Patents

Literature

383 results about "Electrostatic actuator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

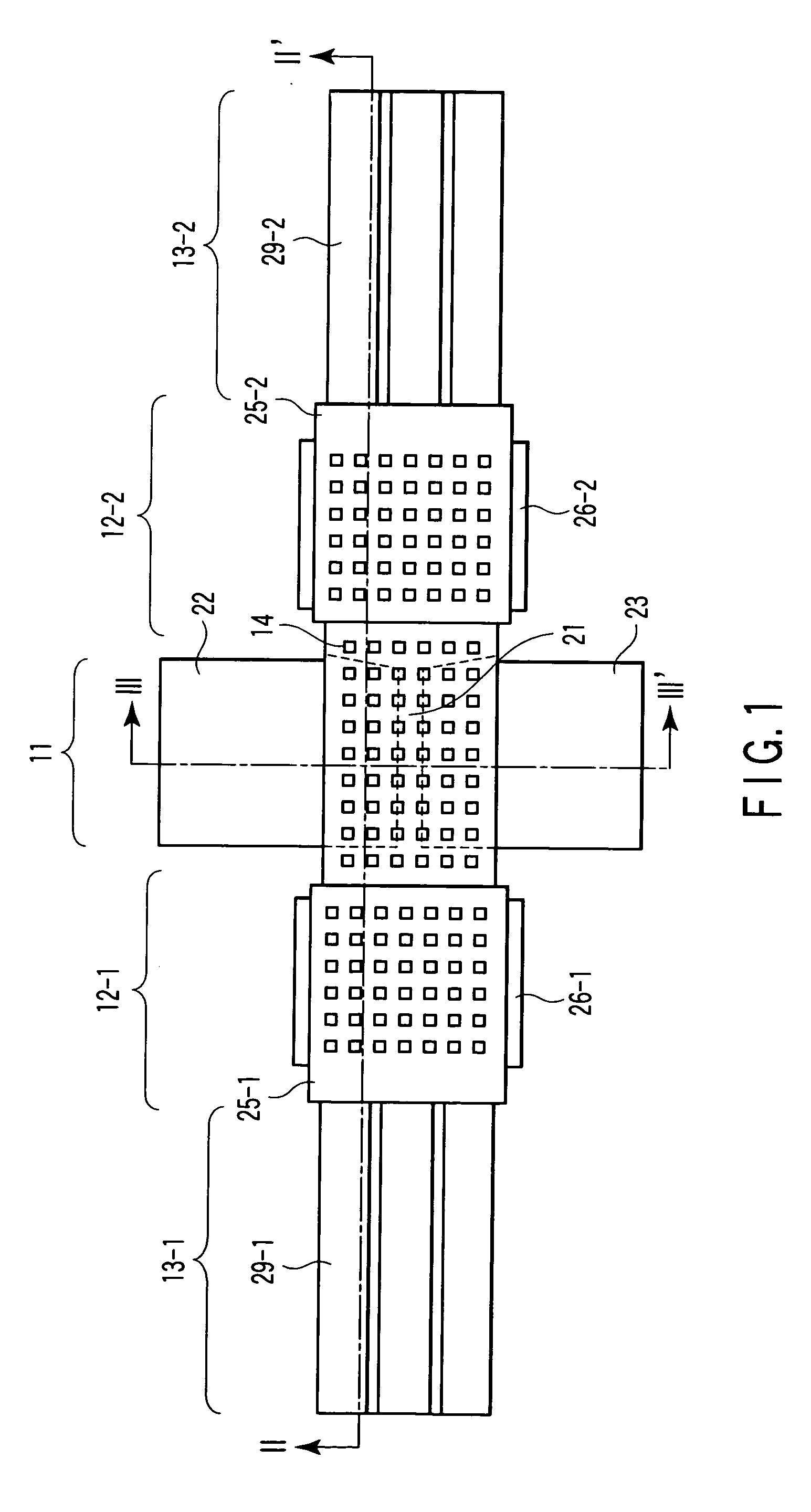

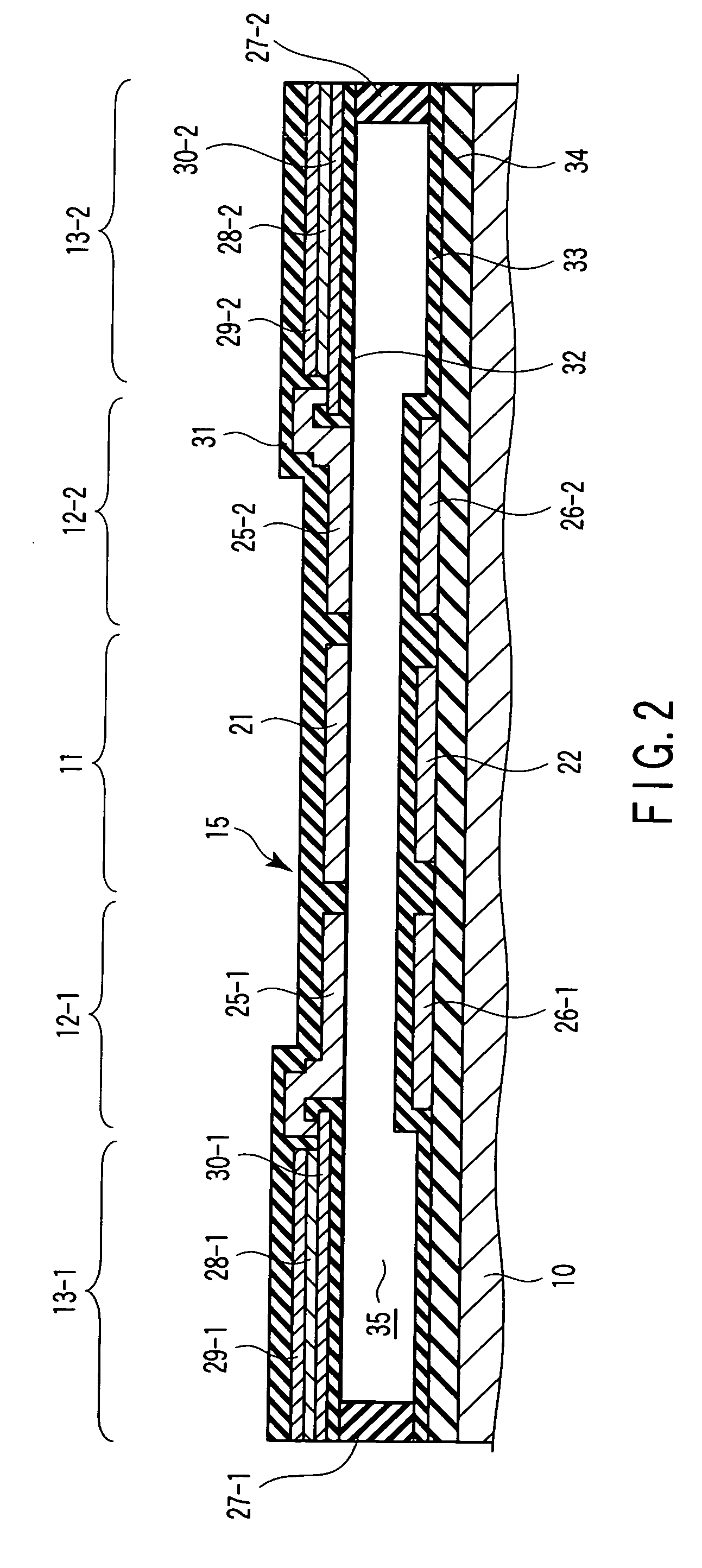

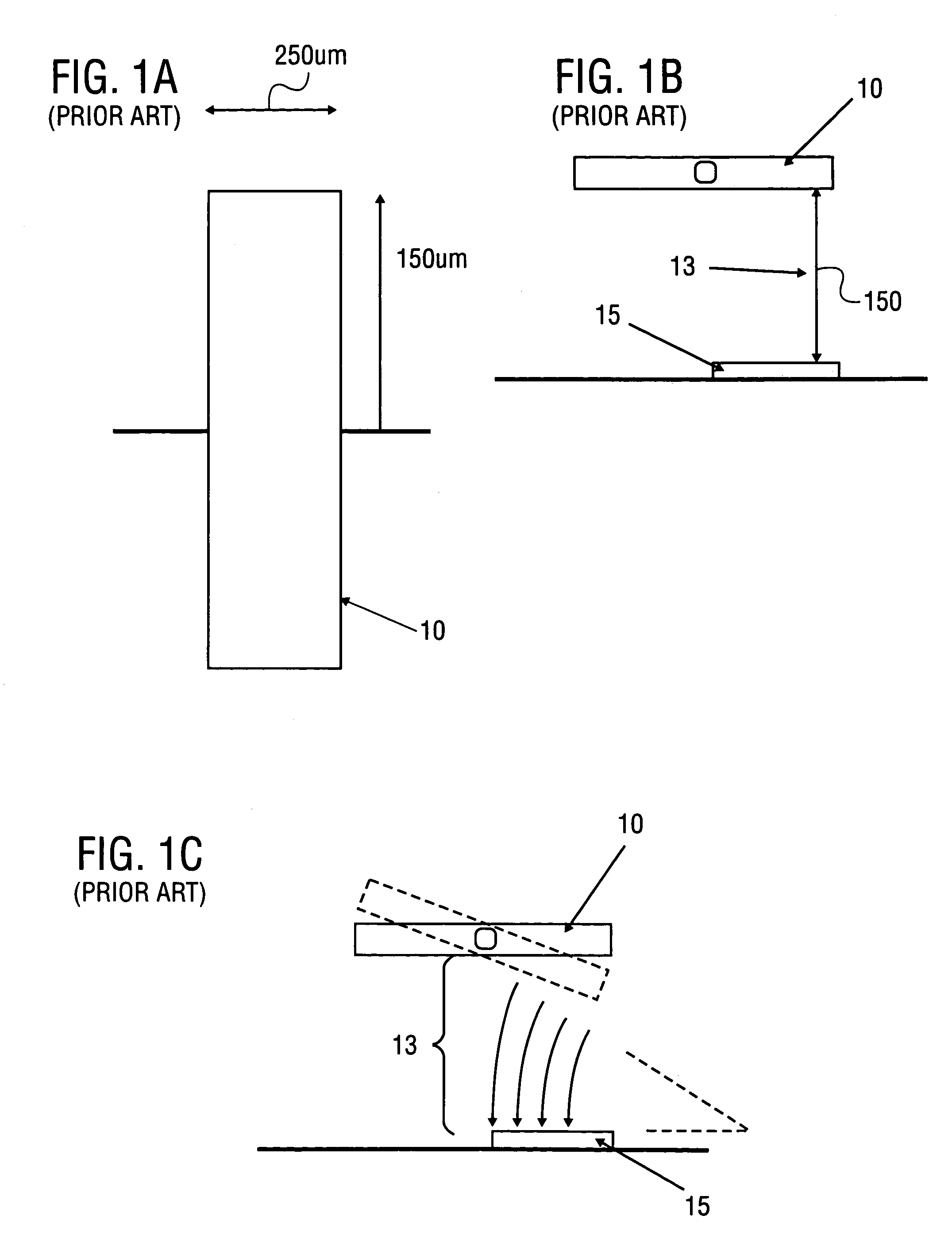

Differentially-driven MEMS spatial light modulator

InactiveUS20040008396A1Non-linear opticsOptical elementsSpatial light modulatorElectrostatic actuator

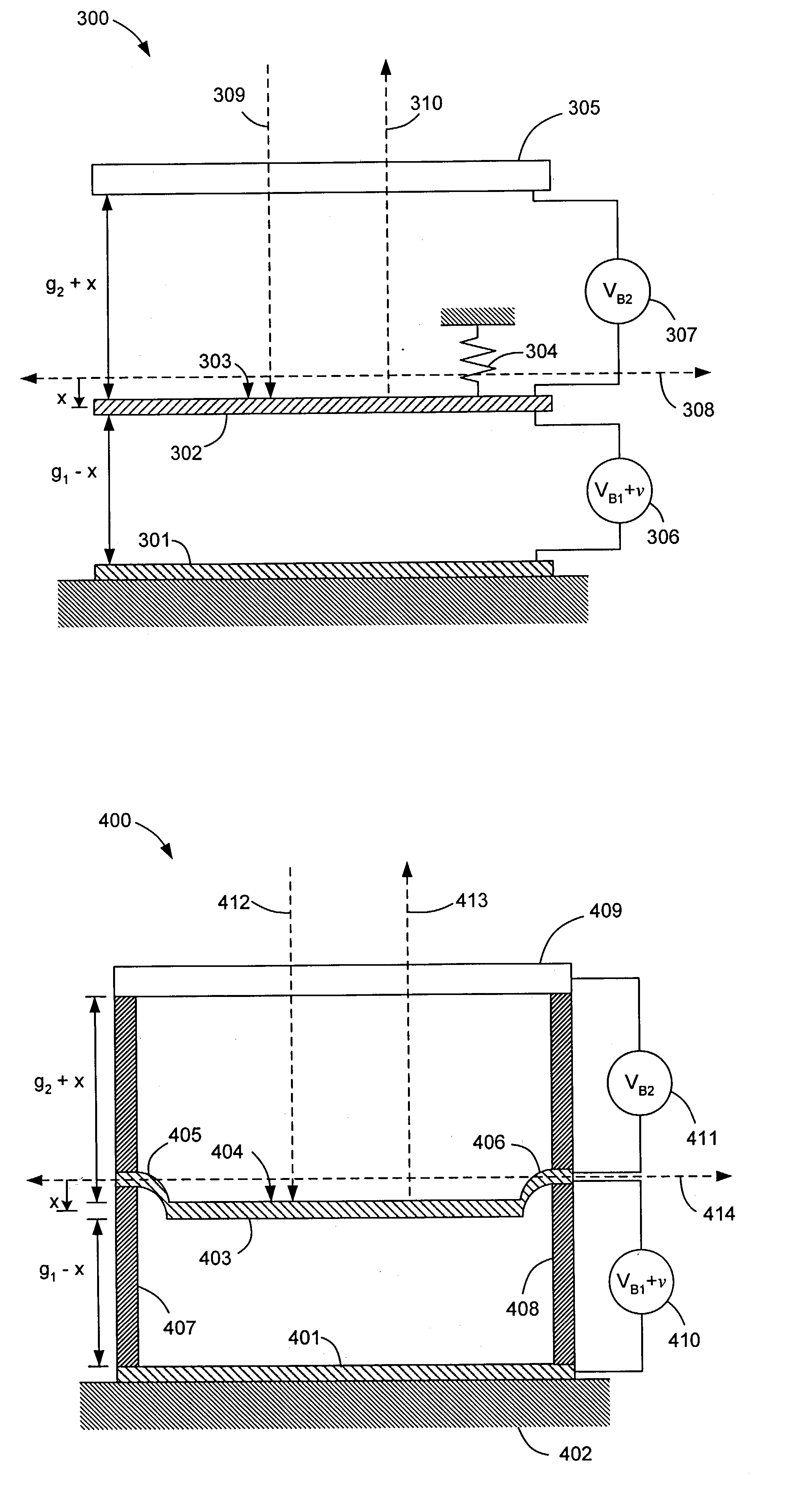

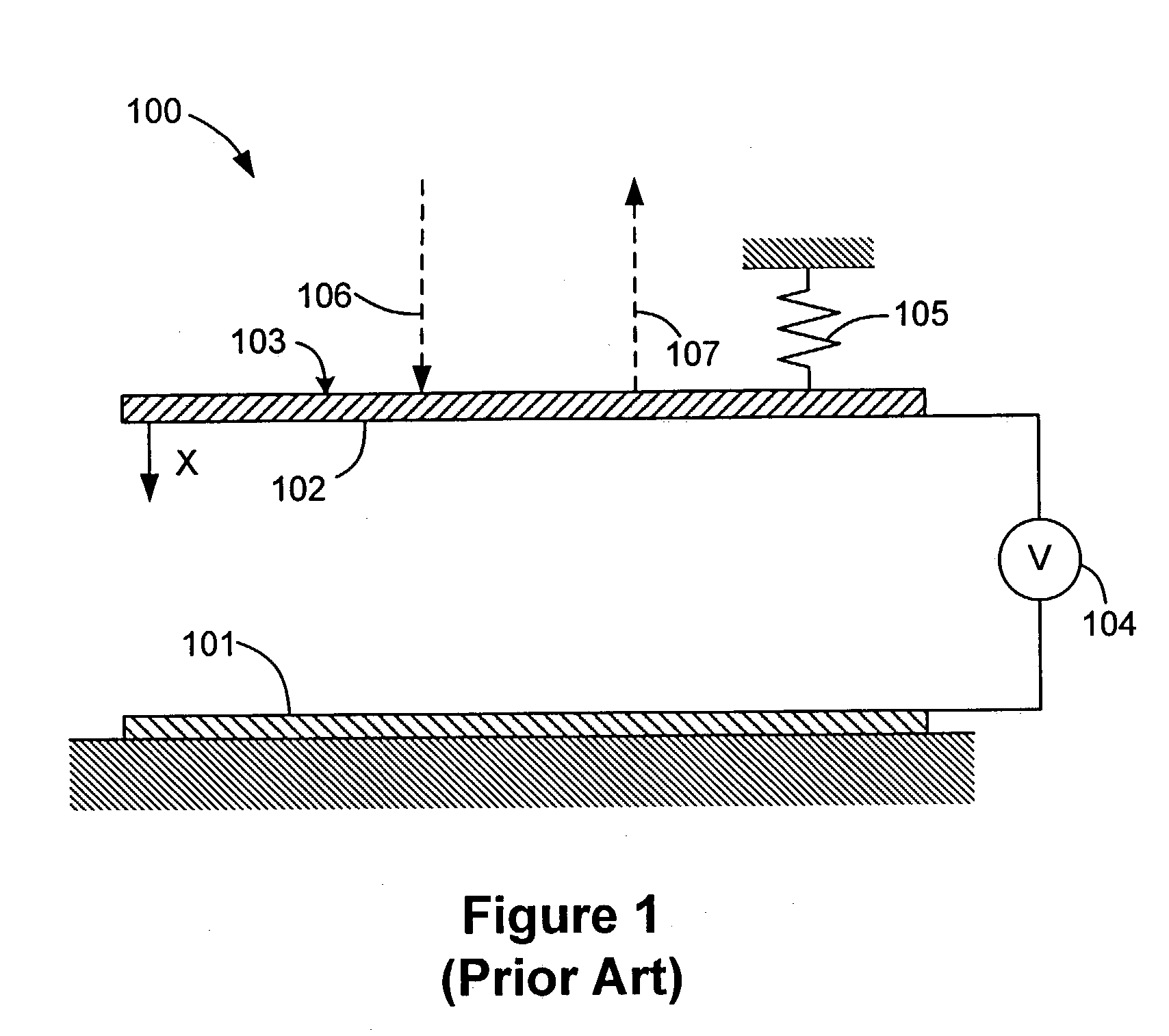

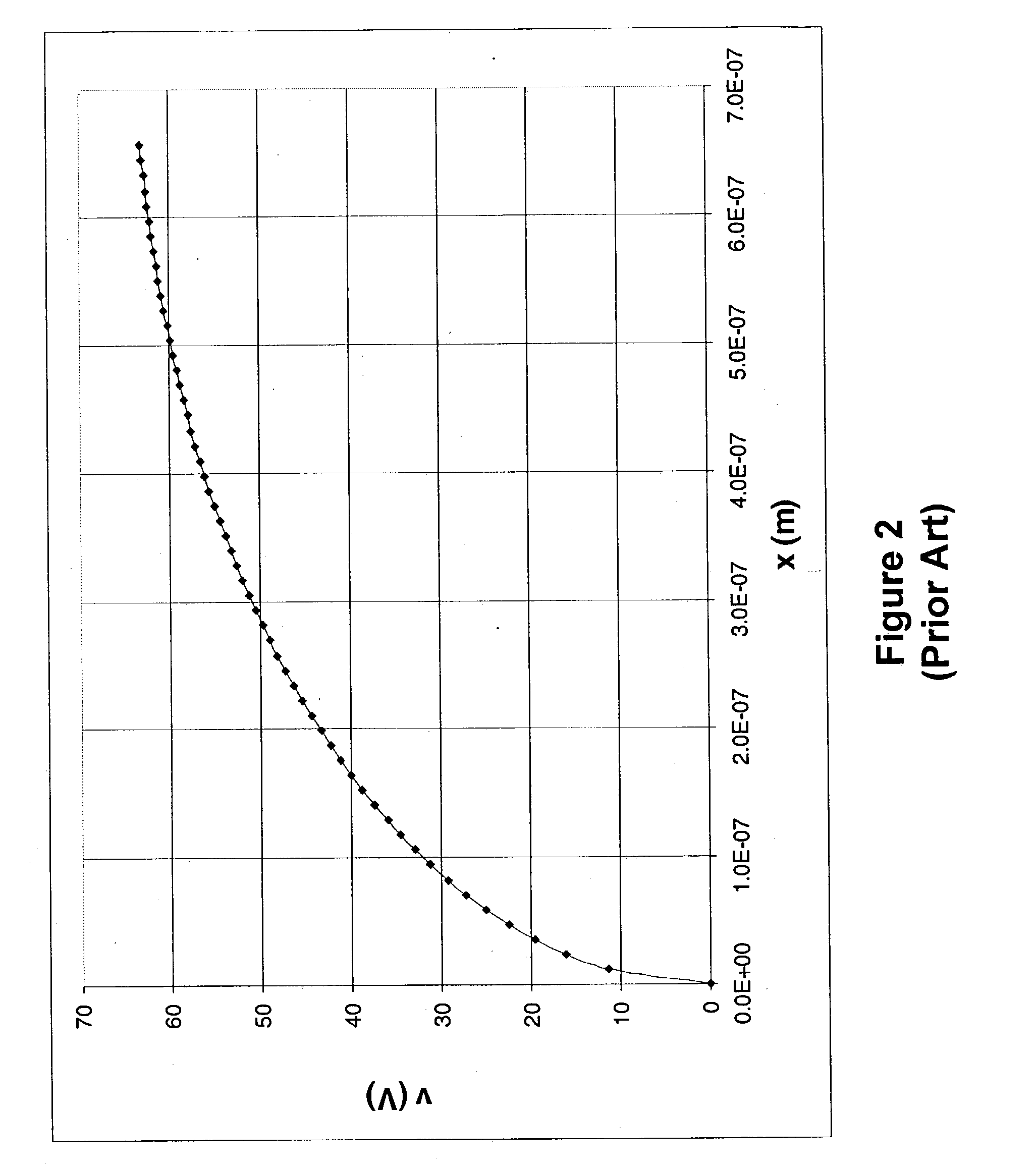

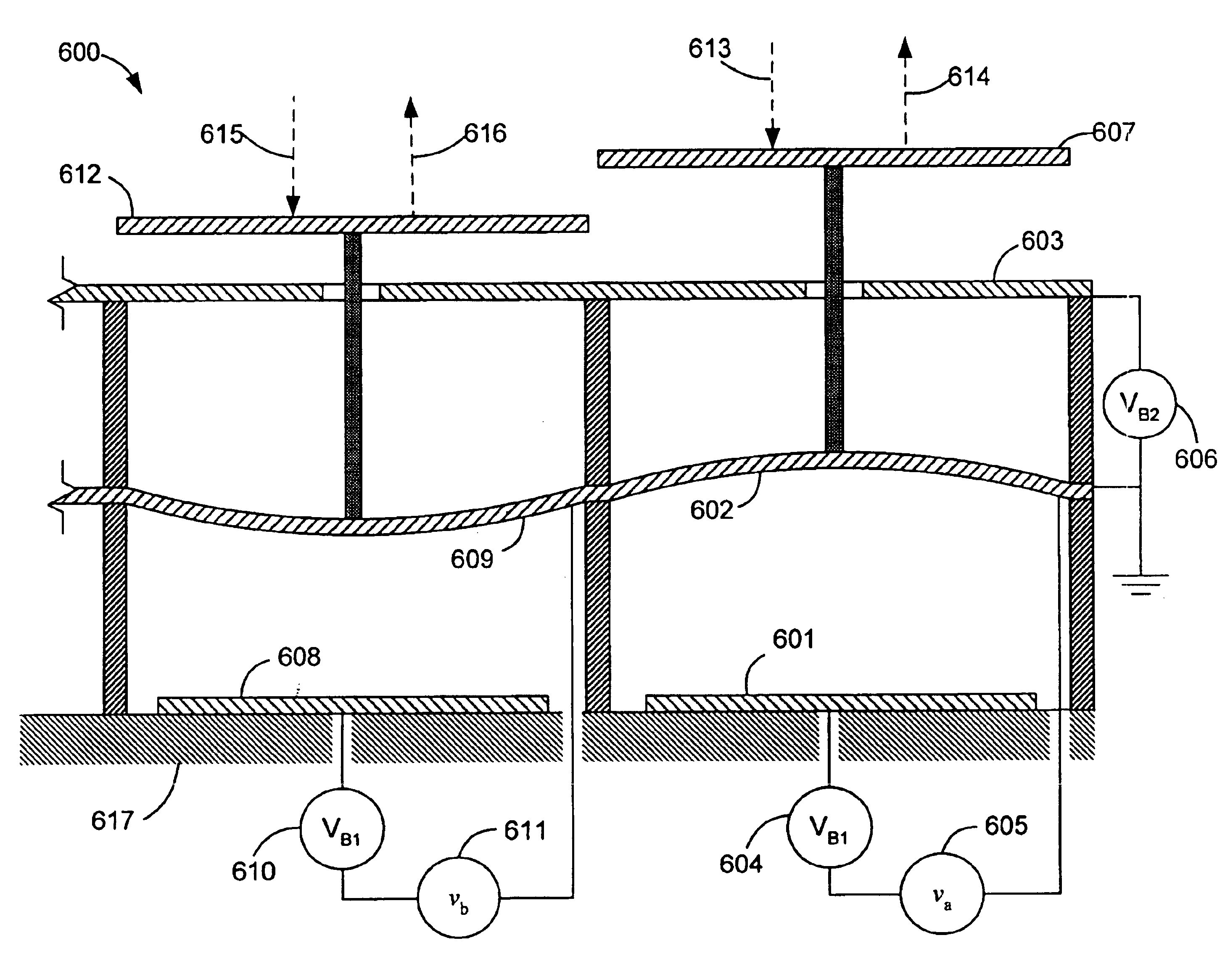

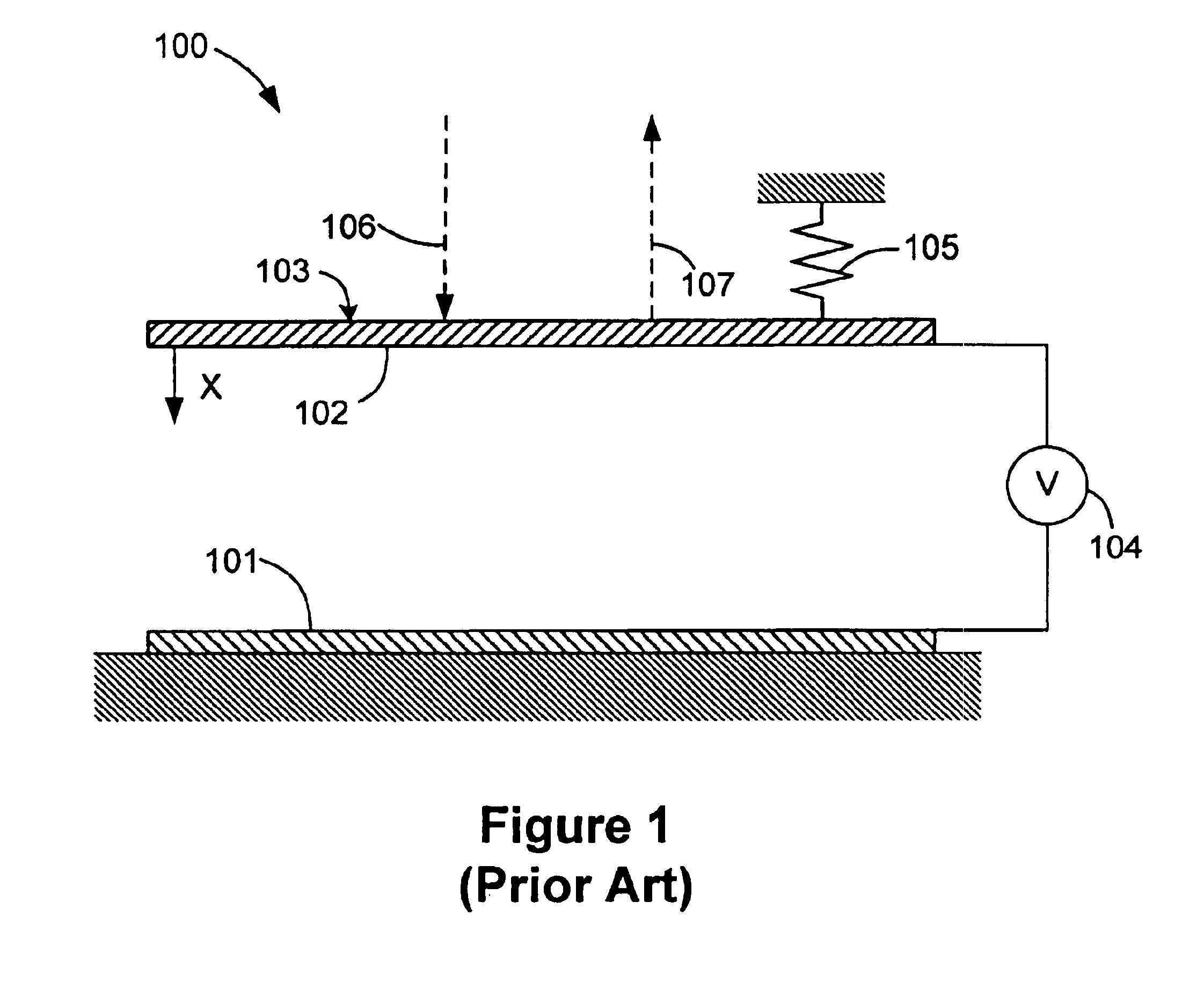

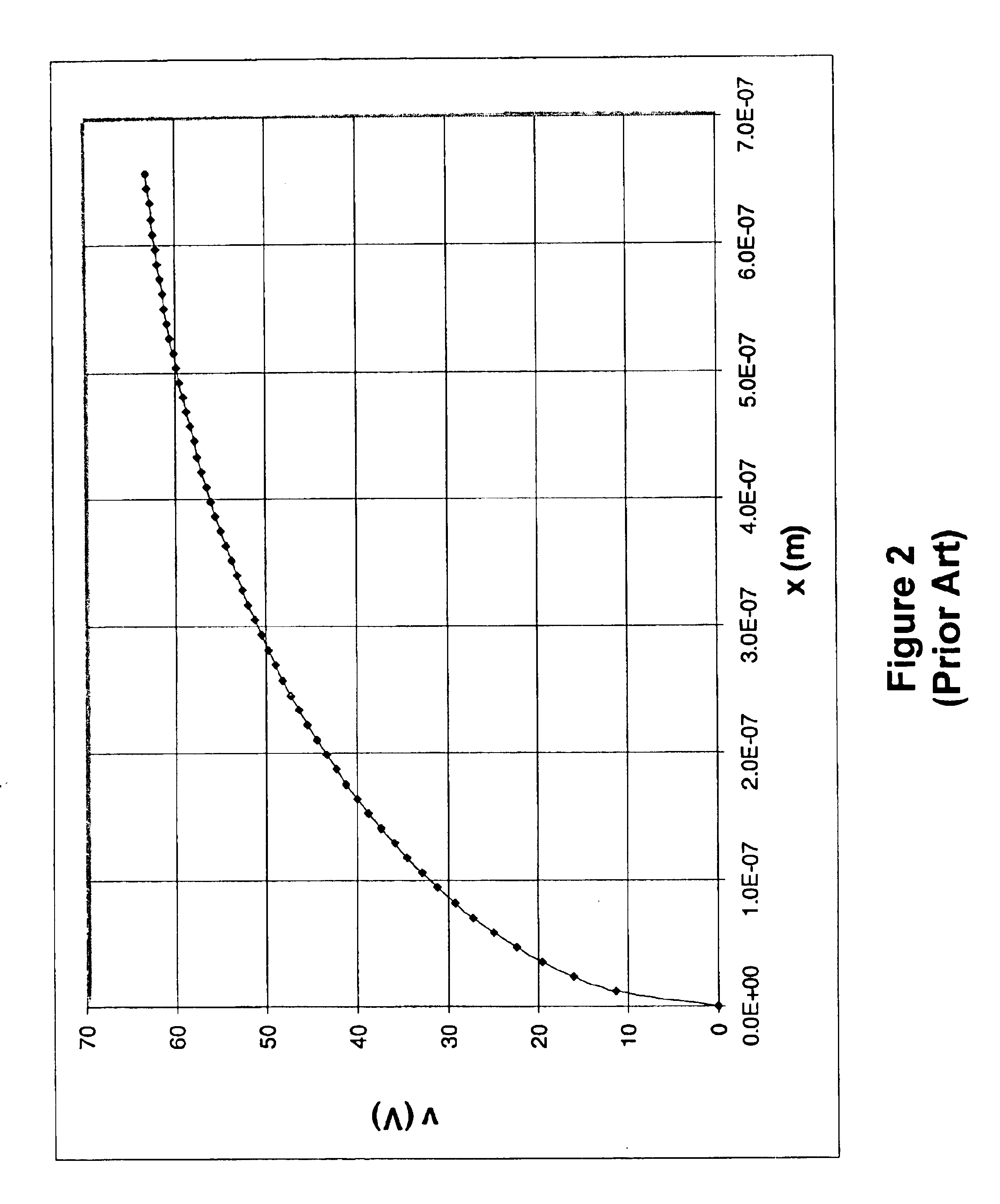

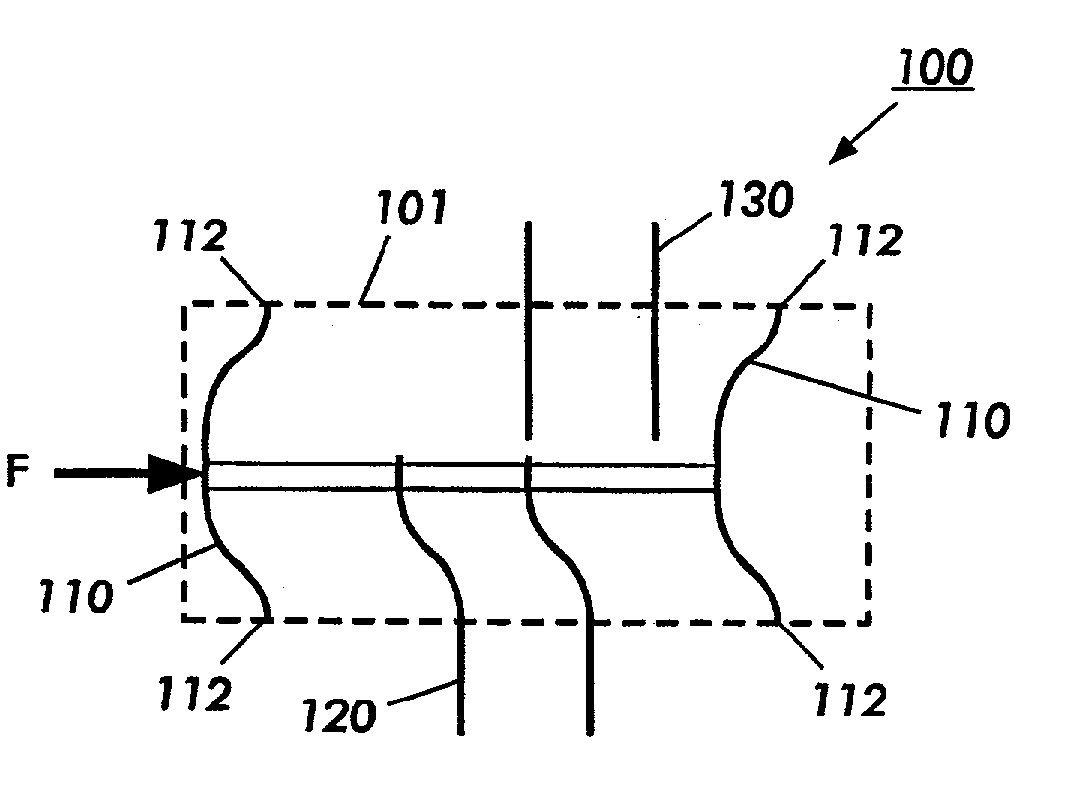

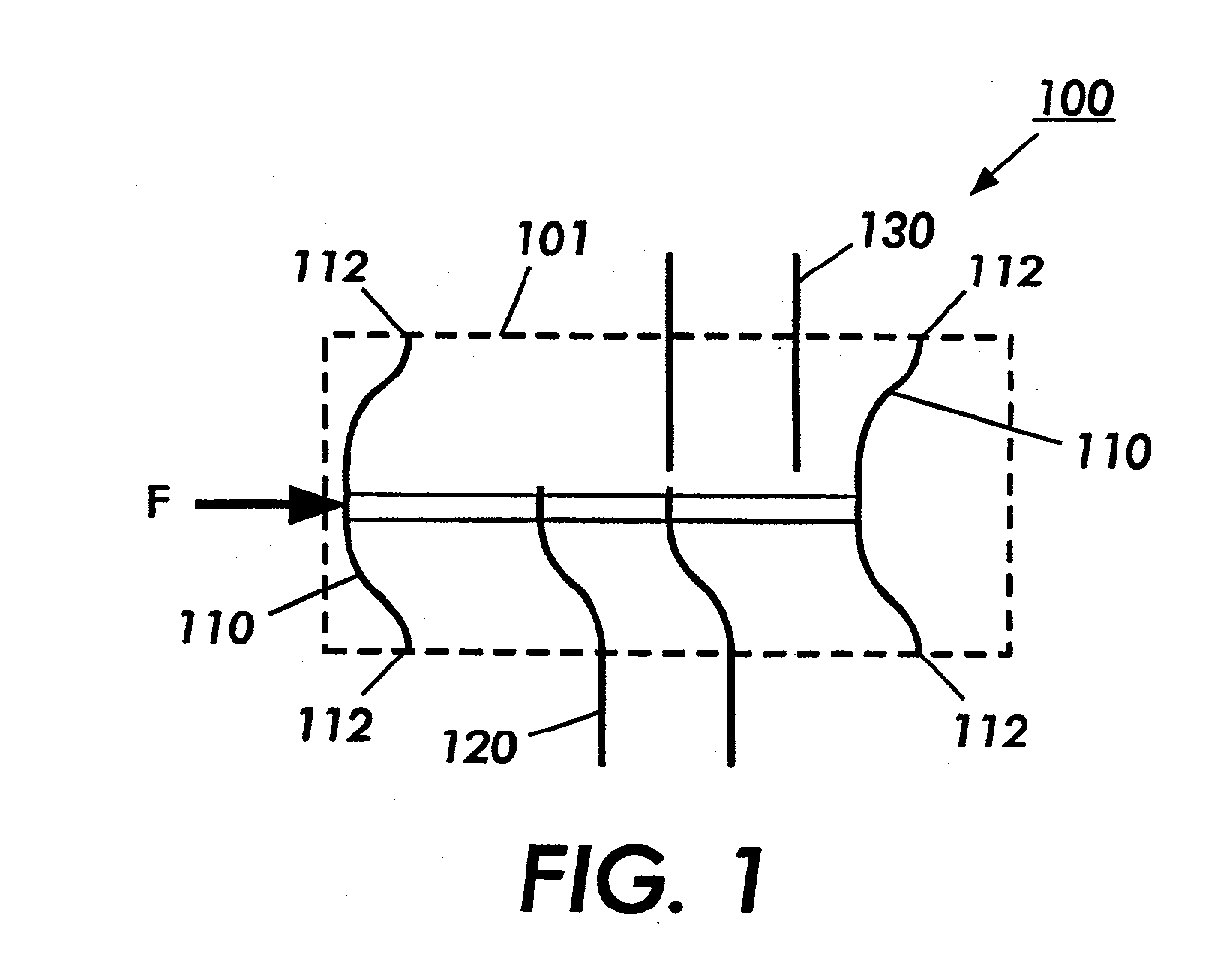

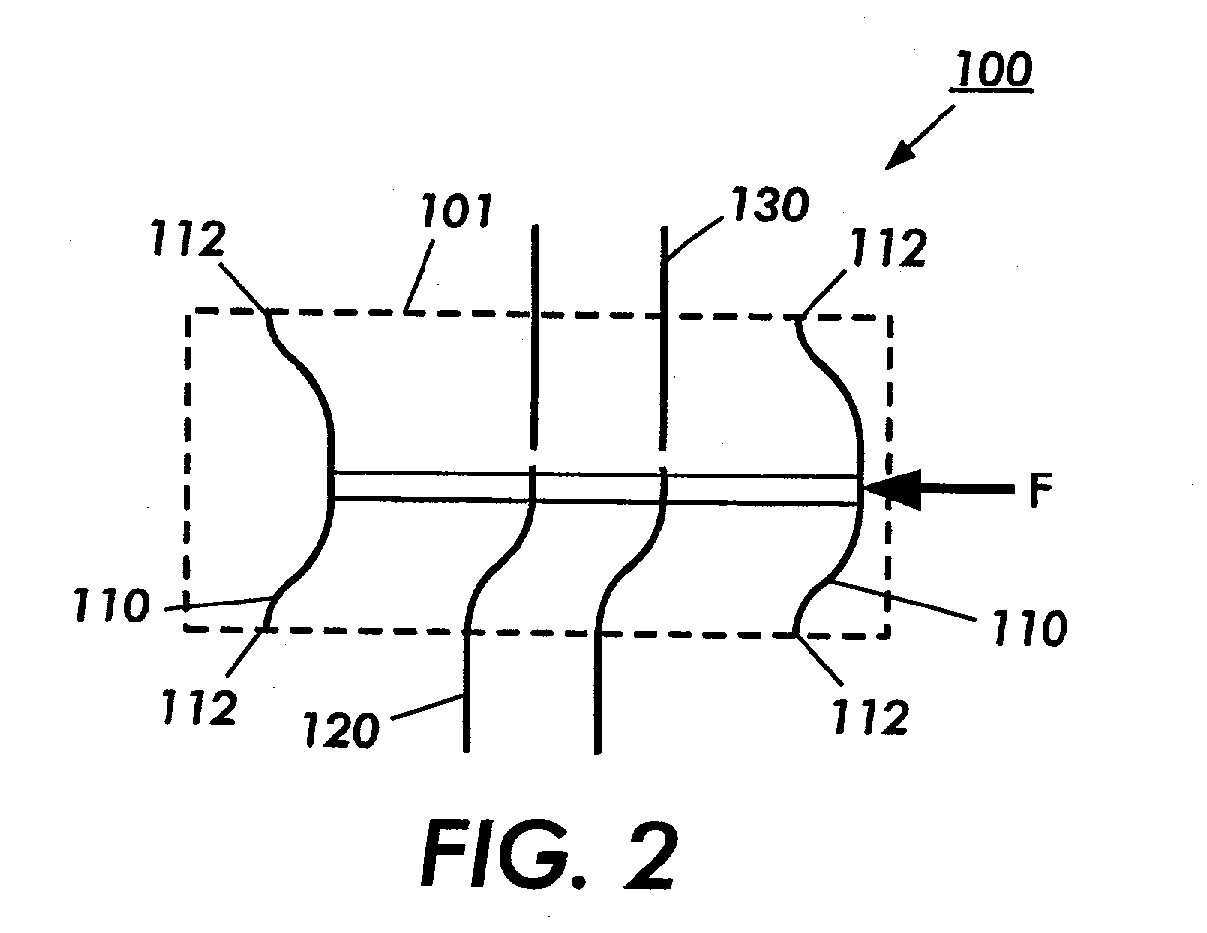

A MEMS SLM and an electrostatic actuator associated with a pixel in an SLM. The actuator has three electrodes: a lower electrode; an upper electrode fixed with respect to the lower electrode; and a center electrode suspended and actuable between the upper and lower electrodes. The center electrode is capable of resiliently-biasing to restore the center electrode to a non-actuated first equilibrium position, and a mirror is operably connected to the center electrode. A first voltage source provides a first bias voltage across the lower and center electrodes and a second voltage source provides a second bias voltage across the upper and center electrodes, with the first and second bias voltages determining the non-actuated first equilibrium position of the center electrode. A third voltage source provides a variable driver voltage across one of the lower / center and upper / center electrode pairs in series with the corresponding first or second bias voltage, to actuate the center electrode to a dynamic second equilibrium position.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

