Construction method for spherical furnace top of industrial furnace

A construction method and technology of industrial furnaces, applied in the direction of furnace crown/roof, lining repair, etc., can solve the problems of unfavorable soil formwork material cleaning, large amount of material usage, and heavy cleaning workload, so as to reduce the cleaning workload and improve Construction efficiency, reduce the effect of process handover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

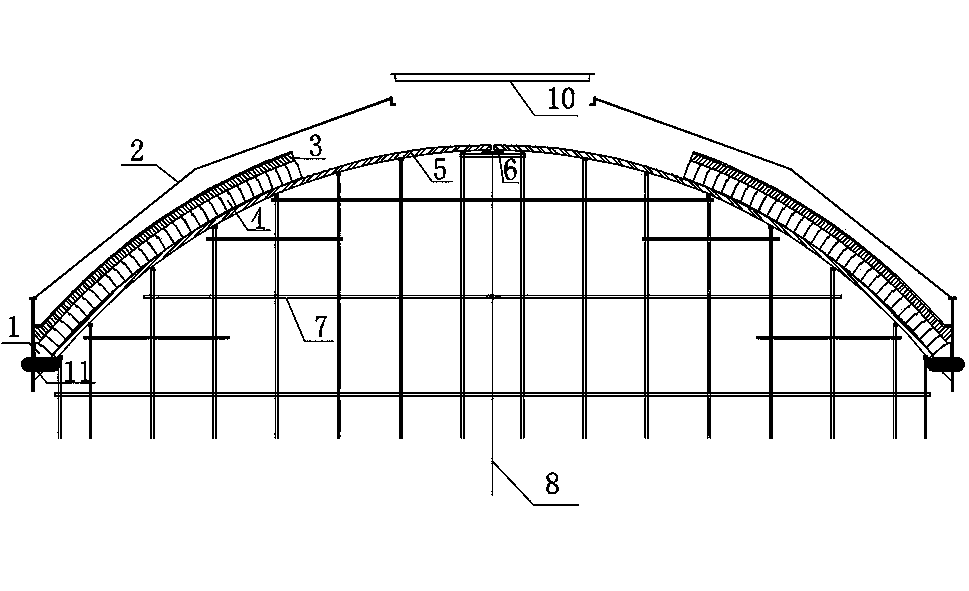

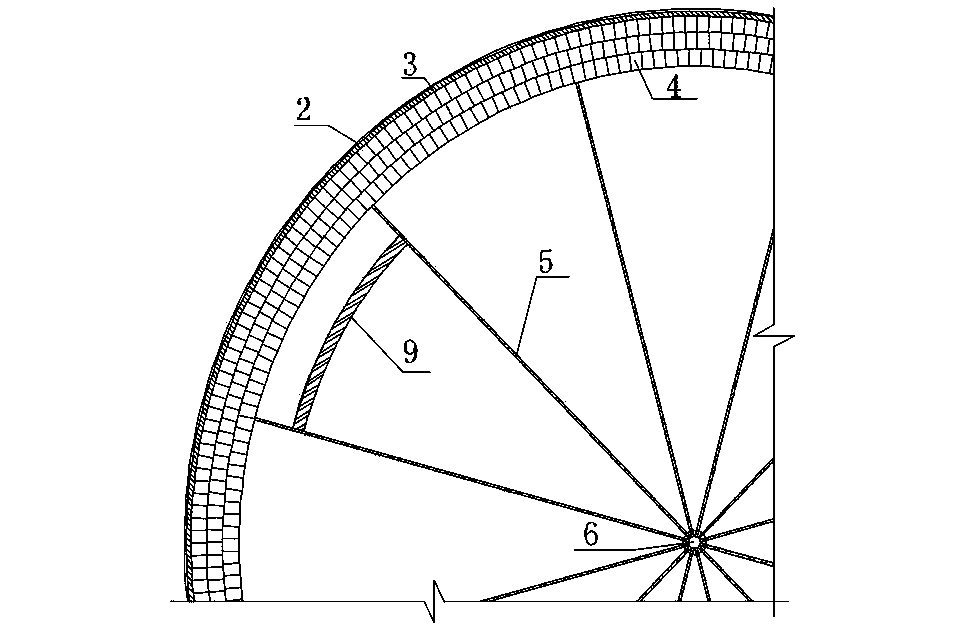

[0031] a kind of like figure 1 , figure 2 The construction method of the spherical furnace roof of the industrial furnace shown in the present invention comprises the following steps:

[0032] (1) First install the prefabricated steel furnace shell 2 at the design position of the spherical furnace roof, and the steel furnace shell 2 is an annular structure with an opening at the center top; figure 1 As shown, the steel furnace shell 2 of the present embodiment is formed by splicing two layers of conical steel shell plates up and down, and the taper of the steel shell plates increases gradually from bottom to top;

[0033] (2) After the steel furnace shell 2 is installed, review the elevation, flatness and inner diameter of the steel supporting plate 11 at the arch foot 1 (brick) of the dome masonry, and calibrate the corresponding size data (parts exceeding the specification to be adjusted);

[0034] (3) A vertical center control line 8 is drawn from the center of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com