Patents

Literature

206results about "Furnace crowns/roofs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance content alteration architecture and techniques

ActiveUS20050229251A1Improve effectivenessIncrease speedGeometric image transformationDigital data processing detailsComputer scienceBitmap

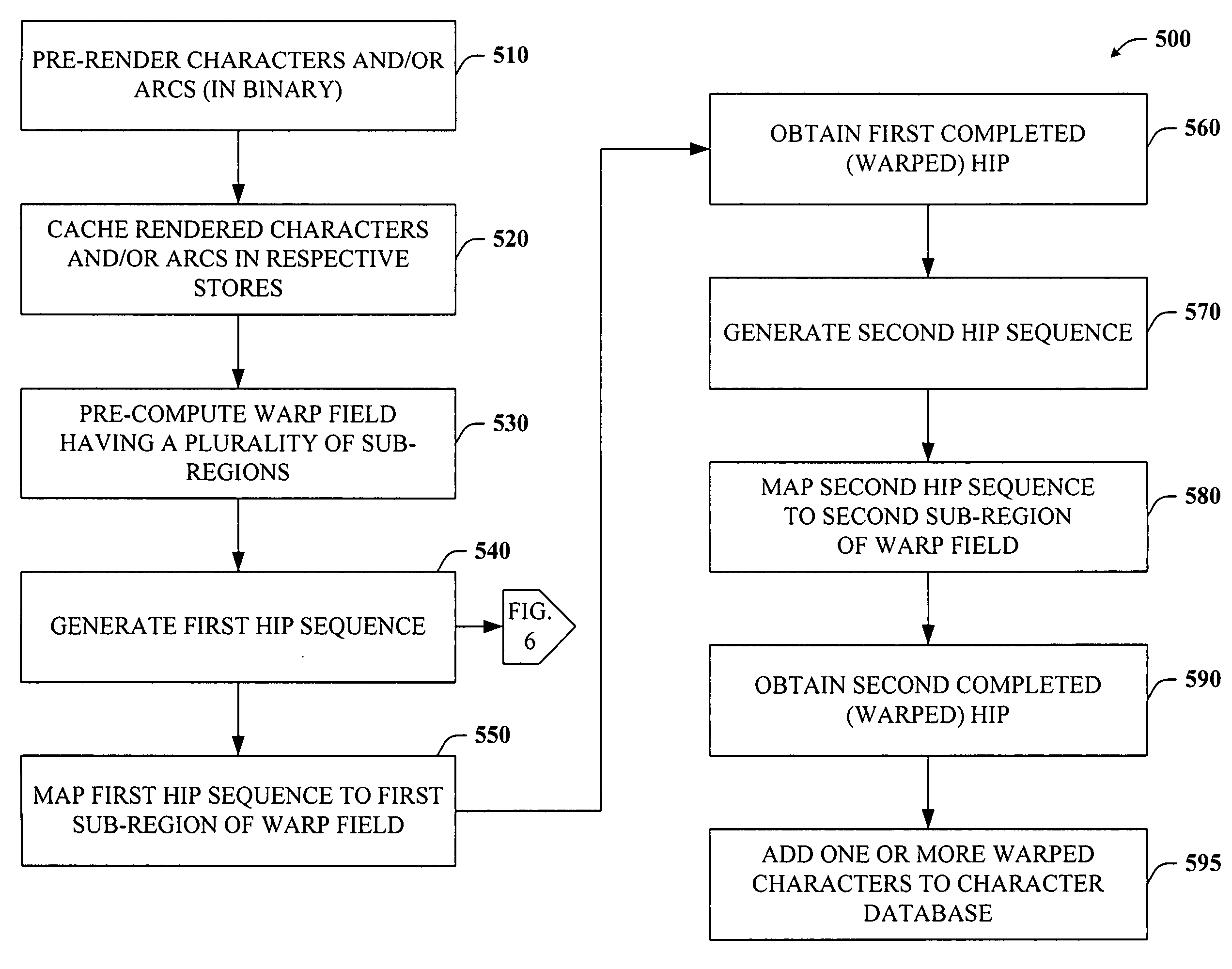

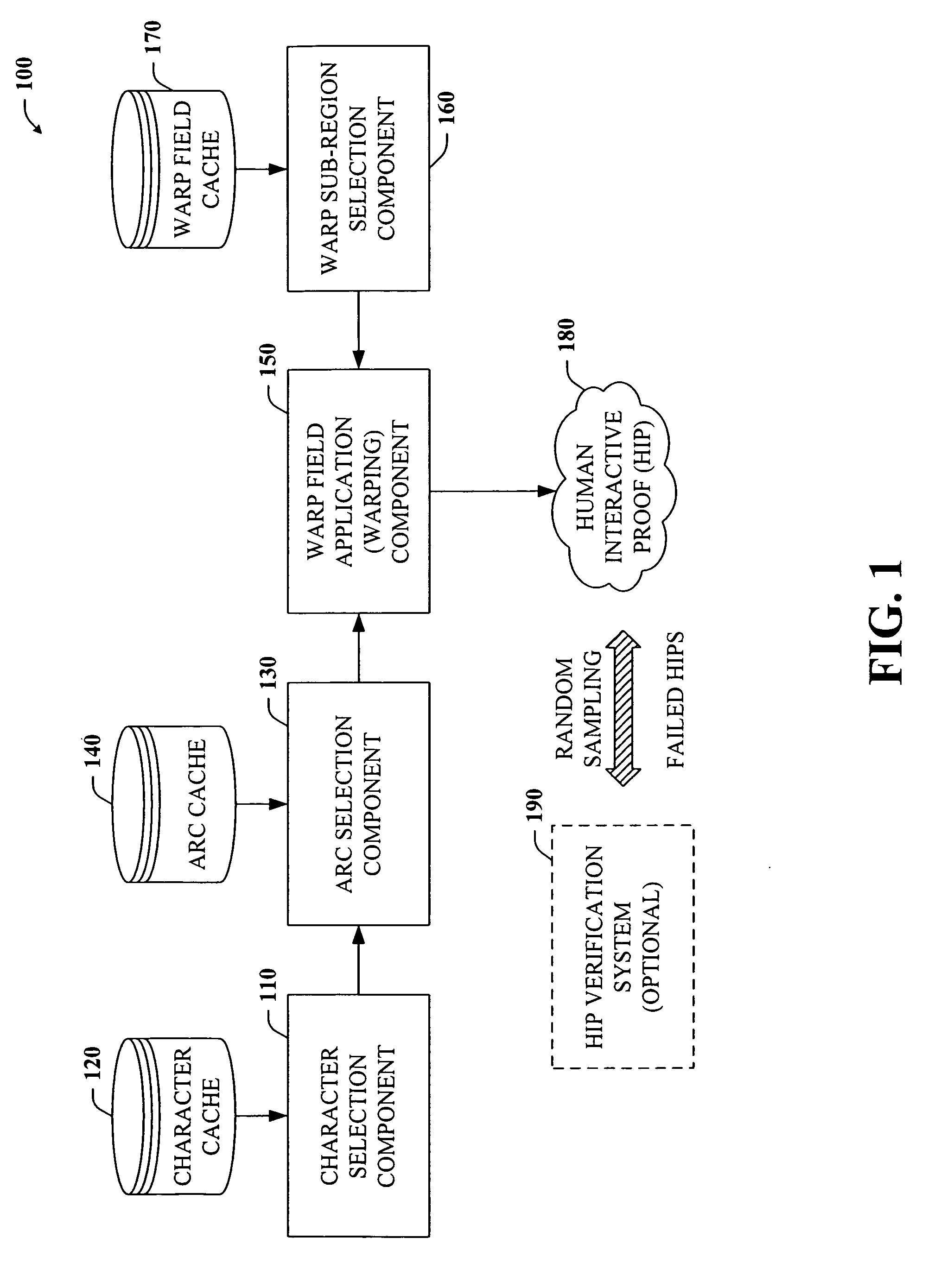

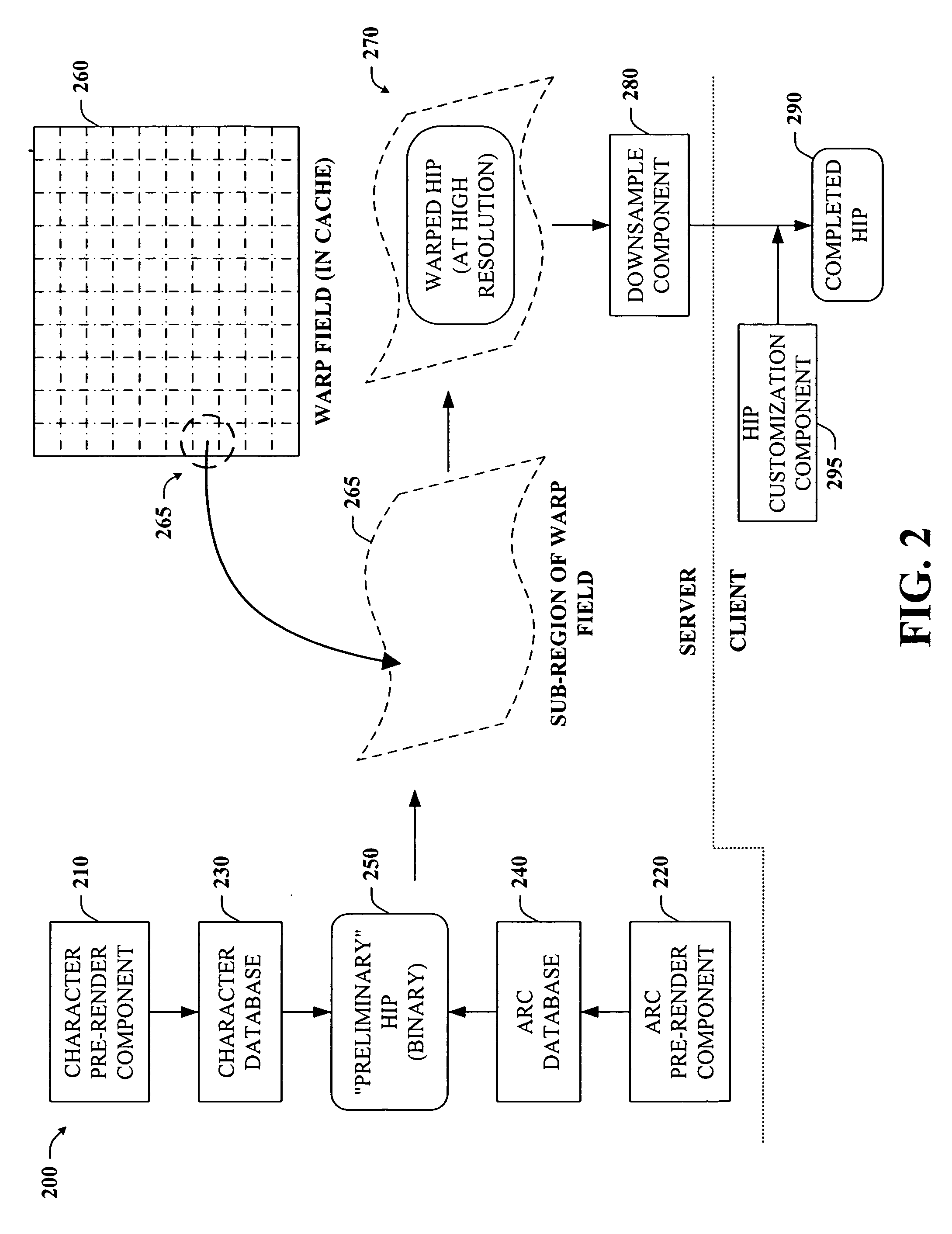

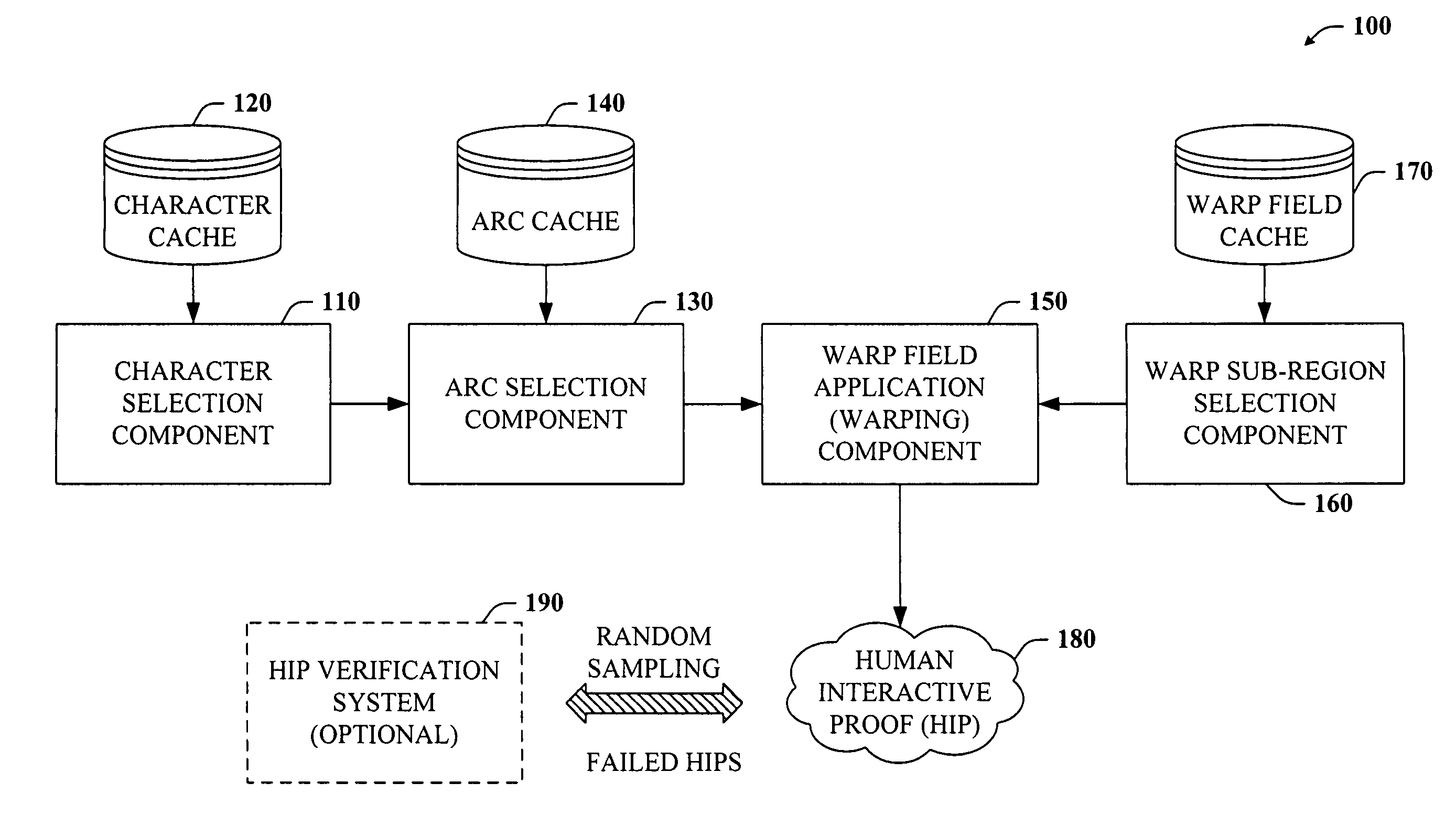

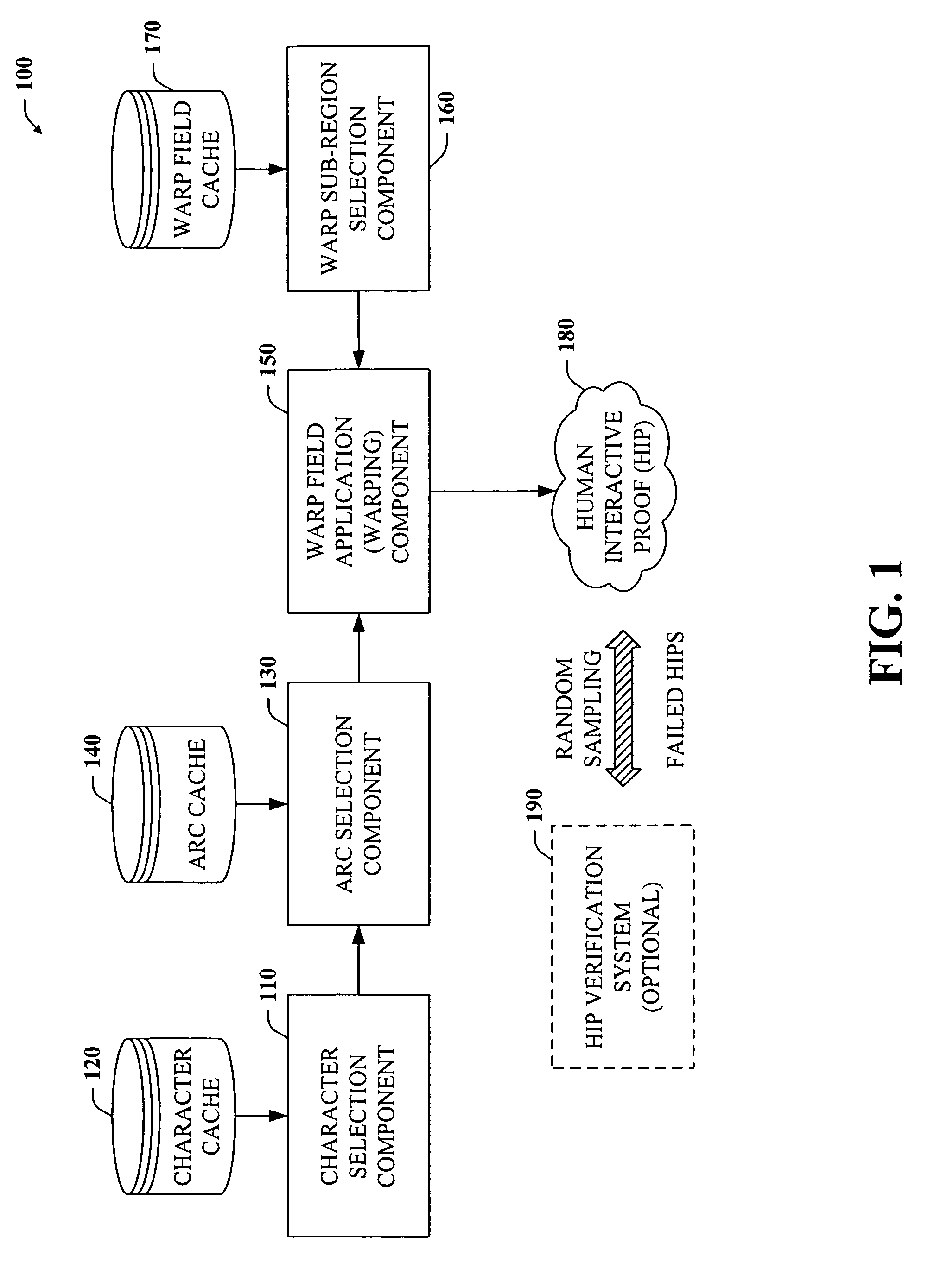

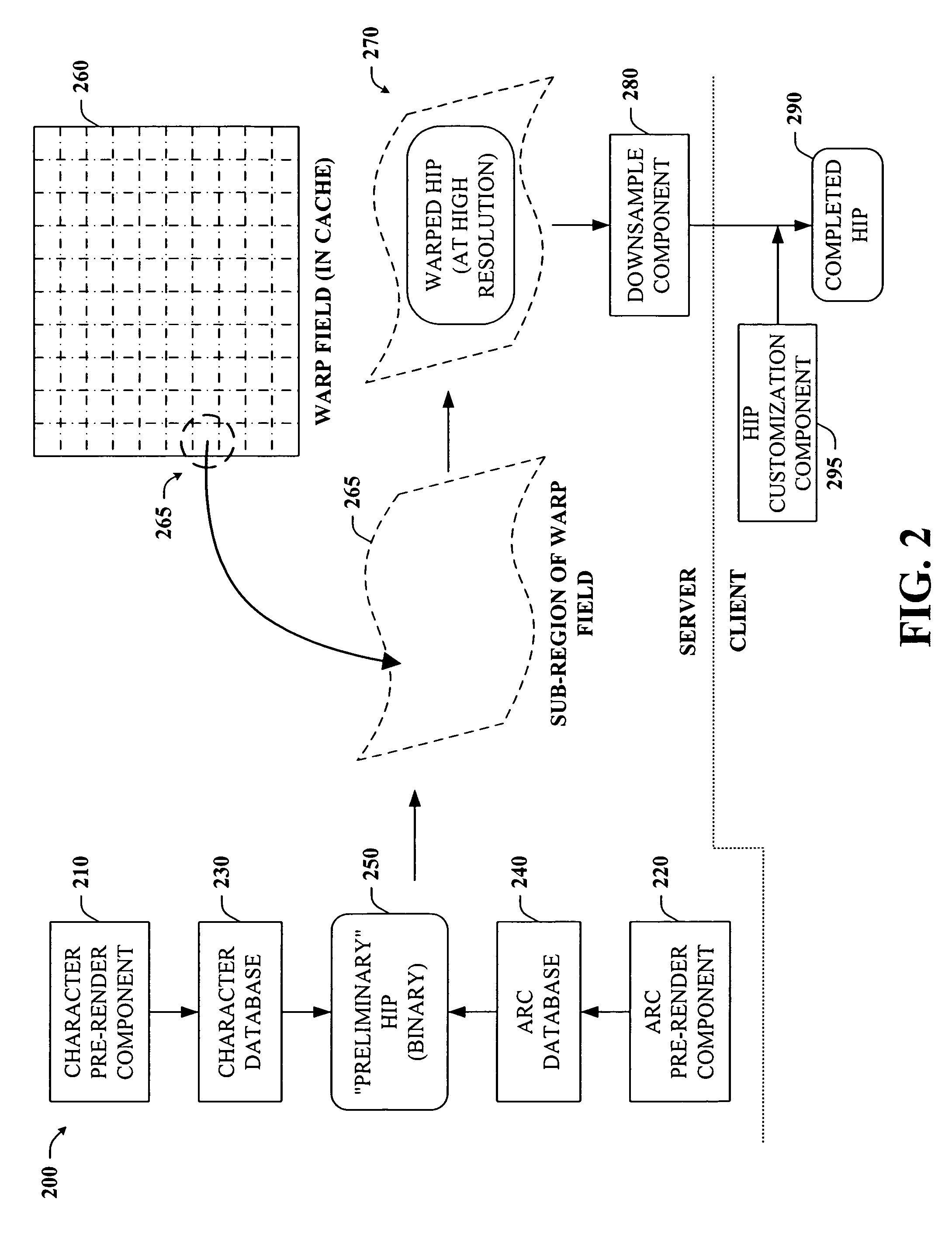

The present invention provides a unique system and method that facilitates obtaining high performance and more secure HIPs. More specifically, the HIPs can be generated in part by caching pre-rendered characters and / or pre-rendered arcs as bitmaps in binary form and then selecting any number of the characters and / or arcs randomly to form a HIP sequence. The warp field can be pre-computed and converted to integers in binary form and can include a plurality of sub-regions. The warp field can be cached as well. Any one sub-region can be retrieved from the warp field cache and mapped to the HIP sequence to warp the HIP. Thus, the pre-computed warp field can be used to warp multiple HIP sequences. The warping can occur in binary form and at a high resolution to mitigate reverse engineering. Following, the warped HIP sequence can be down-sampled and texture and / or color can be added as well to improve its appearance.

Owner:MICROSOFT TECH LICENSING LLC

High performance content alteration architecture and techniques

ActiveUS7505946B2Improve effectivenessIncrease speedDigital data processing detailsGeometric image transformationComputer scienceBitmap

The present invention provides a unique system and method that facilitates obtaining high performance and more secure HIPs. More specifically, the HIPs can be generated in part by caching pre-rendered characters and / or pre-rendered arcs as bitmaps in binary form and then selecting any number of the characters and / or arcs randomly to form a HIP sequence. The warp field can be pre-computed and converted to integers in binary form and can include a plurality of sub-regions. The warp field can be cached as well. Any one sub-region can be retrieved from the warp field cache and mapped to the HIP sequence to warp the HIP. Thus, the pre-computed warp field can be used to warp multiple HIP sequences. The warping can occur in binary form and at a high resolution to mitigate reverse engineering. Following, the warped HIP sequence can be down-sampled and texture and / or color can be added as well to improve its appearance.

Owner:MICROSOFT TECH LICENSING LLC

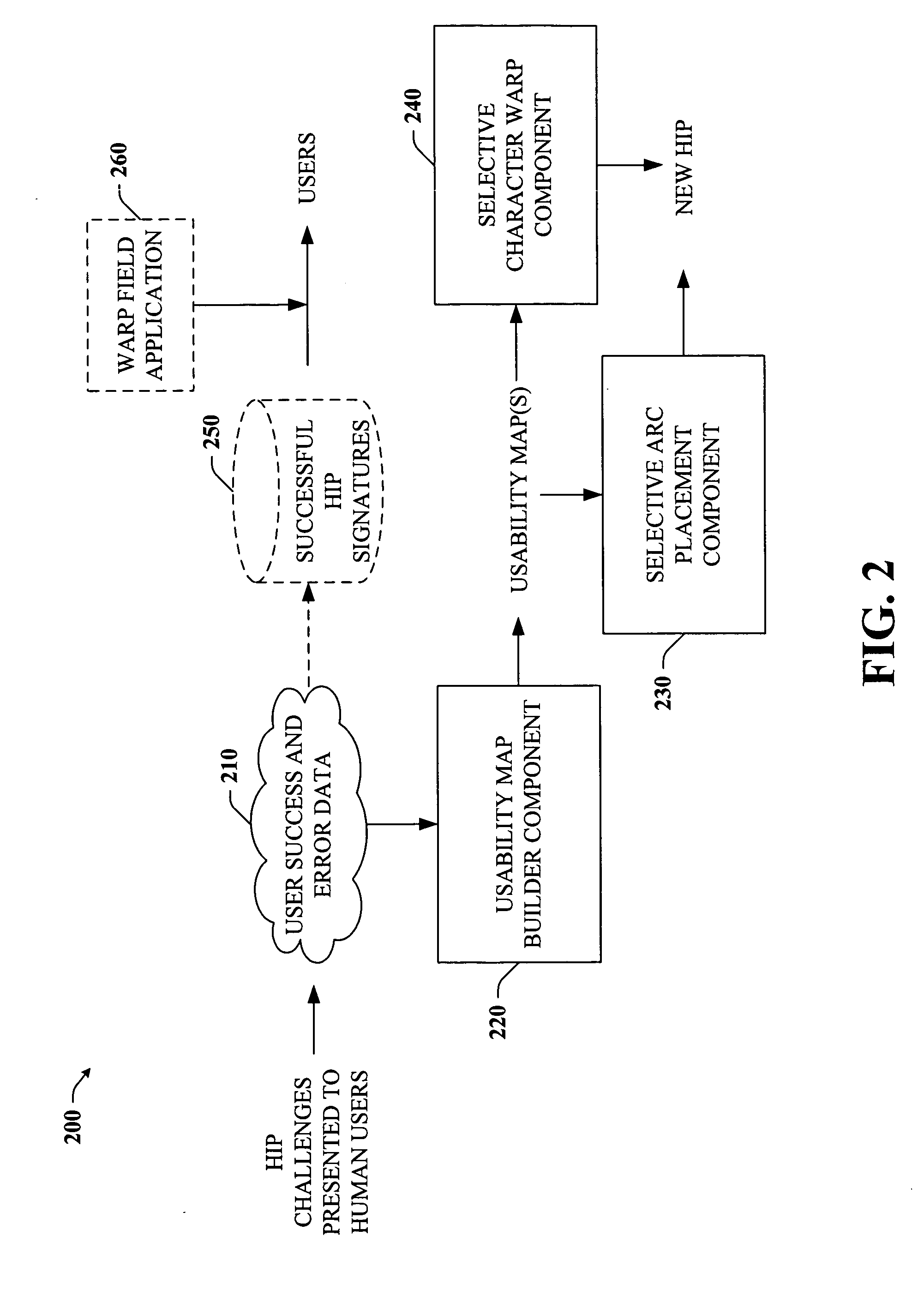

Segmentation based content alteration techniques

ActiveUS20050246775A1Easy to solveFacilitate creating HIP challenges (HIPsDigital data processing detailsGeometric image transformationPattern recognitionUsability

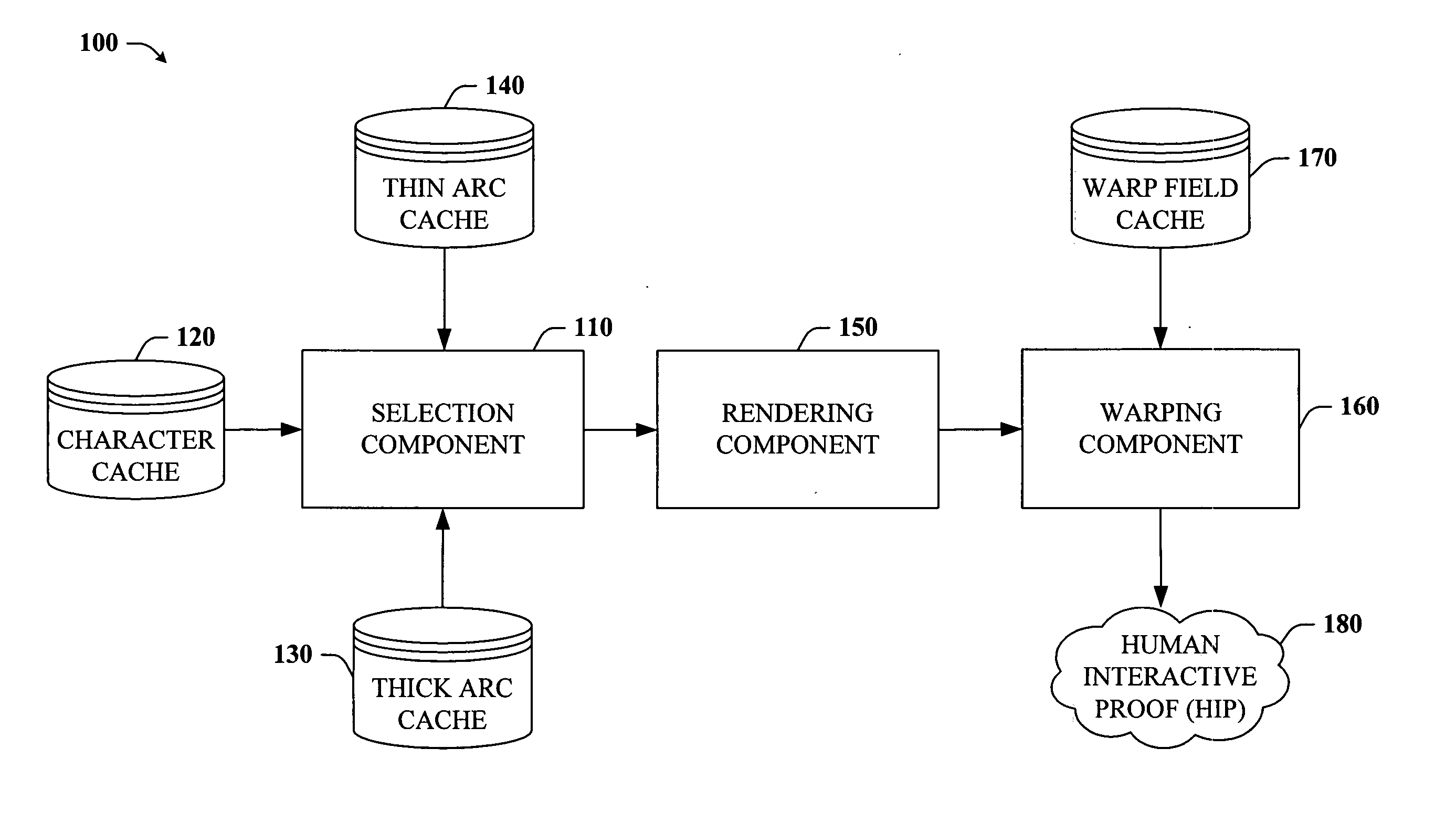

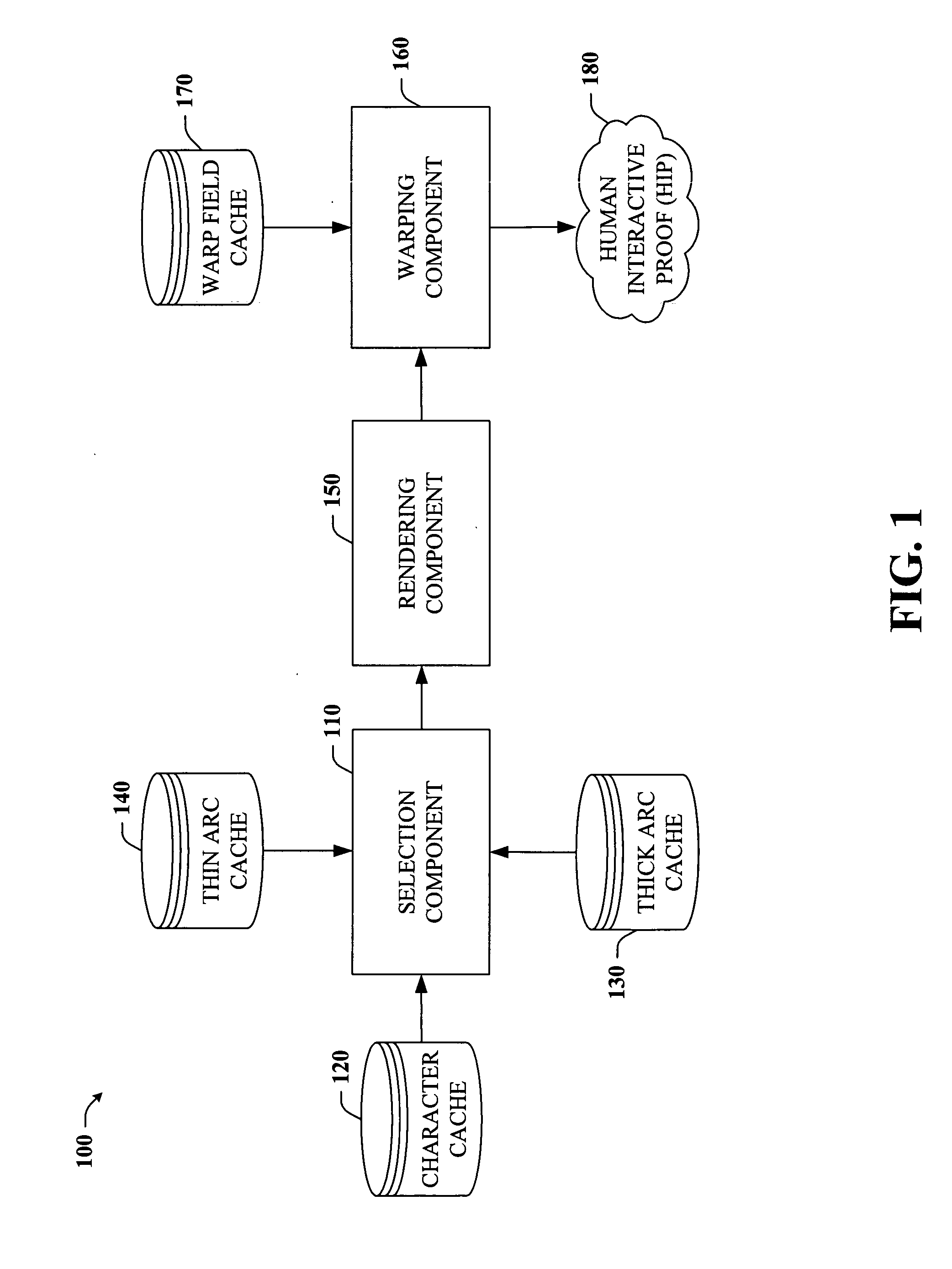

The subject invention provides a unique system and method that facilitates creating HIP challenges (HIPs) that can be readily segmented and solved by human users but that are too difficult for non-human users. More specifically, the system and method utilize a variety of unique alteration techniques that are segmentation-based. For example, the system and method employ thicker arcs or occlusions that do not intersect characters already placed in the HIP. The thickness of the arc can be measured or determined by the thickness of the characters in the HIP. In addition to increasing the thickness, the arcs can be lengthened because longer arcs tend to resemble pieces of characters and may be harder to erode. Usability maps can be generated and used to selectively place clutter or occlusions and to selectively warp characters or the character sequence to facilitate human recognition of the characters.