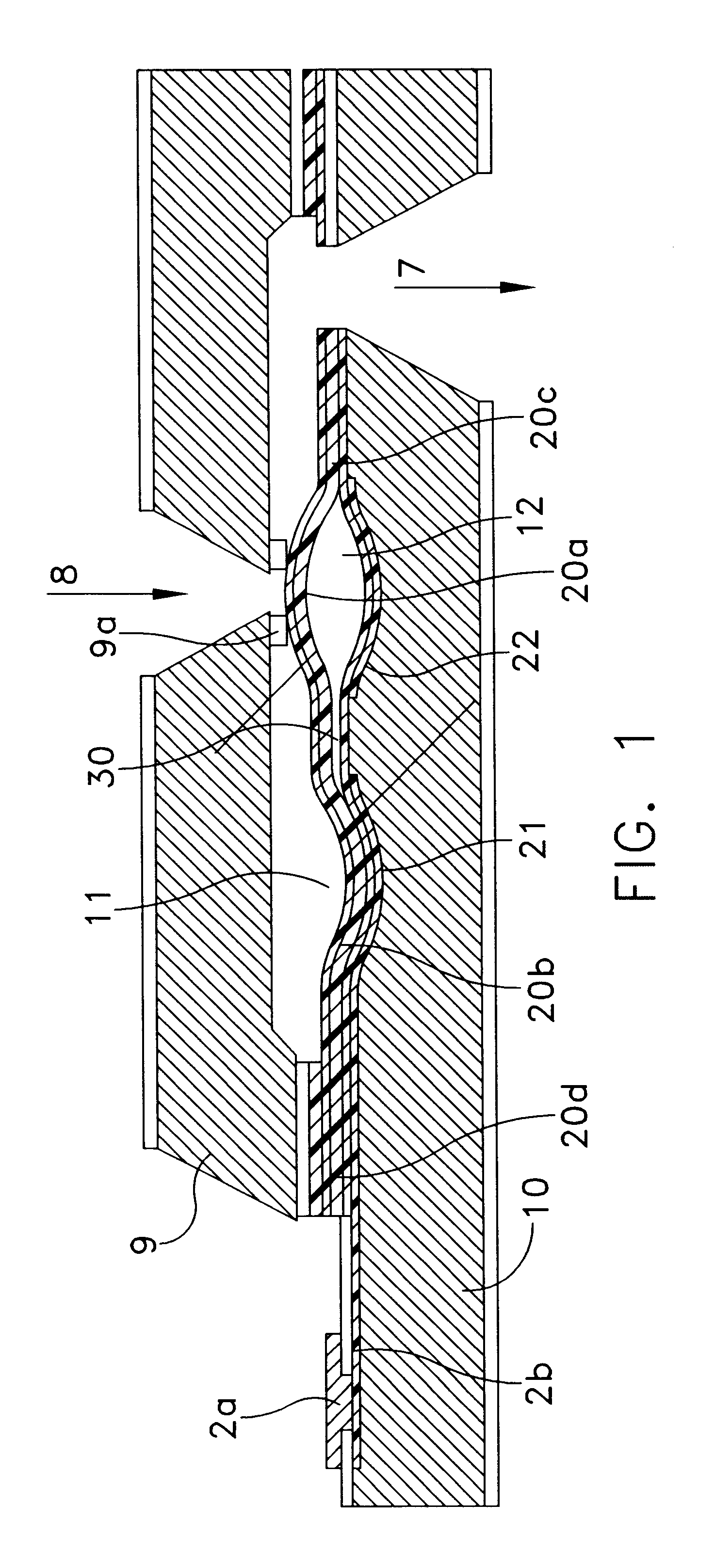

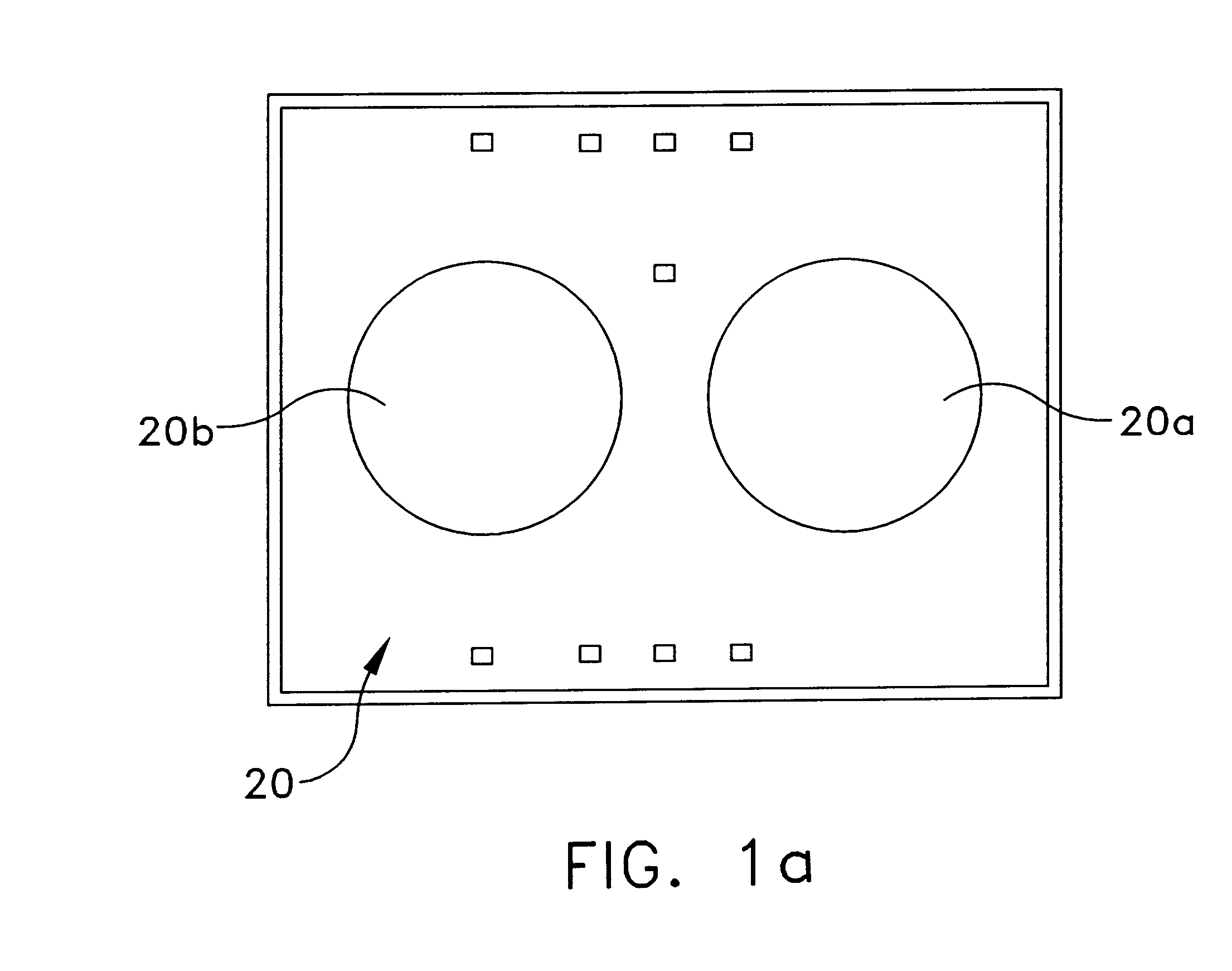

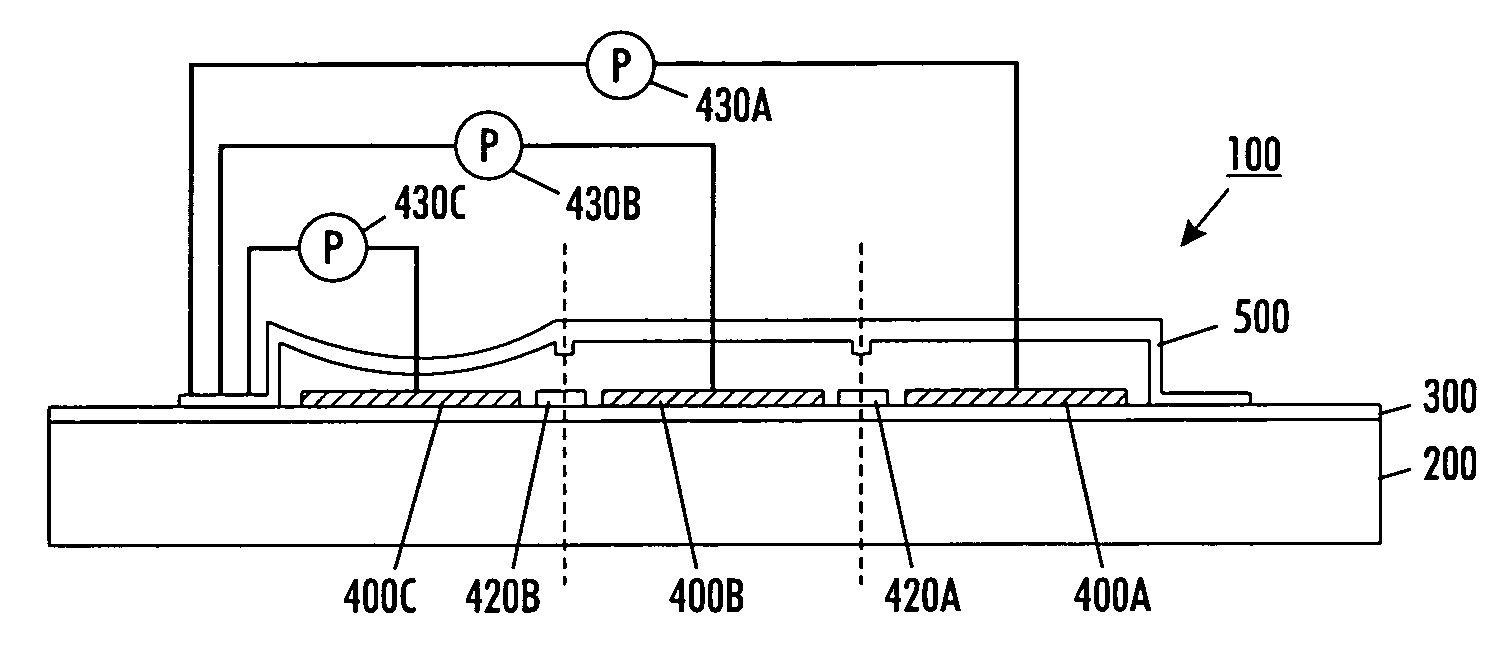

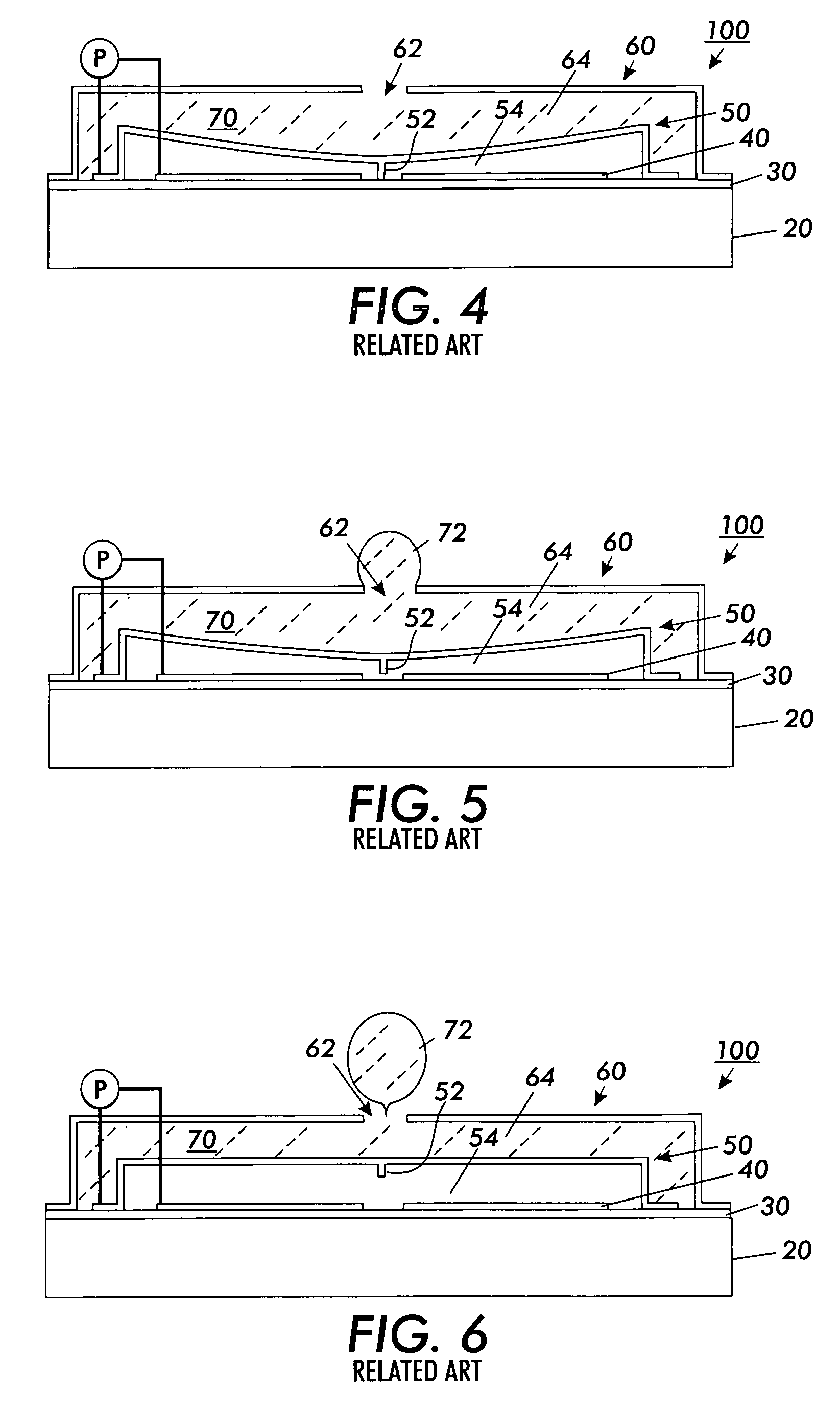

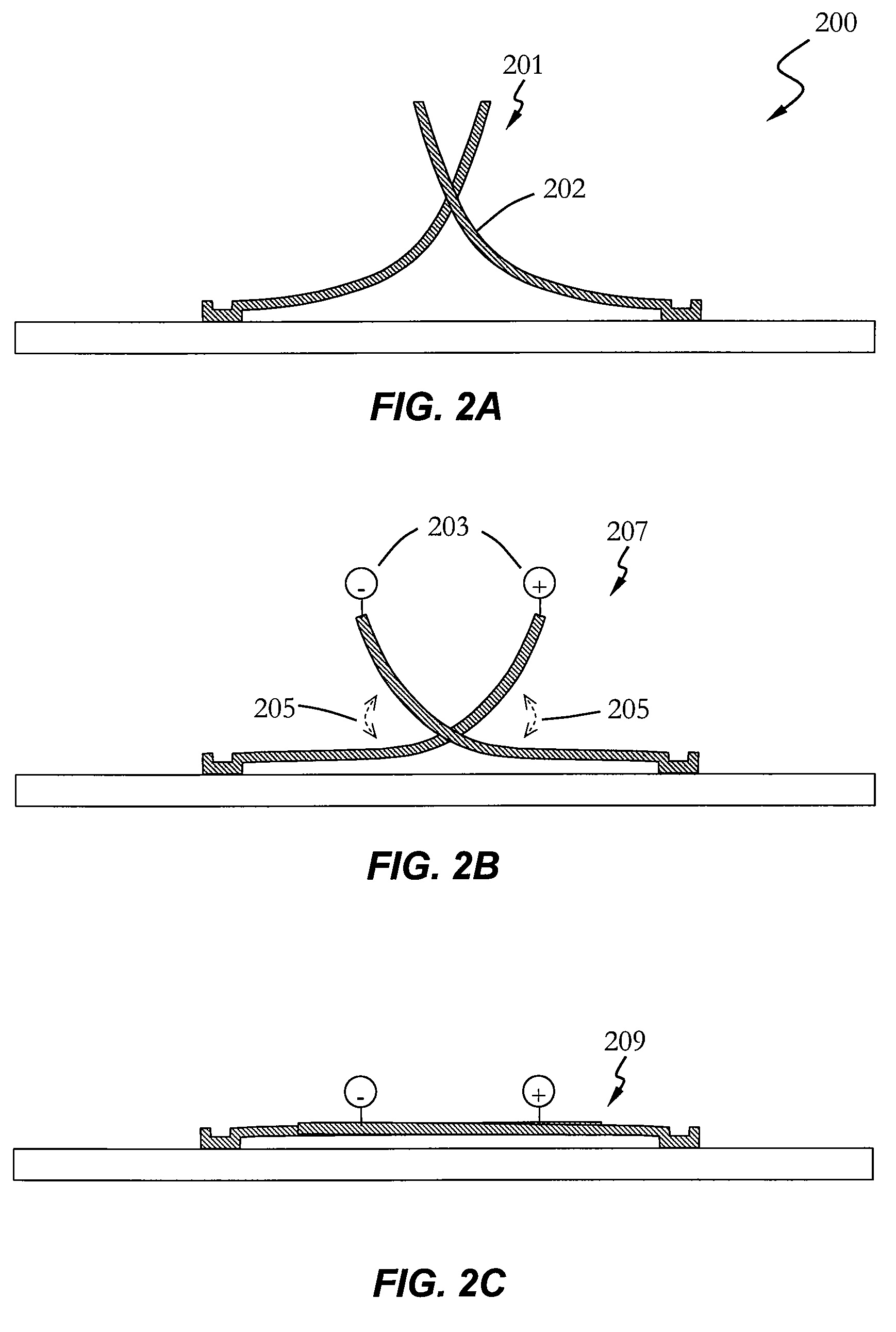

Bistable microactuator with coupled membranes

InactiveUS6168395B1Improves pneumaticImproves liquid couplingCircuit elementsDecorative surface effectsMetallic electrodeCoupling

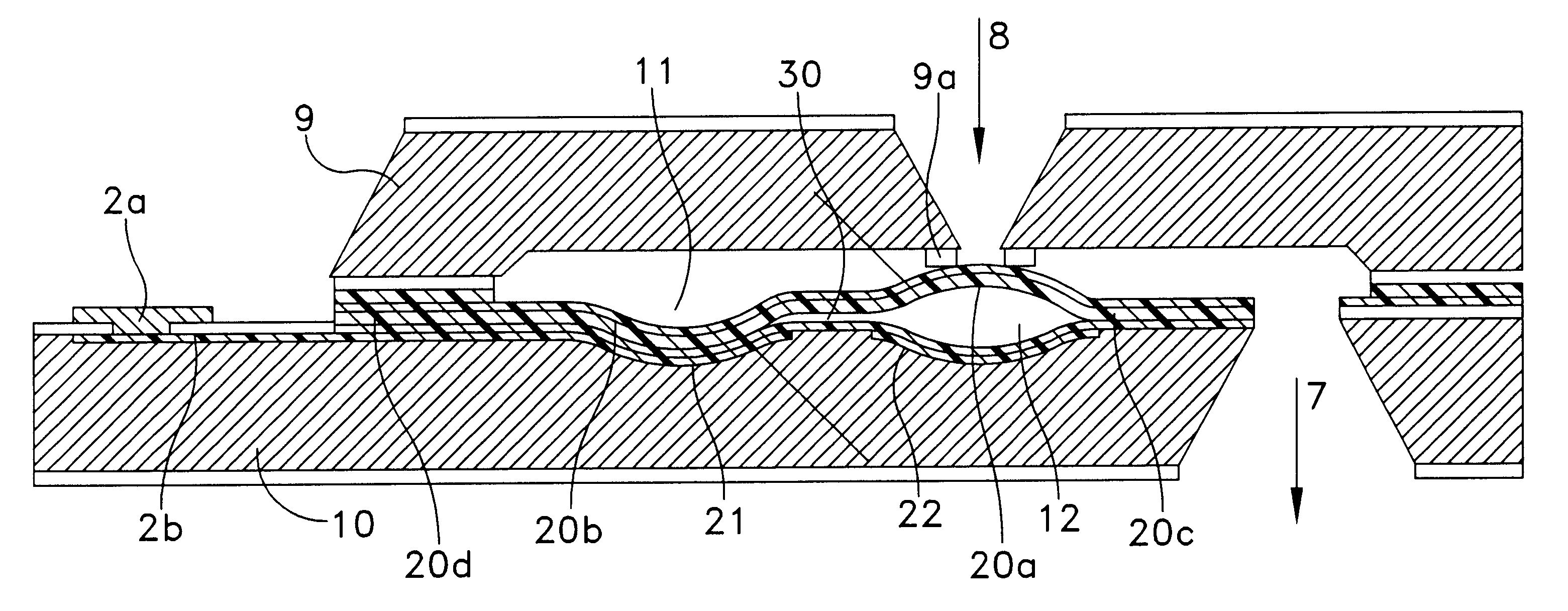

A bistable electrostatic actuator with pneumatic or liquid coupling. The actuator has enclosed metallic electrodes. It can be used for a microvalve or micropump. The actuator has buckled membrane sections in pairs and curved substrate electrodes, locally associated with said membrane sections.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

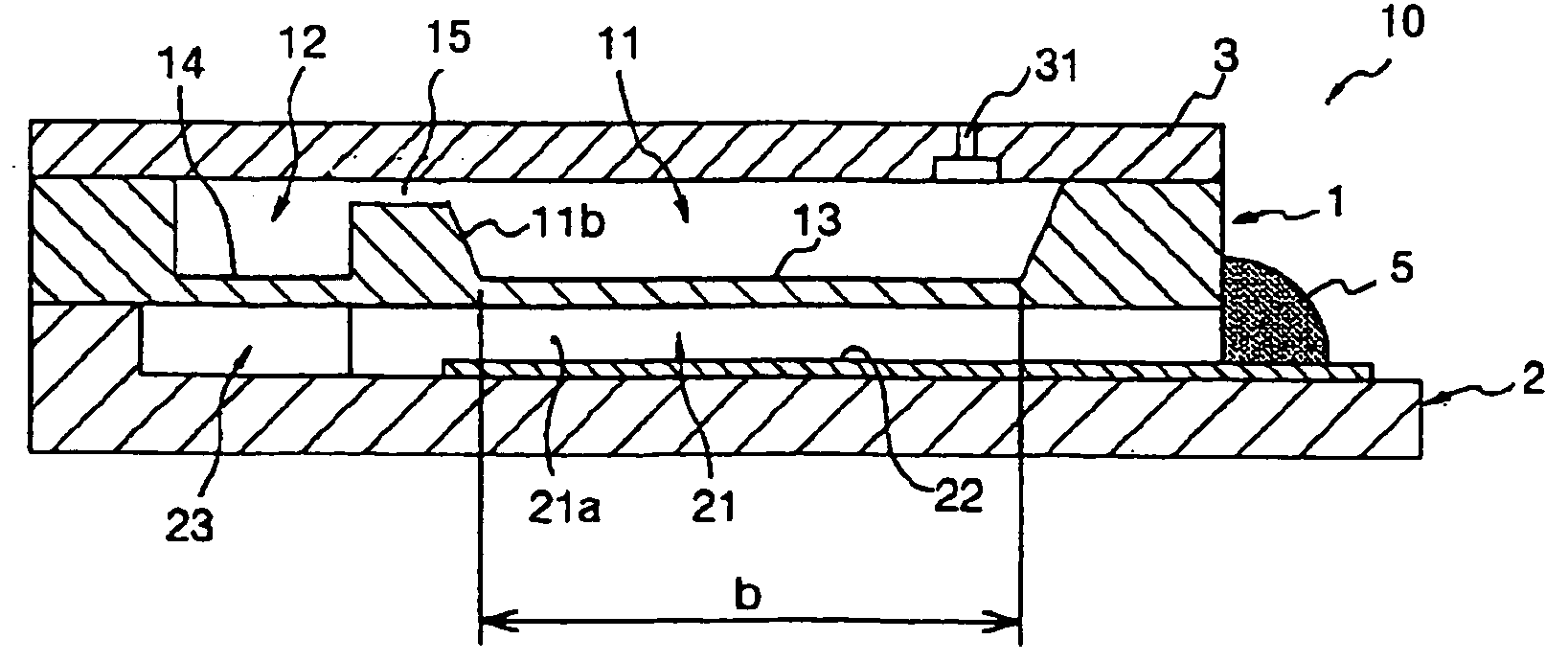

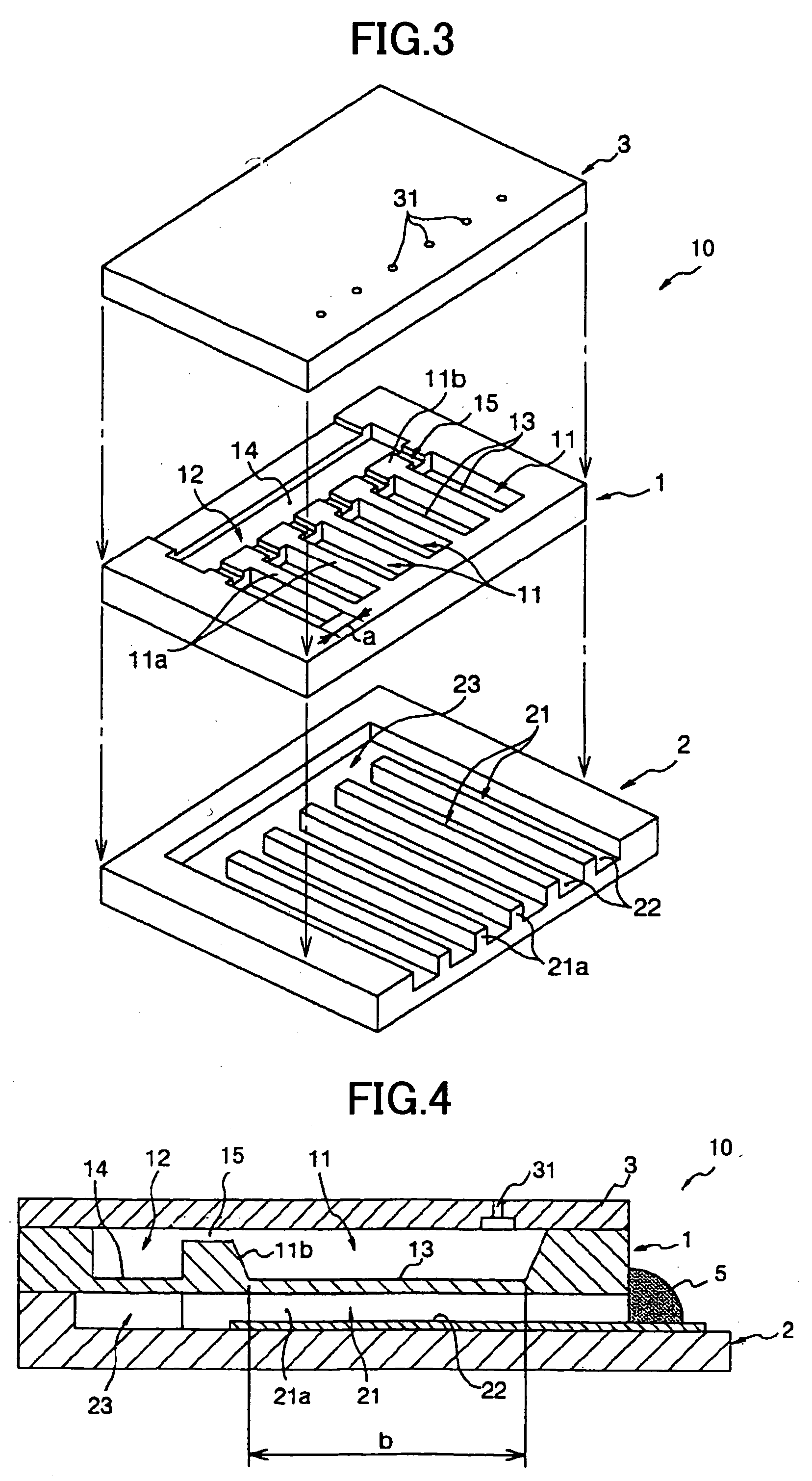

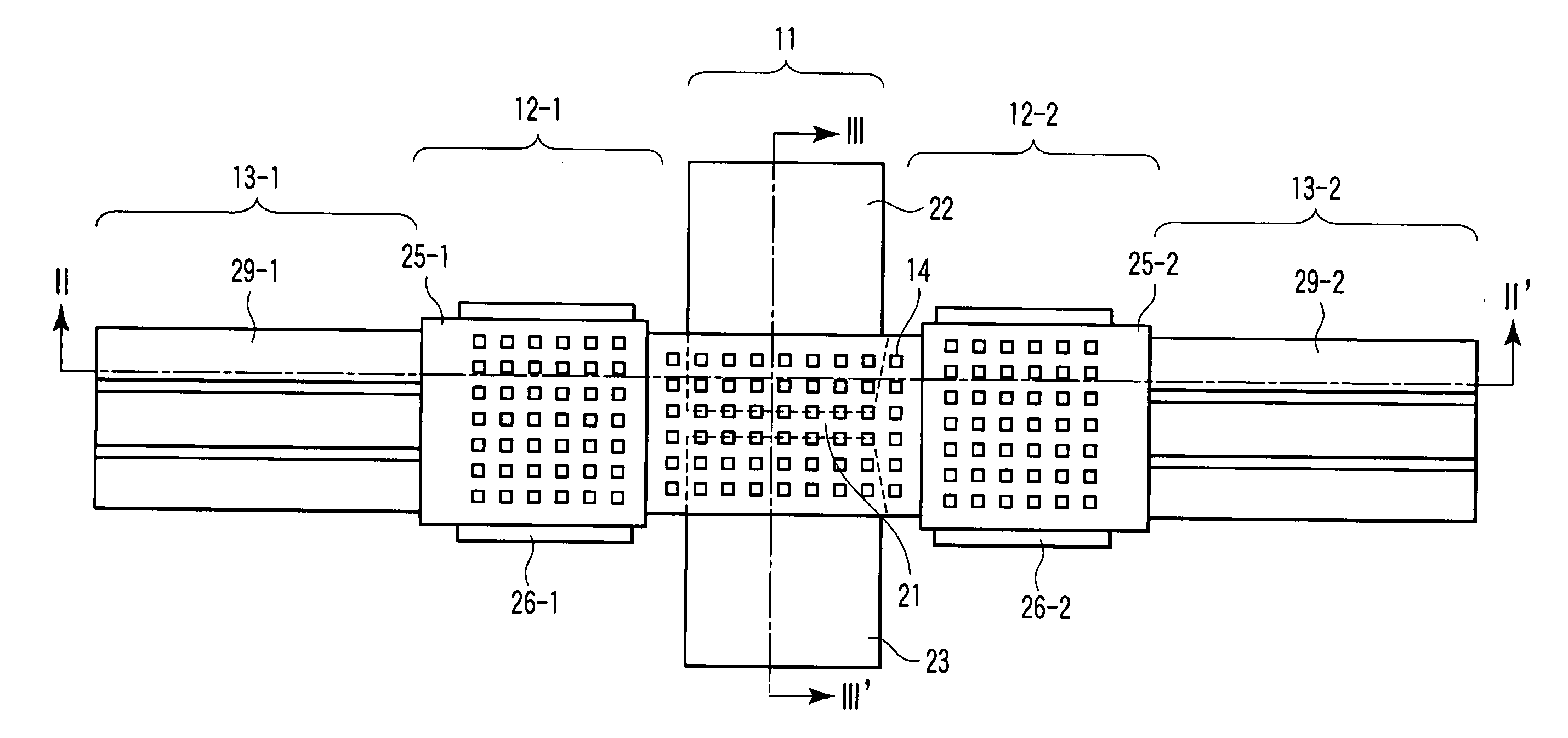

Electrostatic actuator and liquid droplet ejecting head having stable operation characteristics against environmental changes

InactiveUS20050104941A1Eliminate disadvantagesStable characteristicsFlexible member pumpsPrintingEngineeringElectrostatic actuator

A liquid droplet ejecting head includes: one or more nozzle holes ejecting liquid droplets; one or more pressure liquid chambers communicating with the nozzle holes and containing liquid to be ejected; a common liquid chamber communicating with the pressure liquid chambers; one or more diaphragms each forming a wall face of the corresponding pressure liquid chamber; one or more vibration chambers containing air gaps provided in contact with the diaphragms on the opposite side from the pressure liquid chambers; and one or more electrodes provided to oppose the diaphragms through the air gaps. The liquid droplet ejecting head further includes: a deformable plate whose deformation is greater than the total deformation of the diaphragms, the deformable plate forming a wall face of the common liquid chamber, and a pressure correcting chamber provided across the deformable plate from the common liquid chamber so as to communicate with the vibration chambers.

Owner:RICOH KK

Optical structure with ridges arranged at the same and method for producing the same

ActiveUS20160154202A1Small structure sizeLow production costPrismsContact member assembly/disassemblyElectrostatic actuatorEngineering

An apparatus having an optical structure, ridges and an electrostatic actuator with a cantilever electrode is described, wherein the ridges connect the optical structure to a supporting structure and the electrostatic drive is implemented to deflect the optical structure.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

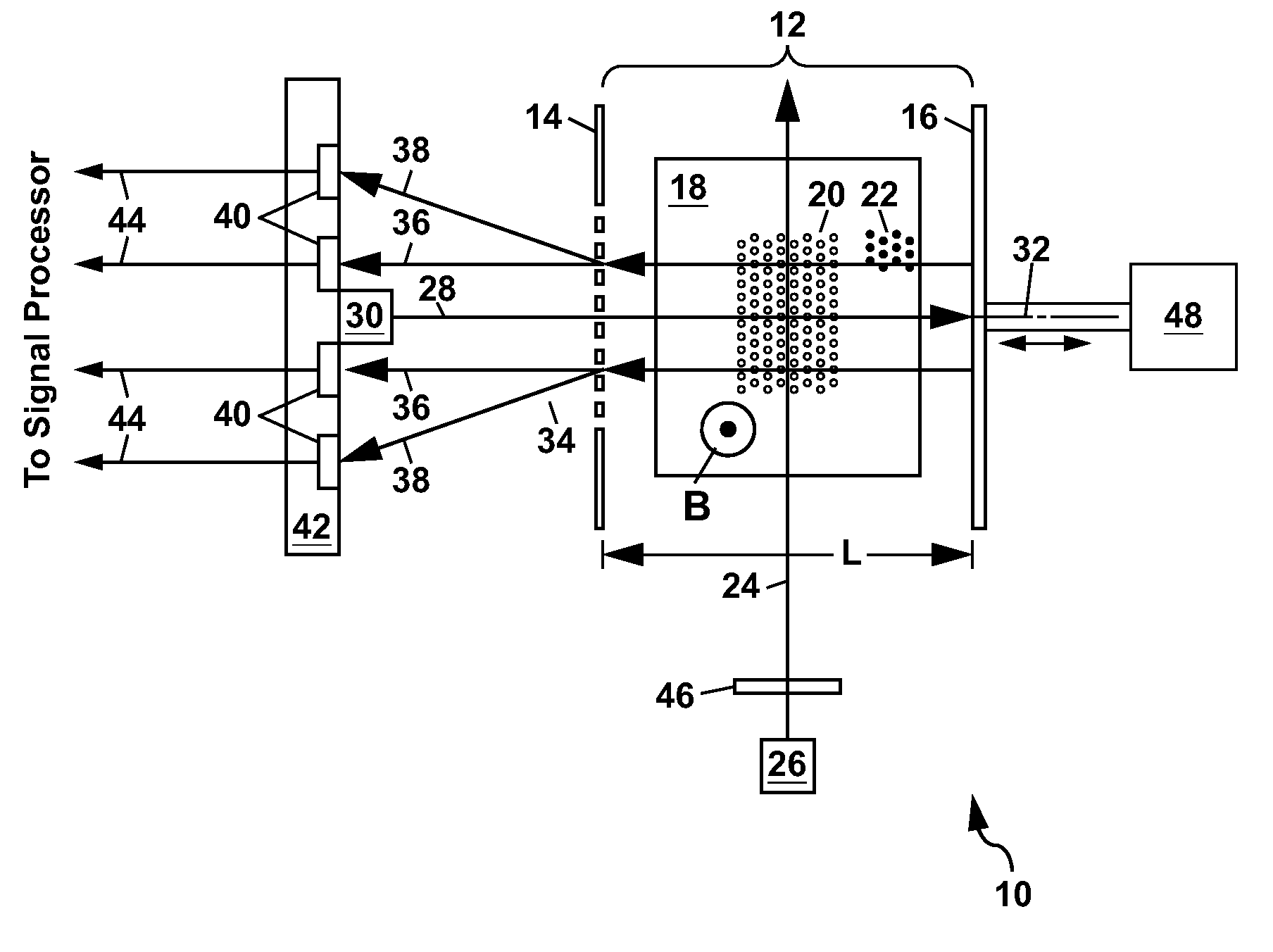

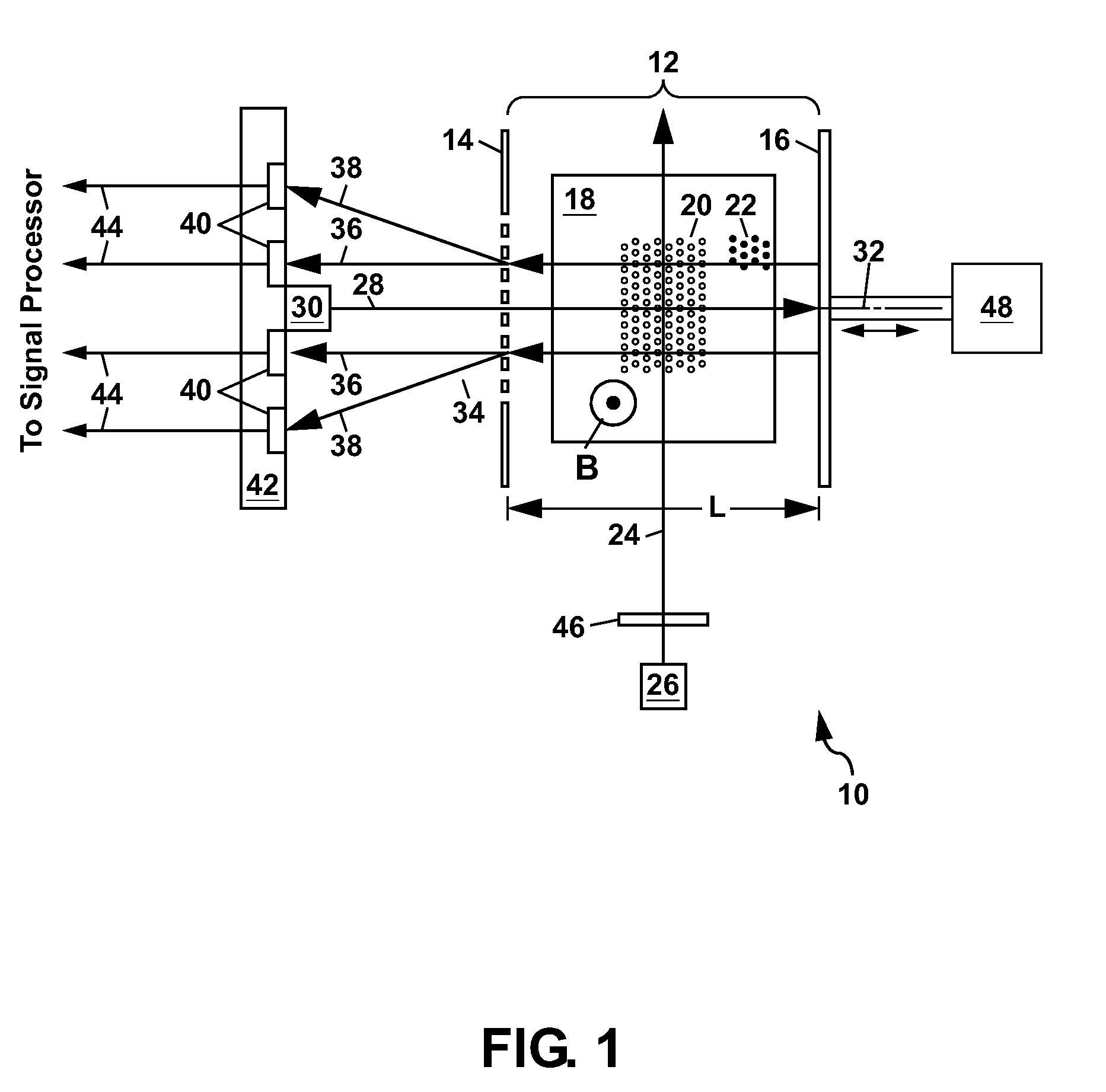

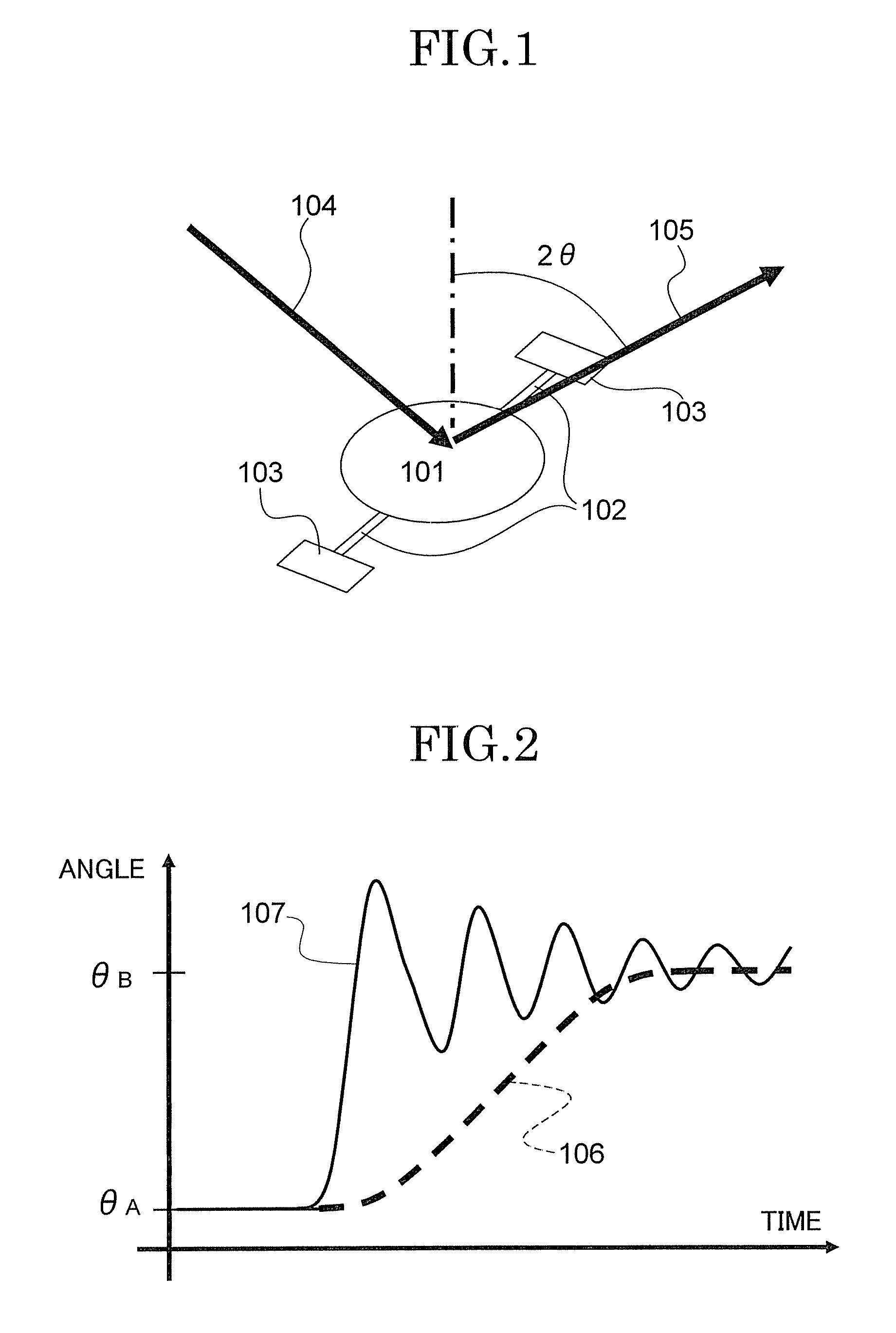

Tuned optical cavity magnetometer

An atomic magnetometer is disclosed which utilizes an optical cavity formed from a grating and a mirror, with a vapor cell containing an alkali metal vapor located inside the optical cavity. Lasers are used to magnetically polarize the alkali metal vapor and to probe the vapor and generate a diffracted laser beam which can be used to sense a magnetic field. Electrostatic actuators can be used in the magnetometer for positioning of the mirror, or for modulation thereof. Another optical cavity can also be formed from the mirror and a second grating for sensing, adjusting, or stabilizing the position of the mirror.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

