Patents

Literature

50results about How to "Play a righting role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

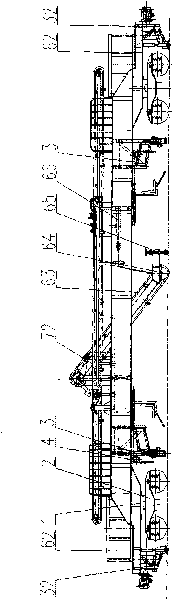

Fast rail-exchanging vehicle for jointless track and rail-exchanging method

InactiveCN101718066AReduce forcePrevent falling offRailway track constructionBogieFront and back ends

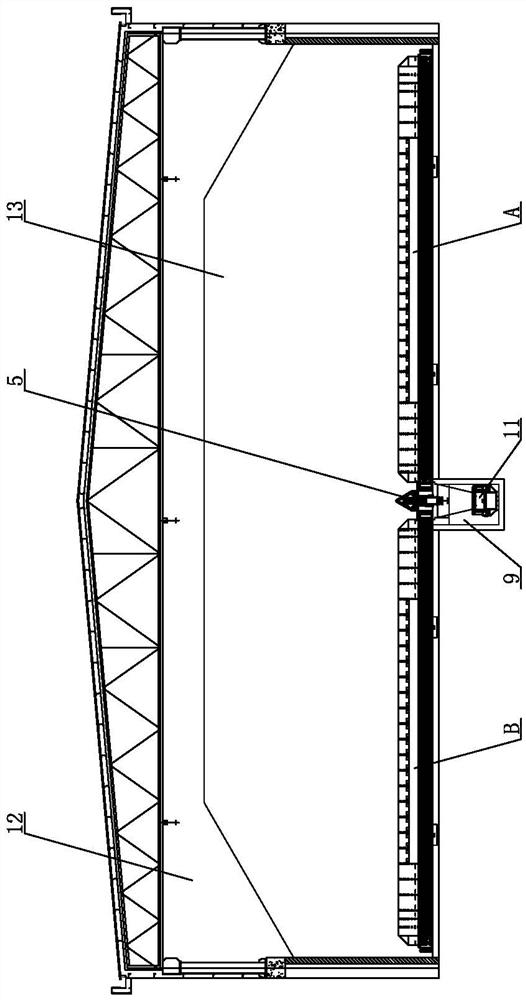

The invention relates to a fast rail-exchanging vehicle for a jointless track and a rail-exchanging method. The front and back ends of a travel mechanism of a fast rail-exchanging vehicle for a railway are provided with a guardrail recovering device; a crosstie-pressing device, a steel rail retraction device for clamping and moving a new steel rail and an old steel rail, a steel rail clincher and an operating position are arranged at intervals below the vehicle body between two bogies of the travel mechanism, the operating position is arranged according to the need; and the crosstie-pressing device and the steel rail clincher are arranged respectively close to the bogies at the two ends; and the vehicle can perform the marshalling operation together with the auxiliary vehicles, such as a fastener recovered vehicle, and the like. When the fast rail-exchanging vehicle for the railway is adopted for construction, the operation is divided into two parts of the old steel rail retraction operation and the new steel rail retraction operation which are synchronously carried out. The vehicle can reach the rail-exchanging speed of more than 2km / h, can be applied to the fast rail-exchanging need of the jointless track, complete the rail exchanging within 50 meters and is suitable for the construction needs of the section with less curve radius. The invention has the advantages of safety and high degree of automation.

Owner:株洲新通铁路装备有限公司

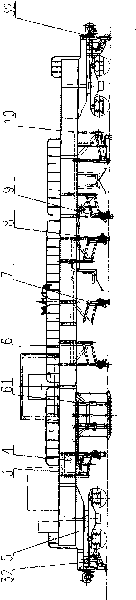

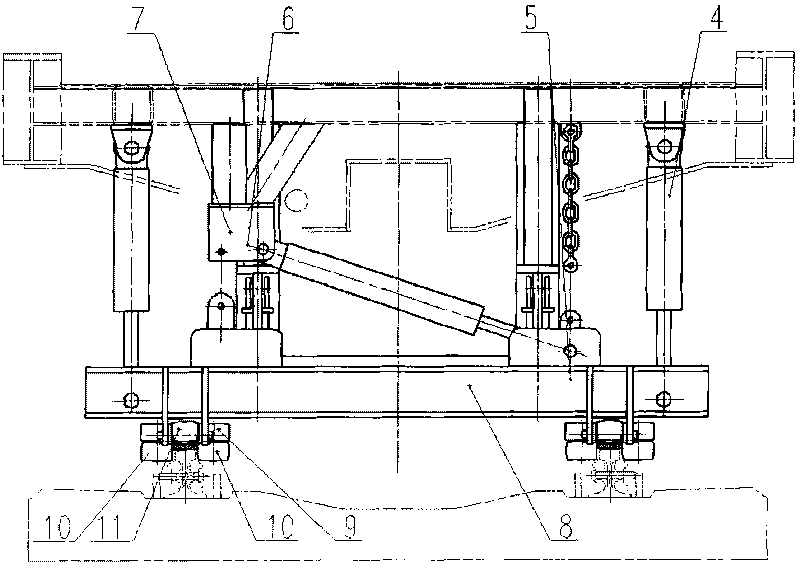

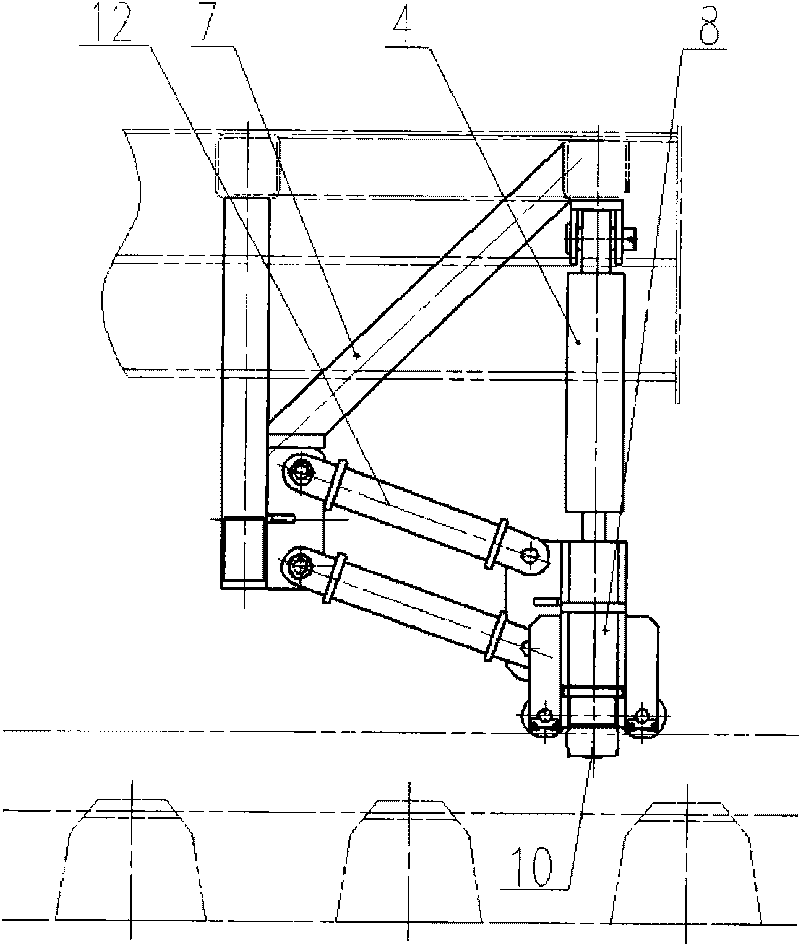

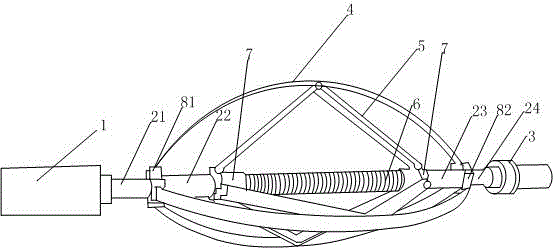

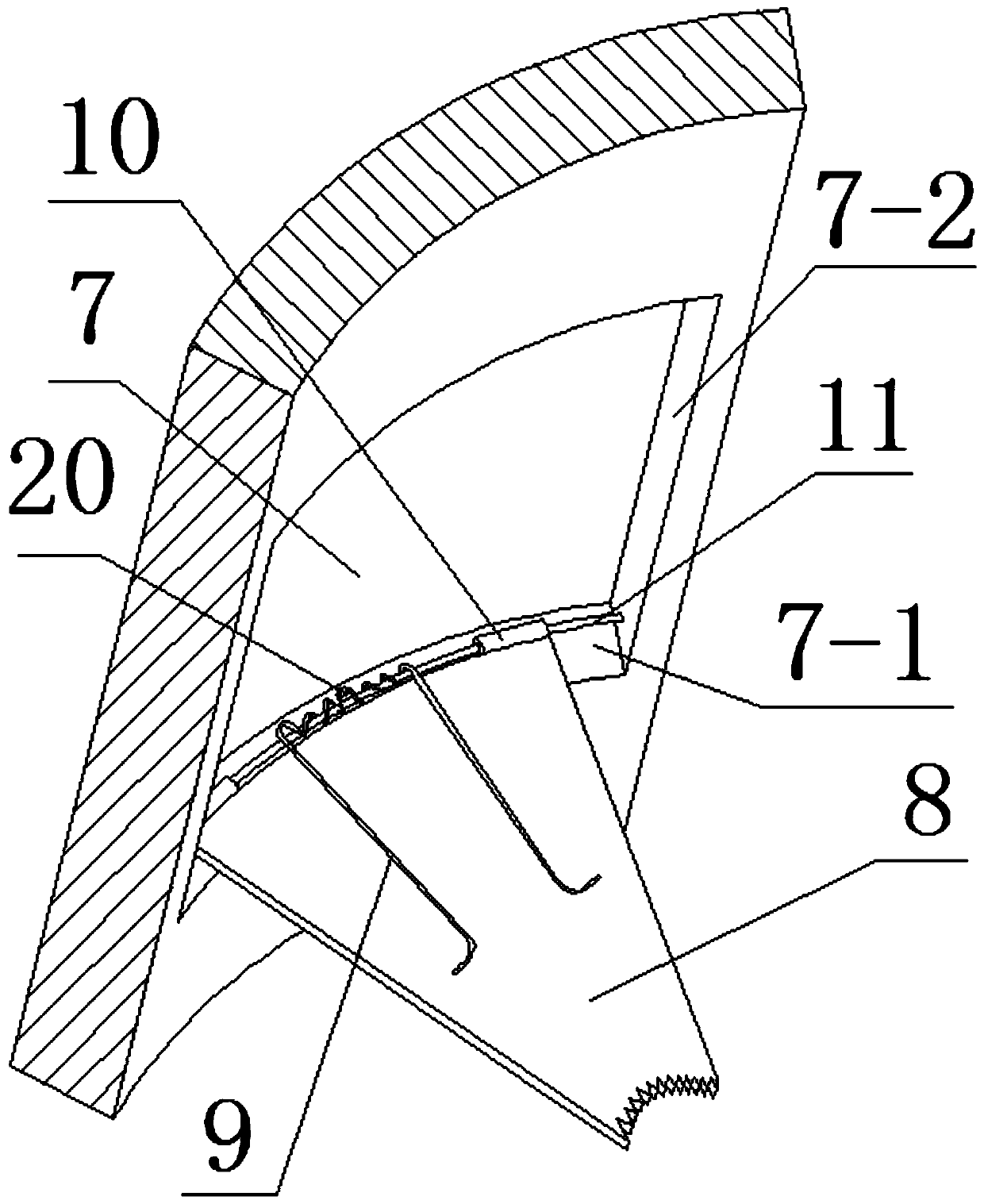

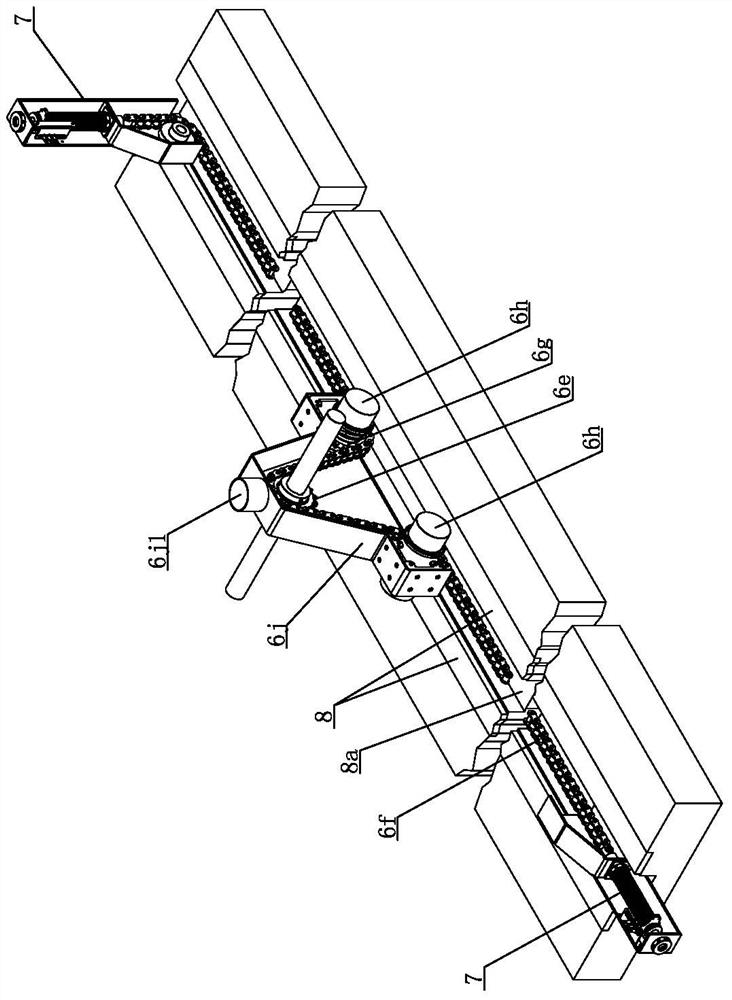

Railway construction machine guard rail hoisting device and rail replacing locomotive guard rail hoisting device

InactiveCN101725095ASmooth entryWalking smoothlyRailway track constructionBogieAutomotive engineering

The invention relates to a railway construction machine guard rail hoisting device and a rail replacing locomotive guard rail hoisting device, comprising a guard rail hoisting apparatus and an anti-loosing device, wherein the guard rail hoisting apparatus is arranged below a railway construction machine, such as a rail replacing operation vehicle traveling mechanism vehicle body and can integrally lift and transversely move a railway construction machine vehicle body, and the anti-loosing device is arranged on each steering frame of a steel rail traveling machine to enable the steering frames and the vehicle body to be vertically fixed into a whole. The guard rail hoisting apparatus comprises an elongated supporting body, a guard rail suspension bracket and a control device, wherein the supporting body is fixedly suspended below the vehicle body through the guard rail suspension bracket, the control device is used for controlling the movement of the supporting body, a guard rail assembly is respectively arranged at both ends below the supporting body, the control device comprises two telescopic guard rail vertical oil cylinders and telescopic guard rail integral swinging oil cylinders, and the guard rail suspension bracket is provided with two downward stretching struts which are respectively hinged with both ends of the supporting body through two guard rail support rods. The invention enables a railway which needs to be born but is not completely fixed to be kept in an upright state in the construction process, farthest prevents the occurrence of a turning-way accident, and also enables the turning-way railway construction machine to rapidly hoist and safely reset.

Owner:株洲新通铁路装备有限公司

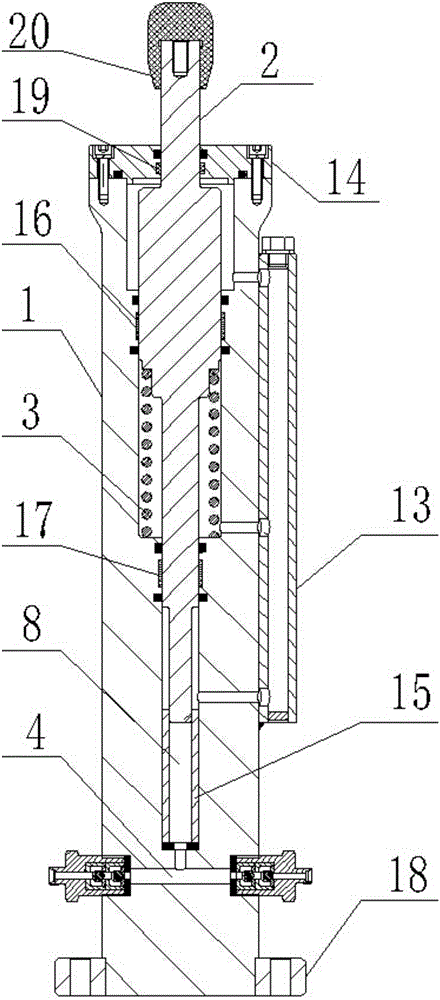

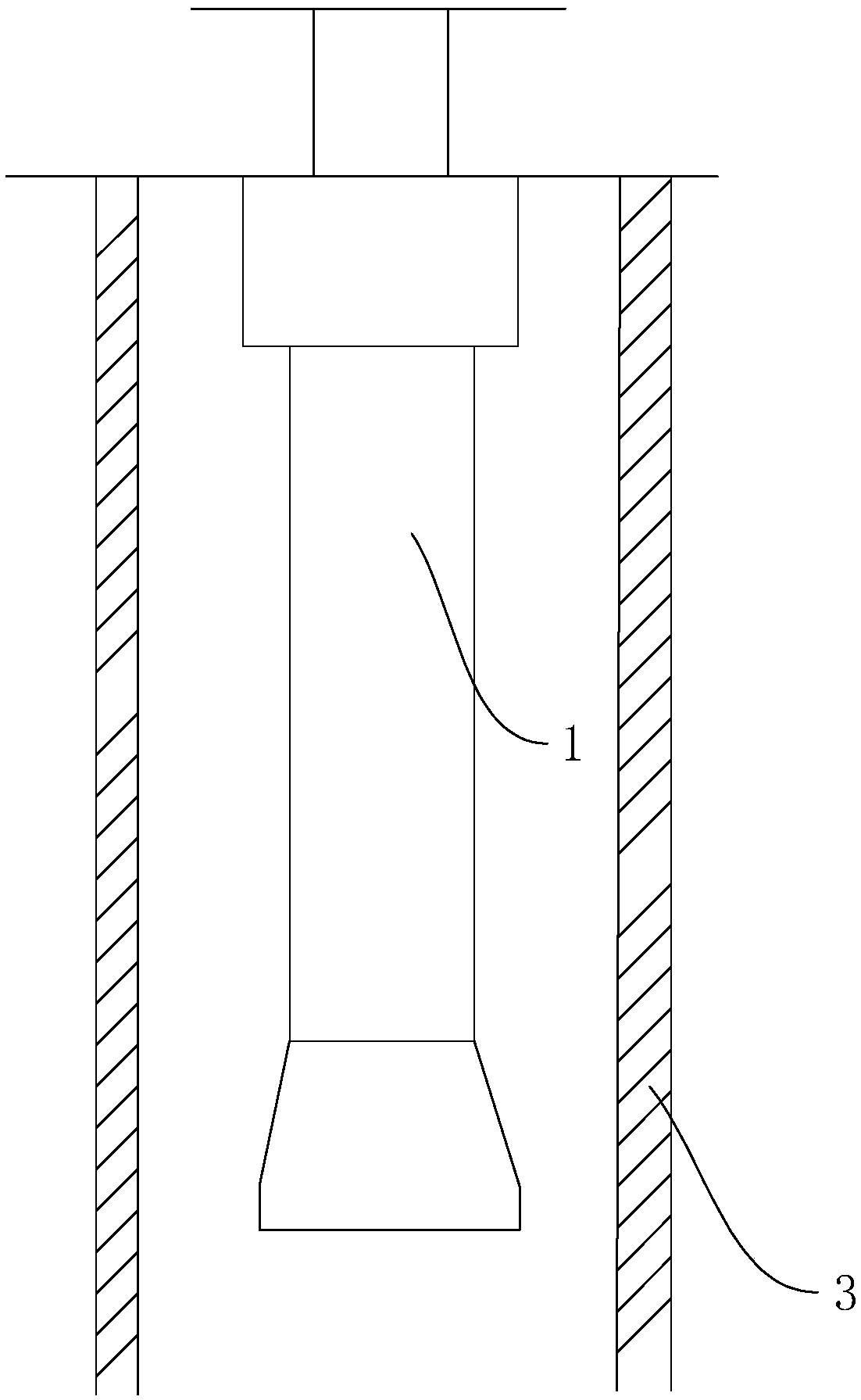

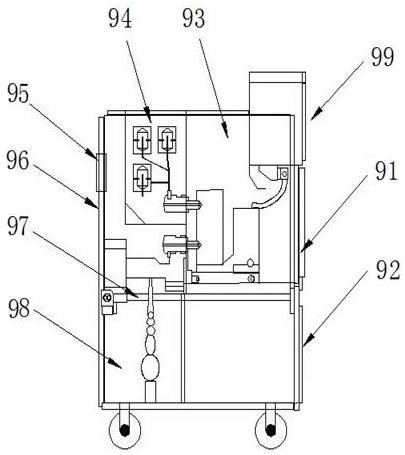

Integrated wellhead continuous dosing device

The invention discloses an integrated wellhead continuous dosing device which comprises a power end and an overflowing end in mutual connection with each other, wherein the power end comprises a cylinder and a plunger; the cylinder is vertically arranged; the plunger is inserted into a chamber of the cylinder; an extending end of the plunger is connected with a power source; a compression spring for resetting the plunger is arranged between the chamber and the plunger; the overflowing end comprises a channel which is respectively in annular communication with the chamber, a drug kit and a wellhead. Compared with the prior art, the integrated wellhead continuous dosing device has the advantages of simple structure, stability and reliability in work, high adaptive capacity to environment, accurate dosage and convenience in maintenance and repairing.

