Patents

Literature

60 results about "Micro mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

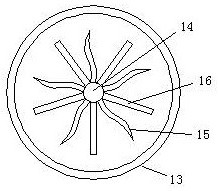

Uniaxle integrated inertia measurement device based on single mass-block

InactiveCN101038299AReduce the difficulty of separationSimple designSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceGlass cover

The present invention which relates to the micro-mechanism electric technology provides a single-shaft and integrated device for measuring the inertia based on the single quality block. And the present solves the problems of the prior single-shaft and integrated assembly for measuring the inertia that the structure is complex, the volume and quality are big, etc. The single-shaft and integrated device for measuring the inertia includes a quality block and a glass cover bottom. The quality block which is hang on the upper of the glass cover bottom through a supporting beam includes a quality chip and four supporting bodies that are fixed with the four sides of the quality chip through the elastic beam. A moveable comb for detecting is fixed on the external of the supporting body relative to the Y direction and a moveable comb for driving is fixed on the external of the supporting body relative to the X direction. A fixed comb for detecting and a fixed comb for driving are fixed on the glass cover bottom, and electrodes for forming the capacitance are fixed on the lower end surface and the glass cover bottom of the quality chip. The device in the present invention has advantages of a reasonable structure, an easy processing, a high reliability, a small volume, a strong ability of resisting the interference, a high precision, a high precision of measuring the paralleling and orthogonality of the vectors, etc.

