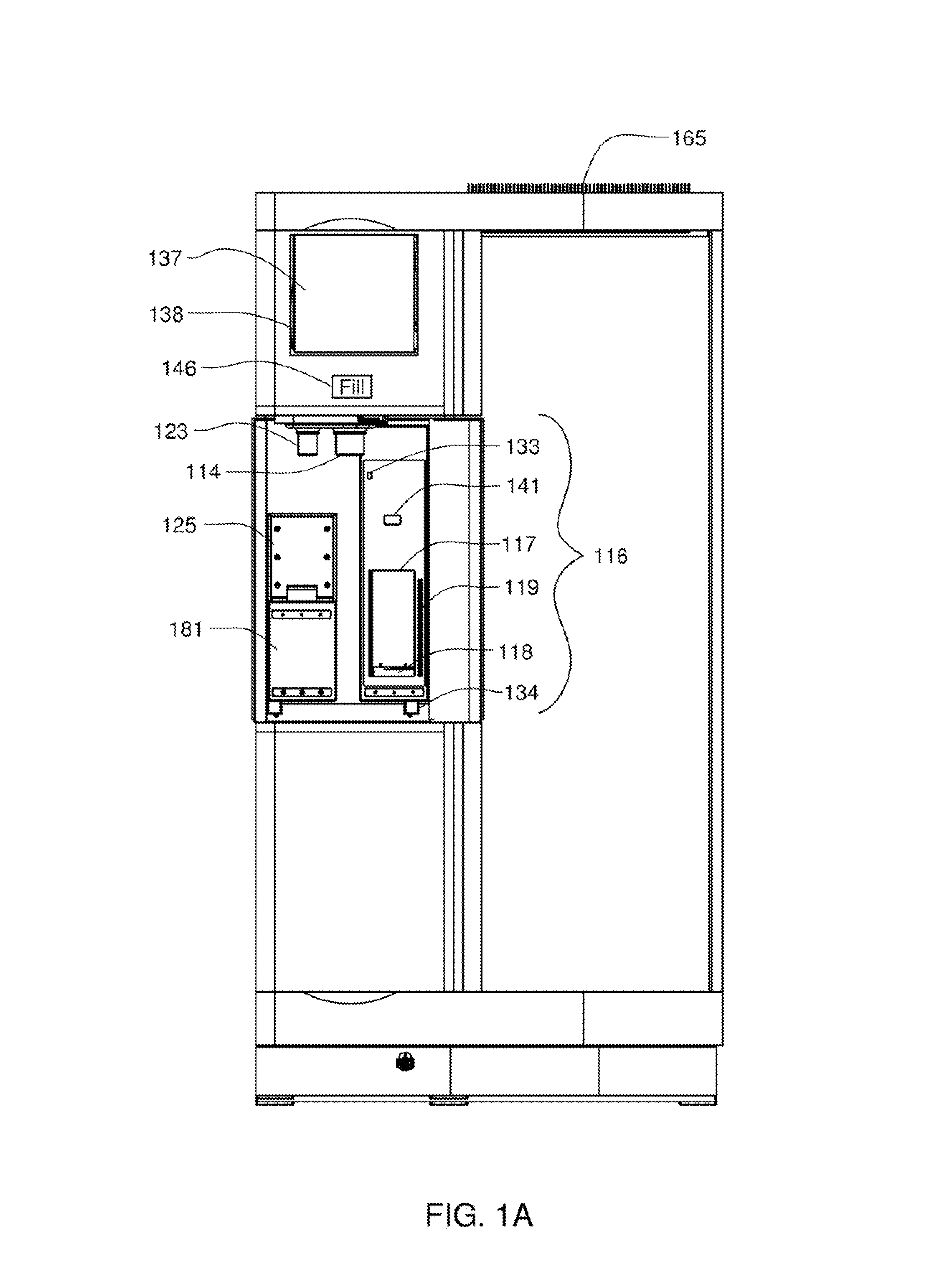

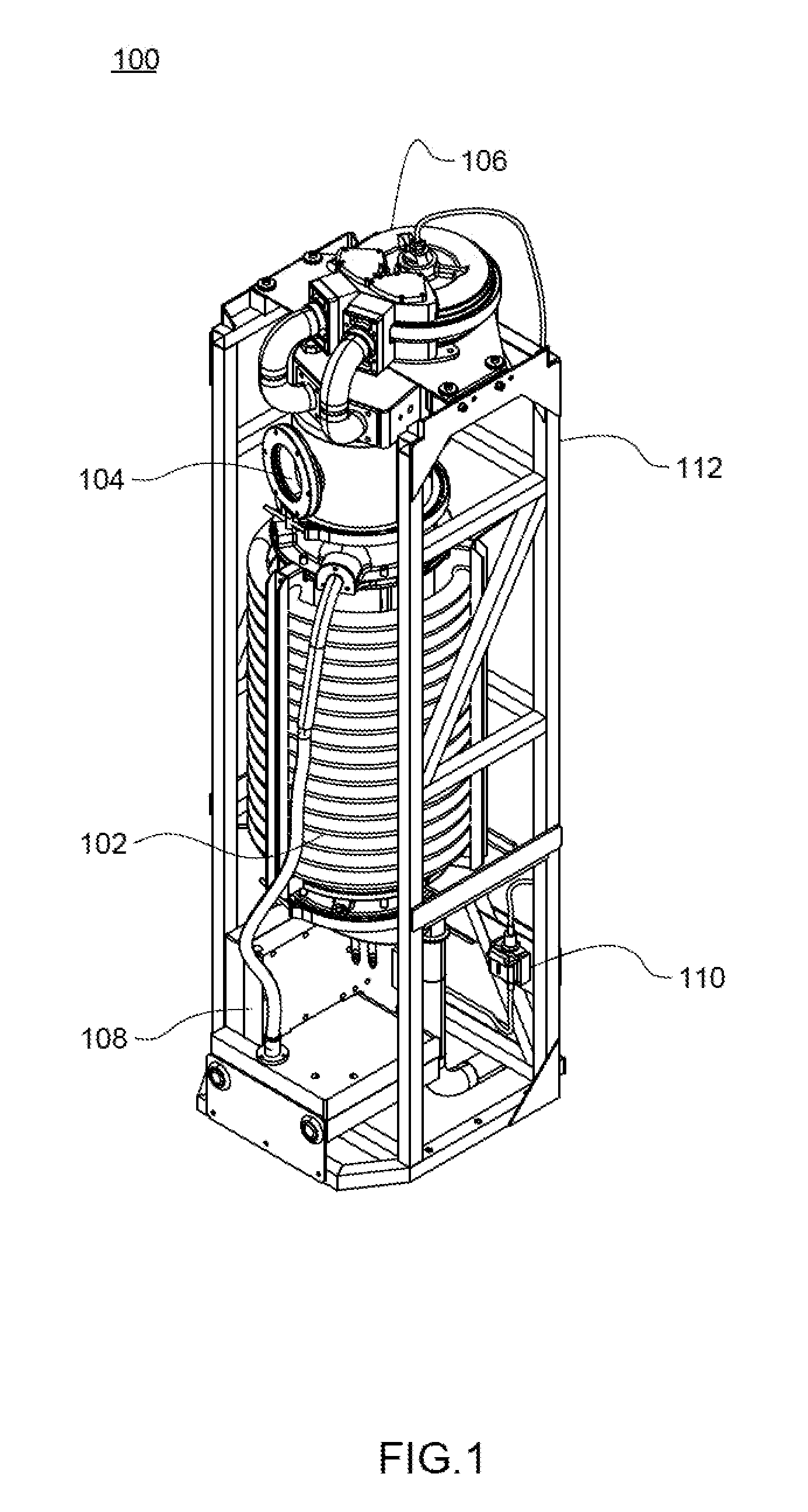

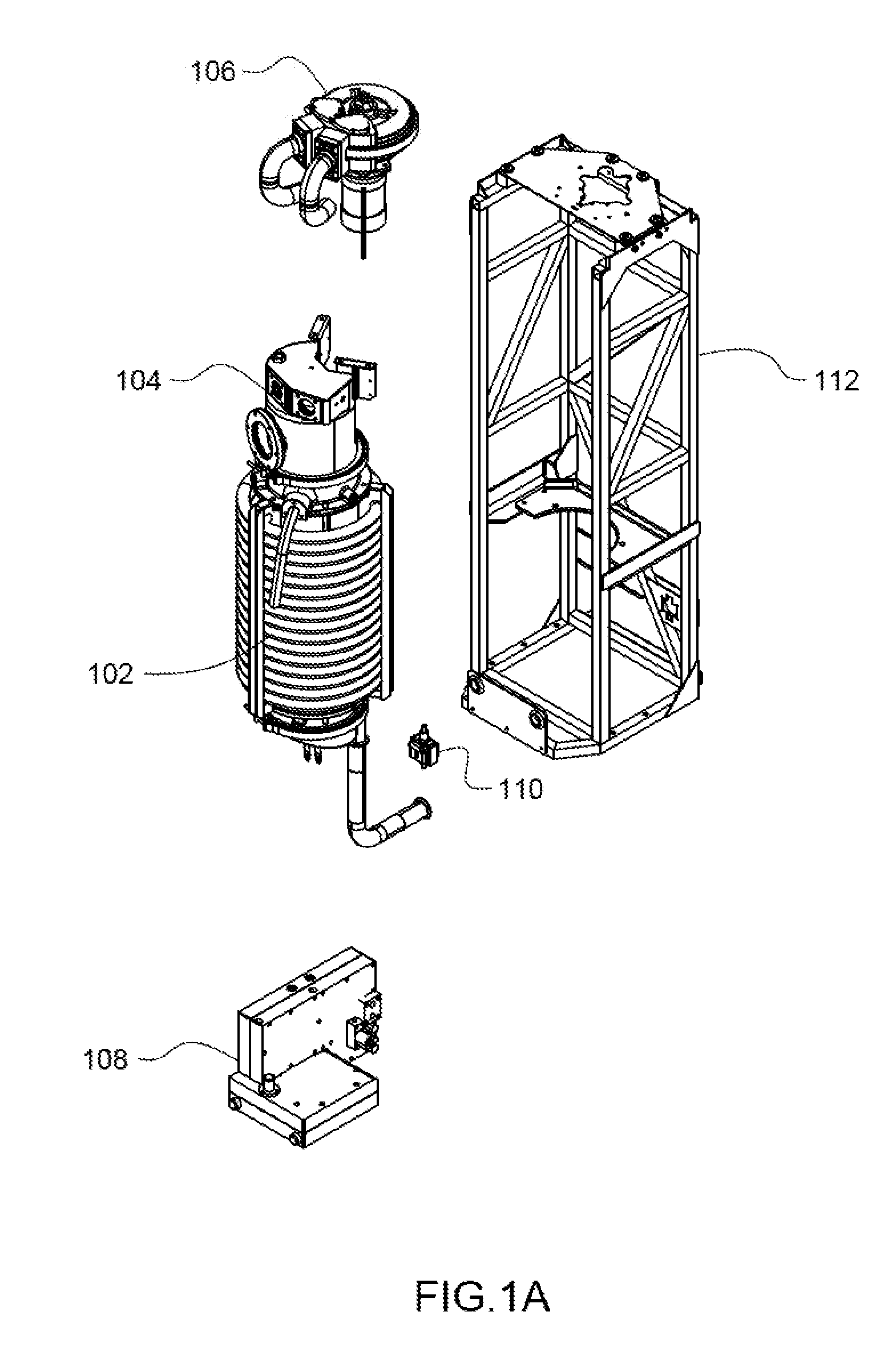

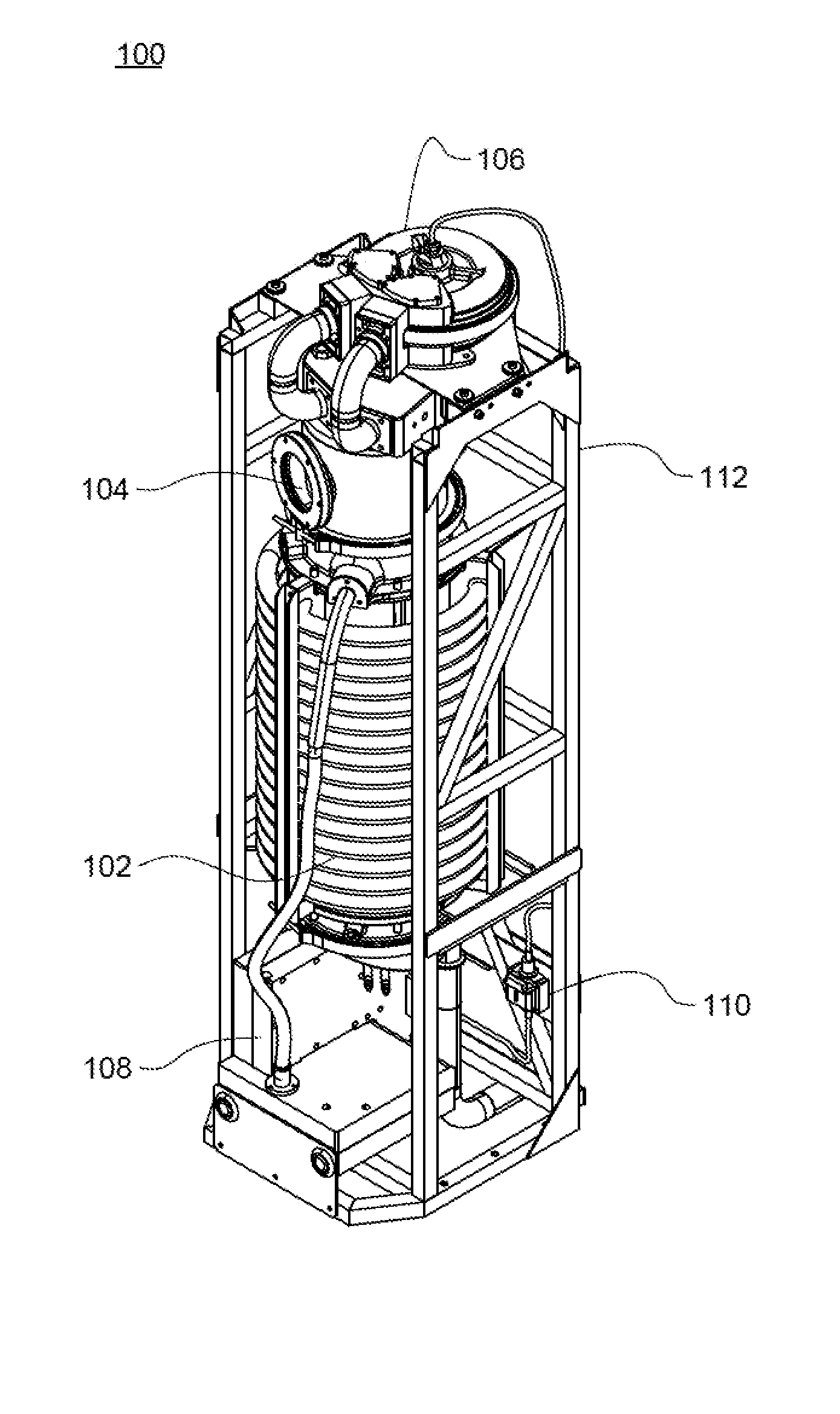

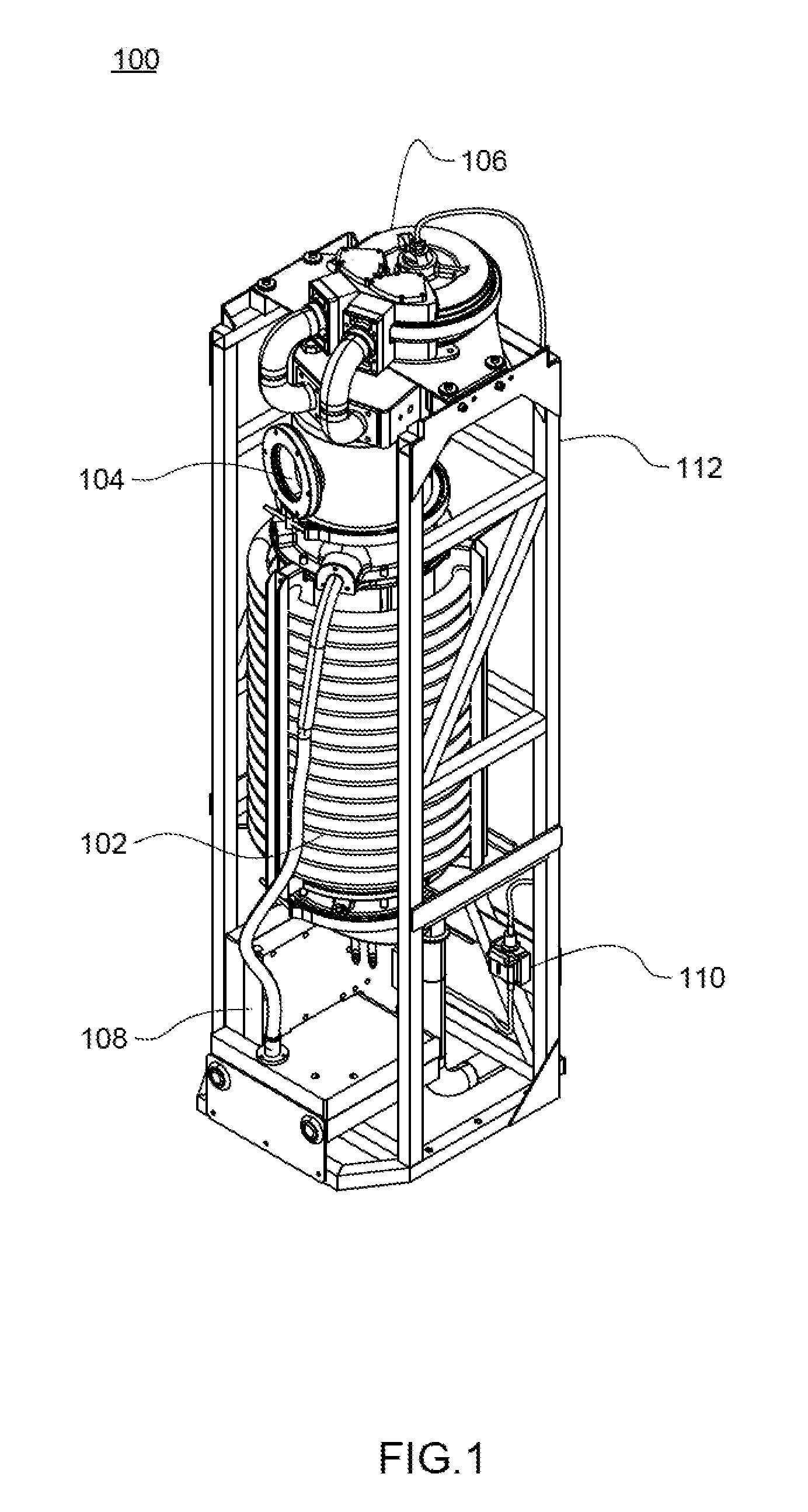

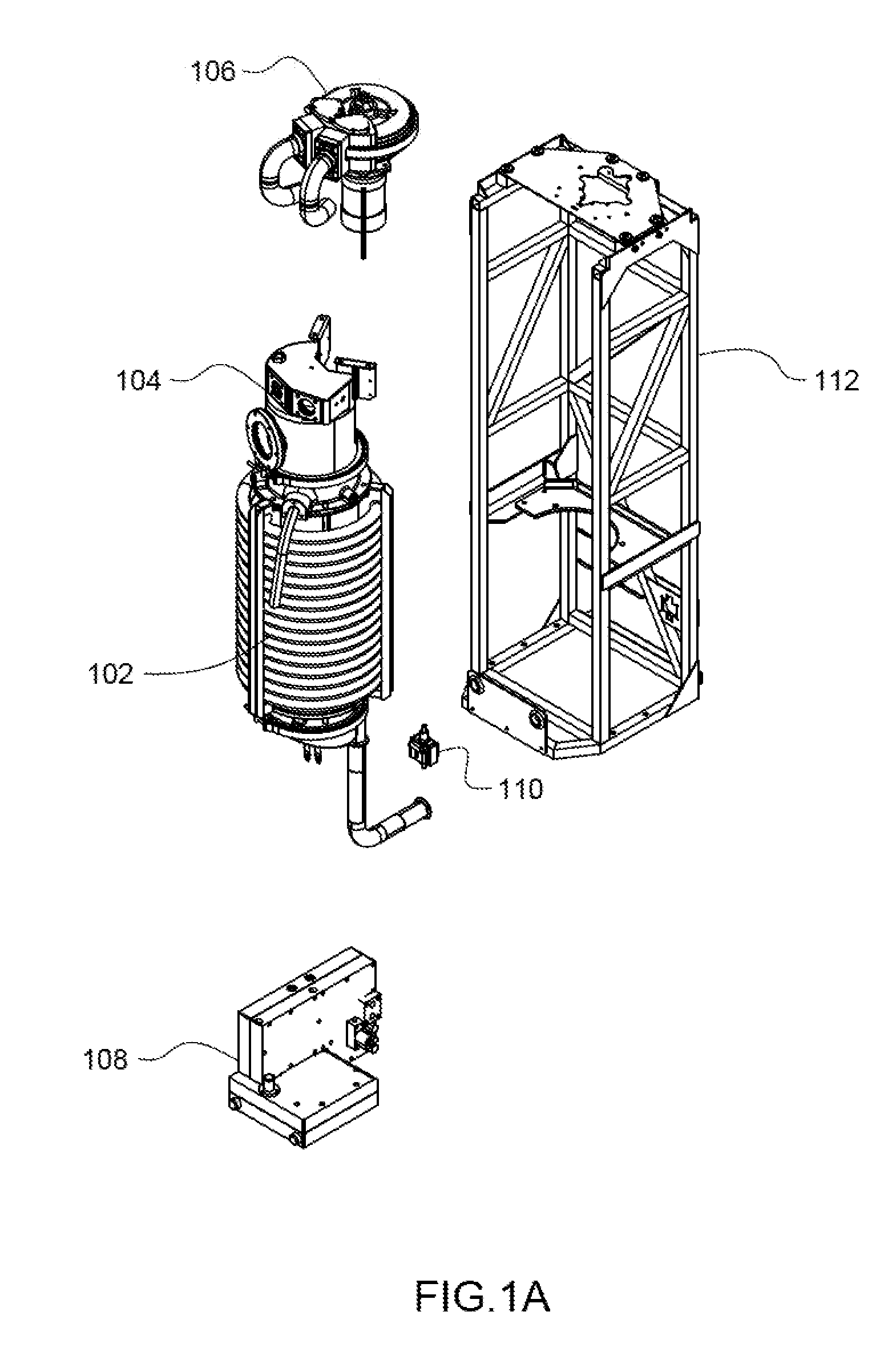

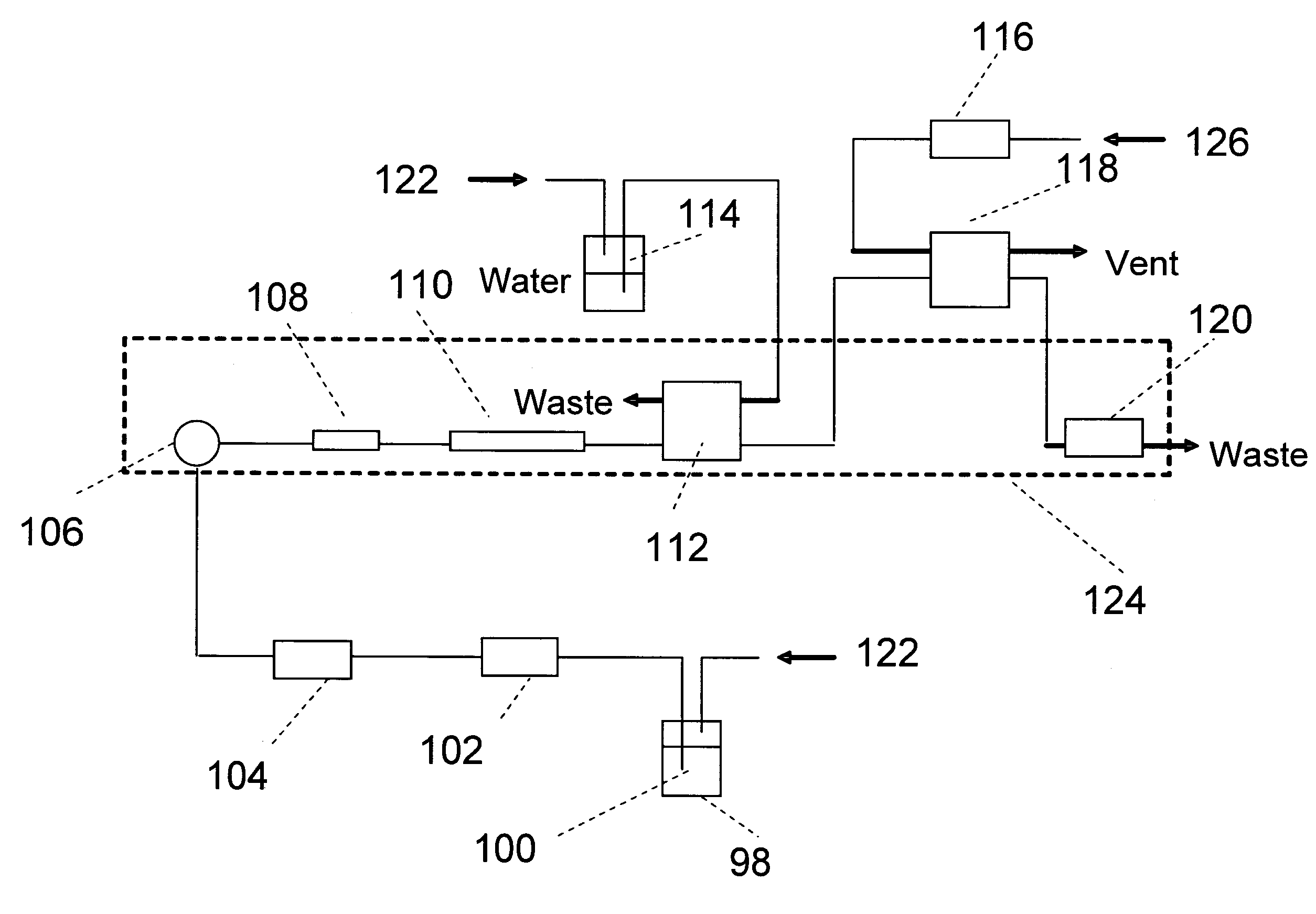

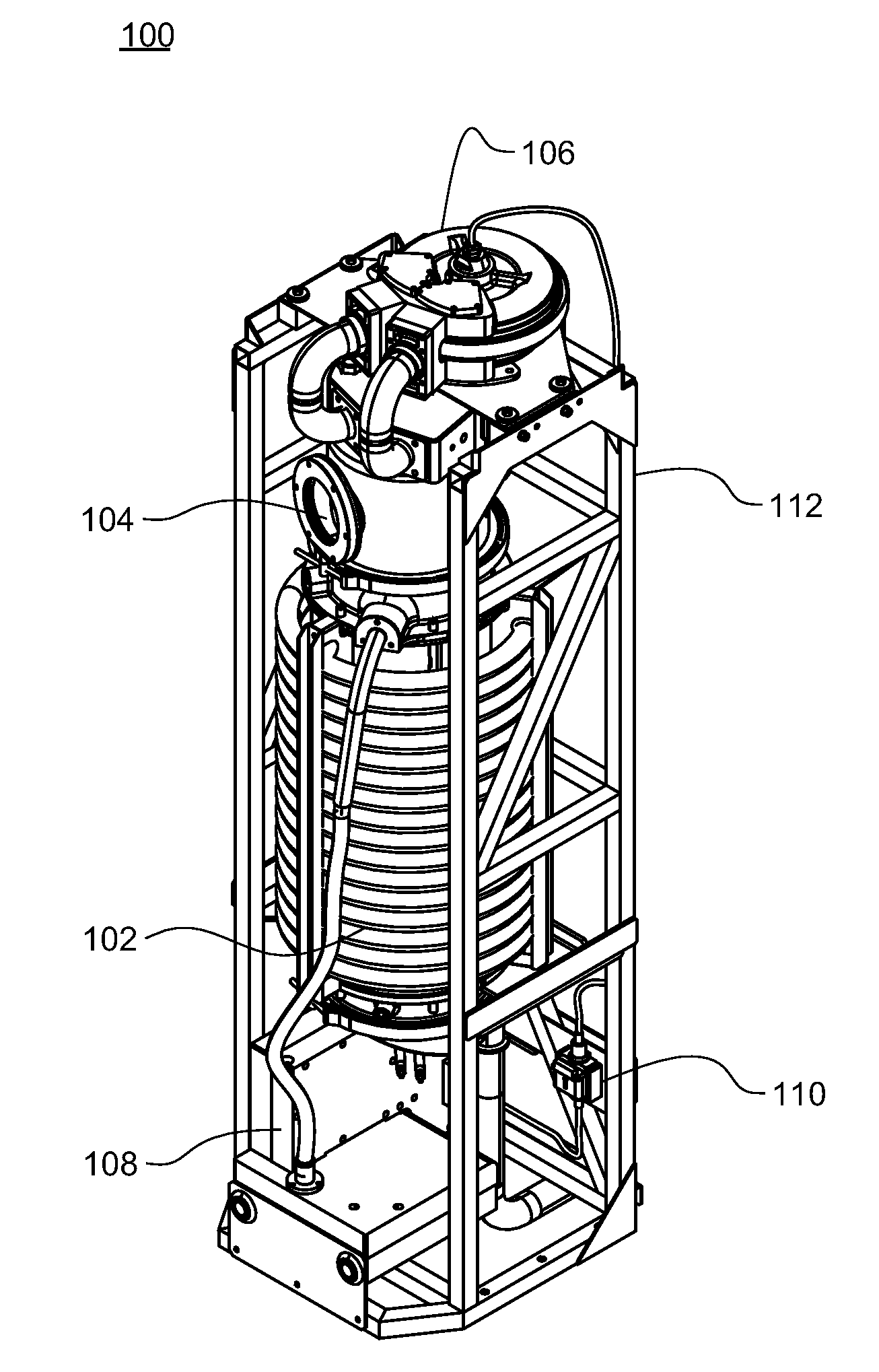

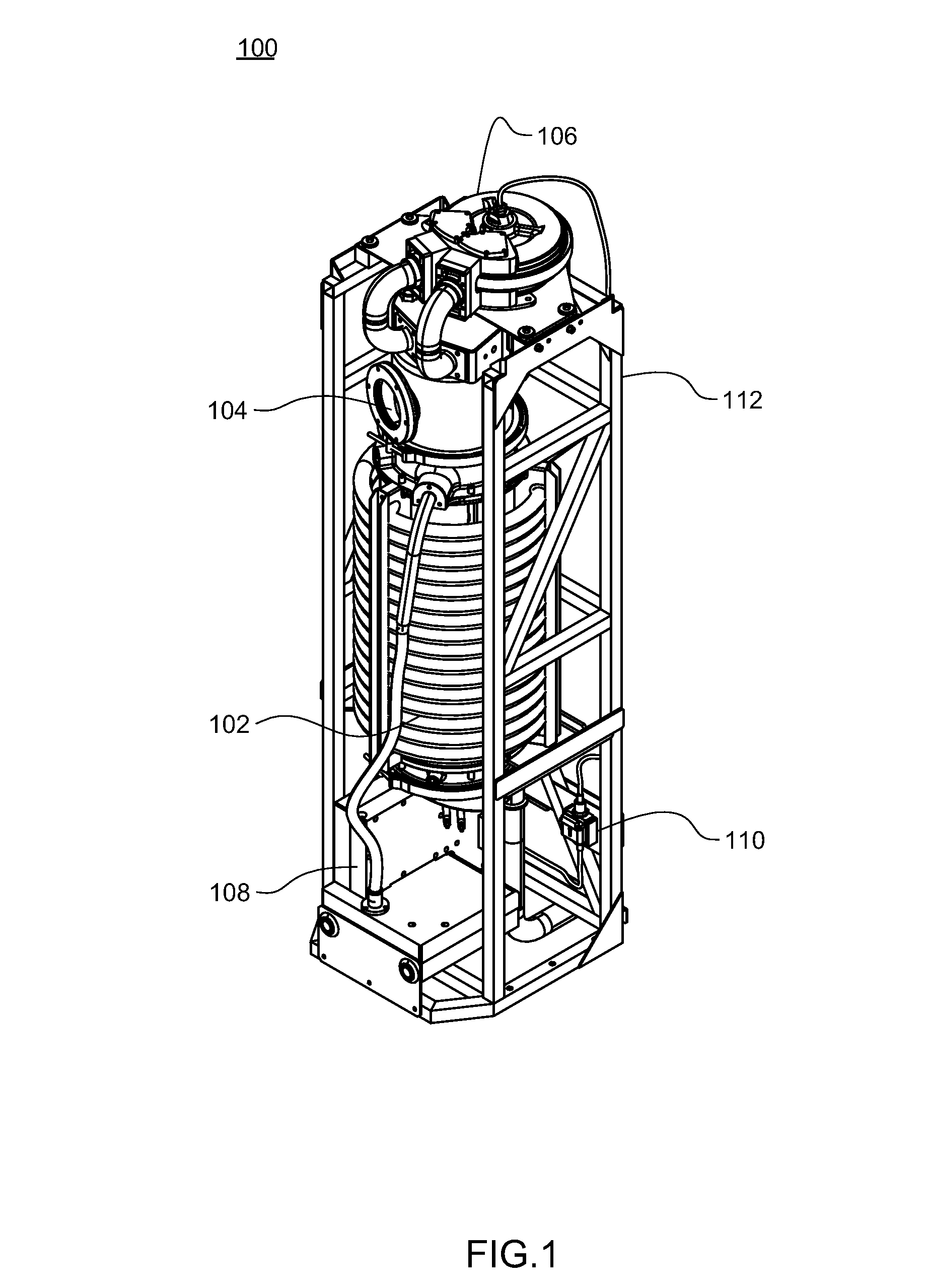

