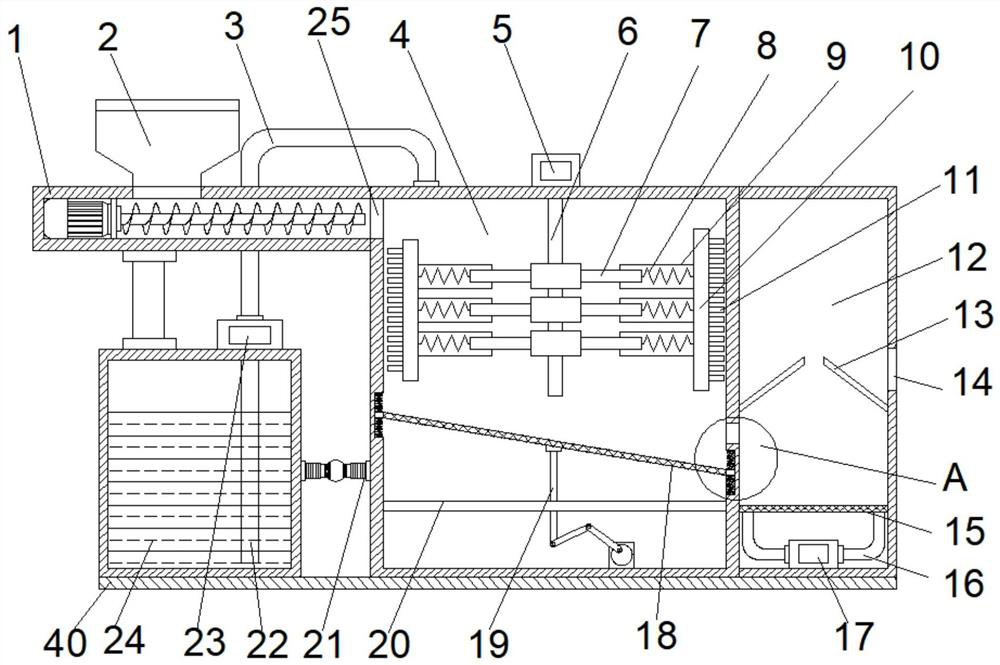

Impurity removal device for wool processing

A wool and miscellaneous box technology, applied in drying gas arrangement, lighting and heating equipment, washing/scouring of animal loose wool fibers, etc., can solve the problems of reduced production efficiency, time-consuming and laborious, and no crushing function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