Owner:MICROSOFT TECH LICENSING LLC

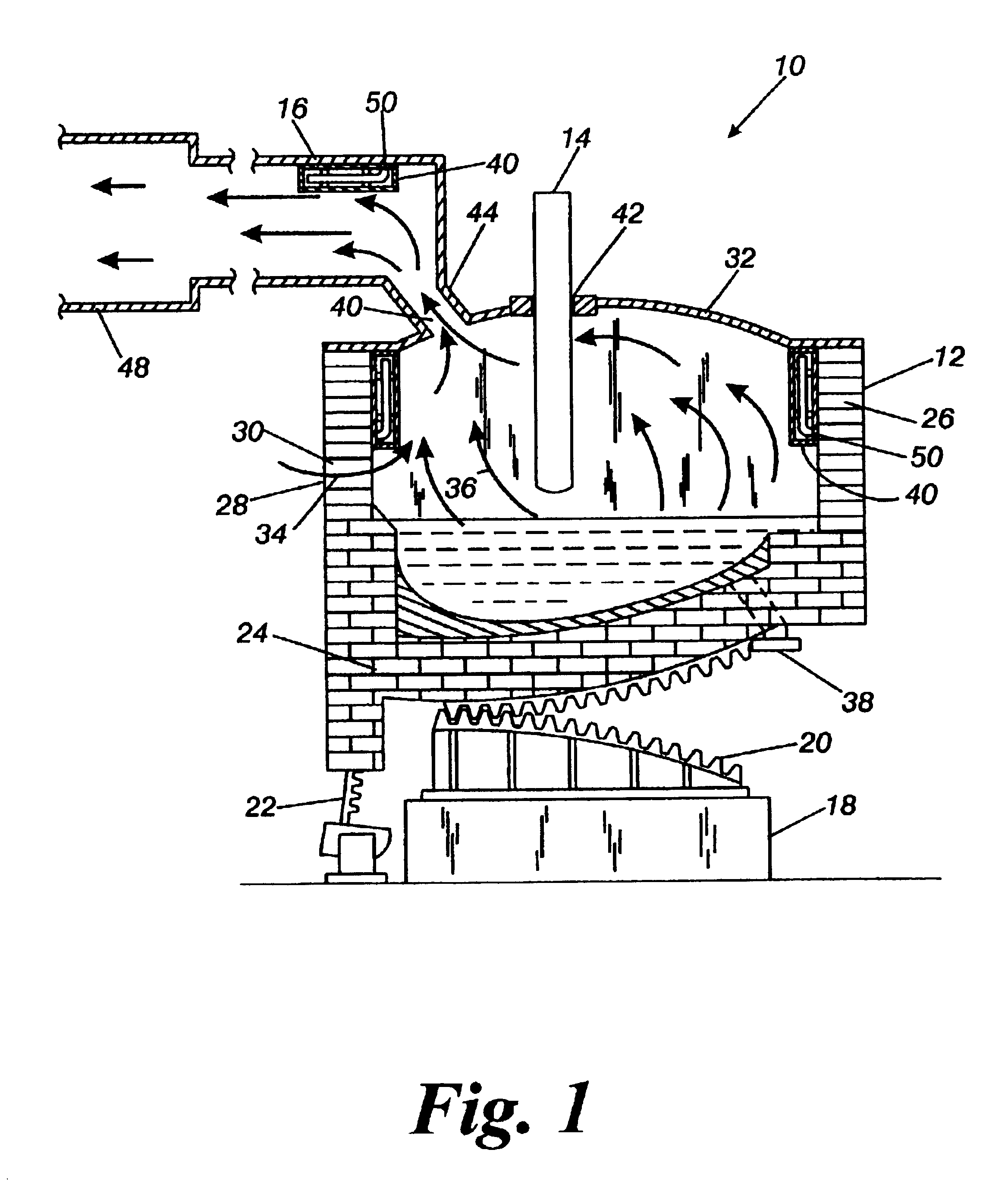

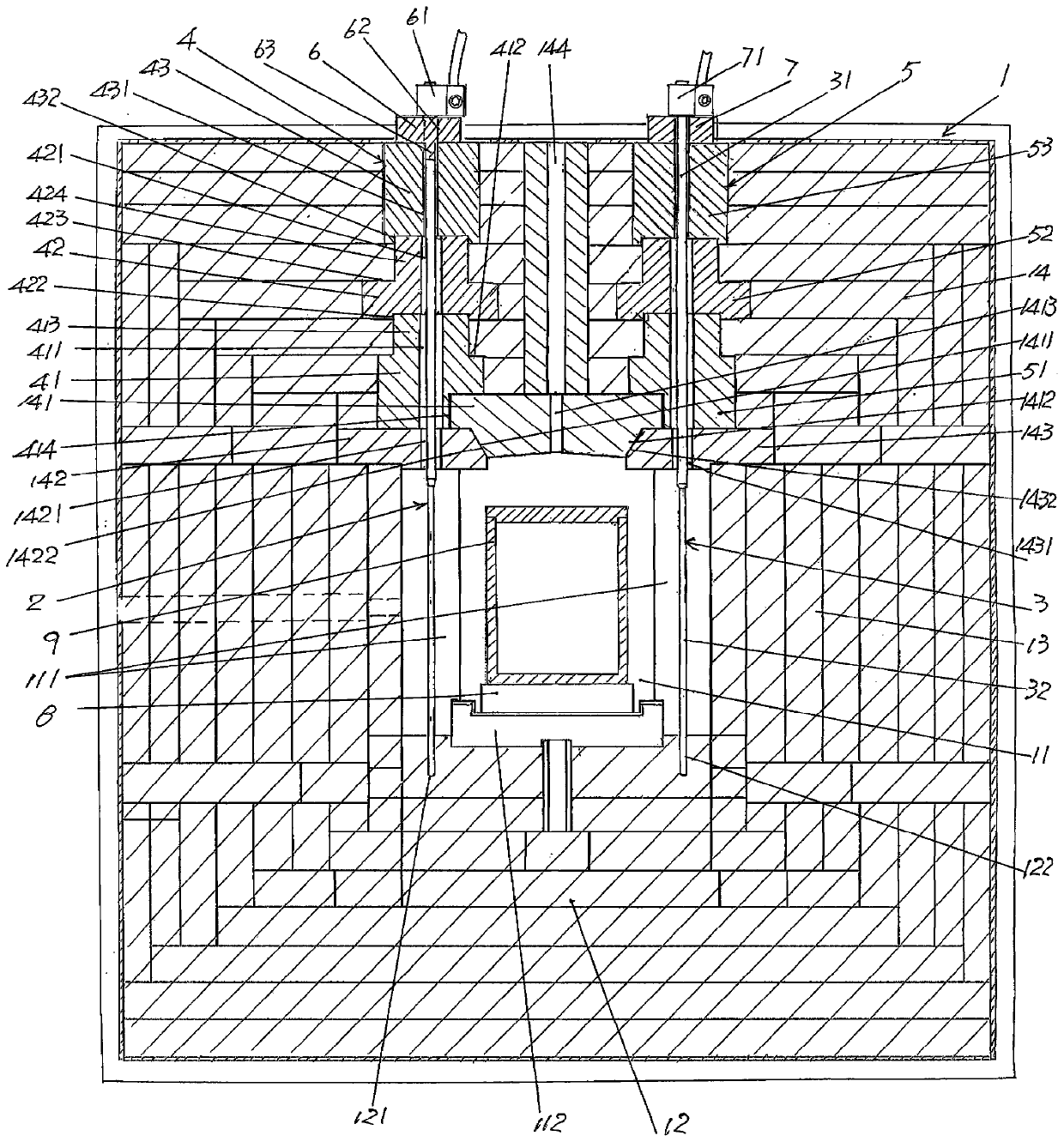

High temperature industrial furnace roof structure

InactiveUS6427610B1Reduces joint lengthImprove accessibilityLining supportsGlass furnace apparatusBrickEngineering

Owner:MERKLE ENGINEERS

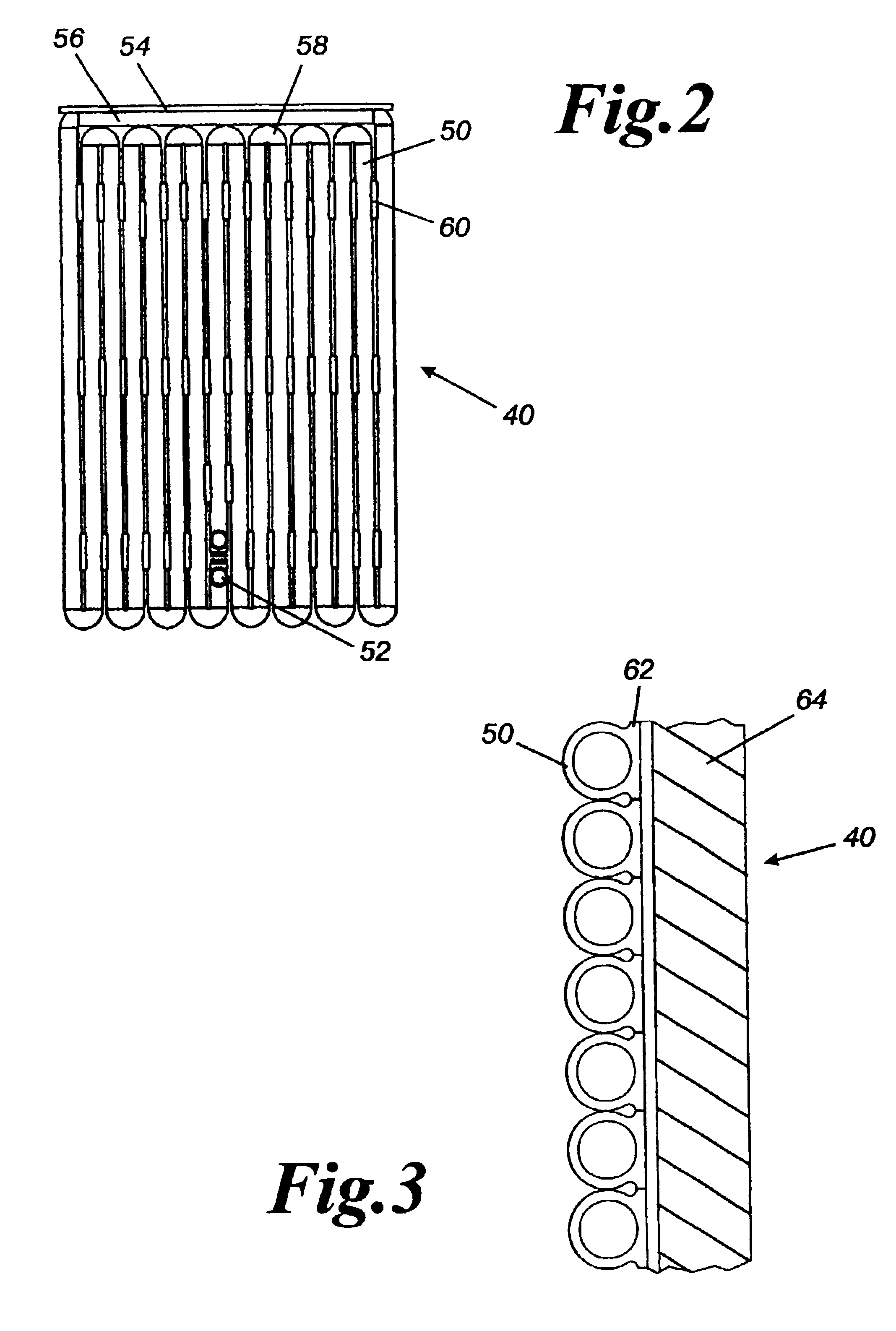

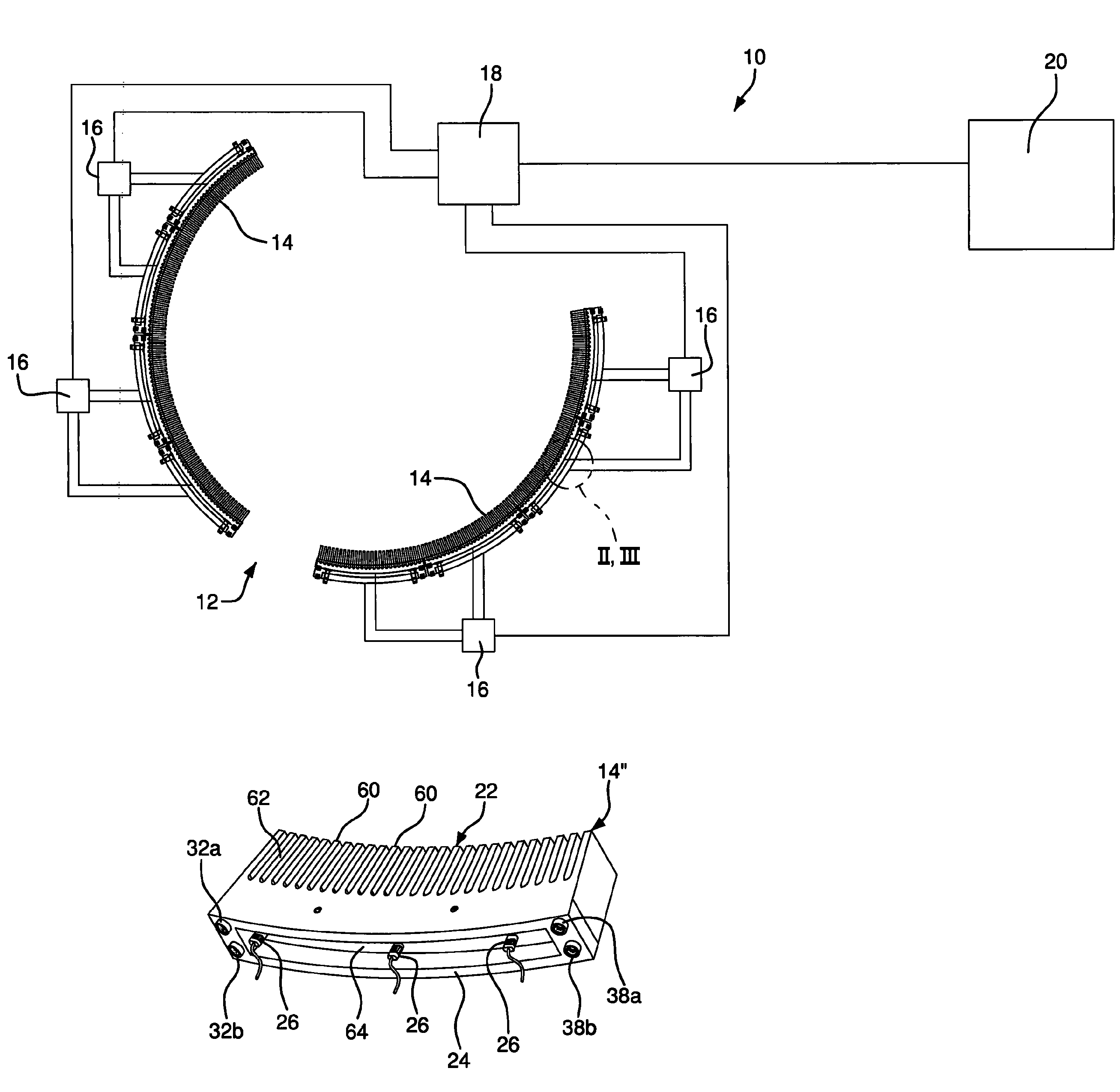

Water-cooling panel for furnace wall and furnace cover of arc furnace

A water-cooled panel for the furnace wall and furnace roof of an electric-arc furnace is integrally fabricated of refractory bricks arrayed on the furnace inner wall in multiple regularly spaced rows to be exposed at the end surfaces and cooling water pipes installed between the rows of refractory bricks (2). A furnace exterior side of the refractory bricks and a furnace interior side of a cooling water pipe are overlapped in a vertical direction of the water-cooled panel, and the cooling water pipe is provided in between an upper and lower side of refractory bricks.

Owner:NIPPON STEEL CORP

System and method for steel making

InactiveUS6890479B2Improve conductivityHigh hardnessTuyeresBlast furnace detailsProduction rateAlloy

A metallurgical furnace, which includes a furnace shell, an exhaust system, and a gas cleaning system, further includes a plurality of improved pipes and fume ducts throughout to increase operational life and productivity. The pipes and fumes ducts are comprised of an aluminum-bronze alloy which provides enhanced properties over prior art materials including thermal conductivity, modulous of elasticity and hardness. The use of the alloy also minimizes maintenance requirements of the pipes and fume ducts, thereby extending their operational life. In operation, gases formed from smelting or refining are evacuated from the furnace shell through the exhaust system into the gas cleaning system. The gases, as well as the system, are water cooled by way of the plurality of pipes displaced throughout.

Owner:AMERIFAB INC

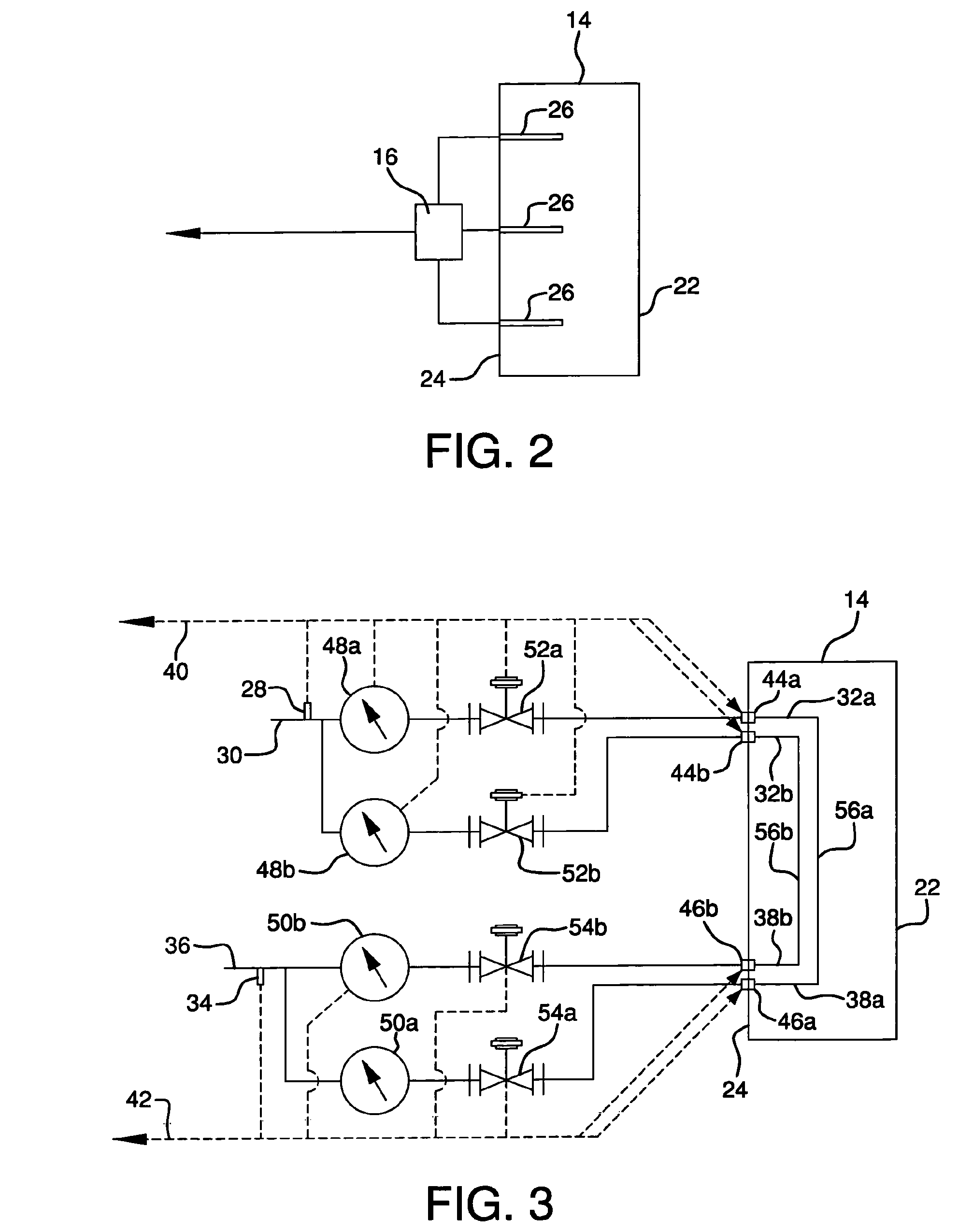

Furnace panel leak detection system

ActiveUS7832367B2Detection of fluid at leakage pointFurnace cooling arrangementsElectric arc furnaceStress sensors

A furnace panel leak monitoring and control system for fluid-cooled panels in high temperature industrial furnaces such as, for example, smelting furnaces, blast furnaces and electric arc furnaces. The system performs at least two and up to four functions simultaneously. At minimum, the system includes one or more temperature sensors received within the body of the panel to monitor temperature within the metal of the panel itself, and pressure sensors installed proximate the inlet and outlet of each panel coolant fluid circuit, which circuits are preferably periodically automatically tested, to check for leaks in the coolant circuits. In addition, the system preferably includes temperature and flow sensors for monitoring the furnace panel coolant circuit(s) for temperature and flow fluctuations, respectively, which may be indicative of leaking cooling circuits. The system triggers visual and / or audible alarms to alert a human operator of an apparent coolant fluid leak situation.

Owner:BERRY METAL

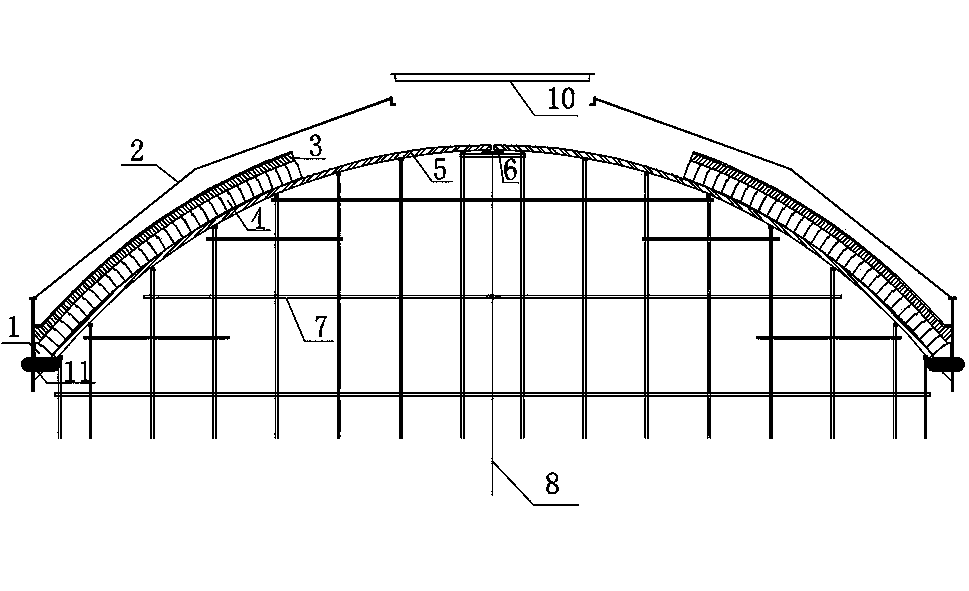

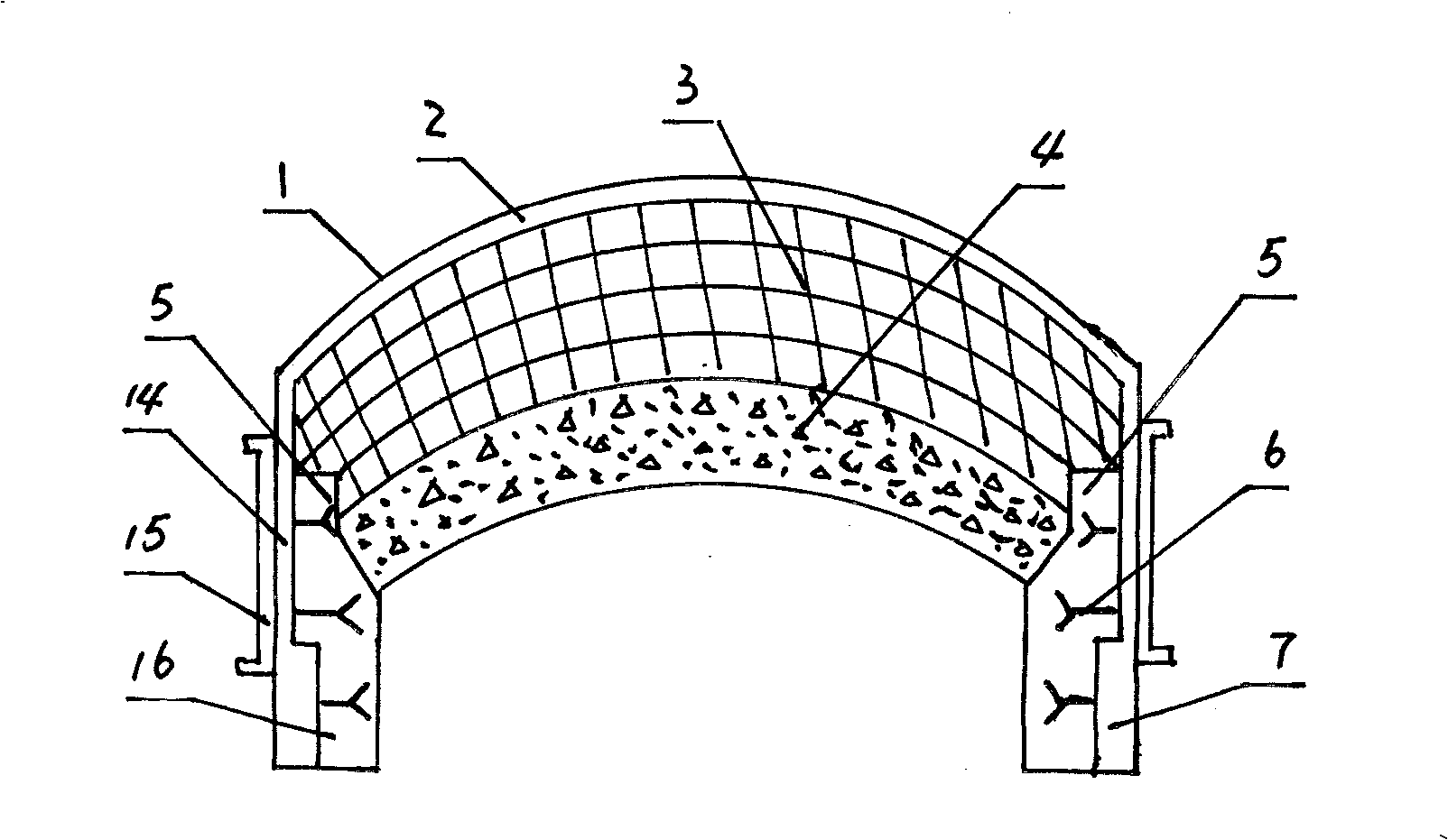

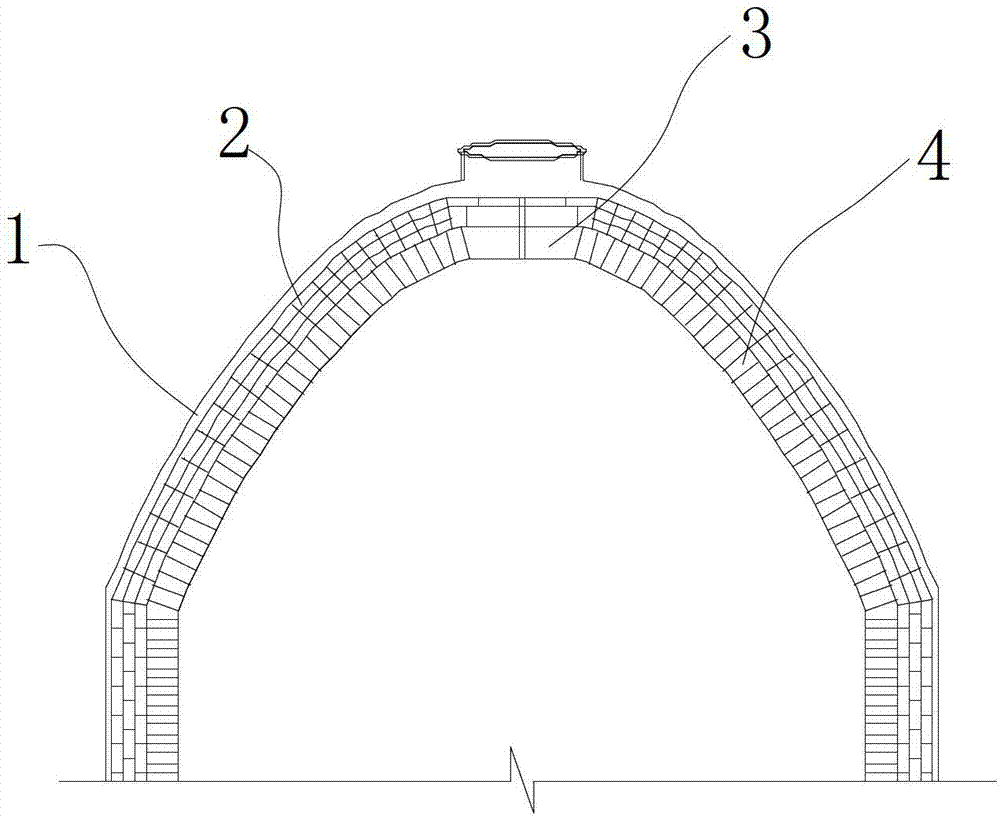

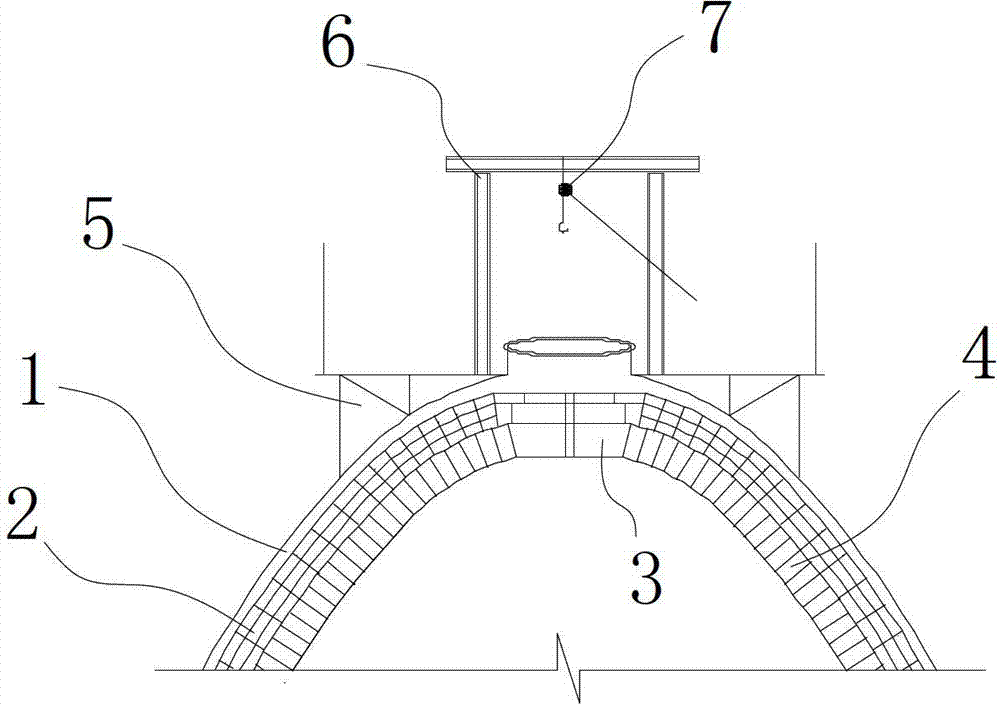

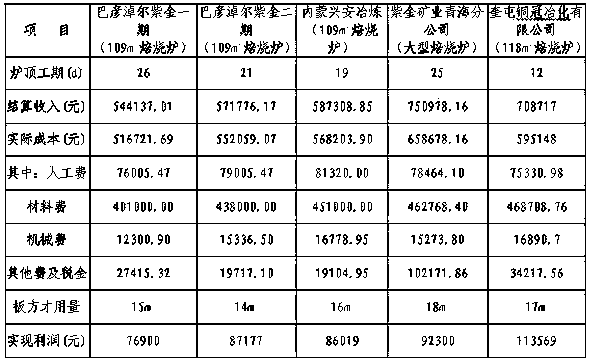

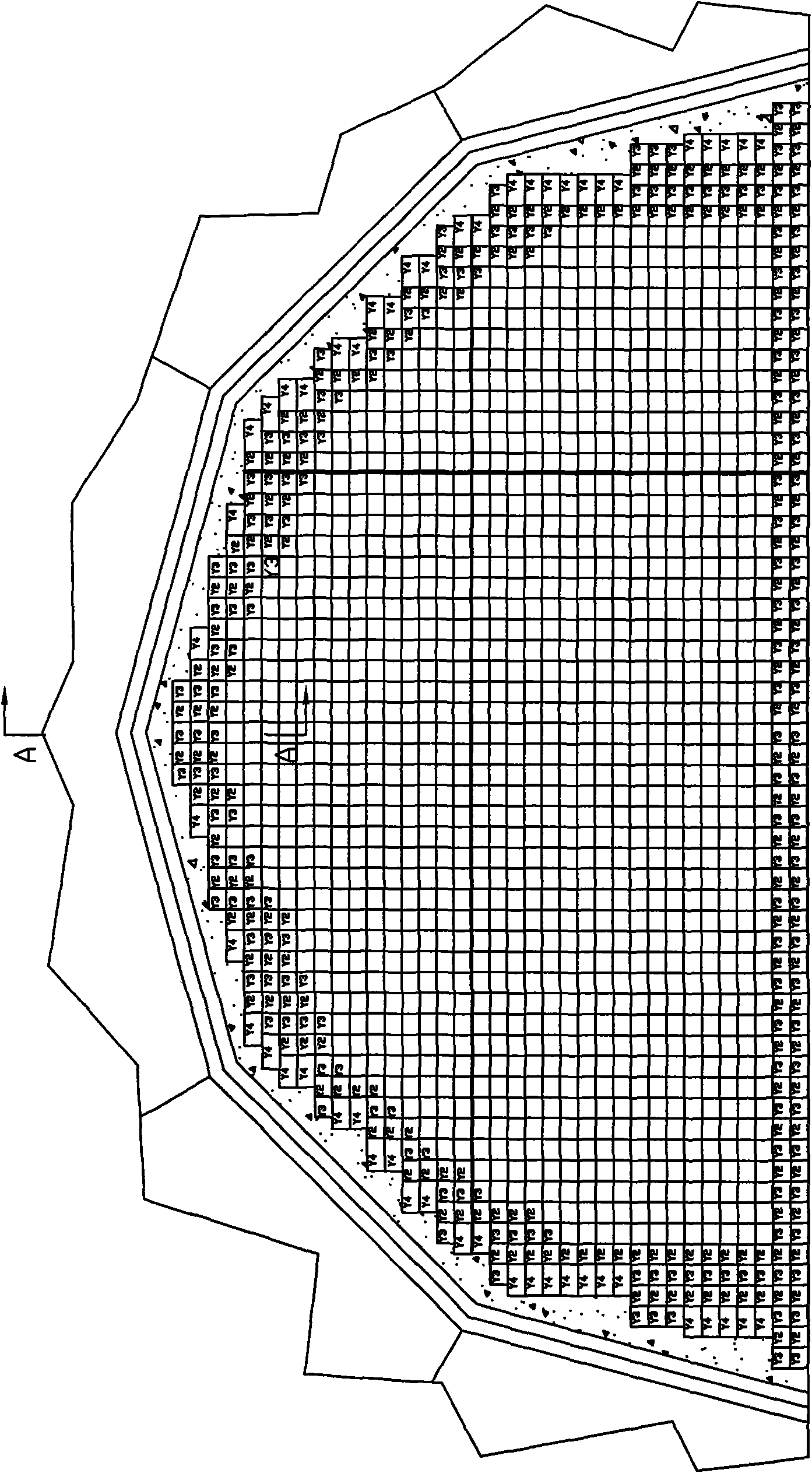

Construction method for spherical furnace top of industrial furnace

ActiveCN103673621AReduce cleanup workloadReduce usageLinings repairFurnace crowns/roofsMetallurgyFire brick

The invention discloses a construction method for a spherical furnace top of an industrial furnace. Firstly, a steel furnace shell is mounted, the elevation and the like of steel supporting plates at the arch springing positions of a globe-roof are rechecked, a vertical control line is arranged from the center of the furnace bottom to the center of the furnace top in a drawn mode, a supporting frame is erected in a furnace body, and a round top plate is arranged in the center of the top; multiple vertical arc plates are then manufactured and are fixed on the round top plate and the supporting frame, and the elevation and the radius of each layers of refractory bricks are marked on the corresponding vertical arc plates; multiple horizontal arc plates are manufactured; the refractory bricks at the arch springing positions are constructed first, the refractory bricks are constructed upwards in sequence, the vertical radian and the elevation of the refractory bricks are controlled by using the vertical arc plates, and the horizontal radius of the refractory bricks is controlled by using the horizontal arc plates; one heat preservation brick layer is constructed after one certain layer of the refractory bricks are constructed, and the construction is carried out in the way until the construction of all the refractory brick layers and the construction of all the heat preservation brick layers are completed; a steel cover plate of the furnace top is mounted in a hanging mode to seal the steel furnace shell. The construction method for the spherical furnace top of the industrial furnace has the advantages of being economical in used material, simple in working procedure, low in cost and the like, and can ensure construction quality more easily.