Owner:ZHONGBEI UNIV

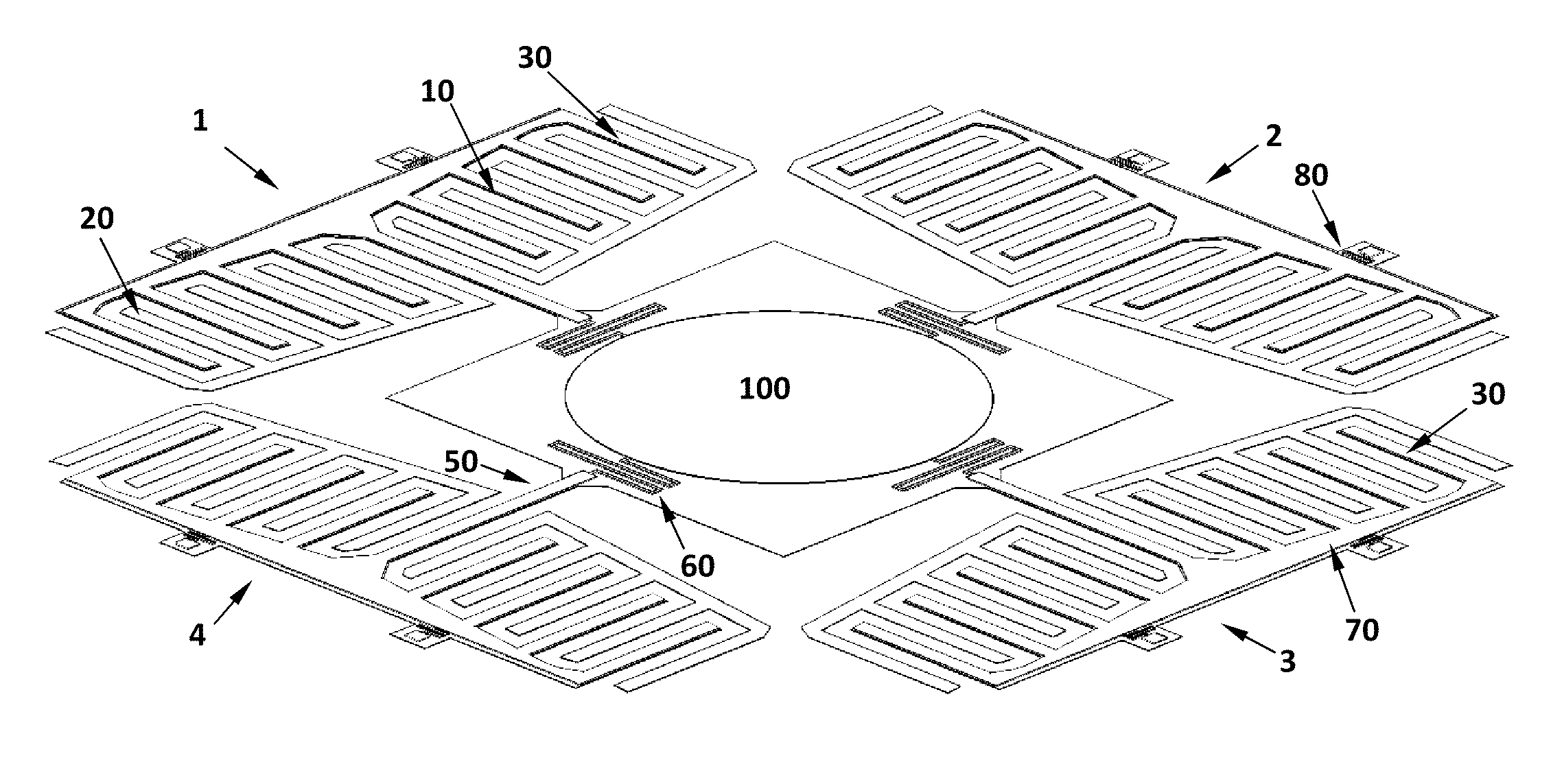

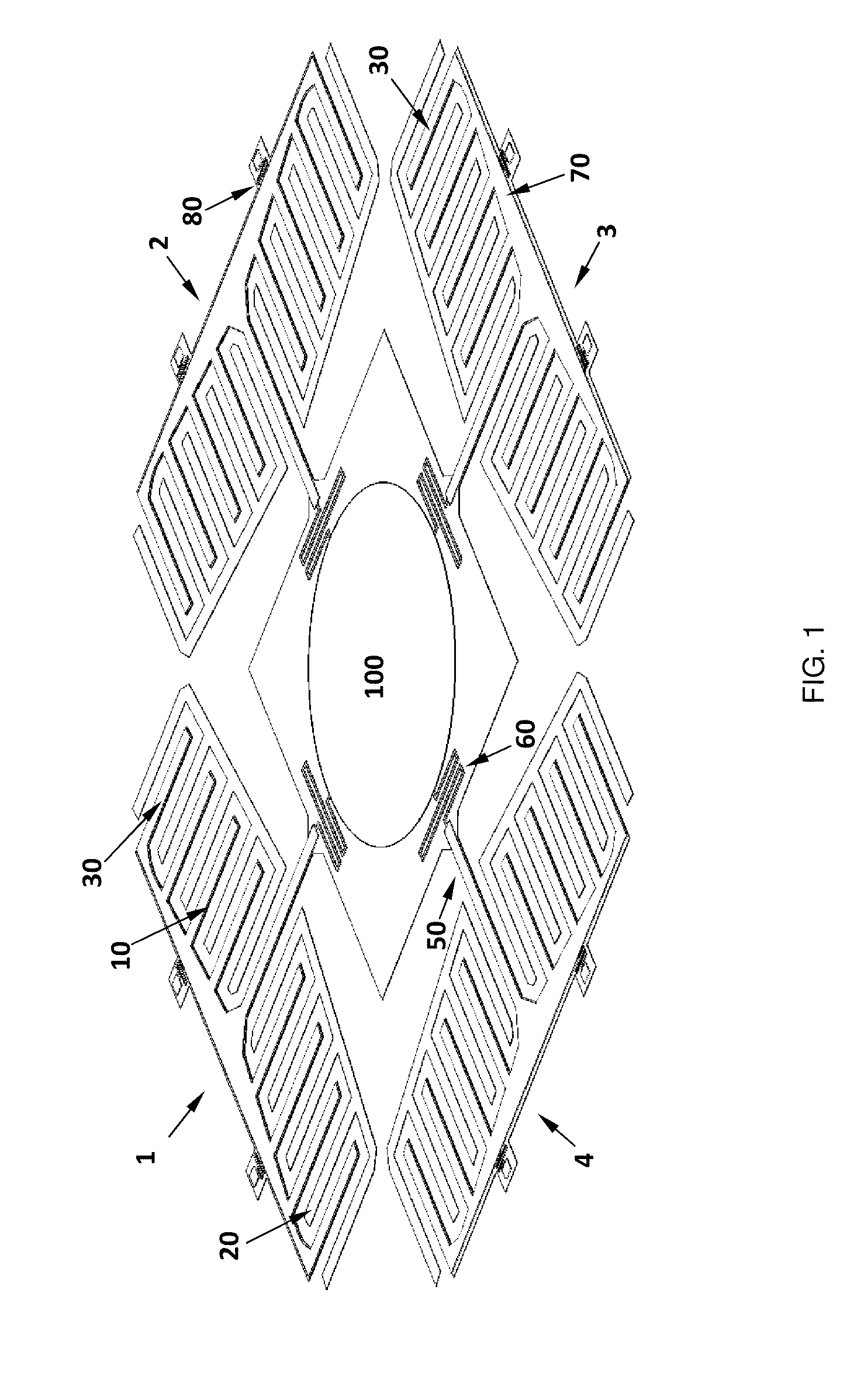

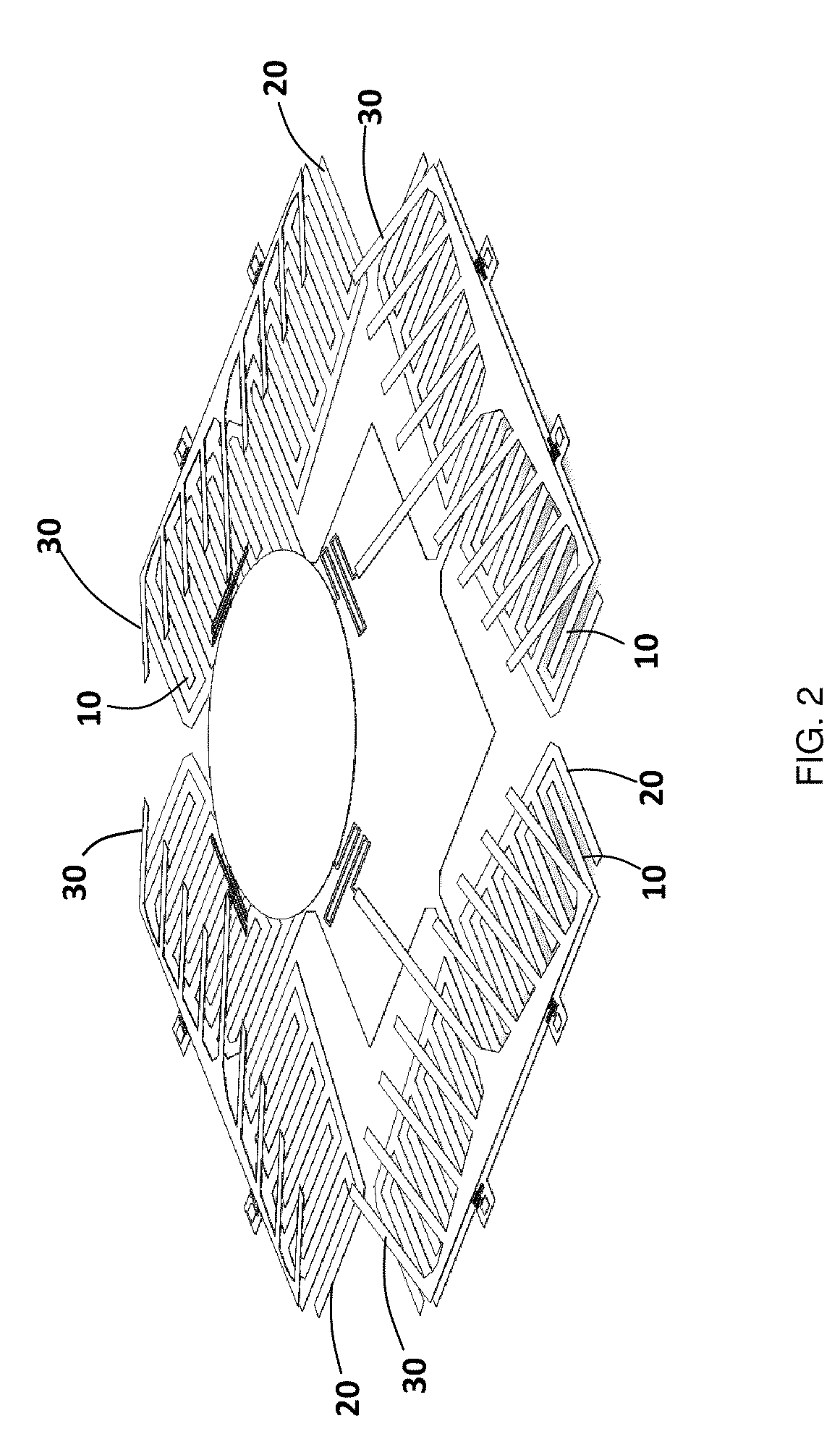

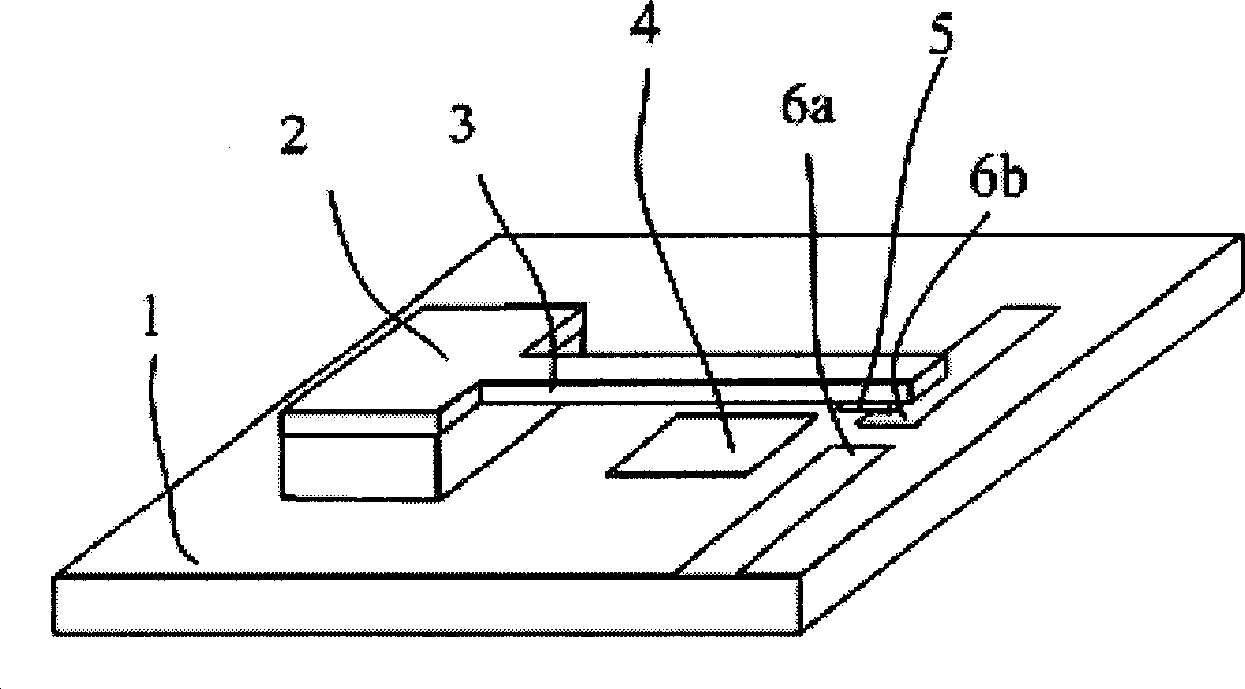

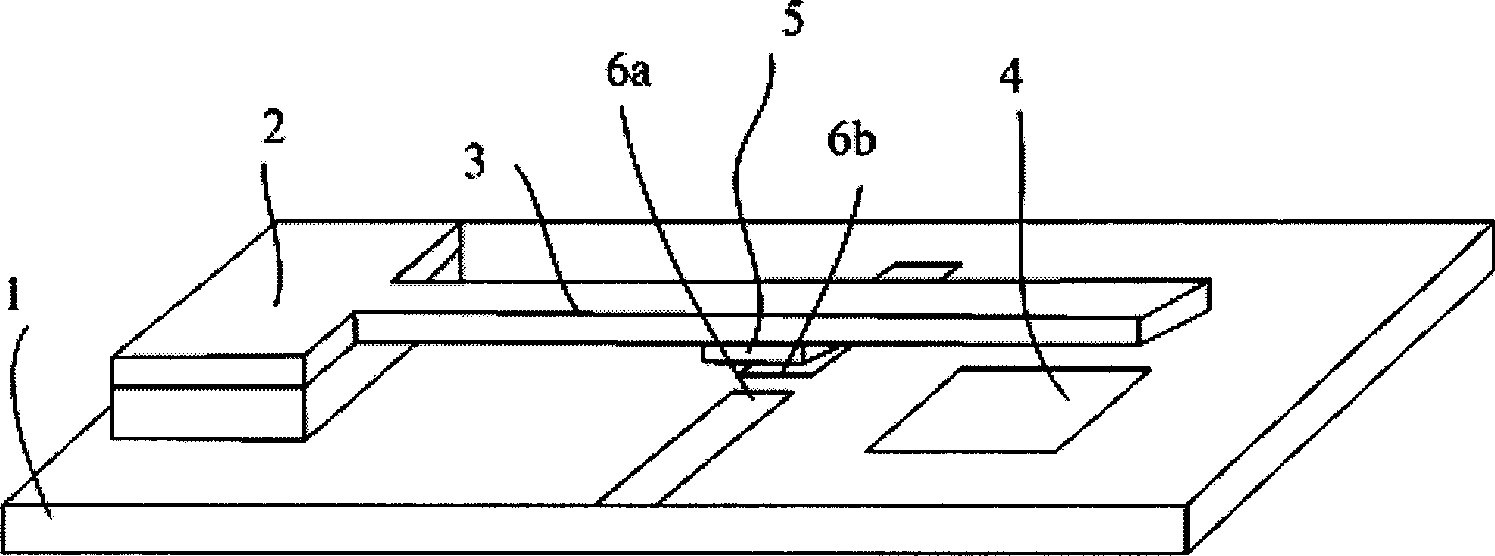

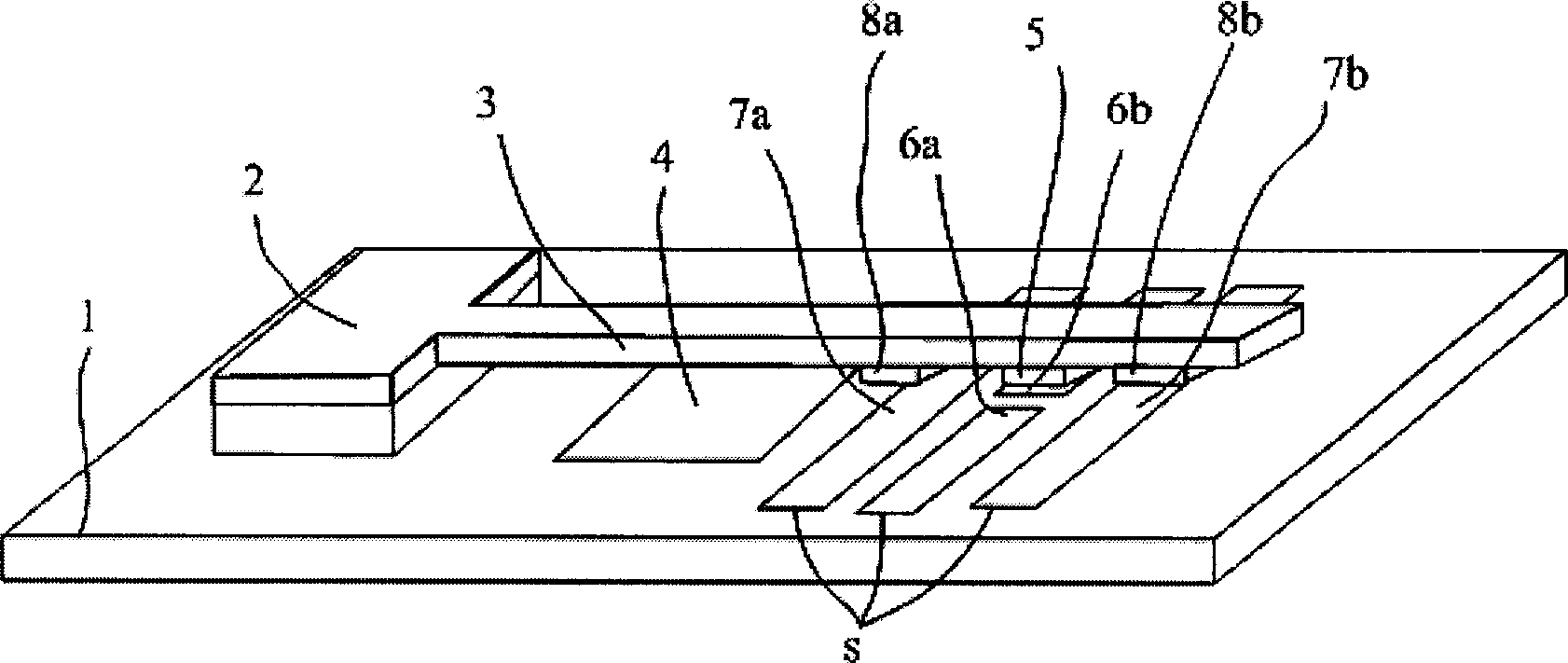

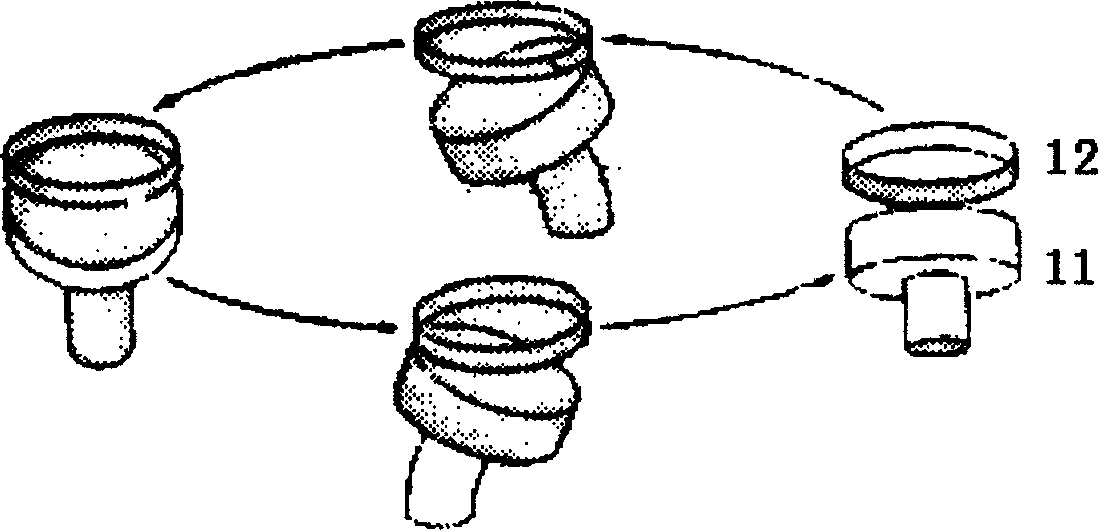

Translating and Rotation Micro Mechanism

InactiveUS20110080627A1Electrostatic generators/motorsFlexible microstructural devicesElectrostatic actuatorMicro mechanism

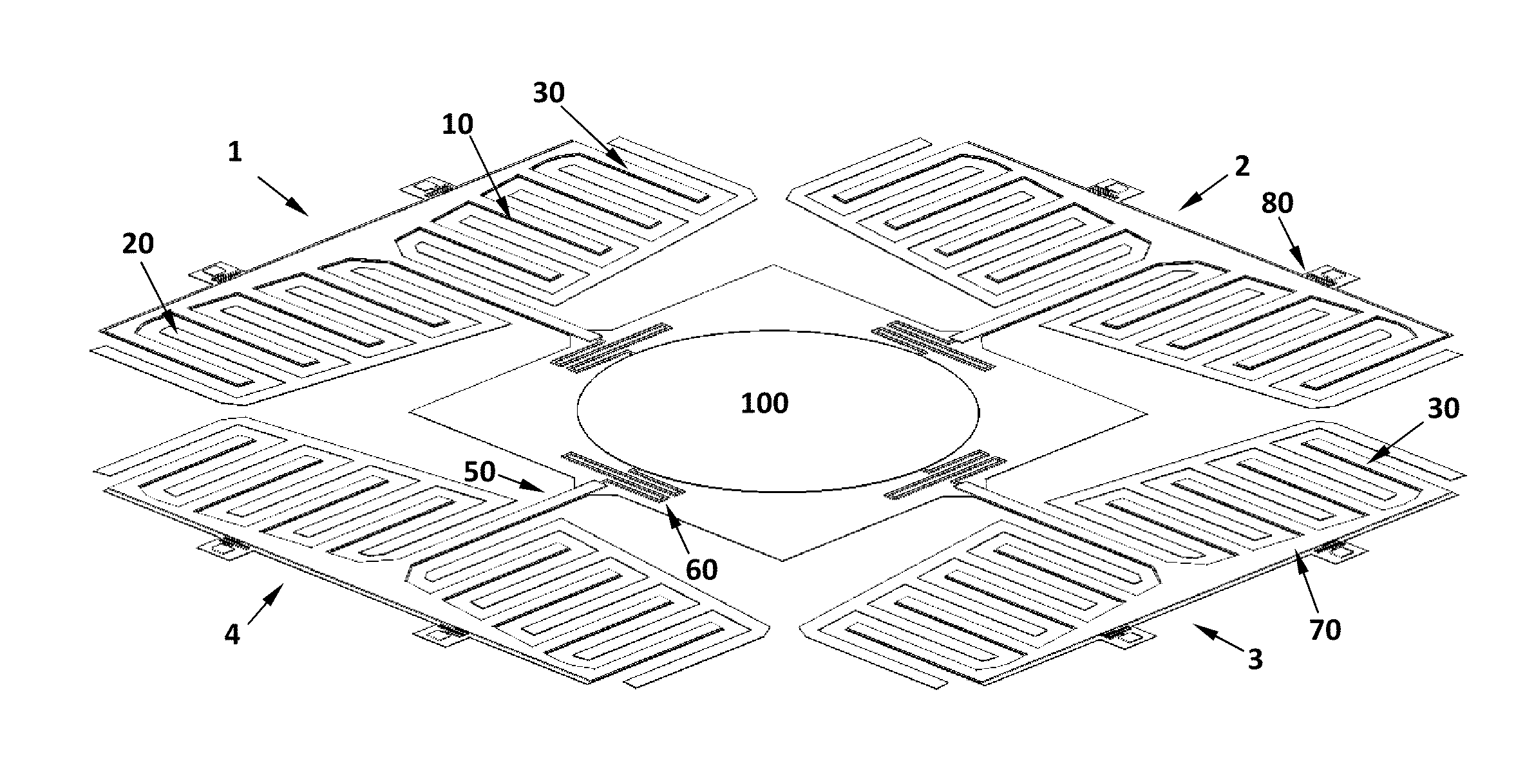

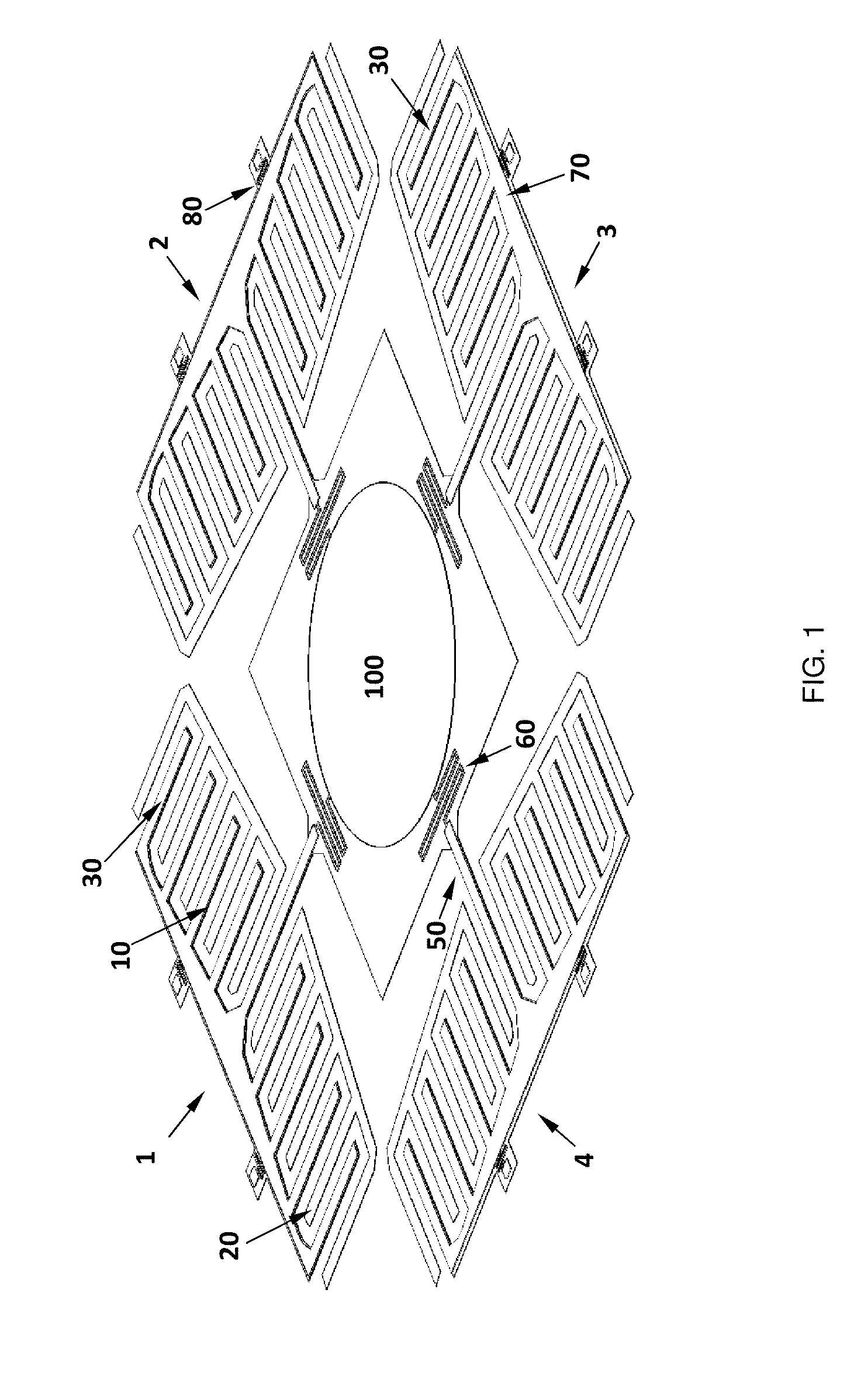

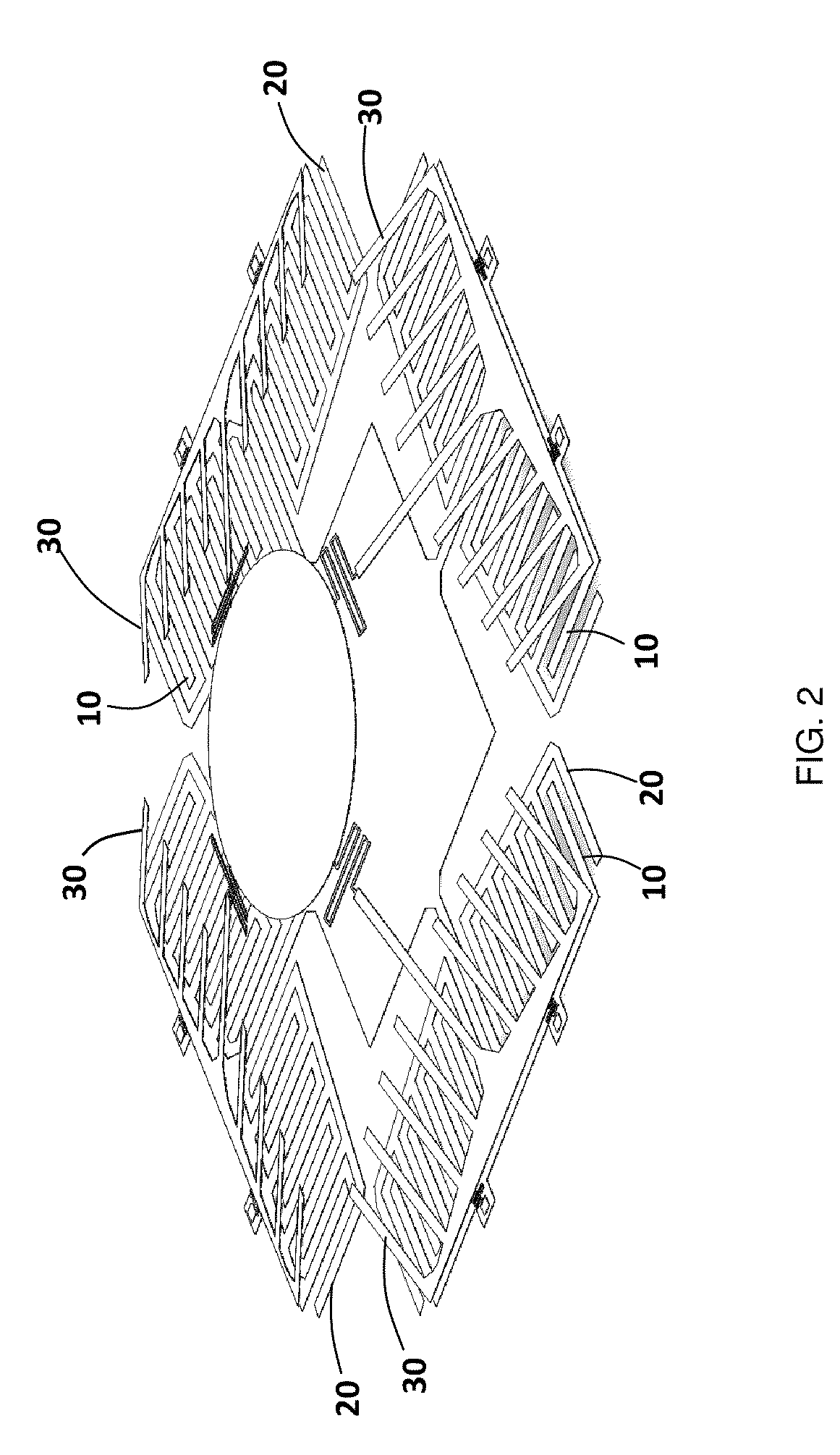

A translation and rotation mechanism is disclosed, which comprises of one or more bi-directional electrostatic actuators. Each bi-directional electrostatic actuator comprising of fixed electrodes and movable electrodes, where the fixed electrodes of each actuator being attached onto a base. The movable electrodes of each actuator are connected to the translating and rotation unit through a spring system. The movable elements of each said actuator being able to rotate with respect to the base plane by applying voltage signals to the actuator and by controlling the voltage signals applied to each said actuator independently, said translating and rotation unit being able to translate, rotate, or translate and rotate simultaneously.

