Logistics storage bin with damp-proof function

A storage warehouse and logistics technology, applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve problems such as difficulty in ensuring storage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

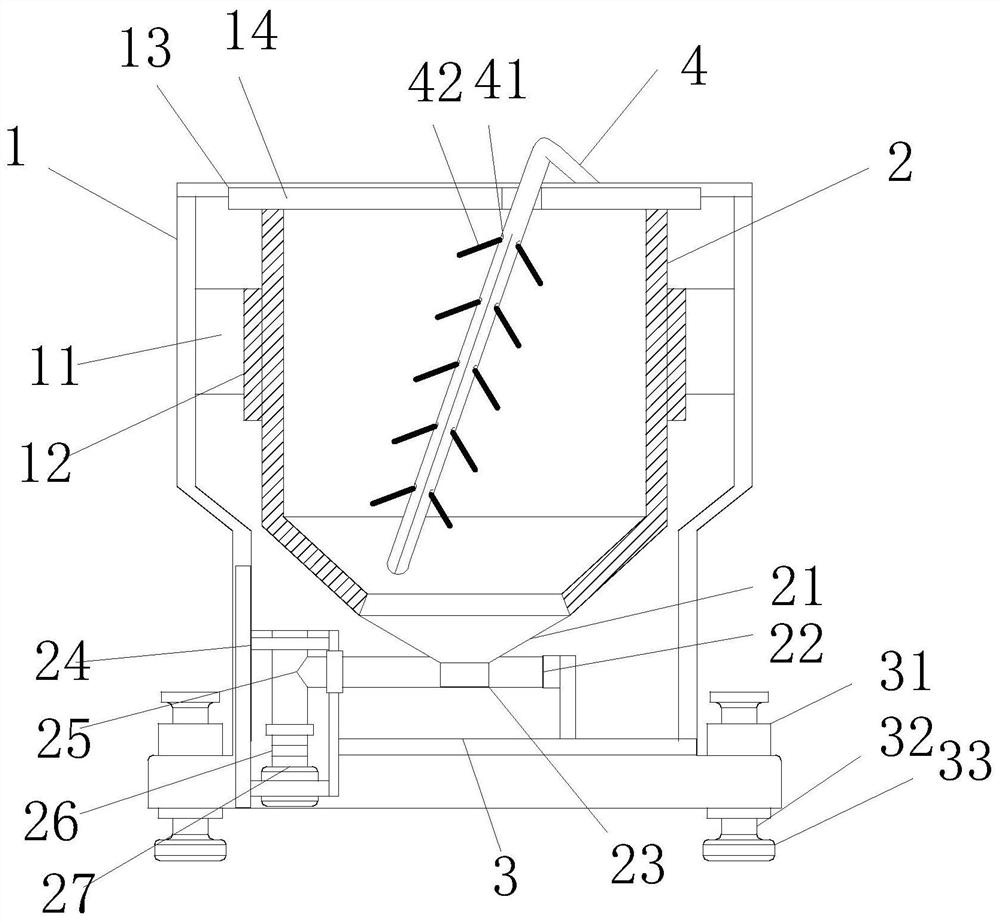

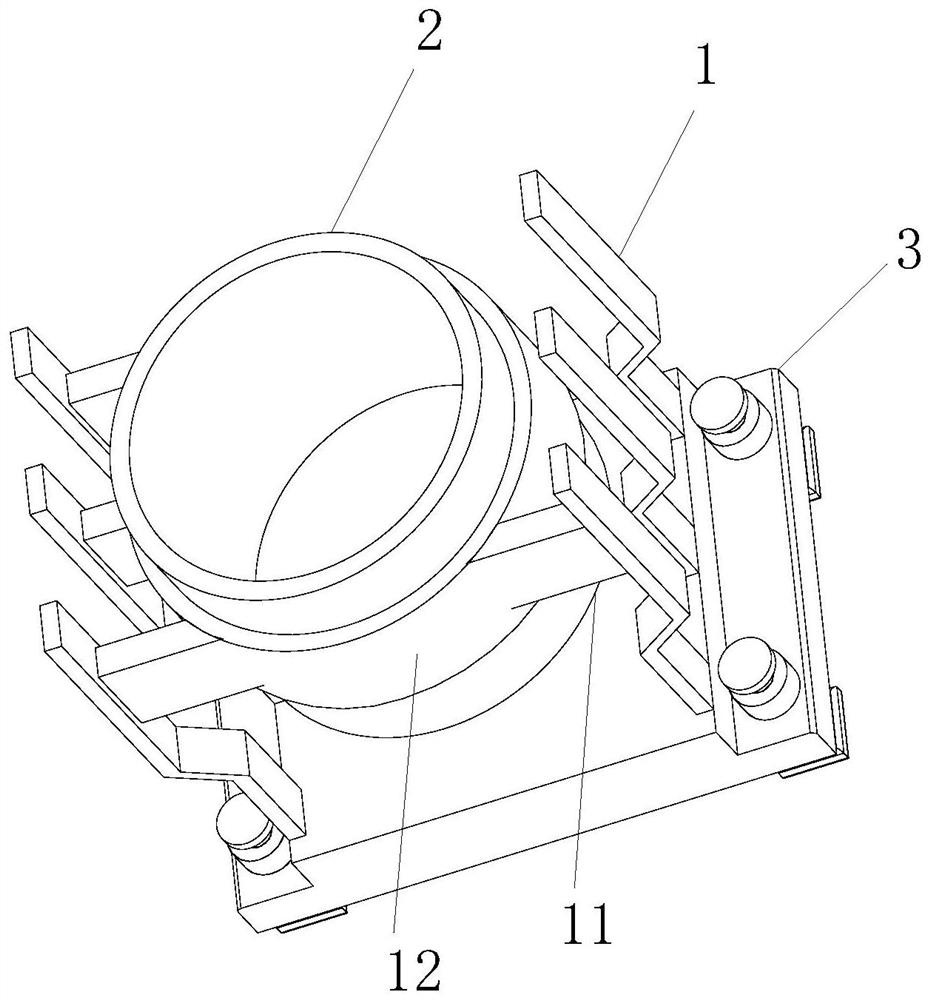

[0026] see figure 1 and figure 2 , a logistics storage warehouse with a moisture-proof function, including a frame 1 and a storage warehouse 2, the storage warehouse 2 is erected in the frame 1, a support plate 11 is provided on the frame 1, and a support plate 11 is placed on the support plate 11 A fixing hoop 12 is installed, and the fixing hoop 12 is installed on the outer wall of the storage bin 2 . The top of the frame 1 is provided with a top frame 13, the top frame 13 is provided with a top cover plate 14, and the top cover plate 14 is covered on the top of the storage bin 2, and the storage bin 2 is not in contact with the ground ; The storage bin 2 of this application is not in direct contact with the ground, and the support structure of the frame 1 is used to avoid the moisture on the ground from infiltrating into the storage bin 2, causing the risk of wet materials.

[0027] The bottom of the frame 1 is provided with an underframe 3, the bottom of the storage bin...

Embodiment 2

[0030] see figure 1 and figure 2 , this embodiment is a further optimization of Embodiment 1. On the basis of it, support screws 32 are installed at the four corners of the base frame 3, and the support screws 32 are installed on the base frame 3 through mounting nuts 31. The bottom of the support screw 32 is equipped with a support base 33, the top of the support screw 32 is equipped with an adjusting screw disk, and the bottom of the chassis 3 is also provided with universal wheels.

[0031] The application also designs that the four corners of the bottom frame 3 are equipped with support screws 32, and the support height of the support base plate 33 can be adjusted through the screws, so as to achieve the effect of leveling and avoid the problem of tilting the storage bin 2; and accommodate the support screws 32, It can be moved by contacting the ground with universal wheels.