Owner:DONGHAO MECHANICAL & ELECTRONICS

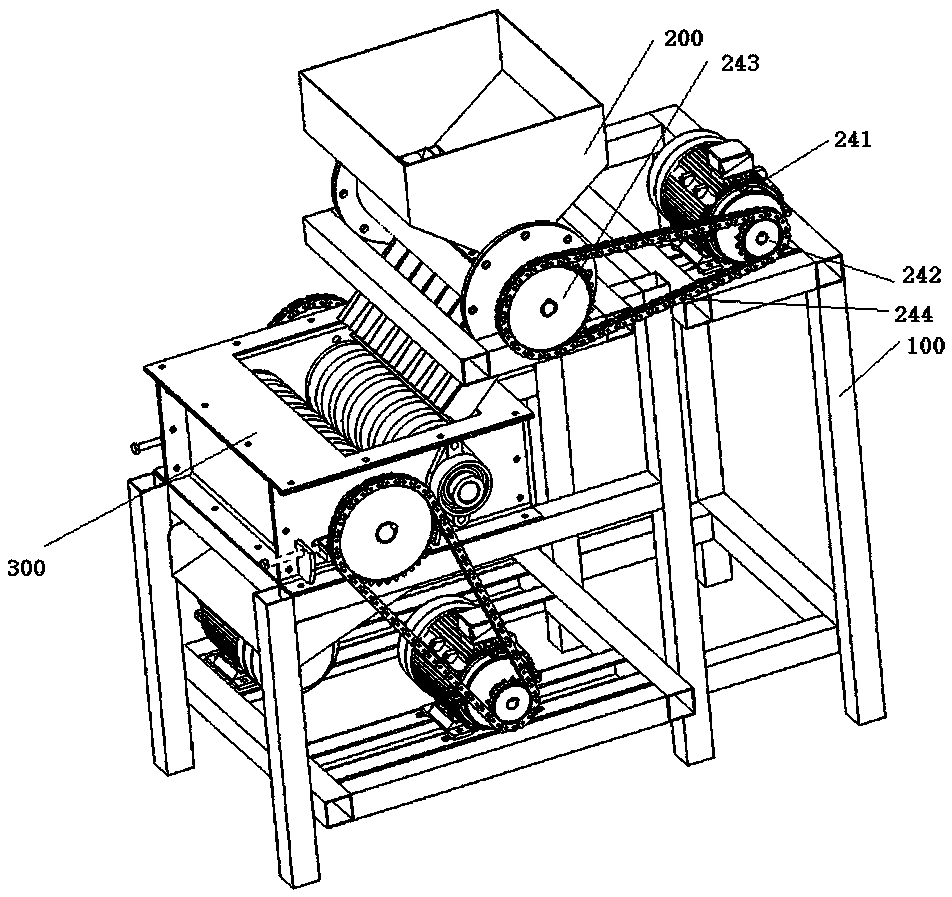

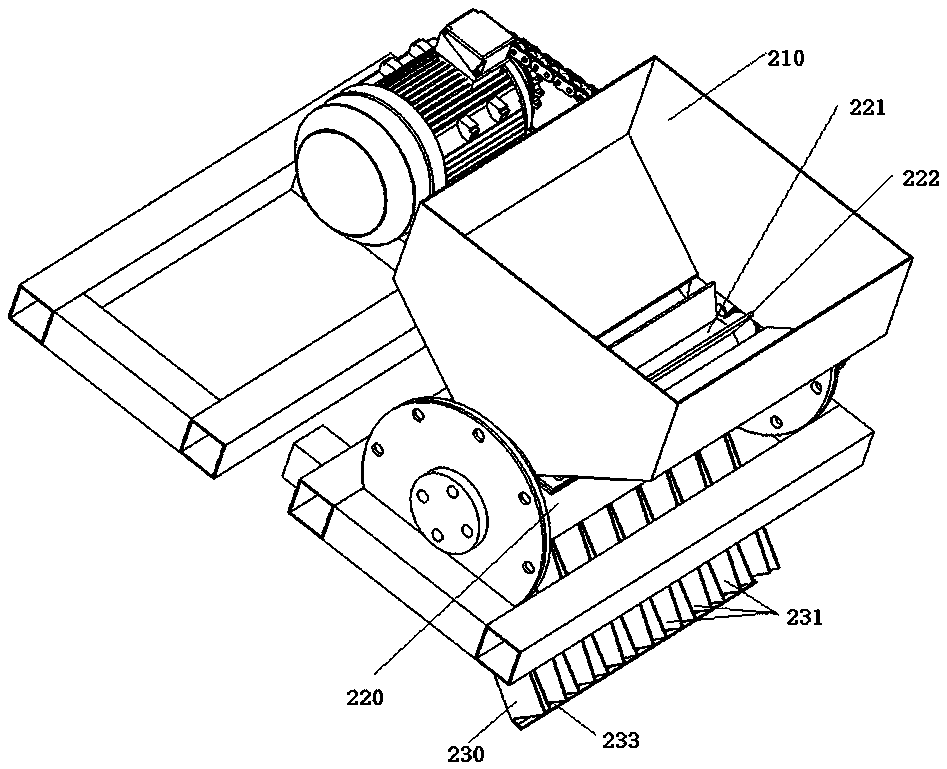

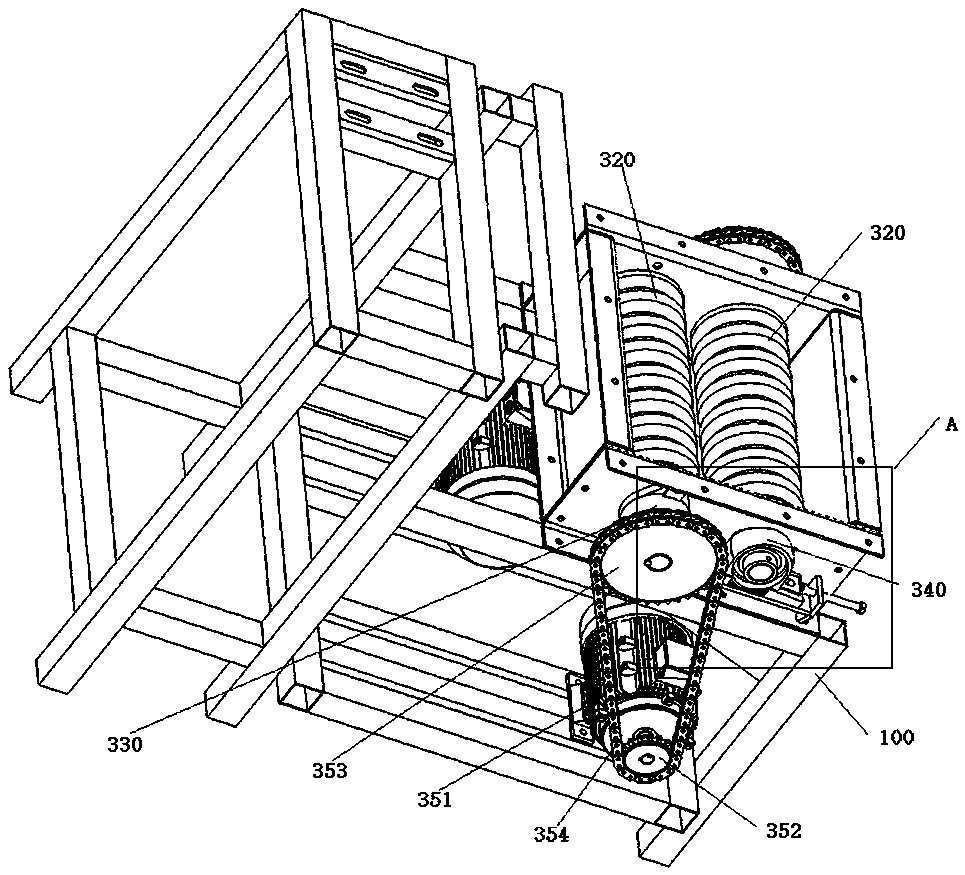

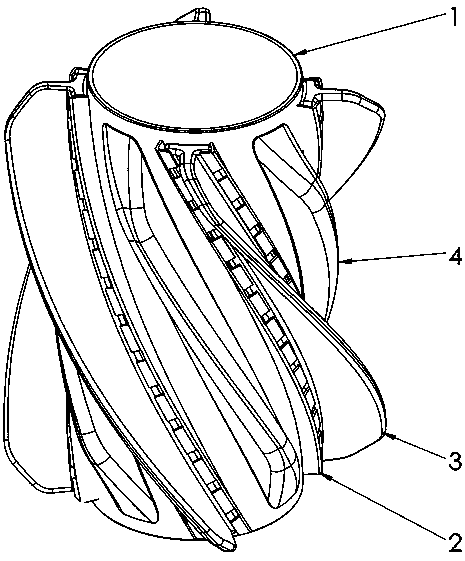

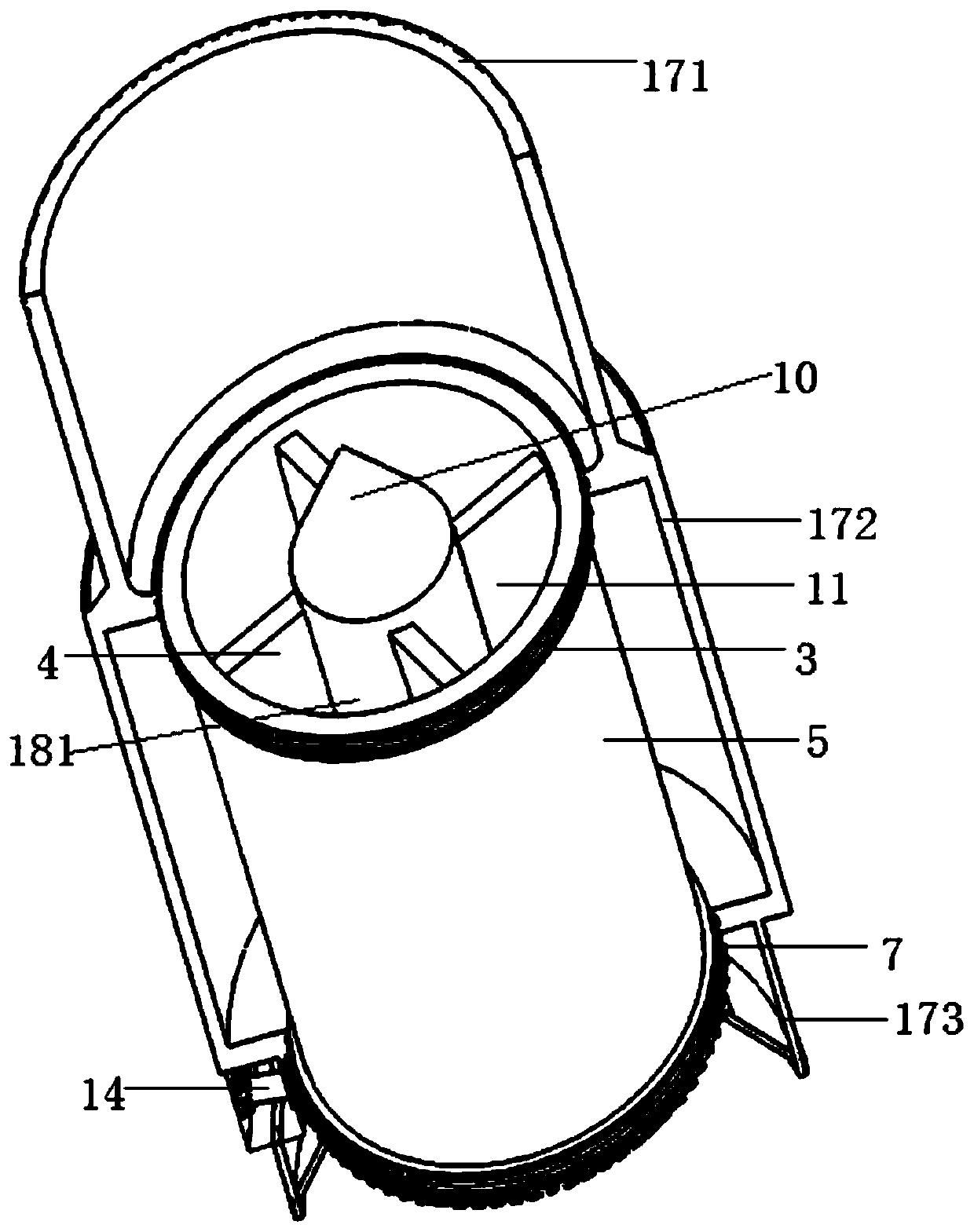

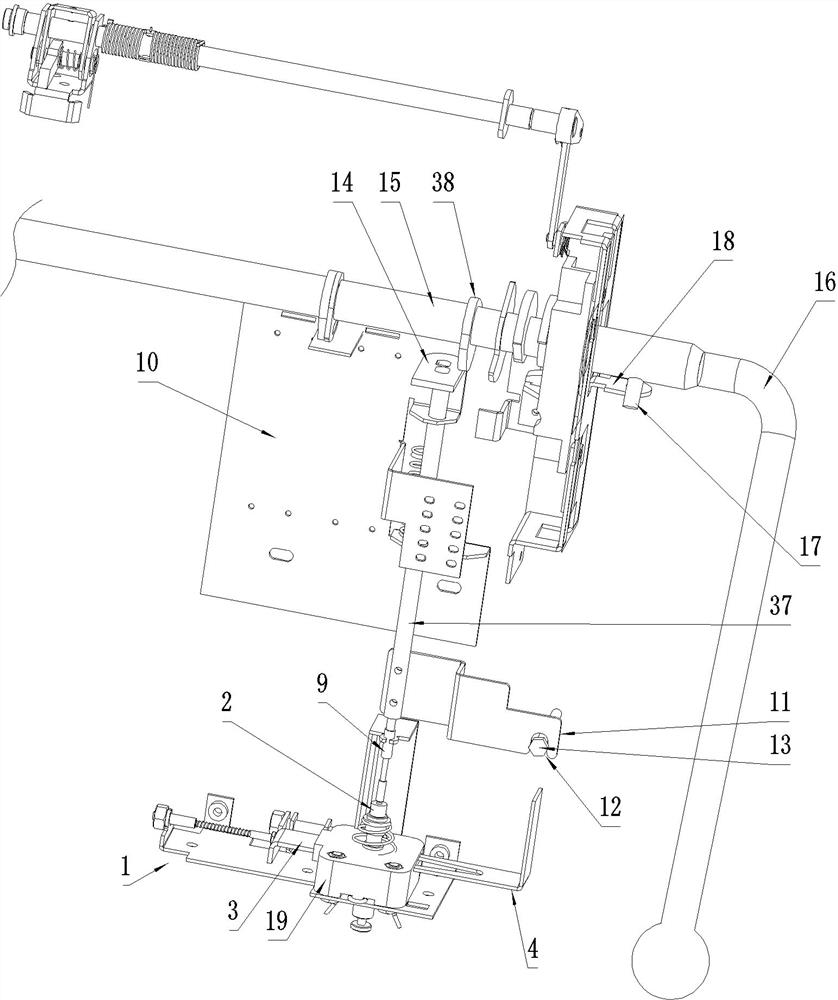

Hull breaking machine based on pretreated walnuts

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

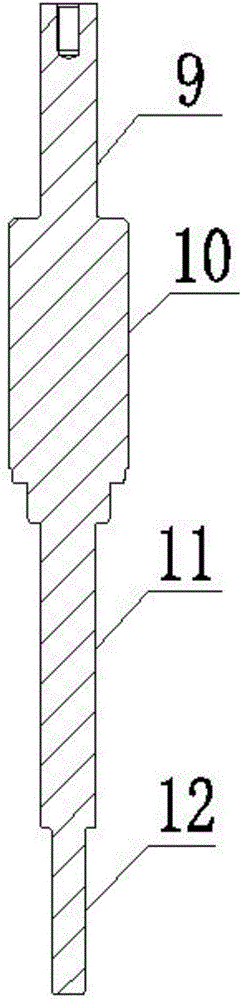

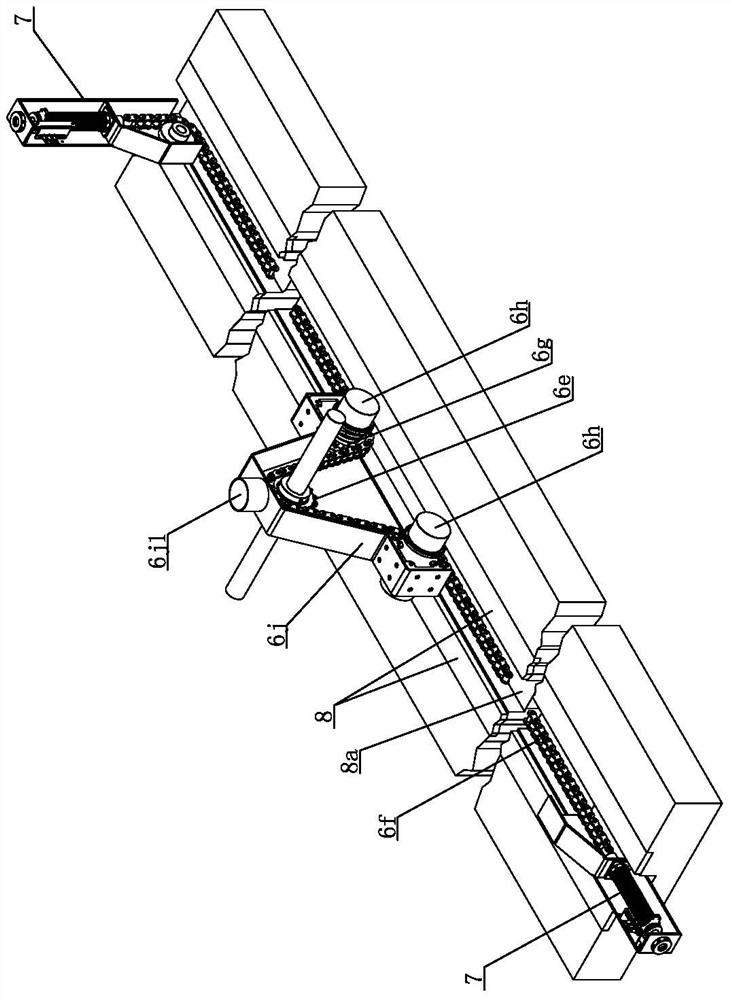

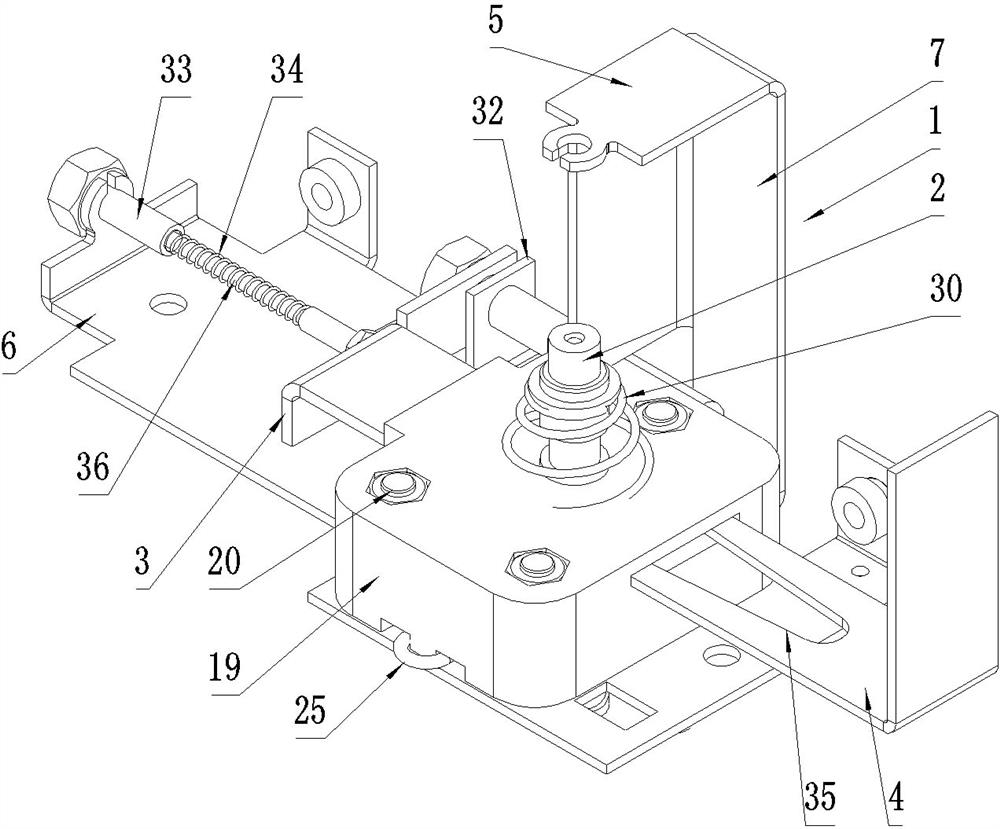

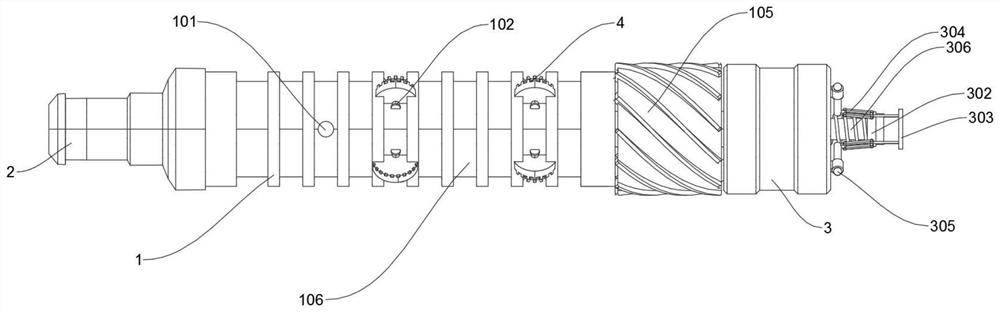

Automated oil tube outside-well cutting device

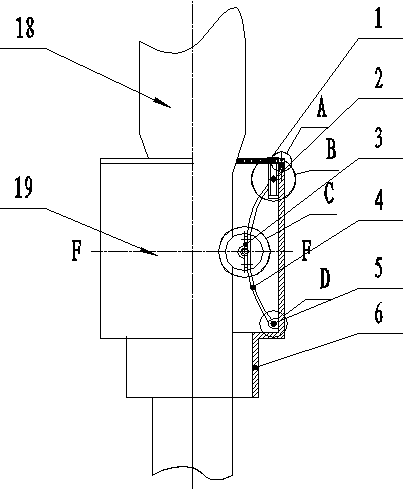

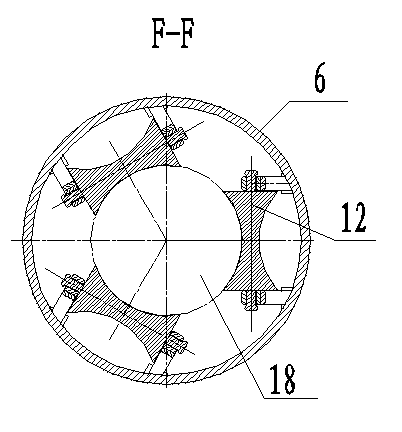

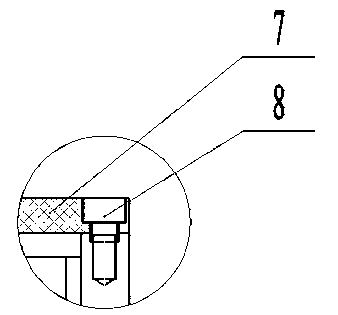

InactiveCN107175364APlay a righting roleReduce transmission frictionTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