Owner:五矿二十三冶建设集团有限公司

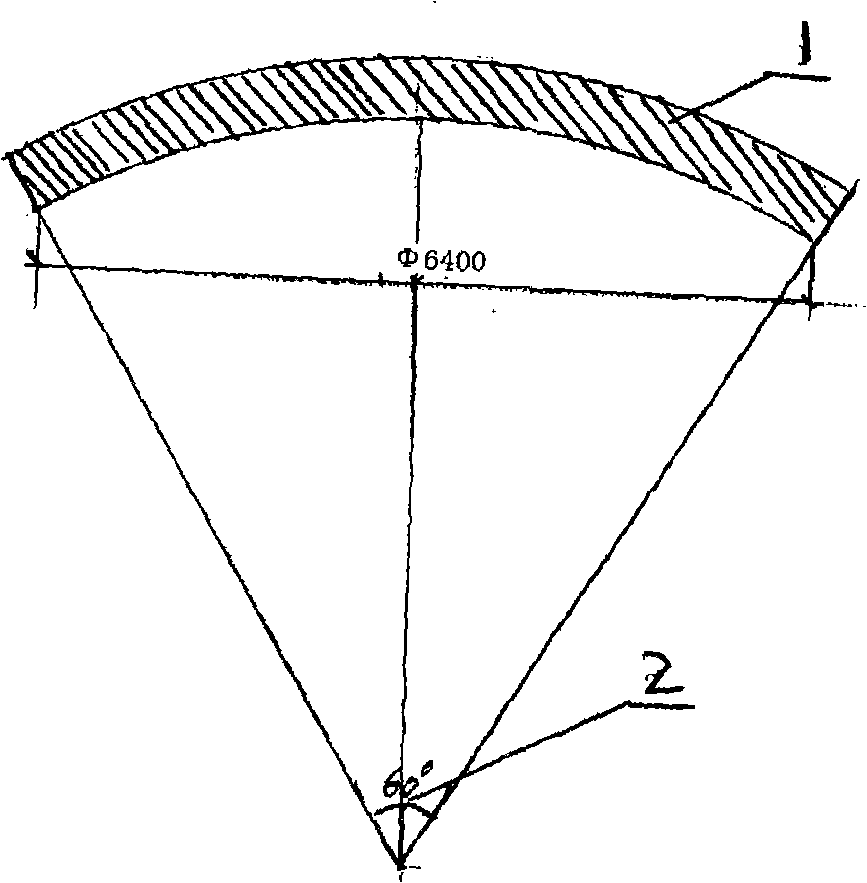

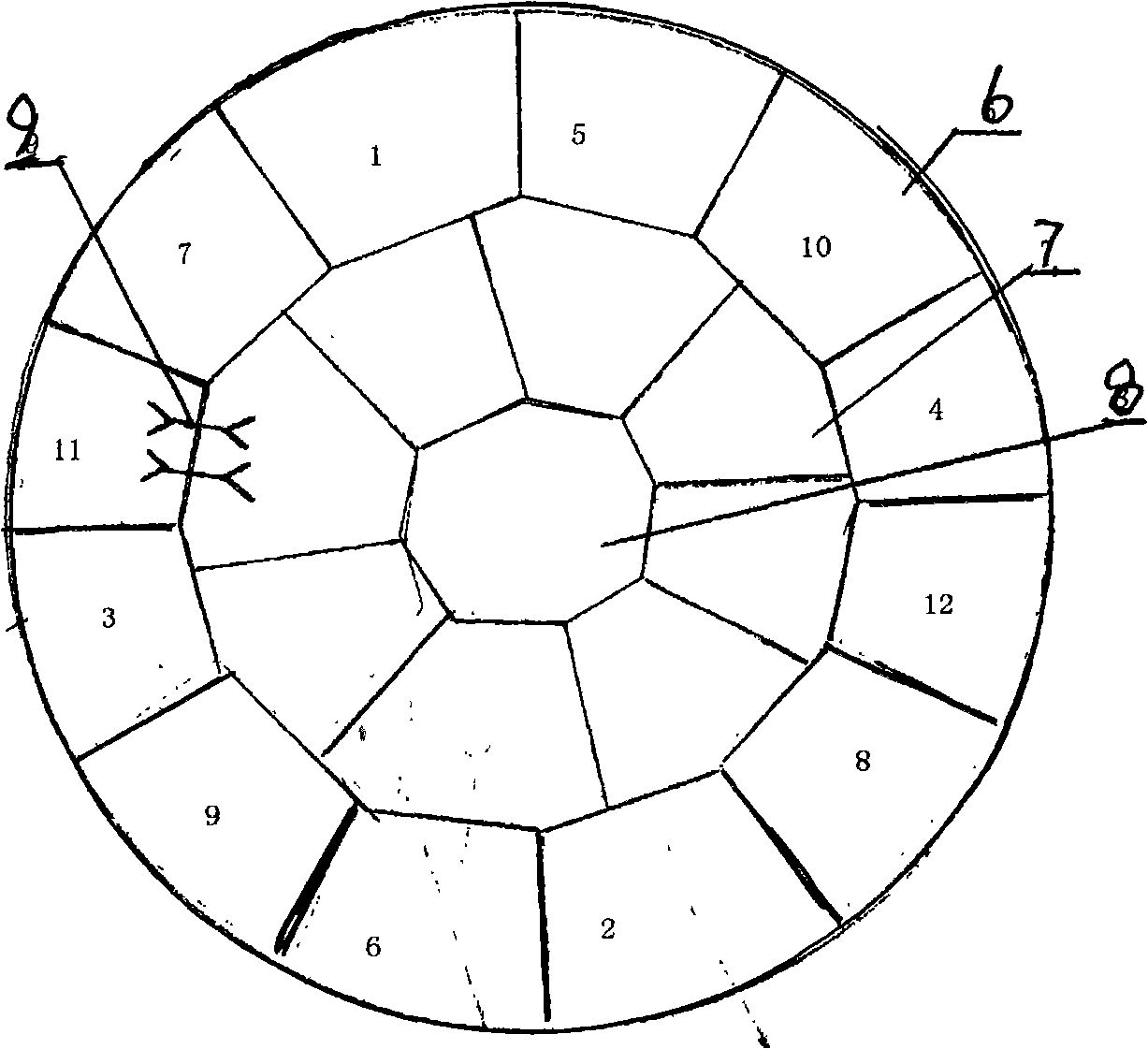

Zinc metallurgy ore smelting electric arc furnace spherical top integral pouring and maintenance method

ActiveCN101261082ASimple construction processShort construction periodCeramic shaping apparatusBuilding material handlingElectric arc furnaceZinc

The invention provides a method for integral casting and maintaining a zinc ore metallurgy thermal-electric furnace globe-roof. A reasonable central angle is selected according to the electric furnace type and the power and an electrode hole and a feeding hole are positioned. The vault is cast in a way of rings and blocks, the thickness is 350 millimeters; the center thickness of the electrode hole is 450 millimeters. A clip is used for connecting blocks into a whole. The middle of each template is provided with thermolability expansion gap vertically and discontinuously. The material adopts a veneer board more than or equal to 3 millimeters. Each template reserves three veneer boards with areas of 80 multiplied by 300 millimeters and is fixed on the upper part of the inner mould vertically. After casting, the demoulding is performed and furnace is dried. The method has the advantages of simple construction technology, short time limit for a project, high construction quality and security, environment protection, good leak tightness of the furnace, low electric energy consumption, long service life and low cost.

Owner:李朝侠

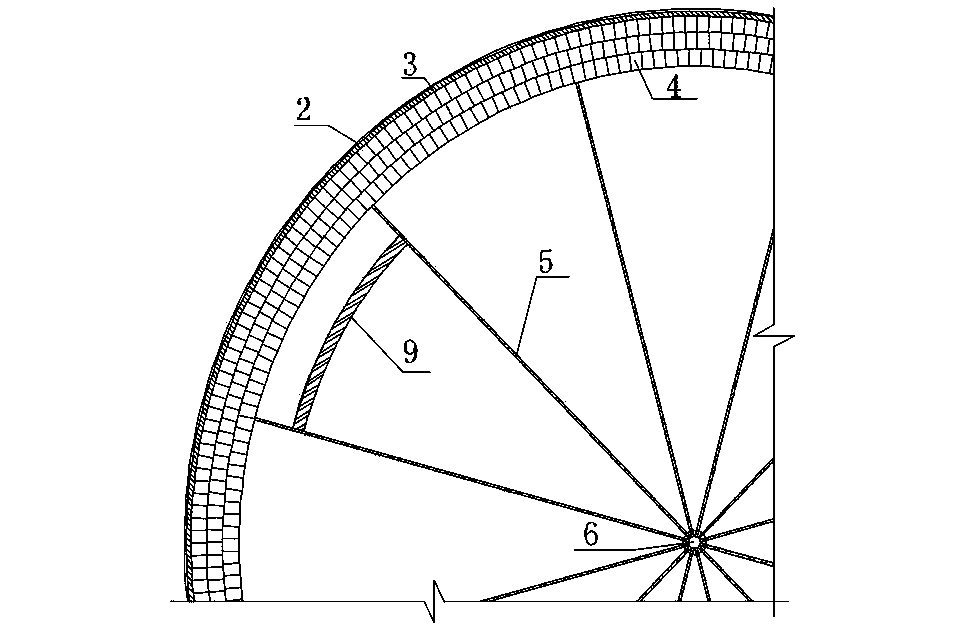

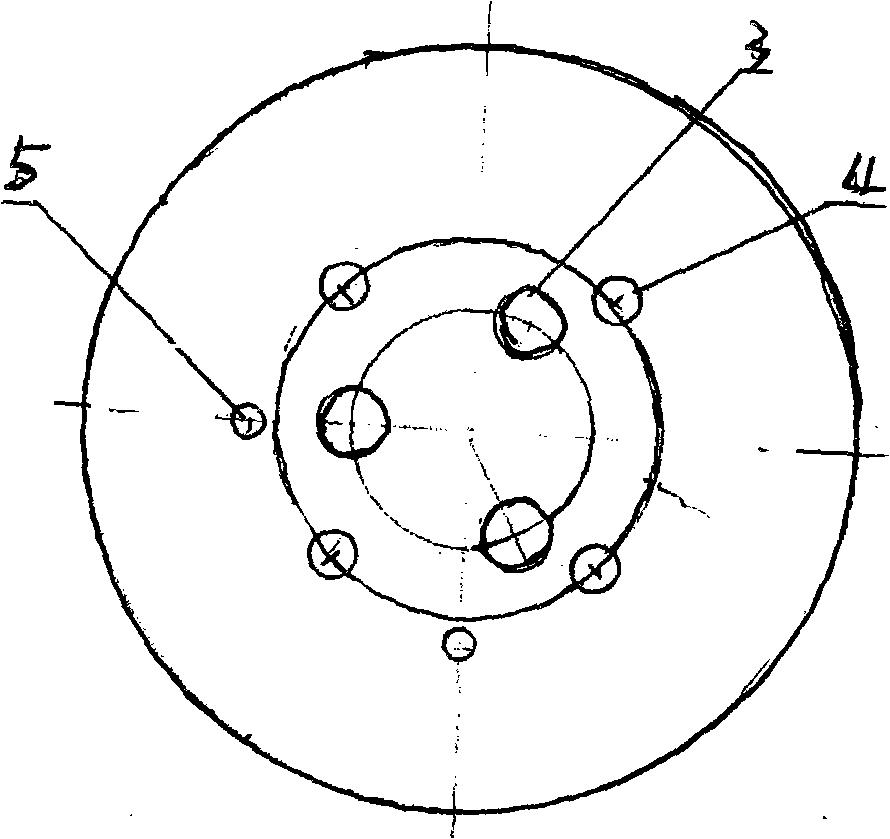

Fluidized calcining furnace ball arc furnace top and method of forming same

ActiveCN101261081ASolve the problem of large area damageImprove sealingFluidised-bed furnacesFurnace crowns/roofsFiberCamber angle

The invention provides a fluidizaton roasting furnace ball arch furnace top. A heavy castable layer working lining adopts a high intensity low cement castable refractory or a steel fiber reinforced castable refractory. The inside of the layer is provided with a plurality of binaural stainless steel clips widthways to connect the castable material casting by different rings and blocks into a whole. The lateral wall of a camber angle ring beam is provided with a light clay brick and a connecting rib, the outside lateral wall is provided with a lateral wall reinforcing channel steel, the inner layer is provided with a plurality groups of stainless steel clips which connect the light clay brick, the heavy castable refractory layer working lining and the lateral wall reinforcing channel steel into a whole. The forming method is as follows: (1) the center of gravity and the symmetric center of the furnace top are arranged in one line; (2) the furnace top is divided into a plurality of small blocks, the bottom arc length is less than or equal to 1.2 meters; (3) the mould is supported according to the divided small blocks; (4) a heat insulating material is arranged and the thickness of the heat insulating material is set; (5) the integral casting is performed. The fluidizaton roasting furnace ball arch furnace top has the advantages of good leak tightness, high intensity, long service life, short construction cycle and low cost, does not have any gap and does not fall off.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

Oven with convection air current and energy savings features

InactiveUS7592570B2Maximize efficiencyAvoid unnecessary power consumptionMechanical apparatusFood processingProcess engineeringEnergy supply

Owner:LINCOLN FOODSERVICE PRODS

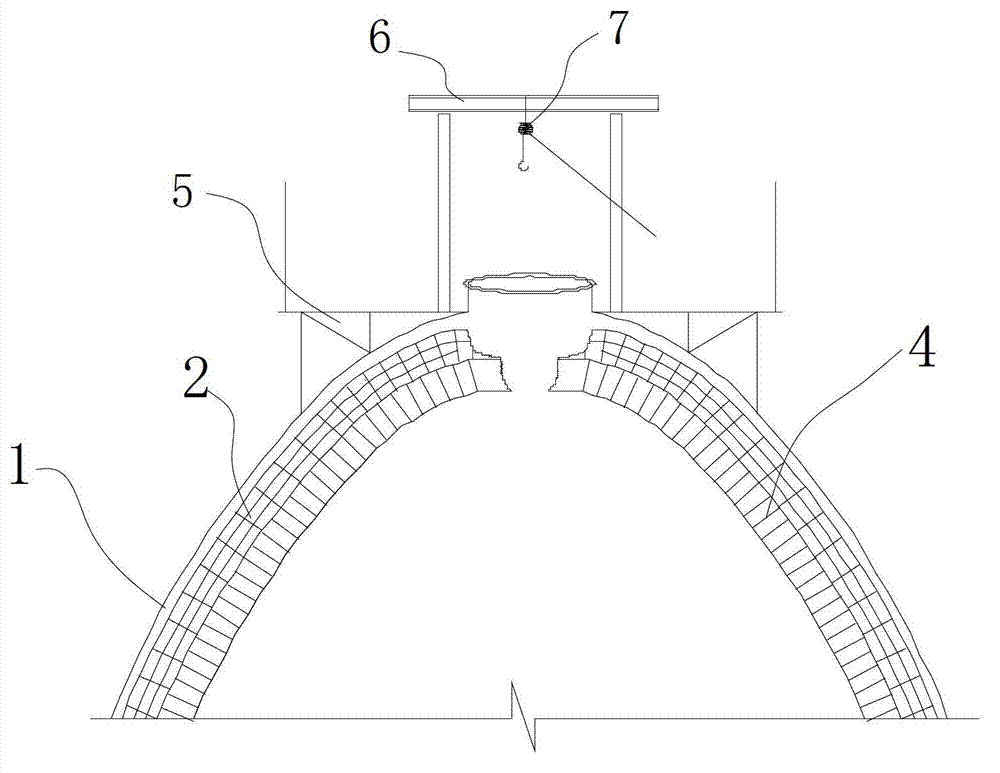

Method and device for dismantling refractory materials at arch crown of hot blast stove

ActiveCN102888481AGood removal effectWill not pose a safety hazardBrick-hot blast stovesLinings repairFire brickRefractory

The invention discloses a dismantling method of refractory materials, and particularly relates to a method for dismantling refractory materials at the arch crown of a hot blast stove, which is high in construction speed, and simple and convenient to implement. According to the characteristics of self-weight falling and mutual extruding and locking function of the refractory materials at the arch crown, stopper bricks are dismantled first, and then an impact bar acts on refractory bricks on the arch crown from bottom to top, so that the refractory bricks at the arch crown move upwards to break away from self-weight falling and mutual extruding and locking states and fall off naturally; and after the refractory bricks fall off,a heat-insulation refractory material layer can be easily removed, and simultaneously, all operators only need to stand on a steel platform at the top of the hot blast stove, therefore, potential safety hazards cannot be caused when the refractory bricks fall into the hot blast stove. Compared with the conventional manner of cracking the refractory bricks, the method directly damages the extrusion locking between the refractory bricks at the arch crown, and does not need to crack the refractory bricks, thereby greatly reducing the workload and reducing a great quantity of work.

Owner:CHINA 19TH METALLURGICAL CORP

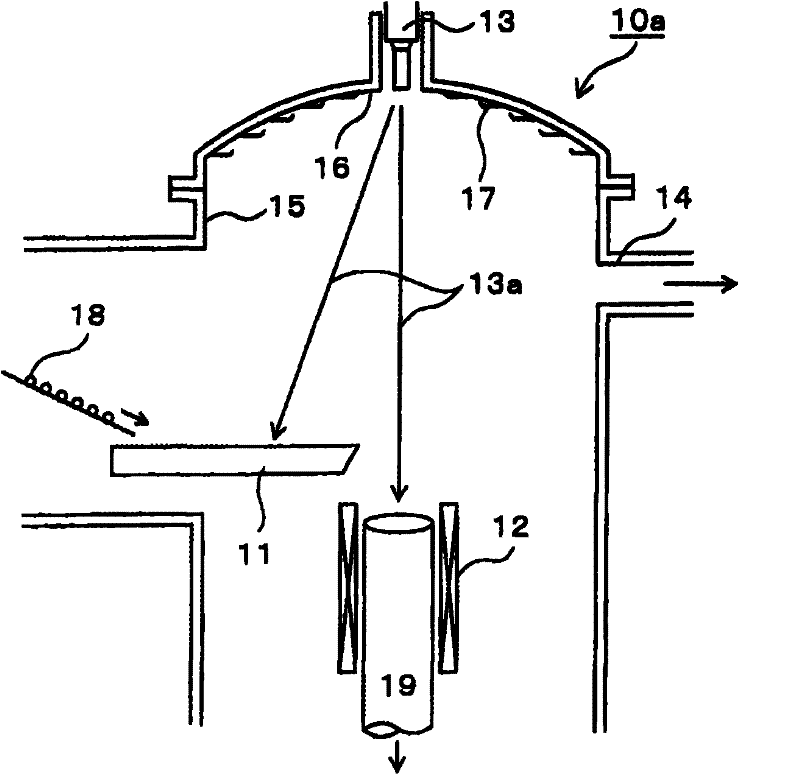

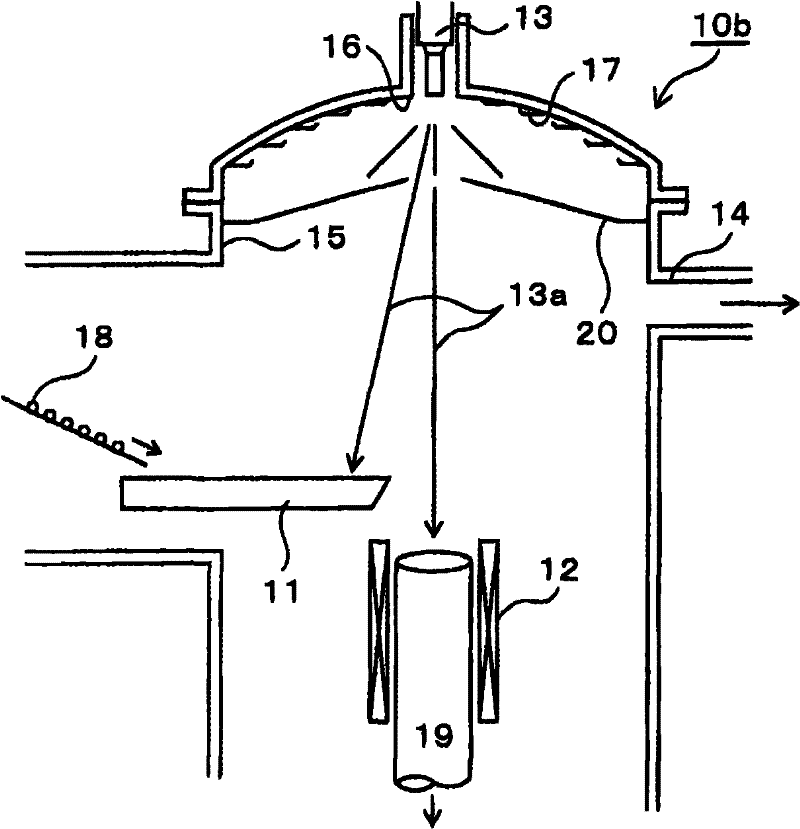

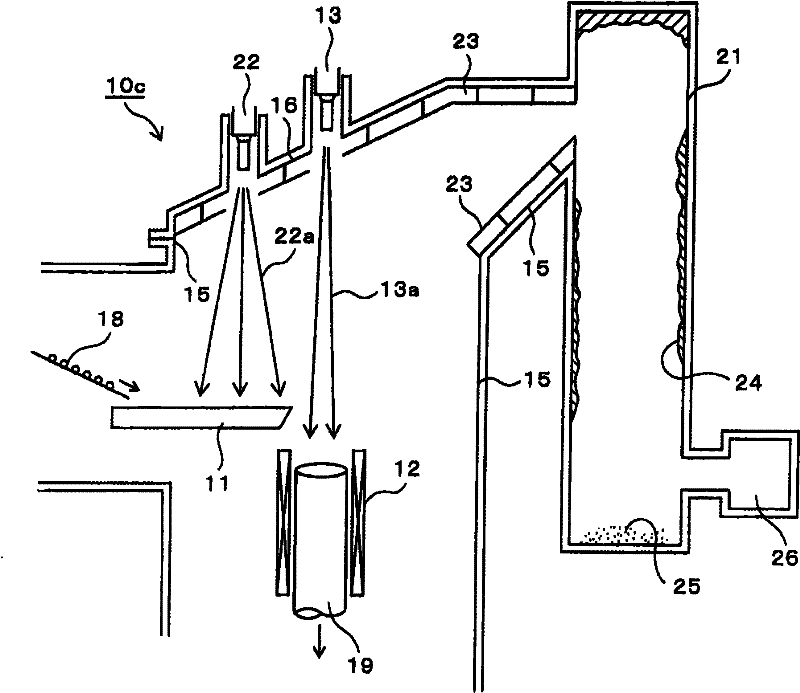

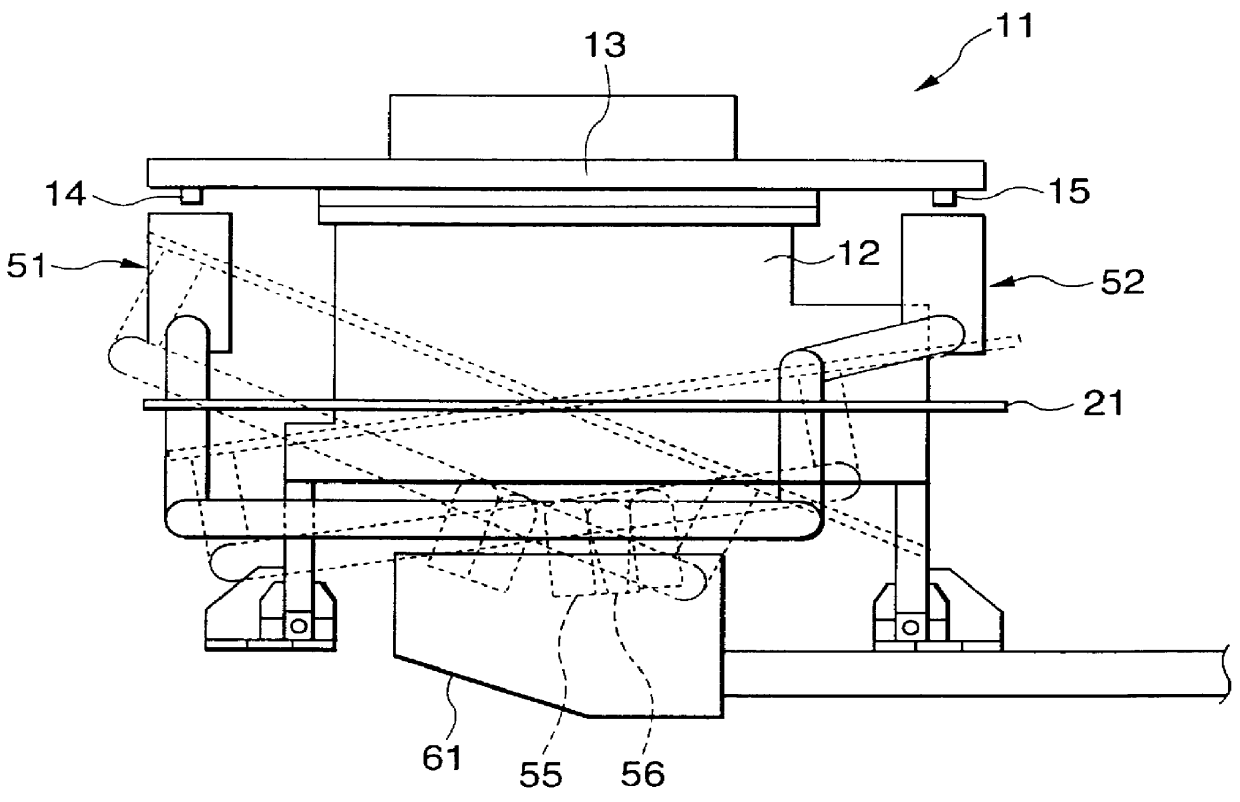

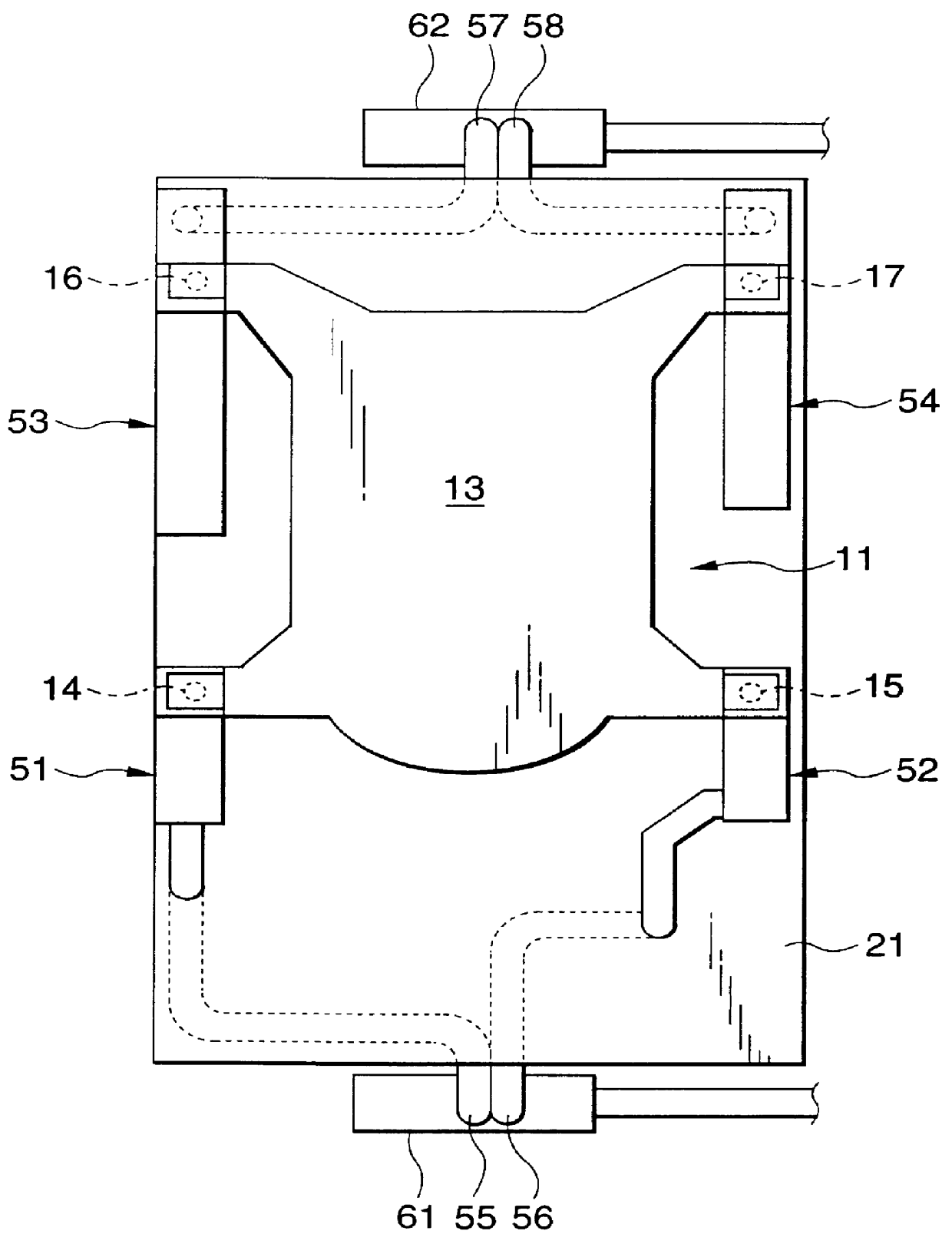

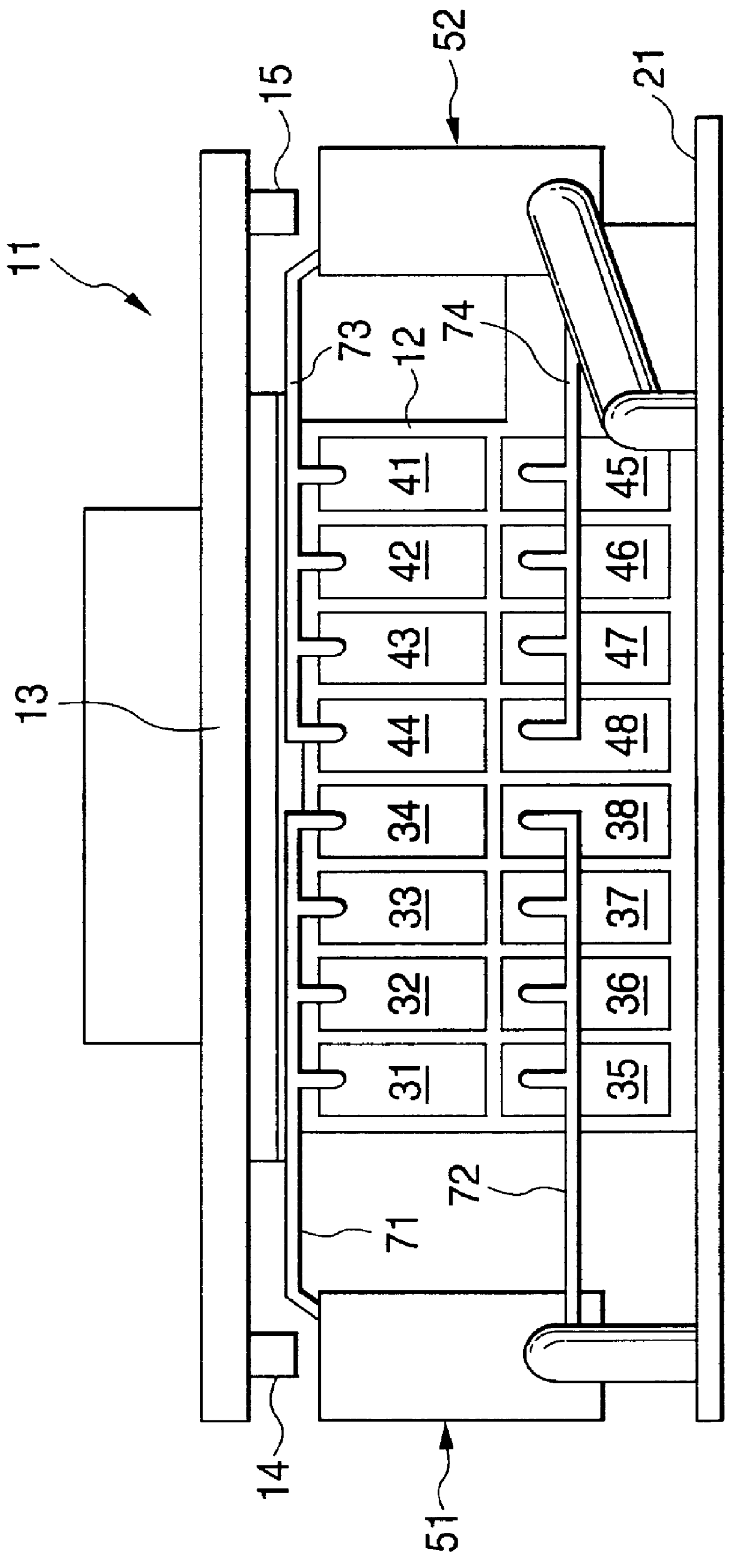

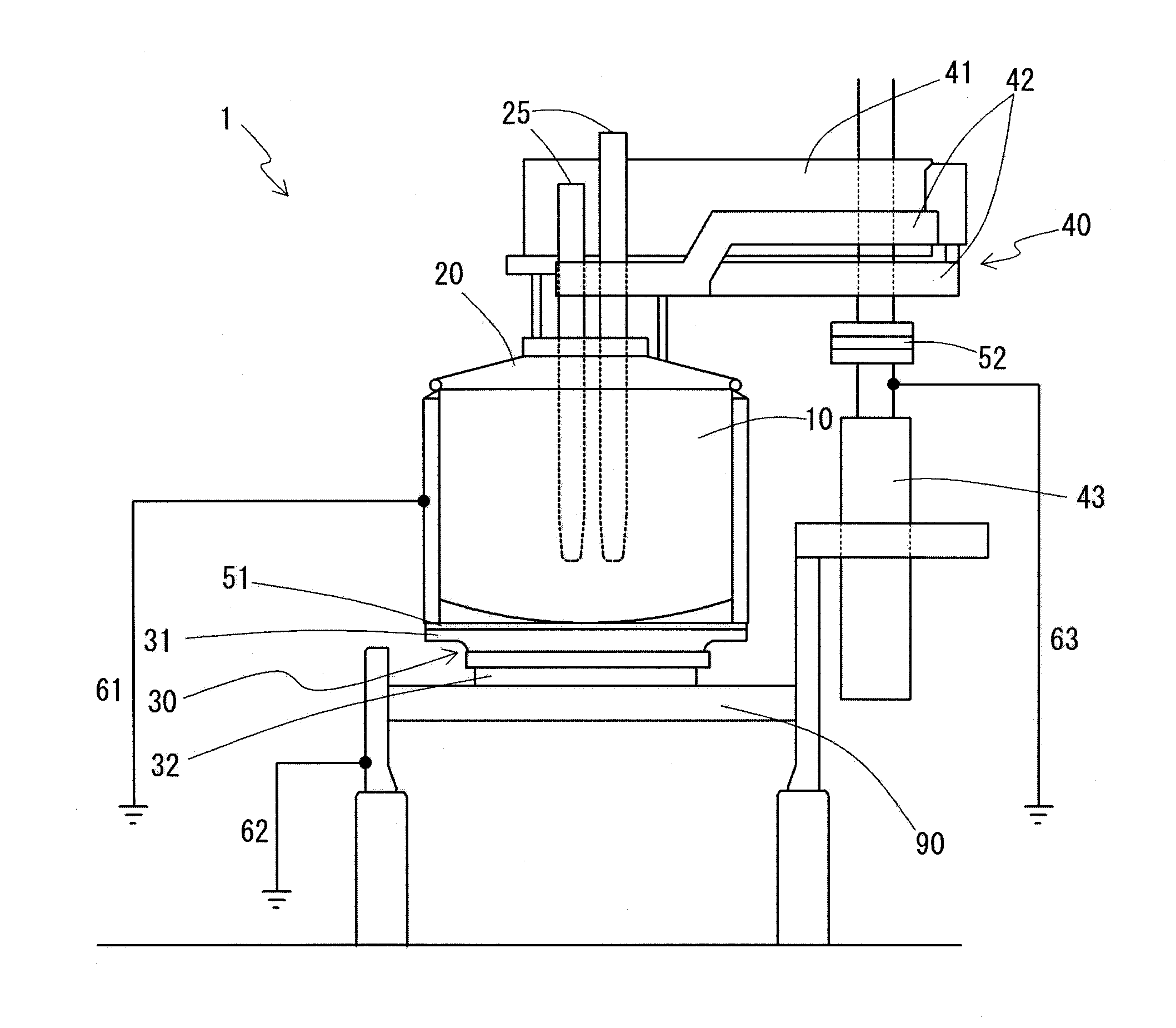

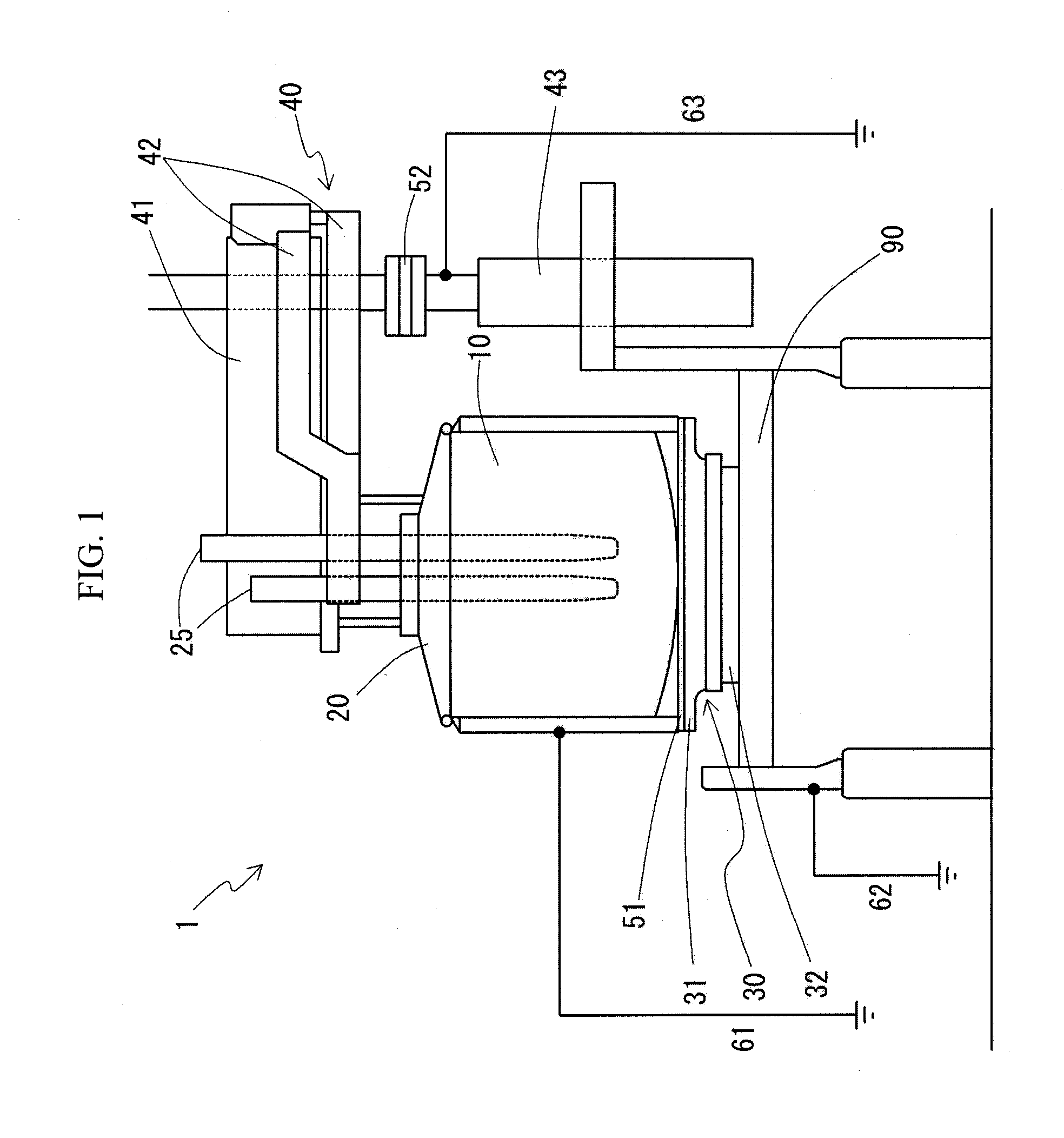

Apparatus for melting metal by electron beams and process for producing high-melting metal ingot using this apparatus

