Patents

Literature

298results about How to "Reduce work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

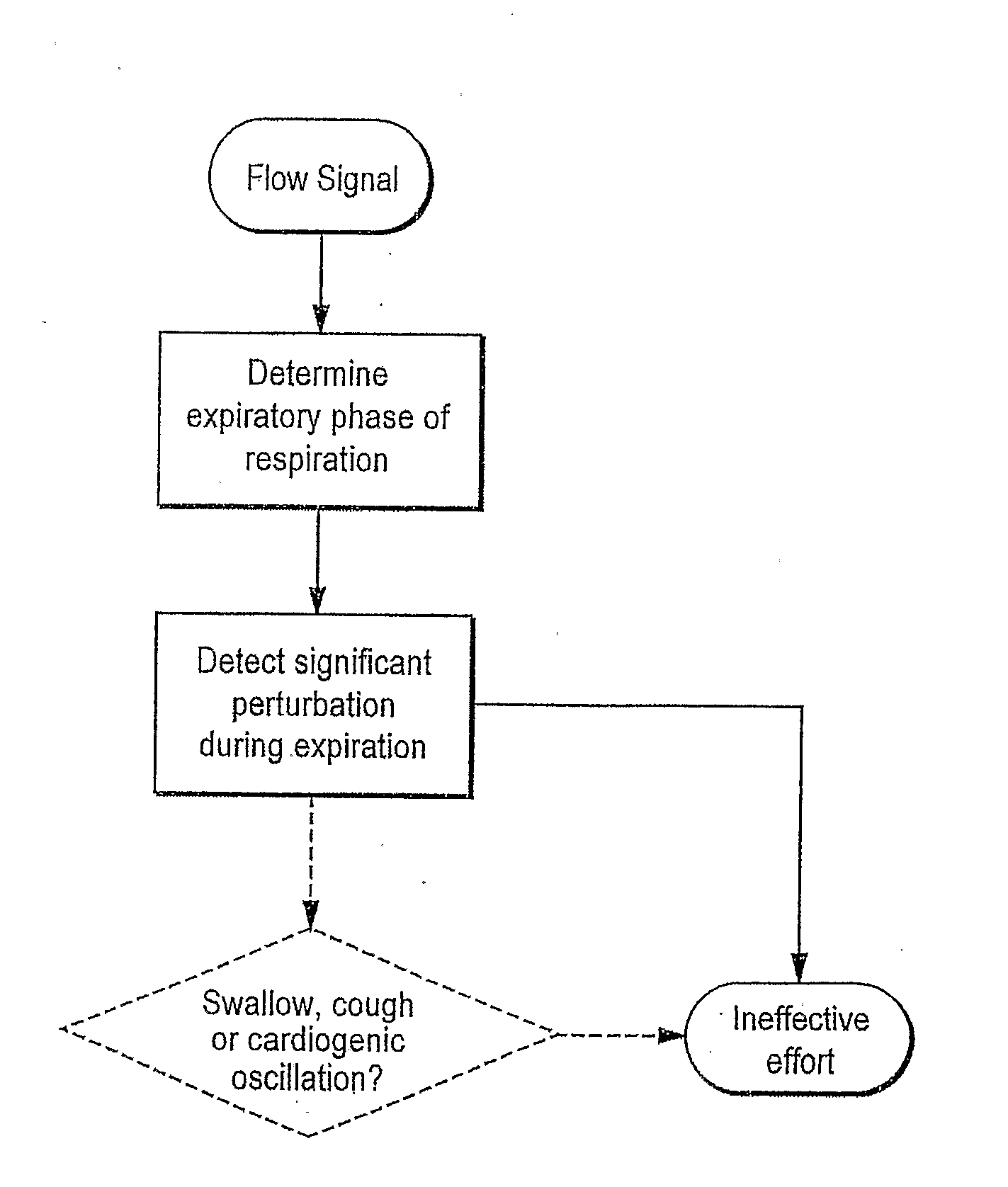

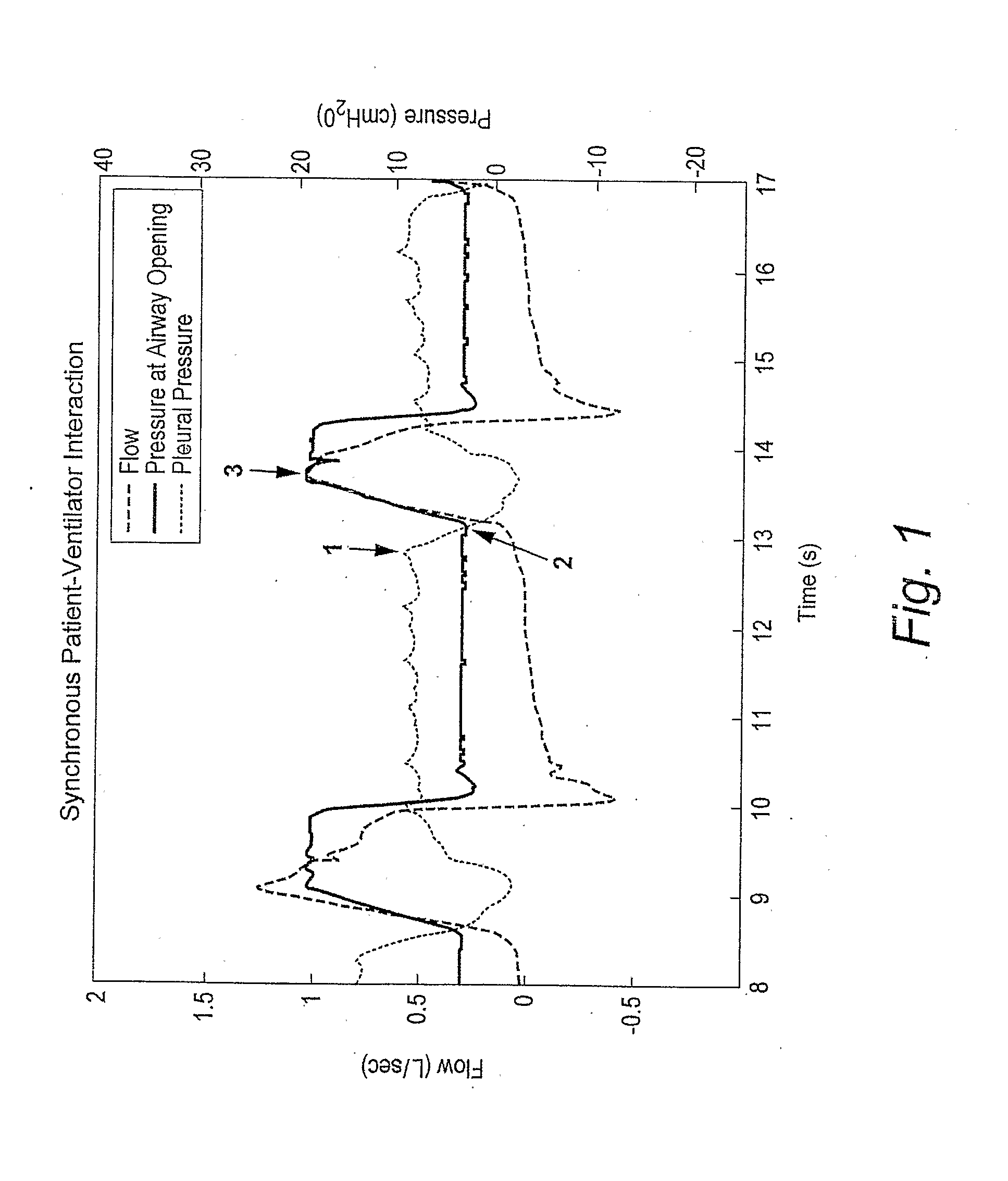

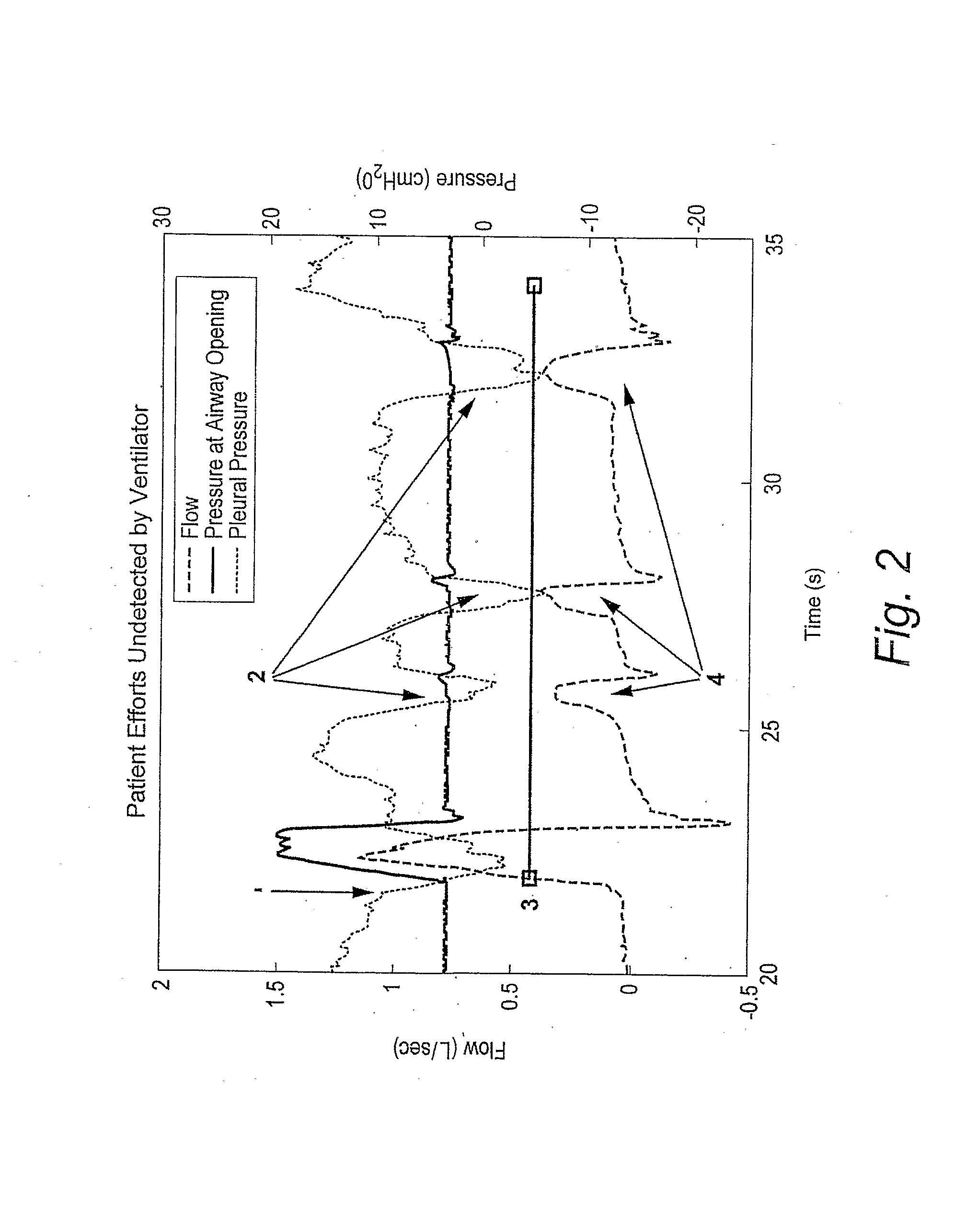

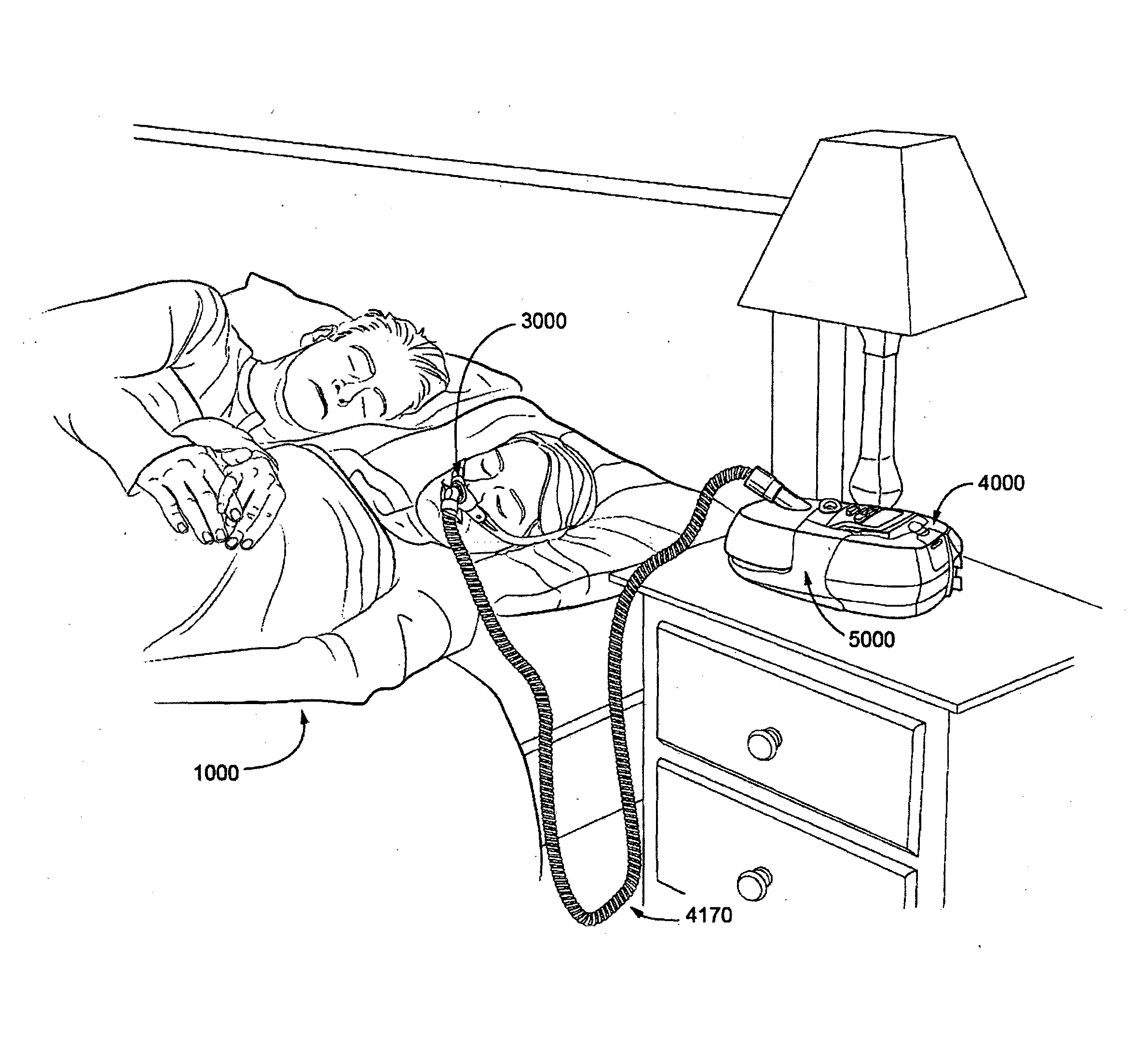

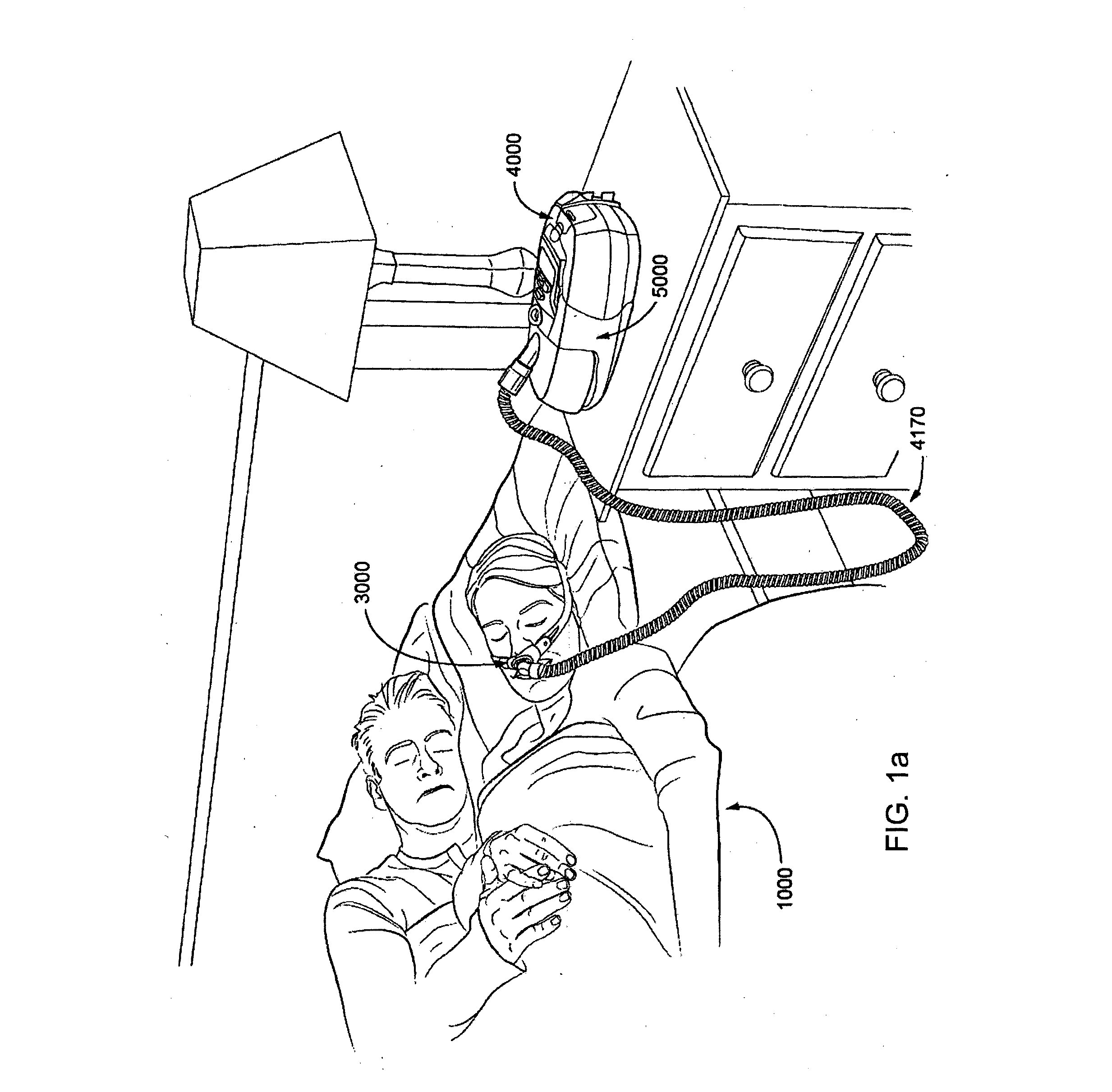

Method and Apparatus For Detecting Ineffective Inspiratory Efforts and Improving Patient-Ventilator Interaction

ActiveUS20080110461A1Reduce workMinimize indexRespiratorsOperating means/releasing devices for valvesTraffic volumeAirflow

A method and system for detecting an ineffective effort of a patient being mechanically ventilated by a ventilator comprises (i) monitoring a respiratory flow of air of the patient after said ventilator has cycled; (ii) creating a signal indicative of said flow; (iii) removing artefact from said signal; (iv) monitoring said signal for perturbations; and (v) determining that an ineffective effort has occurred when said perturbation is significant.

Owner:RESMED LTD

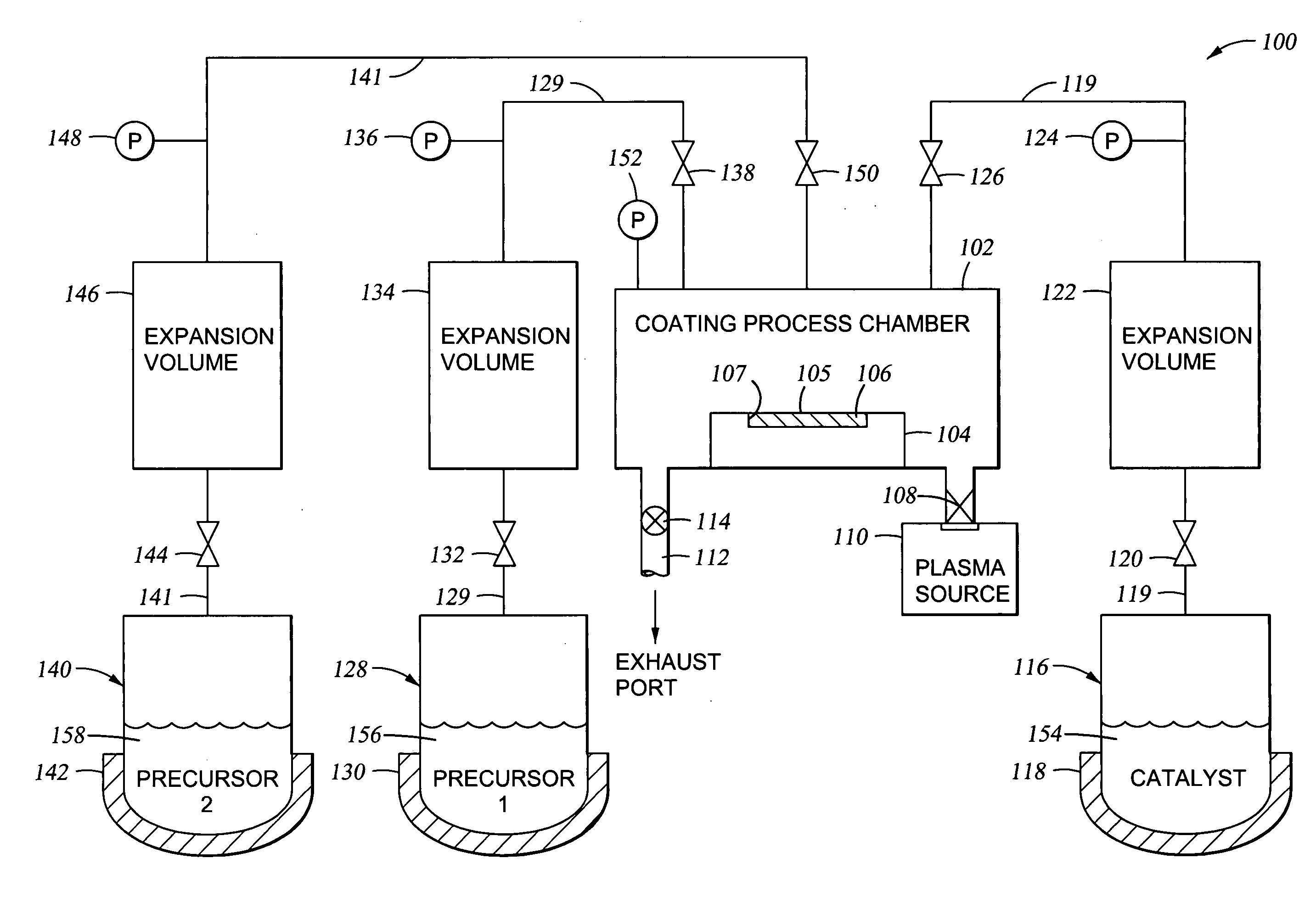

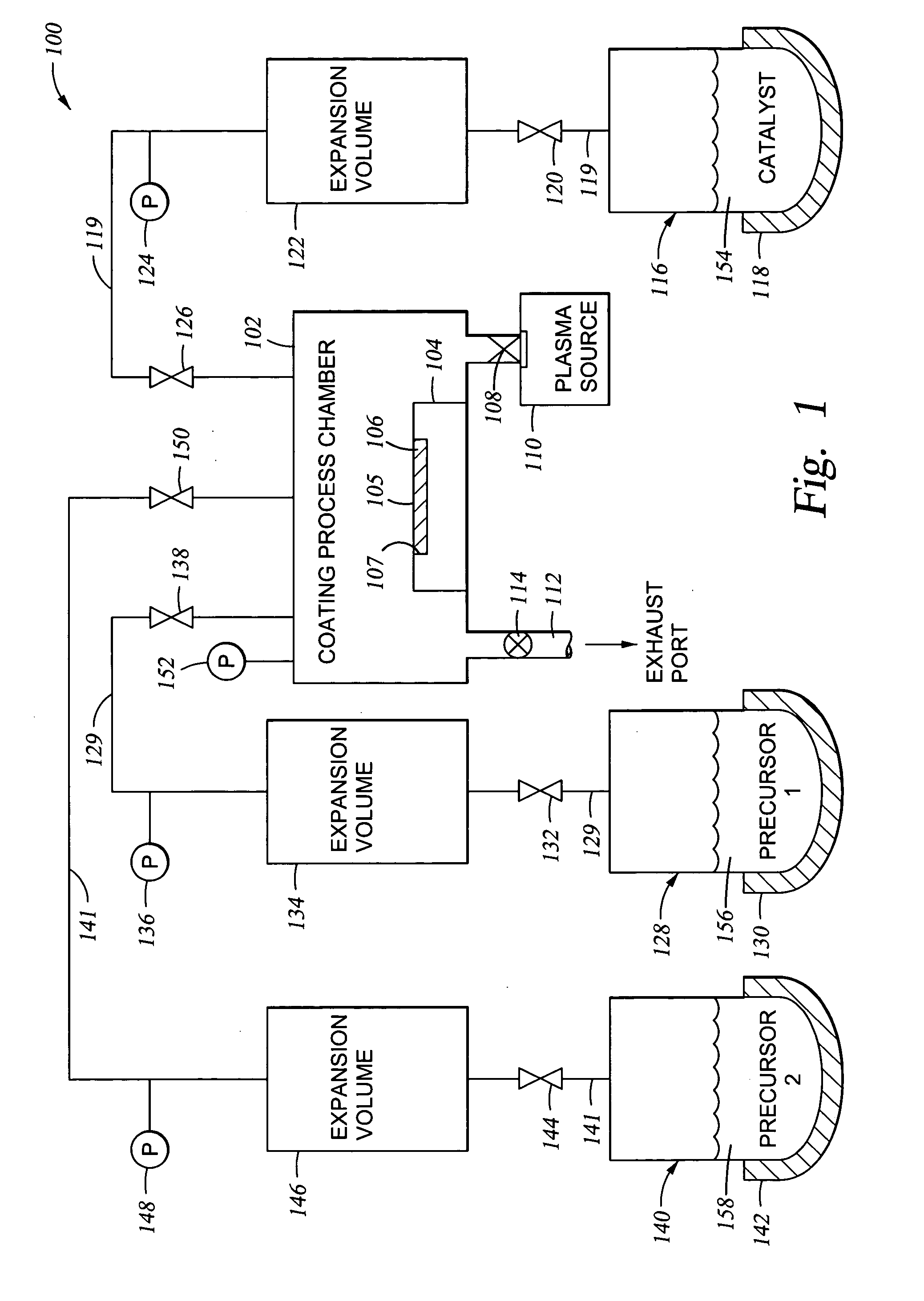

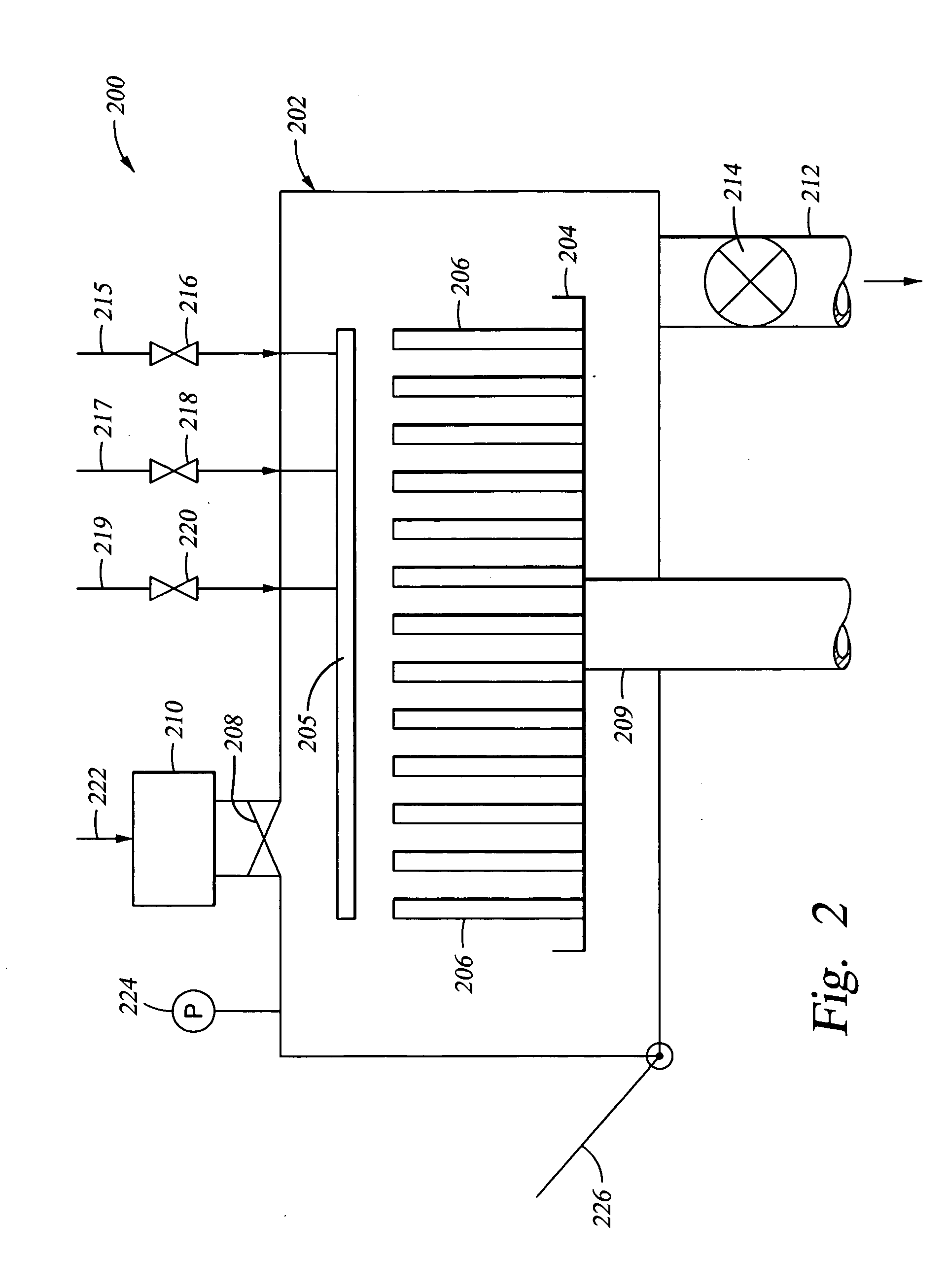

Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

InactiveUS20040261703A1Prevent stictionReduce workMaterial nanotechnologyElectrical apparatusVapor phaseThin layer

A vapor phase deposition method and apparatus for the application of thin layers and coatings on substrates. The method and apparatus are useful in the fabrication of electronic devices, micro-electromechanical systems (MEMS), Bio-MEMS devices, micro and nano imprinting lithography, and microfluidic devices. The apparatus used to carry out the method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. The apparatus provides for precise addition of quantities of different combinations of reactants during a single step or when there are a number of different individual steps in the coating formation process. The precise addition of each of the reactants in vapor form is metered into a predetermined set volume at a specified temperature to a specified pressure, to provide a highly accurate amount of reactant.