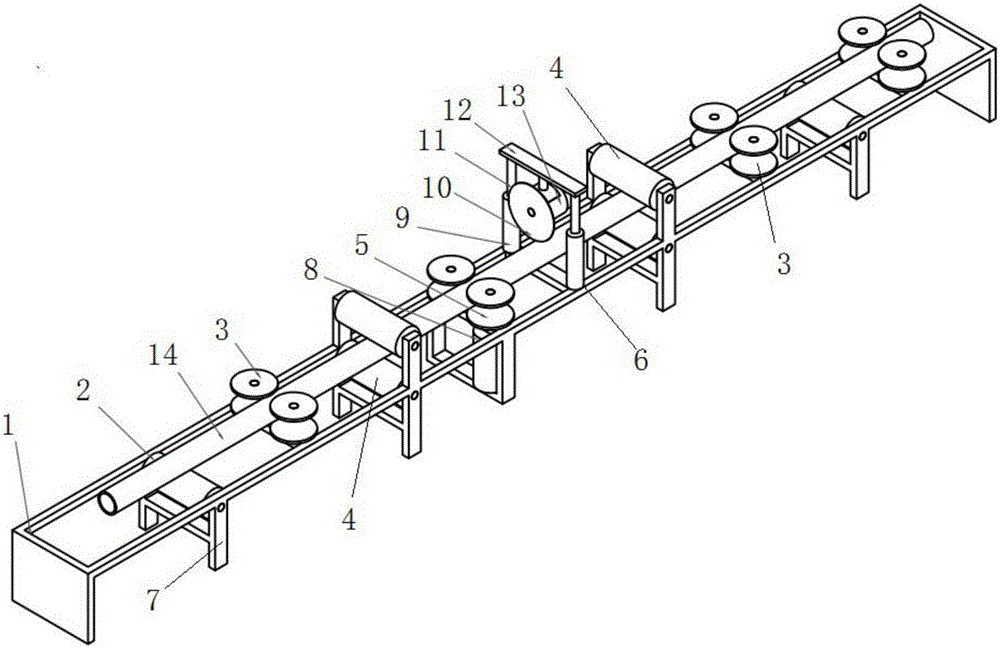

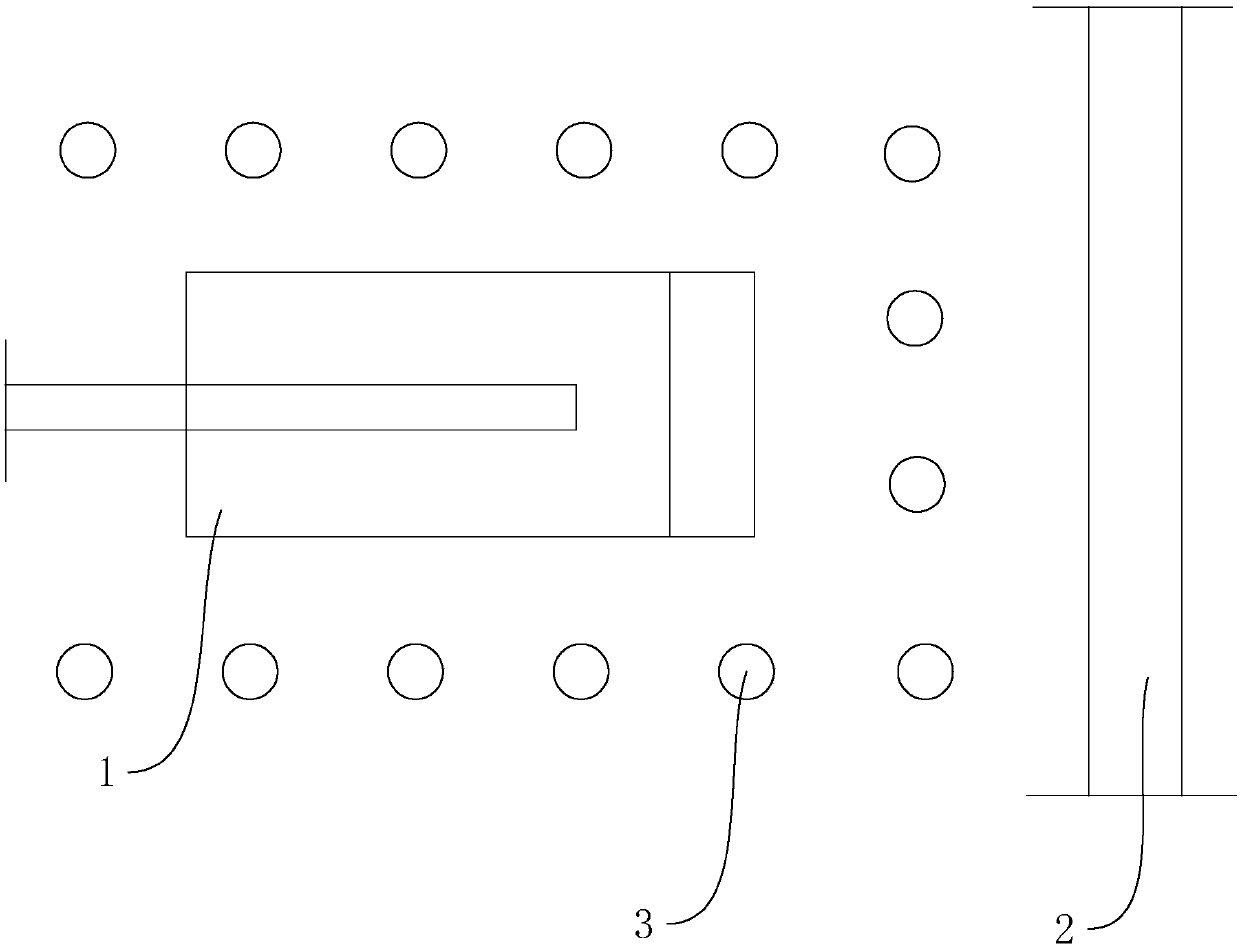

The invention relates to an automated oil tube outside-well cutting device. The automated oil tube outside-well cutting device comprises a rack, conveying rollers, transverse righting rollers, longitudinal righting rollers, a driving roller, a cutting device and a PLC controller, wherein the conveying rollers, the transverse righting rollers, the longitudinal righting rollers, the driving roller and the cutting device are arranged on the rack, and the rolling tangent planes of the conveying rollers and the driving roller constitute a conveying plane together; and the cutting device is arranged in the middle of the rack, the driving roller, the first longitudinal righting roller, the first transverse righting roller and the first conveying roller are arranged at the feeding side of the cutting device sequentially, and the second longitudinal righting roller, the second transverse driving rollers and the second conveying roller are arranged at the discharging side of the cutting device sequentially. According to the automated oil tube outside-well cutting device, the rolling tangent planes of the conveying rollers and the driving roller constitute the conveying plane together, so that the functions of supporting an oil tube and reducing conveying friction are achieved; and meanwhile the transverse righting rollers and the longitudinal righting rollers limit the upper, lower, left and right positions of the oil tube in the rolling advancing process, so that the function of righting the oil tube is achieved.

Owner:中国石油天然气股份有限公司勘探开发研究院

Integrated wellhead continuous dosing device

The invention discloses an integrated wellhead continuous dosing device which comprises a power end and an overflowing end in mutual connection with each other, wherein the power end comprises a cylinder and a plunger; the cylinder is vertically arranged; the plunger is inserted into a chamber of the cylinder; an extending end of the plunger is connected with a power source; a compression spring for resetting the plunger is arranged between the chamber and the plunger; the overflowing end comprises a channel which is respectively in annular communication with the chamber, a drug kit and a wellhead. Compared with the prior art, the integrated wellhead continuous dosing device has the advantages of simple structure, stability and reliability in work, high adaptive capacity to environment, accurate dosage and convenience in maintenance and repairing.

Owner:DONGHAO MECHANICAL & ELECTRONICS

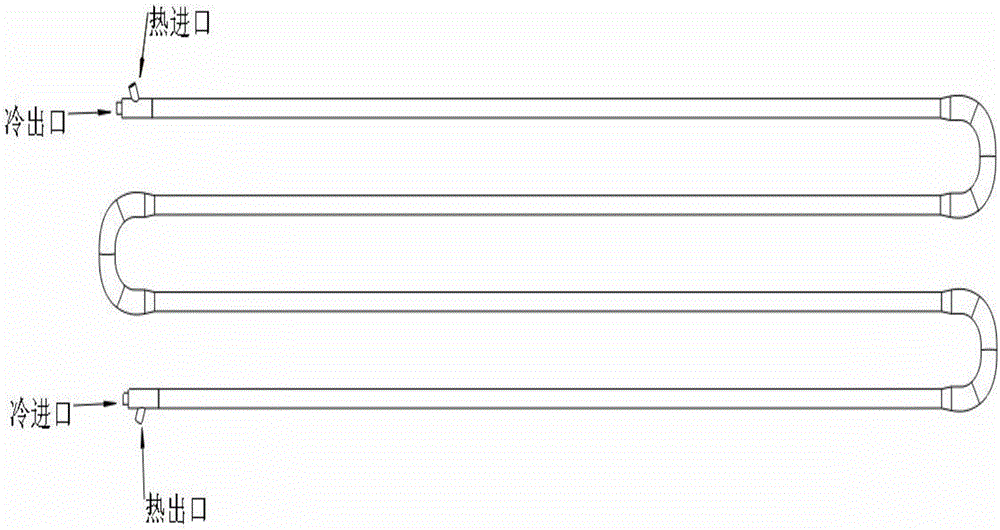

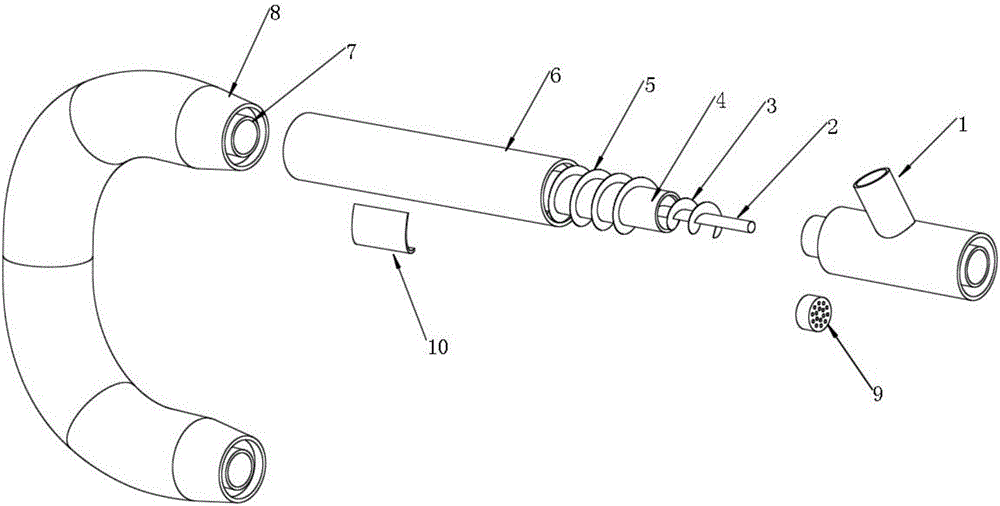

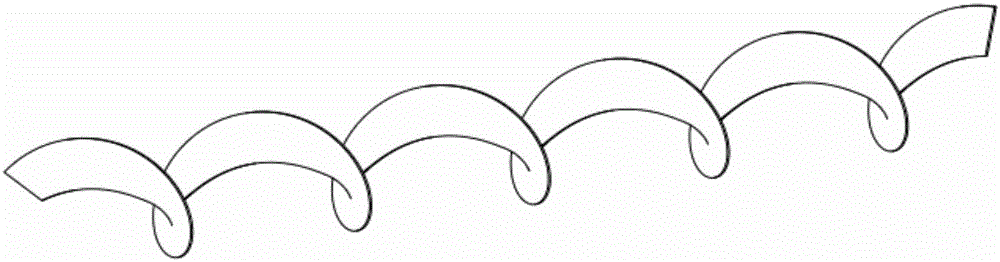

Internal and external dual-spiral-flow centrifugal separation type heat exchanger

InactiveCN106482547ALarge heat transfer temperature differenceImprove heat transfer effectStationary tubular conduit assembliesTubular elementsVapor liquidContinuous flow

The invention provides an internal and external dual-spiral-flow centrifugal separation type heat exchanger. The internal and external dual-spiral-flow centrifugal separation type heat exchanger mainly aims at solving the problem that the heat exchange efficiency of cold and hot media is low, and is especially suitable for heat exchange of vapor-liquid two-phase media. The internal and external dual-spiral-flow centrifugal separation type heat exchanger is characterized in that the device has an internal spiral channel structure and an external spiral channel structure; an internal branch pipe (2) is arranged in an inner pipe (4) of a straight pipe section, a set of internal spiral pieces (3) are fixed around the inner branch pipe, and the outer edges of the internal spiral pieces make contact with the inner wall of the inner pipe (4) of the straight pipe section; a set of external spiral pieces (5) are fixed around the outer wall of the inner pipe (4) of the straight pipe section, and the outer edges of the external spiral pieces make contact with the inner wall of an outer pipe (6) of the straight pipe section. After the heat exchange device and a medium accelerator are used in cooperation, internal and external dual-spiral-flow continuous flow of the cold and hot media can be achieved, the heat exchange temperature difference and the heat exchange area are increased, vibration is lowered, and the heat exchange effect between the media is effectively improved.

Owner:NORTHEAST GASOLINEEUM UNIV

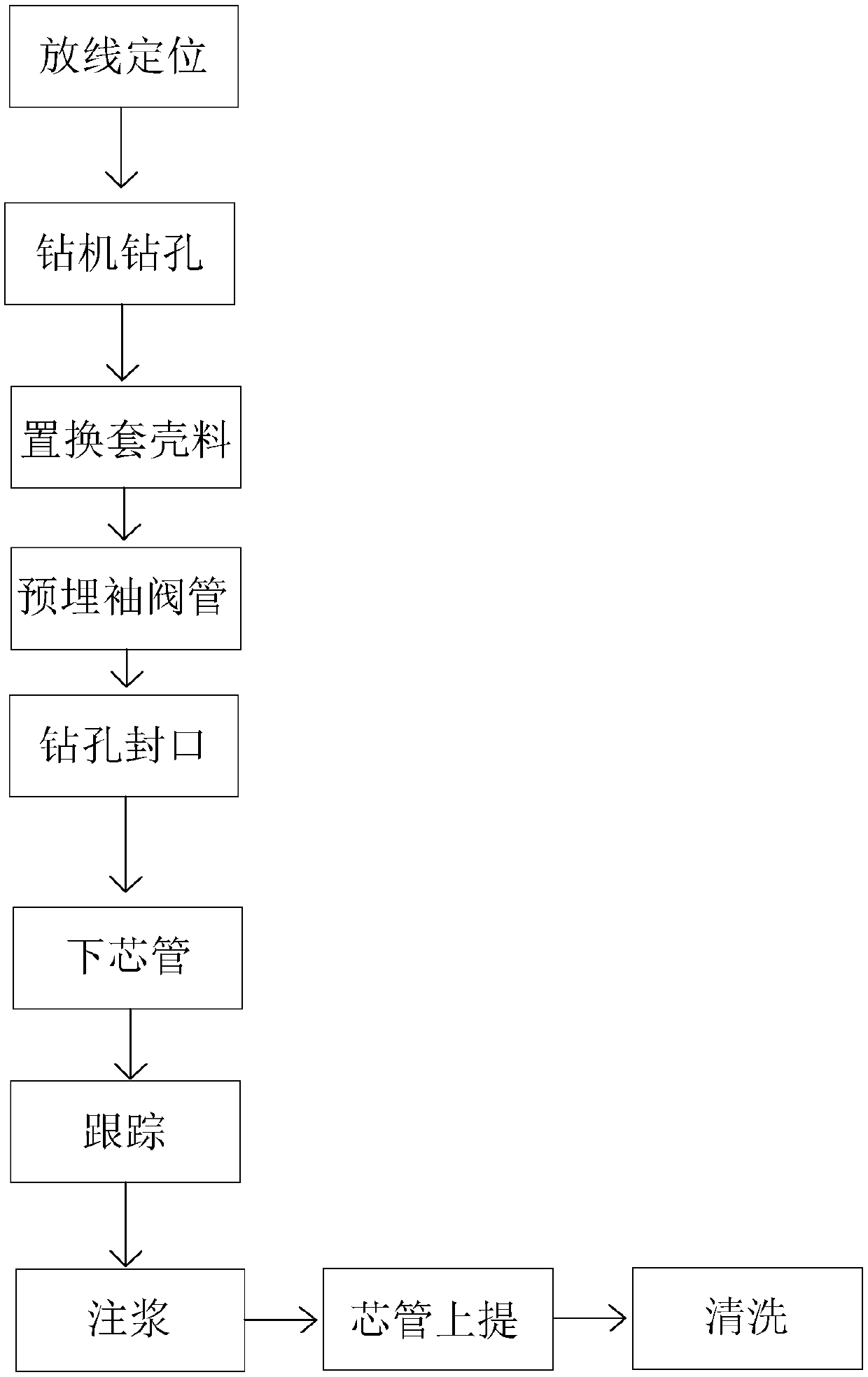

Karst treatment and track grouting construction method

PendingCN109667276AReduce processing timeReduce the case of expansionArtificial islandsFoundation testingSleeve valveKarst

The invention relates to the technical field of karst treatment, and aims to provide a karst treatment and track grouting construction method. The karst treatment and track grouting construction method provided by the invention is characterized by comprising the following steps of 1) despooling for positioning: measuring two coordinate points with the closest distance between a cuboid-shaped housepile foundation bearing platform and a continuous wall, setting drill hole positions between the two coordinate points, enabling the hole positions to be arranged in the circumferential direction ofthe house pile foundation bearing platform at intervals, and marking the hole positions; 2) using a drilling machine for drilling holes; 3) replacing sleeve shell materials; 4) pre-embedding a sleevevalve tube; 5) sealing the drill holes; 6) feeding core tubes; 7) tracking: closely monitoring continuous wall deformation, a subway station circuit, house pile foundation bearing platform settling and the like, and guiding grouting according to a monitoring result; and 8) grouting, wherein through pre-embedding the sleeve valve tube and tracking grouting, the treatment time for guiding holes andpre-embedding the sleeve valve tube is saved at a later period, and the occurrence of a phenomenon that a karst cave is further enlarged due to insufficient competency of a construction team is reduced. The karst treatment and track grouting construction method provided by the invention is applicable to the protection of the subway station circuit and the house pile foundation bearing platform.

