Blast furnace top gas supply system

A gas supply system and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as affecting production stability, production equipment failures, and increasing pig iron costs, achieving simple structure, increasing calorific value, and reducing The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

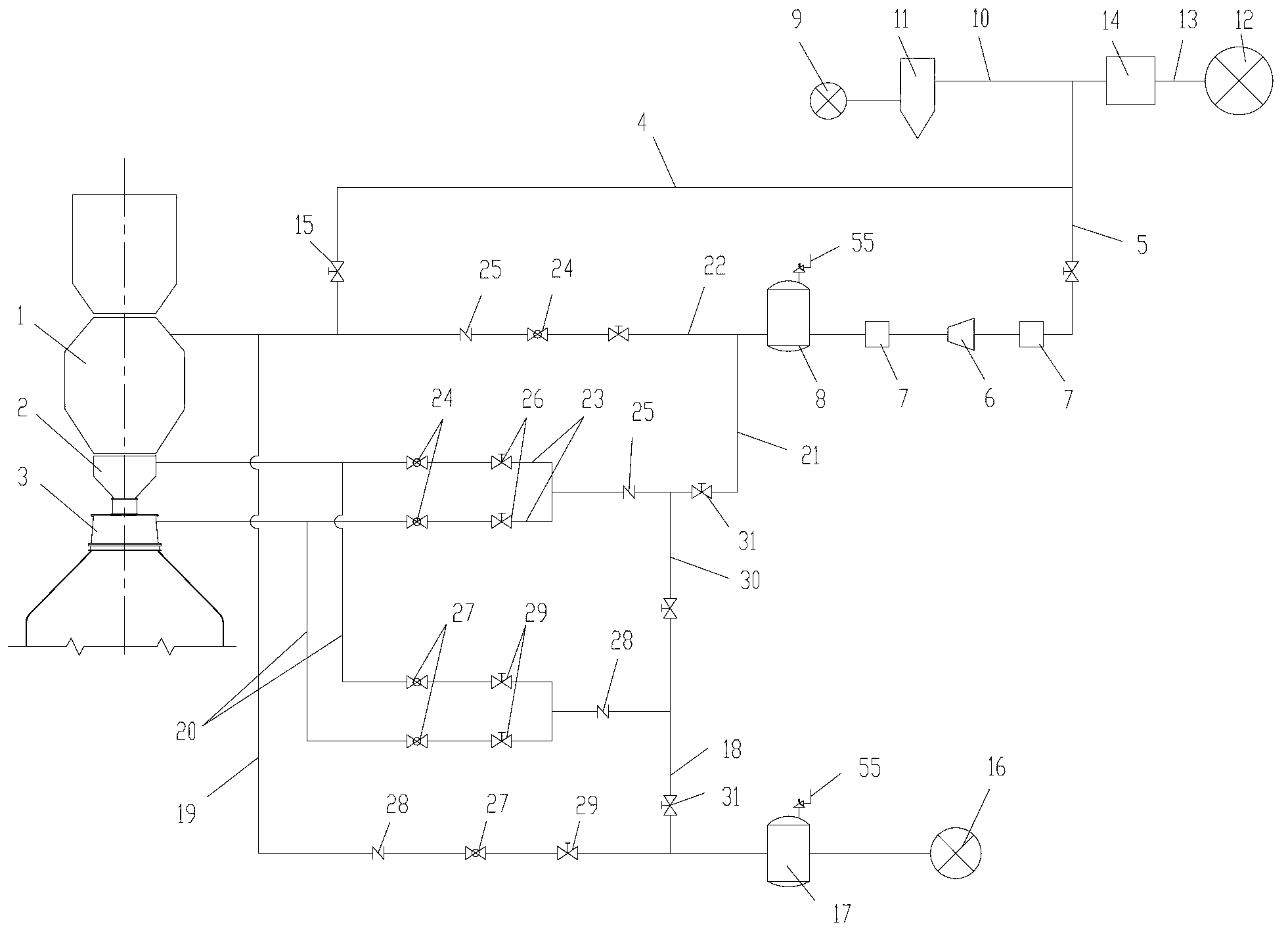

[0035] Such as figure 1 Shown is a schematic structural view of the first embodiment of the blast furnace top gas supply system of the present invention. The top gas supply system of the blast furnace in this embodiment includes a top nitrogen system for supplying nitrogen to the top of the blast furnace and a top gas system arranged in parallel with the top nitrogen system and used for supplying gas to the top of the blast furnace, and the top A switching device for switching and selecting the gas supply source to the top of the blast furnace is provided between the gas system and the top nitrogen system.

