Liquid ammonia evaporator and liquid ammonia evaporation system for flue gas denitration

The technology of a liquid ammonia evaporator and a secondary evaporator is applied to evaporators heated by serpentine tubes, evaporator accessories, chemical instruments and methods, etc., which can solve the problems of low heat exchange efficiency and complex structure, and achieve High thermal efficiency, improved heat transfer efficiency, and simplified ammonia evaporation supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

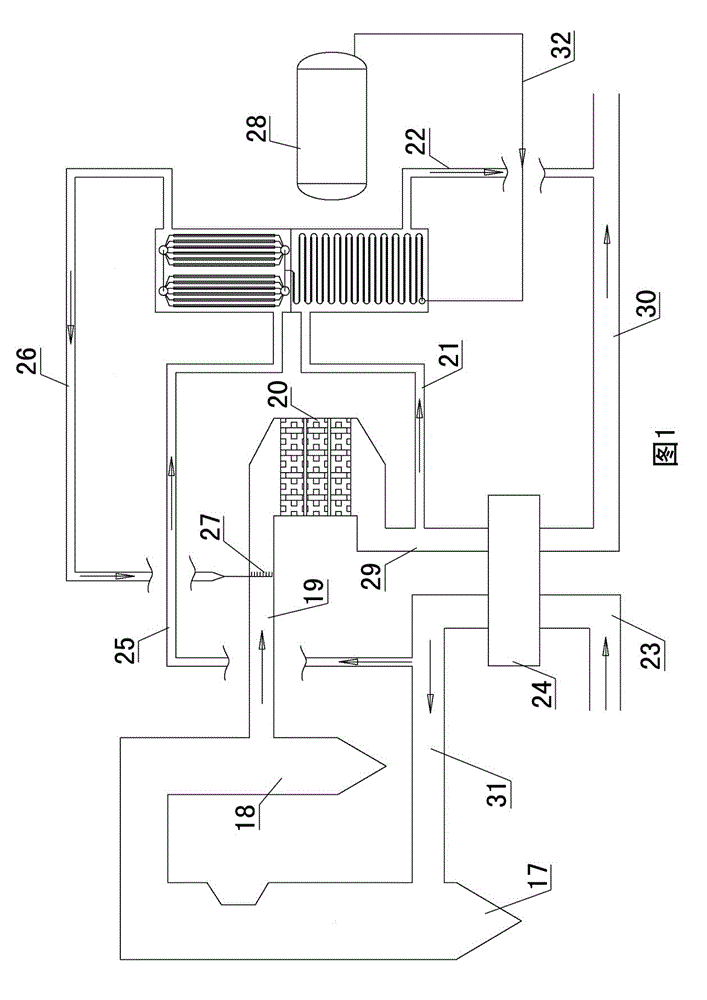

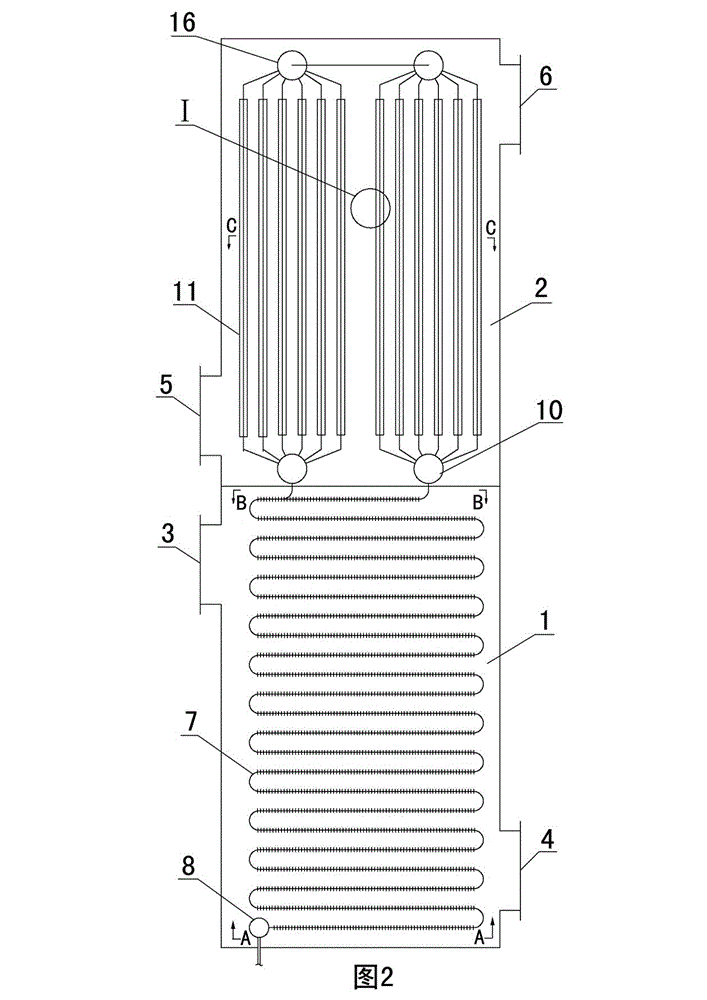

[0029] Examples see Figure 2-7 As shown, this liquid ammonia evaporator for flue gas denitrification includes a heat exchange chamber and stainless steel heat exchange tubes arranged in the heat exchange chamber. The heat exchange