Patents

Literature

140results about How to "Won't skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

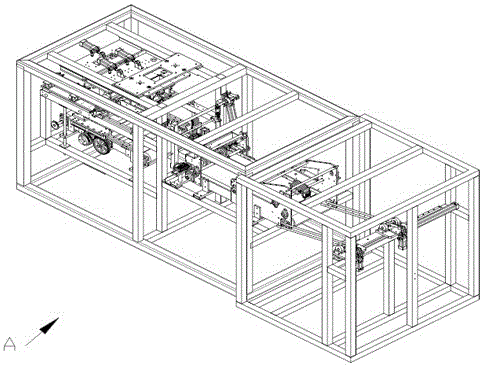

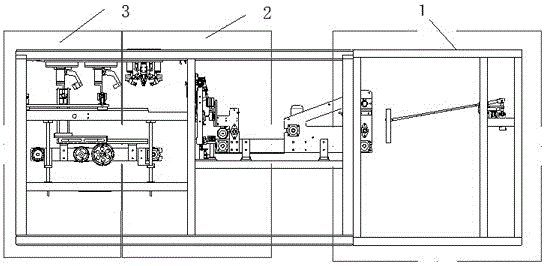

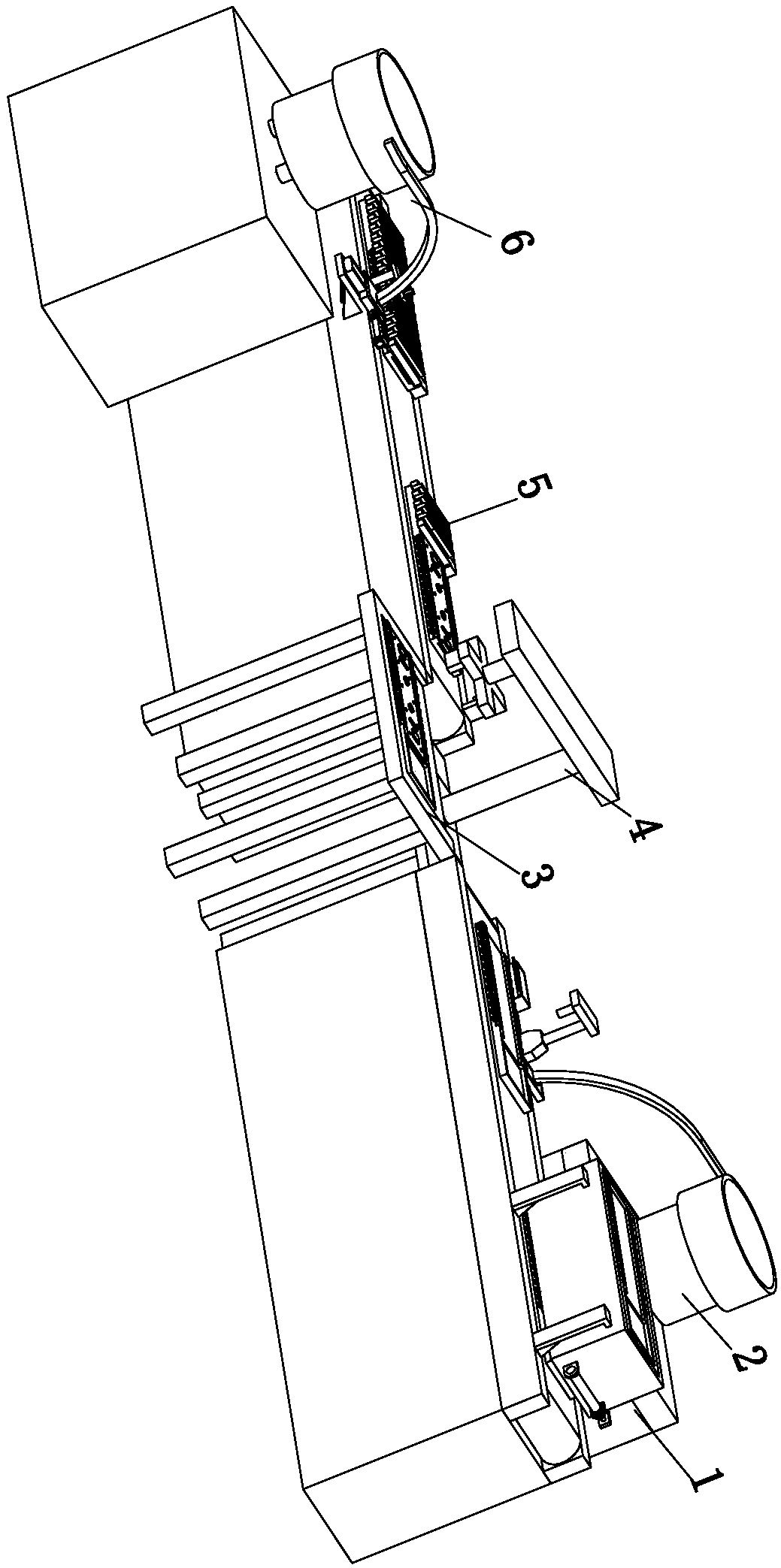

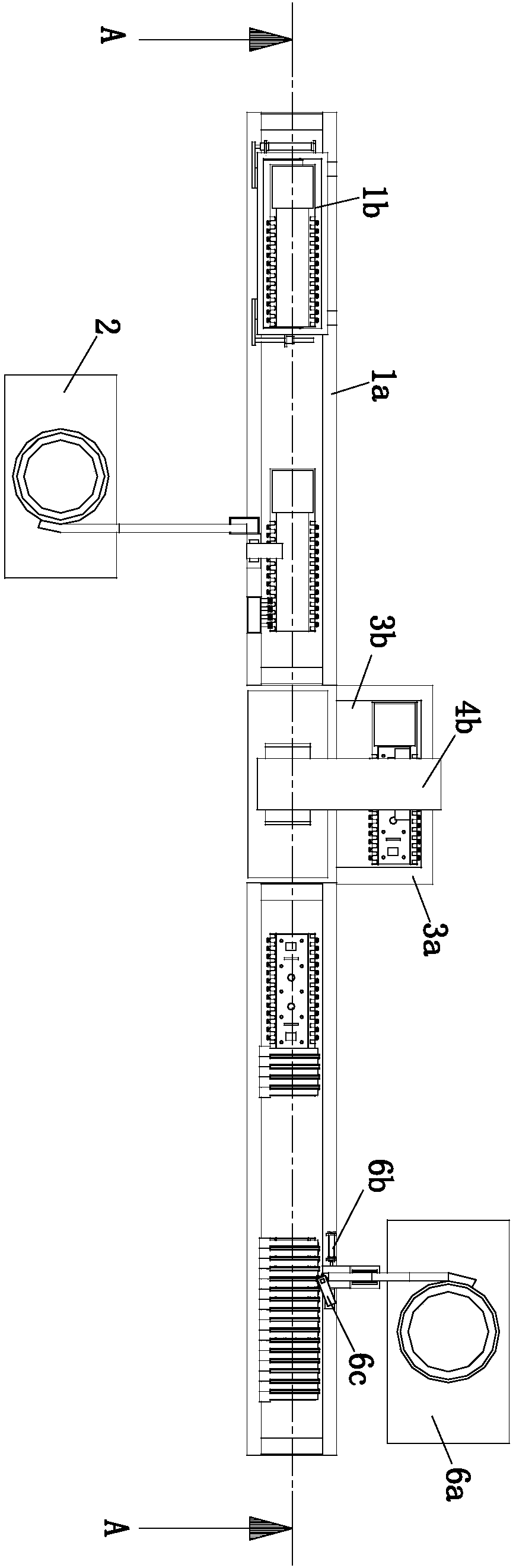

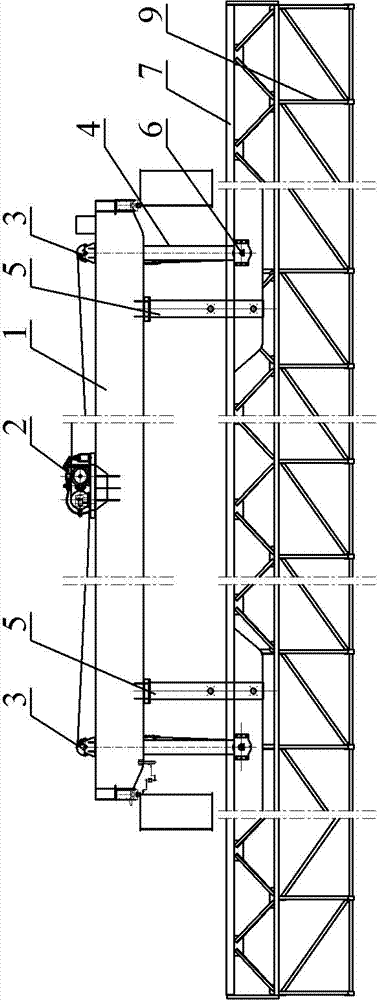

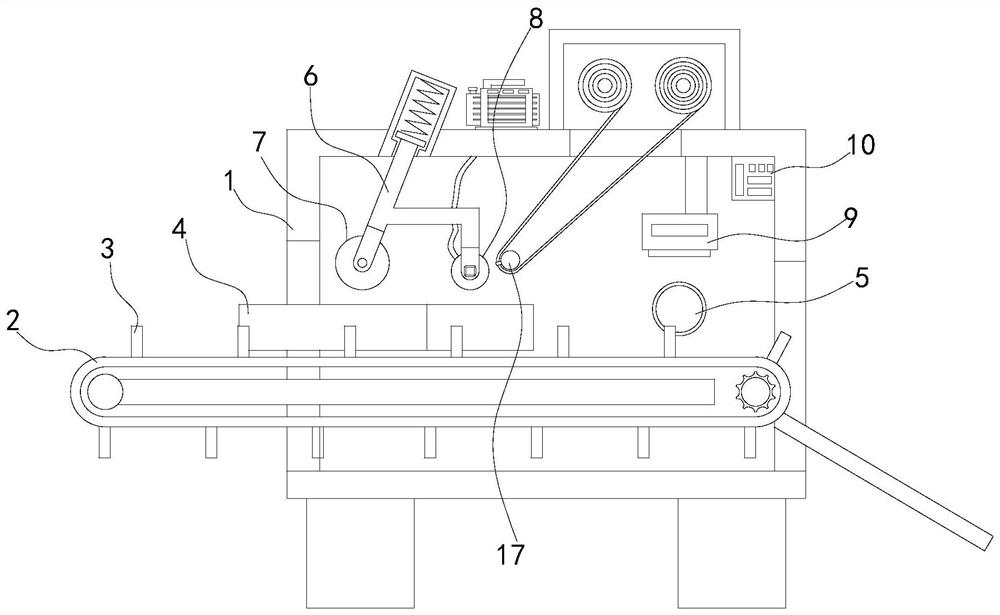

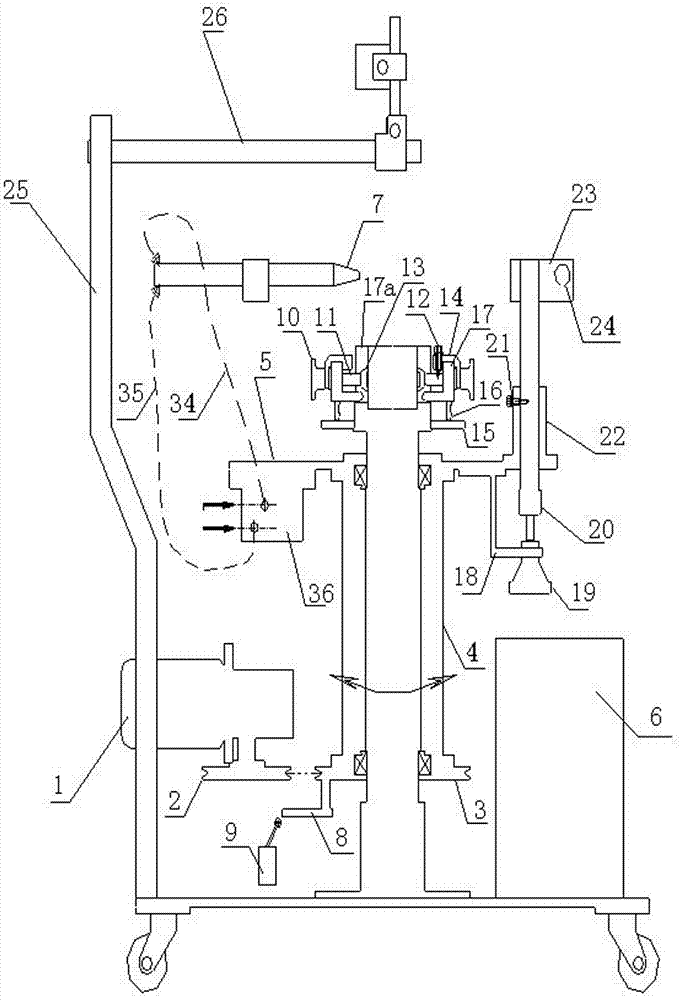

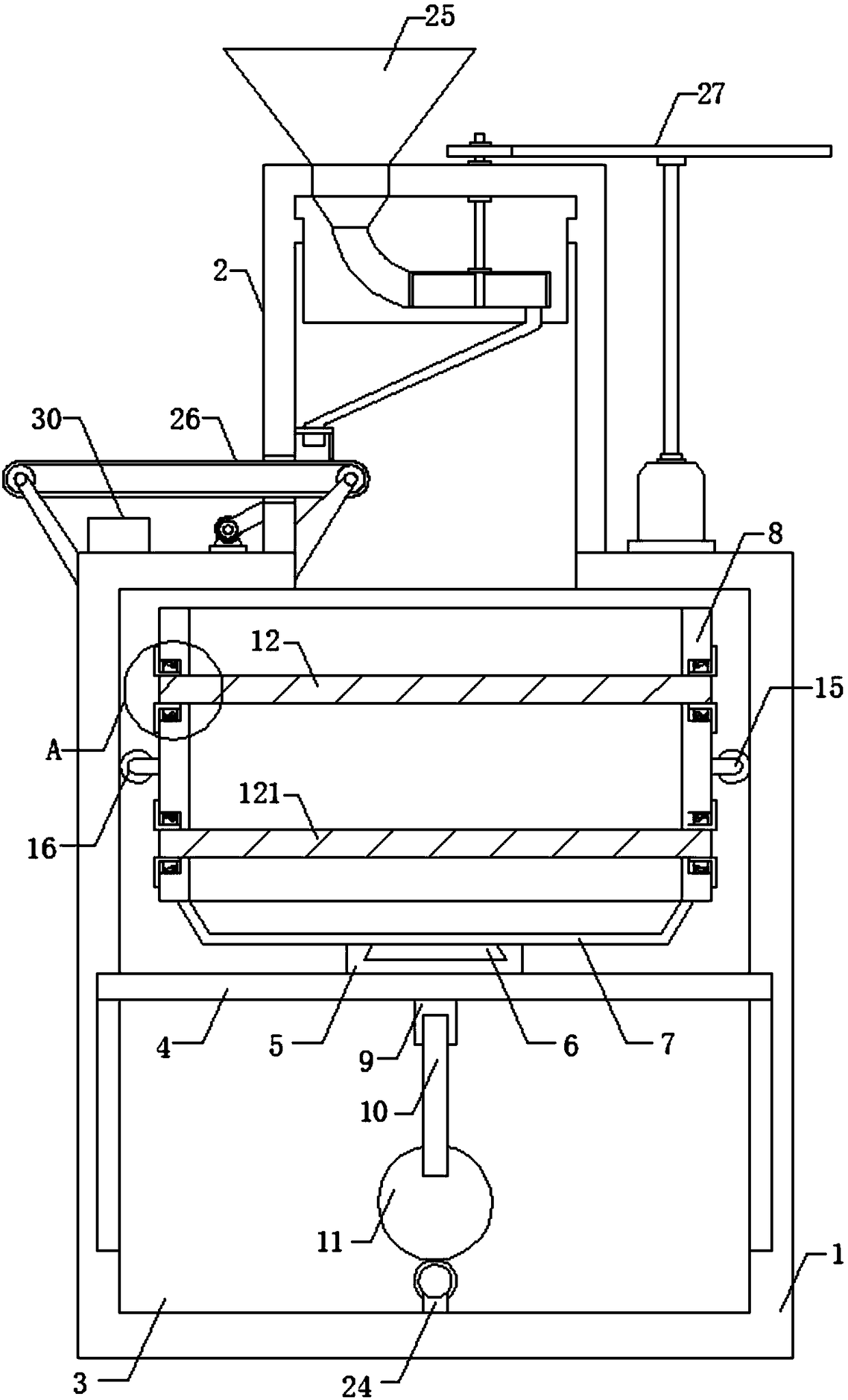

Automatic packaging machine and operating method thereof

ActiveCN106829059ASimple structureStable and efficient workWrapper twisting/gatheringEngineeringMachine tool

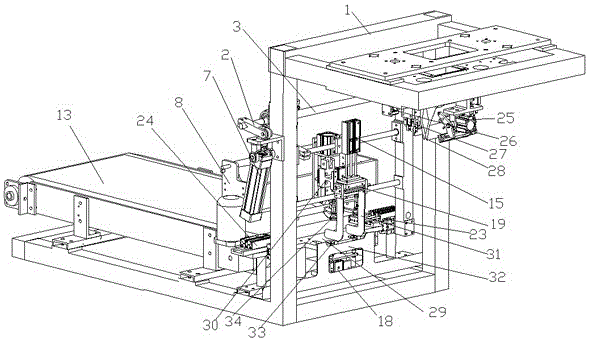

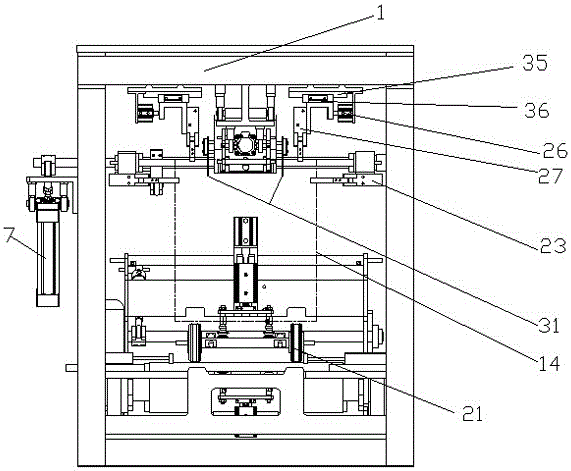

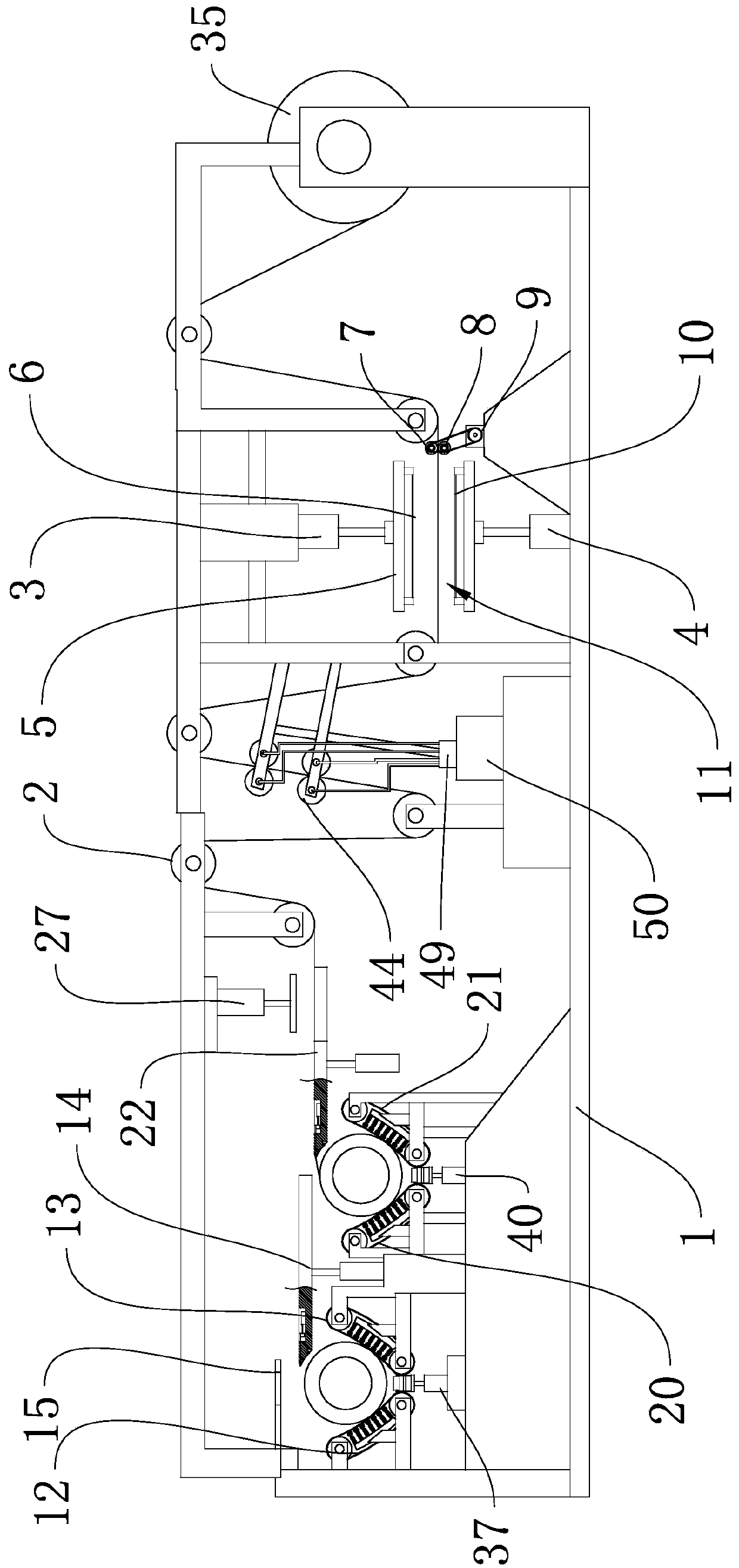

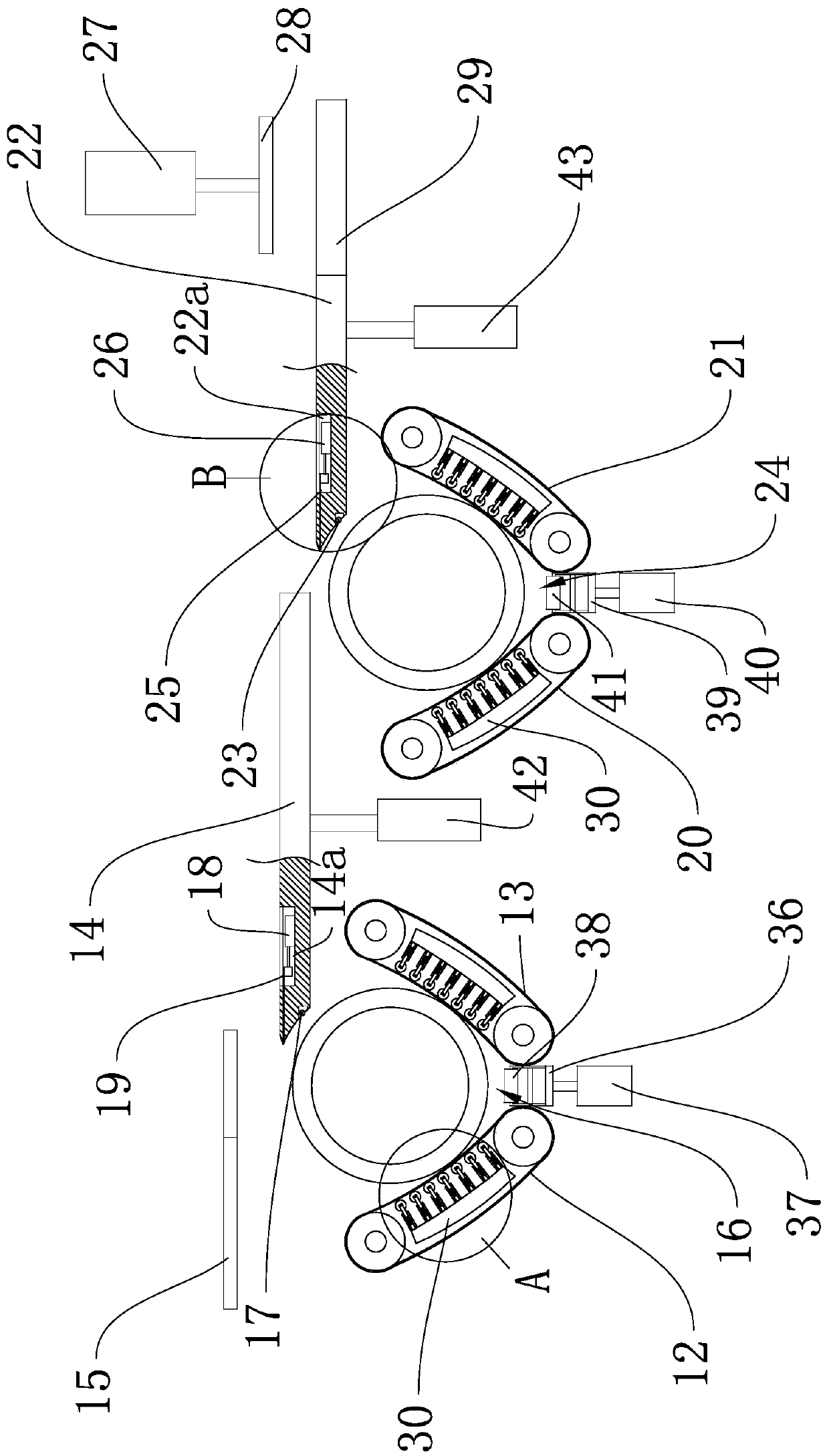

The invention relates to an automatic packaging machine and an operating method thereof. The machine comprises a bag feeding device, a bag sheathing device, and a sealing bag-delivery device. The bag feeding device comprises a bag crossing catch rod for catching on a bag-carrying opening of a packaging bag. The bag crossing catch rod is driven by a first driving mechanism to swing up and down. A first sucking disc is arranged above a first belt conveyor mechanism. The first sucking disc is driven by a second driving mechanism to move laterally and vertically and driven by a third driving mechanism to swing up to place the sucked packaging bag on the first belt conveyor mechanism. The bag feeding device is provided with two bag hanging mechanisms operating alternatively. The bag sheathing device comprises a bag opening mechanism, a bag distracting and conveying mechanism and a bag fixing and arranging mechanism which are arranged on a frame. The sealing bag-delivery device comprises a bag fixing and arranging mechanism, a heat-sealing mechanism and a cold pressing mechanism which are arranged above a second belt conveyor mechanism in order in an output direction. Finger cylinder groups for clamping a packaging bag are arranged on the upper portions of both sides of the second belt conveyor mechanism, and each finger cylinder group comprises a first finger cylinder, a second finger cylinder, and a third finger cylinder, and is fixed to a second slider. The automatic packaging machine is capable of achieving automatic packaging, and also can ensure the quality of sealing.

