Method and device for dismantling refractory materials at arch crown of hot blast stove

A technology for hot blast stoves and vaults, which is applied to furnace crowns/roofs, brick blast furnaces, and lining repairs. It can solve the problems of high work intensity and long time consumption, and achieve the effects of high labor intensity, high efficiency, and reduced workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

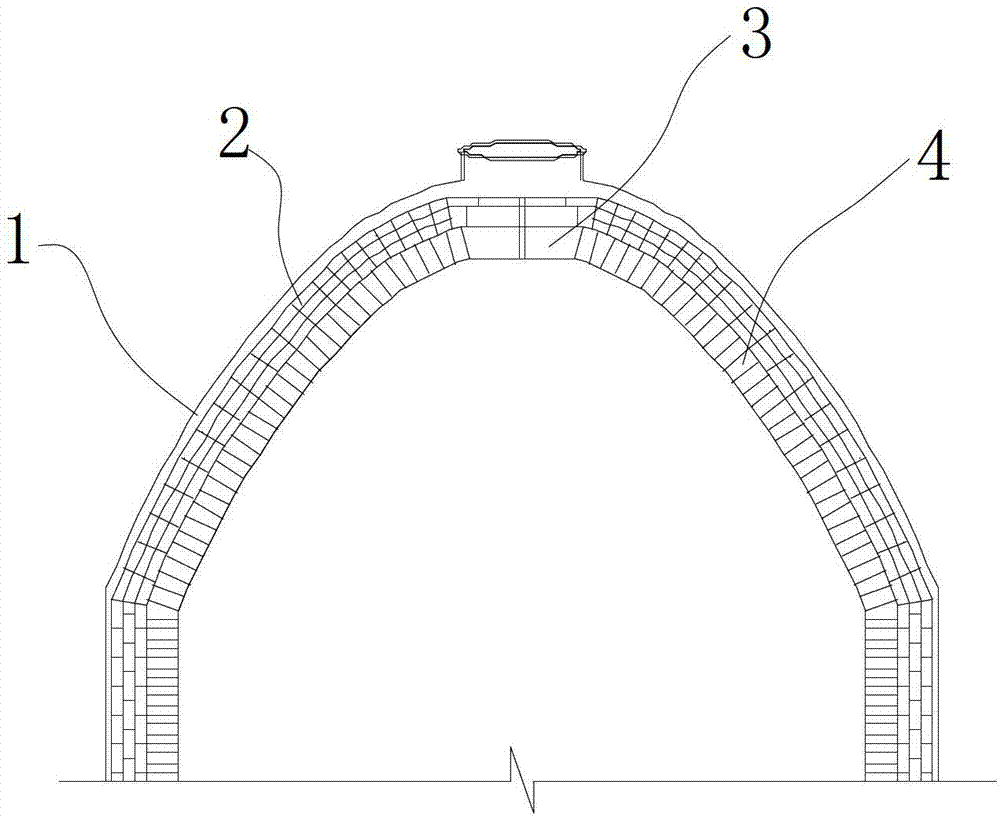

[0028] The present invention will be further described below in conjunction with accompanying drawing.

