Patents

Literature

111results about How to "Avoid risk of clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

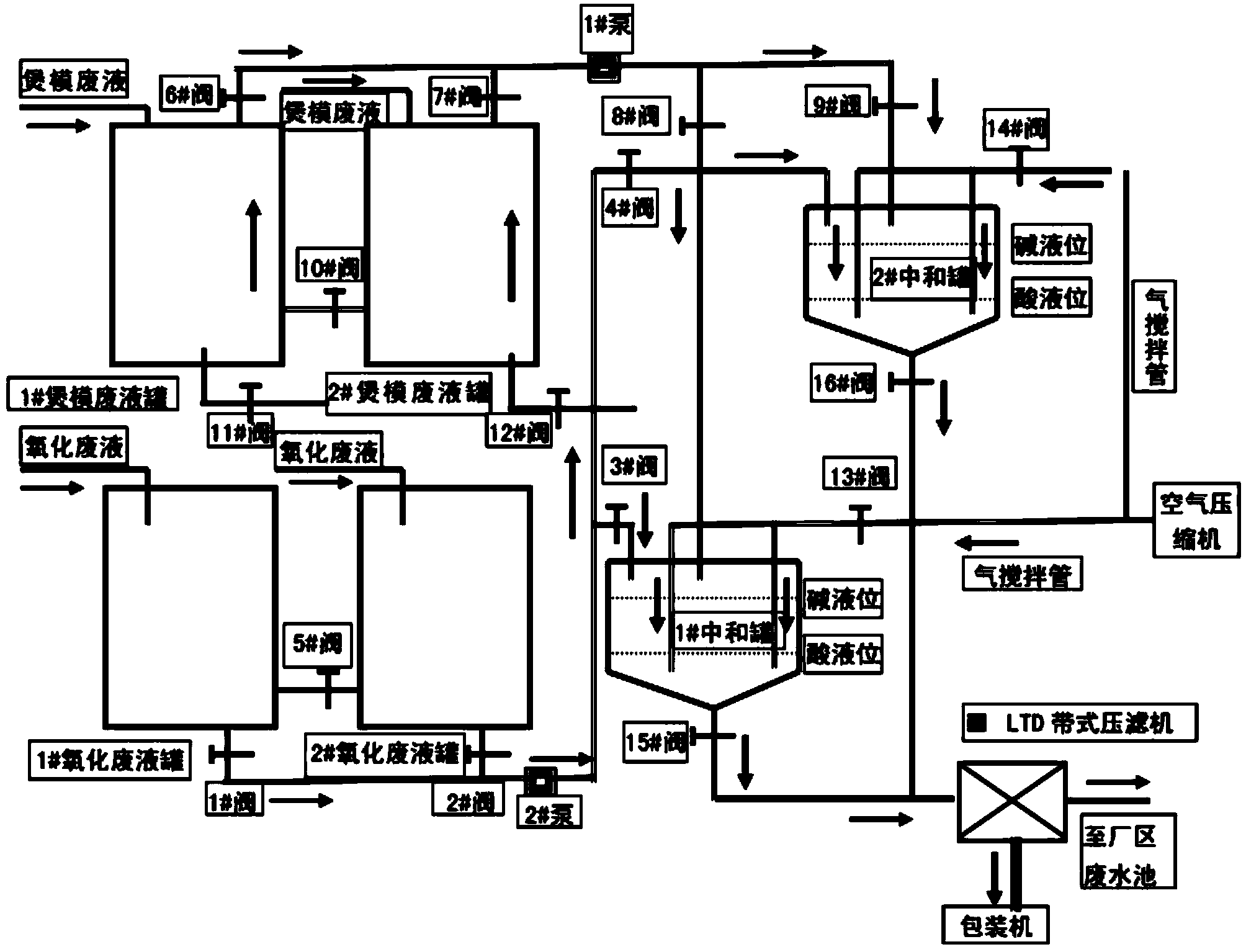

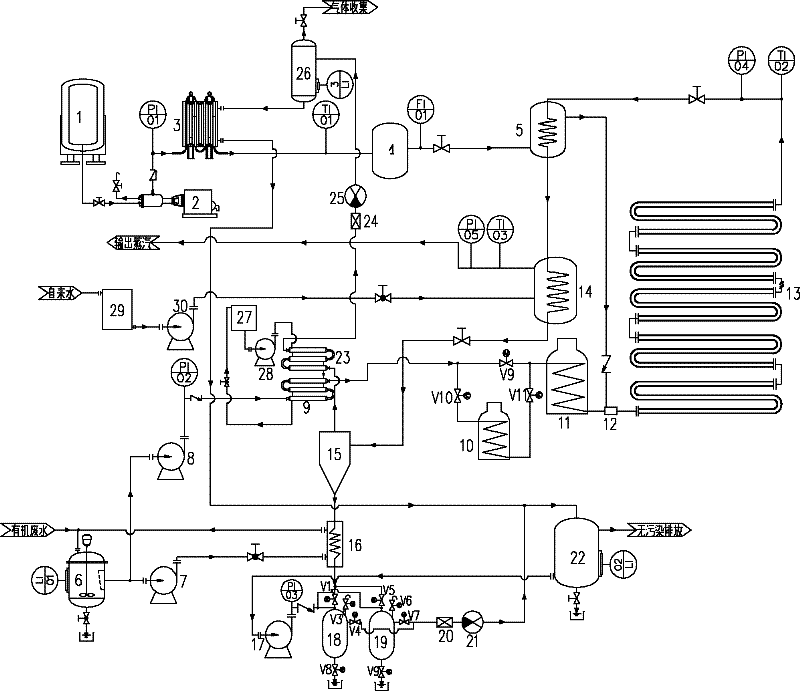

System for neutralizing treatment of demoulding waste liquor and anodic oxidation waste liquor and recovery of aluminum ions of aluminum processing plant

ActiveCN103451436ALower resistanceSimple structureWater contaminantsWaste water treatment from metallurgical processAluminum IonHydrogen

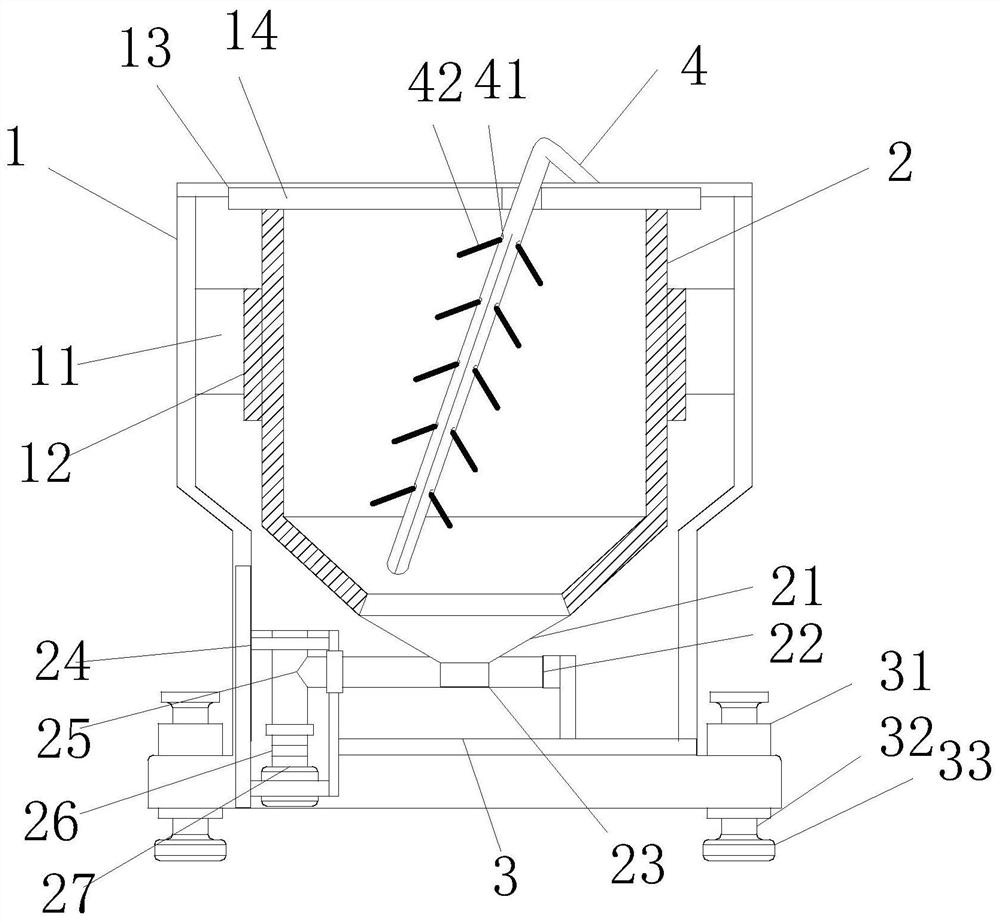

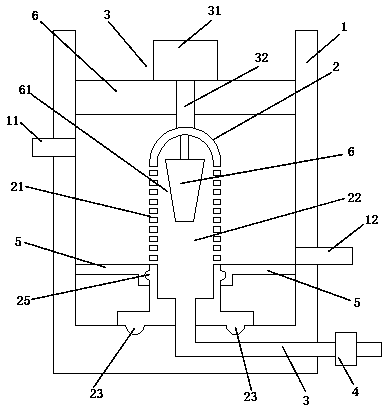

The invention discloses a system for neutralizing treatment of demoulding waste liquor and anodic oxidation waste liquor and recovery of aluminum ions of an aluminum processing plant. The system comprises an alkaline system, an acidic system, a neutralizing system, a pneumatic agitating system and a filter press and packaging system, wherein the alkaline system and the acidic system are respectively connected to the neutralizing system through pipelines; the pneumatic agitating system is arranged in the neutralizing system; the filter press and packaging system is arranged at the back of the neutralizing system through a pipeline; and another pipeline connected with a wastewater tank is arranged on the filter press and packaging system. The alkaline system is composed of a No 1 demoulding waste liquor tank, a No 2 demoulding waste liquor tank, a No 1 pump and pipelines. The neutralizing system is composed of a No 1 neutralizing tank, a No 2 neutralizing tank and pipelines. According to the system, oxidization waste liquor and demoulding waste liquor of the aluminum processing plant are conveyed to a neutralizing tank to be subjected to complete harmless treatment within pH (Potential of Hydrogen) of 6 to 8; a large amount of aluminium hydroxide byproducts can be recovered; and the cost of treating waste liquor can be greatly decreased.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

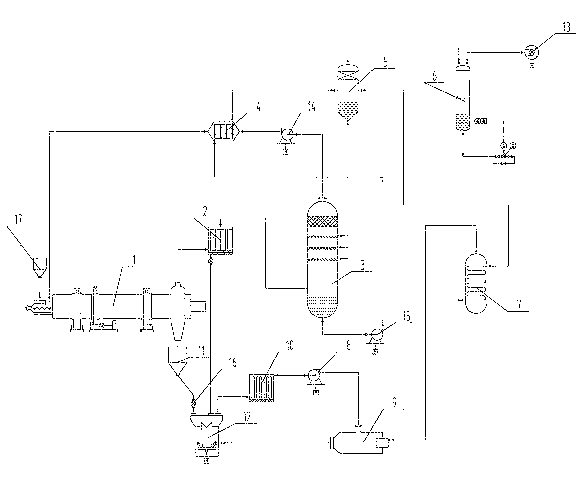

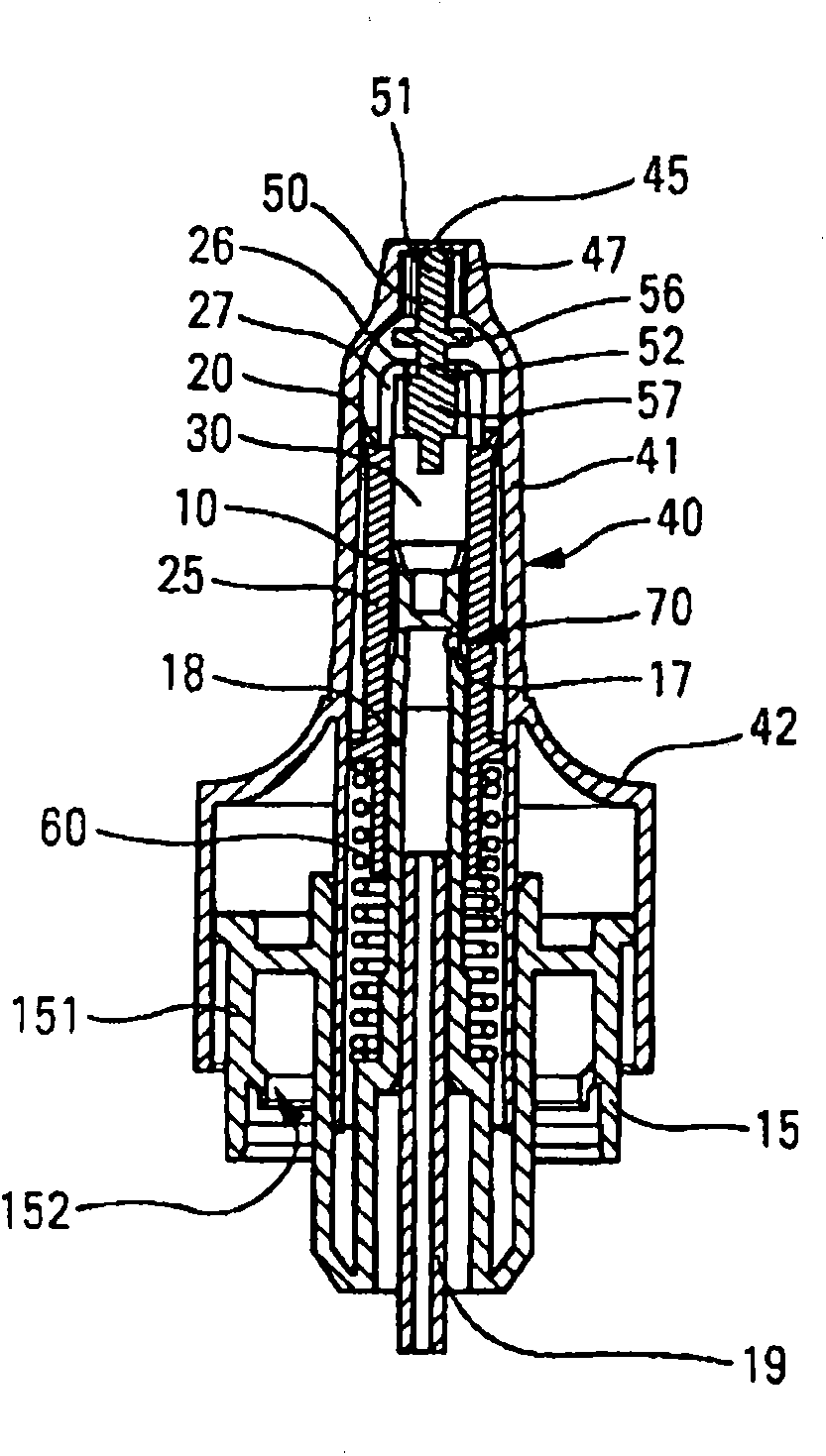

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

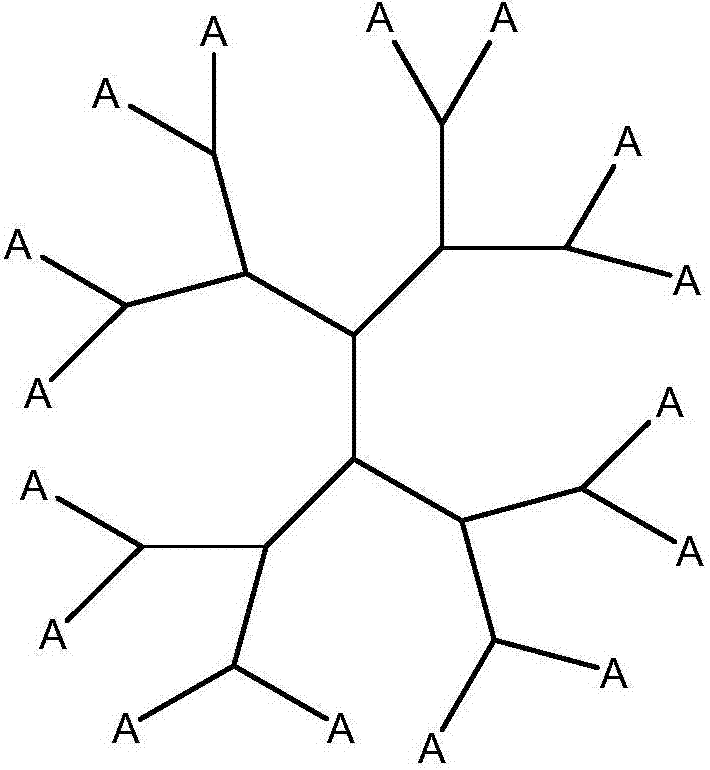

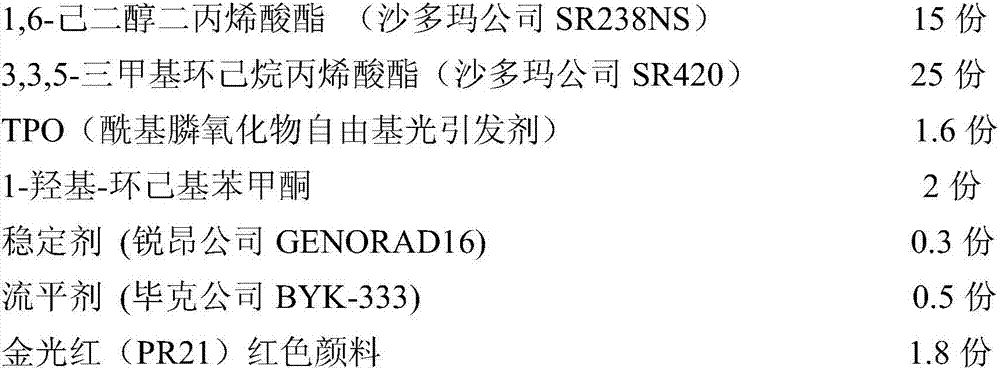

Ink composition for 3D ink-jet printing, ink kit and preparation method thereof

The invention provides an ink composition for 3D ink-jet printing, an ink kit and a preparation method thereof. The ink composition comprises the following components in parts by weight: 45-75 parts of an acrylic acid oligomer, 20-45 parts of an acrylic monomer, 1-9 parts of an ultraviolet photoinitiator, 0.2-10 parts of aids and 0-4 parts of a coloring agent, wherein the acrylic acid oligomer is selected from one or more of polyurethane acrylate, polyester acrylate and polyether acrylate. At the temperature of 25 DEG C, the viscosity of the ink composition is 25-70cps; at the temperature of 40-60 DEG C, the surface tension of the ink composition is 20-35dyn; and under at least one temperature of 40-60 DEG C, the viscosity of the ink composition is 9-14.5cps. The ink composition disclosed by the invention is simple in constitution, and the service life of a printing head can be prolonged. Moreover, the curing process is simple, emission of VOCs (Volatile Organic Compounds) is avoided, pollution is eliminated, and buckling deformation is avoided in the preparation.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