[0036] Such as figure 1 As shown, the furnace top gas system in this embodiment includes a gas main pipe connected to the gas supply system, and the gas main pipe includes a gas primary pressure equalization passage 4 connected to the material tank 1 and a pressurized cooling system for pressurizing the gas. Cooling passage 5, pressurization The cooling passage 5 is prov...

no. 2 example

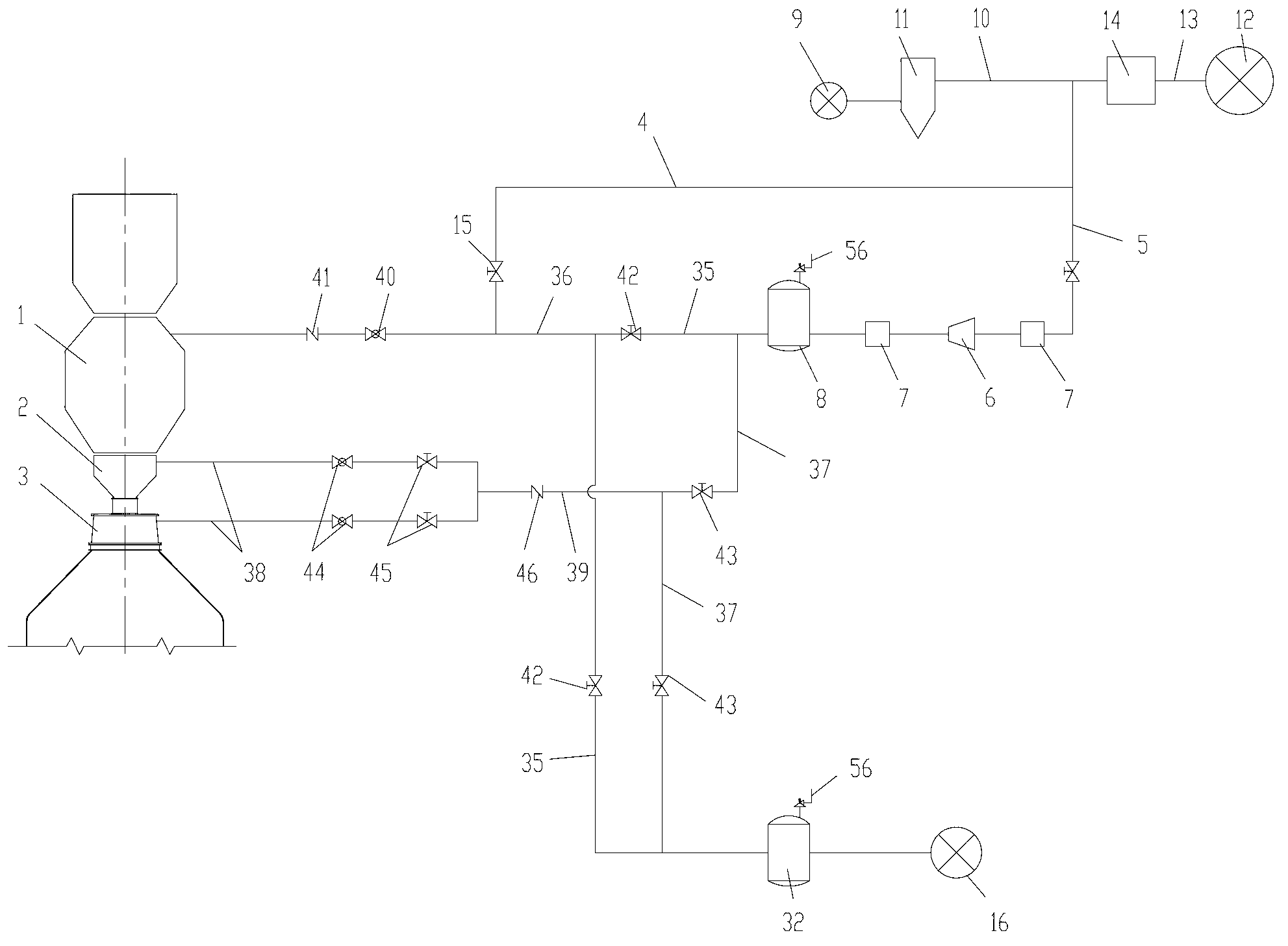

[0046] Such as figure 2 Shown is a schematic structural view of the second embodiment of the blast furnace top gas supply system of the present invention. The top gas supply system of the blast furnace in this embodiment includes a top nitrogen system for supplying nitrogen to the top of the blast furnace and a top gas system arranged in parallel with the top nitrogen system and used for supplying gas to the top of the blast furnace, and the top A switching device for switching and selecting the gas supply source to the top of the blast furnace is provided between the gas system and the top nitrogen system. Such as figure 2 As shown, the furnace top gas system in this embodiment includes a gas main pipe connected to the gas supply system, and the gas main pipe includes a gas primary pressure equalization passage 4 connected to the material tank 1 and a pressurized cooling system for pressurizing the gas. Cooling passage 5, pressurization The cooling passage 5 is provided w...