Owner:广州市天作建筑规划设计有限公司

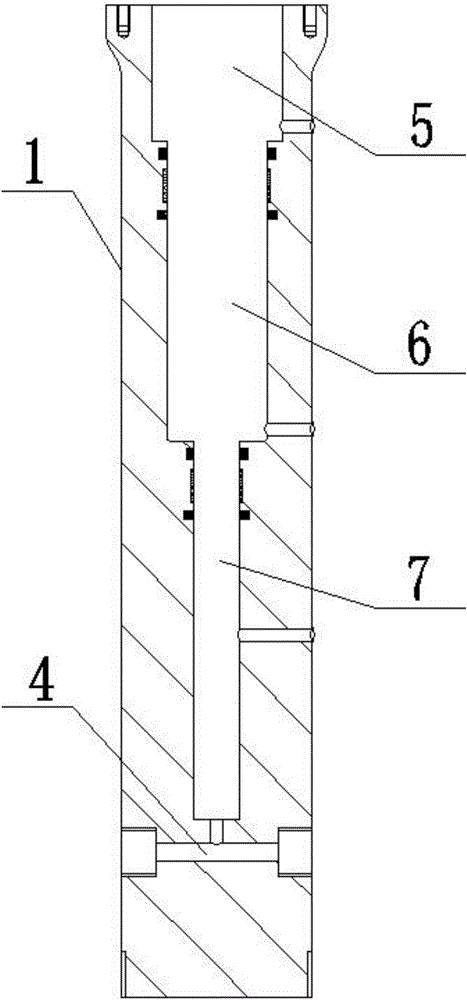

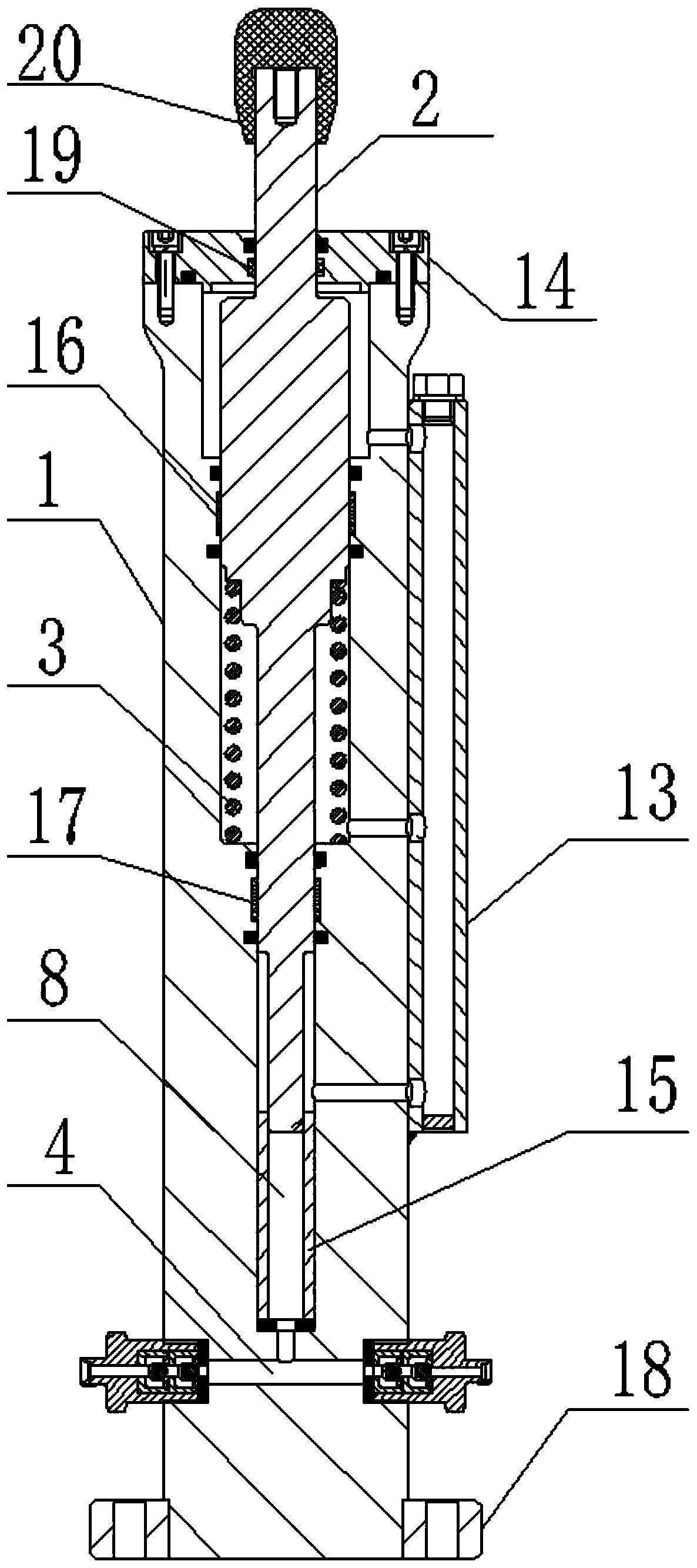

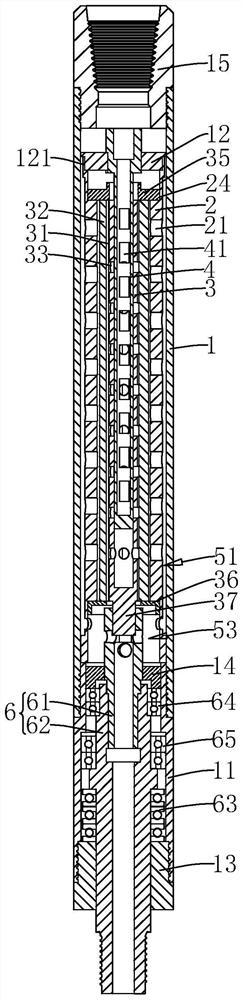

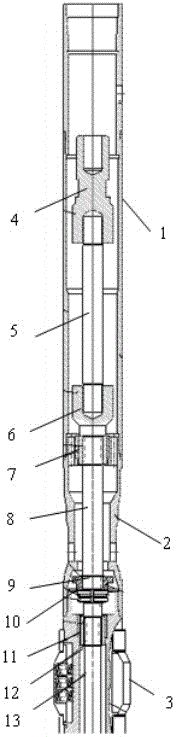

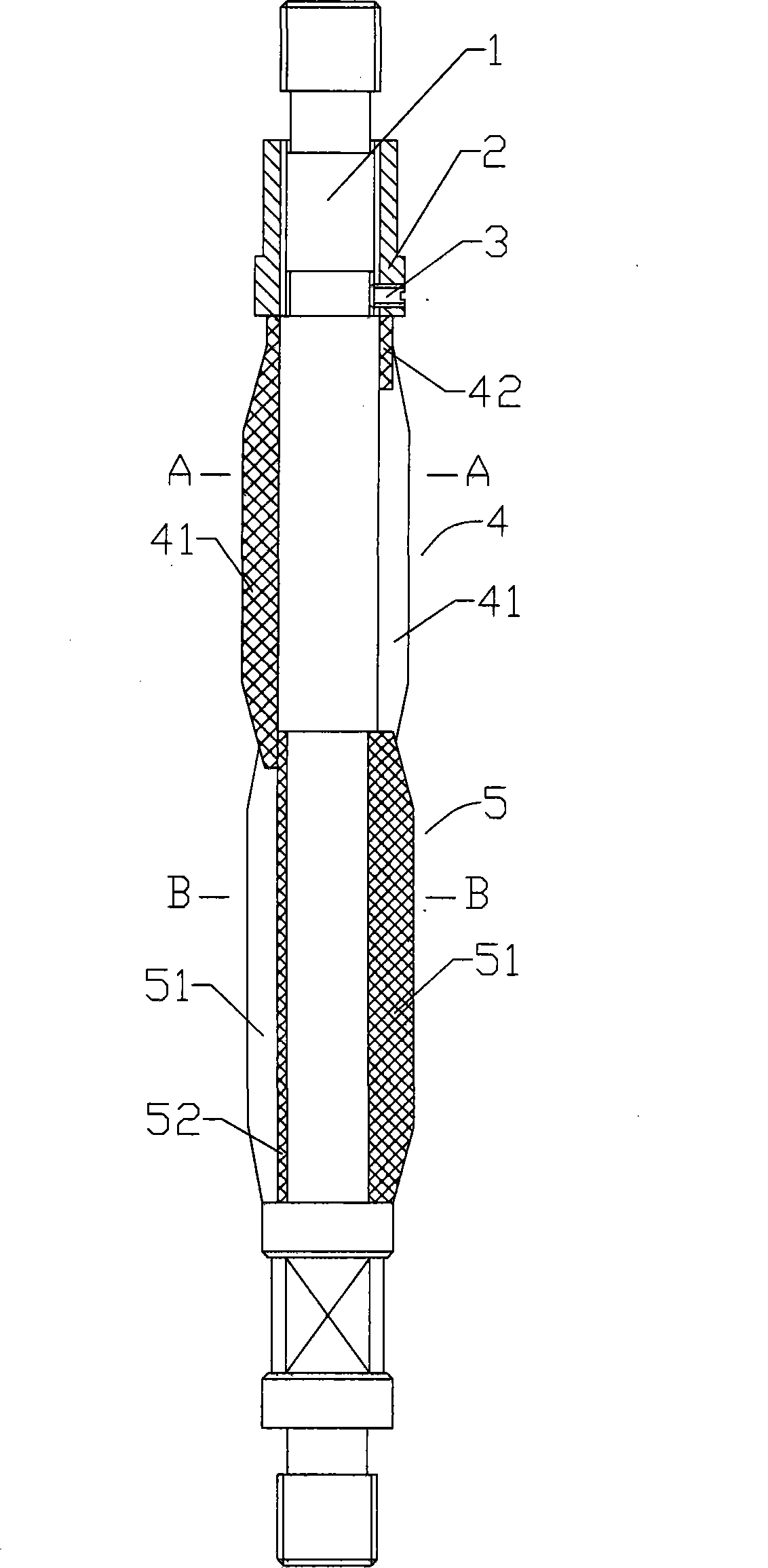

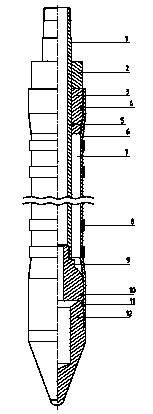

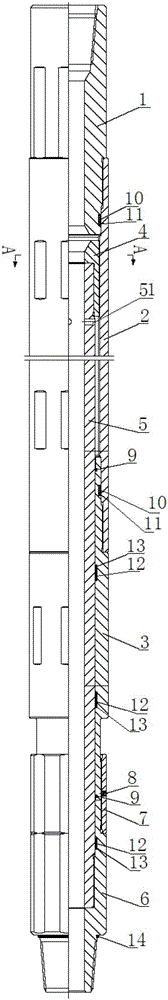

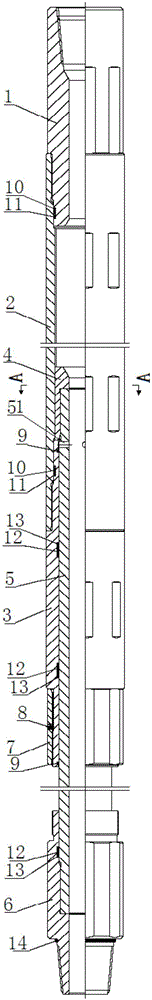

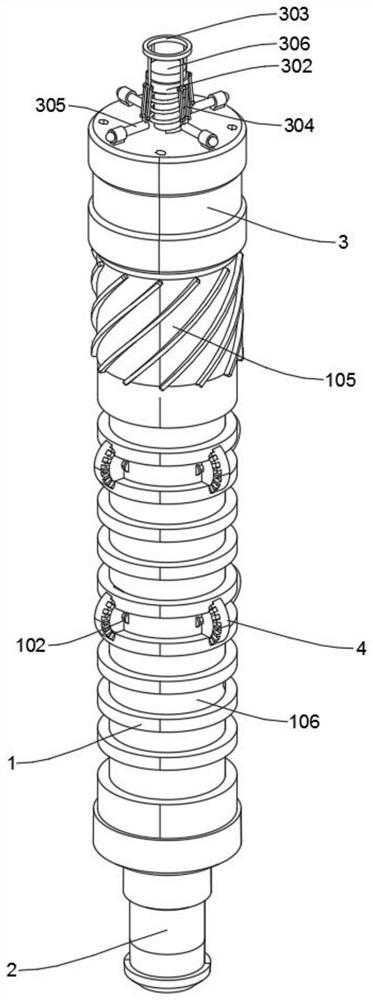

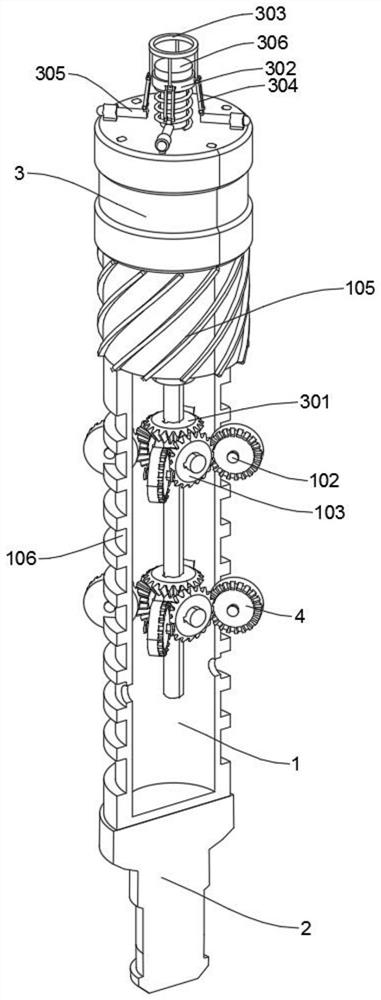

All-metal dynamic seal concentric righting type underground volume motor

InactiveCN113389681AAchieve outputMeet the needs of high temperature drillingBorehole drivesEngine componentsEngineeringMechanical engineering

The invention relates to the field of motors, in particular to an all-metal dynamic seal concentric righting type underground volume motor comprising an outer pipe, a stator fixedly connected in the outer pipe, a rotor rotationally connected in the stator and a flow distribution shaft installed in the rotor in a suspended mode, an annular cavity is formed between the outer pipe and the stator, and an inner cavity of the stator is oval. The upper end of the flow distribution shaft is connected with drilling fluid, and flow distribution holes are formed in the flow distribution shaft. A containing groove is formed in the side wall of the rotor, rotor copper bars are placed in the containing groove, a circulating opening is formed in the portion, in the direction facing each rotor copper bar, of the inner wall of the rotor, when the rotor rotates, the multiple circulating openings communicate with the flow distribution holes in a staggered mode, and a containing space allowing the drilling fluid to flow in is formed among the multiple rotor copper bars. Each circulating opening forms a notch communicating with the containing space on one side of the corresponding rotor copper bar. The stator is provided with pressure relief openings communicating with the annular containing cavity and the containing space, and the flow distribution holes and the pressure relief openings are arranged in a staggered mode in the circumferential direction. The all-metal dynamic seal concentric righting type underground volume motor can meet the requirement for high-temperature drilling in deep wells and ultra-deep wells.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

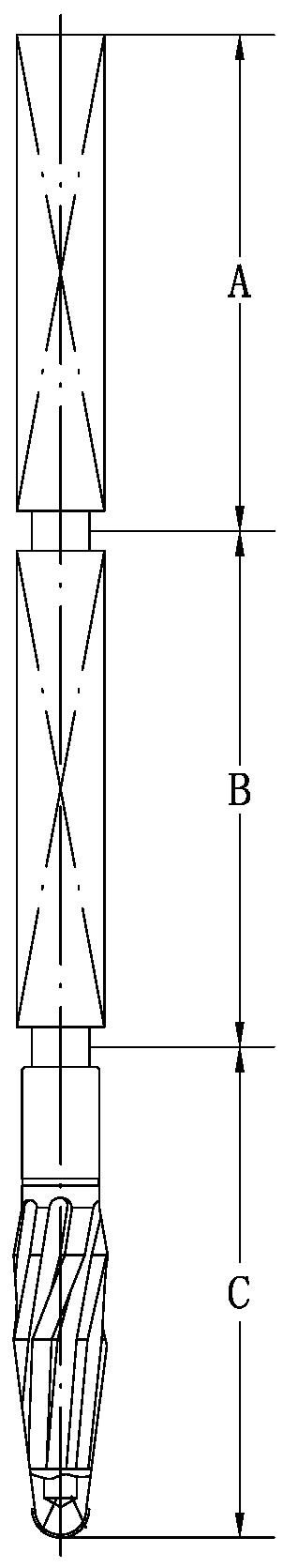

Method for reaming by explosion of detonating cord under well

ActiveCN108843244APlay a guiding roleLow costBlastingDrilling machines and methodsShock waveDetonation

The invention relates to a method for reaming by detonation of a detonating cord under a well. The method comprises the following steps: sequentially mounting a pilot reamer, an explosion reamer and avariable-diameter hole trimming device at the lowest end of a drill stem from bottom to top; enabling the drill stem to rotate and descend simultaneously, and when the drill stem descends until the explosion reamer is completely flush with the height of a predetermined reaming section, enabling the drill stem to stop descending and rotating; opening a mud pump and pressurizing same to the set detonation pressure to detonate the detonating cord of the explosion reamer, wherein shock waves generated by the explosion act on rocks of a well wall to cause stratum rocks on the entire periphery of this section to be crushed and fractured, thereby achieving reaming; opening the mud pump to the construction displacement and taking rock debris generated by the explosion reaming out of the well; enabling the drill stem to continuously descend, so that the variable-diameter hole trimming device reaches the reaming section to trim the well wall of the reaming section; and pulling the drill stem out of the well, putting a hole diameter logging unit into the well to detect the hole diameter and determining whether predetermined reaming requirements are met. By adopting the method, the reaming speed is high, risks under the well are low, the phenomena of repeatedly pulling a drill out of the well and putting the drill into the well is avoided and the well drilling efficiency is improved greatly.