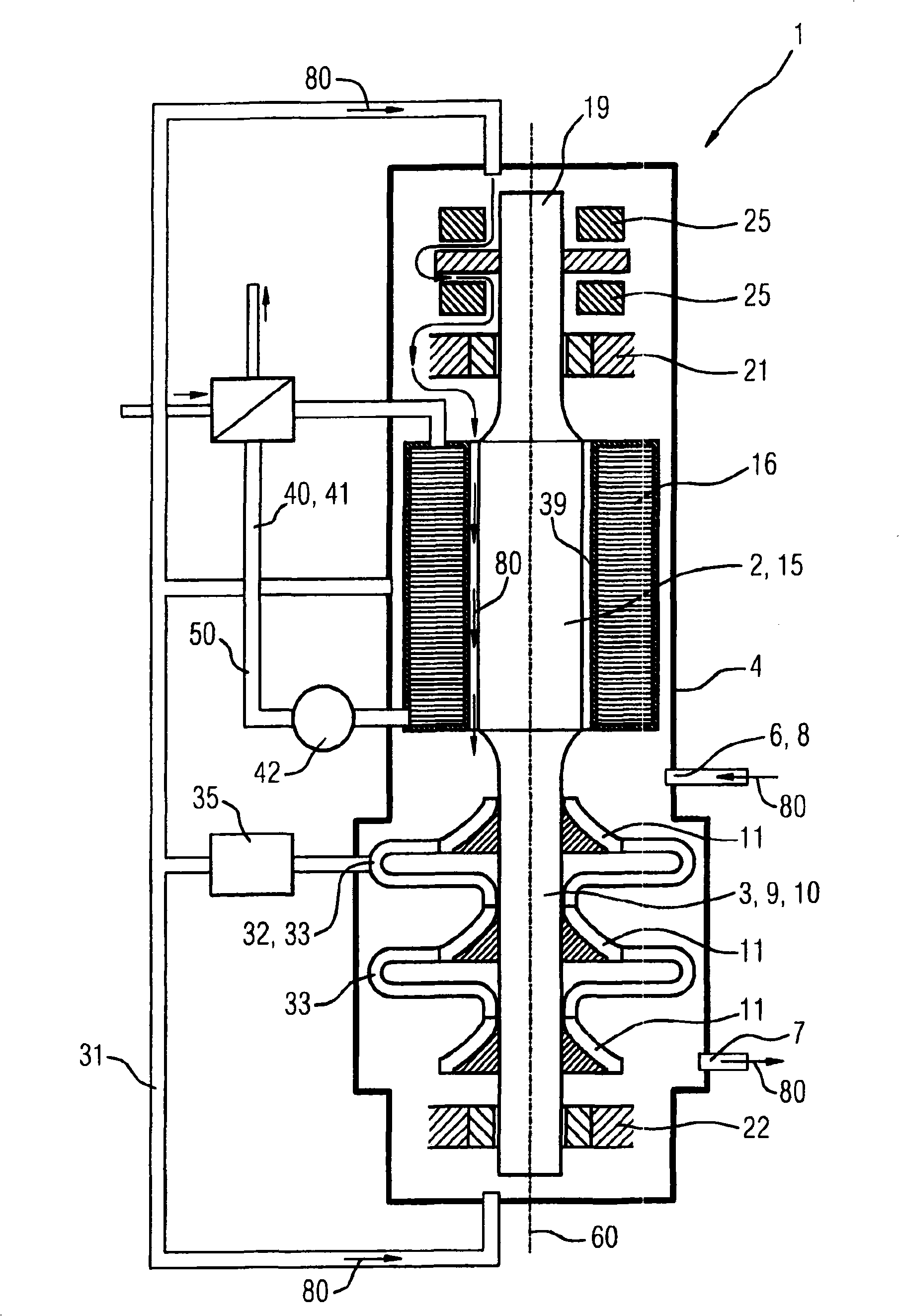

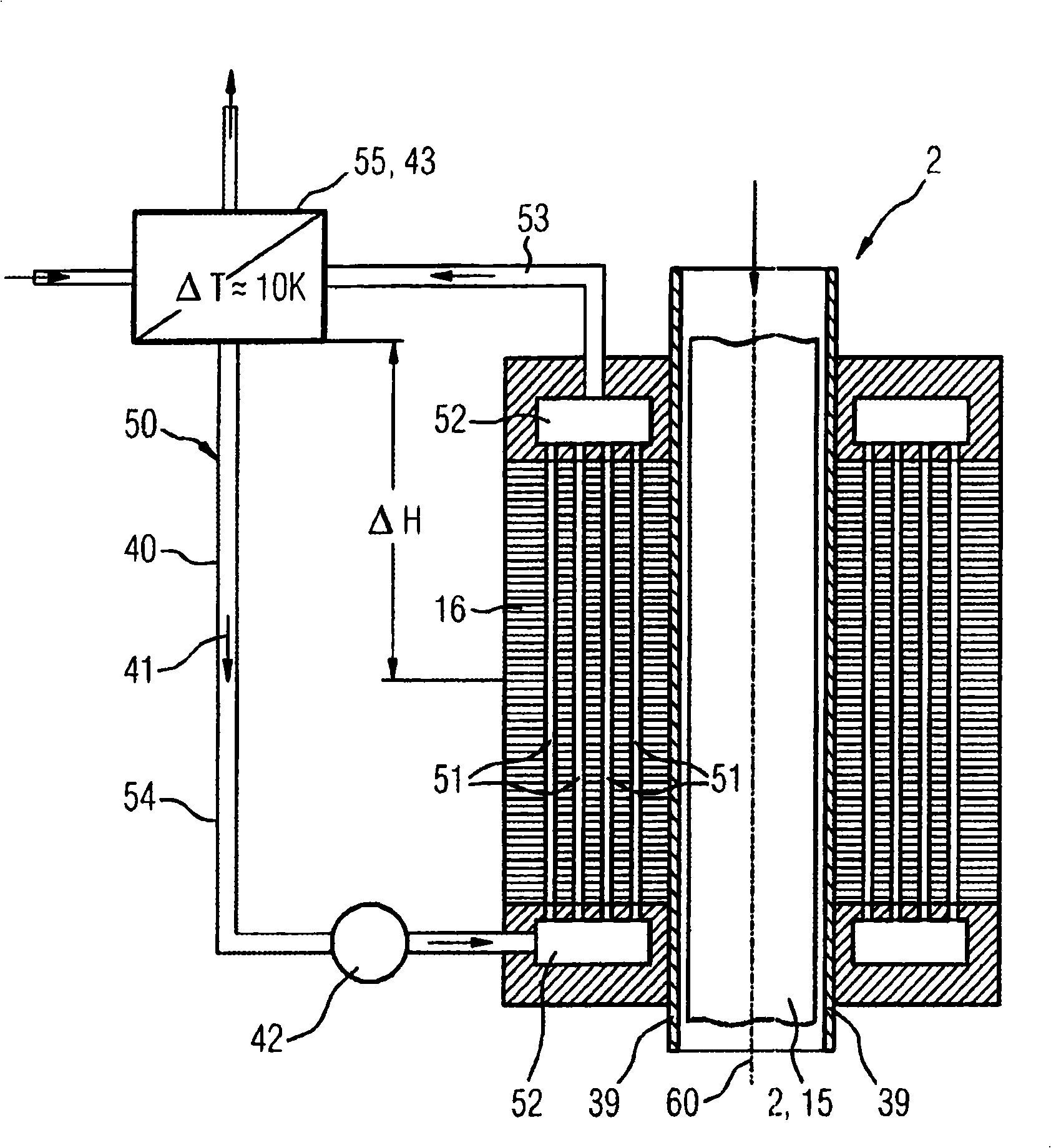

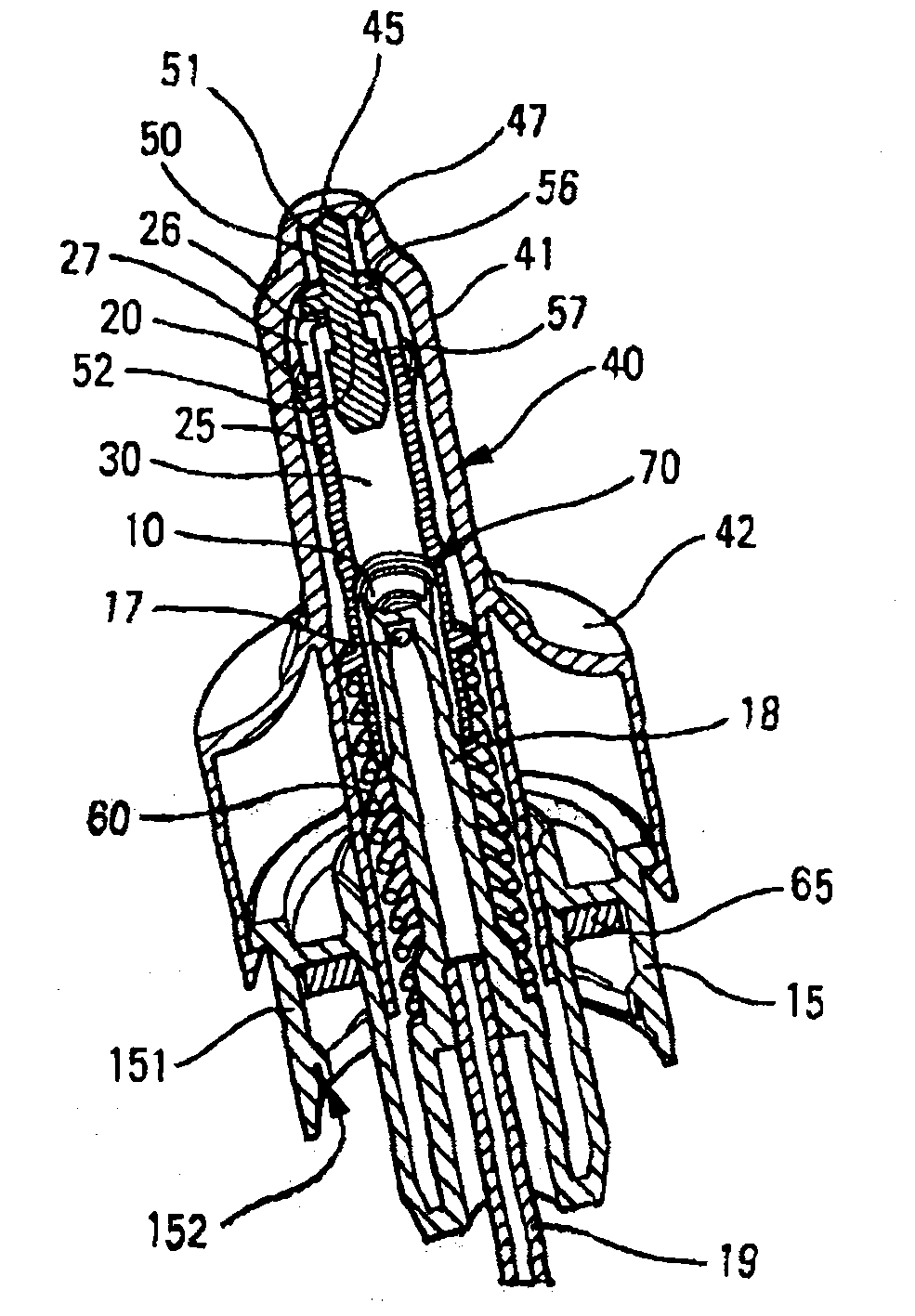

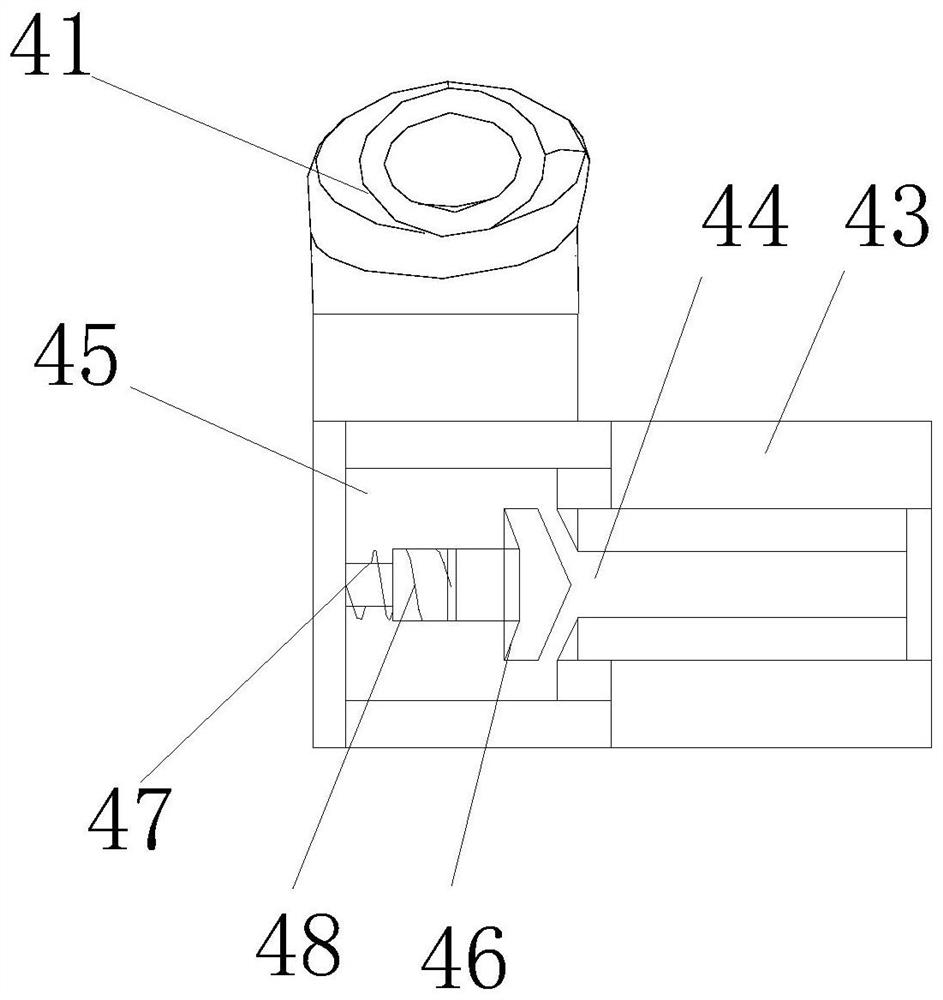

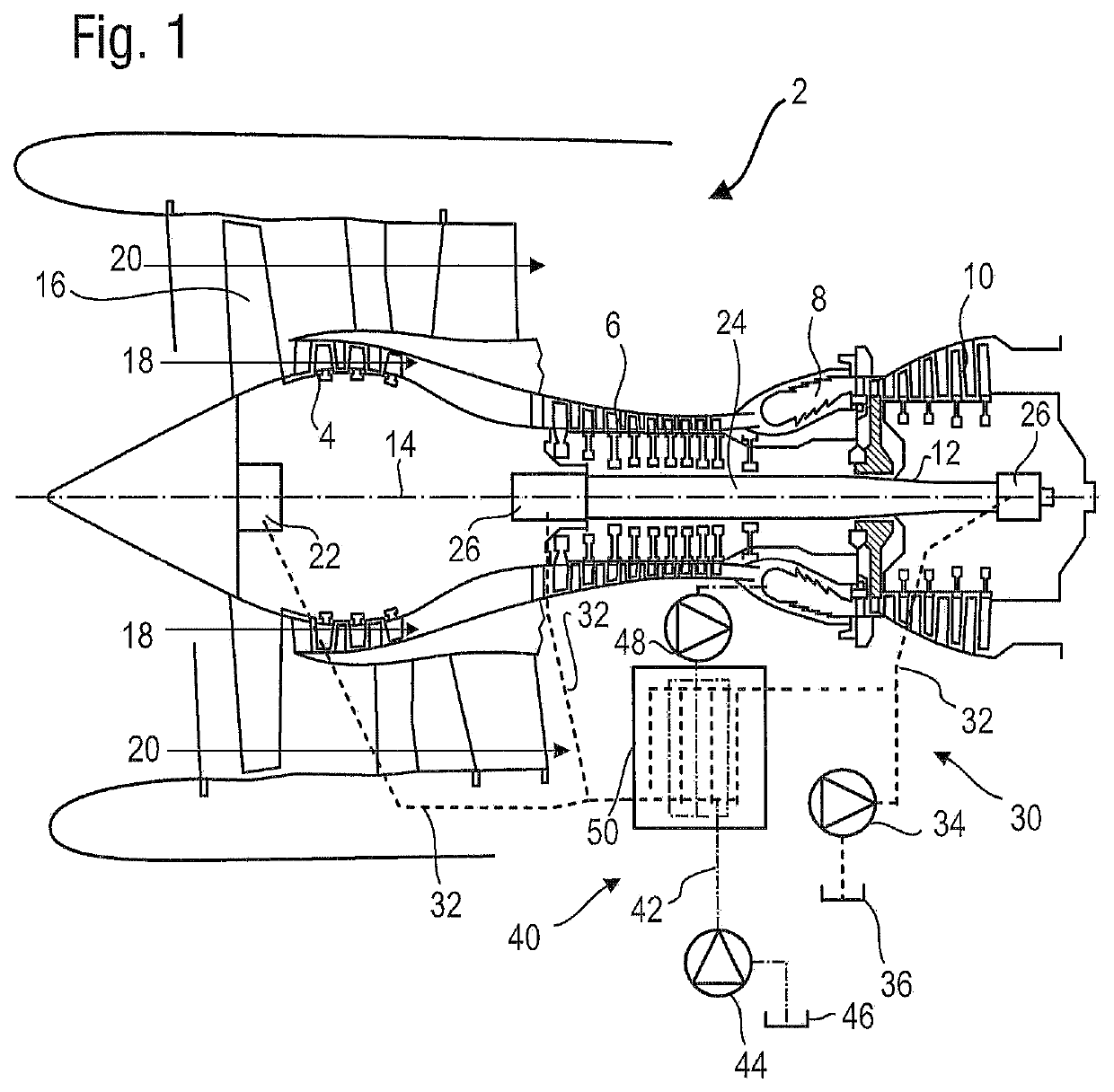

Compressor unit

InactiveCN101410624ASafe coolingAvoid risk of cloggingPump componentsShaftsCooling mediumOperational reliability

The invention relates to a compressor unit (1), in particular for underwater operation, wherein the stator (16) of the motor (2) is connected to a separate cooling means (40). It is an object of the invention to provide a cooling means for the stator of the electric motor, which cooling means firstly affords excellent operational reliability and secondly does not require any exchange of materials with the surroundings during operation. To this end, there is provision for the cooling means (40) to be configured in such a way that there is a natural circulation of a cooling medium (56) in the cooling means (40) of the stator (16) under operating conditions. One decisive advantage of the compressor unit (1) according to the invention lies in the fact that the separate cooling means (40) of the stator (16) can be adapted precisely to the operating conditions of the latter and, in particular, firstly the high power loss and secondly the sensitivity of this component can be taken into consideration.

Owner:SIEMENS AG

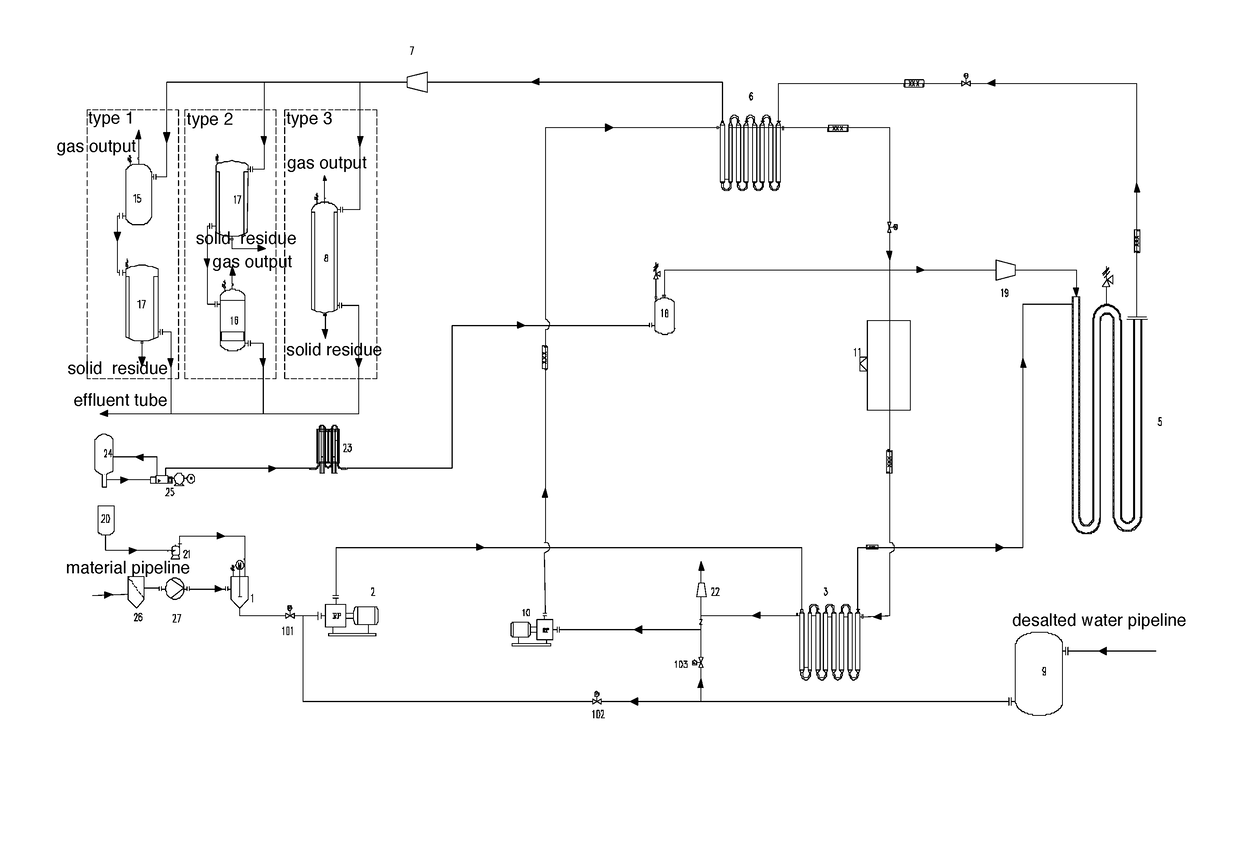

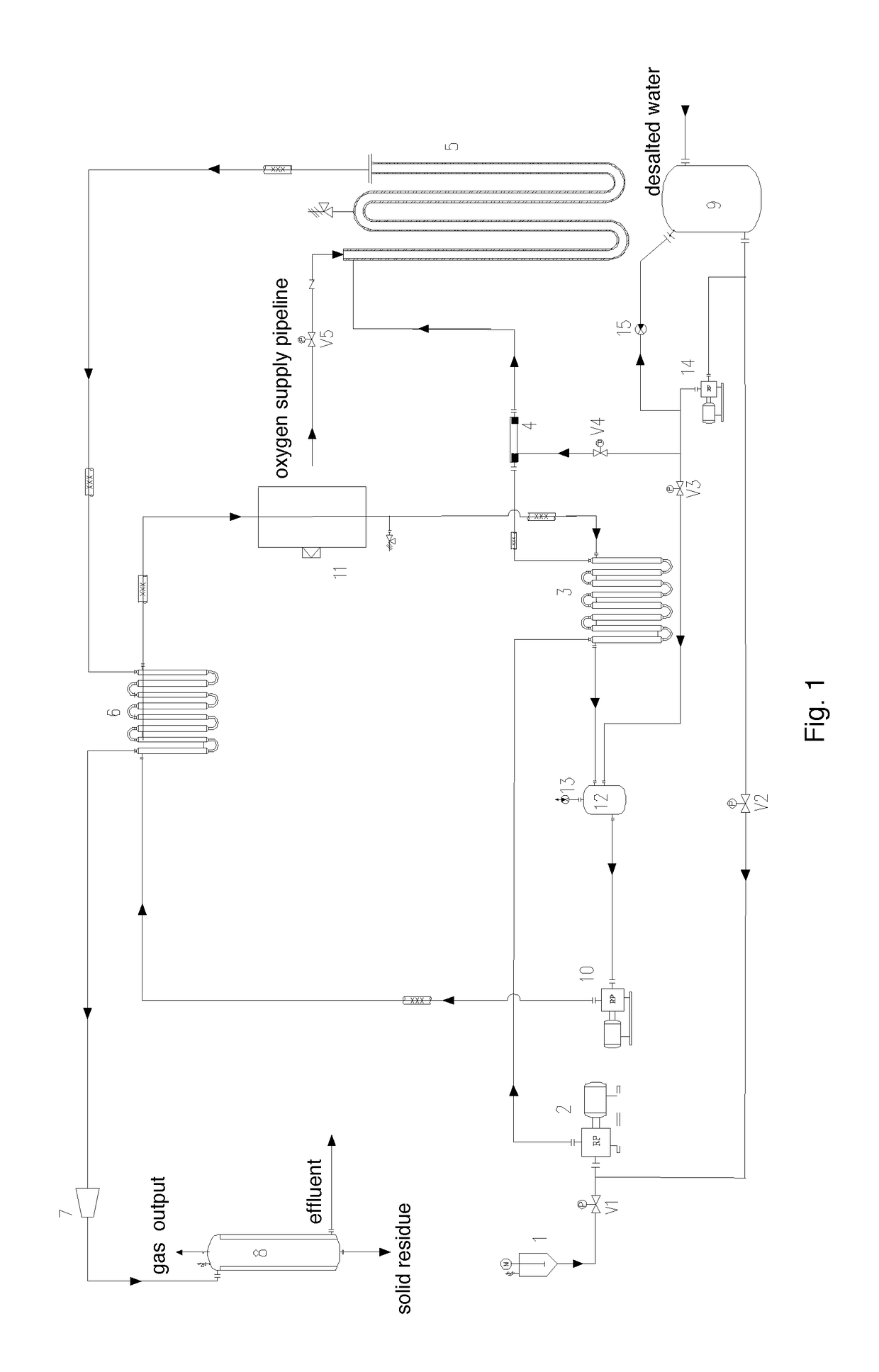

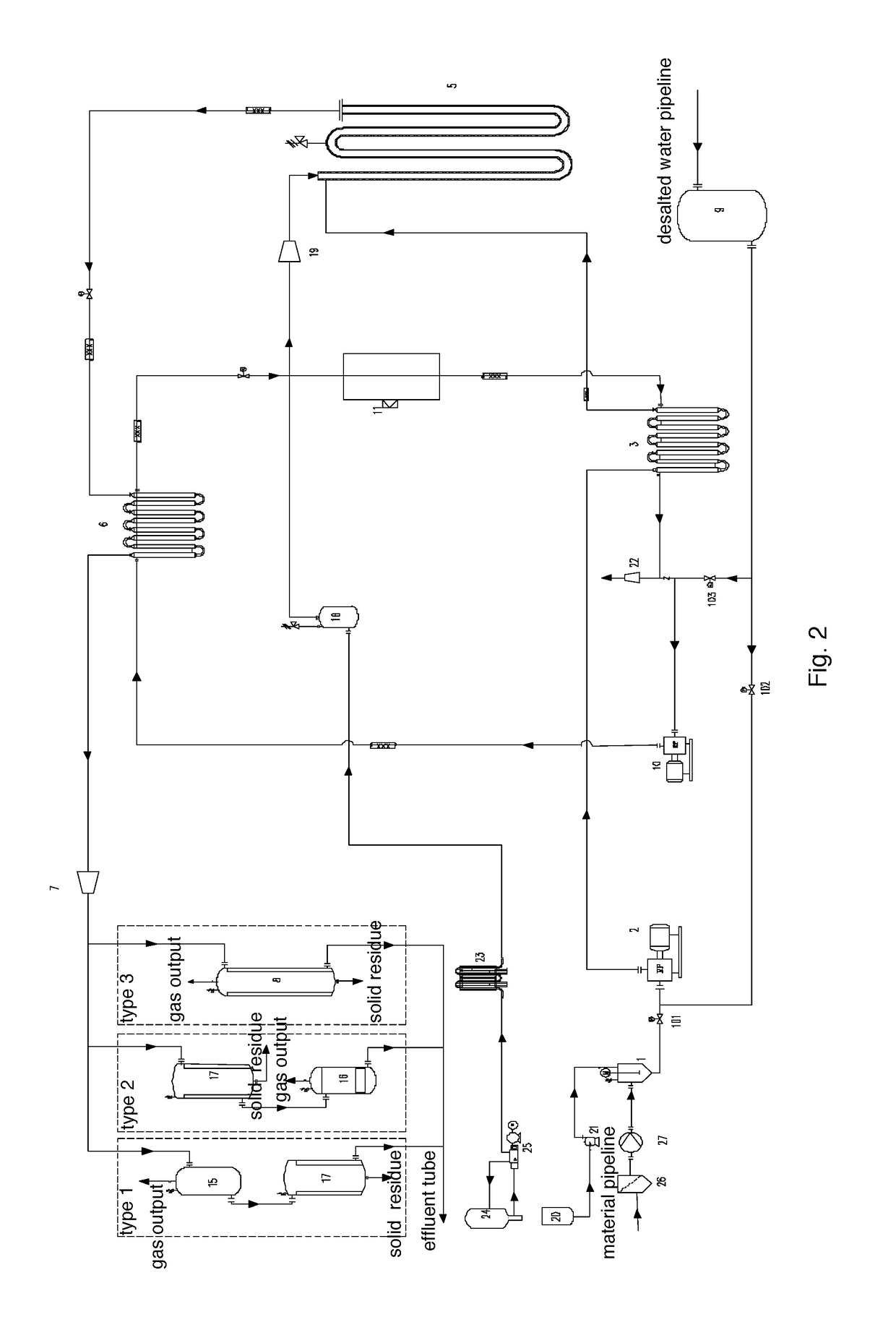

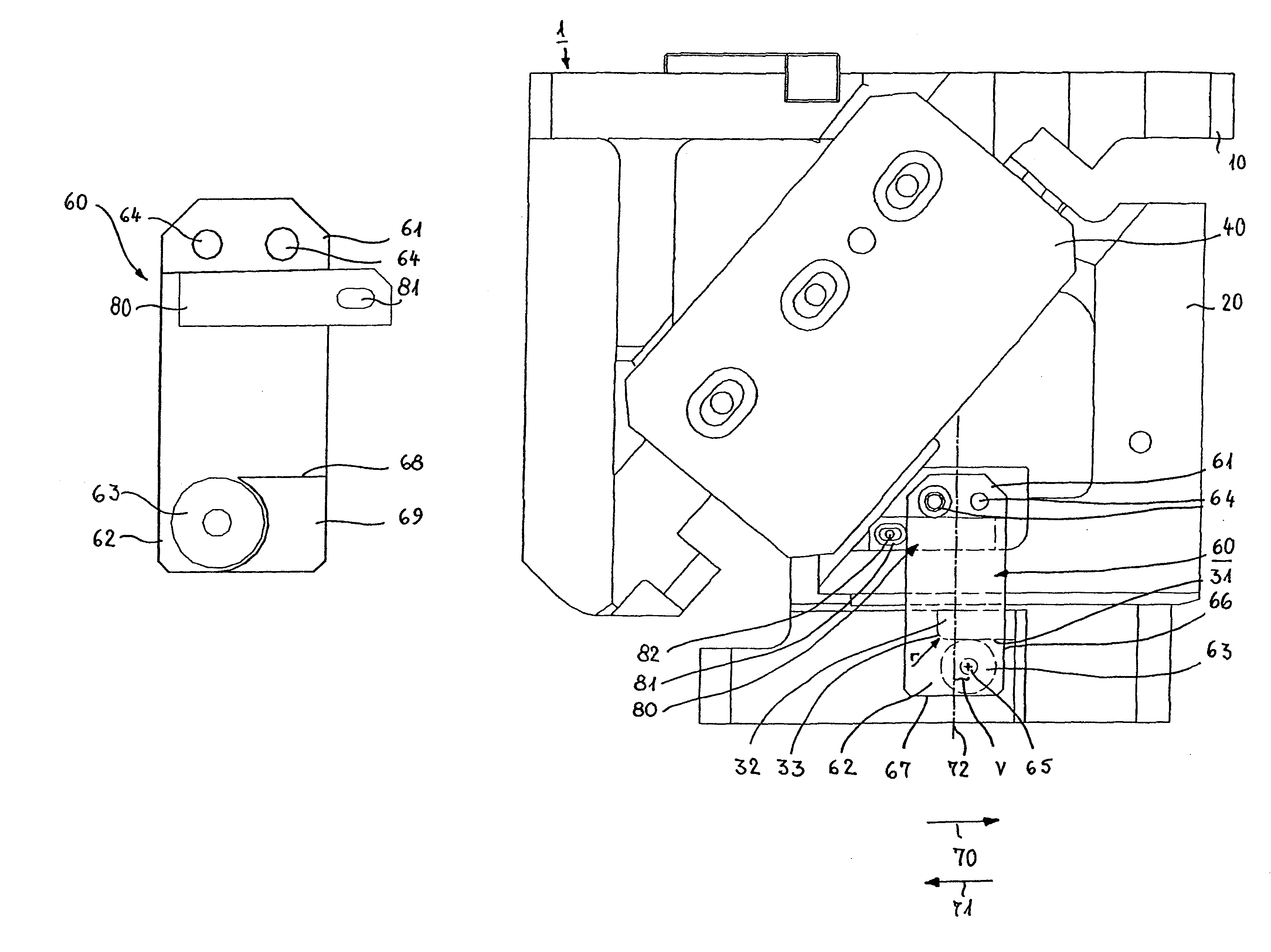

Indirect heat transfer supercritical water oxidation system and control method thereof

InactiveUS20170297941A1Low investment costAvoid risk of cloggingWater treatment parameter controlSludge treatment by oxidationAutomatic controlWorking pressure

An indirect heat transfer supercritical water oxidation system includes a supercritical water oxidation reactant system and an intermediate medium circuit. A control method thereof includes controlling two-process pressure and temperature increase, controlling pressure and temperature decrease and controlling normal operation. The present invention focuses on automatic control strategy of engineering practice of the indirect heat transfer supercritical water oxidation system. The system heating process adopts the idea of circulating heating, which effectively reduces the investment of the heating equipment avoids the mismatch between the working pressure of the two processes, and ensures effectiveness of the heat transfer between supercritical pressure fluid in the inner tube and the outer tube of the preheater / heat exchanger during subsequent heating process. The effective control of a reaction temperature and overpressure protection of critical equipment ensure a process effect and system safety.