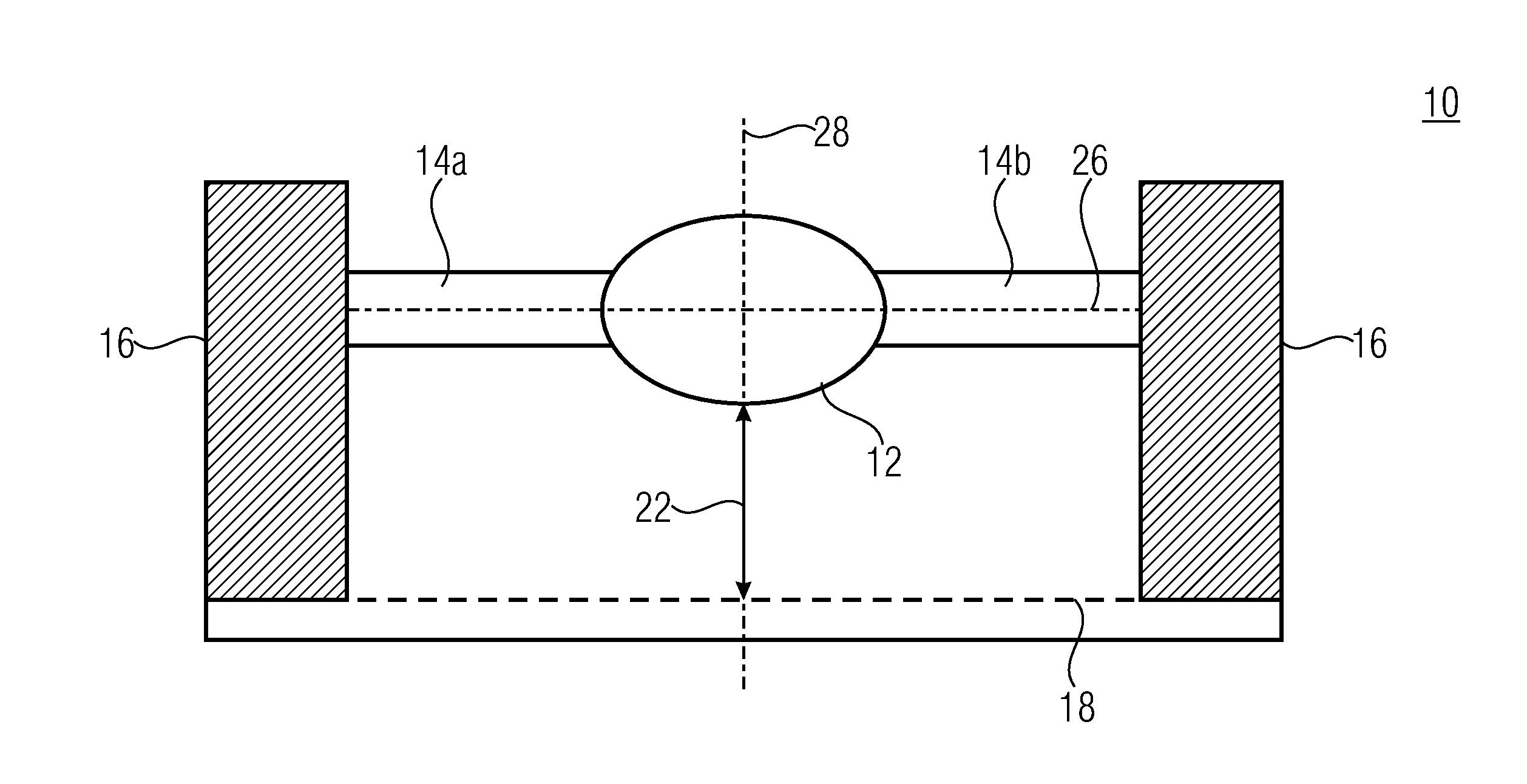

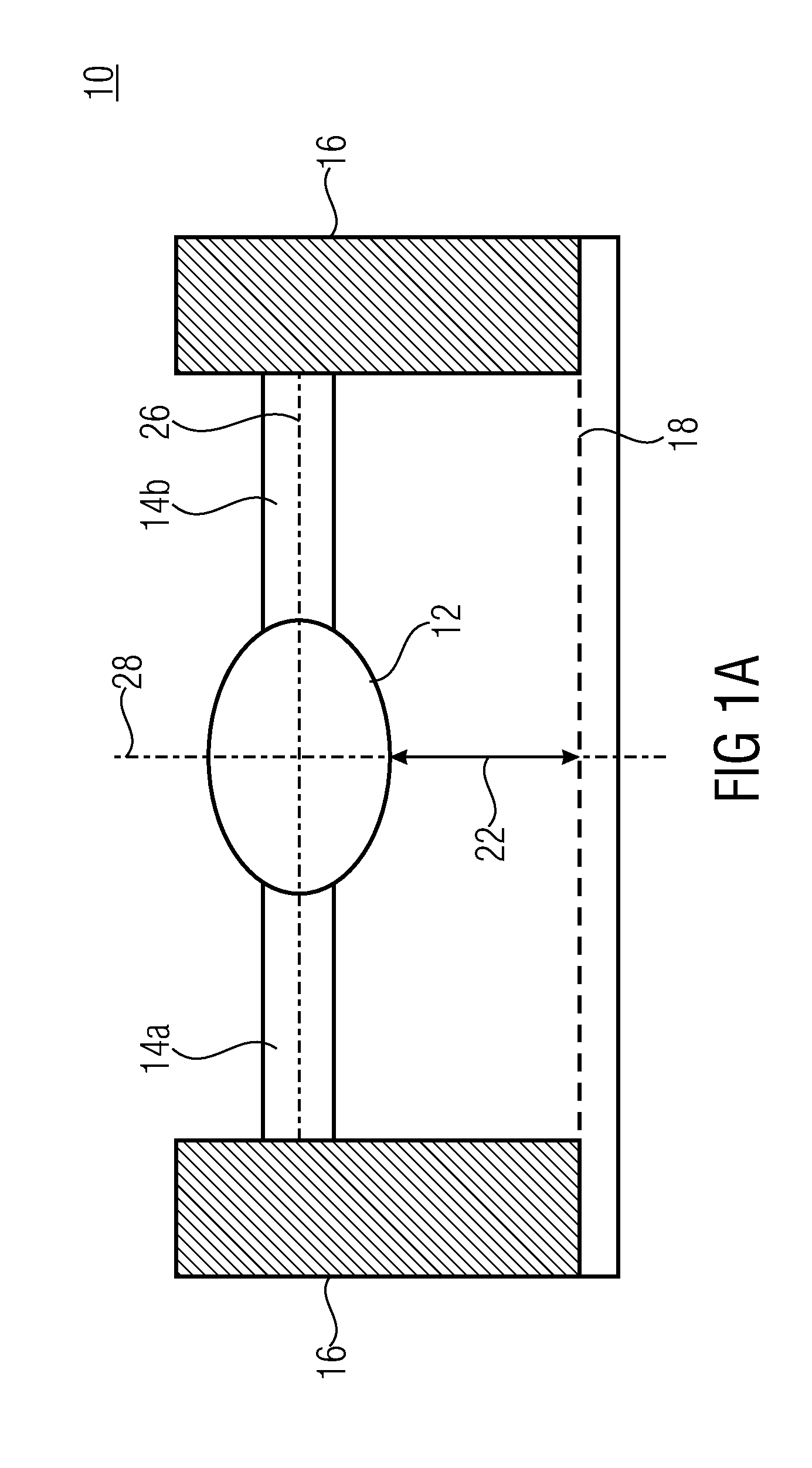

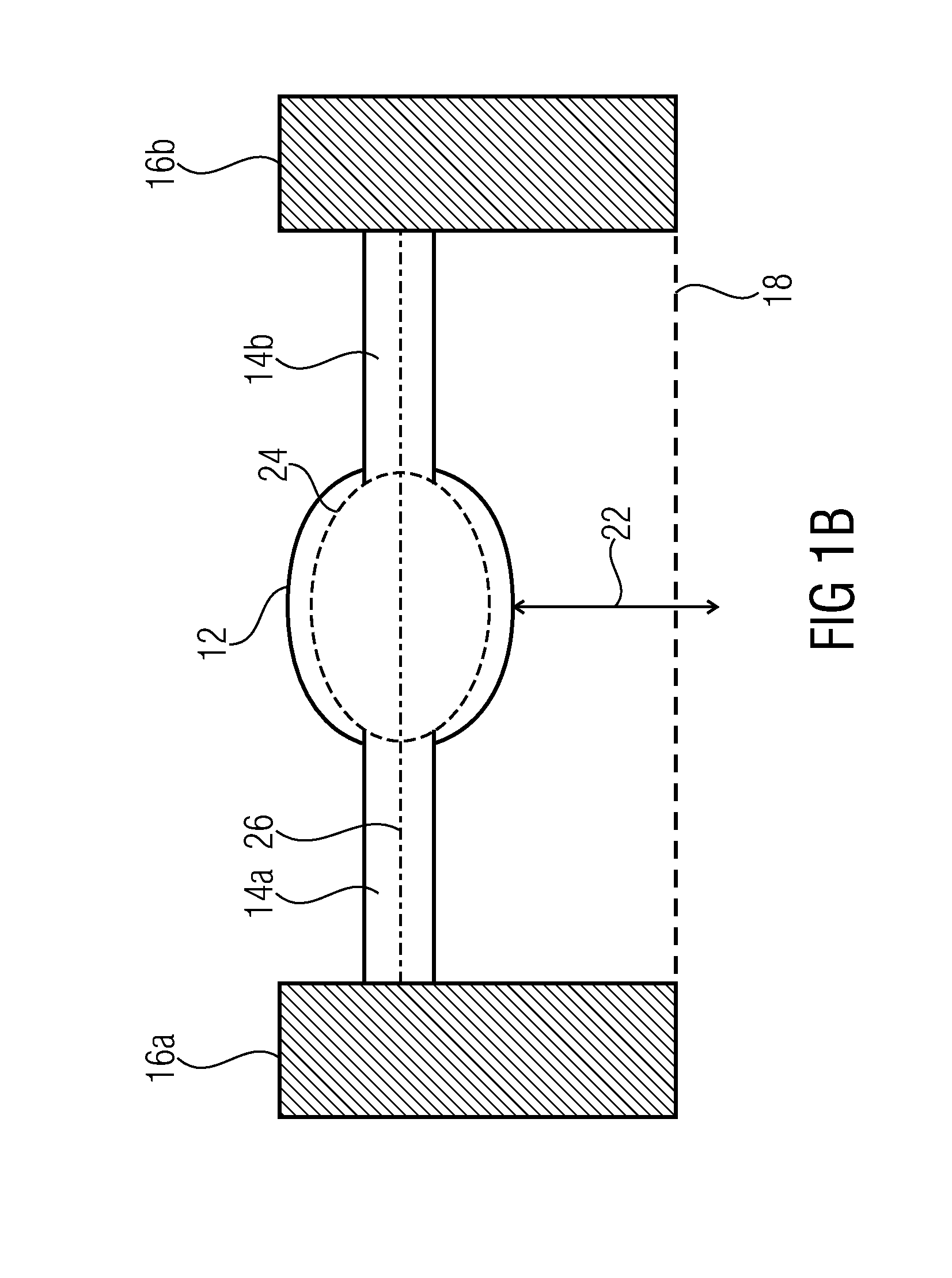

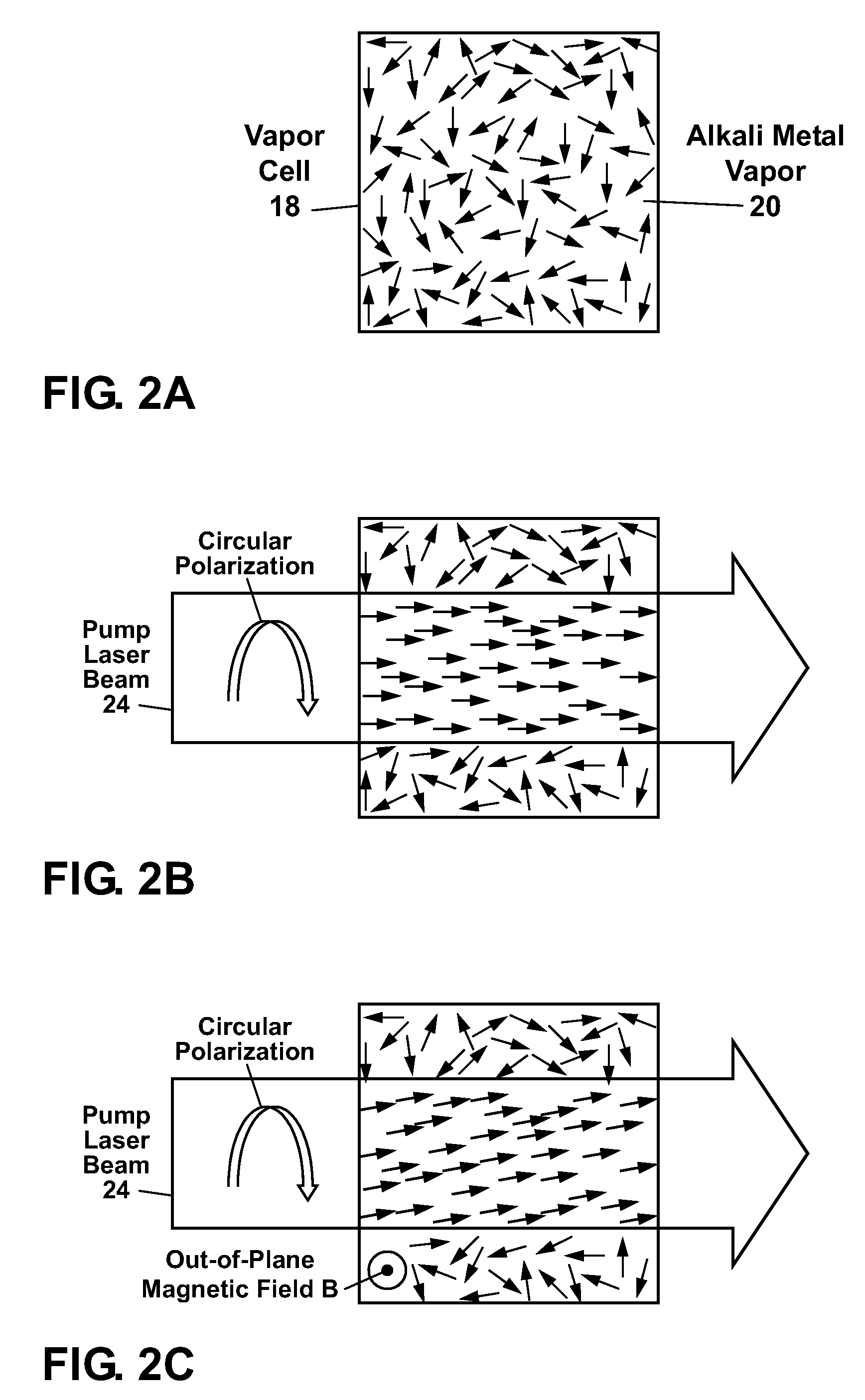

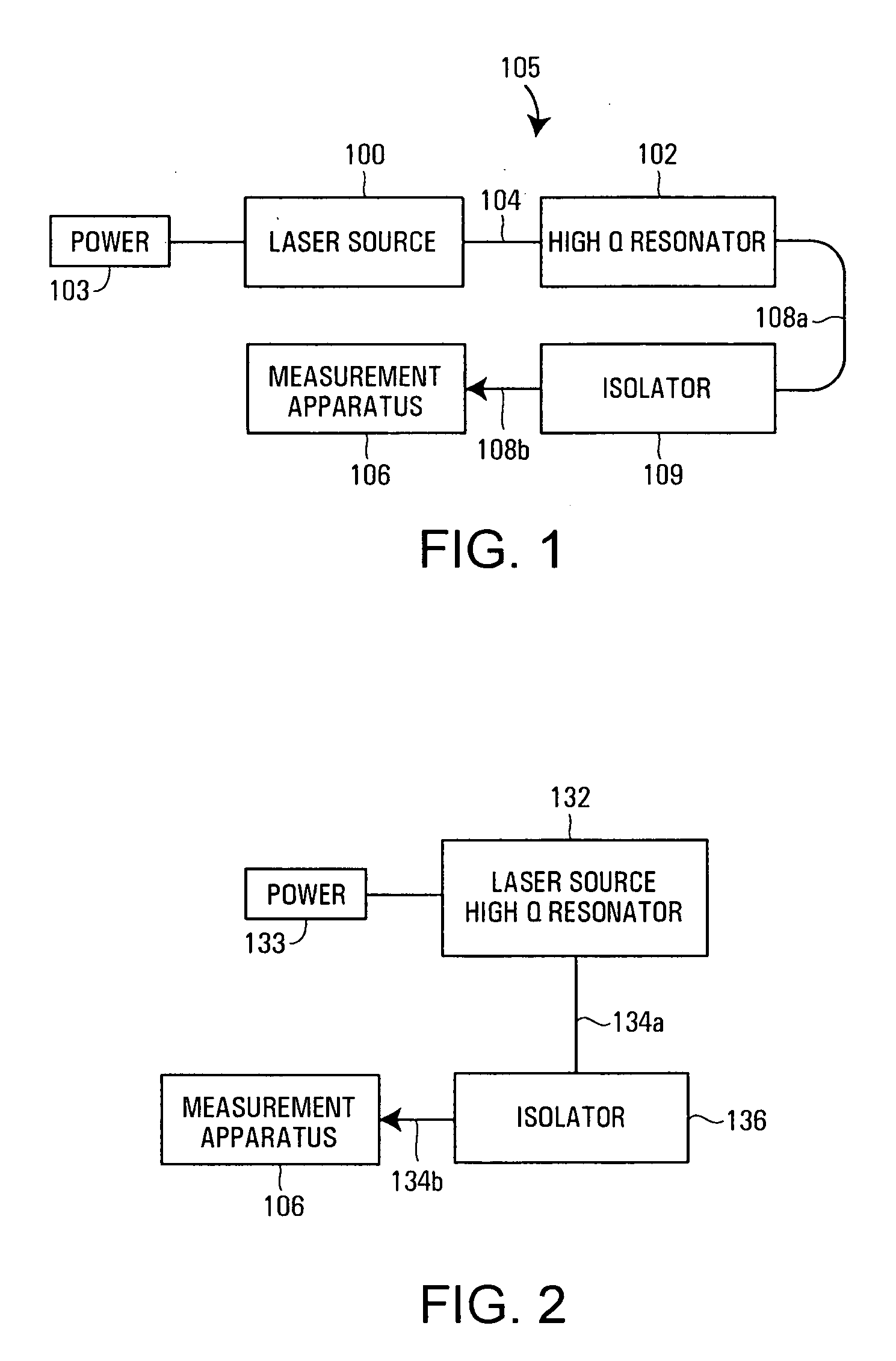

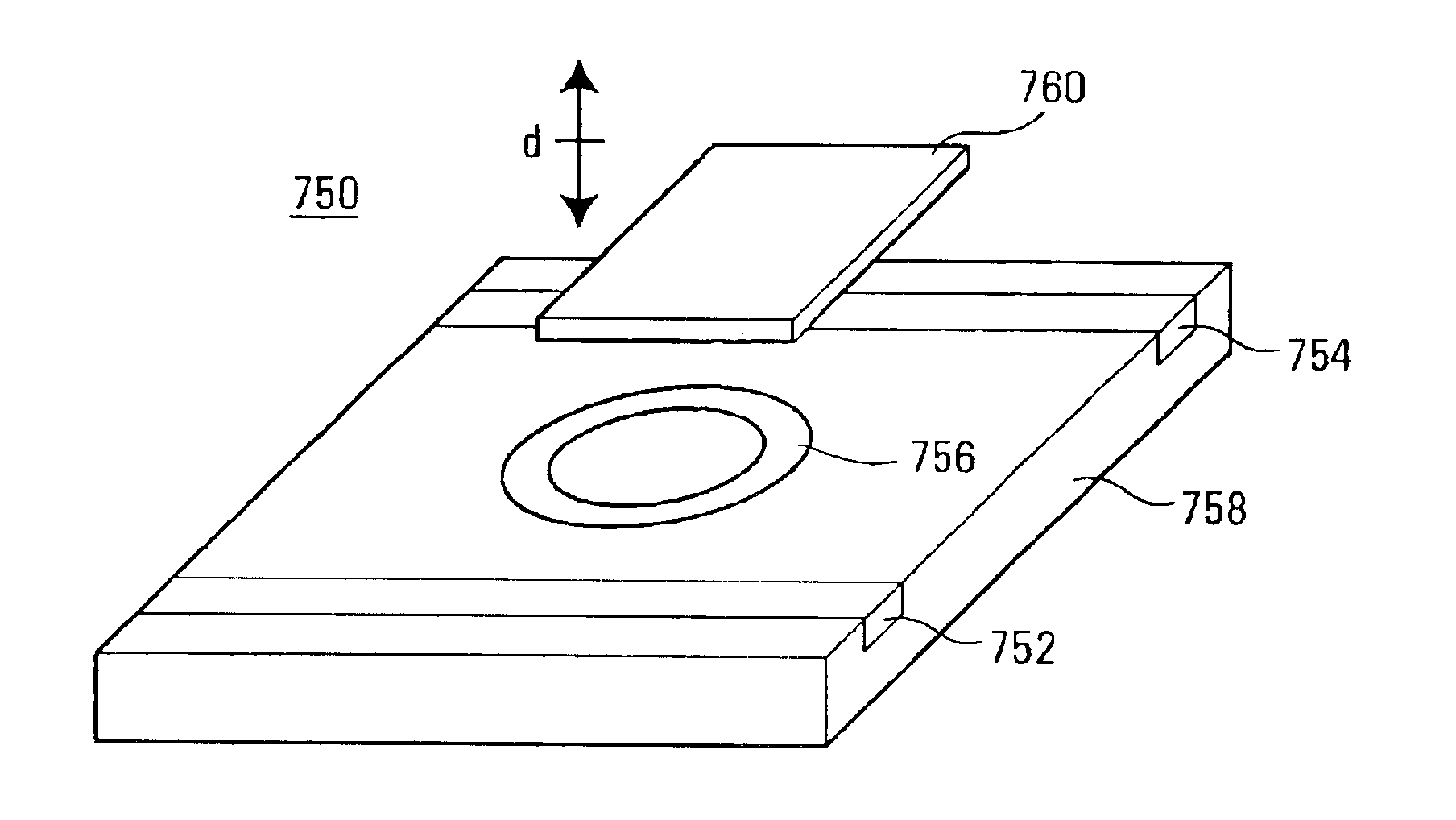

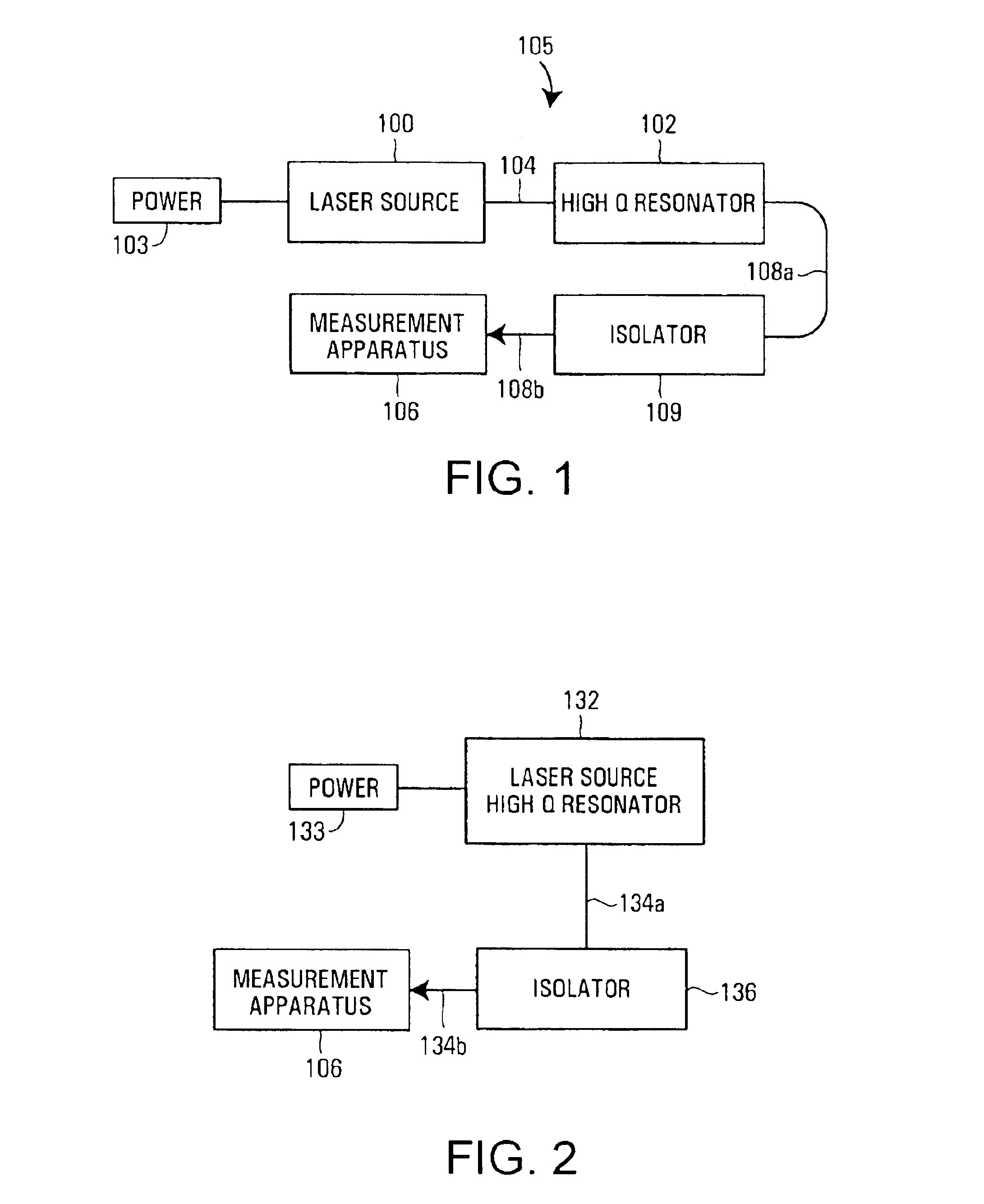

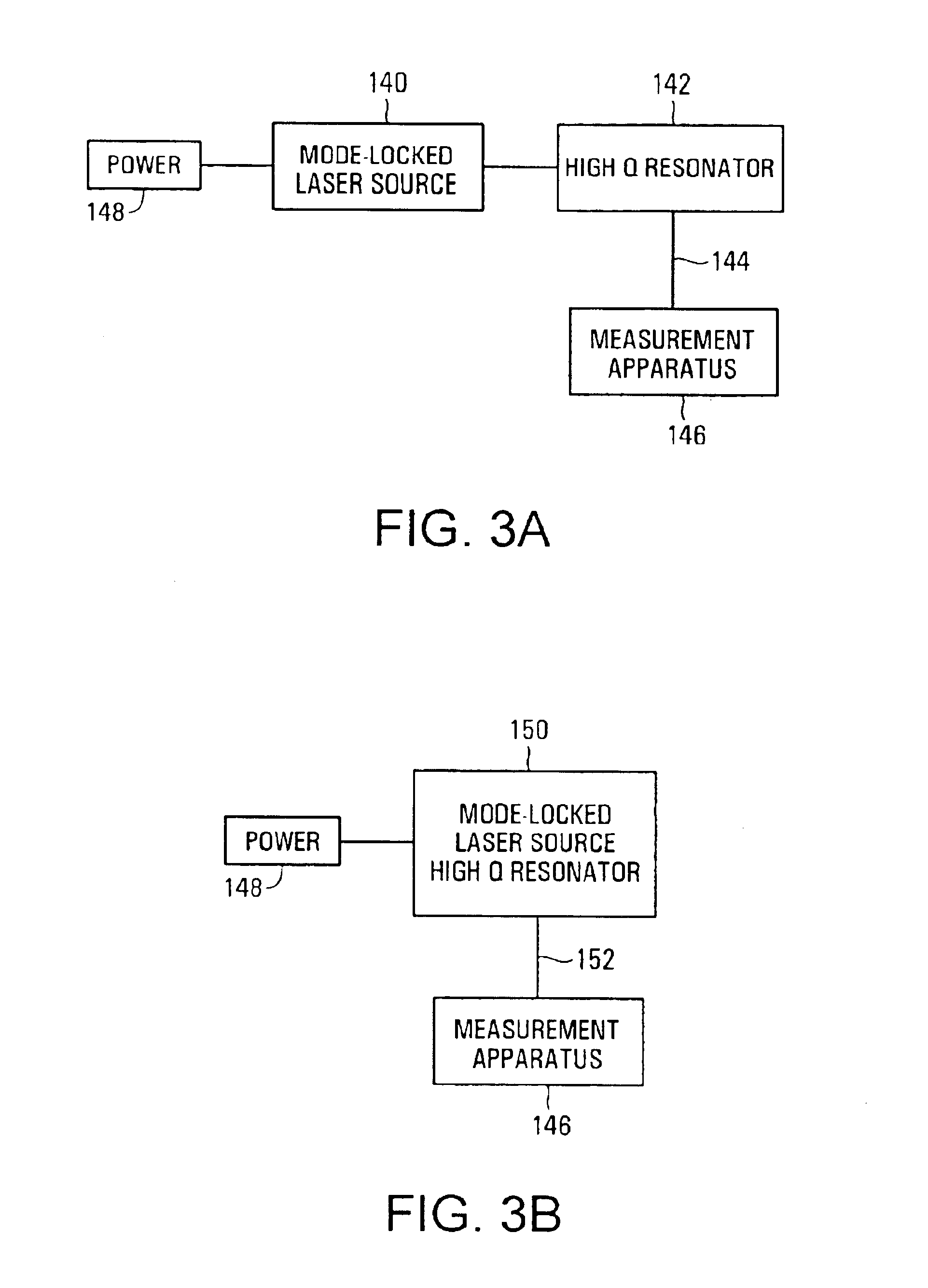

Tunable optical filter

InactiveUS20040120638A1Cladded optical fibreLaser optical resonator constructionDielectric plateMicrosphere

A tunable filter having a resonator with a resonant frequency dependent upon a variable gap is provided. The variable gap may be controllably altered by use of an actuator. The resonator is a high Q resonator that may be formed by a ring resonator, microsphere, microdisc, or other high Q optical structures. Actuation is preferably achieved through an electrostatic actuator that moves a dielectric plate relative to the resonator in response to measured values of gap and temperature.

Owner:ROSEMOUNT INC

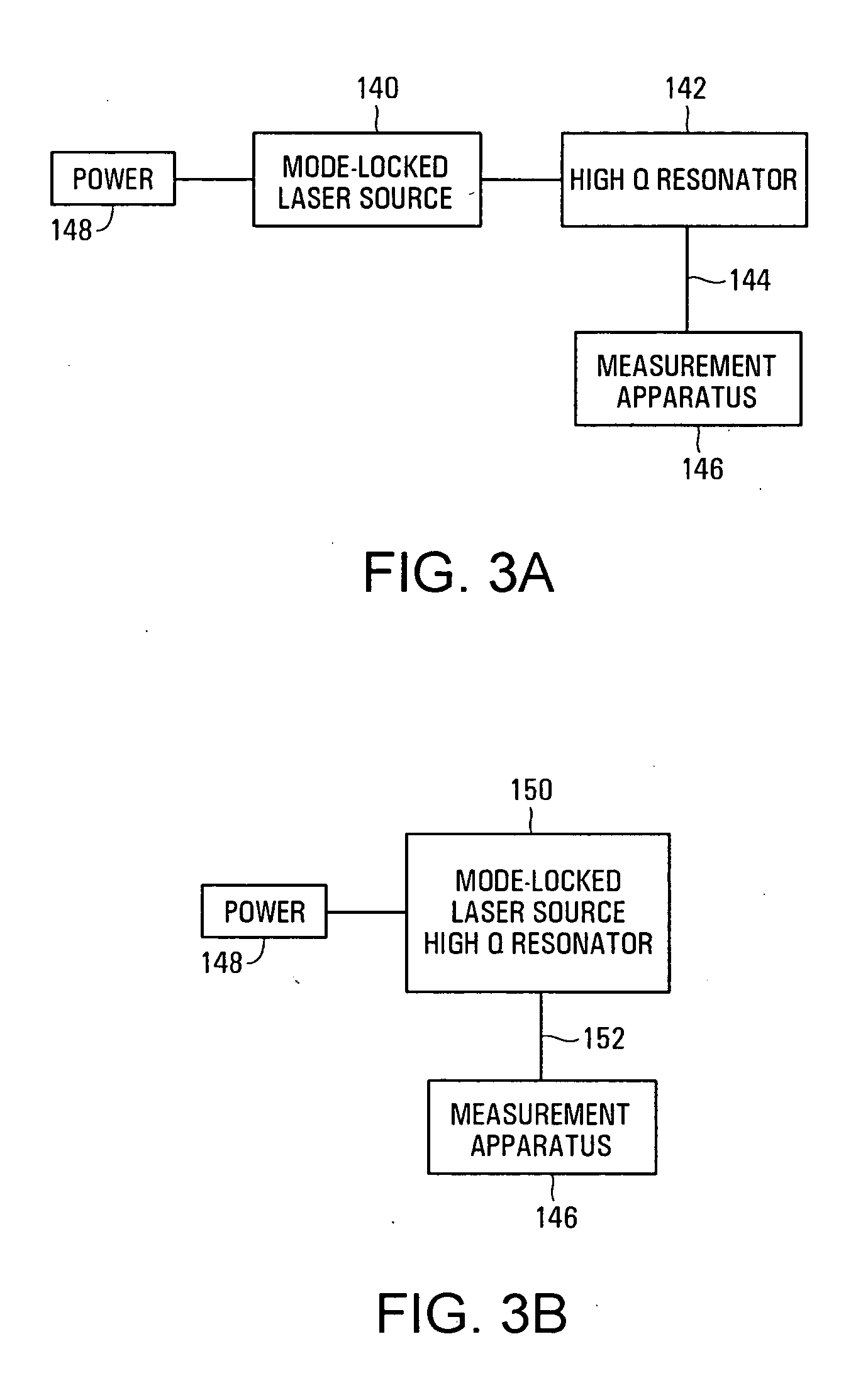

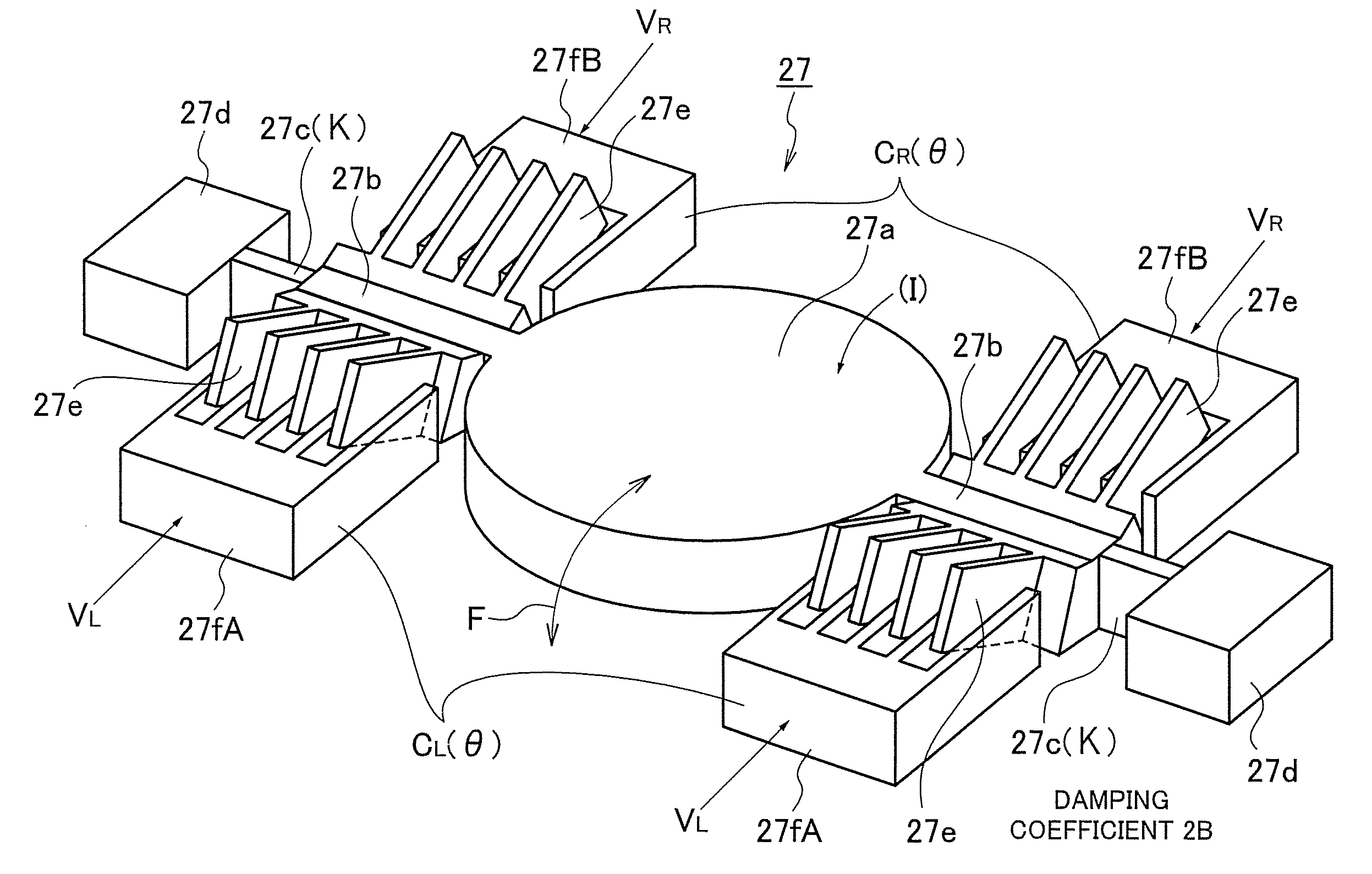

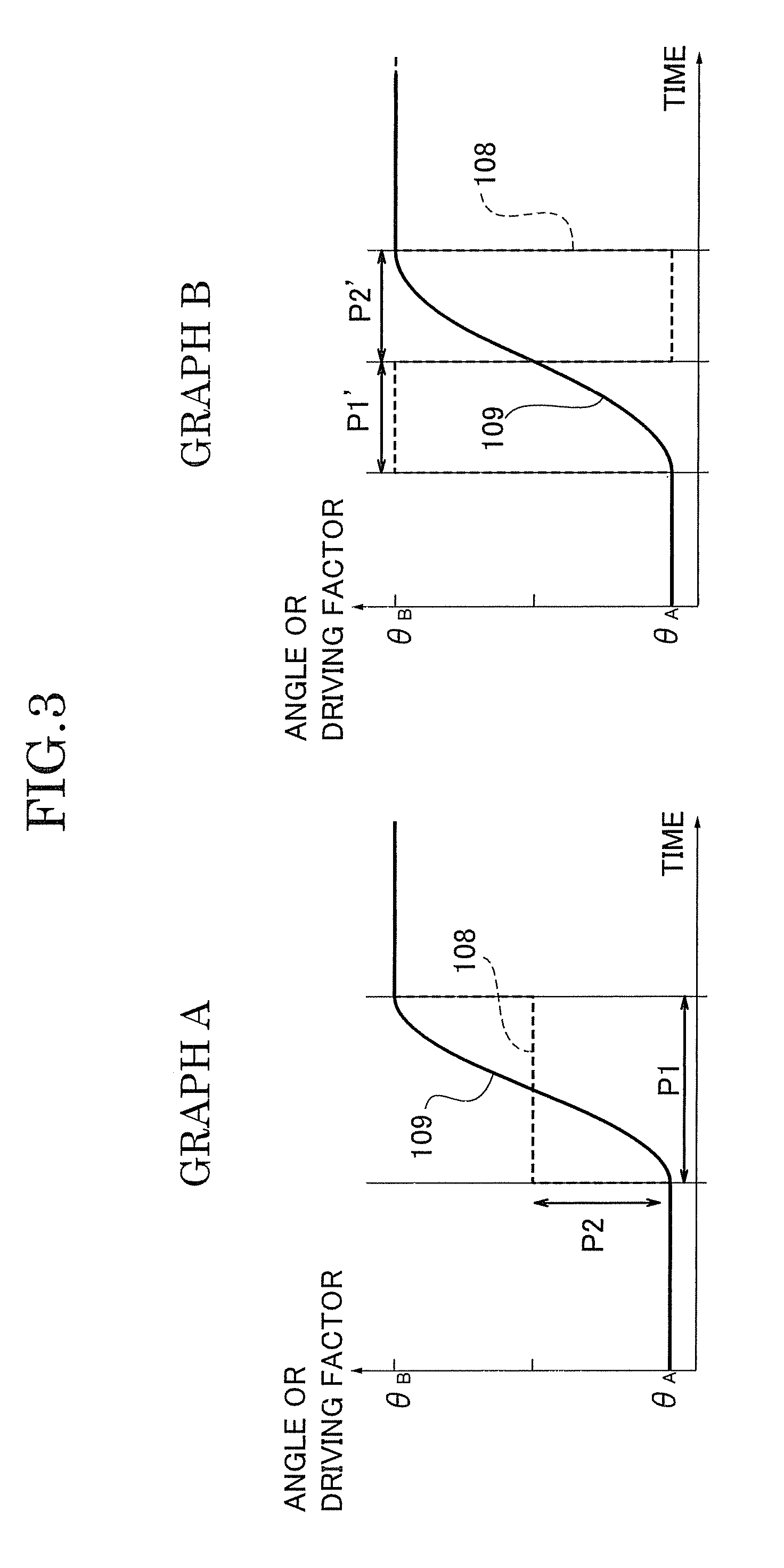

Method of driving MEMS mirror scanner, method of driving MEMS actuator scanner and method of controlling rotation angle of MEMS actuator

InactiveUS20090244668A1Simple planQuickly determine parameterOptical elementsDamping factorMoment of inertia

A method of driving a MEMS mirror scanner having an electrostatic actuator, comprising a step of driving the electrostatic actuator according to an input signal in accordance with a driving waveform obtained by the following equation,whenC+′(θ)≠0VV(t)=1C+′(θ)I[-C-′(θ)IVB+-(1ICL(θ)θ)(1ICR(θ)θ)VB2+C+′(θ)I(θ¨+2BIθ.+κIθ)]whenC+′(θ)=0VV(t)=θ¨+2BIθ.+κIθ2C-′(θ)IVBwhere, B / I, κ / I, (1 / I)·dCL(θ) / dθ and (1 / I)·dCR(θ) / dθ are parameters for obtaining the driving waveform, θ(t) is a desired mirror angle response, I is a moment of inertia of a moving part including a mirror, 2B is a damping factor (damping coefficient), κ is a spring constant, CL(θ) and CR(θ) are angle dependencies of an electric capacitance, VB is a constant bias voltage in differential driving, and C+′(θ) and C−′(θ) are ½ of the sum and the difference of the first order derivative of CL(θ) and CR(θ) with respect to θ, respectively, which are represented by defined equations.