Owner:HE SIYUAN +1

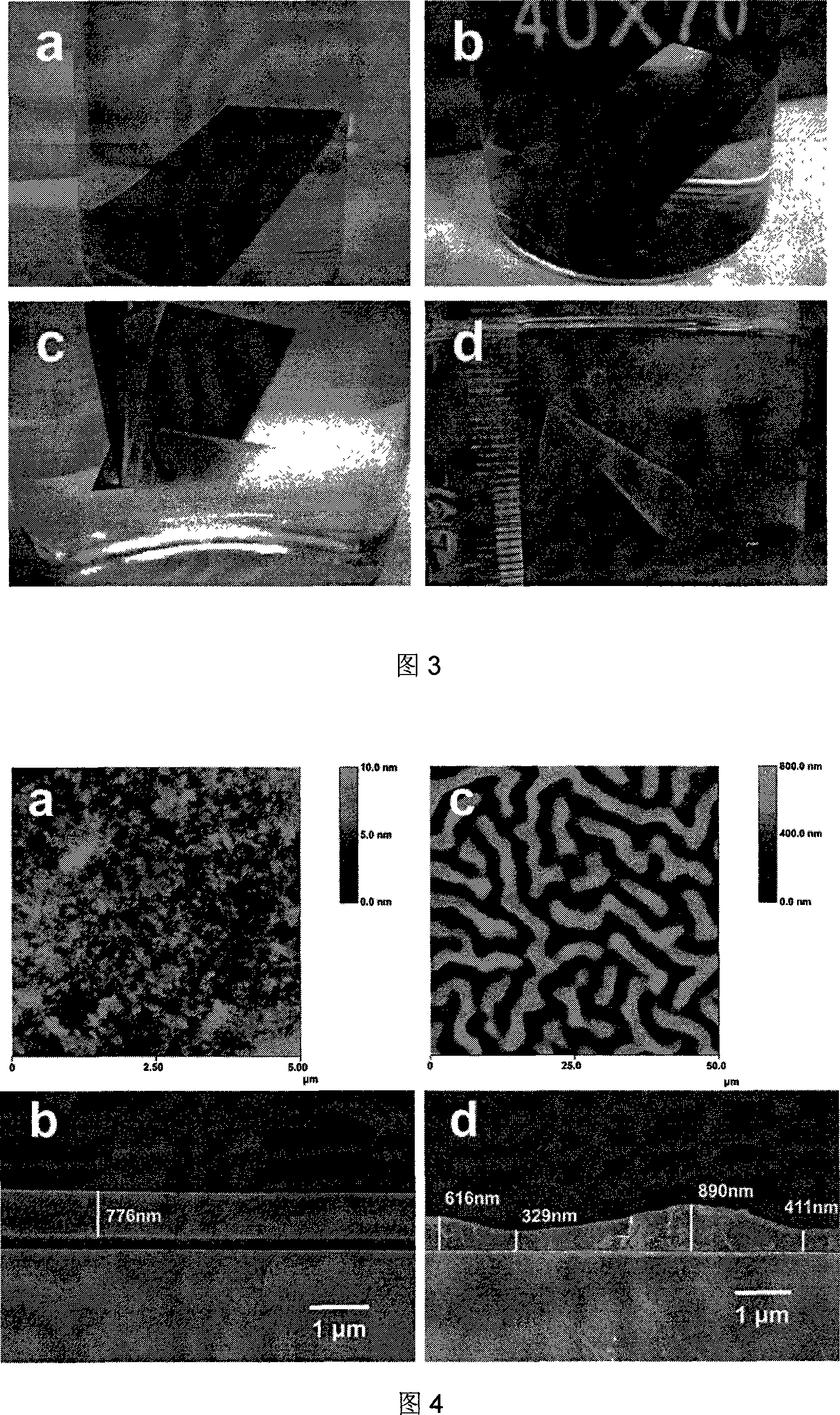

Method for preparing laminar assembled self-supporting membrane by using ion lift-off technology

The invention belongs to the multilayered thin film preparation field; it concretely involves a method that uses the ion peel-off technology to prepare large area layered assembly self-support membrane, including basis processing, layered-assembly membrane preparation, configuration of the peeling solution, preparation layered assembly self-support membrane using ion peel-off technology. The invention is not limited by the basis size, the shape, the type, and always holds true in the plane, the bended surface and the anomalous surface's, it can make the self-support membrane which are tubular or more complex form. This has a vital significance: On one hand, self-support membrane helps to research the layered assembly film's performance expediently, opens out the inner contact between the layered assembly film's performance, the chemical composition of the film and microscopic structure. On the other hand, compared with the layered assembly film which adheres to the solid fundus, self-support membrane will expand the application of the layered assembly film, including separating the membrane, the sensor, the catalyzed function thin film, the micro mechanism, even the man-made apparatus.

Owner:JILIN UNIV

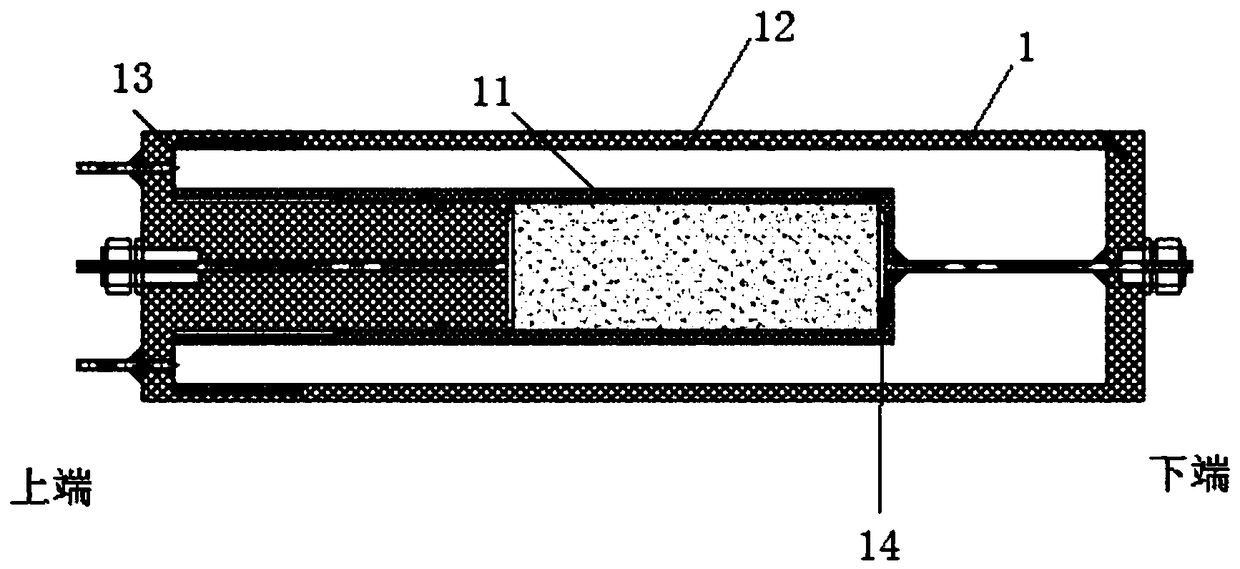

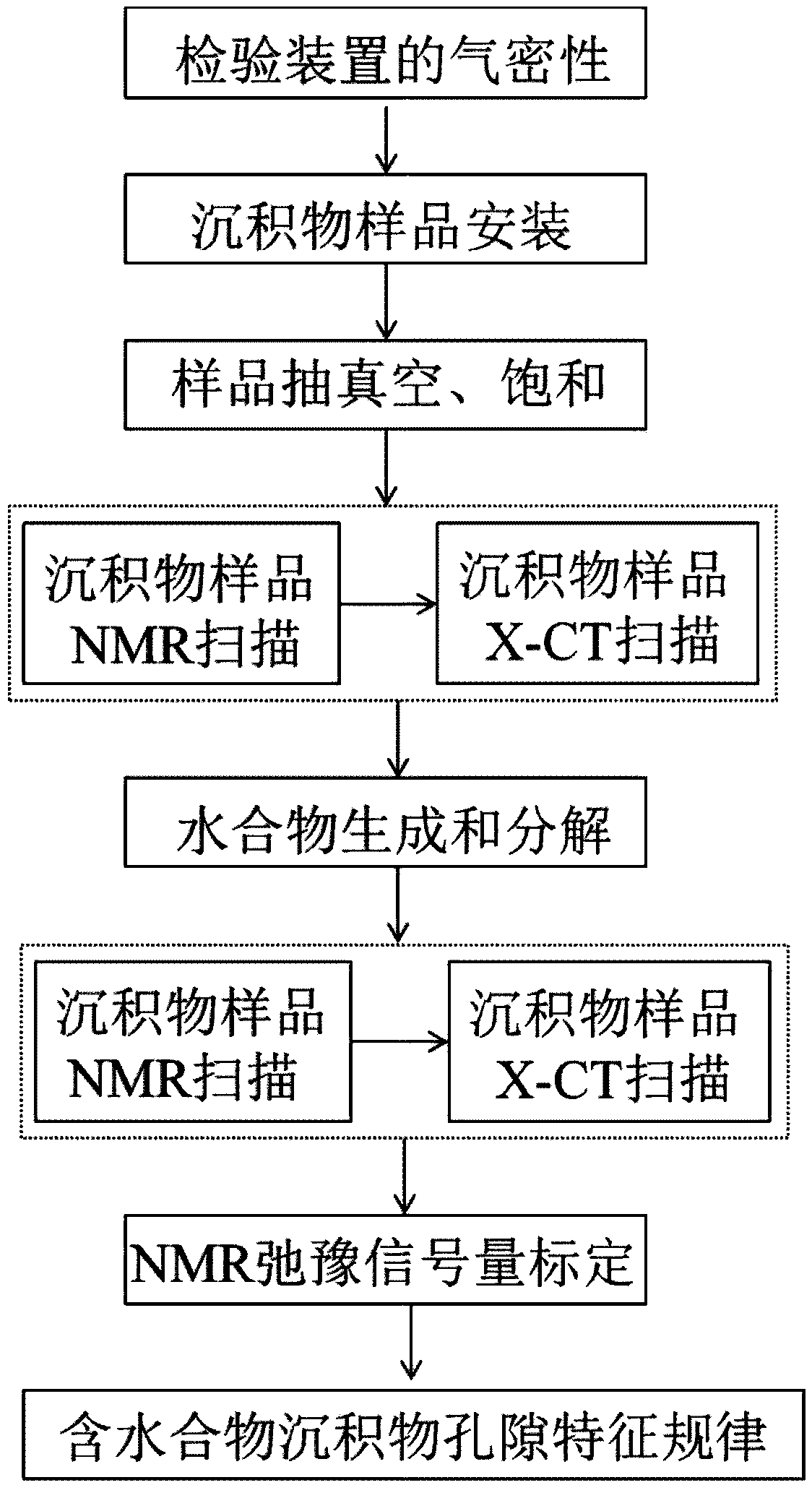

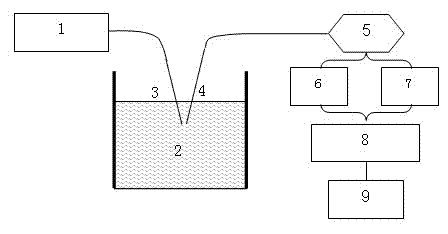

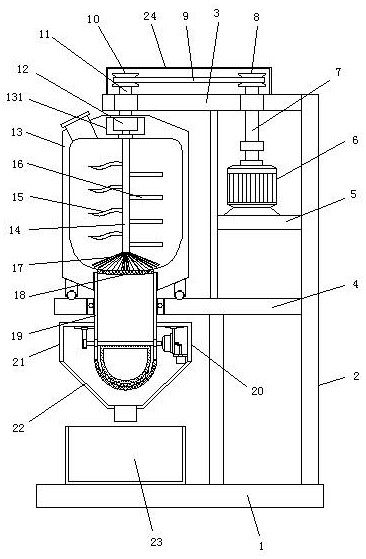

Low-field nuclear magnetic resonance multi-probe quantitative test system and method special for hydrate

PendingCN107807143ARealize the integration of testing and analysisRealize integrationAnalysis using nuclear magnetic resonanceWater resource assessmentPore fluidLow field nuclear magnetic resonance

The invention discloses a low-field nuclear magnetic resonance multi-probe quantitative test system and a low-field nuclear magnetic resonance multi-probe quantitative test method special for hydrate.The test system comprises a low-field nuclear magnetic resonance analyzer, a confining pressure-adding low-temperature high-pressure probe, a confining pressure-free low-temperature high-pressure probe, a confining pressure-free normal-temperature normal-pressure probe, a temperature confining pressure control module, a pore fluid supply module and an industrial personal computer. Through combined use of the confining pressure-adding low-temperature high-pressure probe, the confining pressure-free low-temperature high-pressure probe and the confining pressure-free normal-temperature normal-pressure probe and the improved design of the structure as well as by adoption of a multi-probe combined use mode, research on integration of hydrate-containing deposit low-field nuclear magnetic resonance measuring signal quantitative calibration and hydrate-containing deposit pore scale behavior measuring analysis is realized, research on the hydrate-containing deposit pore scale behavior featureis facilitated, and foundation is laid for discussion on hydrate-containing deposit basic physical property parameter change micromechanism.

Owner:QINGDAO INST OF MARINE GEOLOGY

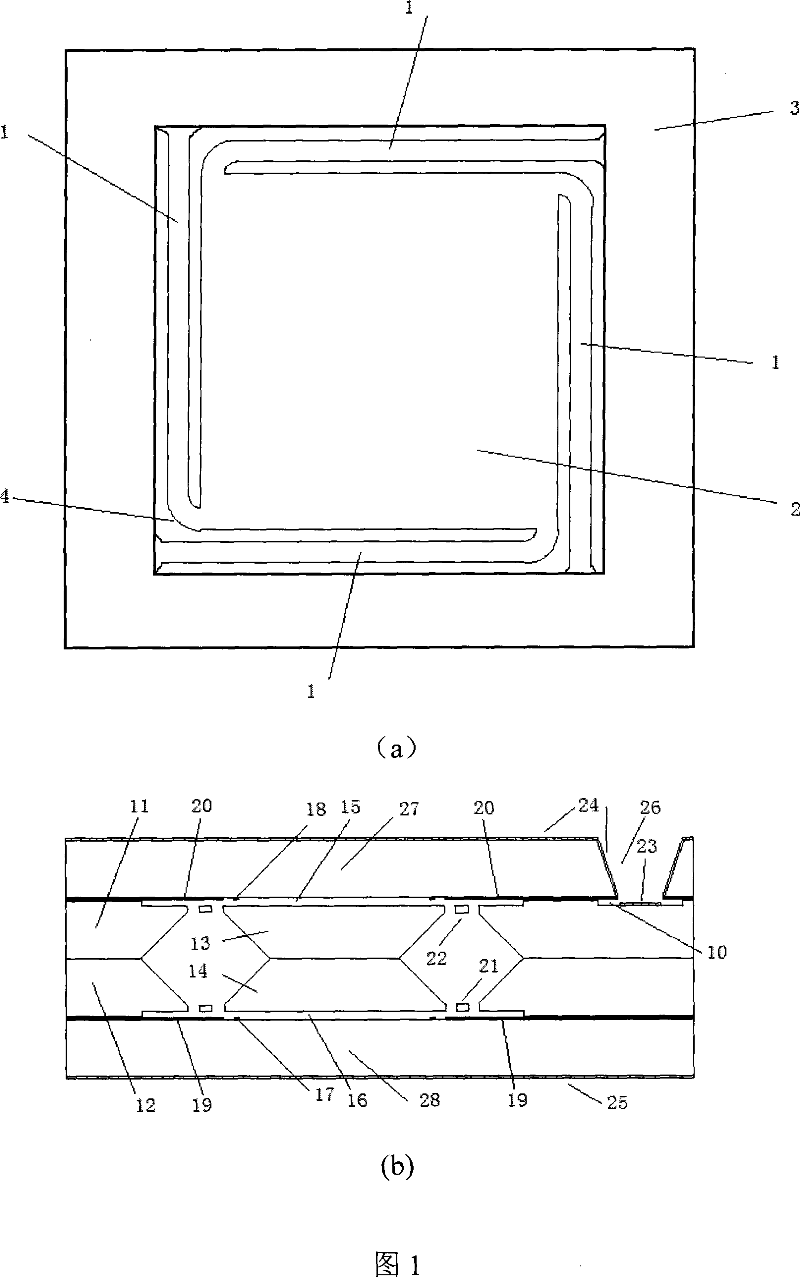

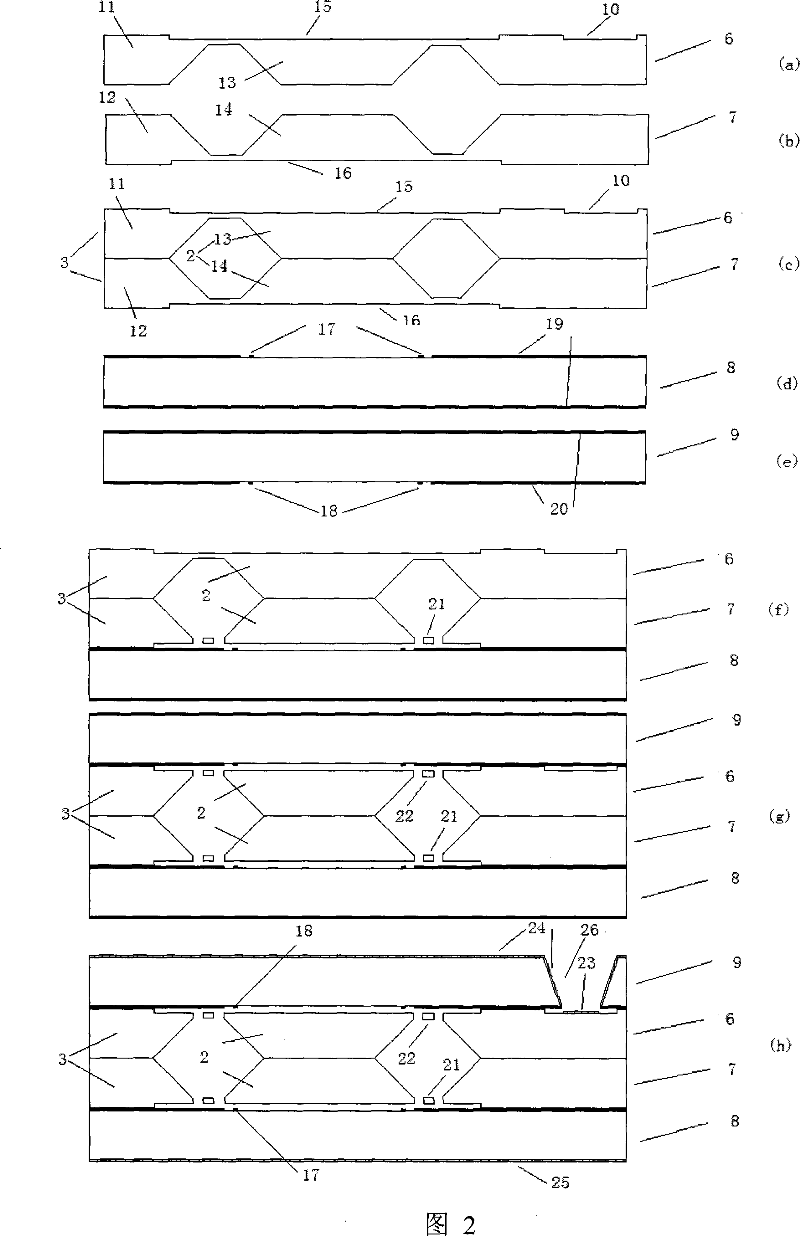

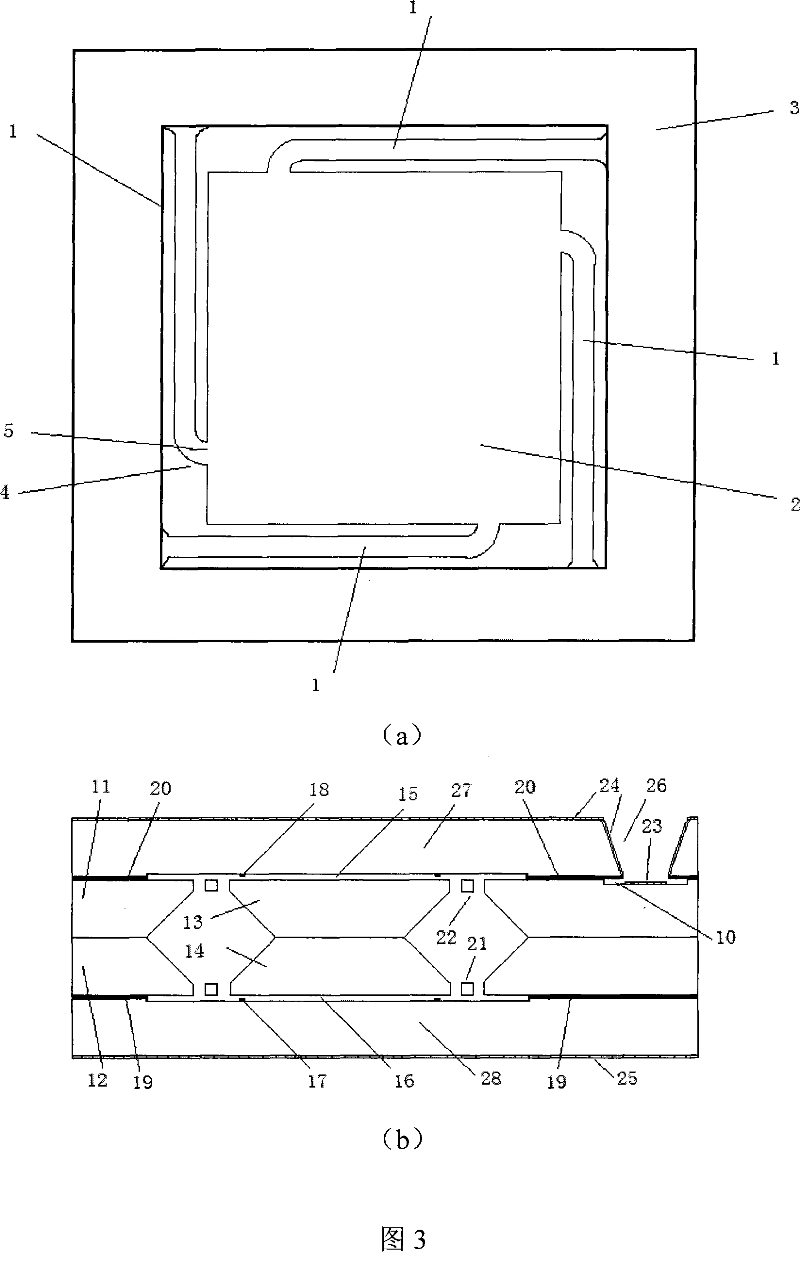

Symmetrical straight beam structure condenser type micro-acceleration sensor and manufacturing method thereof