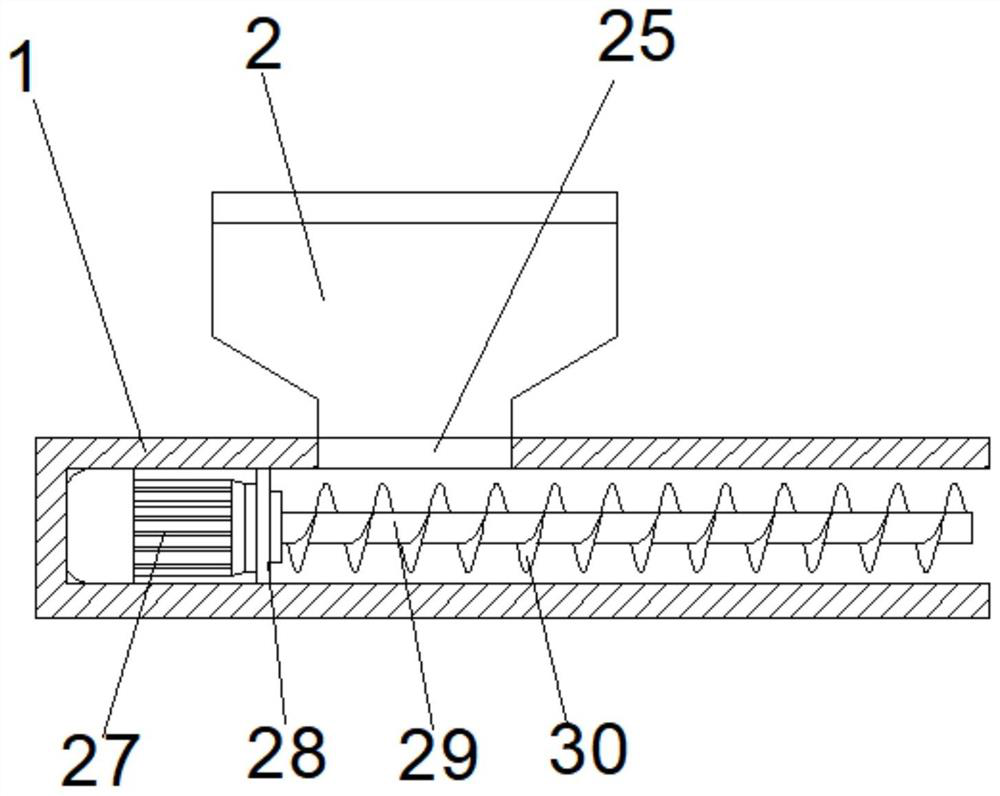

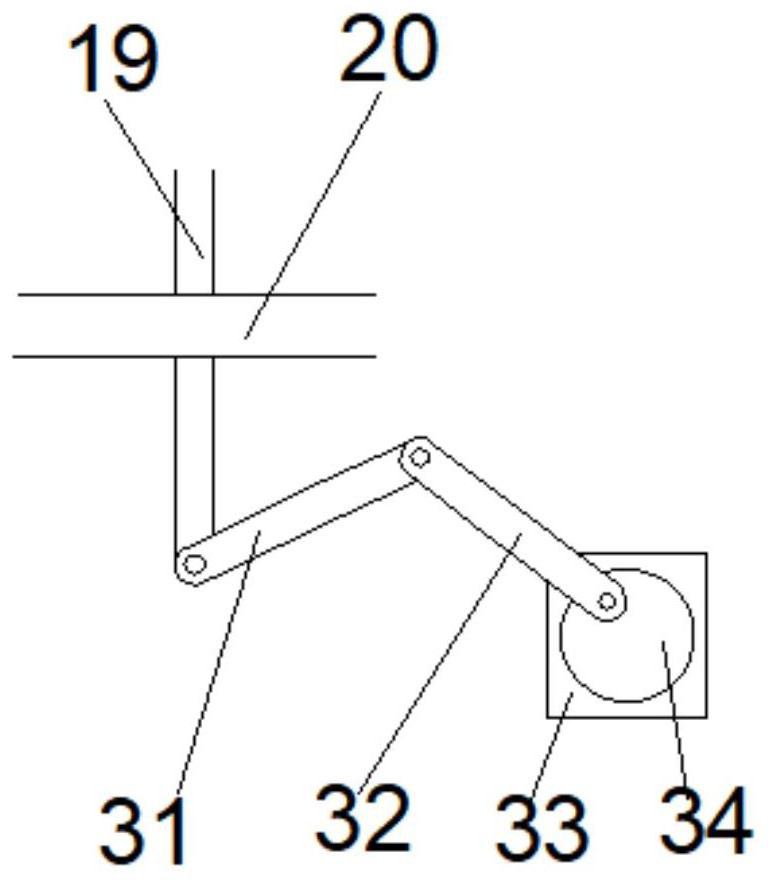

Method used

Image

Examples

Embodiment 2

[0032] On the basis of Example 1, in the embodiment of the present invention, a kind of impurity removal device for wool processing, the water tank 24 is connected with the impurity removal box 4 through a connecting pipe 21, and the connecting pipe 21 is a hose and is located at the first Above the second baffle plate 20 , the connecting pipe 21 is provided with a filter ball 39 , and the inside of the filter ball 39 is provided with a second filter net 26 , and the filter ball 39 and the connecting pipe 21 are threaded.

[0033] The setting of the connecting pipe 21 makes the water in the miscellaneous removal box 4 flow into the inside of the water tank 24 again, realizing the recycling of water and avoiding waste. The setting of the filter ball 39 effectively prevents impurities from entering the inside of the water tank 24 again. Simultaneously, the filter ball 39 is threadedly connected with the connecting pipe 21, which facilitates the staff to disassemble it, and furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com