Owner:KK TOPCON

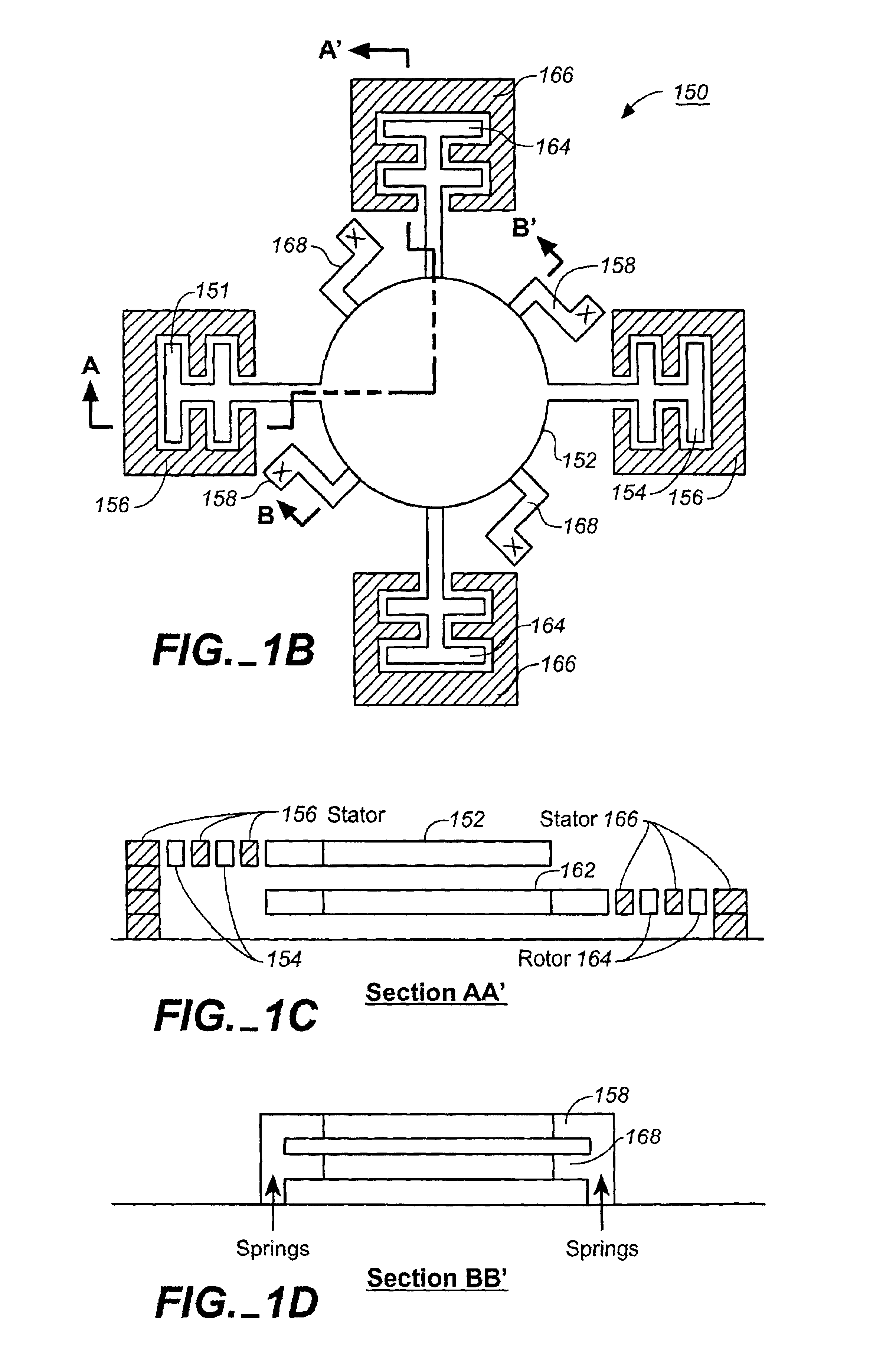

Electrostatic control of micro-optical components

InactiveUS6838738B1Reduce power consumptionEasy to manufactureSolid-state devicesSpectrum generation using multiple reflectionElectrostatic actuatorControl theory

An electrostatic actuator with inter-digital rotor and stator fingers formed in a the insulating and conductive layers of a wafer. The actuator is used to drive MicroElectroMechanical (MEMS) components, specifically micro-optical components such as mirrors, attenuators, switches, and tunable filters.

Owner:DICON FIBEROPTICS

Method of making an electrostatic actuator

InactiveUS6933165B2Reduce stress concentrationHigh stressRailway roofsMaterial nanotechnologyElectrostatic actuatorOptoelectronics

A method of fabricating an electrostatic actuator with an intrinsic stress gradient is provided. An electrode is formed on a substrate and a support layer is formed over the electrode. A metal layer is deposited onto the support layer via a deposition process. Deposition process conditions are varied in order to induce a stress gradient into the metal layer. The intrinsic stress in the metal layer increases in the direction from the bottom to the top of the metal layer. The support layer under the electrode is removed to release the electrostatic actuator.

Owner:SUPERCONDUCTOR TECHNOLOGIES INC

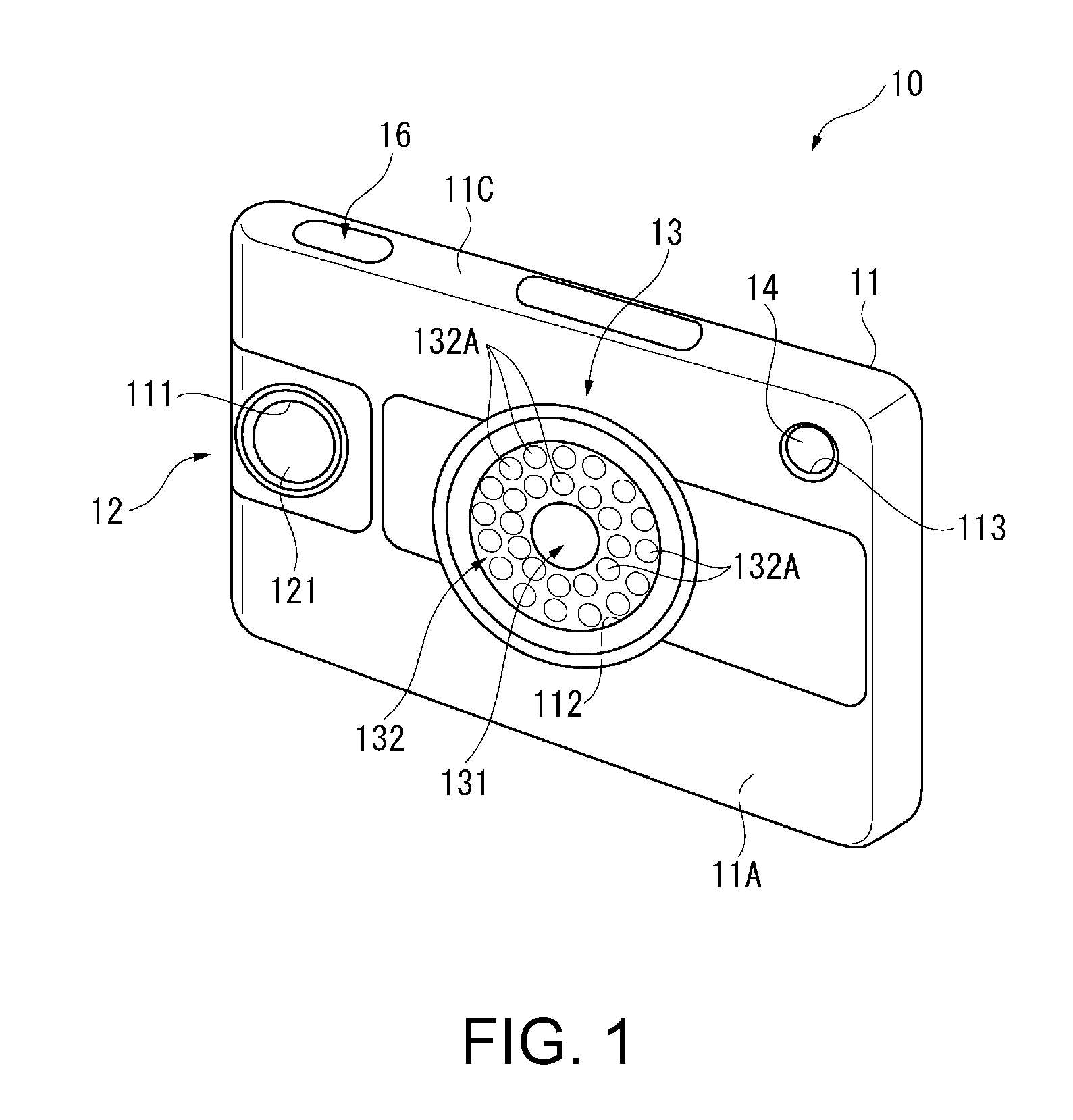

Component analyzer

InactiveUS20130229646A1Improve portabilityEasy to calculateInterferometric spectrometryPhotometryDisplay deviceElectrostatic actuator

A component analyzer includes a casing, a light source unit, a light incident unit guiding light from a test object into the casing, a tunable interference filter extracting light having a predetermined wavelength from the incident light, an imaging unit receiving the extracted light and taking a spectroscopic image, a control unit performing a component analysis of the test object based on the spectroscopic images, and a display displaying a component analysis result. The light incident unit, the imaging unit, and the control unit are provided within the casing. The tunable interference filter includes a fixed substrate having a fixed reflection film and a movable substrate provided to face the fixed substrate and having a movable reflection film opposed to the fixed reflection film across a gap between reflection films, and an electrostatic actuator changing the gap between reflection films.

Owner:SEIKO EPSON CORP

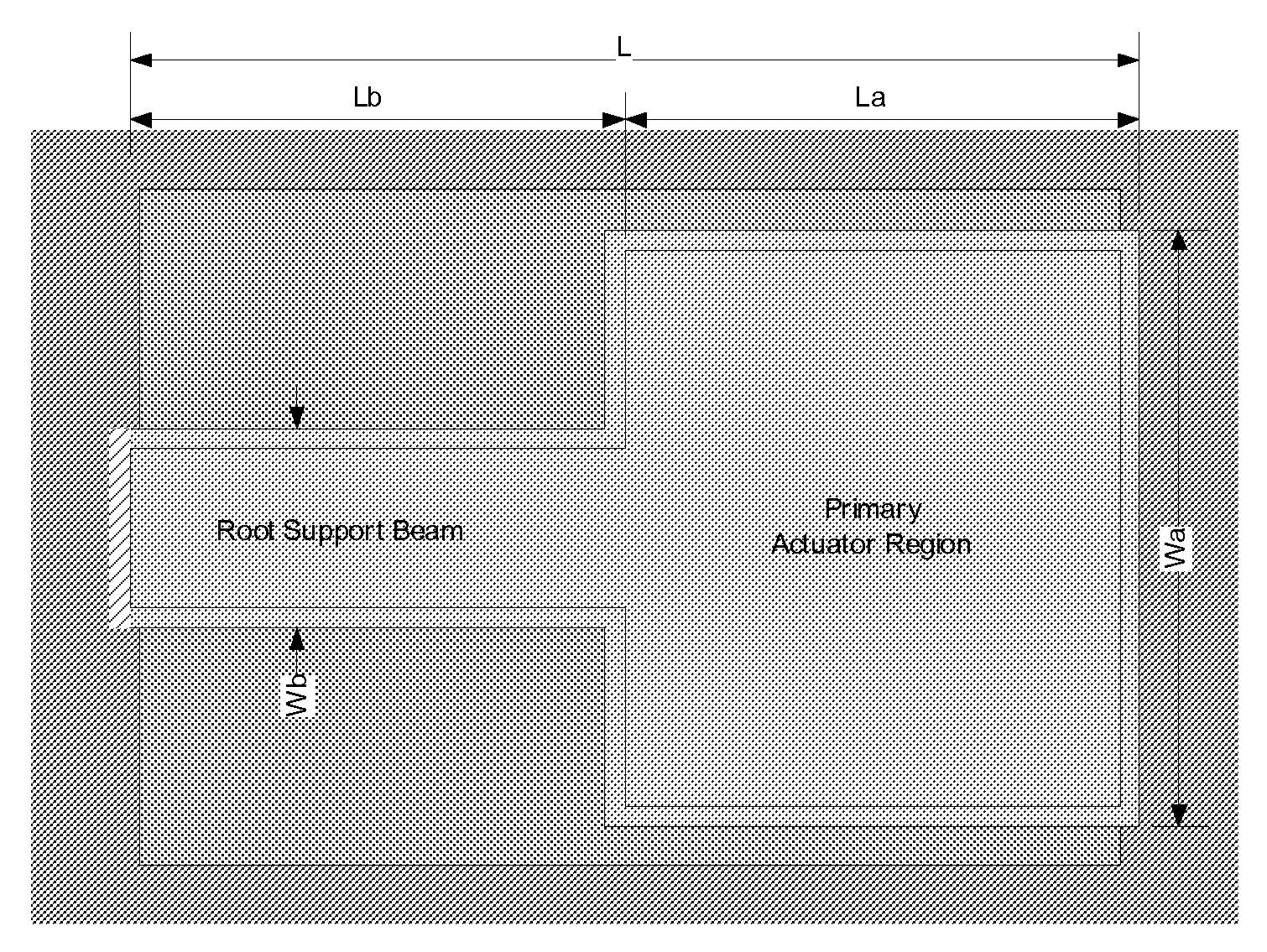

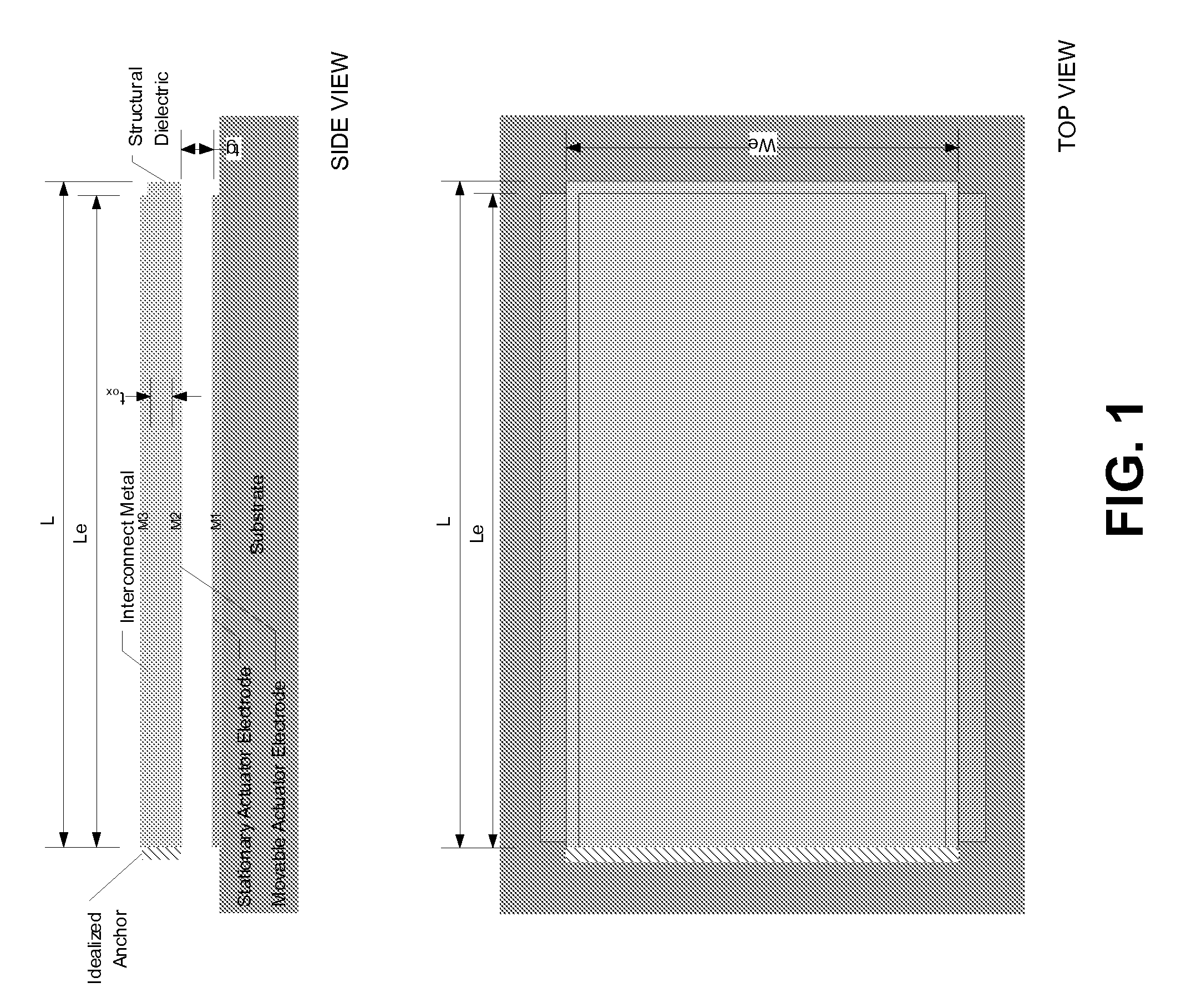

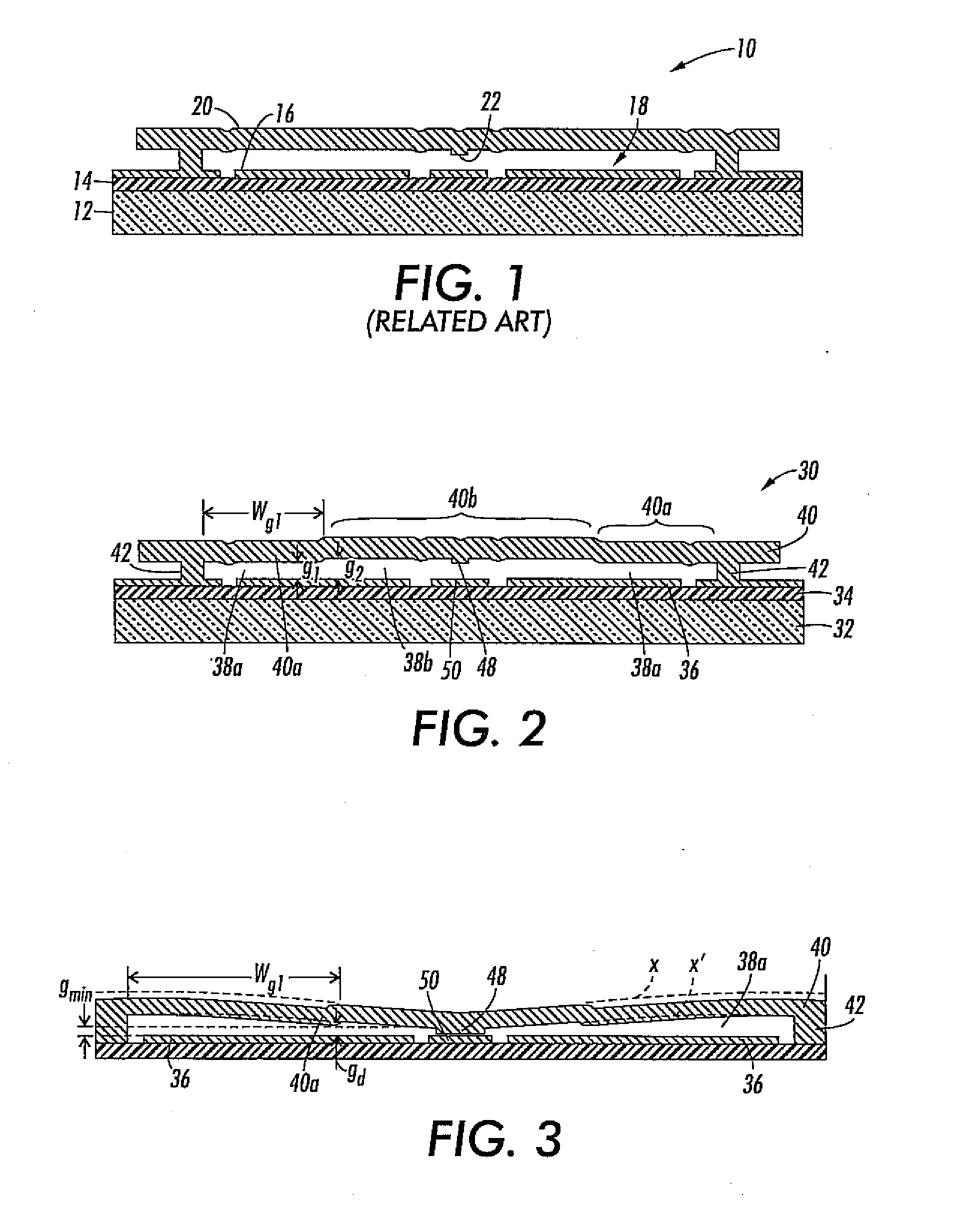

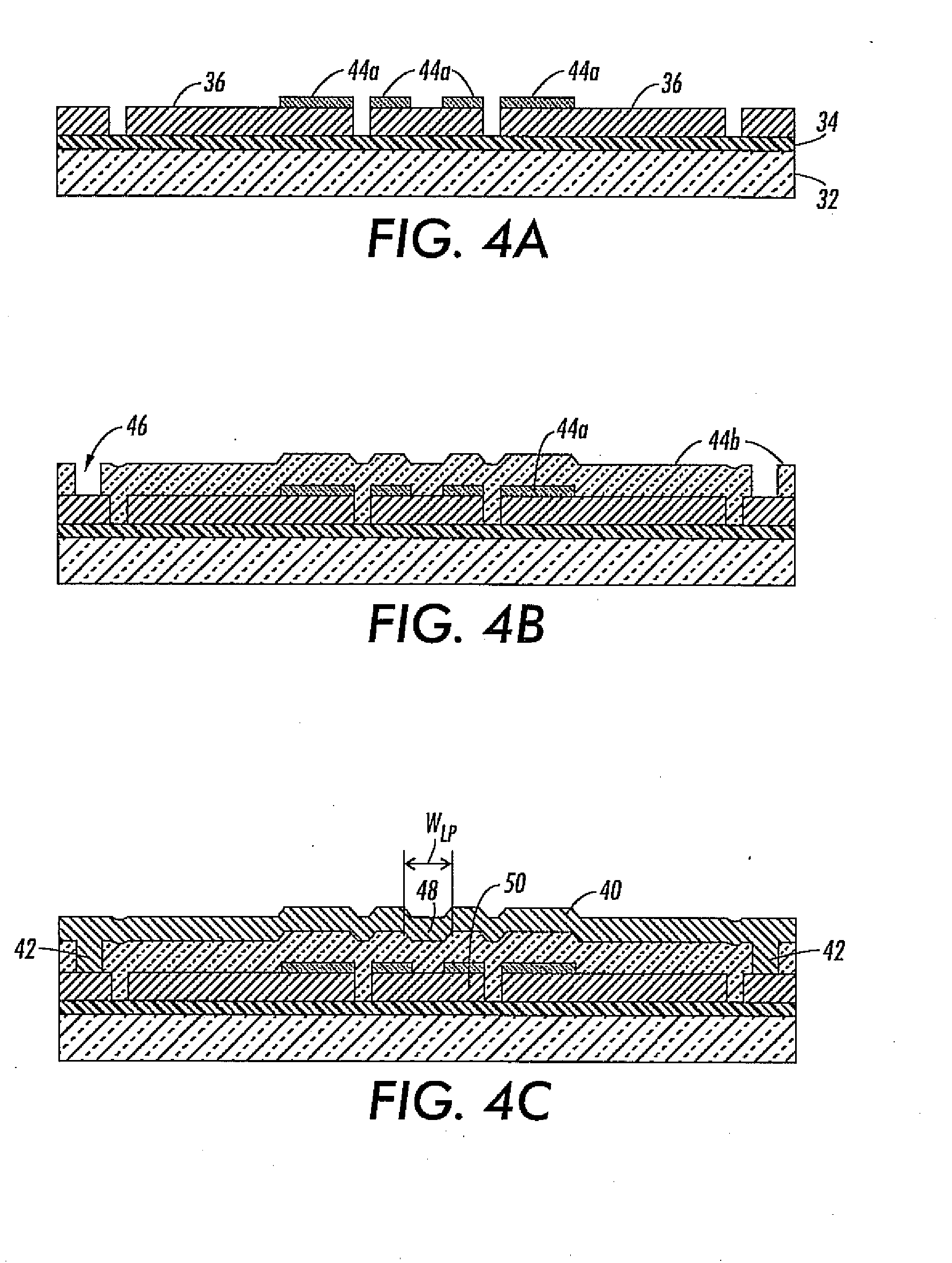

Reduced voltage MEMS electrostatic actuation methods

Cantilever beam electrostatic actuators are disclosed. A cantilever beam electrostatic actuator in accordance with the present invention comprises an actuator beam having a first width at a support anchor point and a second width at a distal end of the actuator, wherein the first width is narrower than the second width. Another actuator in accordance with the present invention comprises an actuator region, having a first width, a beam, having a second width, coupled between an edge of the actuator region and a pivot point, the beam being approximately centered on the actuator region, wherein the second width is narrower than the first width, and at least one auxiliary actuator flap, coupled to the actuator region, the at least one auxiliary actuator flap coupled to the actuator region along the edge of the actuator region, the at least one auxiliary actuator flap being farther away from a centerline of the actuator than the beam.

Owner:AAC TECH PTE LTD

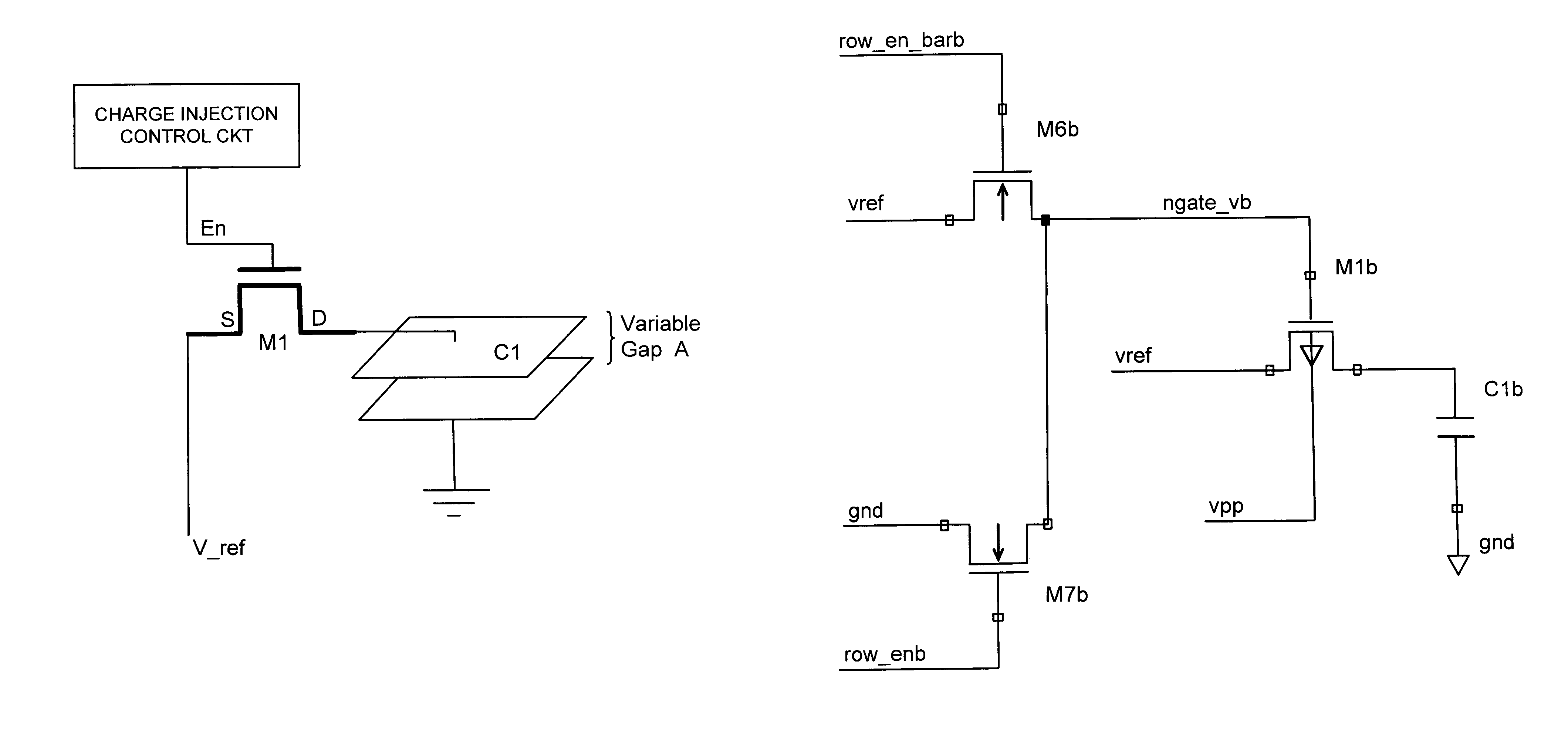

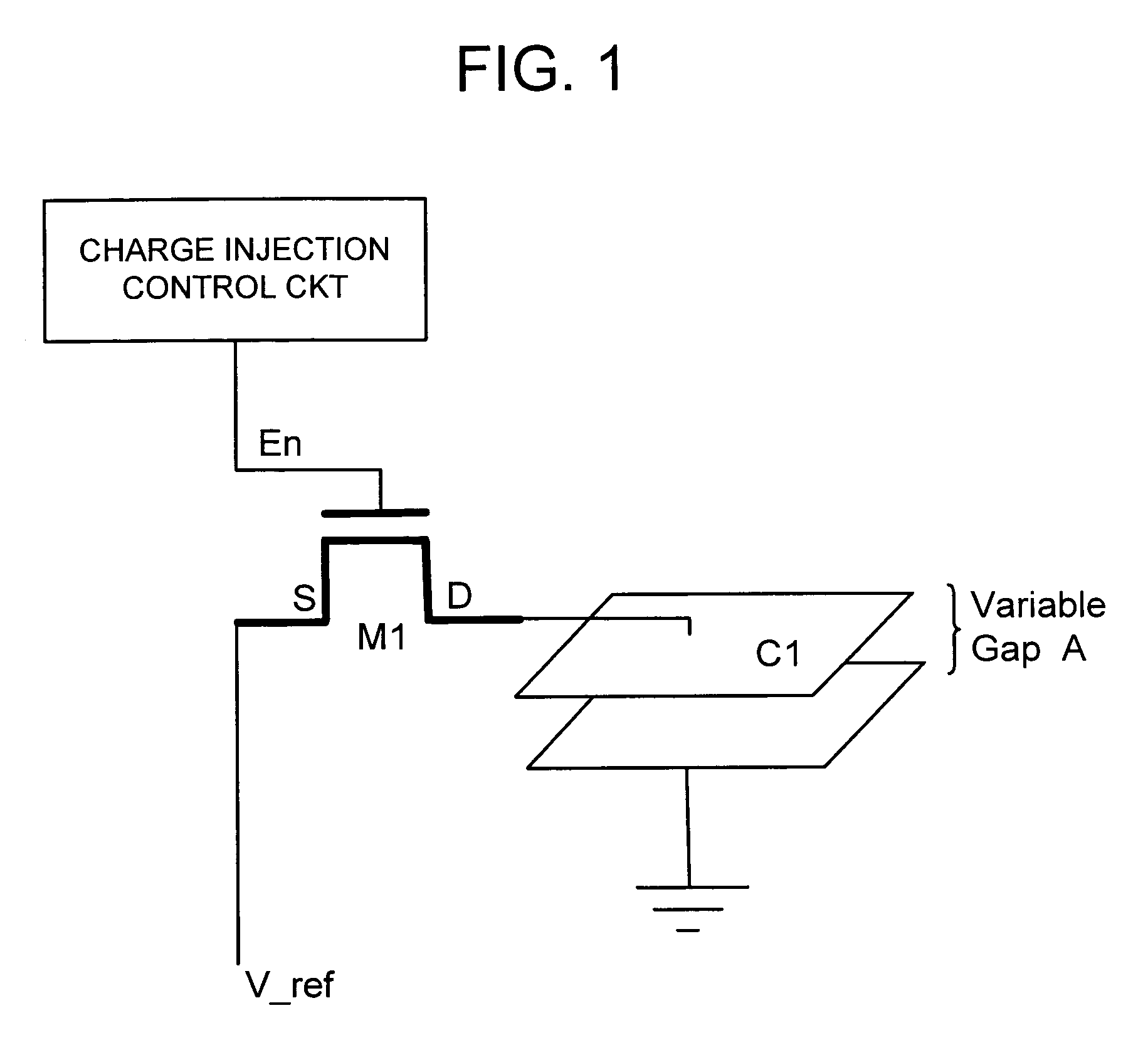

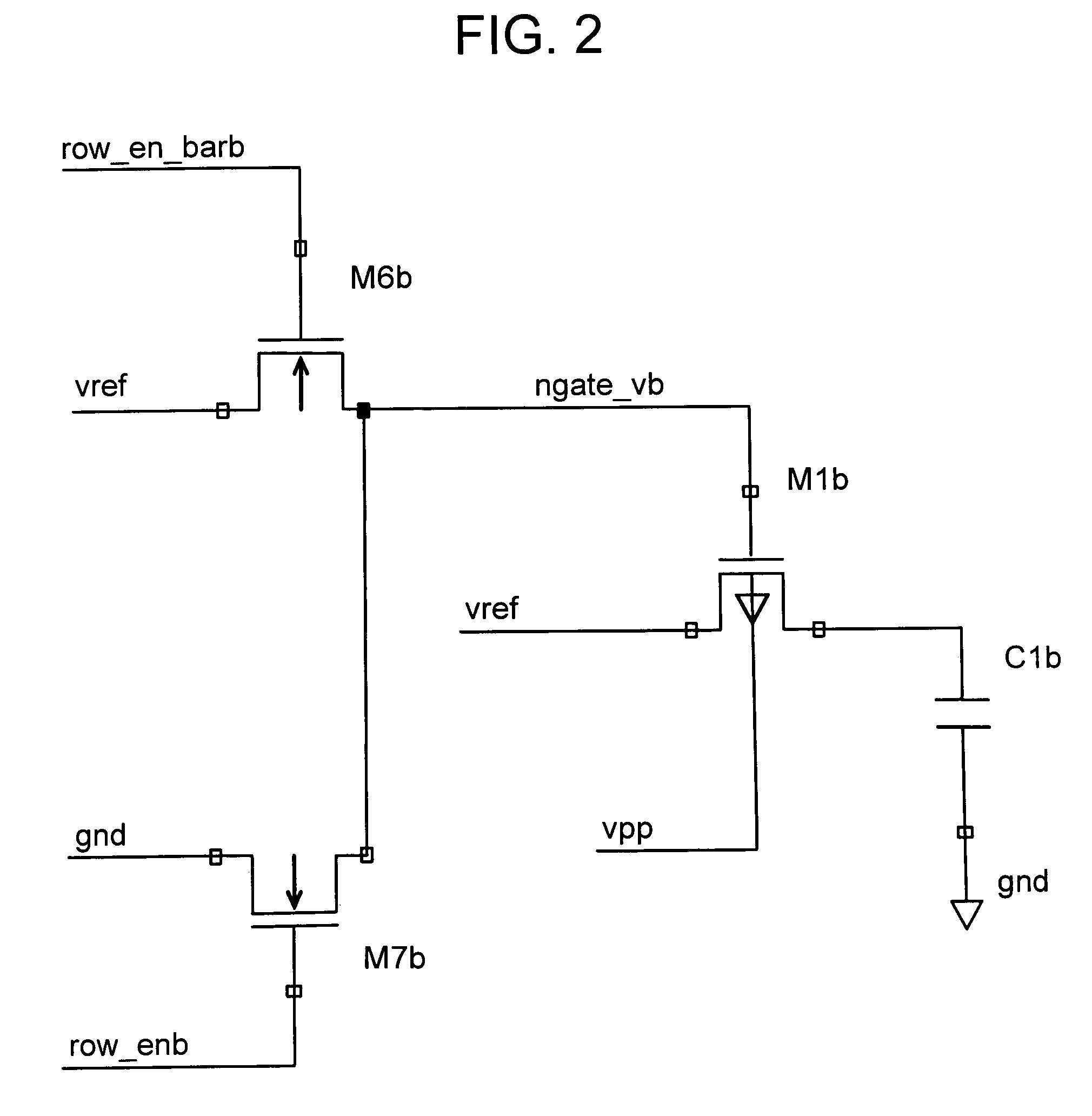

Method and apparatus for reducing charge injection in control of MEMS electrostatic actuator array

InactiveUS6970031B1Pulse automatic controlStatic indicating devicesCharge injectionElectrostatic actuator

A control circuit for a MEMS (Micro-Electro-Mechanical System) has a semiconductor switch which has a source, a drain and a gate, which is associated with a selected one of spatially arranged fixed and movable plates of a variable capacitor, and is arranged to selectively connect the selected one of the fixed and movable plates with a voltage source. A charge injection control circuit is associated with the semiconductor switch and attenuates current injection into the selected one of the fixed and movable plates of the capacitor.