The present invention relates to a capacitance type micro-acceleration sensor with a symmetrical and straight-girder structure and a manufacturing method thereof. The characteristics reside in that said acceleration sensor consists of a centrosymmetric quality block, an external supporting frame, eight direct elastic girders which are up-down symmetrical for connecting the quality block and the external supporting frame, an upper cover board and a lower cover board. On end of each direct elastic girder is connected to the top or the lateral of the bottom of the quality block that is parallel with the elastic girder, while the other end is connected to inner surface of the external supporting frame vertical to the elastic girder. The capacitance type micro-acceleration sensor with a symmetrical and straight-girder structure can improve the sensitivity at the same time of reducing the transversal effect remarkably. The capacitance type micro-acceleration sensor with a symmetrical and straight-girder structure is made by using the technology of a micro-electronics mechanism system and is a micro-mechanism acceleration sensor with a high performance.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Integrated RF MEMS switch

InactiveCN1716492AIncreased process reliabilityReduce process complexityElectrostatic/electro-adhesion relaysWaveguide type devicesMicroelectromechanical systemsEngineering

The RF switch based on micro electromechanical technology includes micro mechanism (MEMS) part and RF part, and has mobile switch structure for the switching function is set on the MEMS substrate. The MEMS part and RF part are first manufactured separately, and the MEMS substrate and RF substrate are then aligned and bonded together. The switch includes several mobile electrodes and has two kinds of drive states including upward drawing state and downward drawing state. The switch in the technological scheme of the present invention has fast switching speed, low drive voltage, high stability and relatively simple manufacture process with high outer contamination resistance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

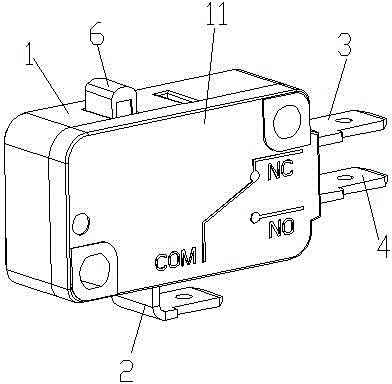

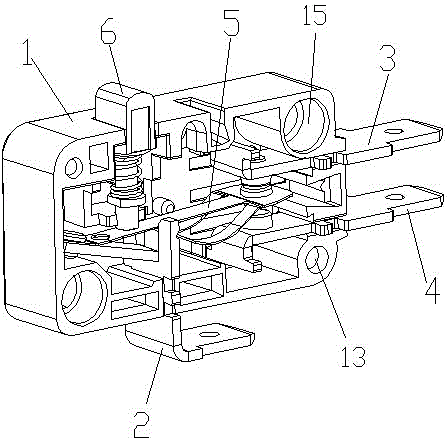

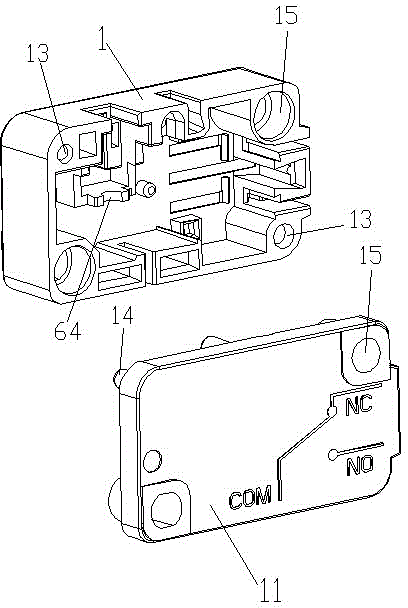

Microswitch

ActiveCN104658788AHigh sensitivityGuaranteed flexibilityElectric switchesBiochemical engineeringMicro mechanism

The invention provides a microswitch. The microswitch comprises a bottom casing, an upper cover as well as a micro-mechanism arranged between the bottom casing and the upper cover, wherein the micro-mechanism comprises a common terminal, a normally-closed terminal, a normally-open terminal and an elastic piece, one end of the elastic piece is fixedly connected with the common terminal, the other end of the elastic piece is arranged between the normally-closed terminal and the normally-open terminal, the elastic piece is connected with the normally-closed terminal in a normal state, and a button device is arranged at the upper end of a position where the elastic piece and the common terminal are connected. The microswitch comprises a few components, the structure is simple, the production cost is greatly reduced, all the components are in close fit by the aid of simple and precise components and the ingenious design, the sensitivity is high, and the service life is long.

Owner:HUIZHOU HONGBAO ELECTRICAL APPLIANCE CO LTD

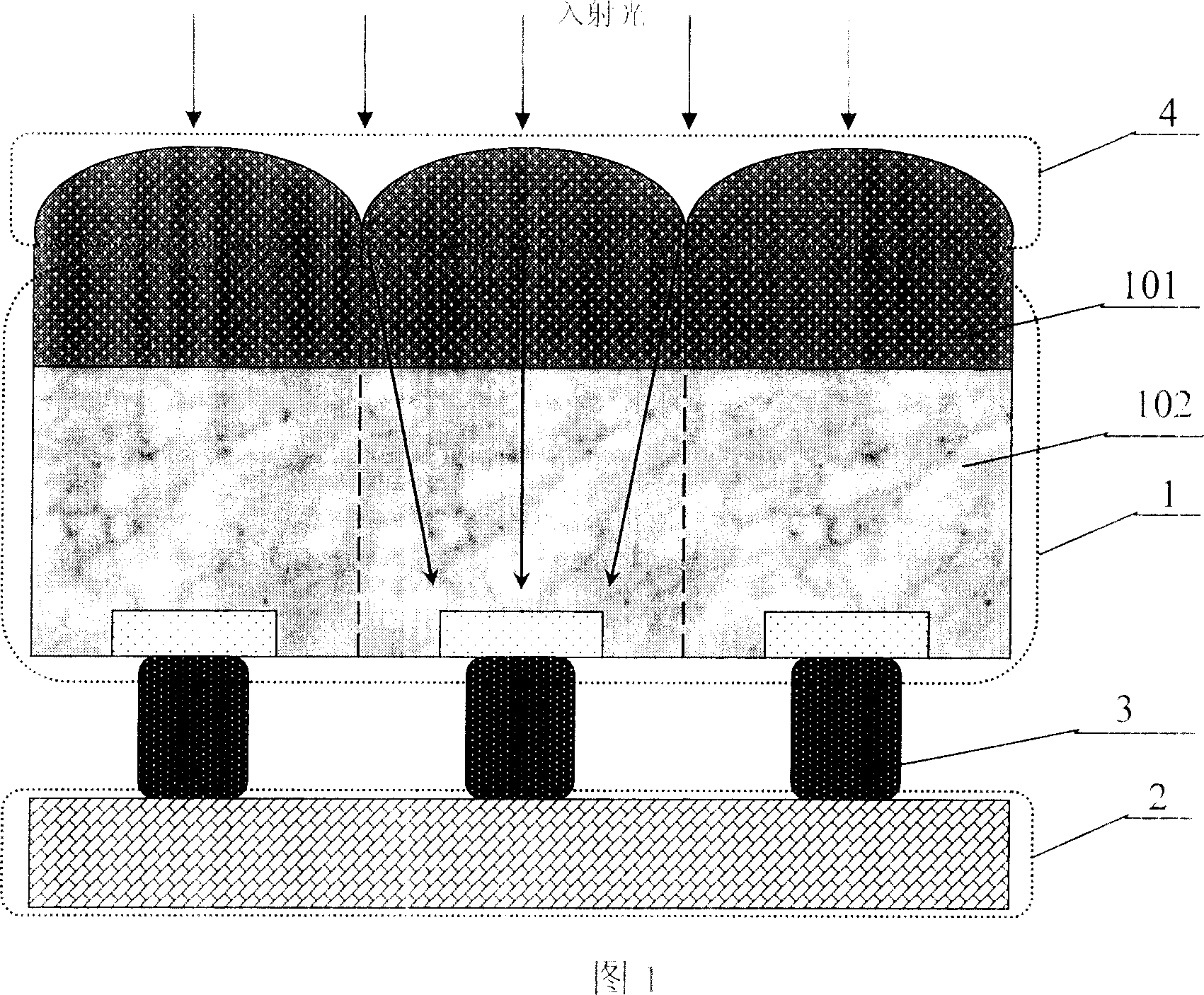

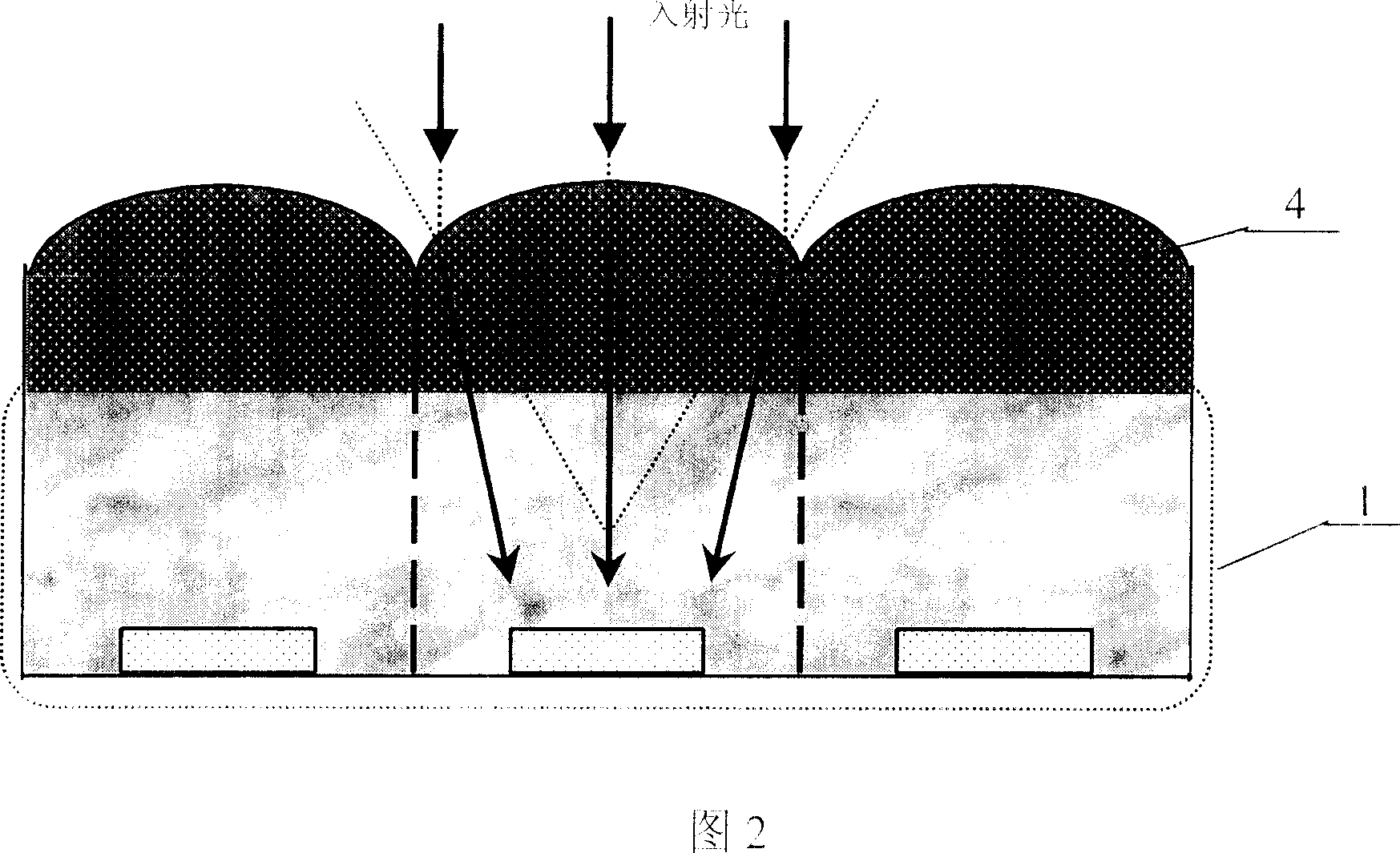

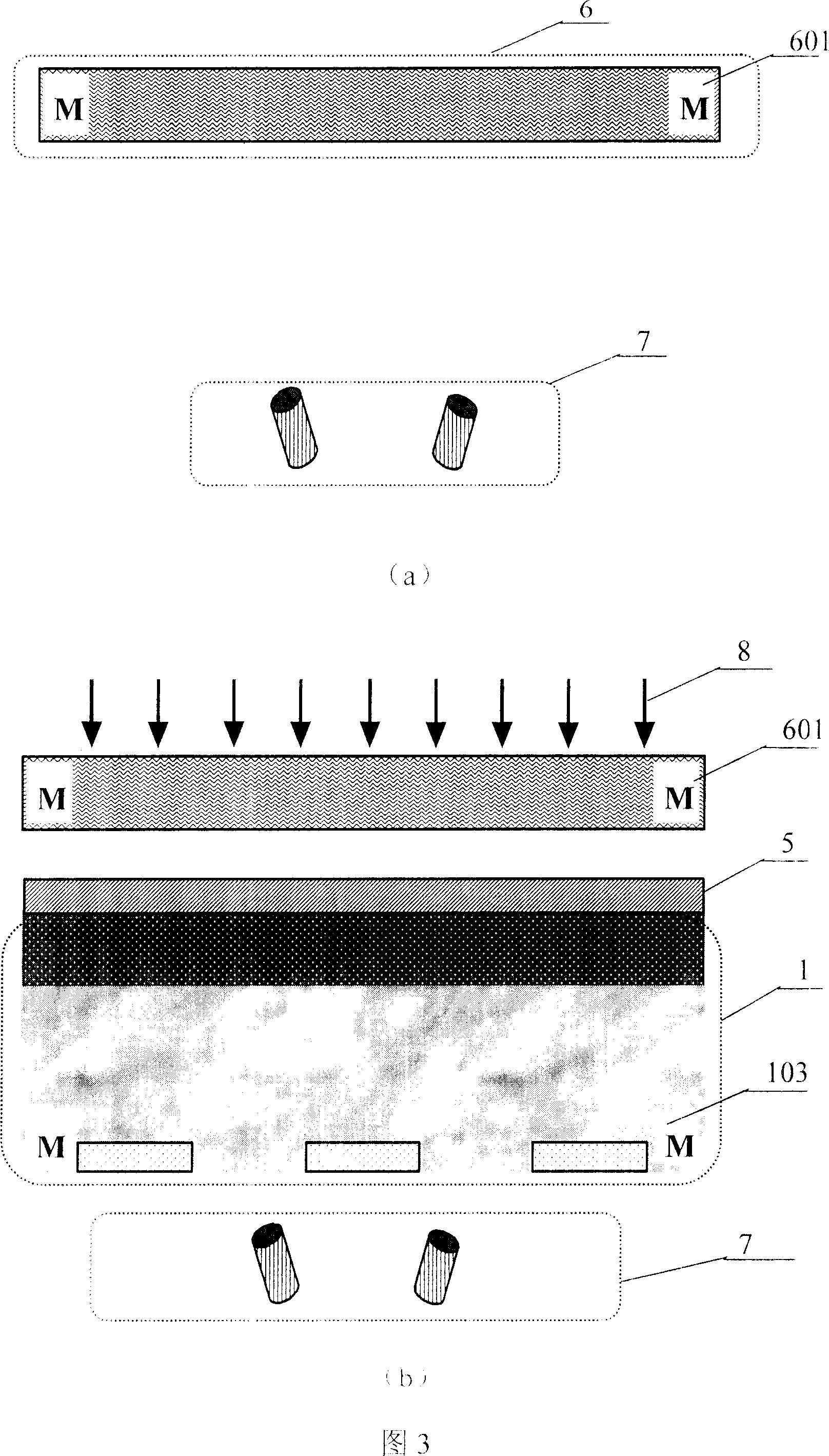

Backward integrated micro-lens infrared focal plane detector and micro-lens producing method

ActiveCN1933149AReduce spatial crosstalkImprove response rateSolid-state devicesSemiconductor/solid-state device manufacturingIndiumResponsivity