Owner:APPLIED MICROSTRUCTURES

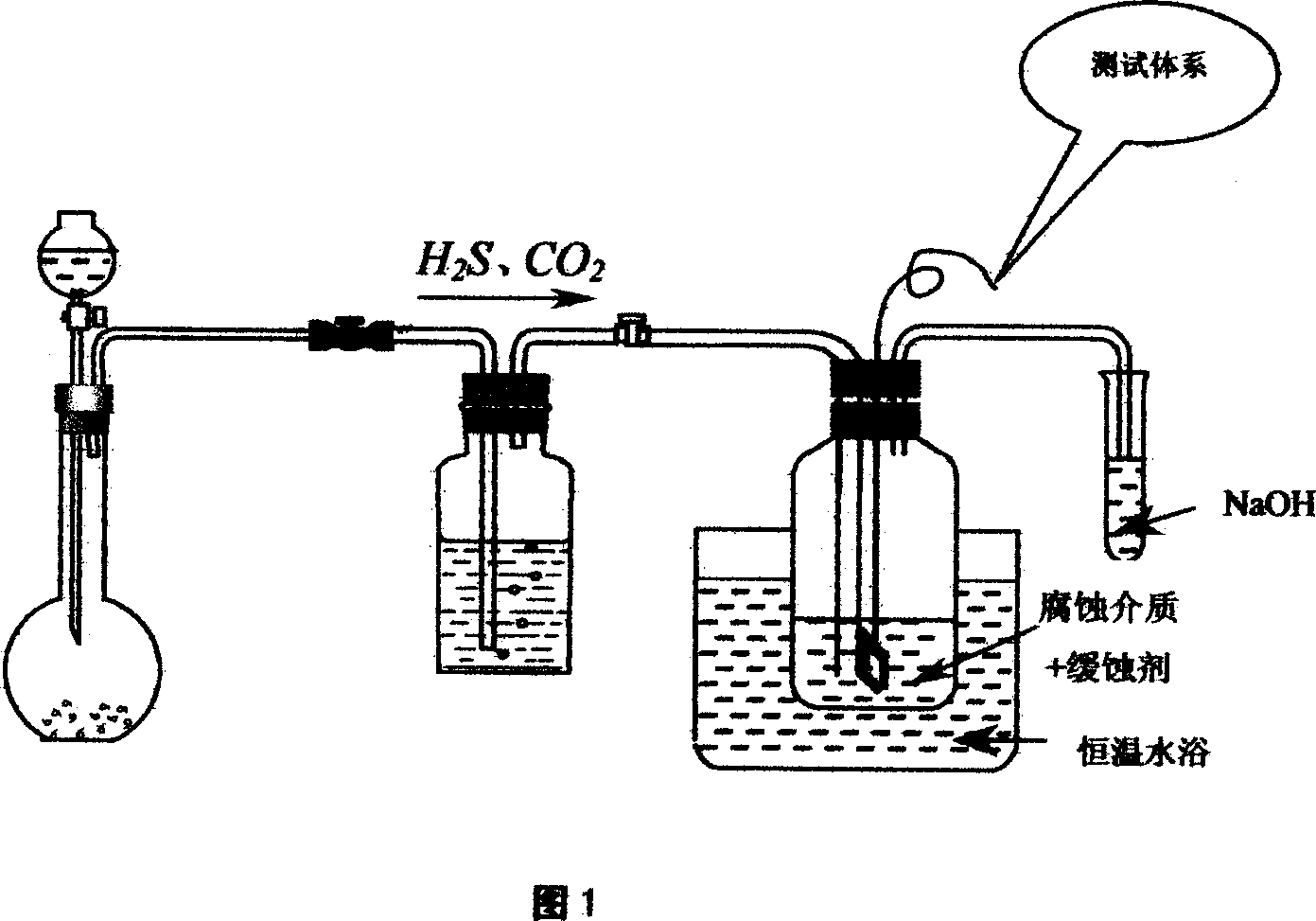

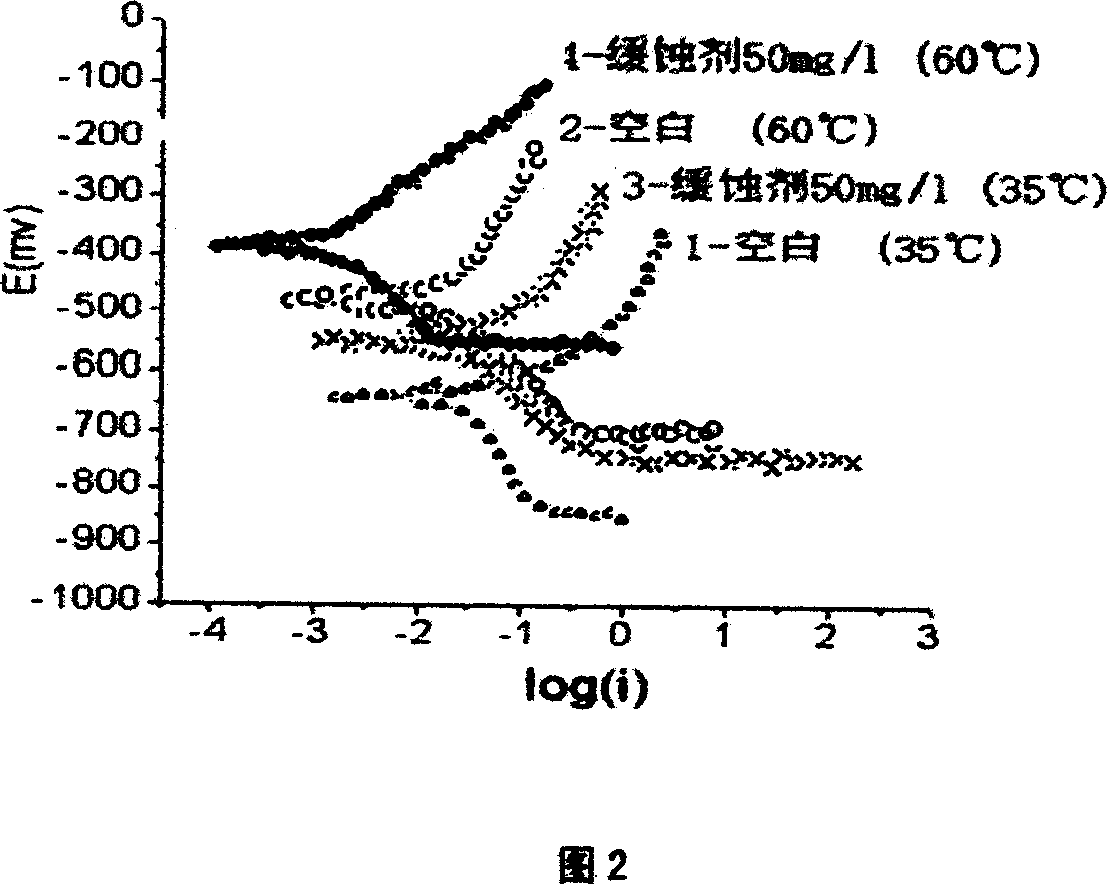

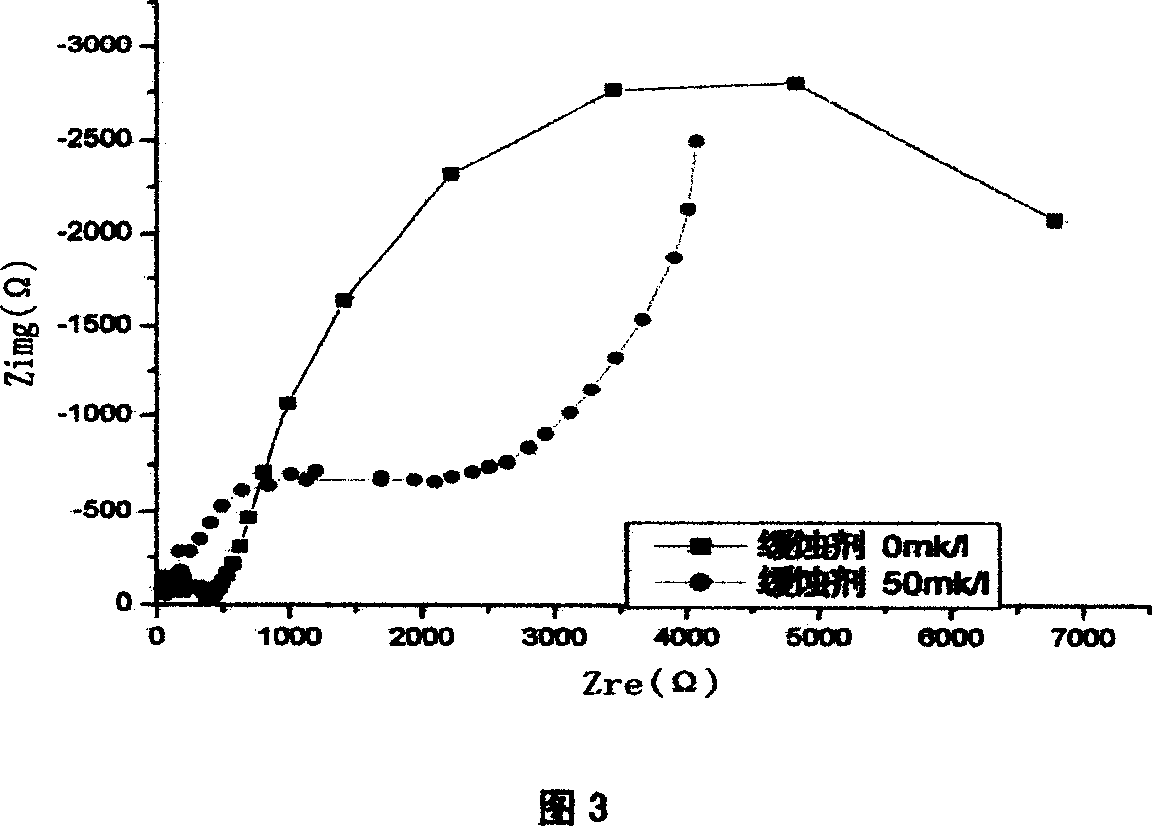

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

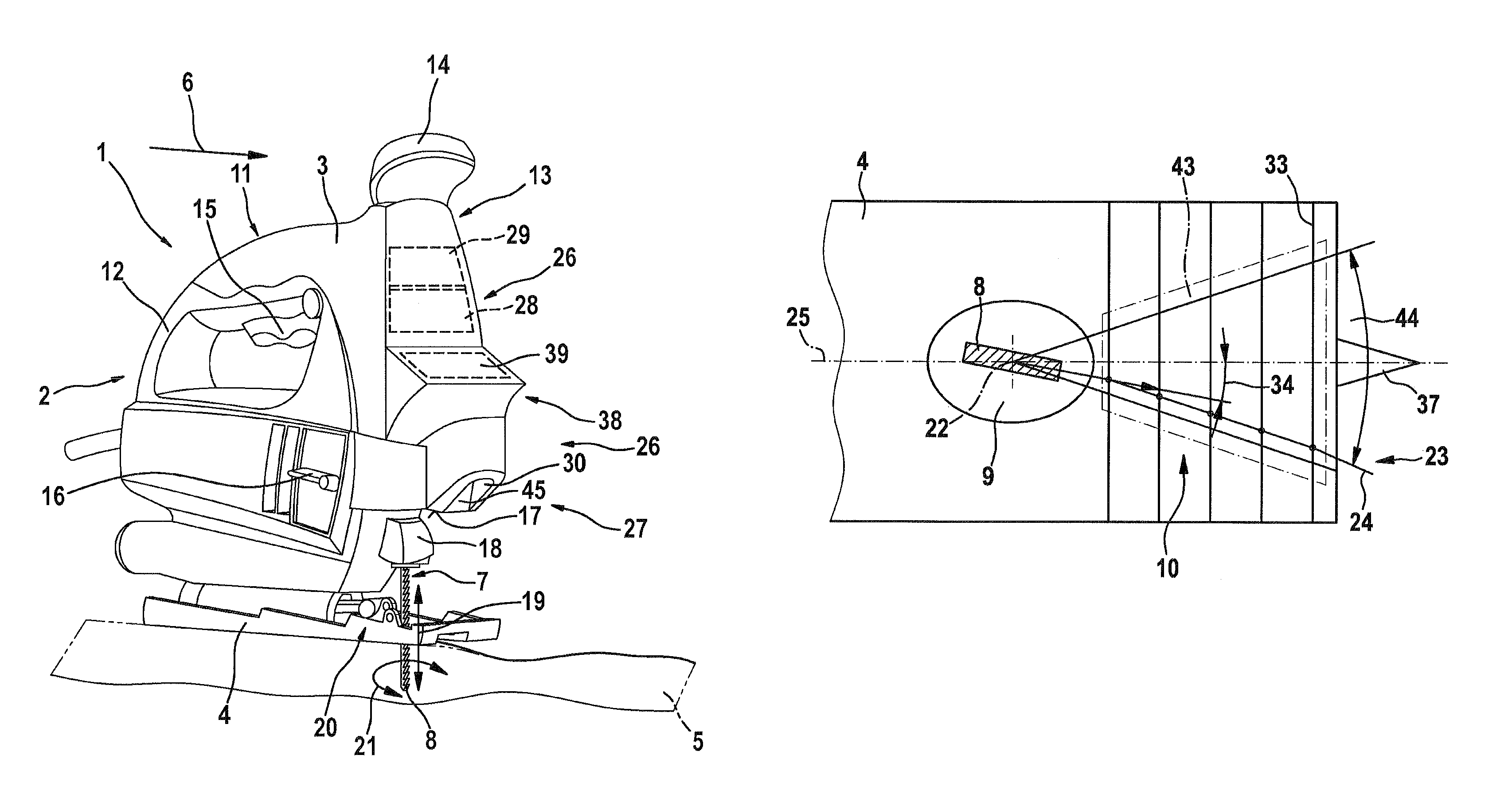

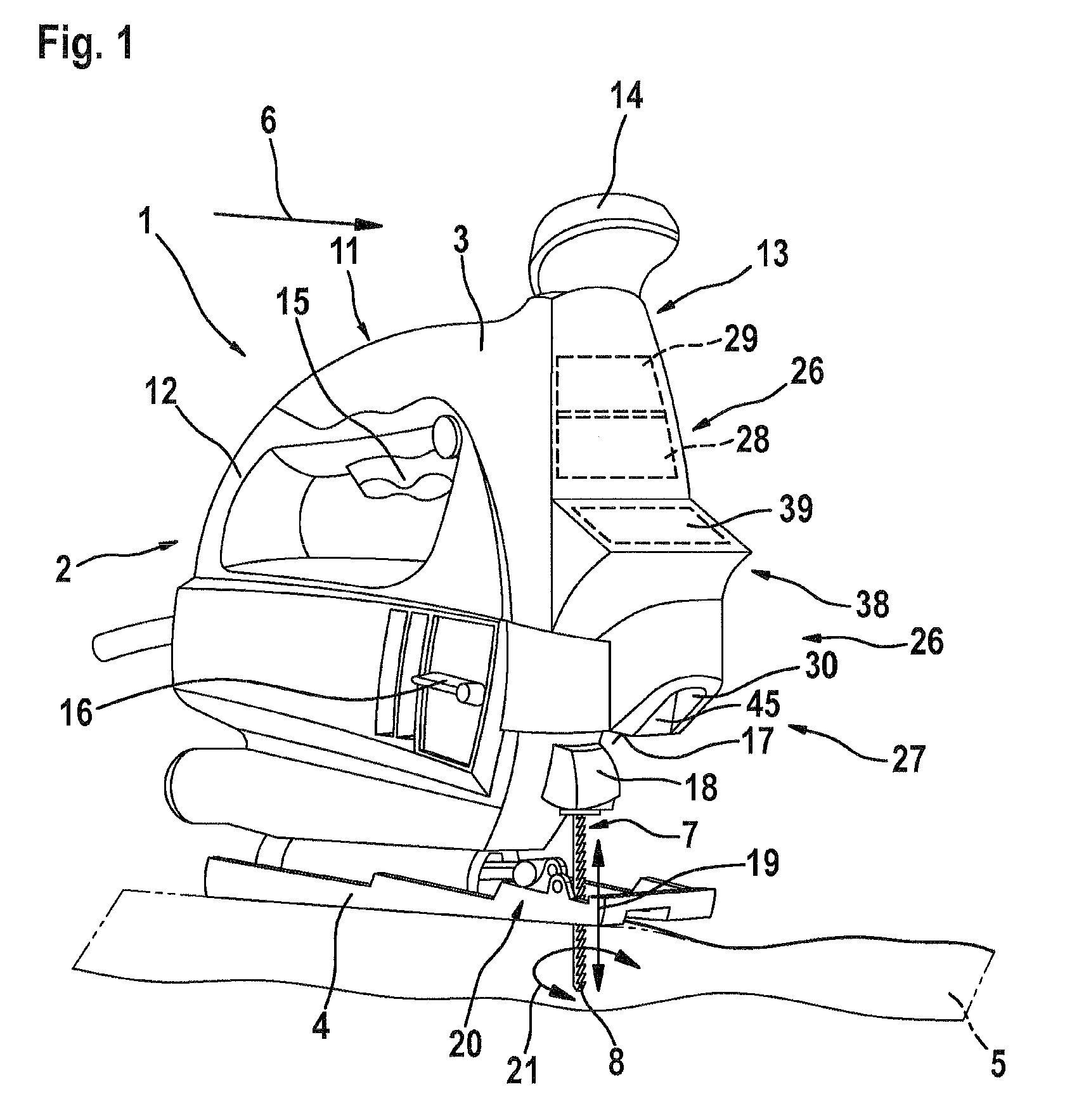

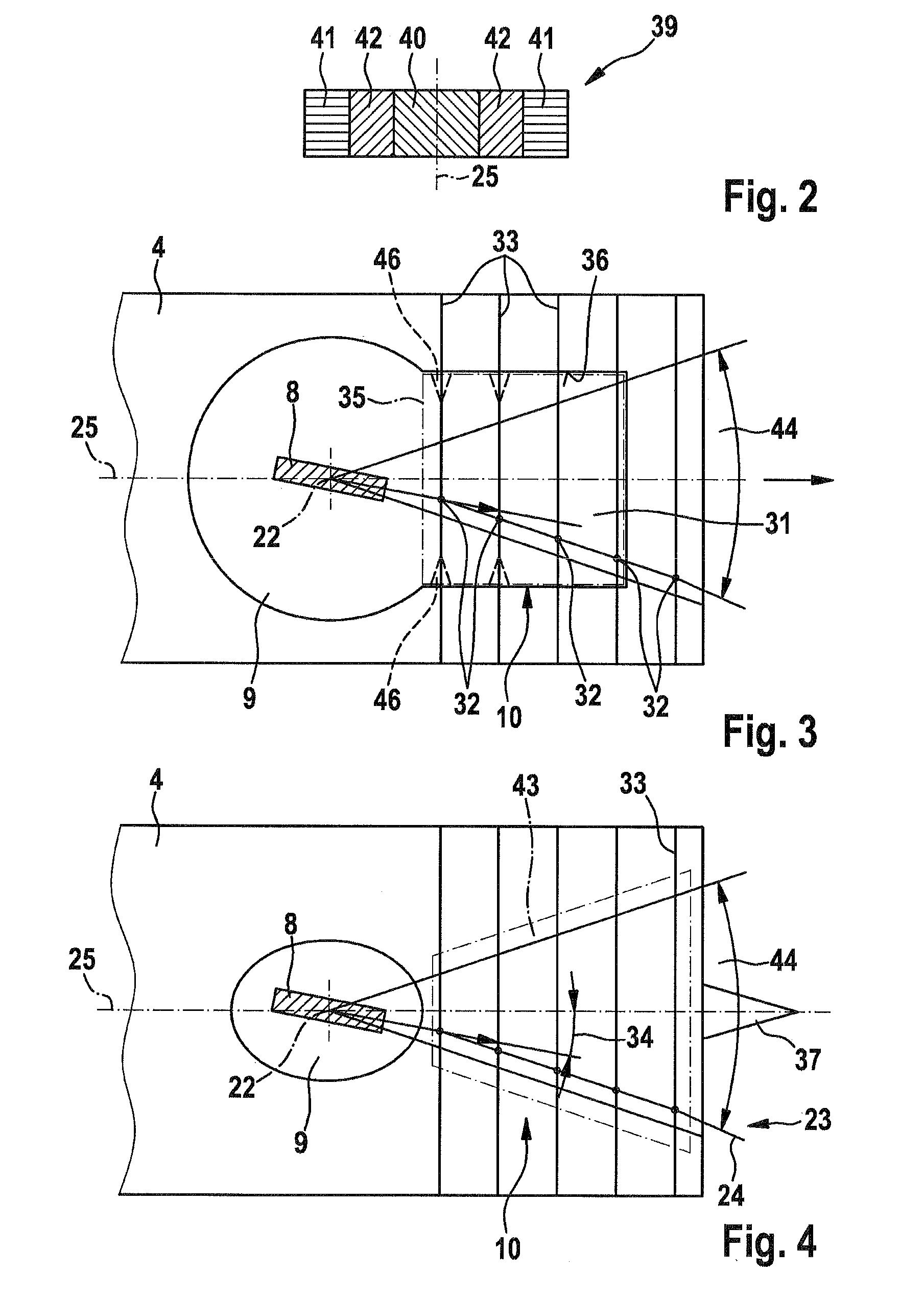

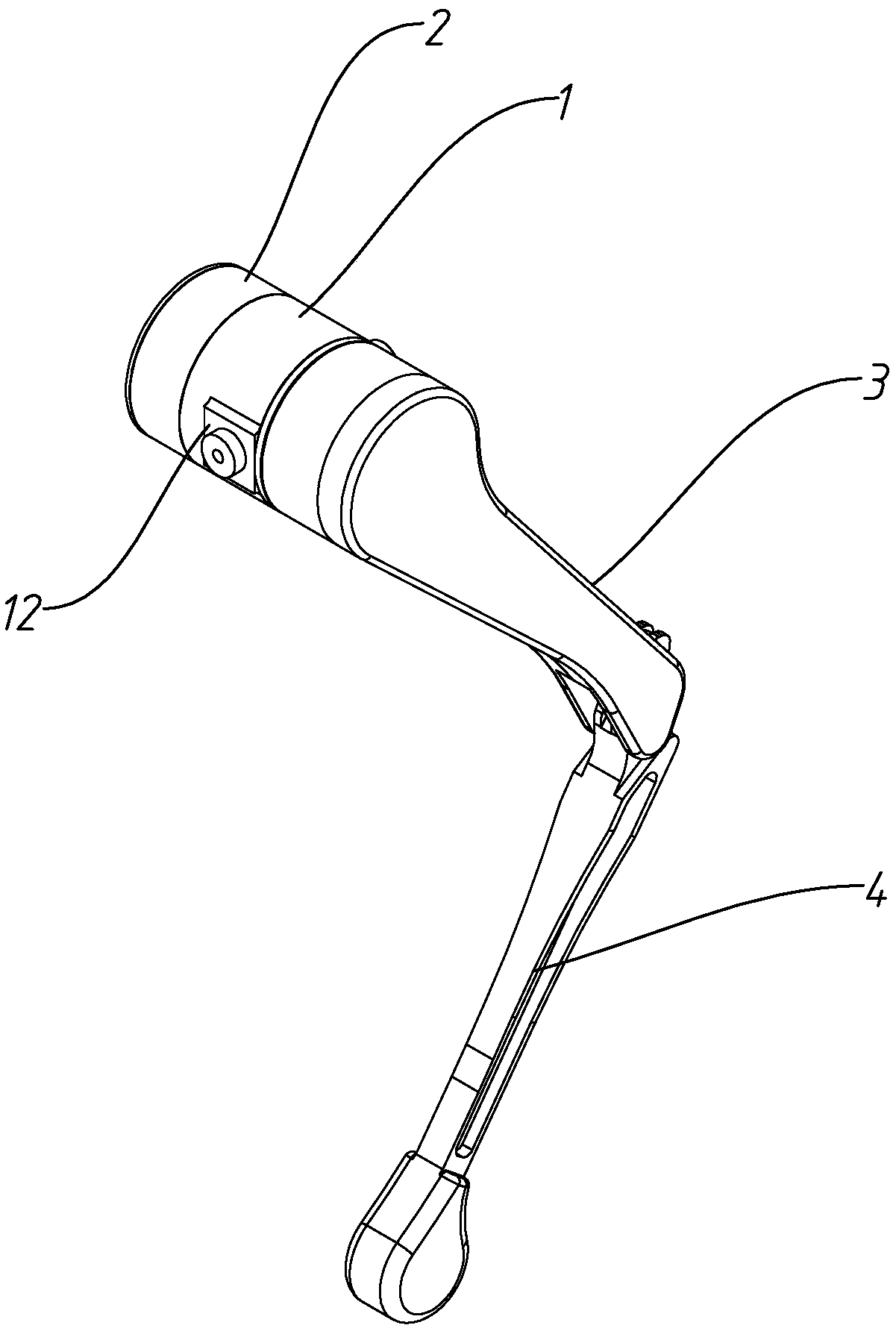

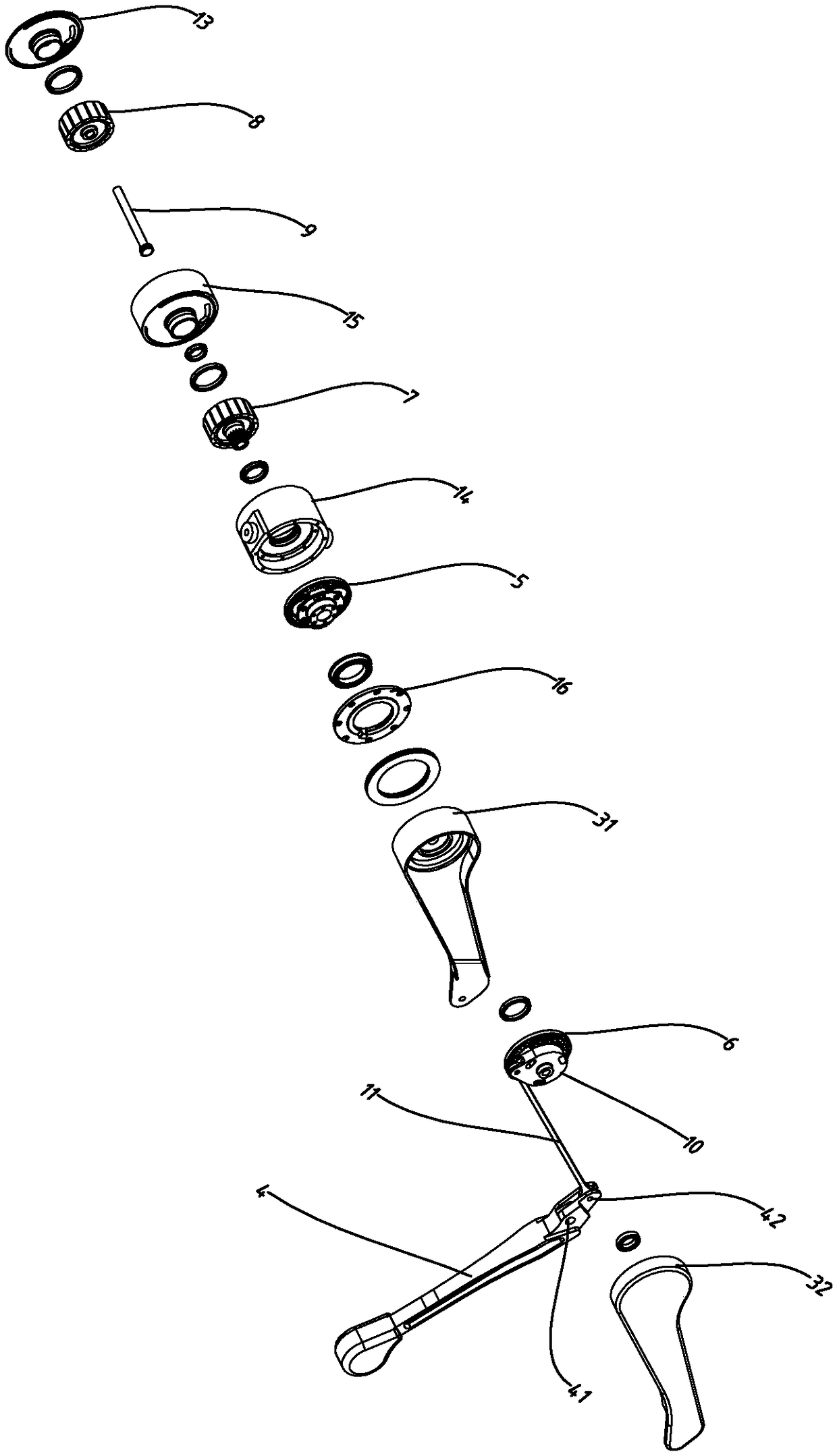

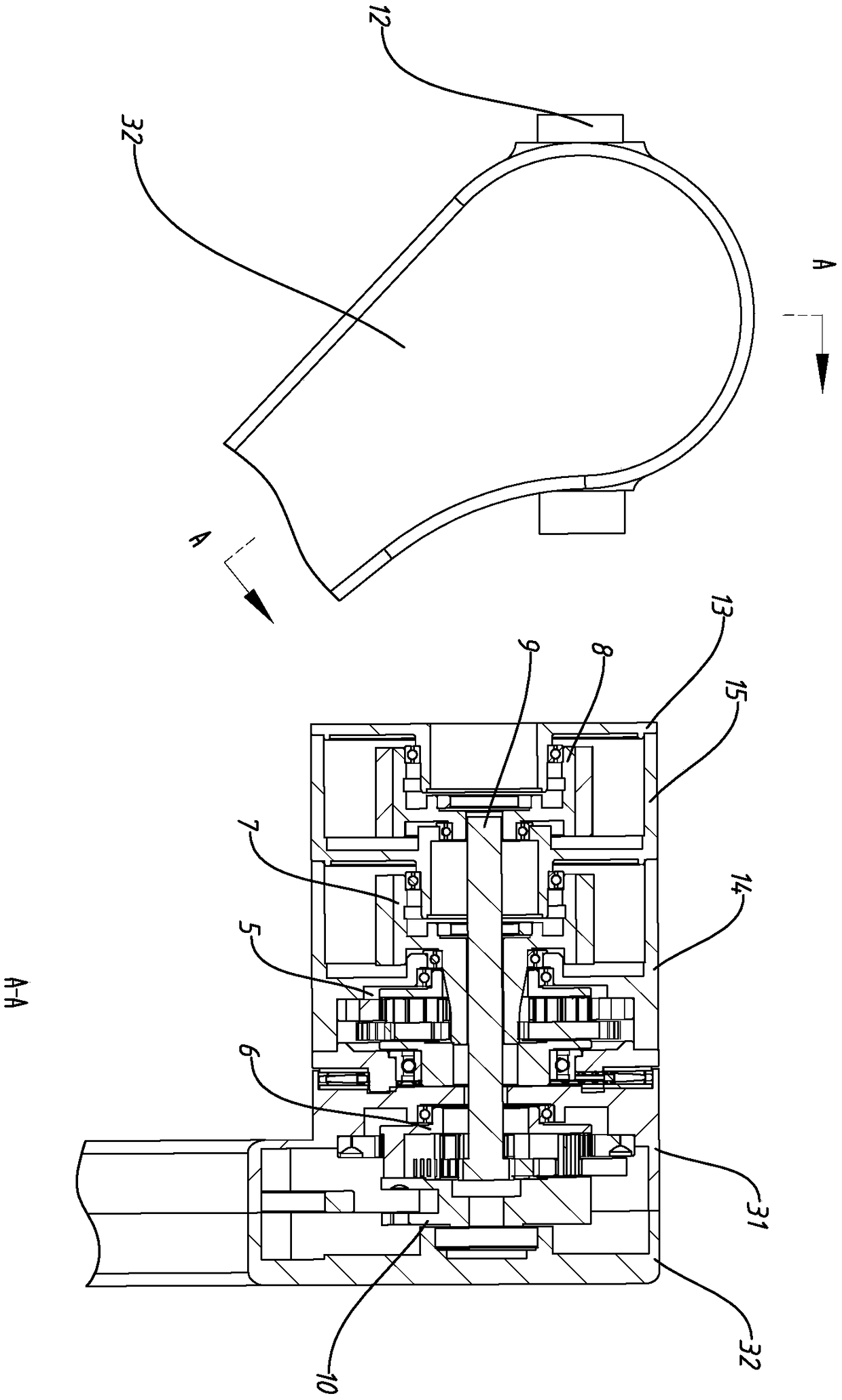

Power tool, particularly a hand-held power tool

InactiveUS9073134B2Easy to placeWork lessMetal sawing devicesMetal sawing accessoriesHand heldPower tool

The invention relates to a power tool (1), especially in the form of a hand-held jigsaw (2). In order to allow for a semi-autonomous operation which assists the user to guide the tool, the tool is provided with a sensor system (27) for observing a detection surface (31, 43) within which the desired working direction is detected as a path default (23) for the saw blade (8) serving as the tool (7) with respect to its alignment relative to the jigsaw (2), the detected path default being intended for downstream control means (26). Said control means align the saw blade (8) relative to the path default (23) by rotating it about its longitudinal axis (25) so that the user guiding the saw blade (2) only has to make sure that the path default (23) extends inside the detection surface (31, 43).

Owner:ROBERT BOSCH GMBH

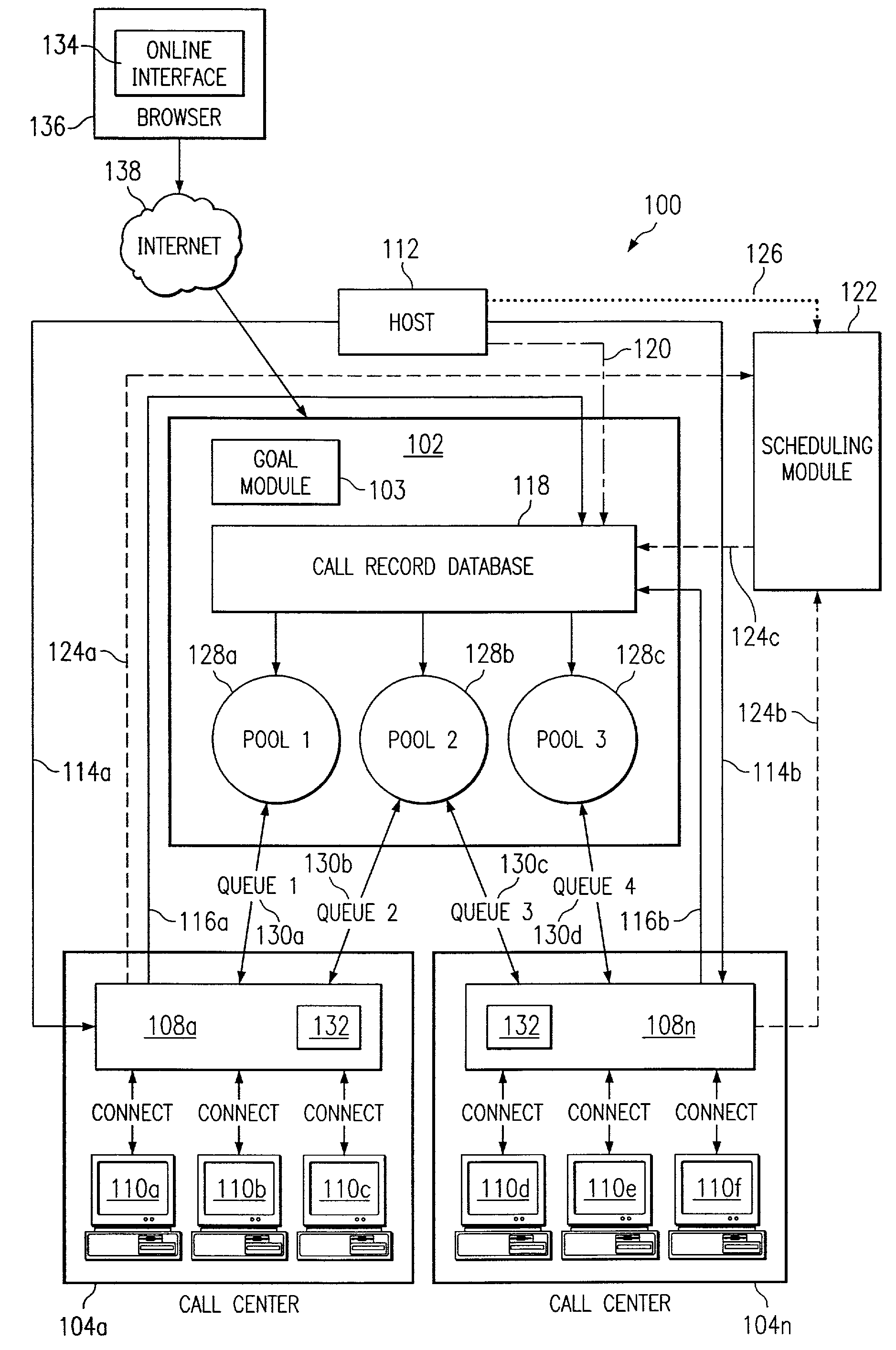

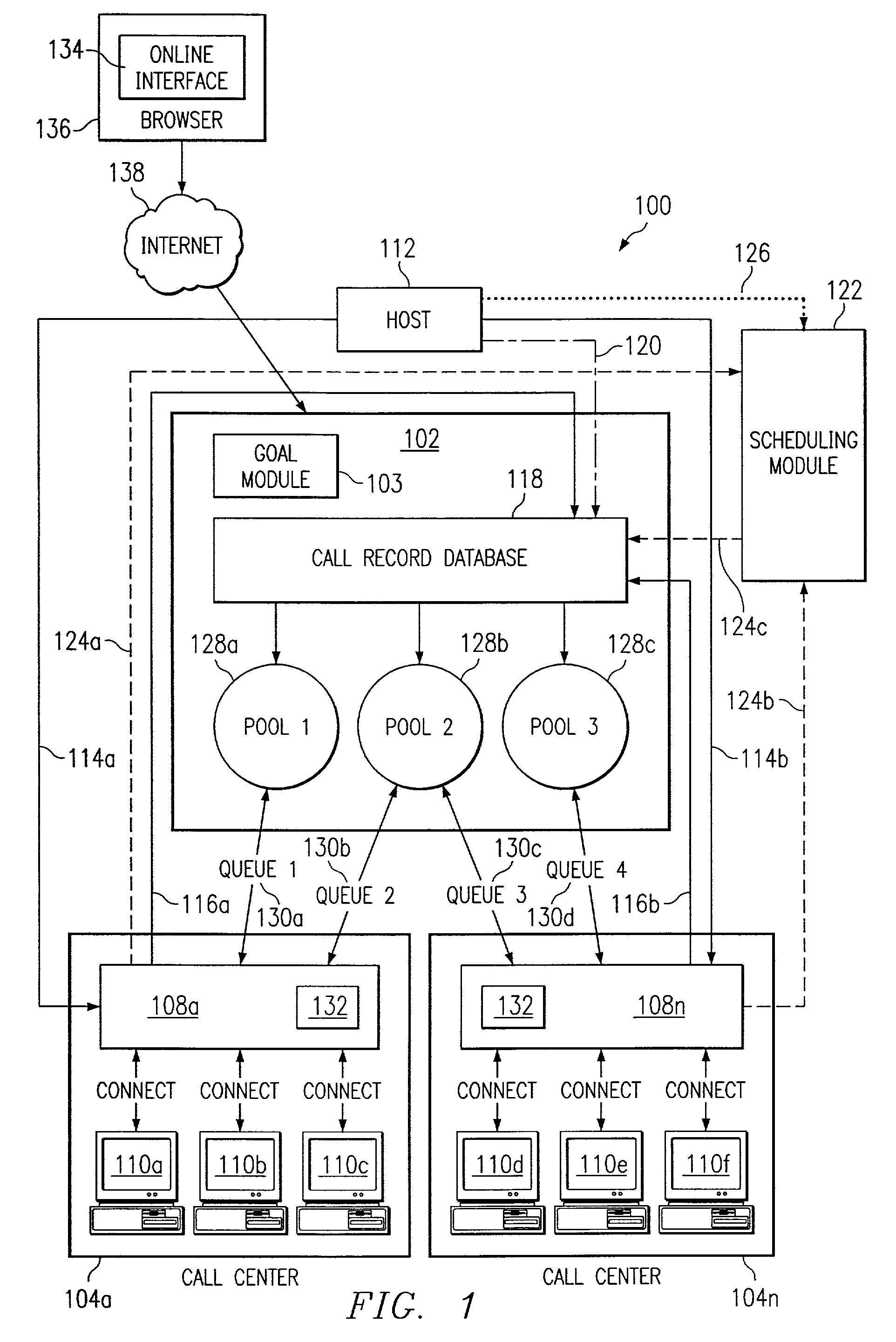

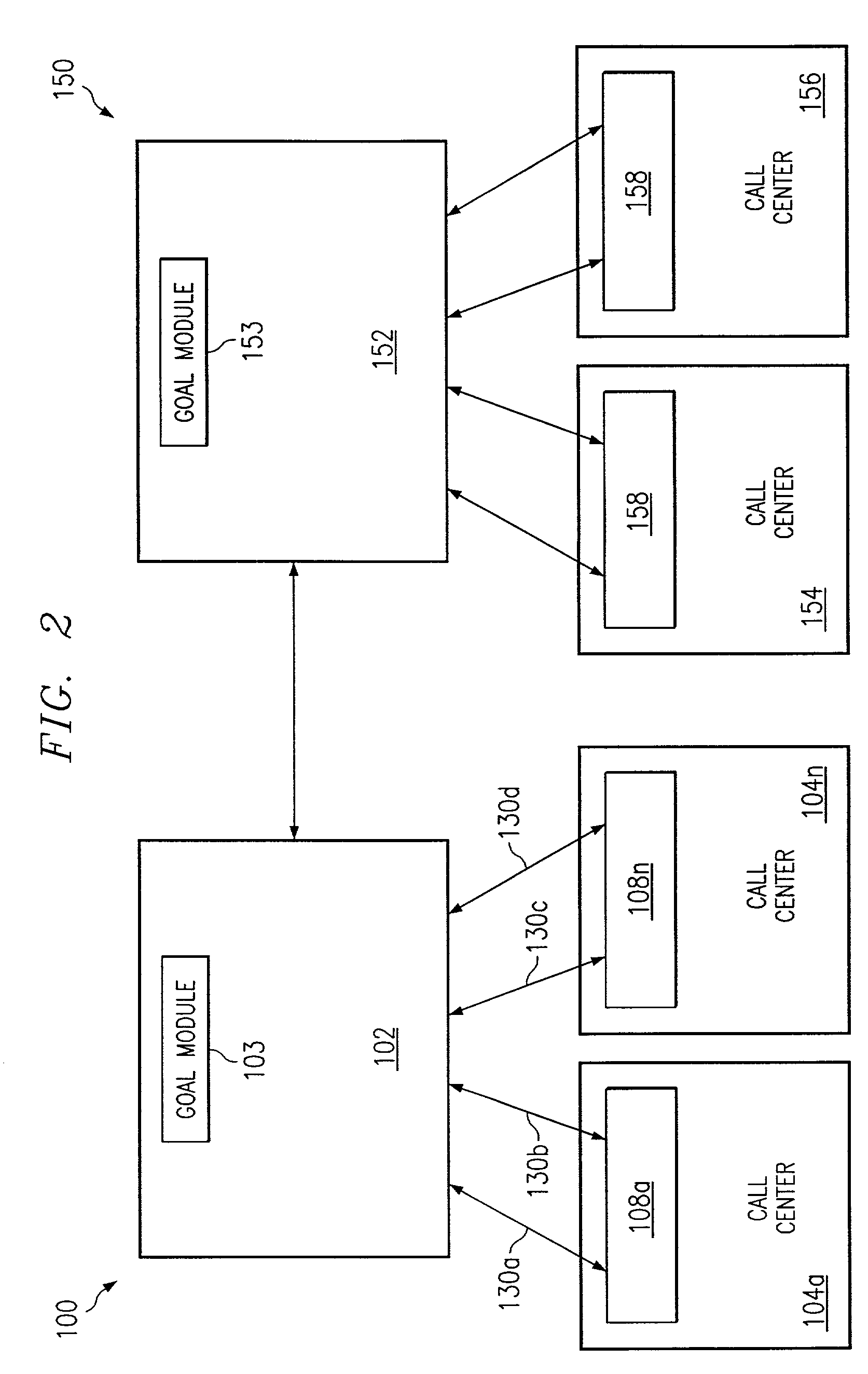

System and method for preemptive goals based routing of contact records

ActiveUS7103173B2Reduce workReduced agent or device downtimeSpecial service for subscribersManual exchangesMaximum efficiencyComputer science

A method and system is provided for the preemptive goals based distribution of contact records. This method and system includes devices receiving contact records and providing customer contacts to one or more agents. Interfaced with the device is a distribution module including pools and queues. The distribution module places the contact records into the pools and transfers less than all of the contact records to the queues to allow for processing by the devices at peak efficiency. The distribution module transfers the queues to the devices so that the device can place customer contact attempts. A goal module, associated with the distribution module, monitors the performance of the pools. The goal module modifies which queues the pools transfer contact records to based on the performance of the pools thereby allowing the contact records to be distributed in accordance with performance goals for the pools.