Owner:中石化石油工程技术服务有限公司 +1

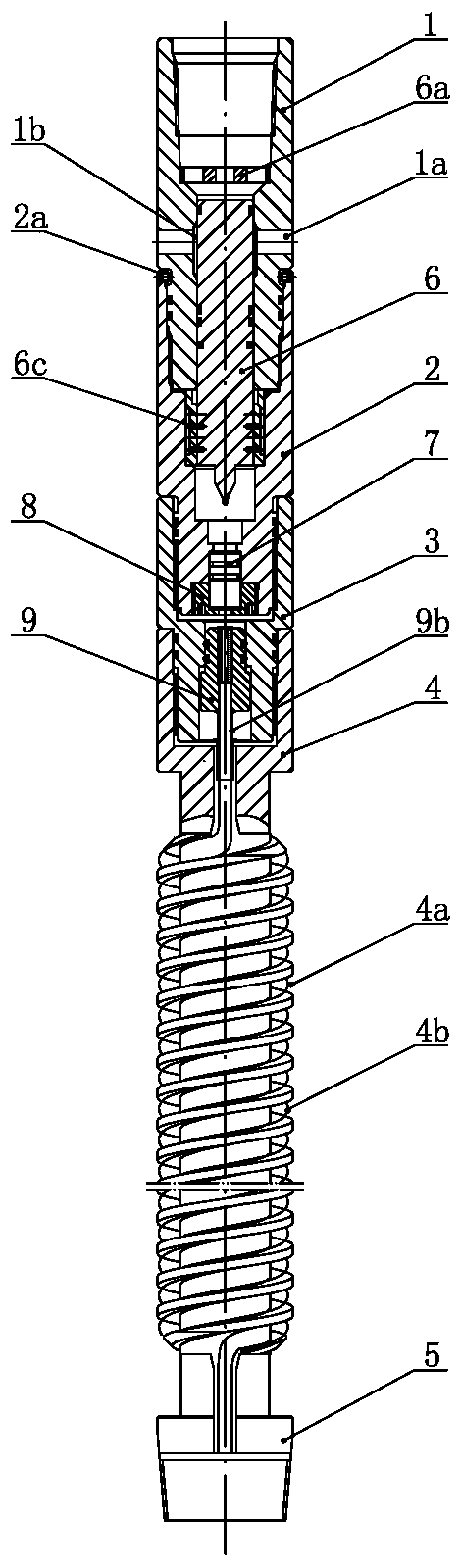

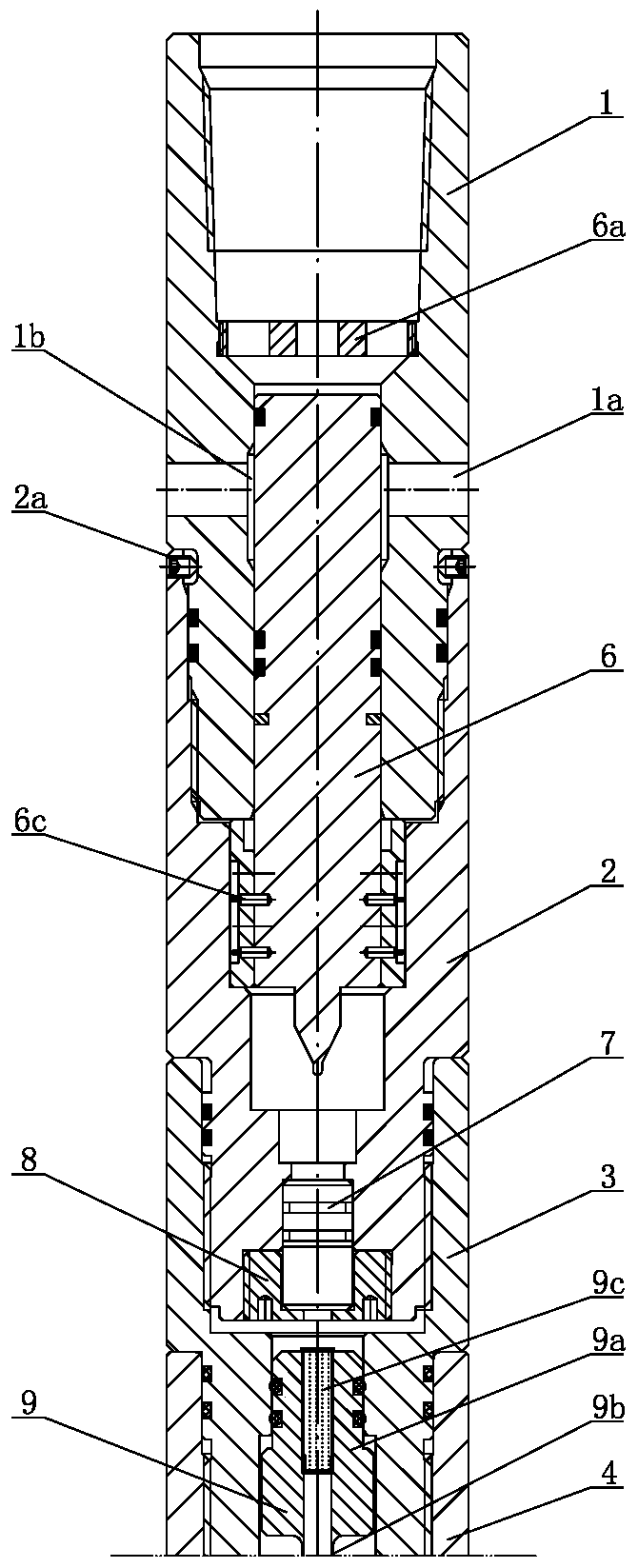

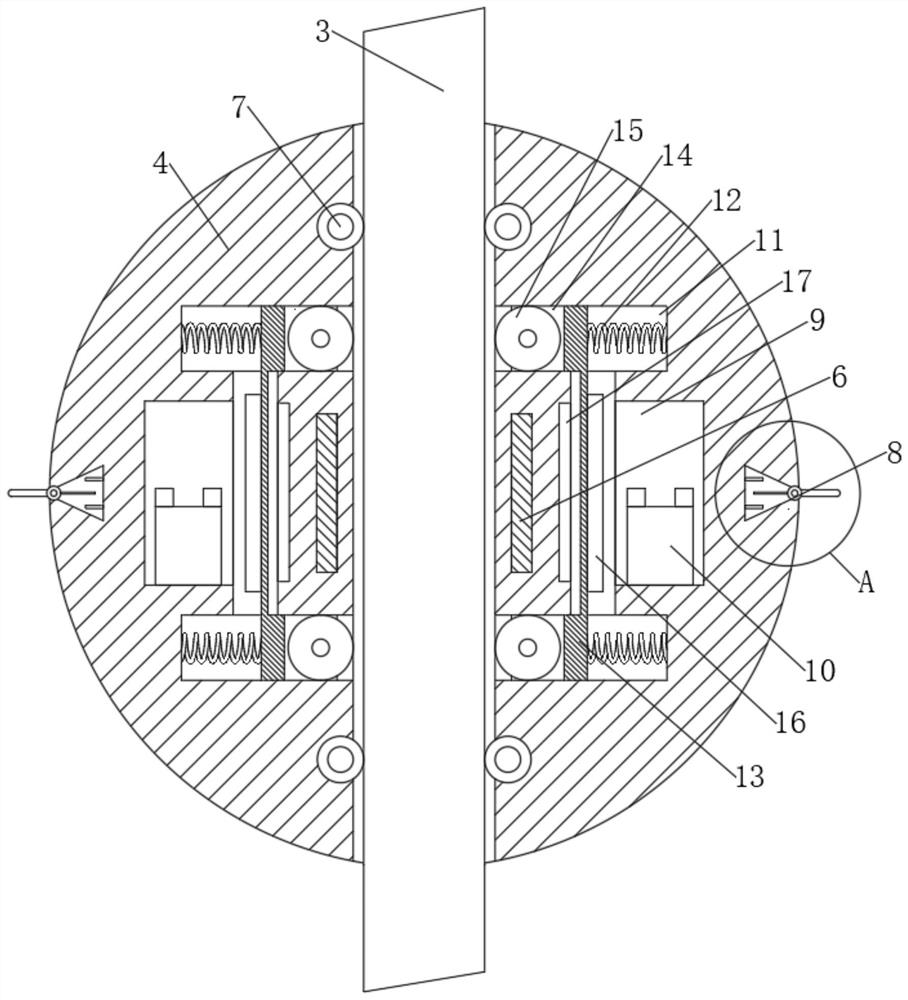

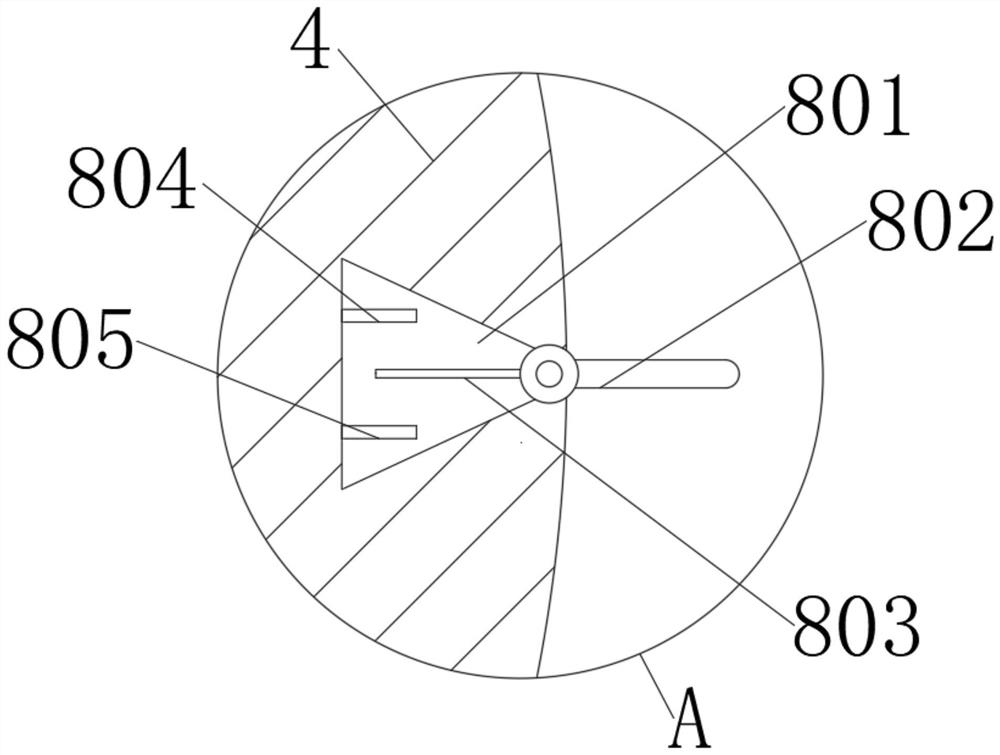

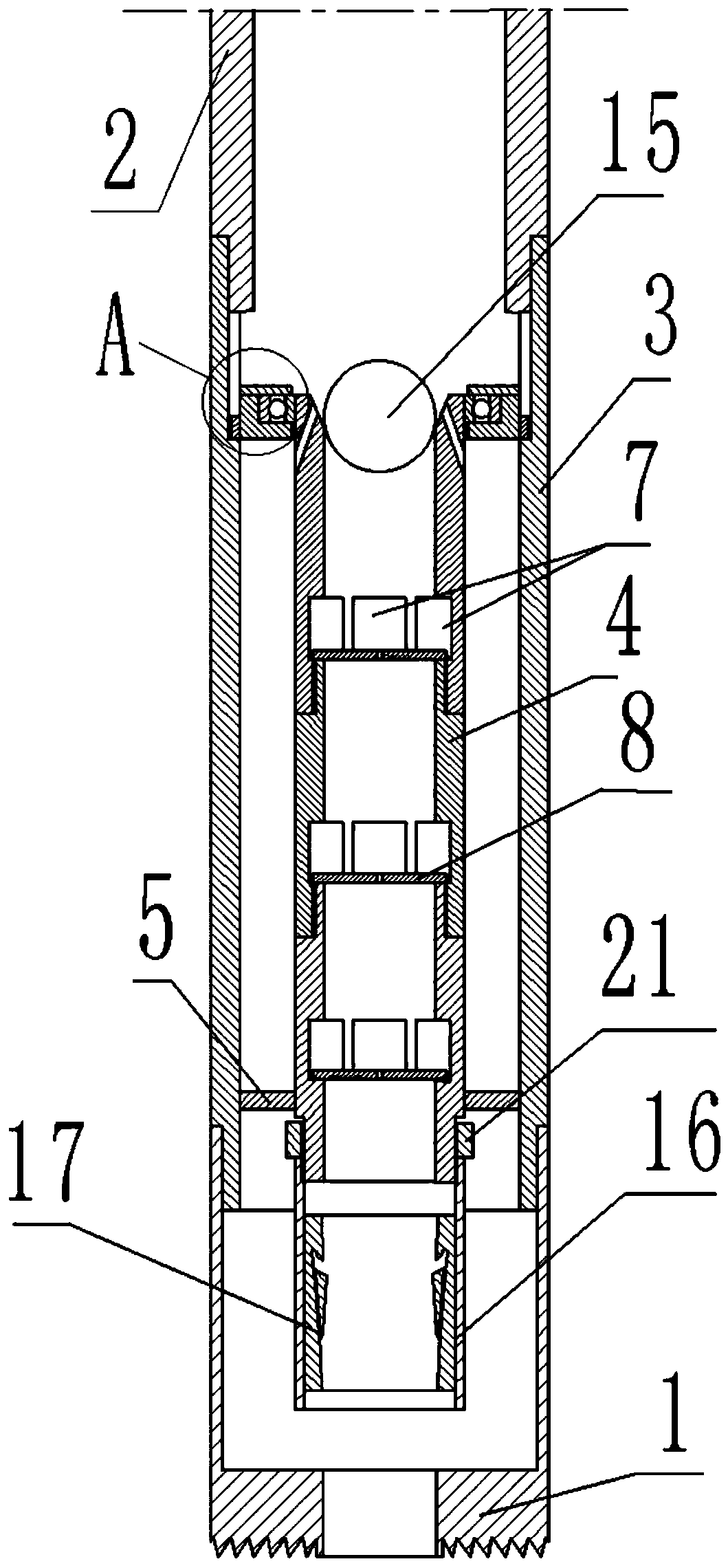

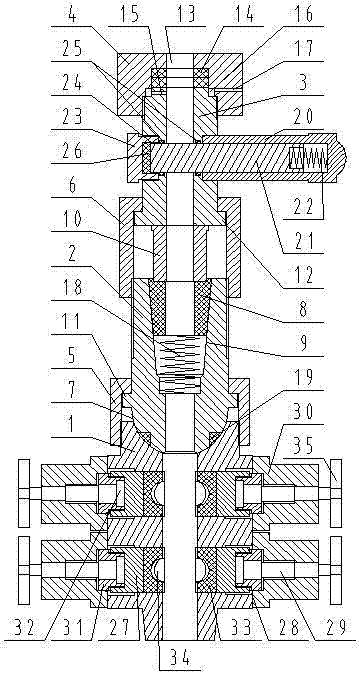

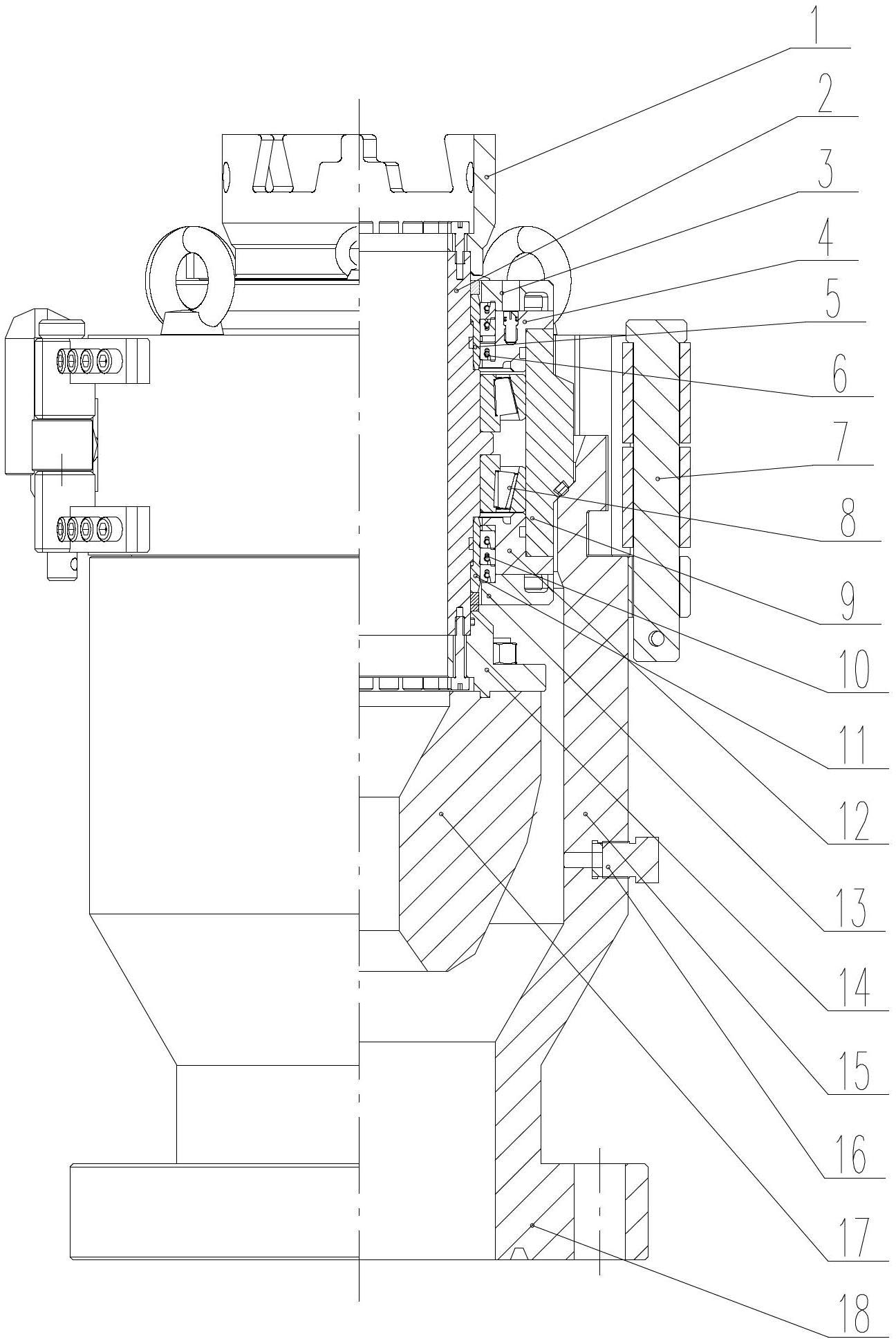

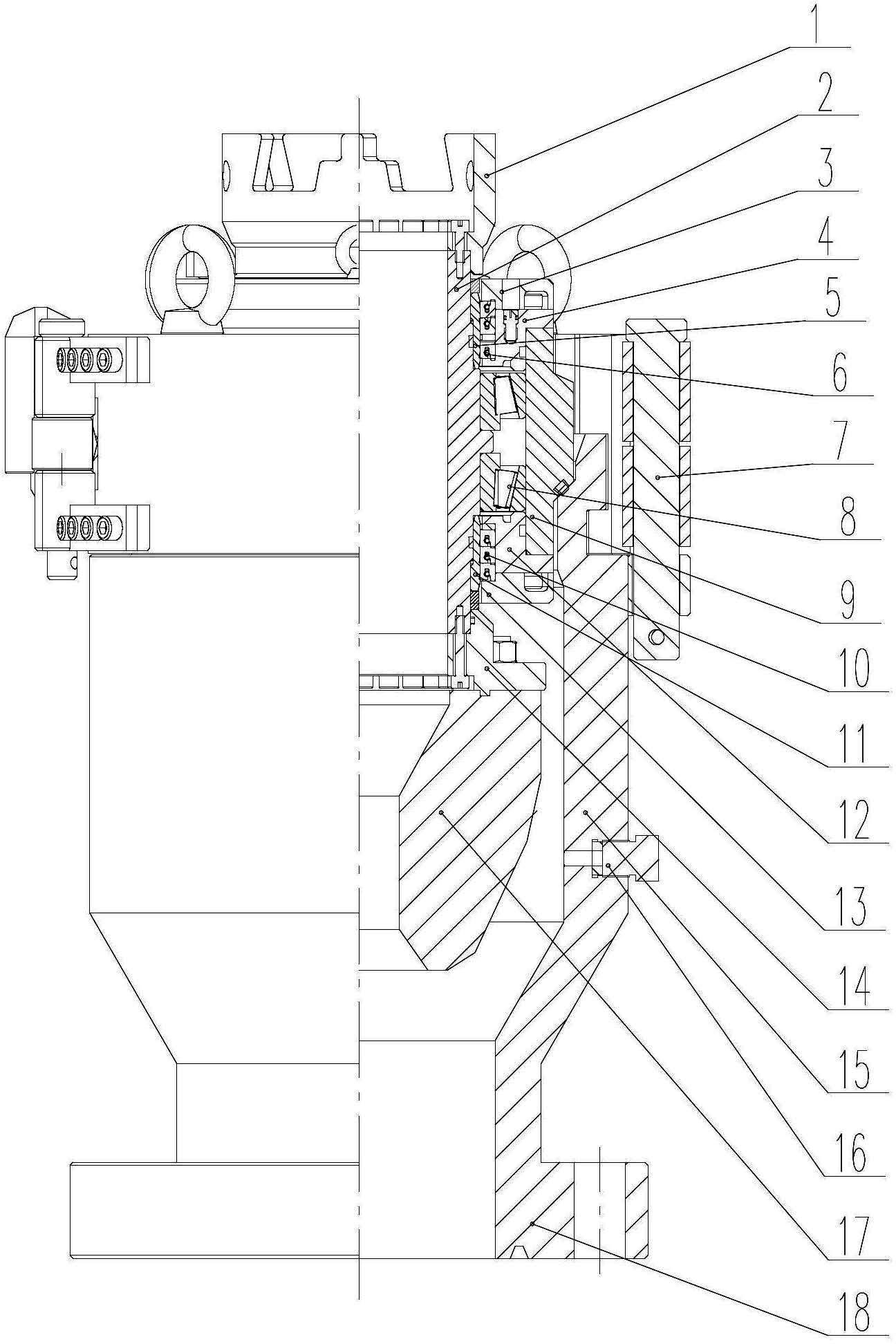

Top drive driver of rotating control head

ActiveCN103015886APlay a righting roleExtended seal lifeConstructionsRotary drillingTop driveBlowout preventer

The invention discloses a top drive driver of a rotating control head, which belongs to the technical field of rotating control heads. The top drive driver of the rotating control head comprises a shell sleeved on a drill rod, wherein the shell and the drill rod can relatively rotate; the lower part of the shell is connected to a center pipe of the rotating control head or a rubber core of a rotary blowout preventer, and a plurality of rollers are arranged in the shell; the rollers are uniformly distributed on the same circumference outside the drill rod, and two ends of each roller are respectively connected to the inner wall of the shell through spring mechanisms; and the rollers are clung to the outer wall of the drill rod through the spring mechanisms, and the rollers are matched with the outer wall of the drill rod and can roll in the axial direction of the drill rod. When the drill rod rotates, the shell is driven through the rollers to synchronously rotate. The top drive driver of the rotating control head solves the problem of the currently used top drive unbalanced drilling rotating control head that the rubber core is not driven and is badly damaged, and provides rotation power for the rubber core of the rotating control head or the rotary blowout preventer in the petroleum and natural gas unbalanced drilling operation under top drive force.