ActiveCN102175077ASuppress generationSuppresses the problem of mixing into the molten poolFurnace typesFurnace crowns/roofsMelting tankIngot

This invention provides an electron beam melting apparatus and a melting method that, in producing an ingot by dissolving a metal with an electron beam, can suppress the occurrence of new impurities in the ingot production, are less likely to again cause inclusion of once evaporated impurities from a melt pool within a hearth or a mold, and can be improved in operating rate. The electron beam melting apparatus for melting a high-melting metal comprises a raw material feed part for feeding a raw material, a raw material melting part, which is continued from the raw material feed part and, at the same time, is defined by a furnace wall and a ceiling wall, and comprises at least a hearth, a water cooling mold and an electron gun, and an exhaust part continued from the raw material melting part. In this electron beam melting apparatus, at least one of the furnace wall and the ceiling wall is lined with titanium or stainless steel, and, in addition, a plurality of fin-shaped members formed of titanium or stainless steel is provided in the ceiling wall. A lining, which can be attached and detached, is provided on the inner face of the electron beam melting apparatus.

Owner:TOHO TITANIUM CO LTD

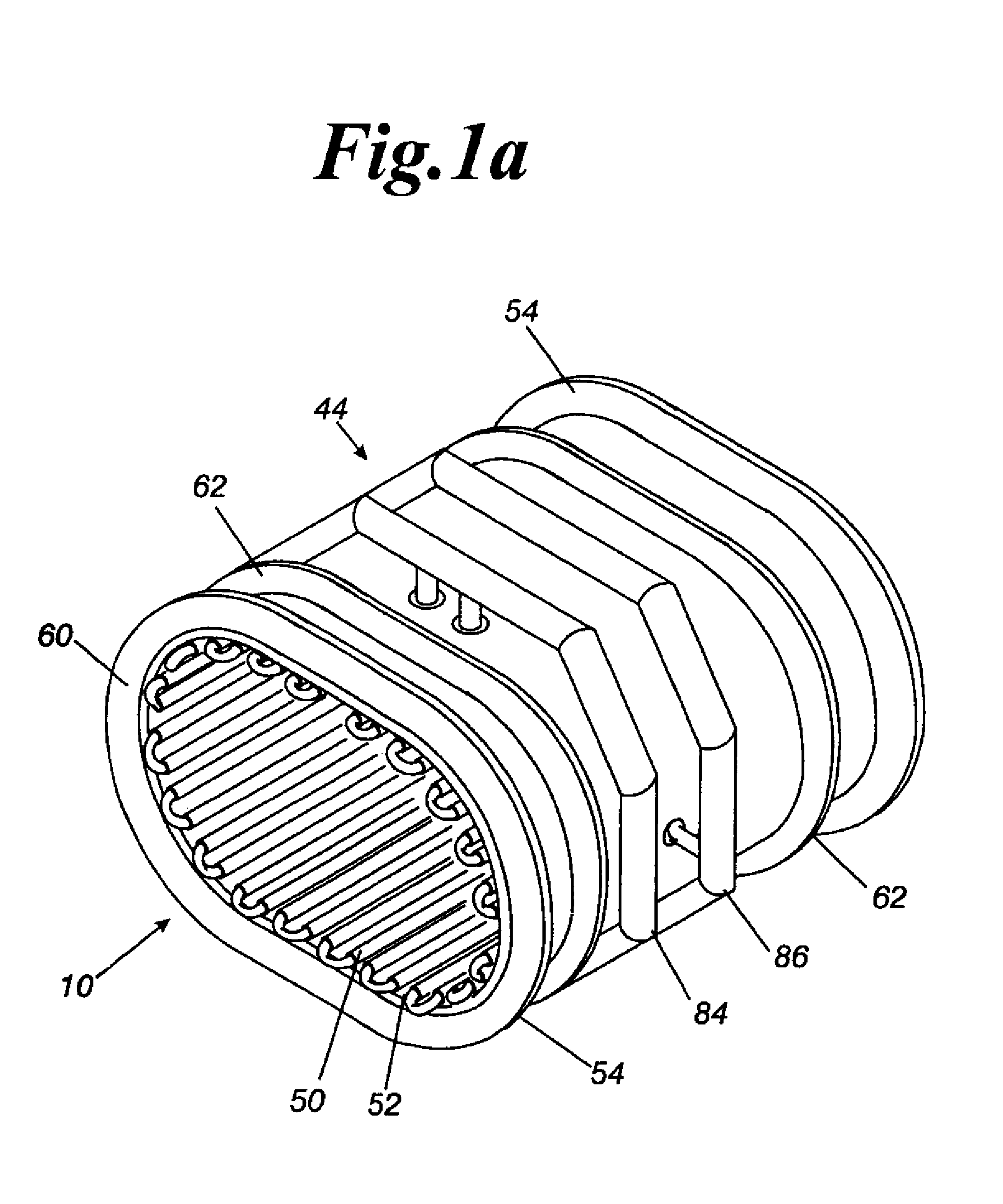

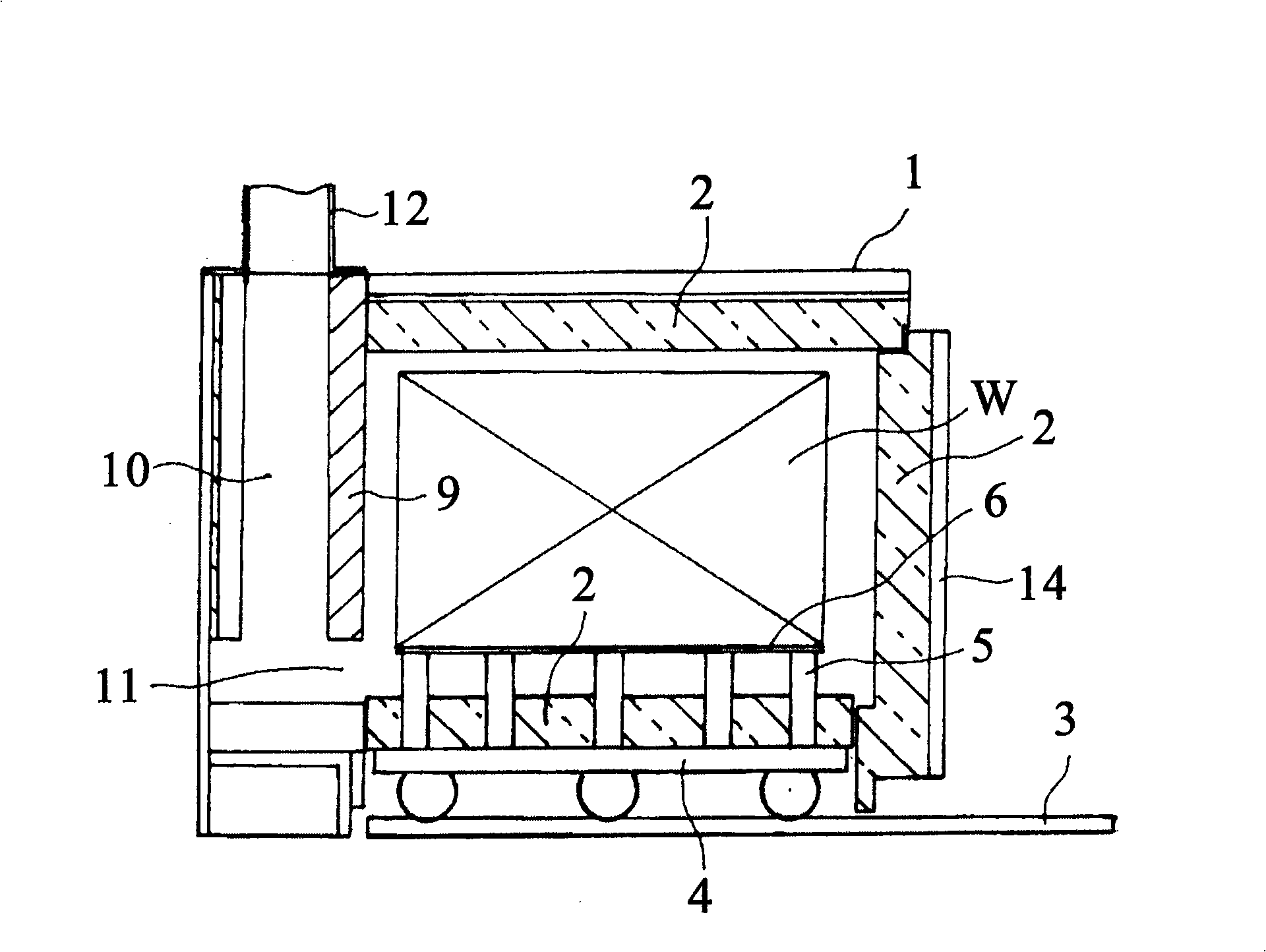

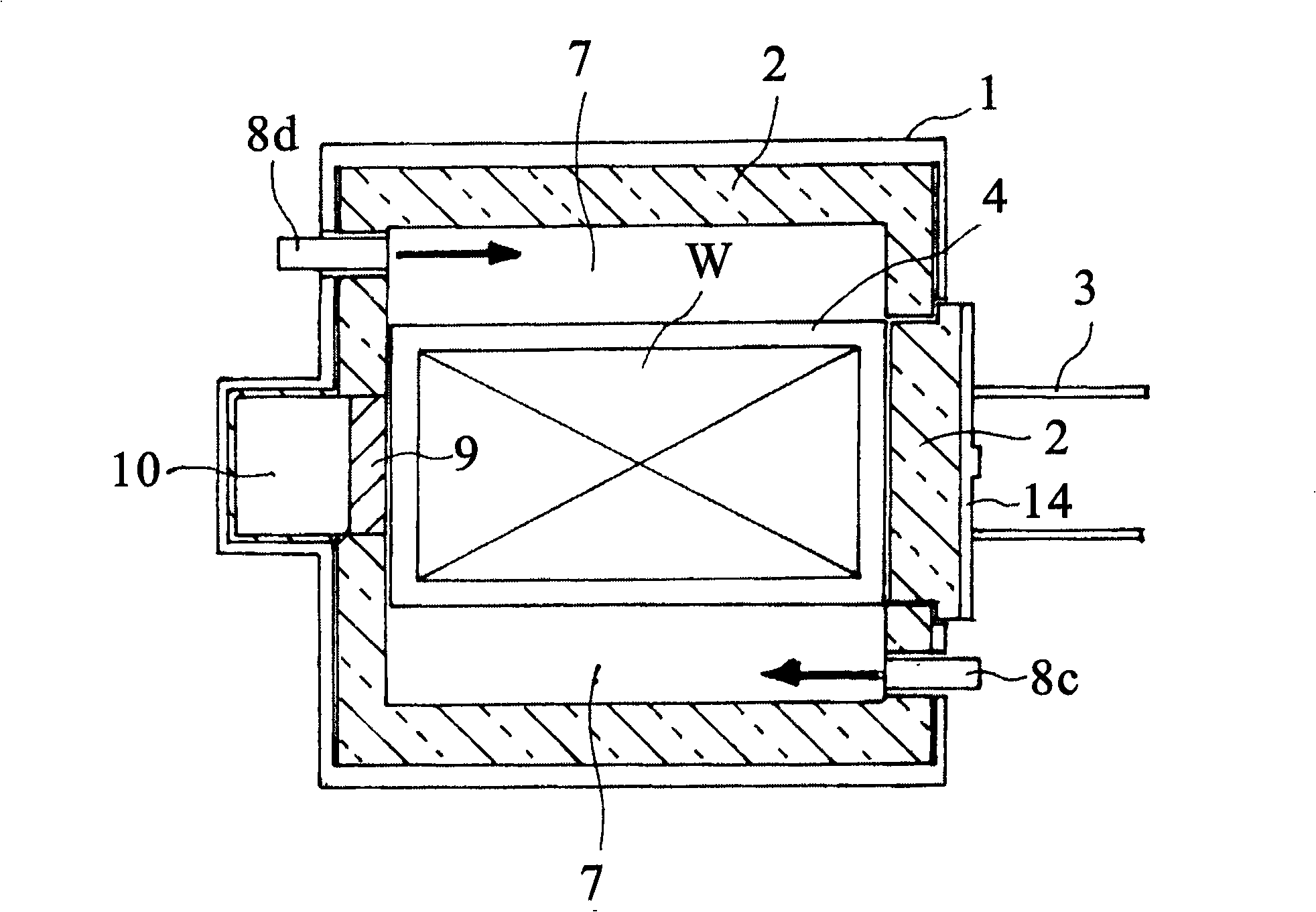

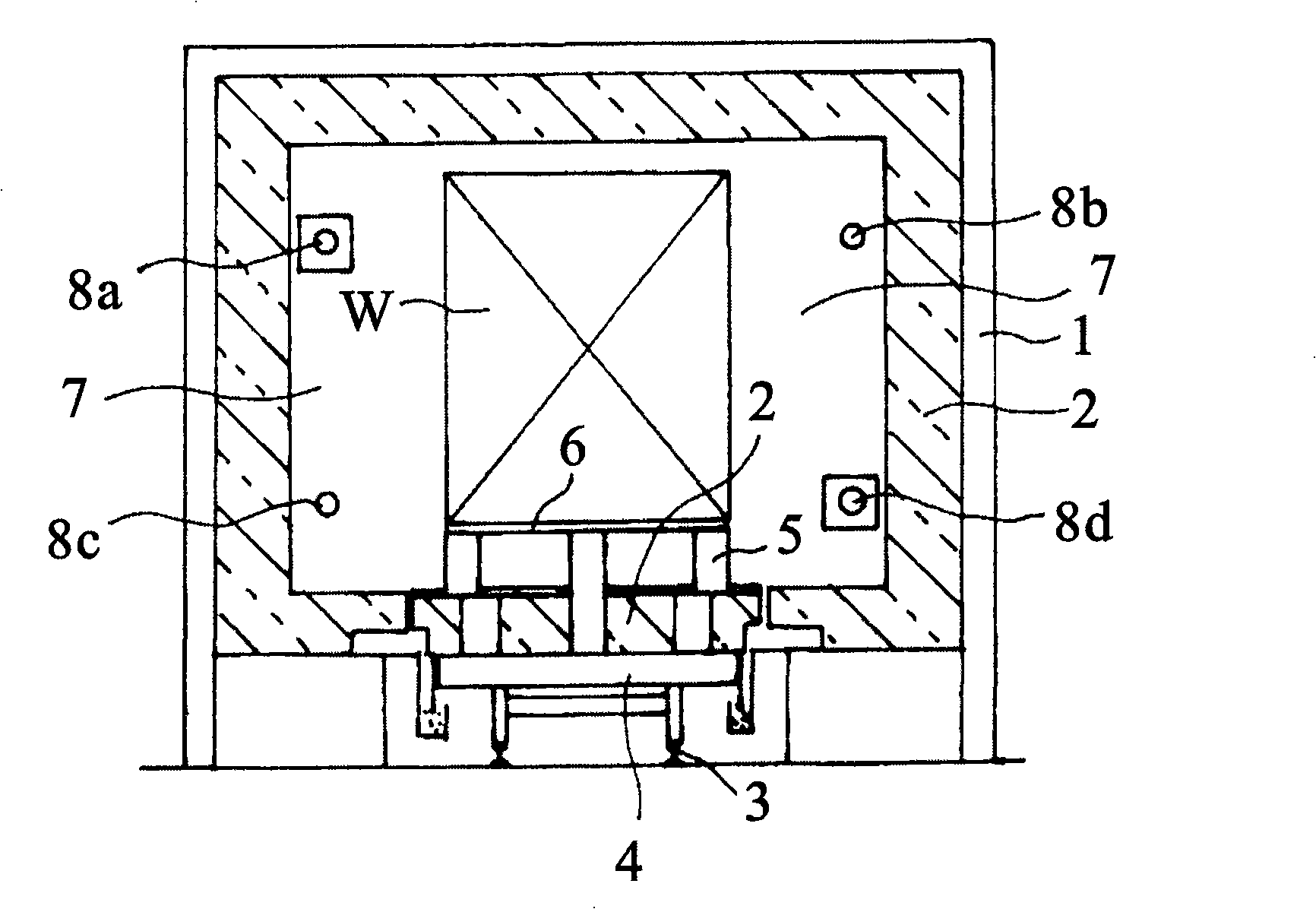

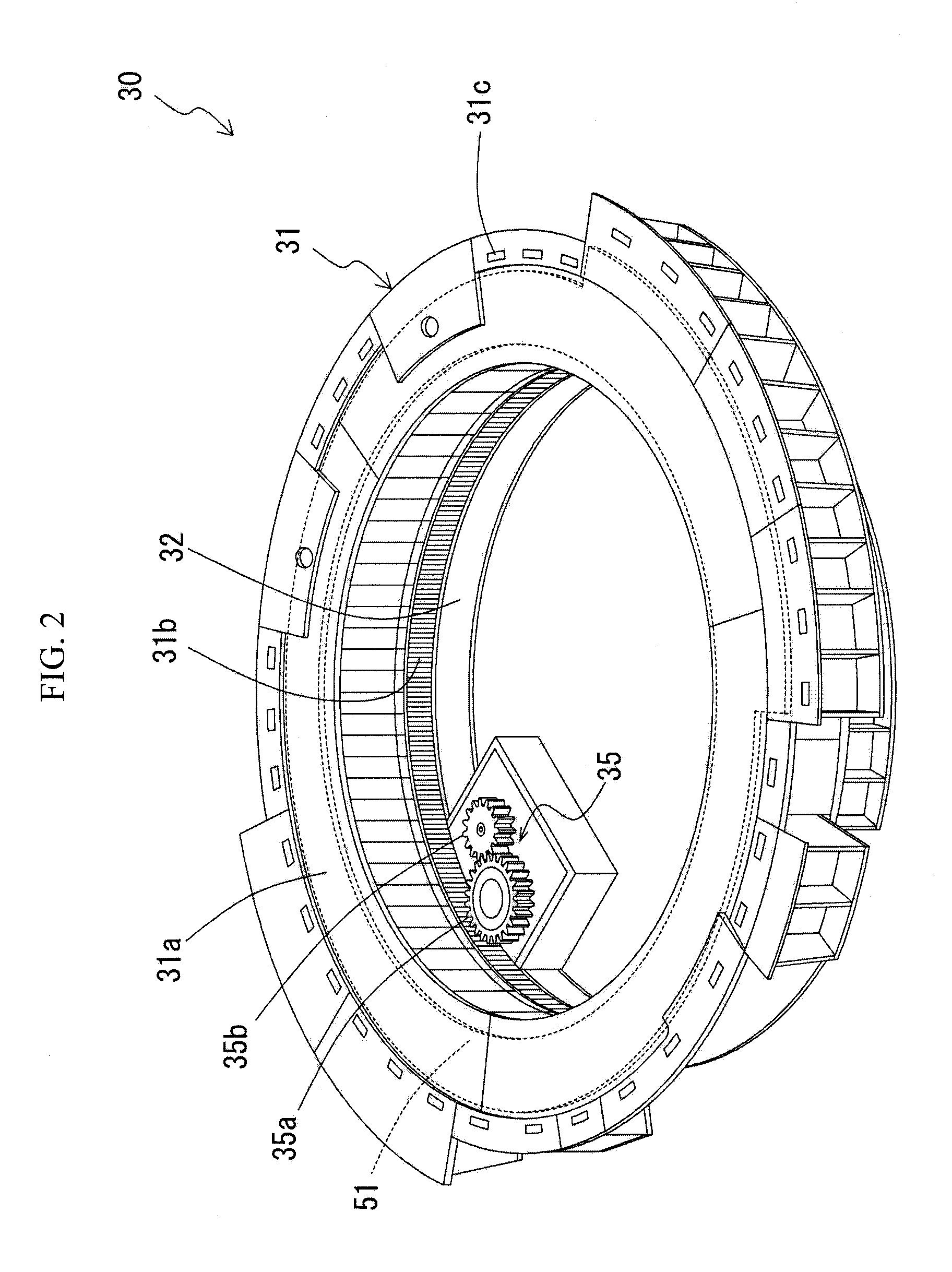

Electric arc furnace cooling apparatus

In an electric arc furnace cooling apparatus in which cooling water is made to flow into a plurality of water-cooled panels provided around side walls of a furnace body of an electric arc furnace to thereby cool the furnace body, a water collecting trough is provided in a platform mounted in the electric arc furnace to thereby collect waste water discharged from the water-cooled panels, and a water receiving trough is provided outside the platform to thereby receive waste water discharged from the water collecting trough.

Owner:DAIDO STEEL CO LTD

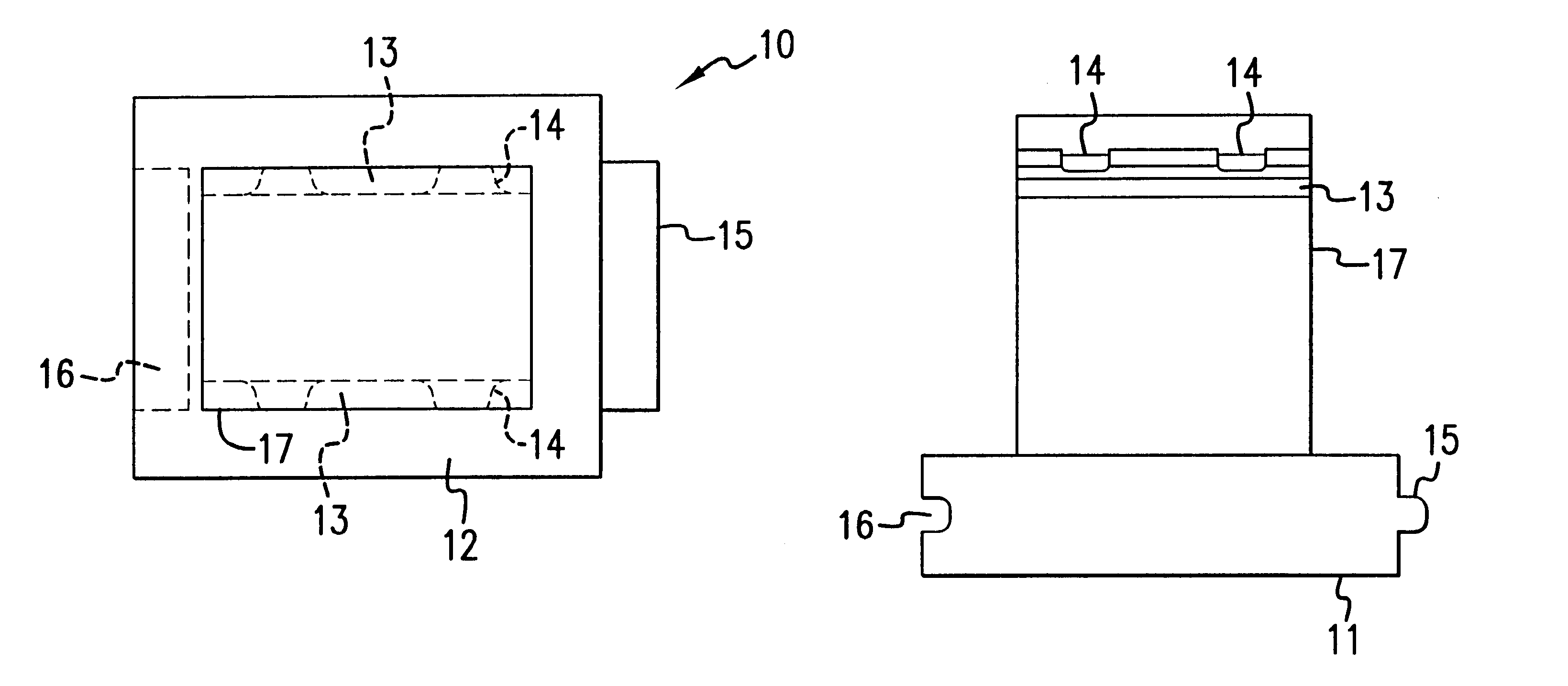

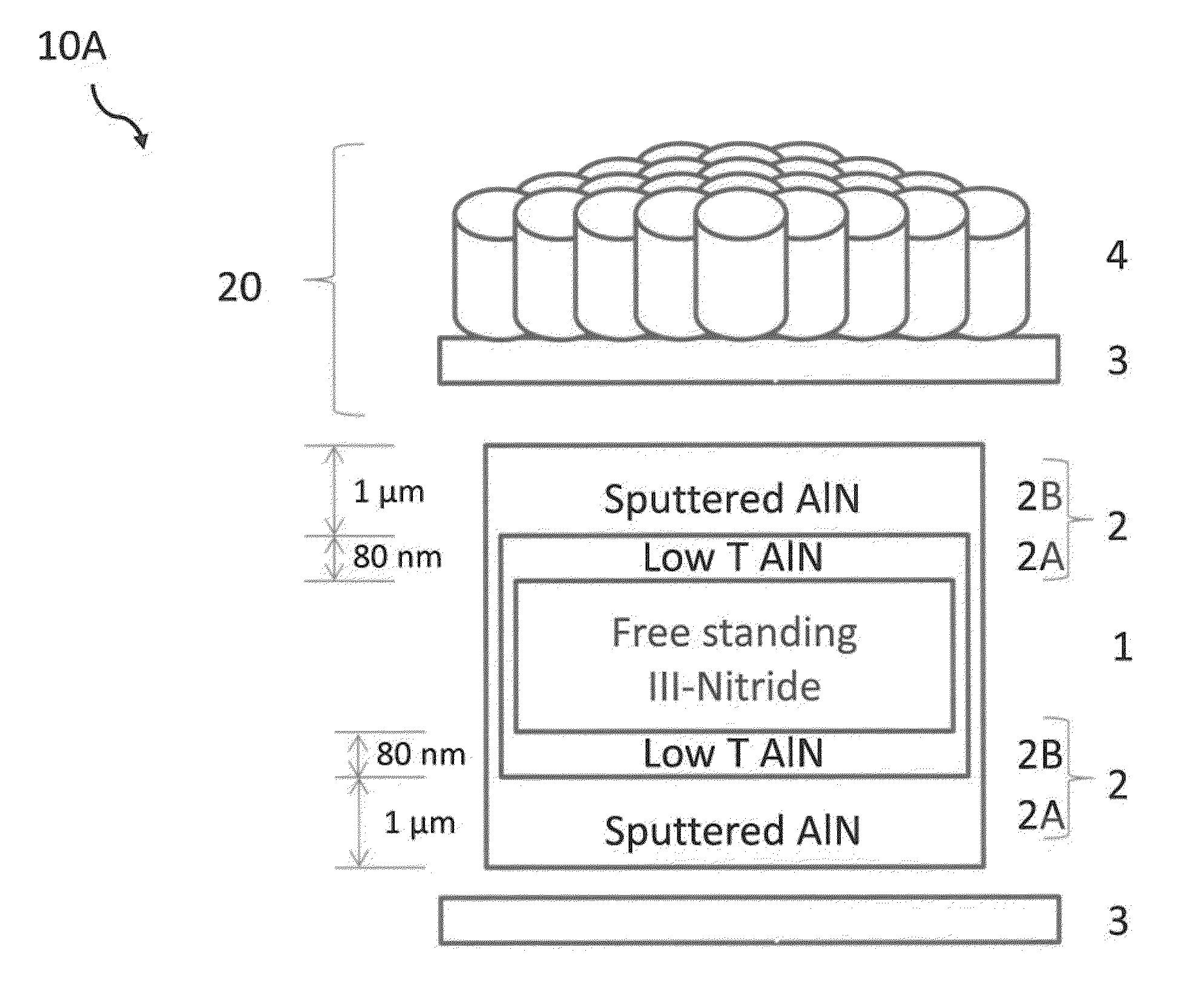

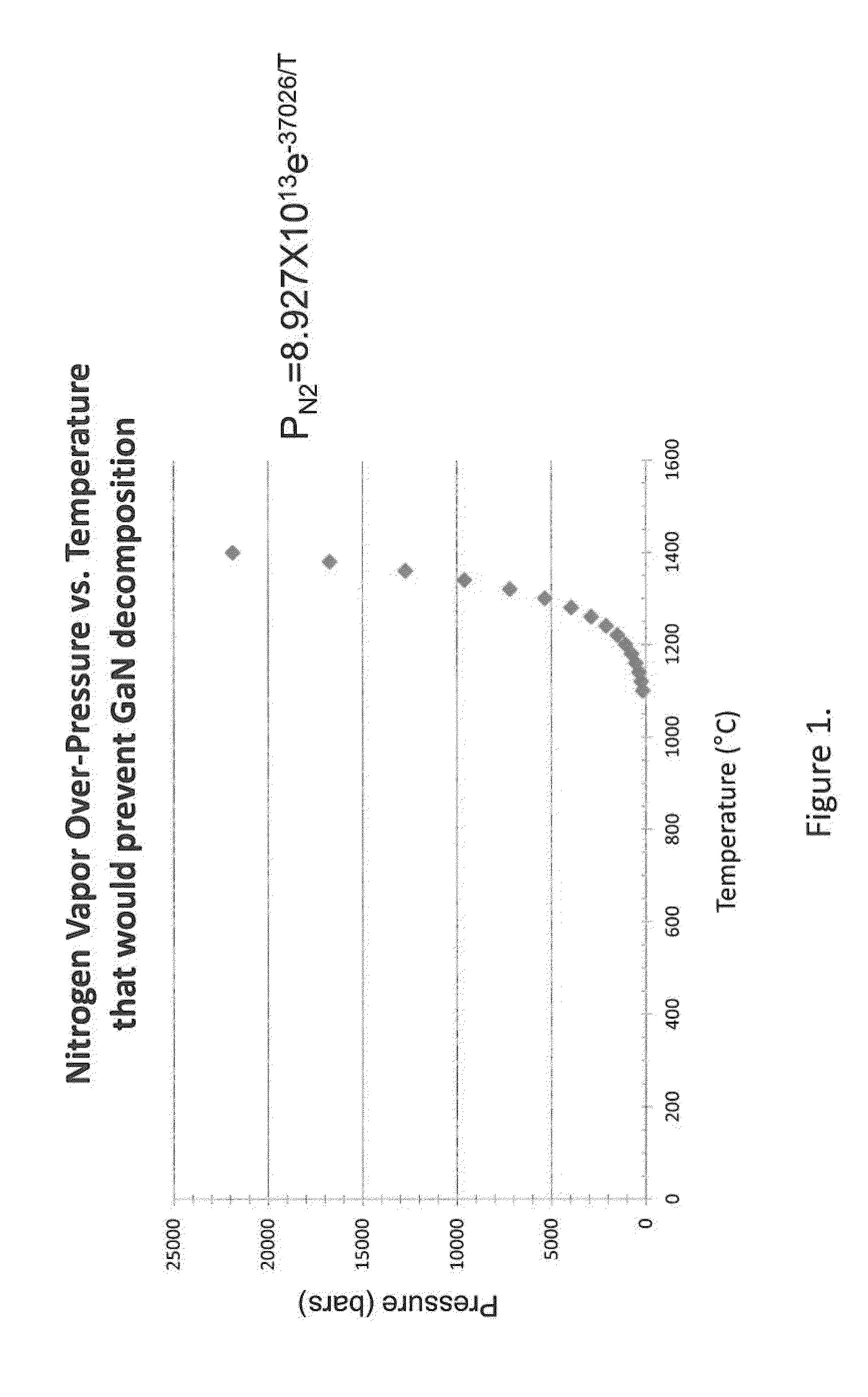

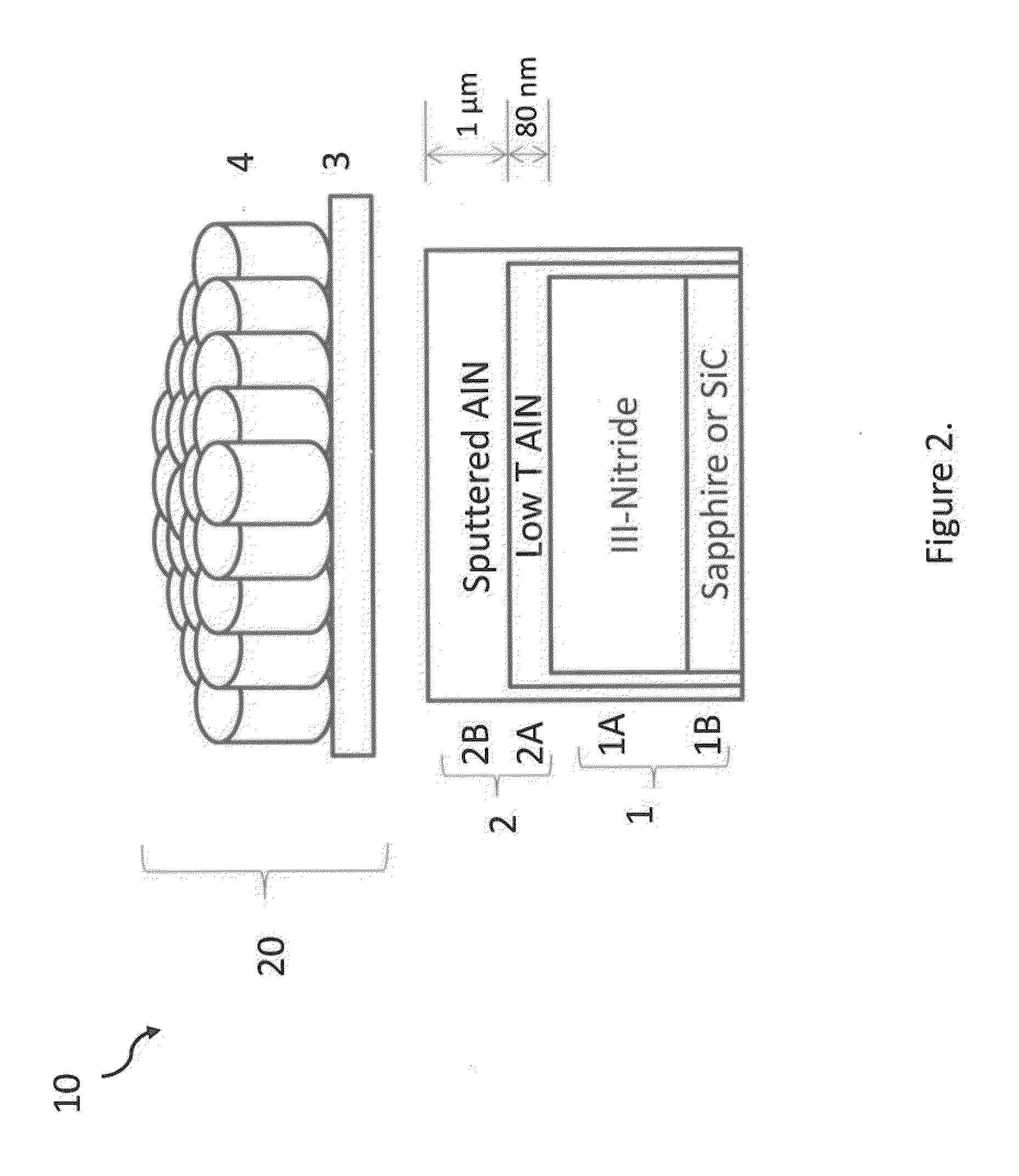

Methodology for annealing group iii-nitride semiconductor device structures using novel weighted cover systems

ActiveUS20160061528A1Sufficient flexibilityAvoid damageAfter-treatment apparatusSemiconductor/solid-state device manufacturingCovering systemNitrogen

An improved methodology for annealing group III-nitride semiconductor device structures using novel weighted cover systems that protect an annealing cap during the semiconductor annealing process is disclosed. The weighted cover system is configured for preventing the escape of nitrogen from the capped semiconductor during annealing. In one particular embodiment, the weighted cover system comprises a protective cover configured to be placed on the capped semiconductor during the anneal, and one or more weights configured to be placed on the protective cover to provide sufficient downward force to the protective cover that is placed on the capped semiconductor.