Owner:NOBLE SYSTEMS CORPORATION

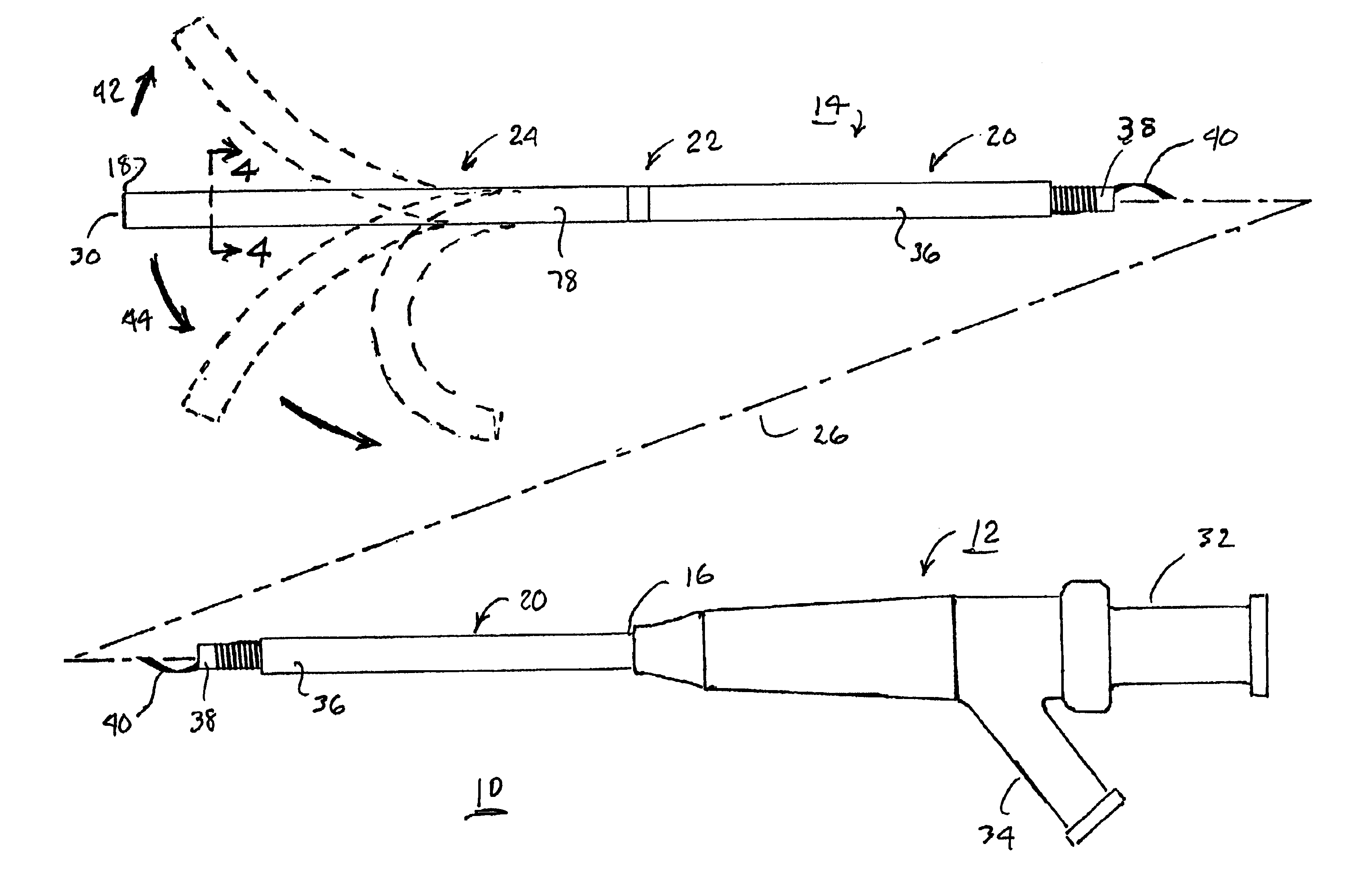

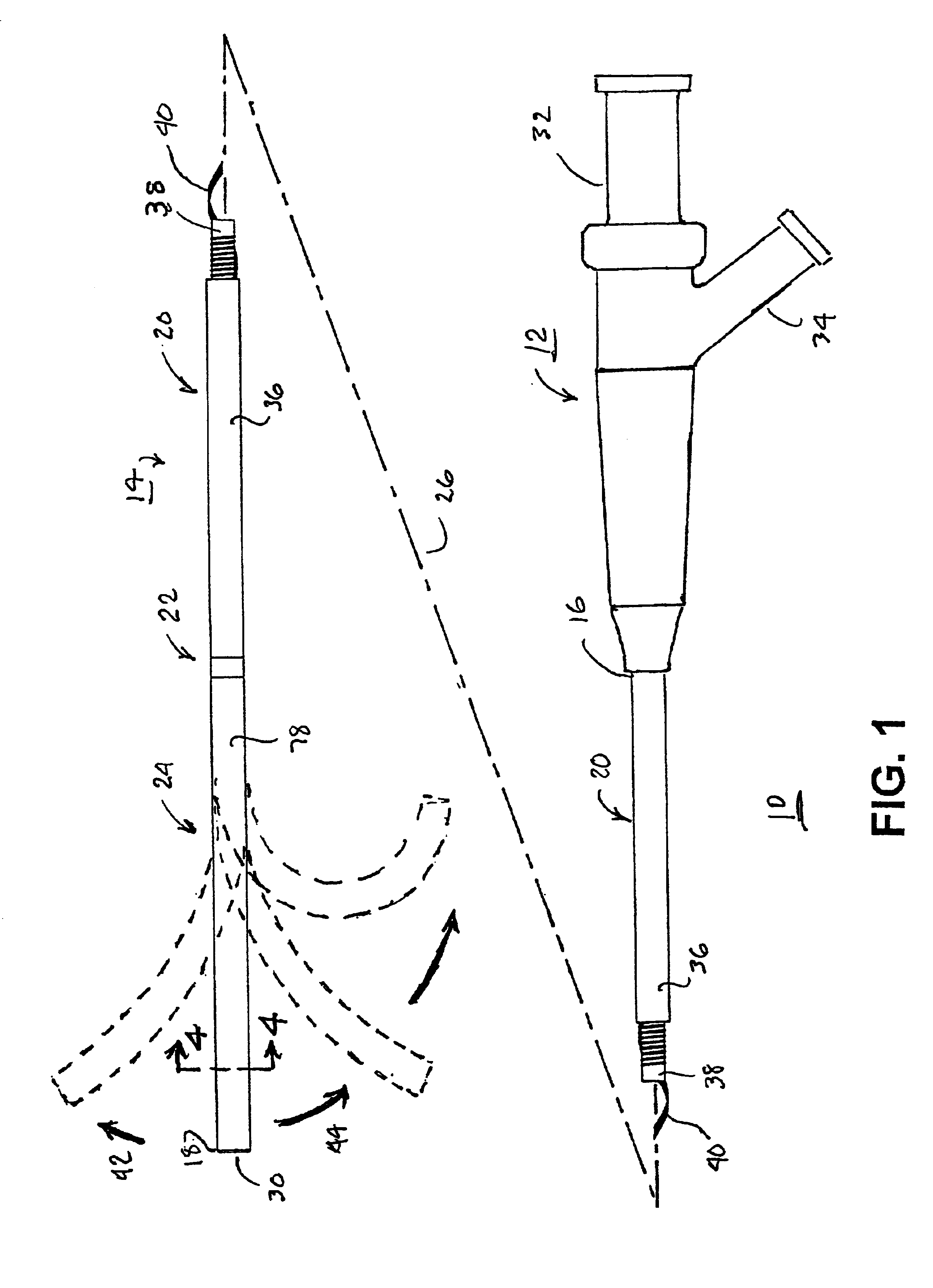

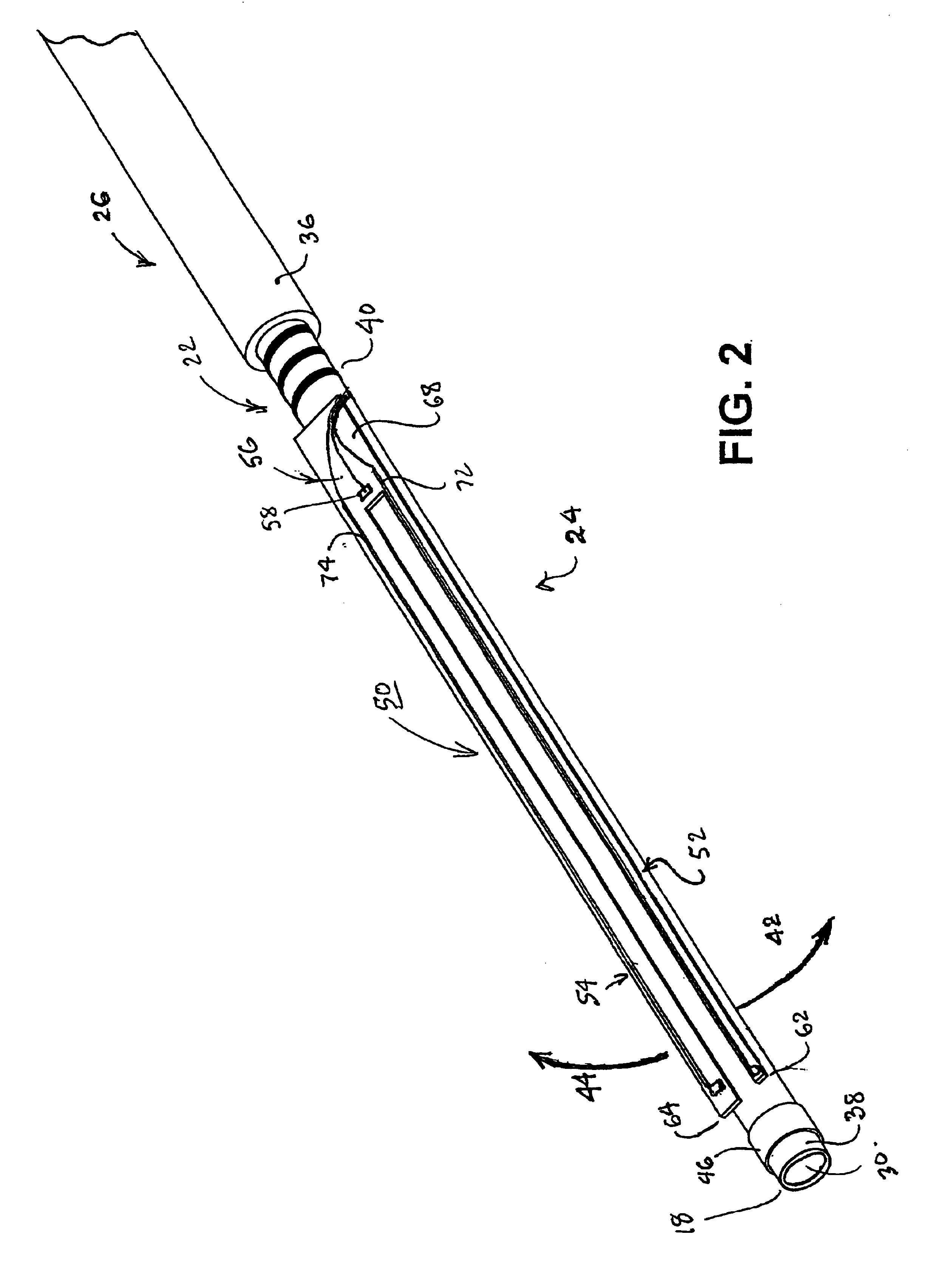

Methods and apparatus for imparting curves in elongated medical catheters

Curves and dynamic shapes are imparted in distal segments of medical instruments e.g., catheters, through use of a temperature-activated actuator coupled to distal segment of the instrument body. The actuator comprises includes members extending side-by-side in substantially a common plane and configured to move in opposite directions when independently activated. A first heating device is coupled to a first actuator member and configured to deliver thermal energy to the first actuator member to activate the first actuator member and cause the first actuator member to move the distal segment in a first direction. A second heating device is coupled to a second actuator member and configured to deliver thermal energy to the second actuator member to activate the second actuator member and cause the second actuator member to move the distal segment in a second direction opposed to the first direction.

Owner:MEDTRONIC INC

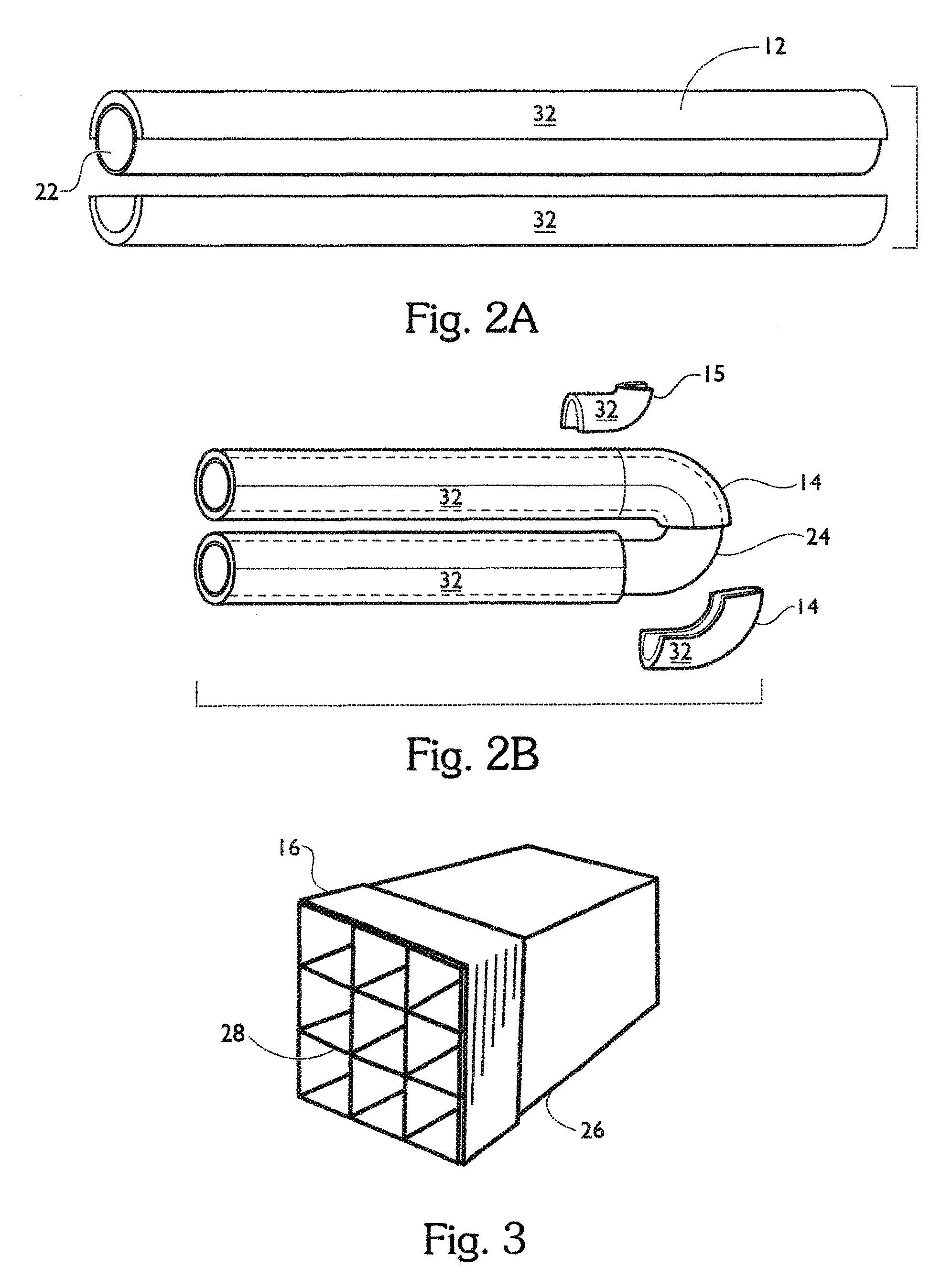

Tube shields having a thermal protective layer

InactiveUS20100038061A1Extend effective repair and replacement cycleReduce use costMetal-working apparatusCorrosion preventionColloidal silicaEmissivity

A tube shield, and method of manufacturing the tube shield, having a support structure with an external surface, an internal surface, and an edge, and a thermal protective layer on at least one surface of the shield support structure. The thermal protective layer is composed of a filler, one or more emissivity agent, and either an inorganic adhesive or a binder that is colloidal silica, colloidal alumina, or combinations thereof. A colorant, a surfactant, and / or a stabilizer may be incorporated into the thermal protective layer.

Owner:WESSEX

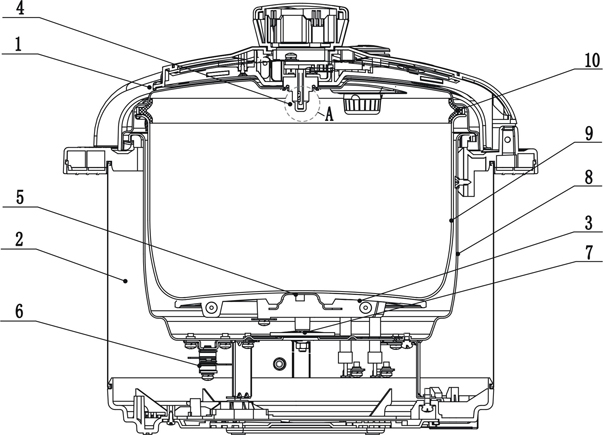

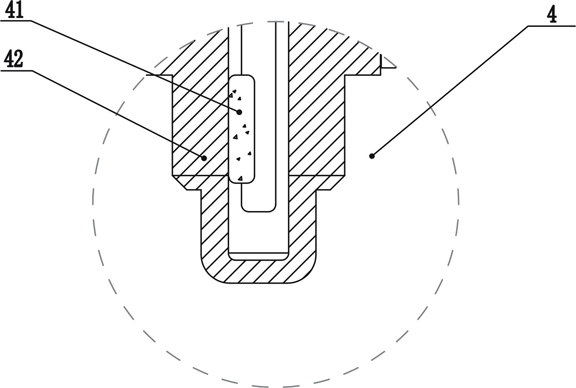

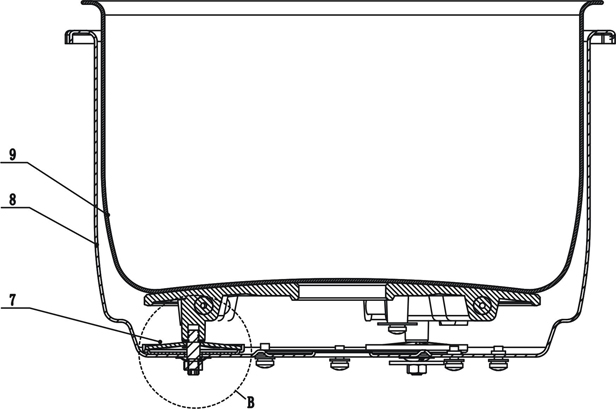

Safety relief temperature controlled electric pressure cooker and precious voltage controlling method thereof

ActiveCN101930241AOvercome the defect that safety pressure relief protection cannot be realizedImprove securityFluid pressure control using electric meansPressure-cookersTemperature controlMaster controller

The invention relates to a safety relief temperature controlled electric pressure cooker and a precious voltage controlling method thereof. The temperature controlled electrical pressure cooler comprises a cooker cover, an inner cooker, an outer cooker, an electric heating device and an electric control gear, wherein the cooker cover and the outer cooker can be connected in a detachably fastened mode; the inner cooker can be freely arranged in a cavity formed between the cooker cover and the outer cooker, and a sealing ring is arranged between the inner cooker and the cooker cover; and the cooker cover is provided with an upper temperature detector for detecting the temperature in the inner cooker, an elastic relief device is arranged between the bottom part of the inner cooker and the outer cooker, and the elastic relief device can sense the cooking pressure in the inner cooker so as to drive the inner cooker to move downwards and comprises an elastic member and a strut member for accommodating the elastic member. The precious temperature controlling method comprises a heating stage in which a master controller heats with small power so as to perform temperature compensation based on the temperature deviation deltaT and the reference temperature deltaTB. The invention can improve the temperature control property and voltage control precision of the temperature controlled electric pressure cooker.

Owner:JOYOUNG CO LTD

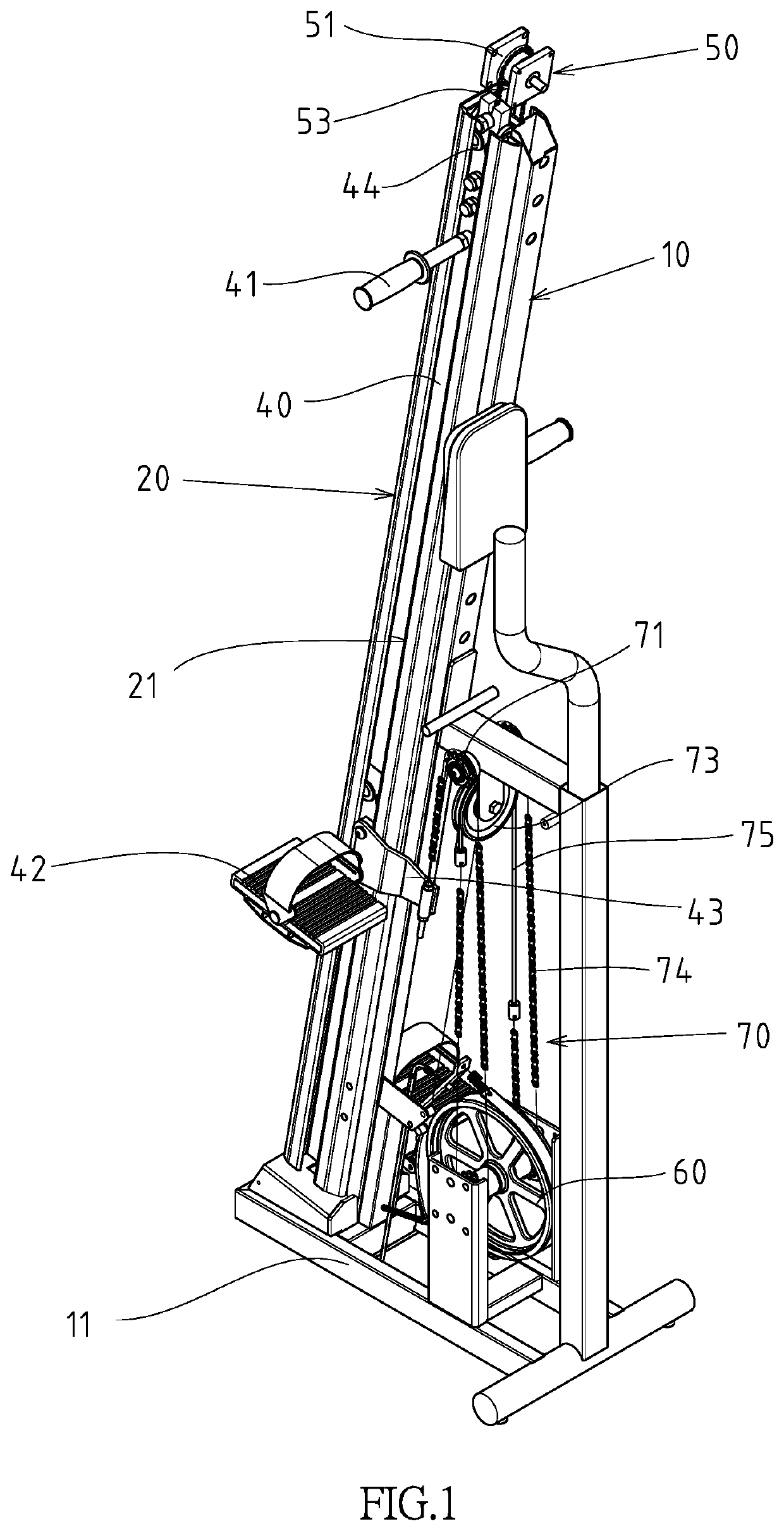

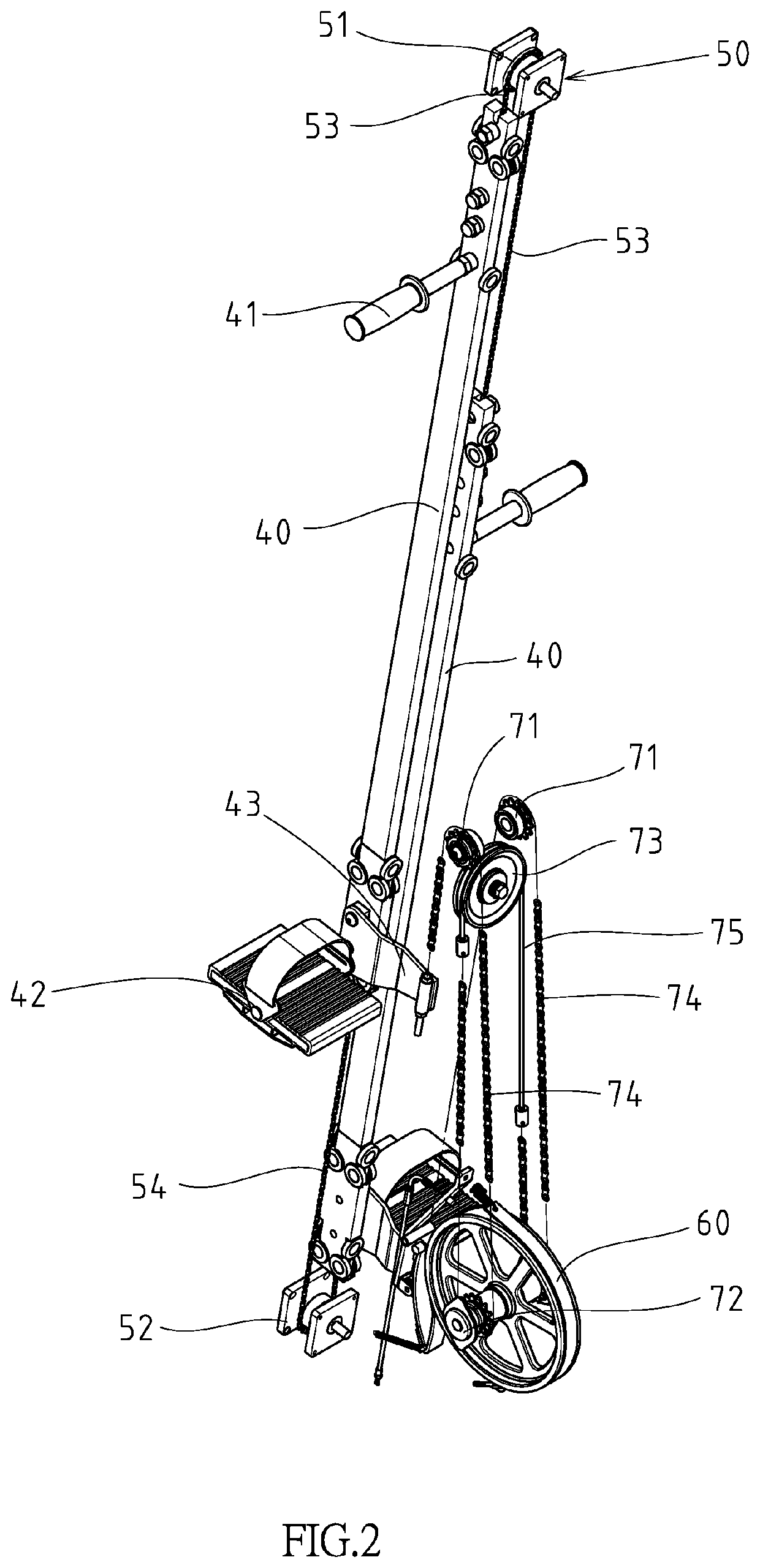

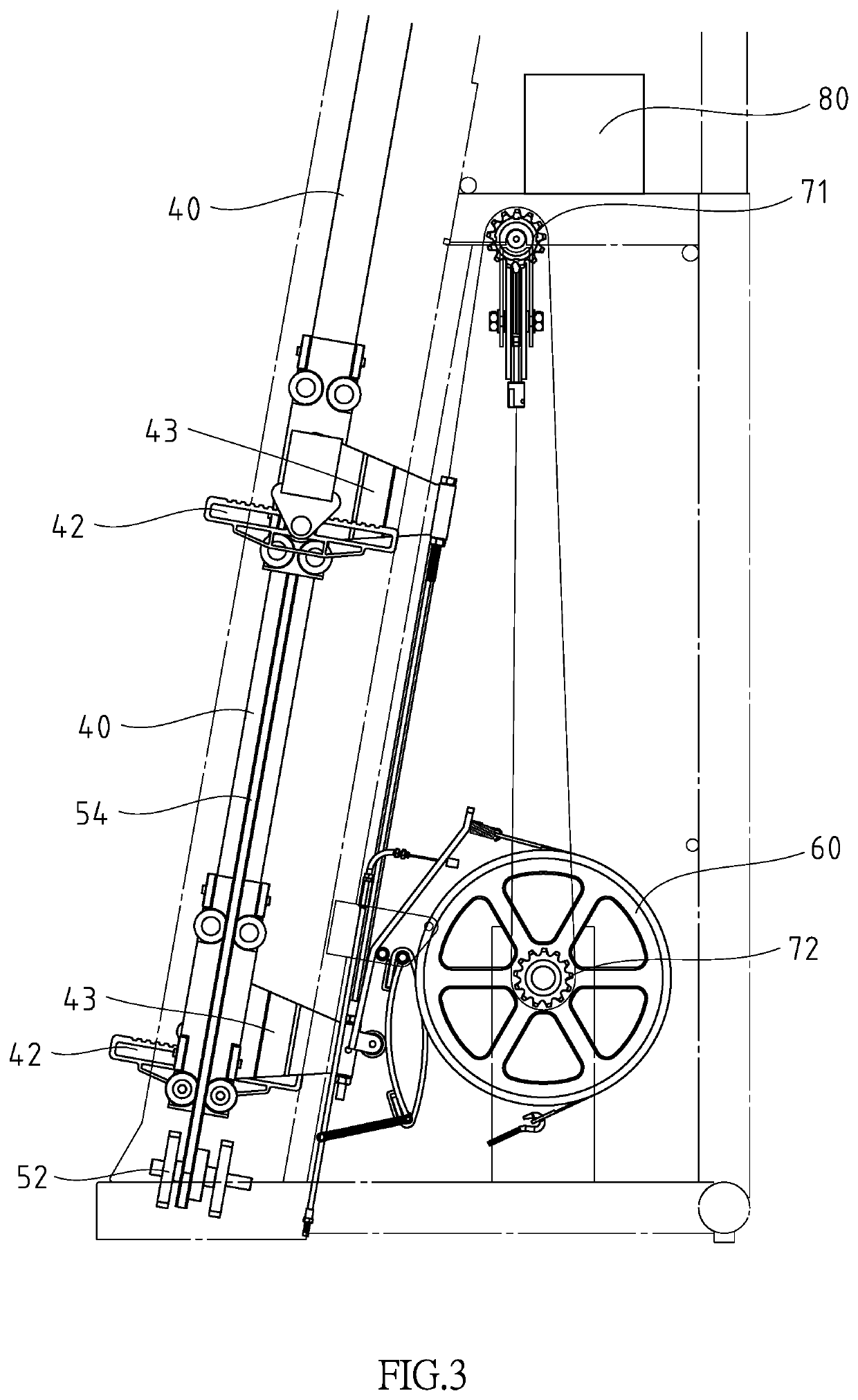

Column-type combination climbing exercise machine

ActiveUS20200171346A1Conveniently arrangeReduce workSpace saving gamesBrake actuating mechanismsTreadleControl theory

A column-type combination climbing exercise machine mainly includes: the bottom end of a stand frame provided with a ground seat; a column is locked with the stand frame through a locking component; two sliding chutes are respectively disposed at the opposite left and right sides of the column; two sliding seats are correspondingly disposed in the two sliding chute, each sliding seat is adjacent to the top thereof, and a handle and a pedal are respectively disposed at the two ends of the bottom; a first linkage mechanism is connected with the two sliding seats to form a mutually opposite lift-fall and linkage action; a damper is assembled in the ground seat; two connectors are respectively disposed in the two sliding a seat; and a second linkage mechanism makes the damper and the two sliding seats in a linkage relationship.