Owner:ZHANGZHOU JIALONG TECH INC

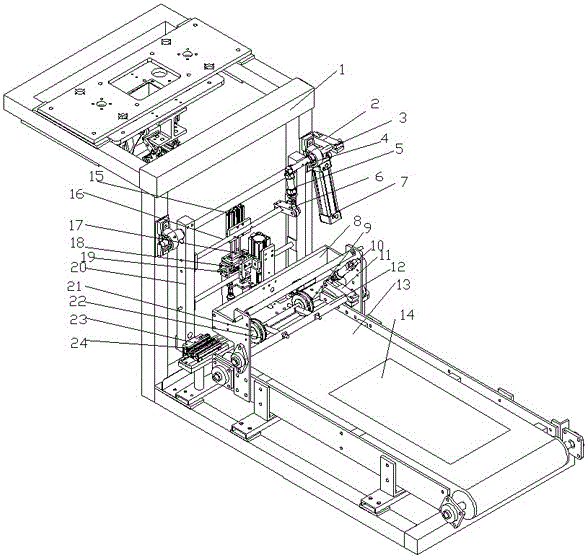

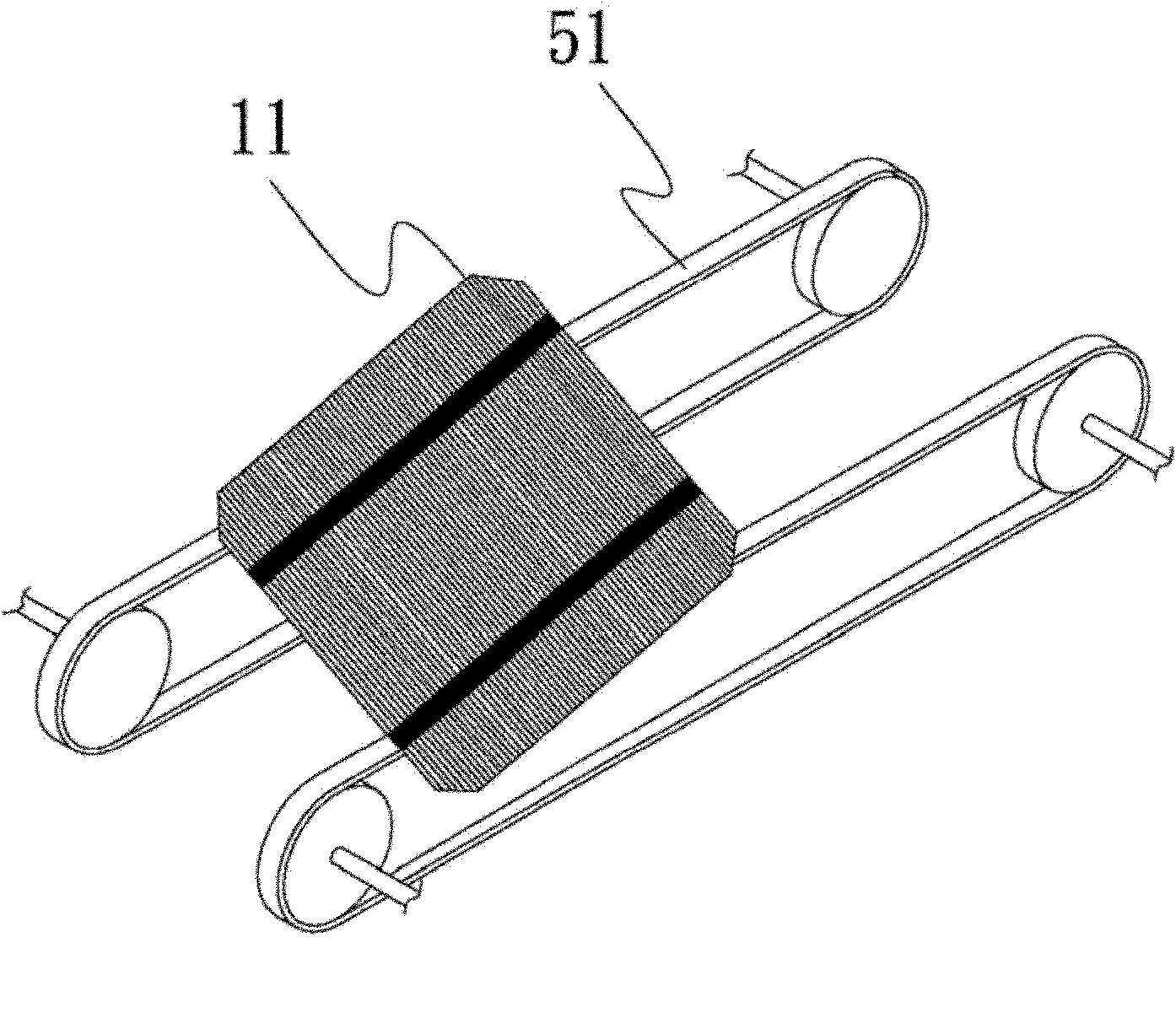

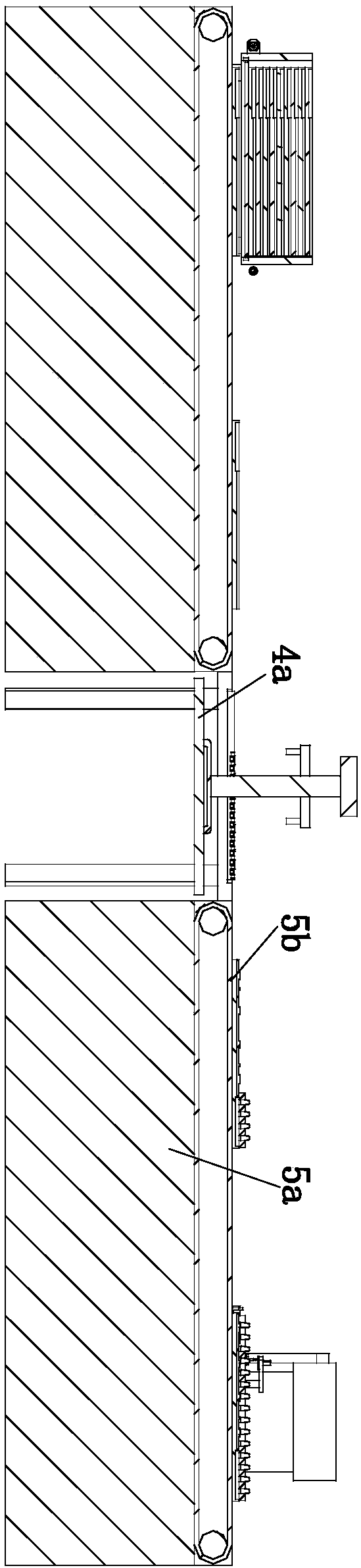

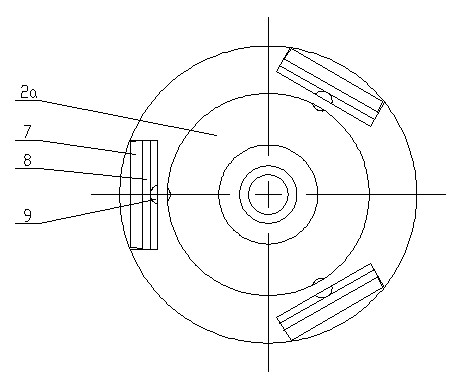

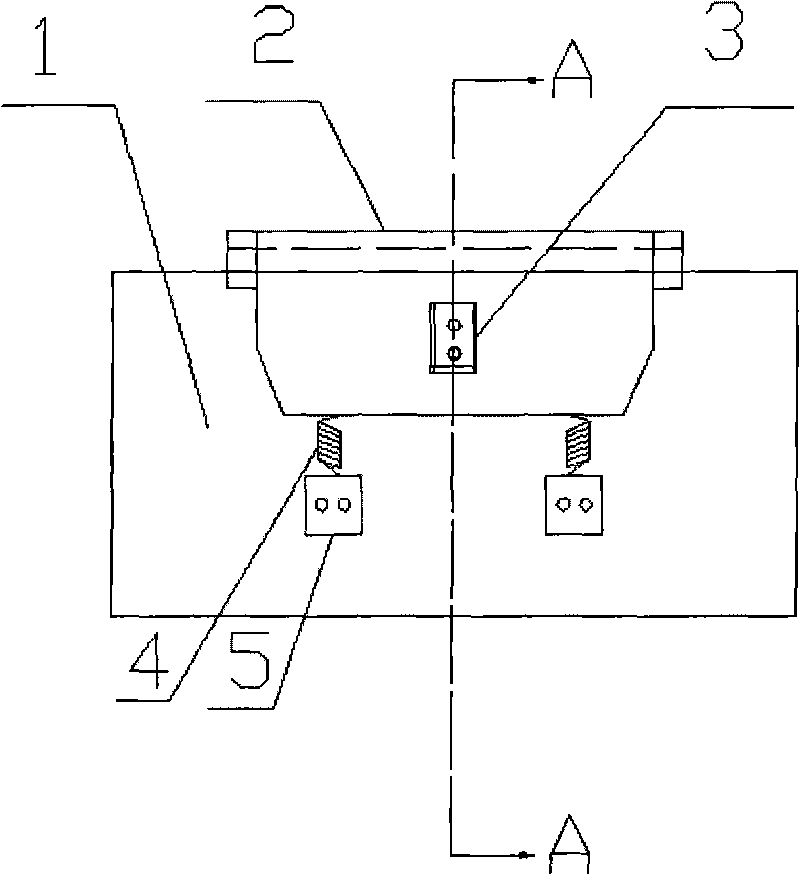

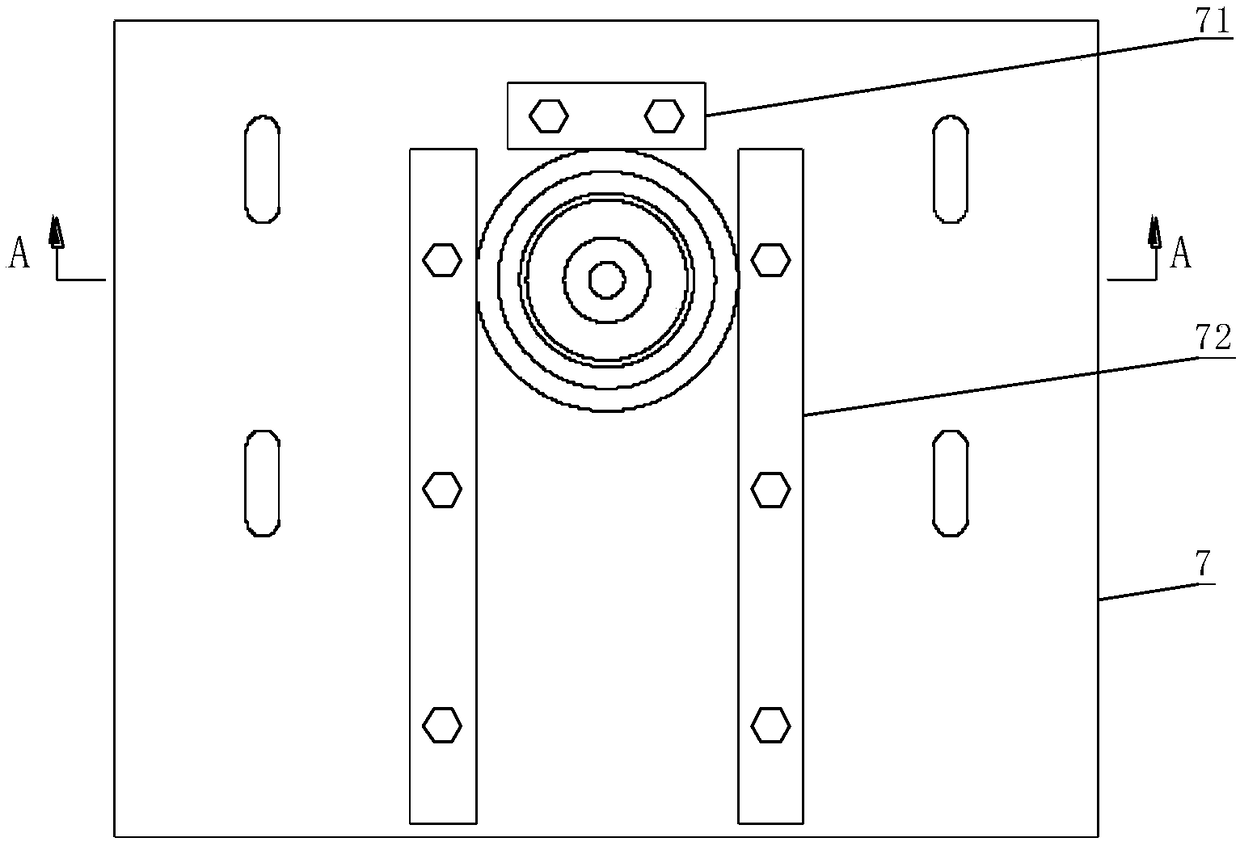

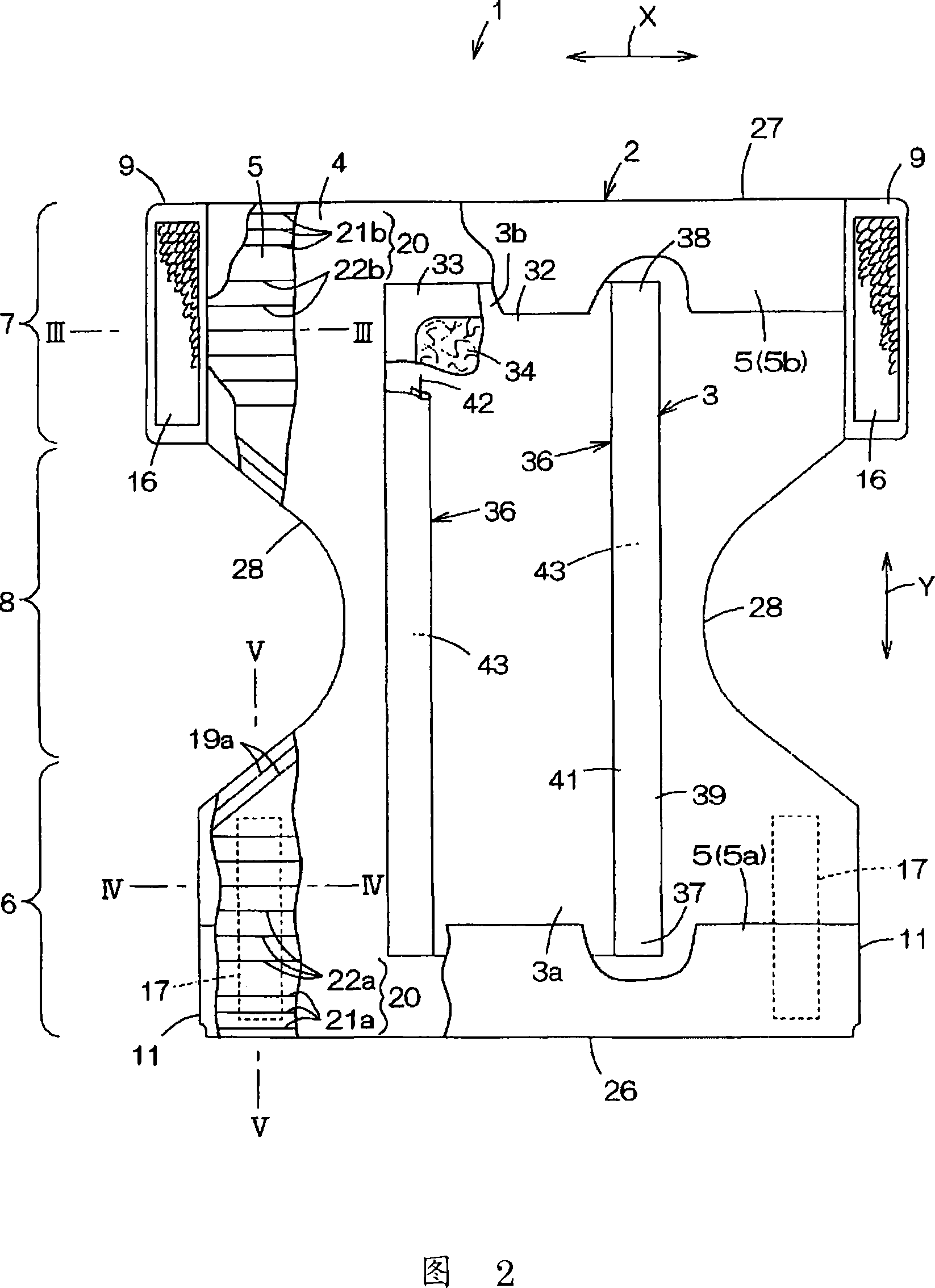

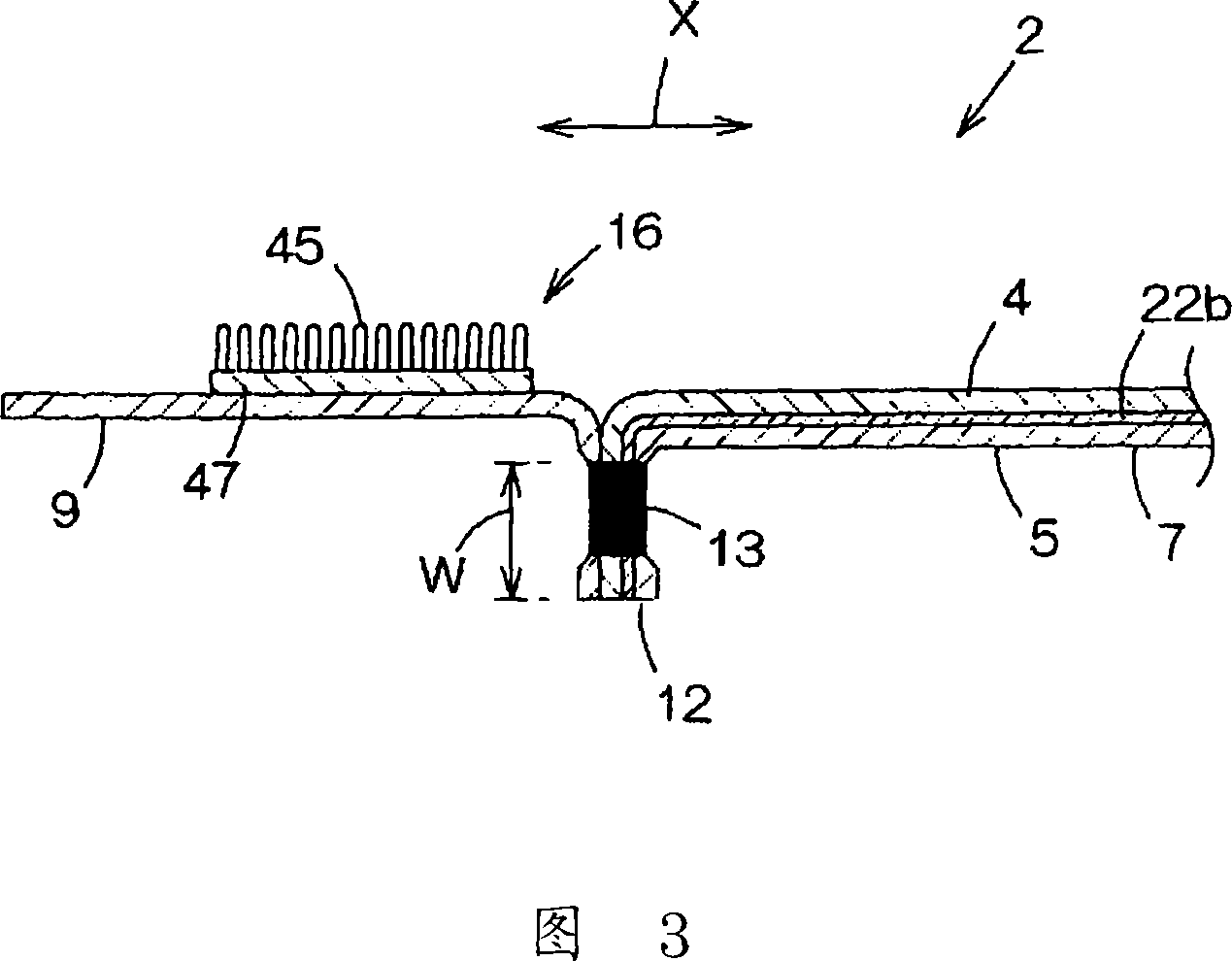

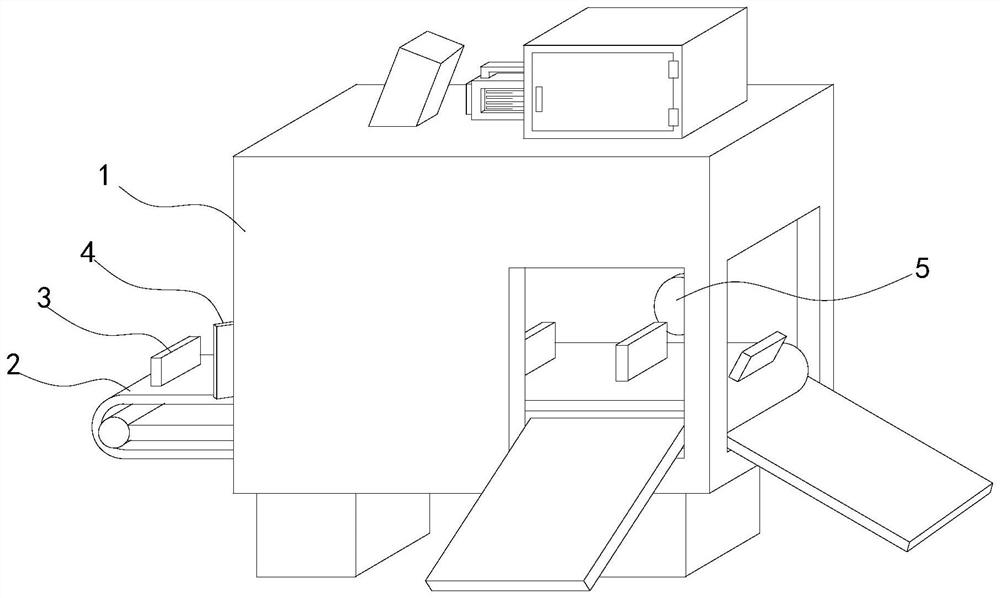

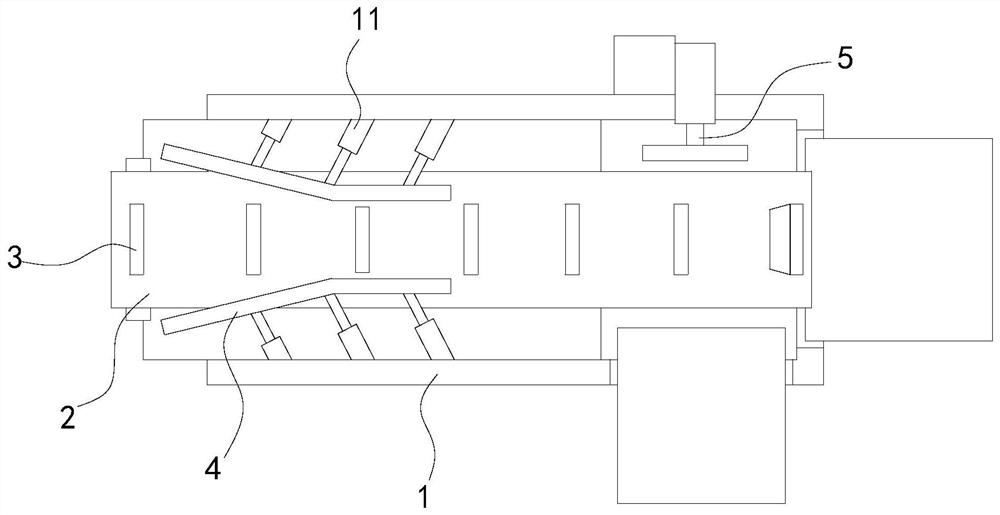

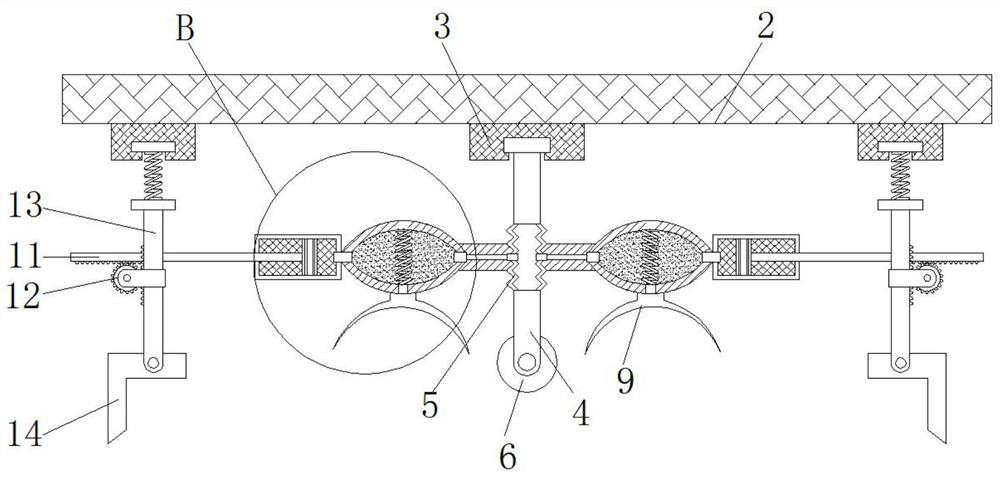

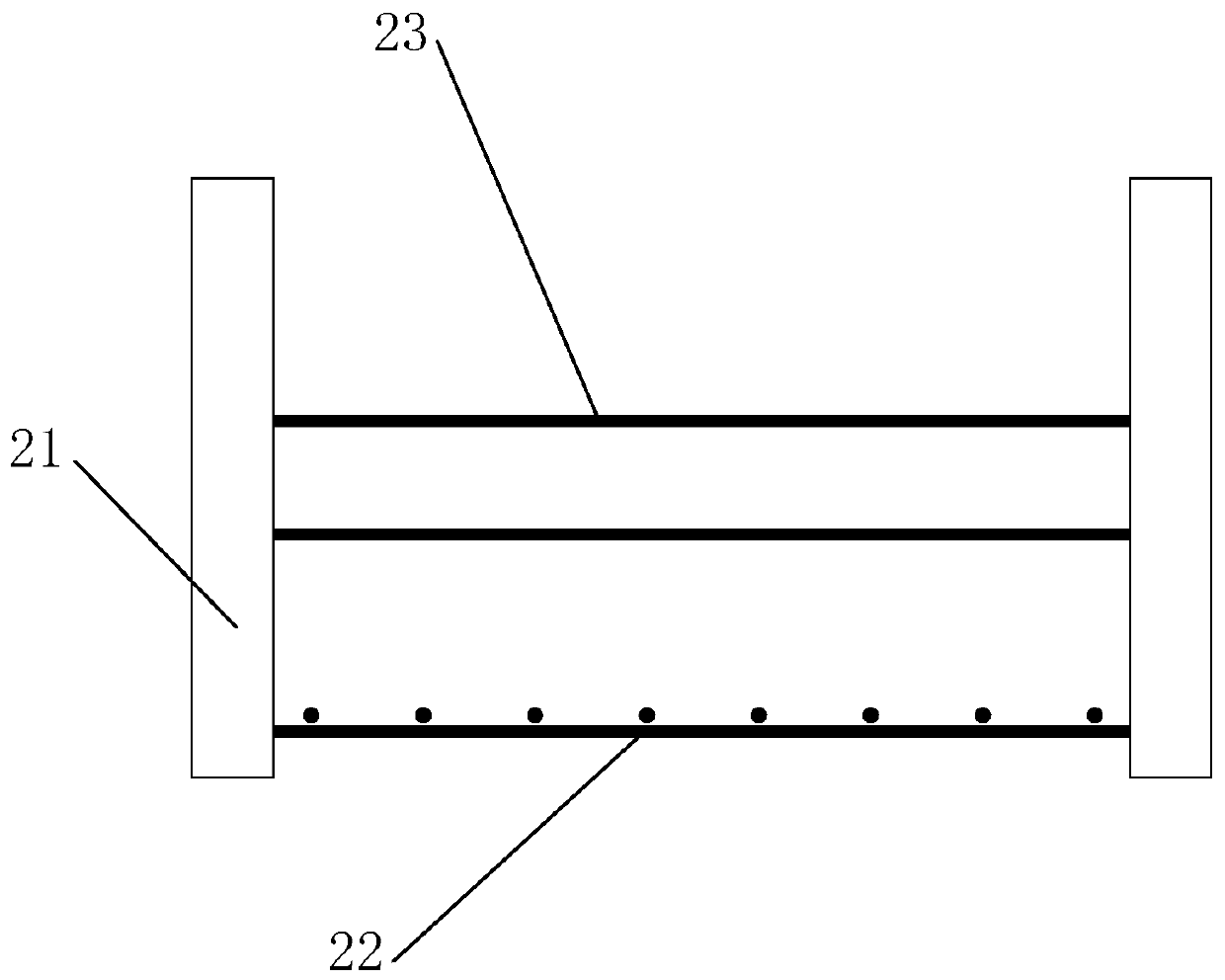

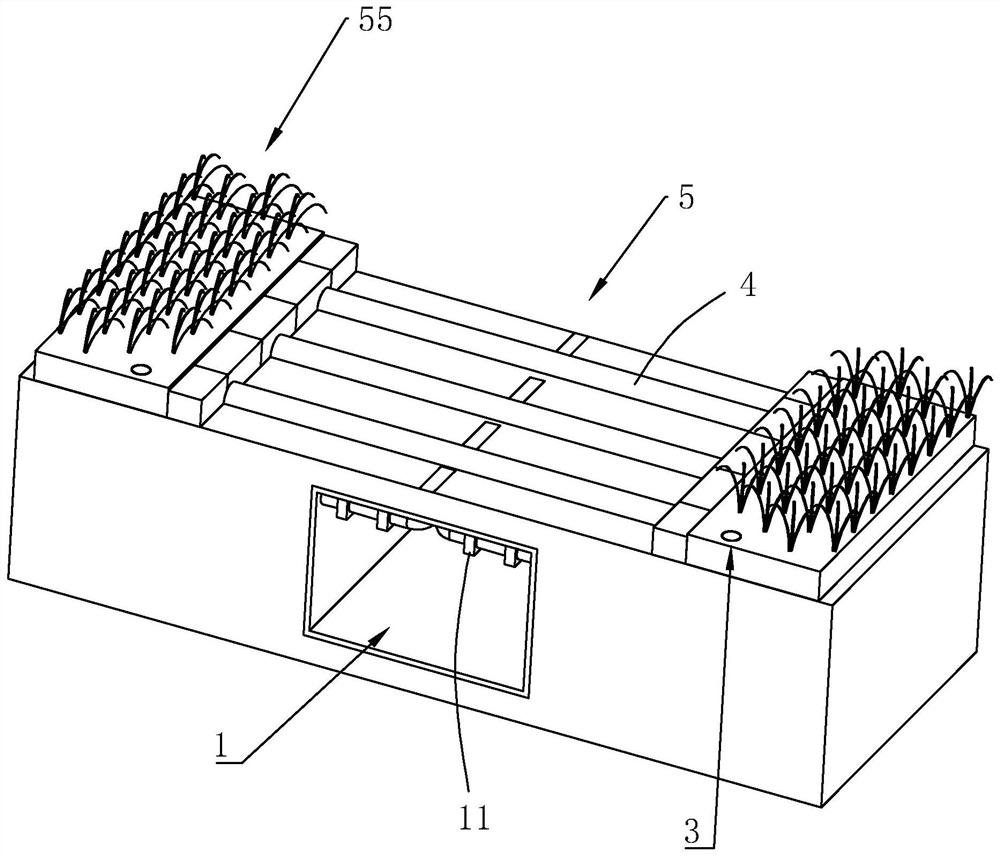