no. 3 example

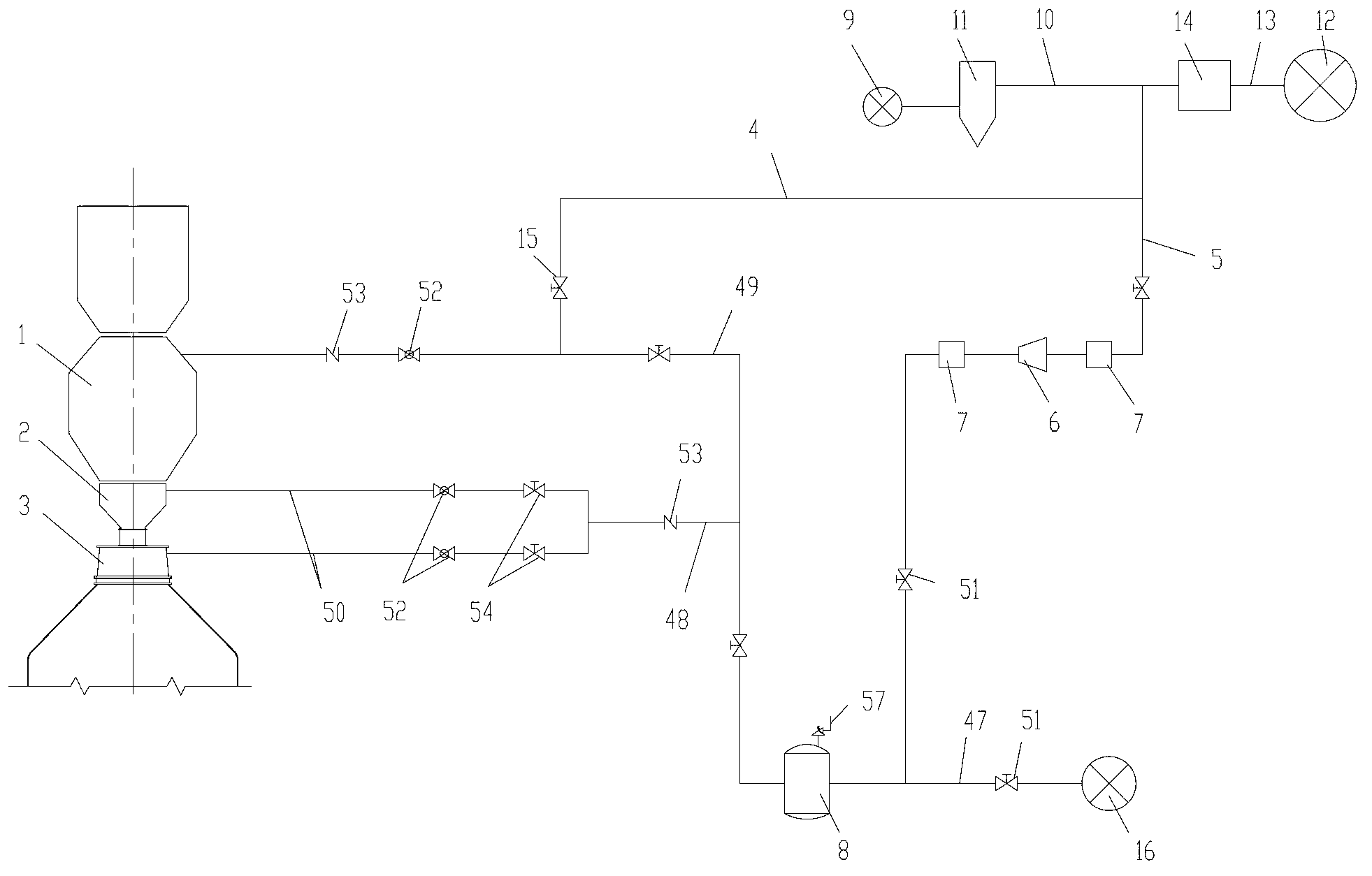

[0051] Such as image 3 Shown is a schematic structural view of the third embodiment of the blast furnace top gas supply system of the present invention. The top gas supply system of the blast furnace in this embodiment includes a top nitrogen system for supplying nitrogen to the top of the blast furnace and a top gas system arranged in parallel with the top nitrogen system and used for supplying gas to the top of the blast furnace, and the top A switching device for switching and selecting the gas supply source to the top of the blast furnace is provided between the gas system and the top nitrogen system. Such as image 3 As shown, the furnace top gas system in this embodiment includes a gas main pipe connected to the gas supply system, and the gas main pipe includes a gas primary pressure equalization passage 4 connected to the material tank 1 and a pressurized cooling system for pressurizing the gas. Cooling passage 5, pressurization The cooling passage 5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com