Owner:CHEN YA CHI

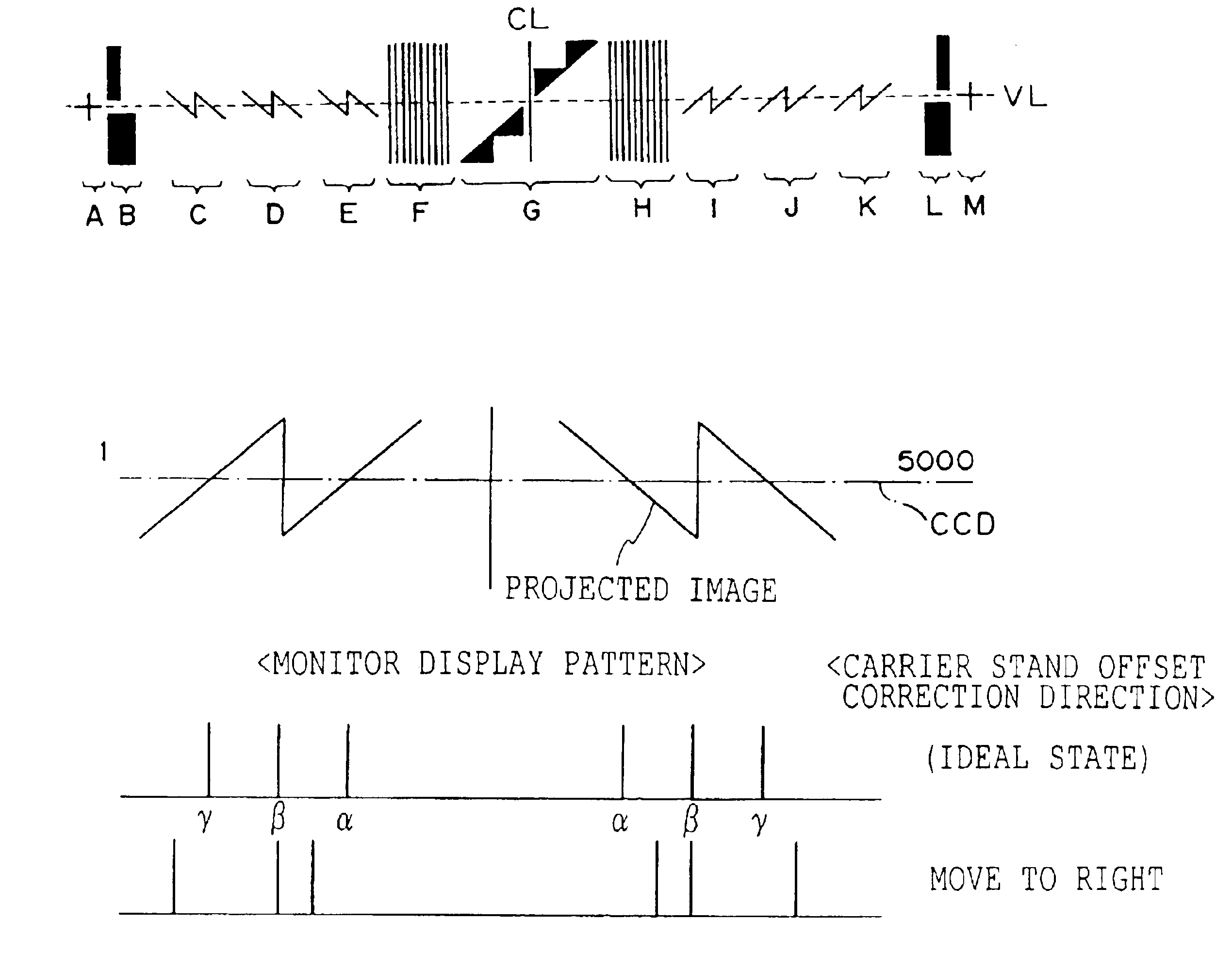

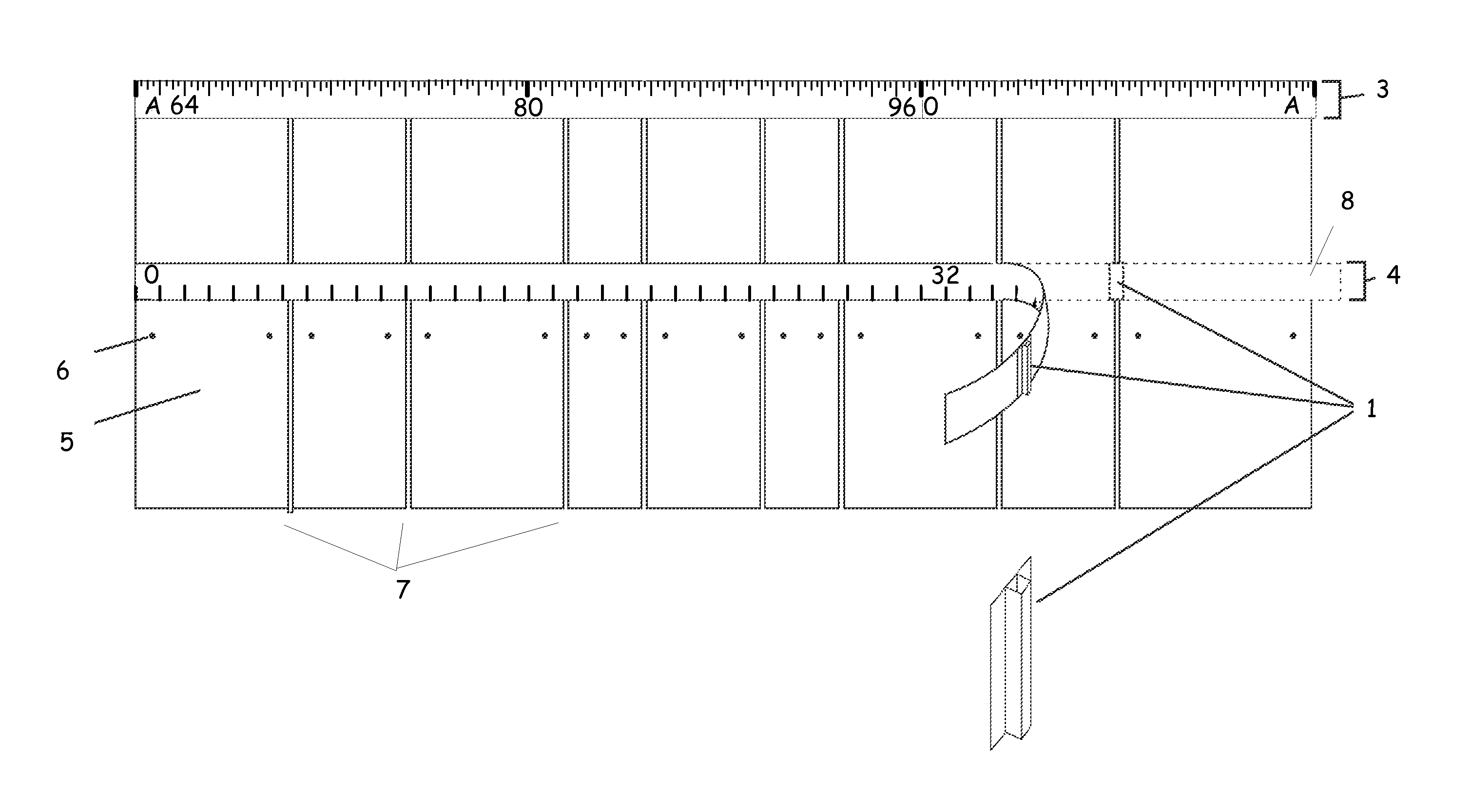

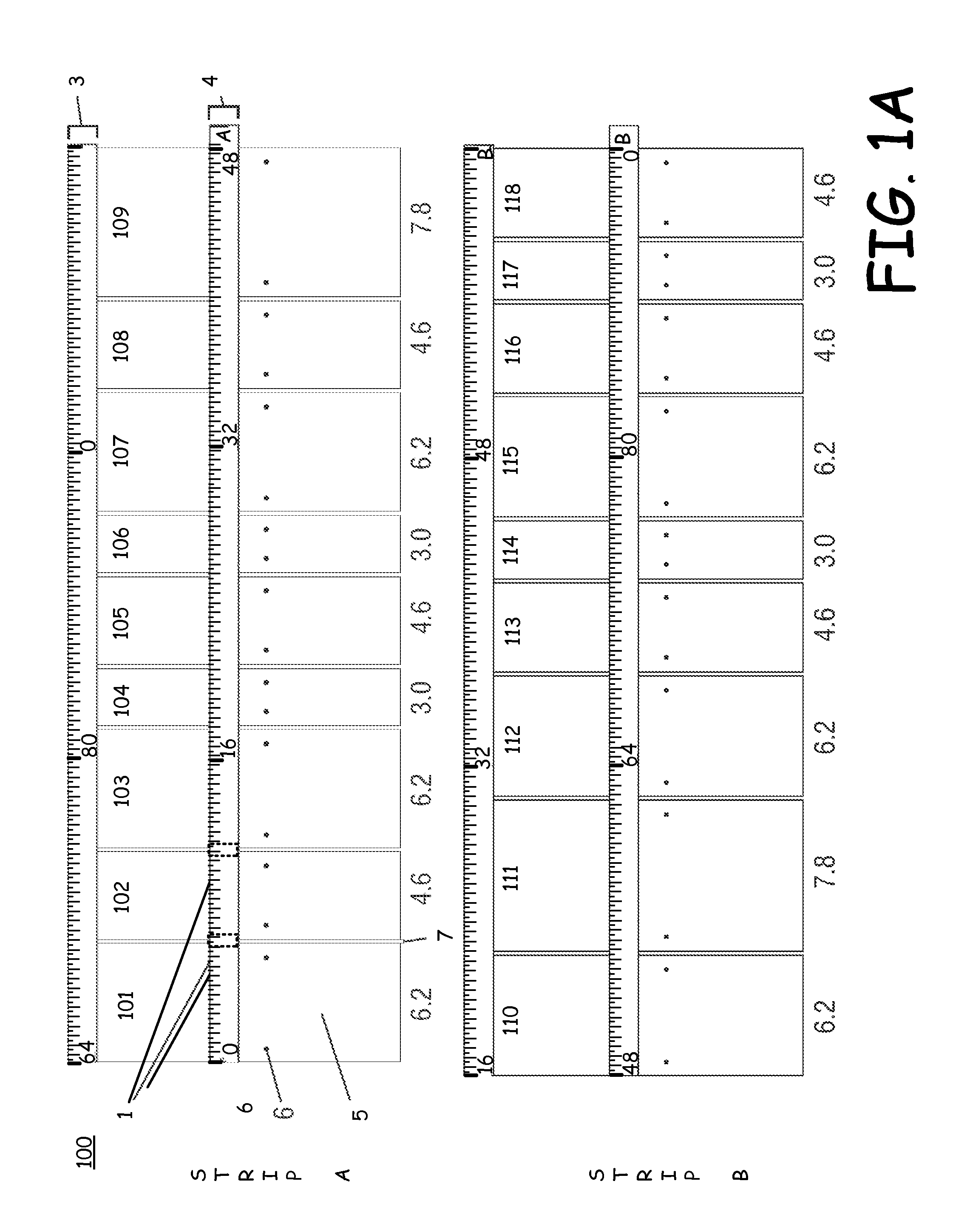

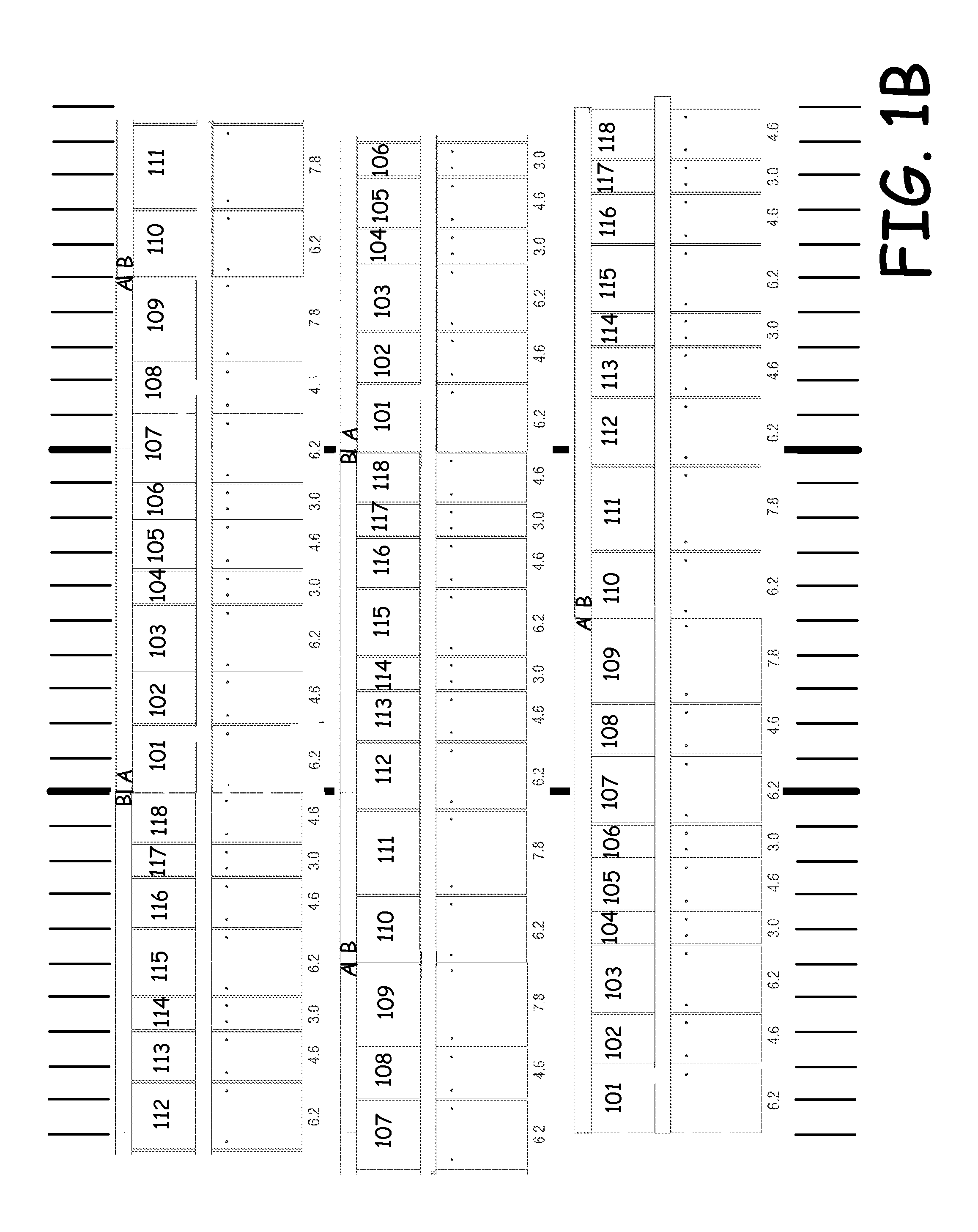

Image reading apparatus, default value adjusting method of image reading apparatus, and chart original

A chart original in which two or more patterns are disposed so as to be separated at predetermined intervals and are symmetric with respect to a second imaginary line which is orthogonal to a first imaginary line. Each of the patterns is formed from a first line segment, which is orthogonal to the first imaginary line, and two second line segments, which are disposed at opposite positions with respect to the first line segment so as to intersect the first line segment. Each of the patterns intersect the first imaginary line at three points.

Owner:FUJIFILM CORP

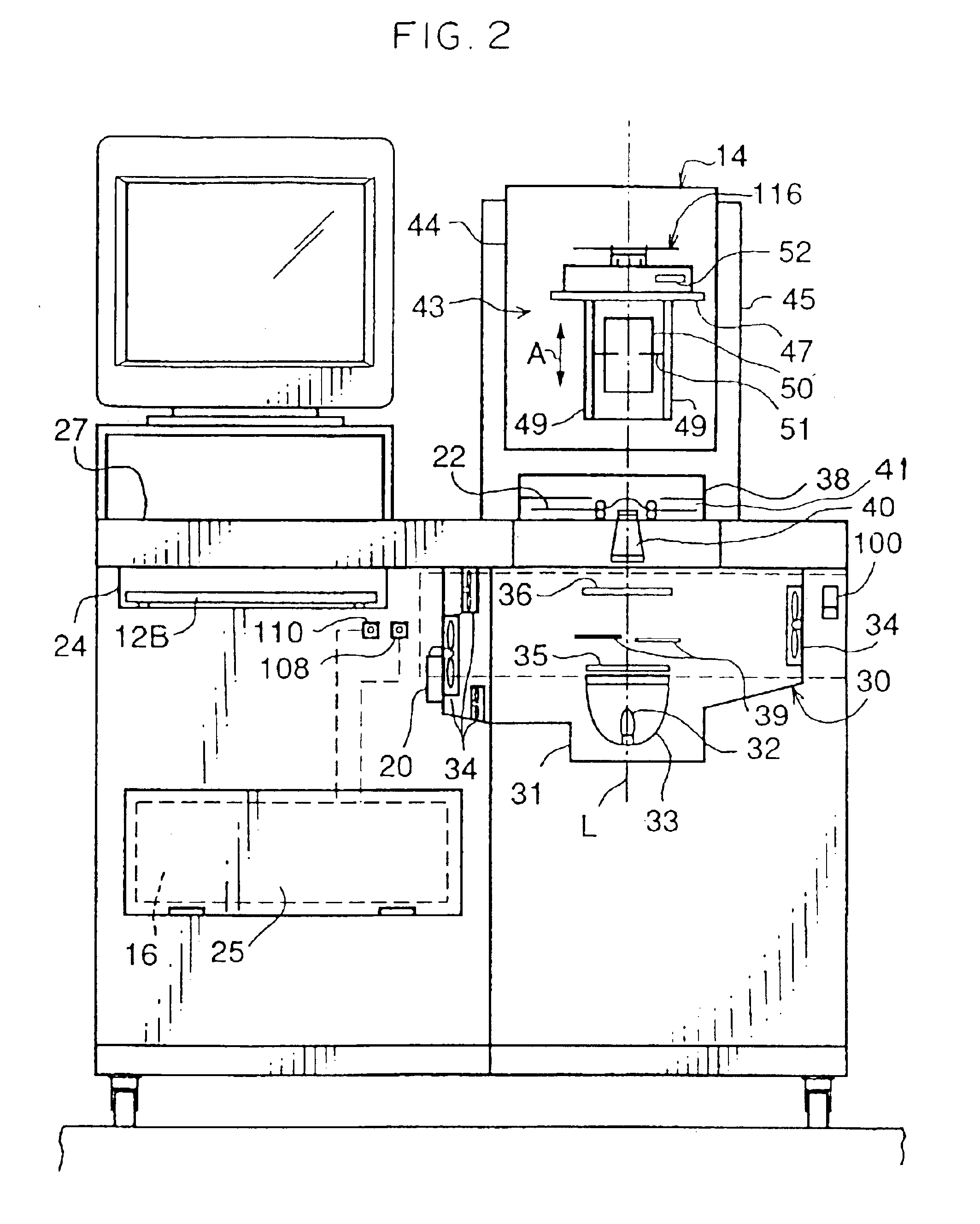

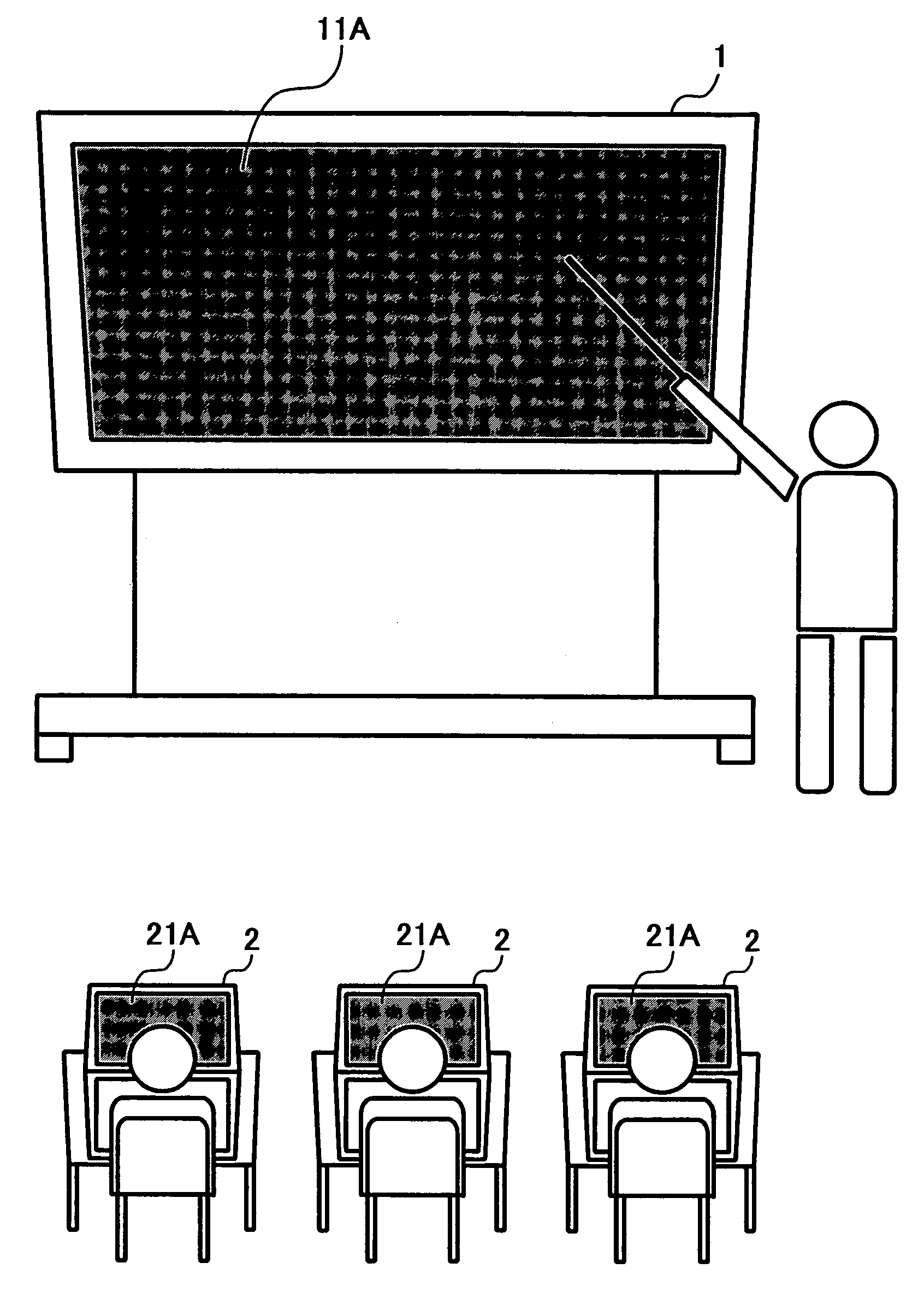

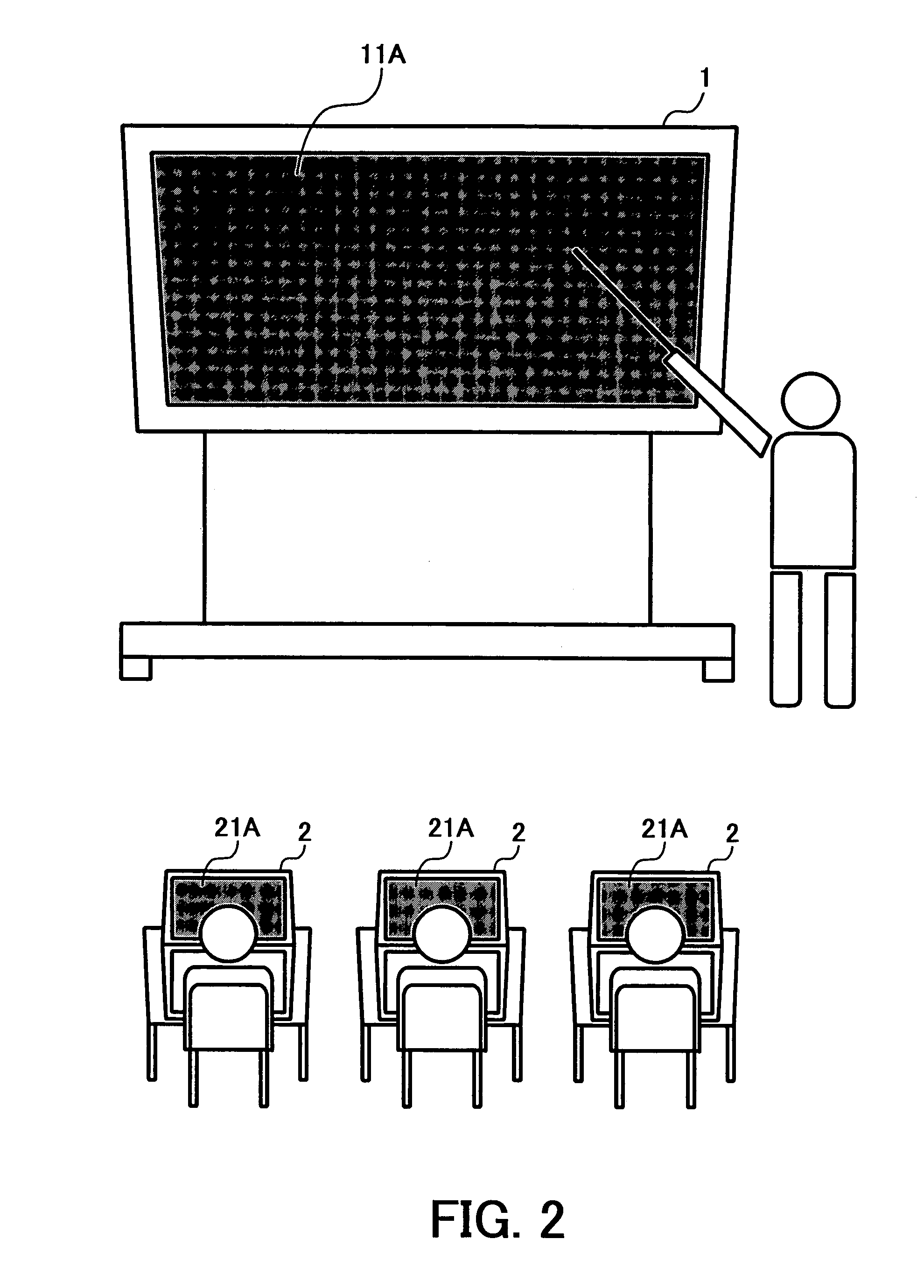

System for facilitating teaching and learning

InactiveUS7092669B2Reduce workWork lessElectrical appliancesMechanical appliancesInput deviceInformation processor

An input device of a multimedia board inputs lecturer-written information that a lecturer writes on a display page. An information processor sends the lecturer-written information input by the input device to a plurality of information terminals. A reader / writer of each of the plurality of information terminals reads out textbook information from a recording medium recording the textbook information representing contents of a textbook. A display device displays the read textbook information and the lecturer-written information supplied from the information processor, which are superimposed one on top of the other. The reader / writer records the textbook information and lecturer-written information, which are displayed by the display device, as a single file on the recording medium.

Owner:RICOH KK

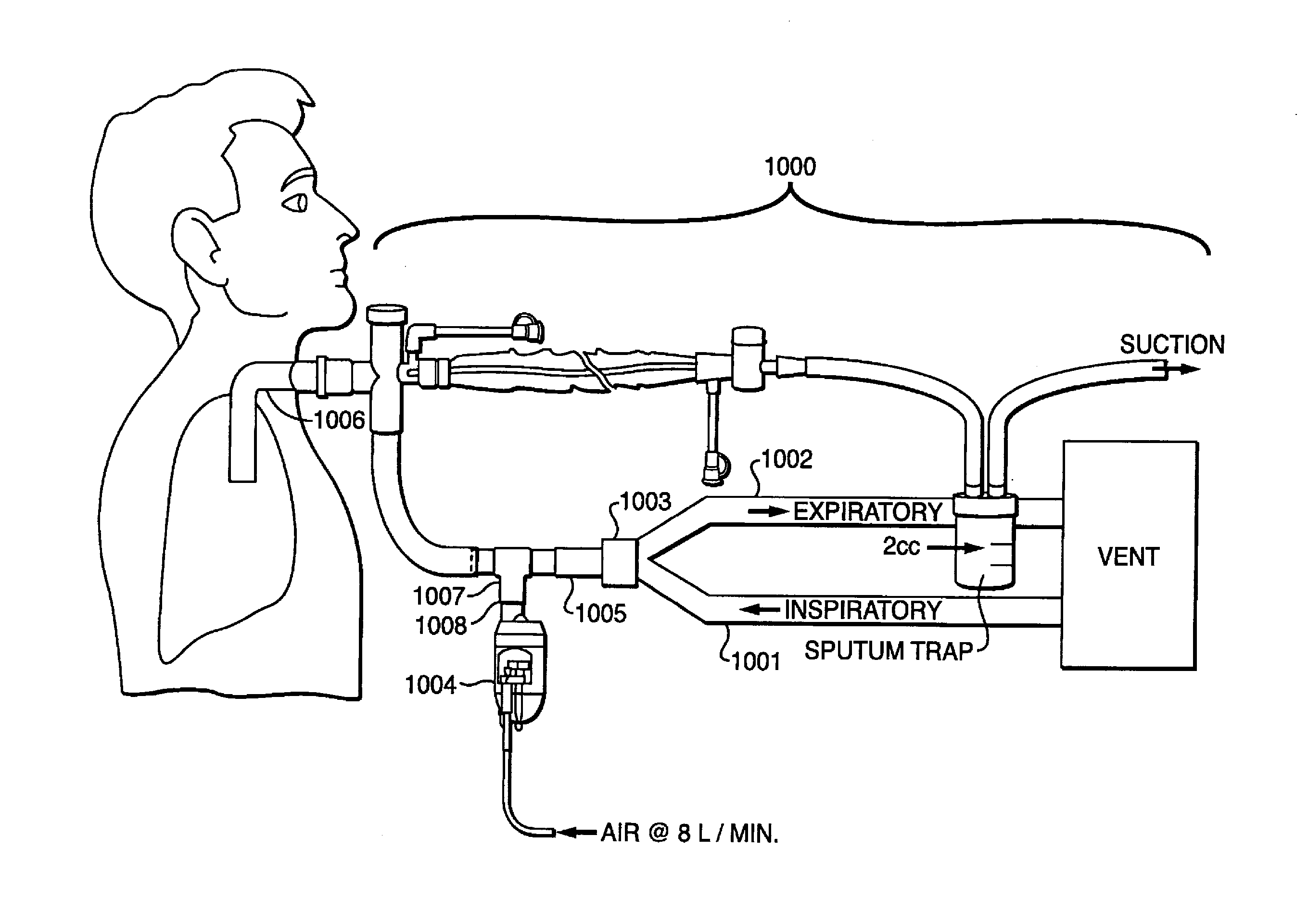

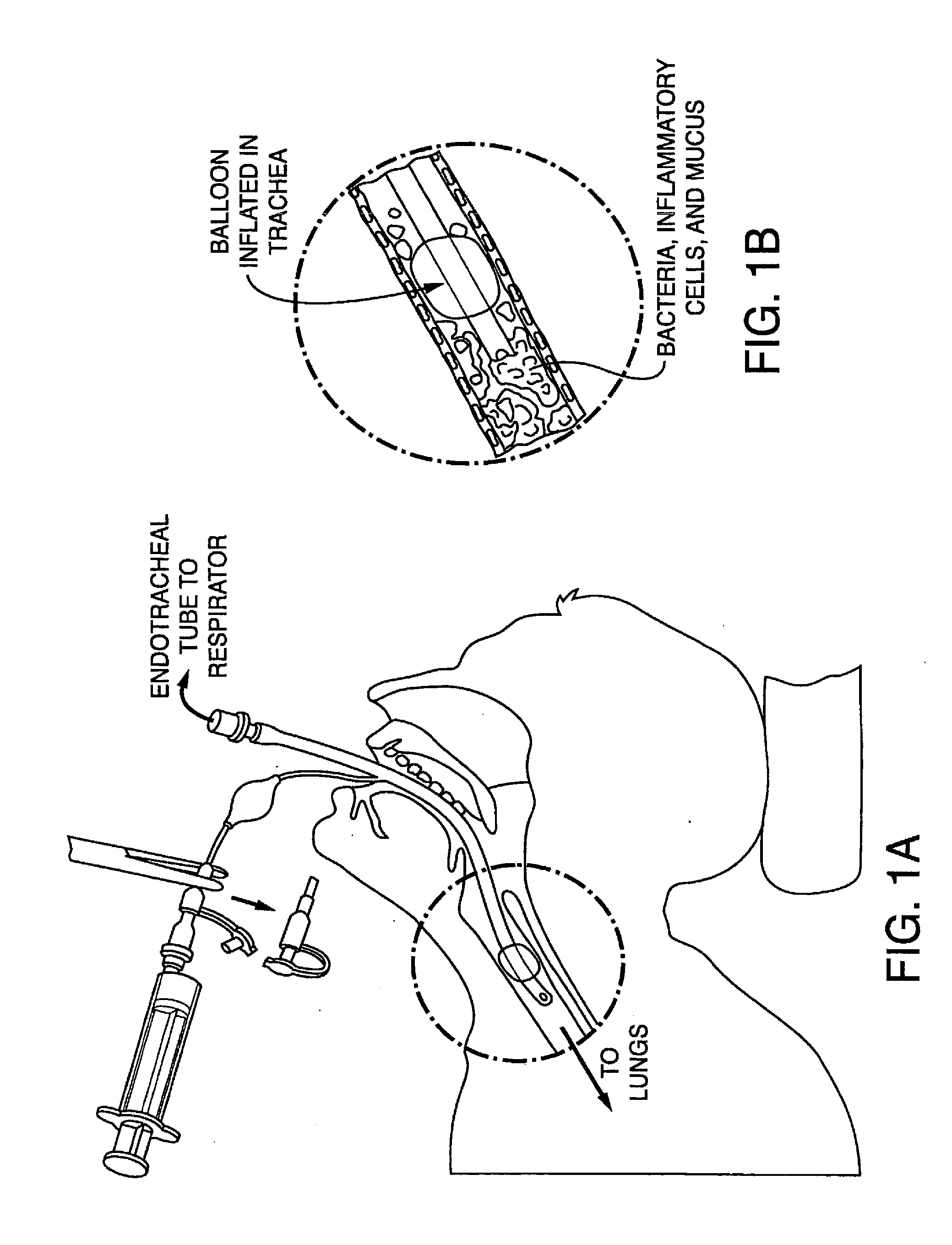

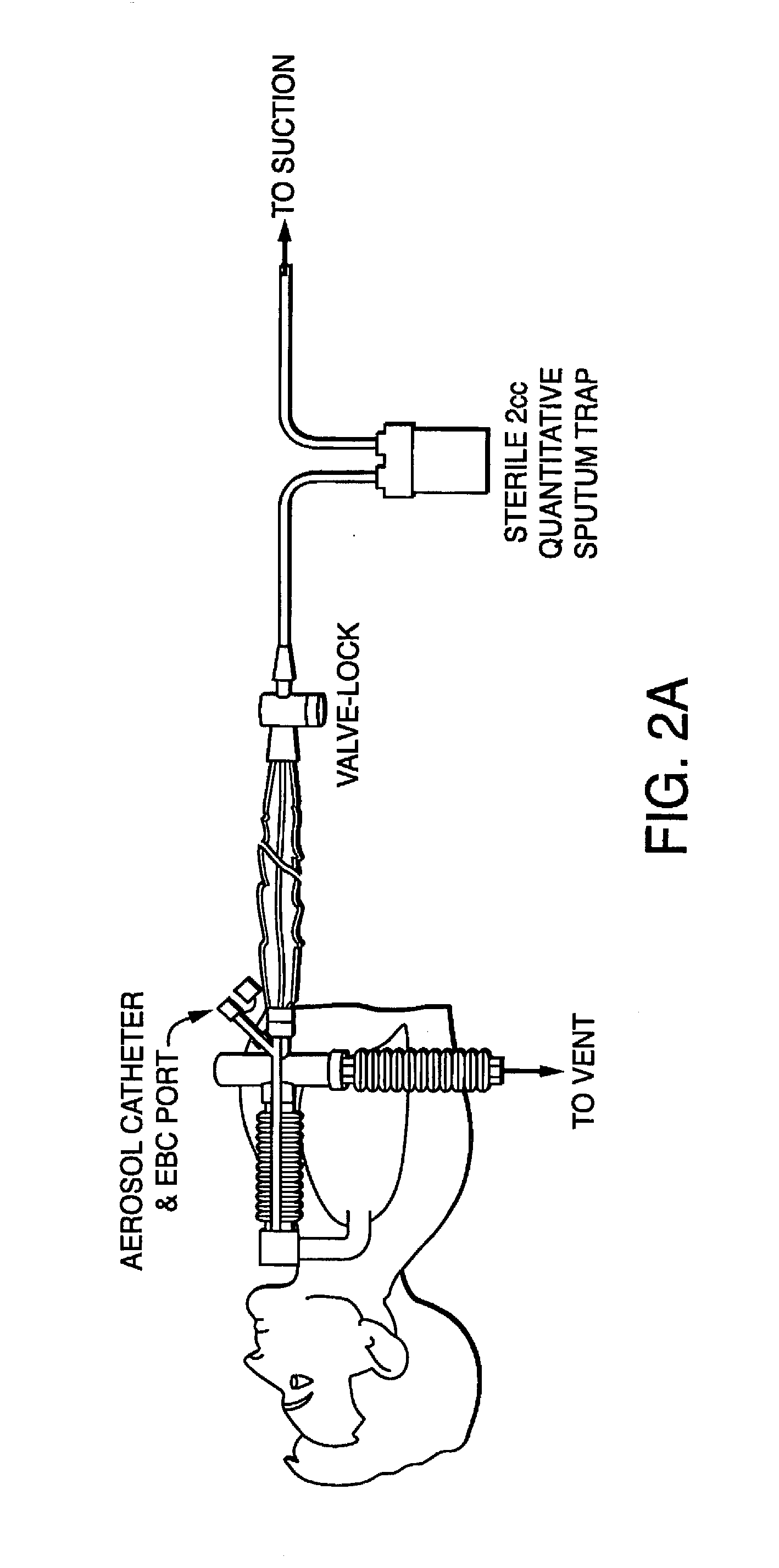

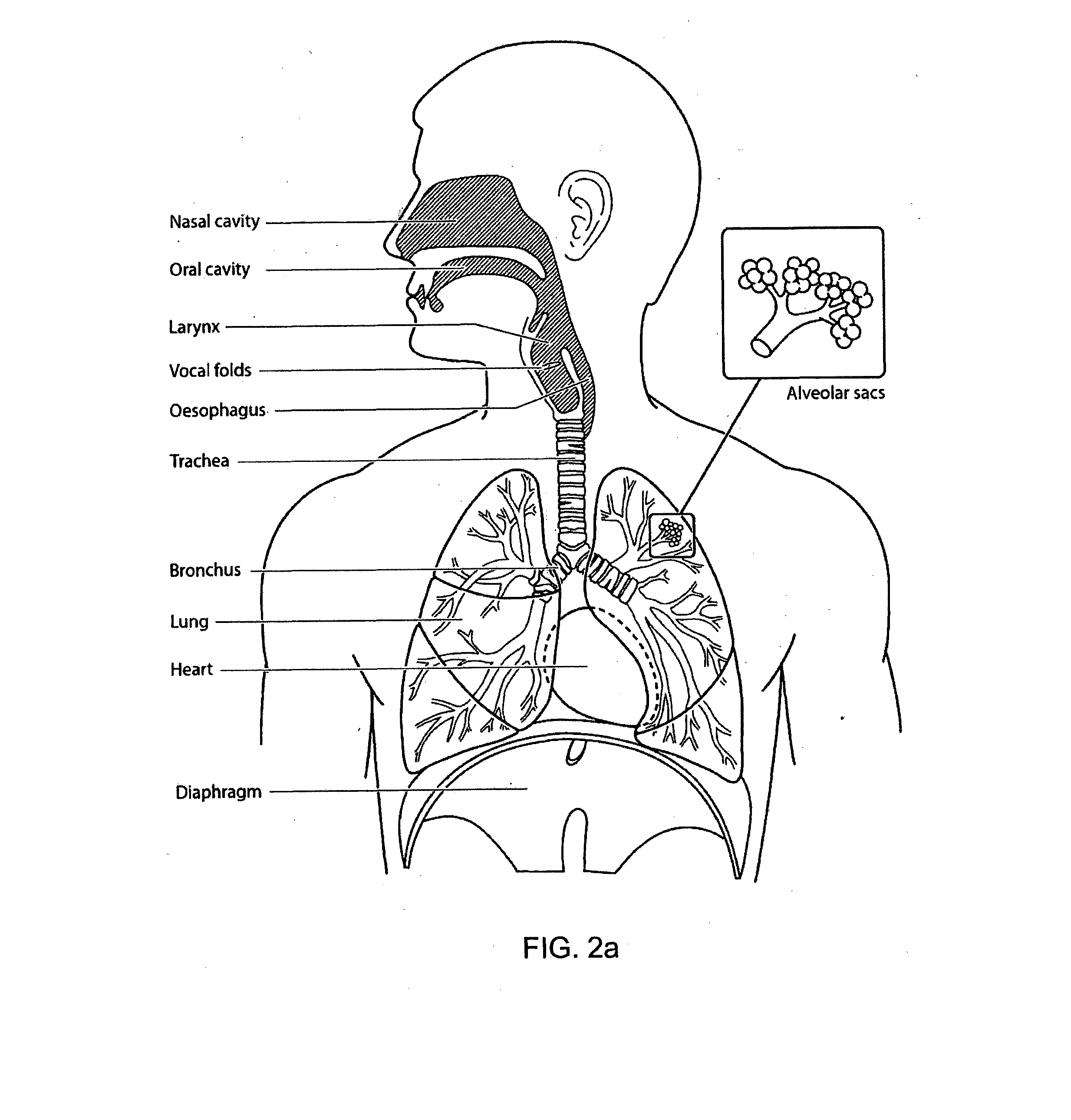

Methods, Devices and Formulations for Targeted Endobronchial Therapy

InactiveUS20140014103A1Mortality rate is decreasedReduce morbidityTracheal tubesMedical devicesTracheobronchitisTreatment effect