Owner:ARMY US SEC THE THE

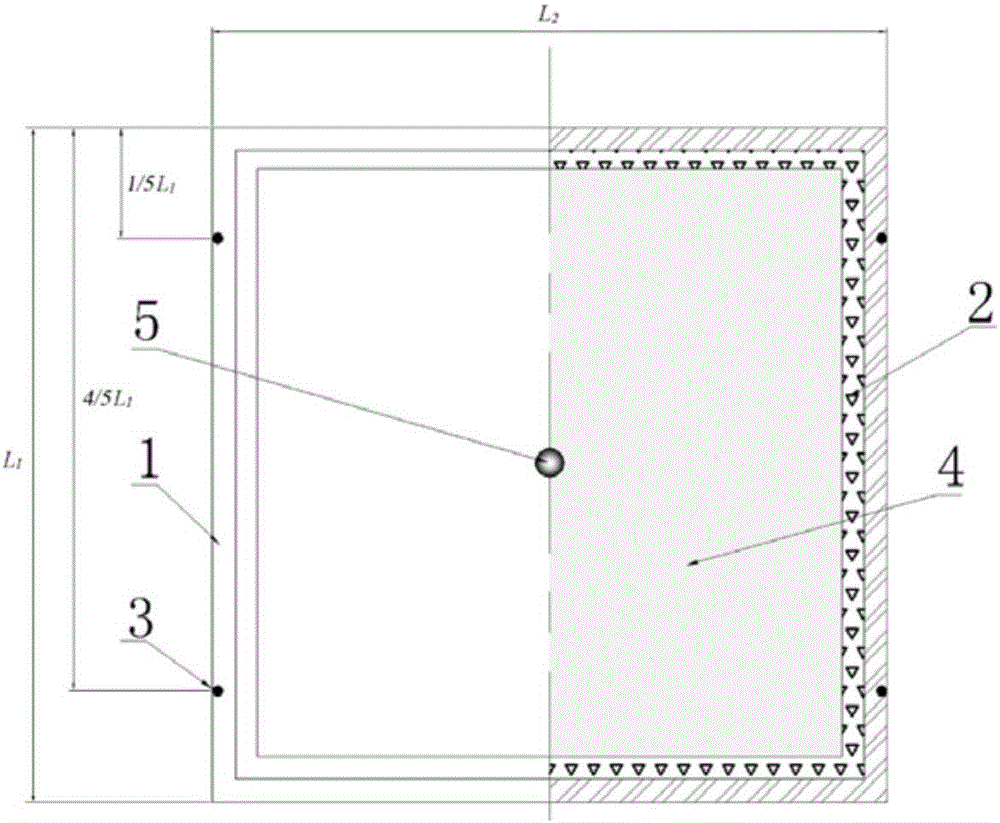

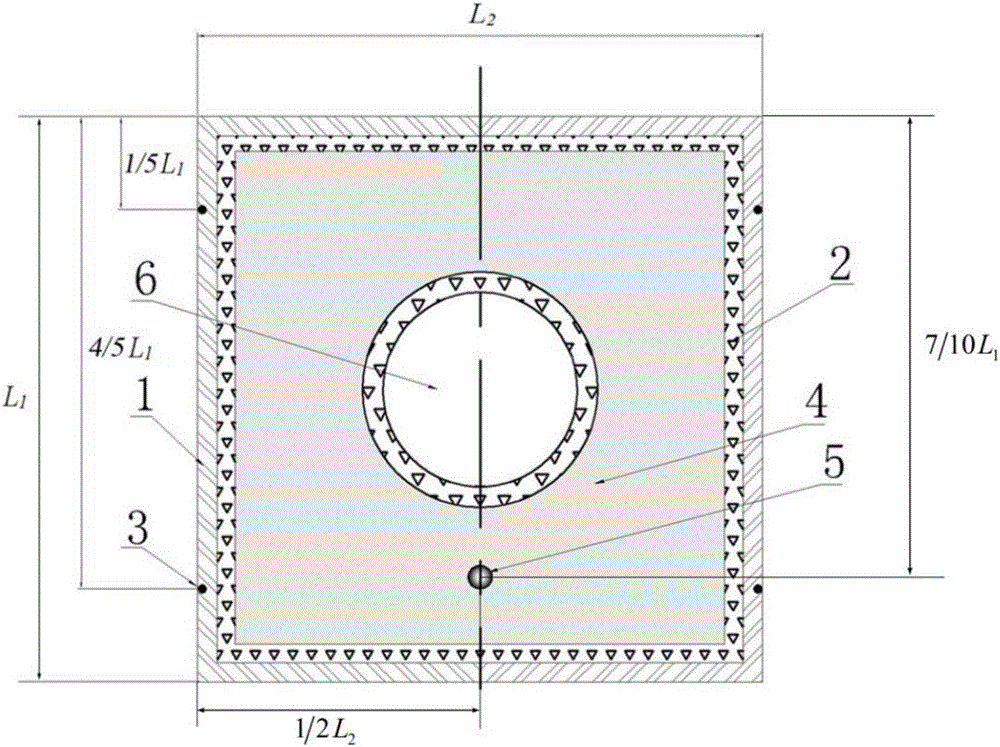

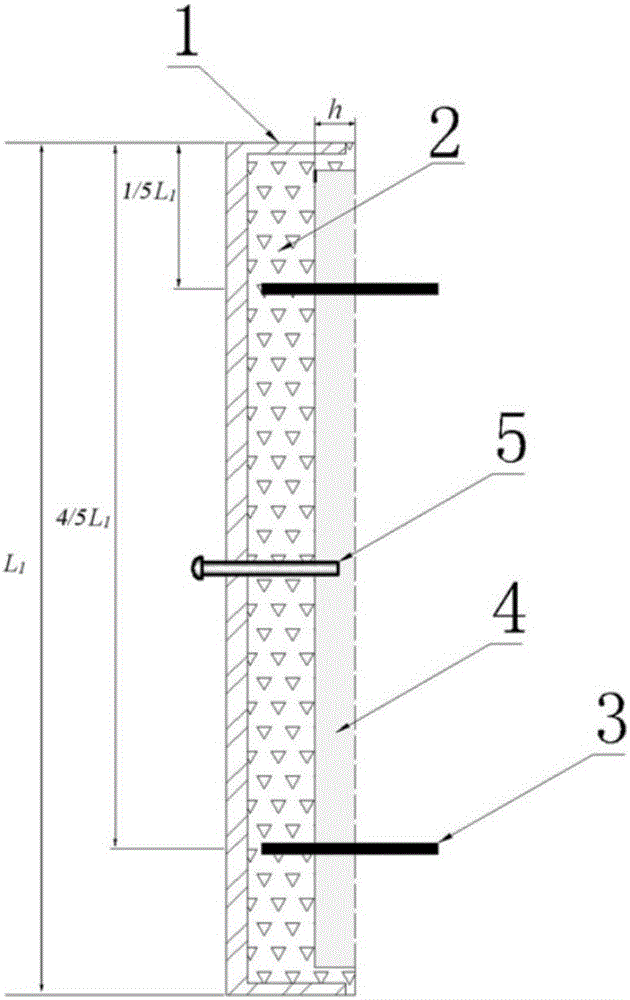

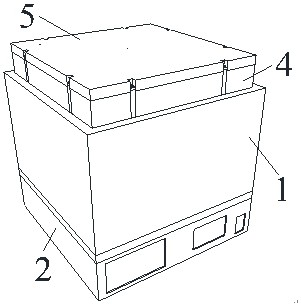

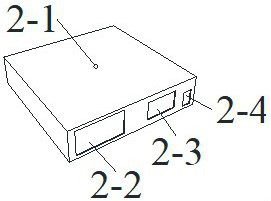

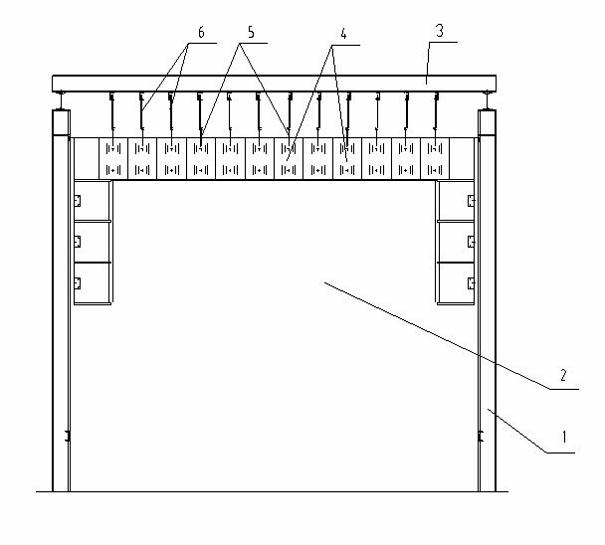

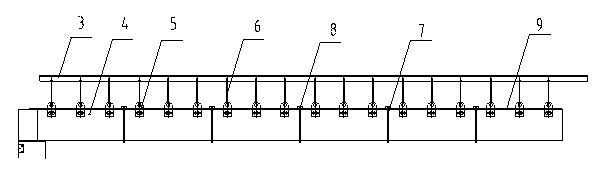

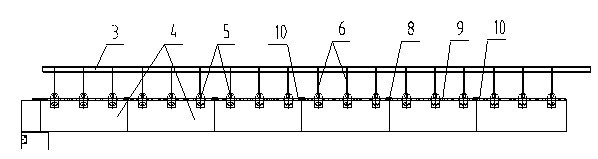

Top thermal insulation device suitable for anode baking furnace

ActiveCN105865207AInsulate heat conductionSmaller than emissivityIncreasing energy efficiencyFurnace crowns/roofsThermal insulationRadiation protection

The invention discloses a top thermal insulation device suitable for an anode baking furnace. An inner filling thermal insulation material (2) is arranged in a semi-open type cavity of a half-surrounded type radiation protection housing; in addition, a semi-open thermal insulation cavity (4) is formed in the opening surface end of the inner filling thermal insulation material (2); a thermocouple is arranged on the half-surrounded type radiation protection housing; in addition, a measuring head of the thermocouple is arranged in the semi-open thermal insulation cavity (4); and landing legs are installed on the inner surface of the half-surrounded type radiation protection housing. When normally running, the top thermal insulation device is fixed to the outer surface of the top part of a high-temperature region of the anode baking furnace, the thermocouple can continuously collect temperature data of the top part of the baking furnace, a worker can detect the running condition of the furnace body through the collected data and a top part observation hole, the thermal insulation device can also be simply and rapidly disassembled from the top part, and a maintainer is convenient to carry out overhauling and maintenance. The top thermal insulation device also has the advantages of long service life, small running and maintenance workload and low running cost and is suitable for being used as an external thermal insulation device for the high-temperature region of the anode baking furnace.

Owner:CENT SOUTH UNIV

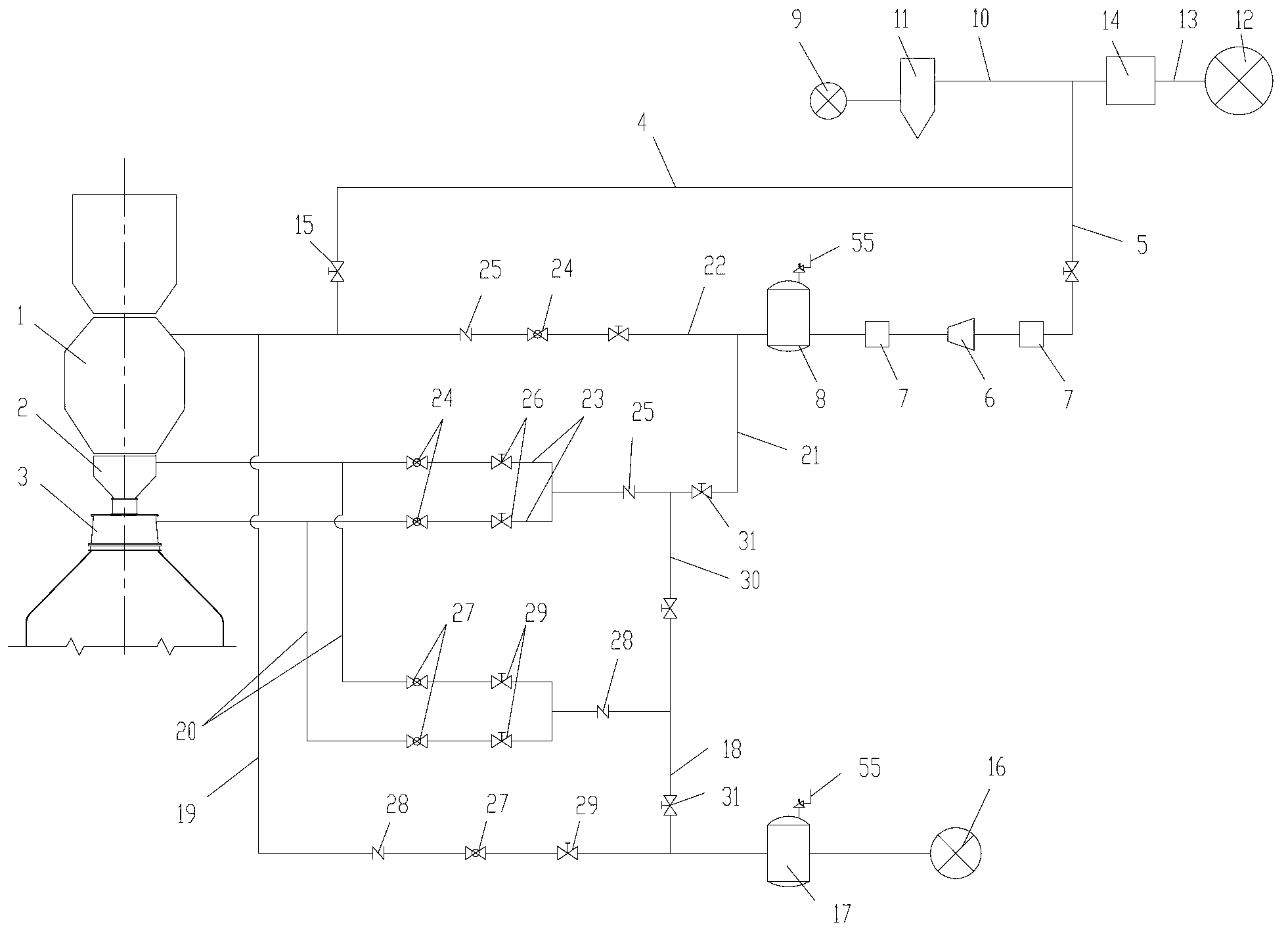

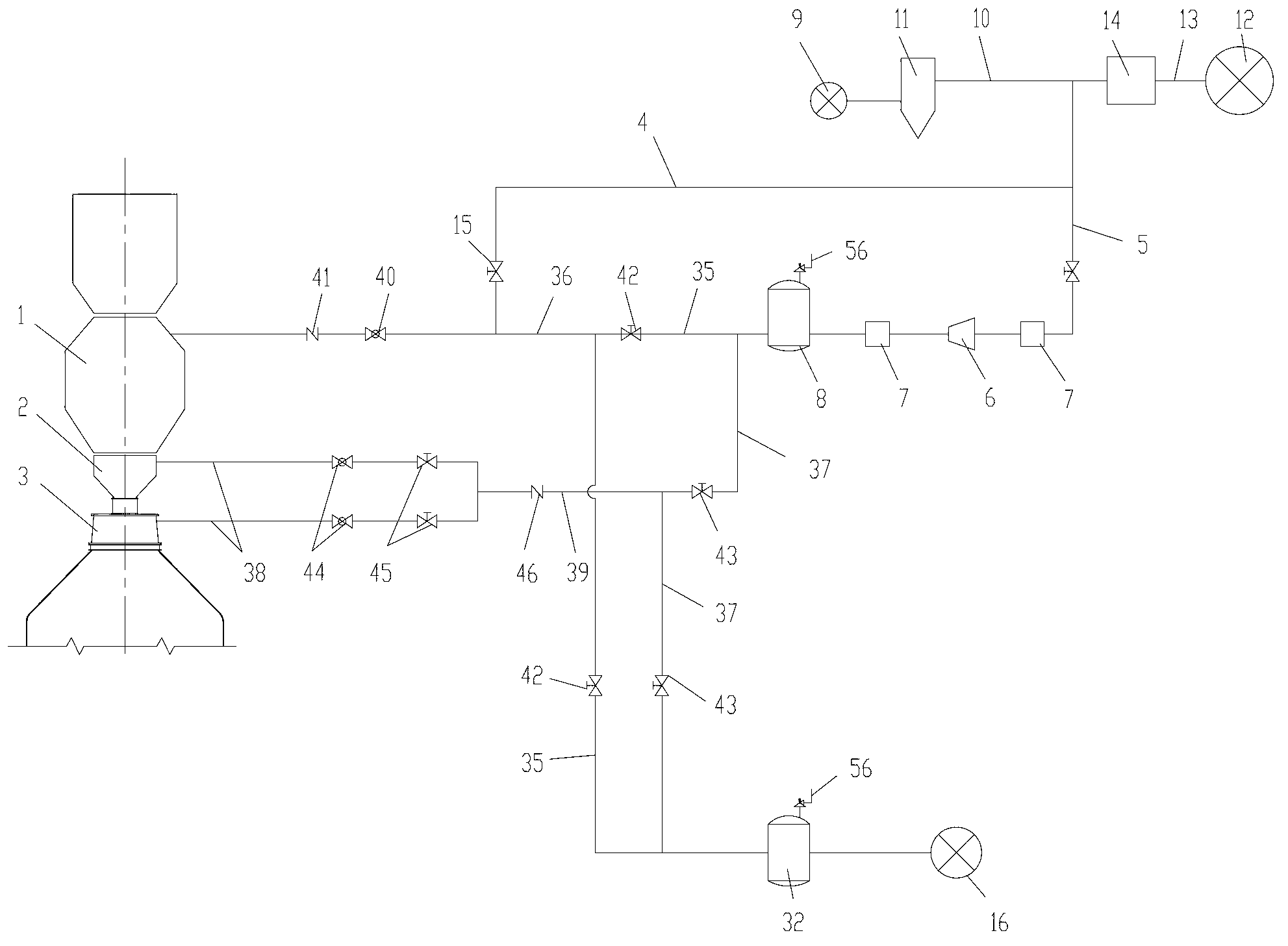

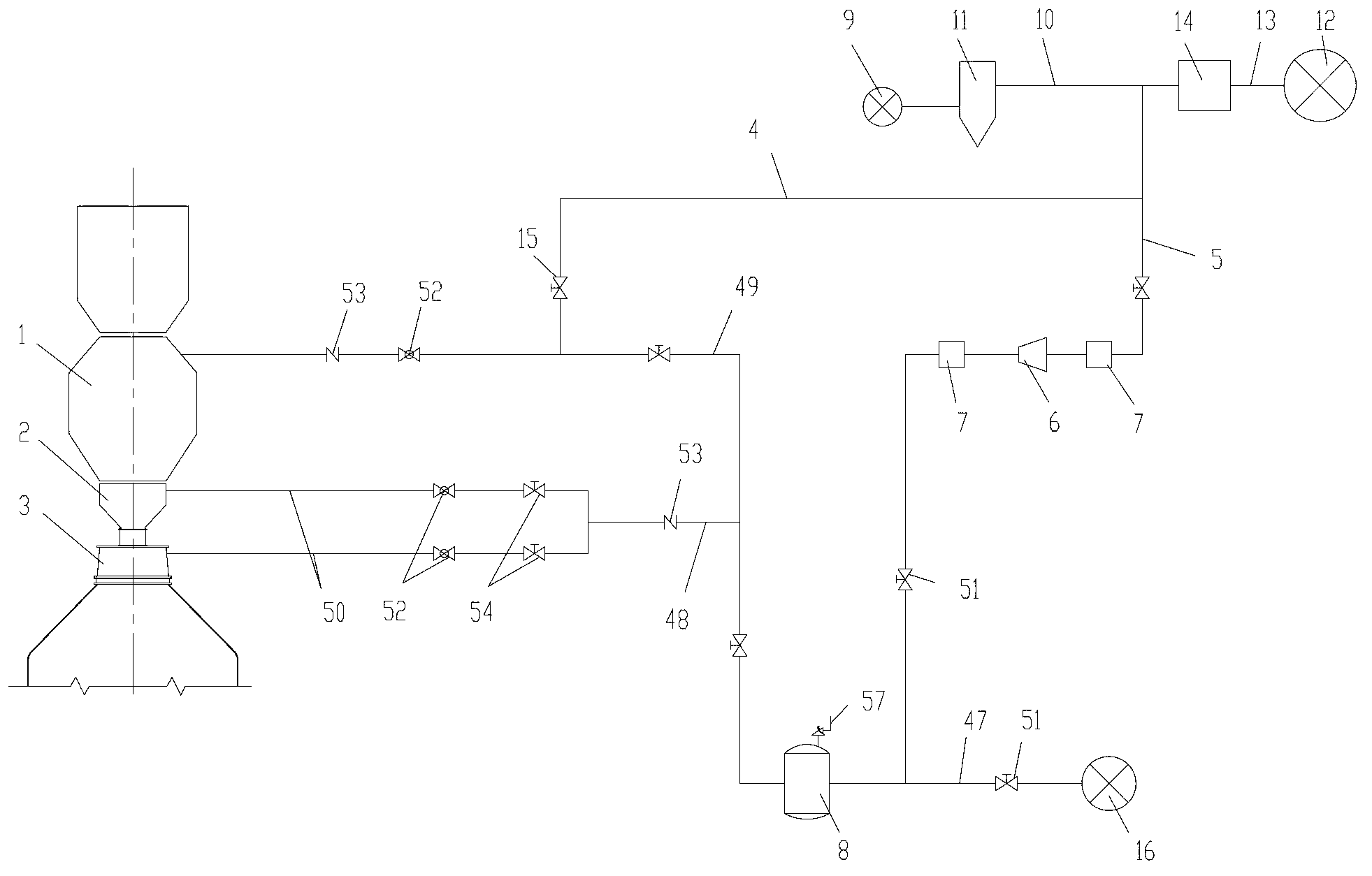

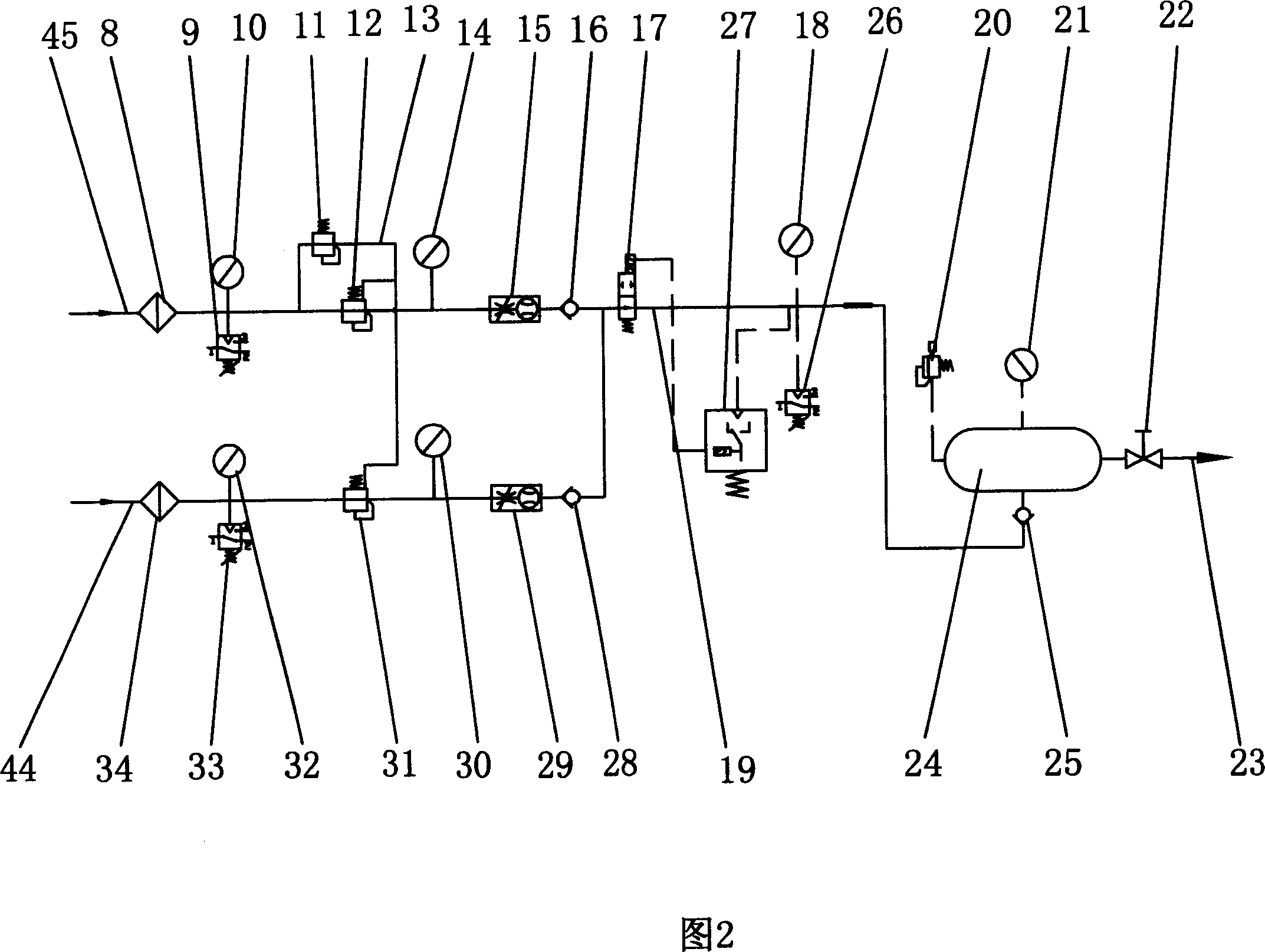

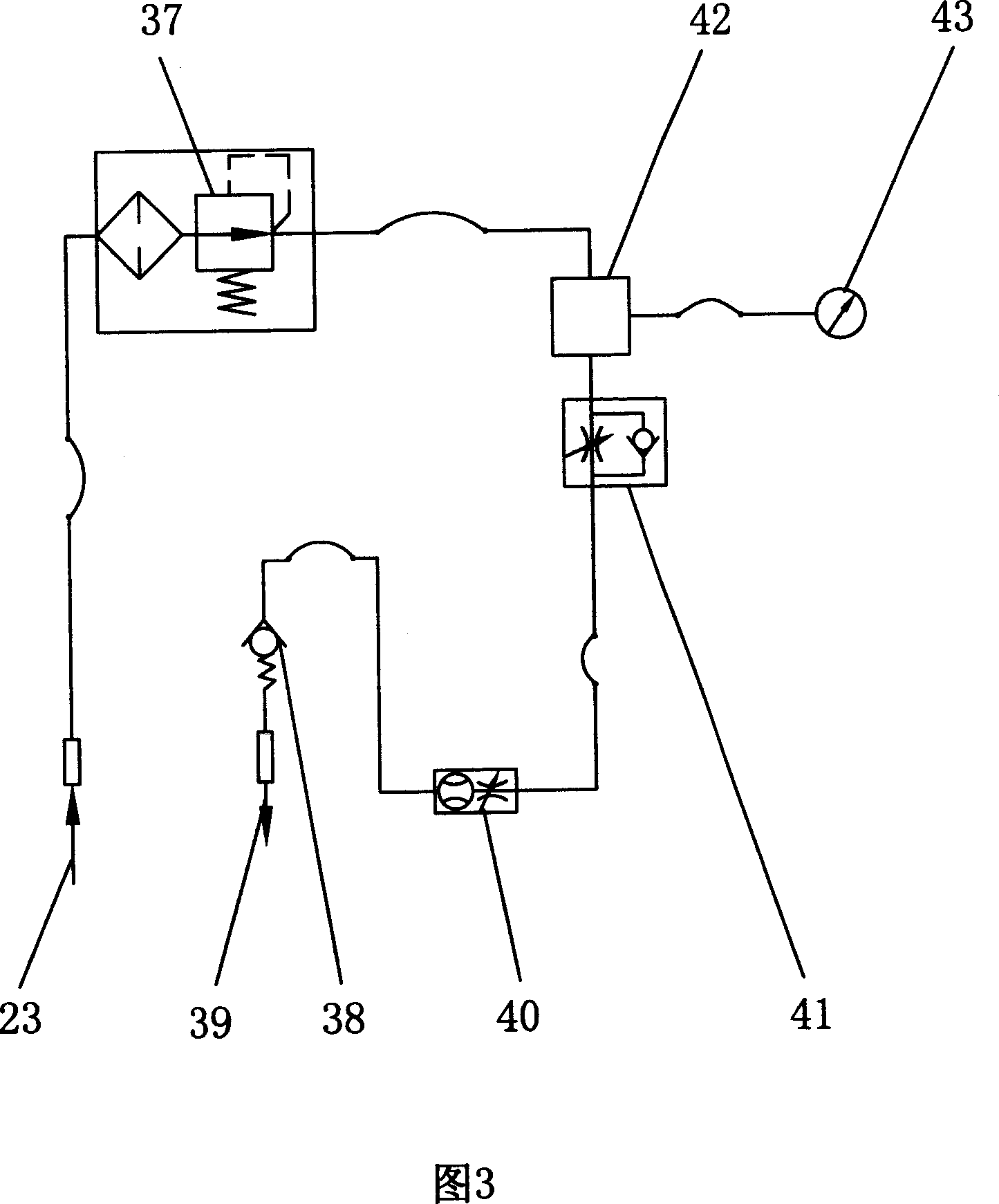

Blast furnace top gas supply system

InactiveCN103255251AHigh calorific valueReduce consumptionMaintainance of heating chambersBell-and-hopper arrangementNitrogenEngineering

The invention discloses a blast furnace top gas supply system which comprises a furnace top nitrogen system for supplying nitrogen to a blast furnace top and a furnace top coal gas system which is connected in parallel with the furnace top nitrogen system and is used for supplying coal gas to the blast furnace top, wherein a switch device for switching and selecting a blast furnace top gas supply source is arranged between the furnace top coal gas system and the furnace top nitrogen system. According to the blast furnace top gas supply system disclosed by the invention, since the furnace top coal gas system is arranged in parallel with the existing furnace top nitrogen system and the switch device is arranged between the furnace top nitrogen system and the furnace top coal gas system, coal gas or nitrogen can be independently supplied to the blast furnace top according to the actual working conditions, or coal gas and nitrogen can be supplied to the blast furnace top at the same time, a sufficient gas source to the blast furnace top and normal operation of the equipment can be guaranteed, the nitrogen consumption can be reduced or canceled, the calorific value of the blast furnace coal gas can be increased, and the blast furnace top gas supply system can be implemented by transforming the existing furnace top gas supply system.