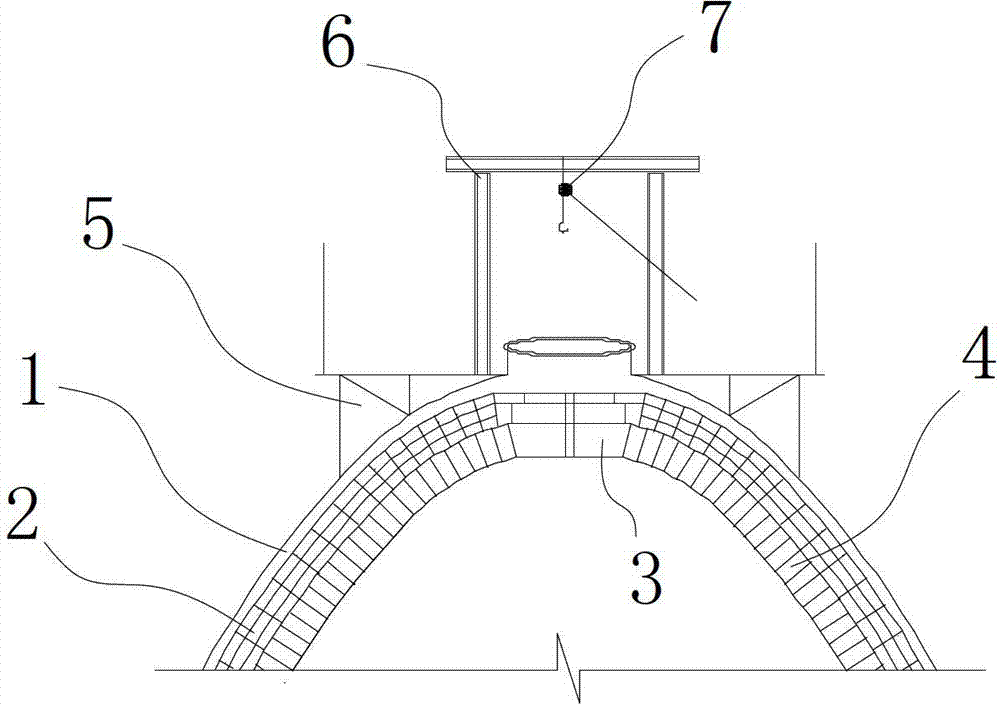

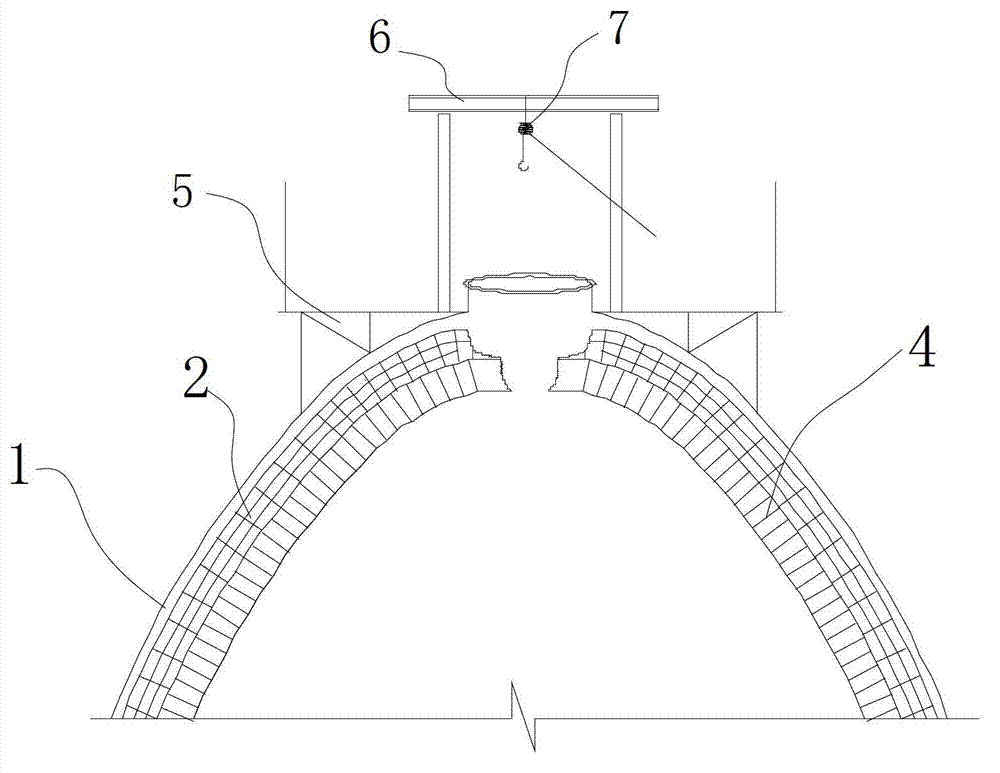

[0029] Such as Figure 2 to Figure 5 Shown, the present invention comprises the following steps:

[0030] A. Set up a profiled steel hanger 6 on the steel platform 5 of the hot blast furnace roof, install the lifting device 7 with the profiled steel hanger 6 as the installation basis, and connect the lifting rope 9 on the lifting device 7; this step can be referred to figure 2 As shown, the steel platform 5 can be built in the past, if not, the steel platform 5 must be built in advance, and the steel platform 5 is built on the basis of the furnace shell 1. Steel hanger 6 generally adopts a frame-type structure, such as a portal frame, and hoisting device 7 is installed on the crossbeam of steel hanger 6, and hoisting device 7 adopts common electric hoist, chain hoist or hydraulic device. Suspension rope 9 can be installed in this step, also can stay to be connected in C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com