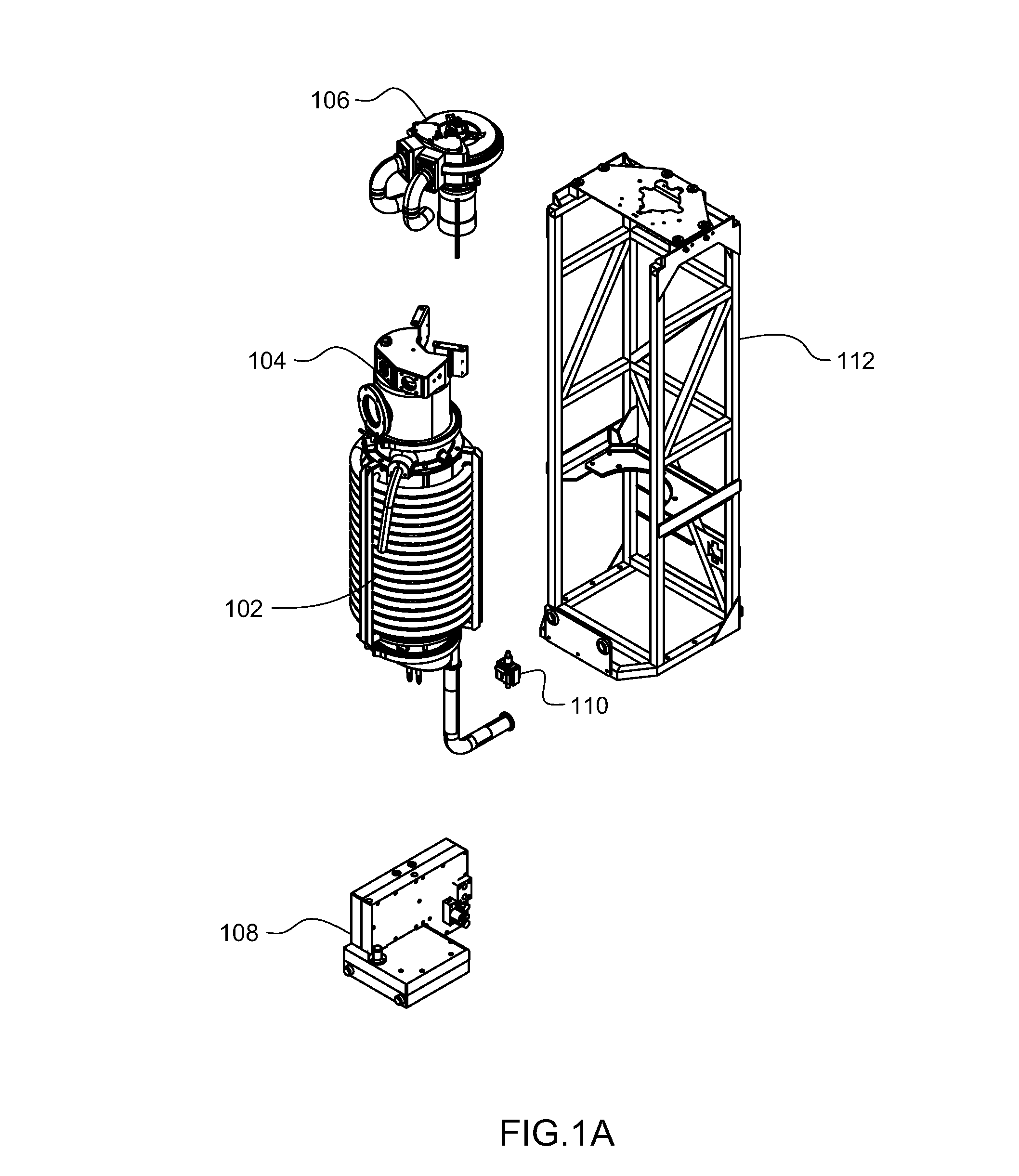

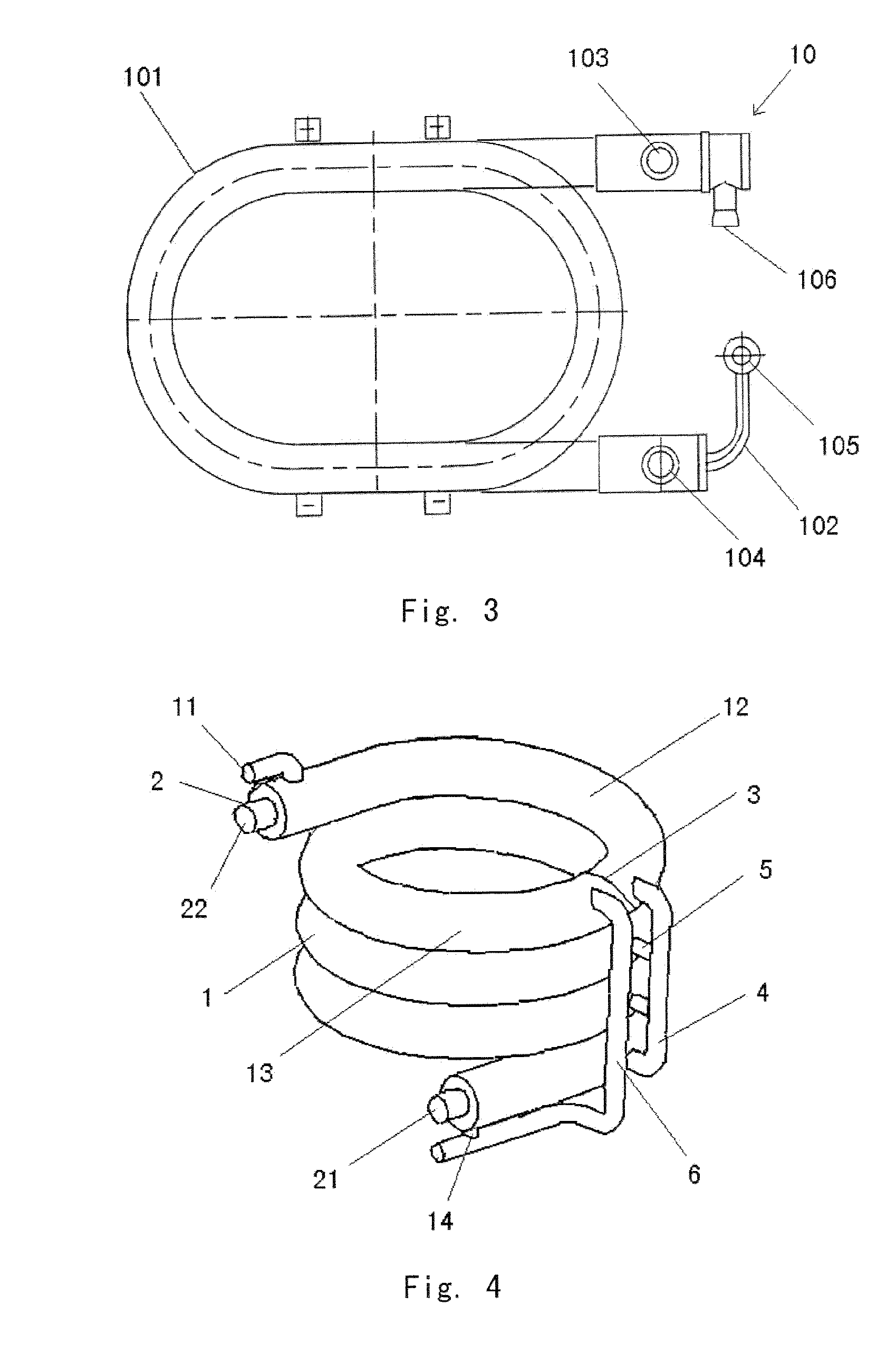

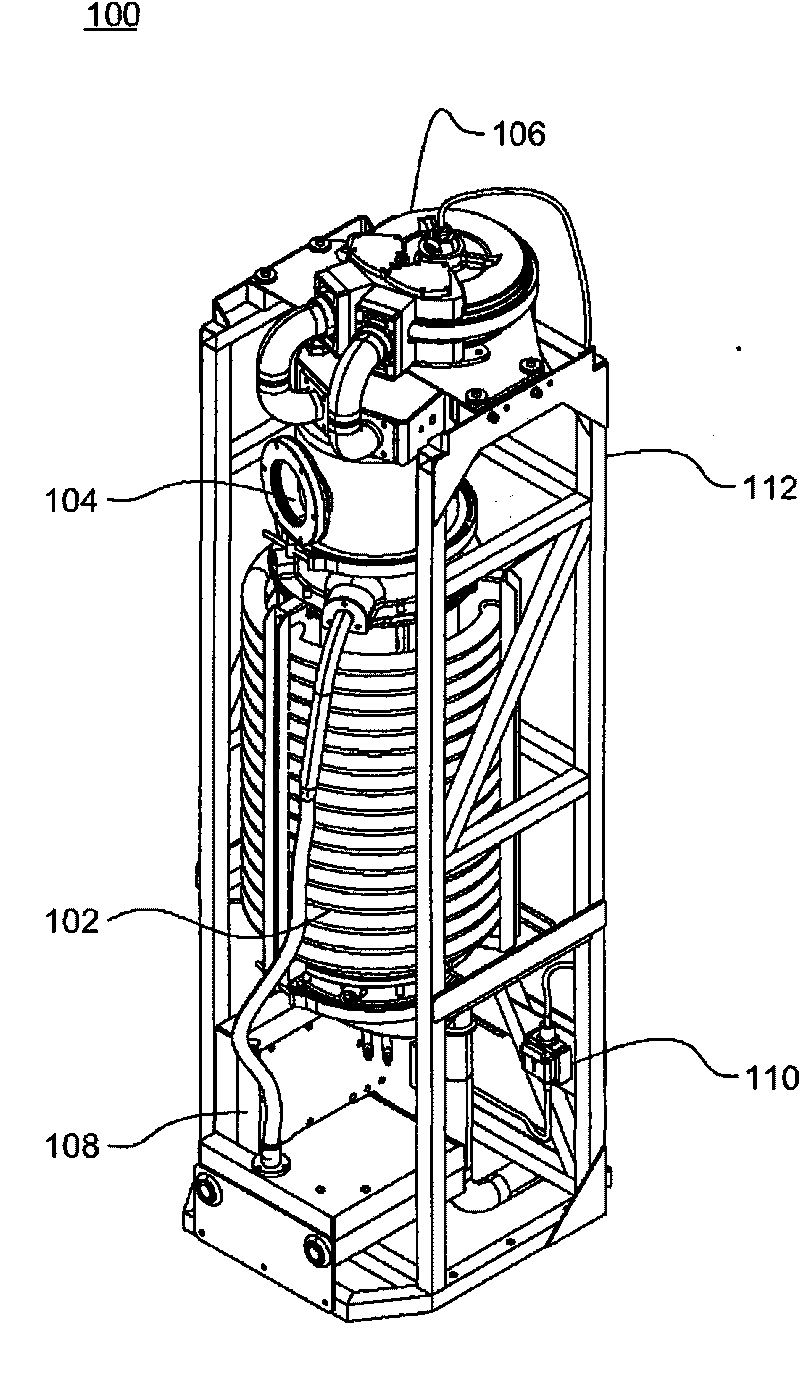

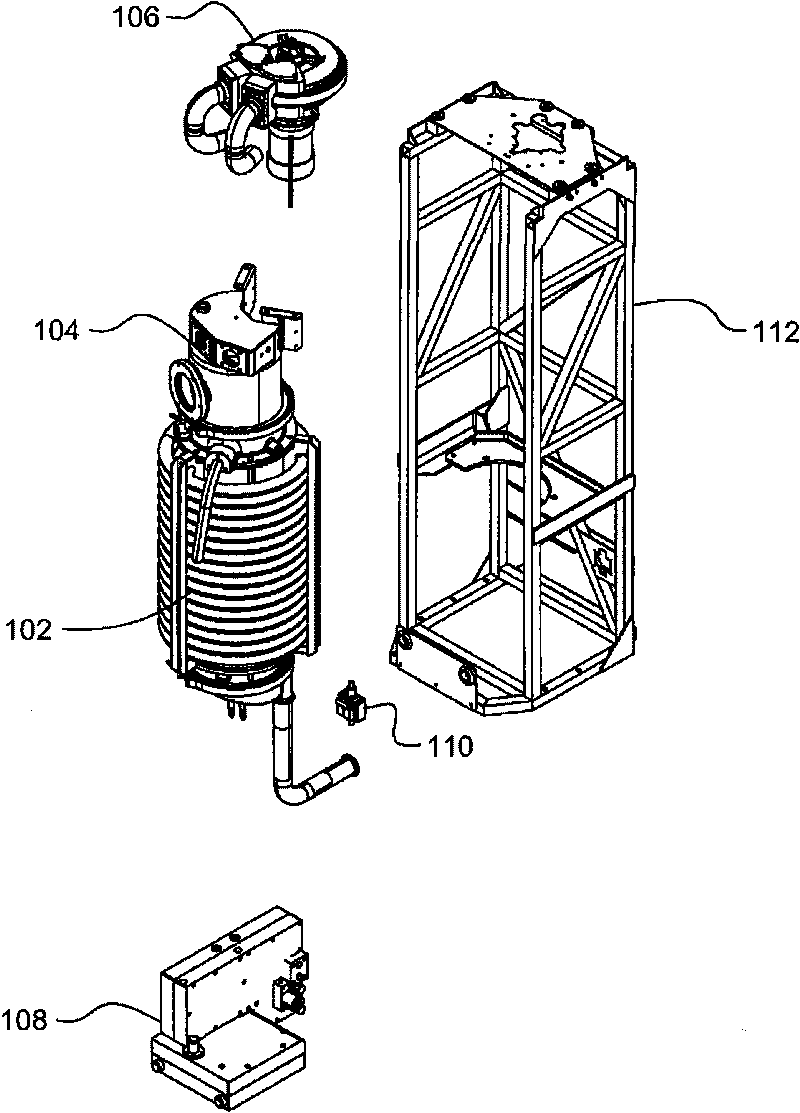

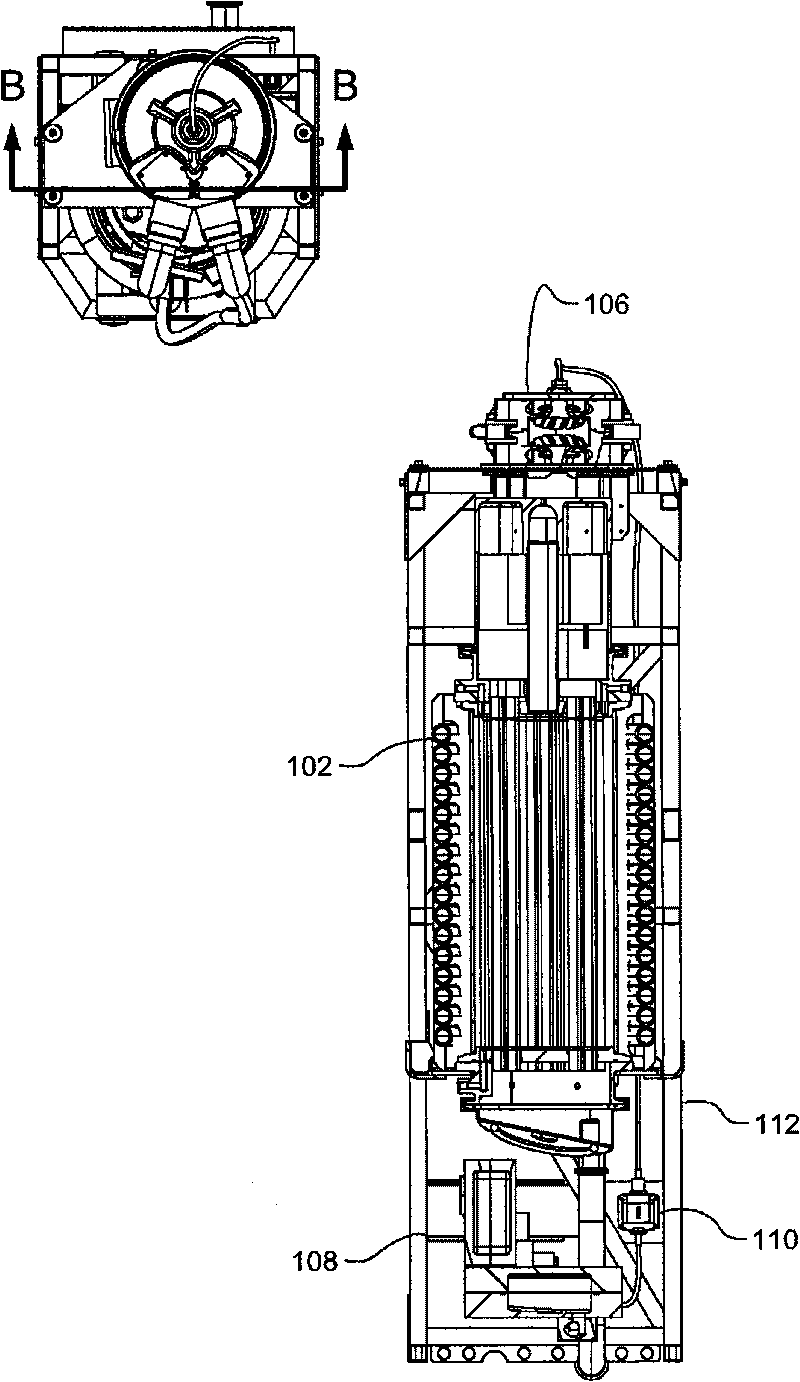

Water vapor distillation apparatus, method and system

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus (104). The evaporator condenser apparatus (104) includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser (104) and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger (102) fluidly connected to the source fluid input and a product fluid output. The heat exchanger (102) includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower (106) fluidly connected to the evaporator condenser (104). The regenerative blower (106) compresses steam, and the compressed steam flows to the evaporative condenser (104) where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

Fluid element

InactiveUS20050249639A1Heating effectPressurized chemical processAnalysis using chemical indicatorsEngineering

Owner:CANON KK

Continuous resin recovery apparatus and recovery method

InactiveUS20050197487A1Improve productivityGood removal effectDrying solid materials without heatEvaporators with heating coilsForeign matterRecovery method

The present invention provides a continuous resin recovery method for recovering resin from which foreign matters and volatile components are sufficiently removed and which is highly purified and suitable for optical use. The continuous resin recovery method comprises a step of heating a resin solution in a heating pipe at a temperature at least the boiling point of the solvent, a step of introducing the resin solution heated at a temperature at least the boiling point of the solvent into a rough drying chamber maintained at a reduced pressure, a step of separating the resin from the solvent vapor in the rough drying chamber, a step of melting the separated resin, a step of introducing the molten resin in a precise drying chamber kept at a reduced pressure, and a step of passing the molten resin through a perforated plate in the precise drying chamber.

Owner:ASAHI GLASS CO LTD

Systems and methods for water distillation

The invention is generally directed to solar distillation methods and systems for recovering potable water from non-potable water. In certain embodiments, a process for water distillation includes a cycled arrangement, alternating between a day cycle and a night cycle to enhance the yield of potable water. Additionally, in certain embodiments, the system includes a solar still having a design and orientation to maximize solar energy capture.

Owner:KII

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com