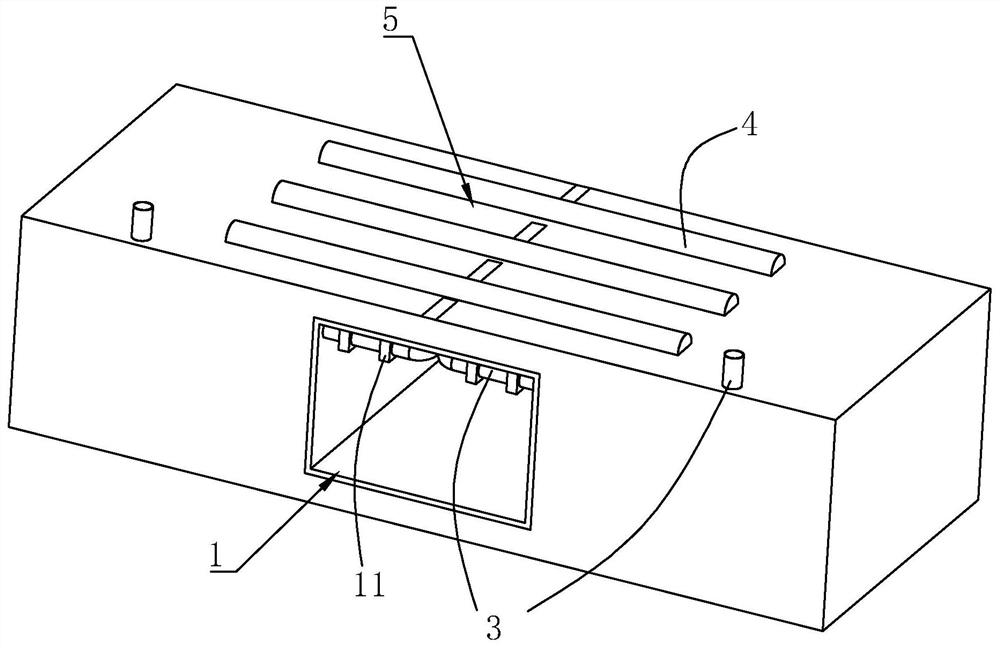

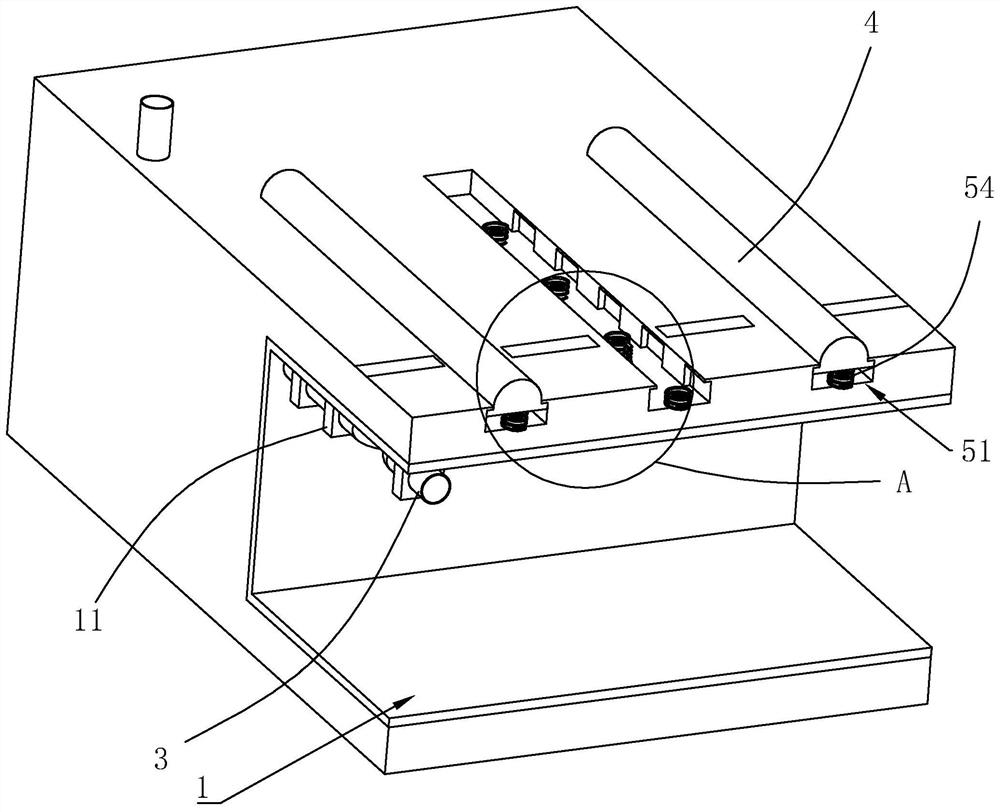

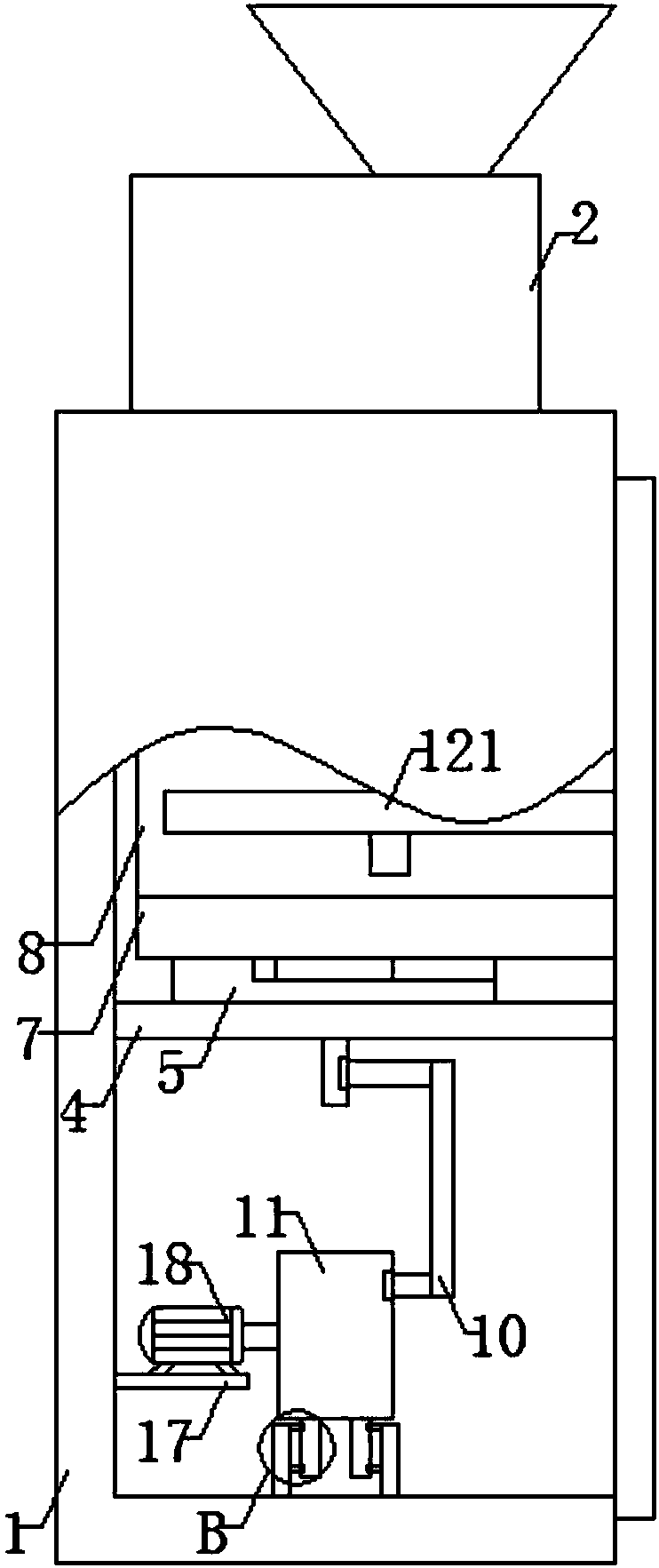

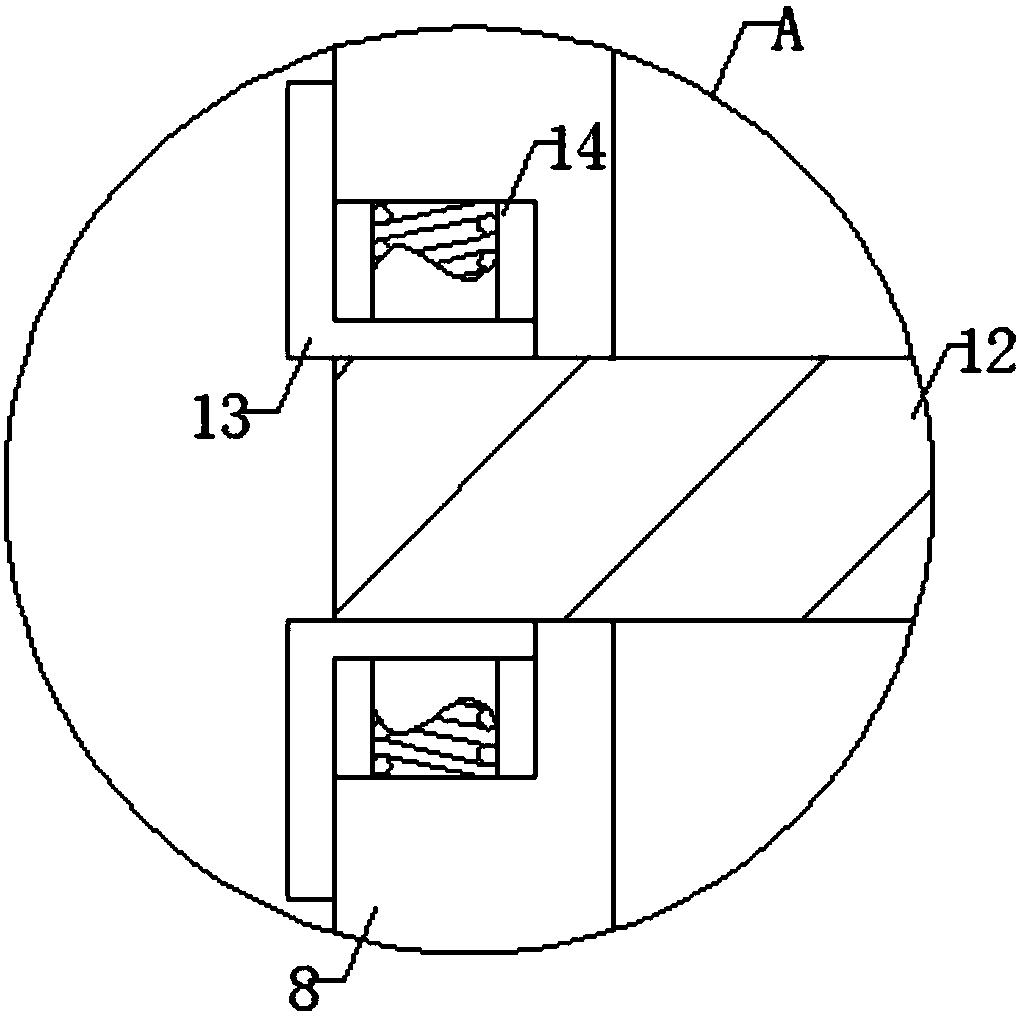

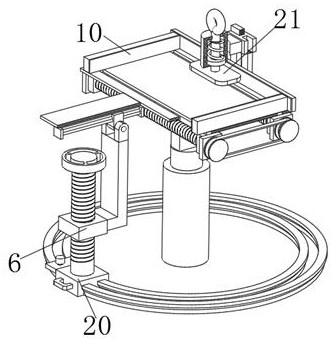

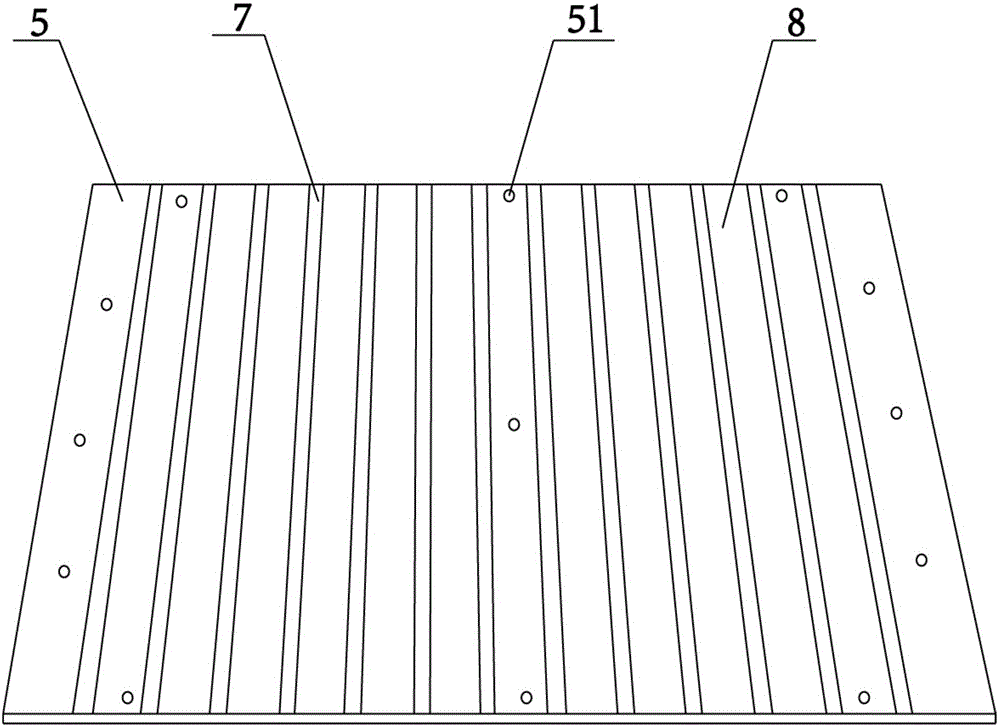

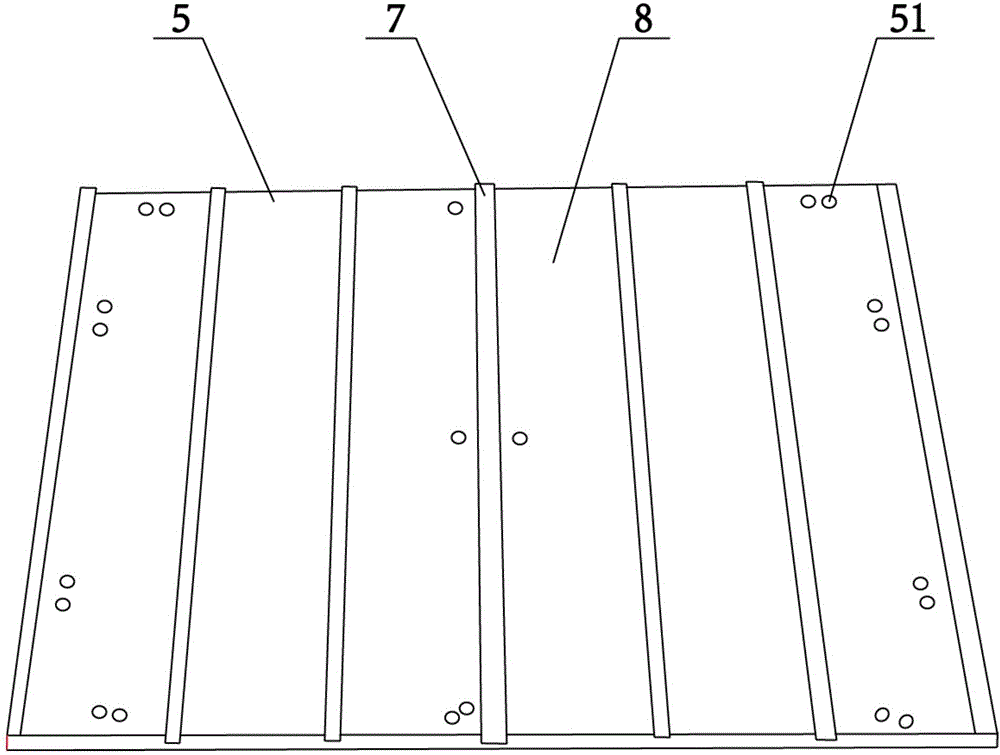

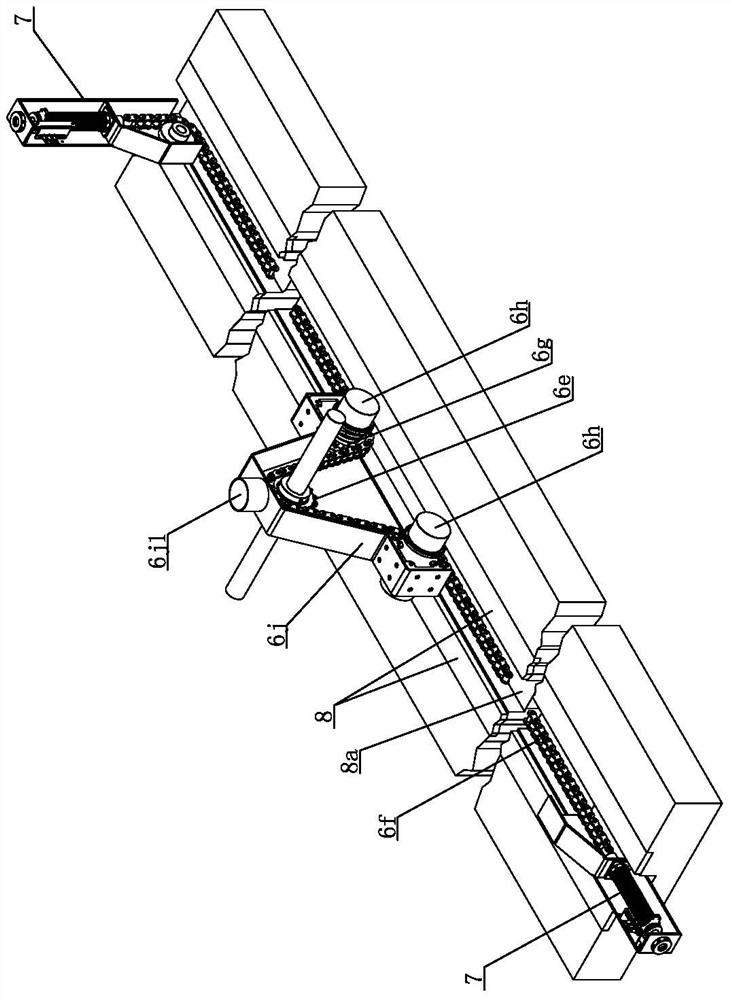

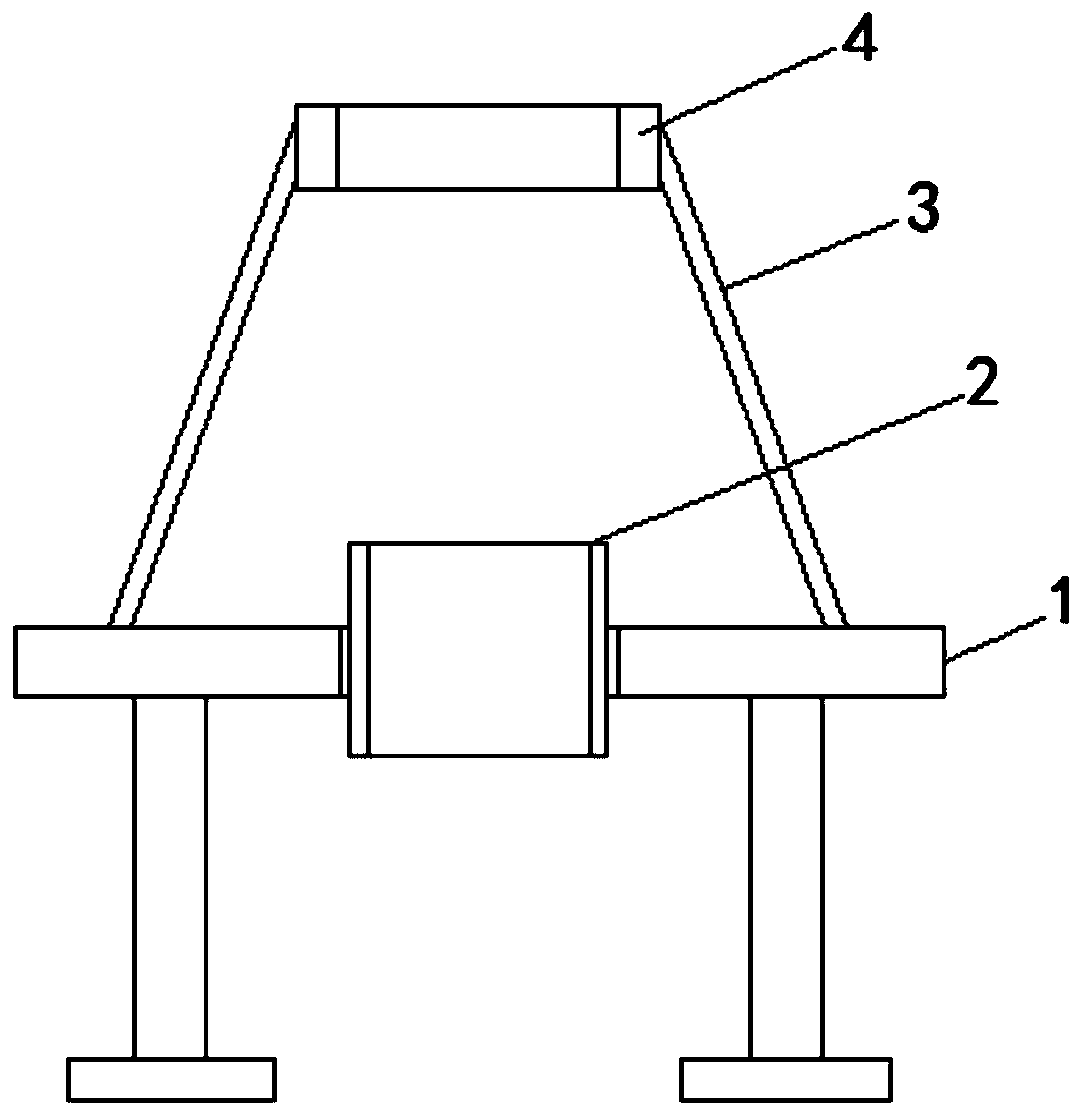

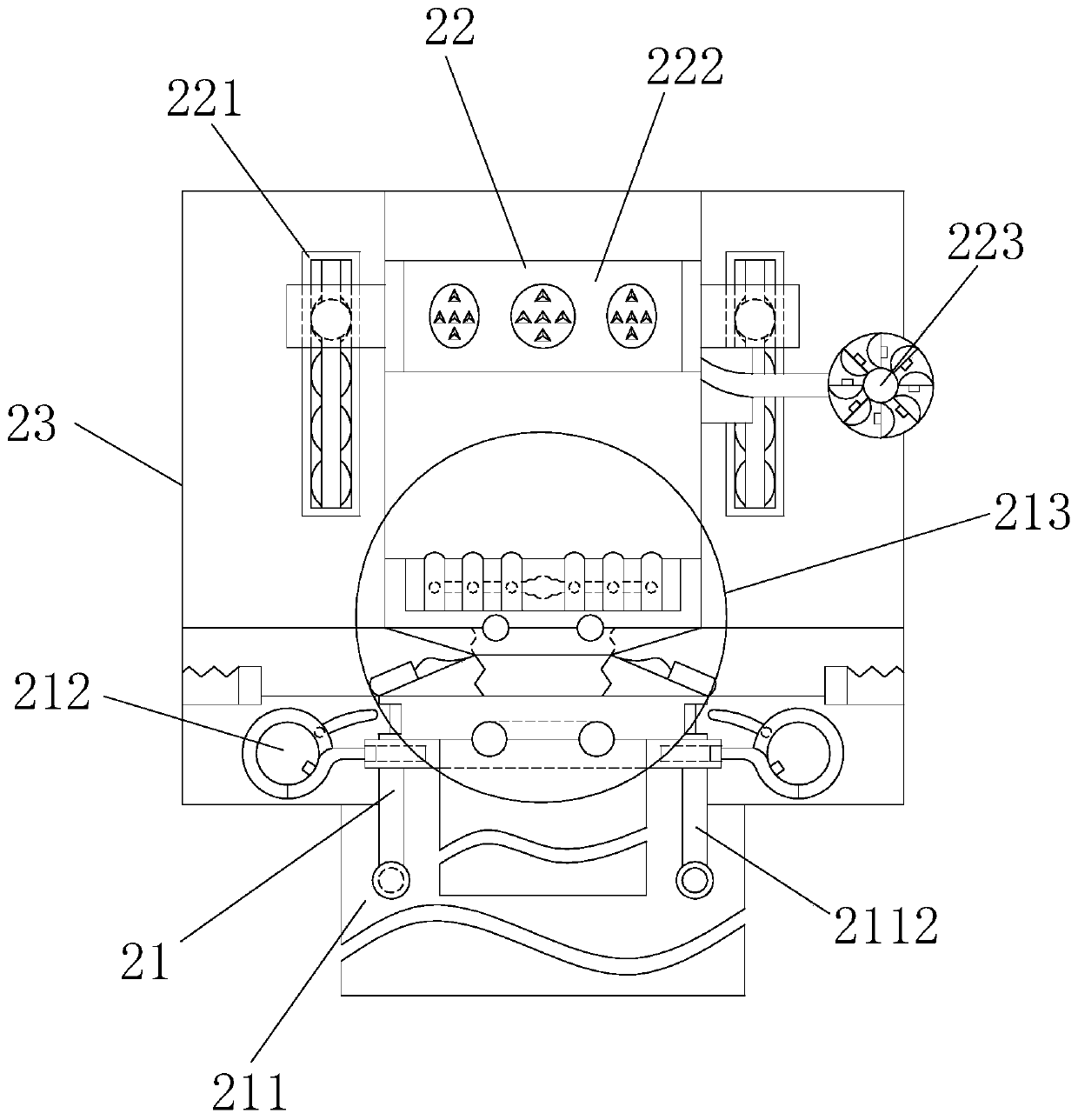

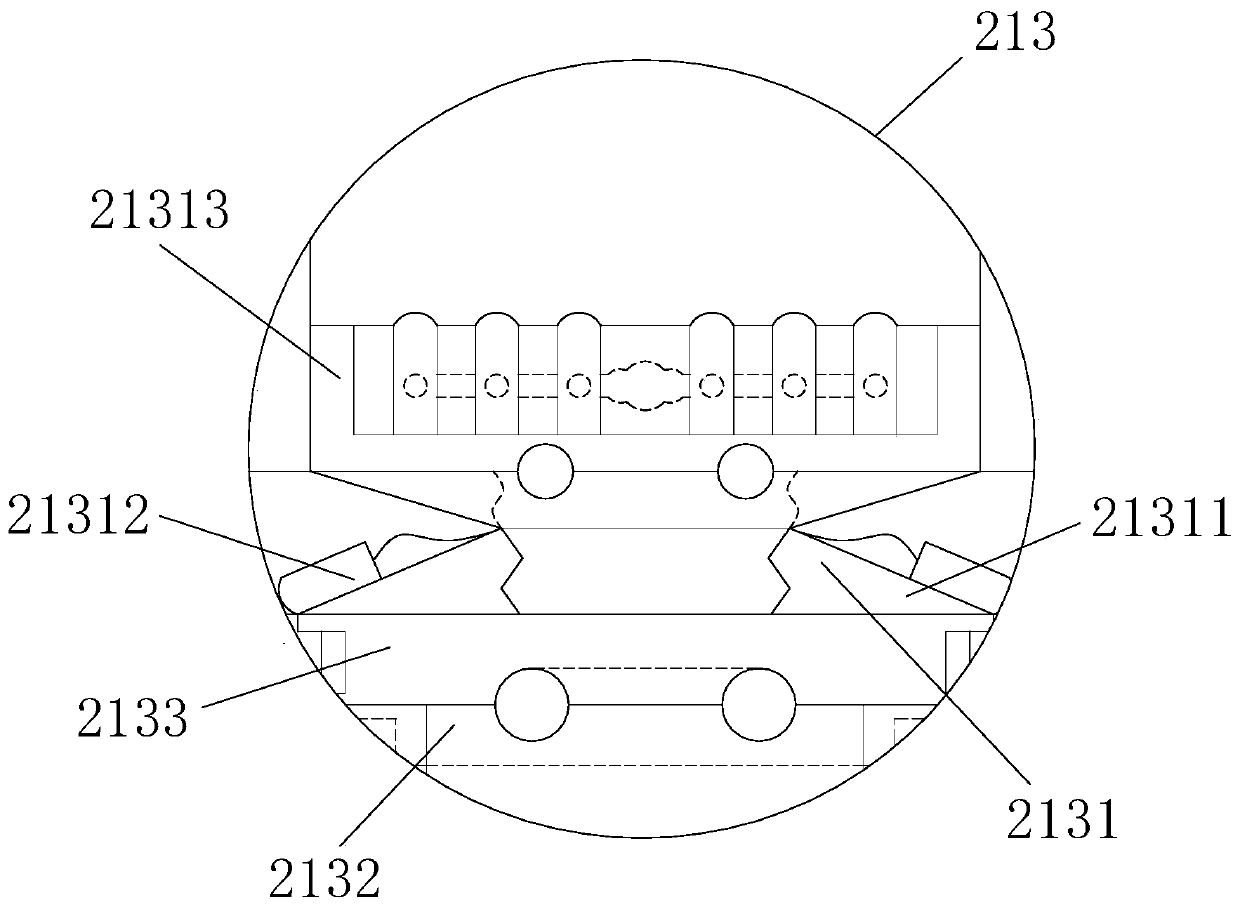

Bag sleeving and settling device for packaging bag filling and use method of bag sleeving and settling device