Owner:HEWLETT PACKARD DEV CO LP

Differentially-driven MEMS spatial light modulator

A MEMS SLM and an electrostatic actuator associated with a pixel in an SLM. The actuator has three electrodes: a lower electrode; an upper electrode fixed with respect to the lower electrode; and a center electrode suspended and actuable between the upper and lower electrodes. The center electrode is capable of resiliently-biasing to restore the center electrode to a non-actuated first equilibrium position, and a mirror is operably connected to the center electrode. A first voltage source provides a first bias voltage across the lower and center electrodes and a second voltage source provides a second bias voltage across the upper and center electrodes, with the first and second bias voltages determining the non-actuated first equilibrium position of the center electrode. A third voltage source provides a variable driver voltage across one of the lower / center and upper / center electrode pairs in series with the corresponding first or second bias voltage, to actuate the center electrode to a dynamic second equilibrium position.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

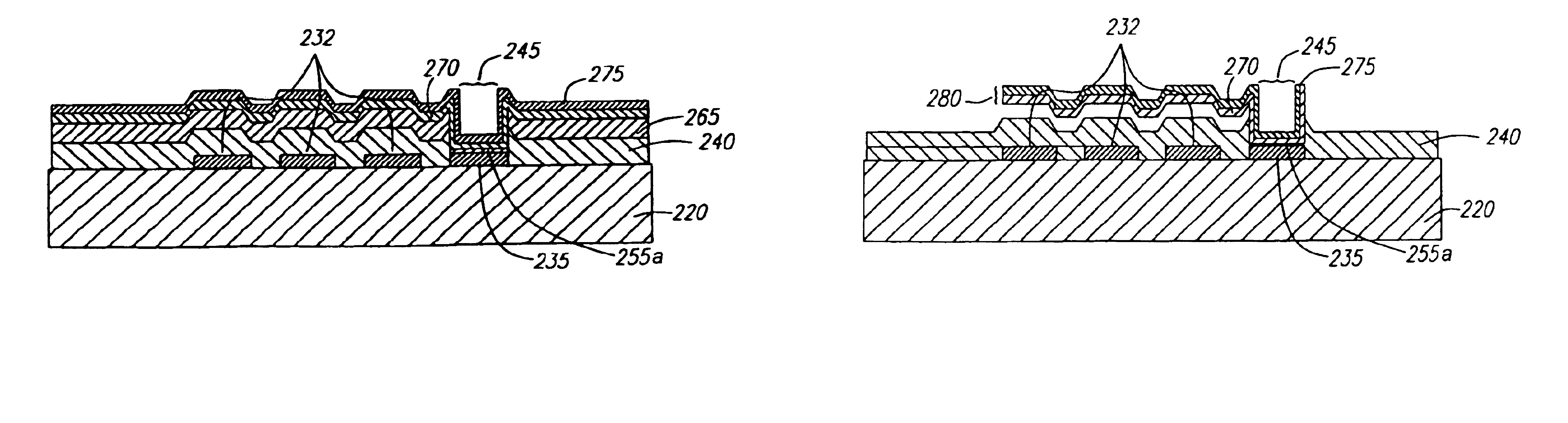

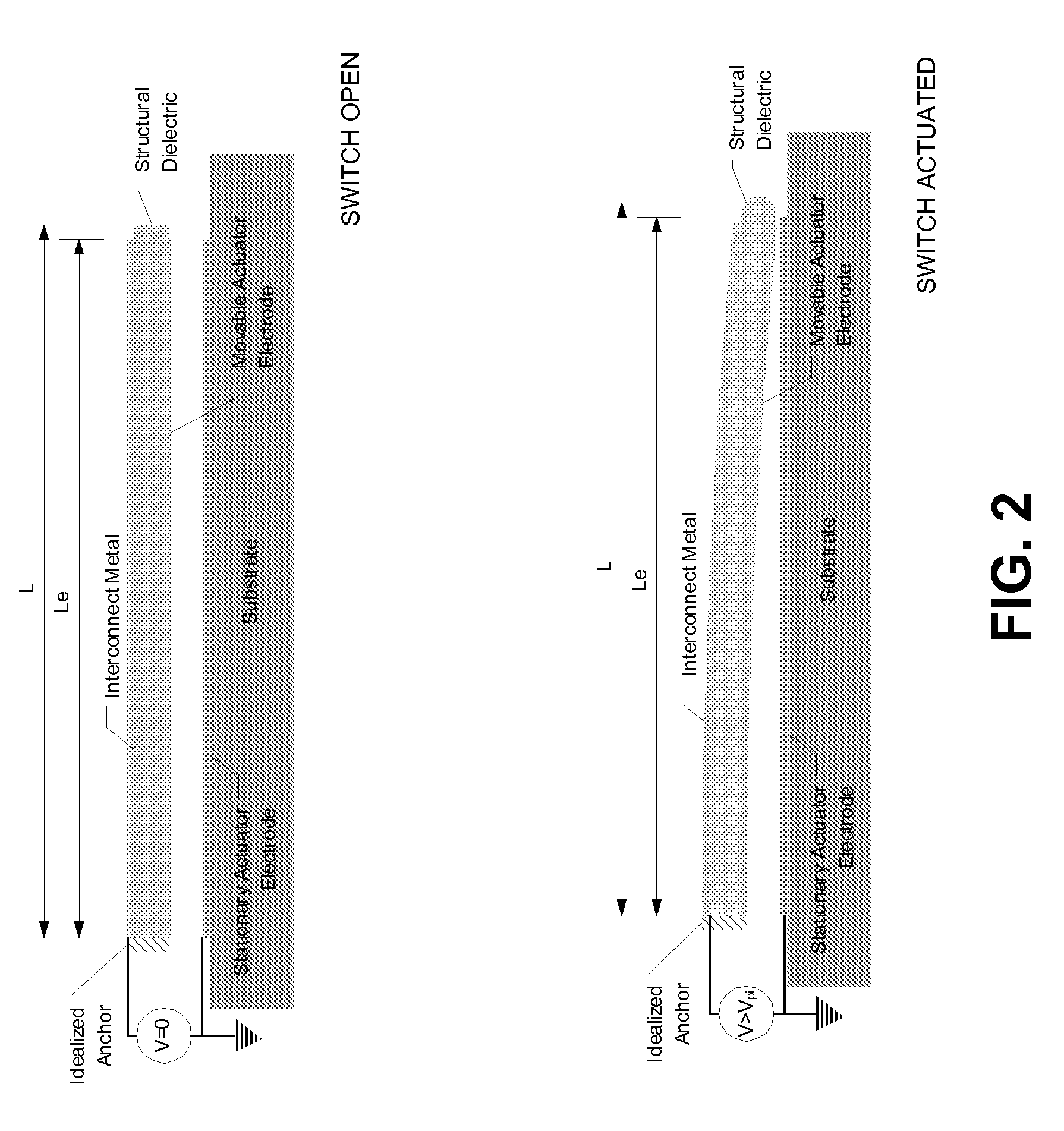

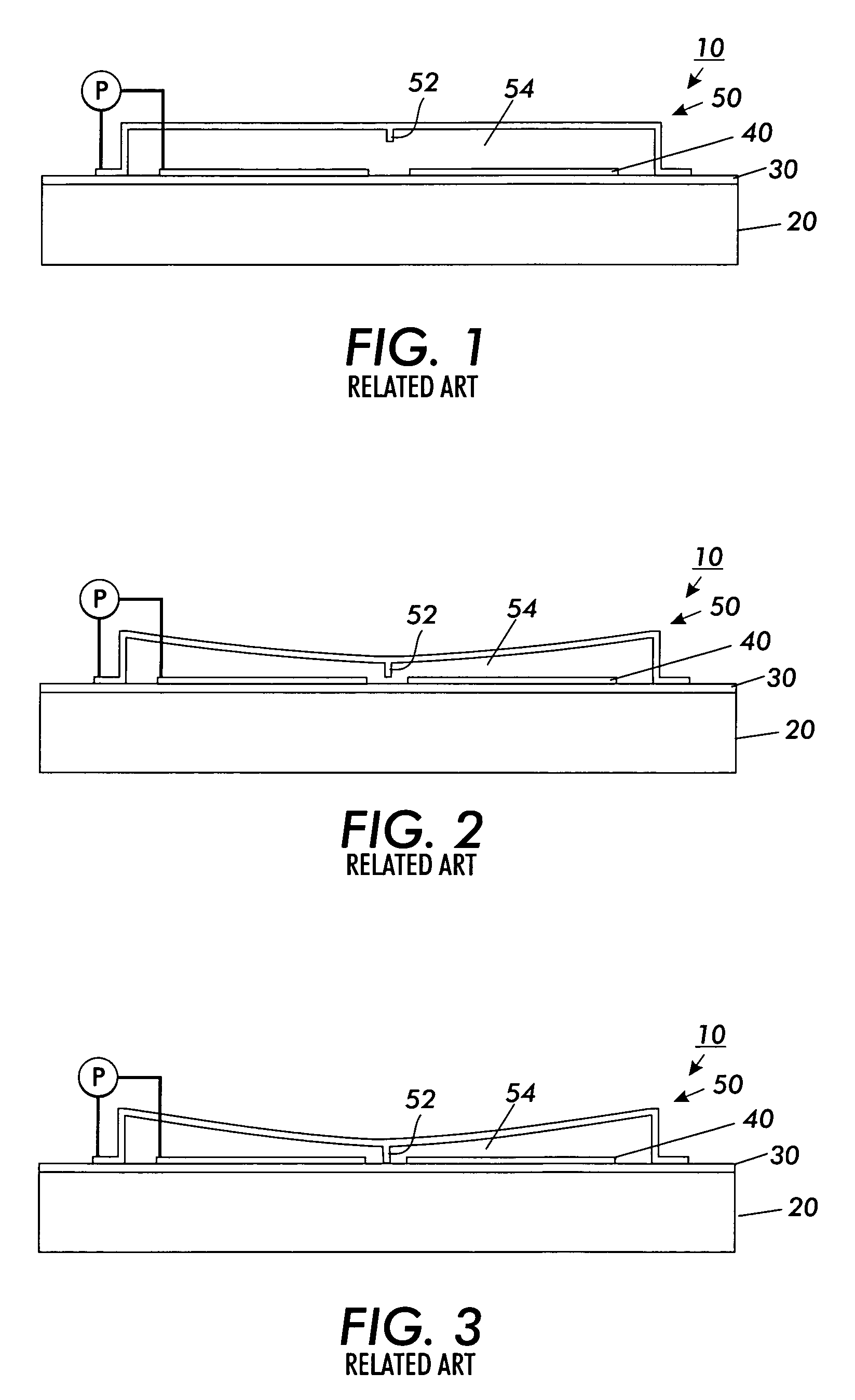

Electrostatic actuator device and method of making the device

InactiveUS20080048520A1Reduce decreaseReduce the amount requiredElectrostatic/electro-adhesion relaysElectrolytic capacitorsEngineeringElectrostatic actuator

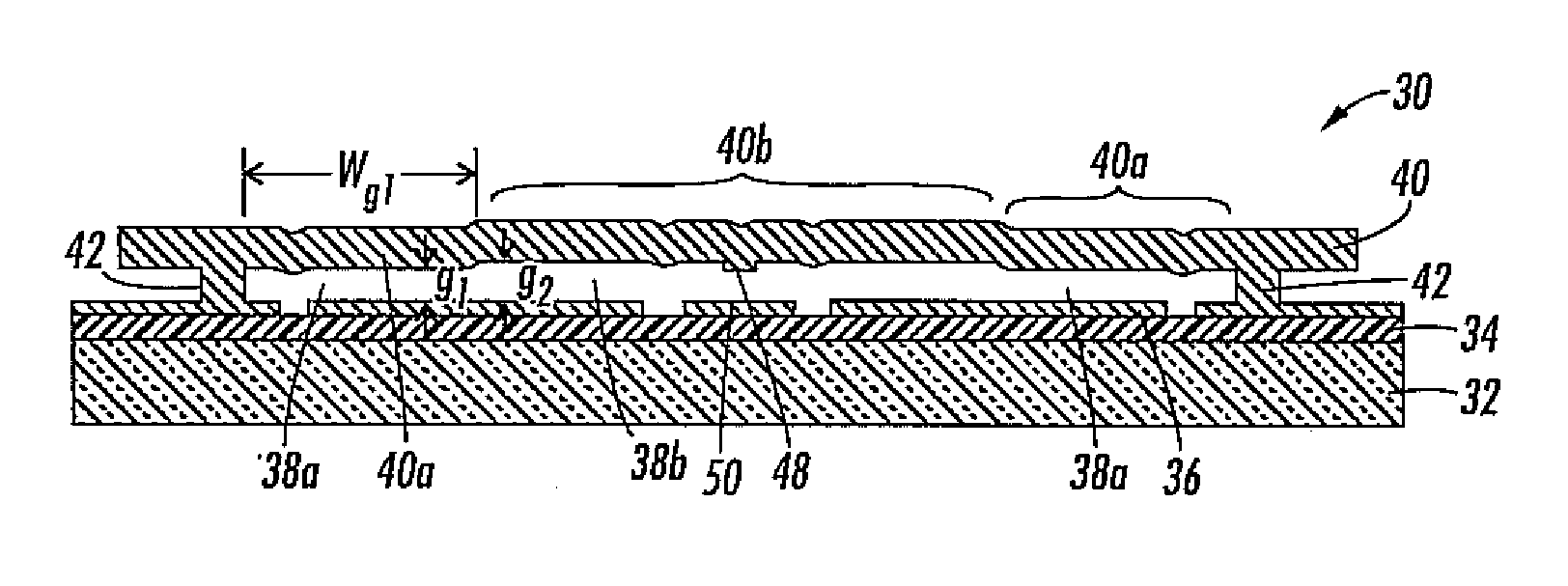

The present application is directed to novel electrostatic actuators and methods of making the electrostatic actuators. In one embodiment, the electrostatic actuator comprises a substrate, an electrode formed on the substrate and a deflectable member positioned in proximity to the electrode so as to provide a gap between the electrode and the deflectable member. The deflectable member is anchored on the substrate via one or more anchors. The gap comprises at least one first region having a first gap height positioned near the one or more anchors and at least one second region having a second gap height positioned farther from the anchors than the first region. The first gap height is smaller than the second gap height.

Owner:XEROX CORP

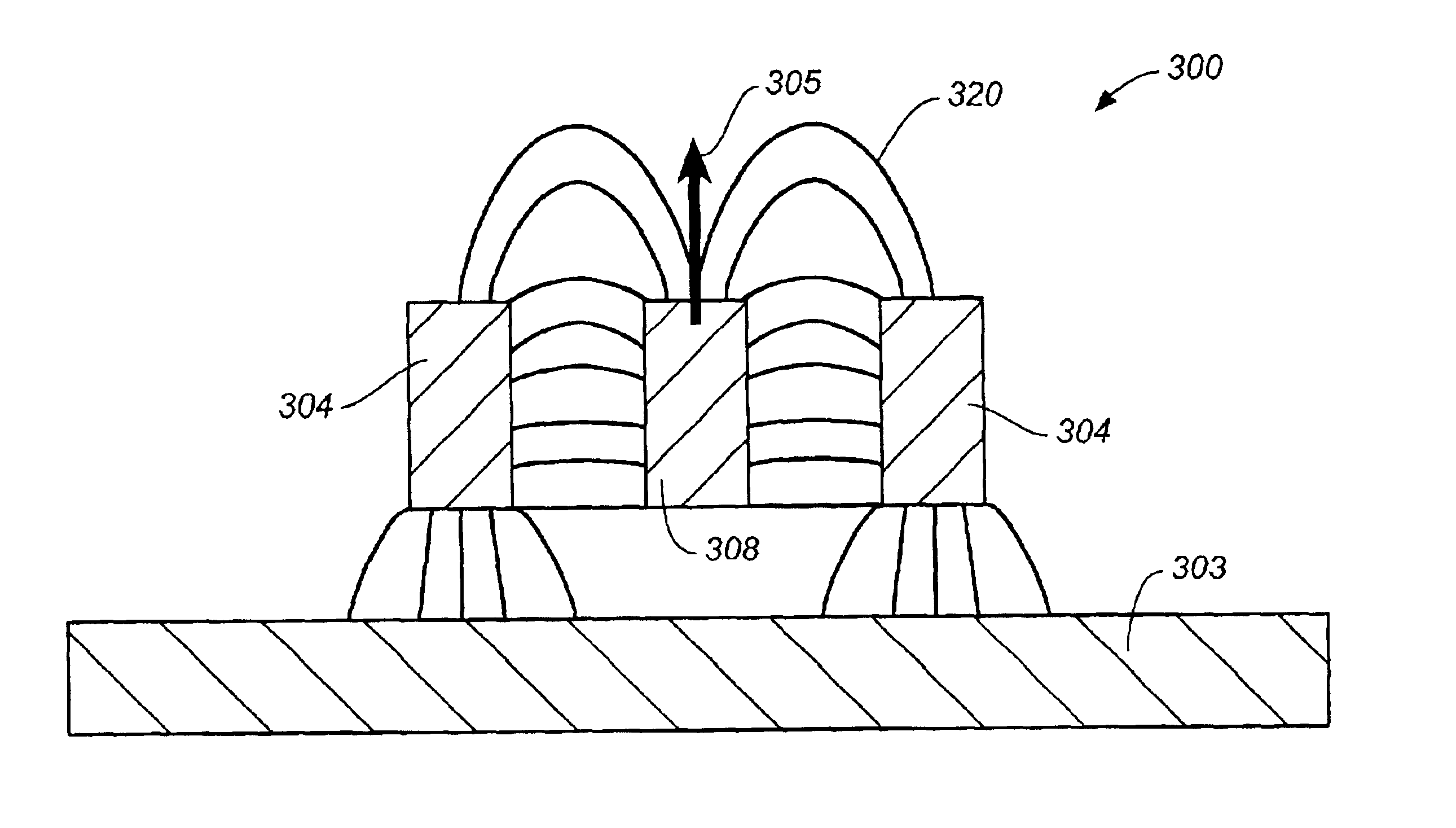

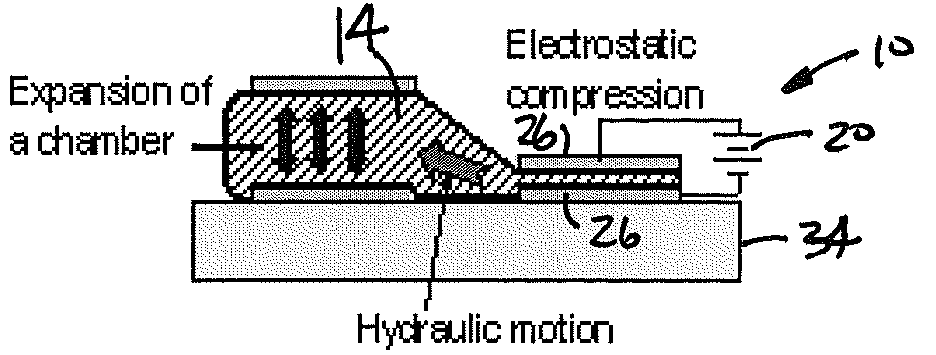

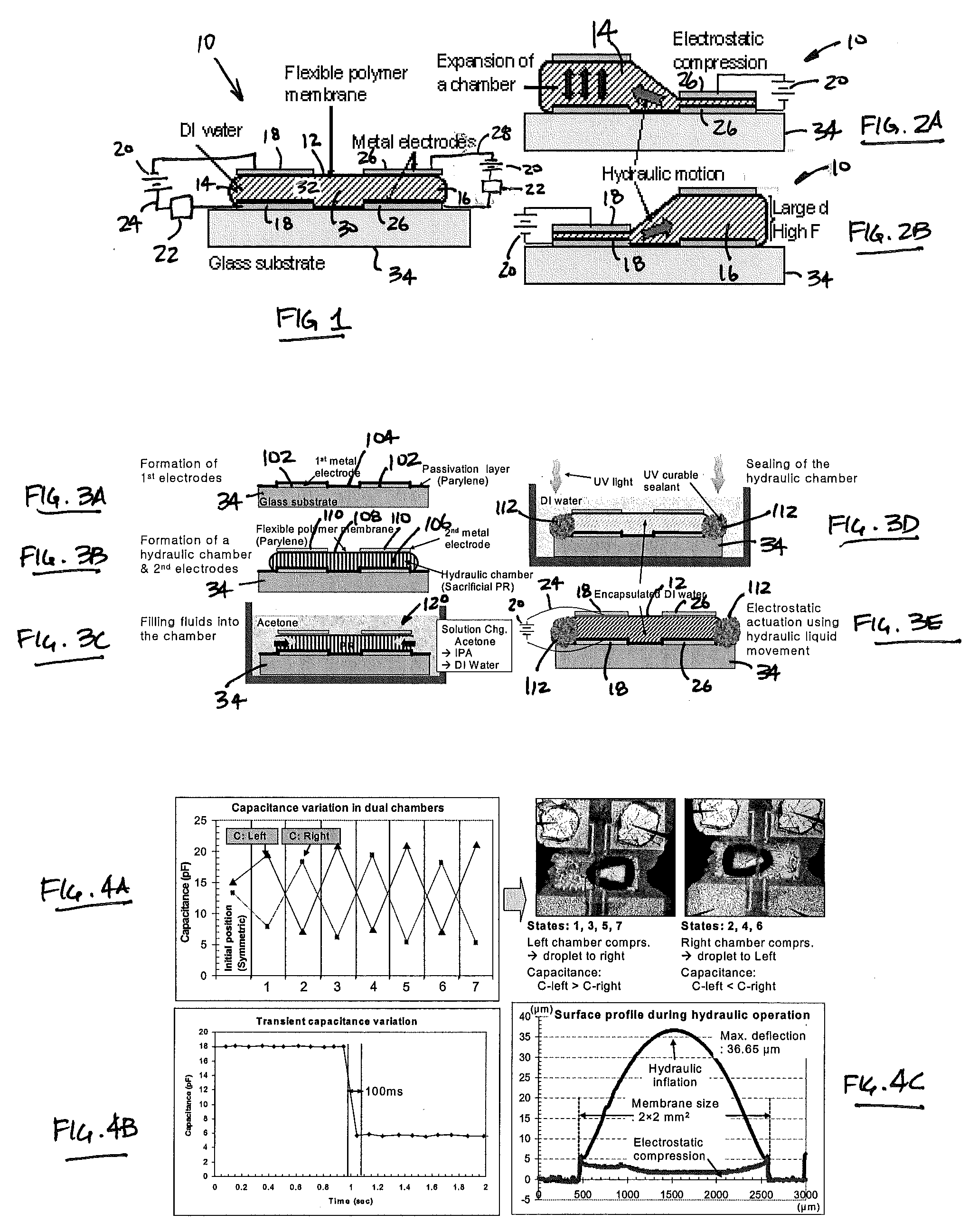

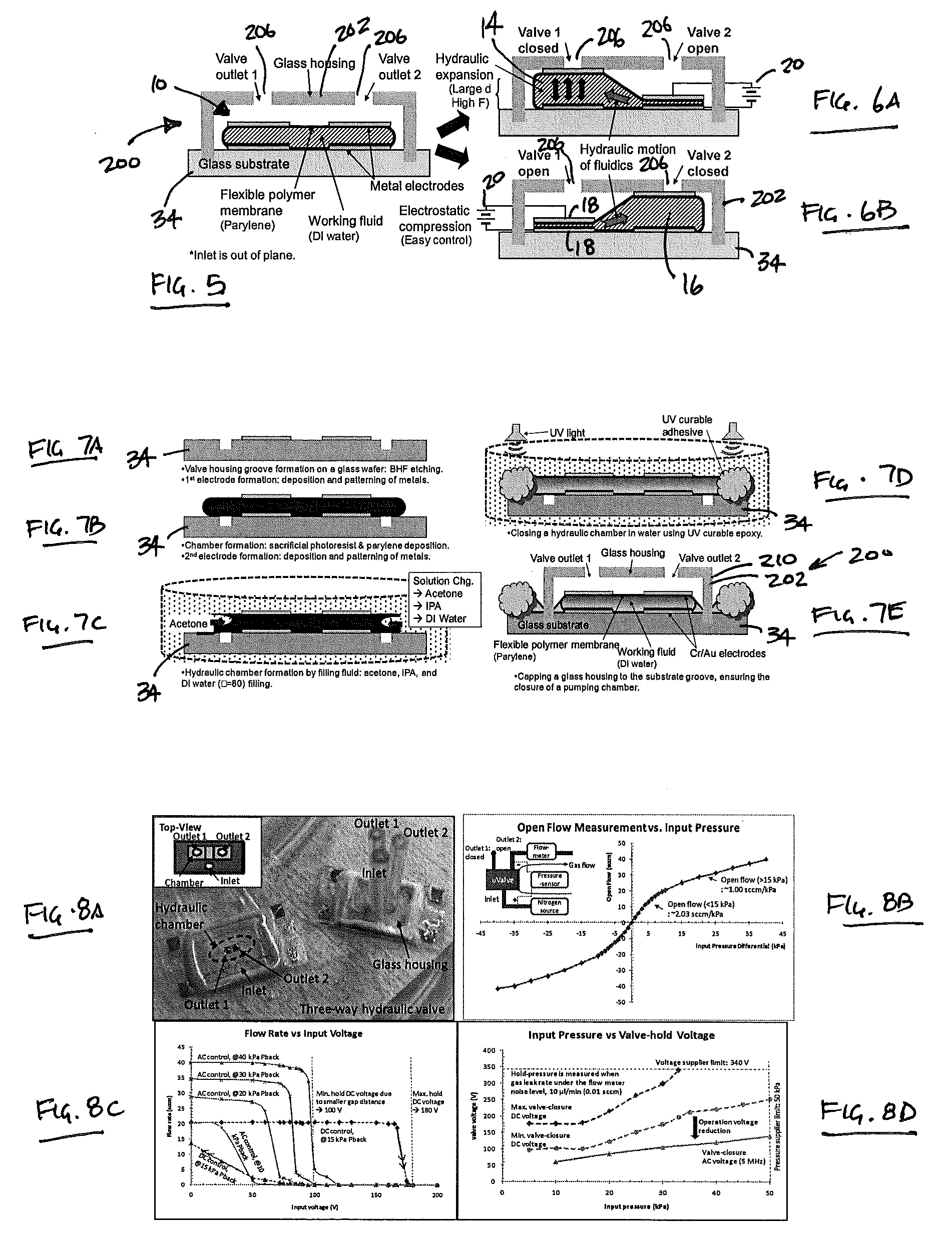

Liquid-gap electrostatic hydraulic micro actuators

InactiveUS20090115285A1Reduce voltageHigh gas conductancePiezoelectric/electrostrictive device manufacture/assemblyOperating means/releasing devices for valvesParallel plateMicro actuator

A liquid-gap electrostatic hydraulic micro actuator is provided that produces higher displacement (in and out of plane) and larger force than typical electrostatic actuators by utilizing a non-conducting liquid as its dielectric material. This new class of actuators utilizes the liquid dielectric for hydraulic amplification and force transfer. The liquid electrostatic actuator consists of two chambers each forming a parallel-plate capacitor, filled with a non-conducting incompressible liquid. One chamber is compressed by pulling down a flexible membrane using electrostatic actuation, thus forcing the liquid under it to transfer into the other chamber. Such movement causes the other chamber's membrane to expand out of plane.

Owner:RGT UNIV OF MICHIGAN

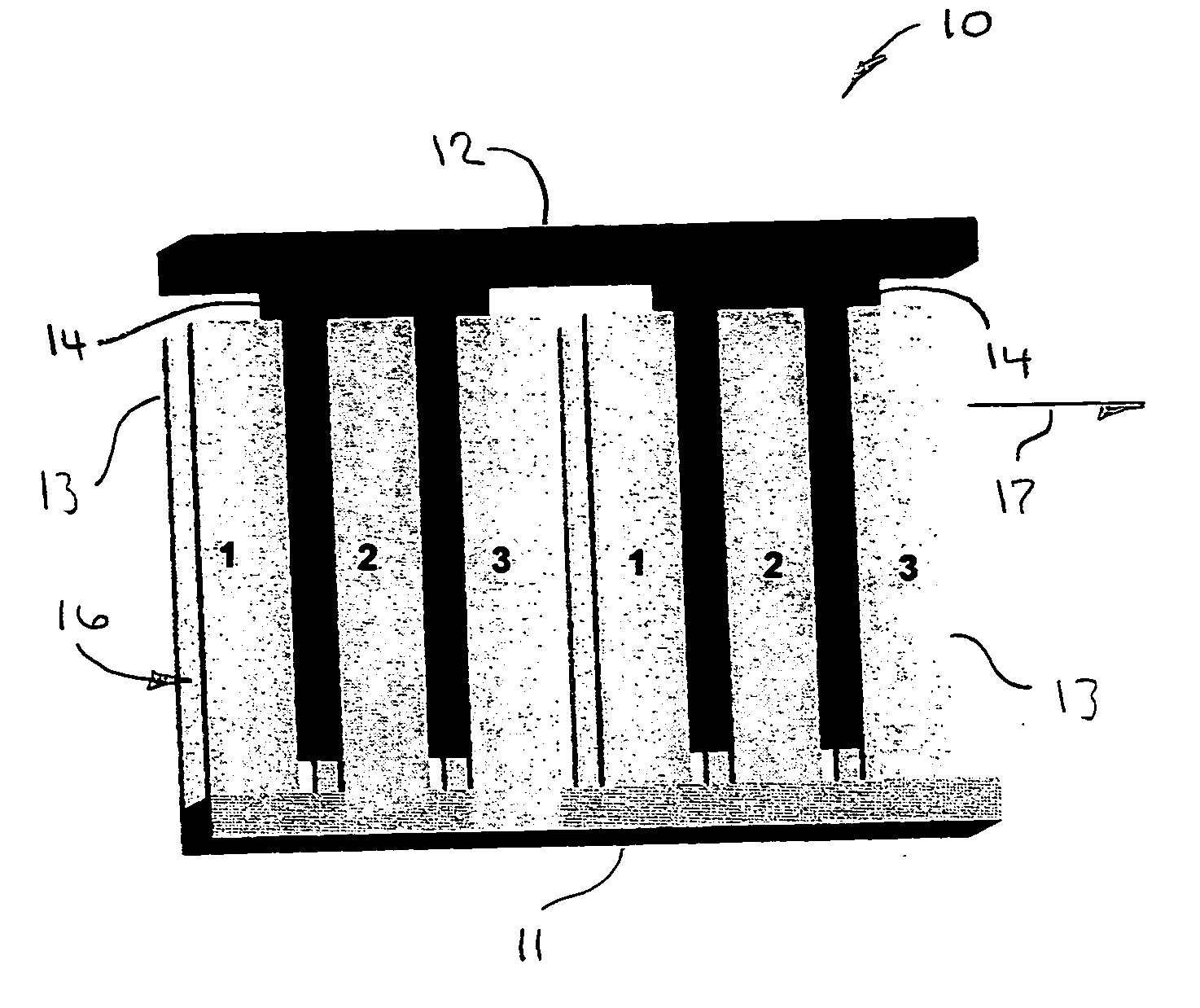

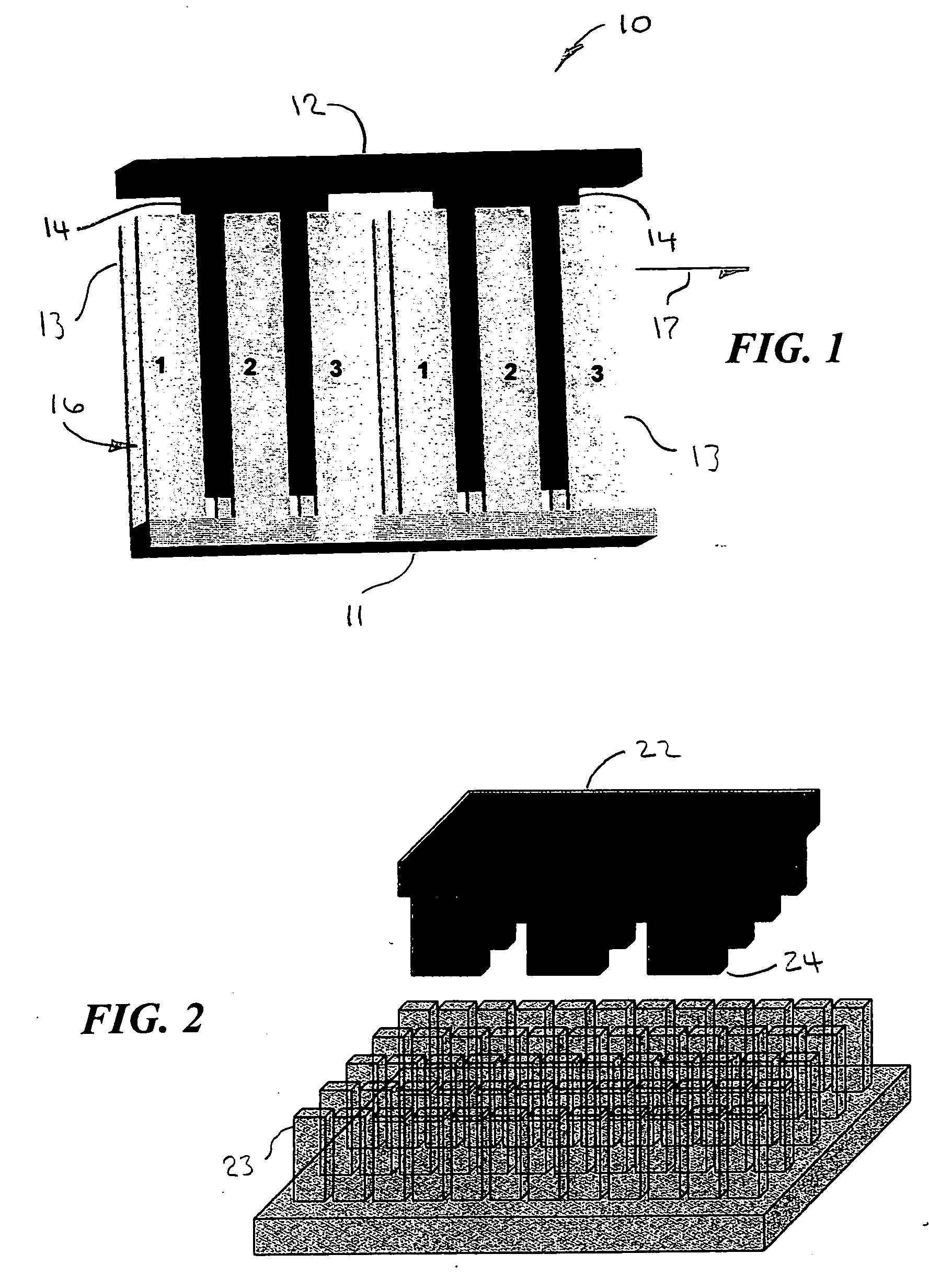

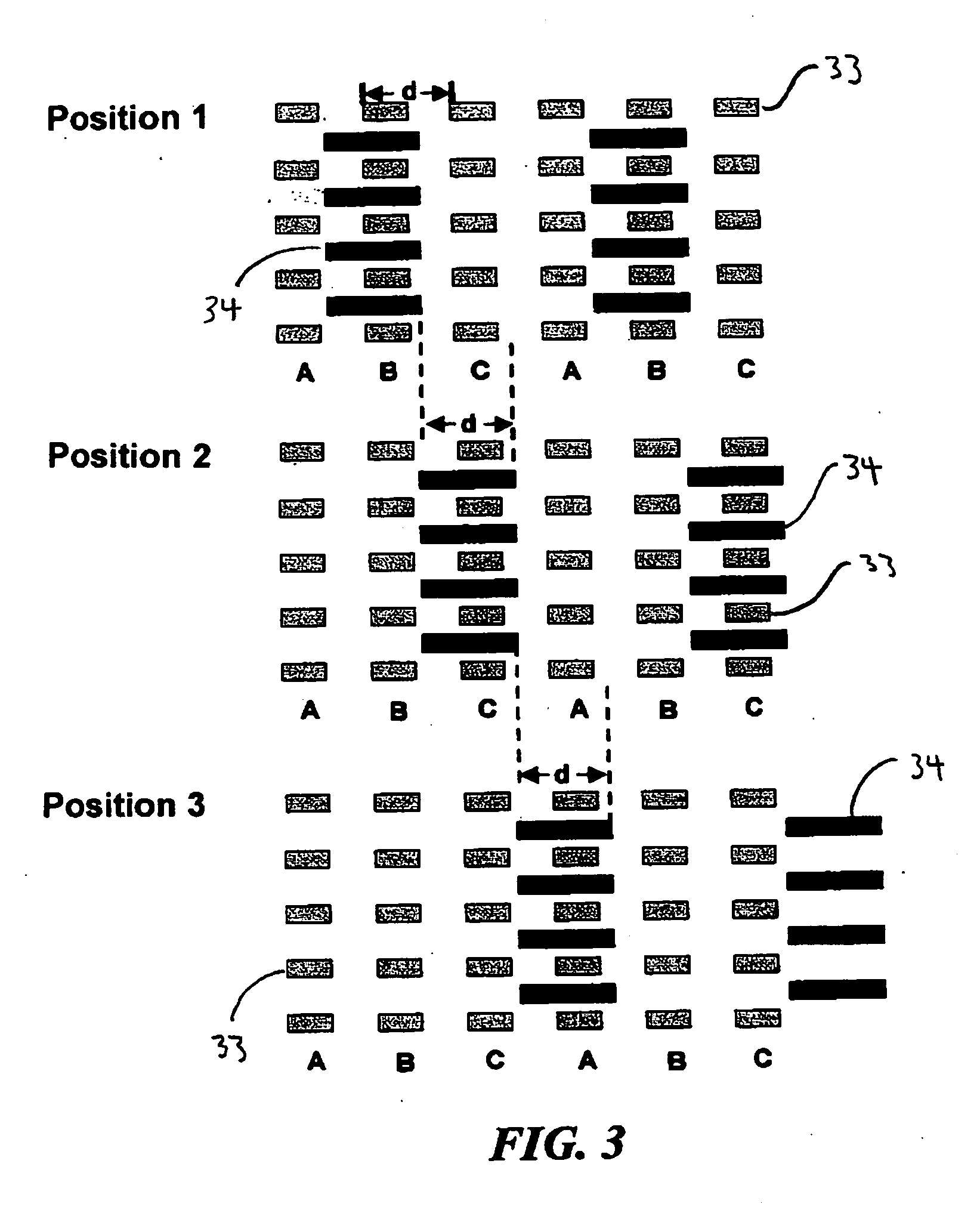

MEMS digital linear actuator

ActiveUS20070024155A1Fine surfaceIncrease electrostatic forceTelevision system detailsColor television detailsEngineeringElectrostatic actuator

In accordance with an embodiment of the present invention, an electrostatic actuator has a base having a plurality of base pillars formed thereon and has a stage having a plurality of stage pillars formed thereon. The controlled application of voltage signals to the base pillars and / or the stage pillars results in electrostatic force that effects movement of the stage with respect to the base.

Owner:DIGITALPTICS MEMS

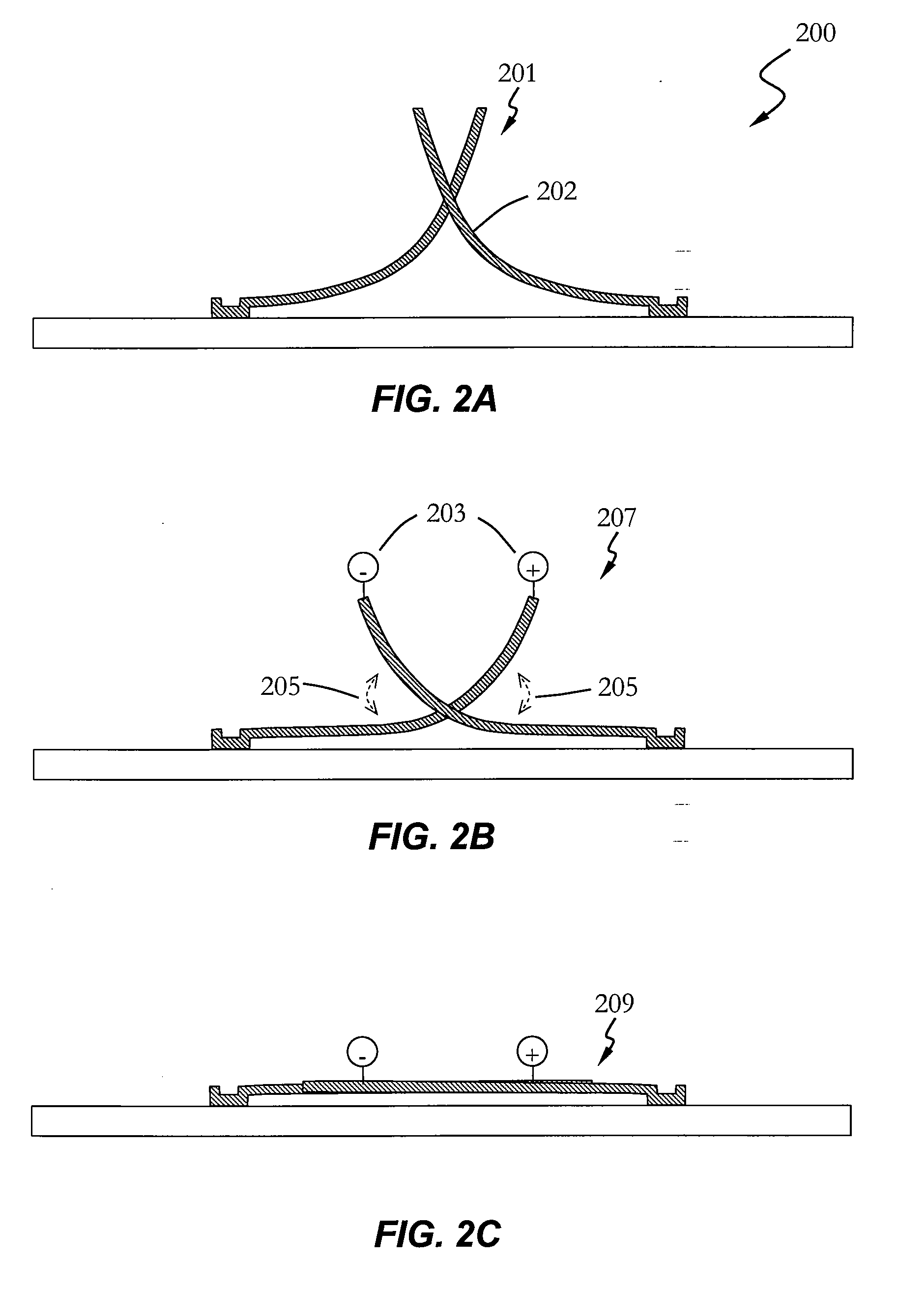

Bistable microelectromechanical system based structures, systems and methods

InactiveUS20030210115A1Increase flexibilityReduce complexityElectrostatic/electro-adhesion relaysCoupling light guidesStable stateThermal impact

A bistable microelectromechanical system (MEMS) based system comprises a micromachined beam having a first stable state, in which the beam is substantially stress-free and has a specified non-linear shape, and a second stable state. The curved shape may comprises a simple curve or a compound curve. In embodiments, the boundary conditions for the beam are fixed boundary conditions, bearing boundary conditions, spring boundary conditions, or a combination thereof. The system may further comprise an actuator arranged to move the beam between the first and second stable states and a movable element that is moved between a first position and a second position in accordance with the movement of the beam between the first and second stable states. The actuator may comprise one of a thermal actuator, an electrostatic actuator, a piezoelectric actuator and a magnetic actuator. The actuator may further comprise a thermal impact actuator or a zippering electrostatic actuator.