Owner:SOUTHWEST PETROLEUM UNIV

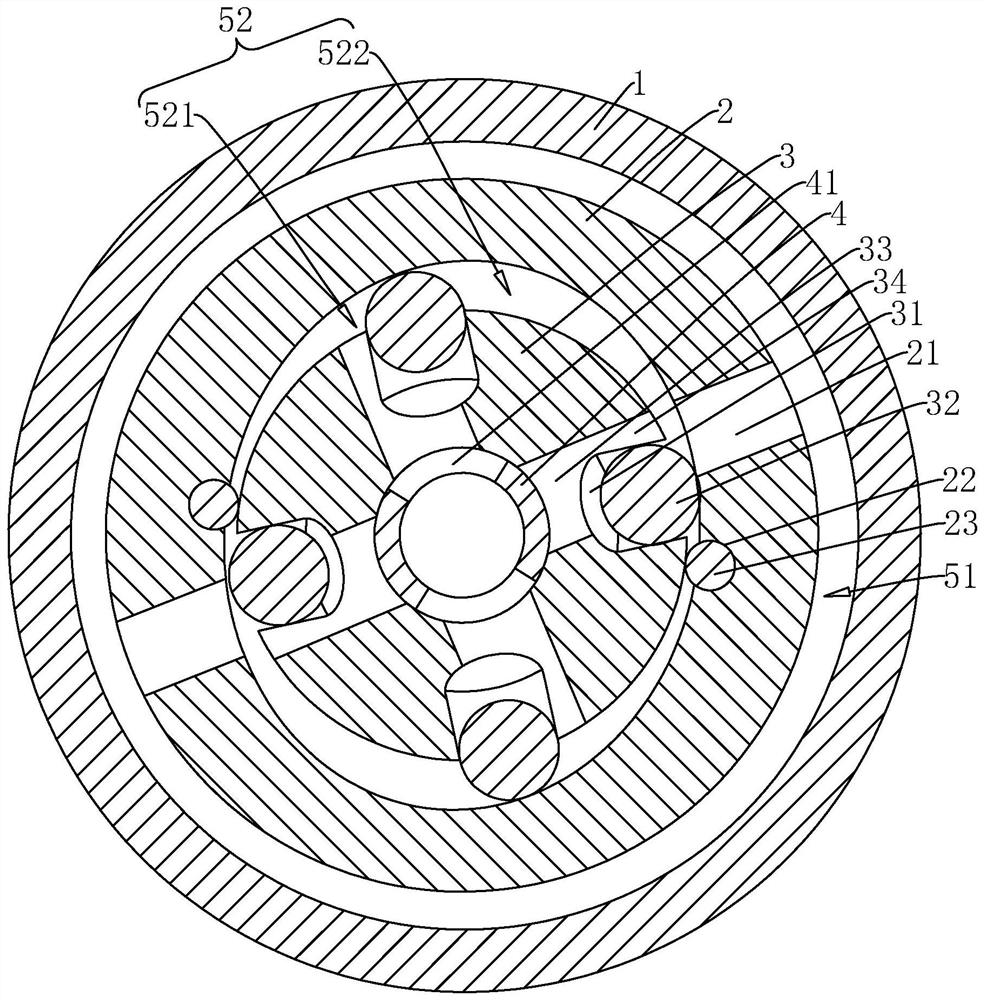

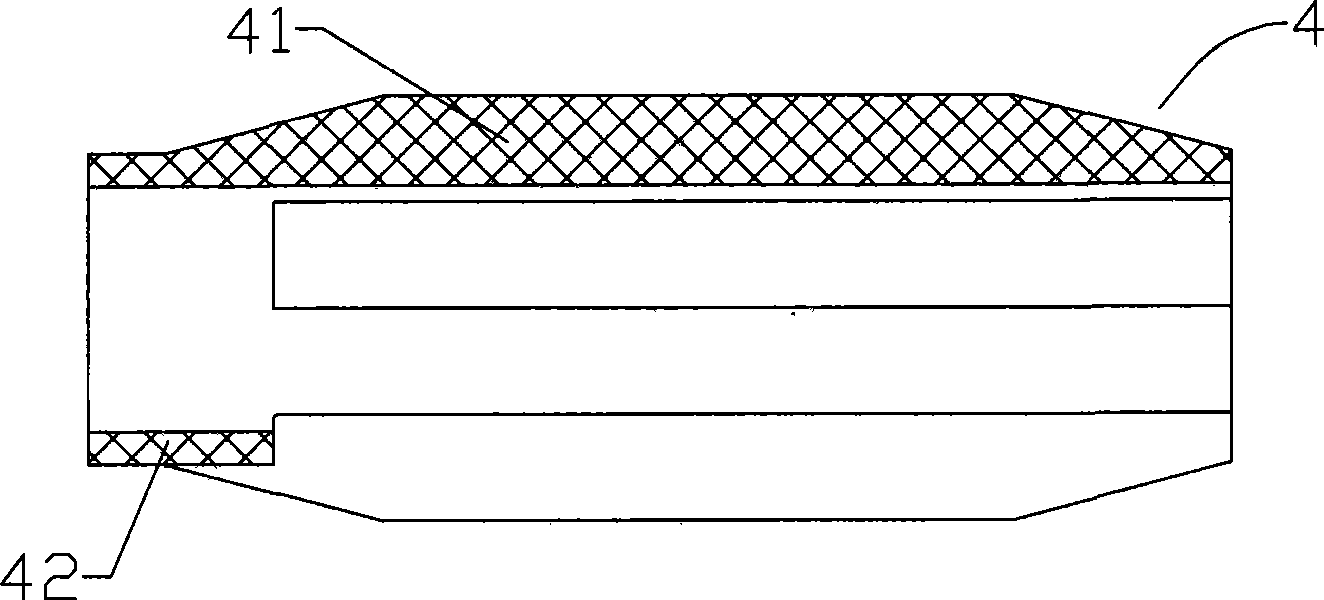

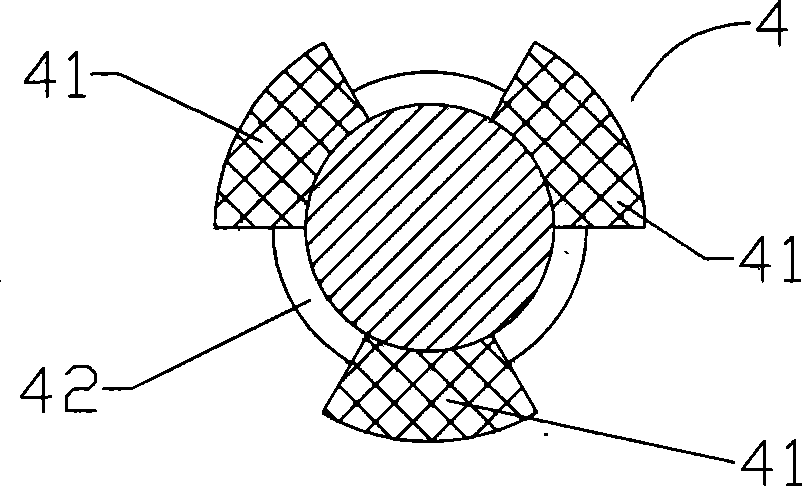

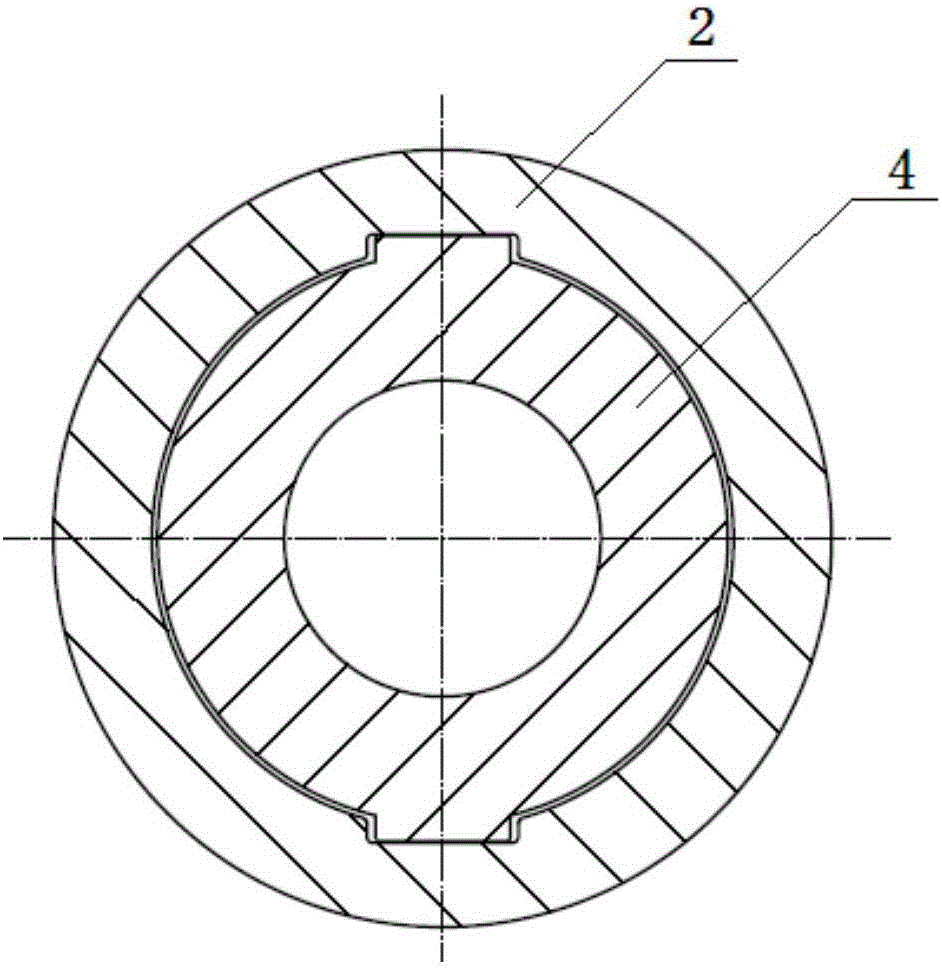

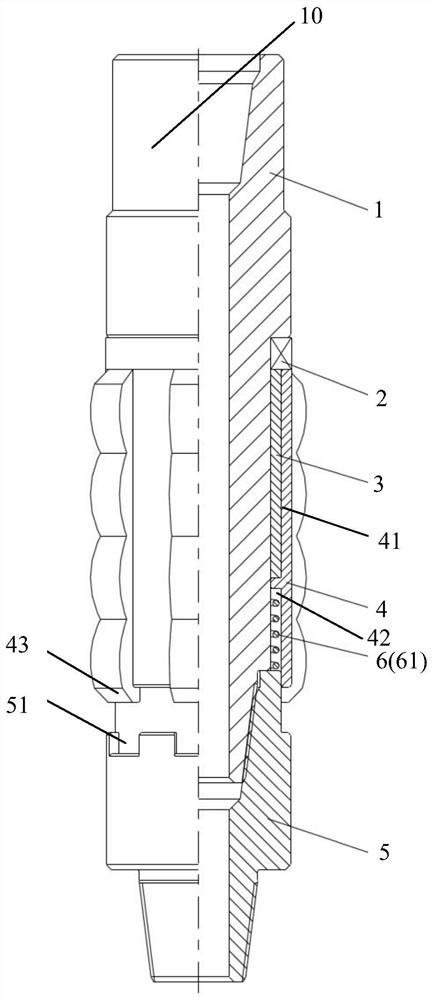

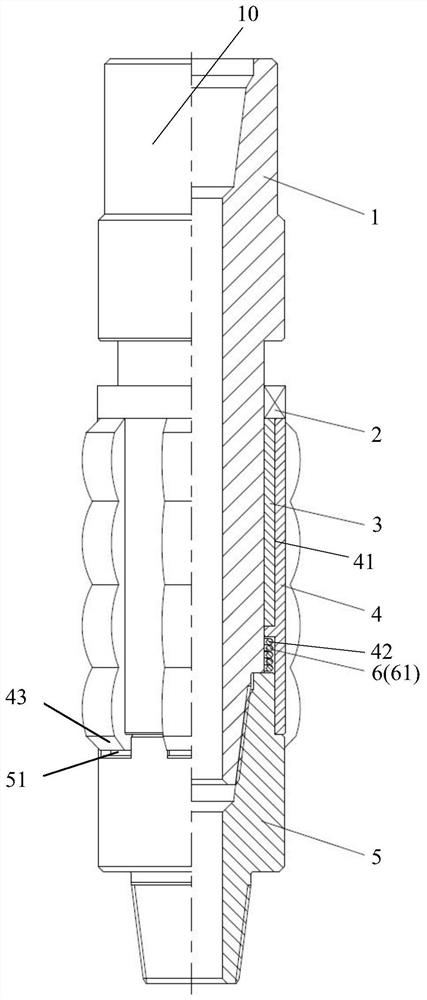

Cement slurry rotational flow generator mud cake scraping rotational flow type centralizing tool

InactiveCN109138861APlay a righting roleShorten the timeDrilling rodsCleaning apparatusWater flowCement slurry

The invention relates to a cement slurry rotational flow generator mud cake scraping rotational flow type centralizing tool. The cement slurry rotational flow generator mud cake scraping rotational flow type centralizing tool mainly solves the problem that an existing casing centralizer cannot scrape mud cakes on a well wall or cause a casing to be stuck. The cement slurry rotational flow generator mud cake scraping rotational flow type centralizing tool is characterized in that rubber spiral wing seats (2) and rigid spiral wings (4) are fixed to the outer wall of an outer sleeve (1), and rubber spiral wings (3) are fixed to the rubber spiral wing seats (2). According to the centralizing tool, the mud cakes on the well wall can be scraped, and meanwhile, rotating water flow is generated toflush the well wall; and when hard objects are encountered, elastic deformation is generated to prevent the casing from being stuck.

Owner:大庆宏测技术服务有限公司

Multi-arm righting device for oil exploitation

InactiveCN104632098APlay a righting roleSimple structureDrilling rodsDrilling casingsEngineeringImpact

The invention discloses a multi-arm righting device for oil exploitation. The righting device is provided with multiple assembling spring plates, the assembling spring plates are arranged on multiple supporting arms, a section of a tension spring which can improve the elastic force is added in the structure, the structure can improve the elastic force of the righting device, therefore, when the righting device is subjected to suddenly increasing external force, the righting device can bear the impact of the external force, and a righting function is achieved. The multi-arm righting device for oil exploitation can extend in time with the increasing of the external force and flexibly respond to the change of the external force to buffer the impact of the external force on the righting device; the tension spring can slowly retract when the external force is decreased, assembling springs are pulled to restore, and therefore the righting function is achieved; the structure is simple, the operation is convenient, and the effect is obvious.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

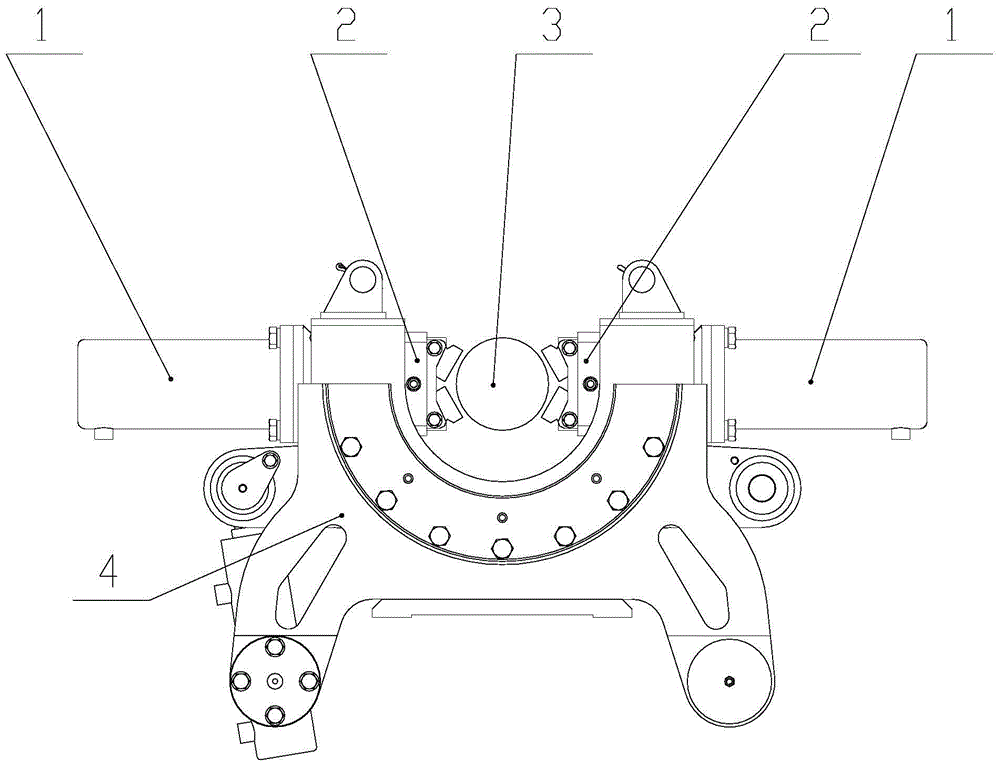

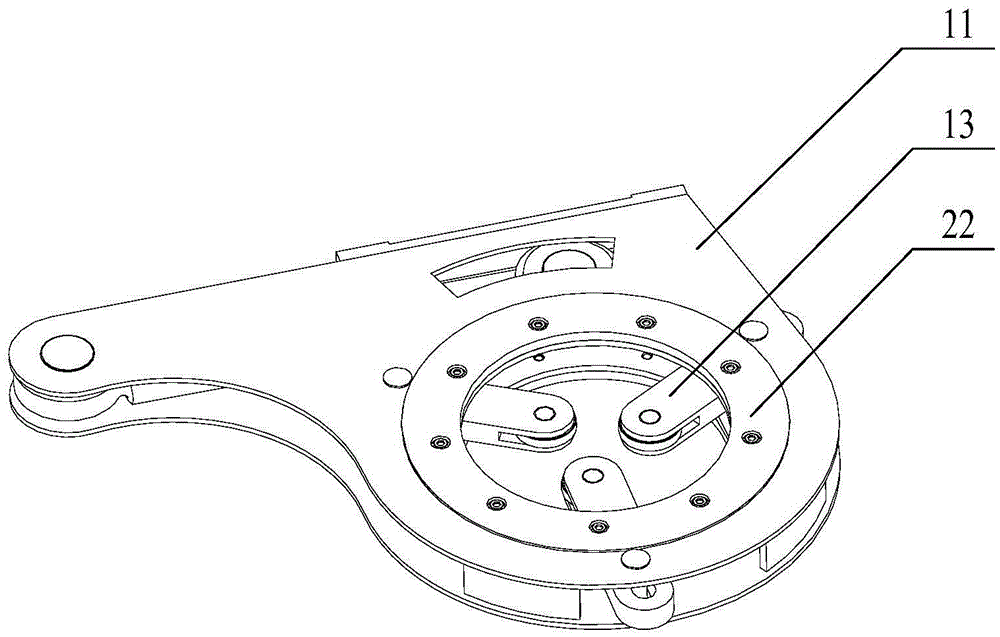

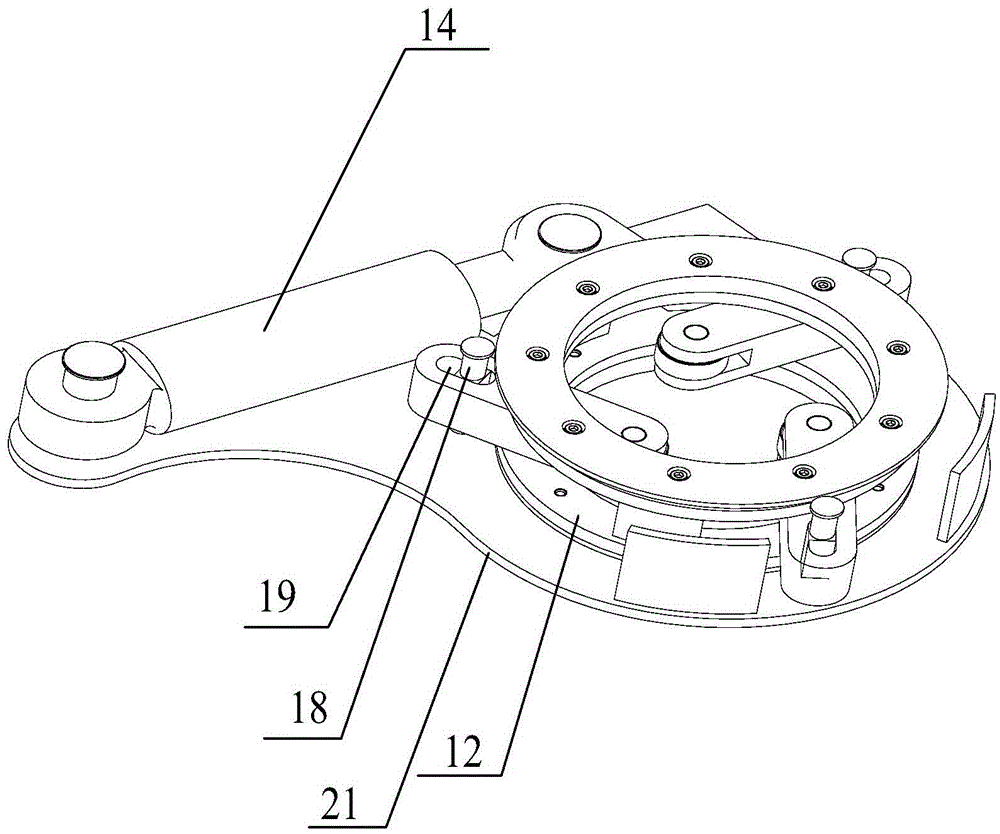

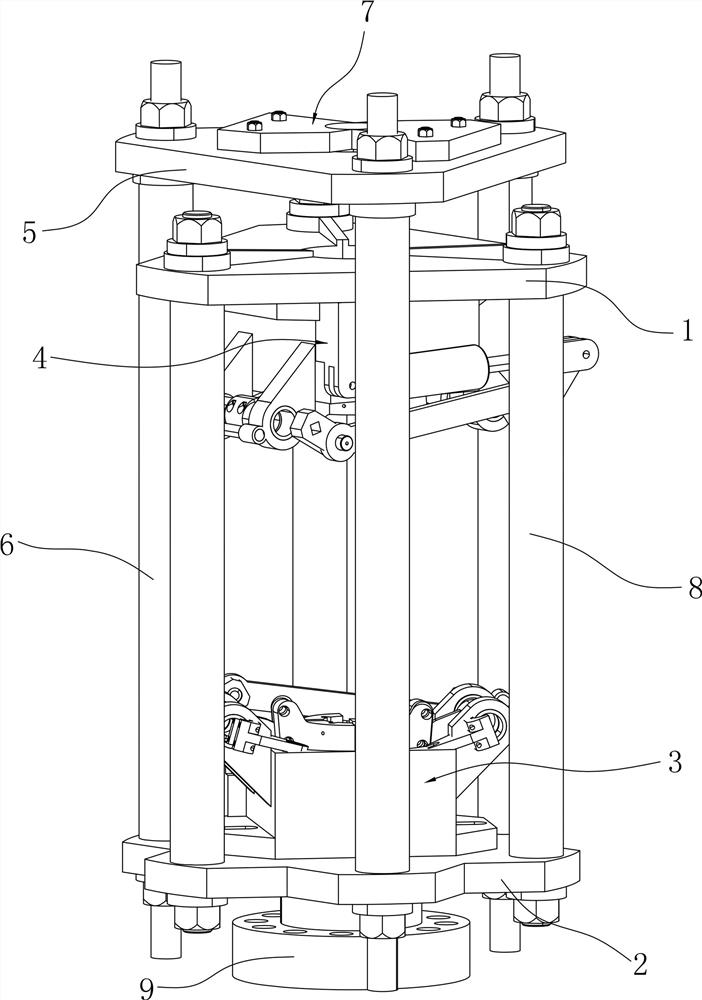

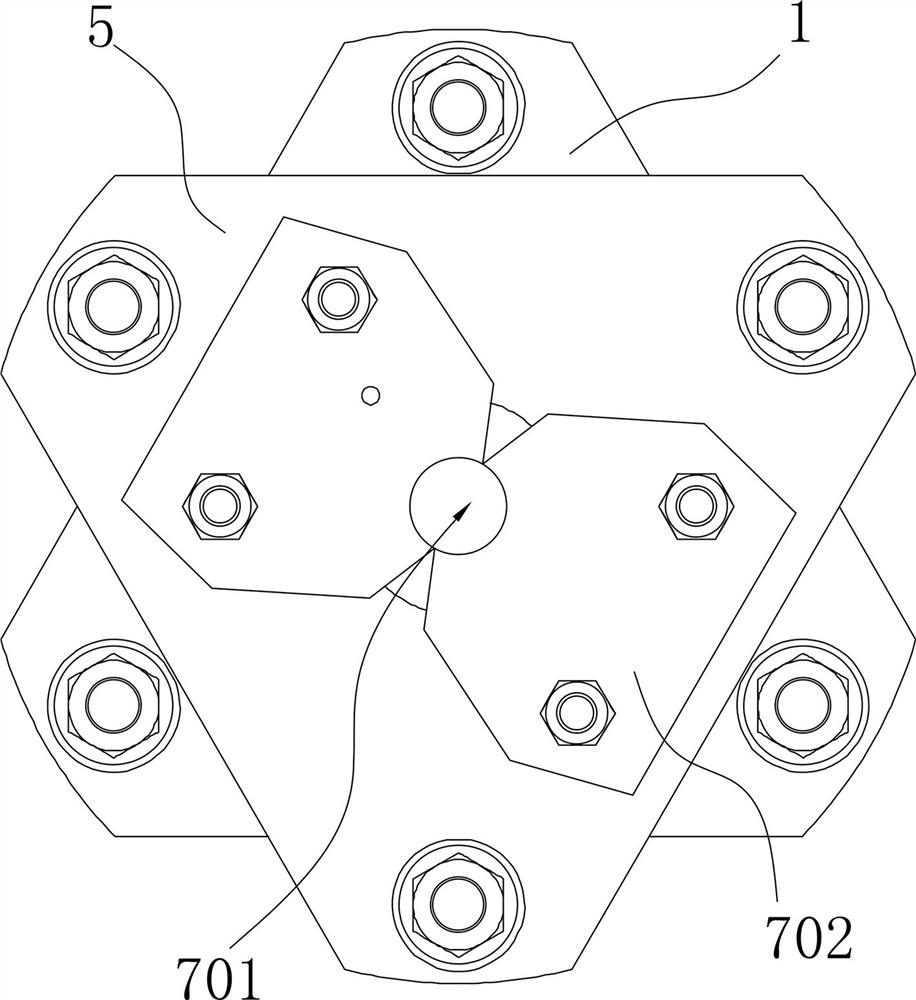

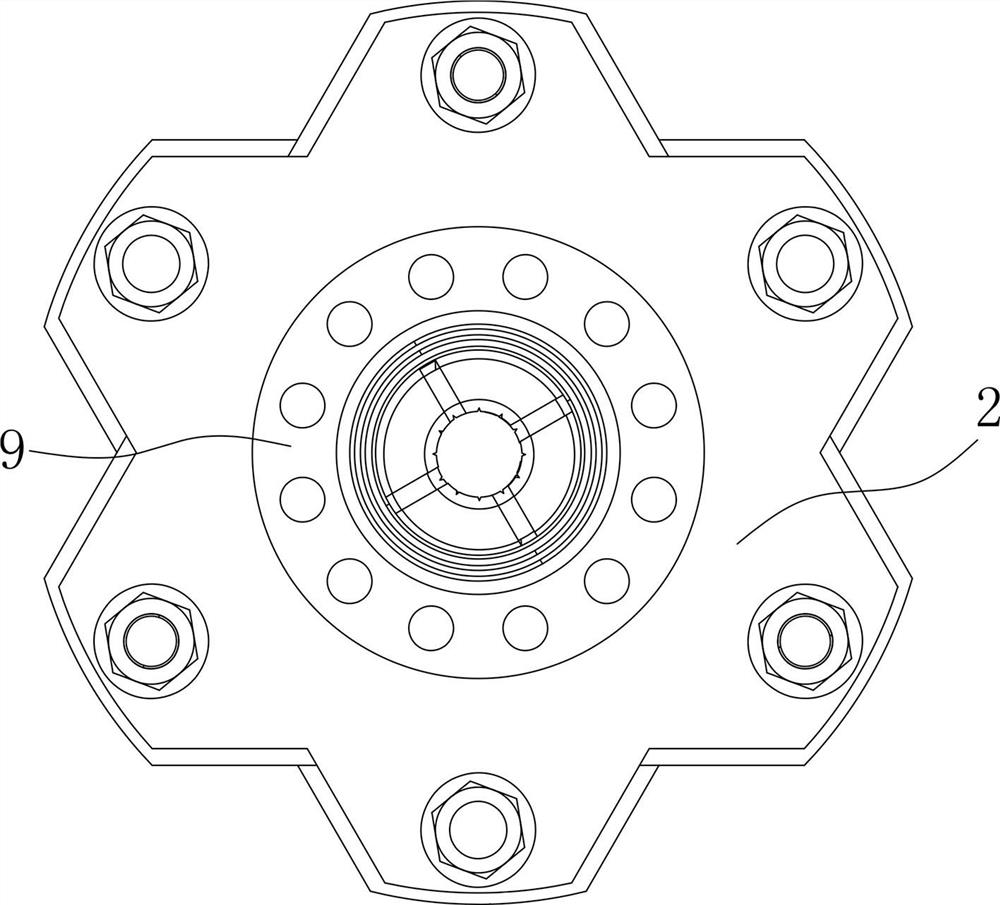

Roofbolter and gripper thereof

The invention discloses a roofbolter and a gripper thereof. The gripper comprises a fixed support, a slide block support, at least three slide blocks and a drive device. The fixed support is provided with a hollow part. The slide block support is arranged on the fixed support in a rotatable mode. The slide blocks are all hinged to the slide block support and the fixed support. Wheels extending into the hollow part are arranged at the inner ends of the slide blocks respectively. The wheels of the slide blocks have an external common tangent circle. The drive device is used for driving the slide block support to rotate. In this way, according to the gripper of the roofbolter, a drill stem is located in the circle surrounded by the slide blocks of the gripper in the whole working process all the time, and when the drill stem inclines, because of the constraint of the slide block on the drill stem, the drill stem can return to the central position.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

a warehouse machine

Owner:MYANDE GRP CO LTD

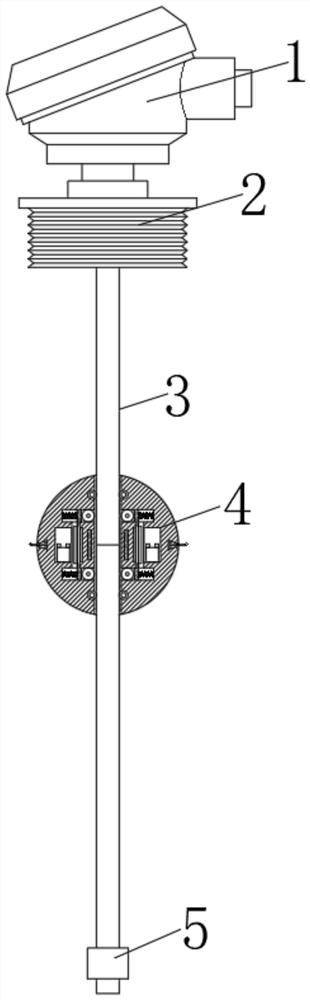

Floating ball liquid level meter capable of improving flexibility of floating ball

The invention relates to the technical field of instruments and meters. The invention further discloses a floating ball liquid level meter capable of improving the flexibility of a floating ball. Thefloating ball liquid level meter comprises a display device, the bottom of the display device is fixedly connected with a threaded connecting piece, a guide rod is fixedly connected to the middle of the bottom end of the threaded connecting piece, a floating ball is movably connected to the outer side of the guide rod in a sleeving mode, a lower baffle is fixedly connected to the bottom of the guide rod, a magnetic ring is arranged in the floating ball, and the bottom and the top of an inner ring of the floating ball are each movably provided with a set of balls. Through arrangement of a detection device and a driving wheel, when the floating ball liquid level meter works normally, the driving wheel is far away from the guide rod, and the normal work of the floating ball is not influenced;when the floating ball is stuck by dirt and cannot work normally, an electromagnet is powered on to generate magnetism, so that the driving wheel moves towards the guide rod, the driving wheel and the guide rod are in contact with each other, contact pressure is generated, the driving wheel rotates at the moment, the floating ball can be driven to move upwards or downwards, and therefore the height of the liquid level is accurately measured.