This invention relates to a trailing integrated micro-lens infrared focal plane detector and a preparation method for micro-lenses, in which, said detector includes: infrared photosensitive meta-array chips, a read-out circuit, a blending mutual-connected indium post and a micro-lens array, which is processed by micro-mechanism at the back of the substrate of the array chip applying an etching method to the positive pattern of a memory focal plane detection chip and a plasma combined etching technology, and the optical shafts of the trailing integrated micro-lens are coincident with the photosensitive face central normal of the corresponding photosensitive pixels.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

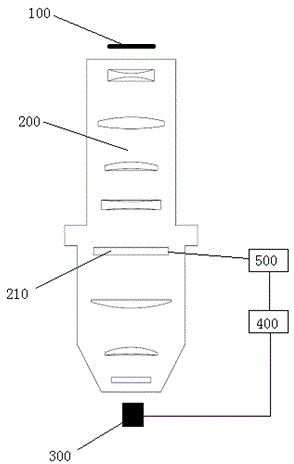

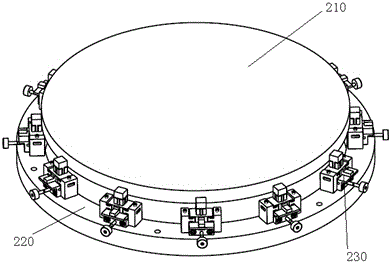

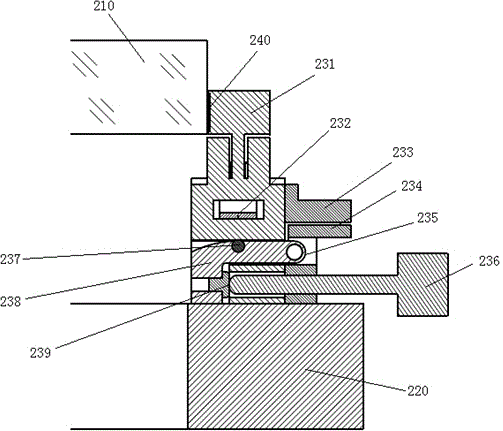

Optical system image quality compensating apparatus

ActiveCN104977710ASimple structureReduce the difficulty of assemblyPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMicro mechanism

The invention provides an optical system image quality compensating apparatus which comprises a distorting lens and a plurality of micro mechanisms. The apparatus is characterized in that optical system image quality compensation is realized by means of the micro mechanisms changing local face types of the distorting lens or adjusting the positions of a micromotion lens along a Z direction or theta X, theta Y directions. The optical system image quality compensating apparatus provided in the invention has the advantages of simple structure, lowered assembling difficulties, stability, reliability and convenient operation.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

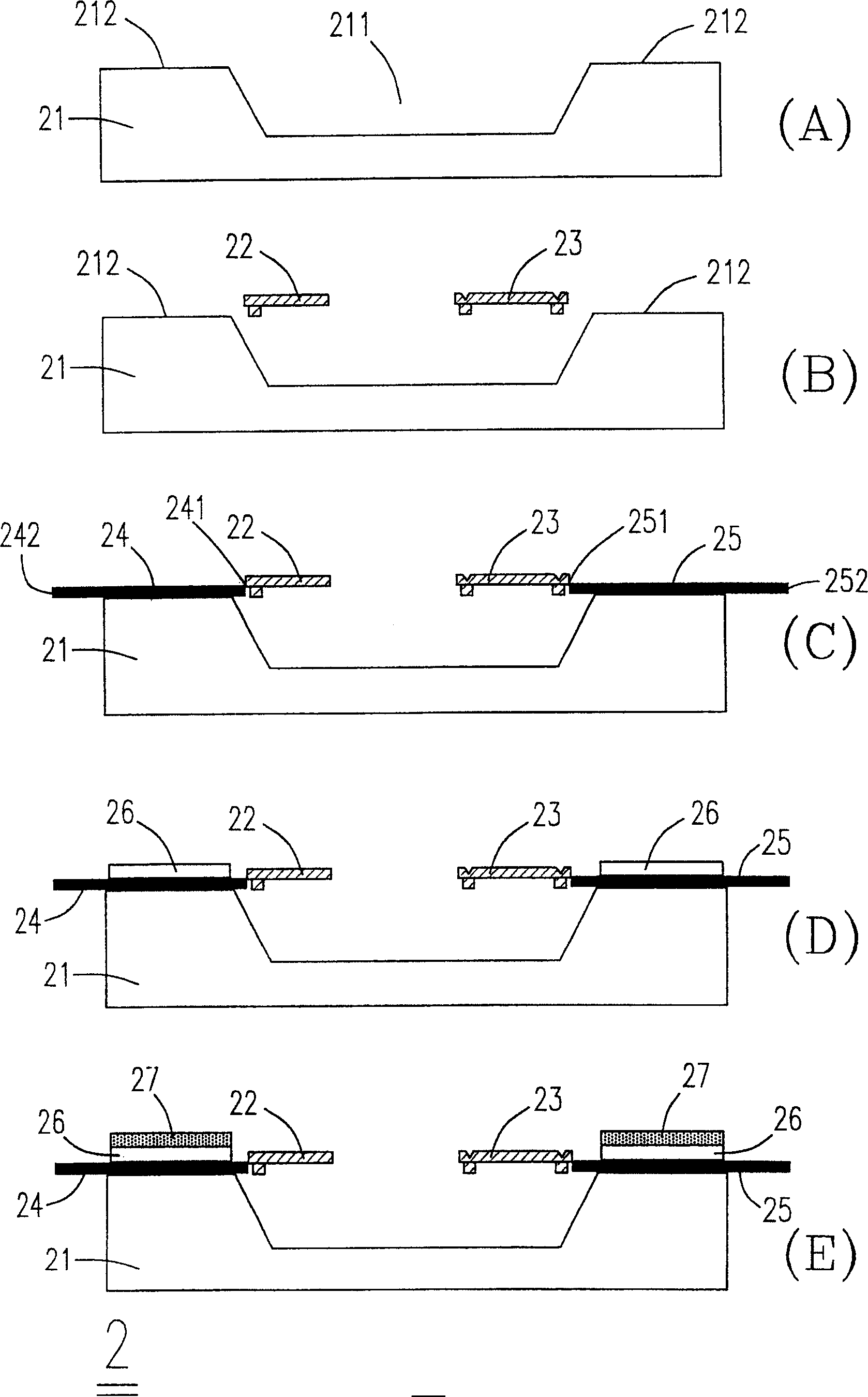

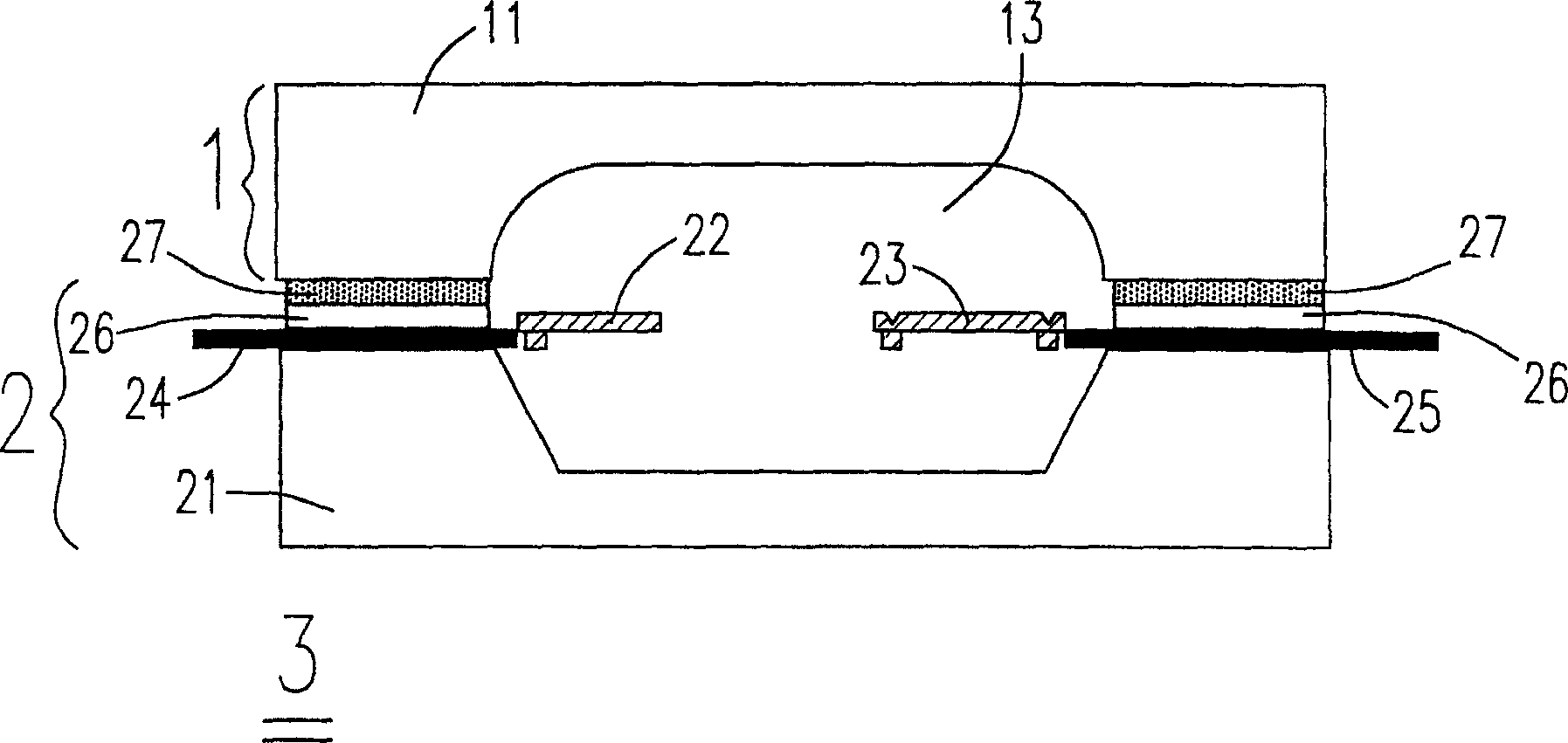

Manufacture of electromechanical element, microelectro mechanical and resonance element and air tightness test method

InactiveCN1724987AAvoid destructionMachine part testingPiezoelectric/electrostrictive devicesResonanceEngineering

The invention provides a method for making electromechanical component and micro-electromechanical and resonance components and the air density testing method, where it provides a method for making the micro-electromechanical component integrating a packaging step and a testing component setting step into a making technique and including the steps: 1) making a protection cover, comprising a cavity; b) providing a base; c) arranging a plurality of micro-mechanisms on the base, where these microstructures comprise the testing components; d) erecting a lead device at the base to control the action of these microstructures; and e) packaging at vacuum environment, i.e. at vacuum environment integrating the protection cover with the base to compose the micro-electromechanical component, where the cavity is used to contain the testing components.

Owner:中国台湾格雷蒙股份有限公司

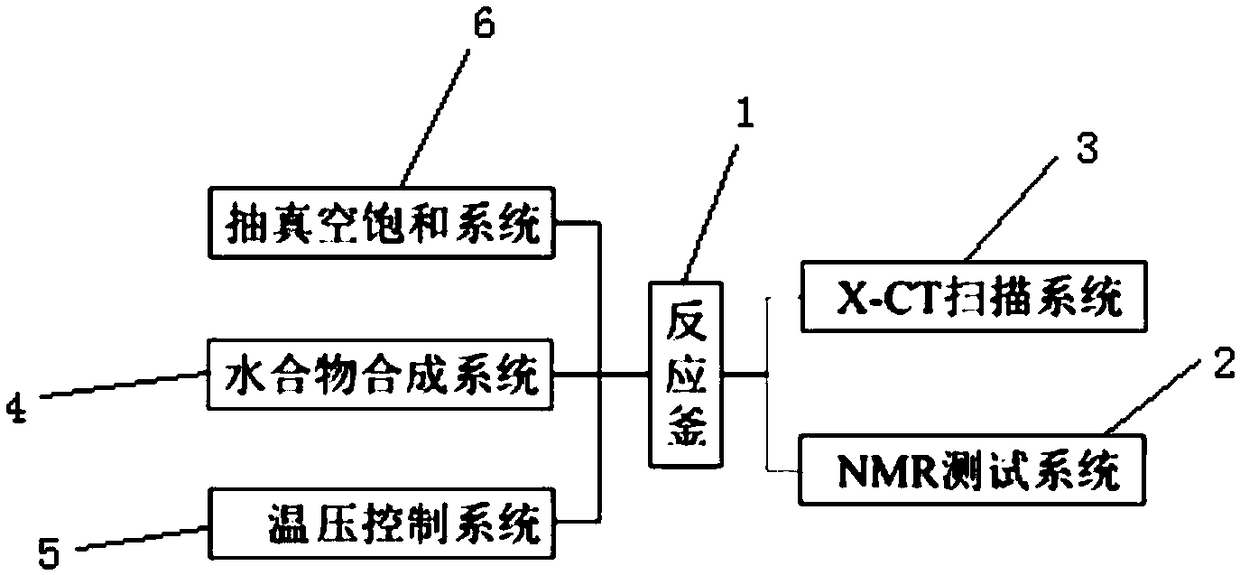

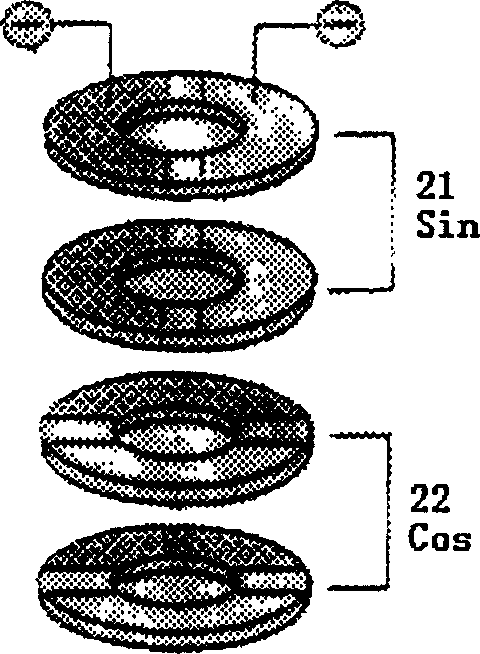

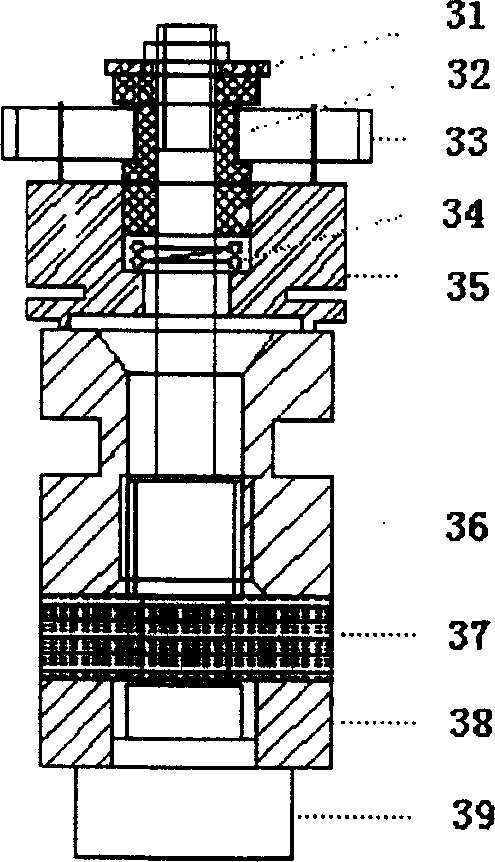

NMR relaxation semaphore calibrating device and method for aquo-complex sediment by combining X-CT technology

ActiveCN109374489ASimplify experimental proceduresAvoid influencePermeability/surface area analysisTransverse relaxationCt technology

The invention discloses an NMR relaxation semaphore calibrating device and method for an aquo-complex sediment by combining an X-CT technology. The device comprises a reaction kettle, an NMR testing system, an X-CT scanning system, an aquo-complex synthesizing system, a temperature pressure control system and a vacuumizing saturated system. The vacuumizing saturated system is connected to the reaction kettle for vaccumizing saturated treatment of the sediment in the reaction kettle. The NMR testing system and the X-CT scanning system are used for scanning and testing microporous structures ofthe aquo-complex sediment and analyzing the behavior characteristics of the aquo-complex sediment in pore scale in the forming and decomposing processes. By means of the device, calibration of nuclearmagnetism transverse relaxation semaphore and the behavior measurement and analysis in the pore scale can be integrated, thereby laying a technical foundation for discussing a micromechanism of basicphysical parameter change of the aquo-complex sediment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Polyhedron piezoelectric column or piezoelectric tube ultrasonic micromotor

InactiveCN1738178AImprove automationEasy to operatePiezoelectric/electrostriction/magnetostriction machinesDiagnostic Radiology ModalityUltrasonic motor

The invention relates to a flexural vibration modality ultrasonic micro-motor based on the polyhedral piezoelectric pole or piezoelectric pipe, belonging to the field of ultrasonic application. The invention comprises a stator vibrated by actuating ultrasonic, a rotor for putting torque or an axis connecting rotor, and a pre-pressure unit for pressing rotor. Wherein, said stator is mainly formed by a piezoelectric ceramic component for actuating vibration and its matching blocks, which is characterized in that: said piezoelectric ceramic component for actuating flexural vibration is polyhedral piezoelectric pole or piezoelectric pipe, whose surfaces of external wall are plated with a plurality of external electrodes for polarization and actuating vibration. The inventive motor has a wide size to be processed, which improves the minimization of ultrasonic motor. And, when inputting the electrical signal, the rotator can rotate on the surface of stator. Said invention has wider application in the fields of biology, medical treatment, micro-mechanism, precision electronic mechanism and the national defence.

