a warehouse machine

A technology of unloading machine and main frame, applied in the field of bulk material unloading equipment, can solve the problems of reducing effective material storage space, high cost, long construction period, etc., to improve scraping effect, improve reliability, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

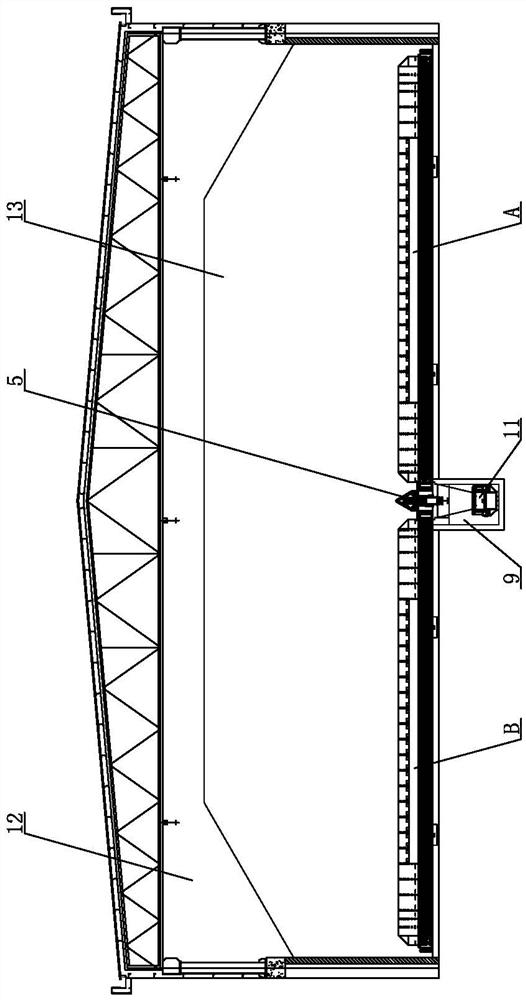

[0064] like figure 1 As shown, a ground groove 9 is provided along the depth direction of the one-story warehouse 12 , and the ground groove 9 can extend along the central axis in the width direction of the ground of the one-story warehouse 12 . The bottom of the ground trough 9 is provided with a general conveyor 11 extending along the entire length of the ground trough 9. The grounds on both sides of the ground trough 9 are respectively provided with unloading machines for discharging materials to the ground trough 9. The unloading machine A and the unloading machine The distal ends of the machines B are respectively close to the side walls of the flat warehouse 12 , and the two unloading machines can travel along the axial direction of the flat warehouse 12 respectively.

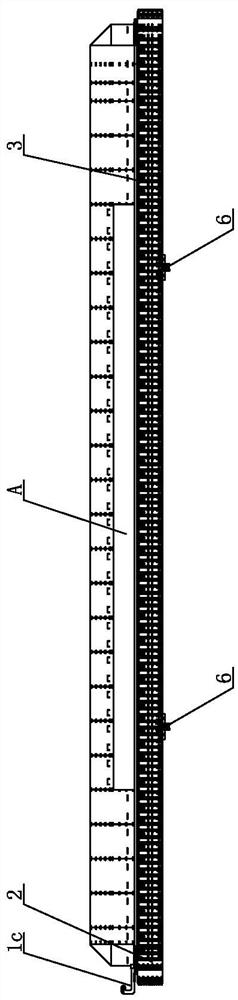

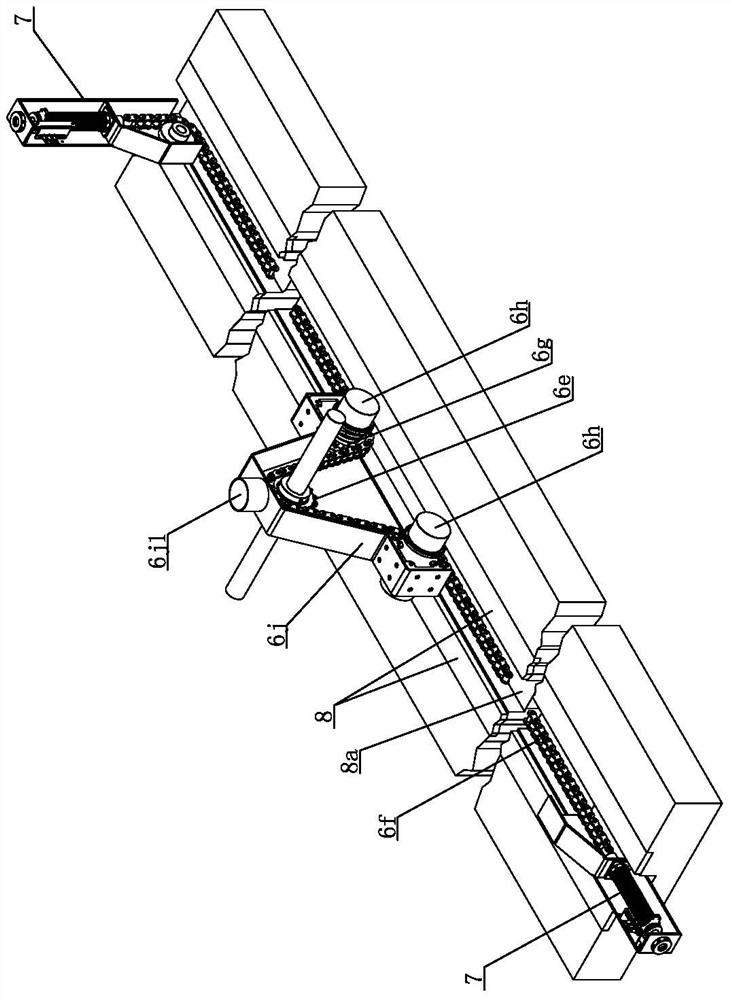

[0065] like figure 2 , Figure 6 to Figure 11 As shown, the warehouse unloading machine of the present invention includes a main frame 1 extending along the width direction of the bungalow. Both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com