Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As a preface to the detailed description, it should be noted that, as used in this specification and the appended claims, the singular forms "a", "an", and "the" include plural referents, unless the context clearly dictates otherwise.

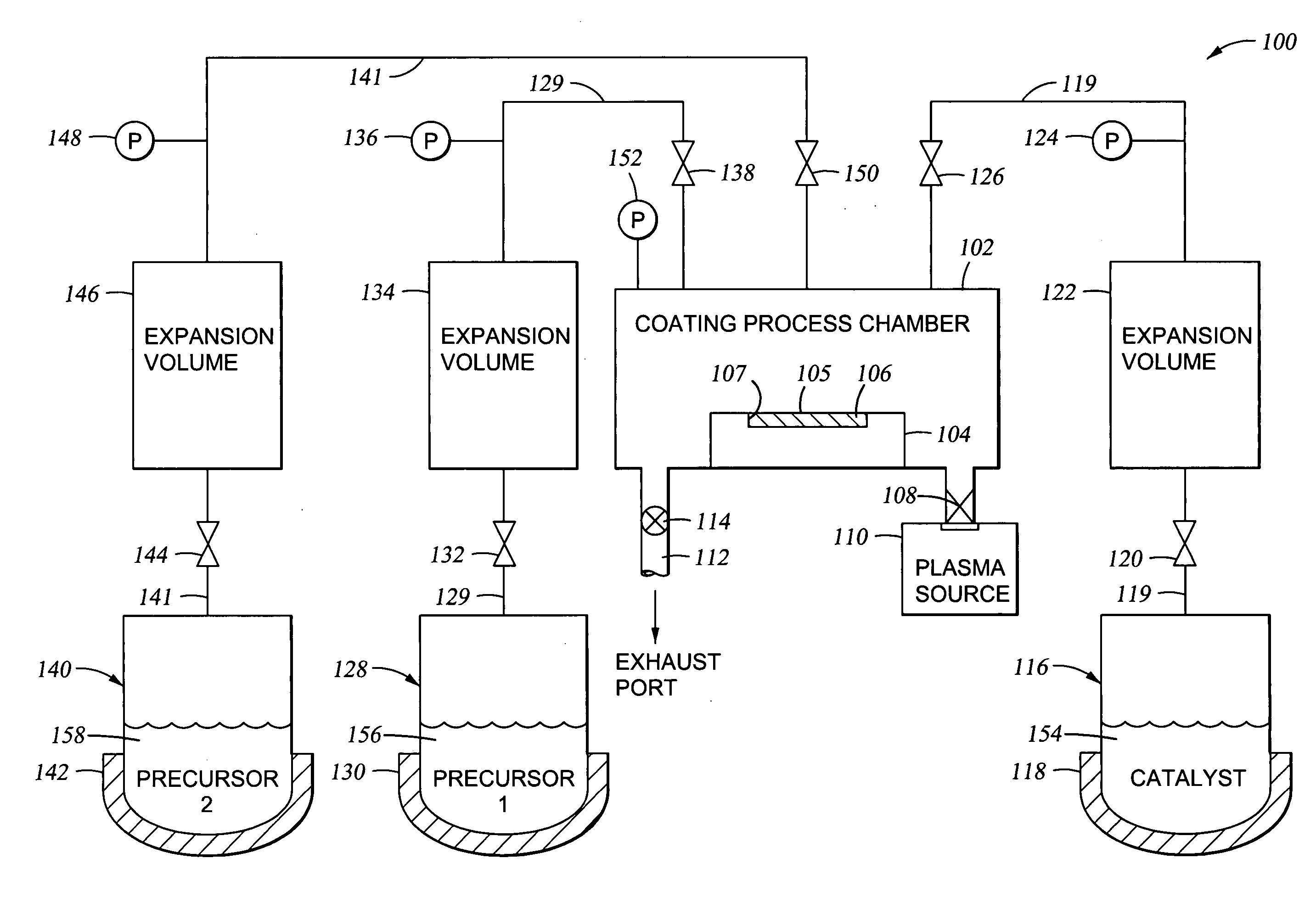

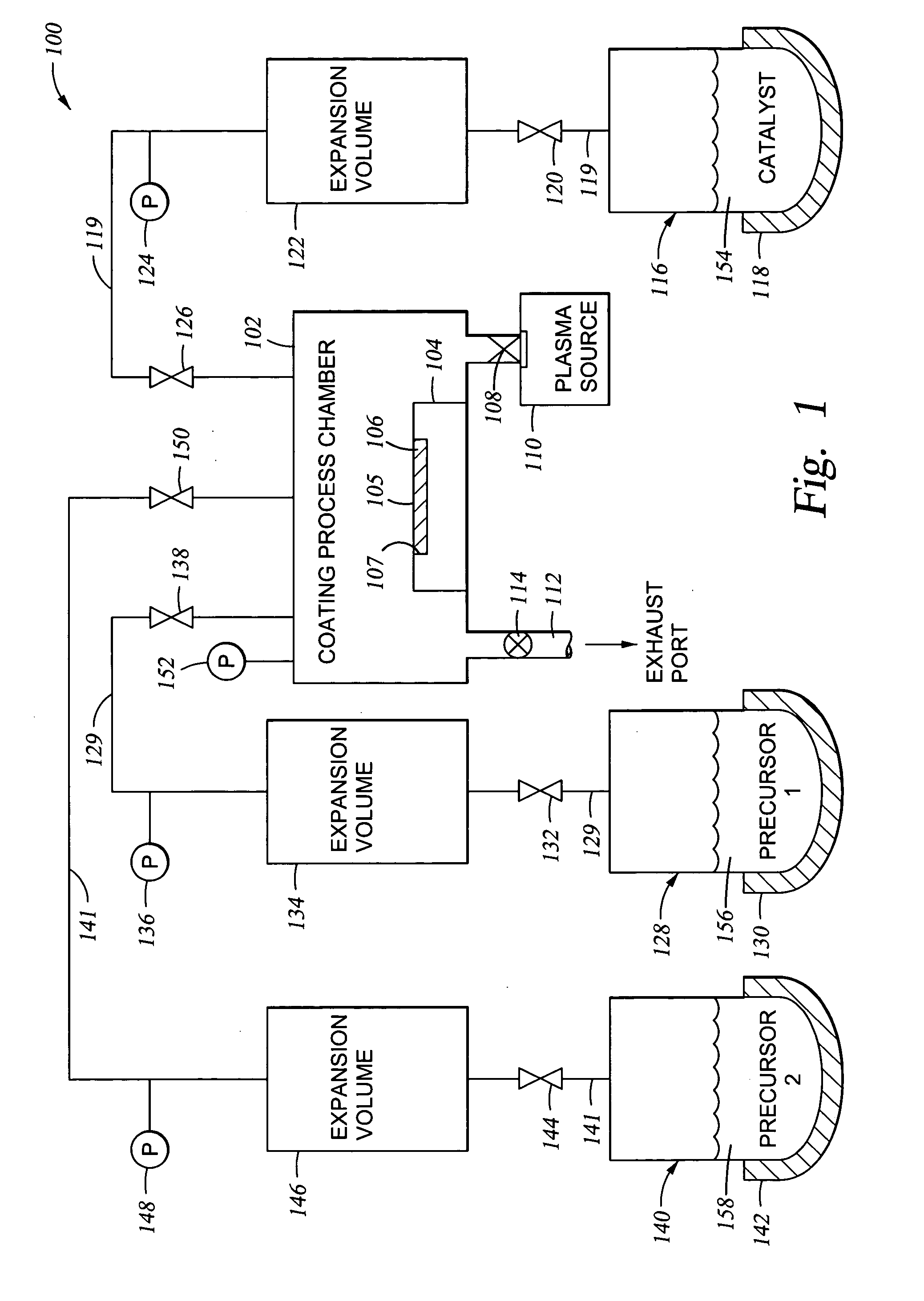

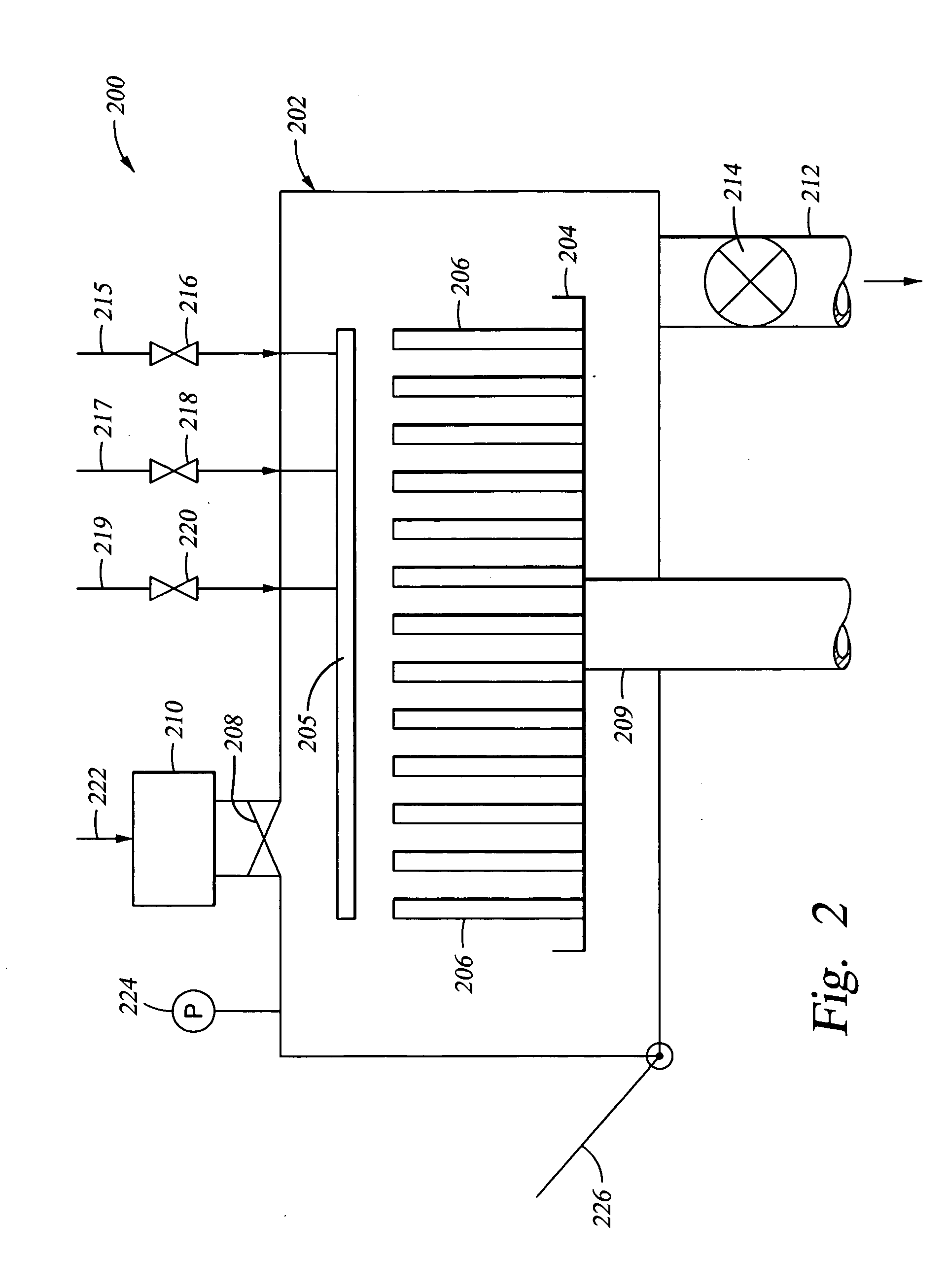

[0026] We have developed an improved vapor-phase deposition method and apparatus for application of a thin (typically 5 .ANG. to 1,000 .ANG. thick, in and in some instances up to about 2, 000 .ANG. thick) film or coating to a semiconductor device substrate or a micro-electromechanical systems device. The method and apparatus are employed when at least one of the reactants or a catalyst used in coating formation must be vaporized prior to use, and where the amount of each reactant must be carefully controlled in terms of quantity available to react, in terms of time available for reaction at a given process pressure, or a combination of both. The method is particularly useful in the deposition of thin films or coatings where the thickness of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Vapor pressure | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com