Owner:XI AN JIAOTONG UNIV +1

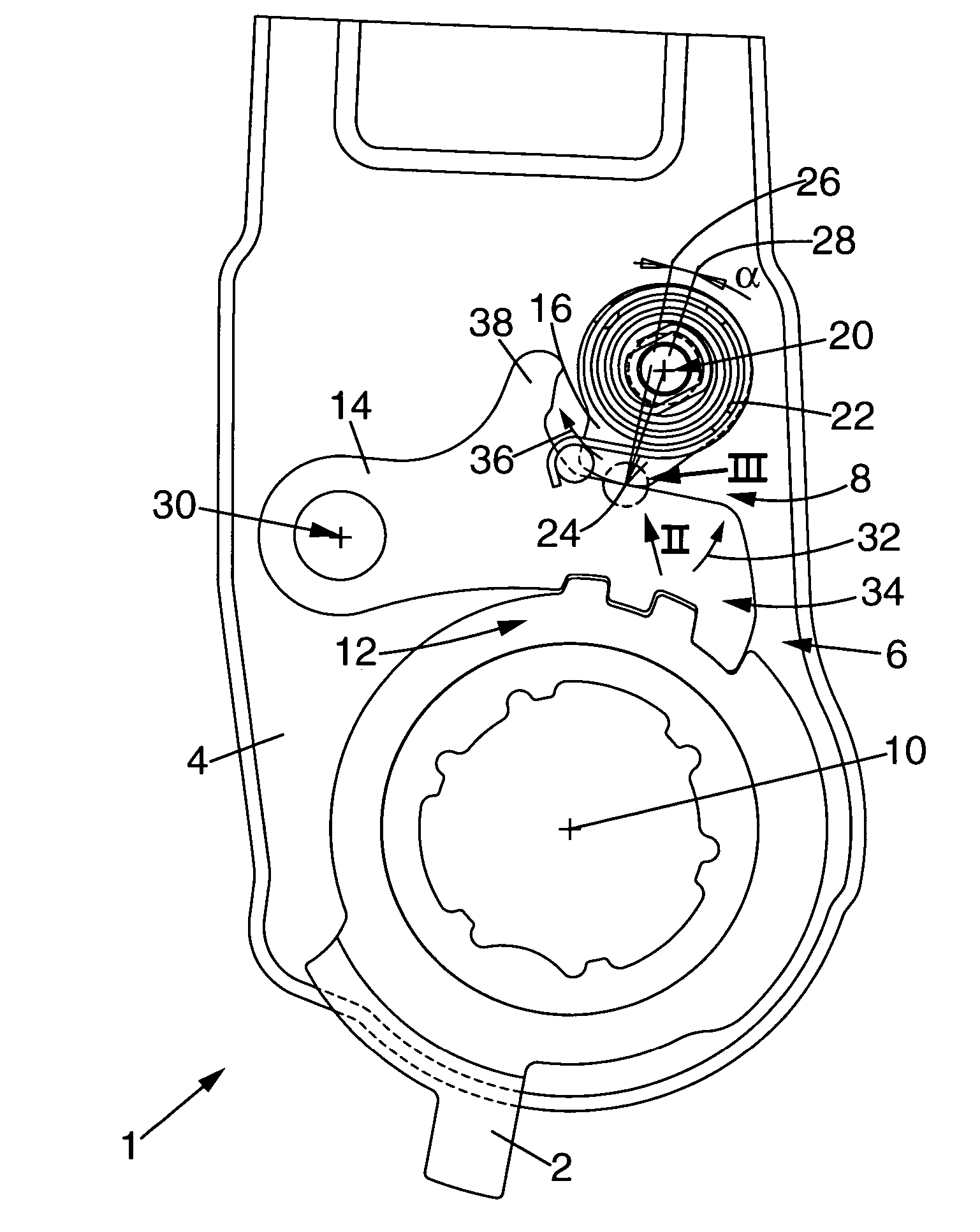

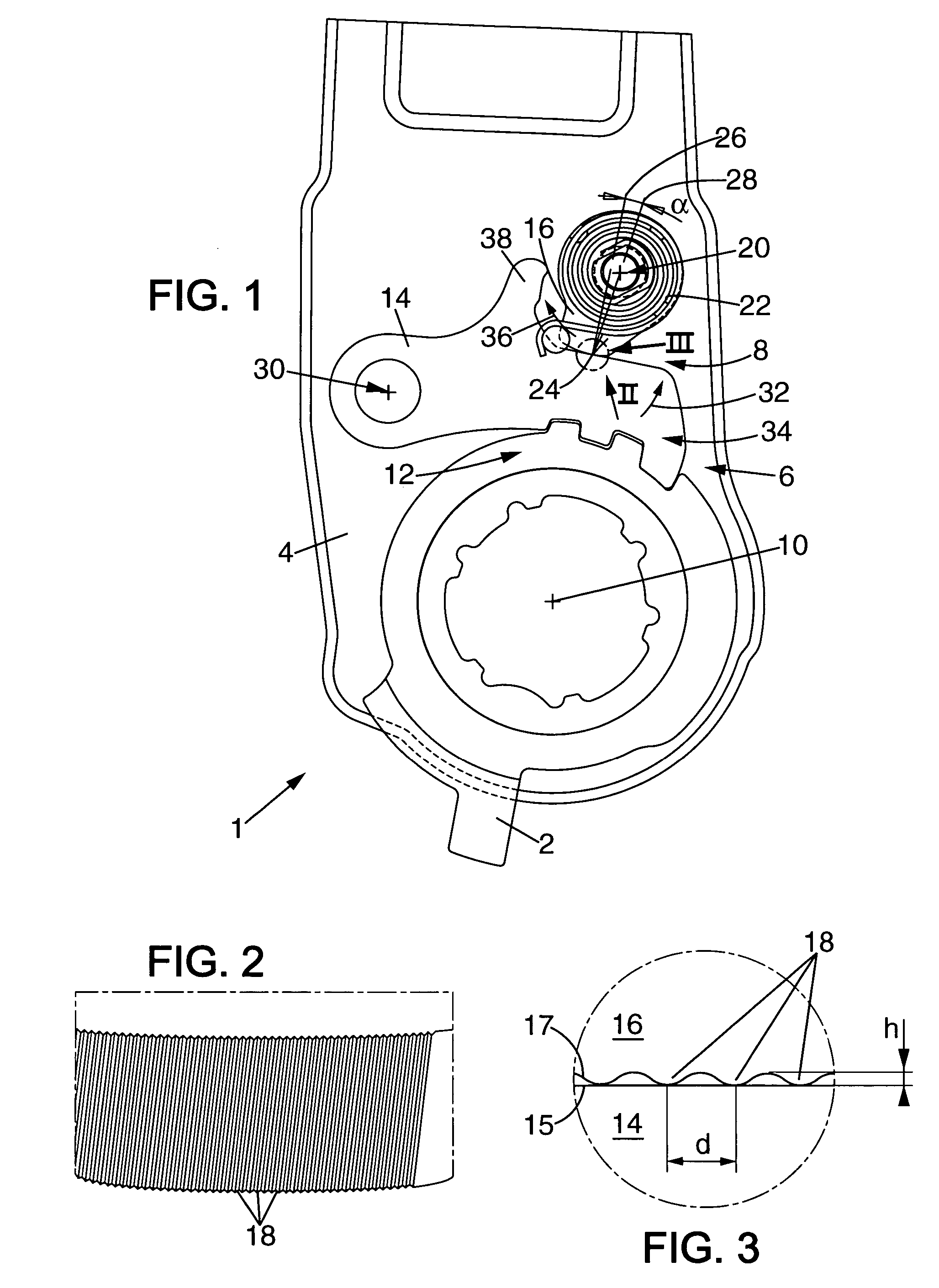

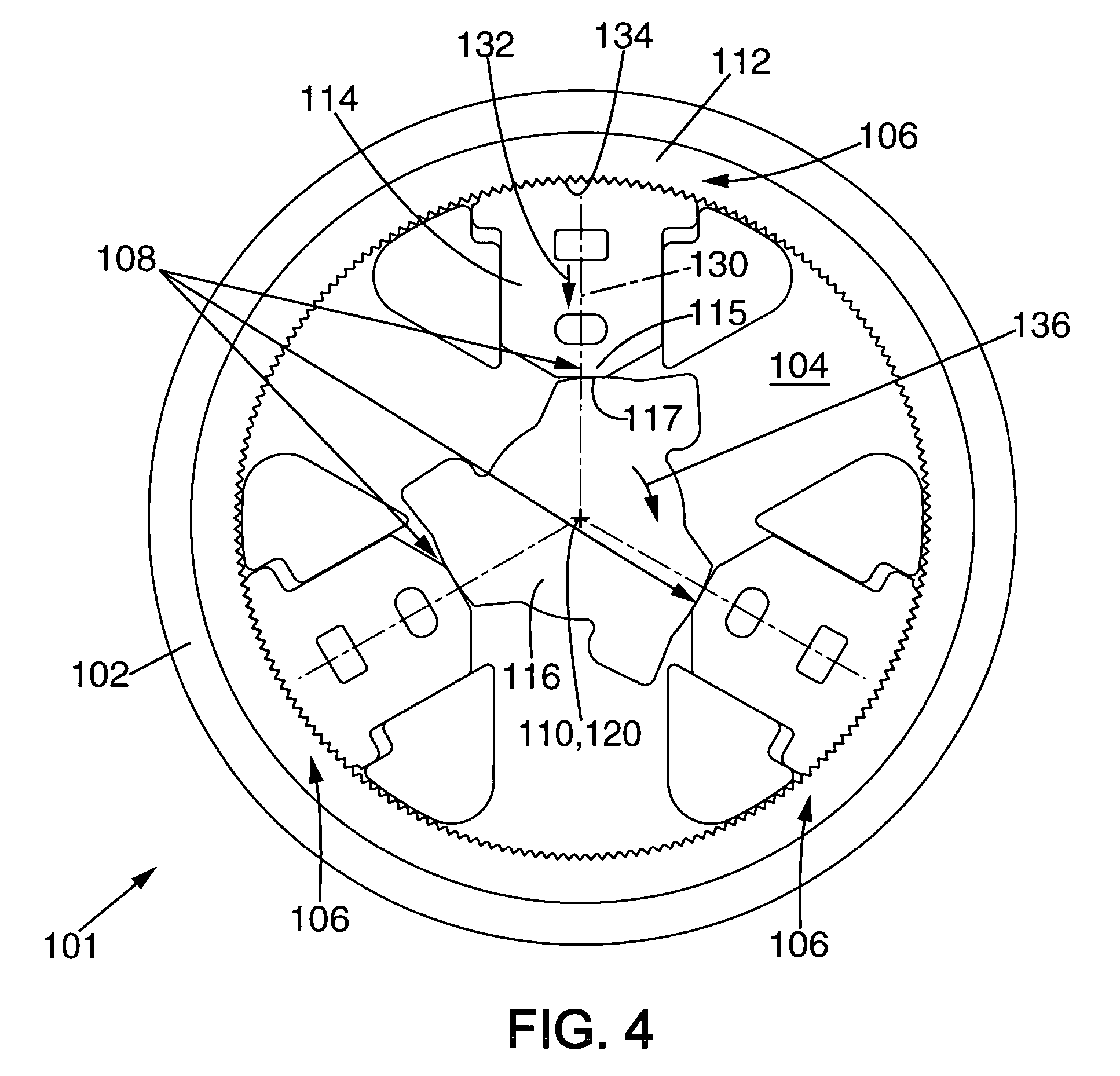

Mechanism for adjusting the inclination of a motor vehicle seat

A mechanism for adjusting the inclination of a motor vehicle seat, said mechanism comprising: a first cheek plate and a second cheek plate, said second cheek plate being mounted to pivot on the first cheek plate; a locking device for preventing the first cheek plate from pivoting relative to the second cheek plate, said locking device comprising a first locking element coupled to the first cheek plate, and a second locking element mounted to move on the second cheek plate between an active position and an inactive position; a non-reverse device comprising a cam mounted to pivot between an active position in which said cam comes into contact with the second locking element, and an inactive position; The cam and / or the second locking element is / are provided with teeth.

Owner:FAURECIA

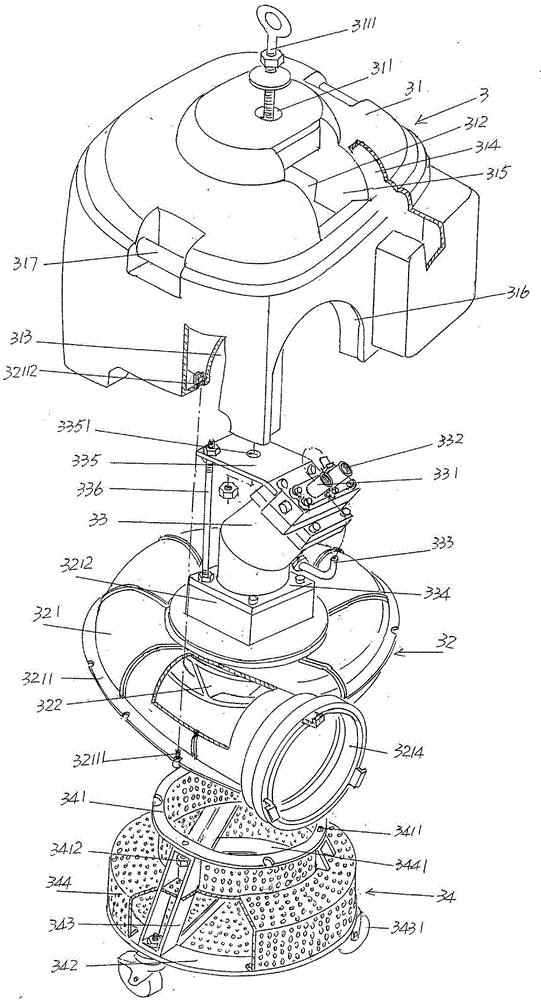

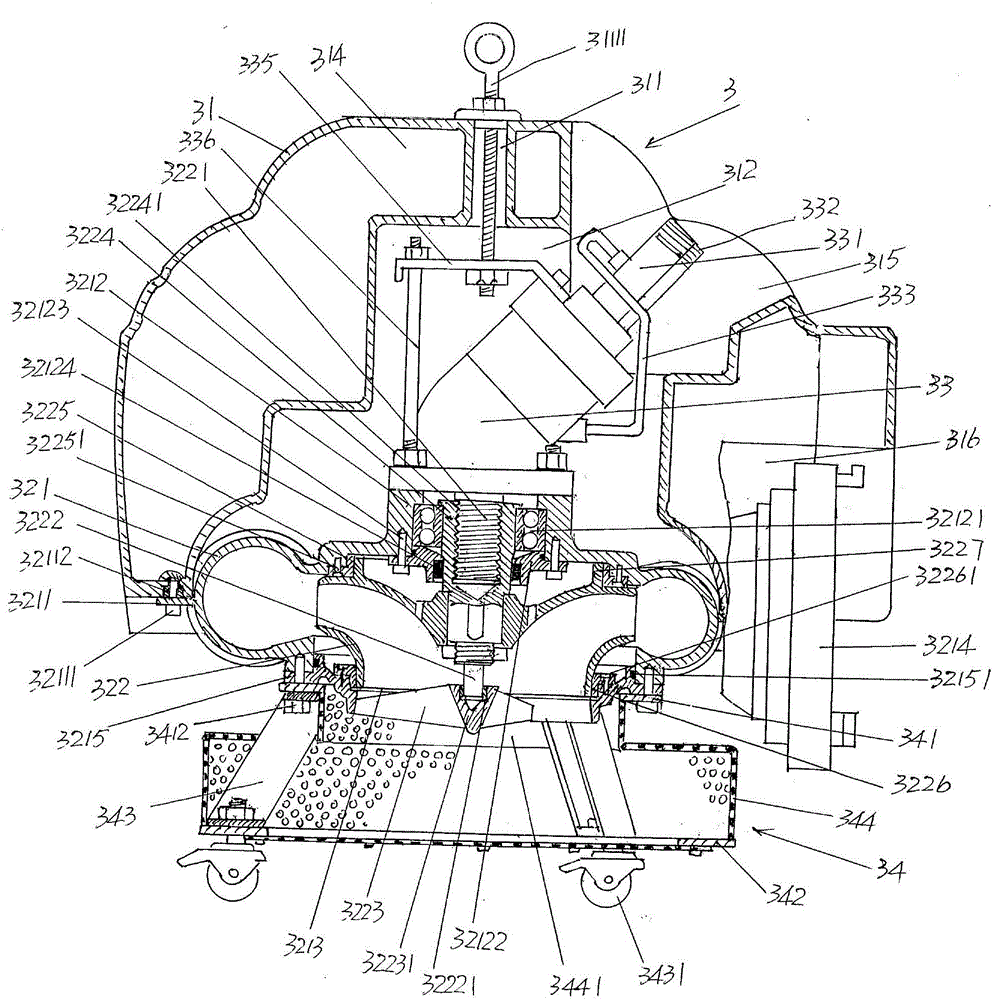

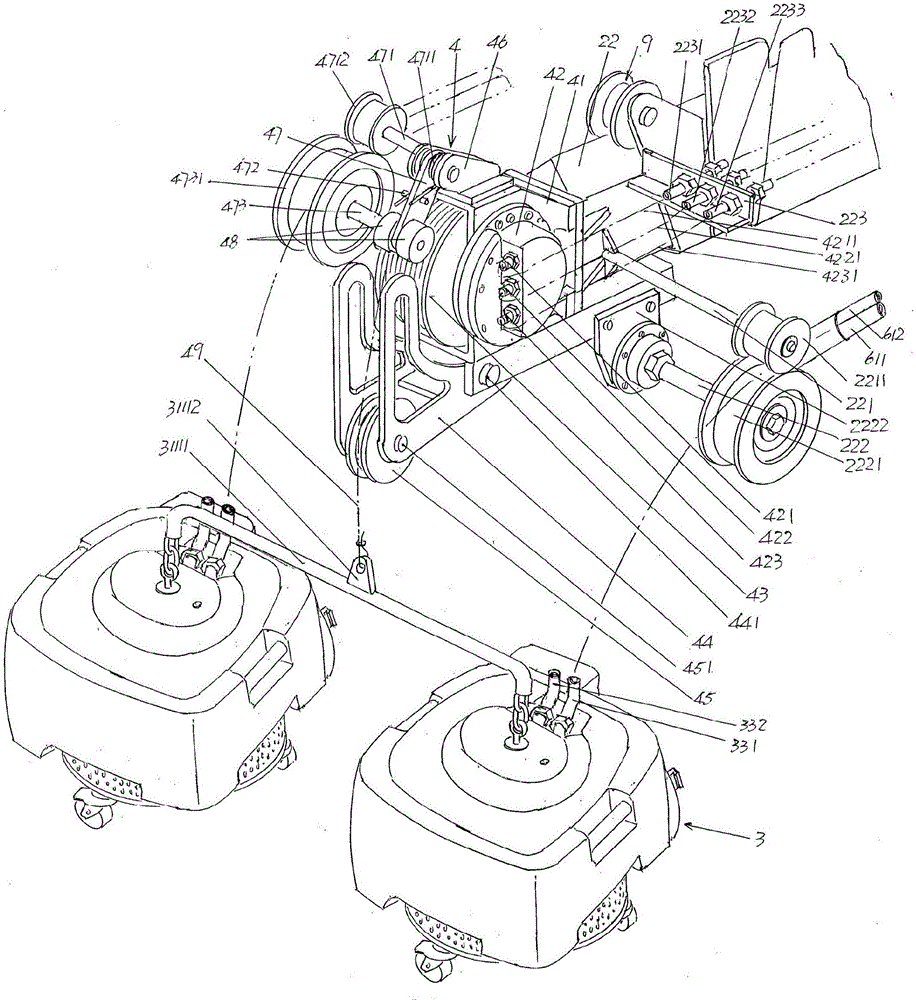

Semi-submersible type floating fire pump structure for automatic water diversion fire fighting truck

The invention provides a semi-submersible type floating fire pump structure for an automatic water diversion fire fighting truck. The semi-submersible type floating fire pump structure comprises a pair of floating fire pump assemblies; and each pair of floating fire pump assembly comprises a floating box, a floating fire pump, a floating fire pump driving oil motor and a filtration net sleeve; and the floating box and the floating fire pump driving oil motor are connected with a drawing mechanism, matched with each other in a transmission mode and fixed with the floating box, the floating fire pump driving oil motor is connected with a winding disc oil tube oil-way of an oil tube winding disc of the automatic water diversion fire fighting truck, and the filtration net sleeve is connected with the lower portion of the floating fire pump. The floating fire pump assemblies can be stretched out of a truck body of the fire fighting truck by a jack mechanism through the drawing mechanism and released to the water face to enable the floating fire pump to independently get water by the drawing mechanism, ideal flexible maneuverability can be reflected, and operating strength of a firefighter can also be remarkably relieved; and owing to the fact that the floating box can enable the floating fire pump to be in the semi-submersible state on the water face, the risk of being blocked by riverbed sludge because of sinking to a riverbed can be avoided.

Owner:JIEDA FIRE PROTECTION VEHICLE EQUIP CO LTD SUZHOU CITY

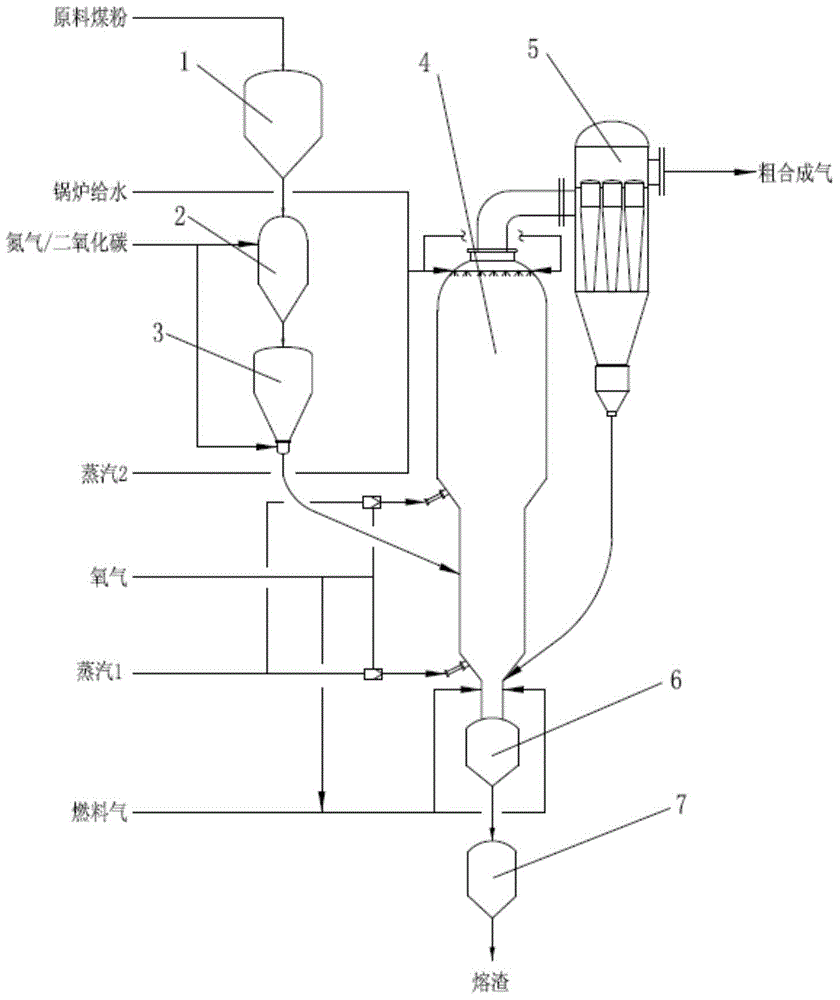

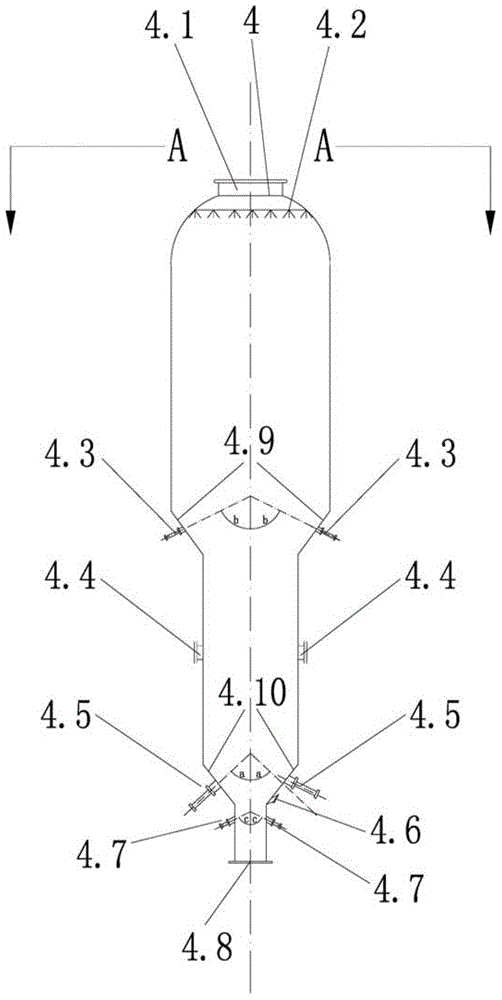

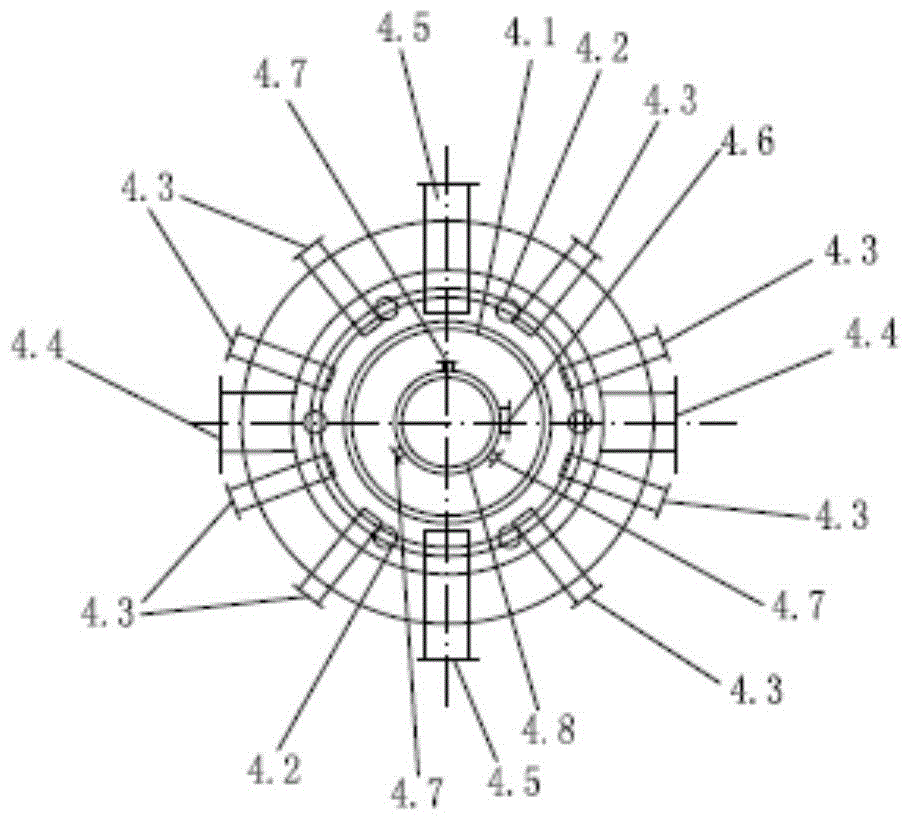

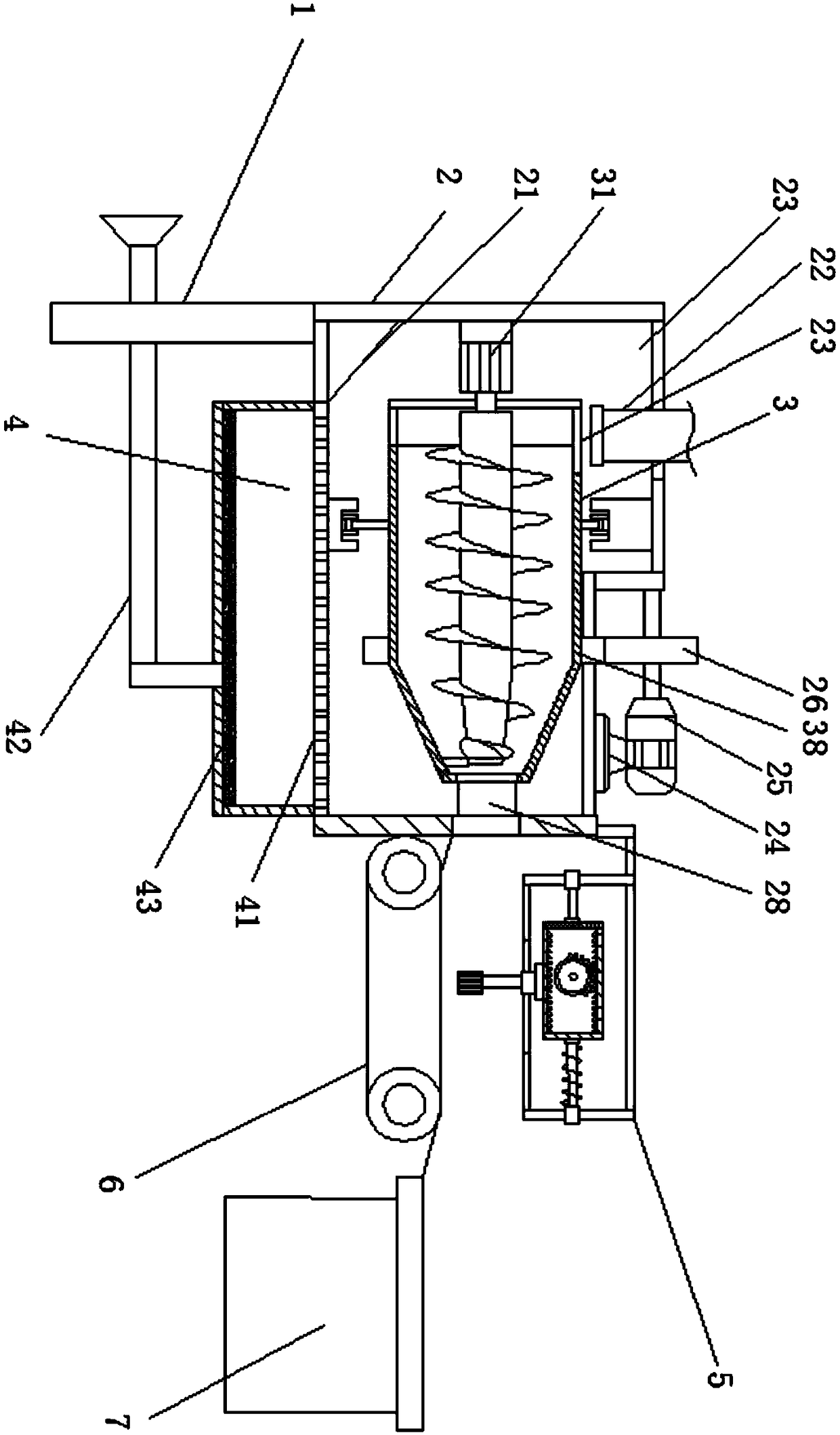

Clean coal pressurized fluidized bed slag gasification process and system

ActiveCN104531224AEffective coagulationEffective returnGasification processes detailsGasification apparatus detailsCycloneFluidized bed gasifier

The invention discloses a clean coal pressurized fluidized bed slag gasification process and system. By means of the gasification process and system, the problems that an existing pressurized fluidized bed industrial gasification process is complex, poor in coal applicability, low in gasification pressure, small in production capacity and low in gasification efficiency, the environment is polluted are solved. According to the technical scheme, the process includes the steps that raw material coal powder is pressurized and sent to a fluidized bed gasification furnace through a material inlet to react with a gasifying agent in a gasification mode, and crude synthesis gas and coal powder ash slag are obtained; the crude synthesis gad rises and is sent to a multi-pipe type cyclone separator through a top outlet of the fluidized bed gasification furnace to be dedusted, fluidizing agents are sprayed twice through a gasification spray nozzle to improve gasification efficiency, the coal powder ash slag is melt through a slag melting device, forms melt slag and then enters a slag quenching tank through a bottom outlet of the fluidized bed gasification furnace to be quenched and discharged through a slag locking hopper. The clean coal pressurized fluidized bed slag gasification process and system are simple in process, easy and convenient to operate, wide in coal applicability, high in gasification pressure, large in production capacity, high in gasification efficiency and environmentally friendly.