ActiveCN106742306AIncrease success rateGuaranteed flatnessPackagingMechanical engineeringInteraction forces

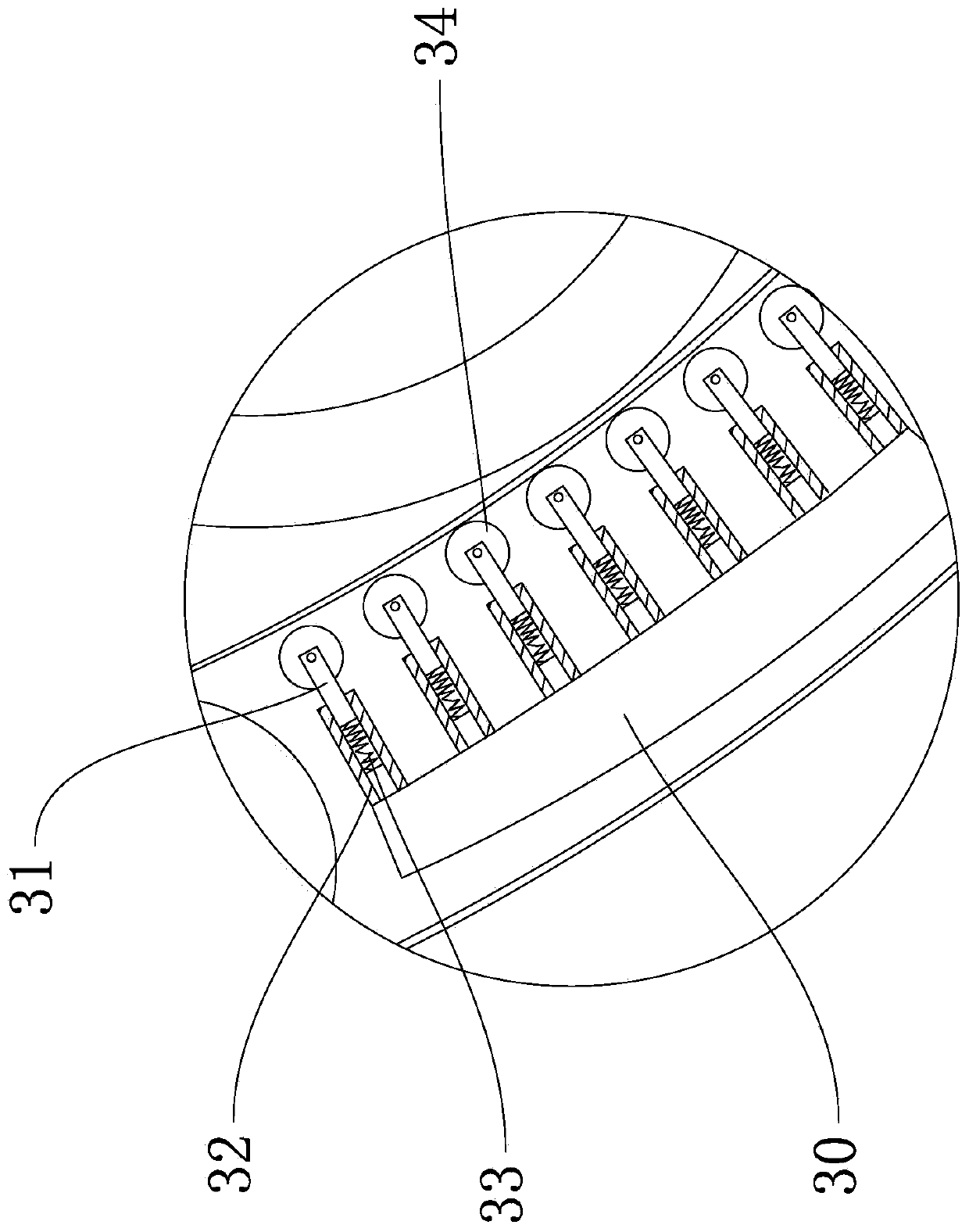

The invention relates to a bag sleeving and settling device for packaging bag filling and a use method of the bag sleeving and settling device. The bag sleeving and settling device comprises a rack, wherein a conveyer belt, a bag opening mechanism, a bag expanding conveying mechanism and a bag fixing and settling mechanism are arranged on the rack; the bag opening mechanism is positioned at an output end of the conveyer belt; the bag expanding conveying mechanism is positioned above the bag opening mechanism; the bag fixing and settling mechanism is positioned above the front part of the bag opening mechanism; and a deviation correcting mechanism is arranged between the conveyer belt and the bag opening mechanism. The bag sleeving and settling device is simple in structure, reasonable in design and high in bag sleeving success rate; due to adoption of a pressing wheel sealing ring and a deviation correction cylinder, the opening of a packaging bag does not deviate; two moveable clamping components are adopted to clamp the packaging bag in a balance state of the two moveable clamping components under mutual action; and due to adoption of a bag pull cylinder, the flatness of the opening of the filled packaging bag can be ensured, and a good basis can be laid for next procedures.

Owner:ZHANGZHOU JIALONG TECH INC

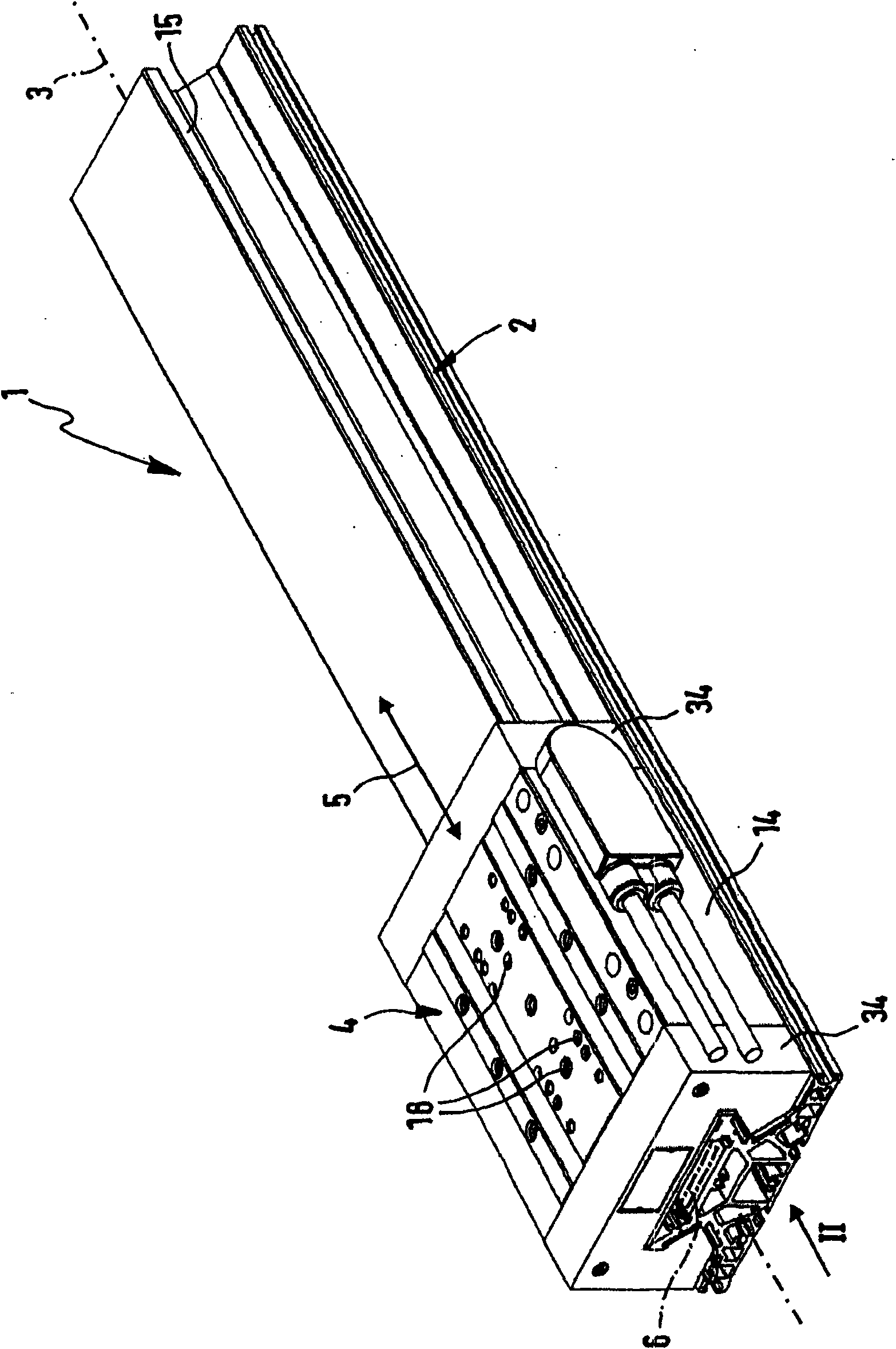

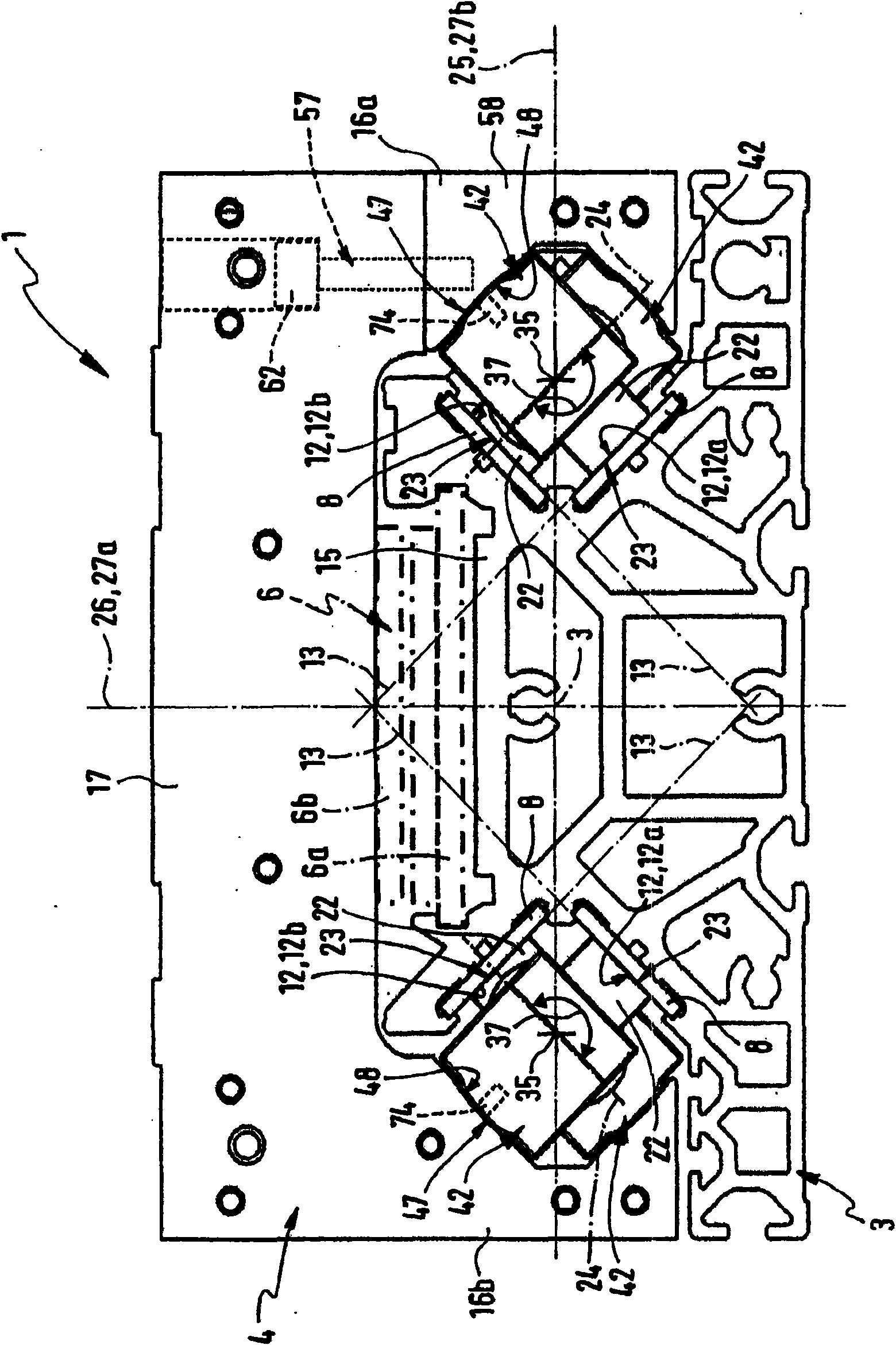

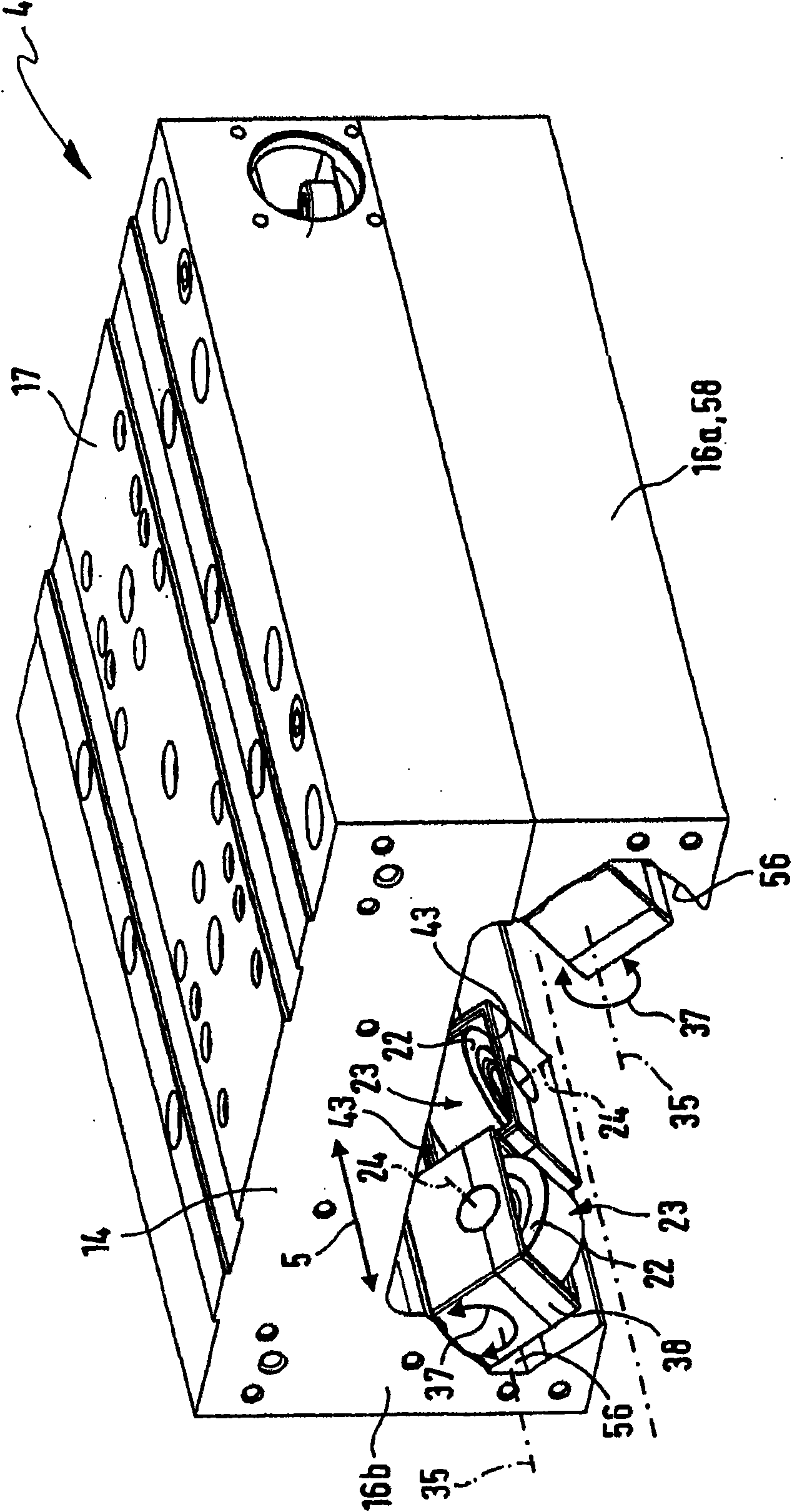

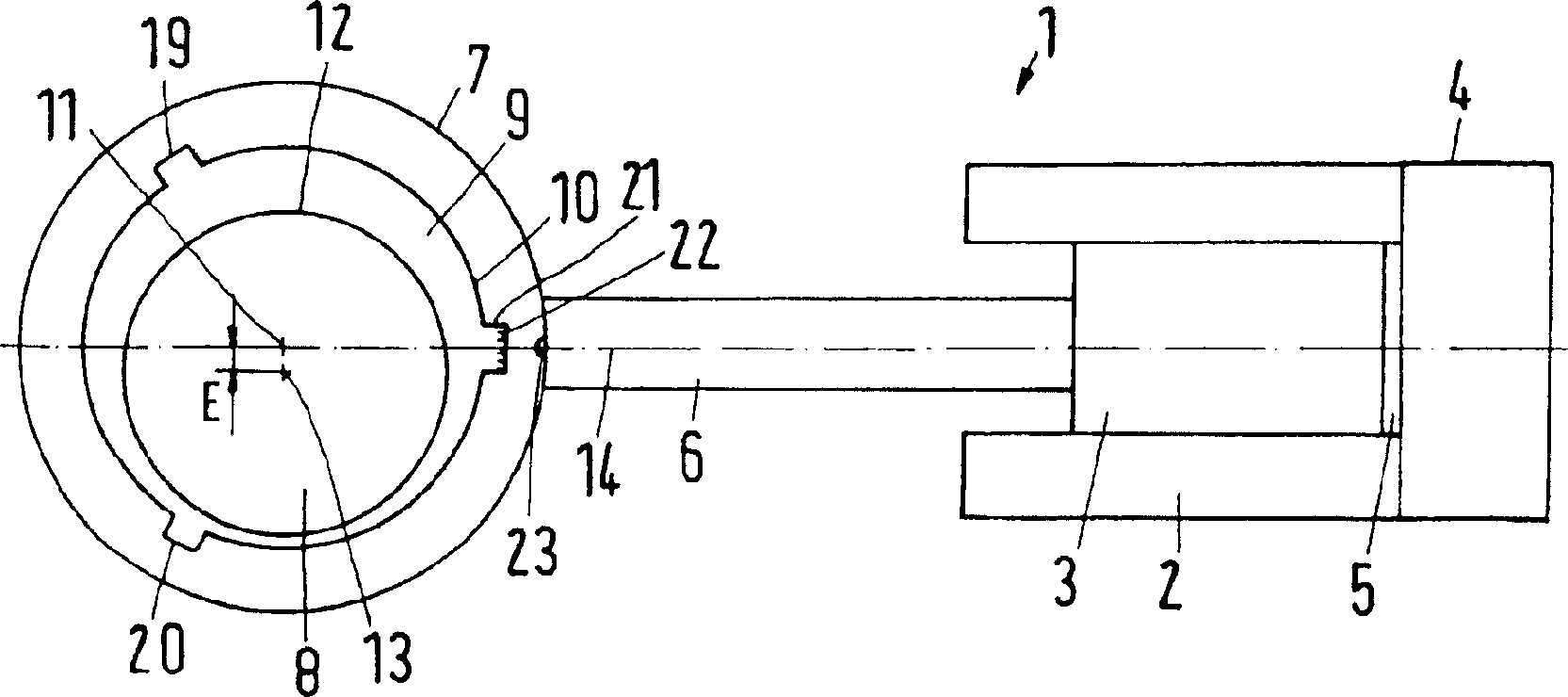

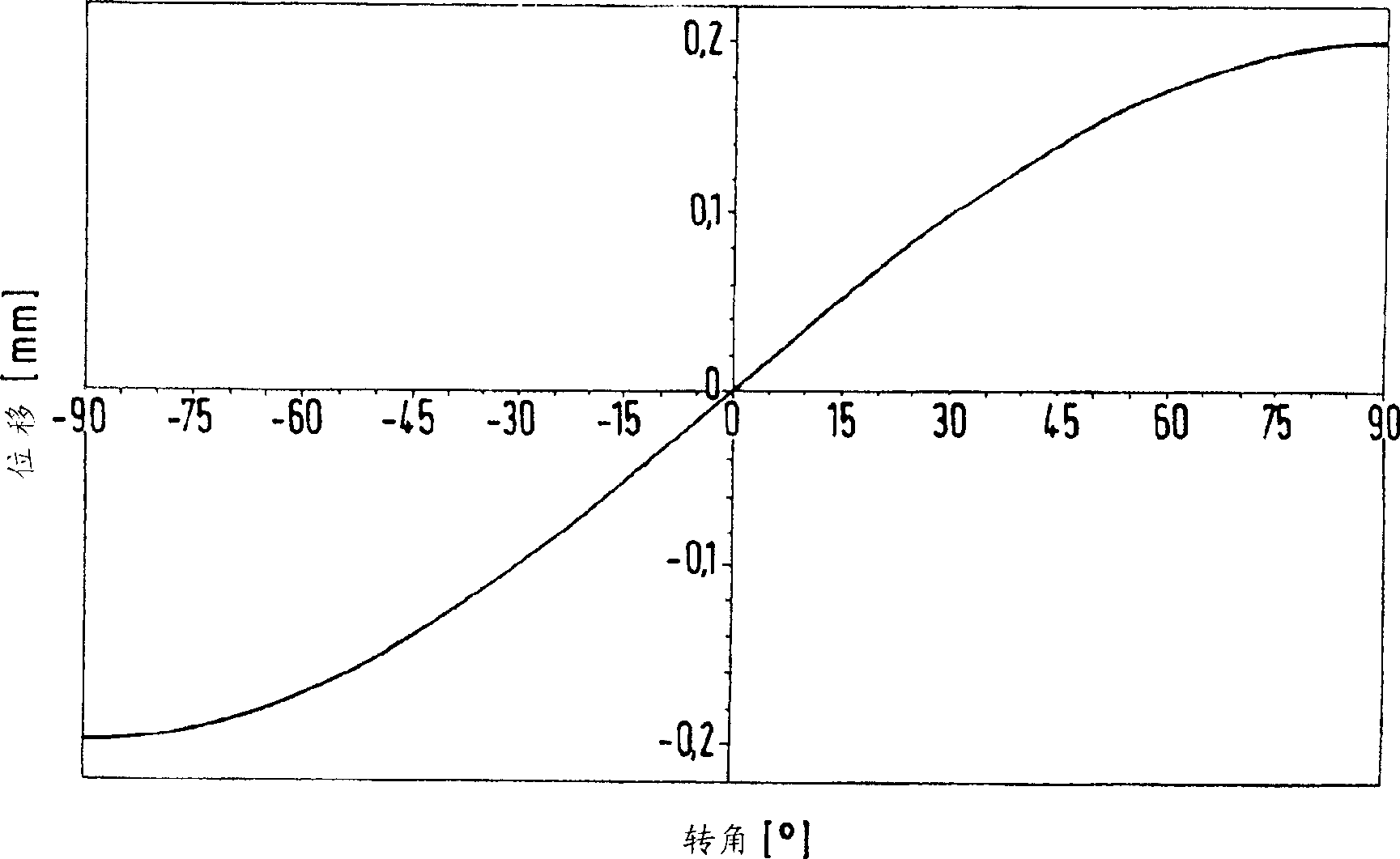

Linear unit

InactiveCN101629600AUniform force transmissionReduce wearLinear bearingsFluid-pressure actuatorsKinematic couplingBearing surface

The linear unit (1) has a base element, at which a carriage (4) is mounted in a linear movable manner in axial direction of a main axis (3). The base element has multiple longitudinal guide paths (12,12a,12b) extended to the main axis. A supporting roller (22) is fixed with a carriage body (14) of a carriage. The supporting roller is movement-coupled with circumferential-sided circular-cylindrical bearing surface (23) such that supporting roller is unrolled during the linear movement of the carriage on the assigned guide paths.