Owner:QIDONG NANHUA INSTR EQUIP

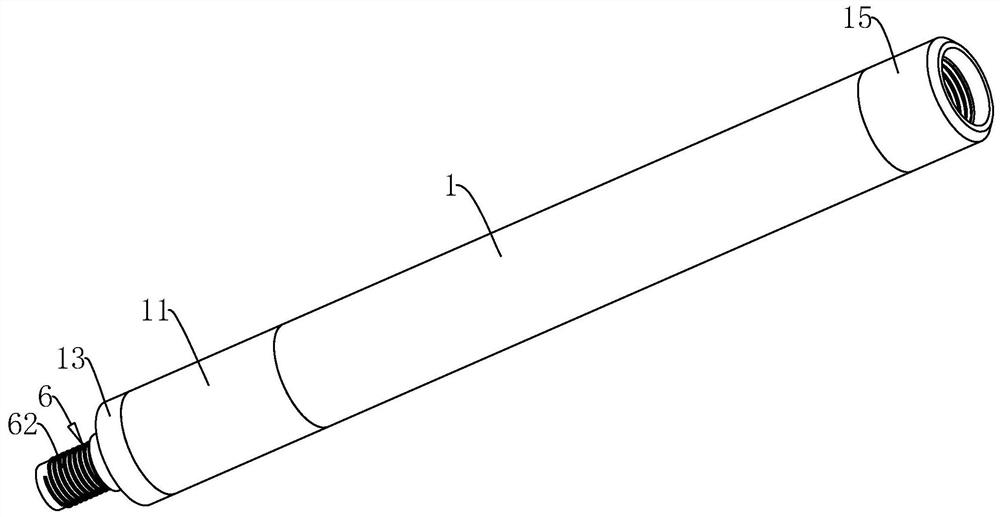

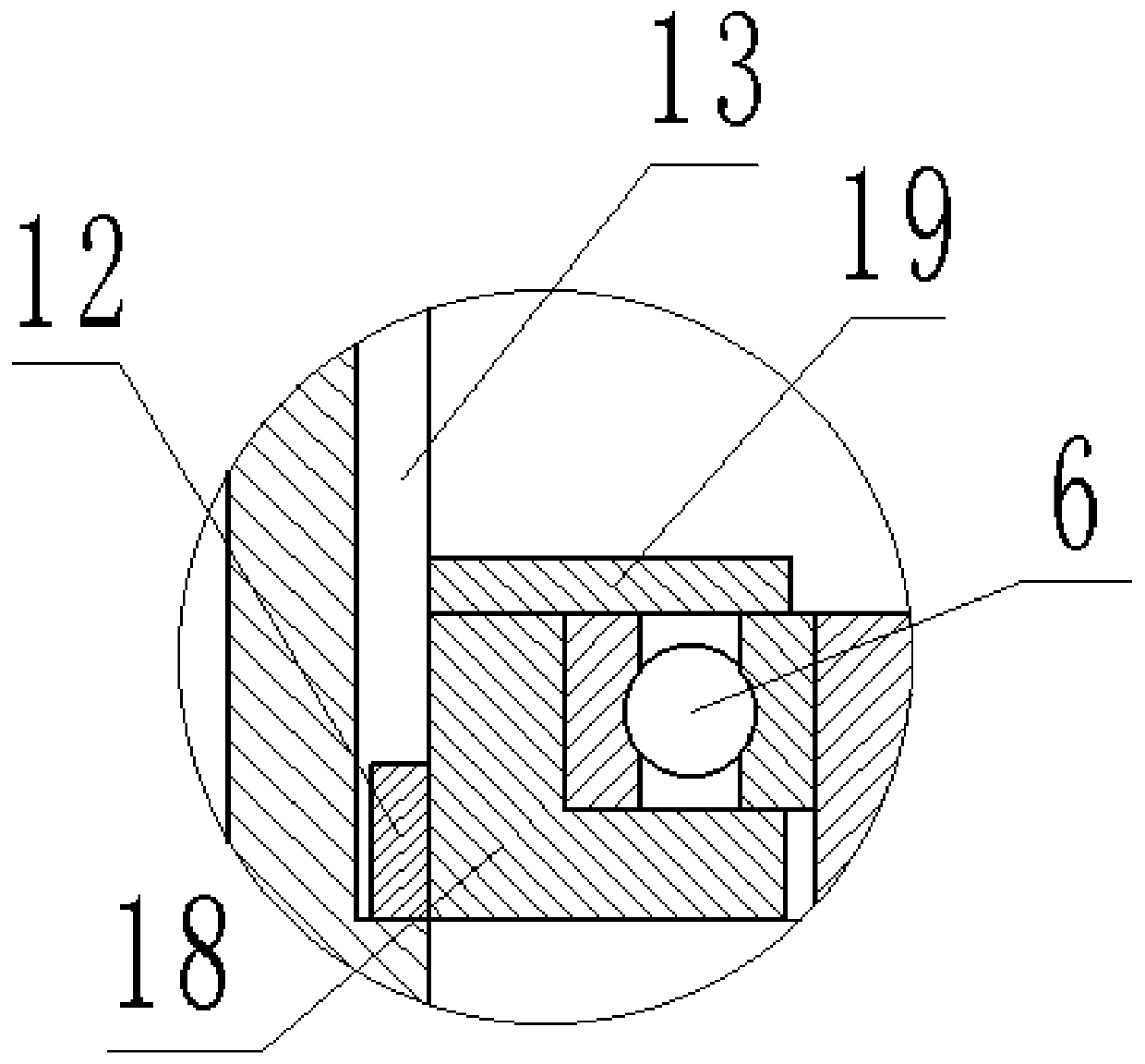

Coiled tubing tractor and working method thereof

The invention provides a coiled tubing tractor and a working method thereof. The coiled tubing tractor is connected between an underground power drilling tool and a coiled tubing, and is characterizedby comprising a shell, a rotor and a steering system, the rotor and the steering system are arranged in the shell, and the rotor can rotate at a high speed under the impact action of high-pressure drilling fluid to generate power; and the steering system comprises a main steering shaft 14, an auxiliary steering shaft 16 and a crawling wheel 13 and is used for changing the output direction of power so as to drive the coiled tubing to advance in a horizontal well. Cable power supply is not needed, the possibility of underground accidents is reduced, and hydraulic driving is adopted, so that energy can be effectively saved; when the coiled tubing works, the tubing does not rotate, so that the wheel type tractor with larger traction force is adopted in the coiled tubing work; and when the coiled tubing is used for horizontal well drilling operation, the coiled tubing tractor can also play a role of a centralizer, and the coiled tubing can be effectively centered, so that abrasion is reduced.

Owner:YANGTZE UNIVERSITY

Flexible shaft transmission device of submersible direct-drive screw pump

The invention provides a flexible shaft transmission device of a submersible direct-drive screw pump. The transmission device comprises a long connection pipe, a stator connection pipe and a straightening device which are sequentially connected from top to bottom; an upper screw connector, a flexible shaft and a lower screw connector are sequentially connected in the long connection pipe from top to bottom; and a connection shaft is arranged in the stator connection pipe; and a lower connection pipe is arranged in the straightening device. The flexible shaft transmission device is simple in structure, only a control cabinet is arranged on the ground part of the system, the occupied area of a well mouth is small, the ubiquitous problem that eccentric abrasion happens to a rod and a pipe of a directional well is fundamentally solved, and later-period running and maintaining cost and labor intensity are reduced.

Owner:PETROCHINA CO LTD

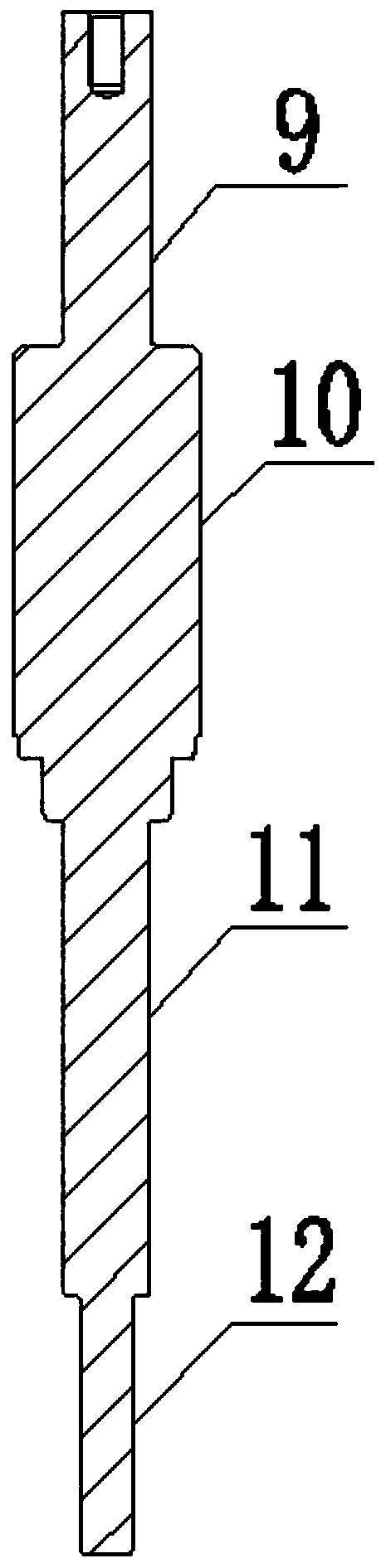

Core drill suitable for hard fractured formation

PendingCN111042756AIncrease success rateAvoid the situation where the inner tube falls offCore removalWell drillingCoring

The invention provides a core drill suitable for hard fractured formation. The core drill comprises a core bit, a drill rod, an outer pipe, an inner pipe, a righting block and a bearing portion. The drill rod is connected to the upper portion of the outer pipe, the lower portion of the outer pipe is connected with the core bit, the righting block is arranged on the inner wall of the lower side ofthe outer pipe, the bearing portion is arranged between the inner pipe and the outer pipe, the inner pipe is composed of multiple pipe barrels, the pipe barrels are connected through threads, multipleaxially-symmetric grooves are evenly distributed in the inner wall of each pipe barrel, a core locking mechanism is arranged on each groove, and comprises a springback part, a shaft hole and a core locking plate, the springback parts are arranged on the grooves, the core locking plates are connected with the springback parts through the shaft holes, the core locking plates are in fan shapes, theshaft holes are formed in the two ends of the outer edge of each fan shape, the parts, close to the circle centers, of the fan shapes are arc shapes, tooth-shaped tip teeth are arranged on the arc sides, the multiple core locking plates are arranged, and the core locking plates are spliced to a core locking ring of a split structure. The coring success rate of the fractured formation can be obviously improved, the well drilling coring efficiency is improved, and the coring cost is reduced.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

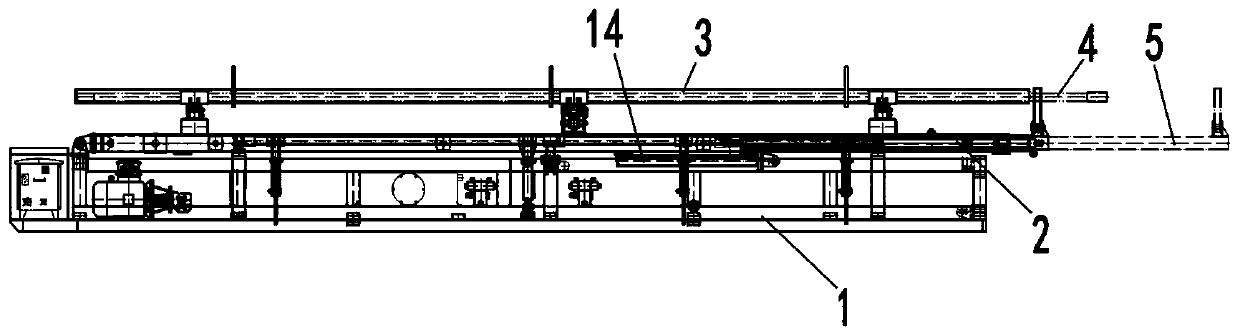

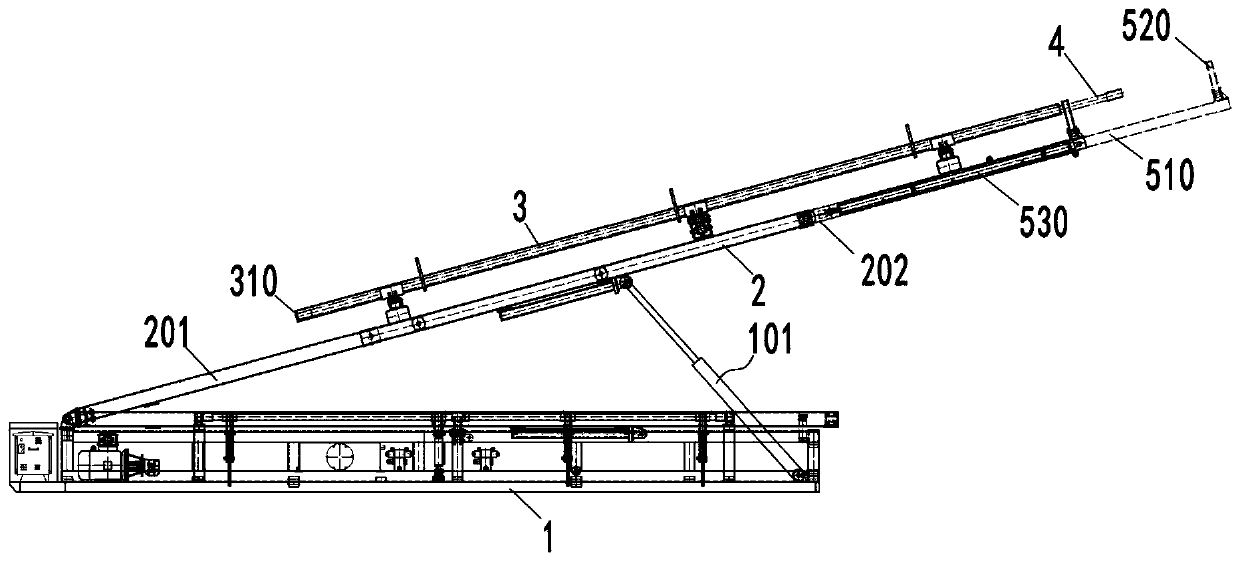

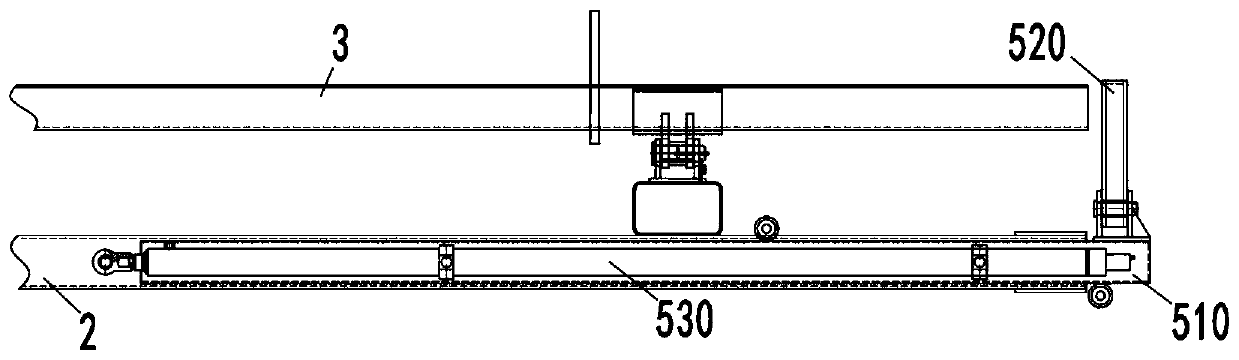

Automatic catwalk and method

ActiveCN111335830AImprove accuracyHigh precisionDrilling rodsMeasurement devicesOil fieldStructural engineering

The invention discloses an automatic catwalk and a method, and relates to the technical field of oilfield equipment. The automatic catwalk comprises a machine frame, a lifting support, a containing groove, a length measuring mechanism and a control unit. The lifting support is connected with the machine frame, the containing groove is in sliding connection with the lifting support, the containinggroove comprises a first end part and a second end part which are arranged oppositely, the first end part is provided with a first baffle, the length measuring mechanism is connected with the liftingsupport, and located on the second end part side of the containing groove, the length measuring mechanism comprises a telescopic part, a second baffle and a length measuring hydraulic cylinder, the telescopic part is in sliding connection with the lifting support, one end of the length measuring hydraulic cylinder is connected with the lifting support, the other end of the length measuring hydraulic cylinder is connected with the telescopic part, the second baffle is connected with the telescopic part, the length measuring hydraulic cylinder comprises a first displacement sensor, the first displacement sensor is used for measuring displacement information of a piston rod of the length measuring hydraulic cylinder, and the control unit is connected with the first displacement sensor and used for calculating the length of a pipe according to the displacement information detected by the first displacement sensor.

Owner:山东诚纳石油机械有限公司

Pumping-improvement centralizer of pumping rod

InactiveCN101446182AReduce pressure difference between upper and lowerReduce frictionDrilling rodsDrilling casingsEngineeringPressure difference

The invention relates to a pumping-improvement centralizer of pumping rod, comprising a central rod; wherein, the two ends of the central rod are provided with joints; the central rod is provided with a first centralizing body and a second centralizing body; the first centralizing body comprises three first centralizing claws; the second centralizing body comprises three second centralizing claws; when the pumping rod moves downwards, the first centralizing body moves upwards under the action of friction force, the first centralizing body and the second centralizing body are separated, and crude oil flows upwards by a clearance between the first centralizing claw and the second centralizing claw; when the pumping rod moves upwards, the first centralizing body moves downwards under the action of friction force, and the first centralizing body slides into the clearance of the second centralizing body to form a piston; when the pumping rod moves upwards and downwards, the first centralizing body and the second centralizing body can have the centralization function and prevent the friction between the pumping rod and the pumping pipe; when the pumping rod moves upwards, the pressure difference of the upper pressure and the lower pressure of the piston can be reduced and the pumping efficiency is improved.