Owner:WUHUAN ENG +1

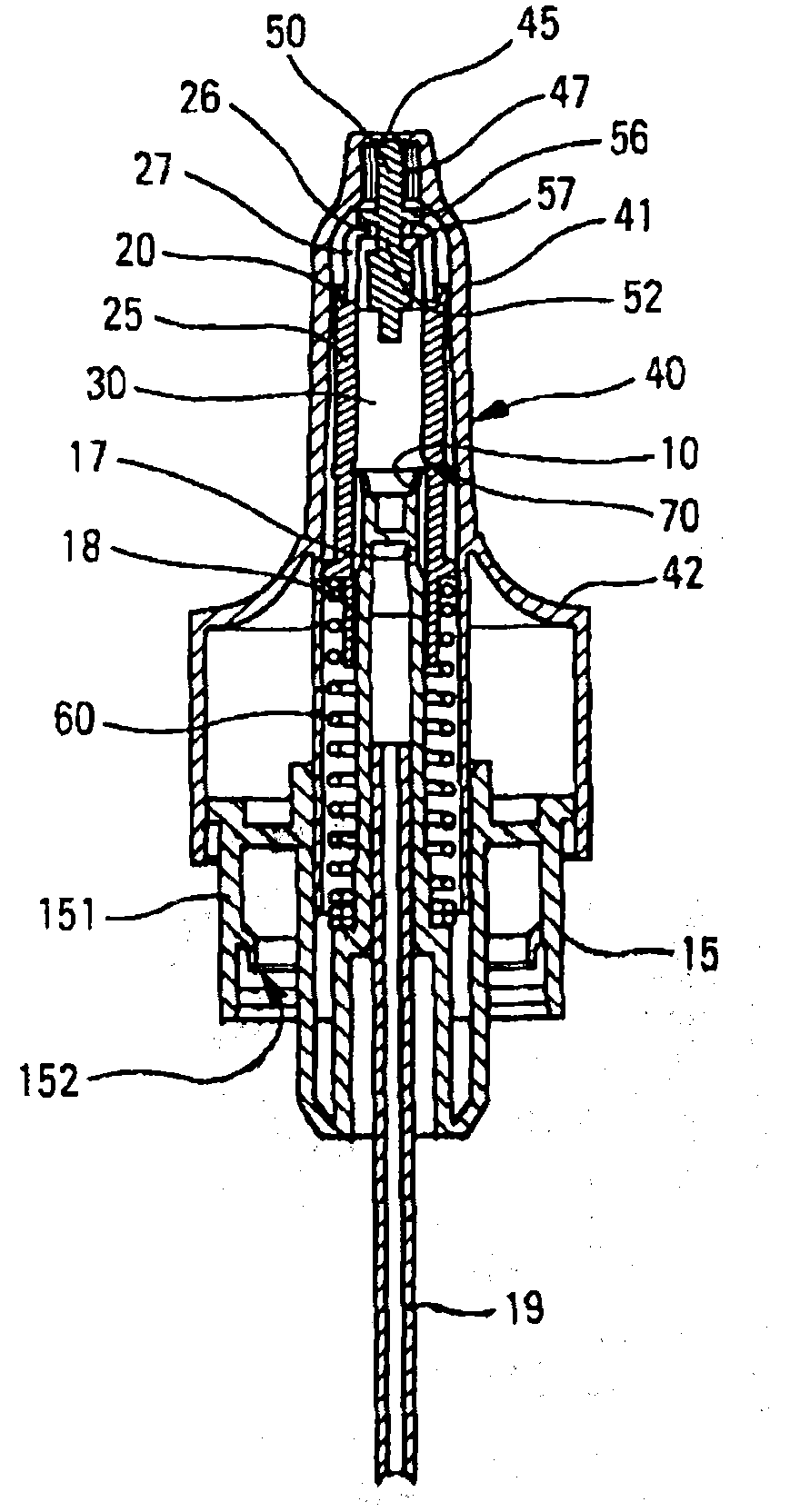

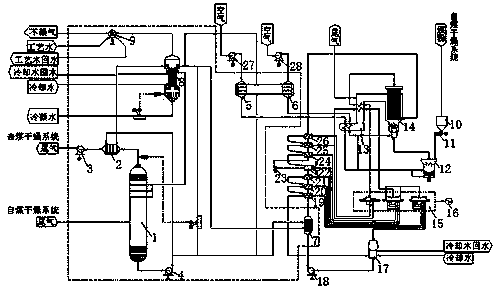

Pump for dispensing a fluid material

InactiveCN103492086AFixed forAllow flowSingle-unit apparatusInhalatorsEngineeringMechanical engineering

A fluid dispenser pump including a first piston, a second piston, and a dispenser head with a dispenser orifice, for actuating the pump, a shutter arranged upstream from the dispenser orifice, the shutter movable between closed and open positions. The second piston is formed outside a hollow part and is slidable inside the dispenser head. The first piston is slidable inside the hollow part, the hollow part including an axial opening defined by a radial edge through which passes a stem portion of the shutter. The stem portion is between a proximal radial shoulder and a distal radial shoulder of the shutter, the shutter being moved from its closed position to its open position by the radial edge of the hollow part co-operating with the distal radial shoulder, and being moved from its open position to its closed position by the radial edge co-operating with the proximal radial shoulder.

Owner:APTAR FRANCE SAS

Method of utilizing coal drying exhaust steam to reduce coal consumption of coal-fired power generator set and recovering water

ActiveCN103968659AReduce coal consumption for power supplyIncrease temperatureDrying solid materialsProcess engineeringThermal water

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

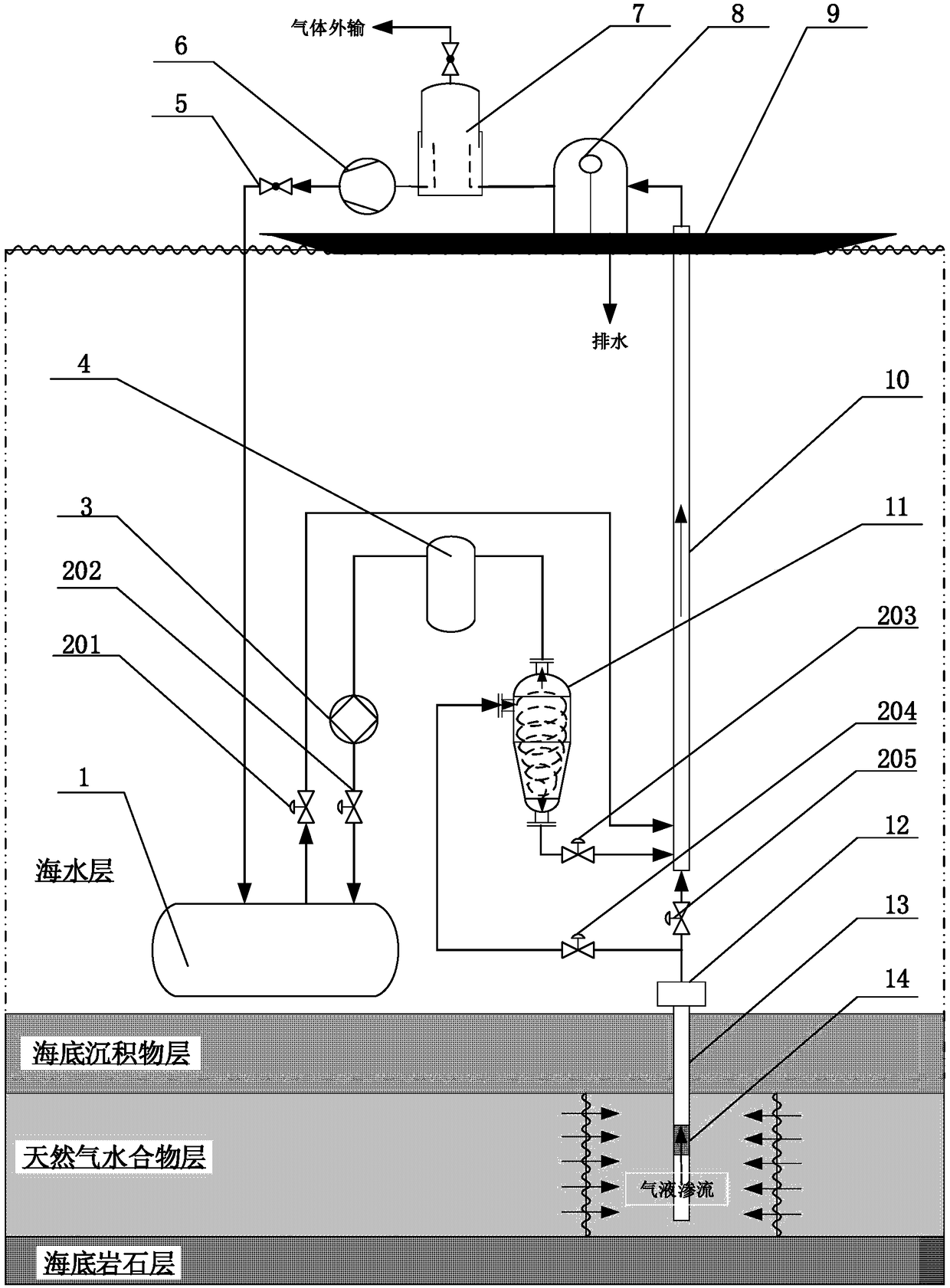

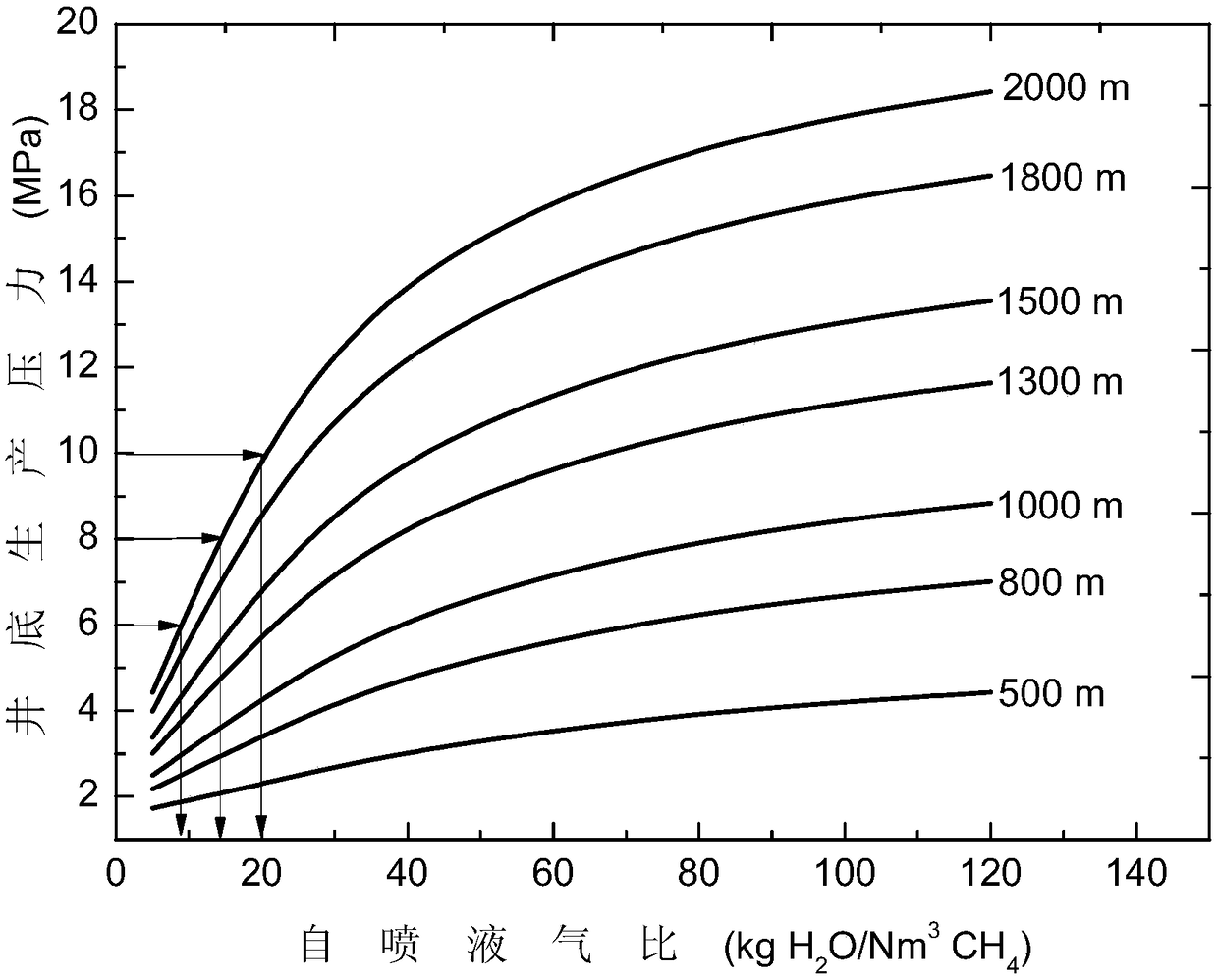

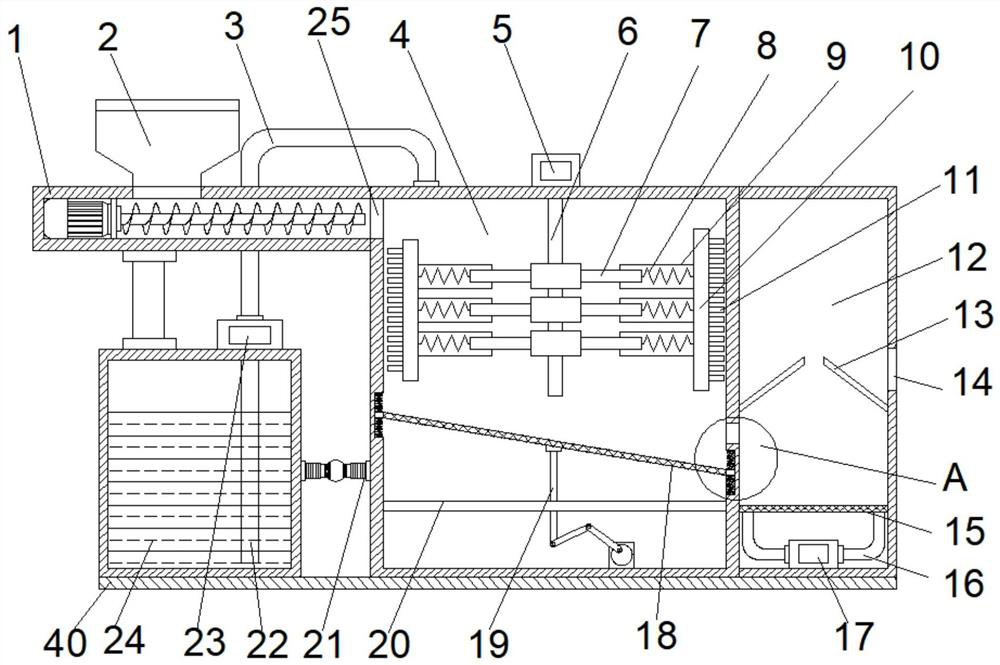

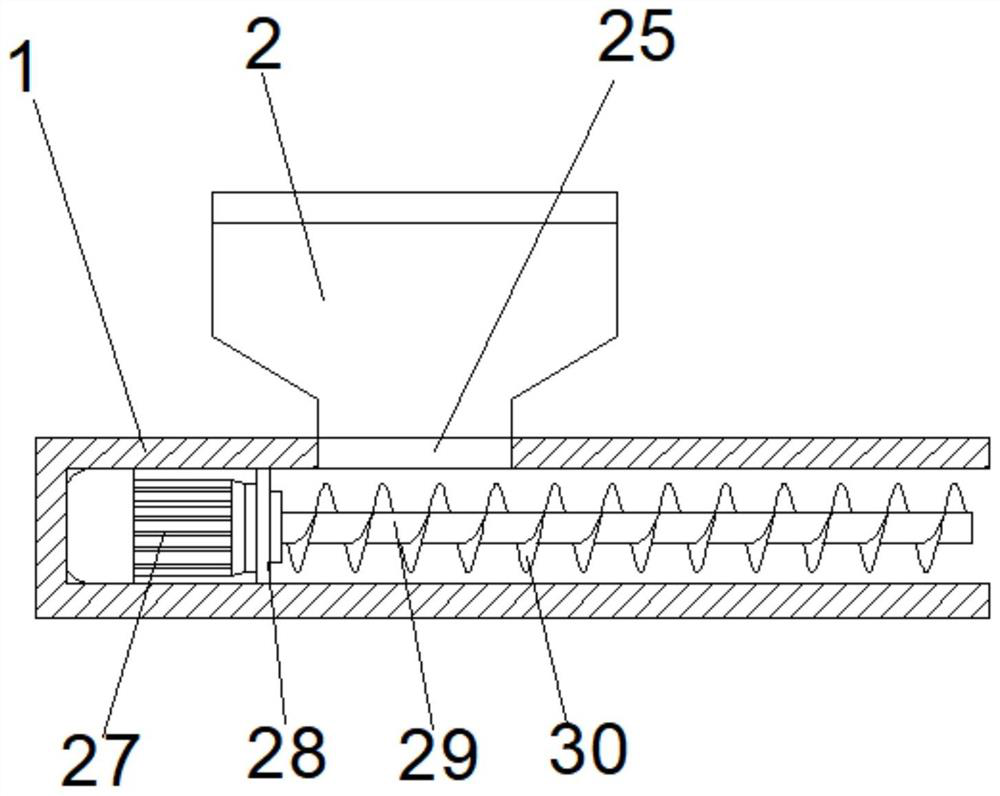

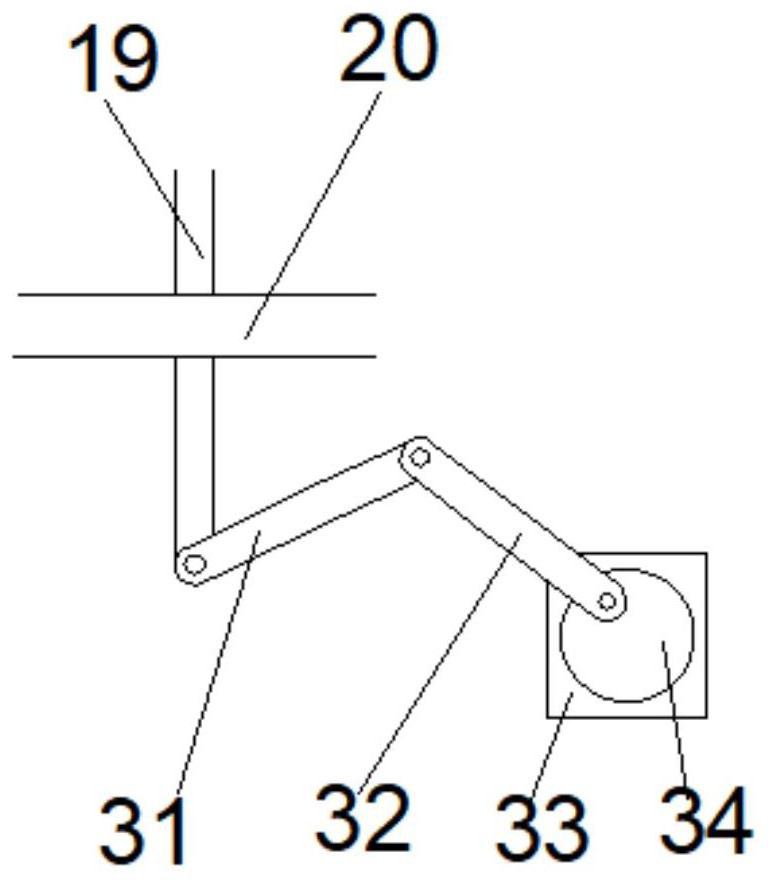

Gas-exploitation method and system for natural gas hydrate exploitation

ActiveCN108278100AReduce consumptionSimple processConstructionsOther gas emission reduction technologiesBottom pressureHydrate decomposition

The invention discloses a gas-exploitation method and system for natural gas hydrate exploitation. Natural gas hydrates are utilized to decompose the gas lift effect of released methane gas, a gas-water mixture at the well bottom of an exploitation well is conveyed to a sea surface platform through an ocean riser, and thus controllable flowing exploitation of the ocean natural gas hydrates is achieved; at the exploitation starting stage, through the gas stripping effect of externally-injected gas, the well bottom pressure is reduced, and thus the hydrates are decomposed; and at the flowing exploitation stage, flowing exploitation is achieved through the gas lift effect of the natural gas hydrate decomposing gas, through a seabed gas storage tank, the flowing speed is adjusted, and gas consumption is supplemented. The gas exploitation technique and equipment are simple, operation is convenient, energy consumption is low, seabed movable equipment is not needed, industrial and automatic production is easy to achieve, the blockage risk caused by forming of secondary hydrates in the ocean riser can be avoided effectively, and the application range is wide.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Impurity removal device for wool processing

InactiveCN112813507APlay a role in looseningAvoid clumpingDrying gas arrangementsWool fibre washing/scouringThermodynamicsElectric machinery

The invention discloses an impurity removal device for wool processing. The impurity removal device comprises a base, wherein an impurity removal box is arranged above the base, a crushing barrel is arranged on the left side of the impurity removal box, a first motor is arranged on the left side of the interior of the crushing barrel, a first rotating rod is arranged at the output end of the first motor, a rotating blade is arranged on the first rotating rod, stirring rods are arranged in the impurity removal box, a filter screen plate is arranged below the stirring rods, the filter screen plate is in sliding connection with the impurity removal box, a water tank is arranged on the left side of the impurity removal box, a water pump is arranged at the top of the water tank, a water outlet pipe is arranged at the water inlet end of the water pump, a water inlet pipe is arranged at the water outlet end of the water pump, and the tail end of the water inlet pipe is in communication with the impurity removal box. During working, wool is poured into the crushing barrel from the feeding hopper, the wool is opened through the arrangement of the rotating blades, and the phenomenon of wool caking is fully avoided; meanwhile, a water pump injects water into the impurity removal box, a second motor drives the stirring rods to rotate, and thus the wool is cleaned.