Embodiment 3

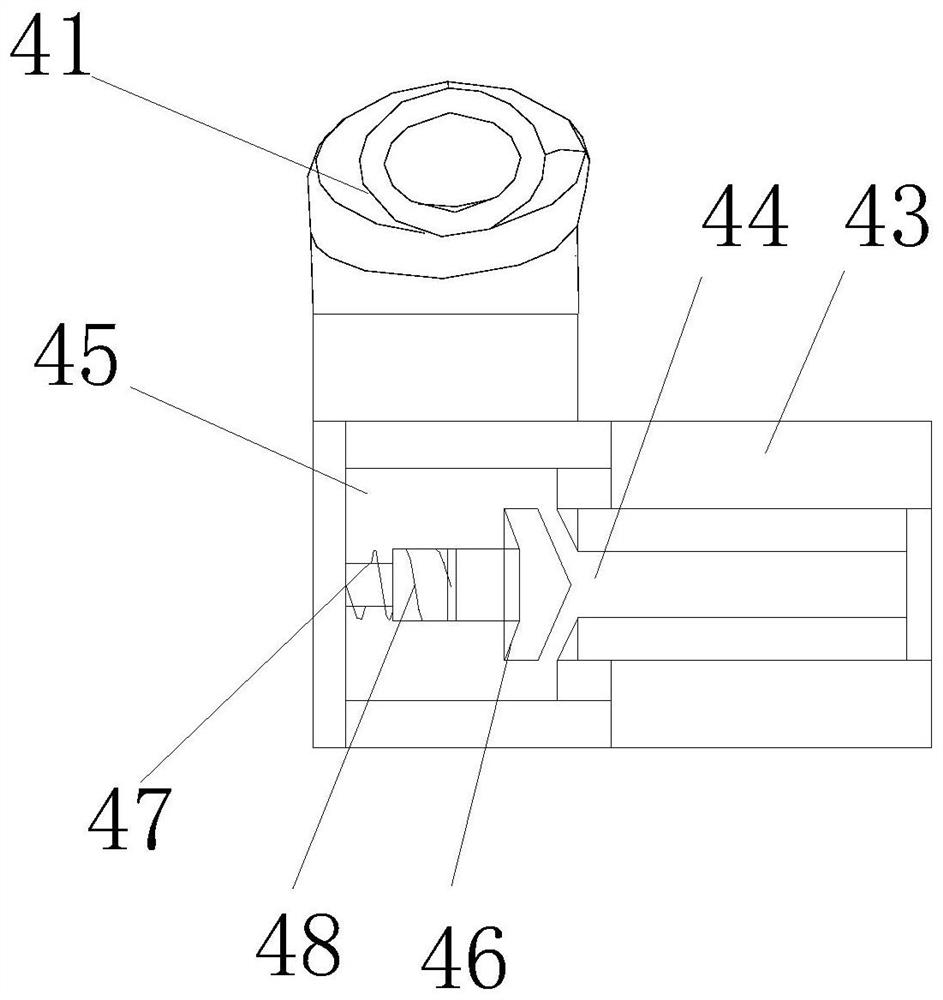

[0033] see figure 1 and image 3 In this embodiment, as a further optimization of Embodiment 1, on the basis of this, a one-way valve 43 is provided at the air outlet hole 41, and an air guide channel 44 is connected to the air inlet end of the one-way valve 43. The one-way valve 43 is provided with an air flow chamber 45, the air flow chamber 45 is connected with the air guide channel 44, the air flow chamber 45 is provided with a telescopic rod 47, and the rod end of the telescopic rod 47 is equipped with a plug 46, The plug head 46 is arranged at the nozzle of the air guide channel 44 , and the telescopic rod 47 is wound with a return spring 48 installed thereon.

[0034] In order to prevent stored materials or environmental dust from entering the air outlet hole 41, the present application is also provided with a one-way valve 43 at the air outlet hole 41. After each ventilation, the pressurized airflow pushes the plug 46, so that the airflow from The air outlet 41 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com