Owner:TSINGHUA UNIV

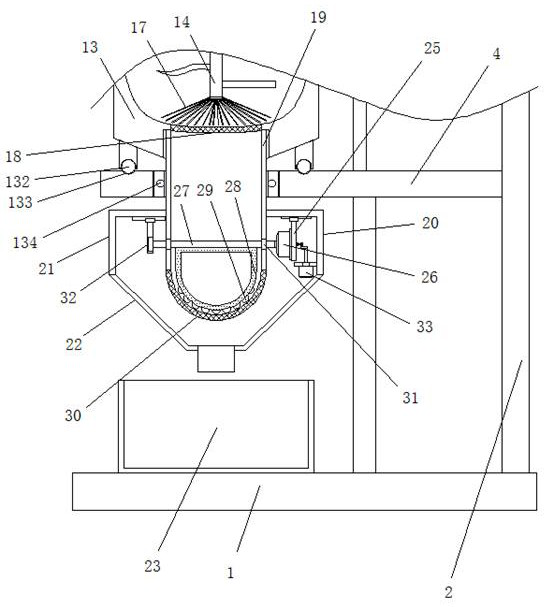

High-load micro-mechanism dynamic characteristic testing apparatus

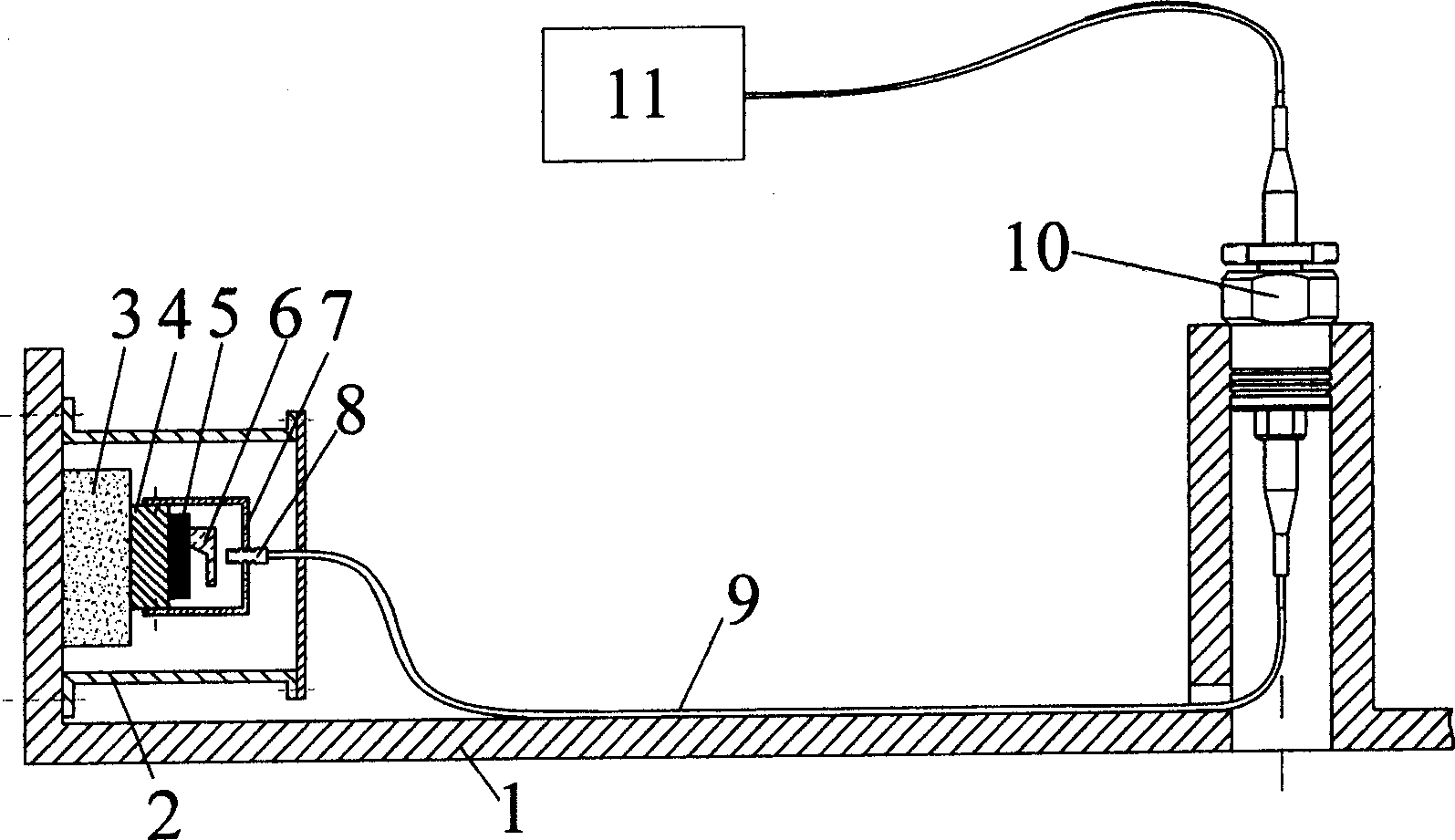

InactiveCN1710428AImprove environmental adaptabilityFunction increaseTesting/calibration of speed/acceleration/shock measurement devicesFeature setMicroelectromechanical systems

A device for testing dynamical property of high load microcomponent is composed of high speed rotary table , microcomponent driving and clamping , test device of optical vibration and optical fibre rotary connector . It features setting rotary arm at one end of said table and making another end be shaft shape , setting vacuum chamber on rotary arm of said table and optical rotary connector in said shaft sleeve and setting foam for isolating vibration , anti-shock mass , piezoelectric activator , micro-component , optical fibre probe and its clamp device in vacuum chamber.

Owner:DALIAN UNIV OF TECH

Translating and rotation micro mechanism

InactiveUS8269395B2Electrostatic generators/motorsFlexible microstructural devicesElectrostatic actuatorEngineering

A translation and rotation mechanism is disclosed, which comprises of one or more bi-directional electrostatic actuators. Each bi-directional electrostatic actuator comprising of fixed electrodes and movable electrodes, where the fixed electrodes of each actuator being attached onto a base. The movable electrodes of each actuator are connected to the translating and rotation unit through a spring system. The movable elements of each said actuator being able to rotate with respect to the base plane by applying voltage signals to the actuator and by controlling the voltage signals applied to each said actuator independently, said translating and rotation unit being able to translate, rotate, or translate and rotate simultaneously.

Owner:HE SIYUAN +1

Particle measurement method and device based on optical fiber type dynamic light scattering mutual correlation technology

ActiveCN102890051AAchievement distanceReduce volumeIndividual particle analysisHigh concentrationMutual correlation

The invention discloses a particle measurement method and device based on an optical fiber type dynamic light scattering mutual correlation technology. A laser device and a first optical fiber probe in a sample pool form an incidence optical path; a second optical fiber probe in the sample pool and the first optical fiber probe form a scattering optical path; scattered light passes through a coupler, a first optical detector and a second optical detector to form a dynamic scattered light signal detection and processing unit through a digital correlator and a micro mechanism; laser irradiates the particle sample pool through the first optical fiber probe; particles scatter the laser; the scattered light is received by the second optical fiber probe, then is divided by the coupler, enters the two optical detectors and is converted into a pulse signal read by the micro mechanism to calculate a particle size. The conventional optical elements are eliminated, so that the size of a system is greatly reduced; more importantly, the optical fiber probes can be directly inserted into a sample solution and can directly measure a sample with high concentration; and therefore, on-line monitoring and remote measurement for industrial production are realized.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

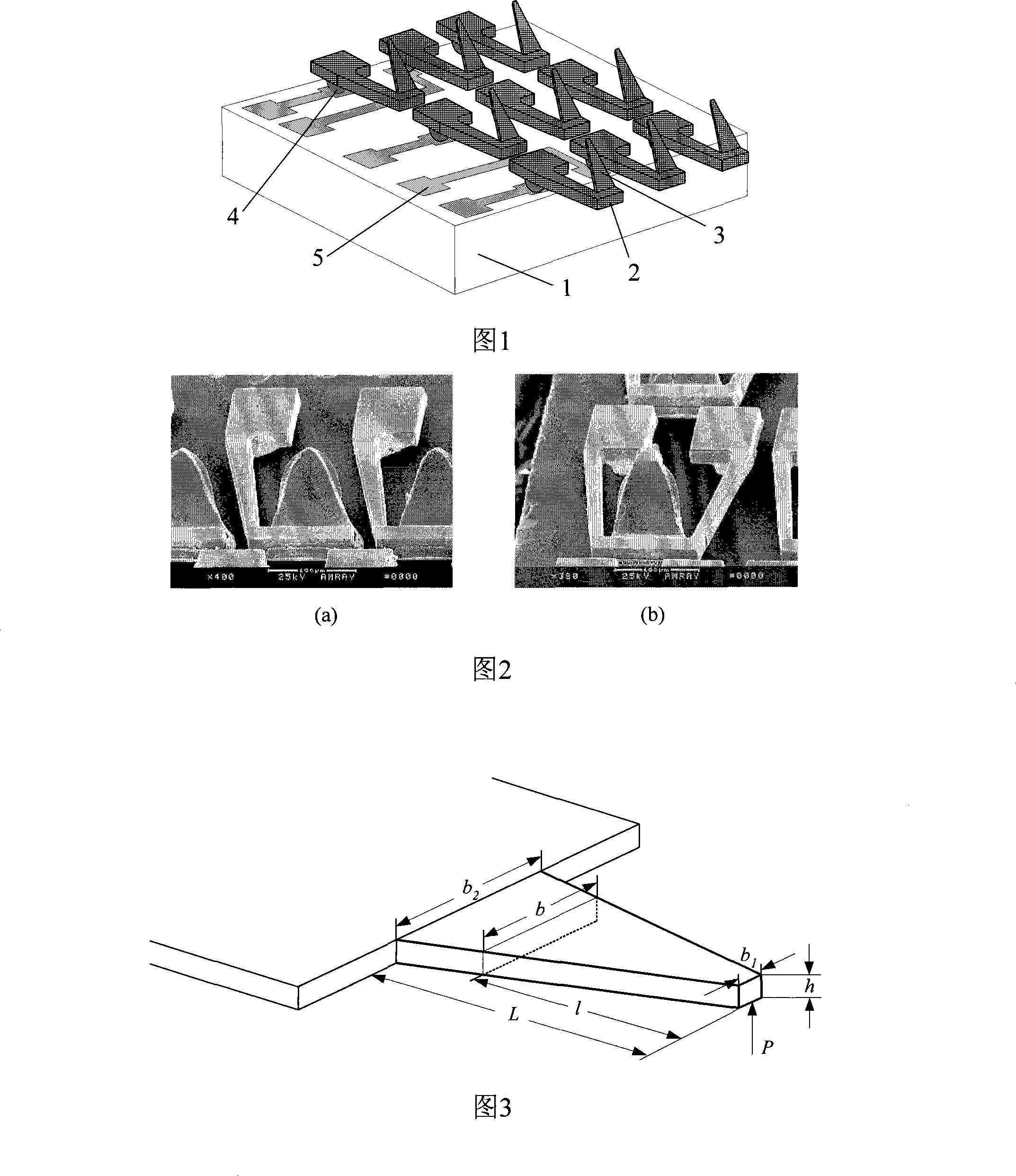

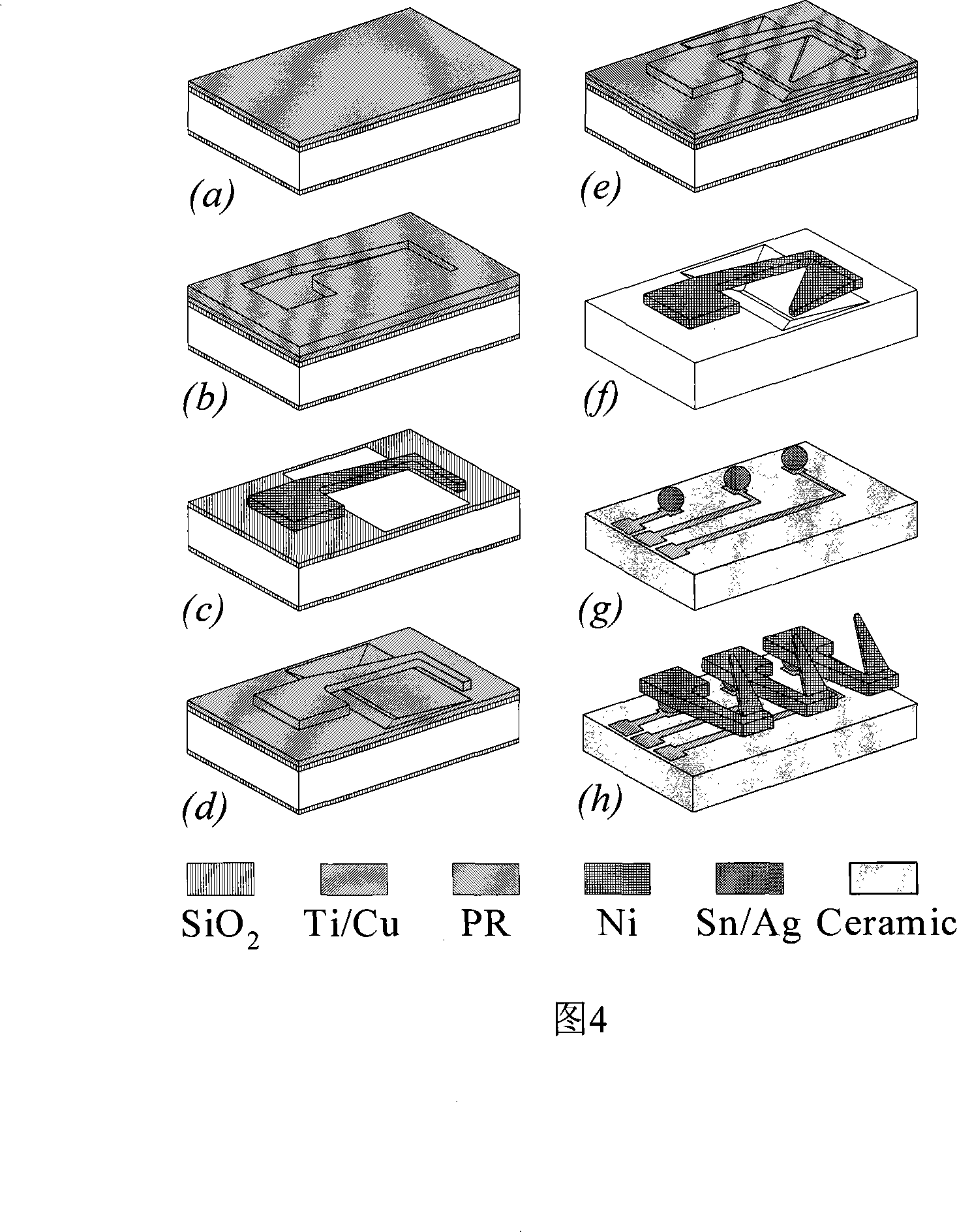

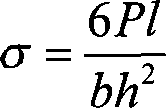

Micro-mechanism testing probe card based on electroplating technique and manufacturing method thereof

ActiveCN101214916AIncreased needle tip displacementIncrease displacementElectronic circuit testingElectrical measurement instrument detailsMicro mechanismAnisotropic etching

The invention relates to a micro mechanical testing probe card based on electroplating process and a manufacturing method thereof, and is characterized in that, cantilevers and probe tips are manufactured and formed on a silicon wafer with electroplated metal nickel; the probe tips are manufactured on an (111) inclined surface of the silicon wafer, and each probe tip is connected with a ceramic substrate with one or two probe cantilevers; the probe cantilevers and the probe tips adopt an isostress beam structure; probes on an flip chip substrate are intensively arranged in two directions. The manufacturing is characterized in that: firstly, the upper surface of the (100) silicon wafer is taken as the electroplated working face, and the probe cantilevers of a low stress nickel layer is formed by electroplating; and then a deep groove (111) inclined surface produced by anisotropic etching is taken as the working face, and the probe tips of the low stress nickel layer is formed by electroplating, and then the probes are connected with a package substrate by a flip chip process, and finally the probe structure is released through a method of removing the corrosion of the silicon wafer.