Owner:XEROX CORP

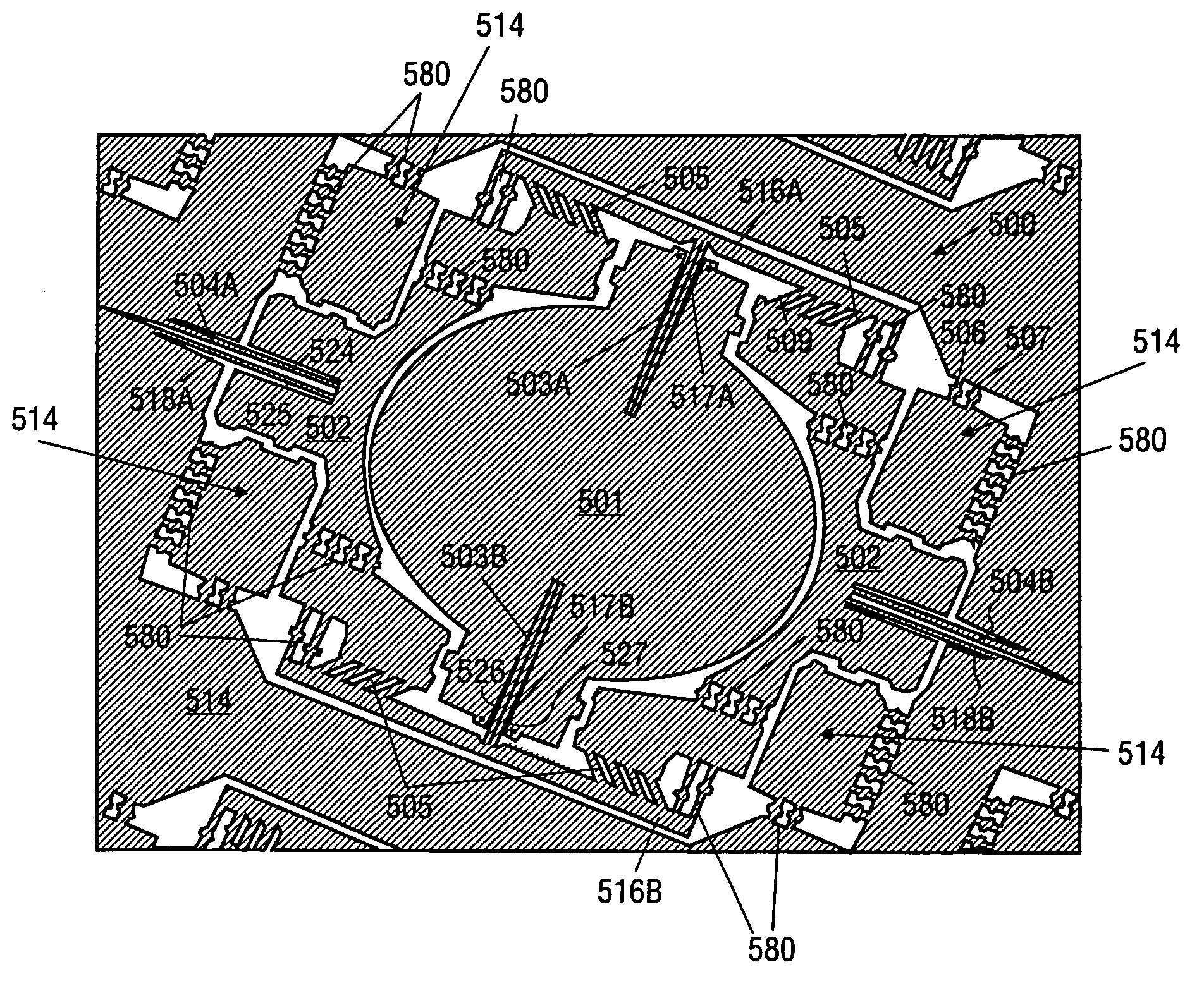

Erected mirror optical switch

A microelectromechanical (MEM) optical switching apparatus is disclosed that is based on an erectable mirror which is formed on a rotatable stage using surface micromachining. An electrostatic actuator is also formed on the substrate to rotate the stage and mirror with a high angular precision. The mirror can be erected manually after fabrication of the device and used to redirect an incident light beam at an arbitrary angel and to maintain this state in the absence of any applied electrical power. A 1×N optical switch can be formed using a single rotatable mirror. In some embodiments of the present invention, a plurality of rotatable mirrors can be configured so that the stages and mirrors rotate in unison when driven by a single micromotor thereby forming a 2×2 optical switch which can be used to switch a pair of incident light beams, or as a building block to form a higher-order optical switch.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

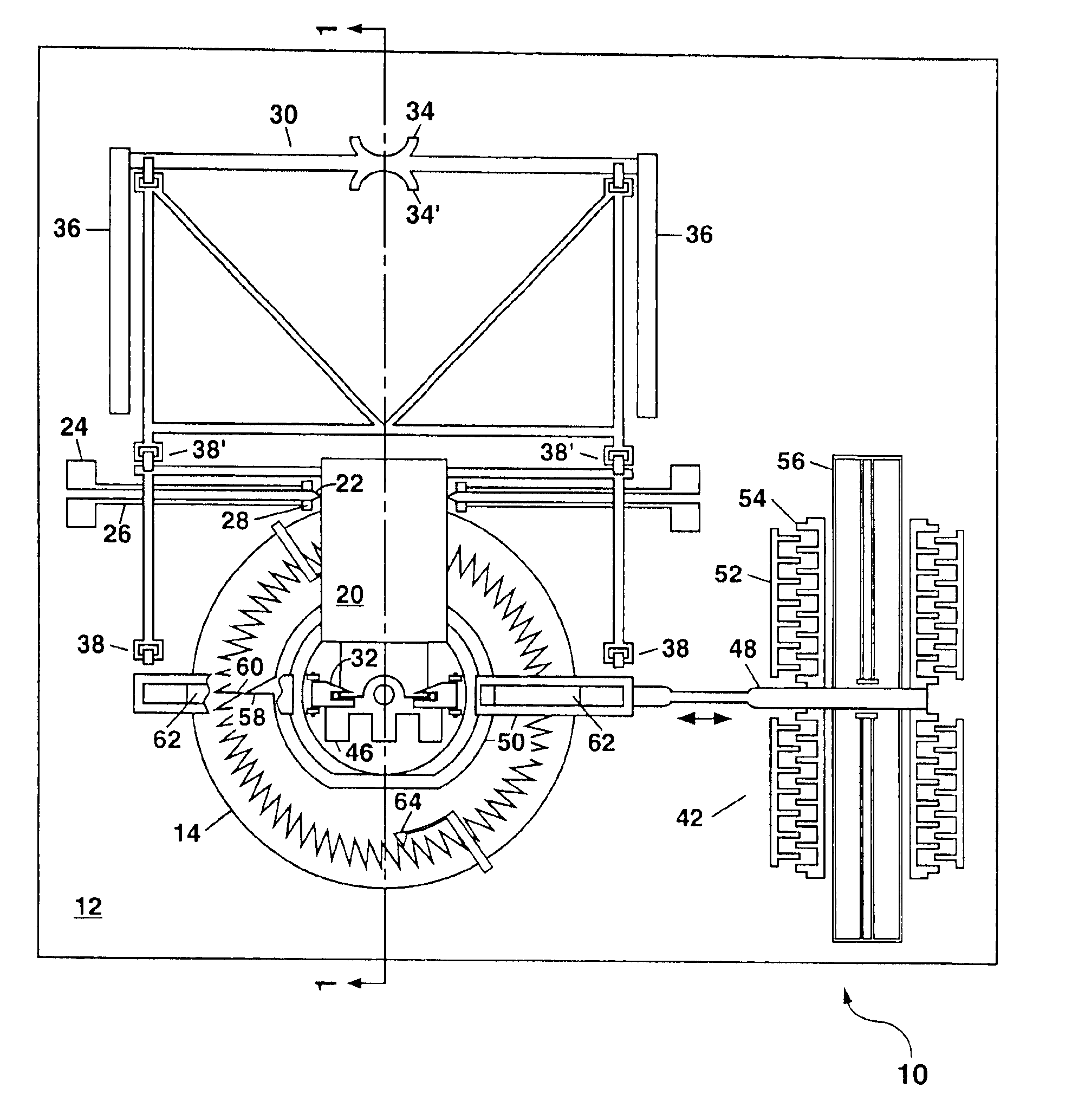

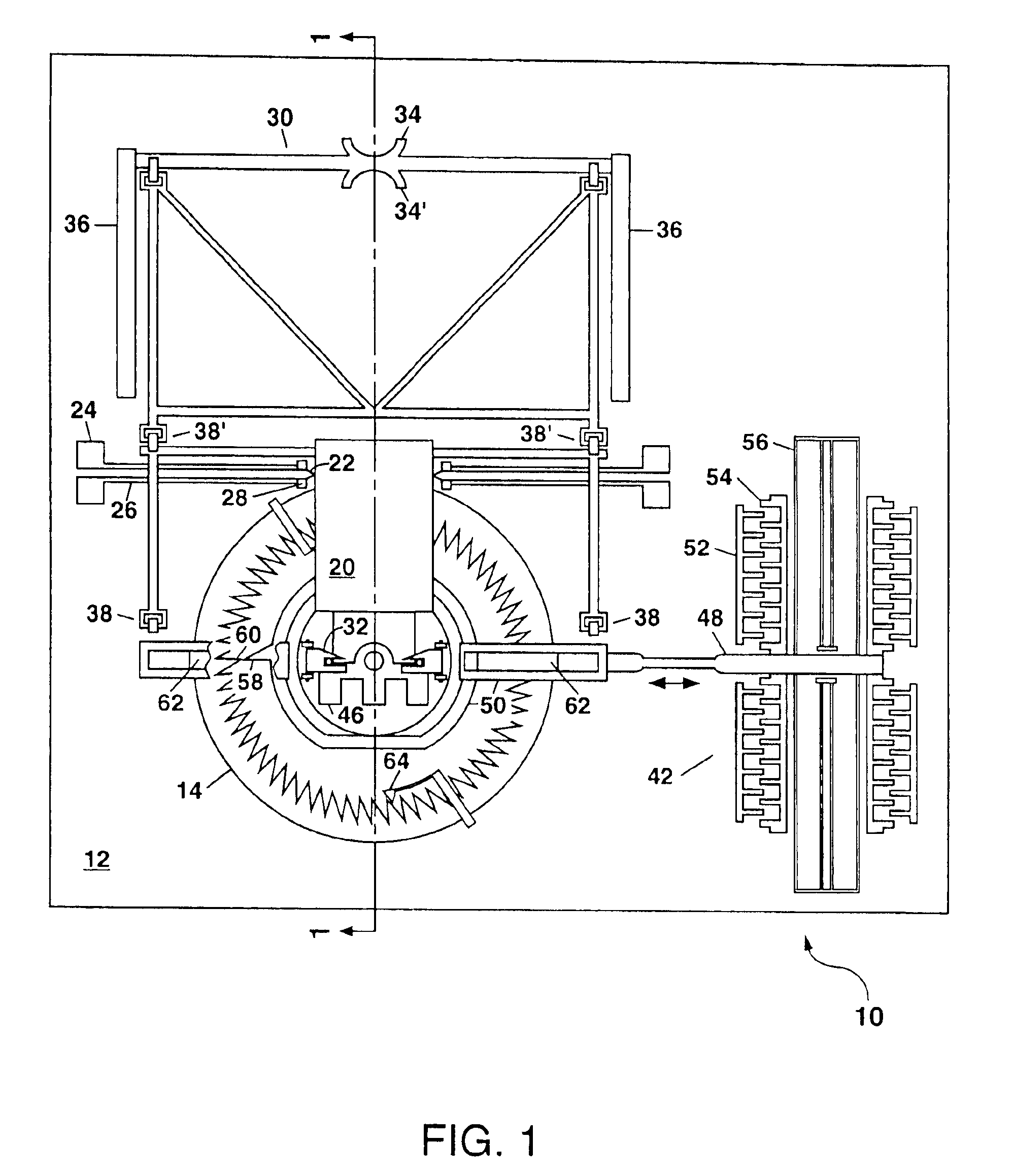

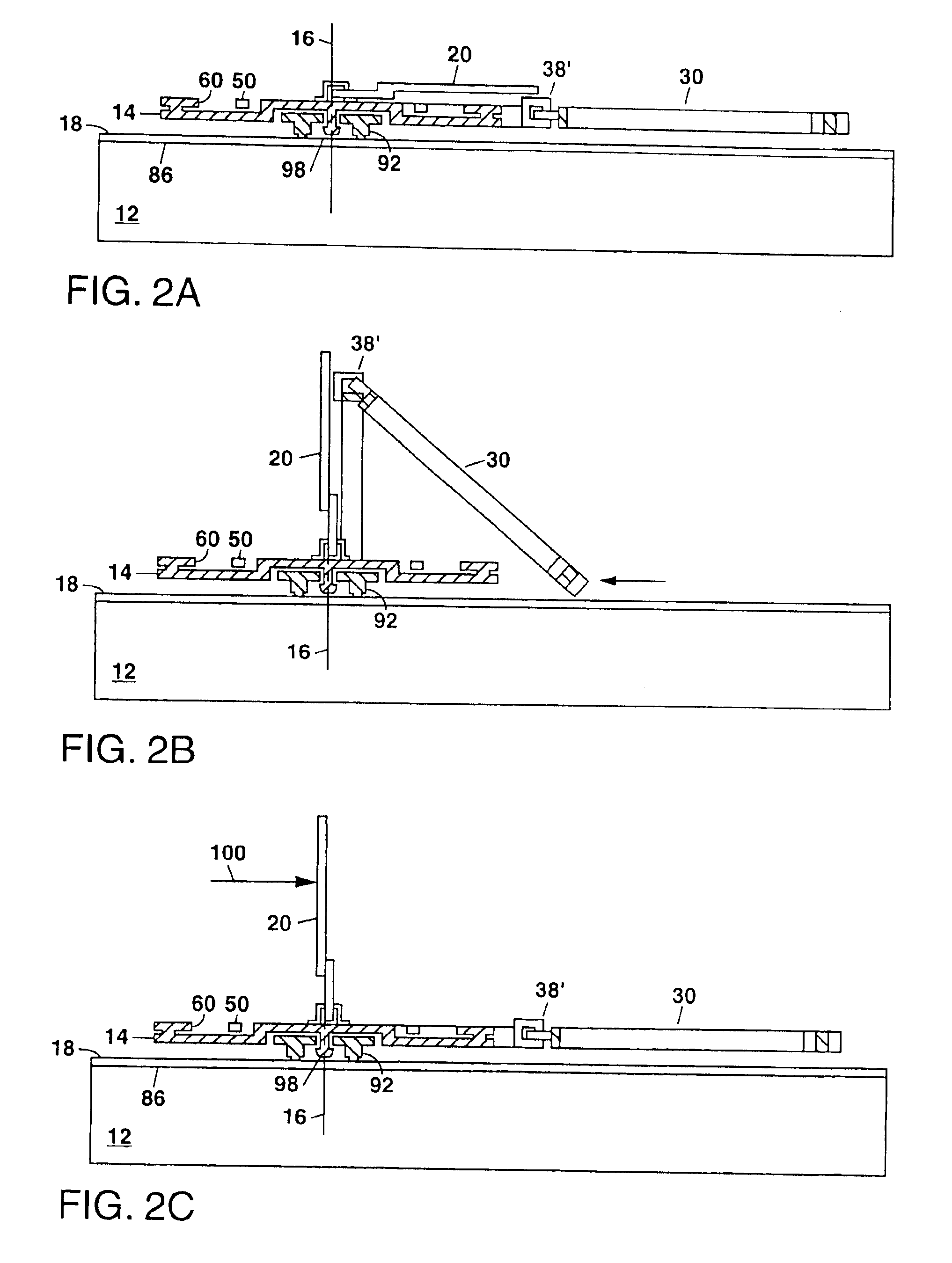

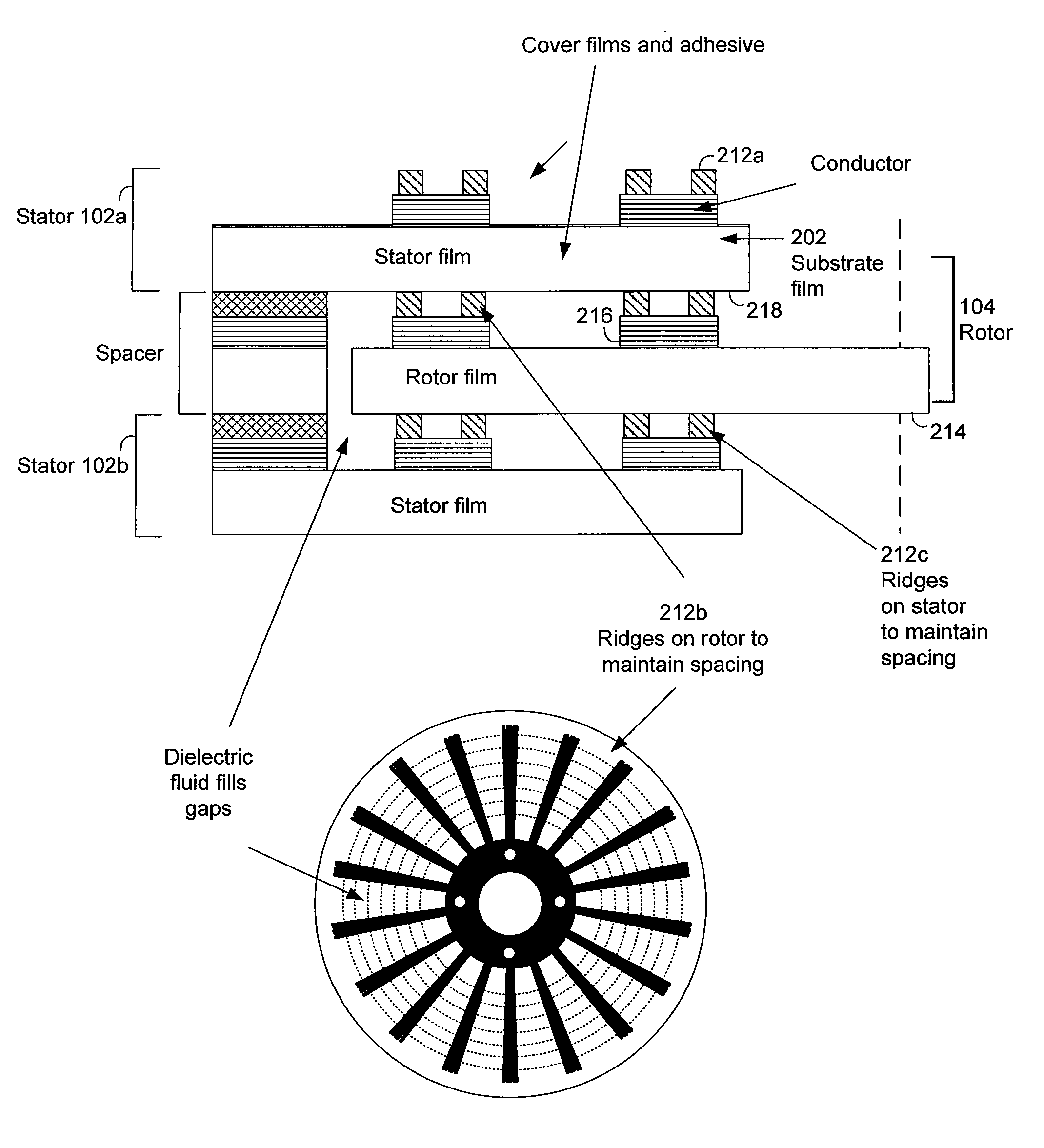

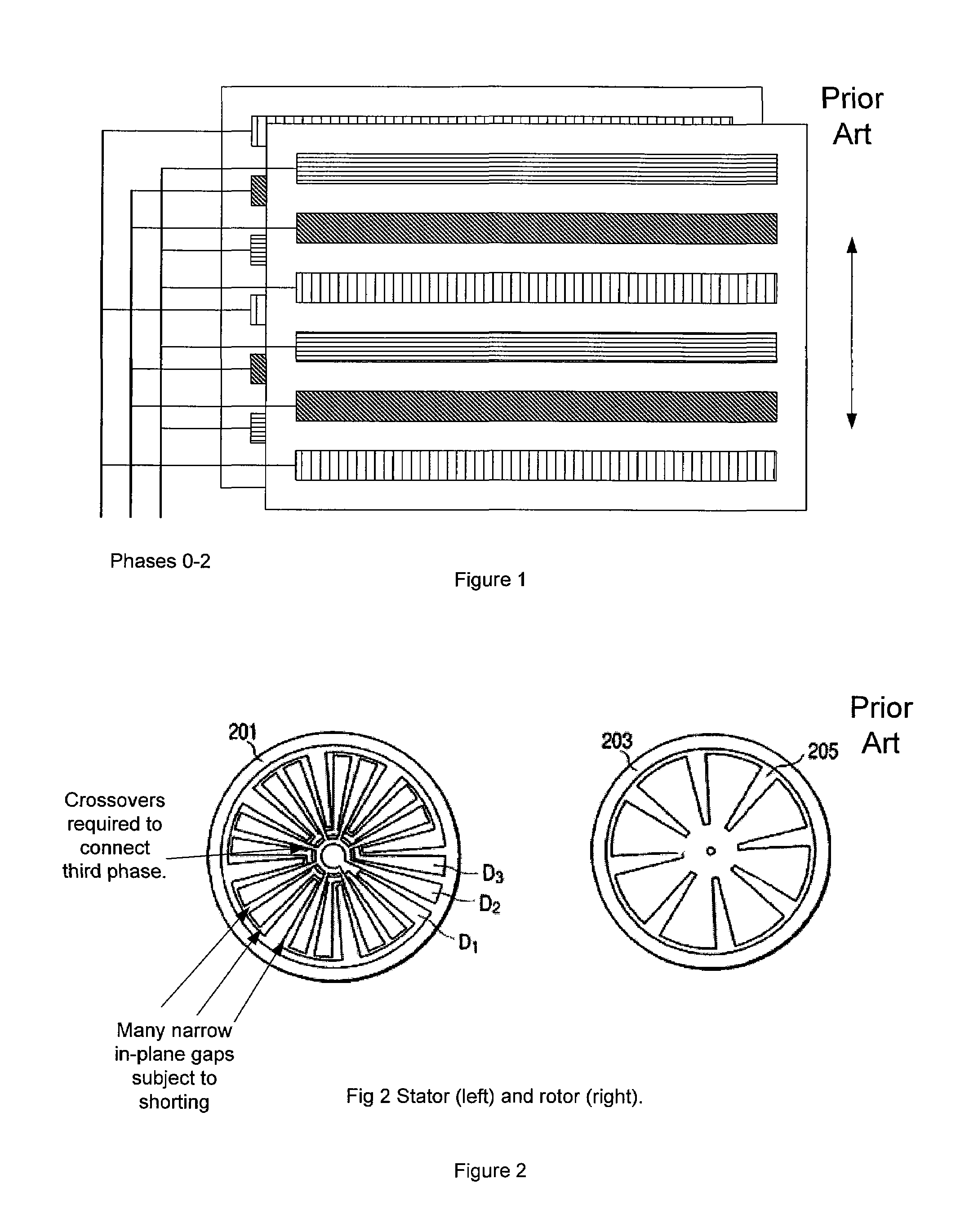

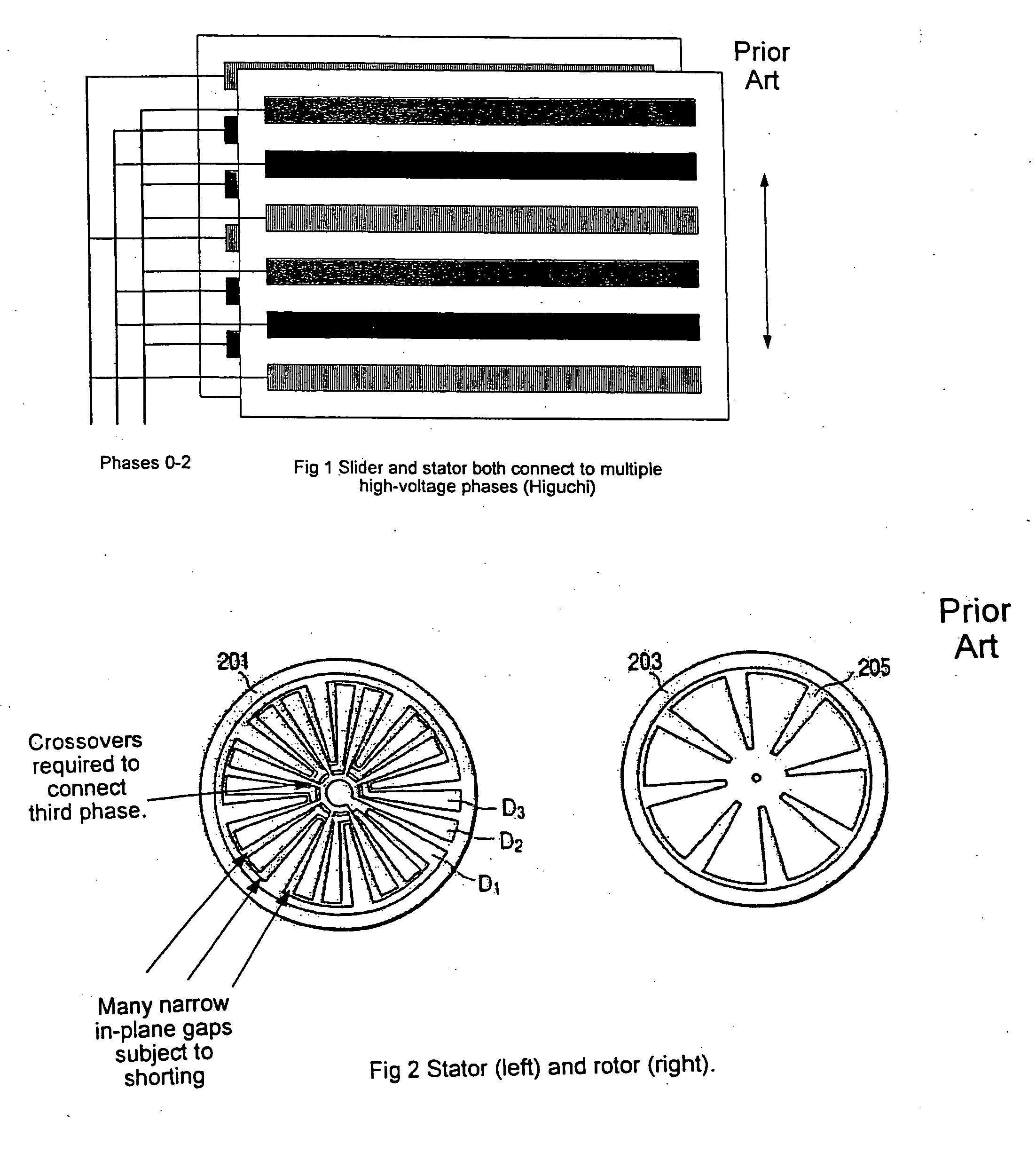

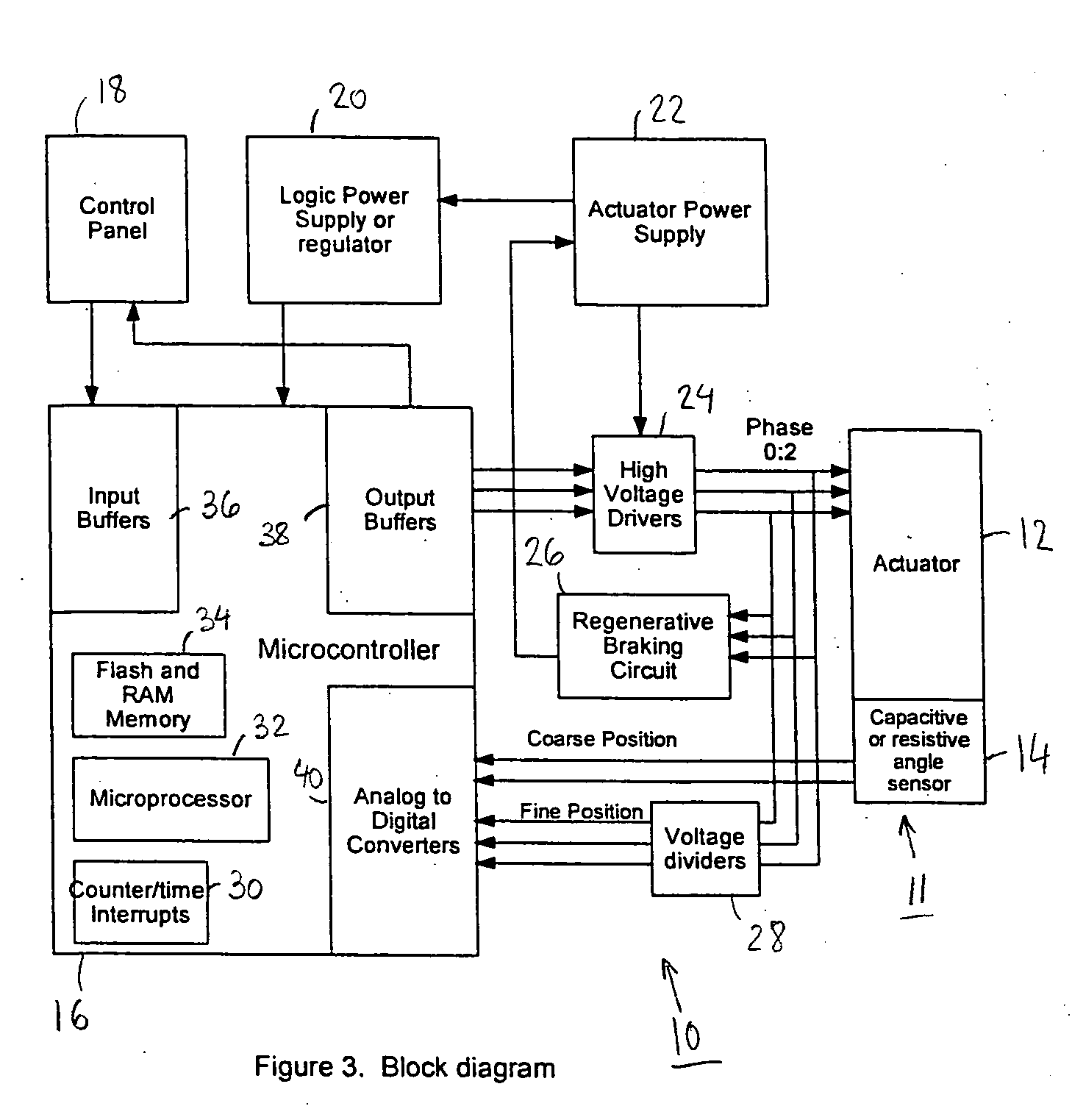

Electrostatic actuator with fault tolerant electrode structure

InactiveUS7239065B2Manufacturing tolerance requiredPrecise alignmentPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionFlexible circuitsLow voltage

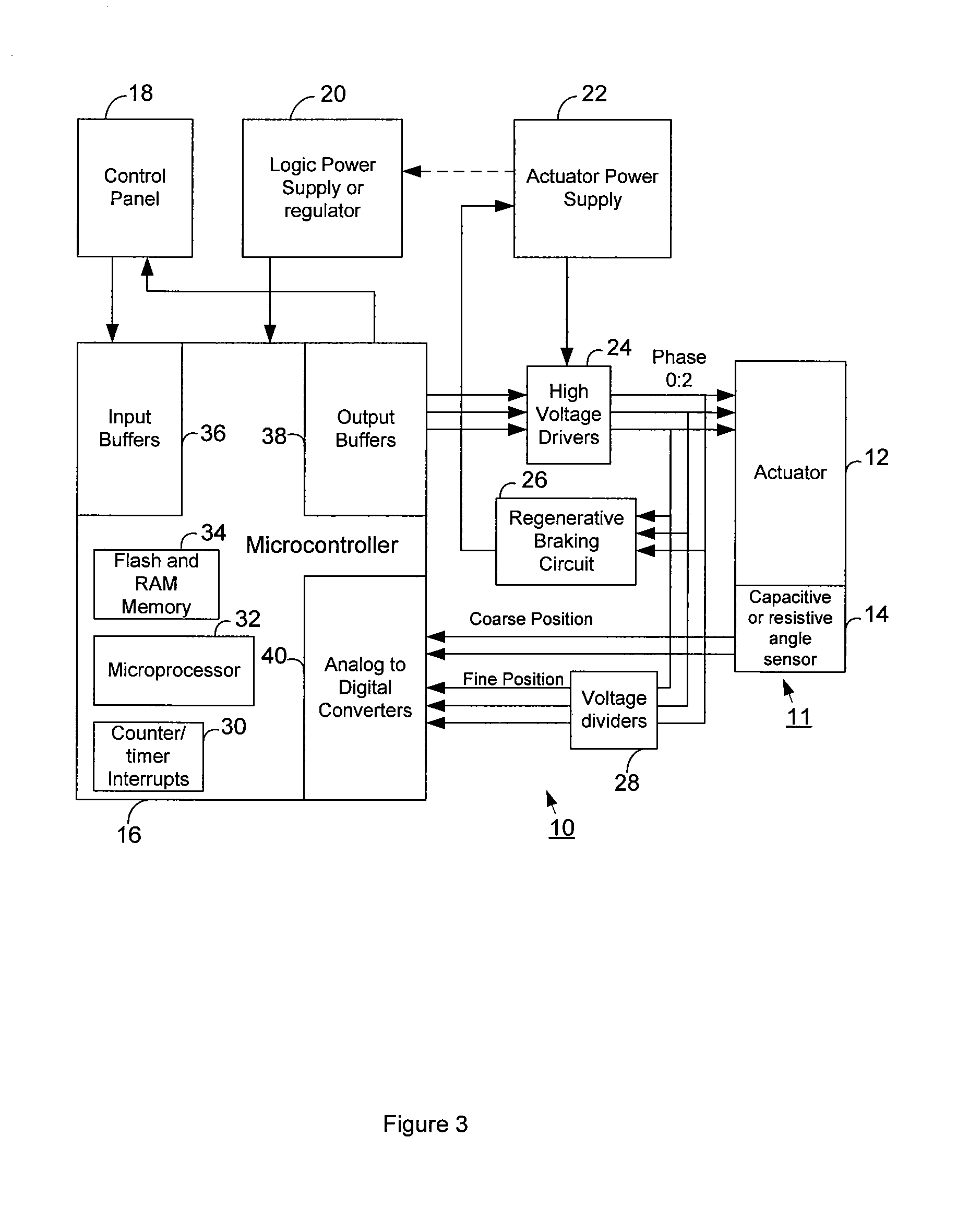

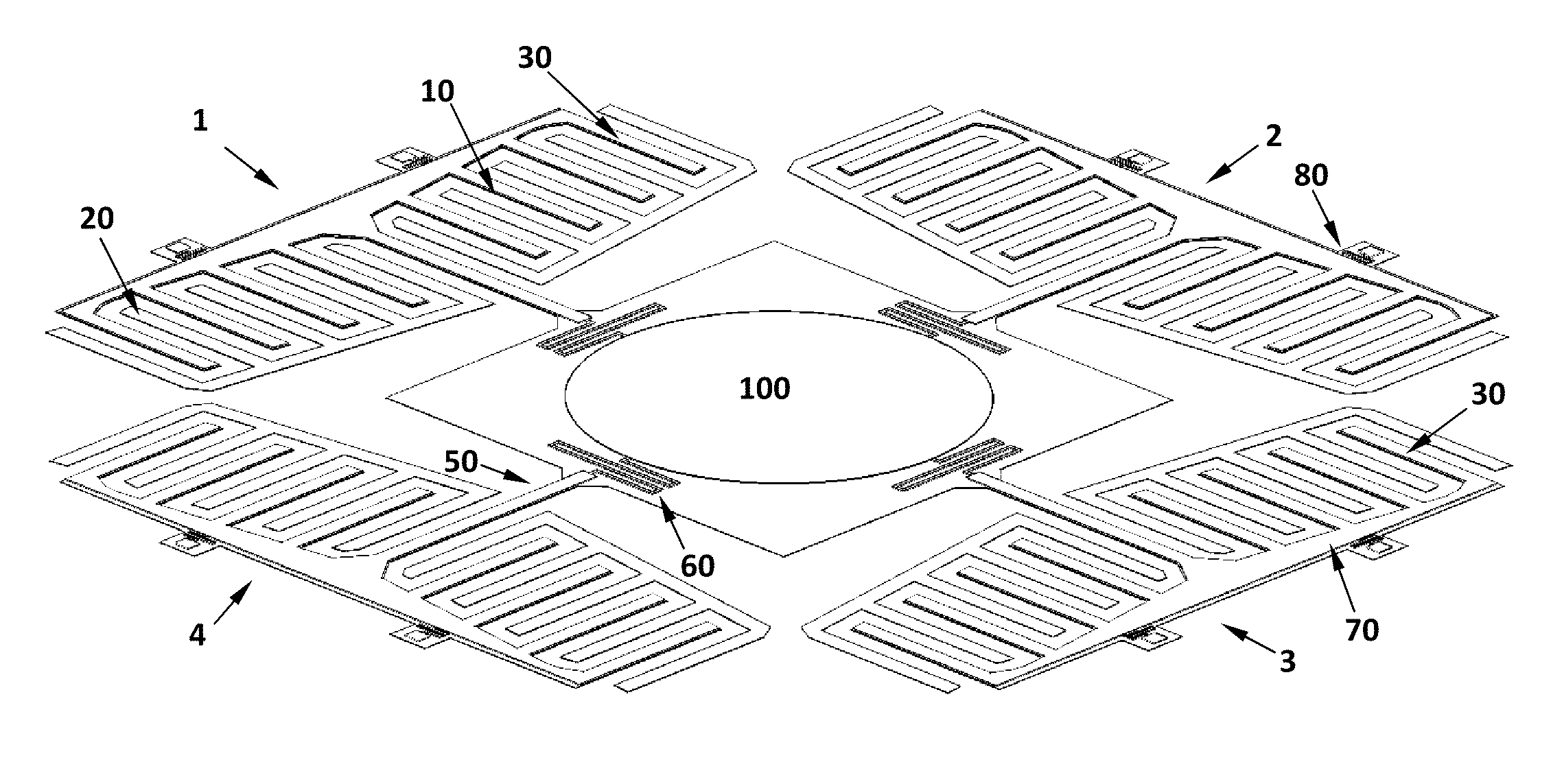

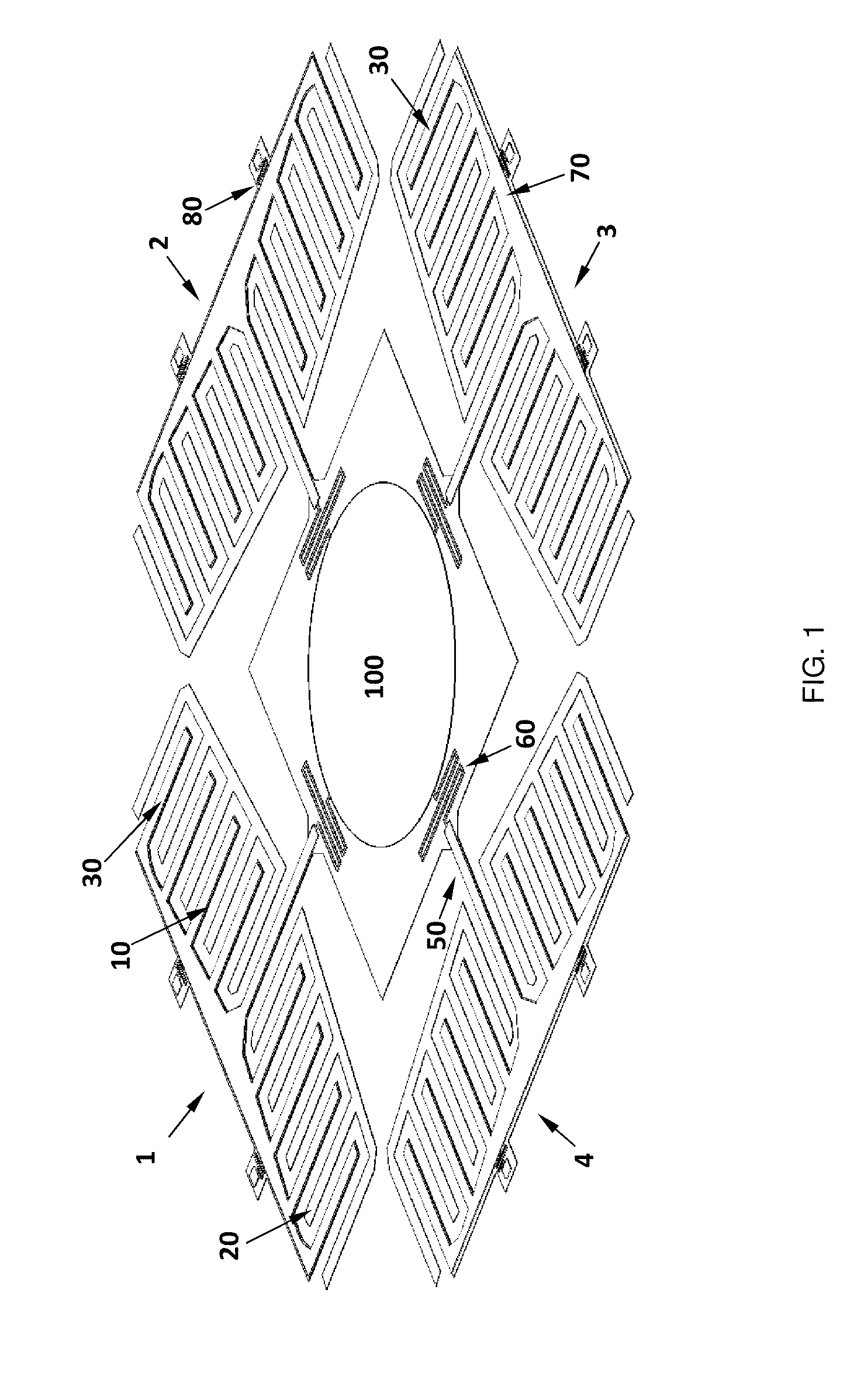

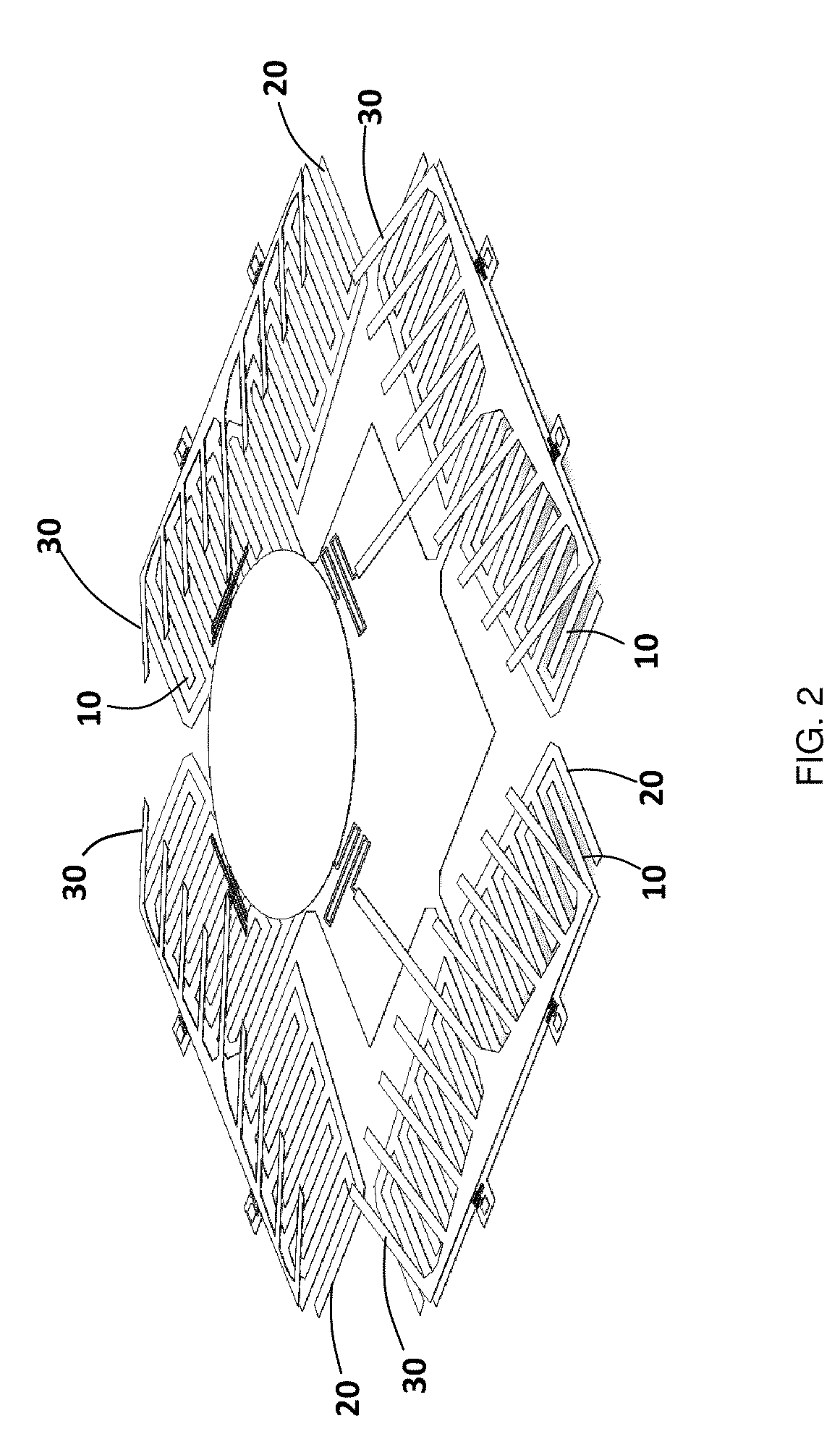

A high-power electrostatic actuator comprising rotor and stator layers with fault-tolerant electrode structures, a housing to contain the electrodes and dielectric fluid, and electronic circuitry driving a plurality of high-voltage phases. The actuator is constructed from multiple rotor and stator films separated by spacing elements. The electrode structure provides self-alignment for precise assembly. The actuator assembly includes built-in fine-position sensors to allow optimal timing in powering phases, and a coarse position sensor for feedback control. The electrode structure has a large region of linear force to provide low torque-ripple allowing simple high / low voltage pulsing instead of analog high voltage waveforms. Single or double sided flexible circuit manufacturing techniques are used to fabricate the rotor and stator films at low cost.