The present invention provides a method and novel devices for treating tracheobronchitis and pneumonia in the intubated patient, preferably with aerosolized anti gram-positive and anti-gram negative antibiotics administered in combination or in seriatim in reliably sufficient amounts for therapeutic effect. In one embodiment the result is achieved mechanically. In another embodiment, the result is achieved by aerosol formulation. In a preferred embodiment, the invention assures the result when aerosol is delivered directly to the airways distal of the ventilator circuit. The devices eliminate the dosage variability that ventilator systems engender when aerosols are introduced via the ventilator circuit. The treatment also concentrates the therapeutic agent specifically at affected sites in the lung such that therapeutic levels of administrated drug are achieved without significant systemic exposure of the patient to the drug. The invention further provides a dose control device to govern this specialized regimen.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

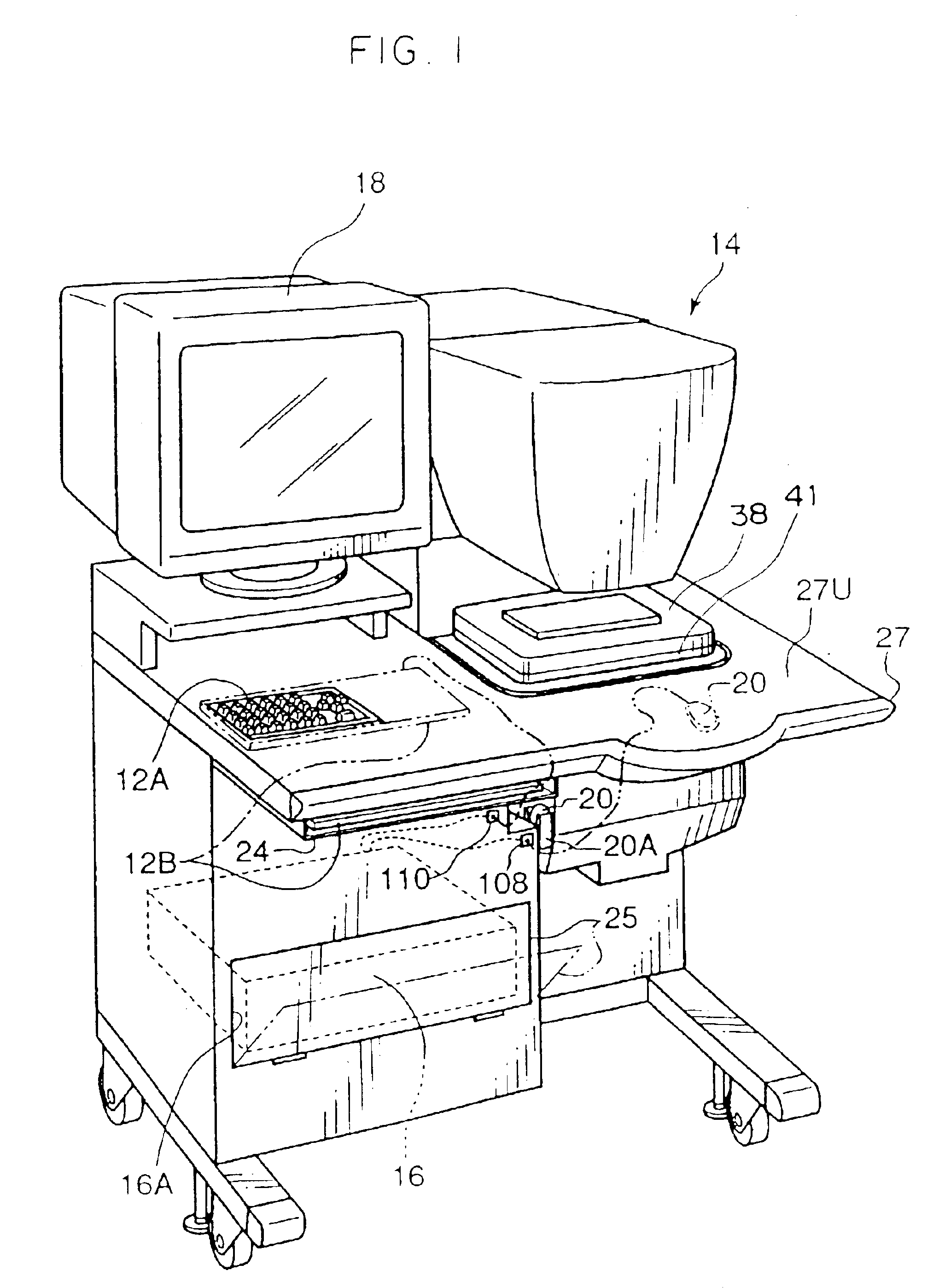

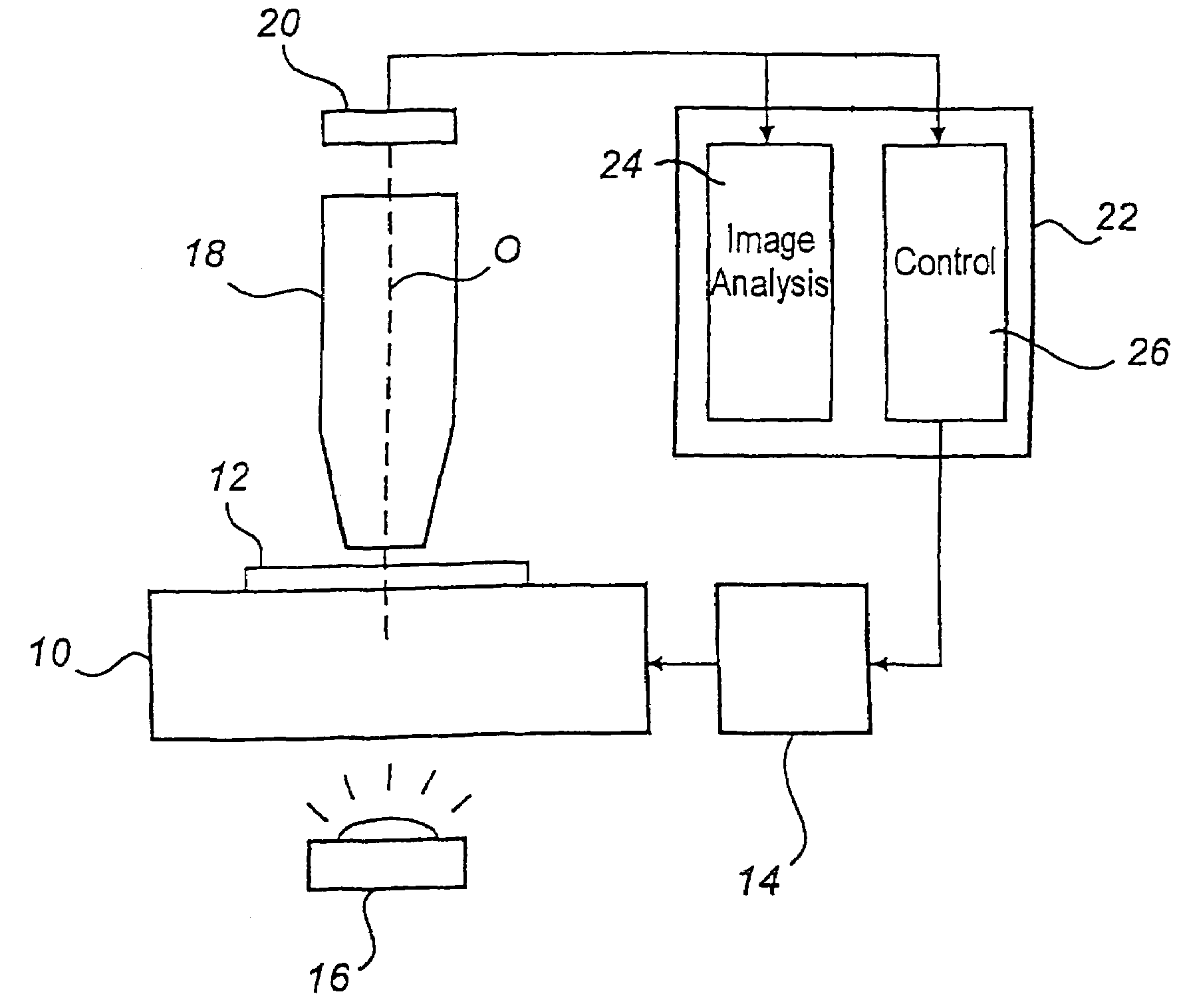

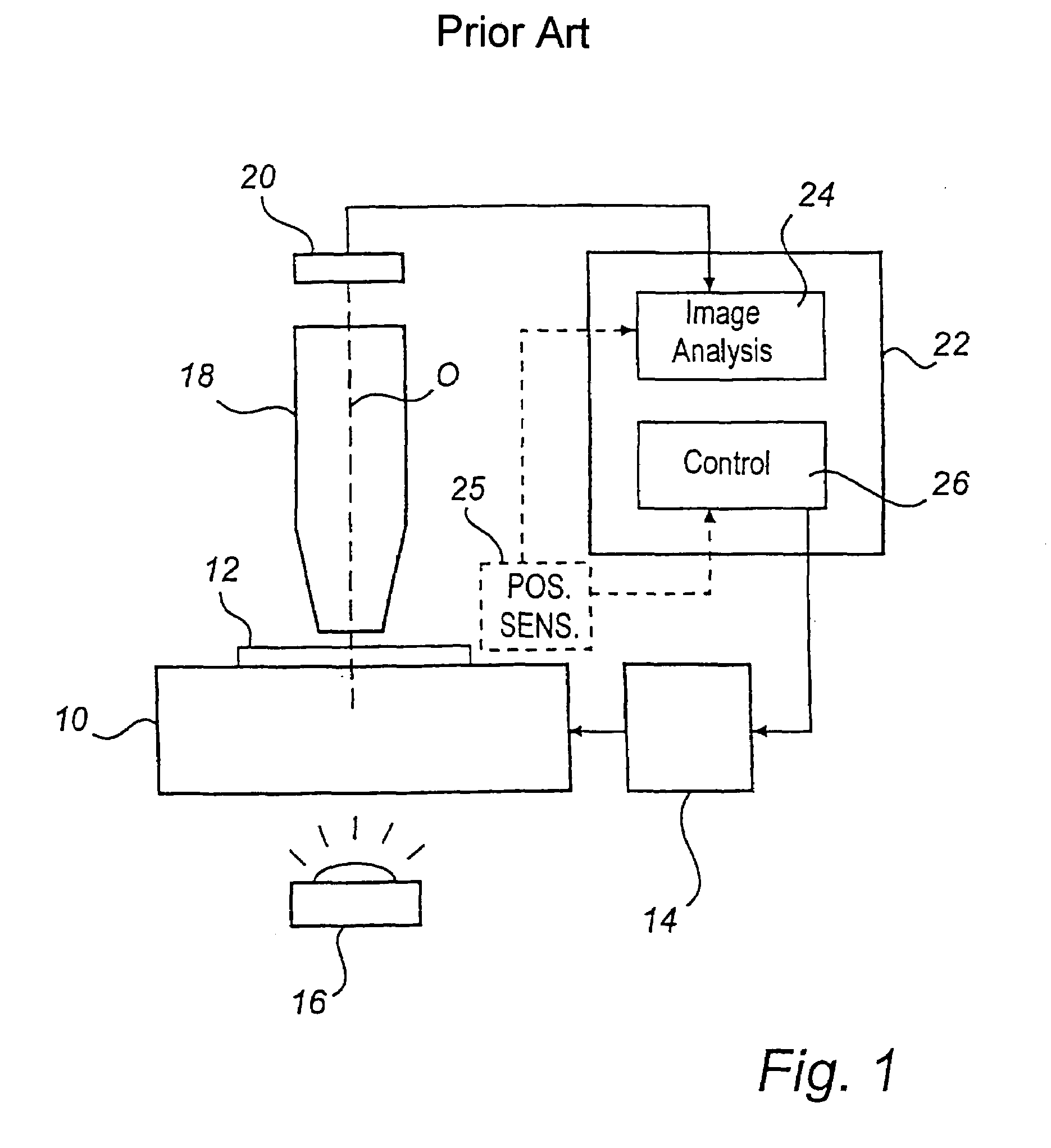

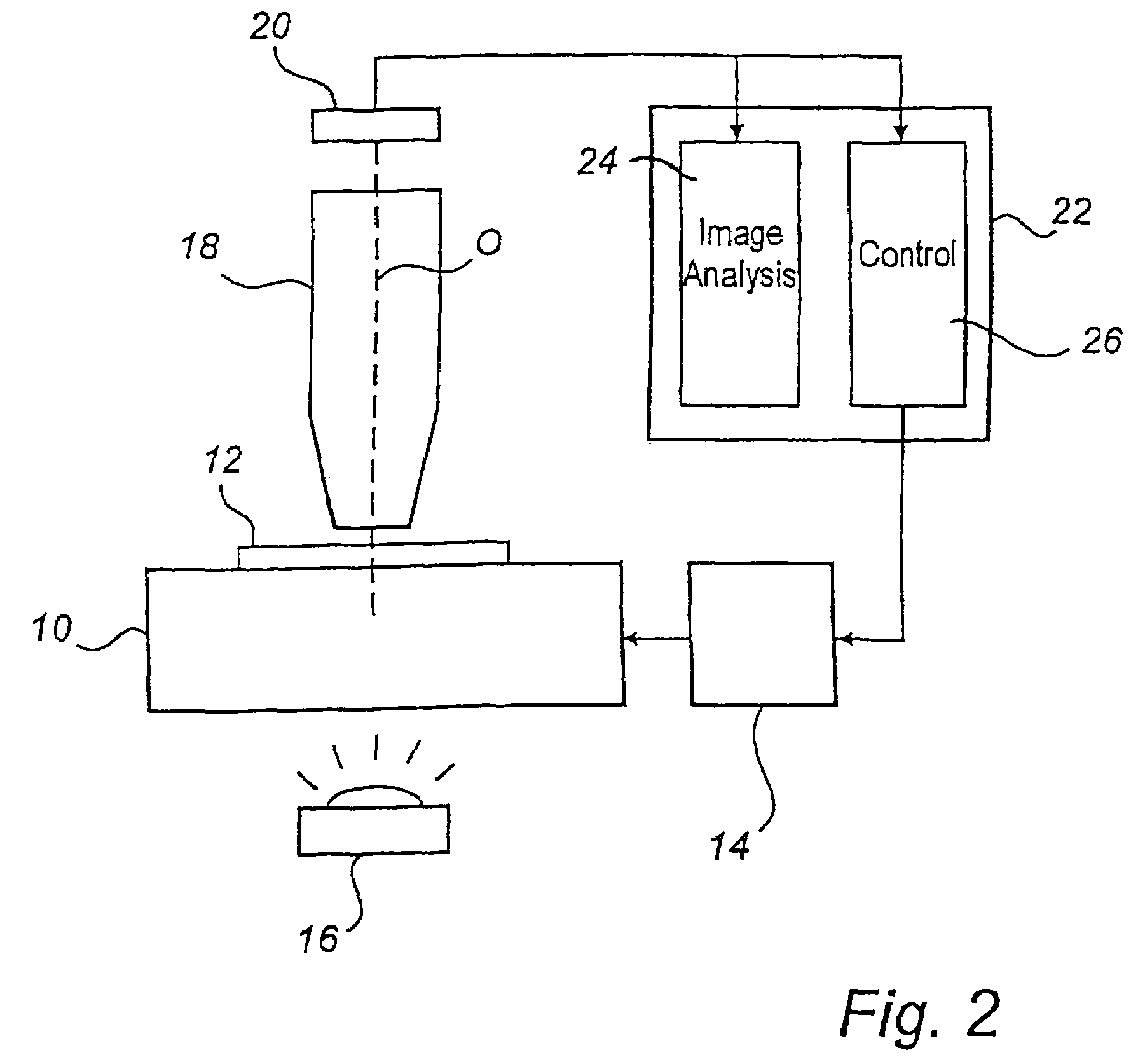

Method in microscopy and a microscope, where subimages are recorded and puzzled in the same coordinate system to enable a precise positioning of the microscope stage

In a microscope, a position signal is generated in the form of coordinates in a pixel coordinate system by registering microscope images with partly overlapping contents. The position signal can be used to indicate the position of a partial object which has been identified in one of the microscope images. It can also be used to control the displacement of the microscope stage of the microscope, in which case it is possible to use a simple inaccurate drive mechanism for the microscope stage, without necessitating installation of position sensors.

Owner:CELLAVISION

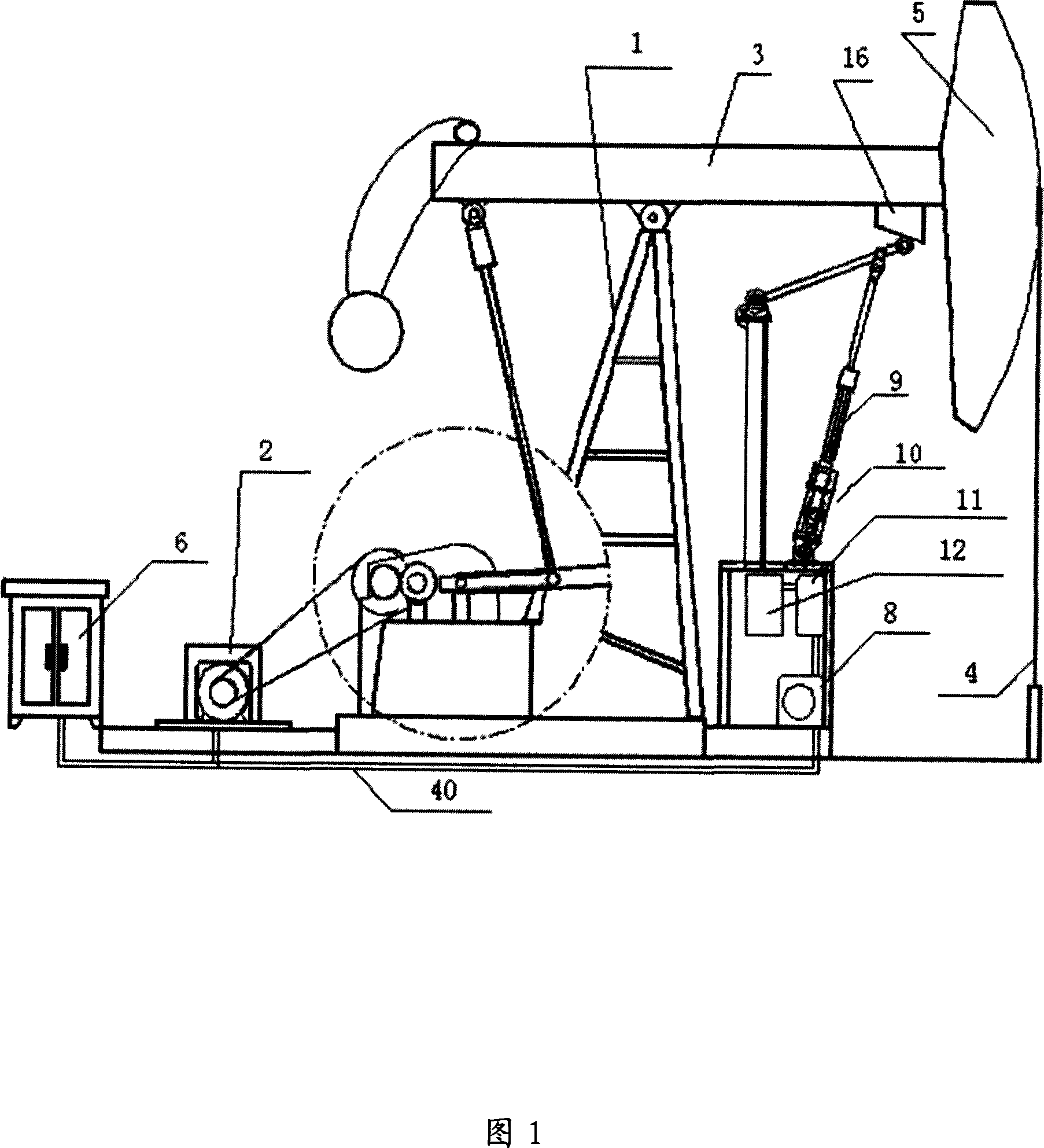

Power generating lying energy recycling electric hydraulic pressure energy-saving balance beam type pumping machine

InactiveCN101109279ASave electricityExtend working lifeGearingFluid removalHydraulic ramEnergy recycling

An electro-hydraulic energy-saving beam type oil pump for reusing the energy under the condition of power generation is provided, which comprises a frame, a drive, a beam, a polish rod, a pre-drive head and an auxiliary hydraulic energy regenerator comprising a hydraulic system and an electric control unit. The hydraulic system comprises an auxiliary supporting truss, a hydraulic pump, a hydraulic cylinder, an accumulator, a hydraulic integration block, an auxiliary hydraulic oil tank and a movably contacting mechanism that is located on the beam and transmits the displacement of the beam to the piston rod of the hydraulic cylinder; the movably contacting mechanism is connected respectively with the piston rod and the auxiliary supporting truss; on the platform of the auxiliary supporting truss, the hydraulic cylinder and the accumulator are arranged parallelly; the hydraulic cylinder is connected with the accumulator through the hydraulic integration block; the base of the auxiliary supporting truss is connected with the hydraulic pump, which is respectively connected with the auxiliary oil tank and the hydraulic integration block. For the invention, the drive motor of the oil pump can be standby in a negative-power area and can recycle and reuse the residual energy of the negative power, so as to save power and energy without changing the structure and operation principle of the former beam type oil pump.

Owner:BEIJING JIAJIE LIANZHONG ENERGY SAVING TECHCO

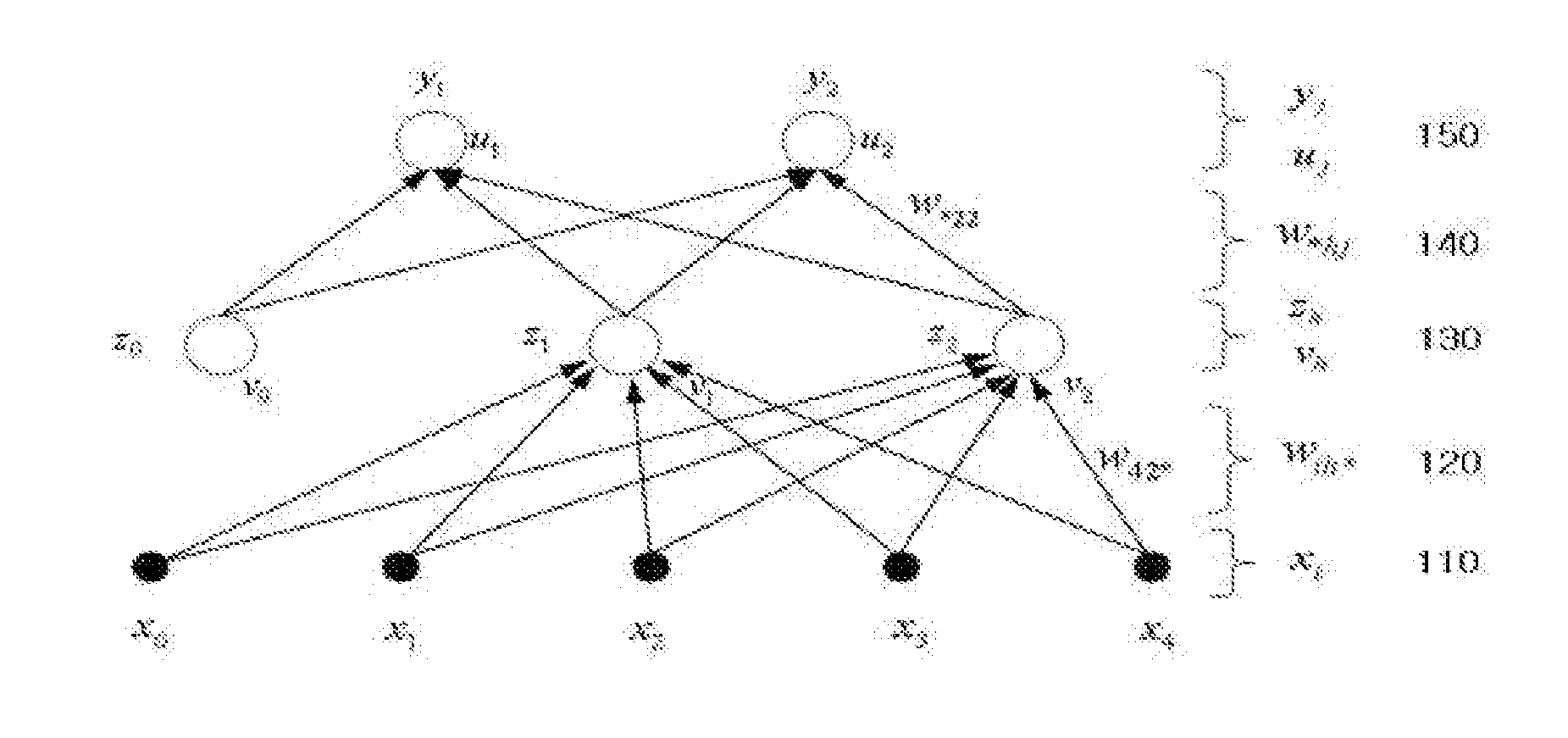

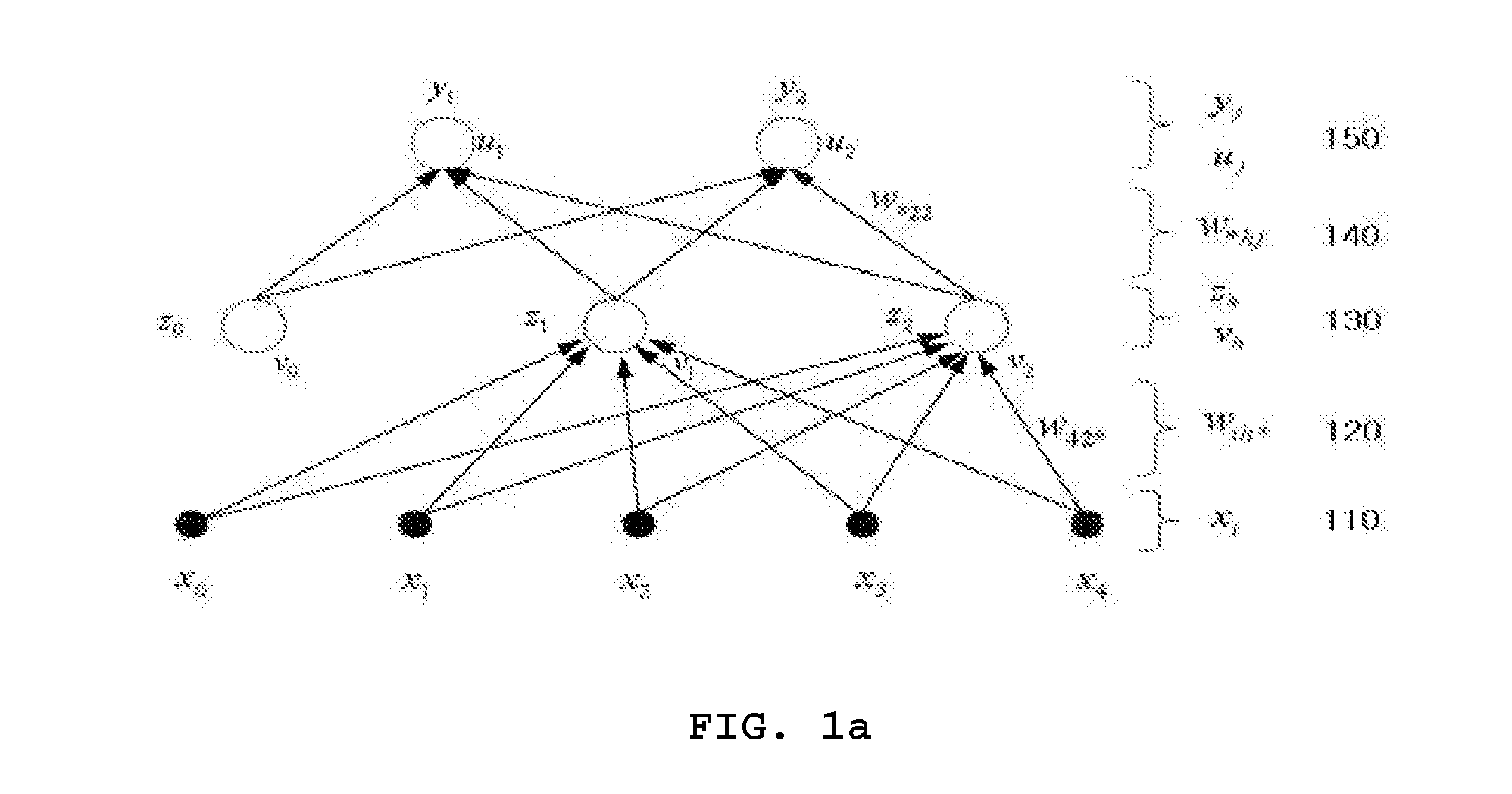

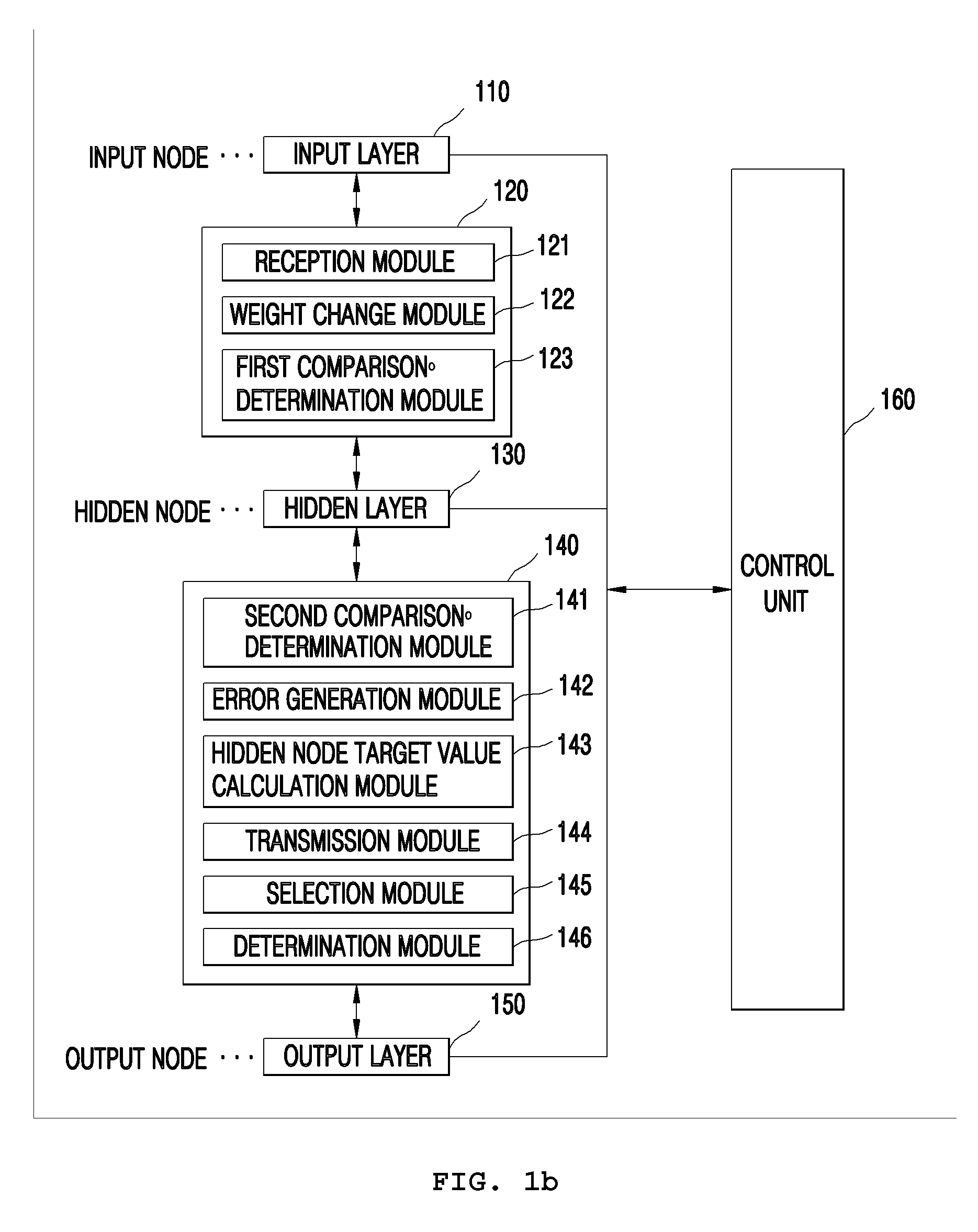

Separate Learning System and Method Using Two-Layered Neural Network Having Target Values for Hidden Nodes

InactiveUS20070282772A1Work lessSmall spacingData processing applicationsDigital computer detailsHidden layerAlgorithm

Disclosed herein is a separate learning system and method using a two-layered neural network having target values for hidden nodes. The separate learning system of the present invention includes an input layer for receiving training data from a user, and including at least one input node. A hidden layer includes at least one hidden node. A first connection weight unit connects the input layer to the hidden layer, and changes a weight between the input node and the hidden node. An output layer outputs training data that has been completely learned. The second connection weight unit connects the hidden layer to the output layer, changing a weight between the output and the hidden node, and calculates a target value for the hidden node, based on a current error for the output node. A control unit stops learning, fixes the second connection weight unit, turns a learning direction to the first connection weight unit, and causes learning to be repeatedly performed between the input node and the hidden node if a learning speed decreases or a cost function increases due to local minima or plateaus when the first connection weight unit is fixed and learning is performed using only the second connection weight unit, thus allowing learning to be repeatedly performed until learning converges to the target value for the hidden node.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

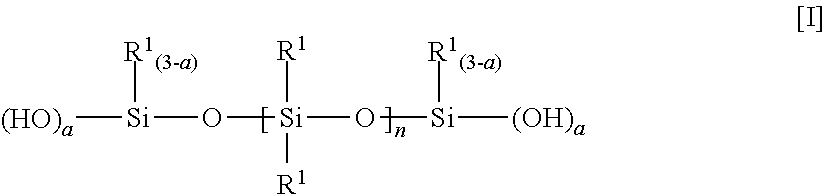

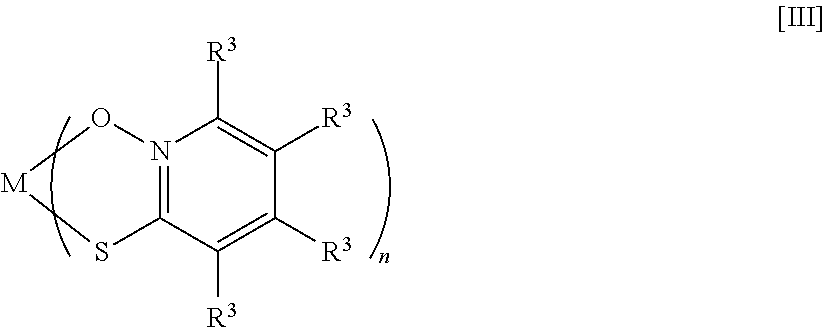

Antifouling coating composition, antifouling coating film, antifouling substrate, and method for improving storage stability of antifouling coating compositions

ActiveUS20150299515A1Low viscosityMaintain good propertiesAntifouling/underwater paintsPretreated surfacesHigh resistanceSodium Pyrithione

In one aspect, the invention has an object of providing antifouling coating compositions which have high resistance to fouling, in particular, fouling by slime, can form coating films with excellent properties such as strength and rubber properties, exhibit appropriate viscosity (sprayability and coating film surface leveling properties during spray coating) and sagging resistance, and have high storage stability suppressing deteriorations of these properties. To achieve the object, the invention provides an antifouling coating composition including (A) a diorganopolysiloxane having at least two silanol groups in the molecule, (B) an organosilane and / or a partial hydrolyzate condensate thereof having at least two hydrolyzable groups in the molecule, and (C) a pyrithione metal salt. The antifouling coating composition can be prepared from a kit in the form of a multiple-component system including respective packages of a component including the component (A) and the component (C), and a component including the component (B). In the (kit for the preparation of the) antifouling coating composition, the pyrithione metal salt (C) functions as an effective ingredient for achieving excellent antifouling properties, in particular, anti-sliming properties, and also as an effective ingredient for improving storage stability.