Owner:深圳市道格特科技有限公司

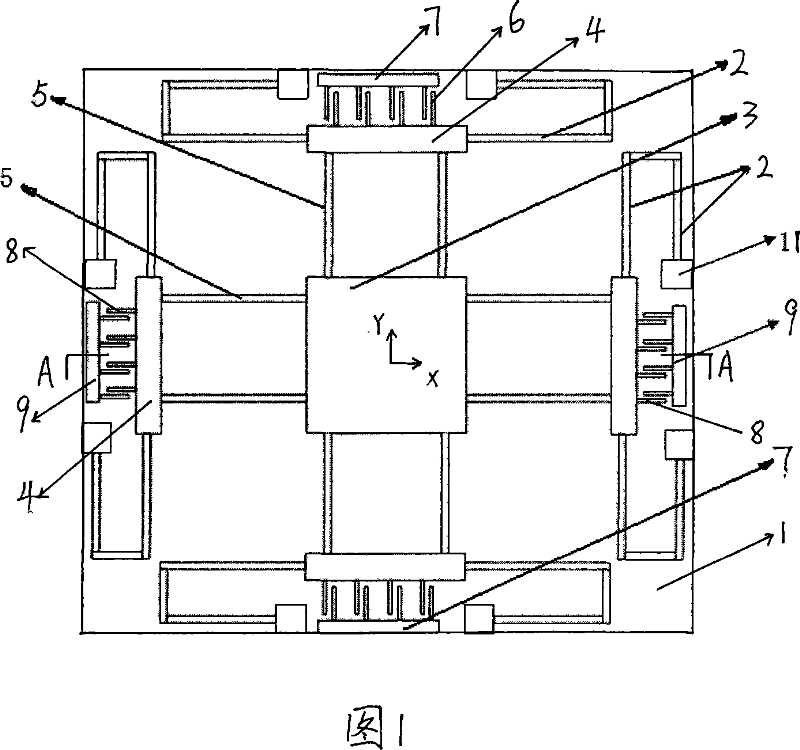

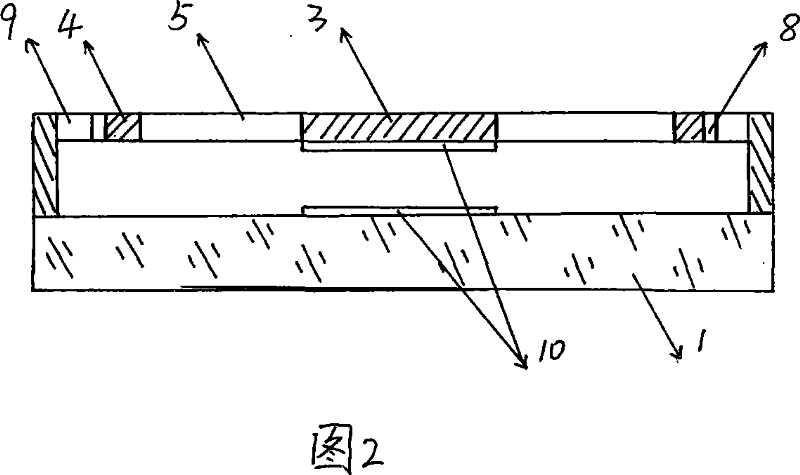

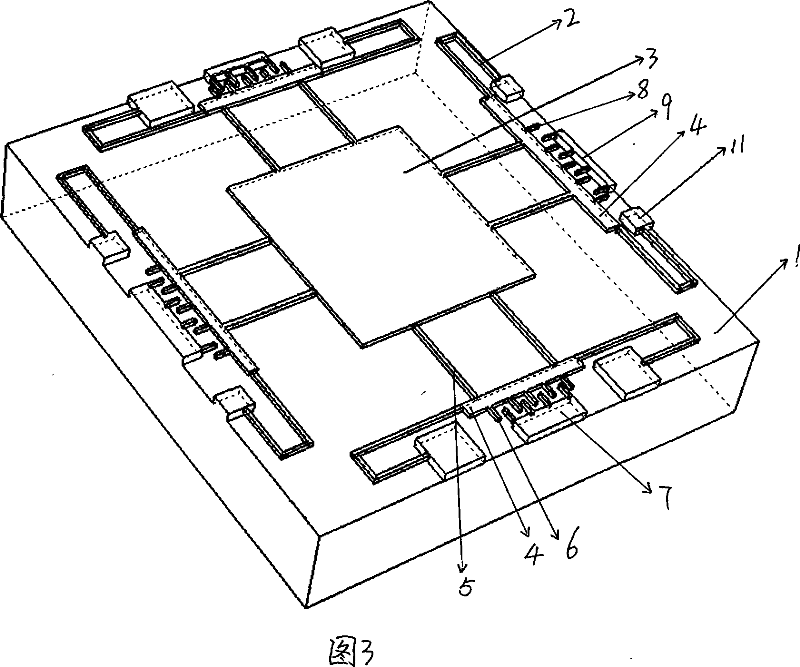

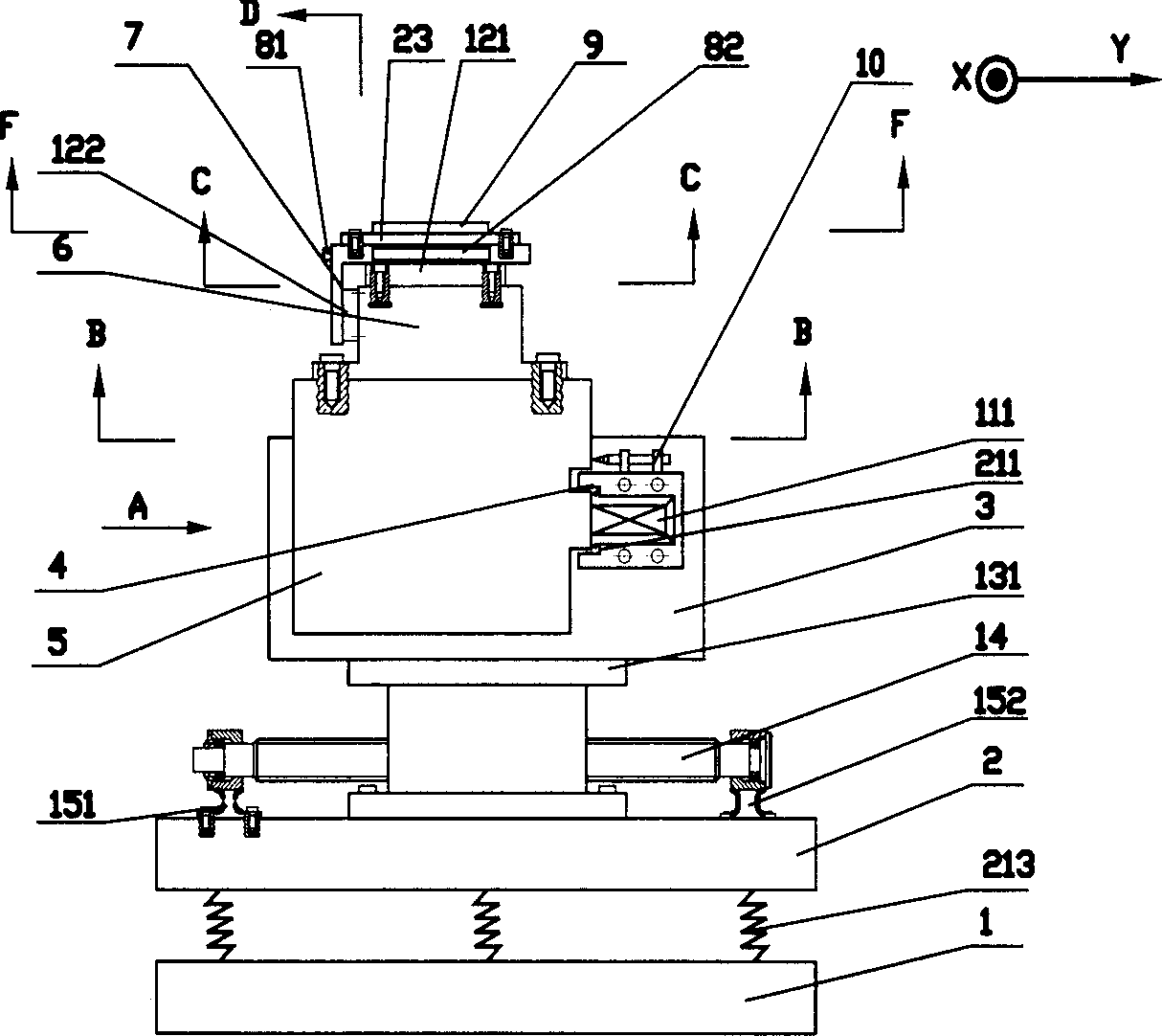

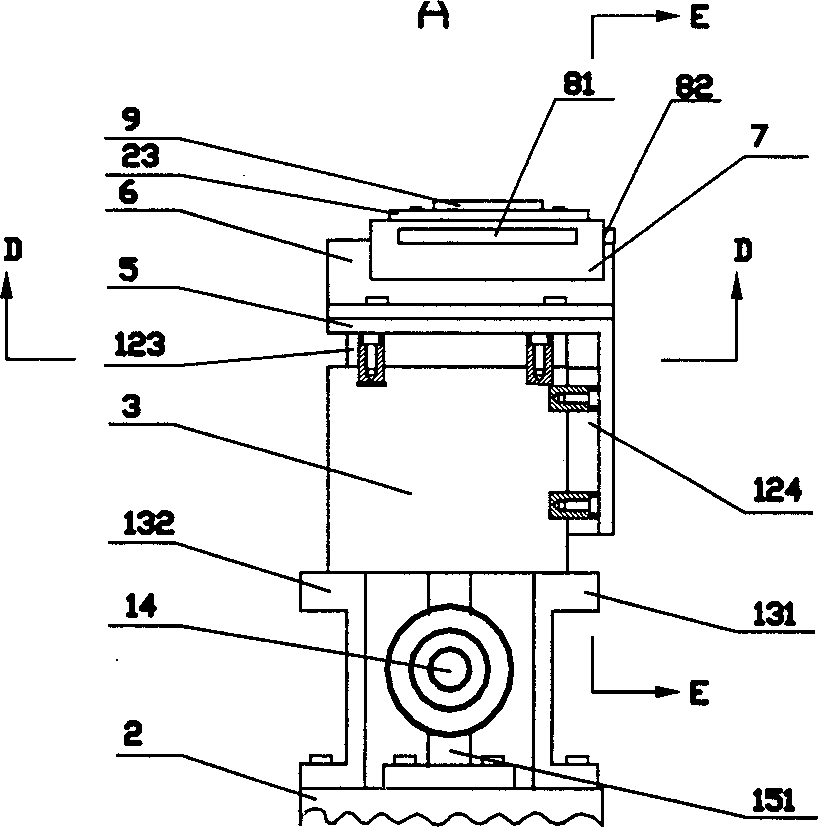

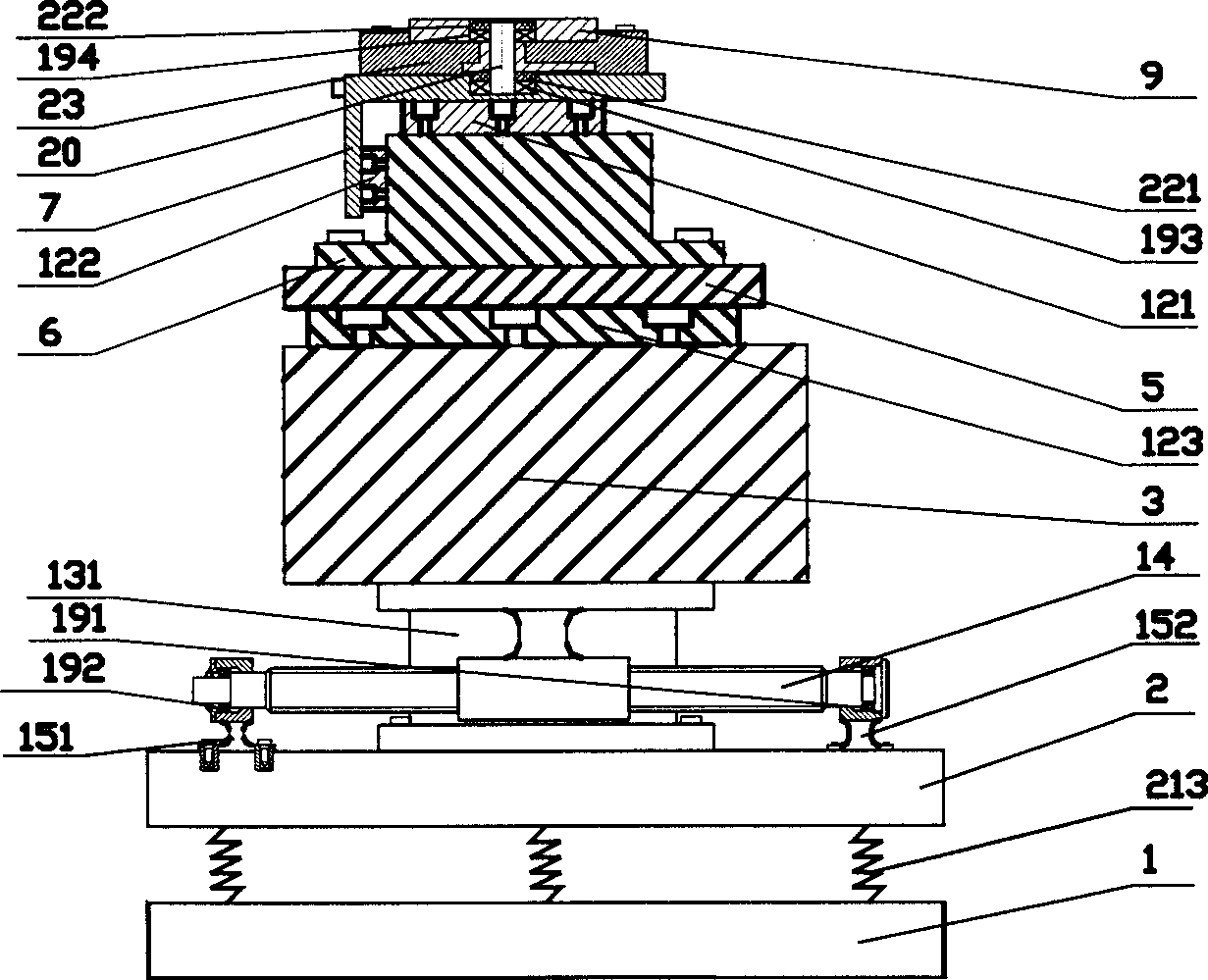

Precise workstable structure for array IC photoetching system

InactiveCN1374563AAchieve expected goalsPhotomechanical exposure apparatusMicrolithography exposure apparatusIntegrated circuit manufacturingReciprocating motion

The present invention belongs to the integrated circuit manufacturing superfine engineering. The precise work table includes micro turntable, turntable seat coaxially connected to the turntable, turntable driving support, small X direction table with X and Y direction mirror and capable of reciprocating in X direction, hydrostatic X direction air guide, Y direction stable, hydrostatic Y directionair guide, Y direction micro mechanism, rolling screw bolt to drive the hydrostatic Y direction air guide and elastic shock-proof worktable. The micro mechanism for the turntable driving support and the Y direction stable are driven with piezoelectrics; and both the X direction table and the Y direction stable are T-shaped. The present invention can ensure both scanning precision and photoetchingefficiency.

Owner:TSINGHUA UNIV

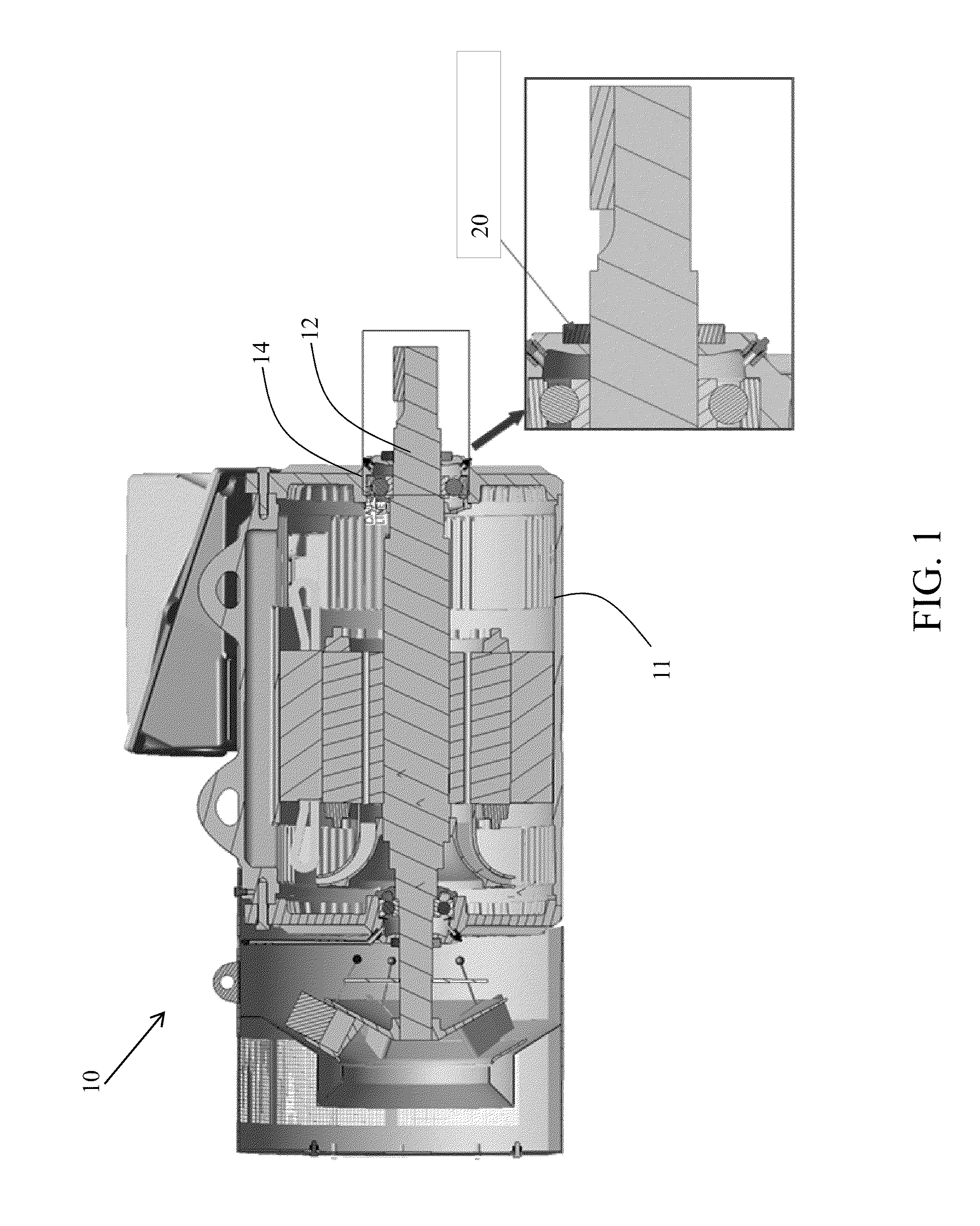

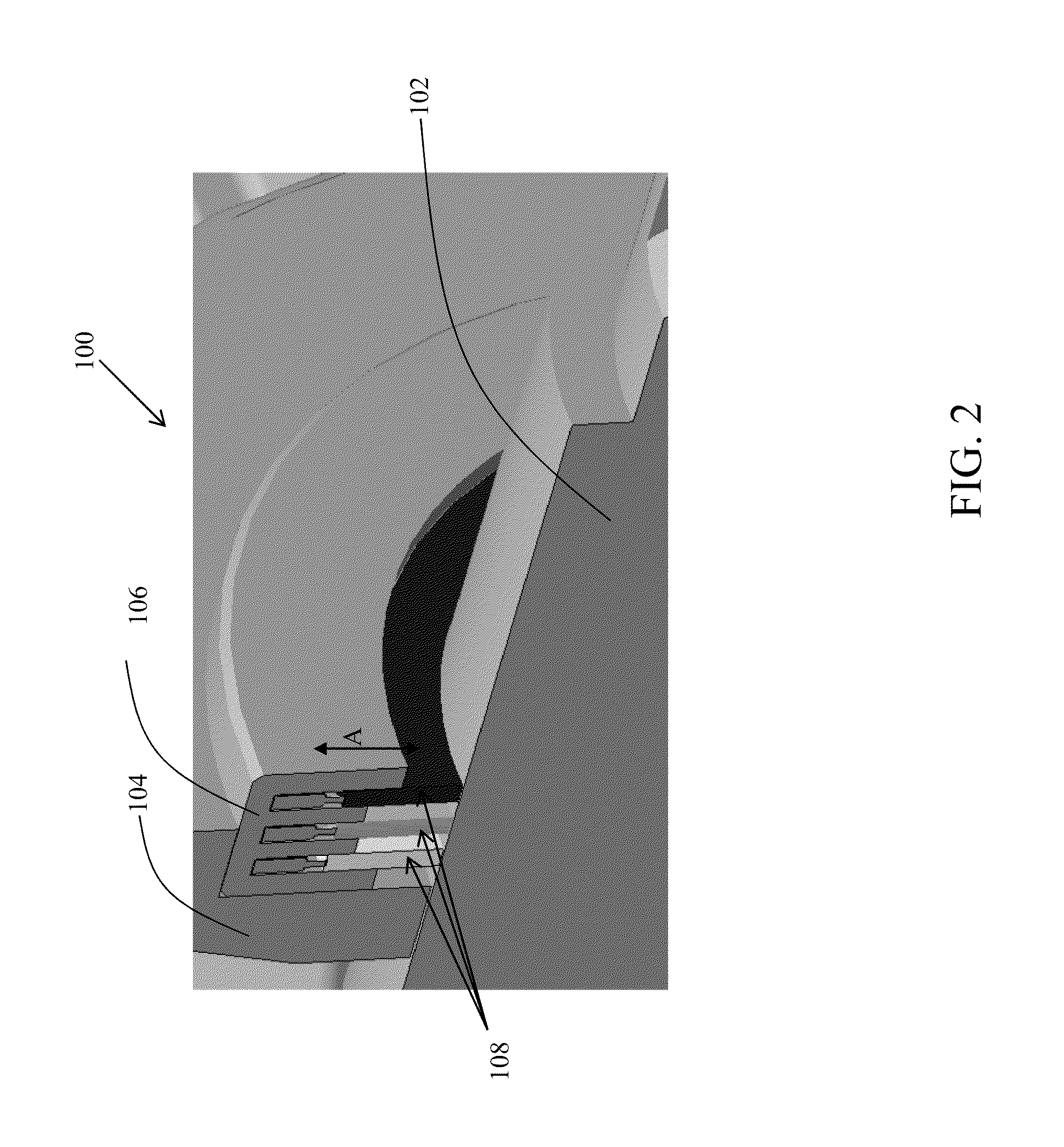

Self-adjusting seal

A sealing system that self-adjusts according to atmospheric conditions is disclosed. The sealing system includes an annular seal casing mounted on a stationary component, the annular seal casing positioned such that a rotating component extends therethrough, at least one annular sealing agent configured to radially move with respect to the rotating component between a sealed position and an unsealed position, at least one sensor for gathering atmospheric data, and at least one micro-mechanism configured to control the at least one annular sealing agent based on the atmospheric data.