Owner:ALTERG INC

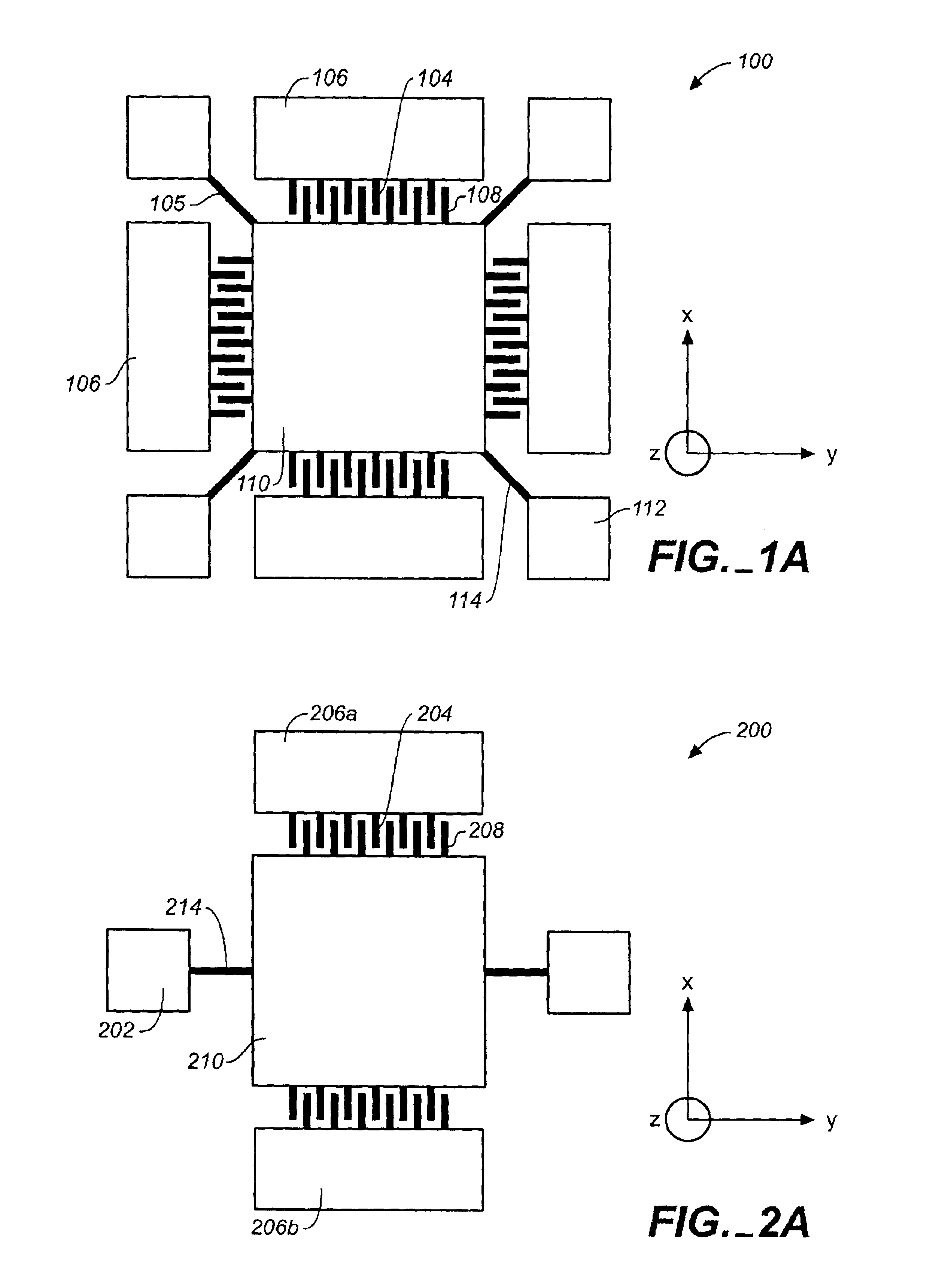

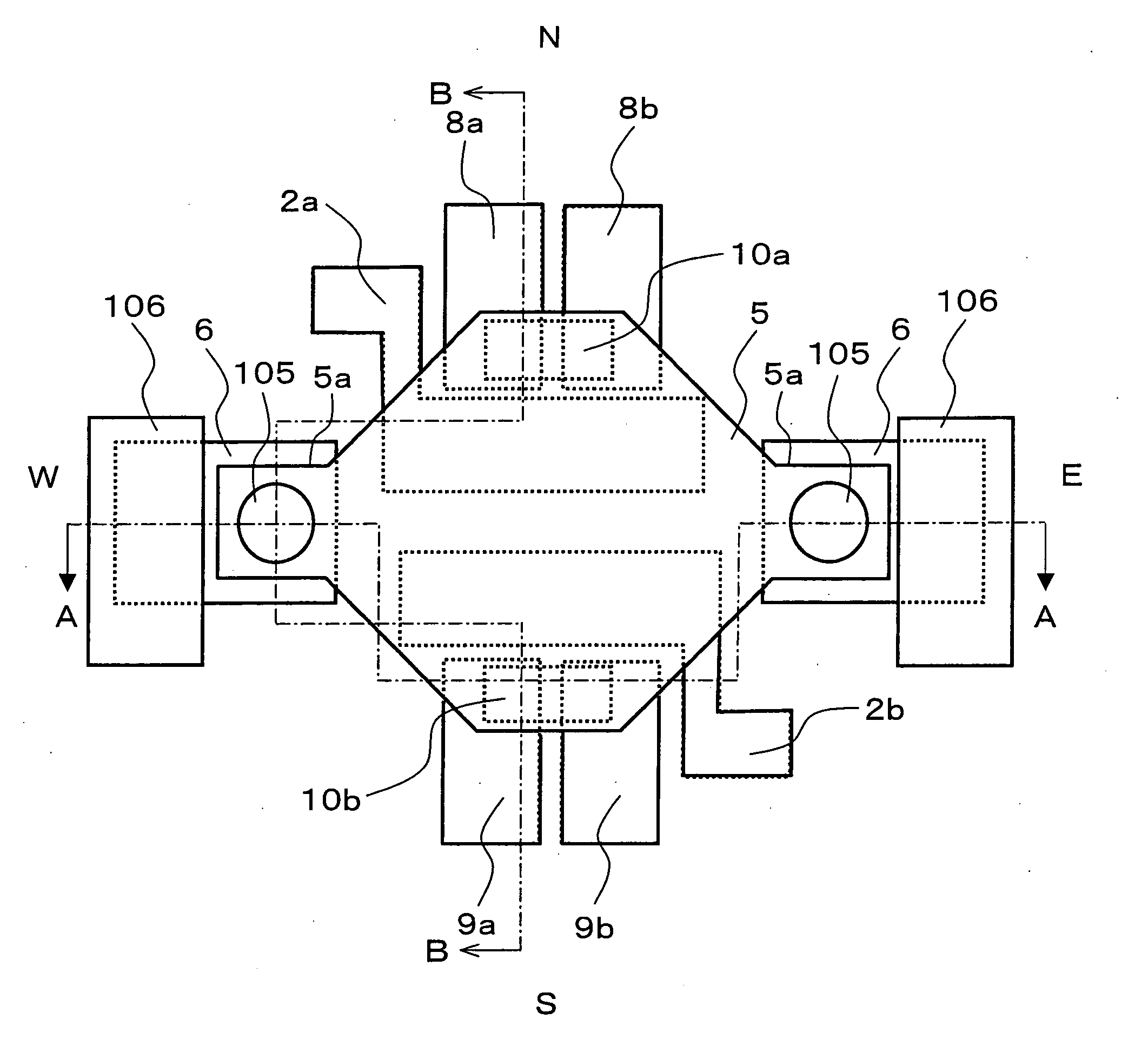

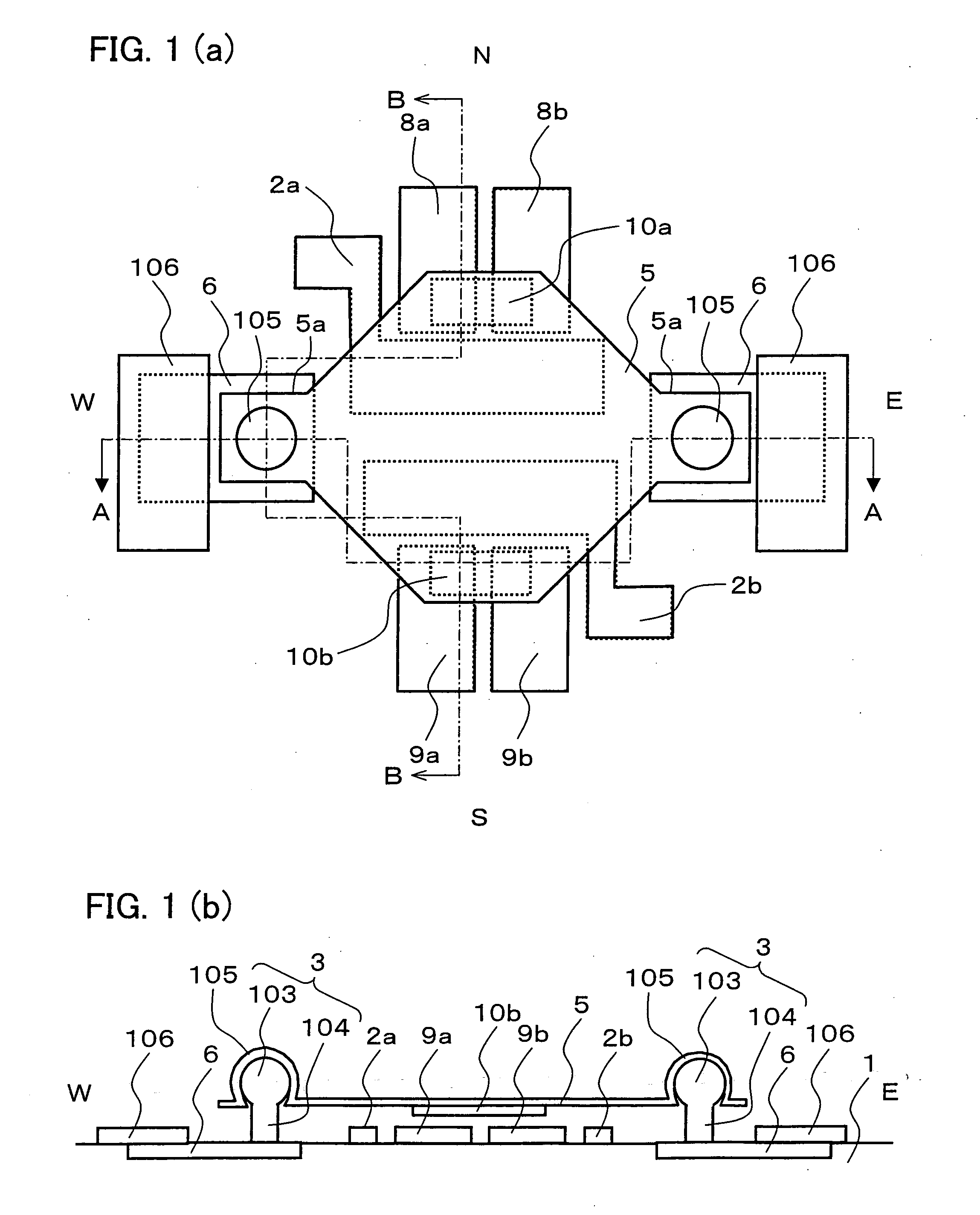

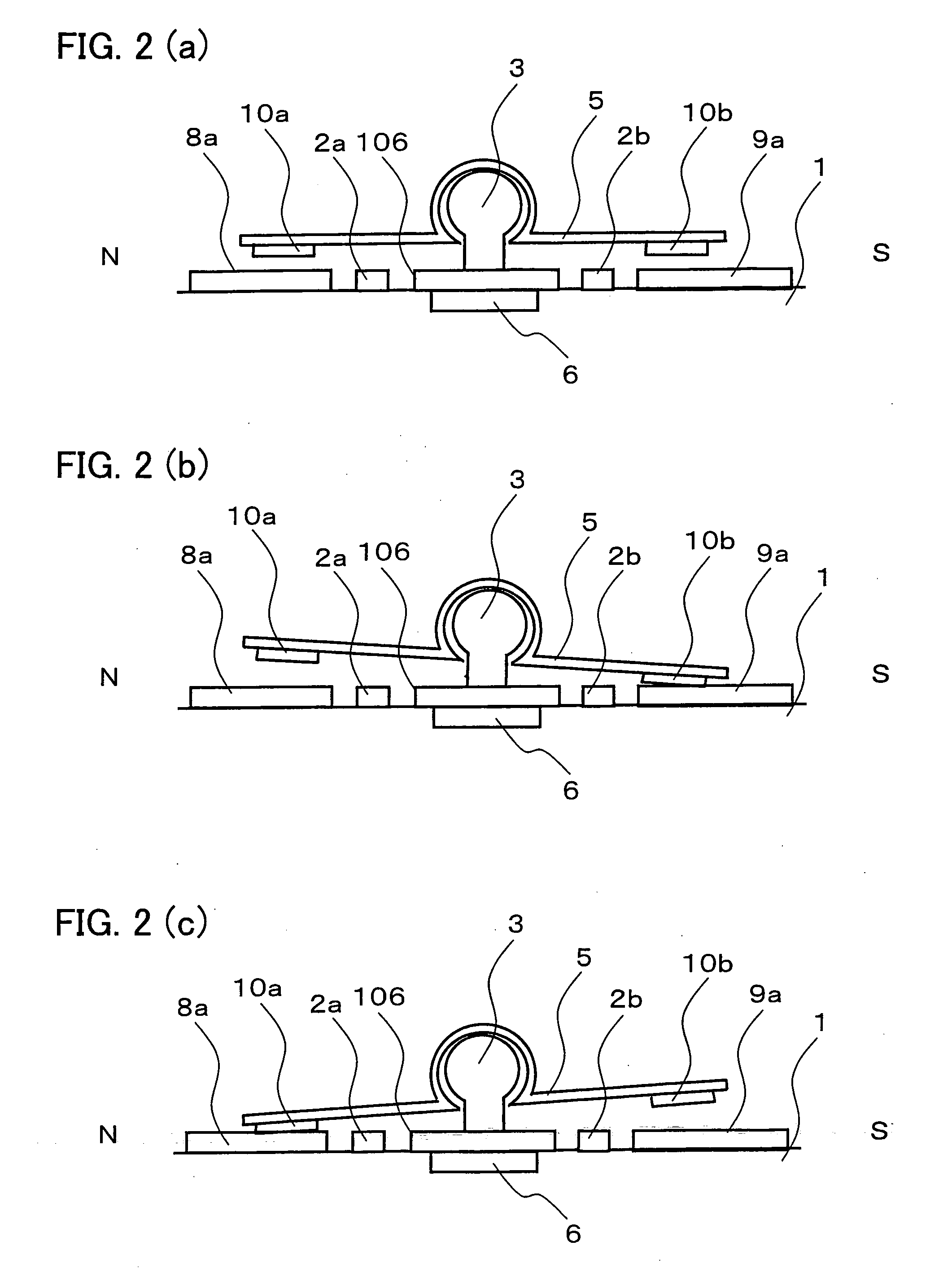

Translating and Rotation Micro Mechanism

InactiveUS20110080627A1Electrostatic generators/motorsFlexible microstructural devicesElectrostatic actuatorMicro mechanism

A translation and rotation mechanism is disclosed, which comprises of one or more bi-directional electrostatic actuators. Each bi-directional electrostatic actuator comprising of fixed electrodes and movable electrodes, where the fixed electrodes of each actuator being attached onto a base. The movable electrodes of each actuator are connected to the translating and rotation unit through a spring system. The movable elements of each said actuator being able to rotate with respect to the base plane by applying voltage signals to the actuator and by controlling the voltage signals applied to each said actuator independently, said translating and rotation unit being able to translate, rotate, or translate and rotate simultaneously.

Owner:HE SIYUAN +1

Electrostatic actuator

InactiveUS20050219017A1Prolong lifePiezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysConductive materialsEngineering

A switch with an actuator has two supporting columns on a substrate, and a rocking plate on the supporting columns. The rocking plate is pivoted by (pivotally mounted on) the two supporting columns. The rocking plate is made of conductive material, so that it can be subjected to electrostatic force of an adsorption electrode. In the switch, it is not necessary to provide a narrow beam to support the rocking plate, because the rocking plate is pivoted by the supporting columns. Therefore, the switch is a long-life microswitch.

Owner:SHARP KK

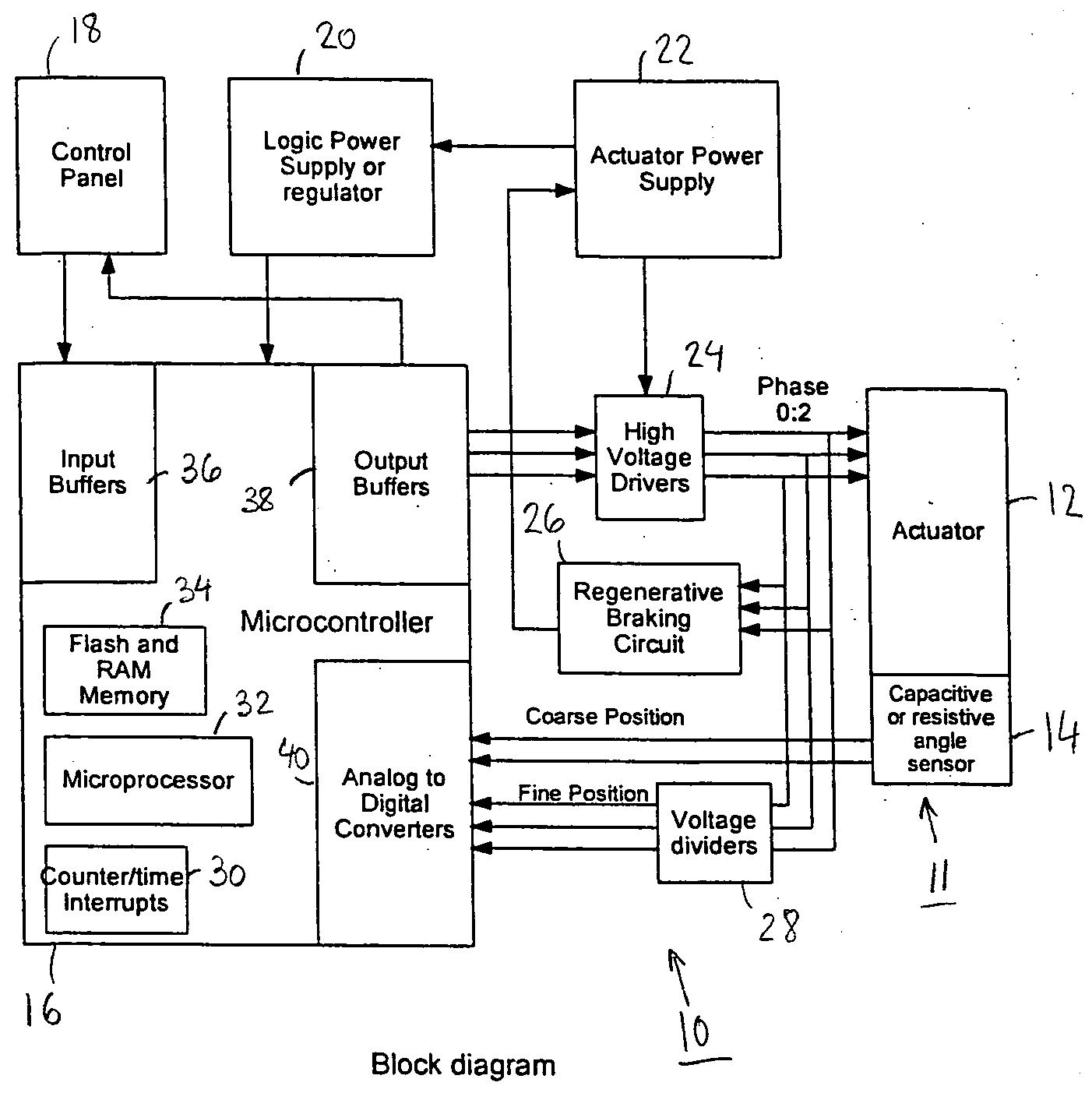

Electrostatic actuator with fault tolerant electrode structure

InactiveUS20050006980A1Manufacturing tolerance requiredPrecise alignmentPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionLow voltageFlexible circuits

A high-power electrostatic actuator comprising rotor and stator layers with fault-tolerant electrode structures, a housing to contain the electrodes and dielectric fluid, and electronic circuitry driving a plurality of high-voltage phases. The actuator is constructed from multiple rotor and stator films separated by spacing elements. The electrode structure provides self-alignment for precise assembly. The actuator assembly includes built-in fine-position sensors to allow optimal timing in powering phases, and a coarse position sensor for feedback control. The electrode structure has a large region of linear force to provide low torque-ripple allowing simple high / low voltage pulsing instead of analog high voltage waveforms. Single or double sided flexible circuit manufacturing techniques are used to fabricate the rotor and stator films at low cost.

Owner:ALTERG INC

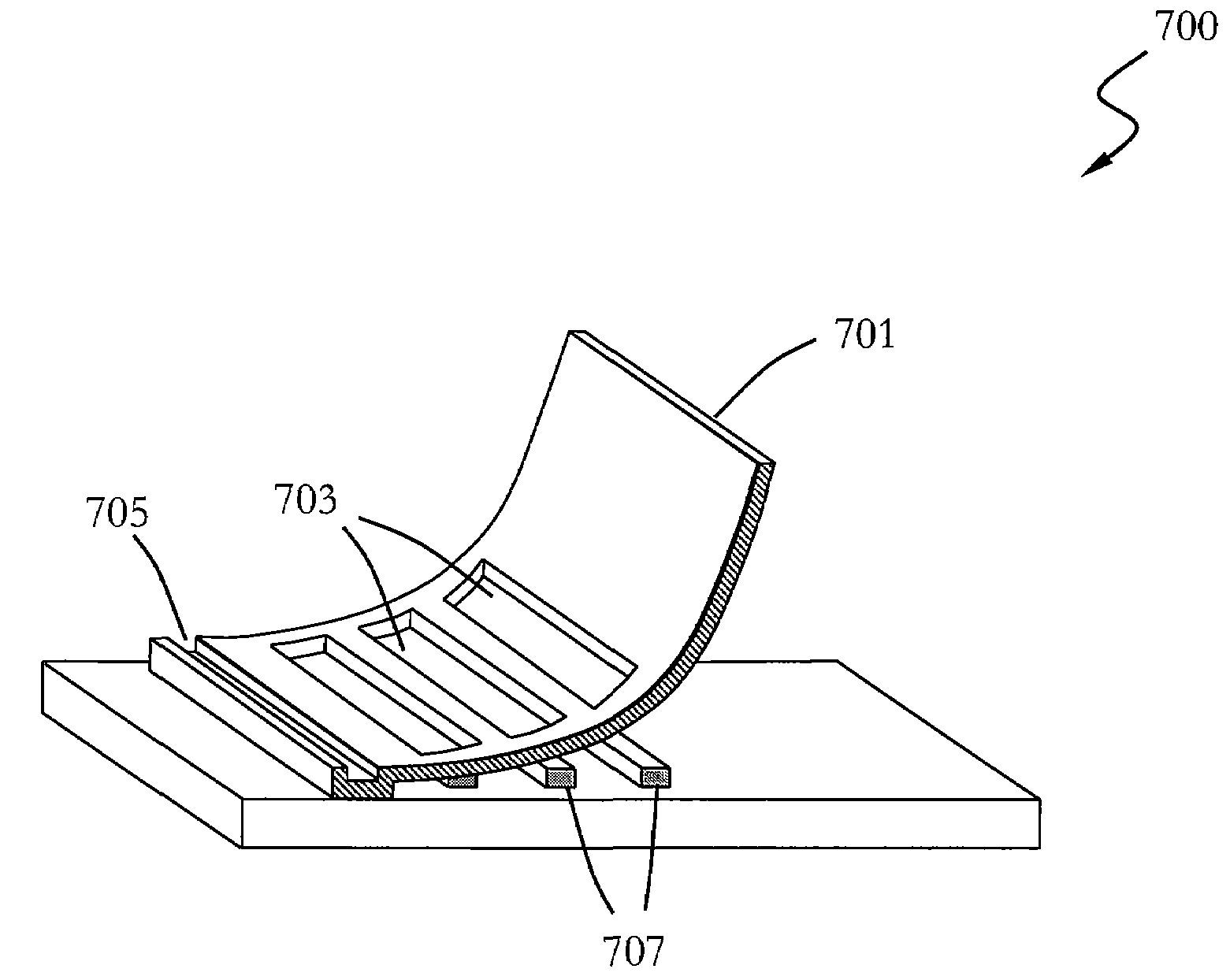

Electrostatic actuator with segmented electrode

An electrostatic actuator includes a segmented flexible membrane associated with individually addressable electrodes, one for each membrane segment. The electrodes are provided beneath a corresponding one of the membrane segments to define a plurality of actuator chambers between each of the electrodes and the corresponding membrane segment. Control electronics independently provide a bias voltage to select ones or all of the electrodes to generate an electrostatic field between any bias electrode and the corresponding membrane segment to attract the corresponding membrane segment toward the respective electrode. Upon elimination of the bias voltage, the corresponding membrane segments are elastically restored to their previous position. This structure can be incorporated into a fluid drop ejector to achieve variable drop size by control of the number of segments actuated. Additionally, by control of the time and space domain of the segment firing, the pressure pulse created by the fluid drop ejector can be precisely controlled.

Owner:XEROX CORP

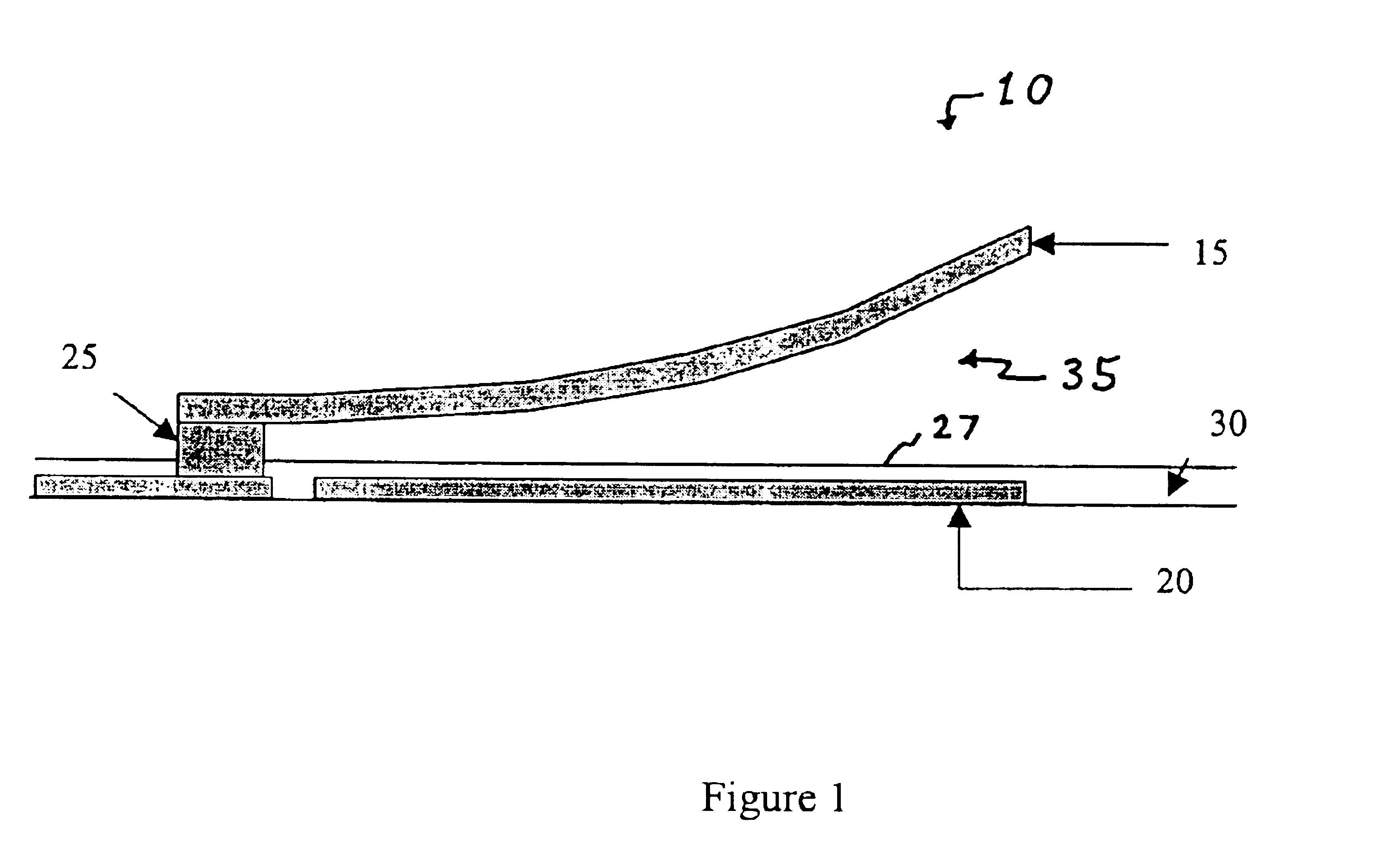

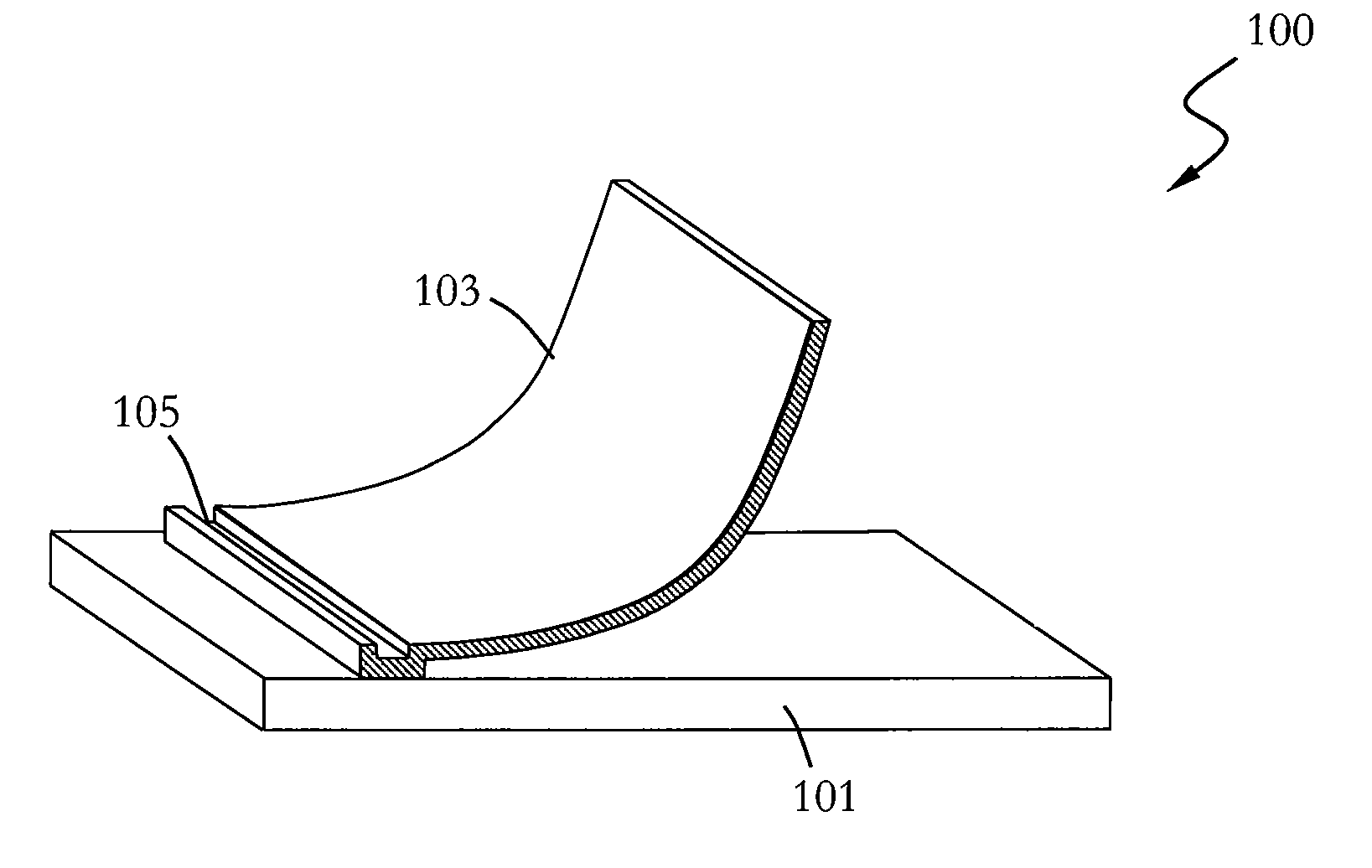

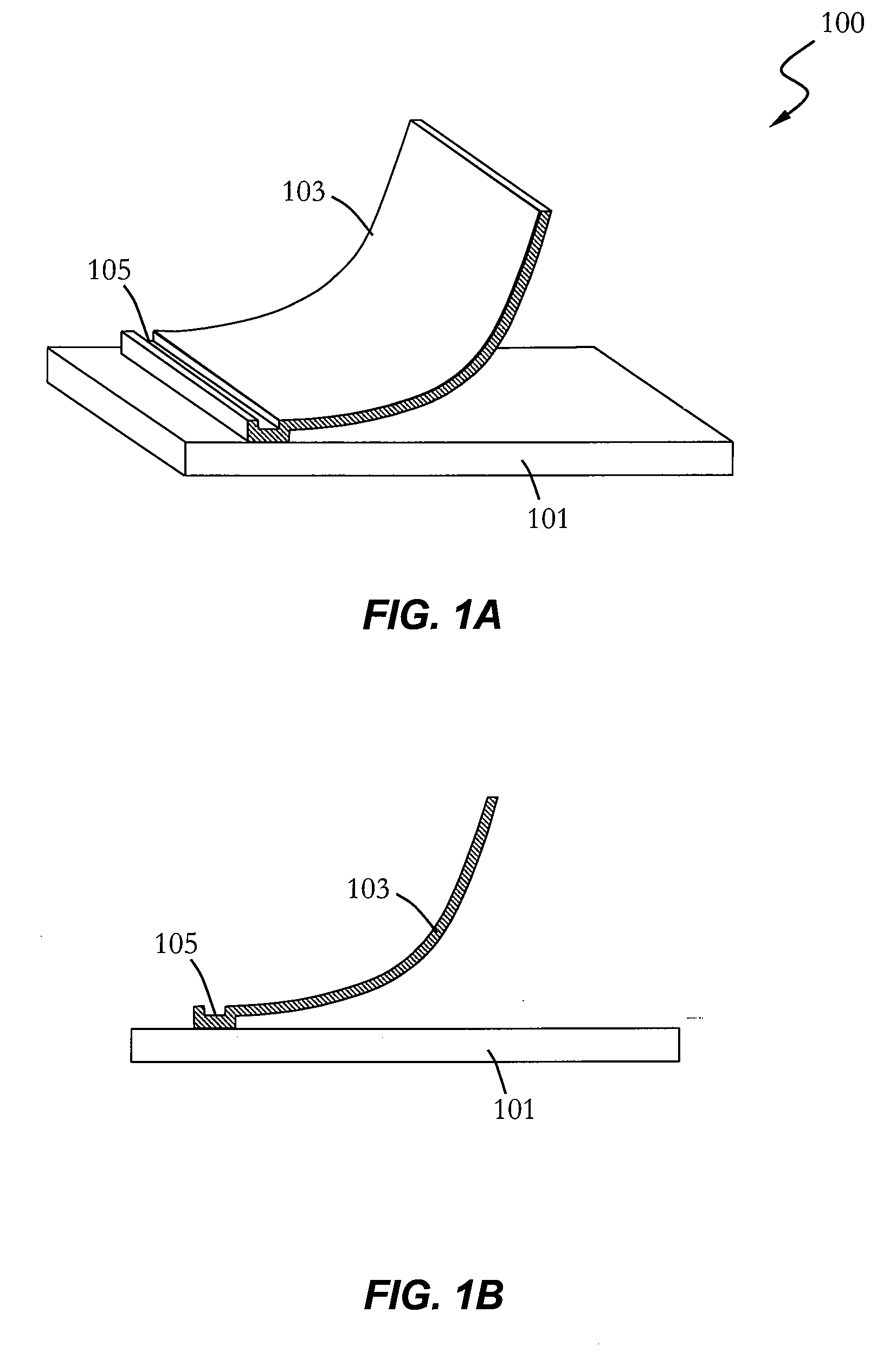

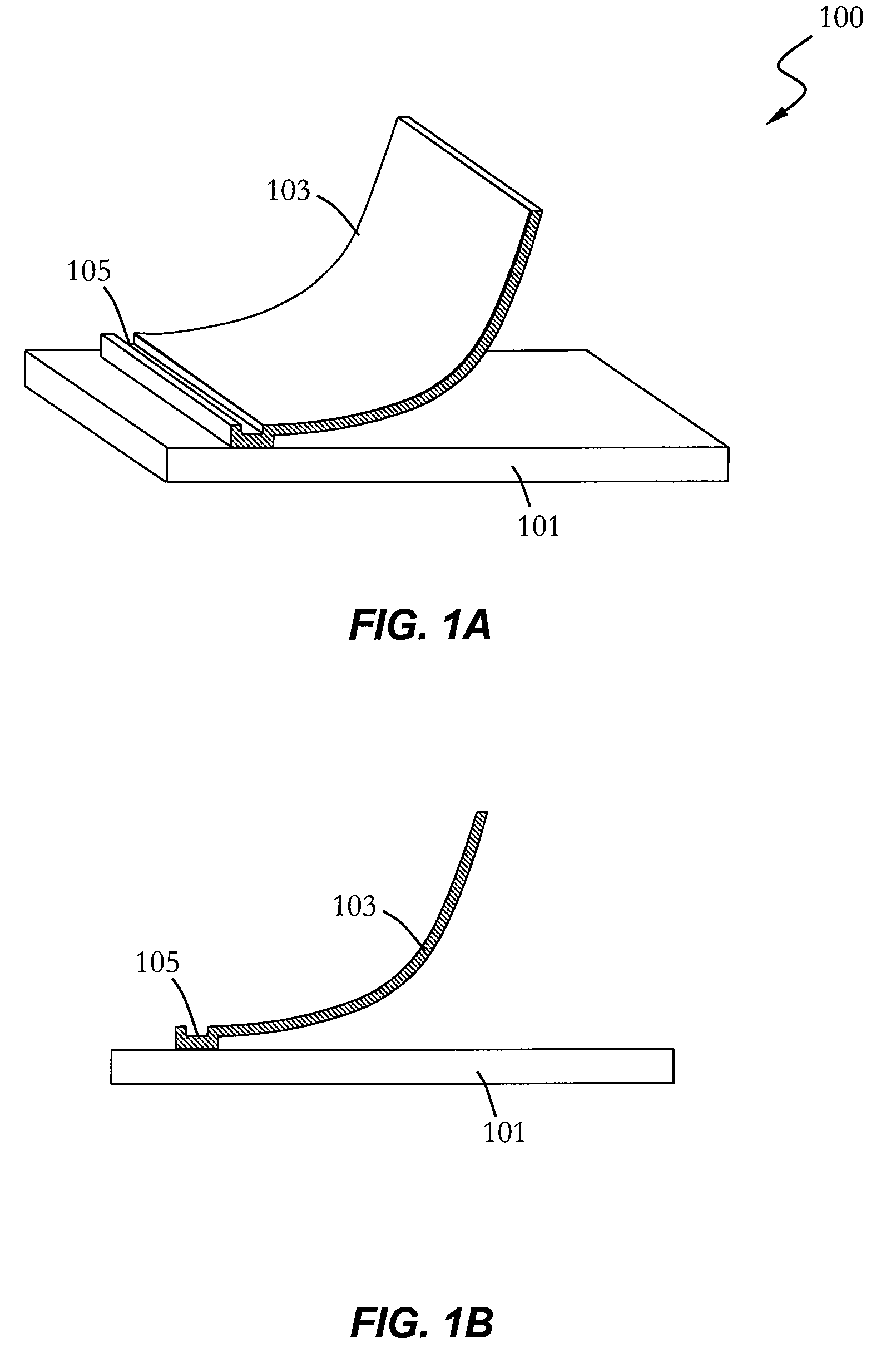

Method and Structure for an Out-of-Plane Compliant Micro Actuator

ActiveUS20070103264A1Easy to useReduce voltageElectrostatic motorsElectromagnets with armaturesLow voltageMicro actuator

This present invention relates generally to manufacturing objects. More particularly, the invention relates to a method and structure for fabricating an out-of-plane compliant micro actuator. The compliant actuator has large actuation range in both vertical and horizontal planes without physical contact to the substrate. Due to fringe field actuation, the compliant actuator has no pull-in phenomenon and requires low voltage by a ‘zipping’ movement compared to conventional parallel plate electrostatic actuators. The method and device can be applied to micro actuators as well as other devices, for example, micro-electromechanical sensors, detectors, fluidic, and optical systems.