Owner:CHUGOKU MARINE PAINTS

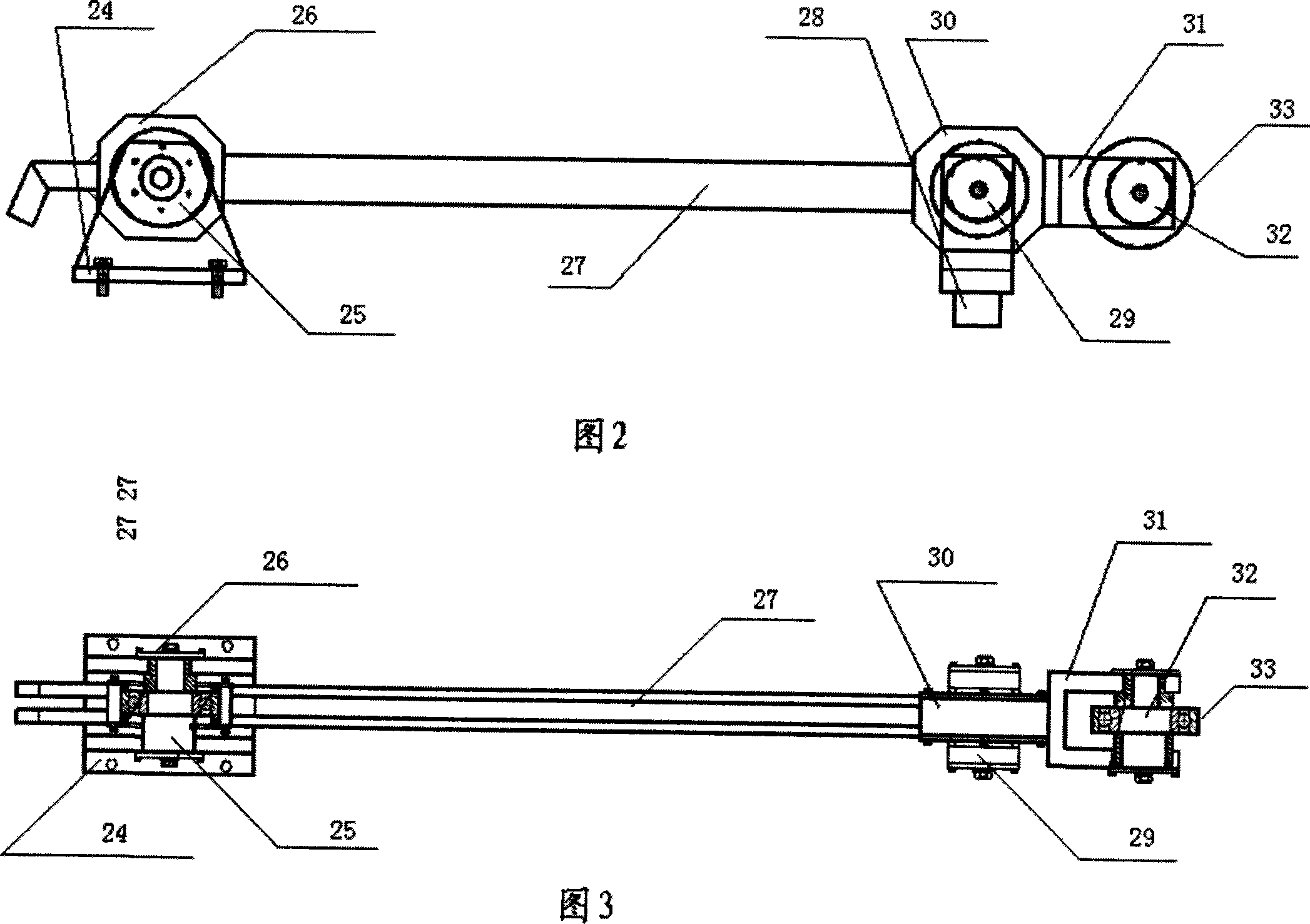

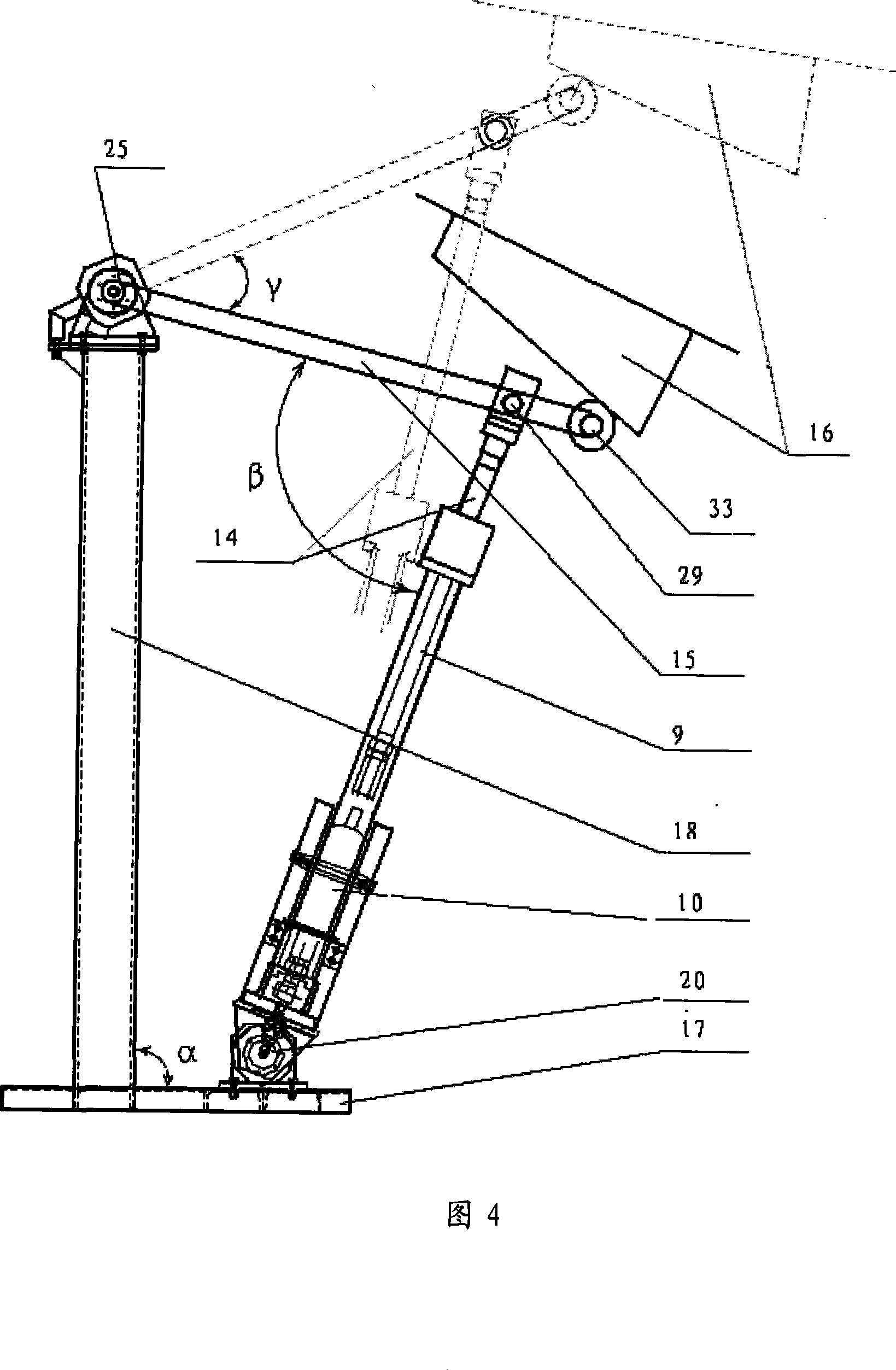

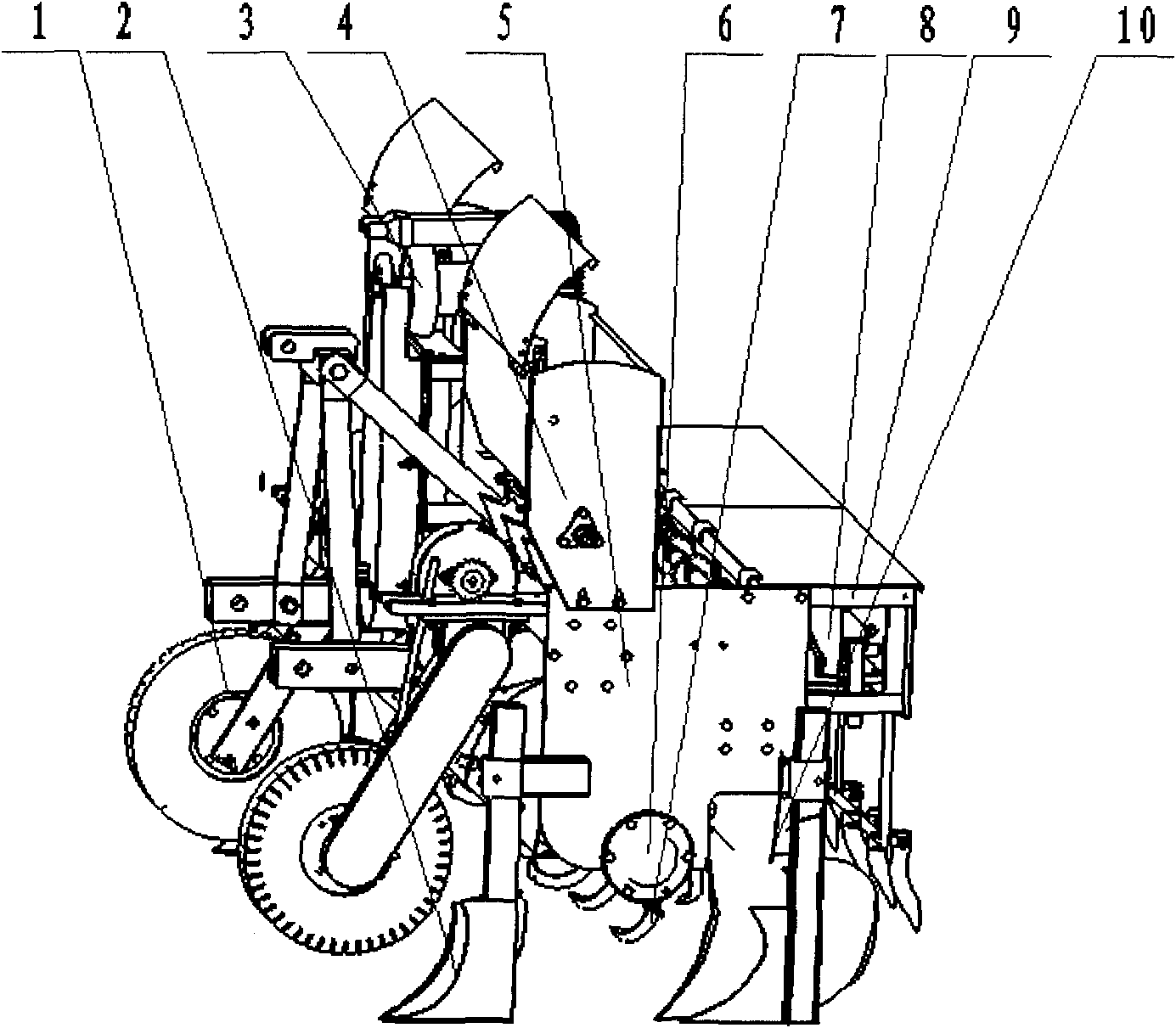

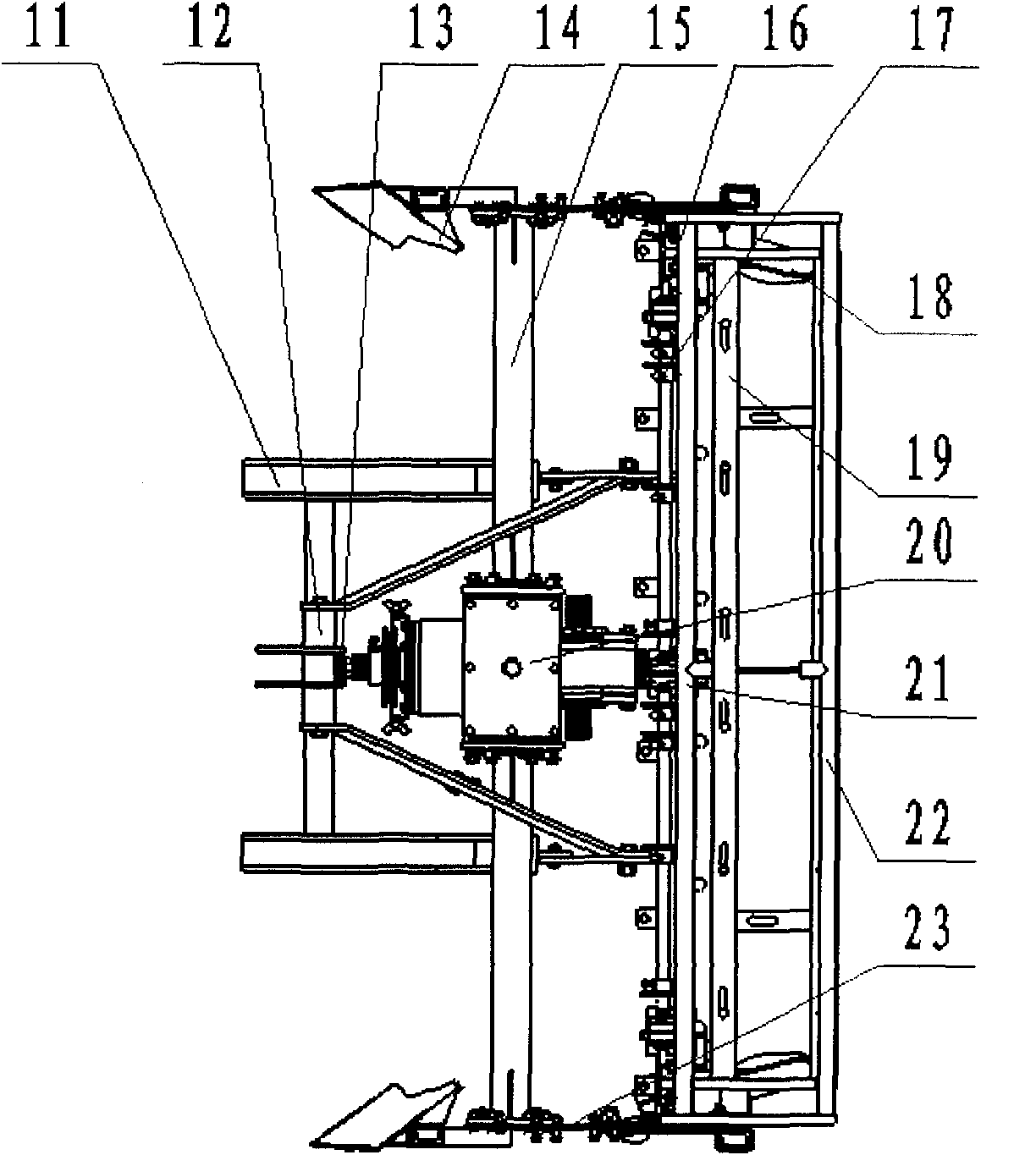

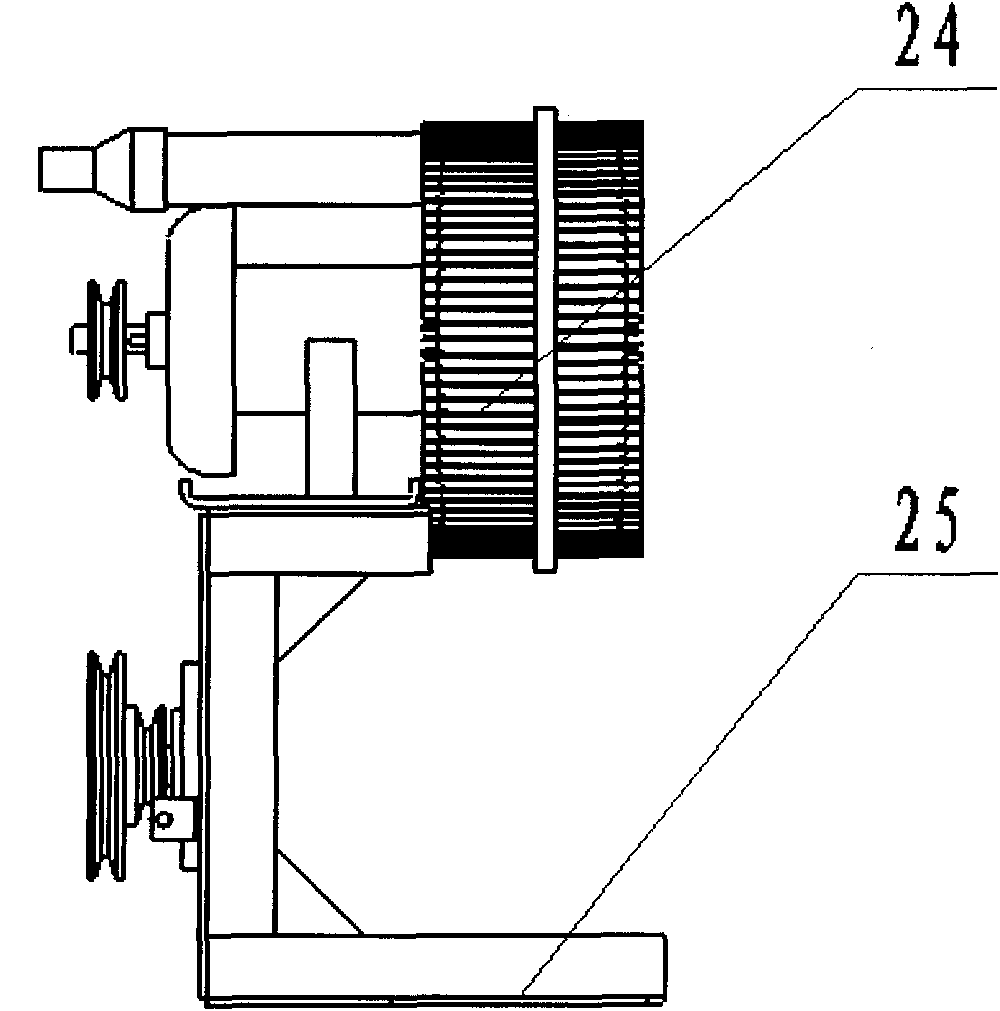

Pneumatic rape precise combined direct seeder

The invention relates to a pneumatic rape precise combined direct seeder, and belongs to the technical field of seeders. The seeder comprises a frame, a rotary tillage unit, a fertilizer unit, a land-wheel profile device, a sub-frame, a positive / negative air pressure working unit, a positive / negative air pressure combined seed-metering device, a ditching unit and a driven system. The pneumatic rape precise combined direct seeder has the advantages of simple structure, compact layout, low power consumption, little damage on soil, low re-sowing rate and seeding absence rate, and no seed damage, and can realize the combined operation of rotary tillage, stubble cutting, ditching, sowing and fertilization. The pneumatic rape precise sowing can save seeds and greatly reduce the thinning and final singling operation of the later growth management of rape; and the combined operation greatly improves the production efficiency. The seeder is used for precise combined direct seeding of rapeseeds, and also can be used for the precise direct seeding of other small spherical grain-size seeds.

Owner:HUAZHONG AGRI UNIV +1

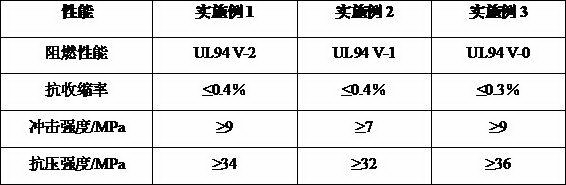

Unsaturated polyester resin composite material for furniture and preparation method thereof

ActiveCN104045986AImprove the overall mechanical propertiesGood flame retardant performanceDefoaming AgentsResin composite

The invention relates to an unsaturated polyester resin composite material for furniture. The composite material is characterized by comprising the following components in parts by weight: 100 parts of unsaturated polyester resin, 20 to 40 parts of modified bamboo fibers, 20 to 50 parts of flame retardant, 0.5 to 3 parts of accelerant, 0.8 to 2 parts of initiating agent, 0.5 to 2 parts of defoaming agent and 1 to 10 parts of coupling agent. The invention further provides a preparation method of the unsaturated polyester resin composite material for furniture. The composite material is good in overall mechanical property and flame retardant property as well as excellent in comprehensive property, and can be used for replacing log materials and can be directly molded in a room-temperature curing manner. Thus, the composite material is simple to prepare and easy for scale production, and meets the modern environmental friendliness requirement. As a result, the composite material provided by the invention is especially suitable for the mass manufacturing of the furniture, especially classical furniture.

Owner:VESACH FURNITURE & DECORATION

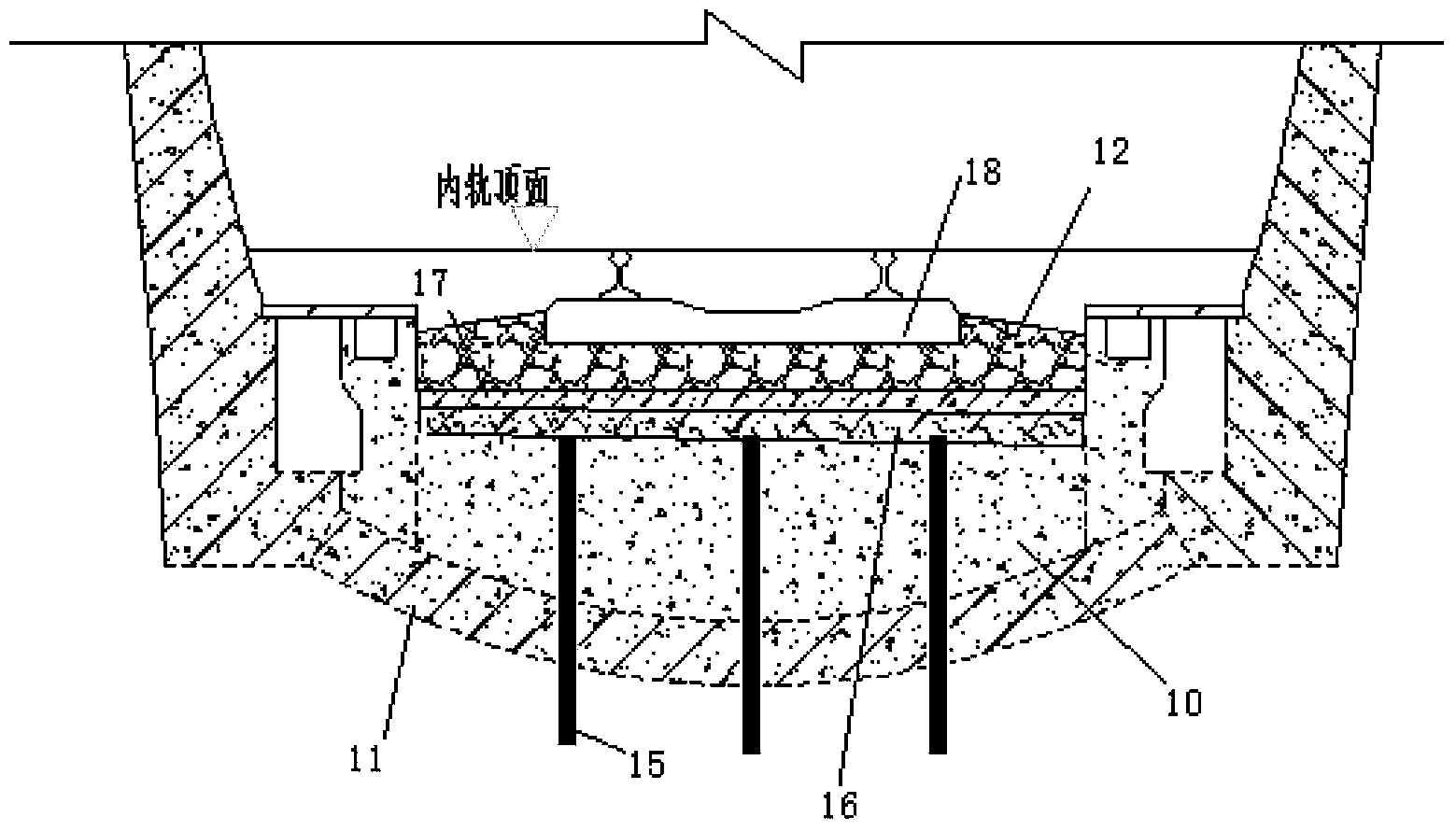

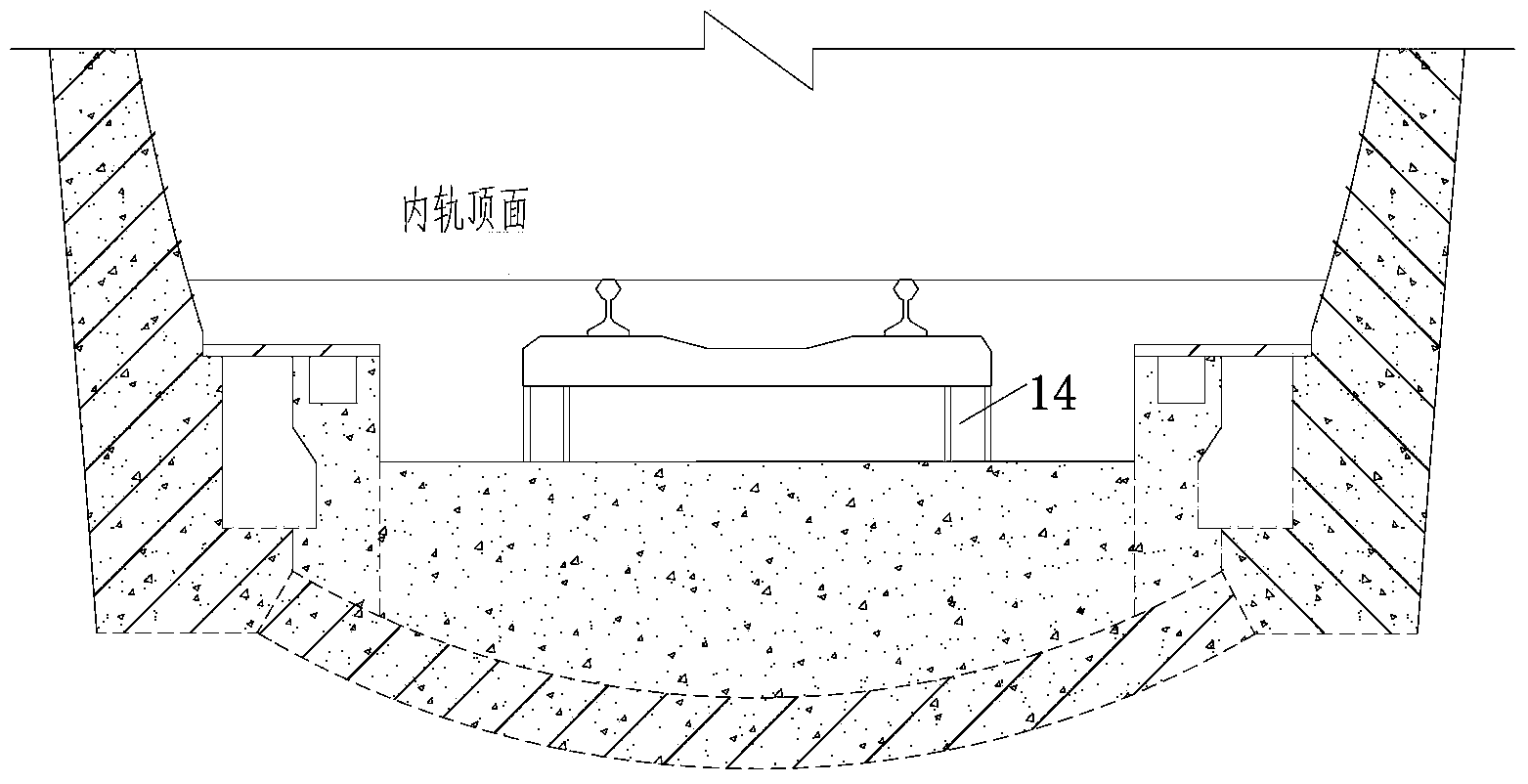

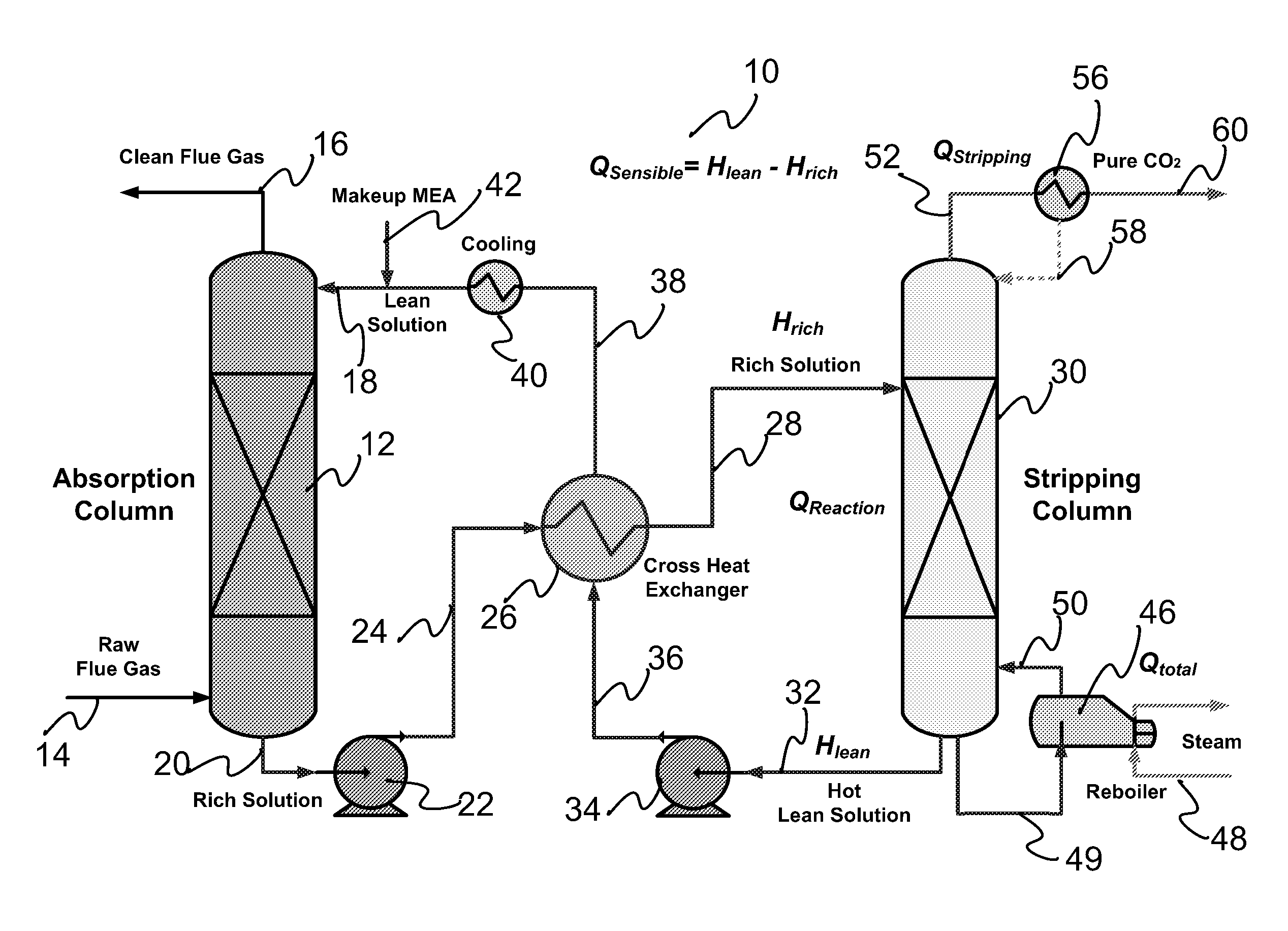

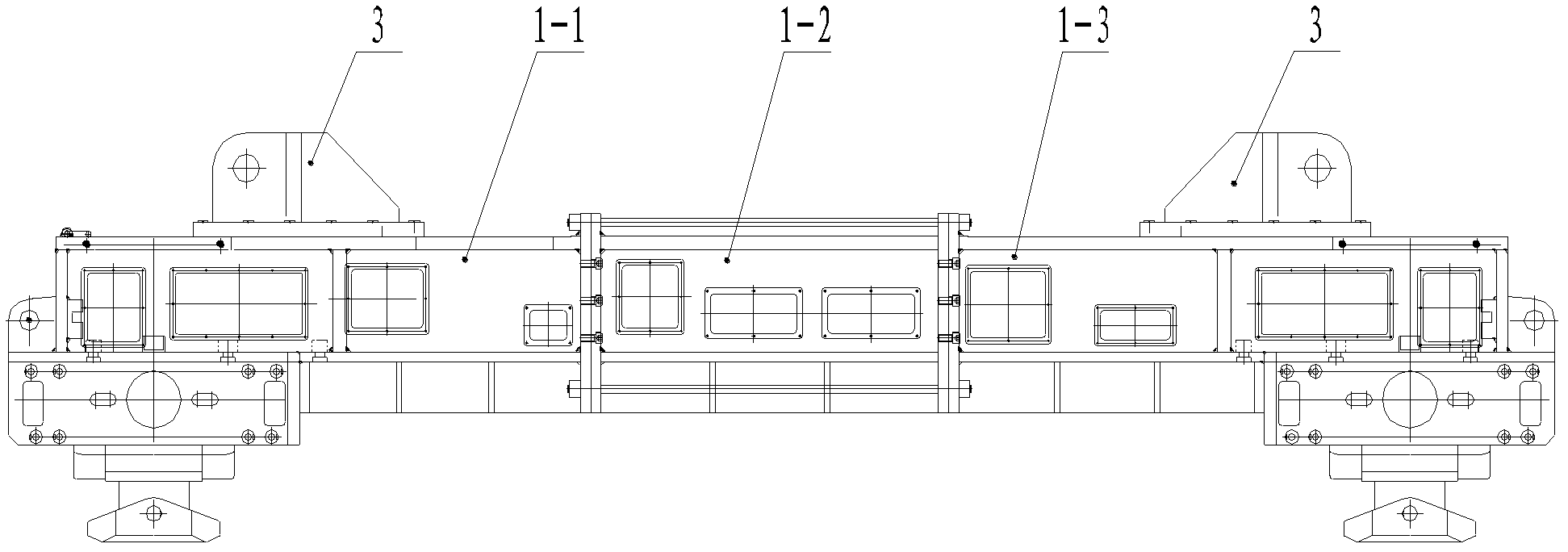

Railway tunnel bottom defect treatment technology based on assembly type beam slab pile

InactiveCN103510532AFast constructionShort construction periodFoundation engineeringRailway tunnelStructure of the Earth

The invention discloses a railway tunnel bottom defect treatment technology based on an assembly type beam slab pile and relates to a rapid treatment technology aiming at solving the problem that the driving potential safety hazard occurs in an existing railway tunnel due to bottom defects. The railway tunnel bottom defect treatment technology comprises the steps of enabling lines to be arranged in the air and drilling a hole at the bottom to enable a precast pile to be embedded; and installing a precast beam slab to form a bottom bearing structure. According to the technology, a precast beam slab pile component is introduced, a main bearing component is prefabricated out of the hole, the integral construction speed is quick, and the construction period is short; in the process of construction in the hole, only part of the lines need to be arranged in the air, an existing bottom structure does not need dismantling, construction processes are fewer, the masonry amount is small, and the cost is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