Owner:FESTO AG & CO KG

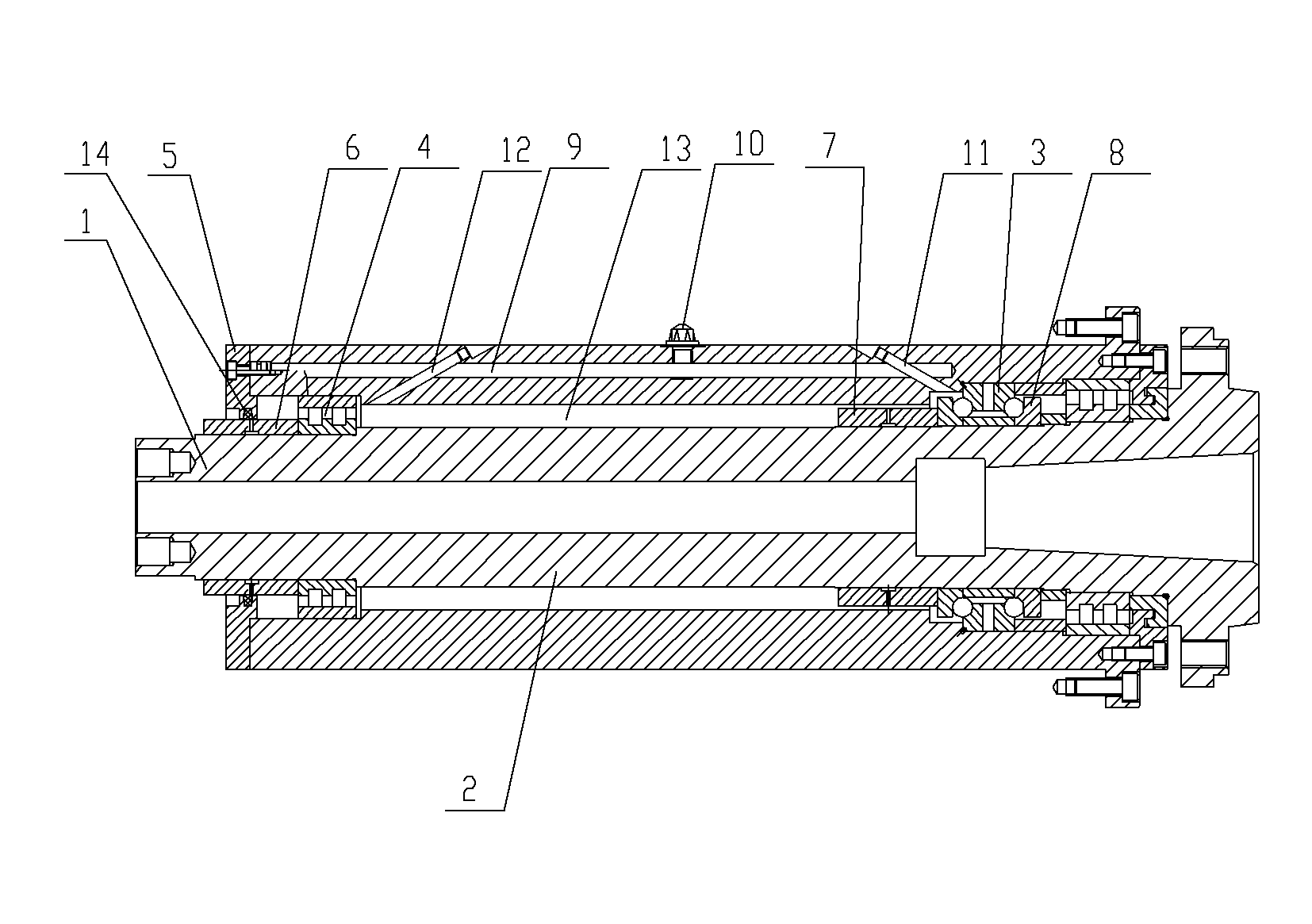

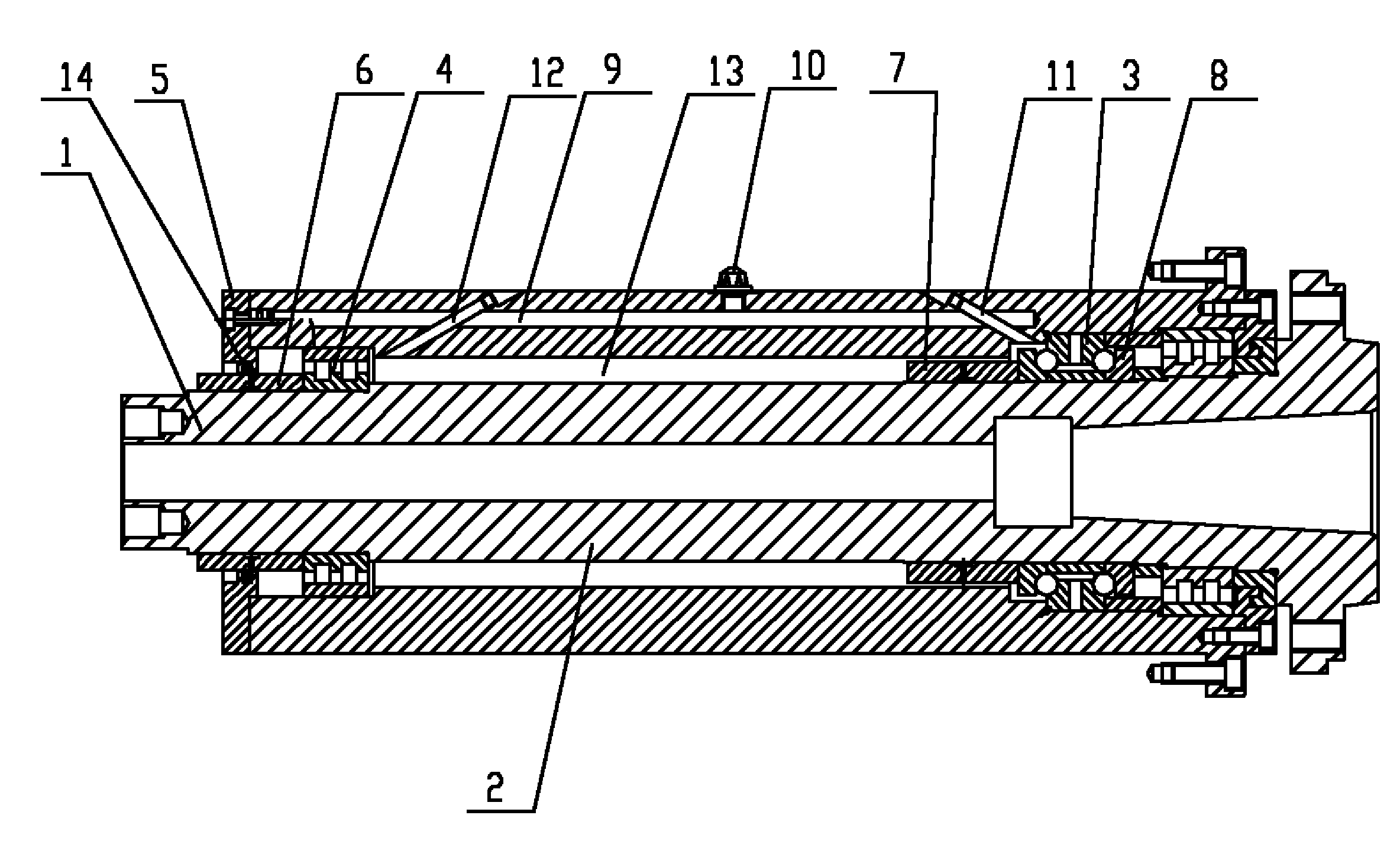

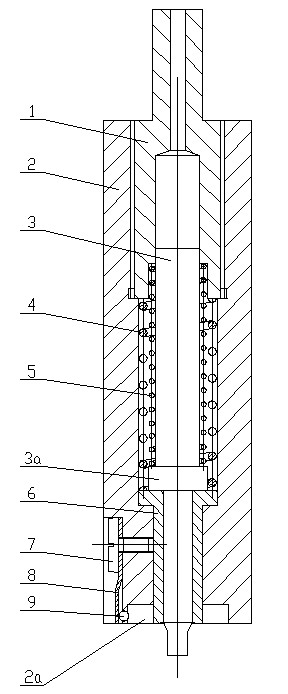

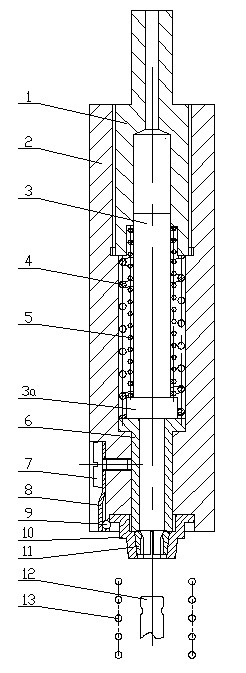

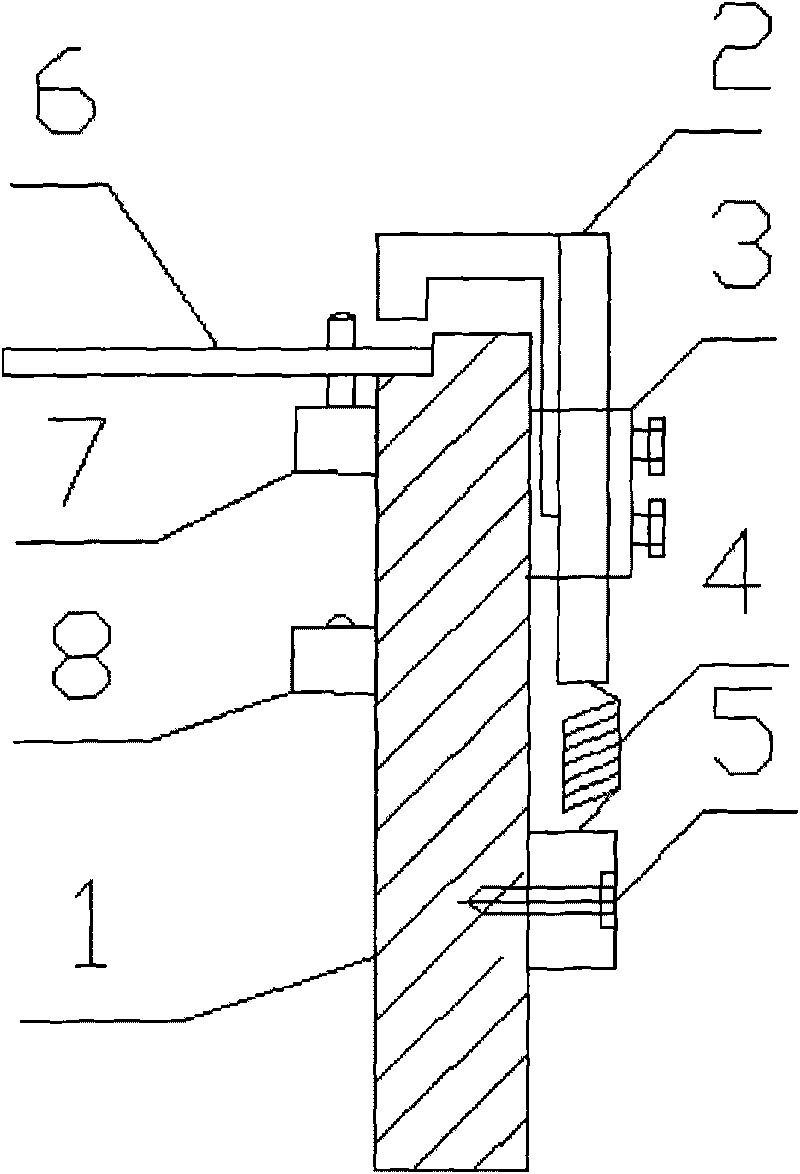

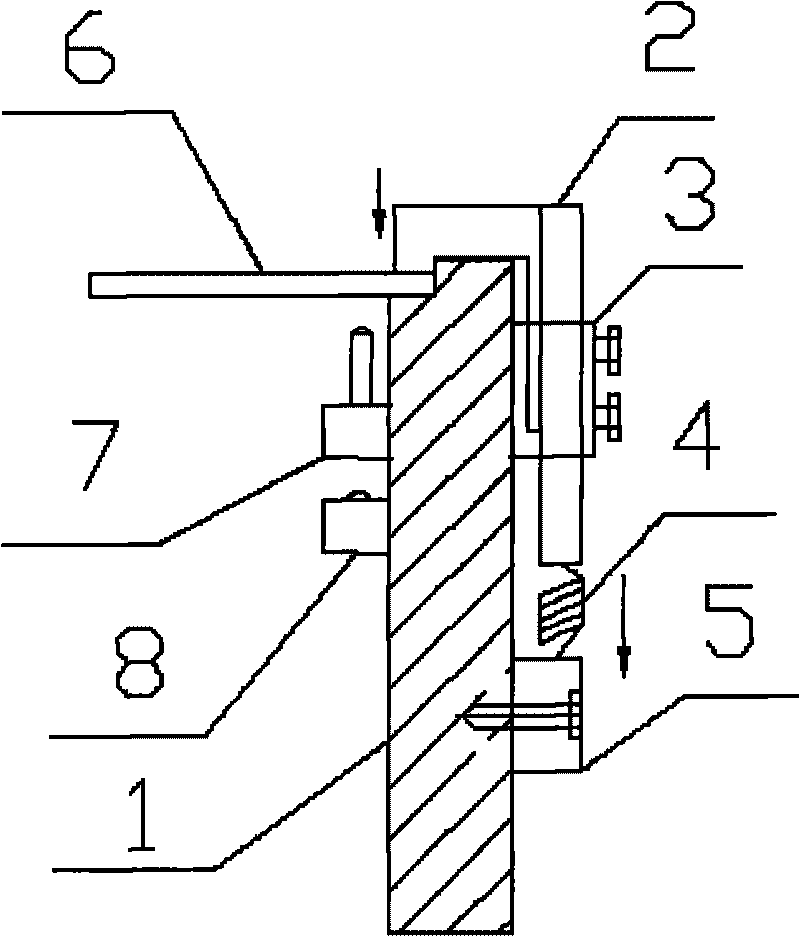

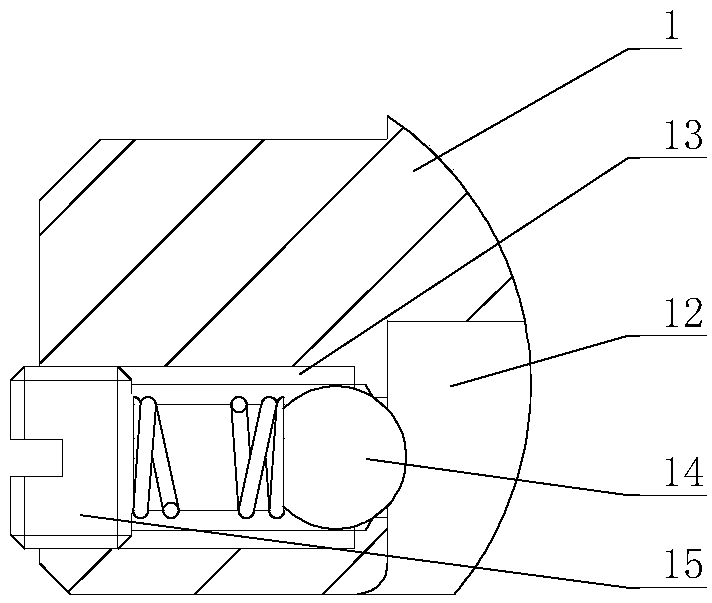

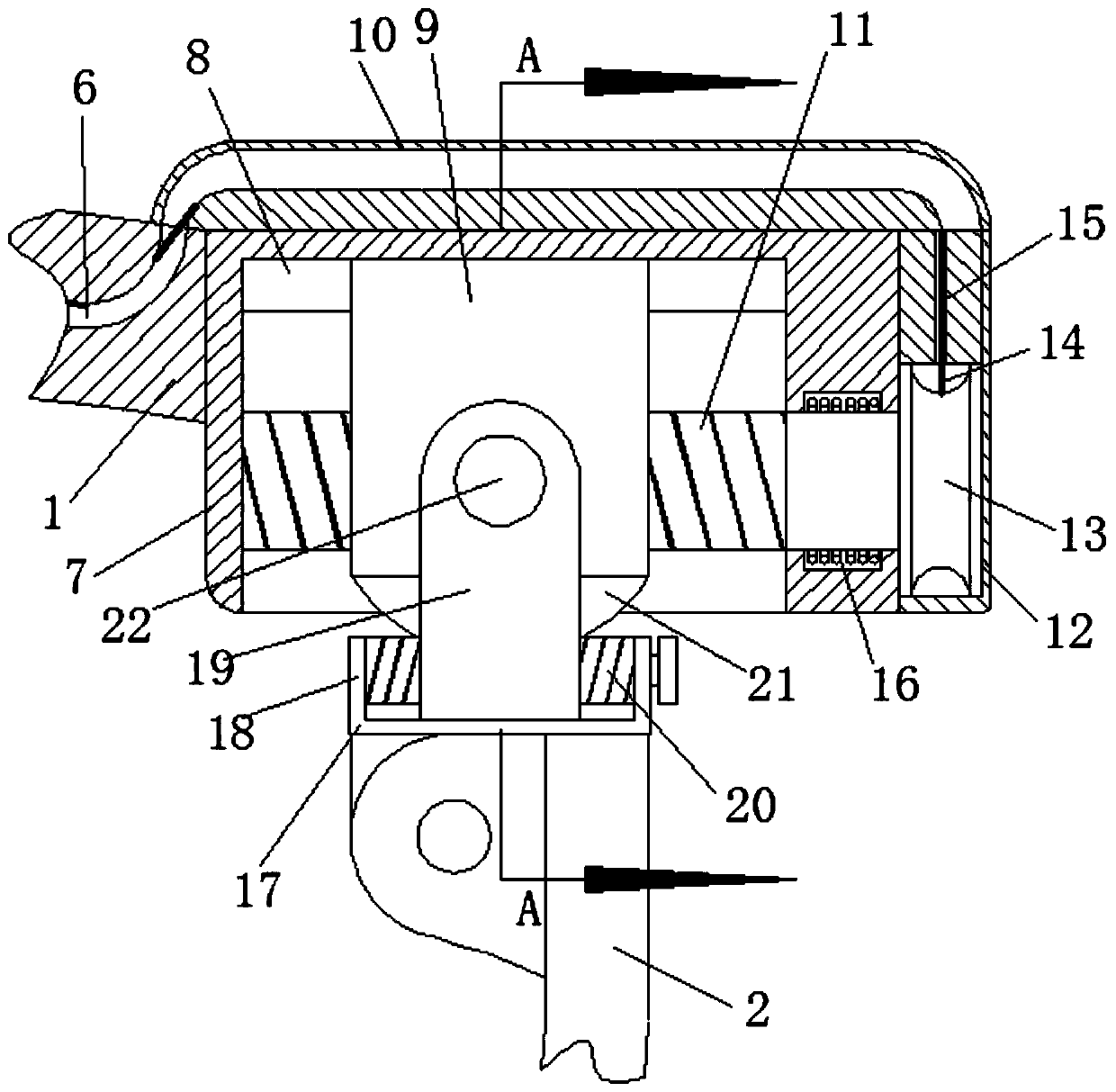

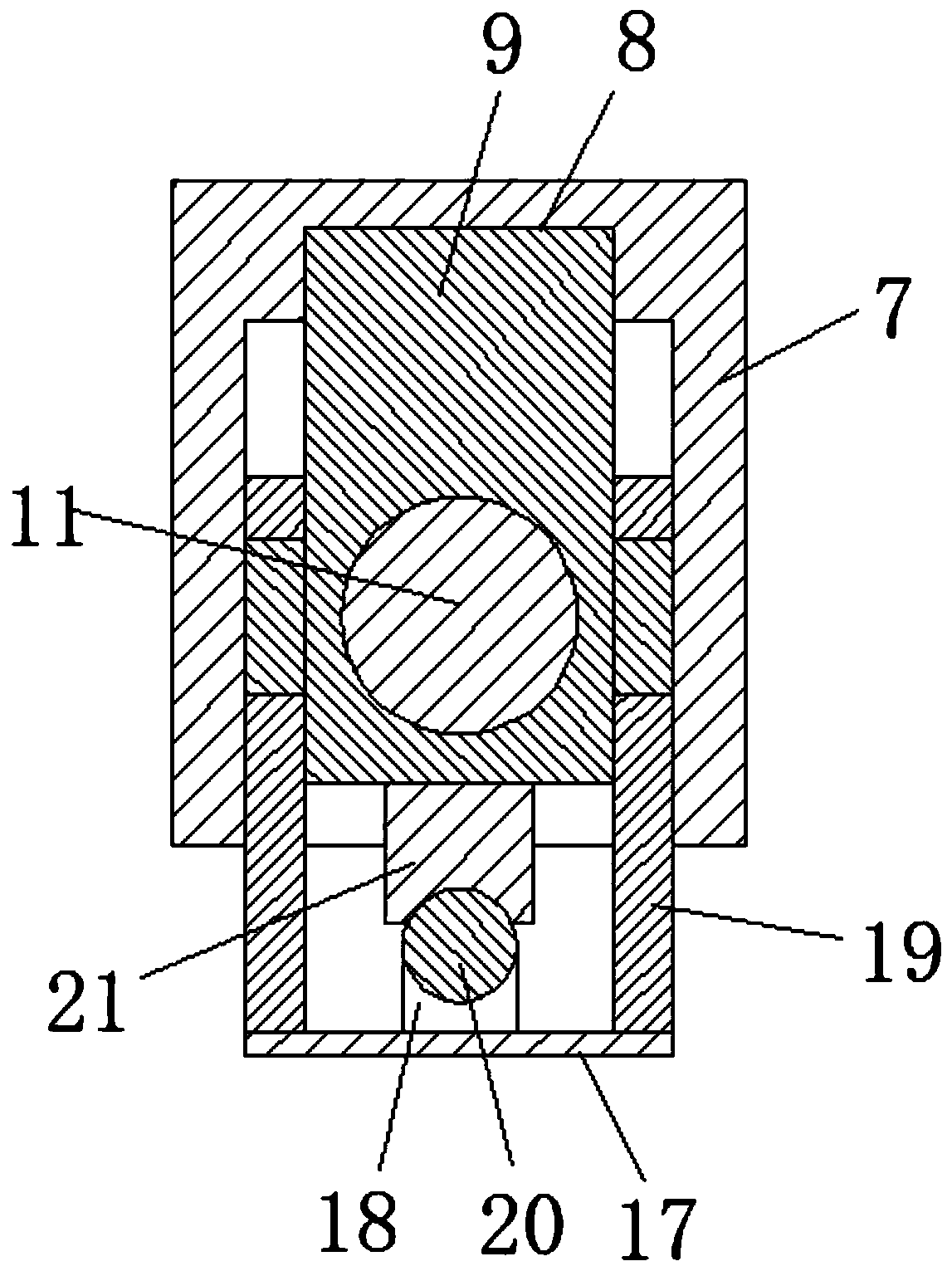

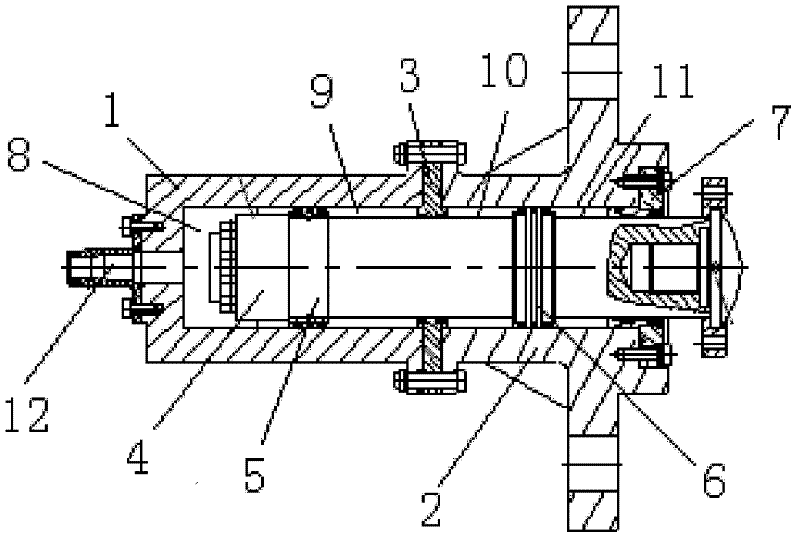

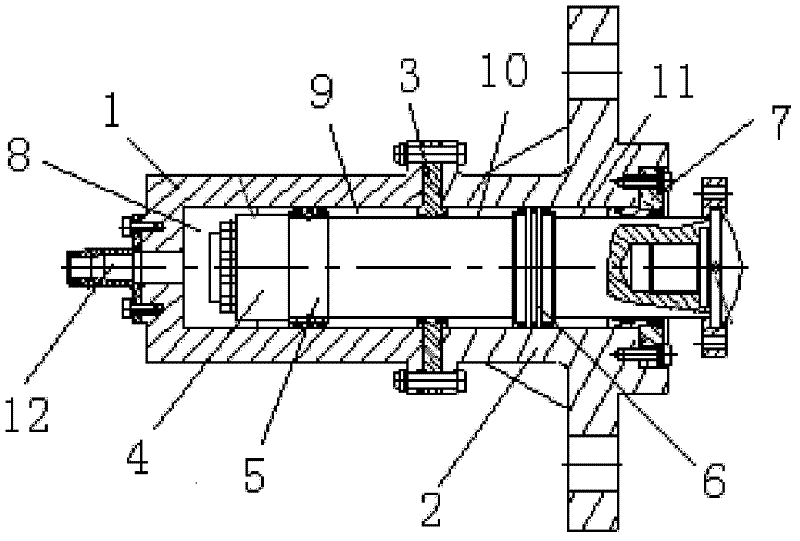

High-accuracy sleeve main shaft structure for machine tool

InactiveCN102059357AWon't skewGuaranteed rotation accuracyMetal-working apparatusInterference fitEngineering

The invention provides a high-accuracy sleeve main shaft structure for a machine tool, which prevents a bearing from deflection during preloading, ensures the running accuracy of a main shaft, and further ensures the high accuracy of the sleeve main shaft. The high-accuracy sleeve main shaft structure for the machine tool comprises the main shaft and a sleeve, wherein the main shaft penetrates through the sleeve and is supported at the inner sleeve wall via a front-end bearing and a back-end bearing, the front end part of the main shaft is embedded and sleeved at the front end part of the sleeve, and a back end press cover is arranged at the back end part of the sleeve; and the high-accuracy sleeve main shaft structure for the machine tool is characterized in that the back end of the main shaft is sleeved with a back end oil press sleeve, the back end oil press sleeve is in interference fit with the back end of the main shaft, the inner end surface of the back end oil press sleeve is in close contact with the back-end bearing, the external circular surface at the outer end of the back end oil press sleeve is in close contact with the internal circular surface of the back end press cover, the front end of the main shaft is sleeved with a front end oil press sleeve, the front end oil press sleeve is in interference fit with the front end of the main shaft, and one end surface of the front end oil press sleeve is in close contact with the front-end bearing.

Owner:WUXI MACHINETOOL

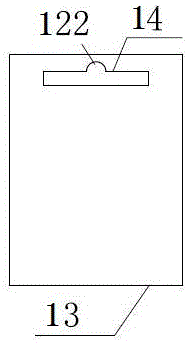

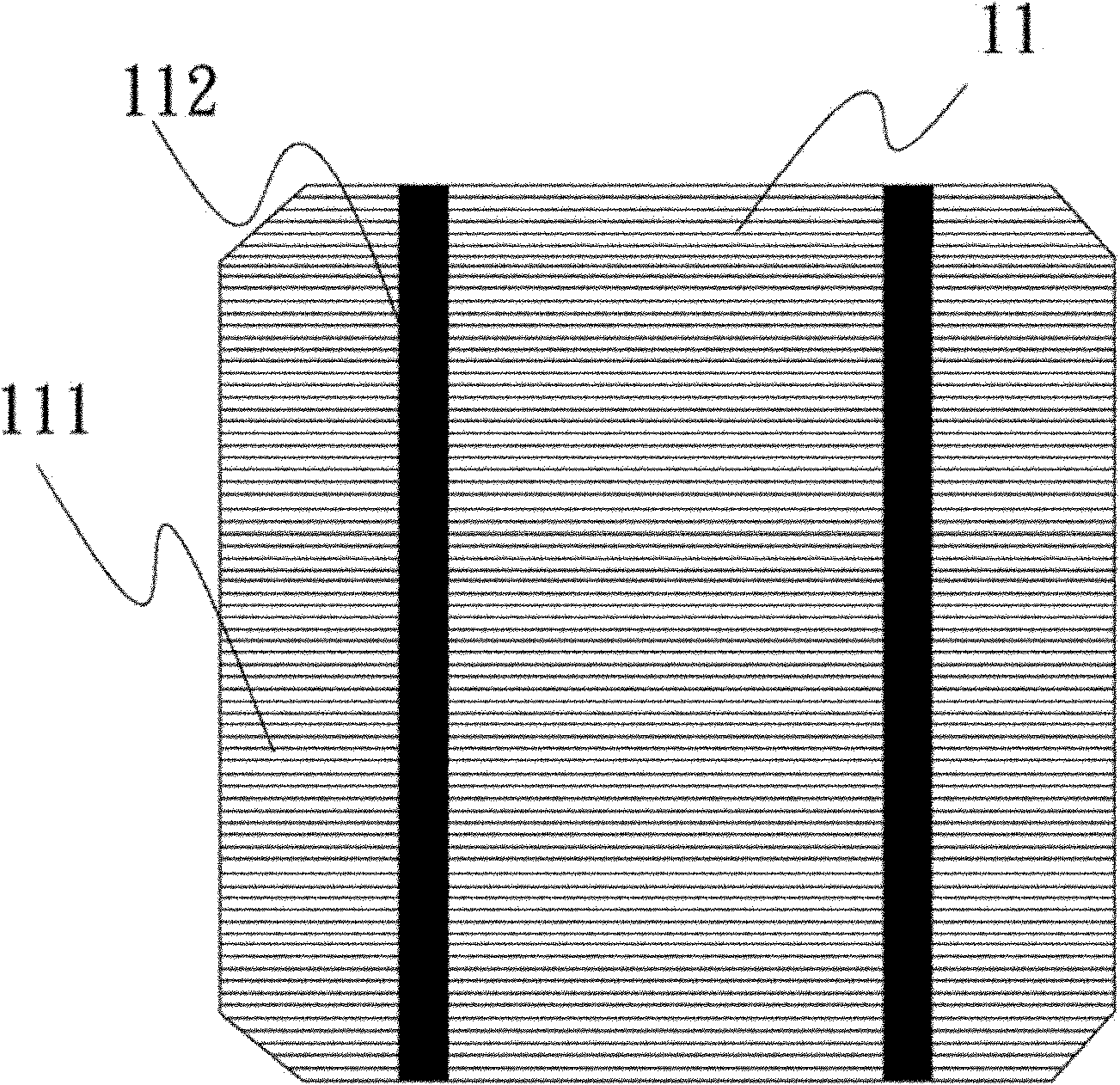

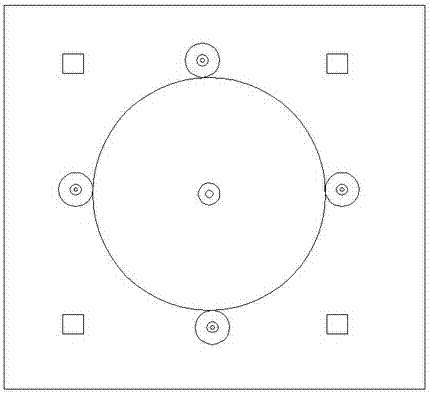

Solar wafer position calibrating device and detection machine station with the same

InactiveCN102384913AWon't skewSmooth inspectionPhotovoltaic monitoringOptically investigating flaws/contaminationEngineeringConveyor belt

The present invention provides a solar wafer position calibrating device and a detection machine station with the same. A transferring device transfers a solar wafer to a conveyor belt for performing transportation. Furthermore the machine station is provided with an optical detection device and an illumination detection device. A clamping member is provided at detection position which corresponds with each detection device. The clamping member is used for calibrating before detection of the detection device when the solar wafer deviates in transferring and transportation processes. The calibration mode is characterized in that the calibration is performed correspondingly with the solar wafer provided at each detection position through a clamping mode from outside to inside in a width direction. Therefore the solar wafer does not incline at a detection position. The solar wafer can be kept in a correct range of each detection position. Finally each detection data set is transmitted to a classification system for being used as a classification basis.