Owner:苏州开江纺织品有限公司

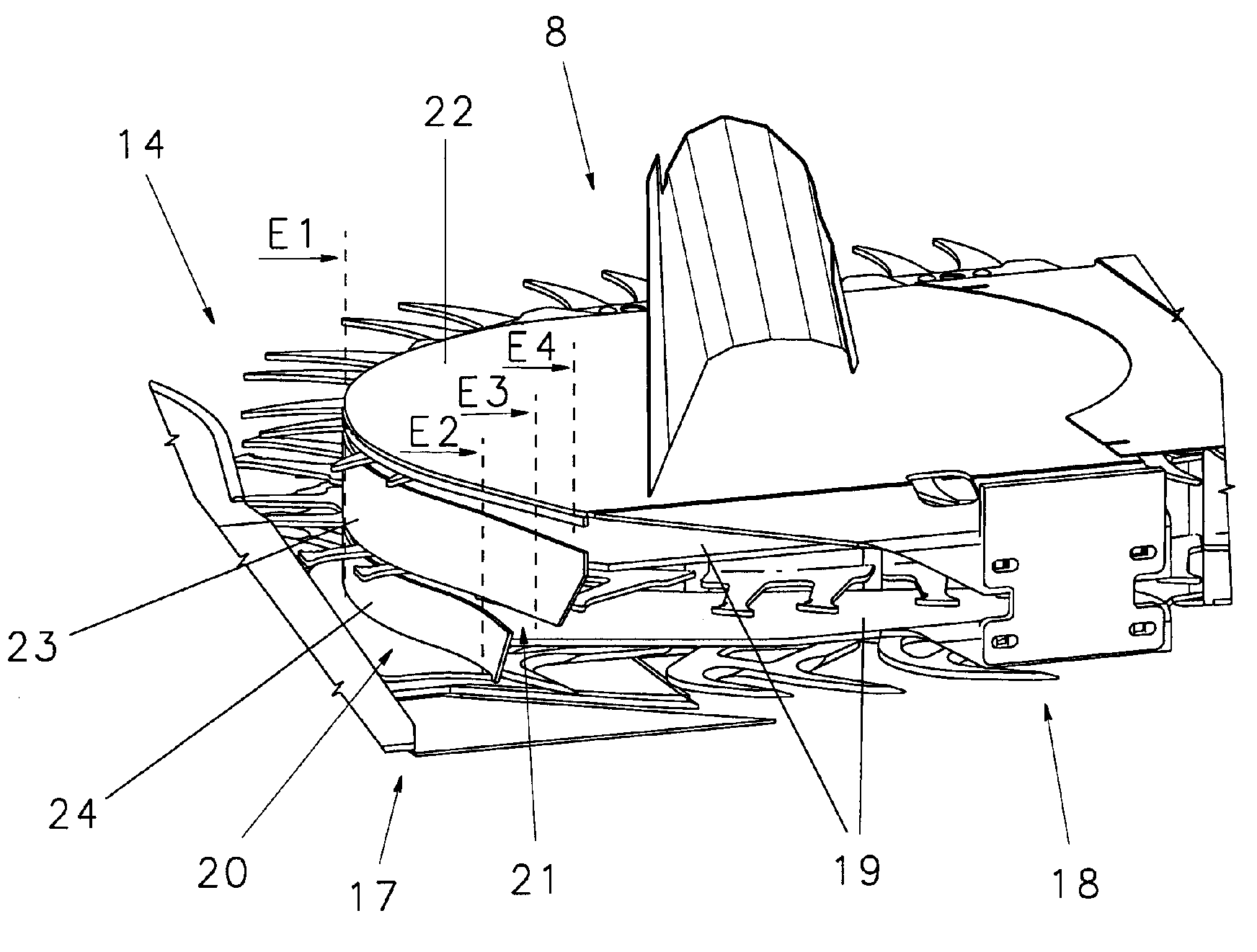

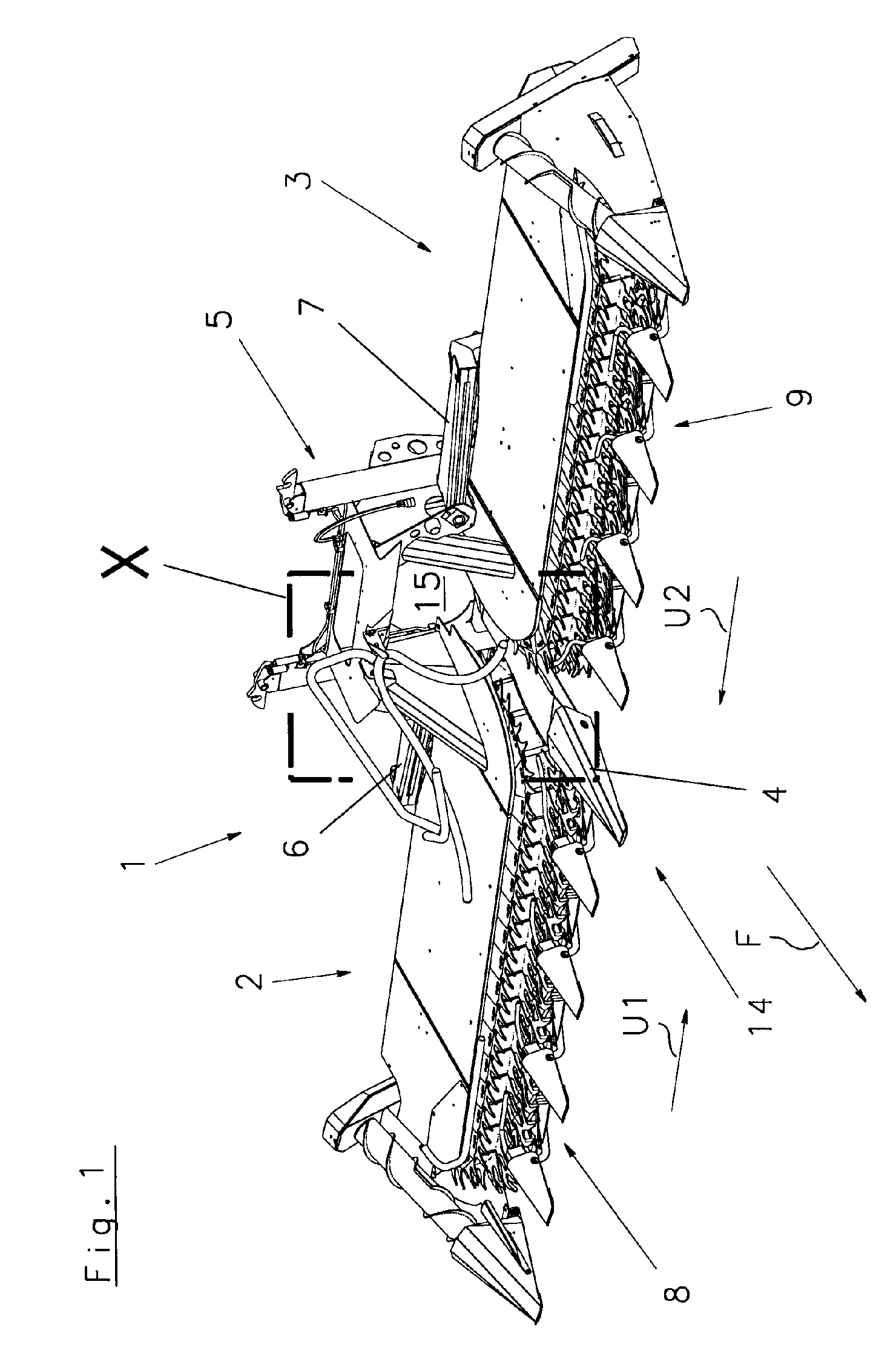

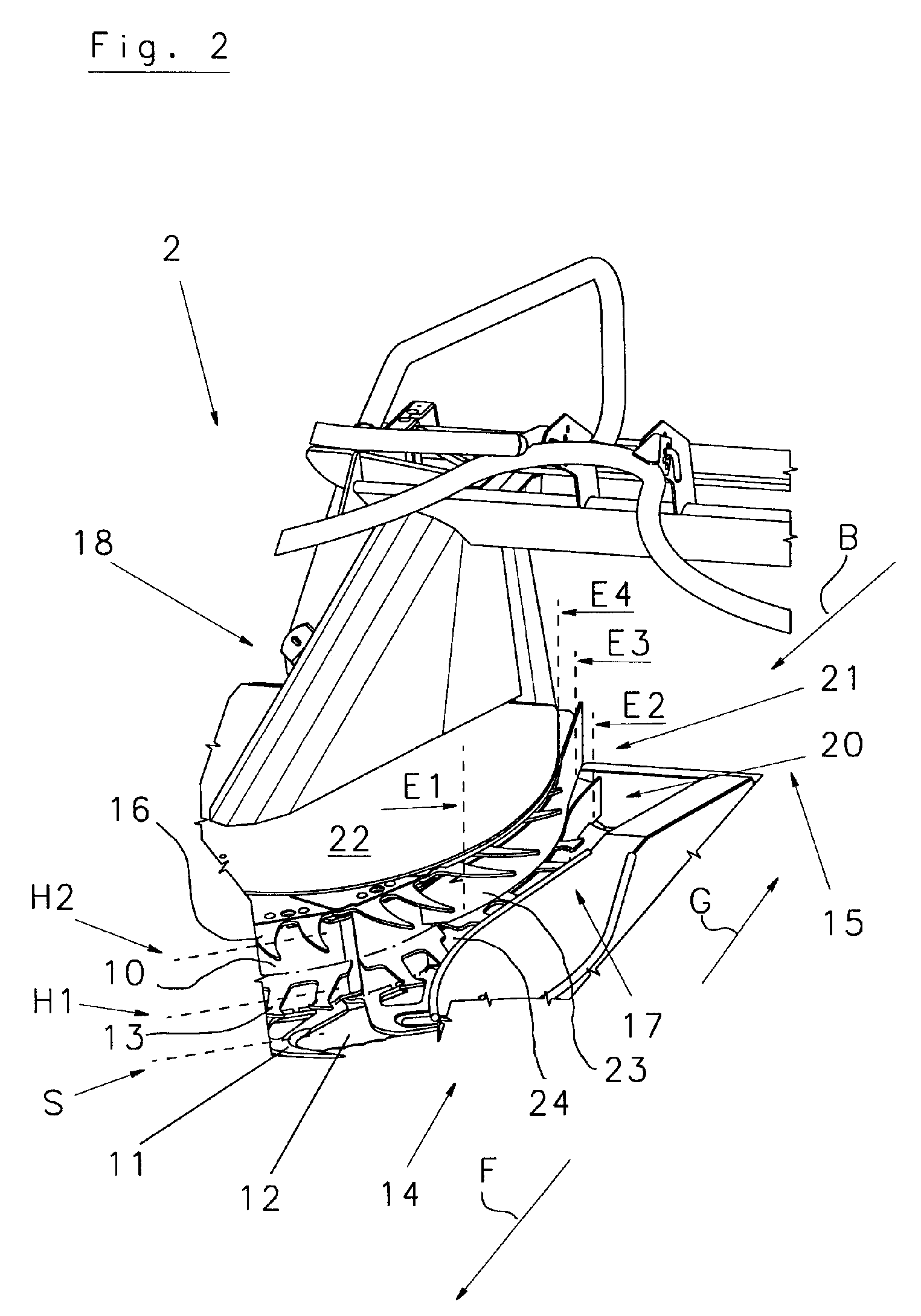

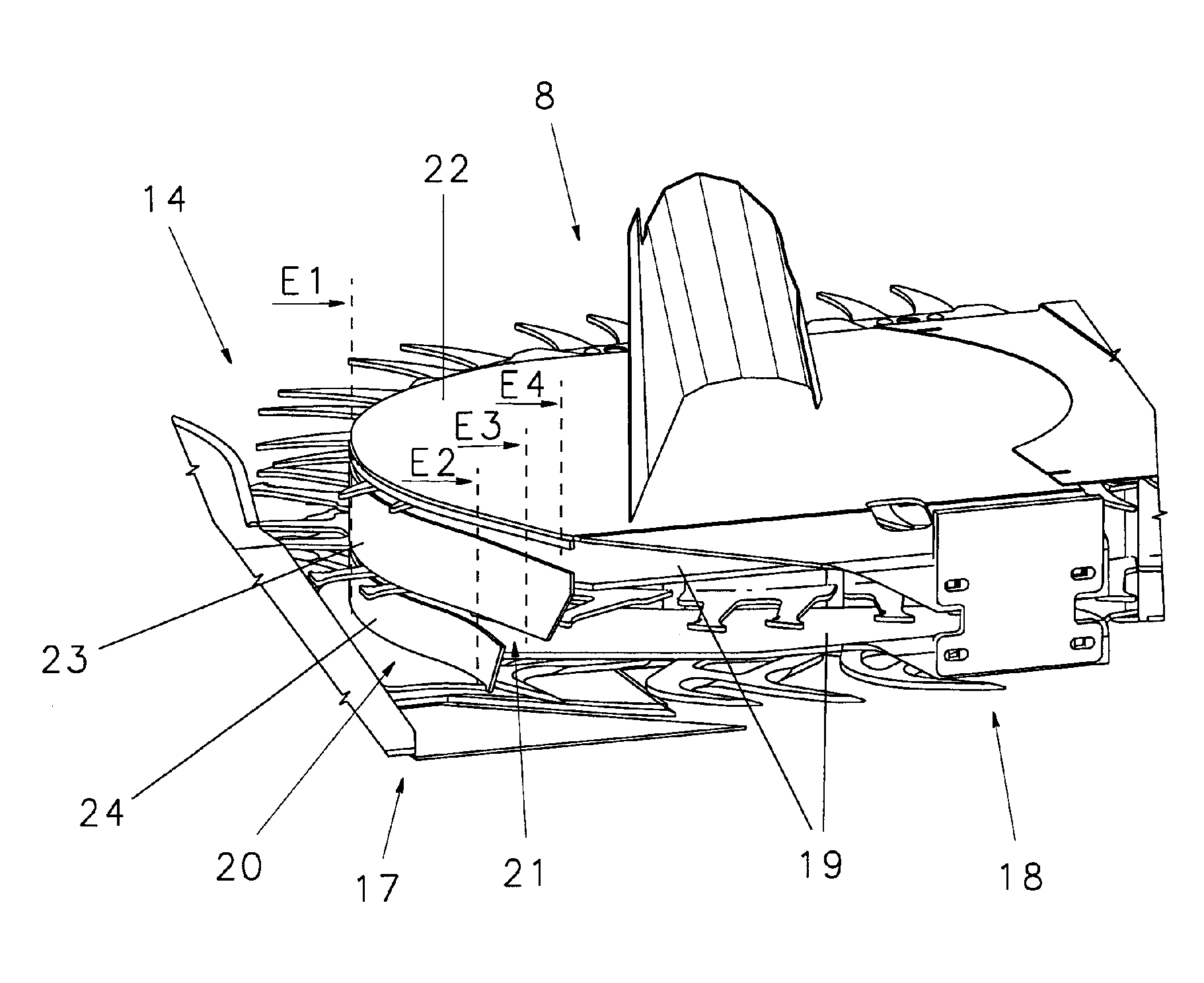

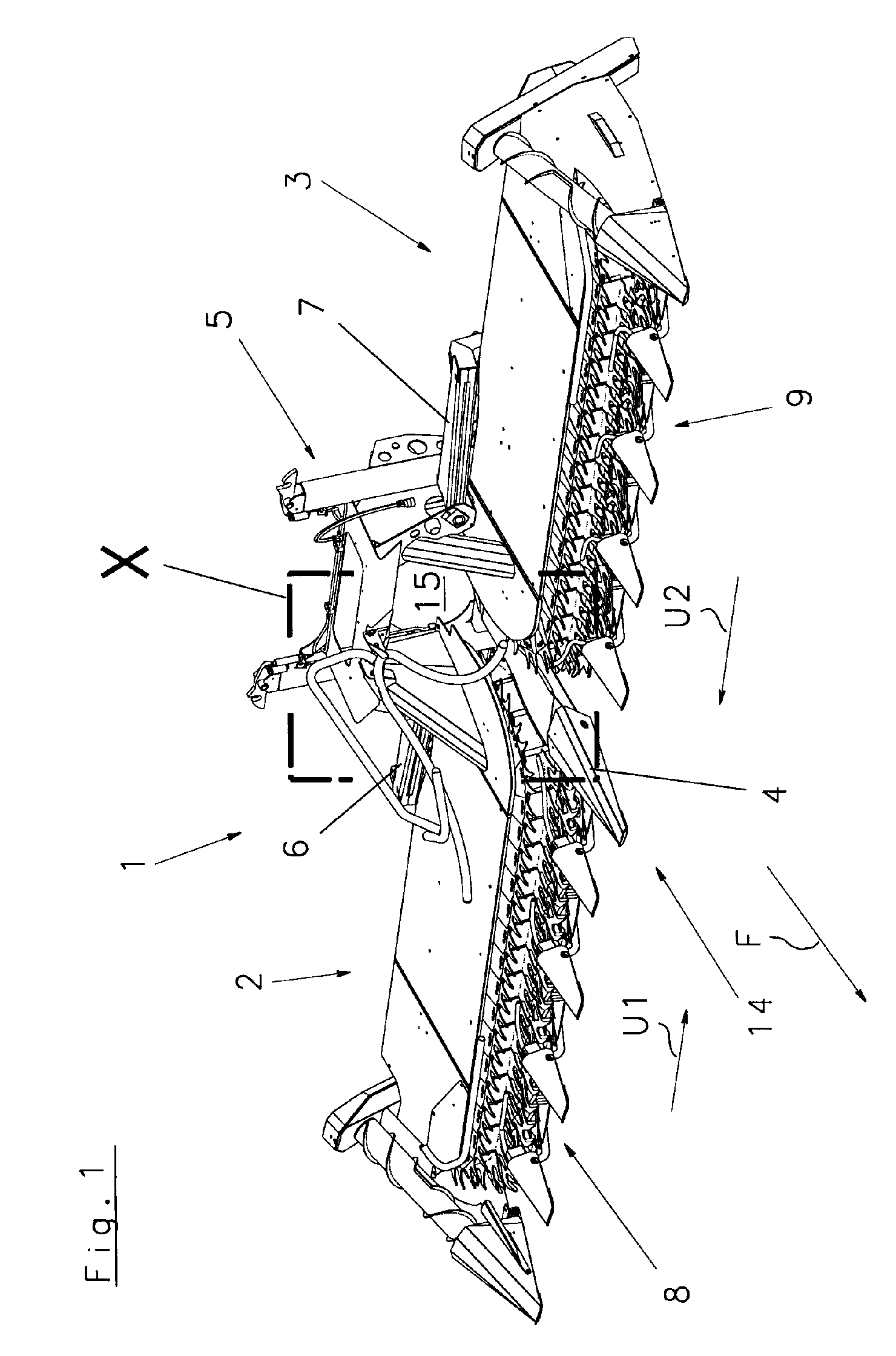

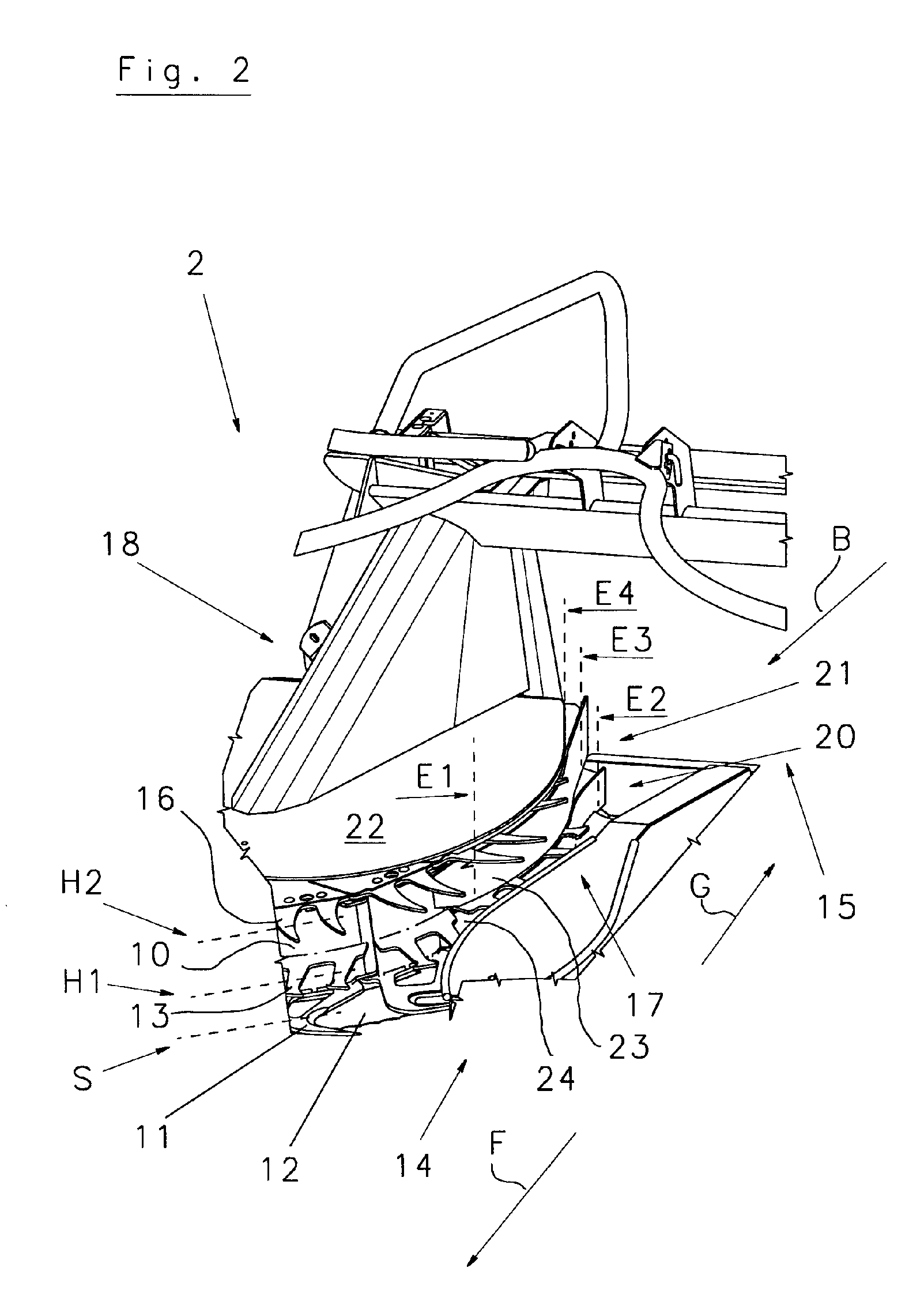

Harvester

A harvester for harvesting stalky crops has an intake and conveying device having an endless conveyor provided with outwardly oriented cutting, holding, and conveying elements that form cutting planes and holding planes. The endless conveyor has a supply area for transferring crop to an inlet opening of a processing device. The supply area has a stripping device with clearing elements each having a stripping surface. The stripping surfaces of the clearing elements are remote from a holder and face forwardly in the traveling and working direction. The stripping surfaces are vertical in an end area pointing in the traveling and working direction and positioned in a common vertical plane. The stripping surfaces have a section extending from the end area in a direction of crop flow and diverge with increasing spacing from one another in the direction of crop flow.

Owner:MASCHFAB BERNARD KRONE GMBH

Logistics storage bin with damp-proof function

InactiveCN111824615ASave spaceAchieve the effect of absorbing moistureLarge containersTank wagonsLogistics managementStructural engineering

The invention relates to the technical field of logistics storage, in particular to a logistics storage bin with a damp-proof function. The logistics storage bin comprises a rack and a storage bin body, the storage bin body is erected in the rack, a supporting plate is arranged on the rack, a fixing hoop is installed on the supporting plate and installed on the outer wall of the storage bin body,the storage bin body does not make contact with the ground, and a bottom frame is arranged at the bottom end of the rack; a bottom bin is arranged at the bottom of the storage bin body, a dischargingcover plate is arranged on the side edge of the bottom bin, a ventilation pipe is arranged on the bottom frame, and the ventilation pipe is connected with the bottom bin through a grid valve; a dryingframe is further installed on the side edge of the rack, a vertical guide pipe is arranged on the drying frame, an air suction pump is arranged at the bottom of the vertical guide pipe, and a dryingcavity is formed in the bottom end of the air suction pump; and a flow guide pipe is further arranged at the top of the storage bin body, the flow guide pipe extends into the storage bin body and is provided with an air outlet hole, and an air guide plate is arranged at the air outlet hole. According to the logistics storage bin with the damp-proof function, moisture at the bottom is pushed to downwards enter the drying cavity and is adsorbed by a drying agent in the drying cavity, and the operation effect of moisture adsorption is effectively achieved.

Owner:岳阳弘发科技服务有限公司

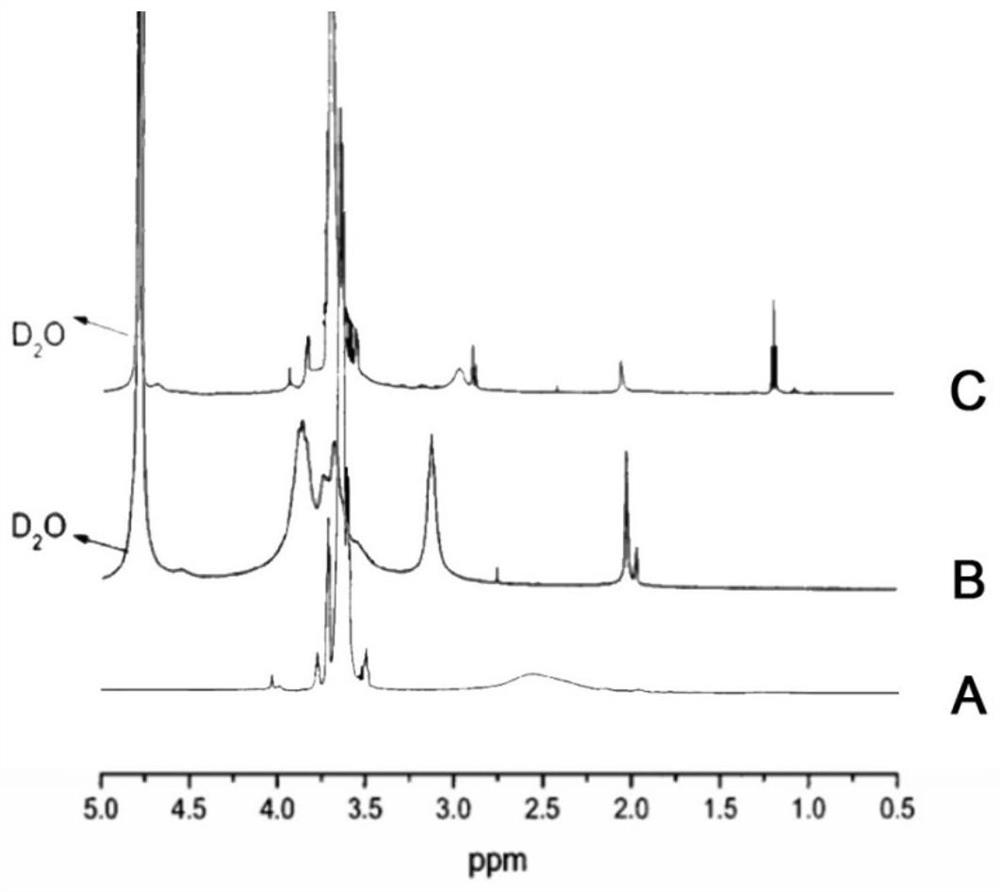

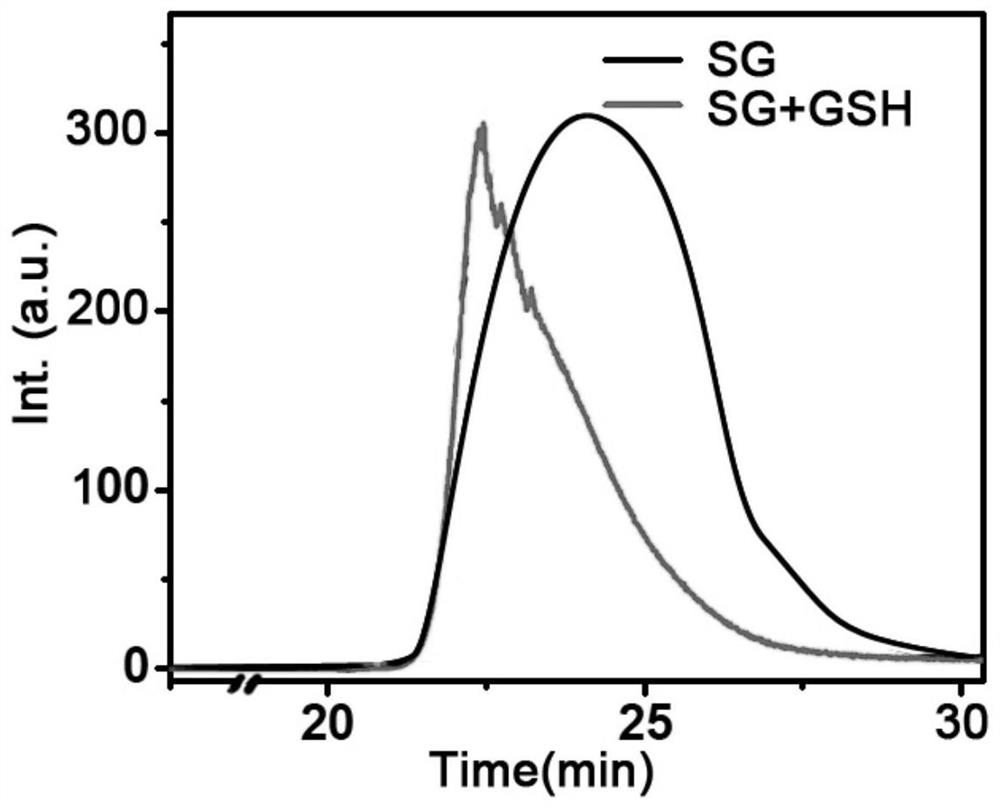

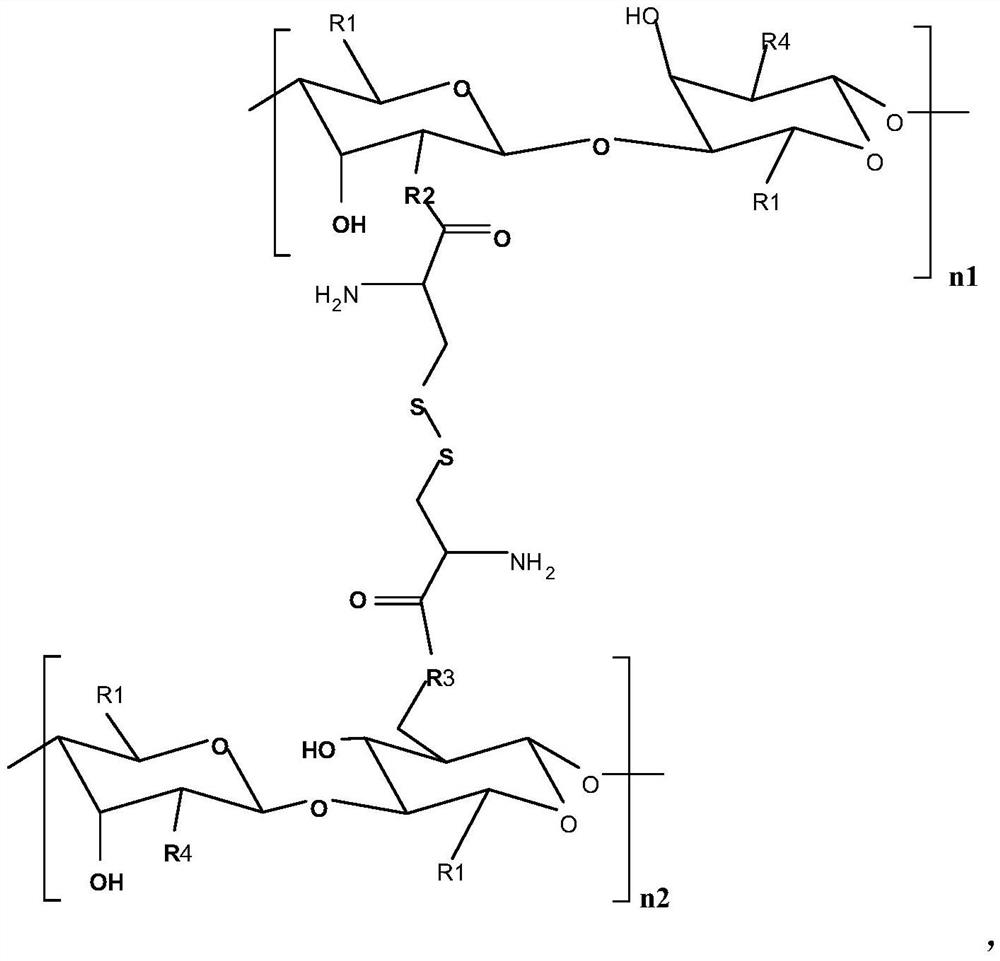

Intragastric superabsorbent gel primary product and preparation method thereof, intragastric superabsorbent gel and preparation method thereof, and weight reducing composition

ActiveCN111704730AImplement Responsive DestructionIncrease satietyOrganic active ingredientsMetabolism disorderGastric emptyingSmall intestine

The invention discloses an intragastric superabsorbent gel primary product and a preparation method thereof, intragastric superabsorbent gel and a preparation method thereof, and a weight reducing composition, and belongs to the technical field of medicines. The structural formula of the hydrogel primary product is as shown in the specification, wherein R1 represents COONa, COOK, CH2OCH2OCOONa orCH2OCH2CH2OH, etc.; R2 is O or NH, etc.; R3 is O, NH, O (CH2CH2O) n4, [CH2CH (OH)] n5 or (CH2CH2) y, etc.,; and R4 is OH, NHCOCH3 or NH2, etc.; and n1 to n5, x and y are integers greater than 0. The hydrogel primary product can increase the satiety of a patient and reduce the weight by reducing the intake, and is high in biocompatibility. The intragastric superabsorbent gel and the weight reducingcomposition also have the above effects, and the weight reducing composition can also avoid the risk that the stomach enters the small intestine to block the small intestine after being emptied. Thepreparation method of the substances is simple and easy to operate.

Owner:王萌燕

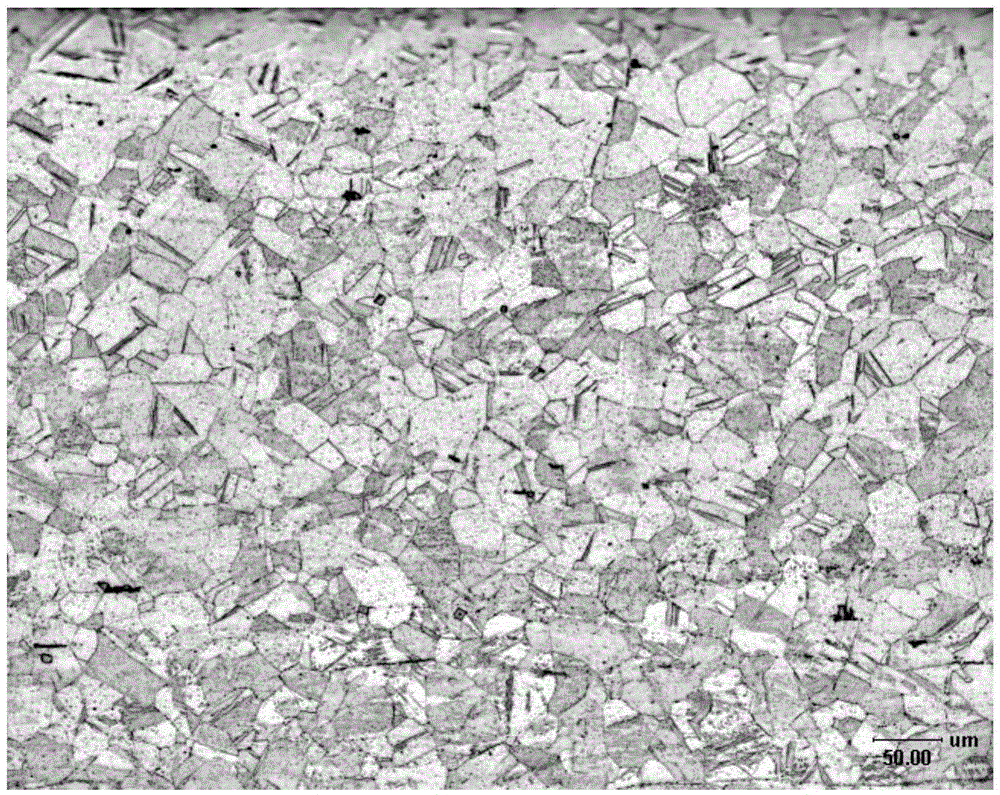

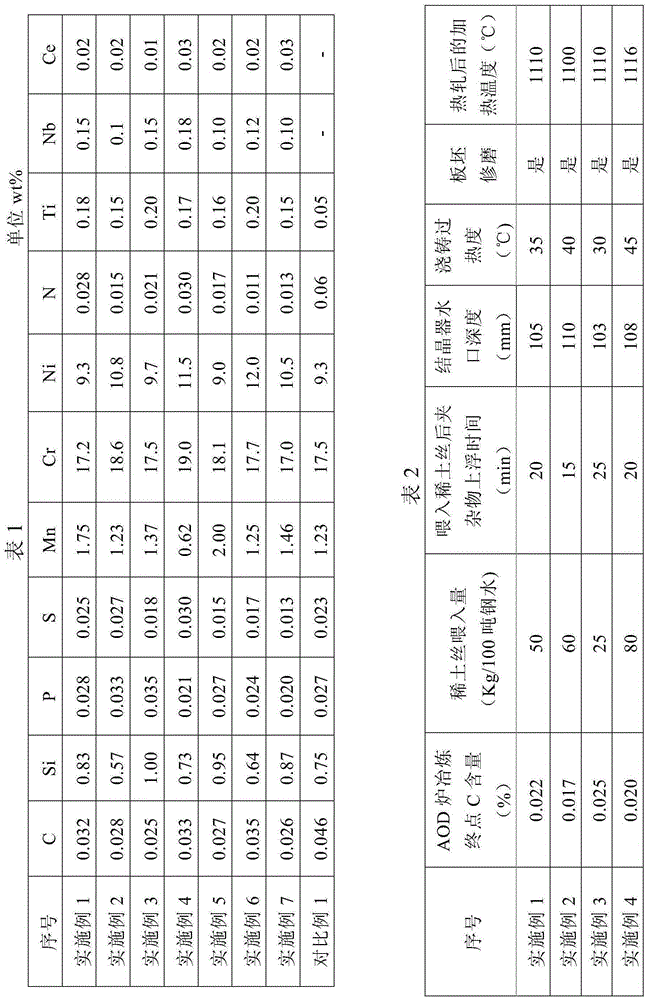

Titanium-containing austenitic stainless steel with good antioxidation performances and manufacturing method thereof

