Rotary traction short section

A rotary and pup joint technology, applied in drilling equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of drill pipe stuck in the hole, reduce friction and improve working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

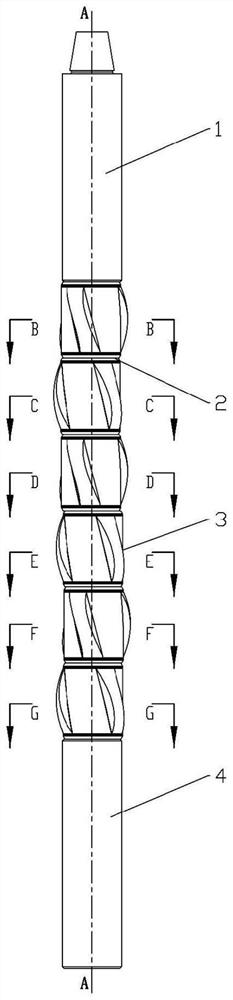

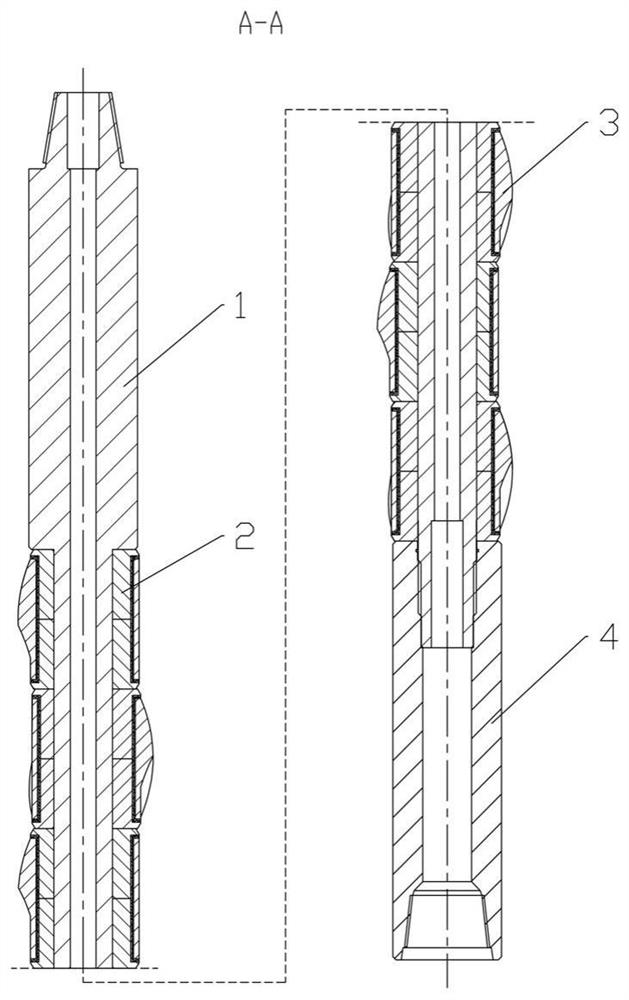

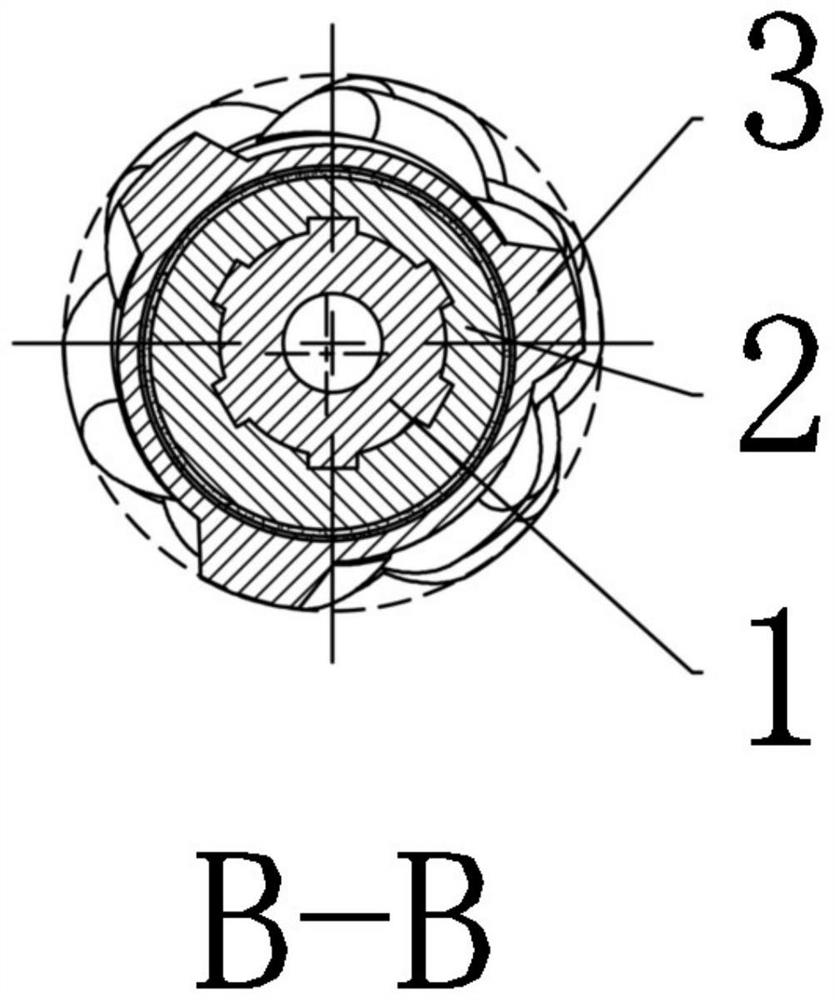

[0035] like Figure 1 to Figure 12 As shown, the present invention discloses a rotary traction pup joint, which includes a centralizer 3 and a mandrel 1, and the two ends of the centralizer 3 are respectively fixedly connected with one end of two centralizer bushings 2, and the two centralizers The other end of the bushing 2 is respectively fixedly connected with the mandrel 1, and the centralizer bushing 2 is connected with the mandrel 1 by a spline; the lower part of the mandrel 1 is threadedly connected with the lower joint 4; the lower part of the lower joint 4 is connected with the drill string Threaded connection; the left and right ends of the centralizer bushing 2 are respectively provided with radial bosses; the centralizer bushing 2 is divided into upper and lower parts along the axial symmetry plane, and are respectively connected with two centralizers 3; change the centralizer 3 and the mandrel 1, so that the sliding frictional resistance between the centralizer 3 ...

Embodiment 2

[0041] On the basis of Embodiment 1, the combination of the centralizer bushing 2 and the centralizer 3 connected end to end is multiple, that is, in actual production work, multiple sets of centralizer bushings 2 and centralizers can be set according to actual needs. The combination of devices 3 connected end to end enhances the drag reduction and jam-releasing effects of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com