Owner:致茂电子(苏州)有限公司

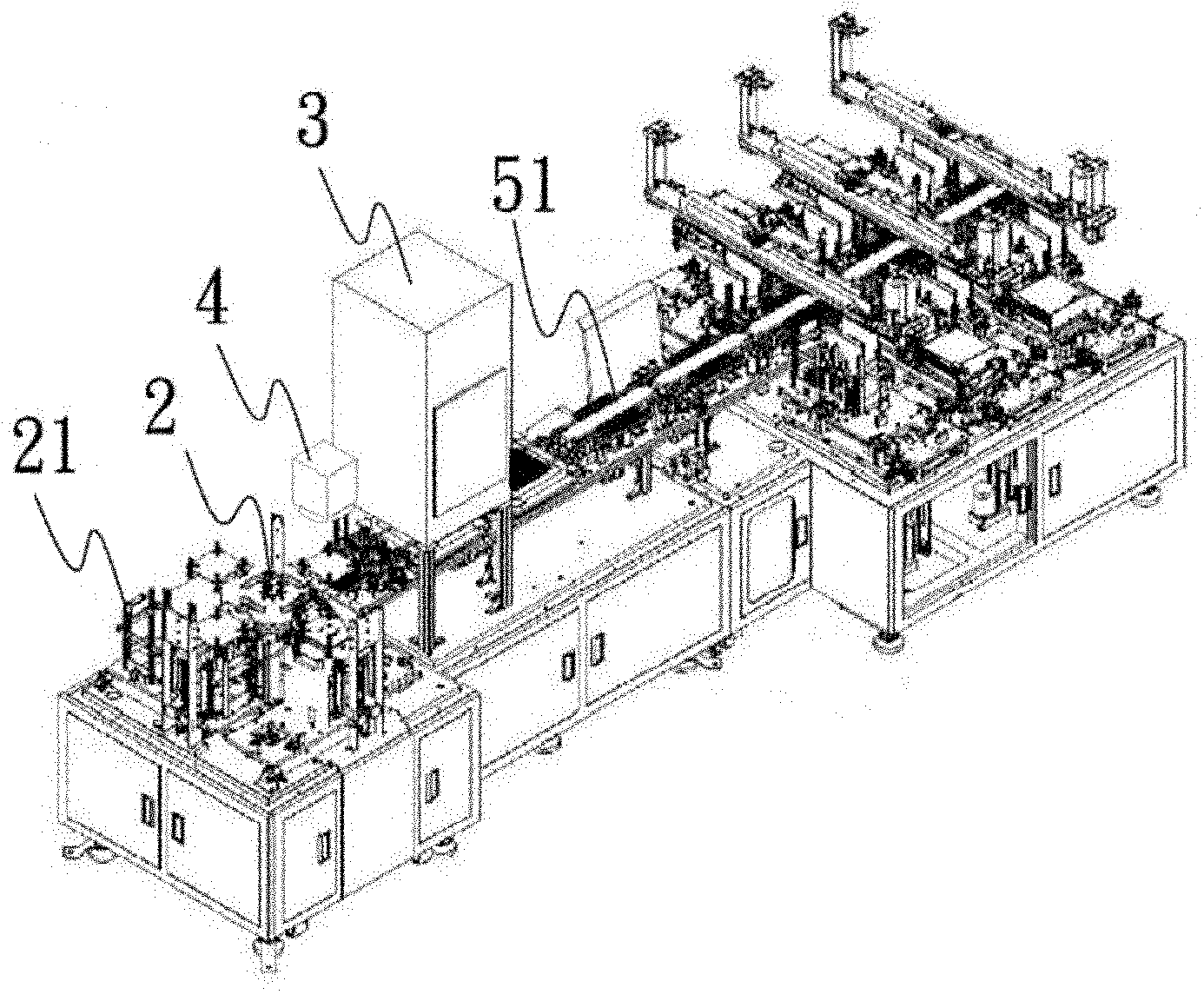

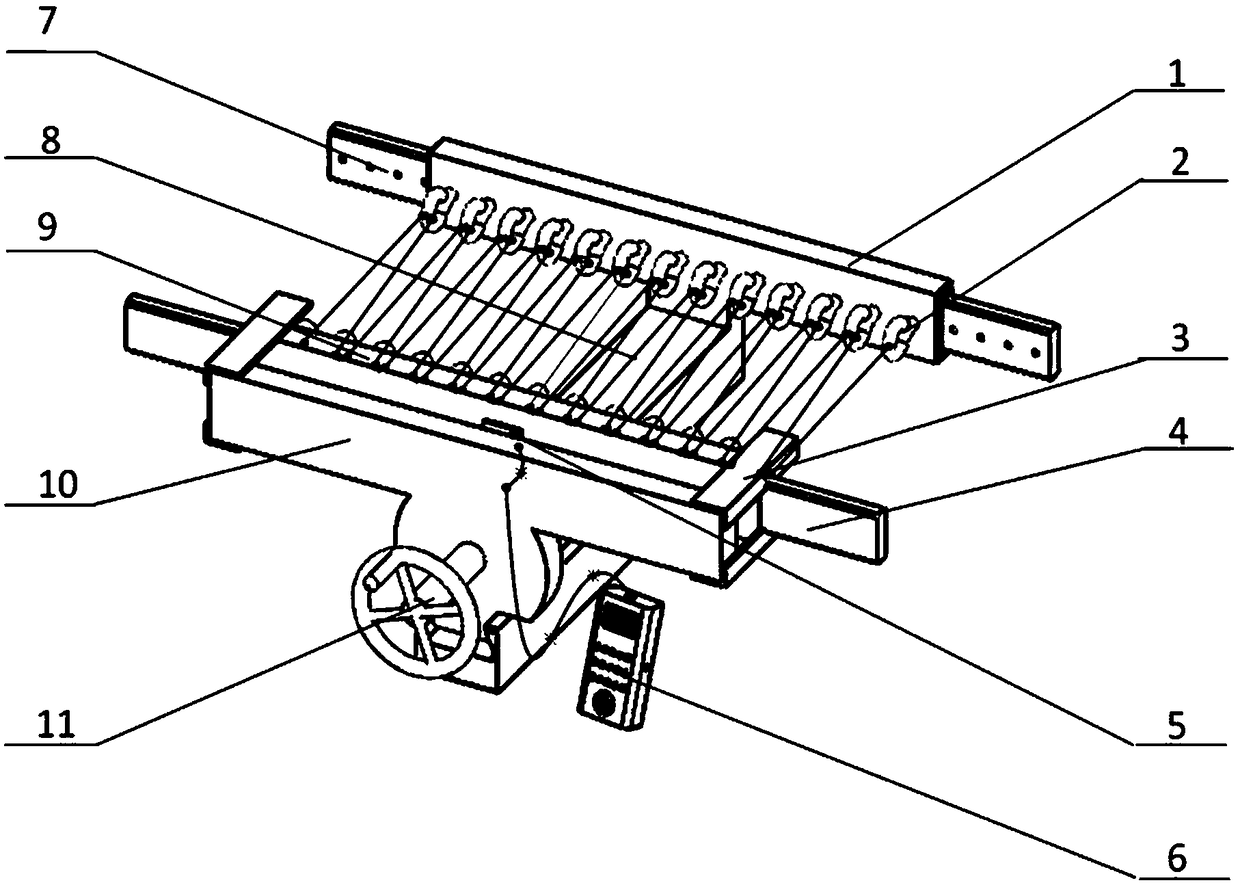

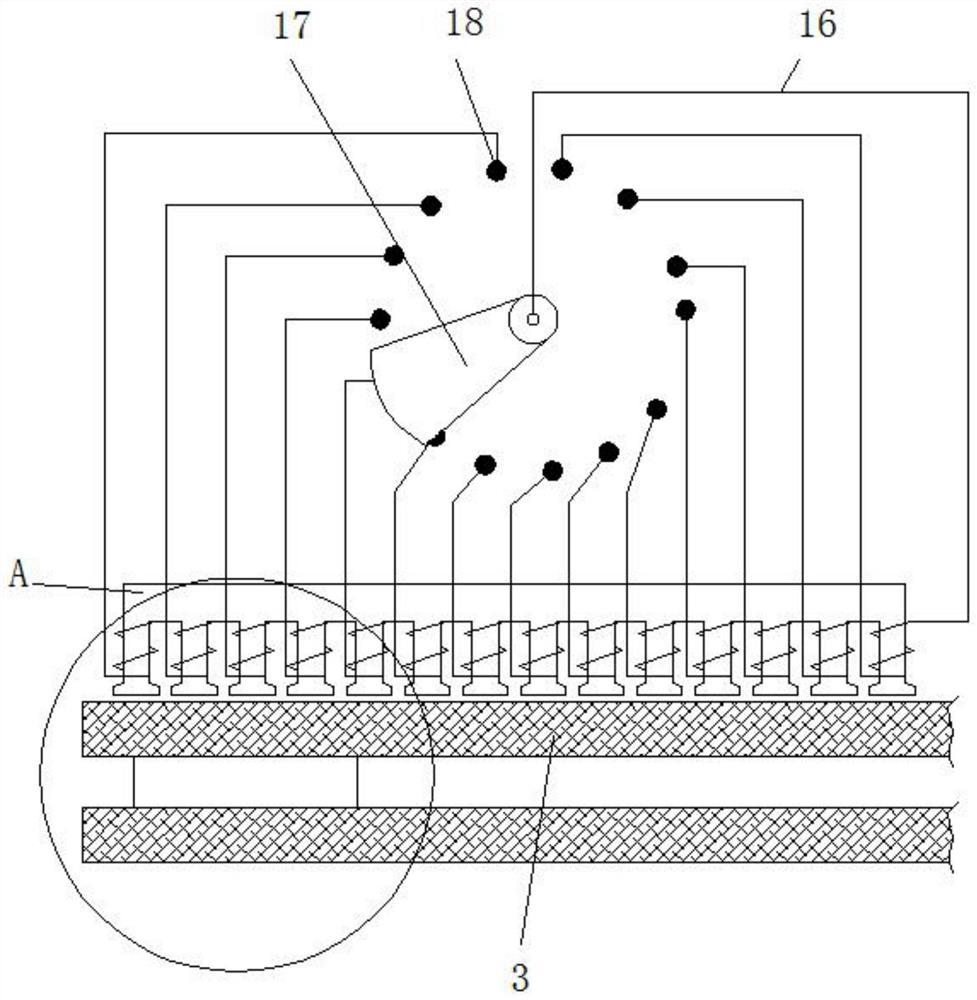

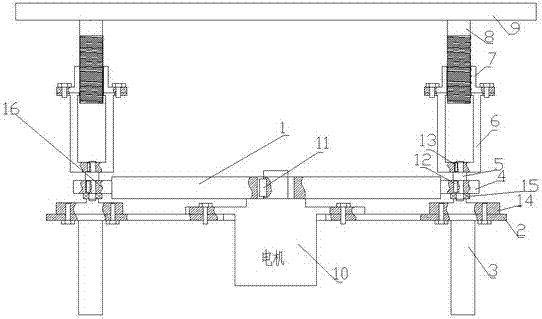

Automatic assembly line of electronic organ and assembly technology thereof

ActiveCN108453502AHigh degree of automationImprove consistencyAssembly machinesEngineeringAssembly line

The invention relates to the technical field of electronic organ assembly, in particular to an automatic assembly line of the electronic organ. The automatic assembly line of the electronic organ comprises a base automatic feeding mechanism, a sound control spring locating silicon rubber sleeve automatic assembly mechanism, a base and circuit board installing mechanism, a mechanical clamping mechanism and a sound control spring automatic feeding and assembling mechanism. The base automatic feeding mechanism comprises a base conveying platform and a base feeding component. The sound control spring locating silicon rubber sleeve automatic assembly mechanism comprises a first workbench, a sound control spring locating silicon rubber sleeve vibrating disk, an automatic assembly component and an automatic oil brushing component. The base and the circuit board installing mechanism comprises a locating installation platform and a locating component. The sound control spring automatic feedingand assembling mechanism comprises a sound control spring feeding component, a sound control spring pushing mechanism and a sound control spring assembling component. The mechanical clamping mechanismcomprises a clamping workbench and a clamping component. The automatic assembly line of the electronic organ completes assembly of one electronic organ, keys, rubber sleeves and sound control springscan be automatically assembled on the circuit board in a one-off manner; and in this way, the production efficiency is improved, the cost is lowered, and the key rubber sleeves cannot be damaged.

Owner:曾庆芳

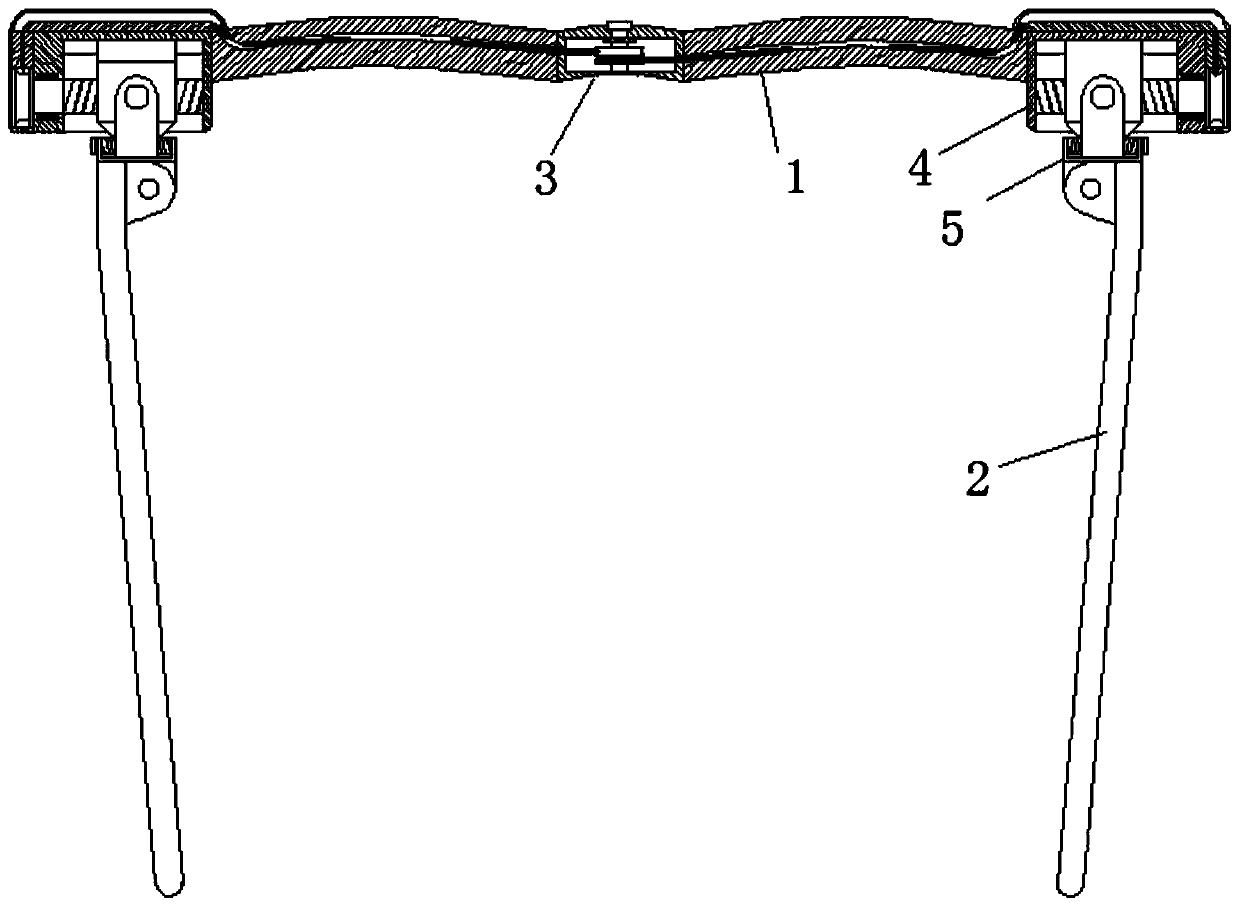

Suspended beam type hanger component and crane using same

Owner:NUCLEON XINXIANG CRANE

Engine air valve locking plate pressure head

InactiveCN101983833AInhibit sheddingPrevent free swingMetal working apparatusInternal pressureSteel ball

The invention discloses an engine air valve locking plate pressure head. A guide positioning shaft, an inner pressure head spring and a positioning shaft spring are arranged in an outer pressure head; a guide screw plug is arranged in an inner hole on the upper part of the outer pressure head, an inner pressure head is arranged in an inner hole on the lower part of the outer pressure head, and the bottom surface of the outer pressure head is provided with a positioning groove; and the peripheral wall of the positioning groove is provided with at least two positioning holes distributed uniformly according to the circumference, a steel ball is arranged in each positioning hole, each steel ball is provided with a reed, the upper part of the reed is fixed with the outer pressure head, and the lower part of the reed is pressed on the corresponding steel bal so that the small part of ball body of the steel ball is positioned in the positioning groove. The engine air valve locking plate pressure head has the advantages of simple operation, low labor intensity of workers and high work efficiency, and is not easy to damage an air valve, an air valve locking plate and an upper spring seat; and the upper spring seat and an air valve rod are positioned more accurately, and the locking plate is pressed in place more easily, so the locking plate is effectively prevented from falling in the running process of an engine, the locking plate is not popped up or inclined, and the assembly efficiency is improved.

Owner:力帆科技(集团)股份有限公司

Piston type compressor and assembling method thereof

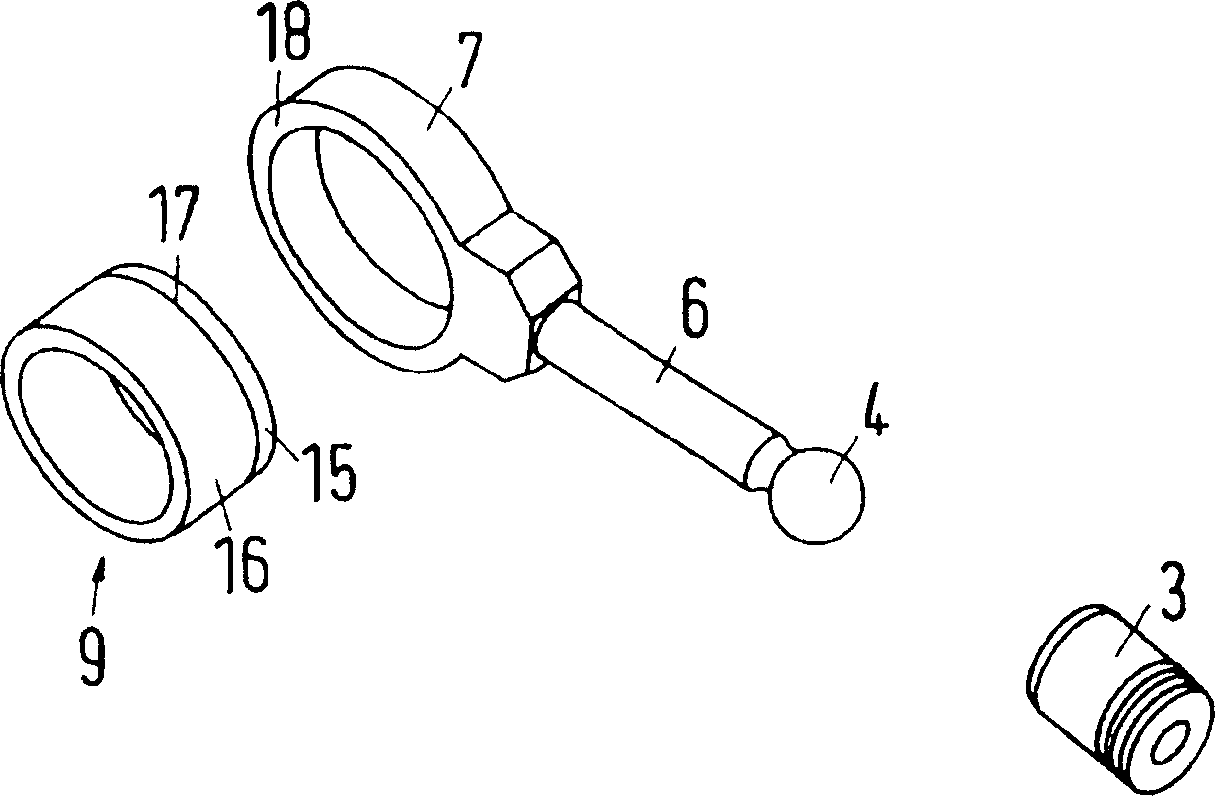

InactiveCN1740565APrecise positioningEasy to assembleConnecting rod bearingsRotary bearingsMechanical engineeringCrankshaft

The piston (3) is moved inside a cylinder of a refrigerant condensing device assembled of a crankshaft with a crank pin accommodated inside an eye (7) at the connecting rod (6) and a bearing bush (9) between the pin and the eye (7). The outer surface of the pin and the inner surface of the eye (7) are asymmetrically arranged. The outer surface of the bearing bush (9) is divided into a shallow sliding segment (15) and a higher main segment (16) facilitating a convenient positioning before the final pressing.

Owner:SECOP GMBH

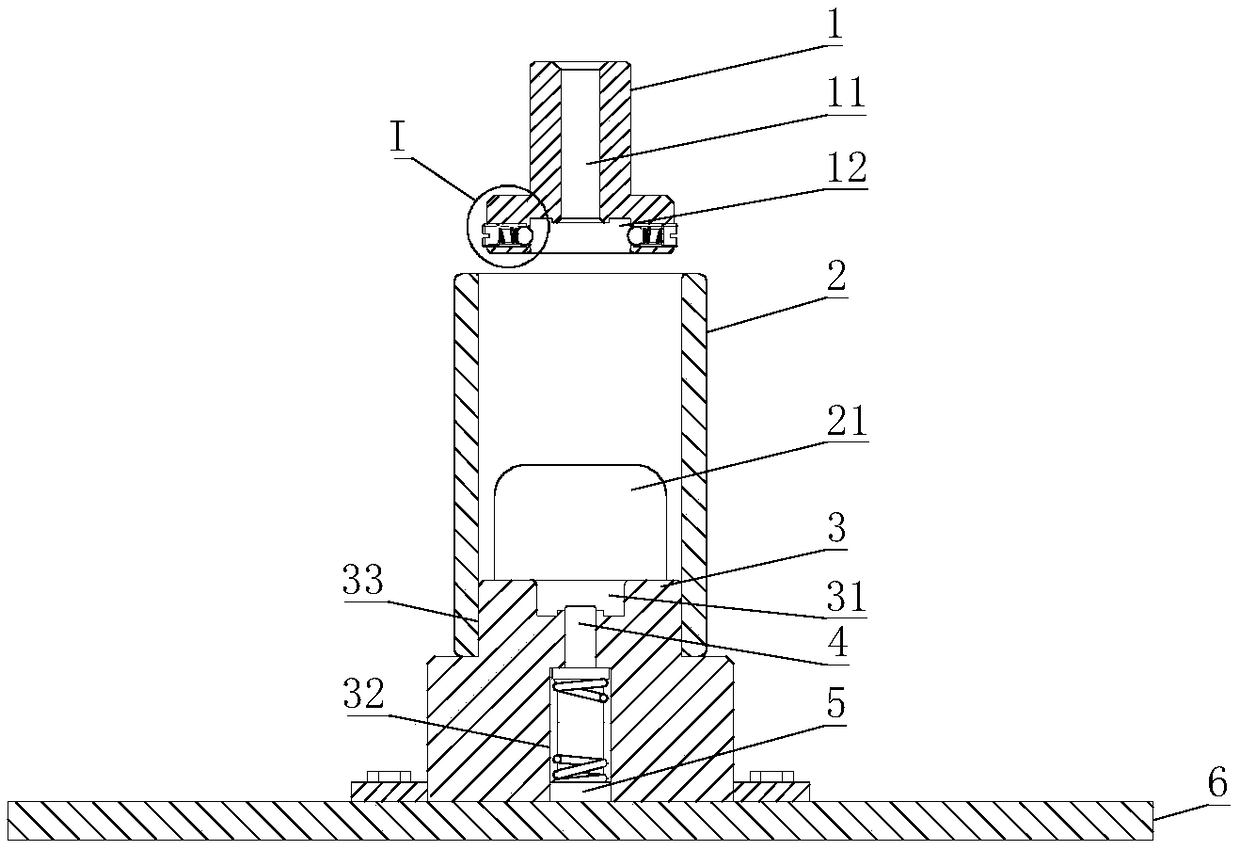

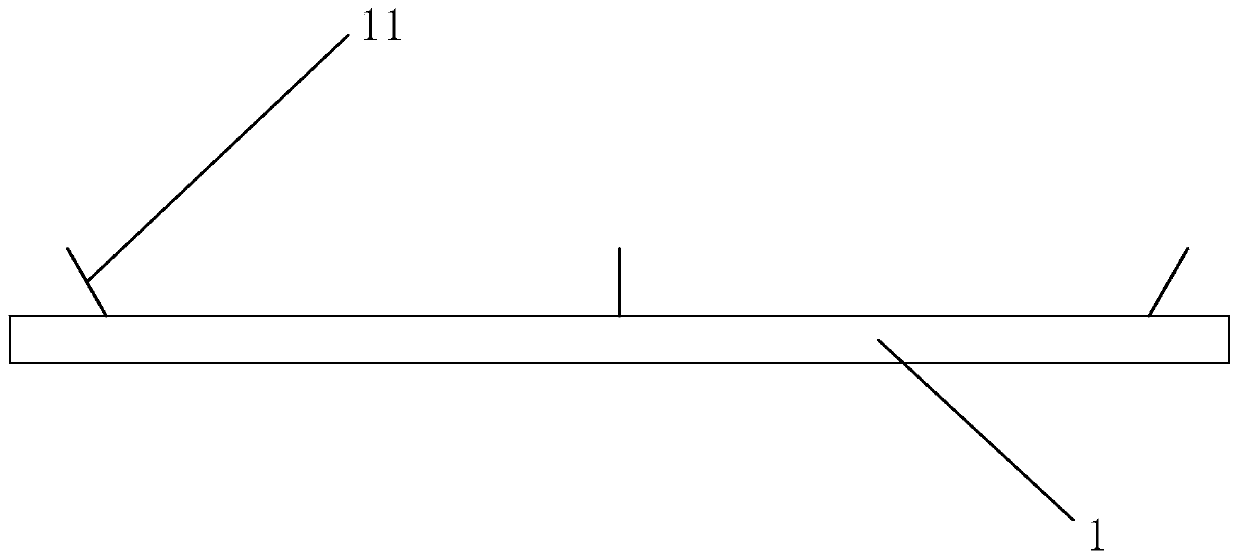

Clamping device of optical detector

InactiveCN101696927ASolve the problem of not being able to touch the PCB boardLimit range of movementMaterial analysis by optical meansInductorBiomedical engineering