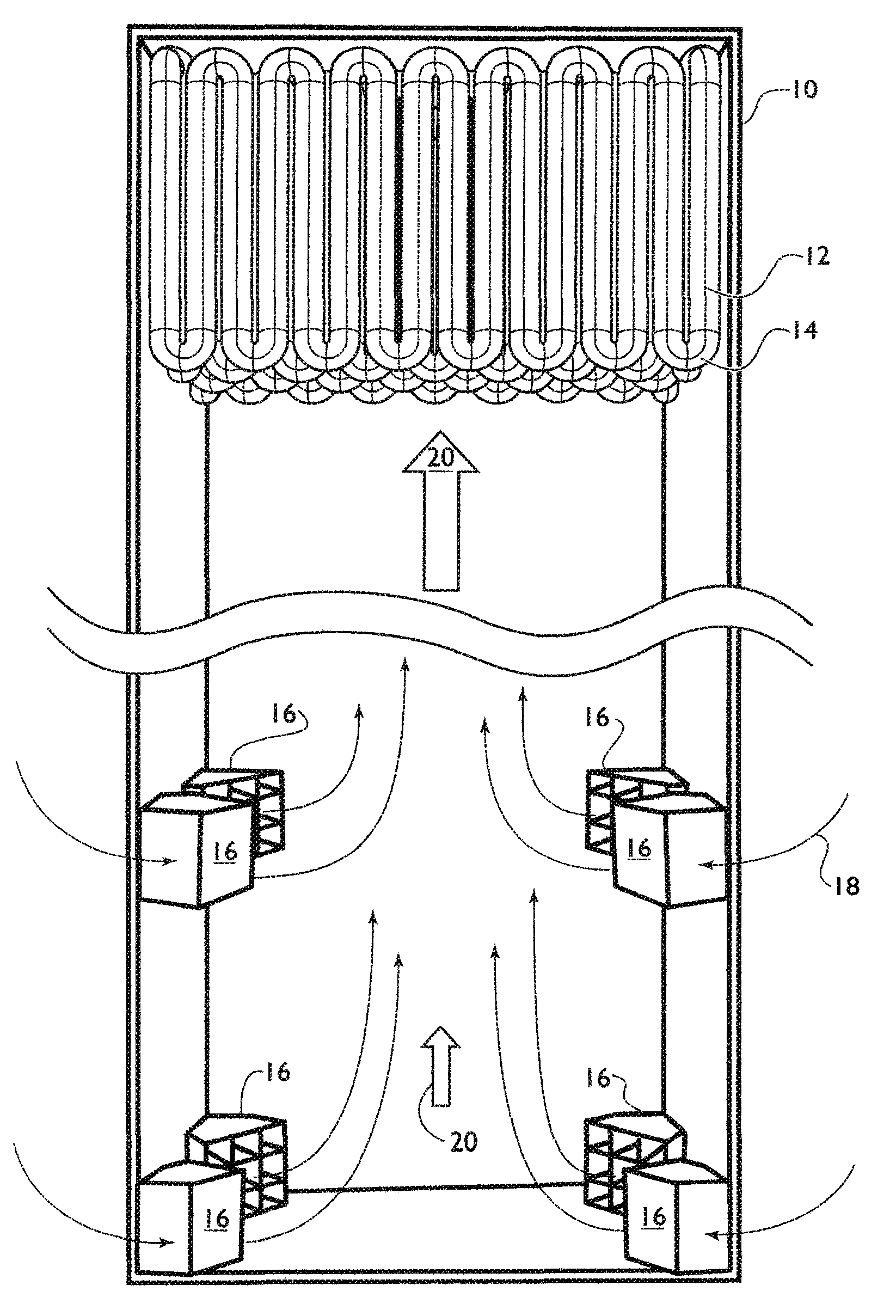

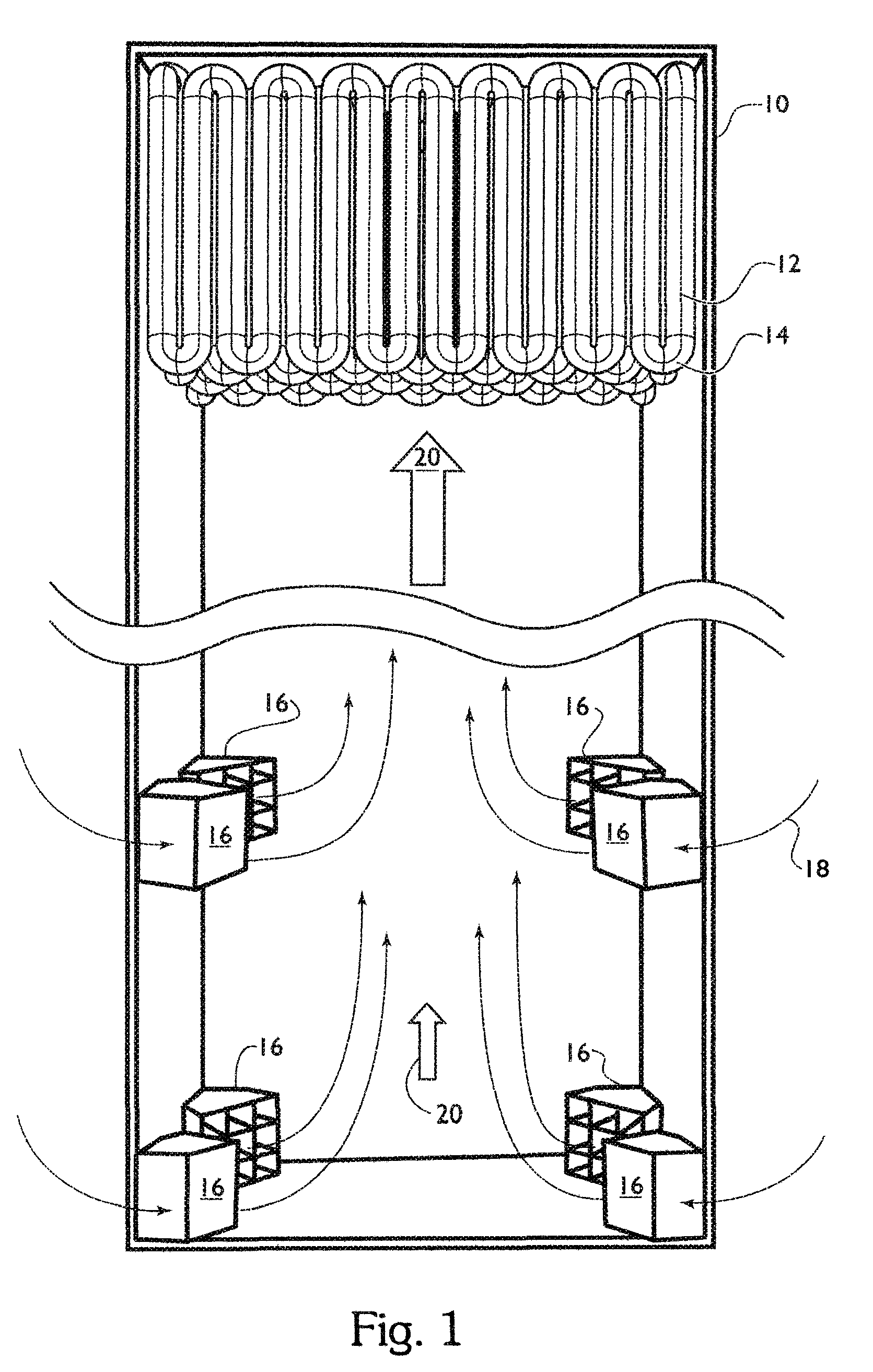

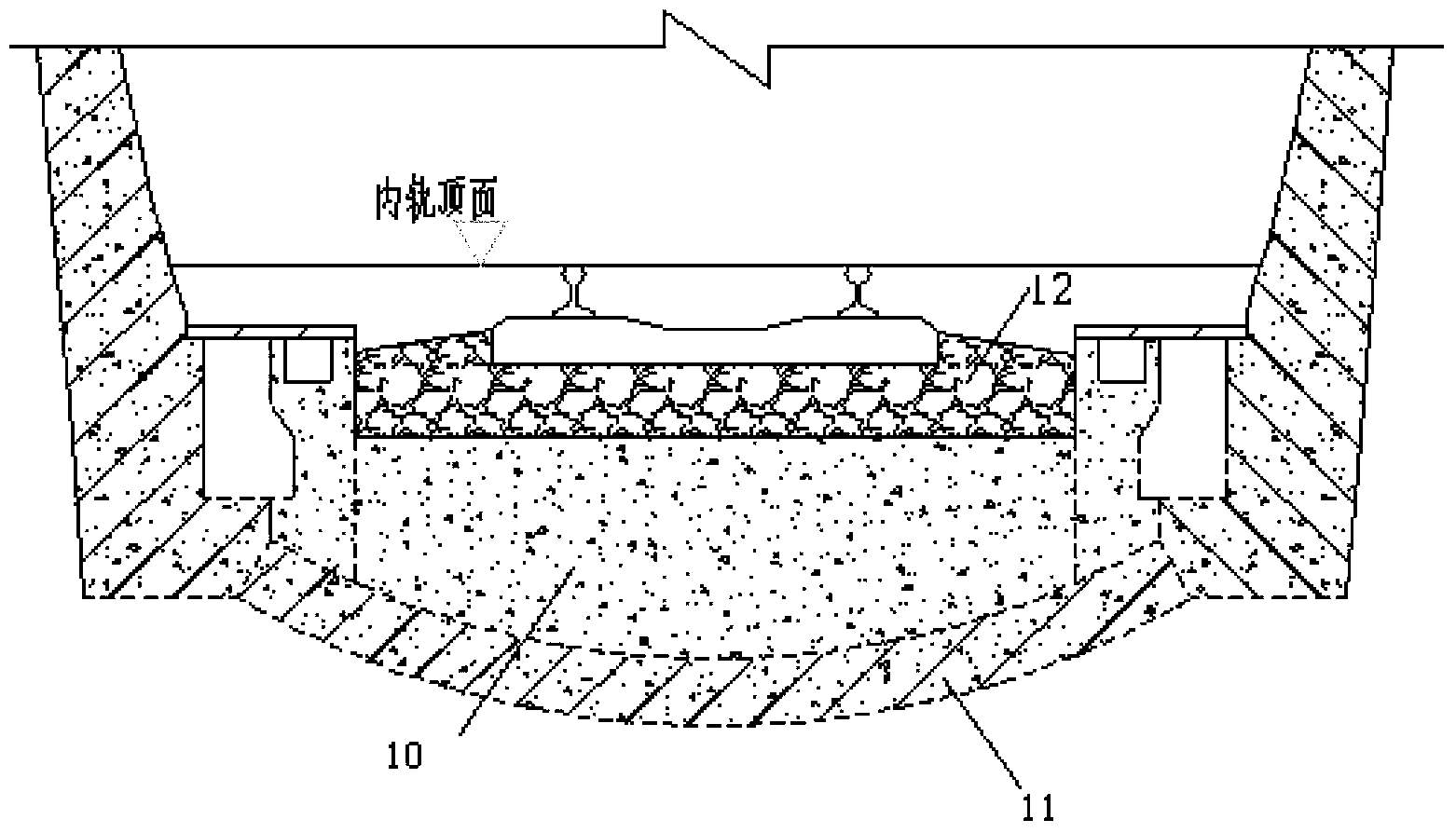

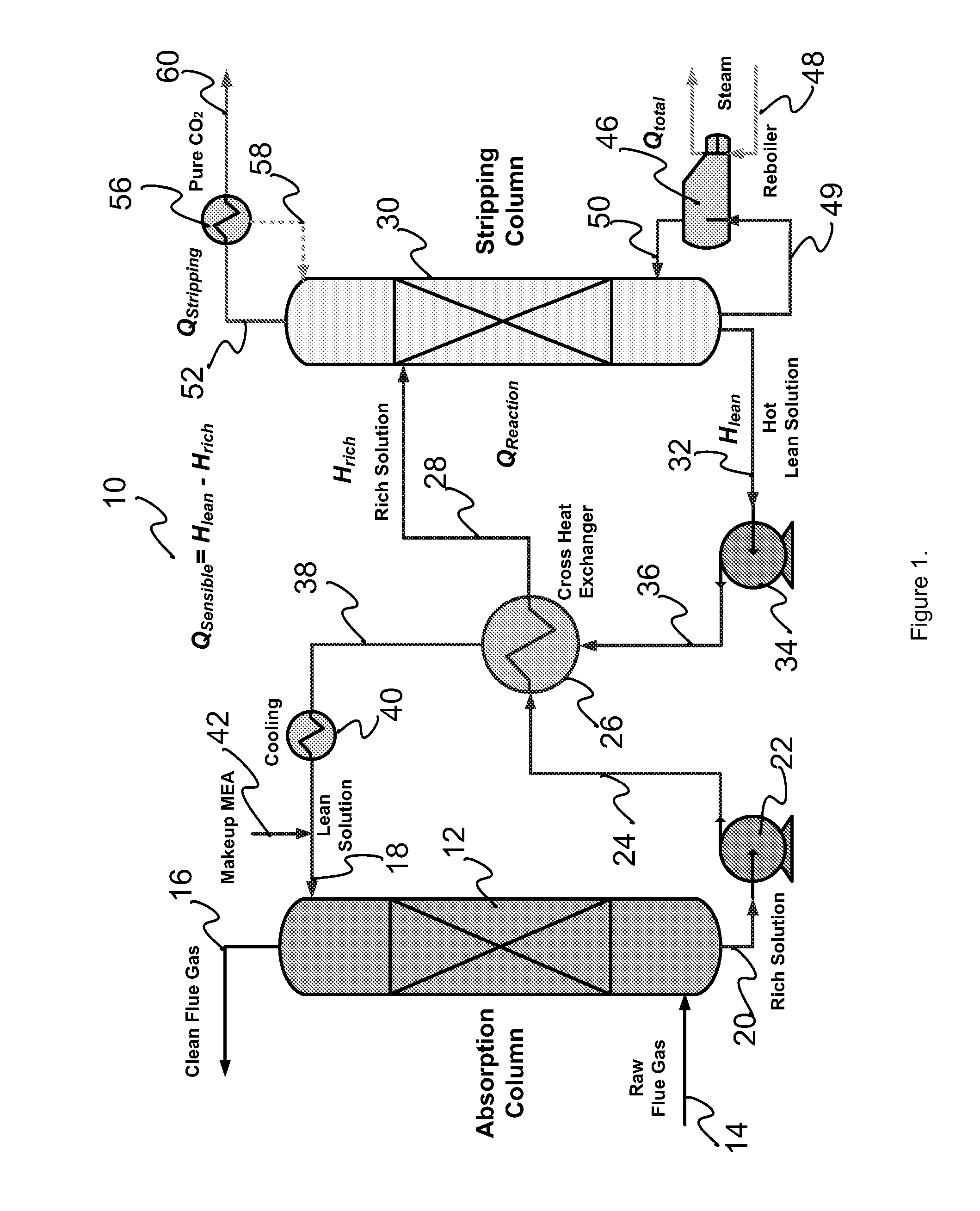

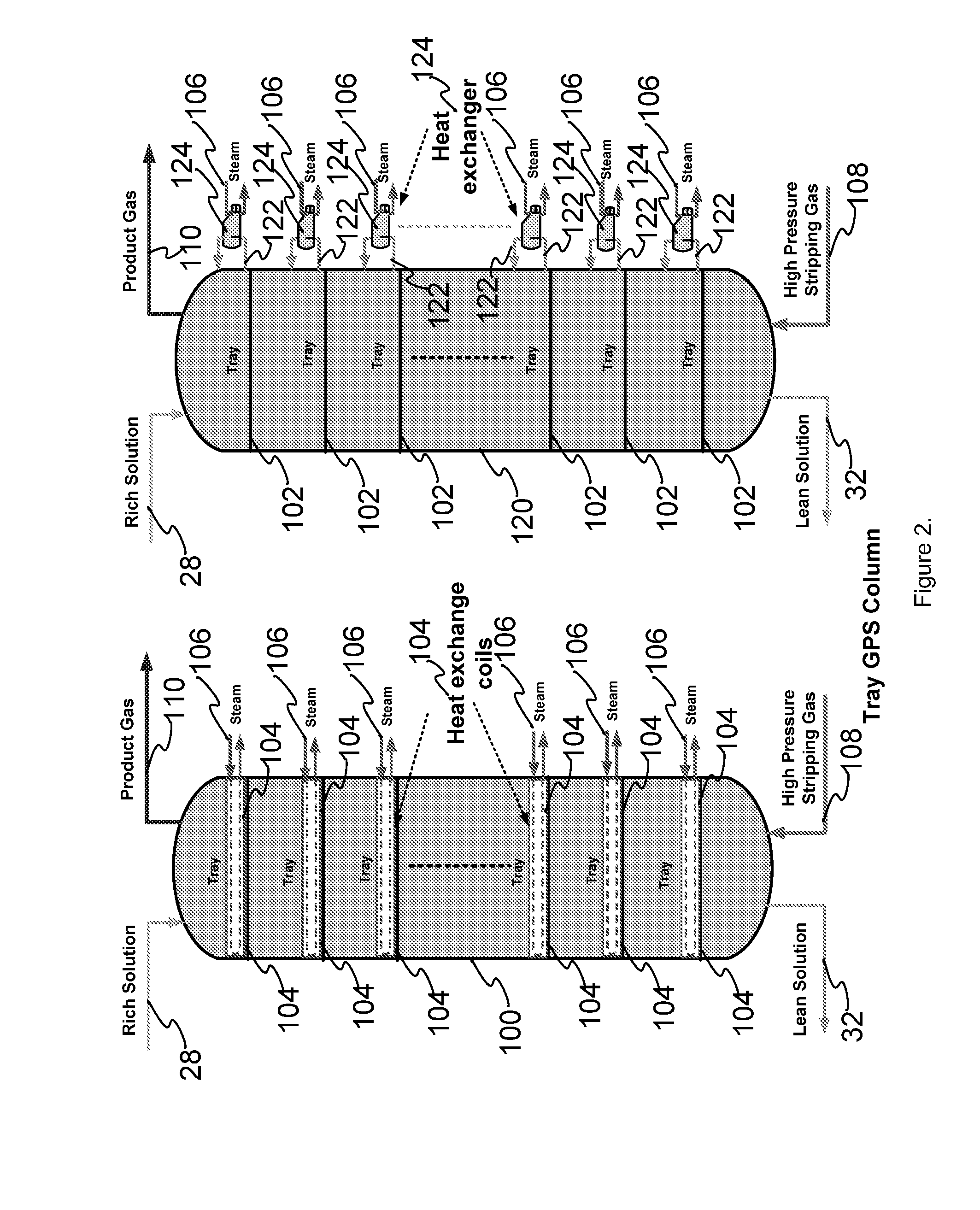

Gas pressurized separation column and process to generate a high pressure product gas

The present invention provides a gas pressurized separation system to strip a product gas from a liquid stream and yield a high pressure gaseous effluent containing the product gas. The system comprises a gas pressurized stripping apparatus, such as a column, with at least one first inlet allowing flow of one or more liquid streams in a first direction and at least one second inlet allowing flow of one or more high pressure gas streams in a second direction, to strip the product gas into the high pressure gas stream and yield through at least one outlet a high pressure gaseous effluent containing the product gas; and two or more heat supplying apparatuses provided at different locations along the column. Processes for separating a product gas from a gaseous mixture to yield a high pressure gaseous effluent containing the product gas, utilize the gas pressurized separation system described above.

Owner:CARBON CAPTURE SCI

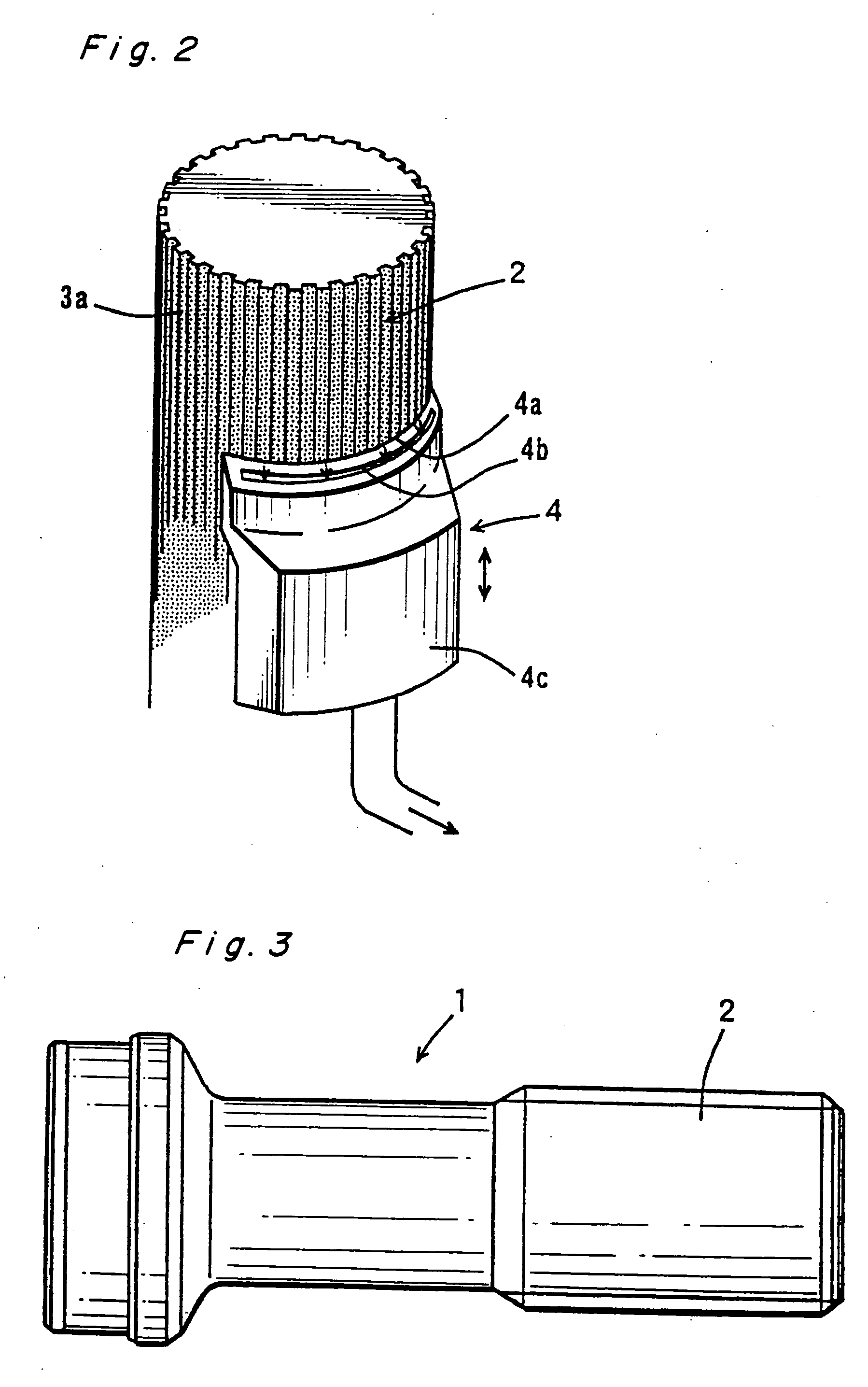

Combined height-adjustable coal cutting machine with small roller and large mining height, as well as coal cutting process of combined height-adjustable coal cutting machine

InactiveCN102536233AReduce energy consumptionReduce cutting resistanceUnderground miningSurface miningElectrical controlCoal

The invention relates to a combined height-adjustable coal cutting machine with a small roller and a large mining height, as well as a coal cutting process of the combined height-adjustable coal cutting machine. The combined height-adjustable coal cutting machine comprises a machine body assembly, coal cutting rollers, a travelling mechanism, an auxiliary device, a hydraulic control system and an electrical control system, and is characterized in that combined height-adjusting devices are symmetrically mounted on two side surfaces of the machine body assembly; and each combined height-adjusting device comprises a main height-adjusting oil cylinder, an auxiliary height-adjusting cutting arm and an auxiliary height-adjusting oil cylinder. The coal cutting process adopts a knife inserting method without notch cutting; the coal cutting roller at the front end of the coal cutting machine cuts residual coal bodies under the action of the oscillation of both the main height-adjusting cutting arm and the auxiliary height-adjusting cutting arm, wherein the moving trace is an arc, and the oscillation angle Alpha is at least 90 DEG; and the coal cutting roller at the rear end of the coal cutting machine cuts coal along a bottom plate, wherein the moving trace is a straight line. The coal cutting machine has the advantages that the structure is compact; the size and the weight are smaller; the suitability is strong; the mounting and the transportation are convenient; and the coal cutting machine is suitable for large, middle or small scale of coal mines with large mining heights.

Owner:闫振东

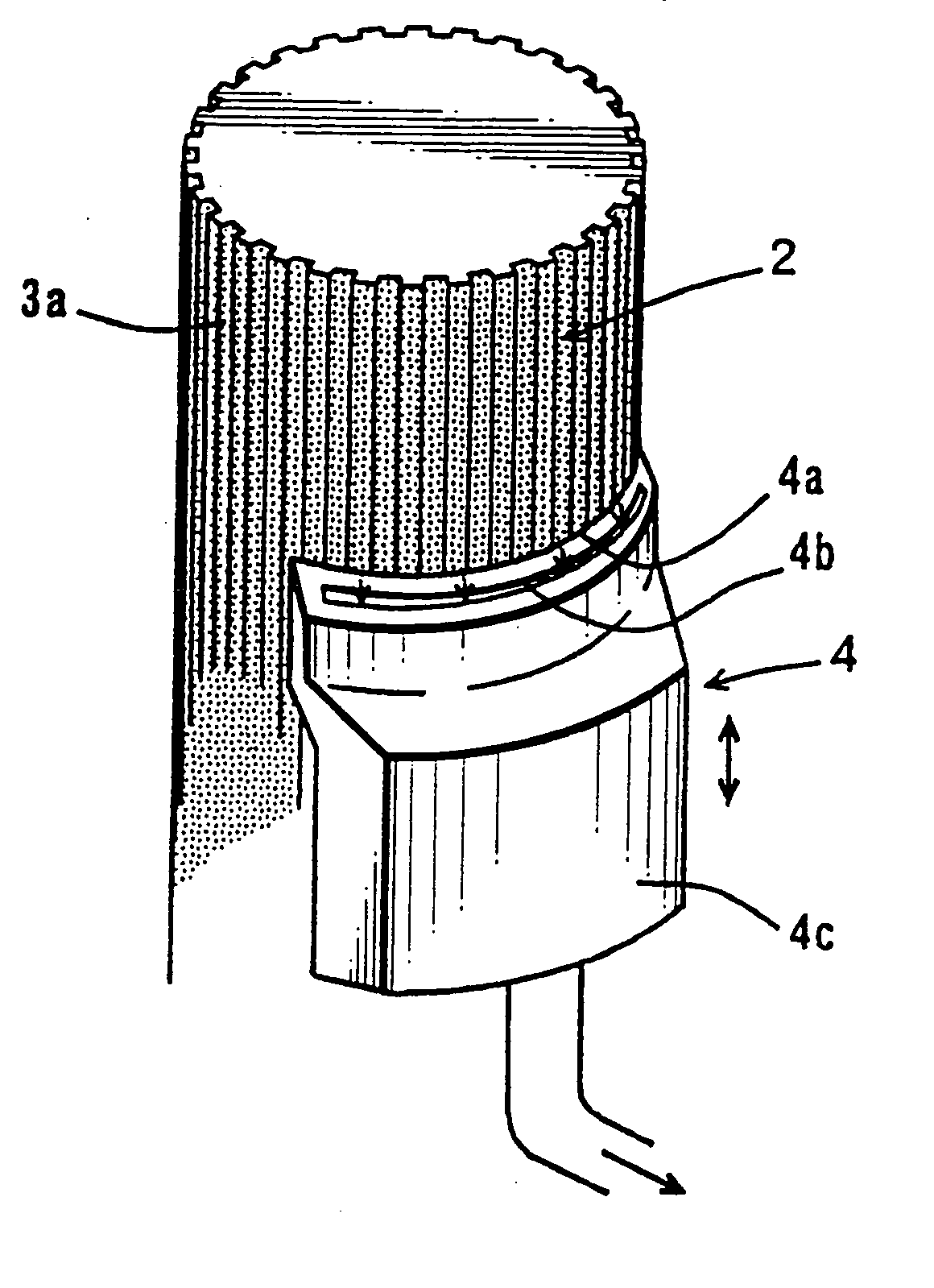

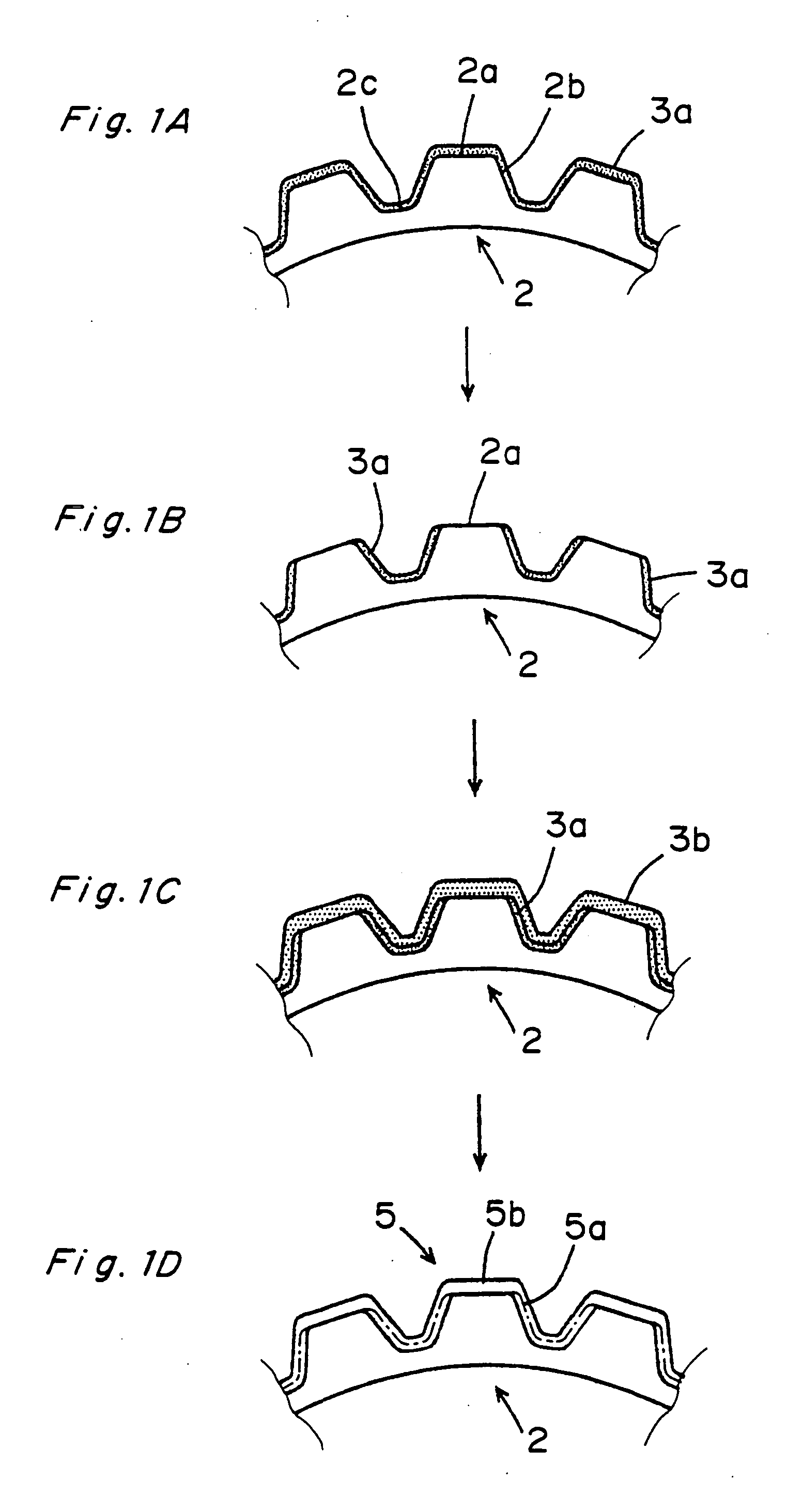

Coated article, manufacturing method therefor and coating apparatus

After forming a primary powder bed at a toothed portion of an article, such as a gear or a spline shaft, by electrostatic powder coating process, the powder bed is removed from crests of teeth in the toothed portion by a specified thickness by scraping it off while sucking up the scraped powder. Next, the electrostatic powder coating process is performed again to form a secondary powder bed over the entire surface of the toothed portion. Then, the primary and secondary powder beds are melted or fused by induction heating to thereby form a coating film of a substantially uniform thickness.

Owner:JTEKT CORP

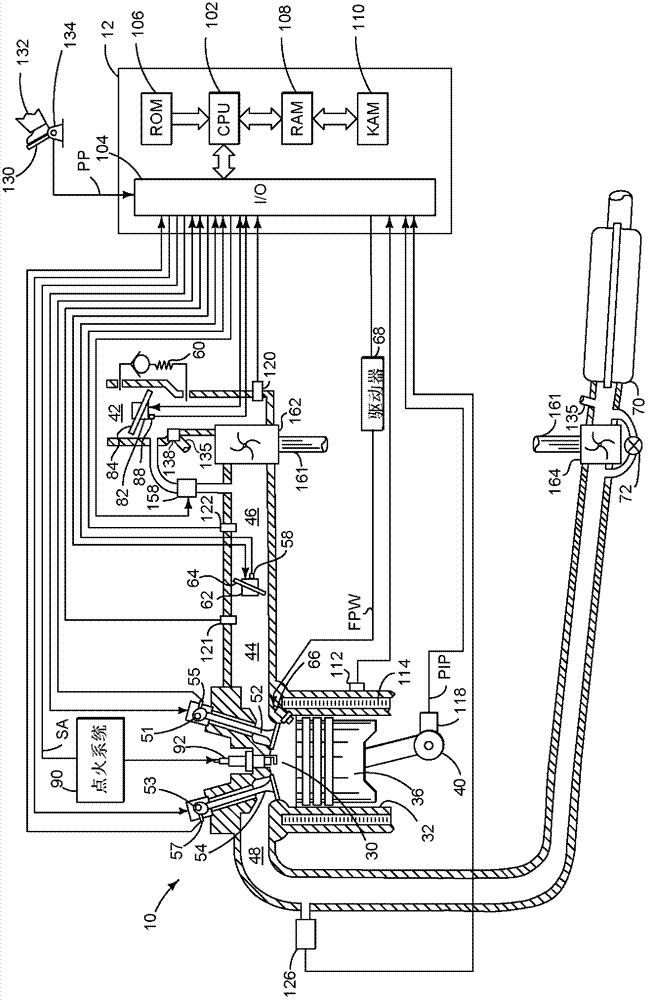

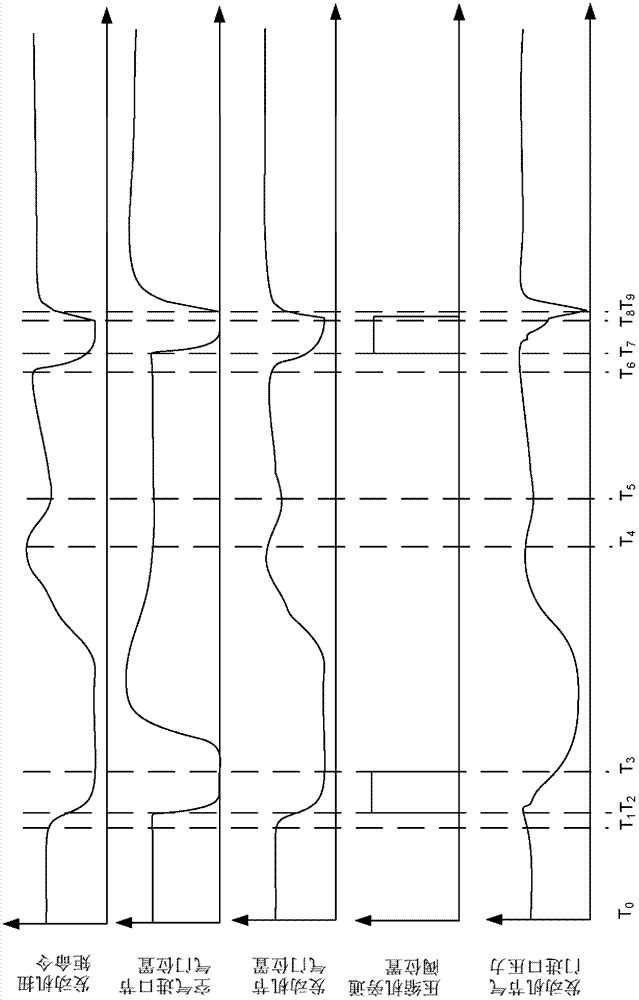

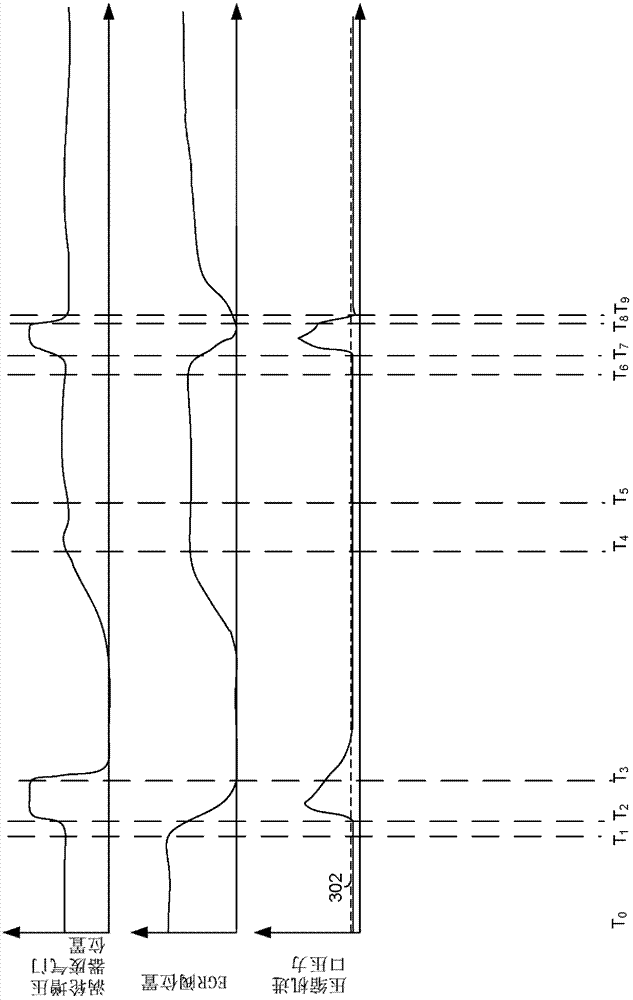

Method and system for providing air to an engine

InactiveCN102733959AReduce noiseReduce the amount of noiseElectrical controlNon-fuel substance addition to fuelEngineeringControl theory

Systems and methods for supplying air to an engine are disclosed. In one example, an air inlet throttle is at least partially closed in response to a change in engine torque request. In another example, the air inlet throttle is adjusted in conjunction with adjusting an engine throttle. The approach can reduce compressor noise and may reduce the possibility of compressor surge.