chamber consists of a lower heat exchange chamber 1 and an upper heat exchange chamber 2 Composition, the top of the lower heat exchange chamber 1 has a denitrification flue gas inlet 3, the bottom of the lower heat exchange chamber 1 has a denitration flue gas outlet 4, the bottom of the upper heat exchange chamber 2 has a hot air inlet 5, and the upper heat exchange chamber The top of 2 has hot air outlet 6.

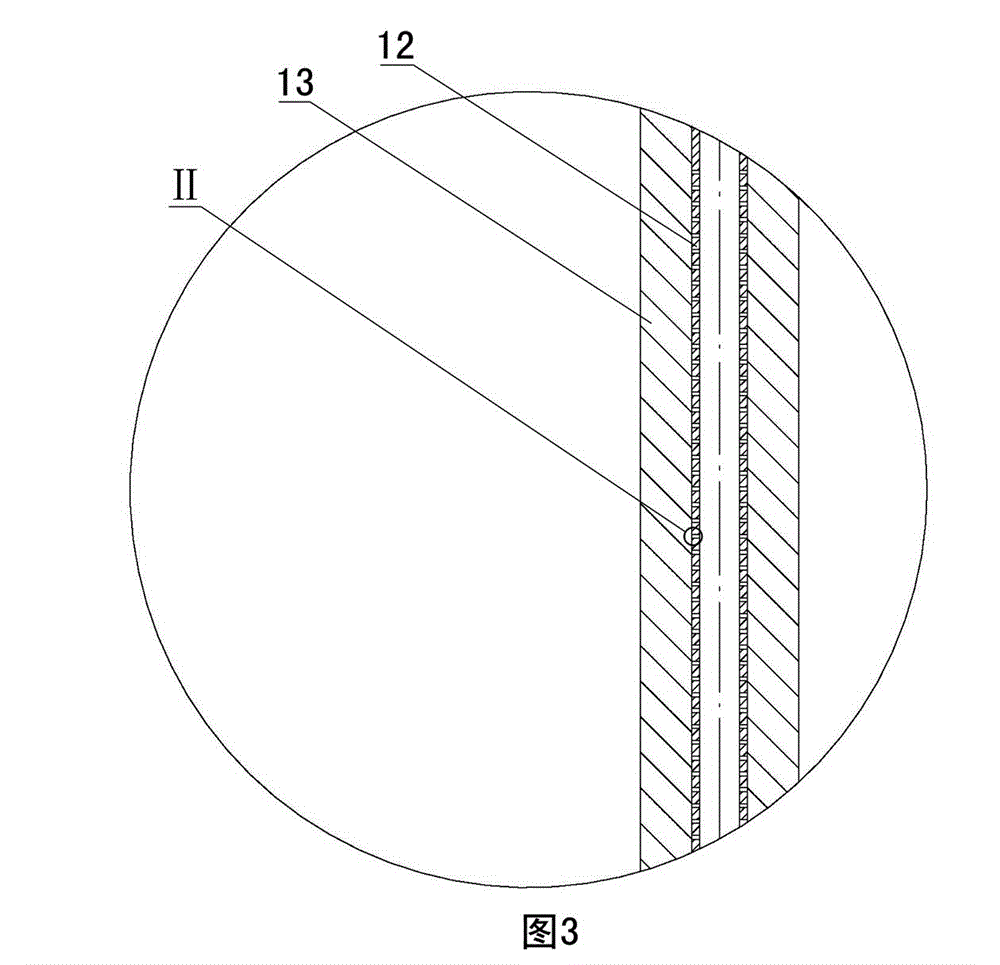

[0030] The stainless steel heat exchange tubes include primary heat exchange tubes 7 arranged in the lower heat exchange chamber 1 and secondary evaporator heat exchange tubes 11 arranged in the upper heat exchange chamber 2, and the primary heat exchange tubes 7 and the secondary evaporation The tube wall of the secondary evaporator heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com