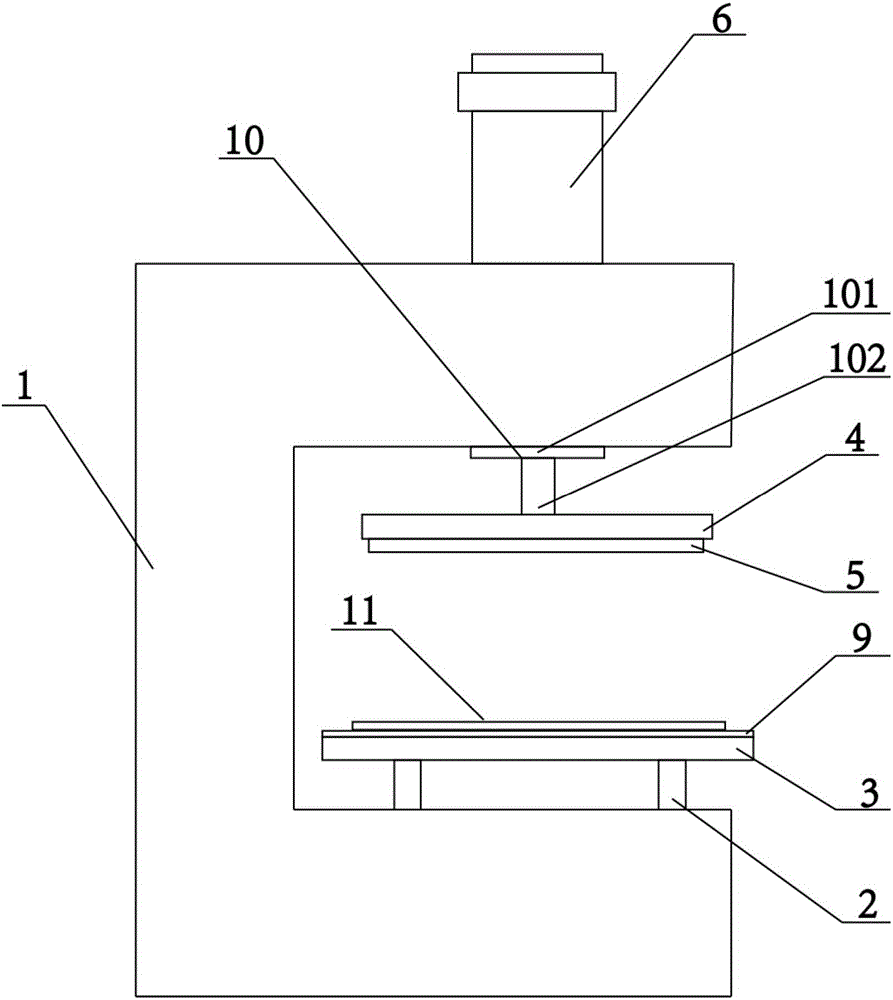

The invention discloses a clamping device of an optical detector, which comprises a clamp body (1), a clamp plate (2) positioned on the clamp body (1), a cylinder (3) on the clamp plate (2), and a baffle plate (7) and an inductor (8) which are positioned on the clamp body (1). The top of the clamp body (1) is step-shaped, the clamp plate (2) has a reverse L-shape inosculated with the top of the clamp body (1) and is contacted with the top and one side of the clamp body (1). The clamping device of the optical detector has the advantages of automatically positioning and clamping workpieces; and meanwhile, a spring and a spring seat are increased so as to play a role in buffering when the clamp plate presses the workpieces, a PCB is not damaged, and the design of the step-shaped clamp body can prevent the PCB from deflecting so as to improve the positioning precision.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

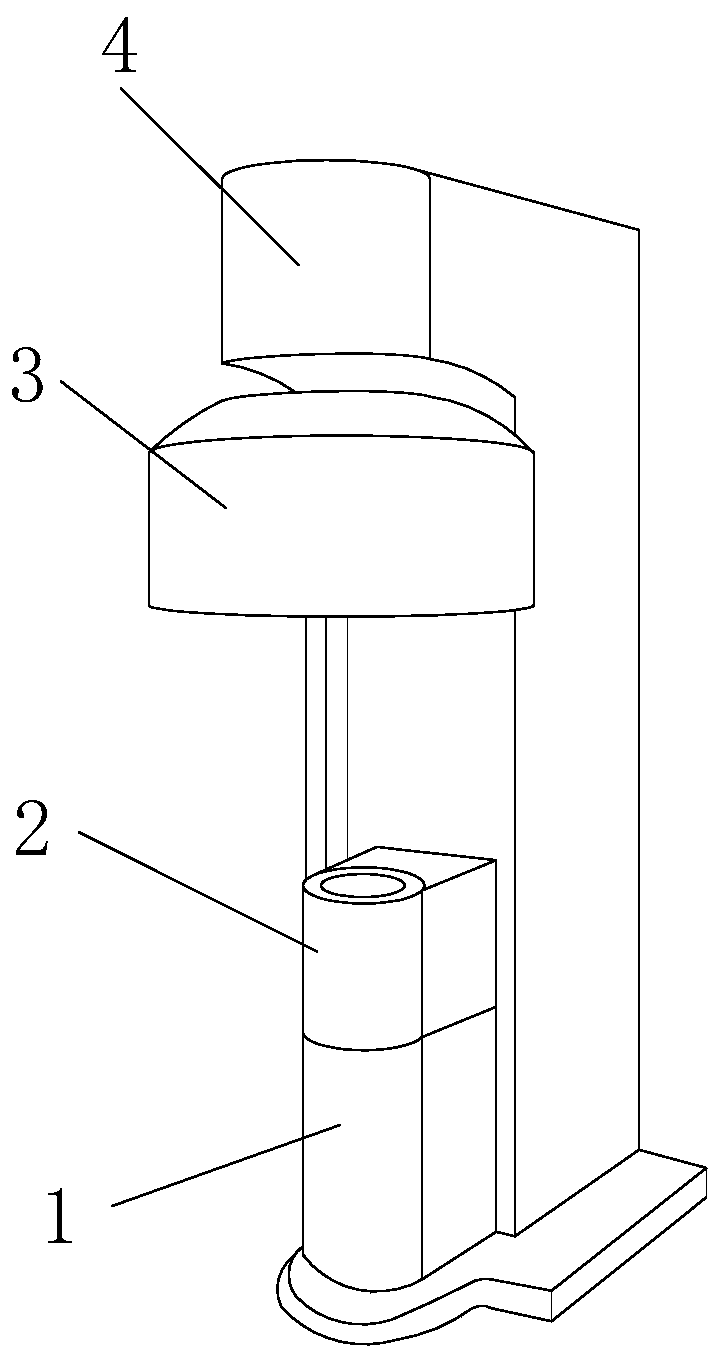

Tool for press fitting of motor rotor bearing

The invention relates to a tool for press fitting of a motor rotor bearing, and belongs to the technical field of motors. The tool for press fitting of the motor rotor bearing comprises a pressing head, a positioning part and a base, wherein a boss is arranged on the base, a groove B is coaxially arranged in the boss, the shape and size of the boss are consistent with those of an inner cavity of the positioning part, one end of the positioning part sleeves the boss, a groove A is formed in the pressing head, a through hole is coaxially formed in the groove A, and the pressing head is placed outside the positioning part. The tool is simple in structure, easy and convenient to operate, high in positioning precision, stable and reliable. A motor rotor does not incline, and the bearing in thepressing head and the base can be pressed on a middle shaft of the rotor at the same time, so that the efficiency is high. By means of a steel ball in the pressing head and a top column in the base, the coaxiality of the bearing and the middle shaft of the rotor during press fitting is effectively ensured, and the press fitting precision is high.

Owner:GUIZHOU HUAFENG ELECTRICAL APPLIANCES

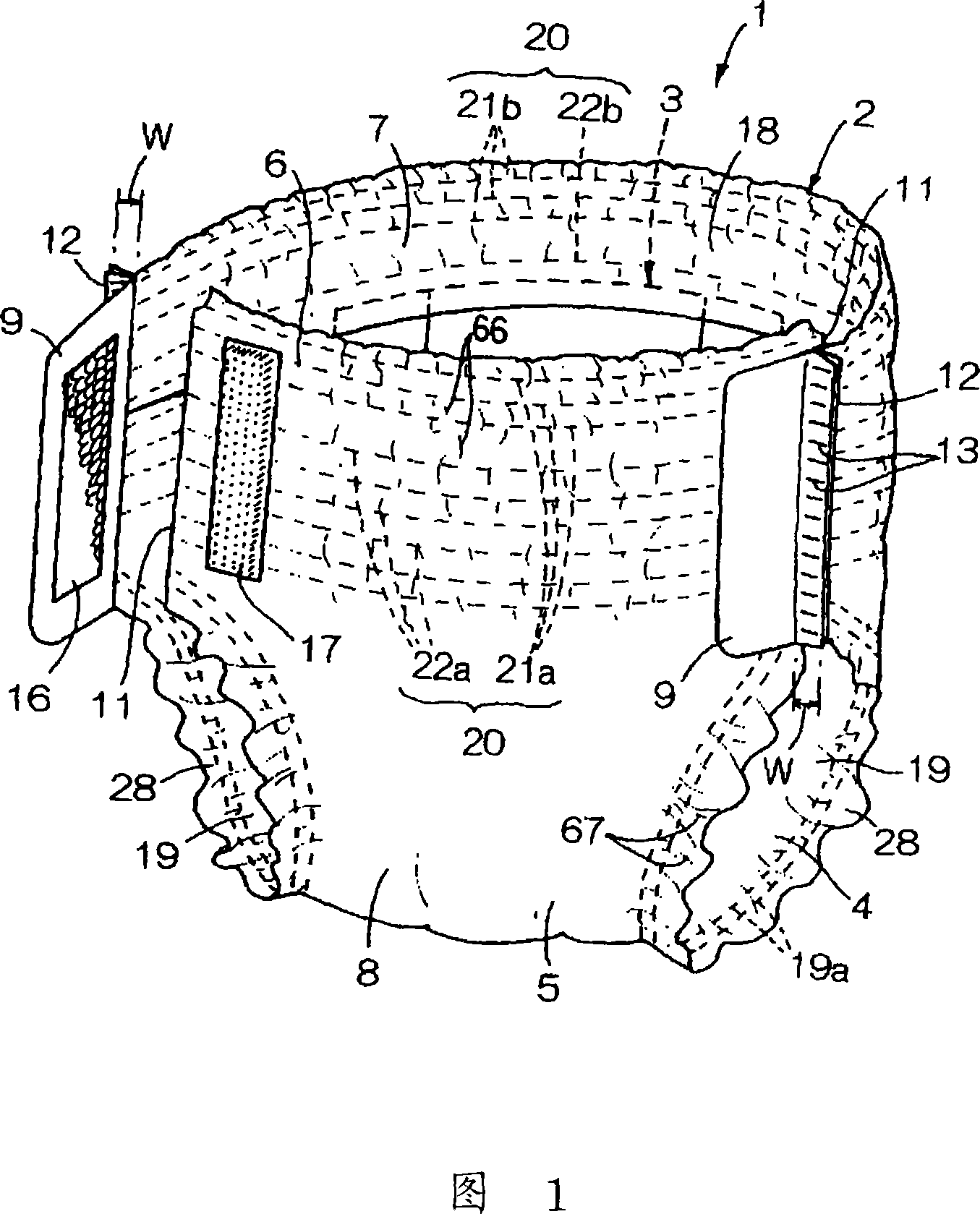

Method of manufacturing disposable wearing article

In a process for making disposable wearing article, a composite web running in a machine direction is formed with a pair of rectilinear slits extending in a cross direction and a notch intersecting these paired slits. A region surrounded by these slits and notch is cut away from the composite web to form a gap. In a step before the composite web is formed with the gap, second fastener means supported on a fastener base sheet strip are engaged with the associated pair of first fastener means previously bonded to the composite web opposed to each other about the gap as viewed in the machine direction and thereby the fastener base sheet strip is attached to the composite web so as to stride over the gap.

Owner:UNI CHARM CORP

Glasses with adjustable glasses legs and using method thereof

The invention relates to the field of glasses, in particular to glasses with adjustable glasses legs and a using method thereof. The glasses comprise a glasses frame and glasses legs, width adjustingmechanisms used for adjusting the widths of the two glasses legs are arranged at the two ends of the glasses frame, angle adjusting mechanisms used for adjusting the included angles of the glasses legs are arranged on the width adjusting mechanisms, glasses leg fixed shafts are rotationally connected to the angle adjusting mechanisms, and clamping mechanisms used for locking the width adjusting mechanisms are arranged at nose pads in the middle of the glasses frame. According to the glasses with the adjustable glasses legs and the using method thereof, the width of the glasses legs can be adjusted, the adjusting process is easy to operate, the wearer can select the glasses or adjust the glasses under different conditions, the inclination angles of the glasses legs and the glasses frame canbe adjusted through the angle adjusting mechanisms, the adjusting process is simple and convenient to operate, and the glasses are convenient for wearers with different head side faces to use.

Owner:瑞安市登第门教育科技有限公司

Labeling device for corrugated carton production and label detection mechanism thereof

InactiveCN112591248AImprove labeling efficiencyAvoid affecting the efficiency of subsequent processingLabelling machinesSuction forceClassical mechanics

The invention relates to the field of corrugated carton production, in particular to a labeling device for corrugated carton production and a label detection mechanism thereof. The labeling device comprises a device body, a limiting device is movably installed on the left side in the device body, a conveying belt is movably installed at the lower end in the device body, a movable frame is movablyinstalled on the left side of the upper end in the device body, a guiding device is movably installed at the lower end of the movable frame, a labeling device is movably installed on the right side ofthe movable frame, an air extractor at the upper end of the exterior of the device body is connected with the interior of an air suction cavity through a pipeline, an air suction channel on the labeling device can generate inward suction force, and therefore the non-sticky side of a label scraped off by a guiding roller is sucked, when the labeling device drives the label to rotate, the label canmake contact with a corrugated carton on the conveying belt, the automatic labeling effect is achieved, the outer end of the air suction channel is obliquely arranged towards the two sides, the contact area of suction force in the air suction channel and the label can be increased, and therefore the stability when the label is driven to move is improved.

Owner:浙江骏驰纸制品有限公司

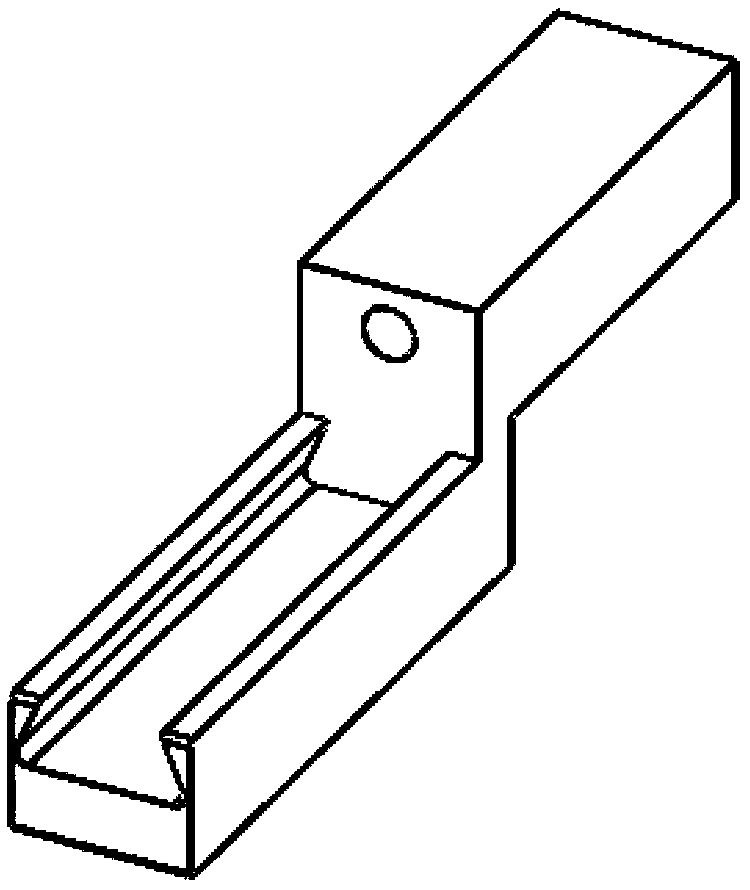

Portable device for preparing fiber reinforced composite material and using method of device

The invention provides a portable device for preparing a fiber reinforced composite material and a using method of the device. One side face of a fixed support plate and one side face of a movable support plate are opposite; threaded holes uniformly distributed are formed in each of the opposite side faces of the fixed support plate and the movable support plate; all the threaded hole in the fixedsupport plate and the movable support plate are corresponding pairwise in position; each pull ring is provided with threads; the pull rings are fixed by the corresponding threaded holes in the fixedsupport plate and the movable support plate; an opening is formed in each of pairwise opposite ends of the pull rings; and the openings are used for twining a fiber material. The device provided by the invention is simple in structure, low in manufacturing cost, has a low demand on the operating skill of operating personnel, and is easy to use; processing can be performed as needed according to different specifications; an electromagnetic inductor is capable of accurately controlling sensitivity and the force measuring range of the device, so that error brought by the device is reduced; distribution of an internal force is more uniform after the material is molded by the device, so that mechanical property of the material is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

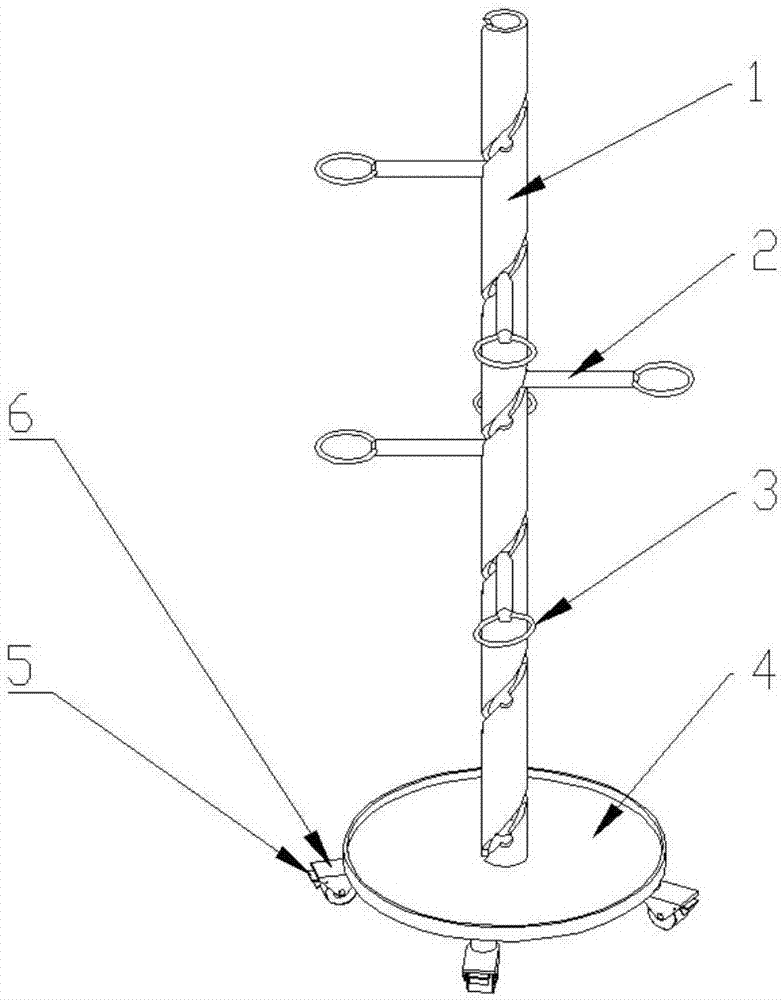

Flowerpot frame capable of rotating, lifting and falling

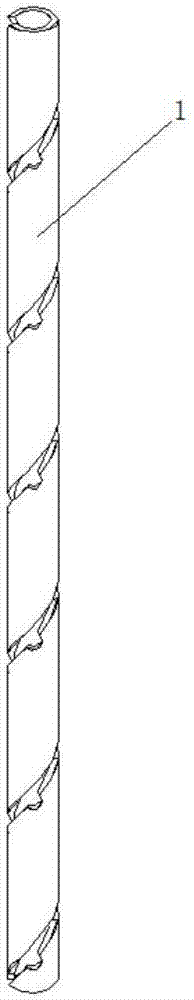

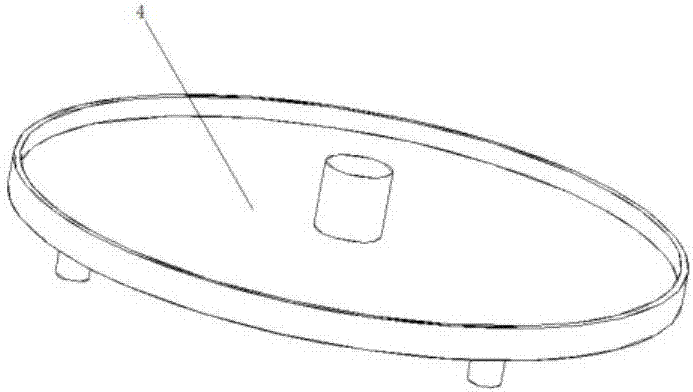

The invention discloses a flowerpot frame capable of rotating, lifting and falling. The flowerpot frame comprises a main rod of a hollow structure, a base is arranged at the bottom of the main rod, and is of a round disc shaped structure, a universal wheel is installed below the base, the portion, from the top to the bottom, of the main rod is provided with a slideway in a spiral mode, the slideway is internally provided with supporte capable of moving along the slideway up and down, the supports is used for placing the flowerpot frame, the slideway is internally provided with semicircular hole grooves at intervals, the support is arranged in the hole grooves, is used for fixation, and comprises several transverse rods, one end of each transverse rod is arranged in the slideway, and a ring used for placing a flowerpot is arranged at the other end of each transverse rod. The flowerpot frame capable of rotating, lifting and falling is novel and attractive in structure, makes it convenient for a user to care flowers, and has the advantages of being novel in design, convenient to move, flexible, stable and the like. The whole structure is simple, reasonable and easy to achieve, and the flower frame capable of rotating, lifting and falling can be widely applied to life occasions.

Owner:YULIN UNIV

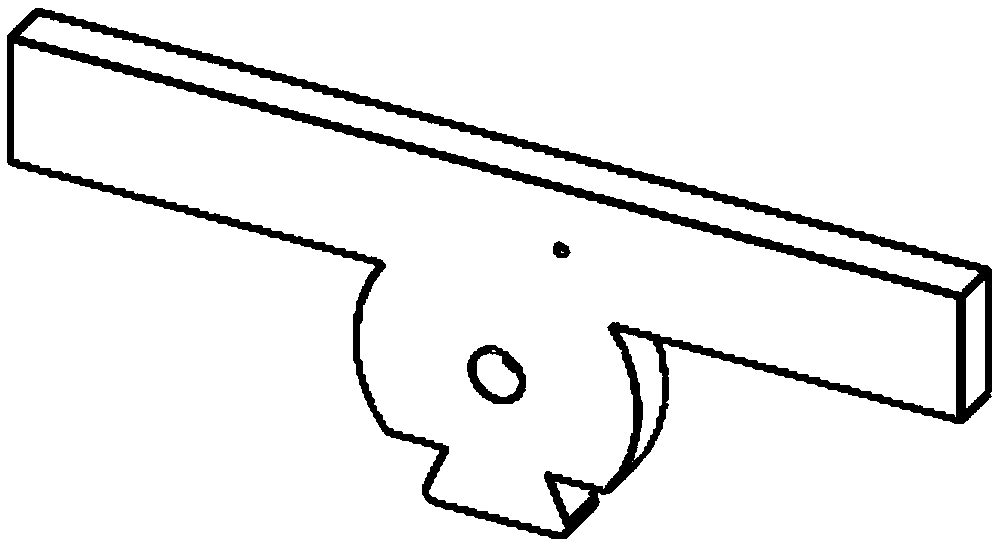

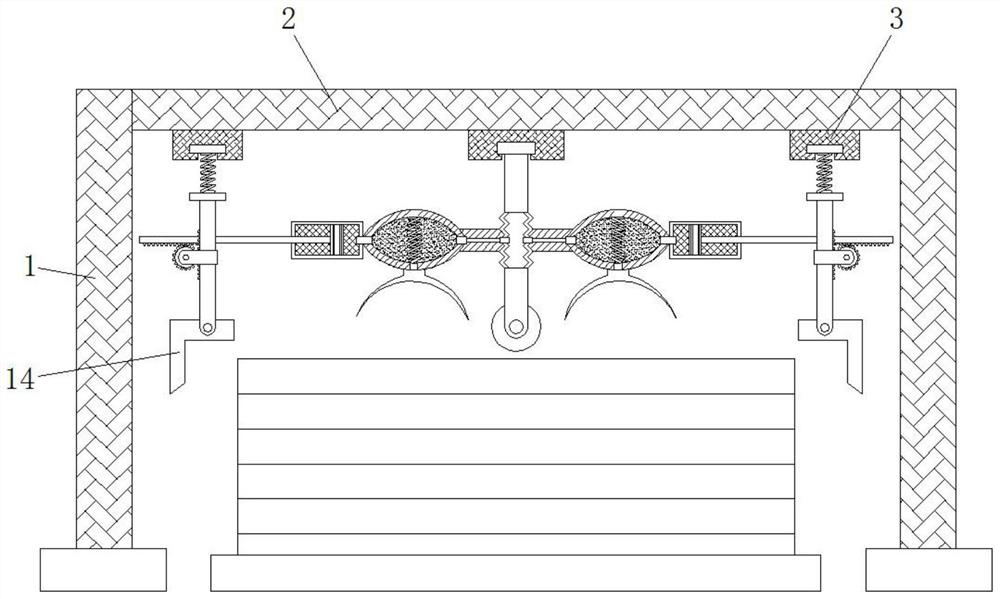

Rapid and efficient bamboo hot-pressing propelling device

InactiveCN112060255AWon't skewSolve the problem of uneven susceptibilityWood compressionCane mechanical workingCompression deviceEngineering

The invention relates to the technical field of hot-pressing auxiliary devices, and discloses a quick and efficient bamboo hot-pressing propelling device. The quick and efficient bamboo hot-pressing propelling device comprises a support, a workbench is fixedly connected to the top end of the support, a sliding groove is fixedly connected to the bottom end of the workbench, a sliding block is slidably connected into the sliding groove, a compression device is fixedly connected to the outer side of the sliding block, a pressing block is rotatably connected to the bottom end of the sliding block,a connecting pipeline is fixedly connected to the outer side of the compression device, an air bag is fixedly connected to the outer side of the connecting pipeline, and a vacuum sucker is fixedly connected to the outer side of the air bag. According to the rapid and efficient bamboo hot-pressing propelling device, through connection of the support and the pressing block, rapid propelling of a bamboo plate is achieved, and the problem that according to an existing hot press plate-dividing propelling device, a telescopic rod is used for propelling a plate, and uneven stress is prone to happening is solved, bamboo cannot incline, a hot-pressing process is facilitated, practicability is high, reliability is high, and propelling of the bamboo plate is facilitated.

Owner:江西安竹科技有限公司

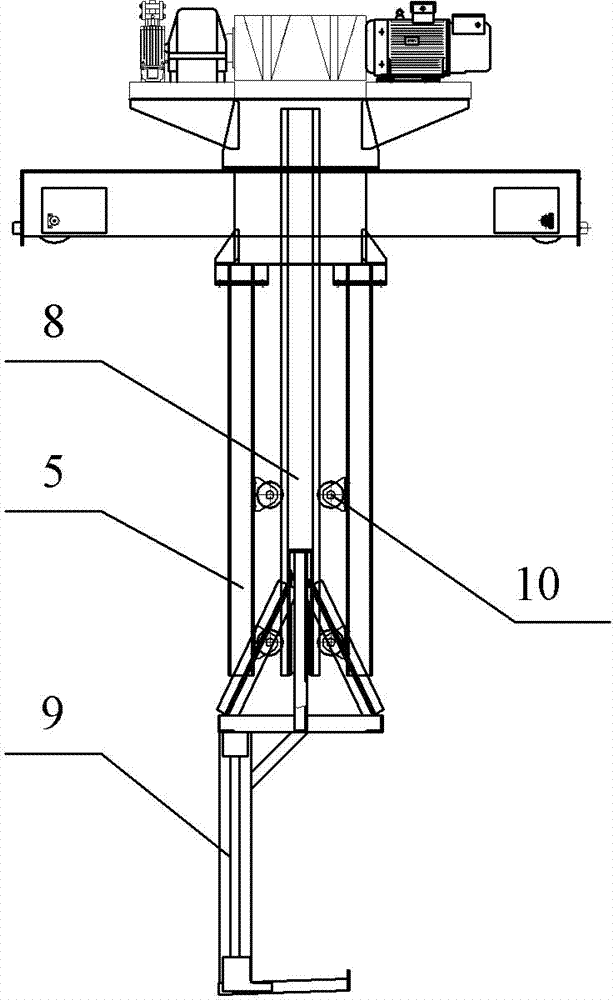

Spiral lifting device for building construction

The invention relates to a spiral lifting device for building construction, which includes a workbench, a column, a lower base plate, and a secondary transmission device. It includes a motor, a large gear, a small gear, a base, a shaft, a transmission rod, an externally threaded rod, and an internally threaded rod. The motor is arranged on the upper part of the lower bottom plate and connected by bolts. The large gear and the motor are connected by a large flat key. The base is arranged on the top of the lower bottom plate and Connected by bolts, the shaft is set in the inner hole of the pinion and connected by a flat key, the pinion is set on the upper end of the base and connected by a bearing, the transmission rod is set at the lower end of the internal threaded rod and connected by bolts, and the external threaded rod is set The periphery of the internal threaded rod is connected by threads. The invention has the advantages of reasonable structure, convenient use, good stability, high precision of start-stop control, no skewing, large bearing capacity and long service life.

