Slope-form independent foundation structure

An independent foundation and slope technology, applied in the field of foundation engineering, can solve the problems of complex process and long construction period, and achieve the effect of simplifying construction steps, shortening construction period and improving installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

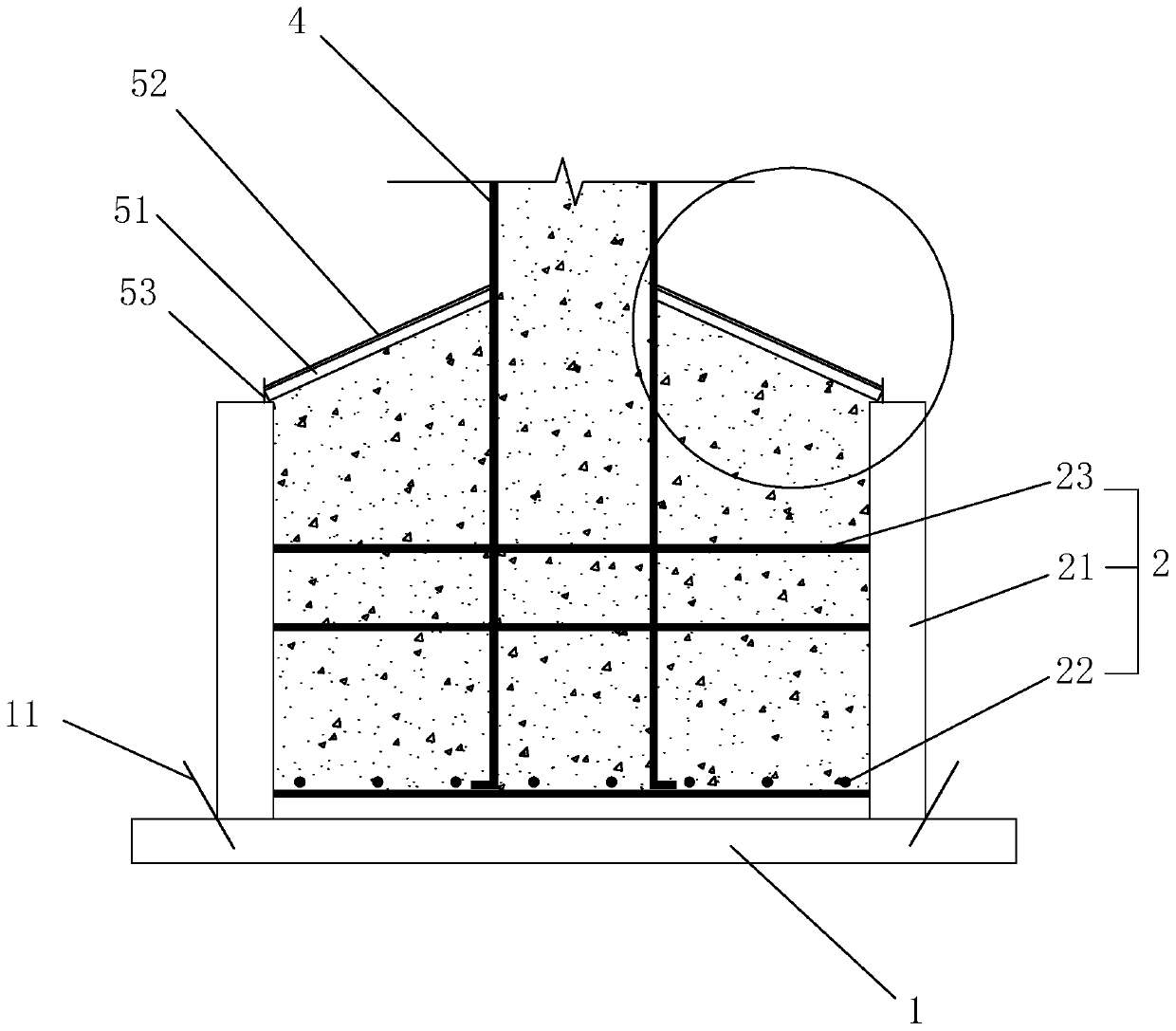

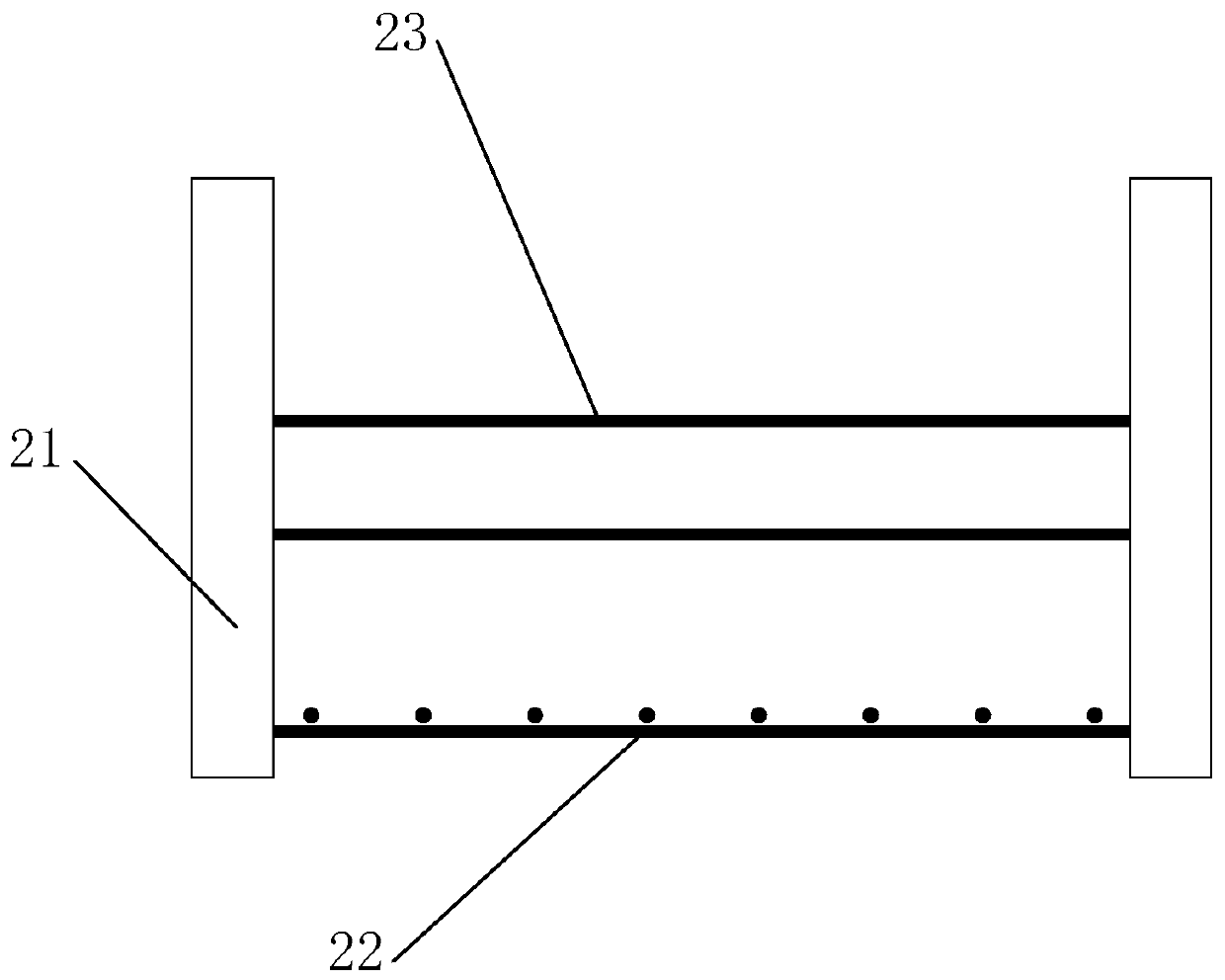

[0030] refer to figure 1 , is a slope-shaped independent foundation structure disclosed by the present invention, including a cushion layer 1, a prefabricated frame body 2, a cast-in-place body 3 and column reinforcements 4. The prefabricated frame body 2 includes surrounding side panels 21 , base reinforcement mesh 22 and middle tie bars 23 . The base reinforcement mesh 22 is arranged horizontally, and its four sides are pre-embedded in the surrounding side plates 21 near the bottom. The base reinforcement mesh 22 includes a plurality of transverse reinforcement bars and longitudinal reinforcement bars arranged crosswise. The two ends of the middle tie bars 23 are pre-embedded in the side panels 21 around the prefabricated frame body 2. After the column bars 4 and the middle tie bars 23 are tied or welded, the position is fixed; the middle tie bars 23 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com