Owner:MOVELLA INC

Method and structure for an out-of plane compliant micro actuator

ActiveUS7498715B2Easy to useReduce voltageElectrostatic motorsElectromagnets with armaturesMicro actuatorLow voltage

This present invention relates generally to manufacturing objects. More particularly, the invention relates to a method and structure for fabricating an out-of-plane compliant micro actuator. The compliant actuator has large actuation range in both vertical and horizontal planes without physical contact to the substrate. Due to fringe field actuation, the compliant actuator has no pull-in phenomenon and requires low voltage by a ‘zipping’ movement compared to conventional parallel plate electrostatic actuators. The method and device can be applied to micro actuators as well as other devices, for example, micro-electromechanical sensors, detectors, fluidic, and optical systems.

Owner:MOVELLA INC

Semiconductor device formed by using MEMS technique

InactiveUS20060226735A1Piezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysDevice materialPiezoelectric actuators

A semiconductor device includes an elastic member, first and second electrodes, a piezoelectric actuator, and an electrostatic actuator. One end of the elastic member is fixed on a substrate through an anchor so as to form a gap between the elastic member and the substrate. The first and second electrodes are placed to face the other end of the elastic member and the substrate, respectively. The piezoelectric actuator deforms the other end of the elastic member to bring it close to the substrate. The electrostatic actuator includes a third electrode placed in the elastic member and a fourth electrode placed on the substrate so as to face the third electrode, and deforms the other end of the elastic member so as to bring it close to the substrate. The distance between the first and second electrodes is changed by driving the piezoelectric actuator and the electrostatic actuator.

Owner:KK TOSHIBA

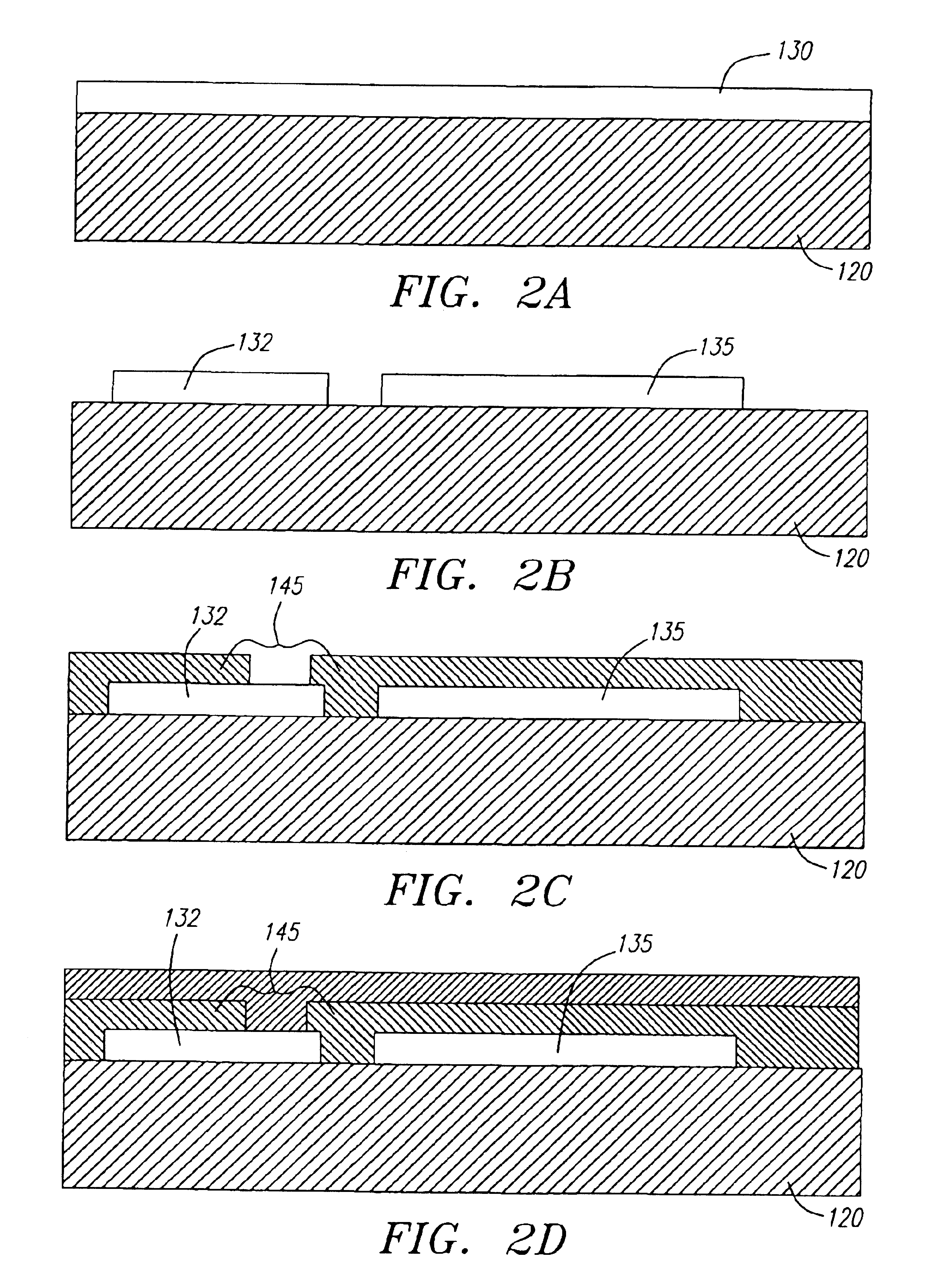

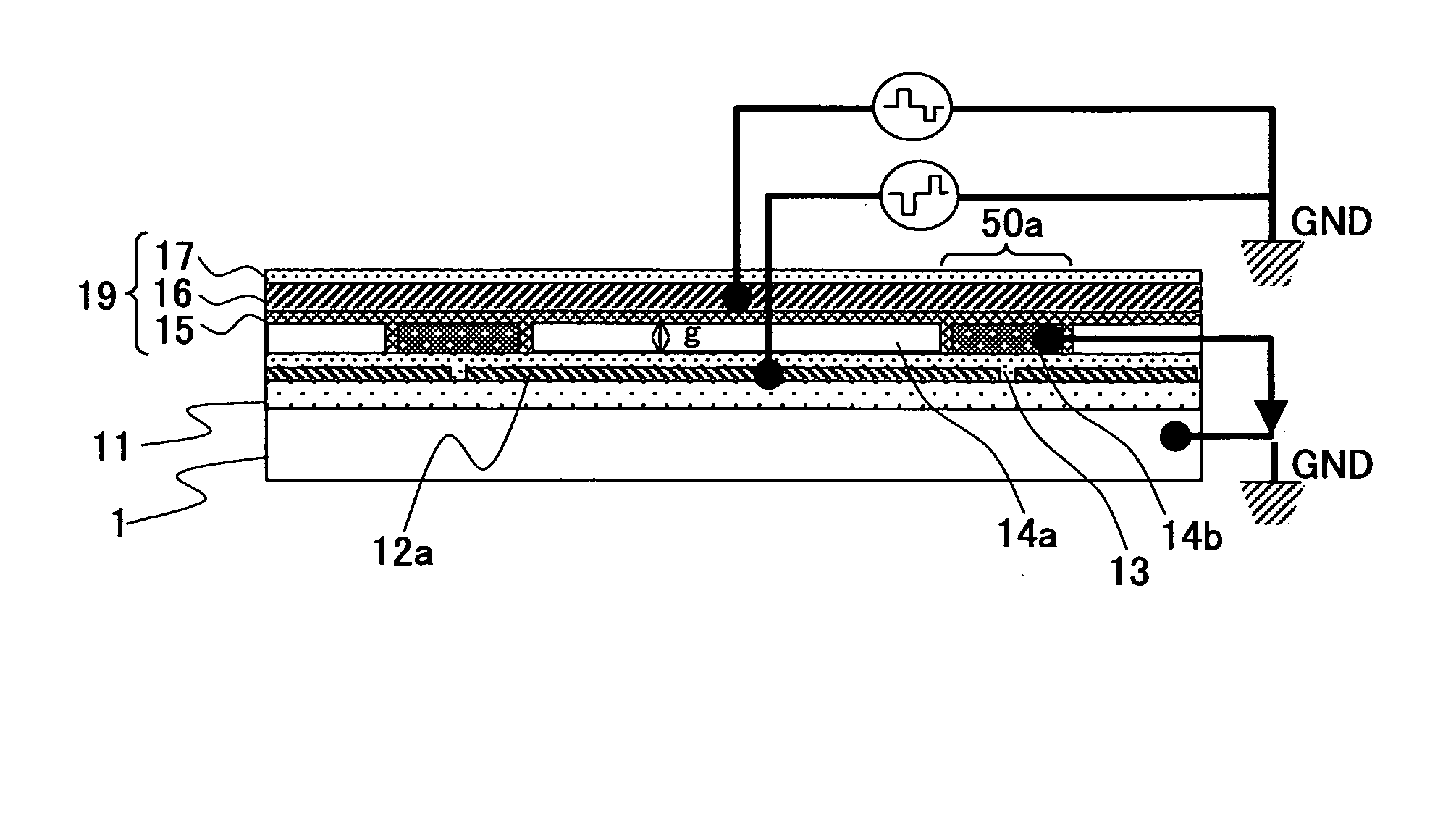

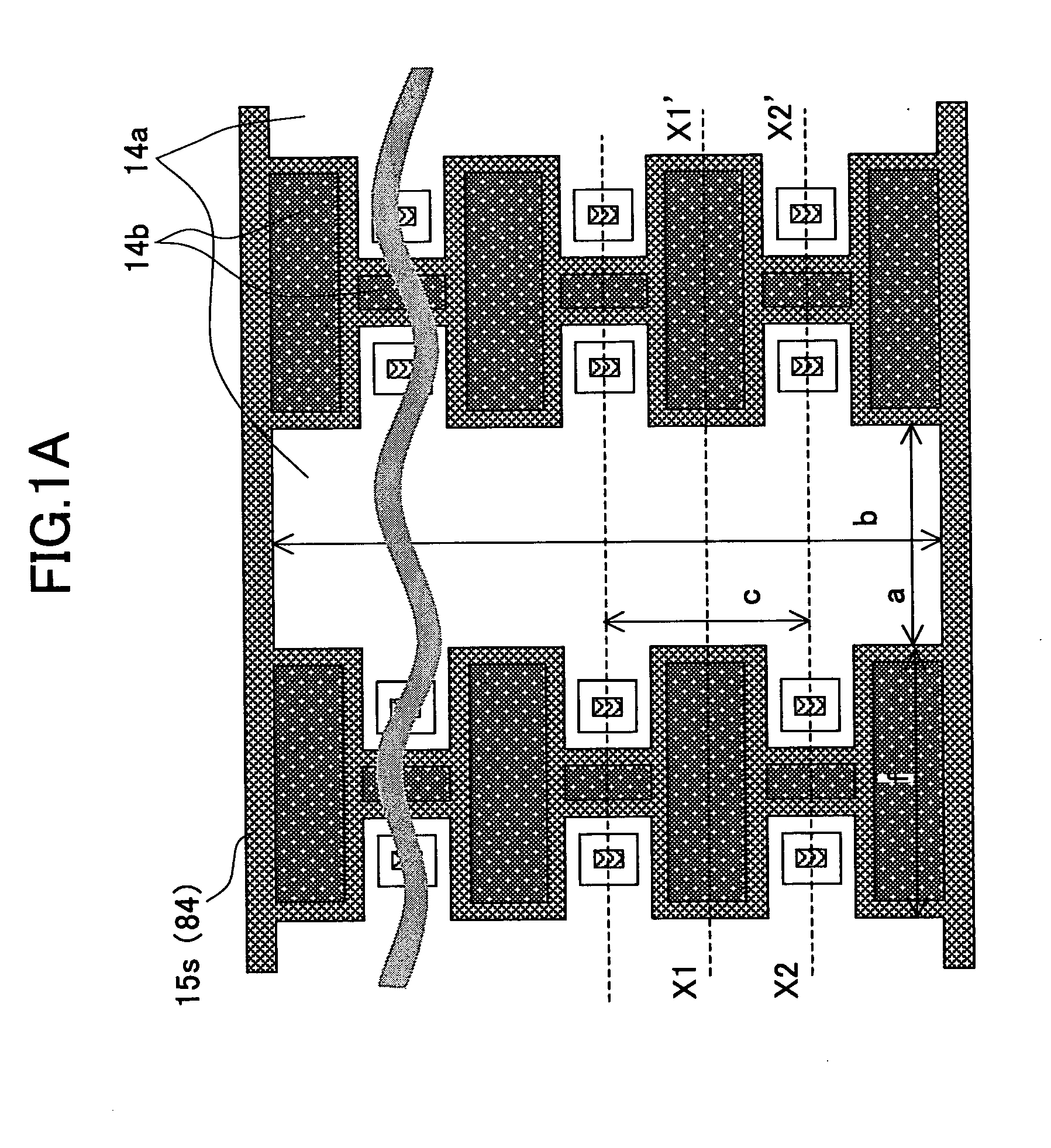

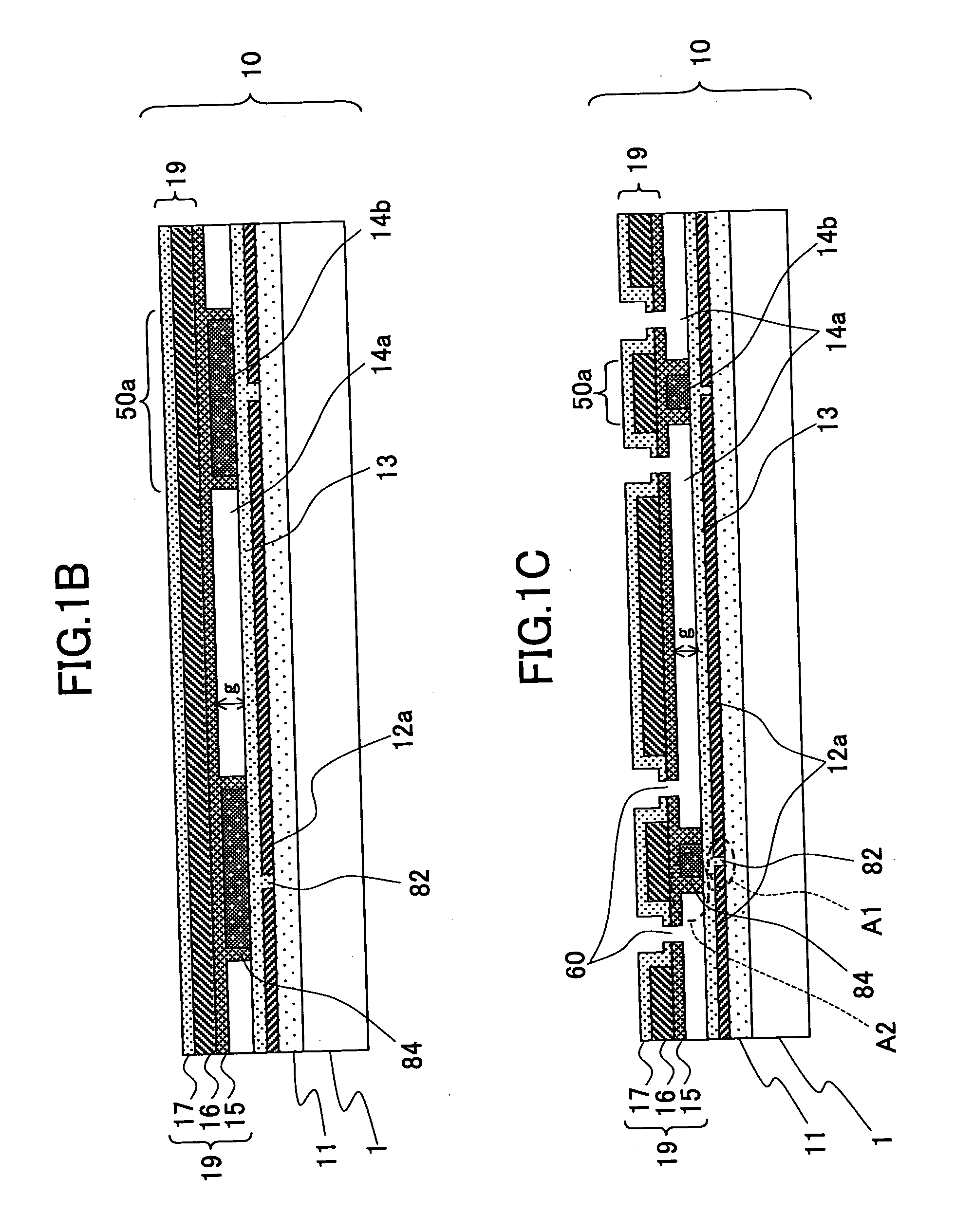

Electrostatic actuator formed by a semiconductor manufacturing process

InactiveUS20050264617A1Improve performanceLess variationMechanical vibrations separationElectrostatic generators/motorsEtchingEngineering

An electrostatic actuator has high-reliability and less variation in characteristics. An electrode (12a) is formed on a substrate (1), and a plurality of partition parts (50a) are formed on the electrode. A vibration plate (19) is formed on the partition parts (50a), and is deformable by an electrostatic force generated by a voltage applied to the electrode (12a) so that an air gap (14a) is formed between the partition parts (50a) by etching a part of a sacrifice layer (14) formed between the electrode (12a) and the vibration plate (19). The partition parts (50a) are formed of remaining parts of the sacrifice layer (14) after the etching.

Owner:RICOH KK

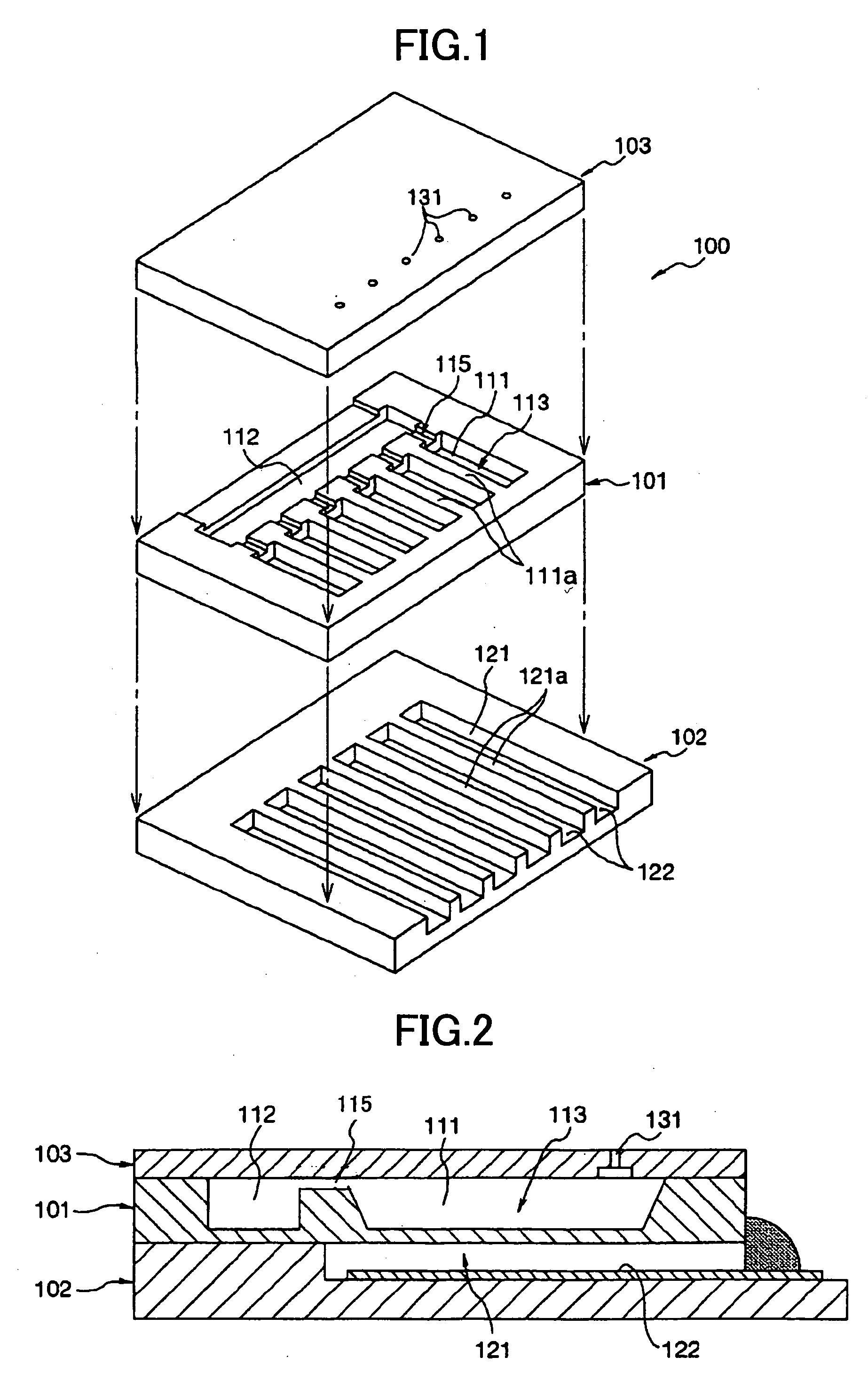

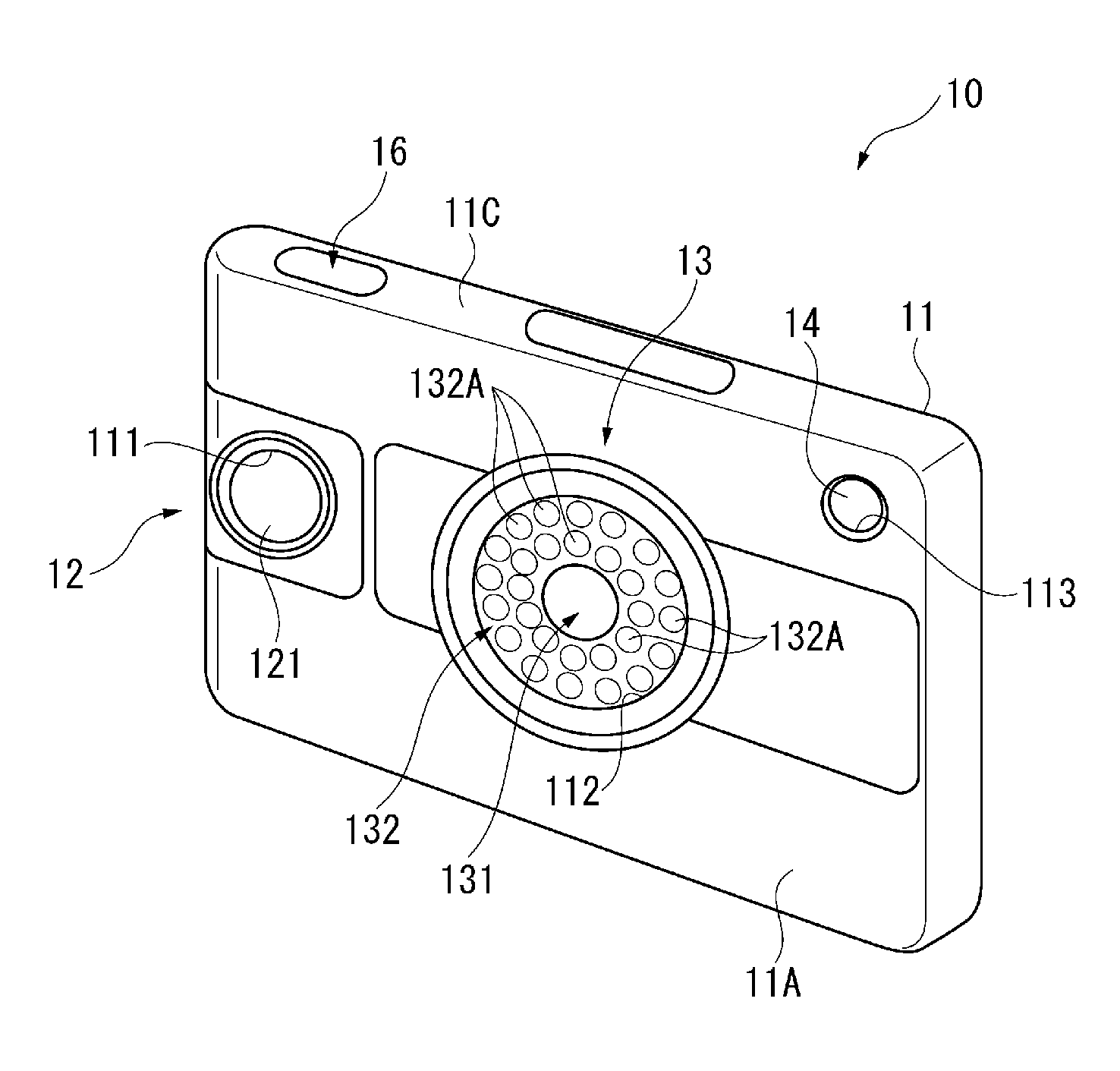

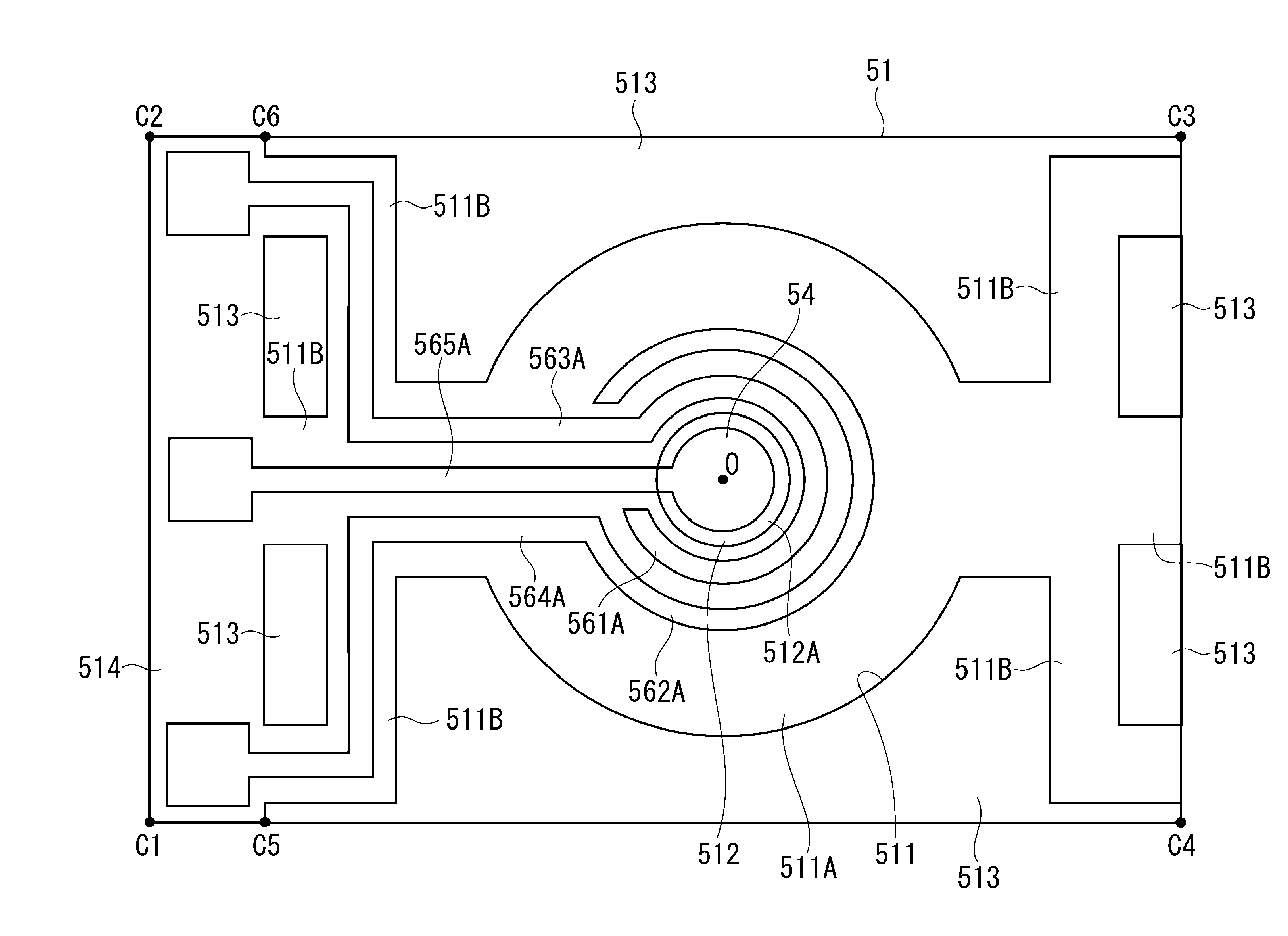

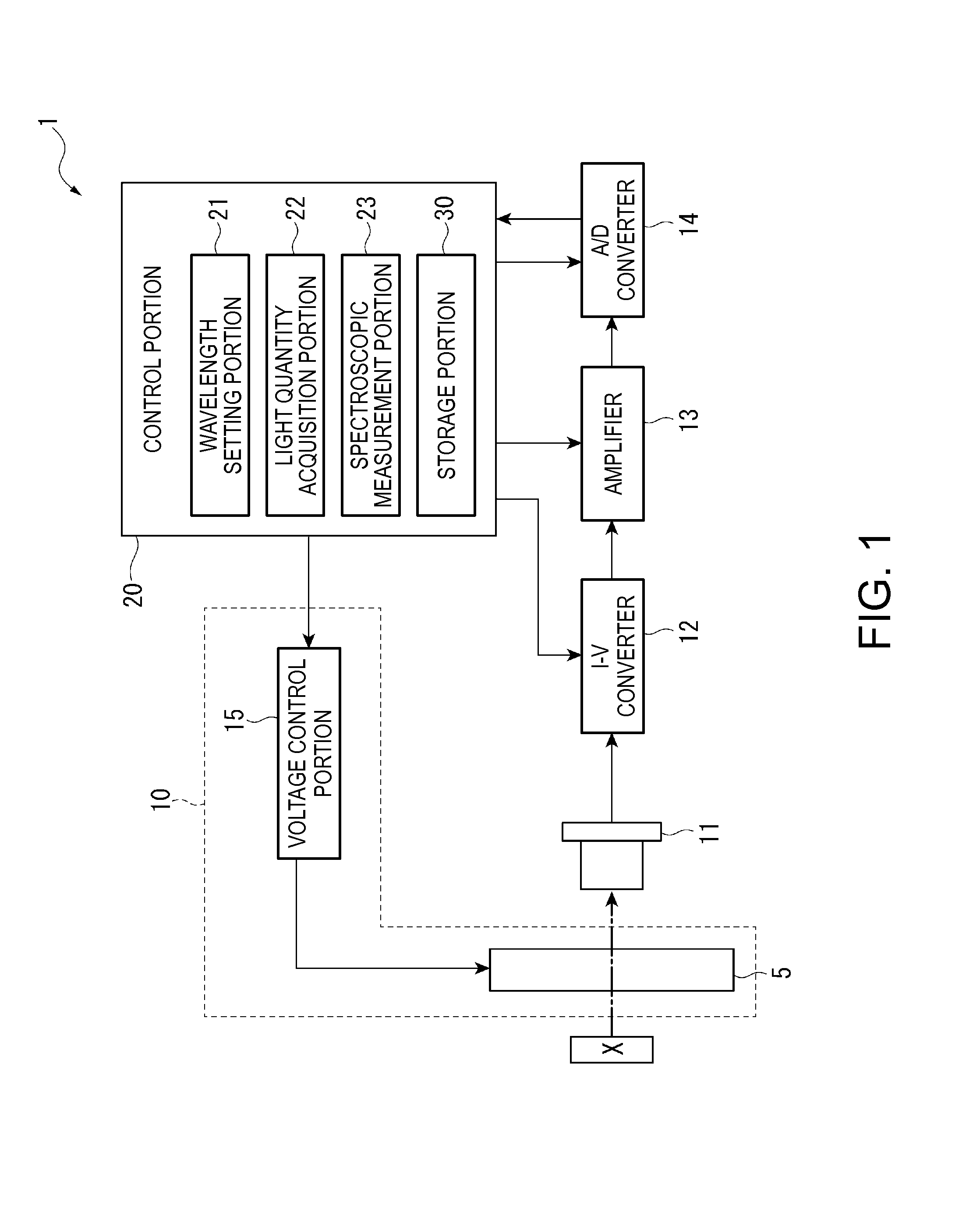

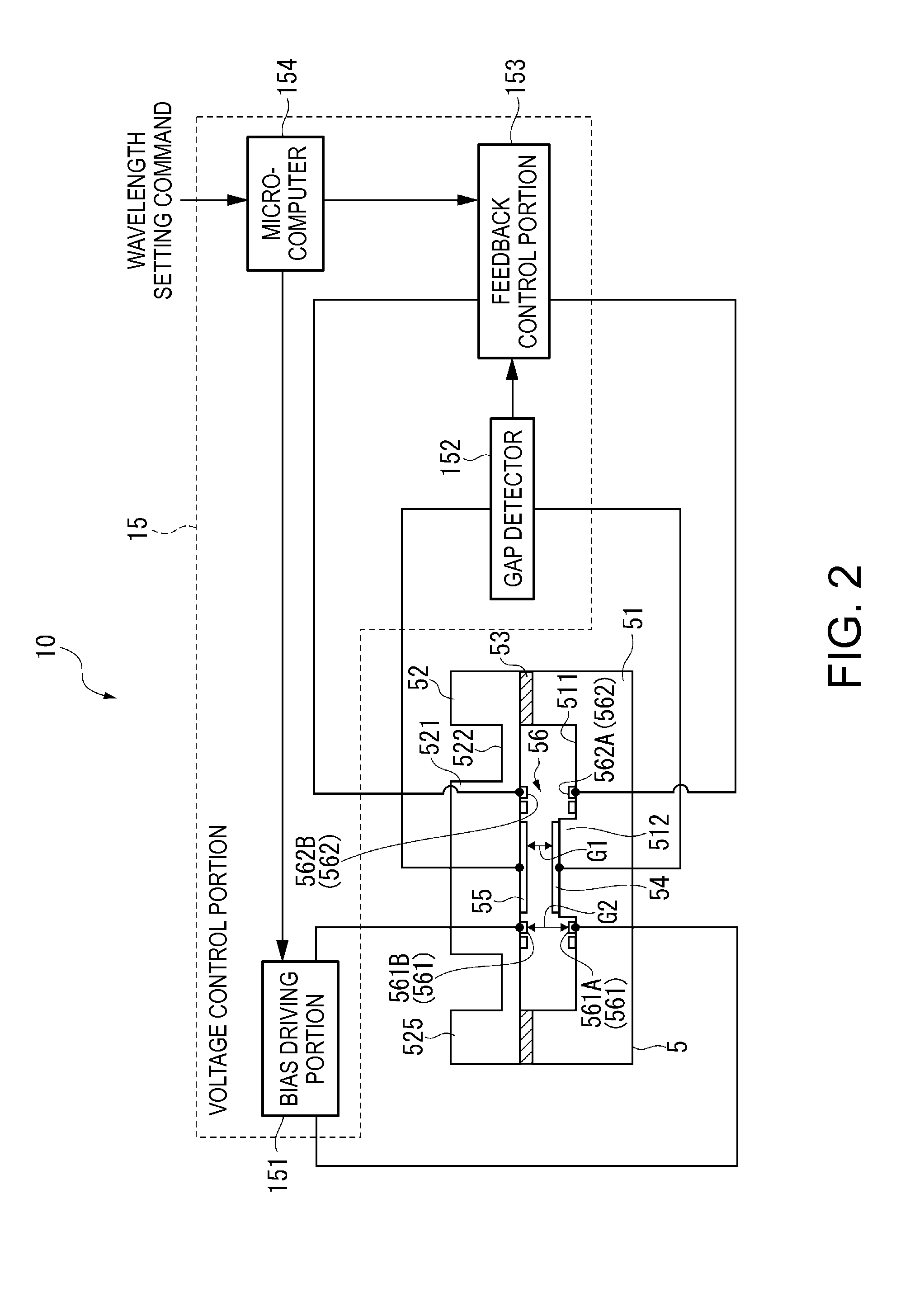

Optical module, electronic device, food analyzer, spectroscopic camera, driving method of wavelength variable interference filter

ActiveUS20130308134A1Accurate extractionThe right amountRadiation pyrometryInterferometric spectrometryOptical ModuleElectrostatic actuator

A optical module includes, a wavelength variable interference filter which include reflection films opposite to each other and an electrostatic actuator portion including a first electrostatic actuator and a second electrostatic actuator and changing a gap between the reflection films, and a voltage control portion which controls voltage which is applied to the electrostatic actuator portion, the voltage control portion includes, a bias driving portion which applies bias voltage to the first electrostatic actuator, a gap detector, and a feedback control portion which applies feedback voltage corresponding to a detected gap amount to the second electrostatic actuator.

Owner:SEIKO EPSON CORP

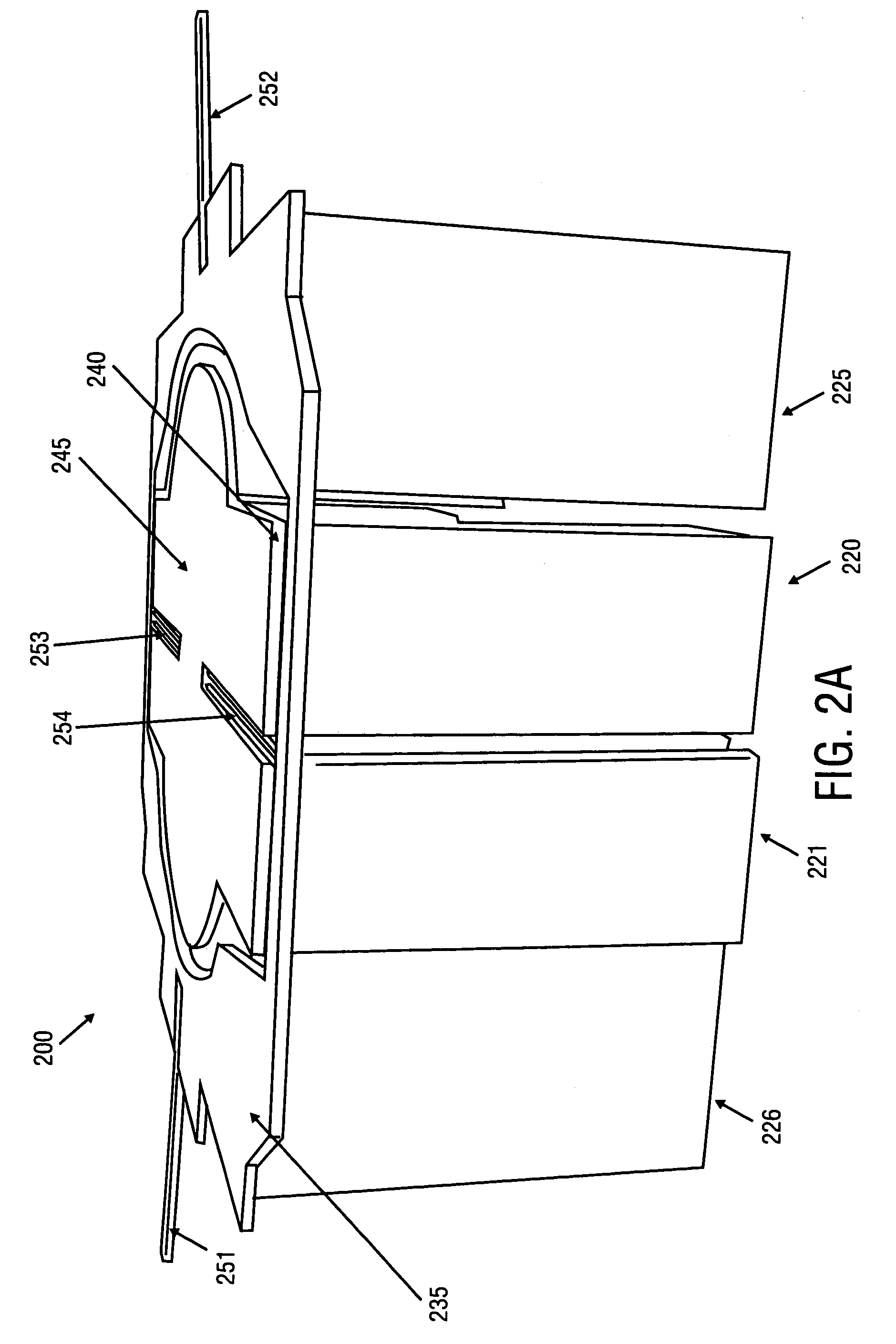

Electrostatic actuator for microelectromechanical systems and methods of fabrication

A method and apparatus are described that may be used to provide decoupled rotation of structures about different pivot points. The apparatus may include one or more fixed blades mounted to a frame or substrate, one or more movable blades mounted to each structure to be moved, and flexures on which the structures are suspended. Separate movable blades may be provided for each degree of freedom. When voltage is applied between the fixed and movable blades, the electrostatic attraction generates a force attracting movable blades toward blades that are fixed relative to the moveable blades, causing a structure to rotate about the flexures. The angle of rotation that results may be related to the size, number and spacing of the blades, the stiffness of the flexures and the magnitude of the voltage difference applied to the blades. The blades are fabricated using deep silicon etching.

Owner:CALIENT TECH

Tunable optical filter

InactiveUS7043115B2Laser optical resonator constructionCladded optical fibreDielectric plateMicrosphere

A tunable filter having a resonator with a resonant frequency dependent upon a variable gap is provided. The variable gap may be controllably altered by use of an actuator. The resonator is a high Q resonator that may be formed by a ring resonator, microsphere, microdisc, or other high Q optical structures. Actuation is preferably achieved through an electrostatic actuator that moves a dielectric plate relative to the resonator in response to measured values of gap and temperature.

Owner:ROSEMOUNT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com