The invention discloses titanium-containing austenitic stainless steel with good antioxidation performances and a manufacturing method thereof. The titanium-containing austenitic stainless steel comprises, by mass, 0.025-0.035% of C, 0.6-1.0% of Si, 1.2-2.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.030% of S, 17.0-19.0% of Cr, 9.00-12.00% of Ni, 0.01-0.03% of N, less than or equal to 0.2% of Ti, less than or equal to 0.2% of Nb, 0.01-0.03% of Ce and the balance Fe and unavoidable impurities. The use amount of Ti and Nb is greater than or equal to five-fold amount of C or the use amount of Ti and Nb is greater than or equal to five-fold amount of C and N. In melting, rare earth Ce is used and after continuous casting, plate blank surface grinding, plate blank heating, rolling and heat treatment, a steel product is obtained so that steel product manufacturability, surface quality and high temperature oxidation performances are substantially improved.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

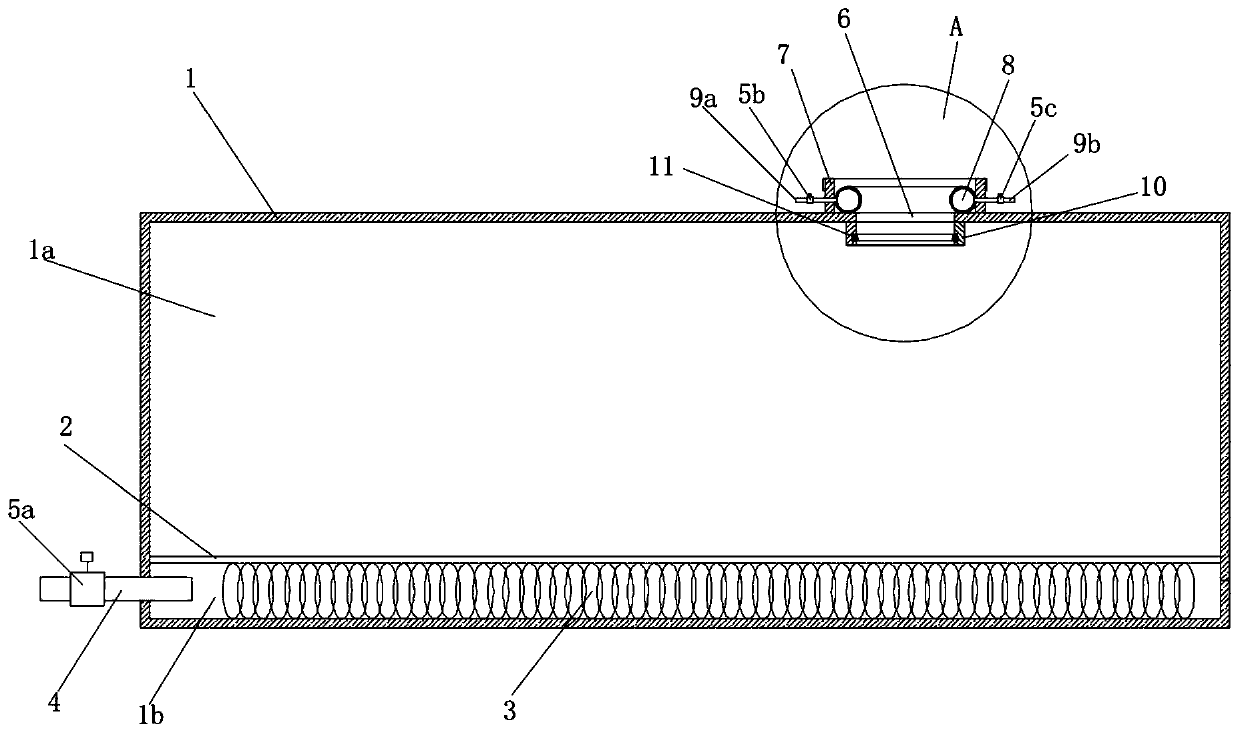

Powder material loading device with dynamic rapid discharging function

The invention relates to a powder material loading device with a dynamic rapid discharging function. According to the technical scheme, the lower part of a body is provided with a breathable layer, the breathable layer divides the interior of the box body into an upper material bin and a lower inflation bin, the side wall of the box body in which the inflation bin is located is connected with an inflation pipeline communicating with an inner cavity thereof, the top of the box body in which the material bin is located is provided with a material opening communicating with the inside and the outside, a discharging pipeline with a sliding connection is arranged on the material opening in a penetrating manner, an annular air bag fixing edge is fixed to the top surface of the box body around the material opening, and an annular air bag used for pressing and fixing the discharging pipeline is arranged in the inner side of the annular air bag fixing edge. According to the device, flow of thepowder material is monitored in real time through a powder flow meter, the height position of the discharging pipeline is adjusted in real time according to the flow value, the lower opening of the discharging pipeline is always kept a closer distance to the top surface of the powder material, a space for releasing pressure and feeding is provided, high-speed unloading is always maintained, the discharging time is compressed, and the discharging cost is saved.

Owner:郭银平

Combined silicon removal and hardness removal technological method for coal-gasification wastewater

InactiveCN108821406AEasy to operateLow investment costWater/sewage treatment by flocculation/precipitationCoal gasification wastewaterHardness

The invention provides a combined silicon removal and hardness removal technological method for coal-gasification wastewater. The technological method comprises the following steps: firstly, adding anagentia A into the coal-gasification wastewater; secondly, simultaneously adding an agentia B, an agentia C and an agentia D into the coal-gasification wastewater subjected to the treatment in the first step; thirdly, standing and clarifying the coal-gasification wastewater subjected to the treatment in the second step. The combined silicon removal and hardness removal technological method for the coal-gasification wastewater, provided by the invention, has the advantages of simple operation, short process flow and low cost; silicon and the hardness in the wastewater can be better removed atnormal temperature and pressure and good economic prospect is achieved.

Owner:CHINA TIANCHEN ENG

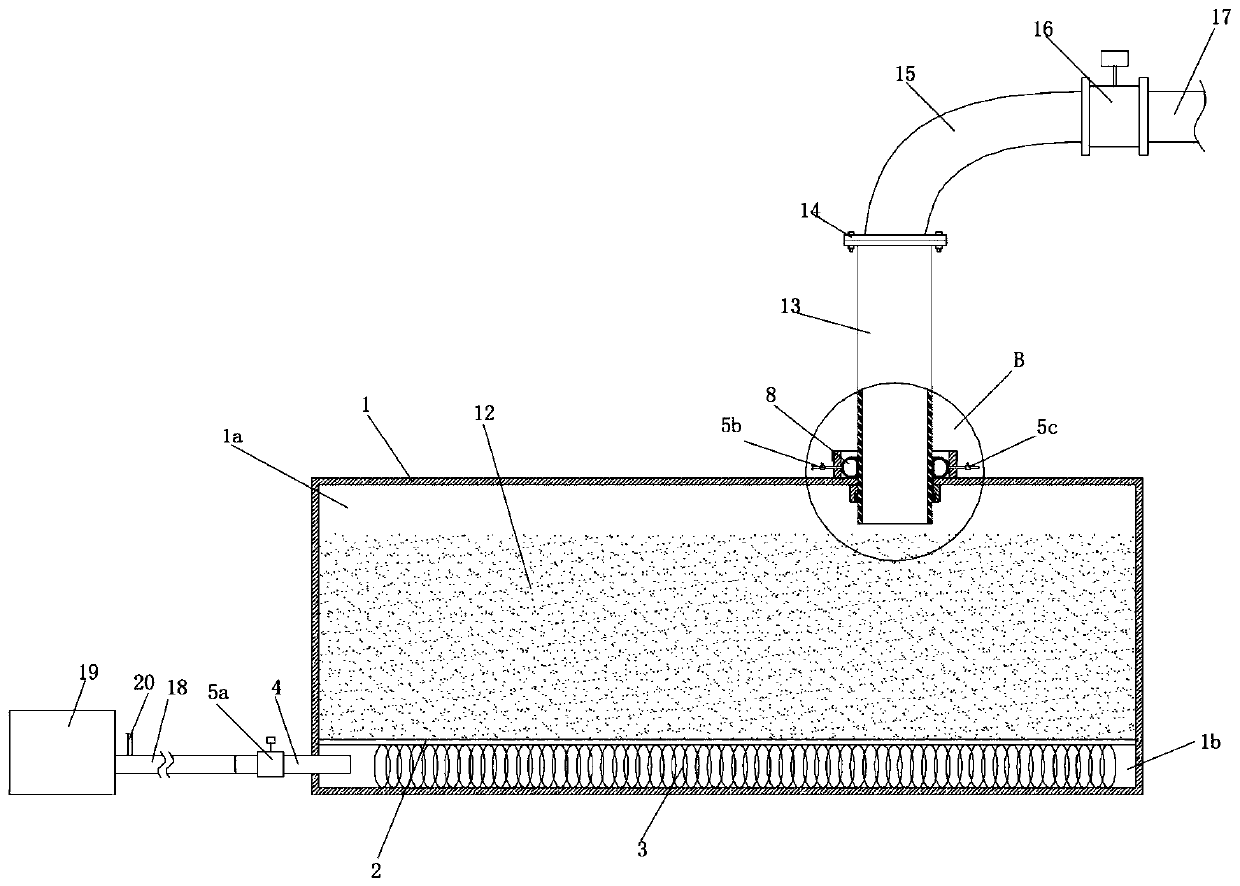

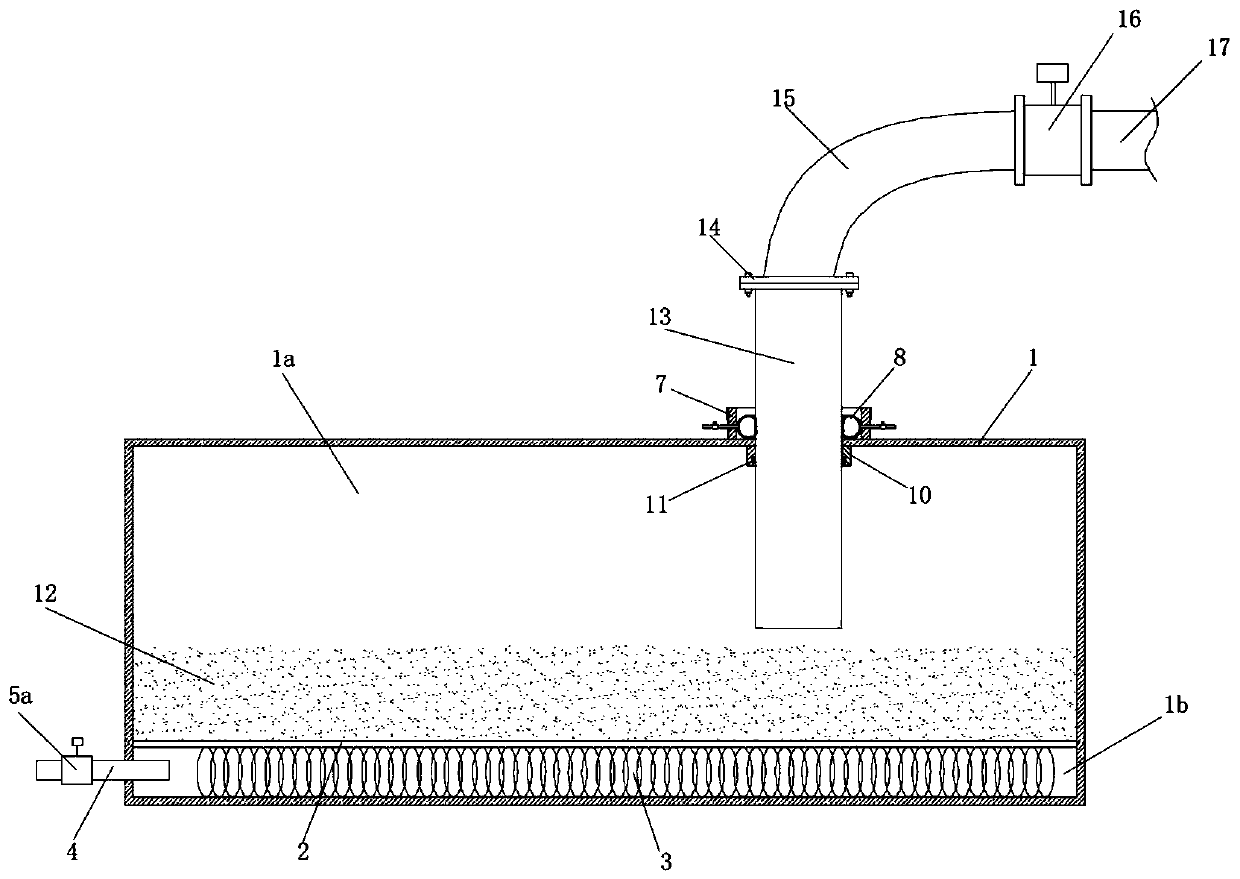

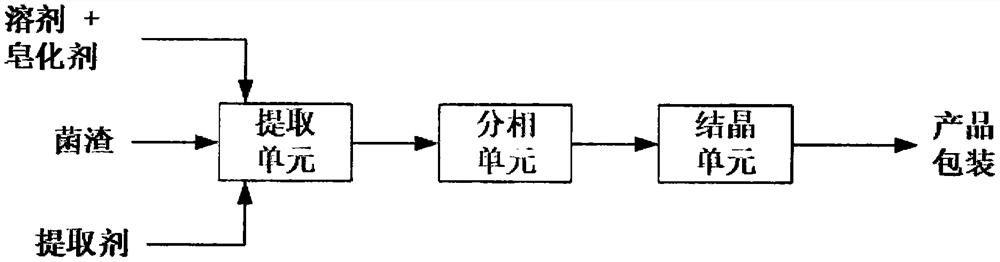

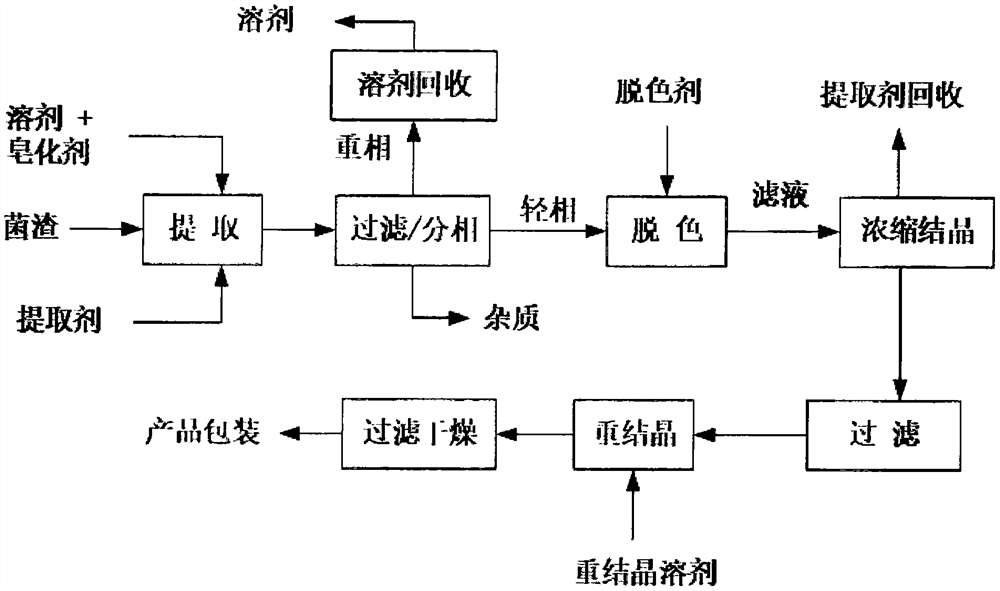

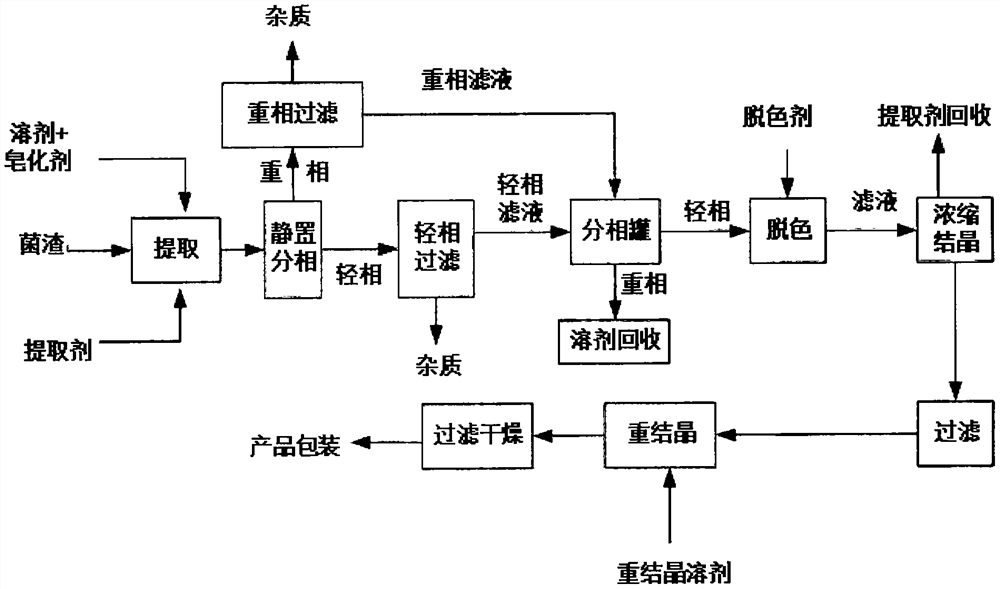

Method and system for extracting ergosterol from zymophyte residues

PendingCN112142815ASimple extraction processSimplified extraction process parametersSteroidsPhase splittingCombinatorial chemistry

The invention discloses a method for extracting ergosterol from zymophyte residues, which comprises the following steps: S1, extraction: adding a solvent, a saponifying agent and an extracting agent into the zymophyte residues containing ergosterol, and carrying out saponification and extraction reaction to obtain an extraction mixture; S2, carrying out phase splitting, namely carrying out phase splitting on the extracted mixture in the step S1 to obtain an extracting solution containing ergosterol; S3, crystallization: concentrating and crystallizing the extracting solution in the step S2 toobtain an ergosterol crude product. The invention further discloses a system for extracting ergosterol from the zymophyte residues. The method has the advantages of short process flow, short extraction time, low energy consumption in the extraction process, high product purity and the like.

Owner:内蒙古麦维生物科技有限公司

Dual-smashing type paper shredder for office work

InactiveCN108080095AEasy dischargeGuaranteed confidentialityGrain treatmentsCardboardConfidentiality

The invention discloses a dual-smashing type paper shredder for office work. The paper shredder comprises a base, a shredded paper box, smashing strip knives, driving motors, smashing rollers and an inclined plate; the smashing strip knives are slidingly installed on the left and right sides in a first smashing cavity, the smashing rollers are rotationally installed between paper baffles on the left and right sides, a stand column is fixedly installed on a paper outlet, the inclined plate is hinged to the stand column, and a wedge-shaped slider is arranged on the lower side of the inclined plate. Through dual smashing by the smashing strip knives and the smashing rollers, it is ensured that waste paper is smashed into powder, so that the confidentiality of data is guranateed; when paper discharge is needed, a push handle is pushed forwards to indirectly drive the wedge-shaped slider to move leftwards, then, the inclination angle of the inclined plate is changed, thus, the waste paper can be conveniently discharged from the paper outlet, the risk of blockage is effectively avoided, and the paper discharge speed is greatly increased.

Owner:苏州德特尼罗电子科技有限公司

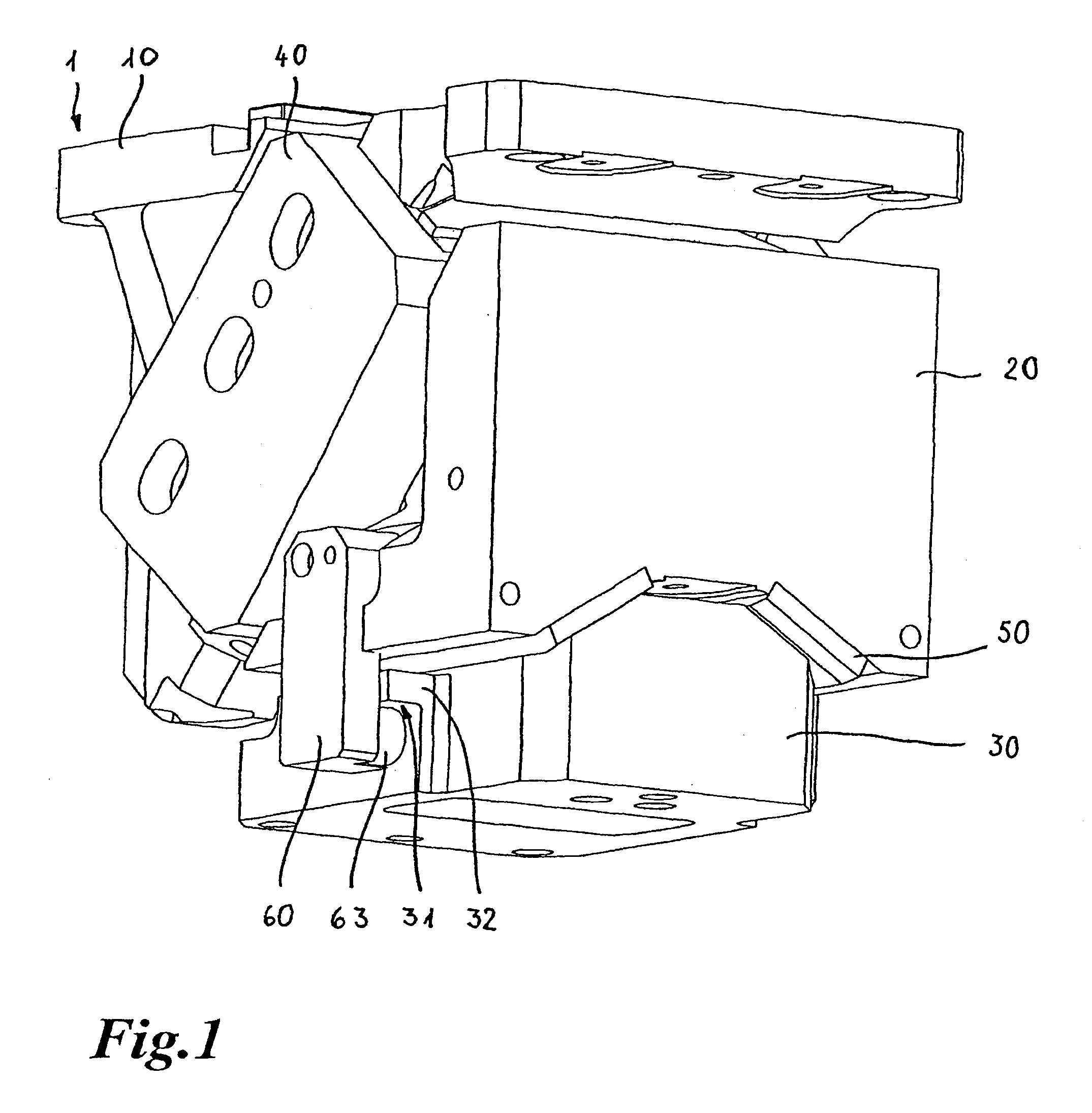

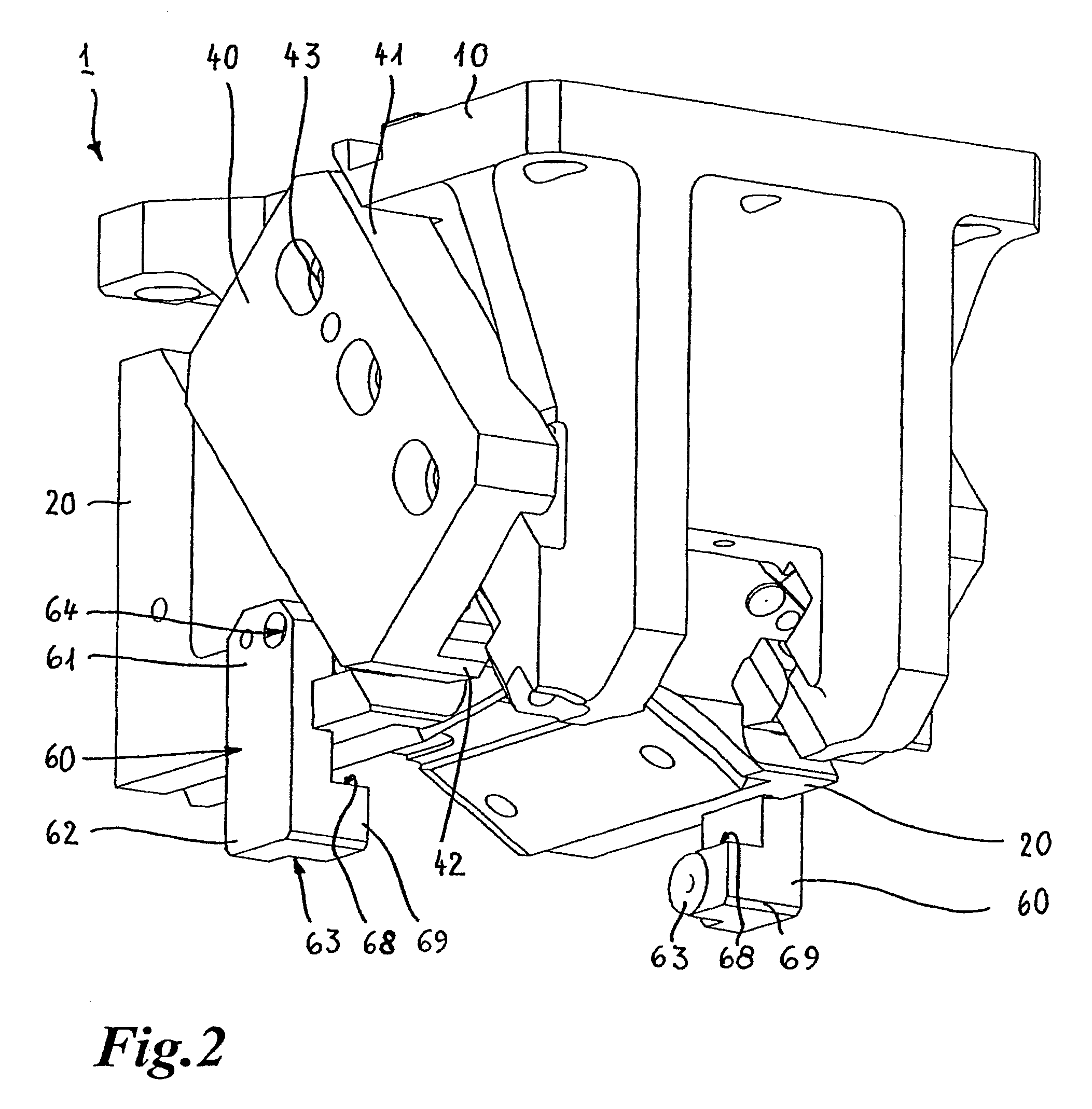

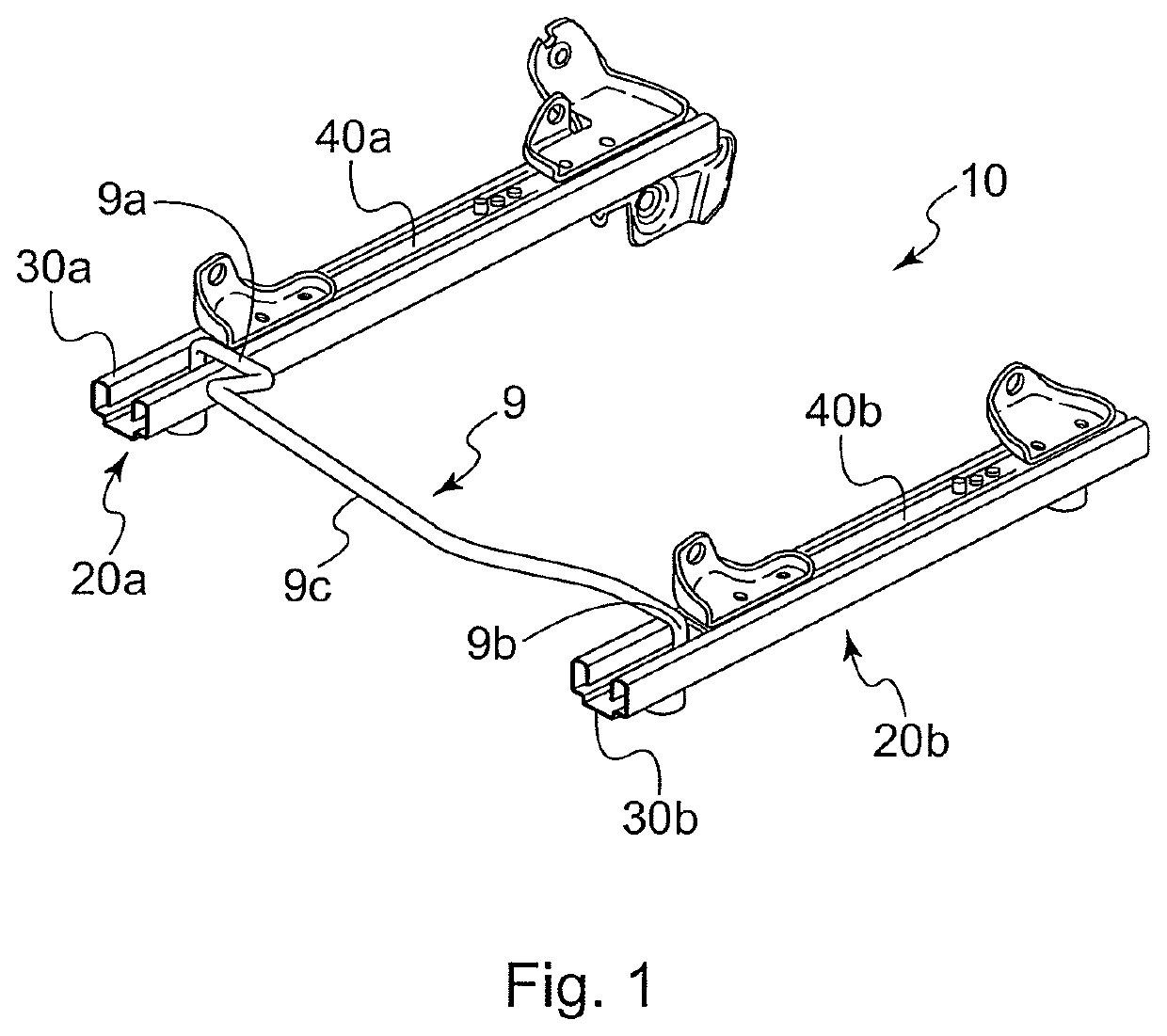

Wedge drive with a force returning device

ActiveUS8689600B2Minimizes retraction forceSpeed up the processForging press detailsForging press drivesEngineeringMachine tool

In a wedge drive (1) with a first part (20) which can be provided with a machining tool and a second part (30), wherein the two parts (20, 30) are arranged movably relative to each other, and there is provided at least one positive-action return device which engages or can engage both parts (20, 30), and a third part (10) which is connected to the first part (20), the at least one positive-action return device is return spring-free and has at least one device for causing and / or supporting the return of the one part (20) and / or for increasing the retraction force which can be applied in the return of the one part (20) in the upward stroke movement of the third part (10).