Owner:CISDI ENG CO LTD

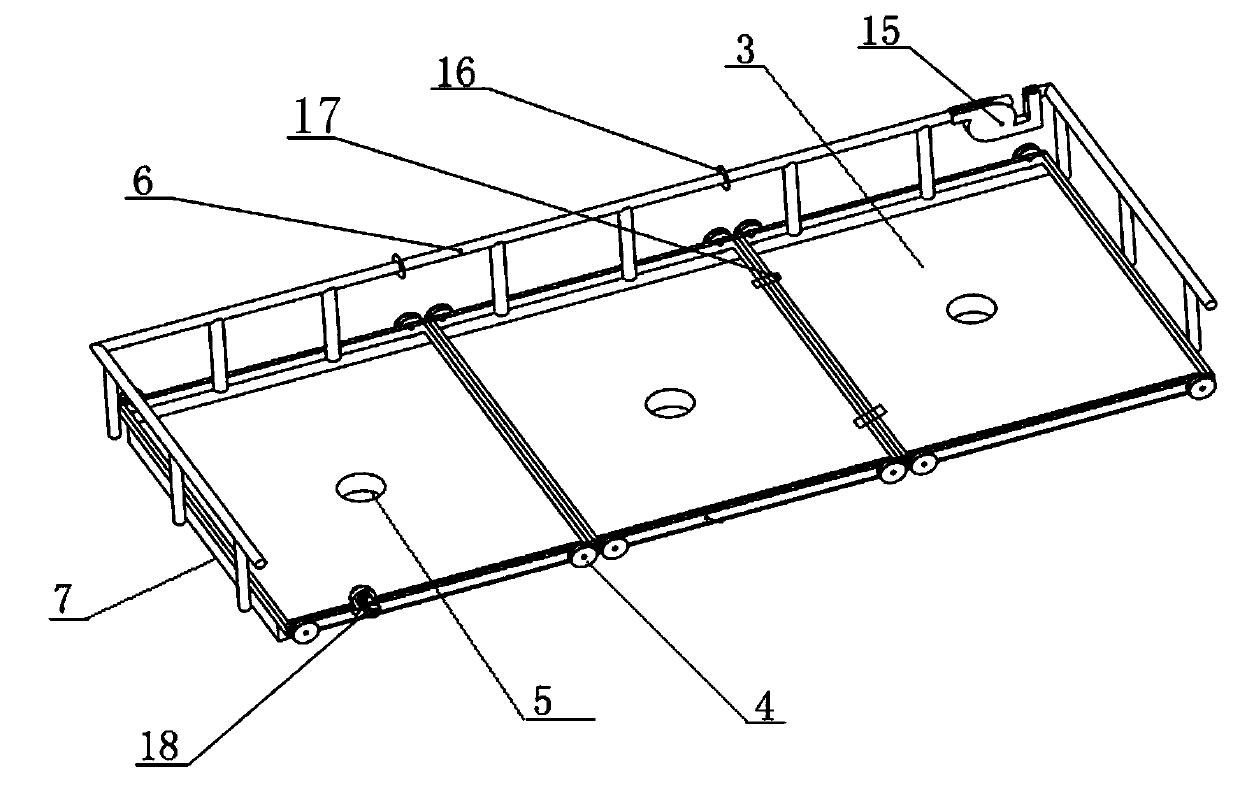

Annular kiln with movable flat top

InactiveCN103499213AIncrease productionFlexible splicing and lengtheningFurnace crowns/roofsWaste heat treatmentBrickLap joint

The invention discloses an annular kiln with a movable flat top. The annular kiln with the movable flat top comprises a kiln body, a kiln crown and kiln walls arranged on the two sides. Compared with the prior art, the annular kiln with the movable flat top is characterized in that the kiln crown is the movable flat top, wherein the movable flat top is formed by detachably connecting a plurality of steel structural frames which are in lap joint with one another; each steel structural frame is provided with idler wheels, wherein the idler wheels are matched with tracks arranged at the upper ends of the kiln walls; the lower end face of the movable kiln crown is provided with an insulating layer; a hot gas recycling pipeline is arranged on the kiln crown. The annular kiln with the movable flat top has the advantages of saving money, and being convenient to place, high in degree of mechanization, capable of lowering labor intensity for workers and improving work efficiency, good in heat preservation effect when green bricks are fired, high in rate of finished products, rapid in cooling speed, easy to cool for brick taking, convenient to maintain, and particularly suitable for overall transformation of an existing old kiln.

Owner:黄五三 +3

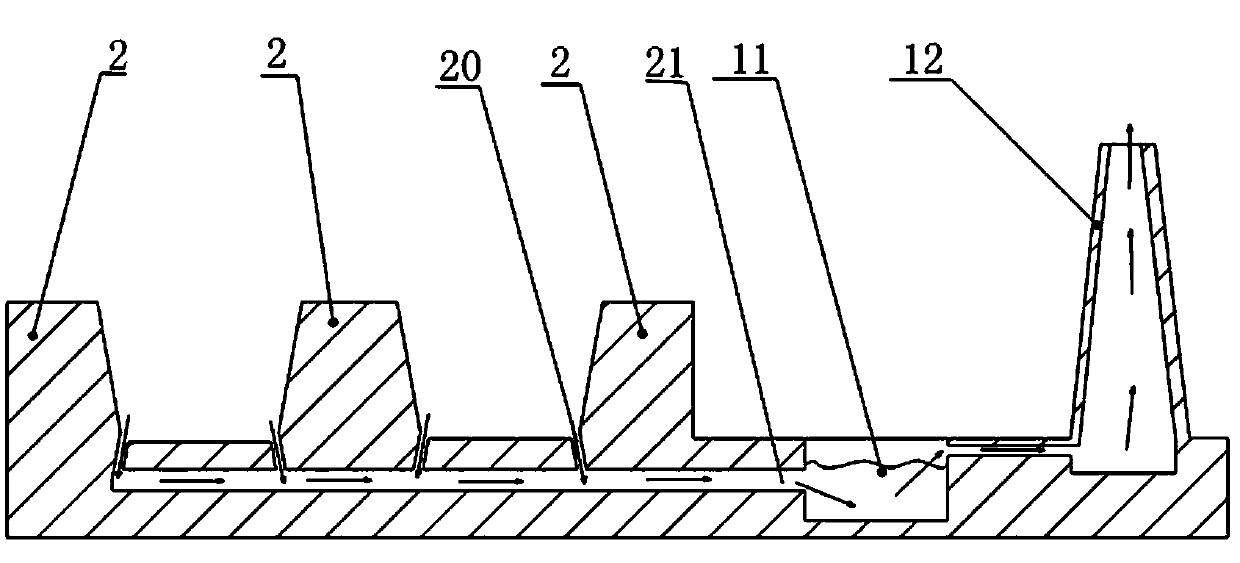

Electronic product high-temperature sintering furnace

InactiveCN110425886AShorten the timeImprove efficiencyElectric heating for furnacesFurnace crowns/roofsBrickSilicon

The invention provides an electronic product high-temperature sintering furnace and belongs to the technical field of electronic kiln furnace facilities. The electronic product high-temperature sintering furnace comprises a furnace body, the center of the furnace body is provided with a furnace cavity, silicon molybdenum bar left heating units and silicon molybdenum bar right heating units are distributed to the rear end of the furnace cavity from the front end of the furnace cavity at the positions corresponding to the left side and the right side of the furnace cavity, the electronic producthigh-temperature sintering furnace is characterized by further comprising left plug brick mechanisms, right plug brick mechanisms, left extraction release bricks and right extraction release bricks,the left plug brick mechanisms and the right plug brick mechanisms are built inside furnace top bricks at the positions corresponding to the silicon molybdenum bar left heating units and the silicon molybdenum bar right heating units, the left extraction release bricks and the right extraction release bricks are located at the top of the furnace body, the lower ends of the silicon molybdenum bar left heating units penetrate through the left plug brick mechanisms and stretch to the bottom of the furnace cavity, the upper ends of the silicon molybdenum bar left heating units penetrate through the left extraction release bricks from bottom to top and poke out of the upper surfaces of the left extraction release bricks, the lower ends of the silicon molybdenum bar right heating units penetratethrough the right plug brick mechanisms and stretch to the bottom of the furnace cavity, and the upper ends of the silicon molybdenum bar right heating units penetrate through the right extraction release bricks from bottom to top and poke out of the upper surfaces of the right extraction release bricks. By means of the electronic product high-temperature sintering furnace, the engineering cost of silicon molybdenum bar replacement is reduced, and the sintering efficiency is improved.

Owner:SUZHOU HUIKE EQUIP CO LTD

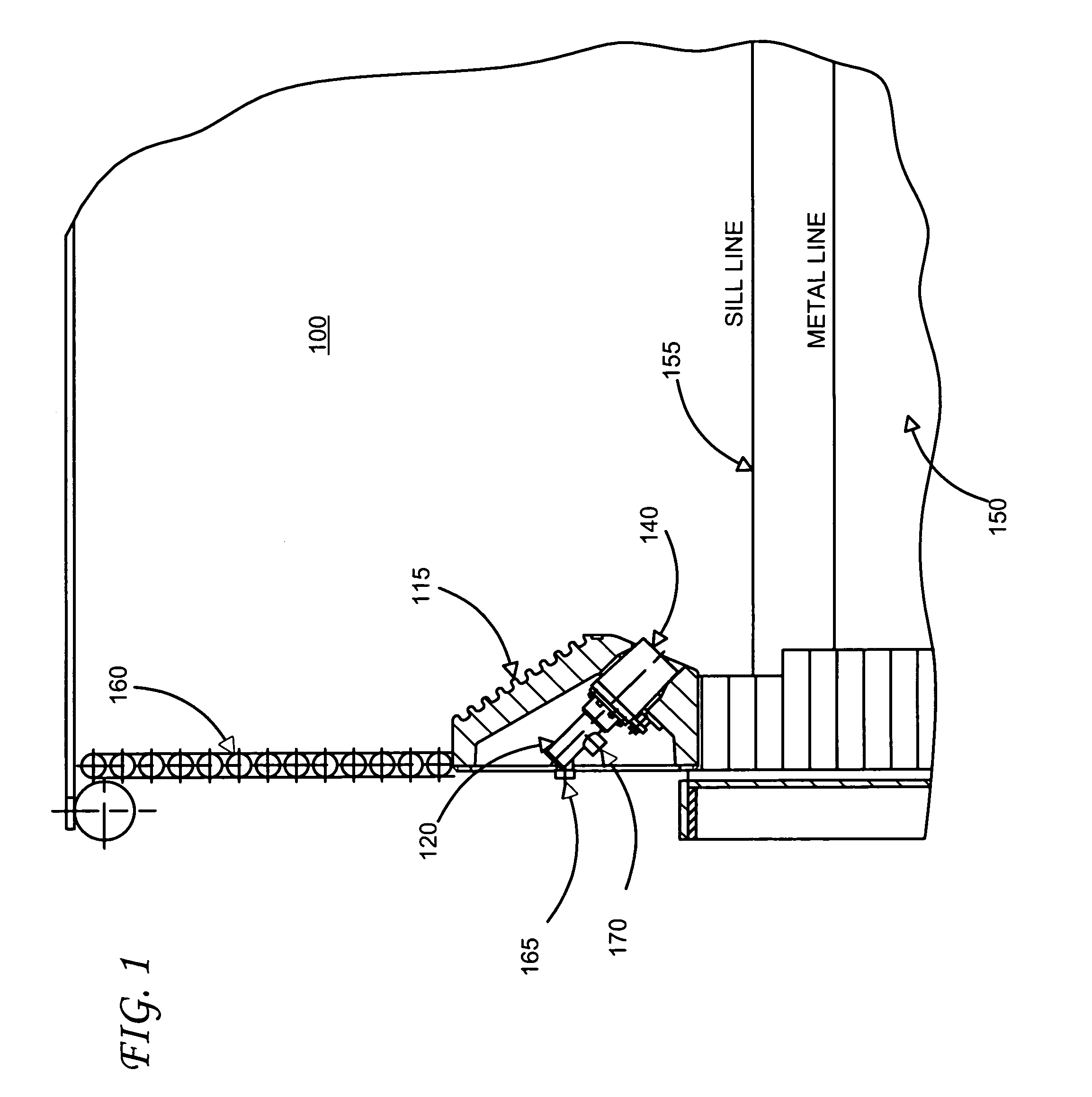

Cooling device for use in an electric arc furnace

InactiveUS7483471B2Effective and efficient coolingOvercome deficienciesFurnace cooling arrangementsHandling discharged materialCombustorElectric arc furnace

Owner:PROCESS TECH INT

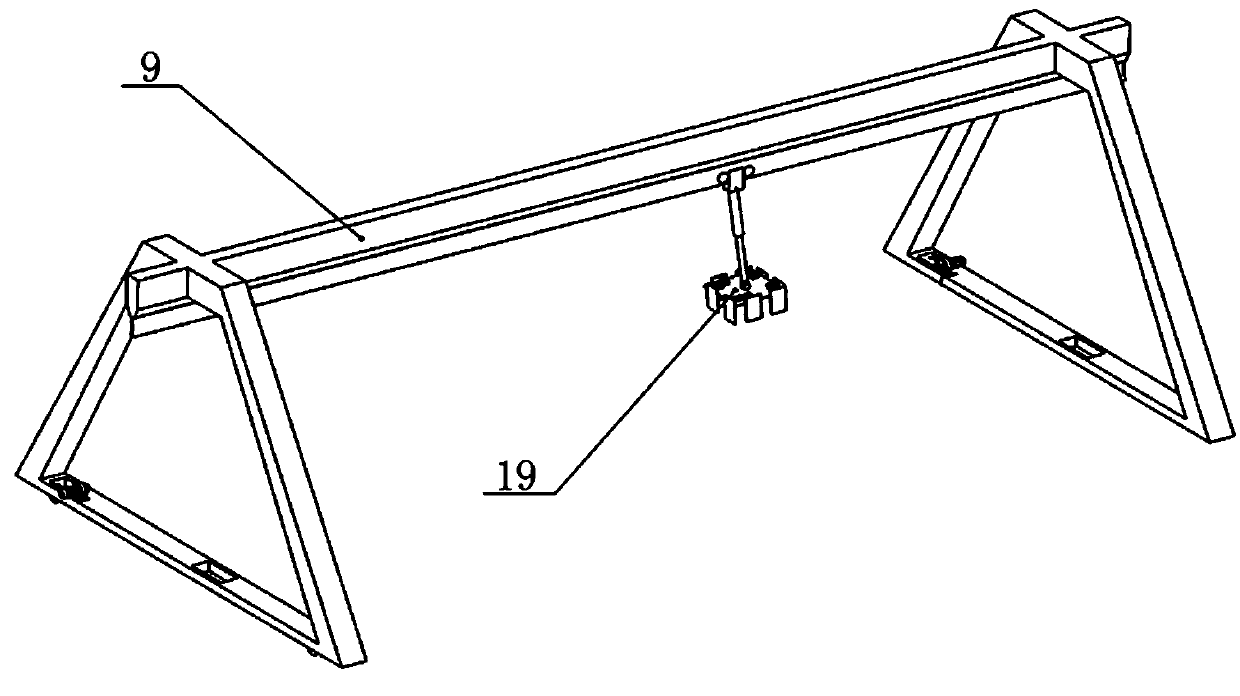

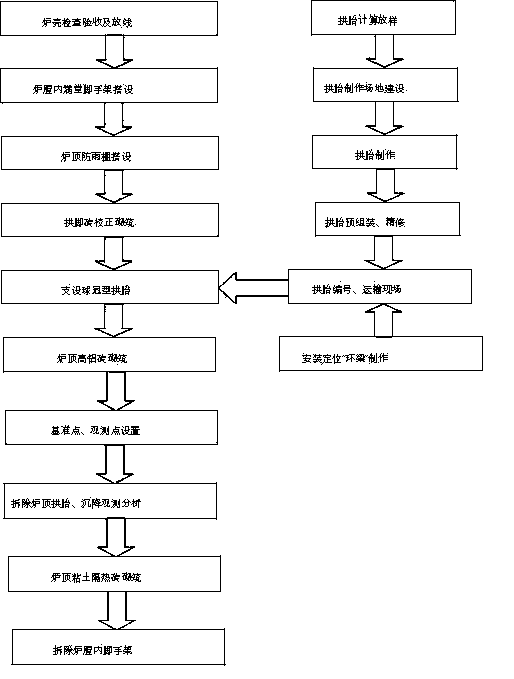

Method for building spherical crown type furnace top by laying bricks

ActiveCN104061786AEffective control of settlementSimple and fast constructionFurnace crowns/roofsBrickThermal insulation

The invention discloses a method for building a spherical crown type furnace top by laying bricks. The method includes the following steps of firstly, establishing a scaffold in a hearth; secondly, correcting and laying skew blocks; thirdly, erecting a spherical crown type arch green body, wherein the arch green body is manufactured first, the arch green body is erected with the skew blocks as the positioning standard, and the arch green body is manufactured through the first step of calculating and lofting the arch green body, the second step of establishing the field for manufacturing the arch green body, the third step of manufacturing the arch green body, the fourth step of preassembling and refining the arch green body and the fifth step of manufacturing an installation positioning annular beam; fourthly, laying furnace top bricks; fifthly, detaching the furnace top arch green body, observing and analyzing sedimentation, laying clay thermal insulation bricks on the furnace top, and detaching the scaffold in the hearth. The method has the advantages of being capable of effectively controlling sedimentation of the furnace top, simple and rapid in construction, high in integrality and high in building accuracy.

Owner:七冶建设集团有限责任公司 +1

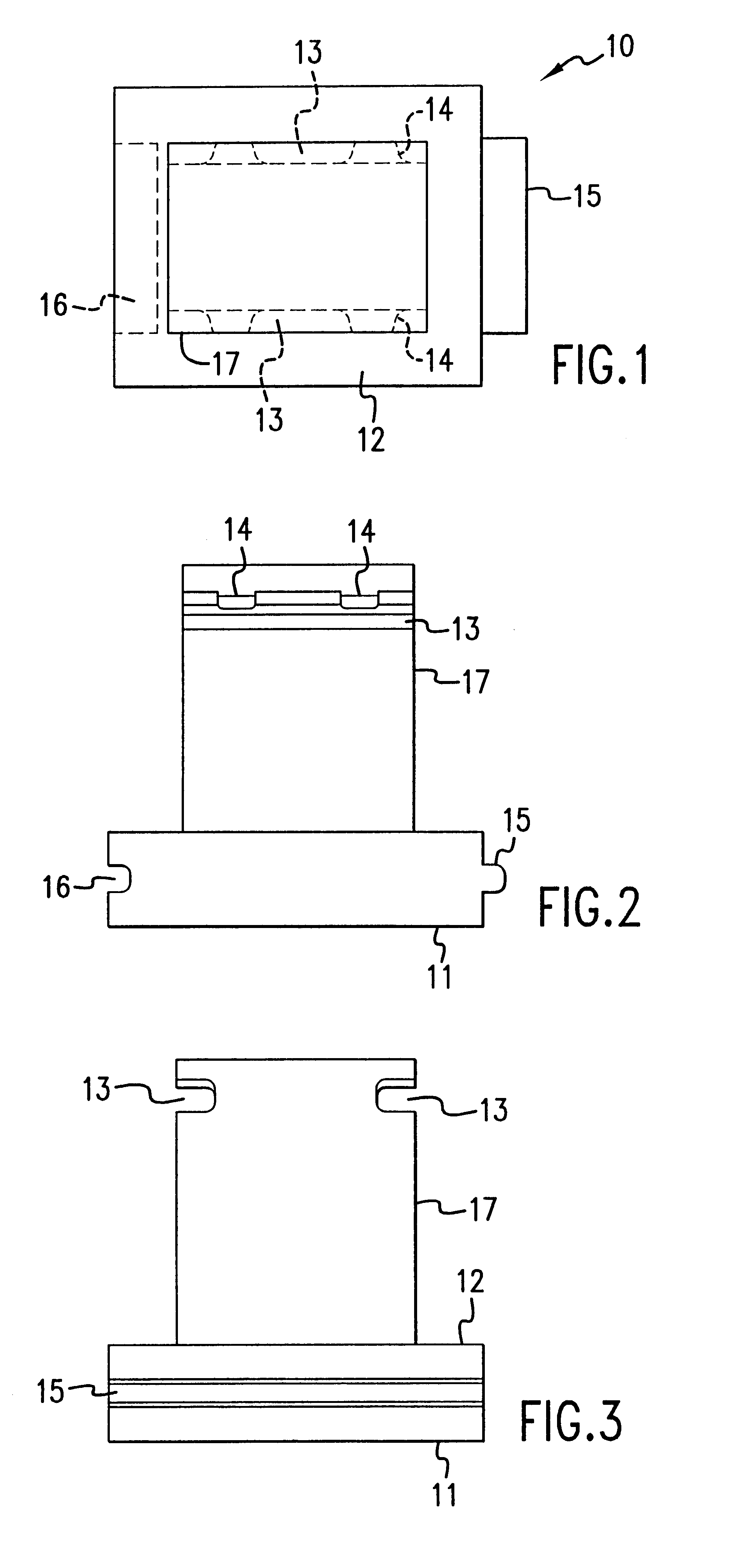

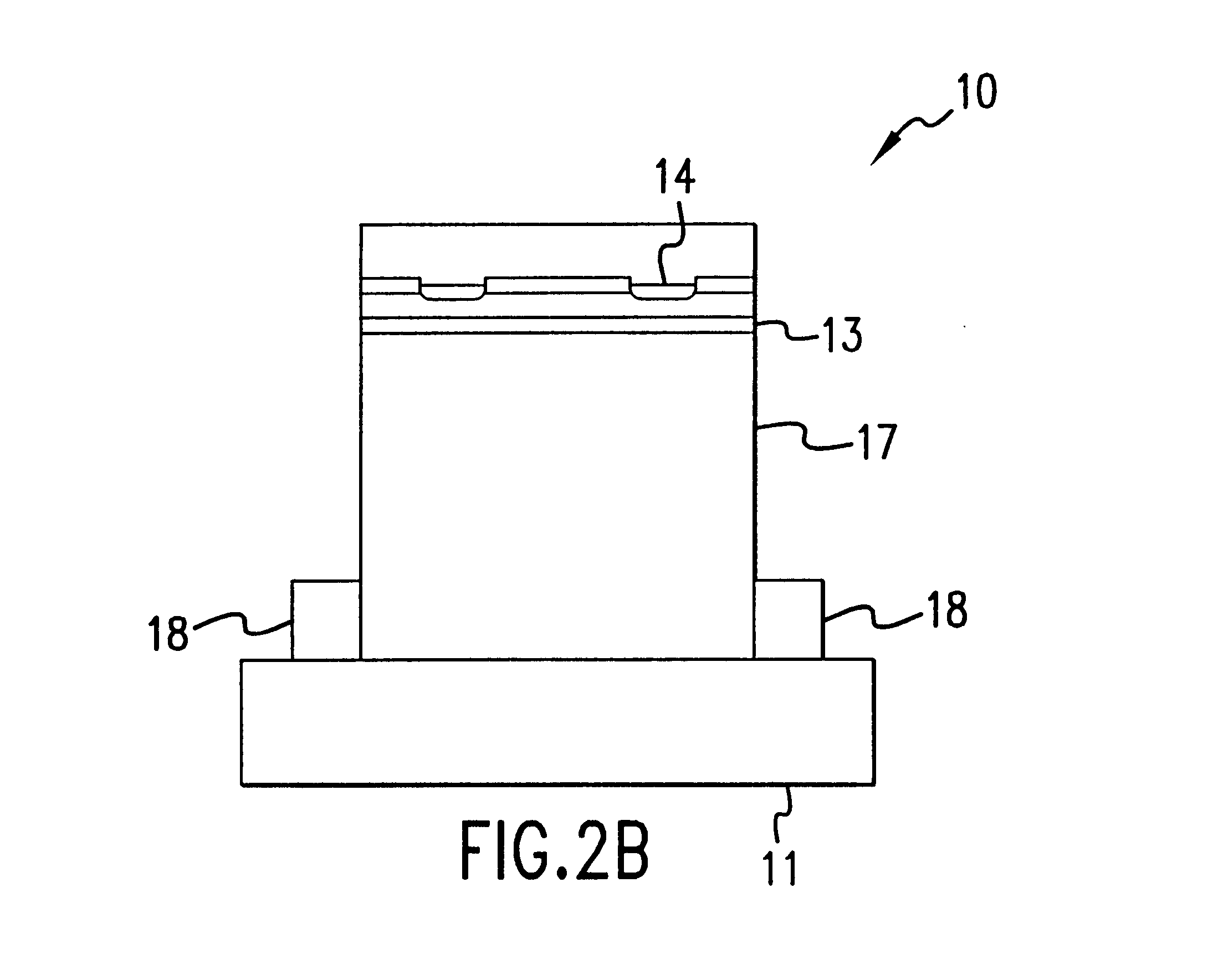

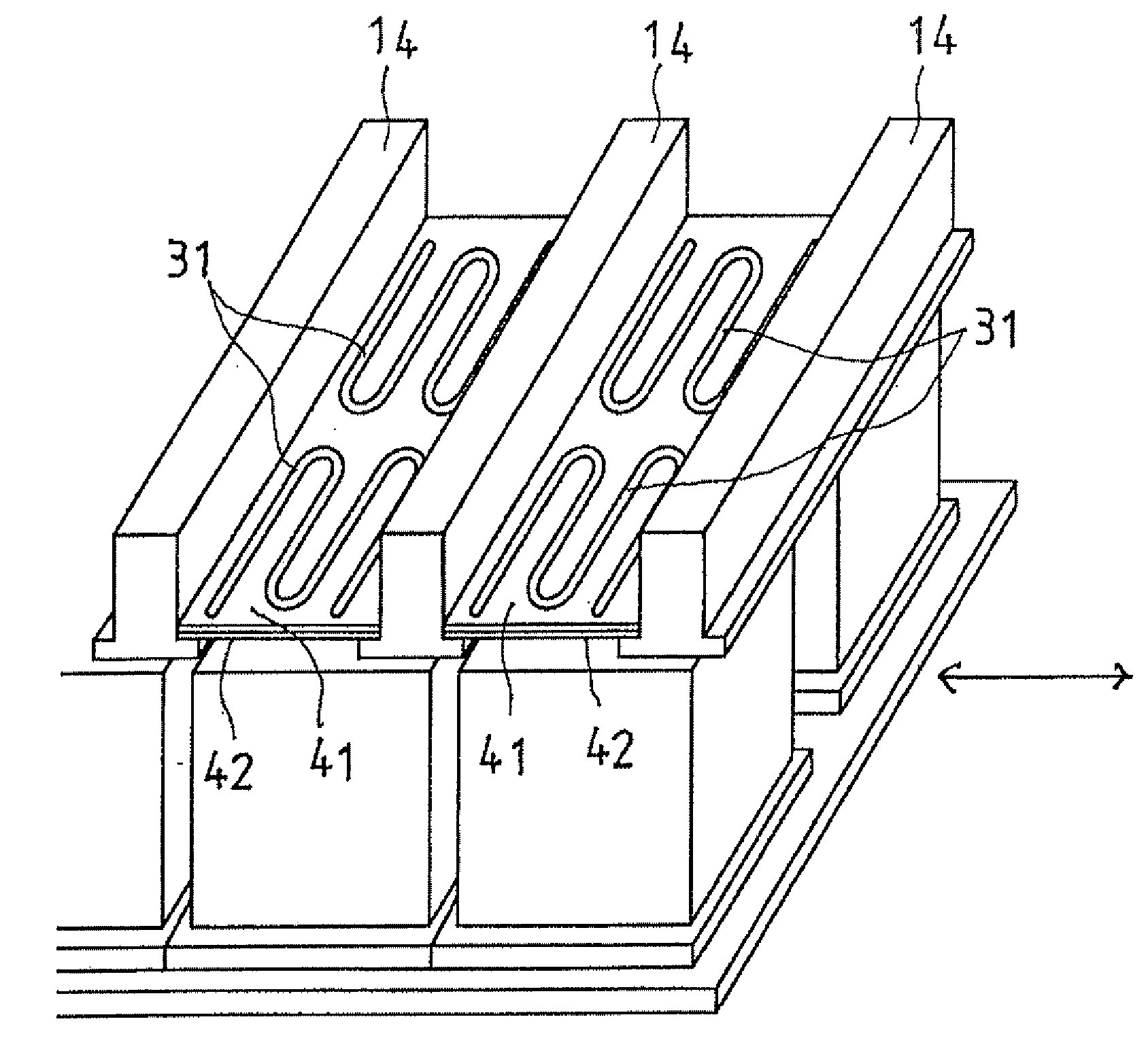

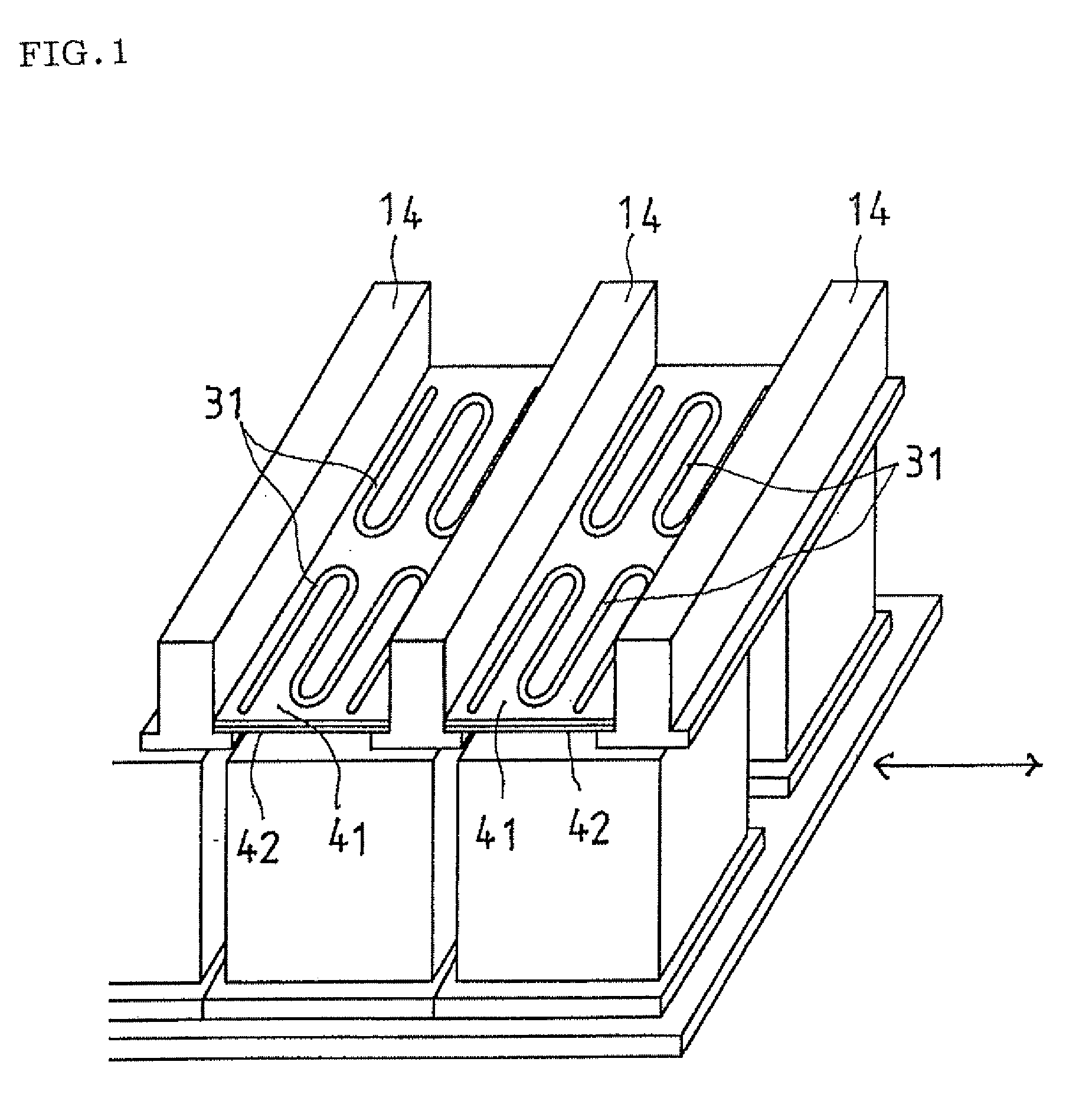

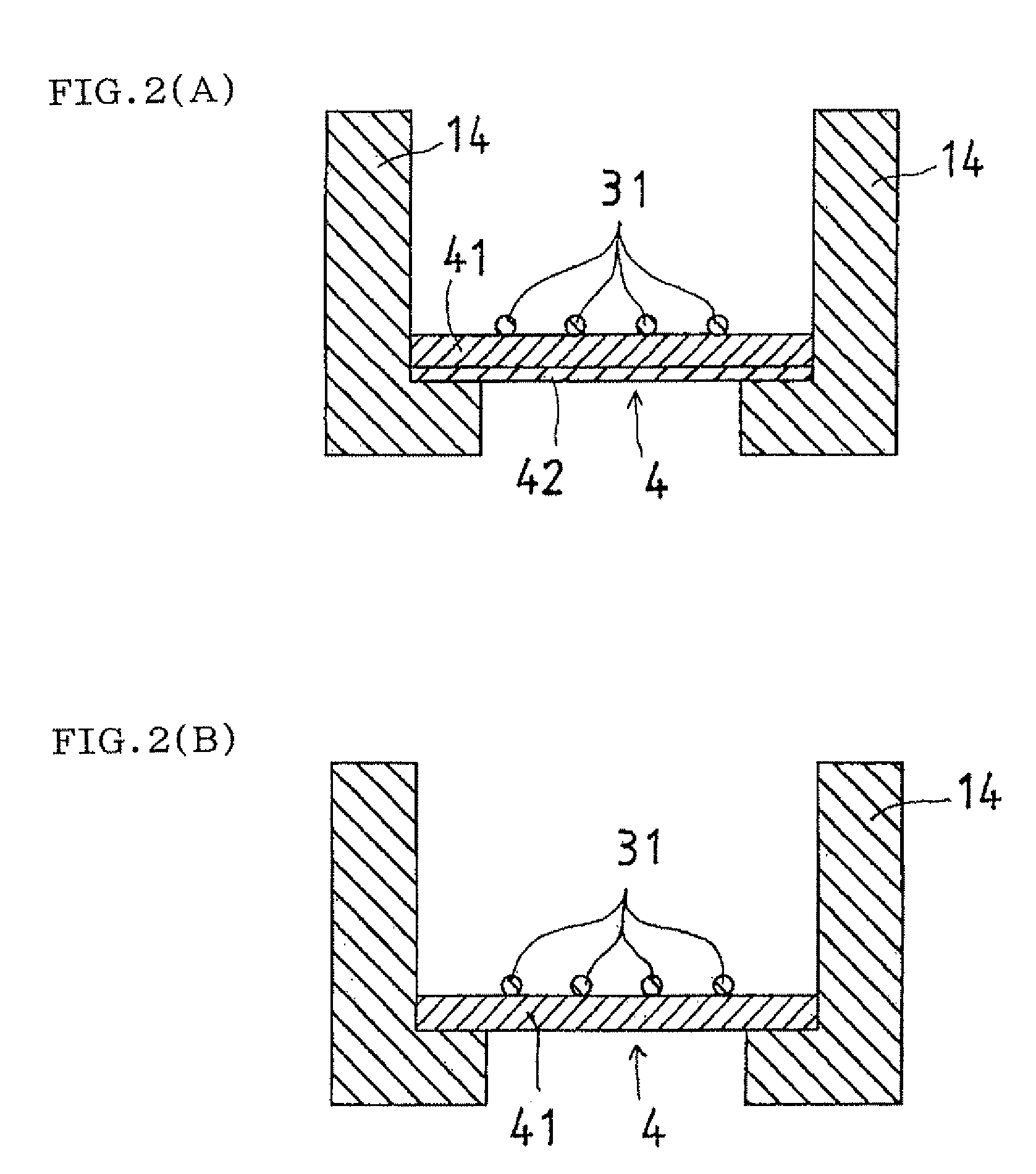

Support structure of heater

ActiveUS20080272111A1Easily softenedAvoid deformationIncandescent ignitionHeater elementsRefractoryMaterials science

There is provided an electric heater support plate which is not likely to be softened or deformed during firing at a high temperature, even if a material to be fired contains an alkaline component or an Si component as a volatile component. A passage 2 for the material to be fired surrounded by a ceiling refractory 11, wall refractories 12 and a floor refractory 13 is provided with an electric heater 3 heating from above and an electric heater 5 heating from below. This electric heater 3 has at least its heating part 31 mounted and supported on a fire-resistant support plate 4, and this support plate 4 in this invention has a two-layer structure in which an insulating ceramic support plate 41 is laminated on an SiC-based ceramic plate 42. The two-layer structure support plates 4 are supported by refractories 14 installed in a furnace and are arranged in parallel in a plurality of rows in a longitudinal direction of the furnace, and the electric heater 3 mounted on the support plates is so constructed as to generate heat by an electric power supplied from an energizing terminal 32 exposed to the outside of a furnace wall.