Owner:FORD GLOBAL TECH LLC

Pre-assembled shingle set and installation system

ActiveUS8256185B2Quick installationReduces moisture damageRoof covering using tiles/slatesBuilding repairsConstruction engineeringStructural engineering

An assembly, and method for constructing the assembly, to aid in the proper installation of shingles by providing panels of shingles and assembly guides that when followed, result in the installation of shingles that meet keyway width requirements, keyway alignment requirements, provide an aesthetically pleasing distribution of the shingles, and provides adequate ventilation.

Owner:ECOSHEL INC

Surfactant composition, and manufacturing method and application of same

ActiveUS20160122621A1High activityImprove stabilityFluid removalFlushingActive agentSurface-active agents

This invention relates to a surfactant composition, production and use thereof in tertiary oil recovery. The present surfactant composition comprises a cationic surfactant and an anionic-nonionic surfactant, and exhibits significantly improved interfacial activity and stability as compared with the prior art. With the present surfactant composition, a flooding fluid composition for tertiary oil recovery with improved oil displacement efficiency and oil washing capability as compared with the prior art could be produced.

Owner:CHINA PETROCHEMICAL CORP +1

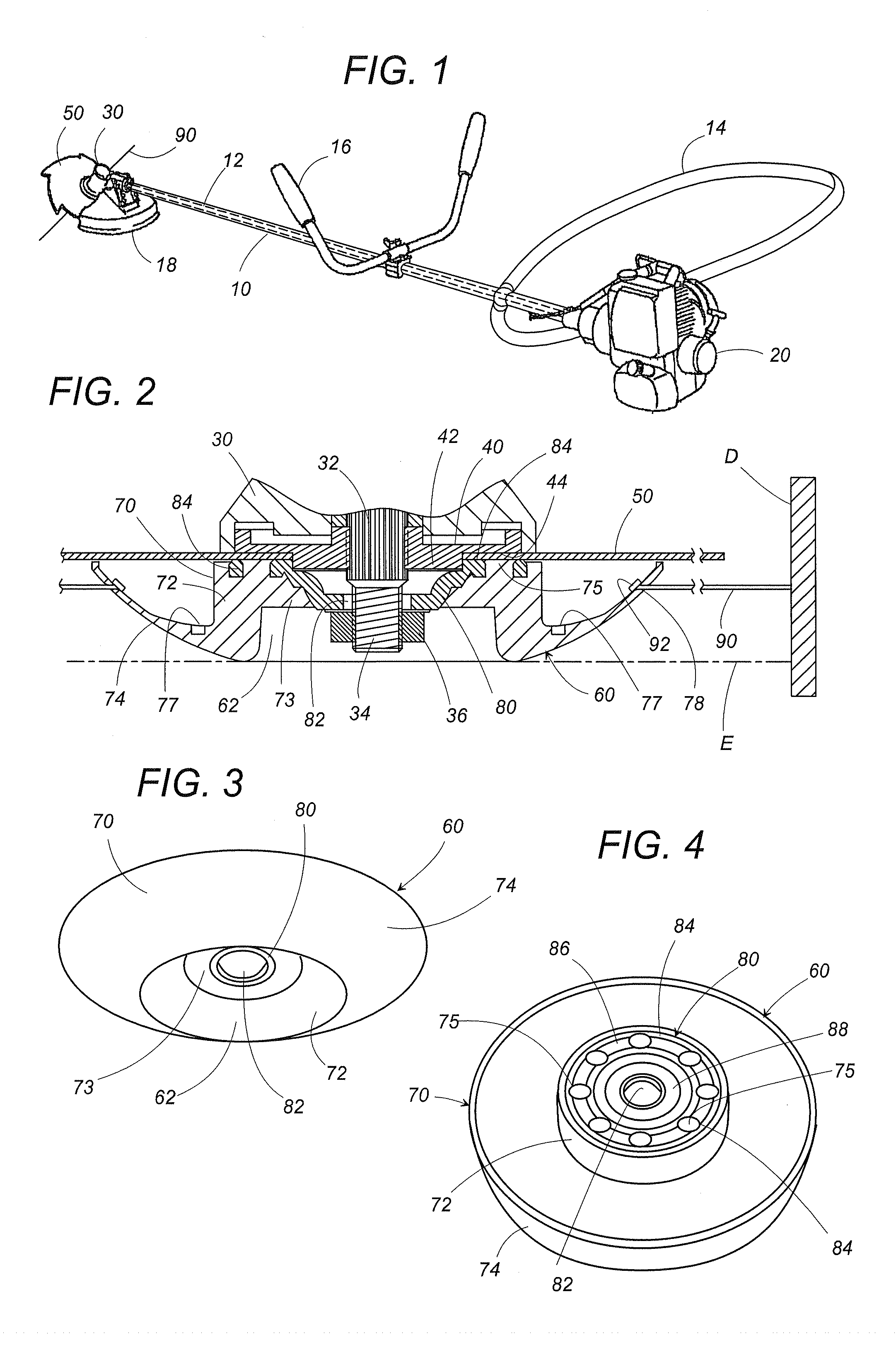

Ground surface slide guide of a grass cutter and grass cutter

ActiveUS20090100815A1Work lessImprove wear resistanceCrop conditionersMowersGround contactDrive shaft

A ground surface slide guide attached to a grass cutter is of light weight and has a large diameter and superior durability, enabling comfortable grass cutting work. The ground surface slide guide has a resin body made of synthetic resin, and a metal hub integrally coupled thereto to rotate together. The resin body is composed of a tubular body and a flange extending upward to the outside from the entire periphery of the lower end of the tubular body and covering the lower surface of the rotary blade. A blade retaining ring pressed against the lower surface of the rotary blade is formed on the outer periphery of the hub, and the blade retaining ring is exposed to the upper end surface of the tubular body. The hub is attached to a drive shaft by a fastener, and the rotary blade is clamped between a blade rest and a blade retaining ring. The lower end of the tubular body serves as a ground contact surface. The metal hub is integrally coupled to the resin body to rotate together. The overall weight is reduced by the resin body, and the lower surface of the rotary blade can be covered over a wide range, thereby improving stability with respect to the surface of the ground. In addition, since wear resistance performance is enhanced by making the thickness of the lower end of the tubular body serving as the contact surface that contacts the ground greater than the thickness of the flange, the durability of the ground surface slide guide can be improved.

Owner:KK KITAMURA SEISAKUSHO

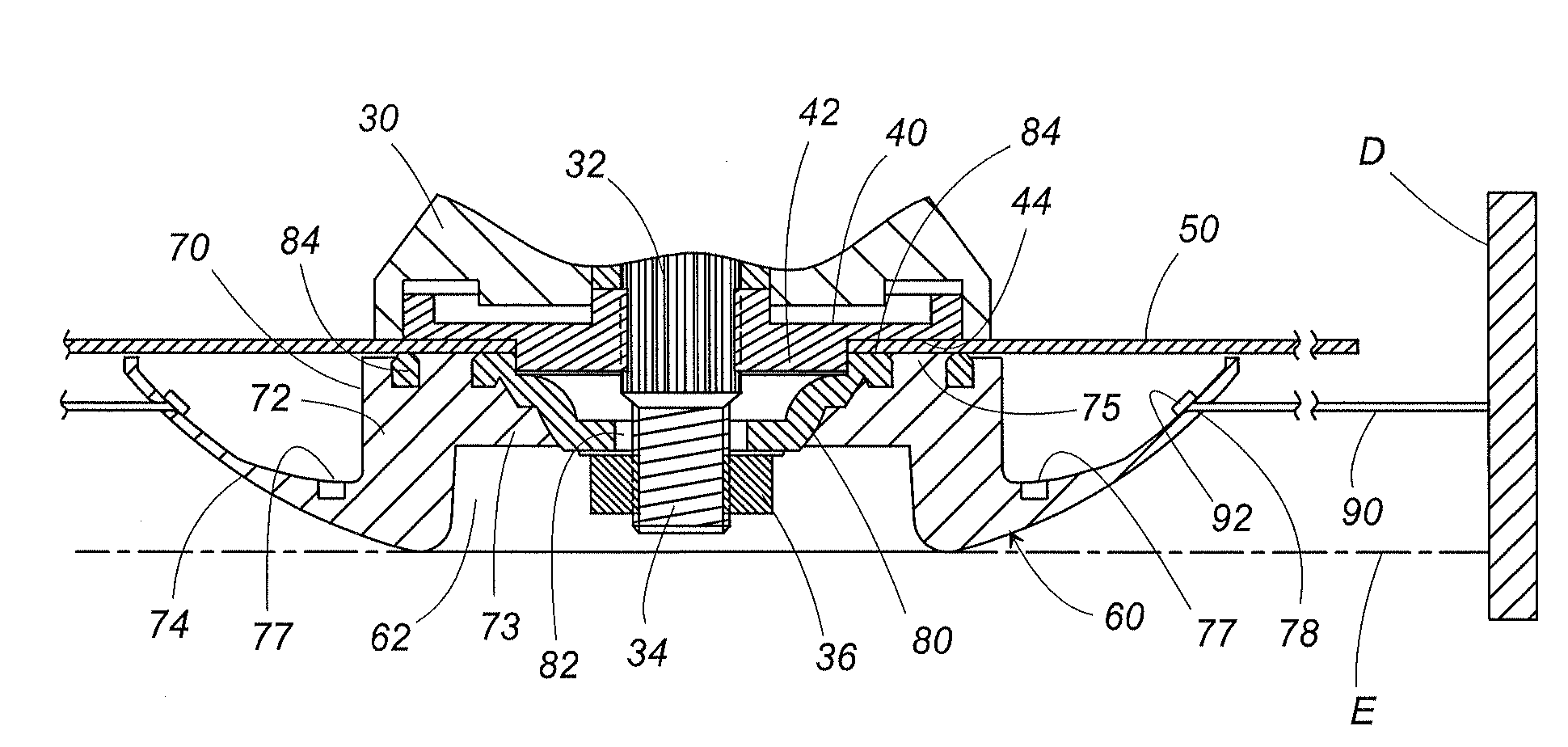

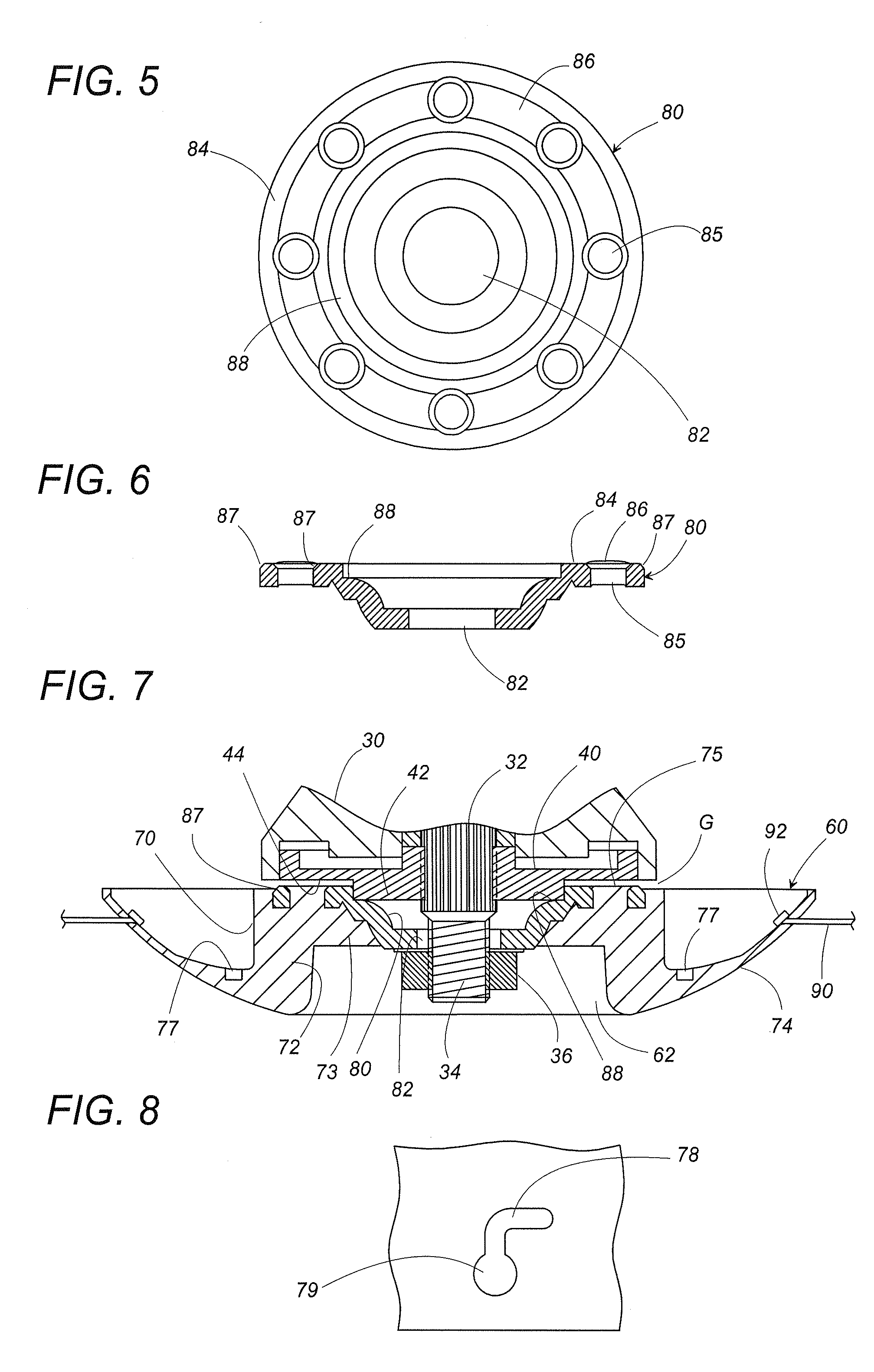

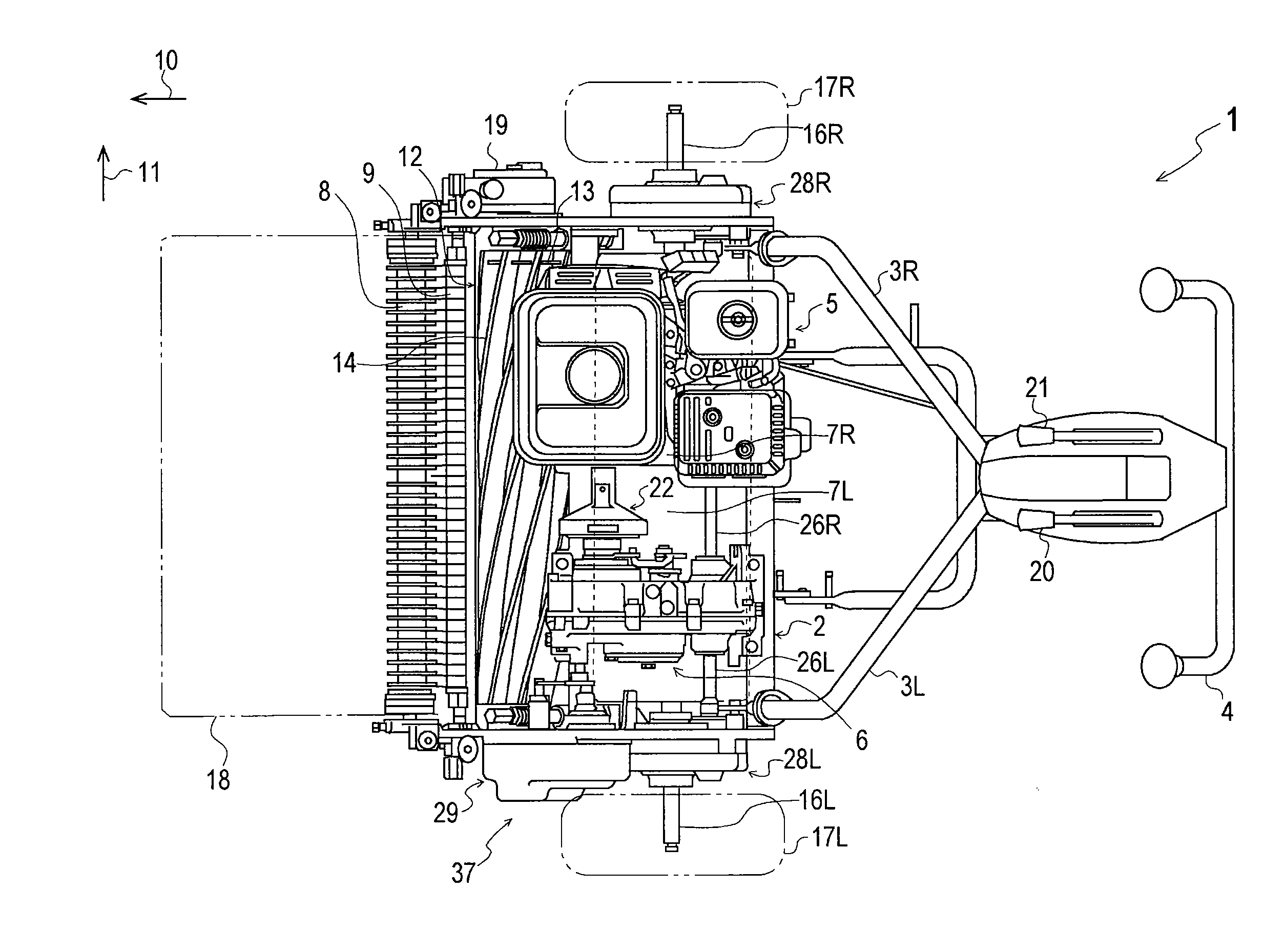

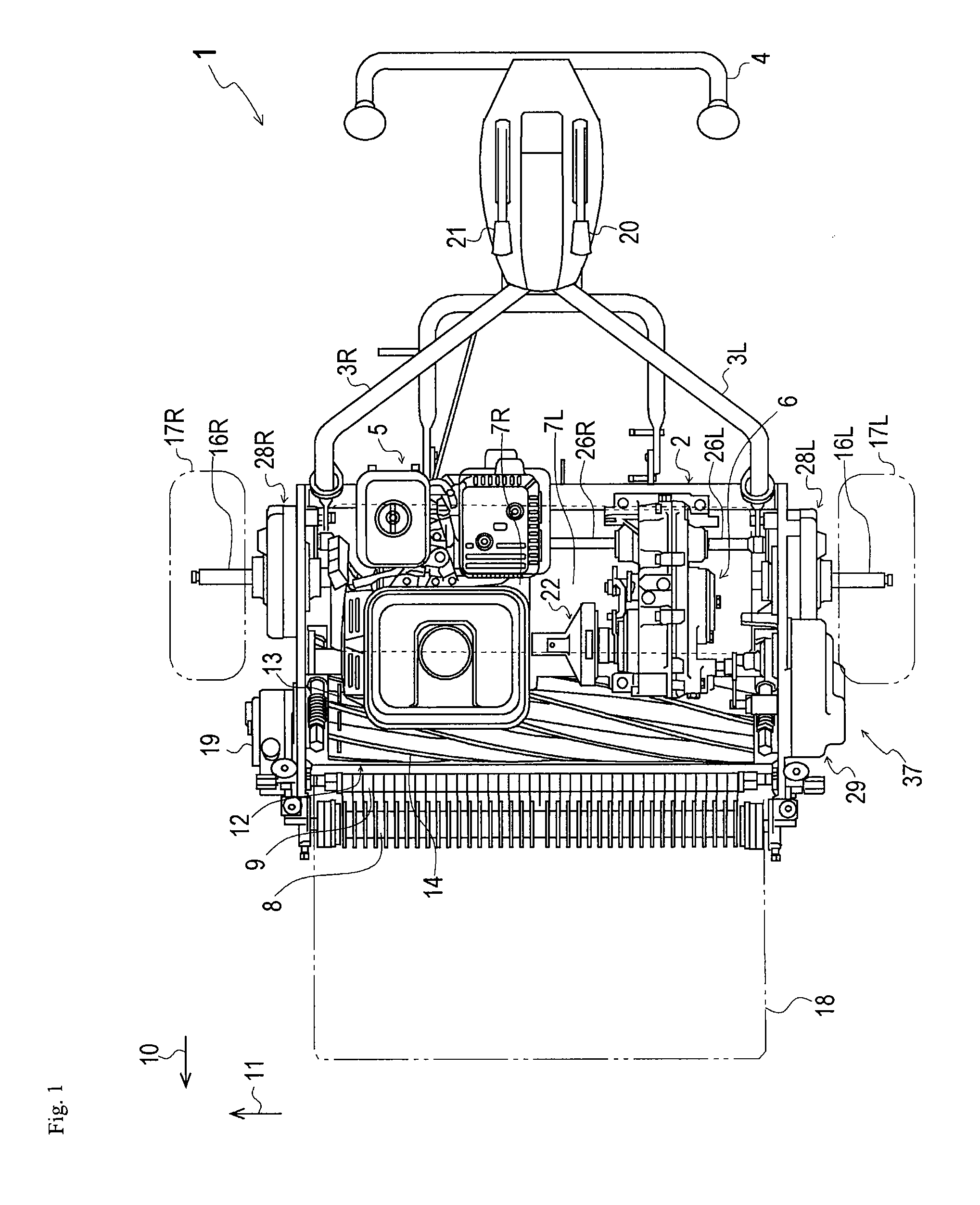

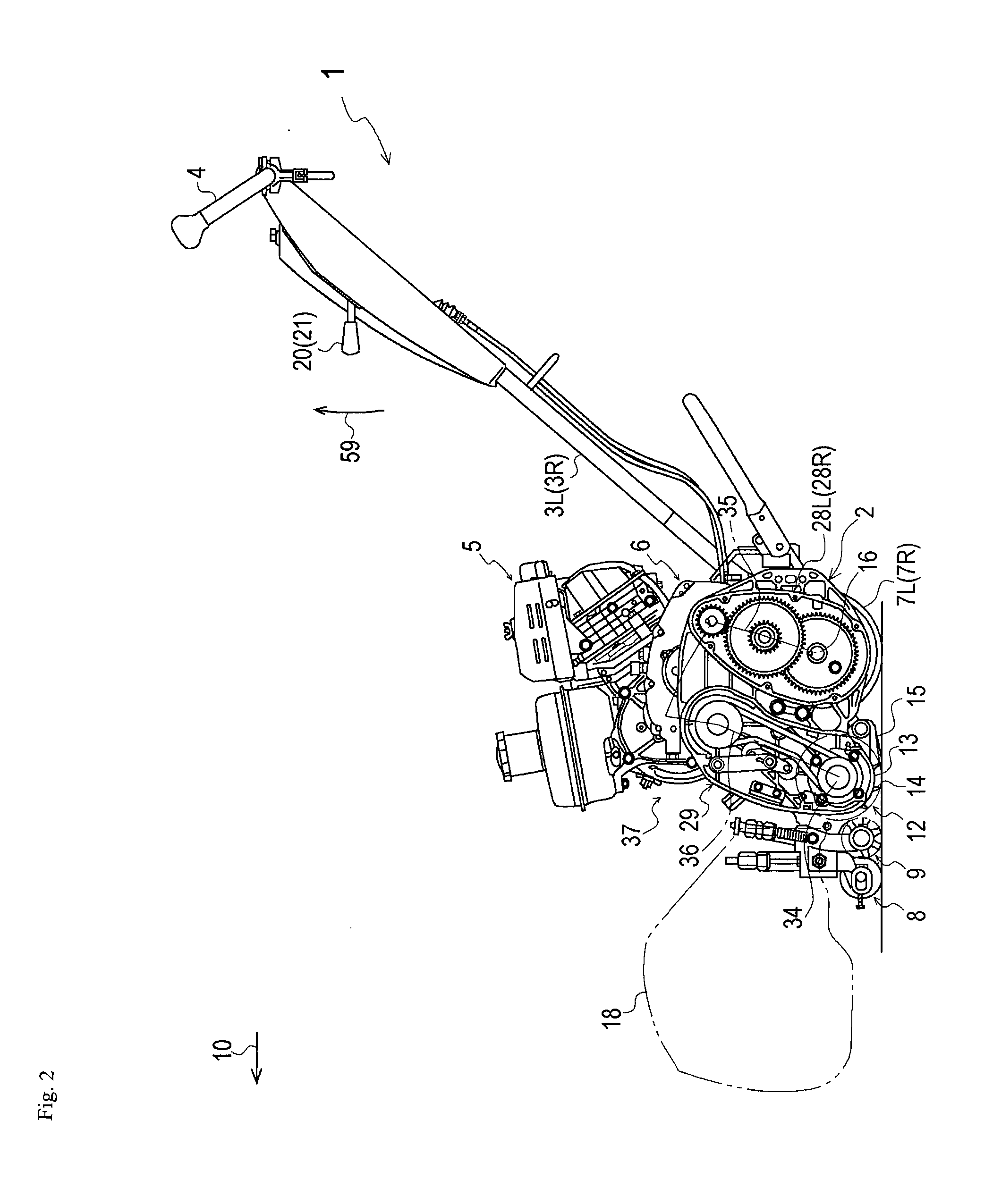

Power Transmission Mechanism for Walk Behind Lawnmower

In a walk behind lawnmower 1 for mowing lawns that bifurcates a power from an engine 5 and transmits it to drum-type wheels 7L, 7R and a reel cutter 12, each of the first power transmission passage 35 for transmitting the power from the engine 5 to the drum-type wheels 7L, 7R and the second power transmission passage 36 for transmitting the power from the engine 5 to the reel cutter 12 has a gear variable speed mechanism 30 and an interchange mechanism 134 as speed changing structures for changing a rotating speed of each of drum shafts 16L, 16R as driving shafts.

Owner:IHI SHIBAURA MACHINERY CORP

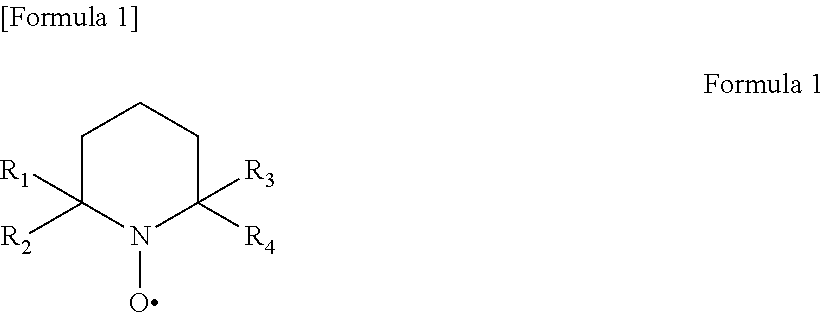

Method for producing cellulose nanofibers

ActiveUS20140053828A1Improve liquidityLow viscosityArtificial filaments from cellulose solutionsPulp properties modificationPolymer scienceNanofiber

Cellulose nanofibers are produced by means of a method comprising a step (A) of oxidizing a cellulosic starting material in the presence of an N-oxyl compound and a step (B) of forming the oxidized cellulosic starting material into nanofibers by defibrating the oxidized cellulosic starting material, and a step (C) of performing at least one selected from the following steps: a step (C-1) of treating the cellulosic starting material in water having a hydroxide ion concentration of 0.75 to 3.75 mol / L prior to performing the step (A); and a step (C-2) of subjecting the oxidized cellulosic starting material obtained from the step (A) to hydrolysis in an alkaline solution having a pH between 8 and 14 after performing the step (A) and prior to performing the step (B).

Owner:NIPPON PAPER IND CO LTD

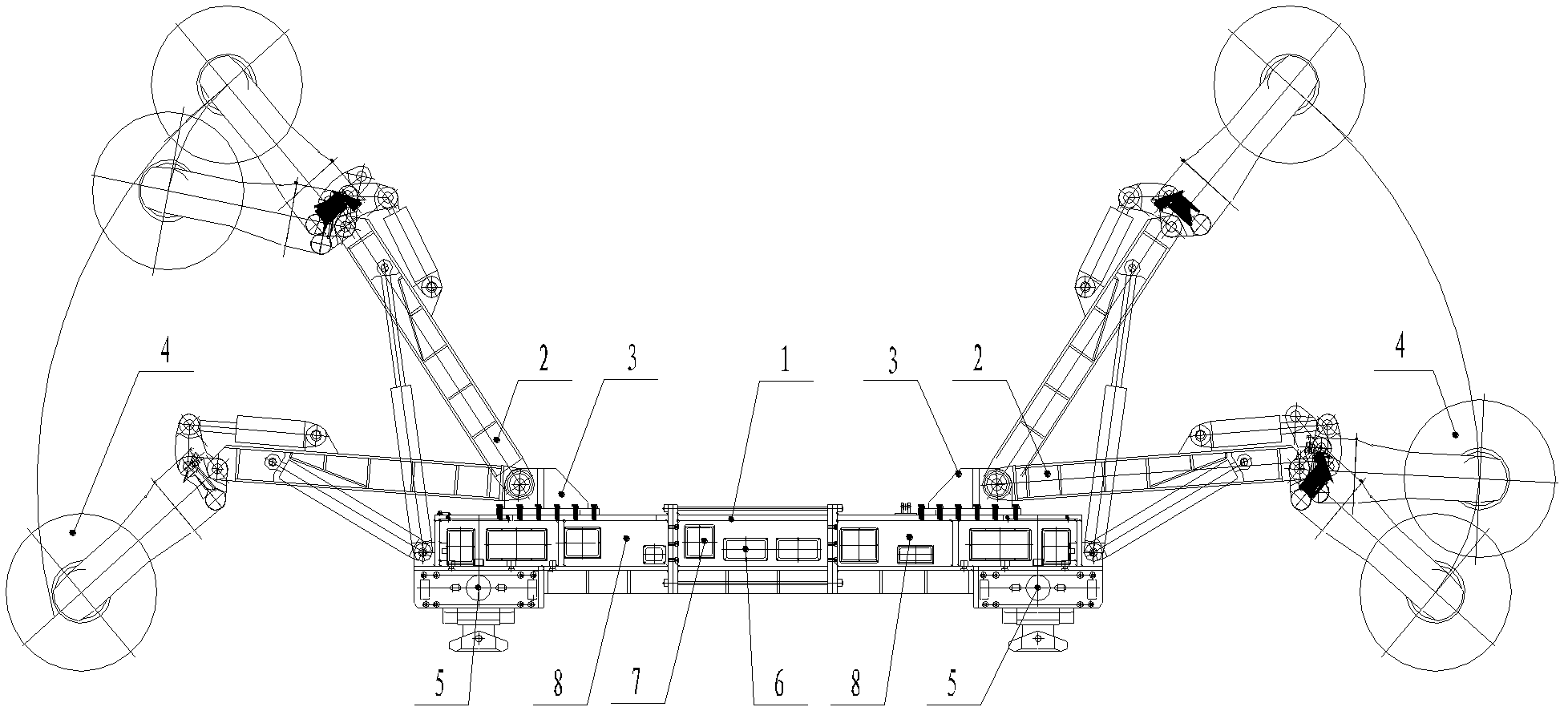

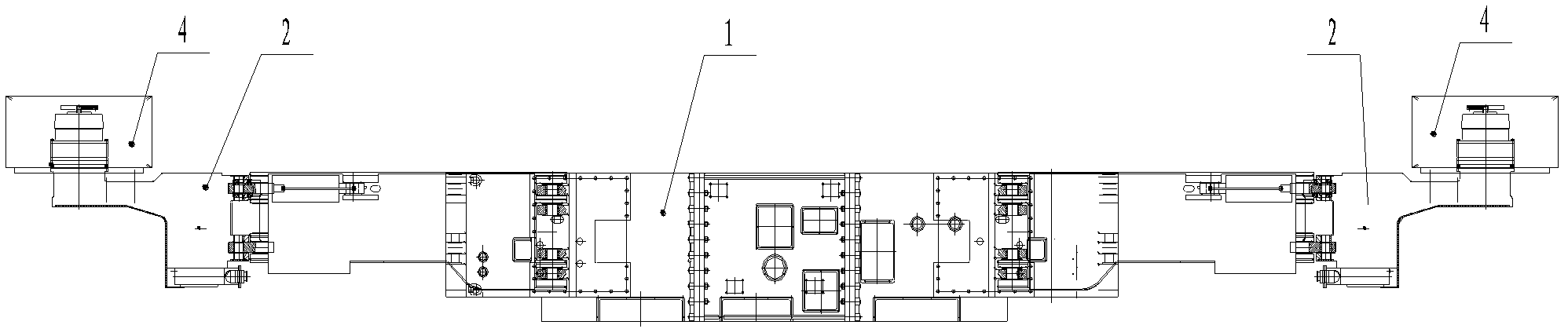

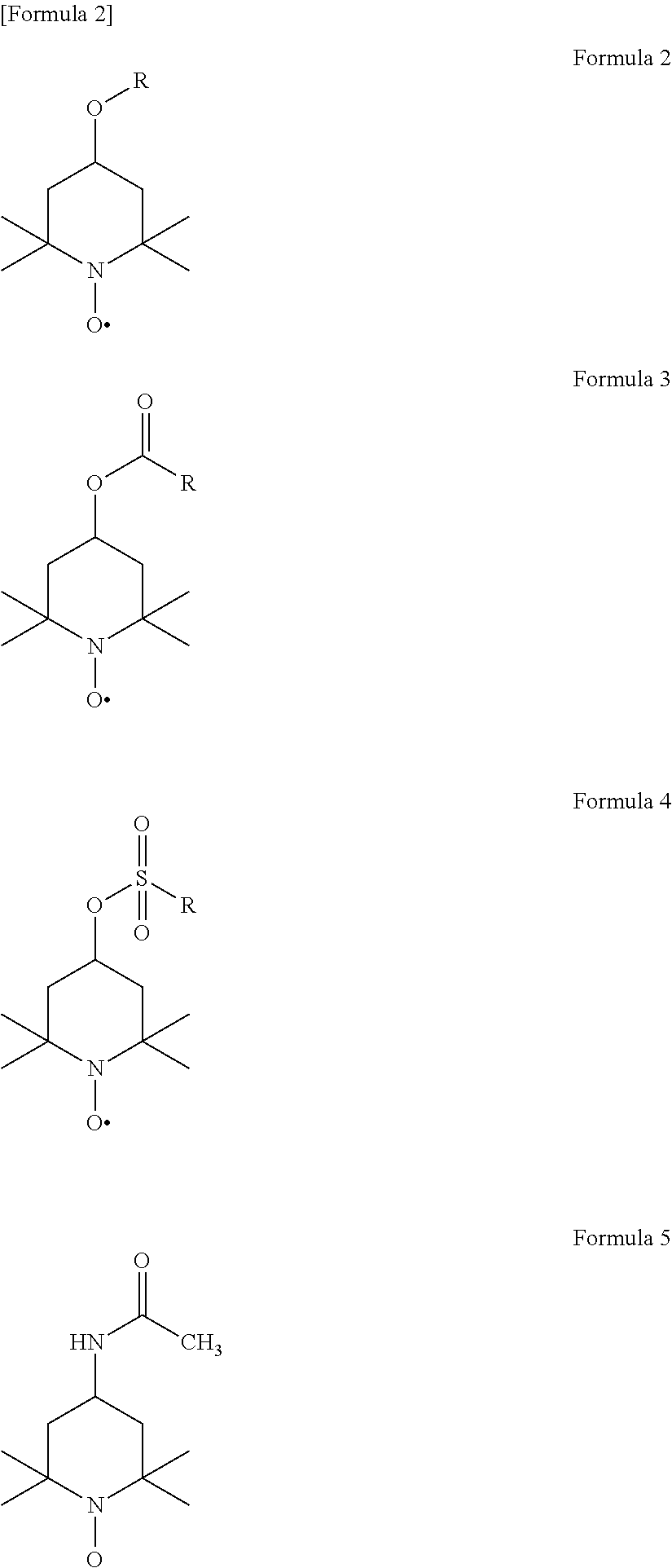

Robot dual-joint unit as well as foot robot applying robot dual-joint unit and cooperative mechanical arm

PendingCN109176595AReduce wiring difficultySmall output inertiaProgramme-controlled manipulatorJointsPower cableReduction drive

The invention relates to the technical field of robot joints, and discloses a highly integrated robot dual-joint unit. The highly integrated robot dual-joint unit comprises a first joint which is composed of a first motor and a speed reducer assembly, and a second joint which is composed of a second motor assembly and a second speed reducer, wherein a first output connecting rod is fixedly arranged on the first motor and an output shaft of the speed reducer assembly; the second speed reducer is arranged in a first output connecting rod; and the second motor assembly drives the second speed reducer through a transmission rod. According to the robot dual-joint unit disclosed by the invention, the fixed end of the second motor assembly, the first motor and the fixed end of the speed reducer assembly are fixed together, and the fixed end of a second motor of a conventional robot joint series structure is not fixedly arranged on the first motor and the output end of the speed reducer assembly, so that output inertia of two output shafts of the robot dual-joint unit is very small; and moreover, power cables which penetrate into the second motor assembly of the second joint are cancelled.

Owner:HZ UNITREE TECHNOLOGY CO LTD

Method and apparatus for oral flow therapy

ActiveUS20150128941A1Reduce amountReduce workOperating means/releasing devices for valvesBreathing masksWork of breathingExpired air

A therapy system configured to wash out or flush out the oral and / or nasal cavity to reduce the effective dead space and reduce the work of breathing. The system may displace the expired air in the oral and / or nasal cavity with atmospheric air, or air with altered concentrations, for example, increased humidity, or oxygen levels. A sealed oral interface is provided to the mouth of a patient to supply a volume of pressurized gas. A control system to synchronize the supply of pressurized gas with the patients respiratory cycle. The supply of respiratory gas may be provided during only a portion of the respiratory cycle.

Owner:RESMED LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com