Owner:WEIGELT HARALD

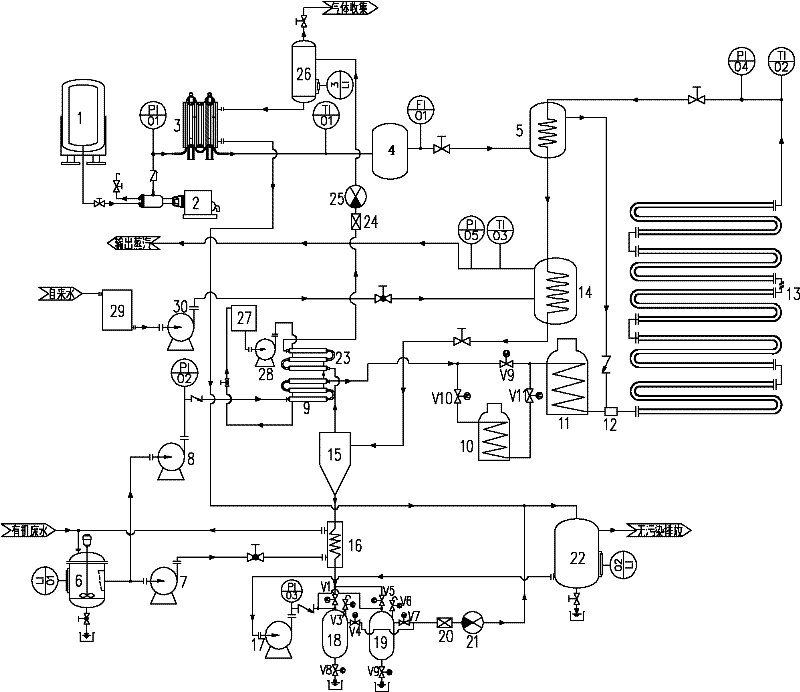

Supercritical water oxidation treatment system for high-salt high-chlorine organic wastewater

InactiveCN102249461BPrevent jam frequencyJam frequency avoidanceWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSolubilityCyclone

The invention discloses a supercritical water oxidation treatment system for high-salt high-chlorine organic wastewater. Heat of reacted fluid is partially recovered by a second heat exchanger to preheat feedstock, and the heat of fluid passing through a reactor is recovered by steam generated by a steam generator, so that the system investment and operating cost are effectively reduced; a hydraulic cyclone, a first salt storage tank, a second salt storage tank, first and second pipeline filters and a high pressure filling pump are arranged, the pressure reduction requirement of the treatmentsystem can be met, the blockage frequency of the first and second pipeline filters is reduced, and insoluble salt can be continuously removed and discharged; meanwhile, the flow rate of the fluid in the system is controlled to be 1-2m / s, the deposition and blockage of the insoluble salt and soluble salt separated out under the supercritical water condition are further effectively reduced. In addition, equipment and conveying pipelines, which are contacted with the high-salt high-chlorine organic wastewater in the system, are made of composite tubes, the corrosion of the system can be effectively reduced and the equipment investment cost is reduced.

Owner:XI AN JIAOTONG UNIV +1

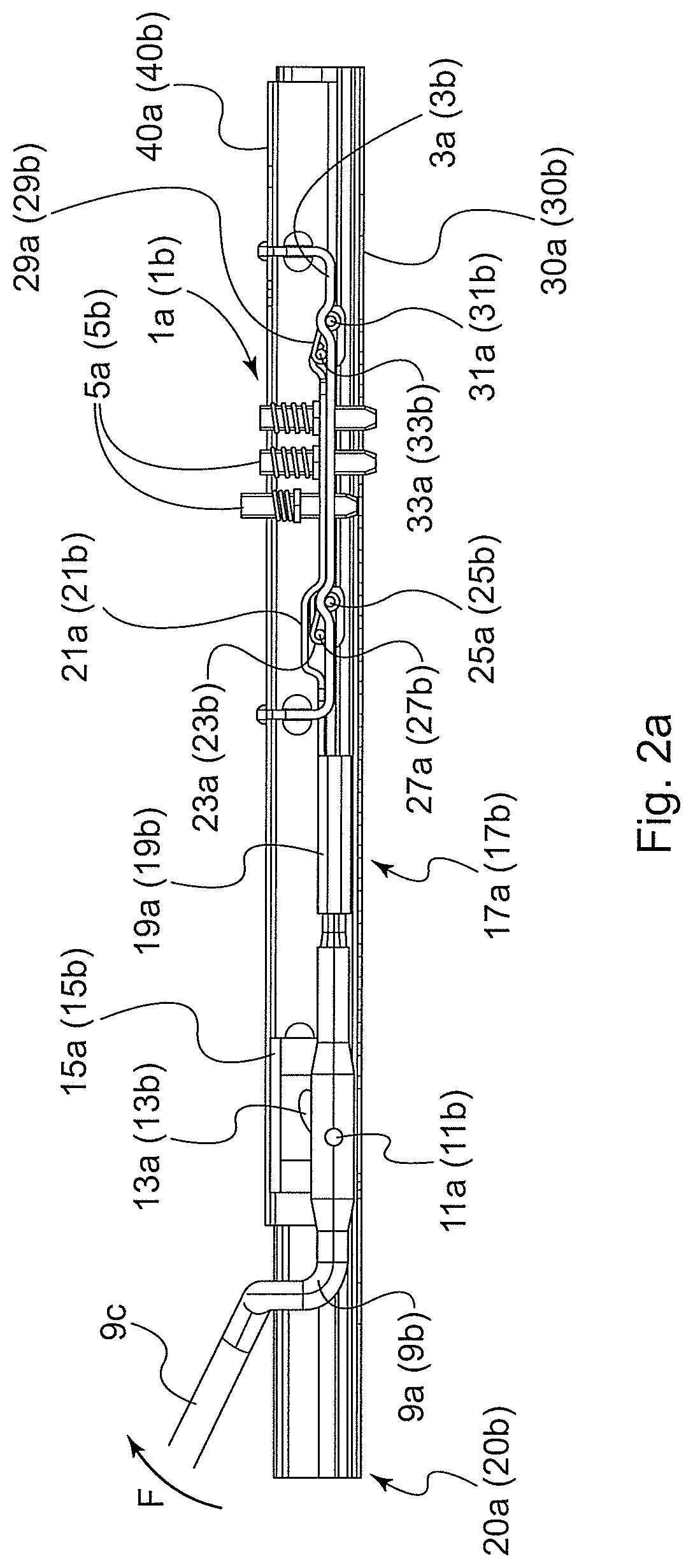

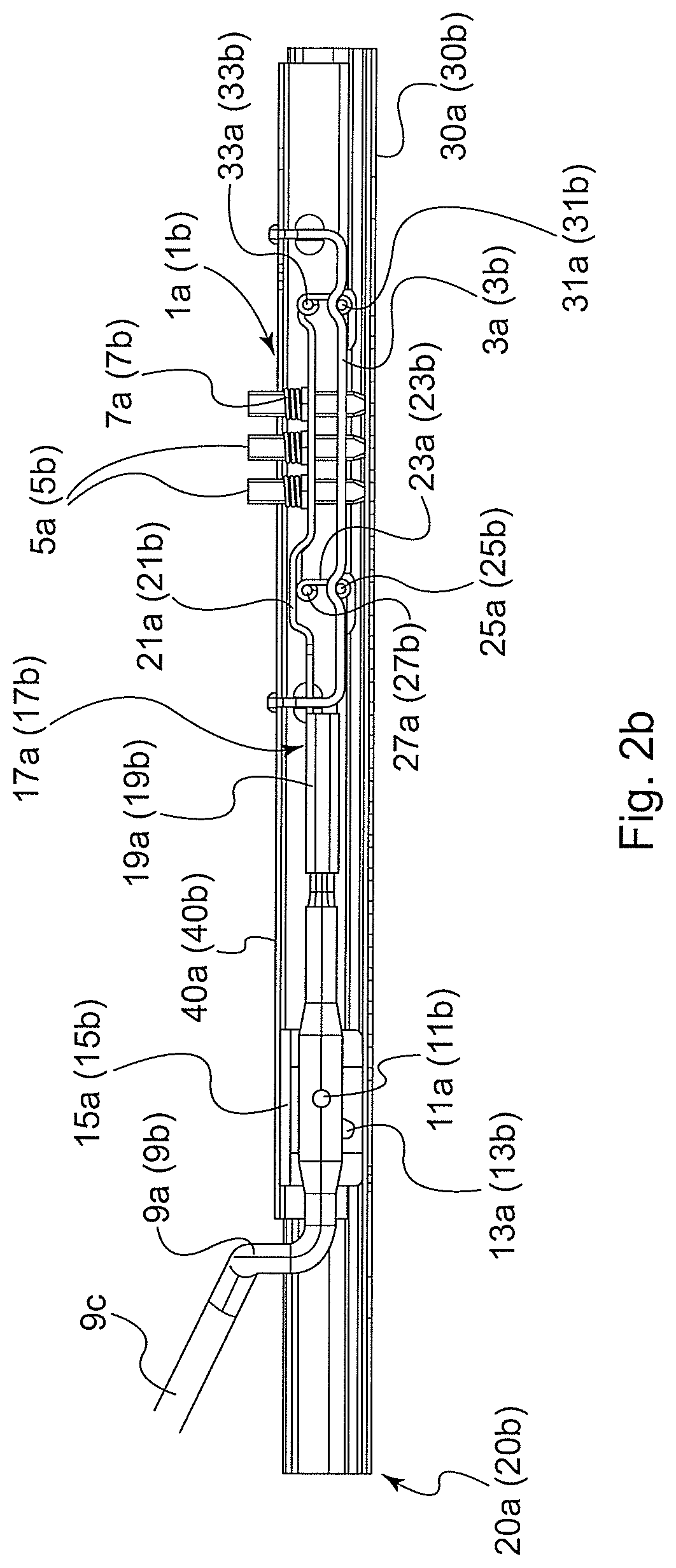

Sliding device for a vehicle seat provided with an improved locking arrangement

A sliding device for a vehicle seat is provided with an improved locking arrangement. The locking arrangement includes a pair of locking assemblies, each including one or more locking pins suitable for locking upper rails of the seat tracks to respective lower rails. The locking arrangement also includes a releasing assembly suitable for driving the locking pins to an unlocking configuration and comprising a releasing member and a pair of connecting members, which are in a force transmission connection with the releasing member and with the locking pins of a respective locking assembly. The connecting members are entirely received within the respective tracks, and the releasing assembly is configured to convert a rotational movement of the releasing member into a linear movement of the locking pins of the locking assemblies.

Owner:MARTUR ITAL SRL

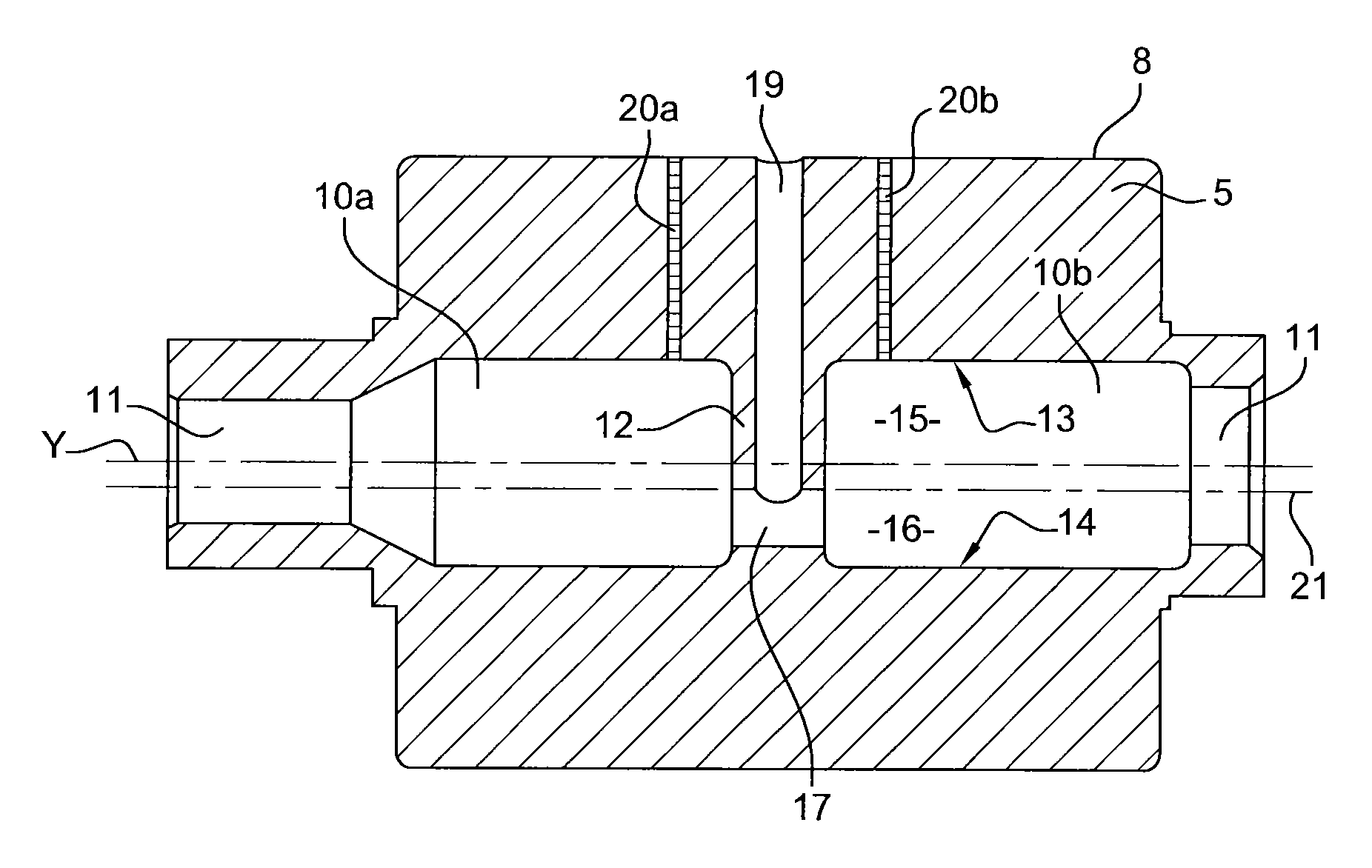

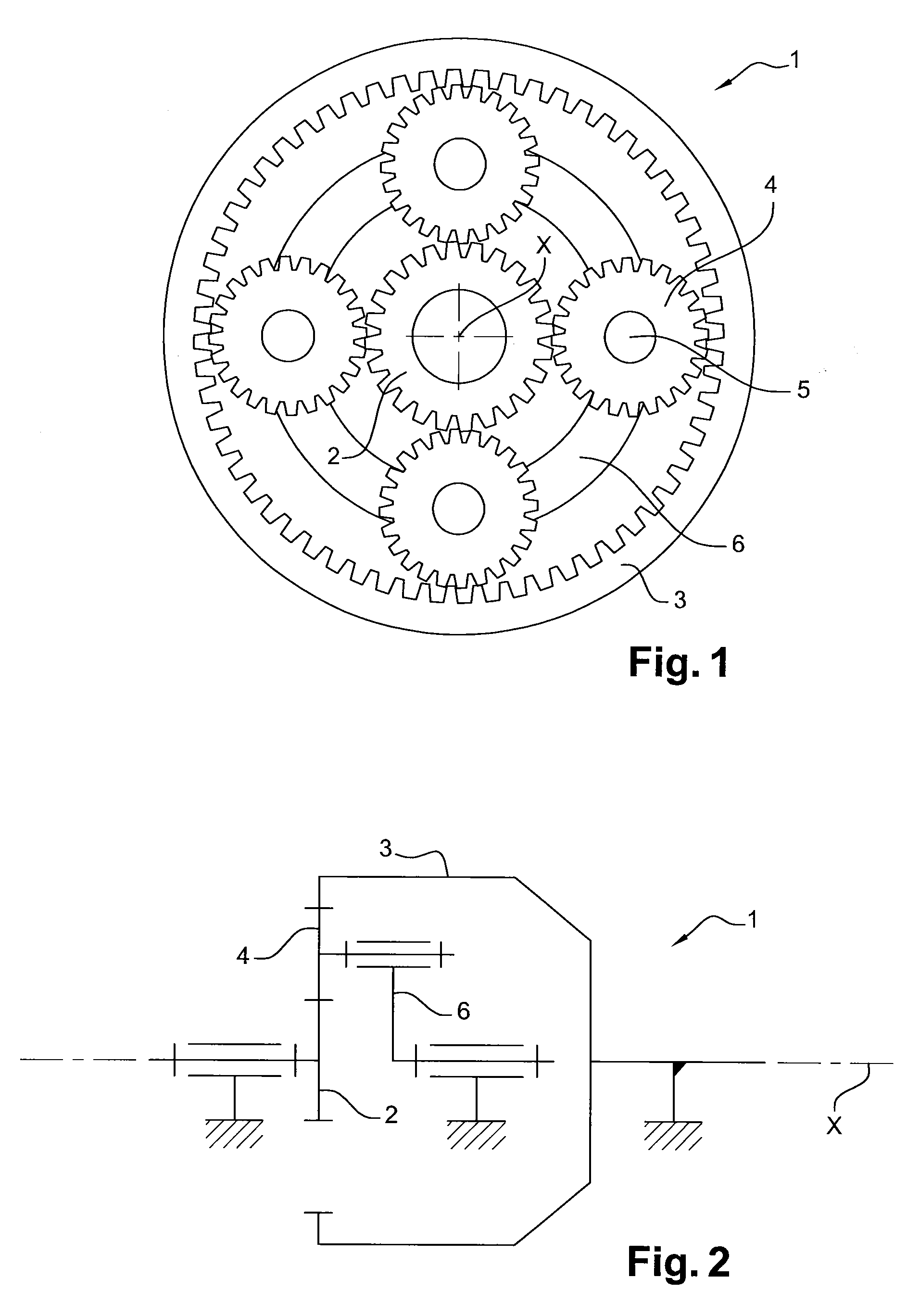

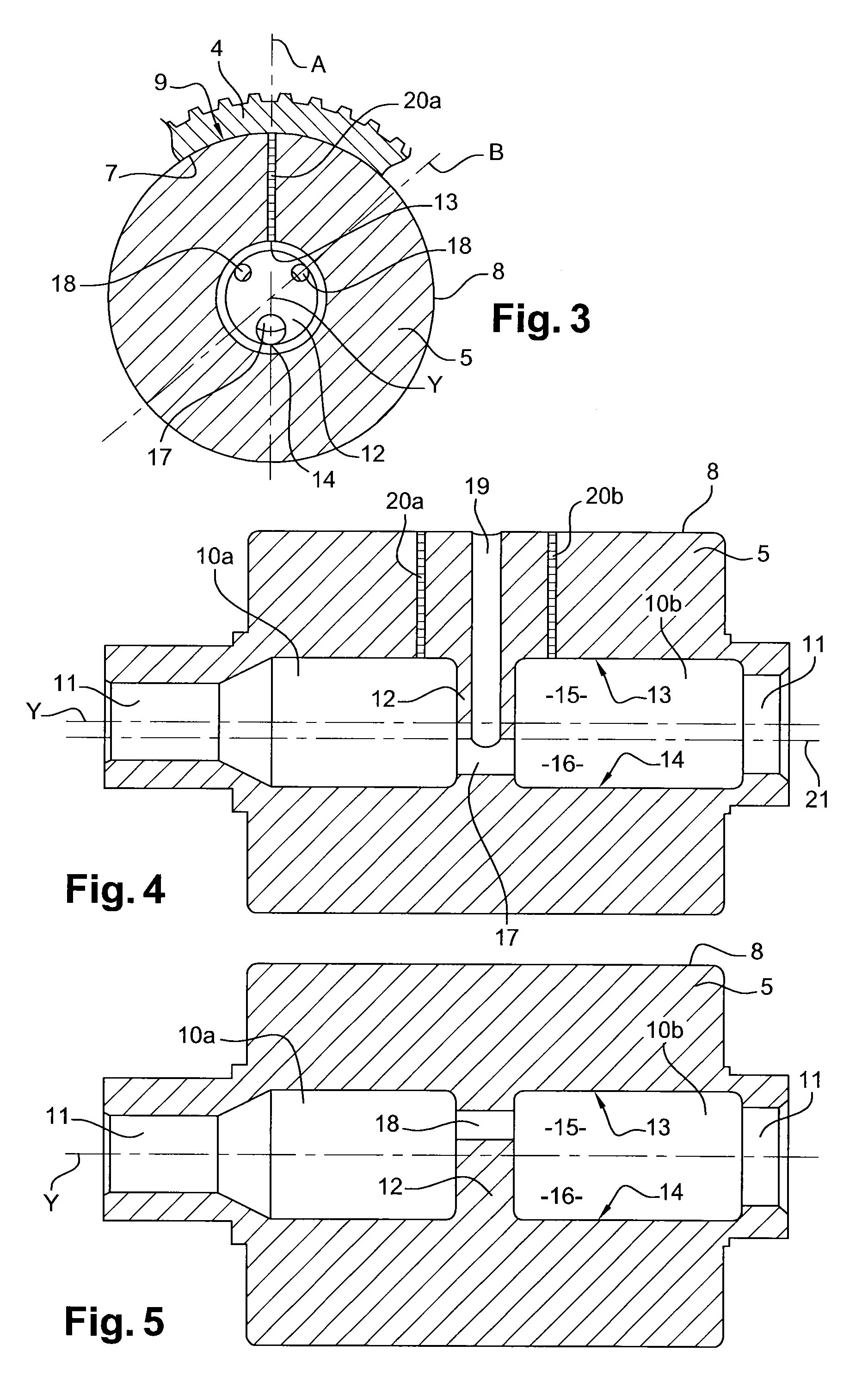

Epicyclic reduction gear, notably for turbomachine

ActiveUS9429225B2Avoid cloggingThe implementation process is simpleGear lubrication/coolingDevice formEngineering

An epicyclic reduction gear, for example for a turbomachine, including a device forming a fluid circulation passage configured to generate a pressure drop, created by stacking at least two elements. Each element includes a passage for carrying fluid configured to generate a pressure drop and including an inlet and an outlet. The outlet, or inlet, of the passage of one of the elements is, respectively, connected to the inlet, or to the outlet, of the passage of the other element.

Owner:SAFRAN TRANSMISSION SYST

Harvester

ActiveUS20050091954A1Reduce adhesionEffective improvement of operational safetyMowersVertical planeEngineering

A harvester for harvesting stalky crops has an intake and conveying device having an endless conveyor provided with outwardly oriented cutting, holding, and conveying elements that form cutting planes and holding planes. The endless conveyor has a supply area for transferring crop to an inlet opening of a processing device. The supply area has a stripping device with clearing elements each having a stripping surface. The stripping surfaces of the clearing elements are remote from a holder and face forwardly in the traveling and working direction. The stripping surfaces are vertical in an end area pointing in the traveling and working direction and positioned in a common vertical plane. The stripping surfaces have a section extending from the end area in a direction of crop flow and diverge with increasing spacing from one another in the direction of crop flow.

Owner:MASCHFAB BERNARD KRONE GMBH

Impurity removal device for rapid flowing type heat shrinkage film production

The invention discloses an impurity removal device for rapid flowing type heat shrinkage film production. The impurity removal device comprises a tank, an upper fixing plate, a drive mechanism, a filter column, a discharging pipe, a power pump, a closed annular plate and a flow guiding column. The flow guiding column is arranged above a filter cavity of the filter column and is of a conical cylinder structure with the large upper portion and the small lower portion. An annular flow guiding cavity is defined between the flow guiding column and the periphery inner wall of the filter column, andconstant filtration and impurity removal are conducted at the same time from the periphery of the filter column, and the raw material liquid filtration and impurity removal speed is increased.