Owner:NGK INSULATORS LTD

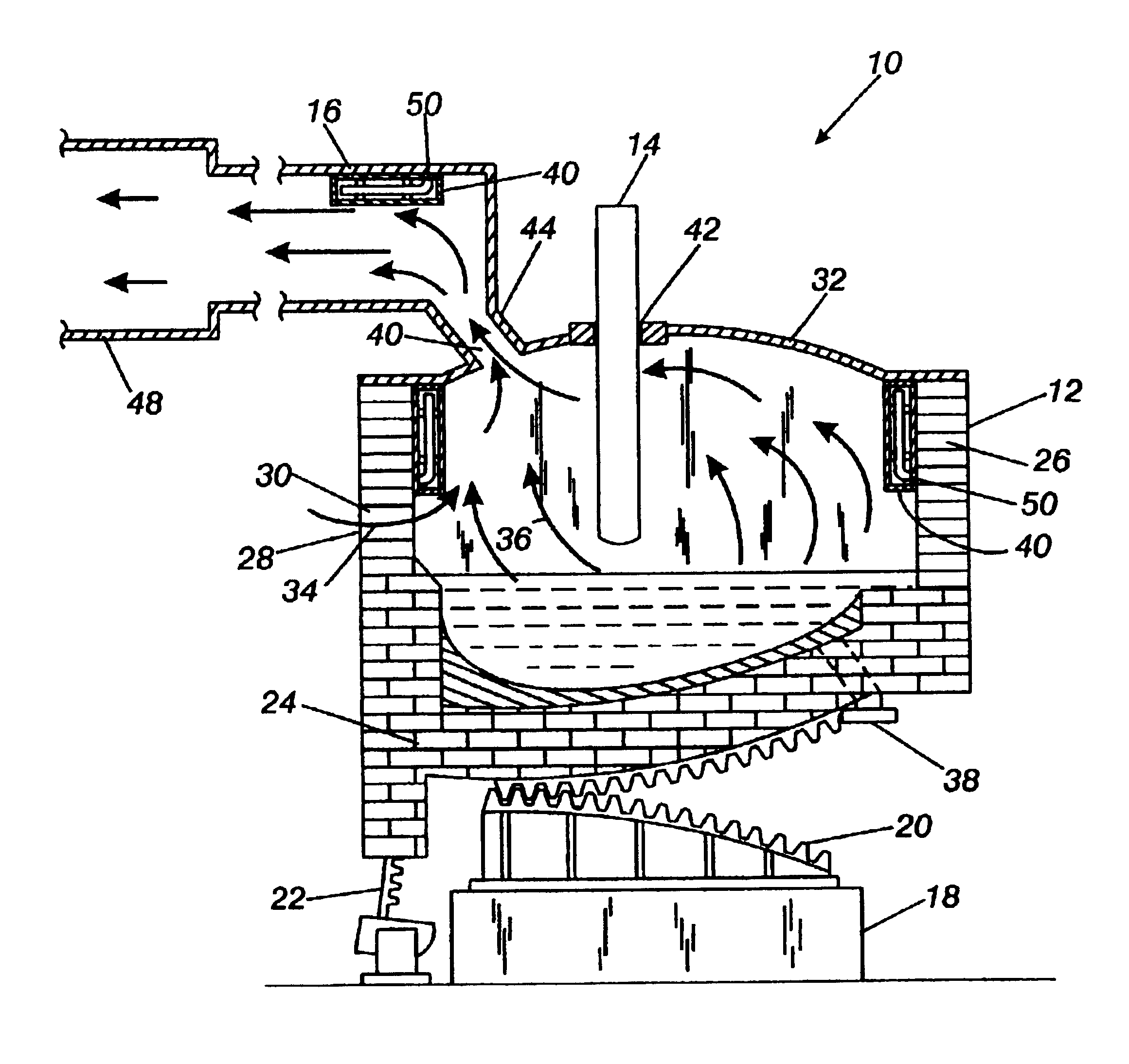

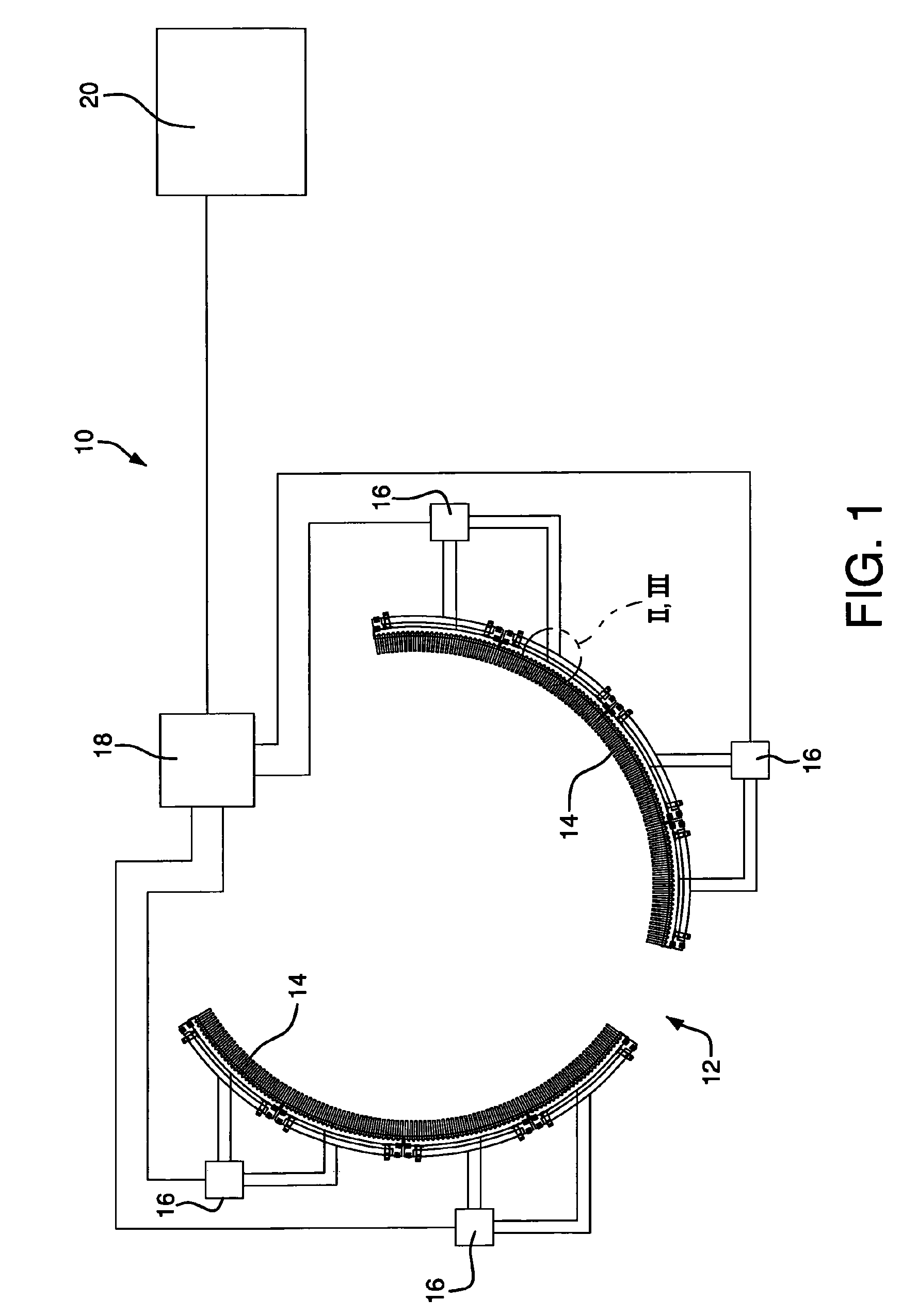

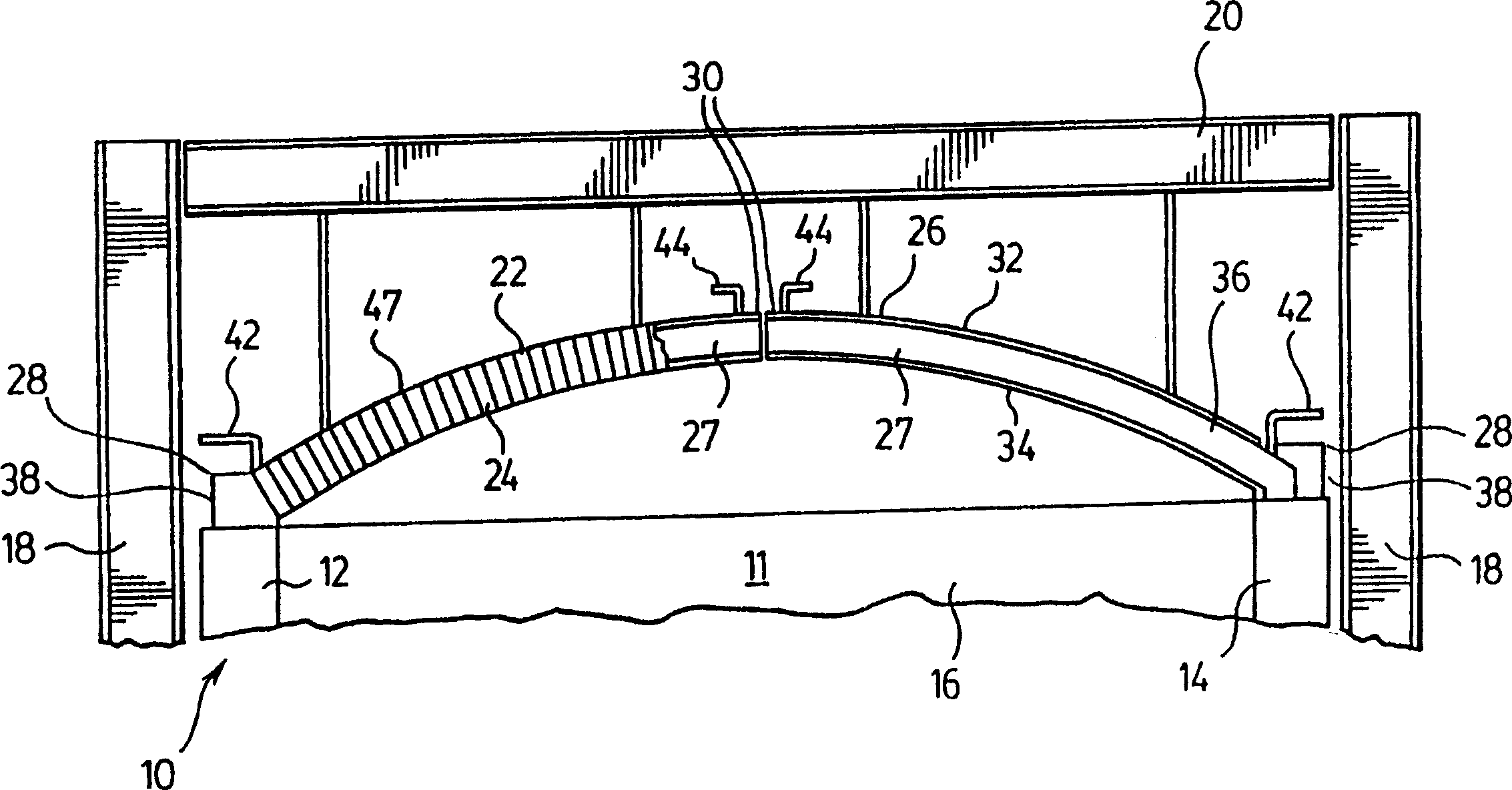

Heat exchanger system used in steel making

InactiveUS20080035320A1Erosion is goodIncrease pressureFurnace cooling arrangementsManufacturing convertersFiltrationPaper manufacturing

The invention is a heat exchanger system suitable for iron making furnaces and their supporting exhaust and cooling system. The heat exchanger has at least one panel of sinuously winding piping having an inlet and an outlet, an input manifold in fluid communication with the inlet of the at least one panel, an output manifold in fluid communication with the outlet of the panel, a cooling fluid flowing through the piping, and a stream of hot exhaust gases flowing over the piping. In application, the heat exchanger system has at least one panel that is mounted to an interior side of a wall, and is in fluid communication with the output and the input manifolds that are on an exterior side of the wall. The wall typically is a wall of a steel making furnace, a furnace roof, a smoke ring exhaust port, a straight section of an exhaust duct, and a curved section of an exhaust duct. It is anticipated that the heat exchanger has other applications, such as cooling exhaust gases from converting plants, paper manufacturing plants, coal and gas fired electrical power generation plants, and other exhaust gas generators, where the gases are cooled for the purpose of capturing one or more components of the gas, where capture is effected by condensation, by carbon bed absorption, or by filtration. The heat exchanger system is preferably fabricated using an aluminum bronze alloy. Aluminum bronze alloys have been found to have a higher than expected thermal conductivity, resistance to etching by the stream of hot gases, and good resistance to oxidation. The operational life of the heat exchanger is extended. Corrosion and erosion of the heat exchanger and related components is reduced, when they are fabricated with aluminum bronze alloy.