Owner:CHENGDU LYUDI TECH

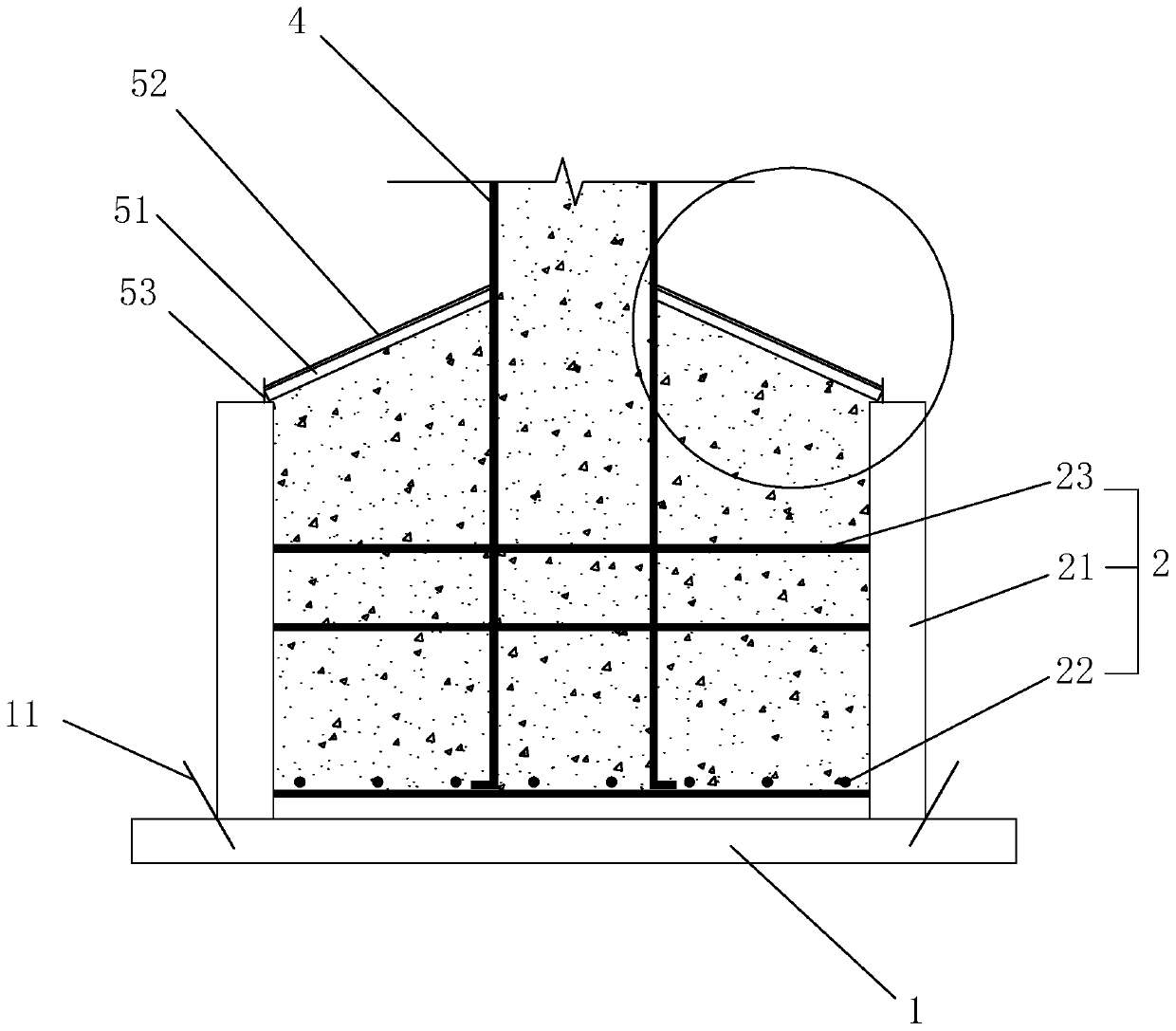

Slope-form independent foundation structure

InactiveCN109763508ASimplify construction stepsEasy to pourFoundation engineeringMesh reinforcementEngineering

The invention relates to a slope-form independent foundation structure. The slope-form independent foundation structure comprises a prefabricated frame body, a cast-in-place body and a column rebar; the prefabricated frame body comprises a surrounding side plate, a foundation bottom mesh reinforcement and a middle tie bar; a cushion layer is arranged under the prefabricated frame body; a locatingreinforcement stick of which the end surface is inclined outwards is arranged on the cushion layer; and a baffle reinforcement is pre-embedded in the side plate of the prefabricated frame body to be connected with a slope surface template. The slope-form independent foundation structure provided by the invention has the advantages that the construction procedure is simplified, the construction efficiency is enhanced, and the construction time is saved.

Owner:XIAN COAL CONSTR ENG

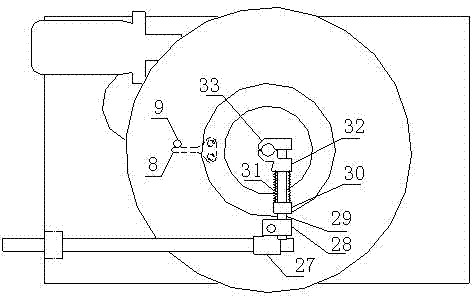

Oxygen torch sealing machine

The invention discloses an oxy-hydrogen torch sealing machine, belongs to the technical field of sealing-in of quartz glass materials, and mainly solves the problems that the sealing-in quality is affected and an air source is wasted due to a manual operation. The oxy-hydrogen torch sealing machine is mainly characterized by comprising a fixed bottom plate, an upright post pipe, a rotary sleeve, a rotary disk, a large belt wheel, a small belt wheel, a worm gear reducer, a gas distribution base, an adjusting seat plate, a lifting poker sleeve, a lifting poker, an adjusting screw, a clamping block, an oxy-hydrogen lance, a gas pipe, an oxygen pipe, a sealing seat, a sealing seat hinge, a sealing seat jack screw, a sealing seat rotating plate, a sealing seat screw, a sealing seat chuck, a sealing seat nut, a sealing seat fixing fork plate, the upright post pipe, a single-arm pipe, a block A, a block B, a large tension rod, a large block C, a spring, a large block A, and a large block B. The oxy-hydrogen torch sealing machine has the characteristics of being high in automatic degree, safe and reliable, can be used for carrying out sealing-in aiming at different specifications of quartz glass tubes, and is mainly applied to vacuum sealing of the quartz glass tubes.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Energy-saving underground comprehensive pipe rack and comprehensive pipe rack system

ActiveCN111608201AReduce bumpy feelingReduce vehicle damageArtificial islandsLighting and heating apparatusDrive motorEngineering

The invention relates to an energy-saving underground comprehensive pipe rack. The energy-saving underground comprehensive pipe rack comprises a pipe rack main body which is located below a road and extends in the length direction of the road; a plurality of bases are fixed to the lower end surface of a top plate of the pipe rack main body; the bases are rotatably connected with a plurality of rotating shafts with horizontally set axes; fan blades coaxially rotate with the rotating shafts; exhaust pipes which are connected with the fan blades in a sleeving manner are also suspended on the piperack main body; two ends of each of the exhaust pipes respectively communicate with the interior and the exterior of a pipe rack; a plurality of speed reducing blocks slide up and down on the upper end surface of the road; the lower end surfaces of the speed reducing blocks are connected with gear racks which penetrate through the top plate; the rotating shafts are connected with gears which areengaged with the gear racks in the sleeving manner; unidirectional rotating devices are arranged between the gears and the rotating shafts; resetting devices for jacking up the speed reducing blocks are arranged between the speed reducing blocks and the road; the speed reducing blocks drive the fan blades to rotate when slide downward. By adopting the technical scheme, the use of a driving motor is reduced compared with the prior art; moreover, power does not need to be supplied in a subsequence using process; the energy-saving underground comprehensive pipe rack is low in cost and energy-saving, and is more friendly to the ecological environment.

Owner:广州市黄埔建筑工程总公司

Medicinal solid screening device for removing metal powder

The invention discloses a medicinal solid screening device for removing metal powder. The medicinal solid screening device comprises a device body, wherein a cavity is formed in the device body, a third-stage screening mechanism is arranged in the cavity, the three-stage screening mechanism moves up and down in the cavity through a transmission mechanism, the third-stage screening mechanism is used in cooperation with the transmission mechanism, and the transmission mechanism can drive the three-stage screening mechanism to move up and down, so that the manual shaking action of a professionalpharmacist is simulated, and the discharging quality of the three-stage screening mechanism is high; and first openings are formed in the two sides of a surrounding frame plate in a penetrating mode,and the left end and the right end of a first pharmacopeia screen are respectively inserted into the two first openings, a second pharmacopeia screen is arranged below the first pharmacopeia screen, and after being screened, coarse materials are located on the first pharmacopeia screen, medium materials are located on the second pharmacopeia screen, and fine materials are located in a material receiving tray, and the first pharmacopeia screen, the second pharmacopeia screen and the material receiving tray form a three-stage material distribution.

Owner:全椒倚天机械制造有限公司

Angle-adjustable clamping mechanism

InactiveCN112428187APracticalEasy to fixWork holdersWork benchesStructural engineeringMechanical engineering

The invention discloses an angle-adjustable clamping mechanism, and relates to the technical field of glass production equipment. The angle-adjustable clamping mechanism comprises a placing plate anda base arranged on the bottom of the placing plate, wherein an adjusting plate is fixedly connected on the side wall of the placing plate; the top of the adjusting plate is fixedly connected to a U-shaped rod; I-shaped blocks are in sliding connection onto the side walls, close to each other, of the U-shaped rod; fixed blocks are fixedly connected on the side walls of the I-shaped blocks; fixed parts are arranged on the side walls of the fixed blocks; the bottom of the placing plate is fixedly connected to two rotary rings and four mounting plates; rotary holes are uniformly formed in the sidewalls of the two rotary rings; the top of the base is fixedly connected to a large slide ring, a small slide ring and a supporting column; and a connecting slot is formed in the top end of the supporting column. The angle-adjustable clamping mechanism is reasonable in structure, can adjust the angle, can stably fix glass, and is more convenient for glass detection by staff.

Owner:含山县龙顺机械配件厂

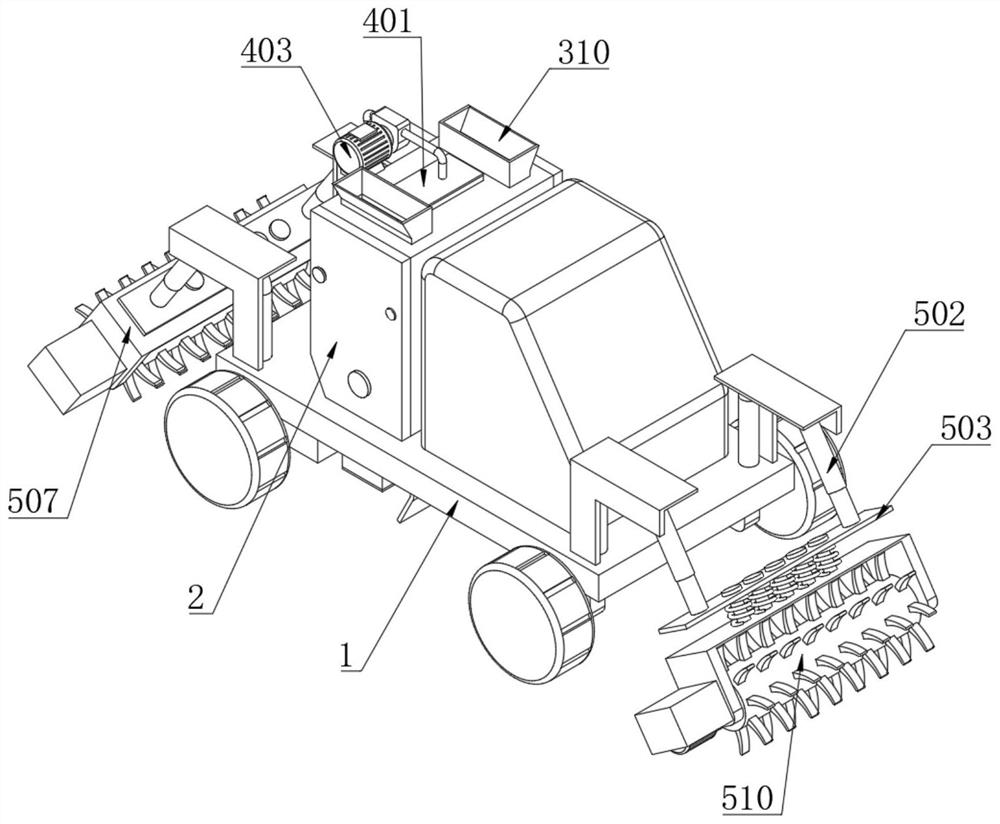

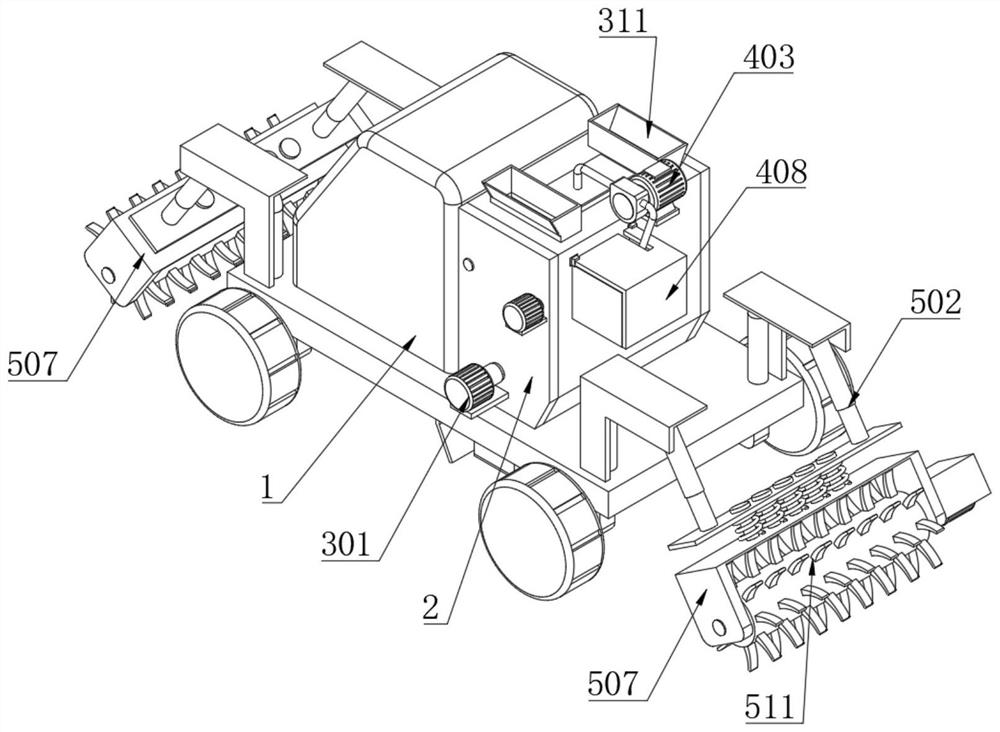

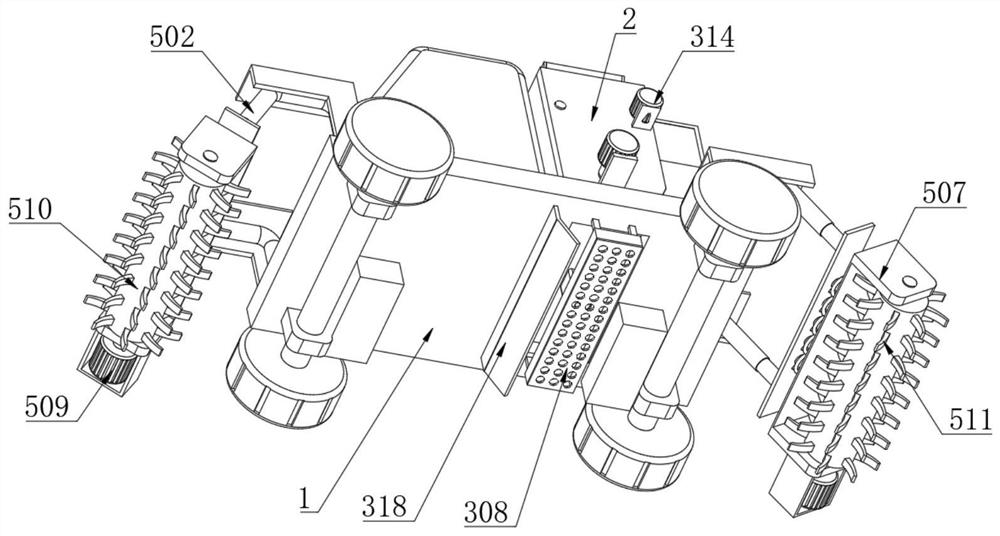

Soil quality conditioning device for medium and low yield fields

InactiveCN113924838AScientific and reasonable structureEasy to useSoil lifting machinesLiquid spraying apparatusSoil scienceElectric machinery

The invention discloses a soil quality conditioning device for medium and low yield fields. A stirring motor is fixedly mounted at one end of the bottom of a storage box, an output shaft of the stirring motor is fixedly connected with a stirring shaft, stirring blades are fixedly mounted on the surface of the stirring shaft at equal intervals, one end of each stirring blade is fixedly connected with a cleaning soft brush, and a filter screen is mounted in the middle of the bottom end of the storage box in an embedded manner. A conditioner used for soil quality conditioning can be conveniently treated, when water and a conditioner enter the storage box, the stirring motor drives the stirring shaft and the stirring blades to rotate, and the water and the conditioner are stirred and mixed to be uniform, so that conditioner can be uniformly fused in water to form a medicament, a discharge pump downwards discharges the mixed medicament into a flow dividing box body, when a construction vehicle walks in a field, the medicament can be uniformly sprayed into soil of the field through spraying holes, the polluted and damaged soil is conditioned, the soil quality and nutrients are recovered, the yield of crops in the field is improved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Surface treatment device for aluminum coil

ActiveCN110293146AImprove efficiencyImprove alignment accuracyCleaning using toolsCleaning using liquidsEngineeringEnergy consumption

The invention provides a surface treatment device for an aluminum coil, belongs to the technical field of machinery, and solves the technical problems that an existing aluminum coil is not convenientto replace and energy consumption is high during processing. The surface treatment device for the aluminum coil comprises a machine frame, wherein an input mechanism for inputting the aluminum coil ina strip shape, a cleaning mechanism for cleaning the surface of the aluminum strip, a removing mechanism for removing substances on the surface of the aluminum strip and a winding mechanism for winding the aluminum strip in a roll shape are sequentially arranged on the machine frame; a plurality of auxiliary rollers for conveying the aluminum coil strip are rotatably arranged on the machine frame; the removing mechanism comprises an upper driving motor, a lower driving motor, a first rotating frame, a second rotating frame, a first brush roller, a second brush roller and a first motor; the lower driving motor and the upper driving motor are fixed on the machine frame; the first rotating frame and the second rotating frame are rotatably arranged on the machine frame; and an output shaft ofthe upper driving motor is connected with the first rotating frame and can drive the first rotating frame to rotate. The surface treatment device has the advantages of convenient aluminum coil replacement and energy saving during processing.

Owner:徐州汉裕铝业股份有限公司

Novel production technology and equipment for tableware bag

InactiveCN105905365AWon't skewReduce labor intensityWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention relates to the technical field of production equipment for tableware bags, in particular to a novel production technology and equipment for tableware bags. The equipment comprises a frame, a support, a bottom plate, an electric heating plate, a heat seal plate and a cylinder, wherein a plurality of projections are arranged on the heat seal plate; the adjacent projections are distributed in a surrounding manner to form a processing region; and the shape of the processing region is matched with the shapes of the tableware bags to be processed. The invention provides the novel production technology and equipment for the tableware bags, the projections of which the shapes are consistent with the shapes of the outsides of the tableware bags are arranged on the heat seal plate, and therefore, a plurality of tableware bags can be processed at a time. Compared with the traditional manual adhesion method, the equipment is safe and sanitary, and is high in processing and production efficiency, and the labor intensity of workers is reduced. By the doubling-up and double-edge-sealing heat seal production technology carried out by the equipment, drawbacks of doubling up bottom side edges of a traditional tableware bag to seal edges are overcome. By the production technology, production materials can be saved, obtained products are stiff and smooth and do not have wrinkles, tableware cannot deflect in the tableware bags, and therefore, the tableware bags are attractive in appearance.

Owner:石峰

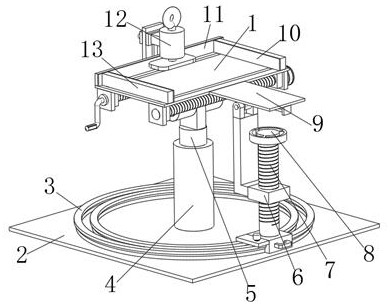

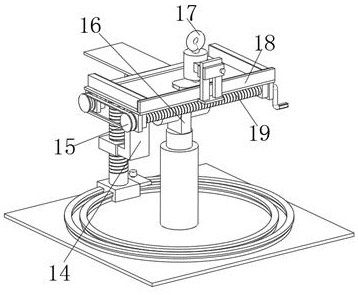

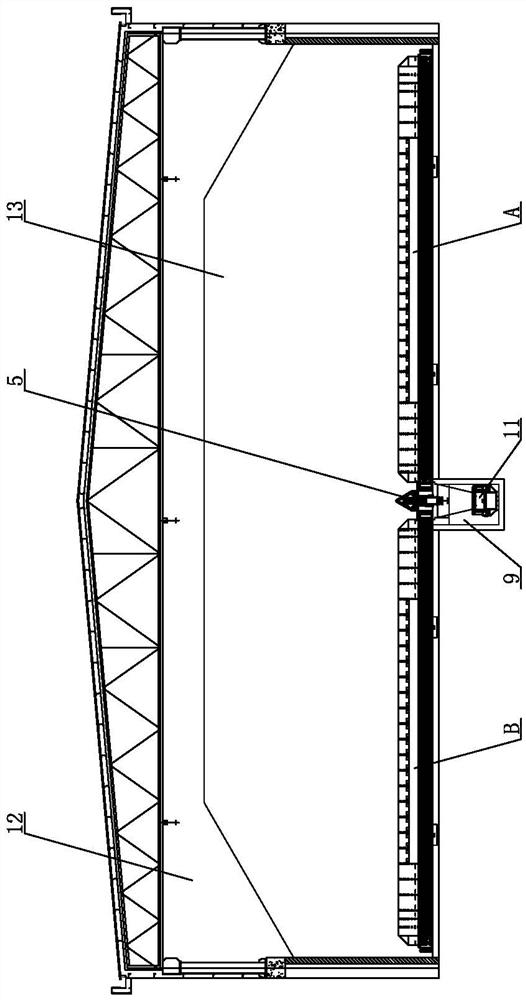

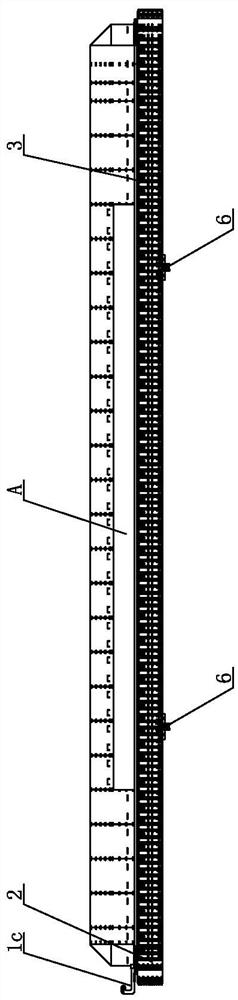

a warehouse machine

Owner:MYANDE GRP CO LTD

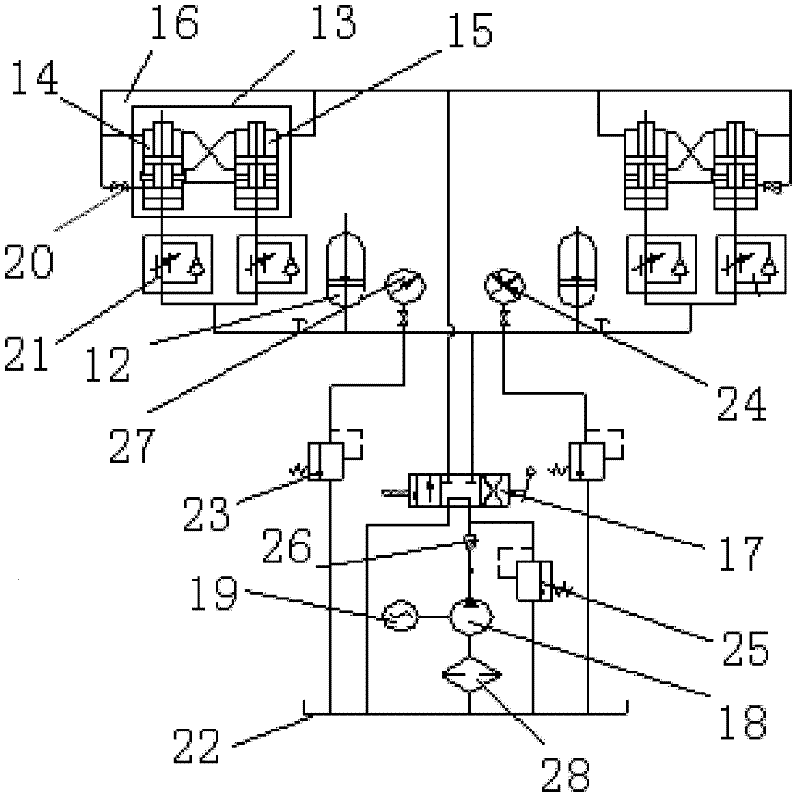

Crushing machine, hydraulic control system and hydraulic cylinder

InactiveCN102392842AReduce noiseImprove crushing qualityFluid-pressure actuatorsGrain treatmentsControl modeLow noise

The invention provides a crushing machine, a hydraulic control system and a hydraulic cylinder thereof. The hydraulic cylinder comprises a cylinder barrel, a guide sleeve and a piston rod, wherein the cylinder barrel comprises a first barrel body and a second barrel body; the first end of the first barrel body is connected to the first end of the second barrel body; a separating sleeve is arranged between the first end of the first barrel body and the first end of the second barrel body; the guide sleeve is arranged at the second end of the second barrel body; the piston rod is arranged in a cavity which is formed by the cylinder barrel and the guide sleeve; a first piston and a second piston are arranged on the piston rod at an interval; the separating sleeve is arranged around the piston rod in a sliding sealing manner; and the first piston and the second piston are respectively located on two sides of the separating sleeve. Compared with a mechanical control mode, a hydraulic control mode which is utilized to control a space between rollers in the hydraulic cylinder has the advantages of labor saving, convenience and low noise.

Owner:ZOOMLION HEAVY IND CO LTD

Method for hot-charging for roll skin of loop roll

PendingCN111347217APrecise temperature controlHot loading effect is goodMetal working apparatusTemperature controlEngineering

The invention relates to the technical field of hot-charging for roll skins, and discloses a method for hot-charging for a roll skin of a loop roll. The method for hot-charging for the roll skin of the loop roll comprises the following steps: a fixture table surface is calibrated to be level, the roll skin penetrates through a limit ring on a support rod, and is connected outside a location ring in a sleeving manner and fixed, and the roll skin is wrapped through five crawler-type heaters; the crawler-type heaters are connected with a temperature controller; and meanwhile, a thermocouple is placed at a contact part of each heater and the roll skin. According to the method for hot-charging for the roll skin of the loop roll, the fixture table surface is calibrated to be level, the roll skinpenetrates through the limit ring on the support rod, and is connected outside the location ring in a sleeving manner and fixed, the roll skin is wrapped through the five crawler-type heaters, the crawler-type heaters are connected with the temperature controller, meanwhile, the thermocouple is placed at the contact part of each heater and the roll skin, and after the wrapping is completed, the heaters are wrapped through heat-insulation cotton; and the parameters of the temperature controller are set, a heating process is heating to reach 450 DEG C in 30 minutes, and insulating heat for 2 hours, accurate temperature control during hot-charging and a good hot-charging effect are achieved.

Owner:安徽羿维表面工程技术有限公司

Stabilizing smoothening and rotary grinding device for capacitor tank sealing equipment

ActiveCN110281143AThe core structure is stableGuaranteed aestheticsLapping machinesLapping toolsEngineeringCopper

The invention discloses a stabilizing smoothening and rotary grinding device for capacitor tank sealing equipment. The structure of the device comprises a punching seat, a stabilizing smoothening and rotary grinding device body, a sealing head and a machine body. According to the device, a multi-rail plate is driven to rotate through a floating shaft rounding about a grooved pipe, and thus force is stored in a guide plate; air pressure in the guide plate increases to push a pneumatic rotating wheel to drive a flying ball to rotate at high speed; an elastic cushion at the side edge is extruded through the flying ball in transverse rotating, and meanwhile, the shaking force is consumed by the flying ball in transverse rotating, so that spring copper cannot be inclined during sealing, and a capacitor can reach normal service life; and meanwhile, a core covering structure of the capacitor is stable, and the capacitor is prevented from exploding due to unstable core covering structure during use; burrs at a connecting part of a gluing cover plate of a variable-capacity vacuum capacitor can be removed through a fine pyramid on a grinding cone pulley in a rotary grinding manner, so that the nice appearance of the variable-capacity vacuum capacitor is ensured, and moreover, the circumstance that workers are punctured by the burrs can be avoided.

Owner:江西抚州新兴化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com