Owner:JIANGSU ZHONGDA PACKING MATERIAL CO LTD

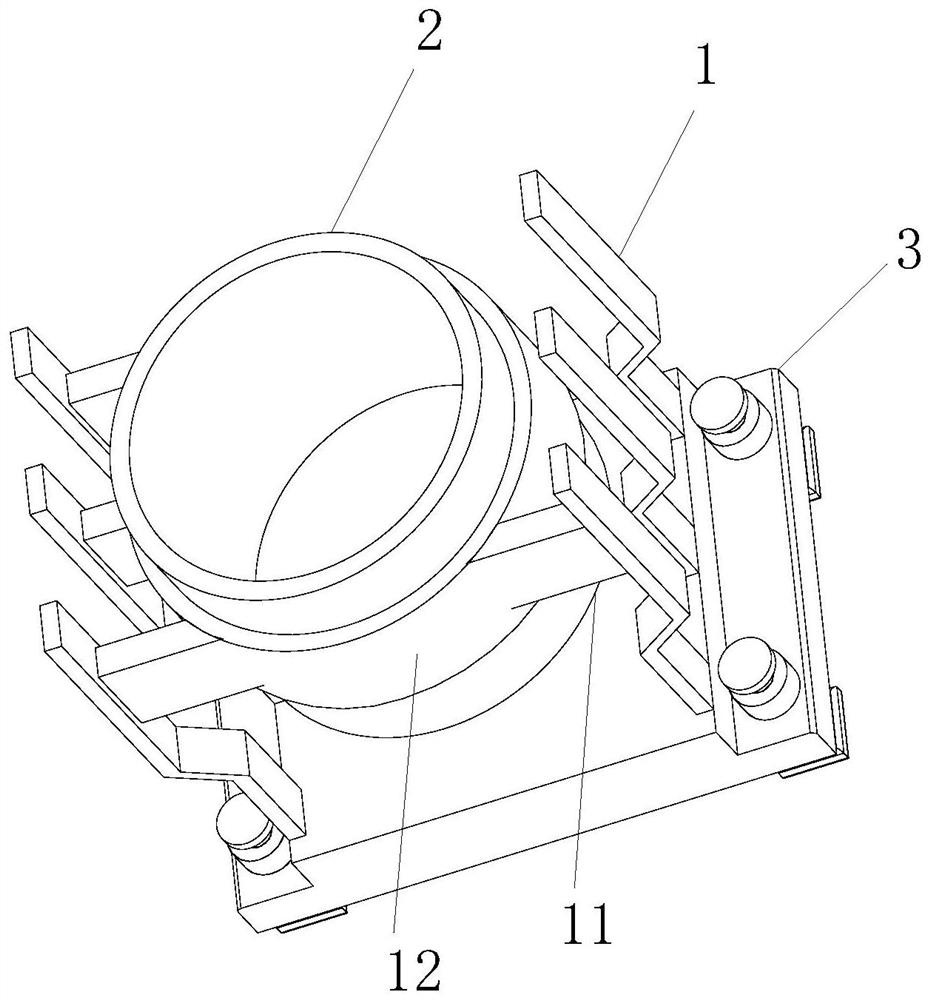

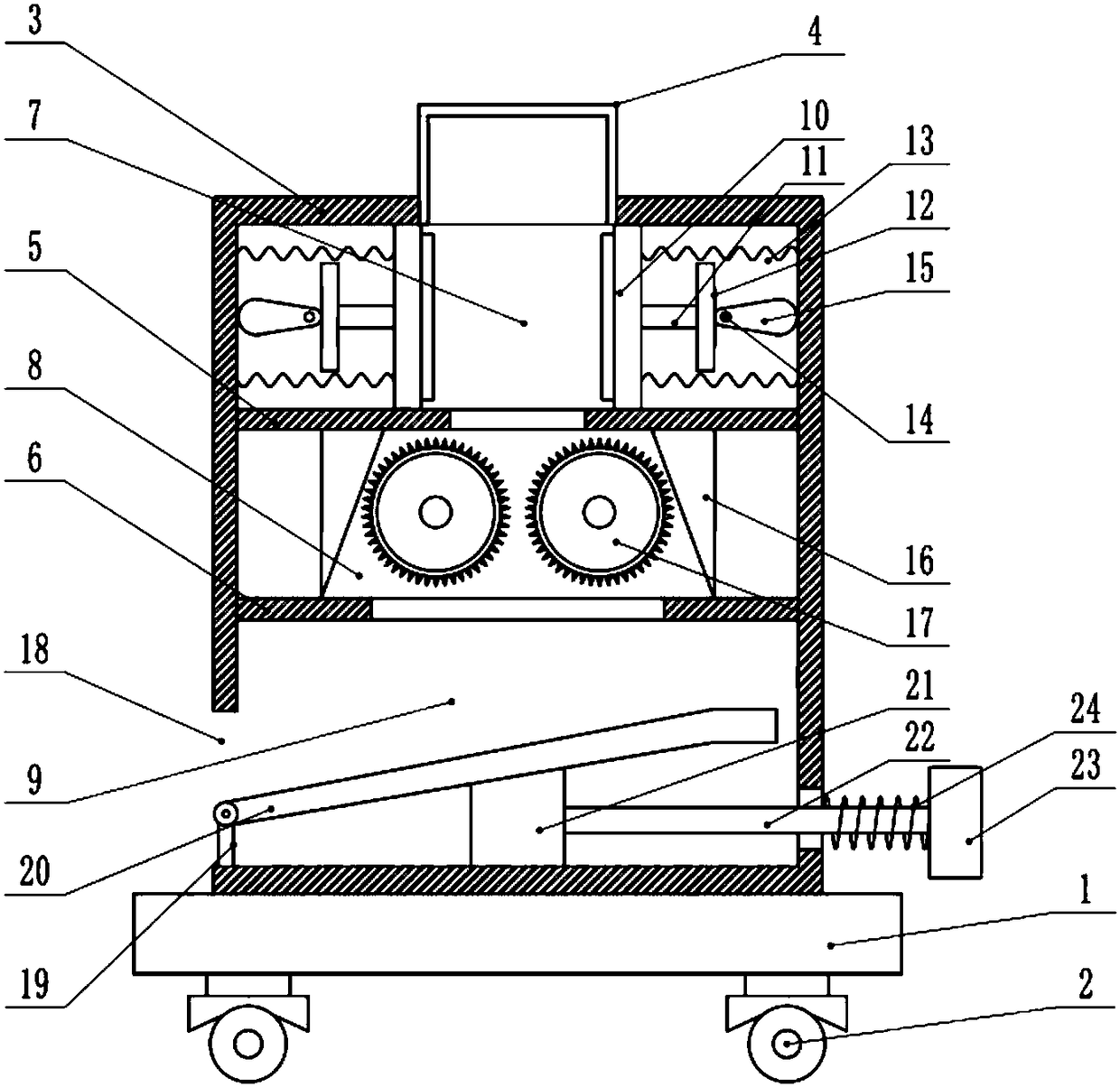

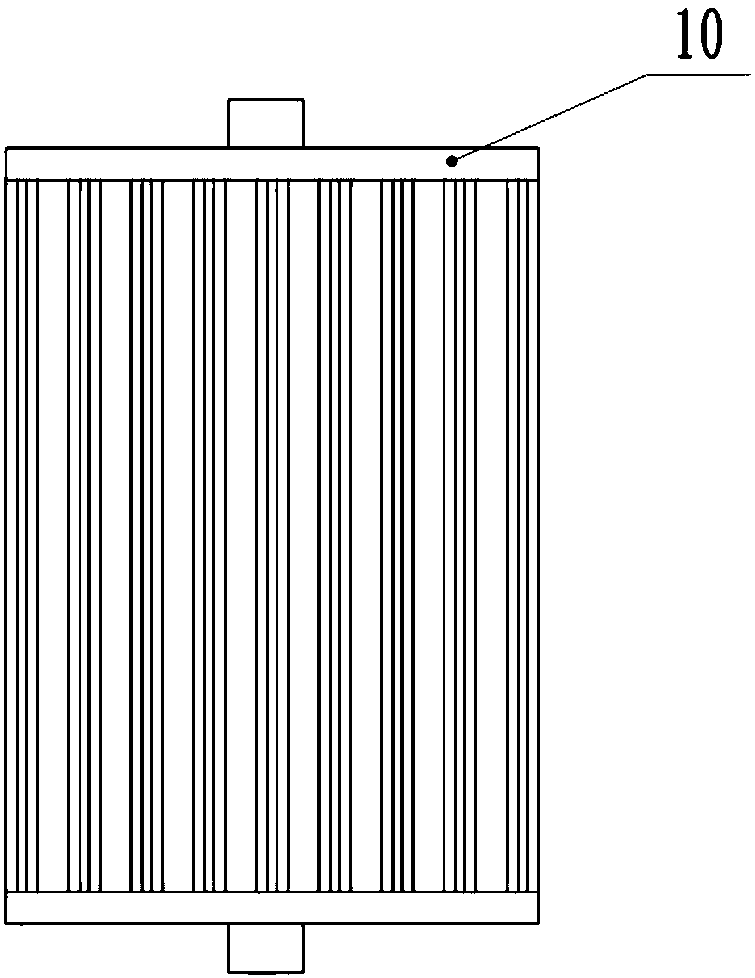

Pipe clamp supporting structure and construction method for long-distance pumping of machine-made sand concrete

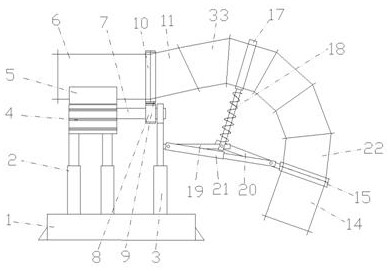

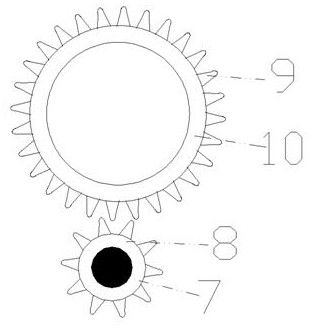

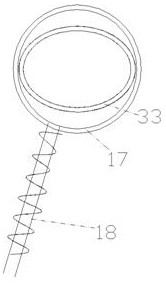

PendingCN111877764AAvoid risk of cloggingAchieve unblockingBuilding material handlingDrive shaftGear wheel

The invention discloses a pipe clamp supporting structure. The pipe clamp supporting structure comprises a supporting table, wherein the supporting table is provided with first hydraulic rods and a second hydraulic rod, and the first hydraulic rods are fixedly connected with a servo motor, a driving shaft, a driving gear and a gear ring; an input pipeline is connected with an oval material pipe Ithrough an input pipe clamp, the input pipe clamp comprises angle iron and an annular strip block, and the annular strip block is provided with an annular clamping groove and a flange hole; an outputpipeline is connected with an oval material pipe II through an output pipe clamp, and an oval material pipe III is arranged between the oval material pipe I and the oval material pipe II; and the outer wall of the oval material pipe III located in the middle is sleeved with a round supporting ring, the round supporting ring is fixedly connected with a spring rod, the spring rod is riveted to a horizontal fixing rod and an inclined swing rod, and a third hydraulic rod is riveted between the horizontal fixing rod and the inclined swing rod. The invention further provides a construction method for long-distance pumping of machine-made sand concrete. According to the pipe clamp supporting structure, two aspects of adjustment of a machine-made sand concrete formula and a pumping structure are synthesized, the problem of long-distance pumping of the concrete is thoroughly solved, and the pipe clamp supporting structure is suitable for pumping of 300 m or above.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Wastewater pretreatment device for food processing industry

InactiveCN108970814ATo achieve the separation effectEffective centrifugal filtrationWater/sewage treatment by centrifugal separationTreatment involving filtrationPre treatmentDrive motor

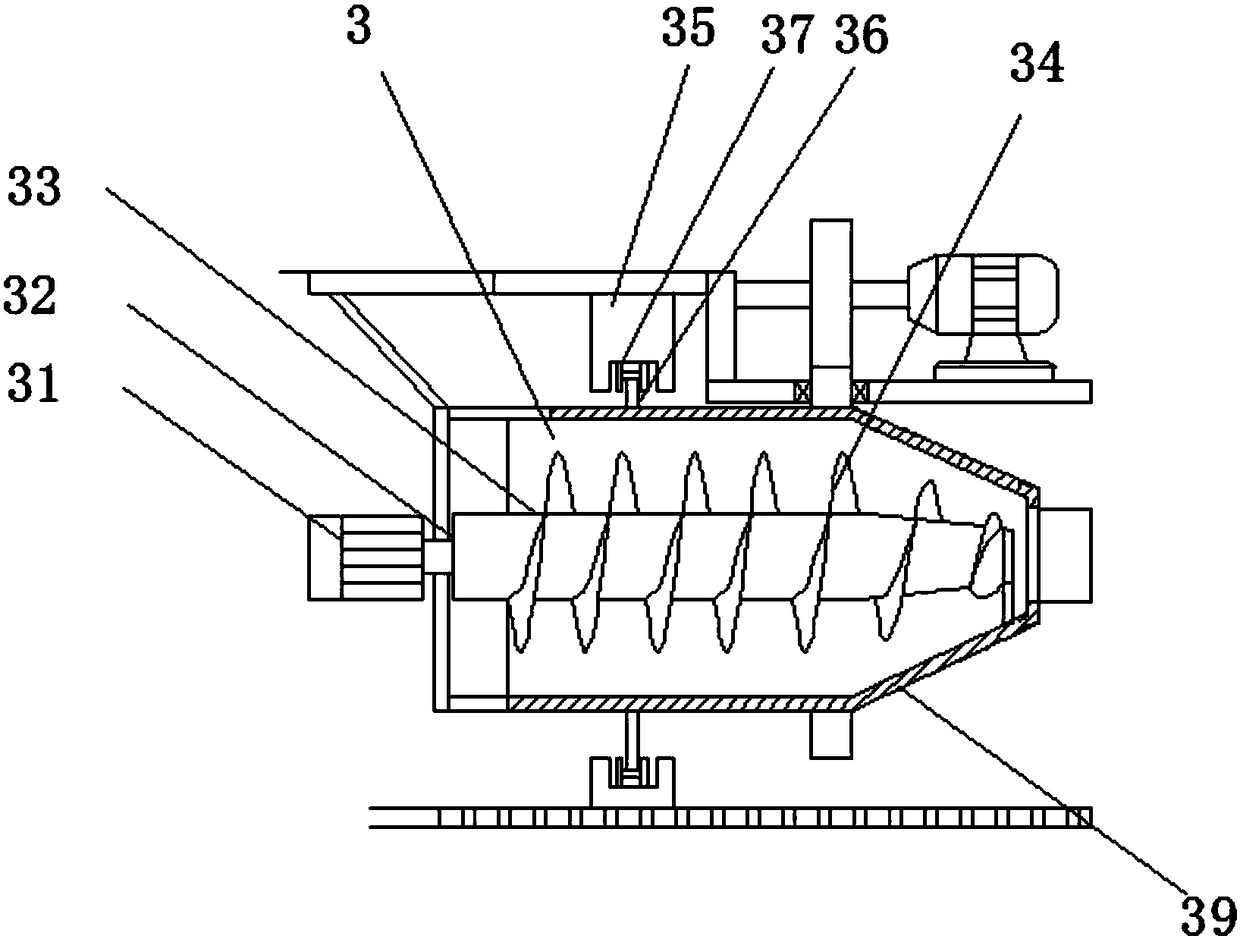

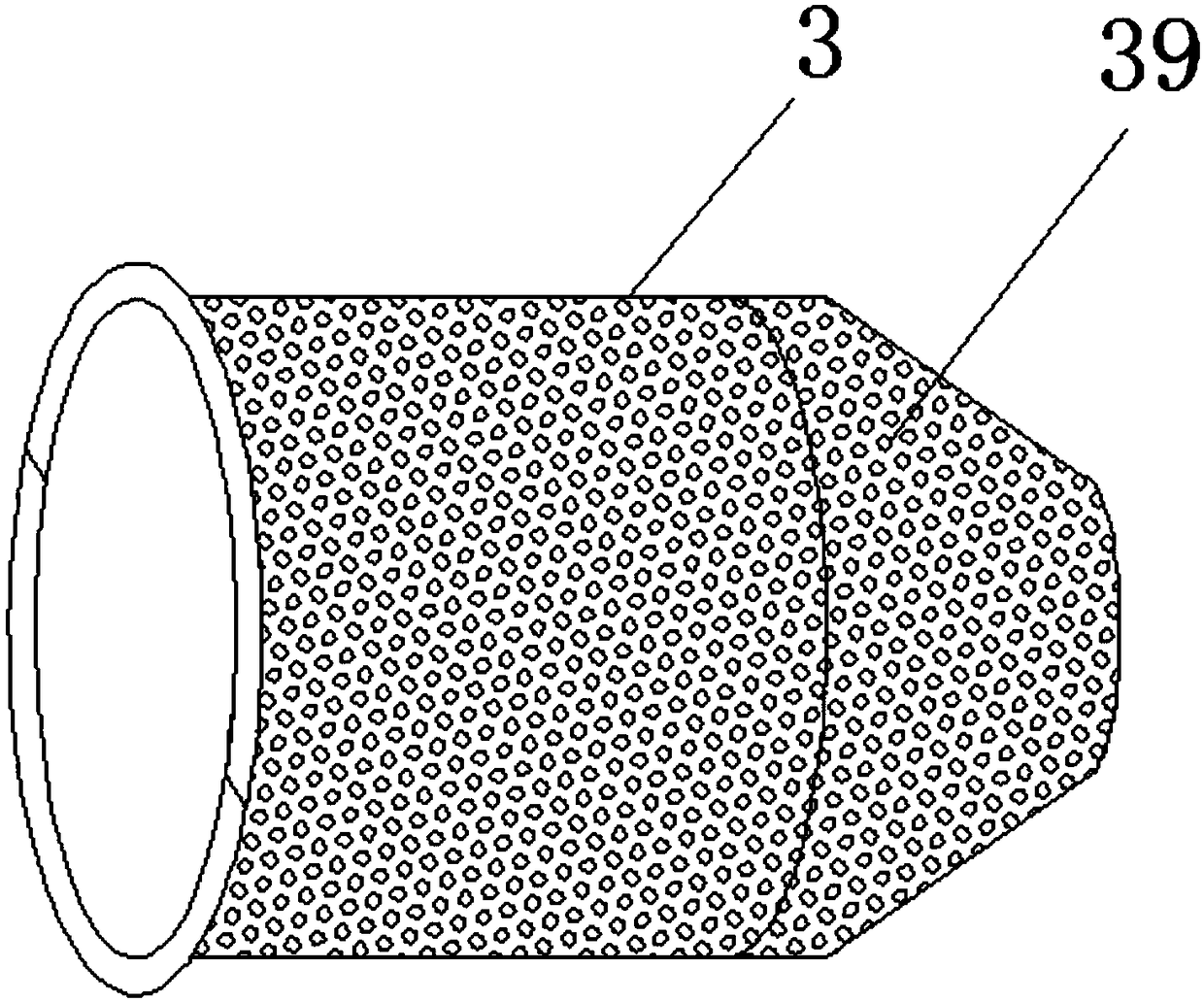

The invention discloses a wastewater pretreatment device for food processing industry. The wastewater pretreatment device comprises a pretreatment device body and is characterized in that a filter cavity, a centrifuging barrel, a draining cavity, a cleaning rack, a conveying belt and a recycling tank are mounted on the pretreatment device body, the centrifuging barrel is mounted in the filter cavity, a water inlet pipe is arranged at the top end of the filter cavity, a water inlet is mounted in the centrifuging barrel, a drive motor is arranged at the front end of the centrifuging barrel, thedrive motor is mounted on the front inner wall of the filter cavity, a roller shaft is mounted at the rear end of the drive motor, the roller shaft extends into the centrifuging barrel, a spiral augeris mounted on the roller shaft, a transmission motor is mounted on the upper wall of the filter cavity, a transmission gear is mounted on the transmission motor through a transmission shaft, a drivengear is mounted on the outer wall of the centrifuging barrel, and the driven gear meshes with the transmission gear. The wastewater pretreatment device has the advantages that centrifuging can be performed on wastewater solutions, mass-liquid separation is achieved, and residues in wastewater can be effectively centrifugally filtered.

Owner:陈海荣

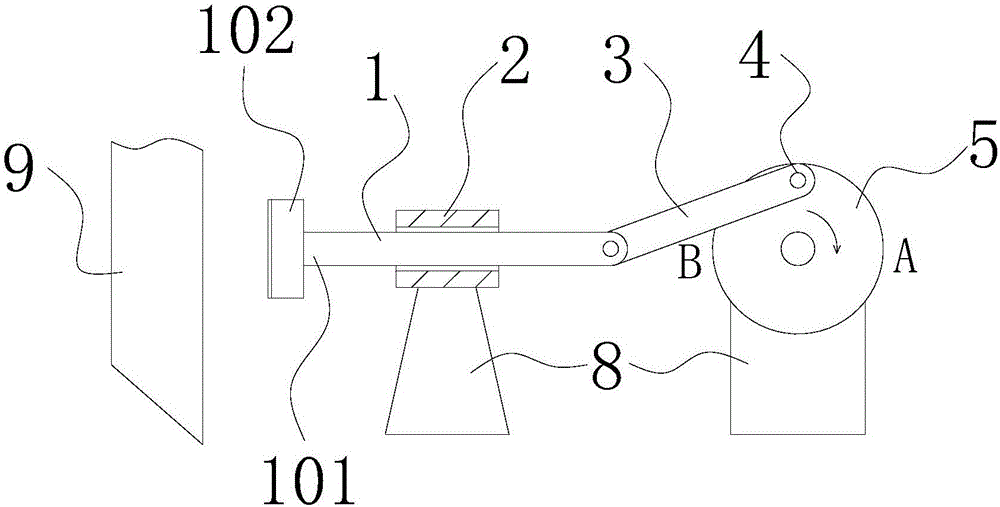

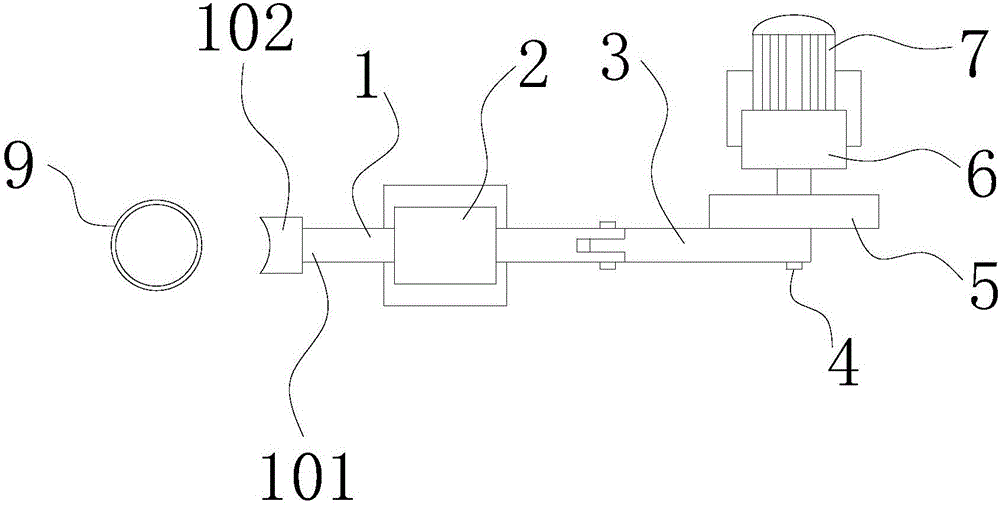

Discharge pipe rapping device

InactiveCN106477232AAvoid risk of cloggingExtended service lifeChutesVertical planeReciprocating motion

The invention discloses a rapping device, particularly a discharge pipe rapping device. The device solves the problem of raw materials sticking to the inner wall of a discharge pipe. The discharge pipe rapping device comprises a discharge pipe, a rapping rod, a shaft sleeve, a drive link, a spindle, a hub, a reducer, a motor, and a base. The rapping rod is set horizontally and passes through the shaft sleeve fixed on the base. One end of the rapping rod is a rapping end which corresponds to the outer wall of the discharge pipe, and the other end of the rapping rod is connected to the end of the drive link in hinge mode. The spindle is fixed on the side of the hub and away from the center of the hub. The other end of the drive link is connected with the hub through the spindle. The drive link can rotate in the vertical plane with the spindle as a shaft. The motor, the reducer and the hub are transmission connected in turn, and the motor and the reducer are fixed on the base. Through the installation of the spindle on the hub, the rapping rod is driven to do reciprocating motion, and the vibration force is passed to the discharge pipe, so that the raw materials sticking to the inner wall of the discharge pipe come off, avoiding the risk of blocking the discharge pipe.

Owner:攀枝花市仁通钒业有限公司

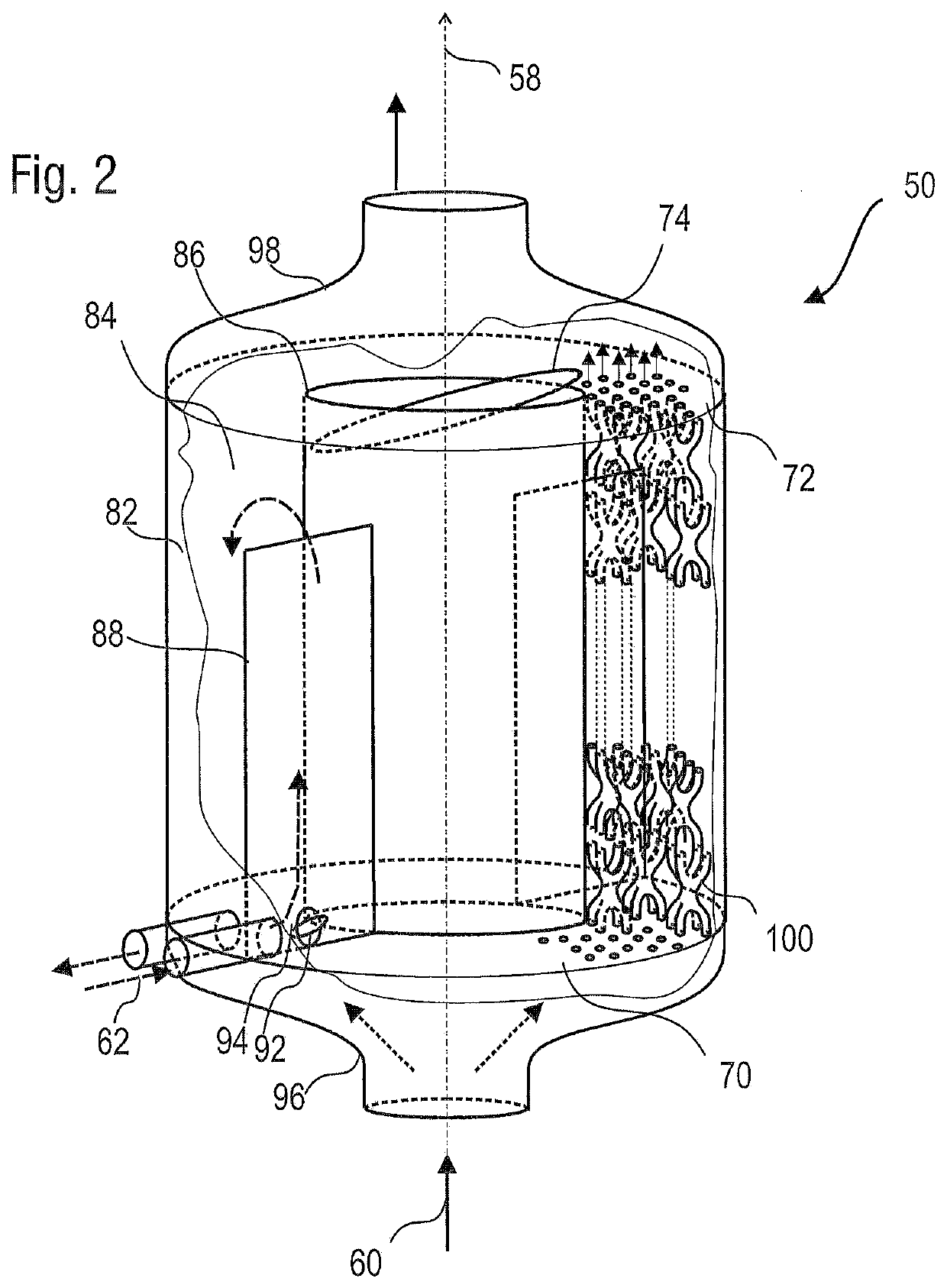

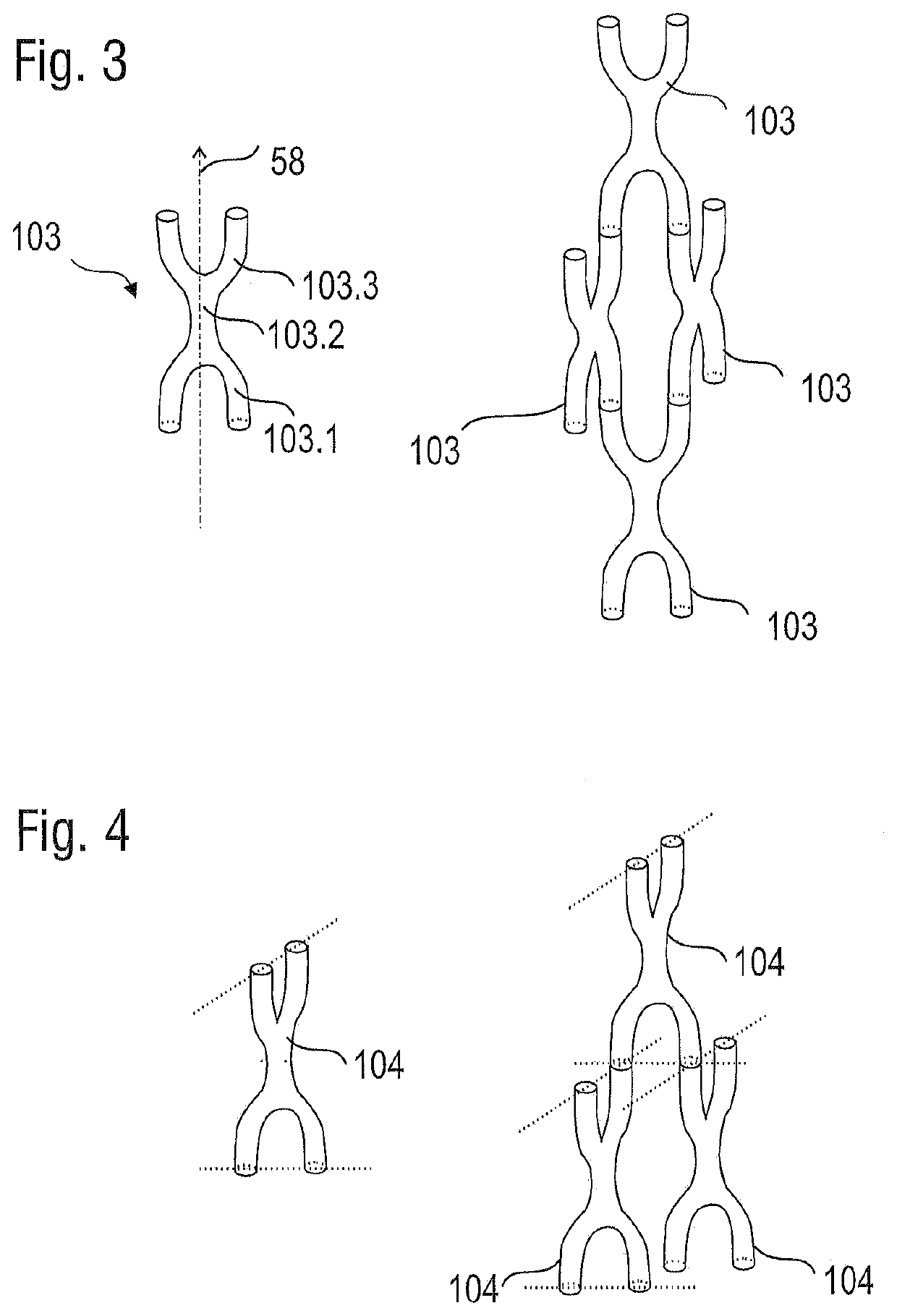

Fuel-Oil Heat Exchanger

ActiveUS20200200482A1Reduce weight and sizeSimple designEngine fuctionsTurbine/propulsion engine coolingEngineeringTurbine

A turbine engine heat exchanger for exchanging heat between a first fluid and a second fluid includes a reference axis, a network of tubular meshes having a plurality of meshes each of which is formed, successively in a reference direction, of at least two curvilinear branches, called anterior branches, of a junction where the two anterior branches meet, and of at least two curvilinear branches, called posterior branches, diverging from the junction, wherein the meshes are stacked in staggered rows.

Owner:SAFRAN AERO BOOSTERS SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com