Owner:AMERIFAB INC

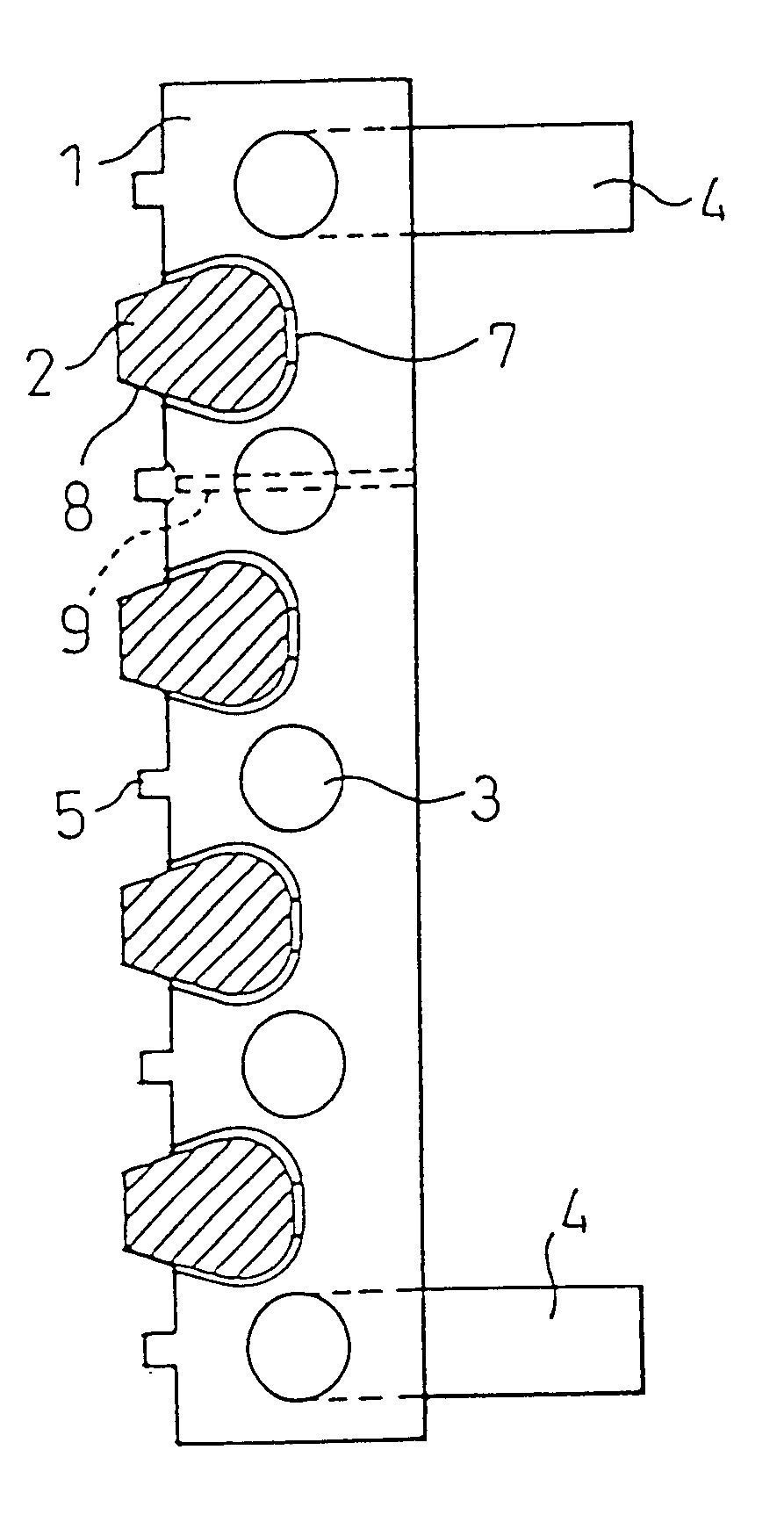

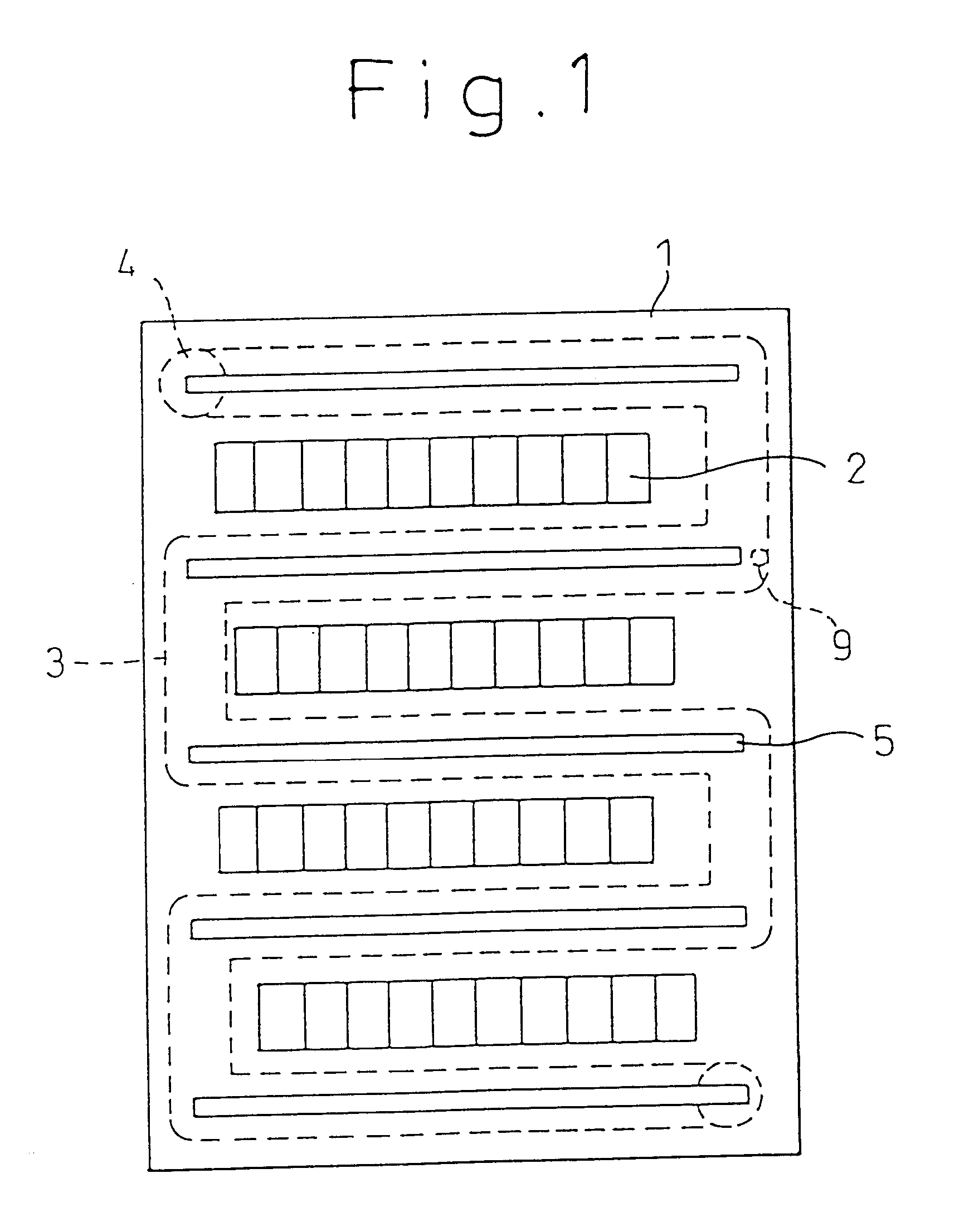

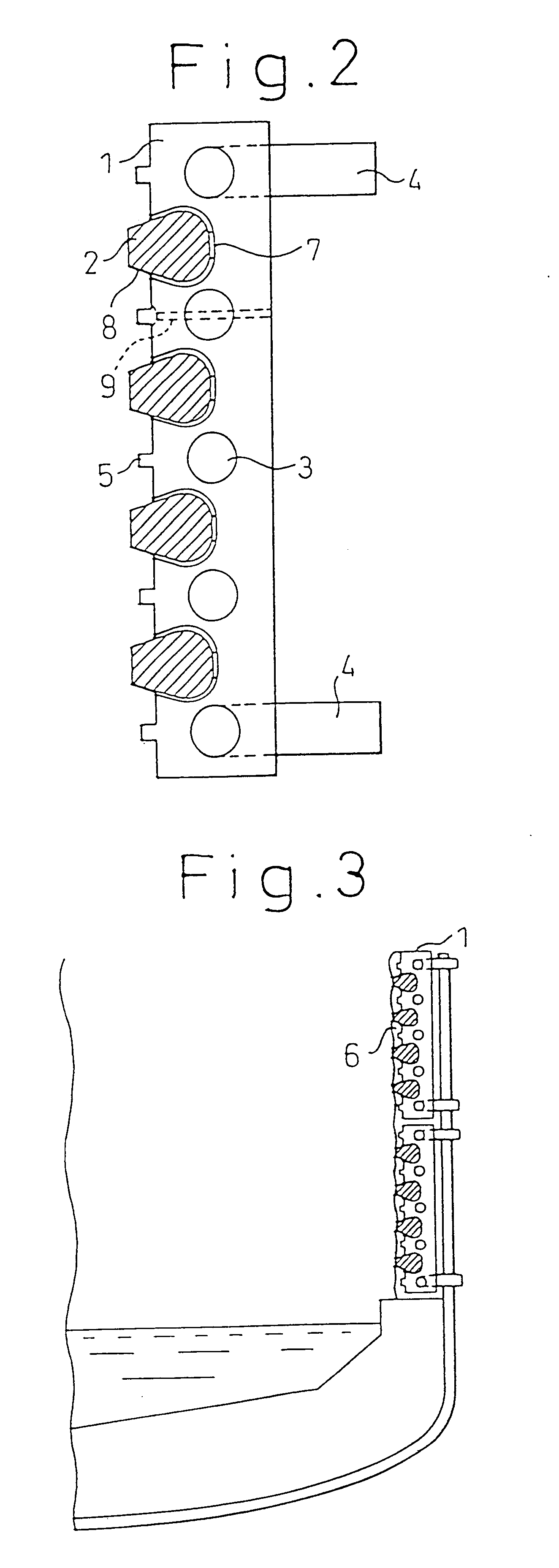

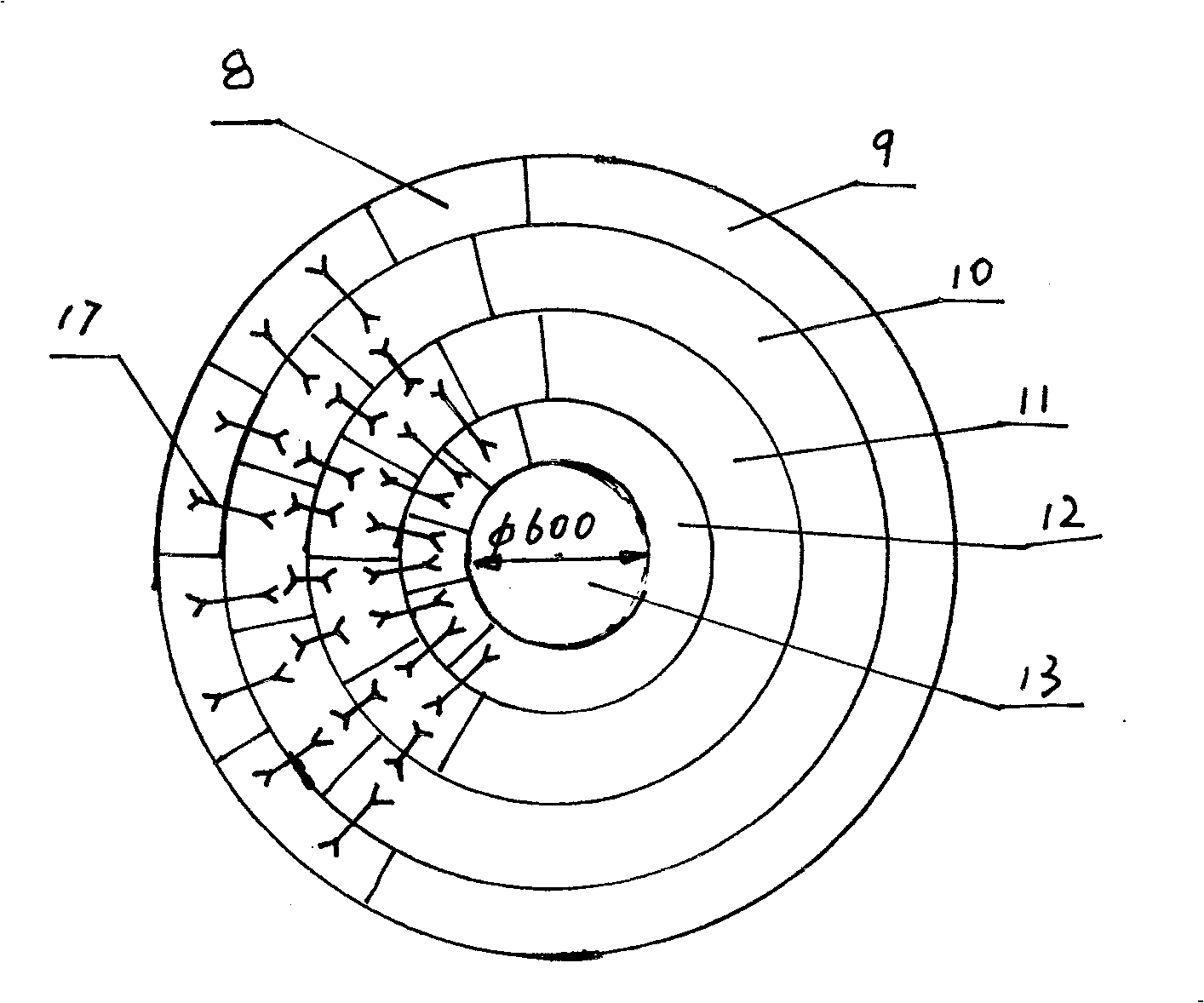

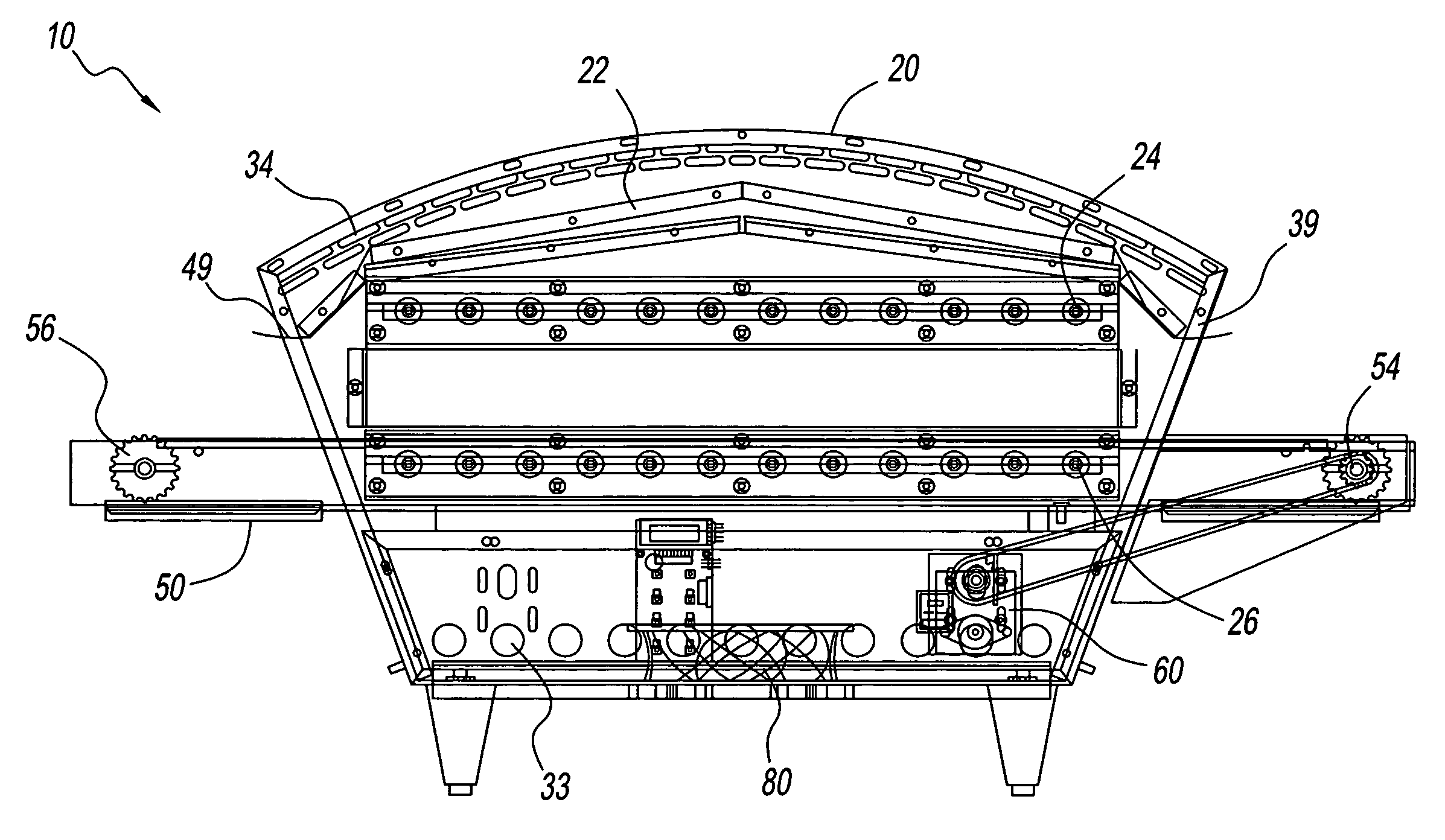

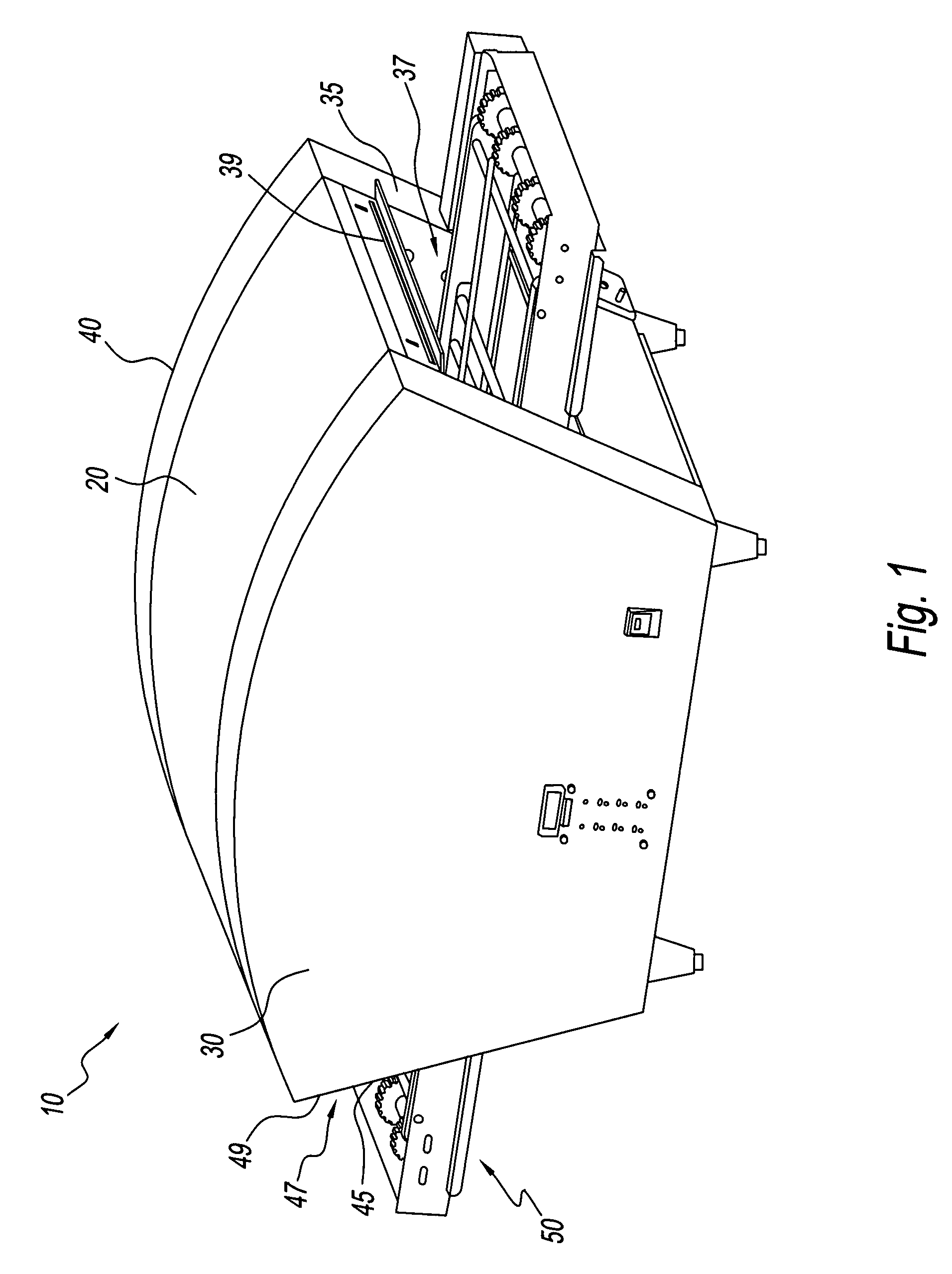

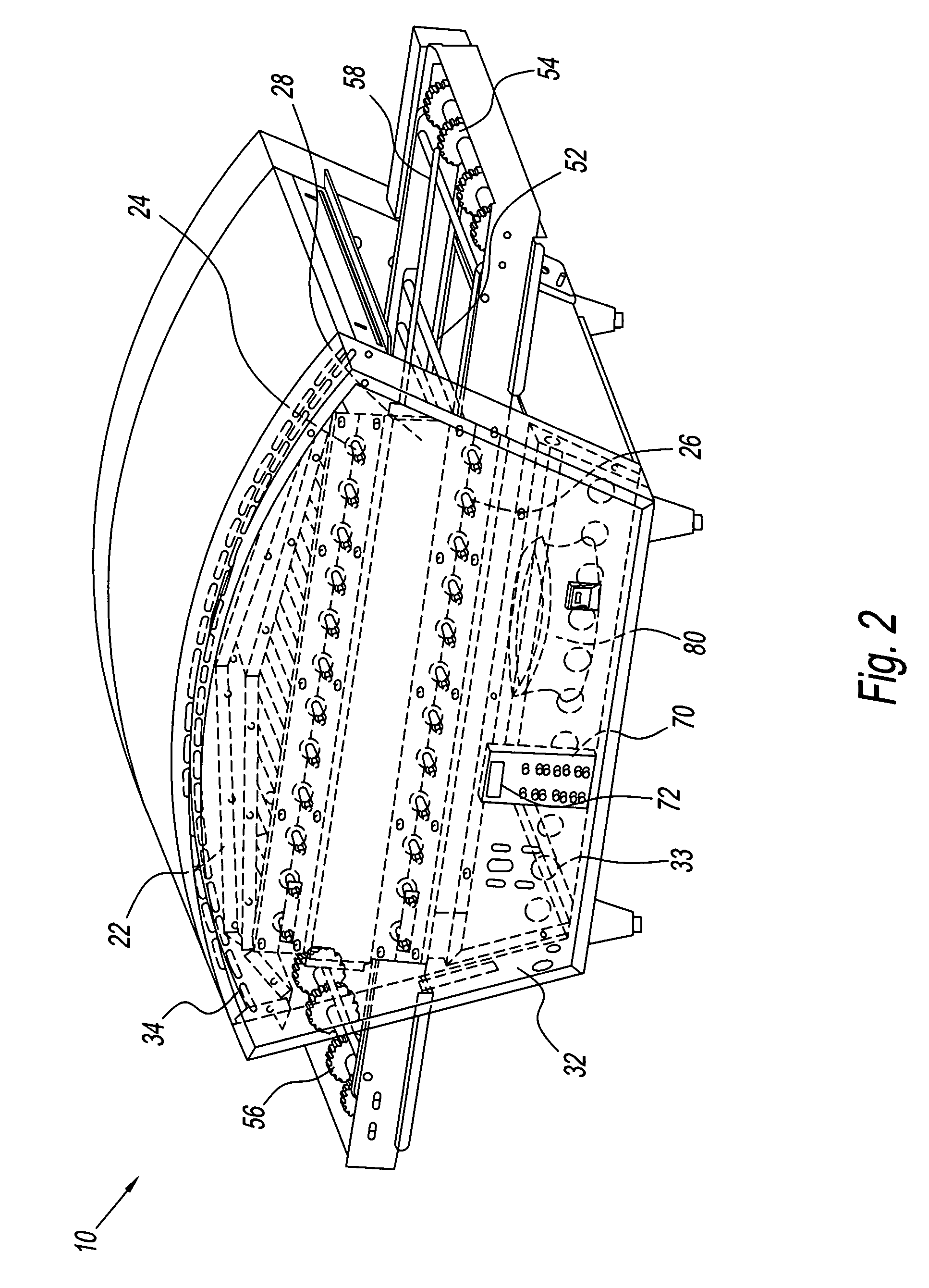

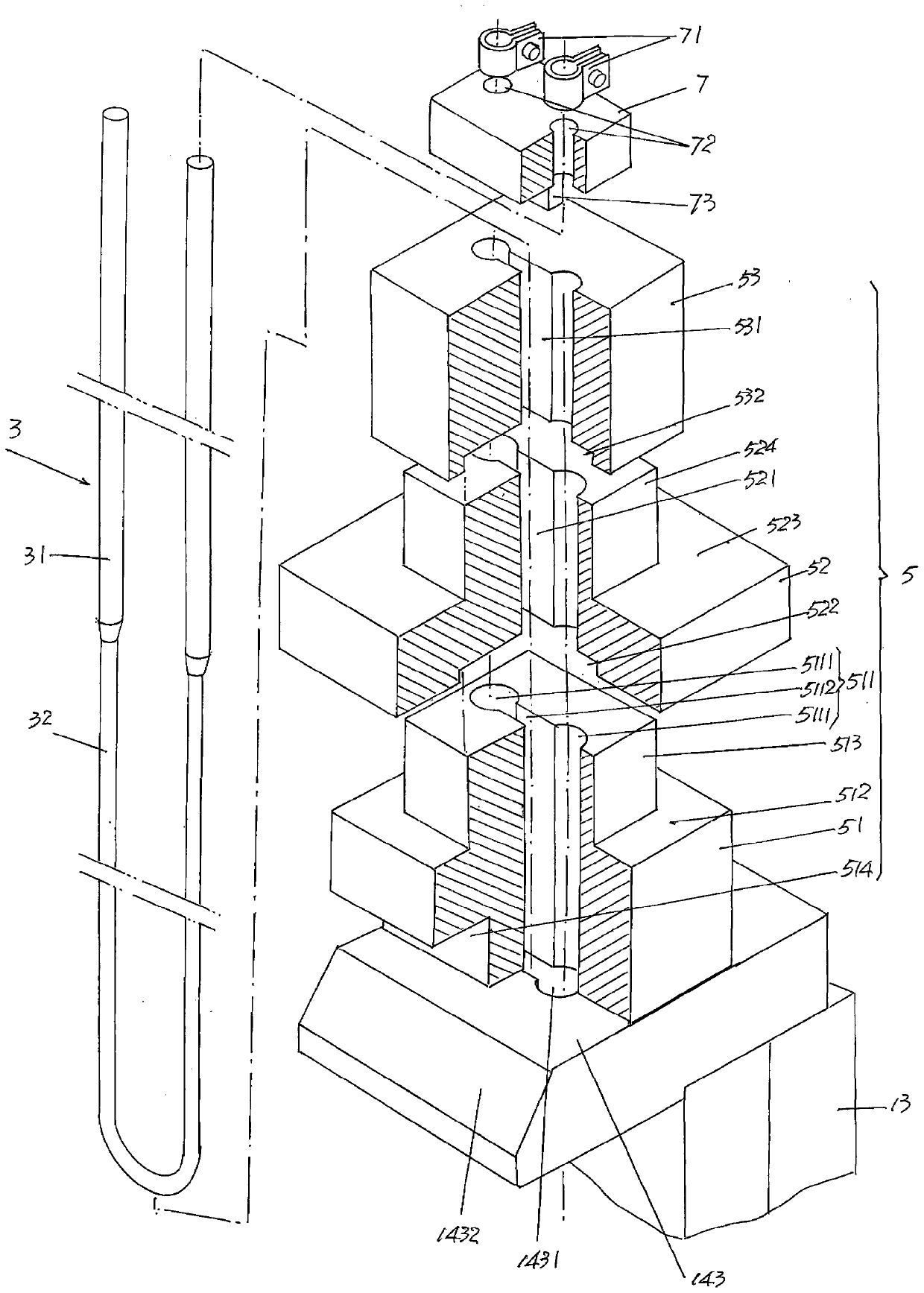

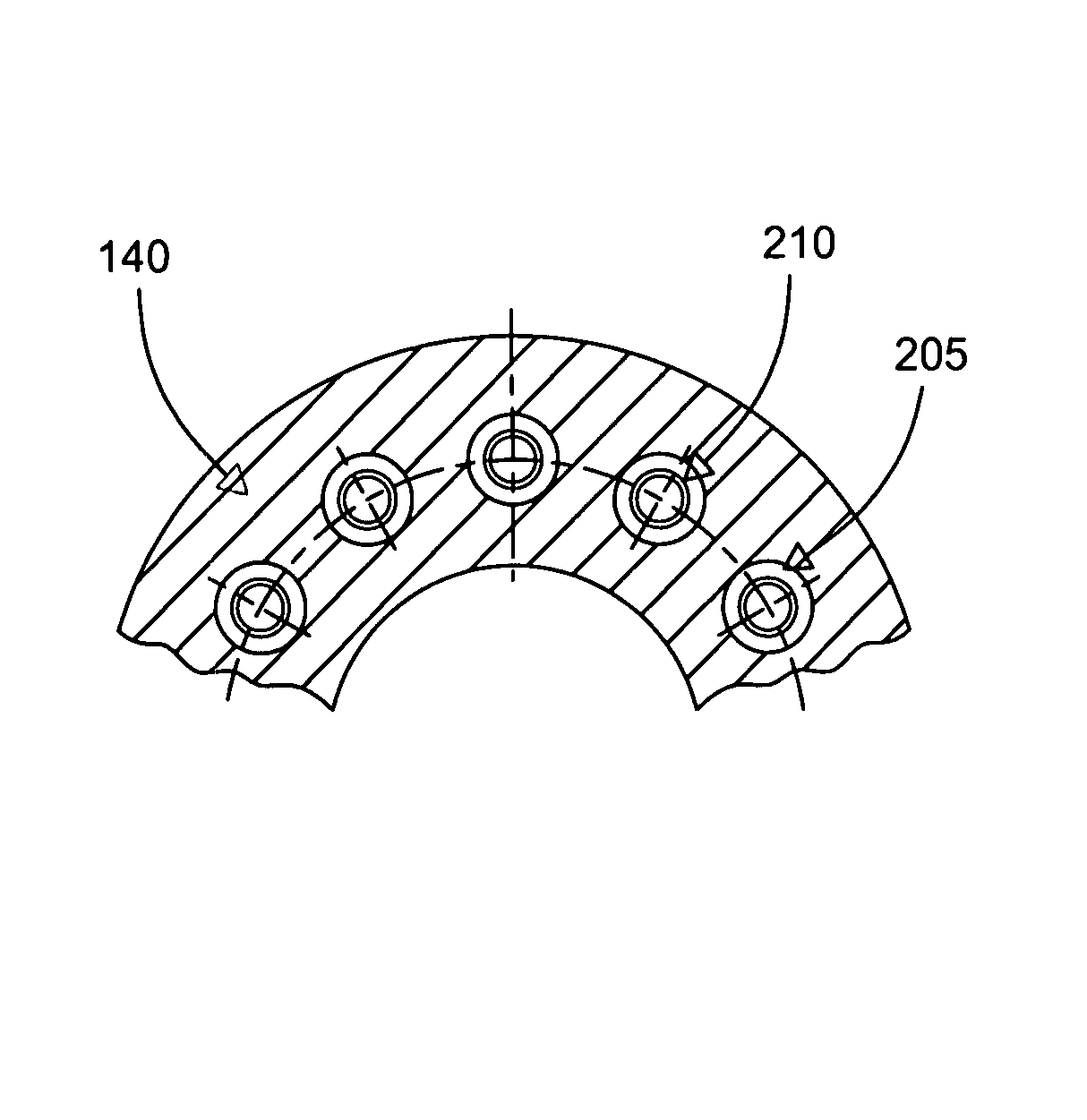

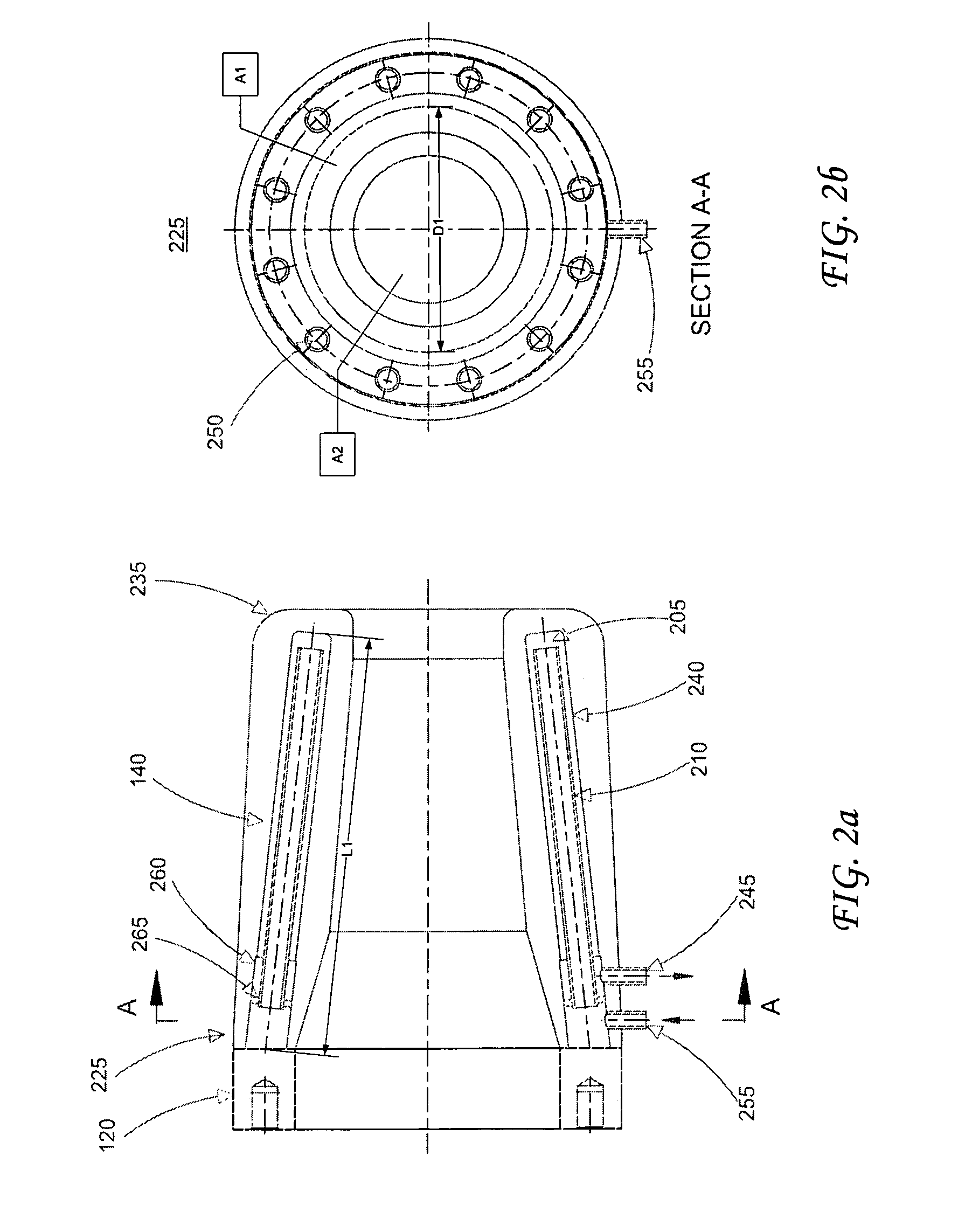

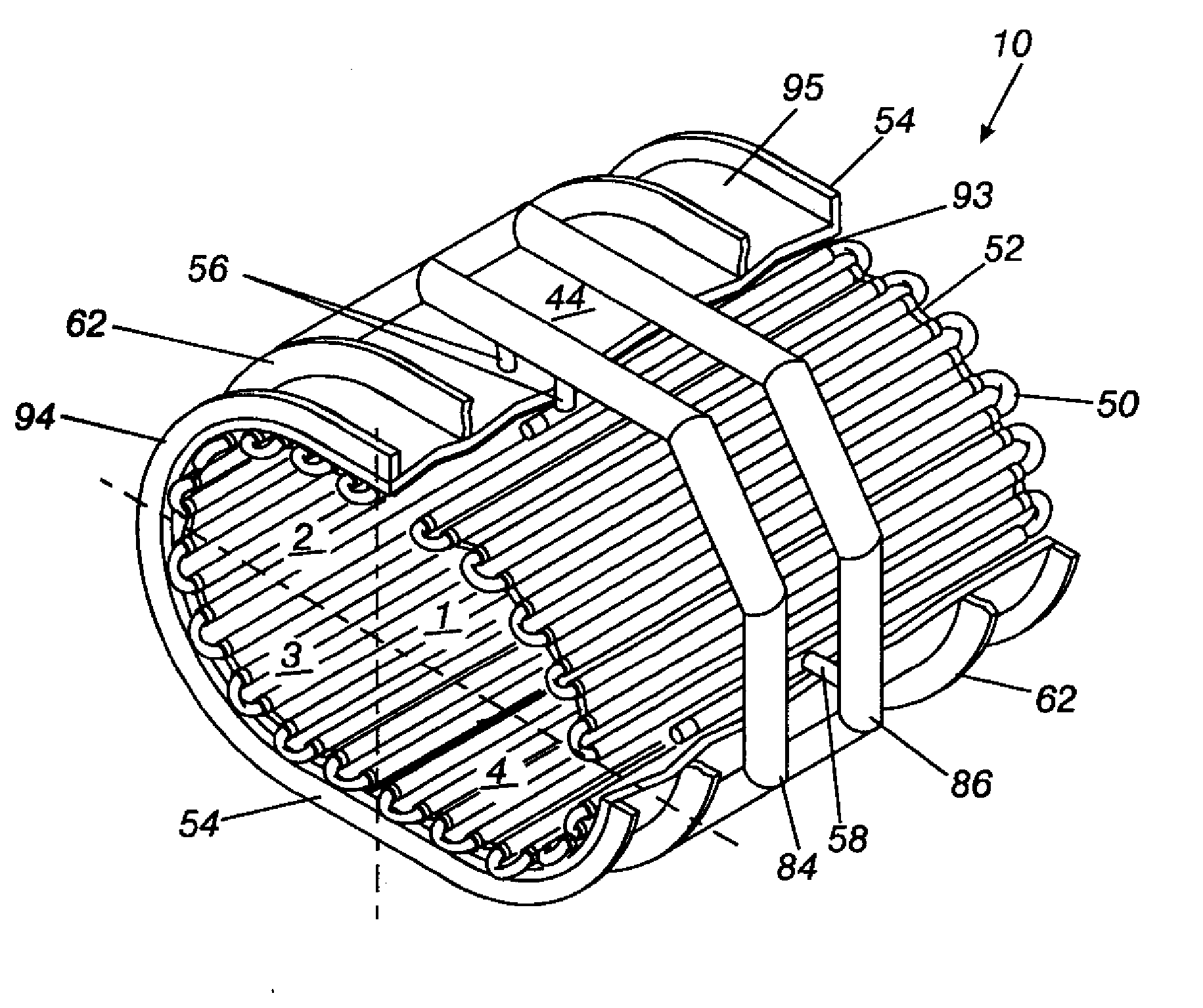

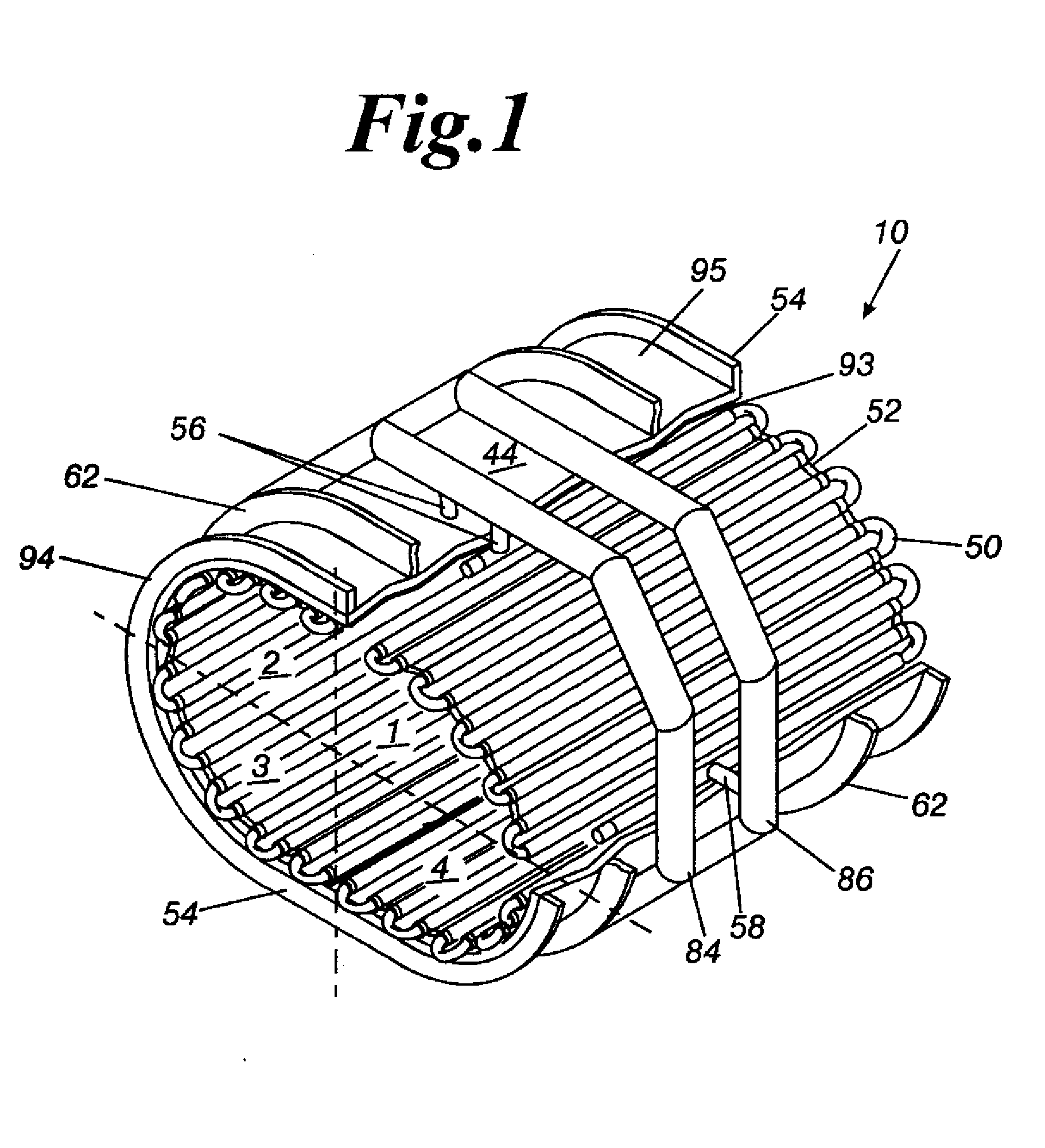

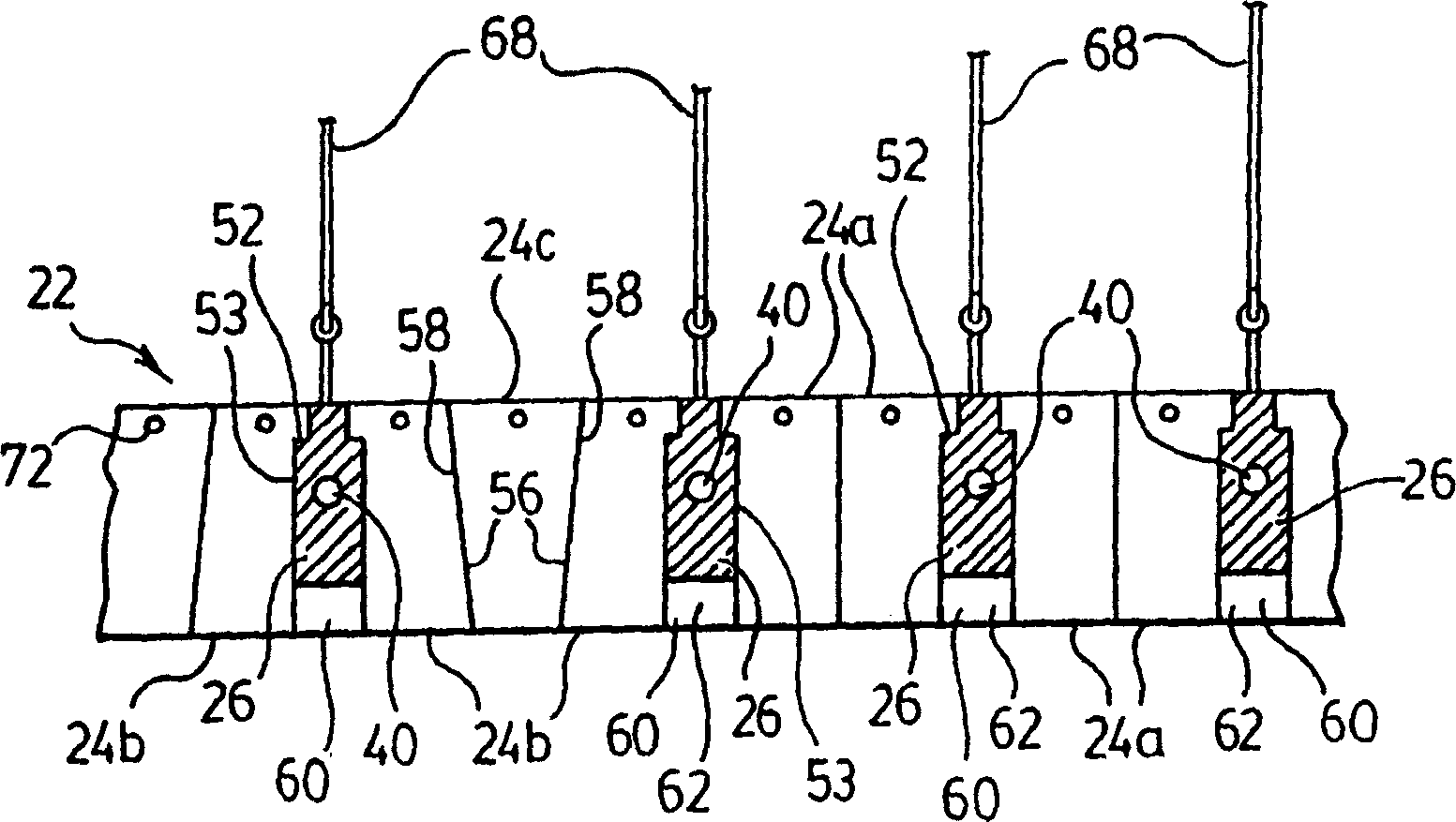

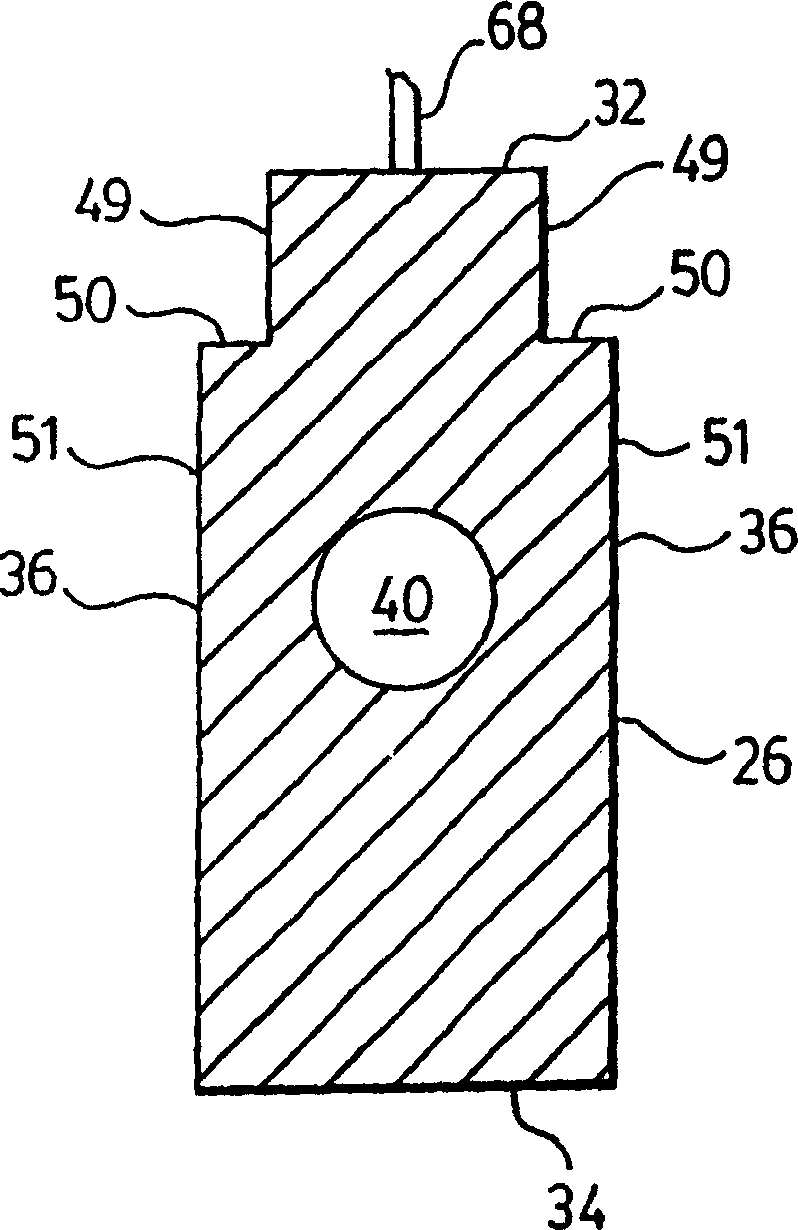

Cooling and support systems for furnace roofs

A system for supporting and cooling a furnace roof comprised of refractory bricks comprises a plurality of roof support members extending across the furnace and being supported from above the furnace roof. The support members are provided with internal channels for circulation of a cooling fluid, and are provided with side surfaces adapted to support rows or refractory bricks between adjacent roof support members. The system eliminates the need to suspend individual bricks from above the roof, and provides simultaneous support and cooling of the roof structure.

Owner:HATCH LTD

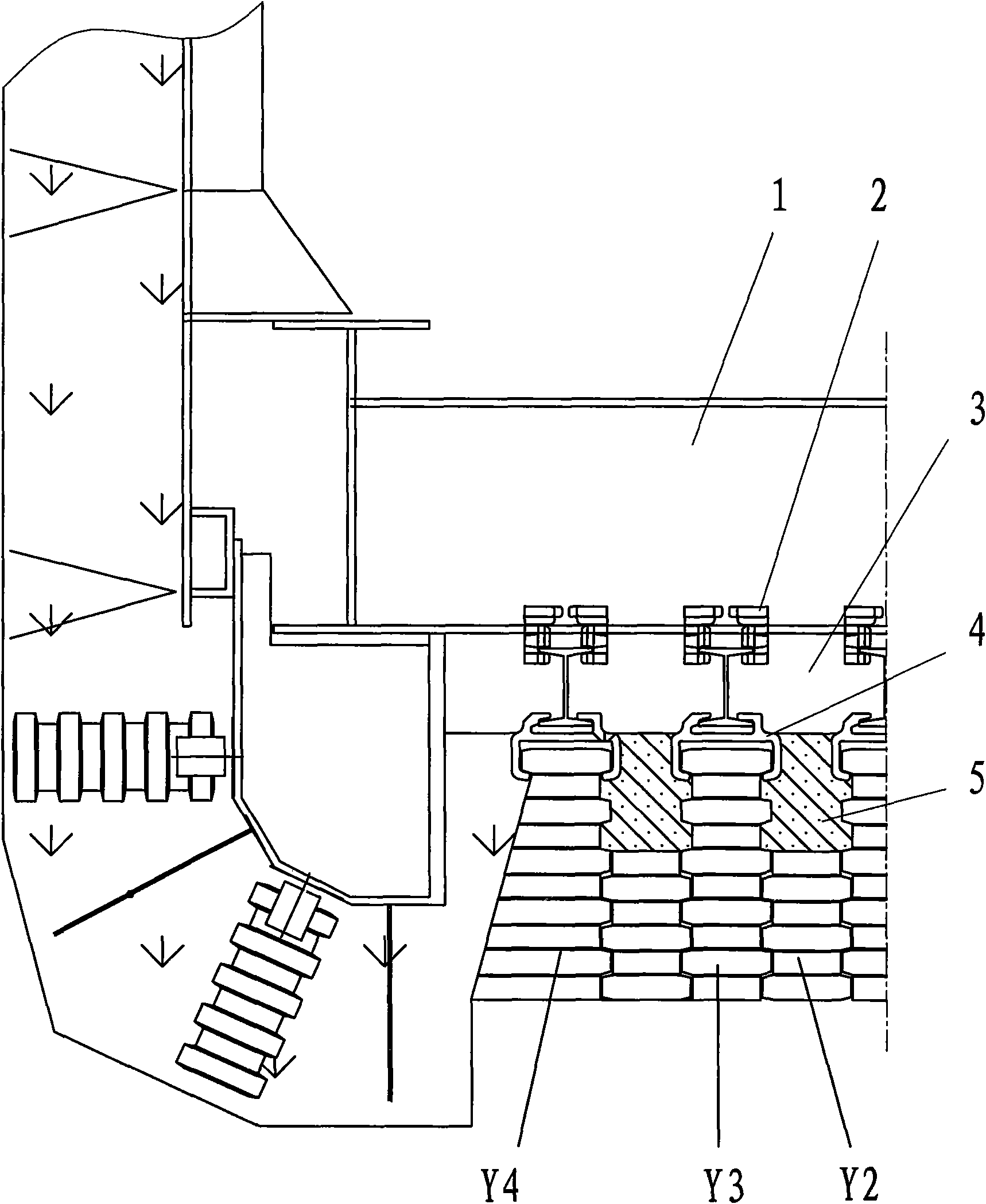

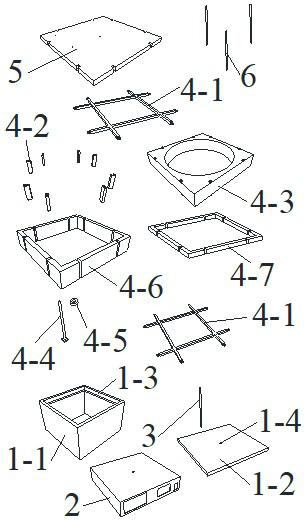

Furnace top of preheating furnace

The invention relates to a furnace top of a preheating furnace, in particular to a furnace top masonry structure. The upper part of the furnace top is constructed by a large joist steel, the lower end of the large joist steel is fixed with the upper end of a small joist steel through an upper anchoring piece, the lower end of the small joist steel is fixed with a wedge-shaped anchoring brick Y4 and a main anchoring brick Y3 through a lower anchoring piece, anchoring bricks Y2 are embedded between the wedge-shaped anchoring brick Y4 and the main anchoring brick Y3 and between two main anchoring bricks Y3, light pouring materials are filled between the wedge-shaped anchoring brick Y4 and the main anchoring brick Y3 which are positioned above the anchoring bricks Y2 and between the two main anchoring bricks Y3 positioned above the anchoring bricks Y2, and the wedge-shaped anchoring brick Y4 is used for connecting the surrounding pouring materials. The invention has shock absorption and long service life.

Owner:XINXING HEBEI ENG & RES INC

Electric furnace device for component fire protection design and fire protection supervision and using method

PendingCN111735307AReduce heating effectLower requirementMaterial heat developmentFurnace typesFurnace temperatureHeat conservation

The invention provides an electric furnace device for component fire protection design and fire protection supervision and a using method. The using method comprises the following steps of: step 1. determining a test scene; step 2. installing the device in position on site; step 3. installing a test sample to be tested, to be specific, step 3A, adopting installation steps described in specifications when a cube test sample is adopted, and step 3B. adopting installation steps described in specifications when a cylindrical test sample is adopted; step 4. unexposed surface heat preservation selection, to be specific, step 4A. when the test sample to be tested is the cube test sample or the cylindrical test sample, adopting installation steps of a heat insulation cover described in specifications, and step 4B. the heat insulation cover is not used; step 5. preparing furnace temperature setting; step 6. selecting a control mode, to be specific, step 6A. using the control test process of a control part, and step 6B, using the control test process of a mobile terminal; and step 7. completing the whole test process, and storing the electric furnace device and the mobile terminal. The electric furnace device can simulate the true boundary relationship between a protected material and a heat insulation material, provides a simple and reliable equivalent heating curve setting method, canquickly form a test report, and greatly improves the efficiency of supervision and law enforcement.

Owner:应急管理部天津消防研究所 +1

Furnace top structure of heating furnace

ActiveCN102121795AEasy to replaceEasy maintenanceFurnace crowns/roofsStructural engineeringHeating furnace

The invention discloses a furnace top structure of a heating furnace. The furnace top structure comprises a furnace body of the heating furnace, wherein multiple steel beams are arranged above the furnace body; and furnace linings are arranged below the steel beams; the furnace top structure is characterized in that: the hanging pieces of the refractory fiber furnace linings are connected to the steel beams through hanging rods; a cavity in which the steel beams and the hanging rod are positioned is communicated with the atmosphere or communicated with air outside the furnace body through multiple vent holes; and the steel beams and the hanging rods are exposed in the air. According to the furnace top structure disclosed by the invention, each furnace lining is separately arranged and hung on the steel beam, and the upper end of the furnace lining is exposed in the air; the furnace lining can be replaced at the top of the furnace top as required, thereby realizing convenient maintenance and replacement and reducing the maintenance and replacement expenses; as the metal hanging rods, steel beams and the like for fixing the furnace linings are not closed but positioned in the air, the good radiating performance is obtained; even if flames in some areas soar upwards from gaps, the metal hanging rods, the hanging pieces, the steel beams and the like cannot be burnt, thereby prolonging the service life; and all maintenance operations are performed on the furnace top, and the maintenance and replacement are convenient.

Owner:CHONGQING AOKEQI TECH

Shuttle type kiln

InactiveCN101270958ASmall heat capacityCurb energy consumptionCharge manipulationFurnace crowns/roofsFiberEngineering

The invention provides a shuttle kiln for ceramics firing with good energy-saving performance, simple kiln structure and low manufacturing cost, which is not easy to produce non-uniformity of ceramics firing caused by kiln placing position. The invention is composed of a kiln wall and a kiln roof made from ceramic fiber (2), which is a shuttle kiln having a kiln car (4) inside. A flue (10) forms with a kiln wall by protruding a central part of a rear wall of the kiln body (1) outwards, and an exhaust vent forms at the lower part thereof from a kiln chamber to the flue (10). A plurality of section of a burner (8) is configured oppositely fore and after at fore and after positions of left and right kiln walls, in the manner of forming opposite swirling flow of fire in each horizontal plane up and down. Compared with current product, the invention is capable of reducing the cost greatly.

Owner:NGK INSULATORS LTD

Protecting mixed gas supplier for magnesium-alloy smelting furnace

InactiveCN1982825ASuit one's needsWill not affect normal workCrucible furnacesFurnace crowns/roofsShielding gasProduct gas

The invention comprises a gas-mixing unit, a gas-collecting unit and at least one gas supply unit for supplying gas into the smelter. The gas-mixing unit includes a SF6 gas pipeline, a nitrogen gas pipeline and a mixed gas pipeline. The SF6 gas pipeline and the nitrogen gas pipeline are connected with the gas inlet of the mixed gas pipeline. The gas outlet of the mixed gas pipeline is connected with the gas-collecting unit and the gas-collecting unit is connected with each gas supply unit through the mixed gas pipeline.

Owner:BYD CO LTD

Electric arc furnace

ActiveUS20160123667A1Avoid flowImprove accuracyCrucible furnacesElectric heating for furnacesElectricityElectric arc furnace

The present invention relates to an electric arc furnace, containing a furnace shell, an electrode, a furnace shell moving mechanism that supports the furnace shell so as to be movable on an installation surface, and a first insulation that electrically insulates between the furnace shell and the furnace shell moving mechanism.

Owner:DAIDO STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com