Owner:刘献春

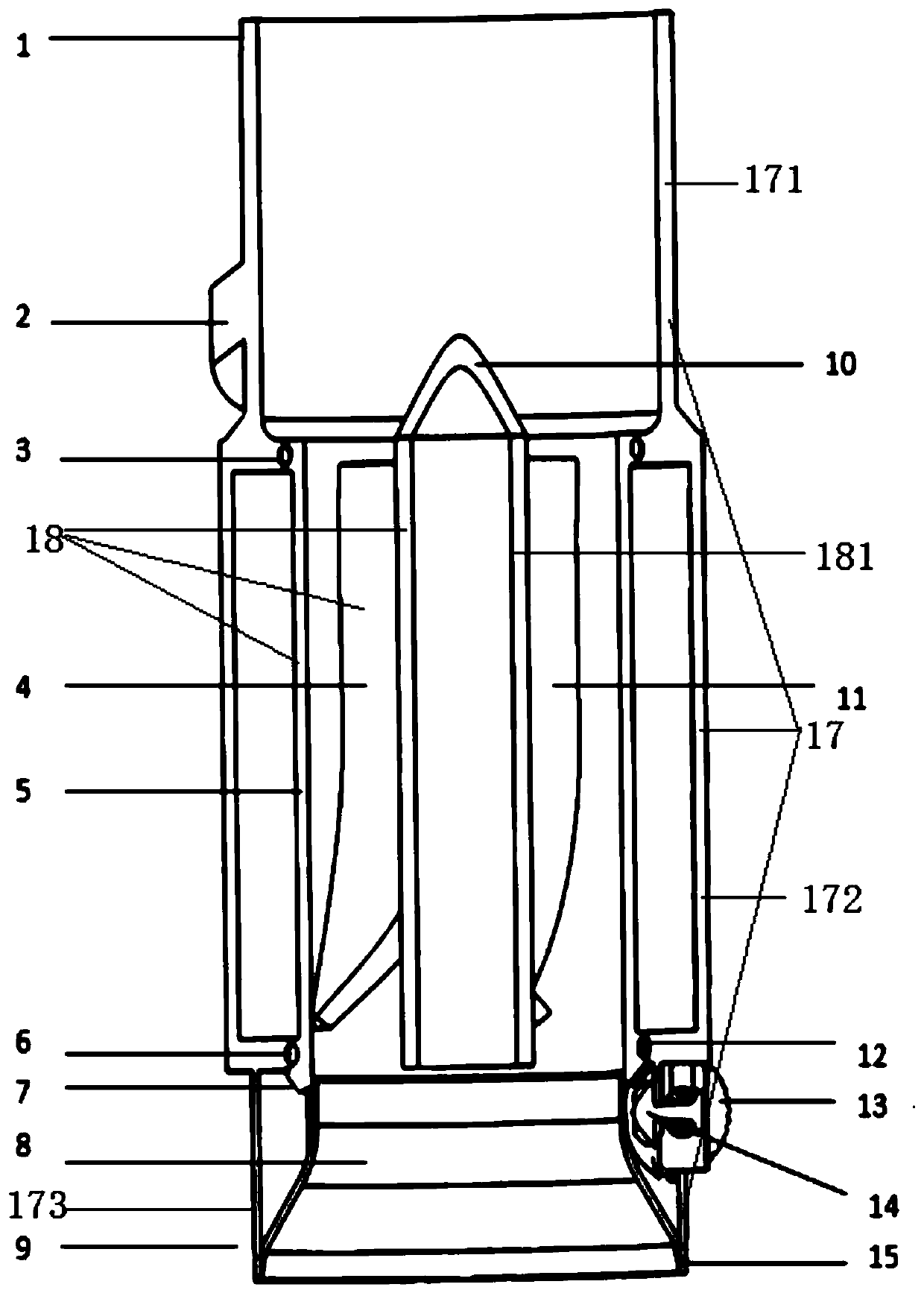

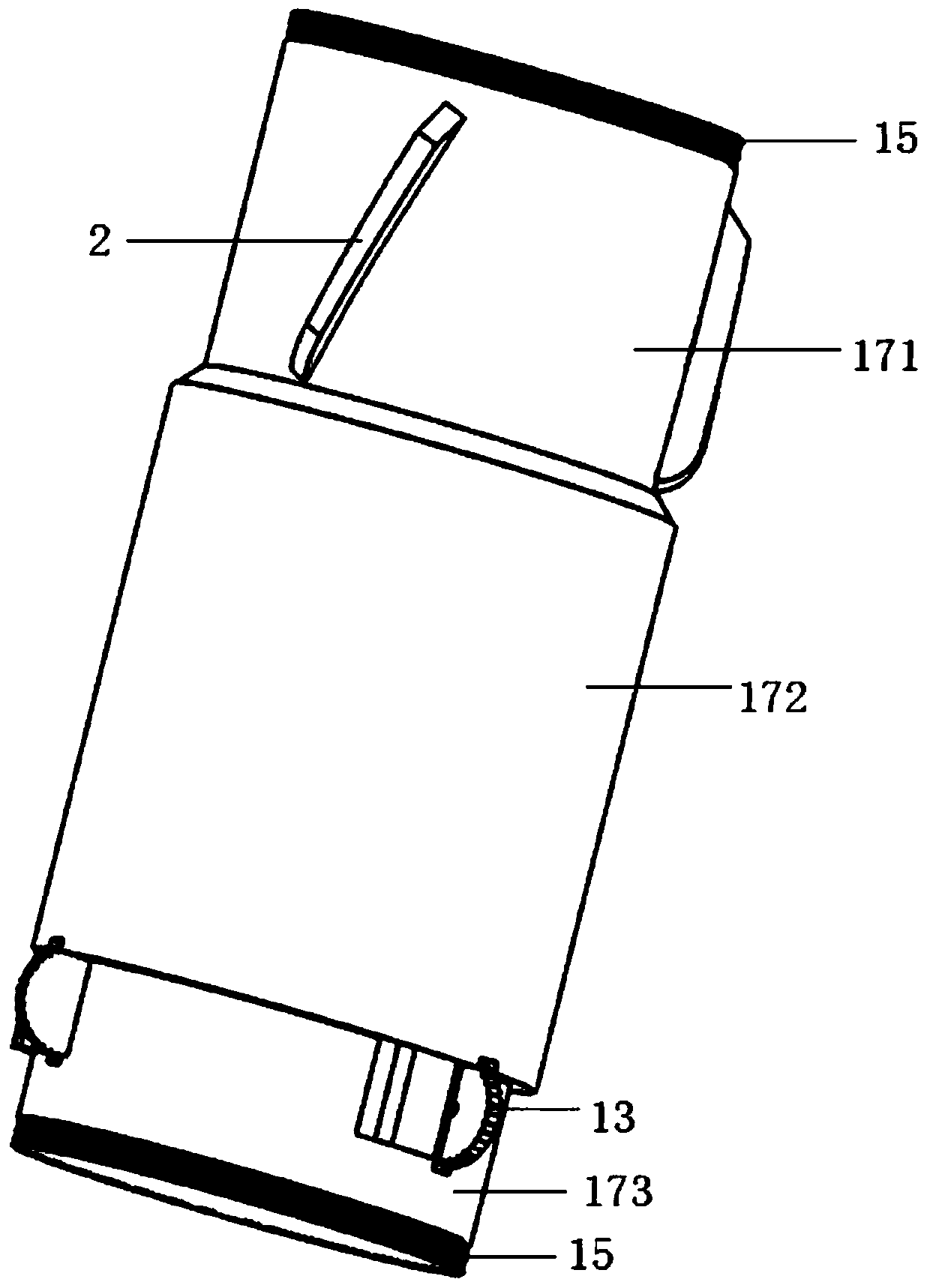

Portable blowout prevention and pollution prevention full-functional pumping wellhead device

PendingCN107100578AGuaranteed tightnessExtended service lifeDrilling rodsSealing/packingInterference fitEngineering

The invention discloses a portable blowout prevention and pollution prevention full-functional pumping wellhead device. A sleeving pipe A and a sleeving pipe B are fixed sequentially and upward on the top of a bottom pipe; the lower portion of the sleeving pipe A is fixedly connected with the top of the bottom pipe through a thread sleeve A, and the lower portion of the sleeving pipe B is fixedly connected with the top of the sleeving pipe A through a thread sleeve B; a sliding groove of a truncated-cone-shaped structure with the diameter of the upper portion being large and the diameter of the lower portion being small is formed in the upper portion of an inner pipe body of the sleeving pipe A; a sealing sleeve with the outer side wall matched with the sliding groove is arranged in the sliding groove and fixed in the sliding groove through the bottom of the sleeving pipe B; the top end of a smooth sucker rod stretches out of the wellhead, upward penetrates through the bottom pipe, the sleeving pipe A, the sealing sleeve and the sleeving pipe B in sequence and stretches out of the top of the sleeving pipe B; and the inner diameter of the sealing sleeve is in interference fit with the diameter of the smooth sucker rod. According to the structure, it can be known that according to the portable blowout prevention and pollution prevention full-functional pumping wellhead device, by tightly screwing the thread sleeve B, the sleeving pipe B is made to press down the sealing sleeve to enable the inner diameter of the sealing sleeve to be tightened, the sealing effect of the sealing sleeve can be still guaranteed, and the service life of the sealing sleeve is prolonged.

Owner:盐城金澳特石油机械有限公司

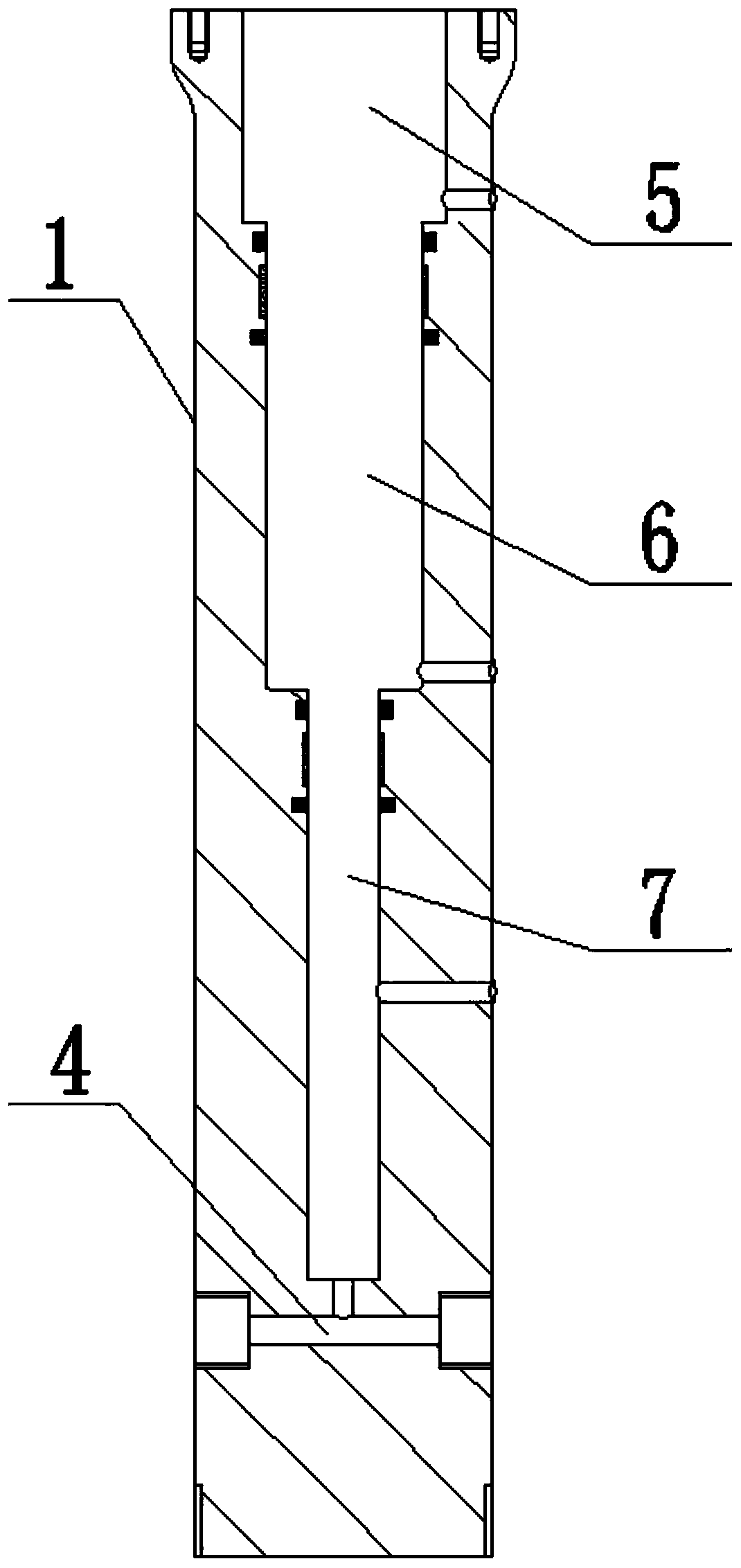

Special rotary blowout preventer for 27/8' drilling tools

InactiveCN102644447AExtended service lifePlay a righting roleSealing/packingEngineeringBlowout preventer

The invention relates to a special rotary blowout preventer for 27 / 8' drilling tools, which mainly solves the problems of waste and poor centralizing and sealing capabilities which are caused by the fact that existing rotary blowout preventers are not applicable to 27 / 8' drilling tools. The special rotary blowout preventer is characterized in that a bolt at the bottom of a central tube (2) is connected with a rubber core flange (14), a rubber core (17) is connected with the bottom of the rubber core flange (14), an upper friction sleeve (5) and an upper moving sealing group (6) are arranged inside a circular gap between the central tube (2) and an upper pressing cover (4), a lower friction sleeve (11) and a lower moving sealing group (10) are arranged inside a circular gap between the central tube (2) and a lower pressing cover (12), and the upper pressing cover (4) and the lower pressing cover (12) are in bolted connection and are arranged on a middle outer cylinder (9) outside a bearing (8). The rotary blowout preventer has the advantages of being small in volume, fast to install, reliable in sealing and high in centralizing capability and is particularly applicable to 27 / 8' drilling tools.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

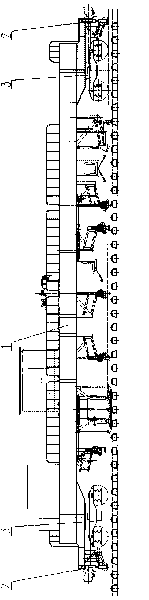

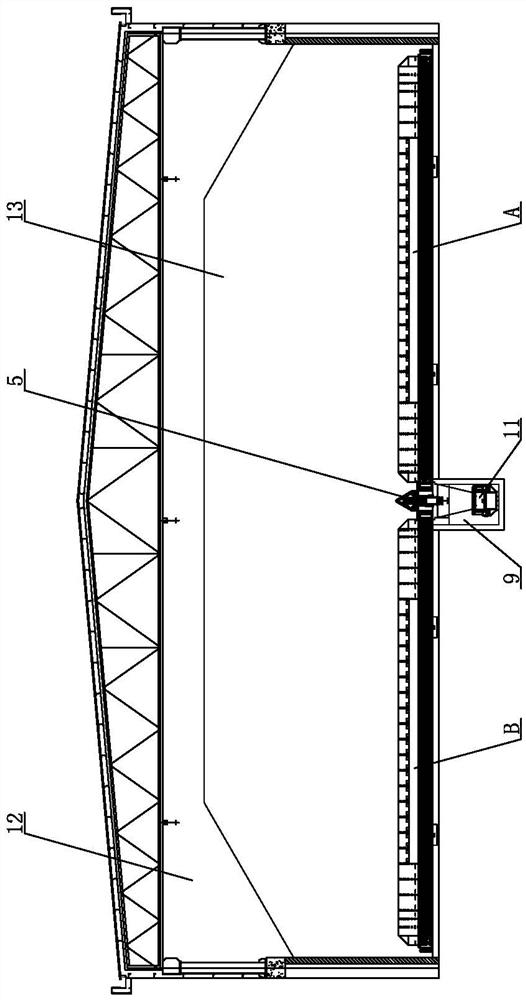

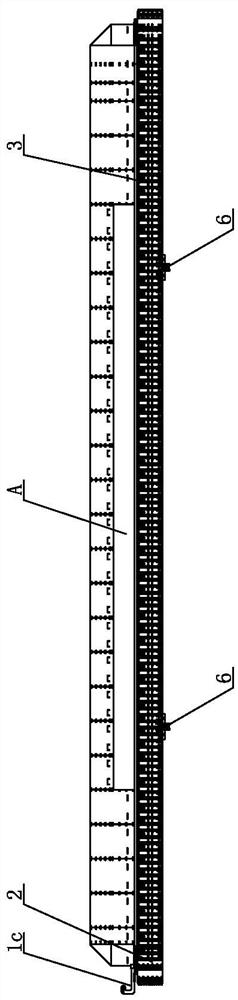

Warehouse-out machine

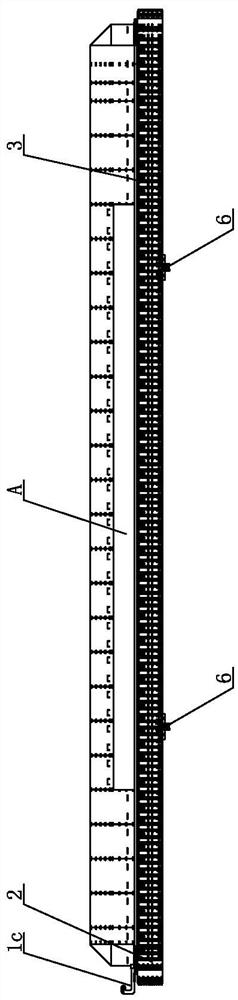

ActiveCN113173368AImprove the effectReduce maintenance costsConveyorsLoading/unloadingAutomotive engineeringSprocket

The invention relates to a warehouse-out machine. The warehouse-out machine comprises a main machine frame, a driving end and a driven end are arranged at the two ends of the main machine frame respectively, a driving chain wheel is arranged at the driving end, a driven chain wheel is arranged at the driven end, a discharging chain is arranged between the driven chain wheel and the driving chain wheel in a wrapped mode, a plurality of scraping plate assemblies extending in the vertical direction are evenly and fixedly arranged on the circumference of the discharging chain at intervals, a walking mechanism for bearing the warehouse-out machine to move horizontally in the front-back direction is installed on the main machine frame. walking driving chain wheels are symmetrically installed on a walking driving shaft, walking redirection chain wheels are arranged below the front side and the rear side of each walking driving chain wheel respectively, walking rolling wheels are symmetrically installed at the left end and the right end of a chain wheel shaft of each walking redirection chain wheel, each set of walking rolling wheels are supported on walking rails on the two sides of ground rail grooves respectively, walking chains are laid in the ground rail grooves respectively, and each walking chain sequentially bypasses the walking redirection chain wheels and the walking driving chain wheels. The warehouse-out machine is low in equipment investment and operation cost, capable of achieving two-way continuous discharging, low in warehouse-out power consumption and high in efficiency.

Owner:MYANDE GRP CO LTD

Interlocking device of grounding switch and front lower door in switch cabinet and switch cabinet

ActiveCN112509835ASolve the problem of openingEasy to pushEarthing arrangementsSubstation/switching arrangement casingsControl theoryMechanical engineering

The invention relates to an interlocking device of a grounding switch and a front lower door in a switch cabinet and the switch cabinet. The interlocking device comprises a limiting rod ejector rod and a clamping plate pushing piece; the limiting rod ejector rod has an upward movement trend under the action of a corresponding elastic structure; the limiting rod ejector rod is provided with a blocking position and a receding position in the moving stroke, and the blocking position corresponds to the upper end of the moving stroke of the limiting rod ejector rod and is used for blocking the vertical limiting rod on the switch cabinet from moving downwards; a limiting groove is formed in the outer circumferential face of the limiting rod ejector rod, an ejector rod bayonet is formed in the side, close to the limiting rod ejector rod, of an ejector rod clamping plate, and the ejector rod bayonet is used for being clamped into the limiting groove to limit downward movement of the limiting rod ejector rod when the limiting rod ejector rod is located at the blocking position; and the clamping plate pushing piece is used for pushing the ejector rod clamping plate under the driving of the front lower door when the front lower door is closed, so that the limitation of the ejector rod bayonet in the ejector rod clamping plate on the limiting rod ejector rod is relieved. According to the scheme, the problem that in the prior art, when the front lower door of the switch cabinet is not closed, the grounding switch can still be switched off is solved.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

Tool for repairing sleeve with expansion pipe

ActiveCN103967438AReduce up pressureCircumstances that interfere with workBorehole/well accessoriesEngineering

The invention discloses a tool for repairing a sleeve with an expansion pipe. The tool is used for repairing wells with broken sleeves in oil fields. The tool comprises the expansion pipe, wherein the two ends of the expansion pipe expand to form an upper expansion cavity and a lower expansion cavity, the lower end of the expansion pipe is connected with a guiding head and is sealed, an expansion head is arranged in the lower expansion cavity of the expansion pipe and located above the guiding head, the expansion head and the lower expansion cavity are sealed through a sealing piece, the upper end of the expansion head is connected with a pull rod in a sealed mode, a seal ring is arranged on the outer circumference of the pull rod in a sleeved mode and located in the upper expansion cavity of the expansion pipe, an inner hole of the seal ring and the pull rod are sealed through a sealing piece, the seal ring and the upper expansion cavity are sealed through a sealing piece, threads are arranged on the outer circumference of the portion, above the seal ring, of the pull rod, a limit ring is installed above the seal ring through the threads and fixes the seal ring into the upper expansion cavity, and the expansion pipe, the pull rod, the expansion head and the seal ring are sealed through the sealing pieces and form a sealing cavity jointly. According to the tool for repairing the sleeve with the expansion pipe, due to the fact that the low-pressure sealing cavity is adopted, force of the expansion head for expanding the expansion pipe can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Telescopic pipe suitable for floating platform testing

InactiveCN106401499ASimple structureIncrease twist strengthDrilling rodsDrilling casingsFloating platformEngineering

The invention relates to a telescopic pipe suitable for floating platform testing. The telescopic pipe is characterized by comprising an outer cylinder string and a core shaft string located in the outer cylinder string; the outer cylinder string comprises an upper connector, a spline outer cylinder and a sealing short joint, wherein inner threads are arranged at the upper end and the lower end of the spline outer cylinder correspondingly, the lower end of the upper connector is connected with the upper end of the spline outer cylinder through an outer thread in a matched manner, and the upper end of the sealing short joint is connected with the lower end of the spline outer cylinder through an outer thread in a matched manner; the core shaft string comprises a spline short joint, a torsion core shaft and a lower connector, wherein outer threads are arranged at the upper end and the lower end of the torsion core shaft correspondingly, the lower end of the spline short joint is connected with the upper end of the torsion core shaft through the corresponding inner thread in a matched manner, the upper end of the lower connector is connected with the lower end of the torsion core shaft through the corresponding inner thread in a matched manner; and the spline short joint is arranged on the inner side of the spline outer cylinder in the manner that the spline short joint can slide and cannot rotate.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Oil pipe centralizing device for operation under pressure

ActiveCN113250627AEasy to operatePlay a righting roleDrilling rodsDrilling casingsPhysicsEngineering

The invention belongs to the technical field of oil and gas drilling and production, and discloses an oil pipe centralizing device for operation under pressure. The oil pipe centralizing device comprises an upper mounting plate and a lower mounting plate which are fixedly connected, wherein a fixed bearing slip is mounted on the upper end surface of the lower mounting plate; a fixed anti-jacking slip is mounted on the lower end surface of the upper mounting plate; a movable plate is arranged above the upper mounting plate; the movable plate is connected with the lower mounting plate through a telescopic column; a centralizing mechanism is arranged on the movable plate; a centralizing hole for allowing an oil pipe to pass through is formed in the centralizing mechanism; the telescopic column comprises a sleeve mounted on the lower mounting plate and a telescopic pole mounted on the movable plate; the telescopic pole is mounted in the sleeve in a sliding mode; a spring is arranged on the bottom of the sleeve; and the spring is connected with the telescopic pole. According to the oil pipe centralizing device for operation under pressure provided by the invention, in an ascending or descending process of a movable beam, the centralizing mechanism can achieve the centralizing effect on the oil pipe, and stroke of the centralizing mechanism can be flexibly regulated, so that operation is convenient.

Owner:SICHUAN SHENGNUO OIL & GAS ENG TECH SERVICE CO LTD

Downhole crawl type power gas lift plunger

The invention discloses an underground crawling type power gas lift plunger, and relates to the technical field of oil and gas plunger gas lift drainage gas production equipment. The device comprises a plunger, two spraying holes are symmetrically formed in the lower half section of the circumferential outer wall of the plunger, eight mounting columns are symmetrically welded to the plunger, and a crawling wheel is rotationally mounted on each mounting column; the bottom end of the plunger is fixedly welded with a circular thickening block, the circular thickening block is fixedly locked with a driving motor, and a rotating shaft of the driving motor penetrates through the circular thickening block and is inserted into the inner space of the plunger. The lead screw nut reducing mechanism can convert power output by the driving motor into rotating power of a rotating shaft of the lead screw nut reducing mechanism and walking power of eight crawling wheels. According to the four-crank sliding rod buffering mechanism, the impact force borne by the driving motor when the driving motor stops sliding upwards can be buffered, and the probability that the driving motor is collided and damaged is reduced.

Owner:BAOJI UNIV OF ARTS & SCI

A drilling tool centralizer

ActiveCN110080693BExtended service lifeEasy to replaceDrilling rodsDrilling casingsWell drillingClassical mechanics

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com