Owner:GENERAL ELECTRIC CO

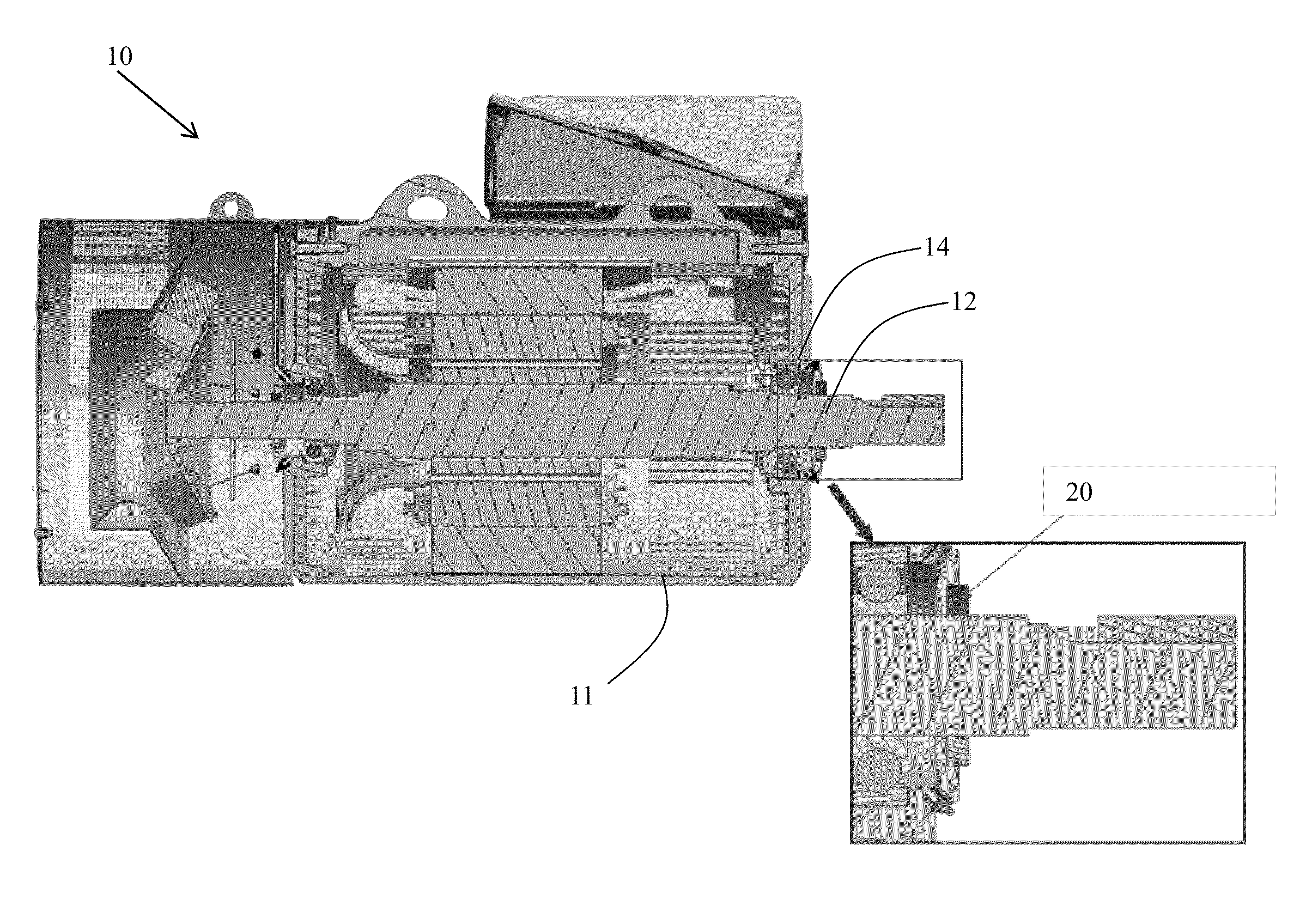

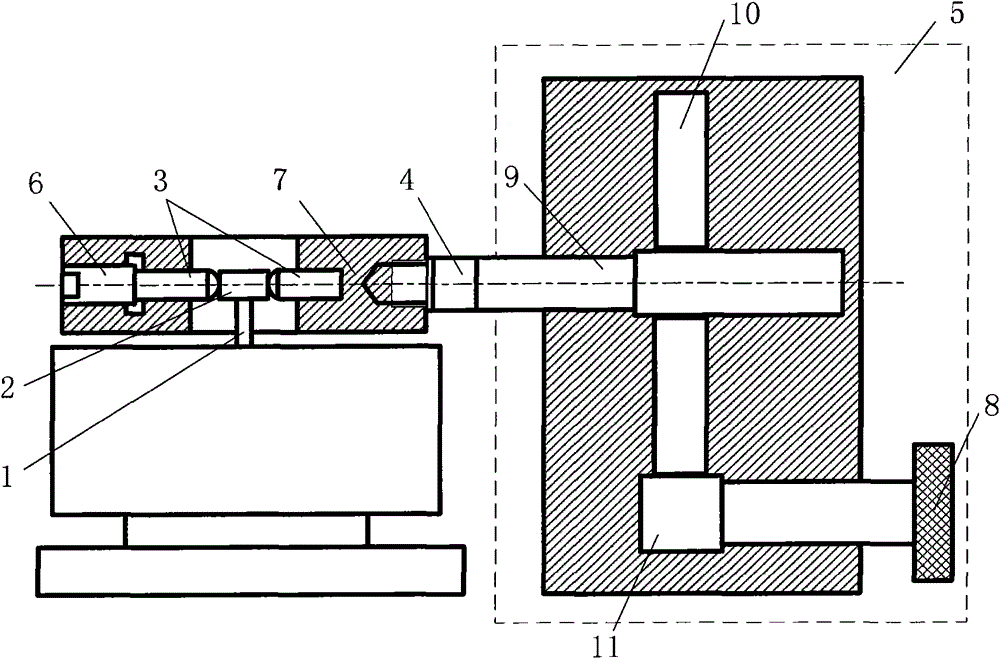

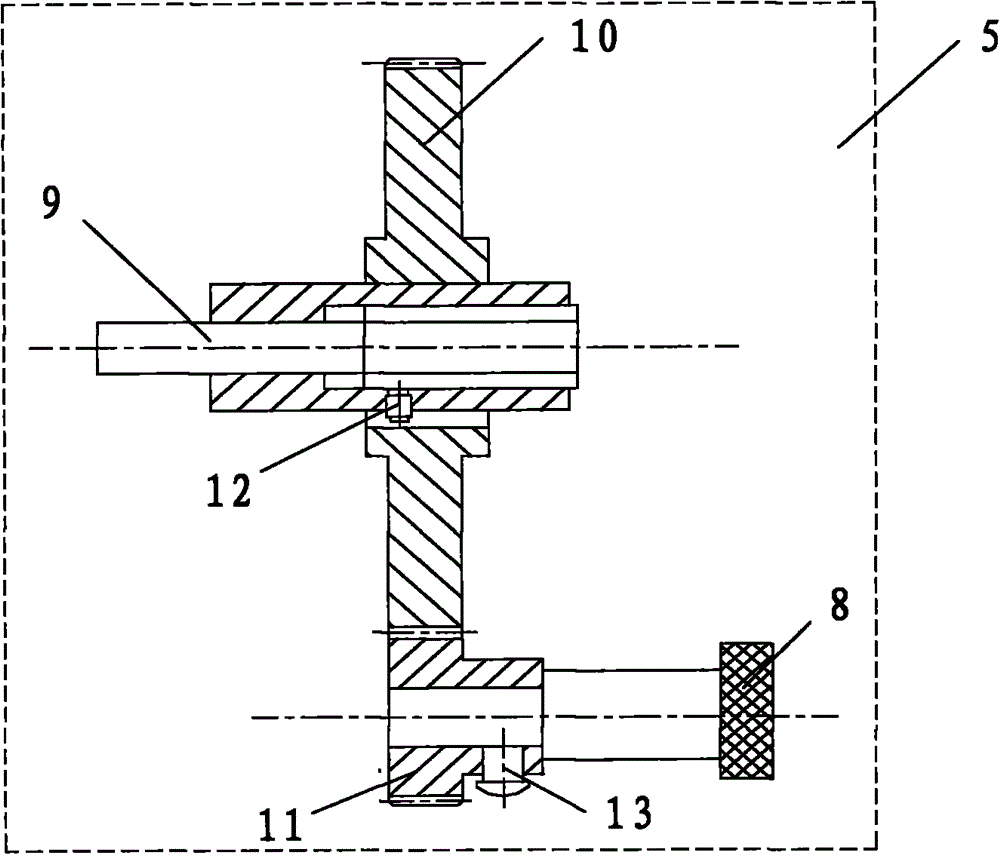

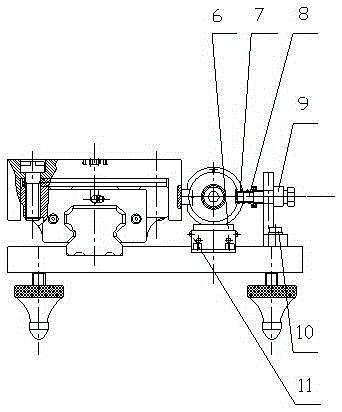

Zero adjusting device for magnetic performance parameter test of torque motor

ActiveCN104568450AMeet the needs of fine-tuningZero adjustment is preciseEngine testingMicrometerTorque motor

The invention provides a zero adjusting device for a magnetic performance parameter test of a torque motor. The zero adjusting device comprises a measuring bar (2), chucks (3), a micro force sensor (4), an inching mechanism (5) and an adjusting screw (6), wherein the measuring bar (2) is rigidly connected with a to-be-zeroed component in the torque motor (1); the measuring bar (2) is inserted between the chucks (3); the chucks (3) are arranged on a chuck installation base (7); the left sides of the chucks (3) can be manually adjusted through the adjusting screw (6); one end of the micro force sensor (4) is fixed on the chuck installation base (7) through threads, and the other end of the micro force sensor (4) is connected with the inching mechanism (5). Fine tuning of the micro mechanism (5) is realized through cooperation of a hand wheel (8), a micrometer screw (9), a big gear (10) and a pinion (11); the two ends of the measuring bar (2) are in point contact with the chucks (3). The zero adjusting device can be used for meeting fine-tuning needs, realizing minimization of zero adjusting errors, and guaranteeing zero adjusting accuracy.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +2

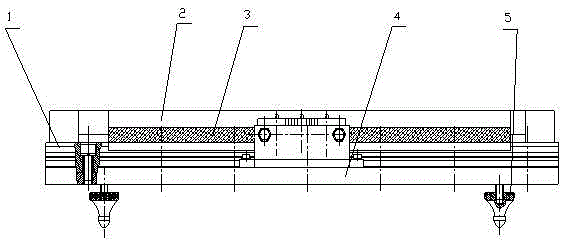

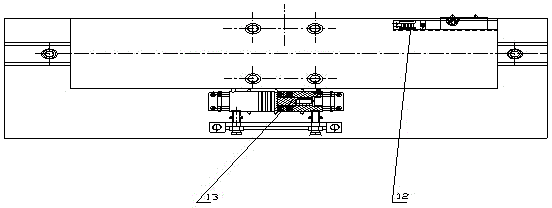

Ultrasonic high-precision linear displacement device

The invention discloses an ultrasonic high-precision linear displacement device, relating to a precision mechanical platform device. The device comprises a guide rail, a workbench, a ceramic wear-resistant coating, a base, pins, a range finder, a vibrator base, a bolt pre-tightening mechanism, a self-locking nut, a pre-tightening mechanism base fixing nut, a vibrator base fixing nut, a linear micro sliding table and a vibrator; the single-sided double-leg longitudinal flexural vibrator drives the workbench, and piezoelectric ceramic plates are arranged inside the vibrator; the guide rail (1), the vibrator base (7) and the bolt pre-tightening mechanism (8) are arranged on the base (4); the workbench (2) is arranged on the guide rail (1), the linear micro sliding table (12) is arranged on the workbench, and the vibrator (13) is arranged on the side of the workbench (2). The device excites ultrasonic vibration by utilizing the inverse piezoelectric effect of piezoelectric ceramic, amplifies resonance by means of an elastomer, generates linear motion through friction coupling to directly drive the workbench, and realizes nano precision through a laminated piezoelectric element linear micro mechanism on the workbench.

Owner:SHENYANG UNIV

Method for preparing three-dimensional micro-configuration of unidimensional nanometer material

InactiveCN1731279AEasy to operateMature and reliable technologyPhotomechanical apparatusScreening processesScreen printingCasting mold

The invention relates to a method for preparing three-space micro mechanism of a one-space nanometer material in the field of nanometer technology, which comprises: preparing for the base chip: doing preprocessing to the base chip; steel micro electric molding: forming the photoresist micro casting mold of the mental electrode structure with the needed structure and the displacement characters on the processed base chip, and cladding the mental material on the micro casting mold to form the mental micro mechanism; silk-screen printing one-space nanometer material paste: preparing one-space nanometer material paste and adopting silk-screen printing method to coat the one-space nanometer material paste on the side wall and the surface of the steel micro mechanism; micro mechanism solid shaping: extracting the organics of the one-space nanometer material micro mechanism to stable the nanometer material structure by heating and heat preservation process.

Owner:SHANGHAI JIAO TONG UNIV

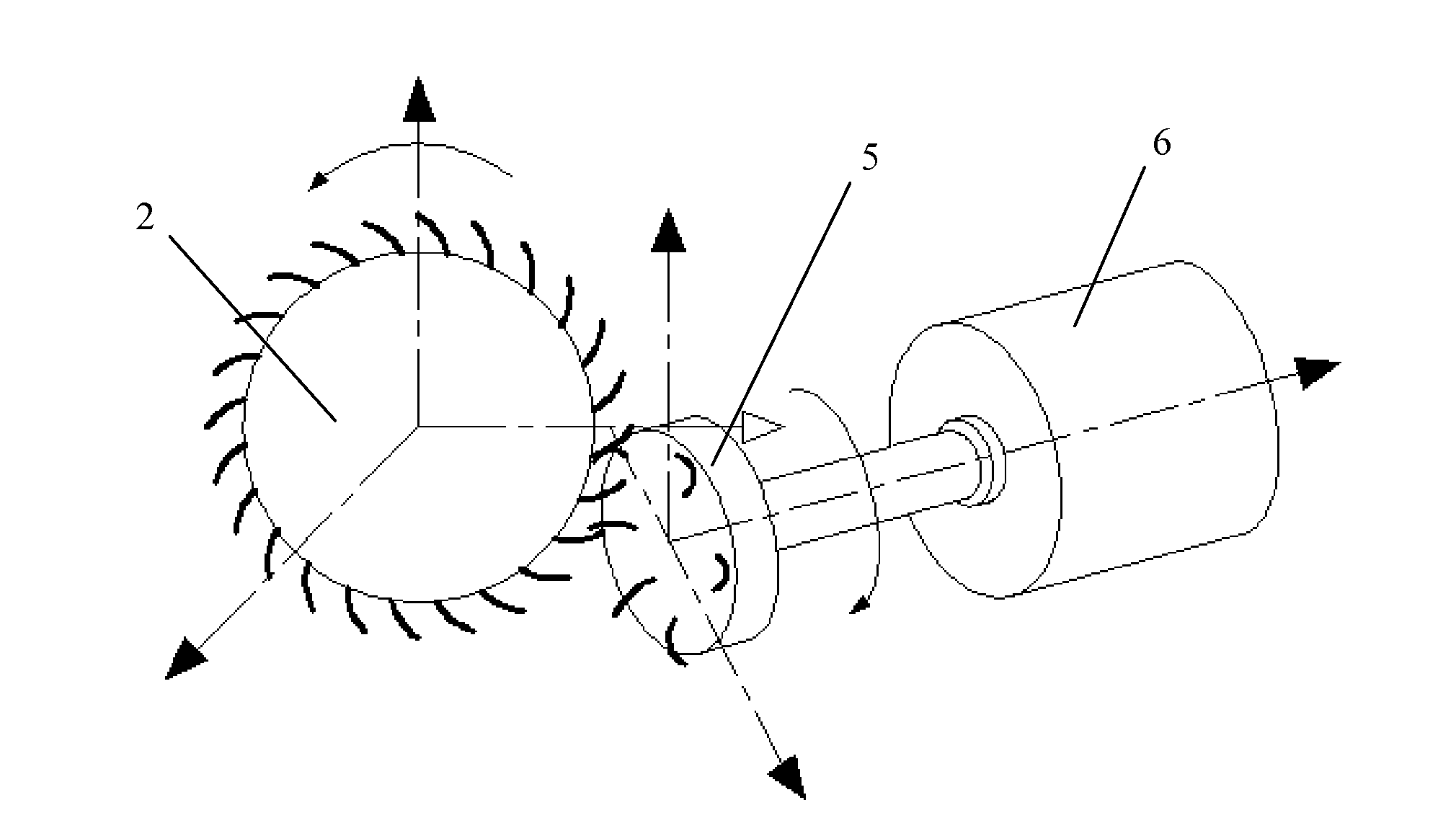

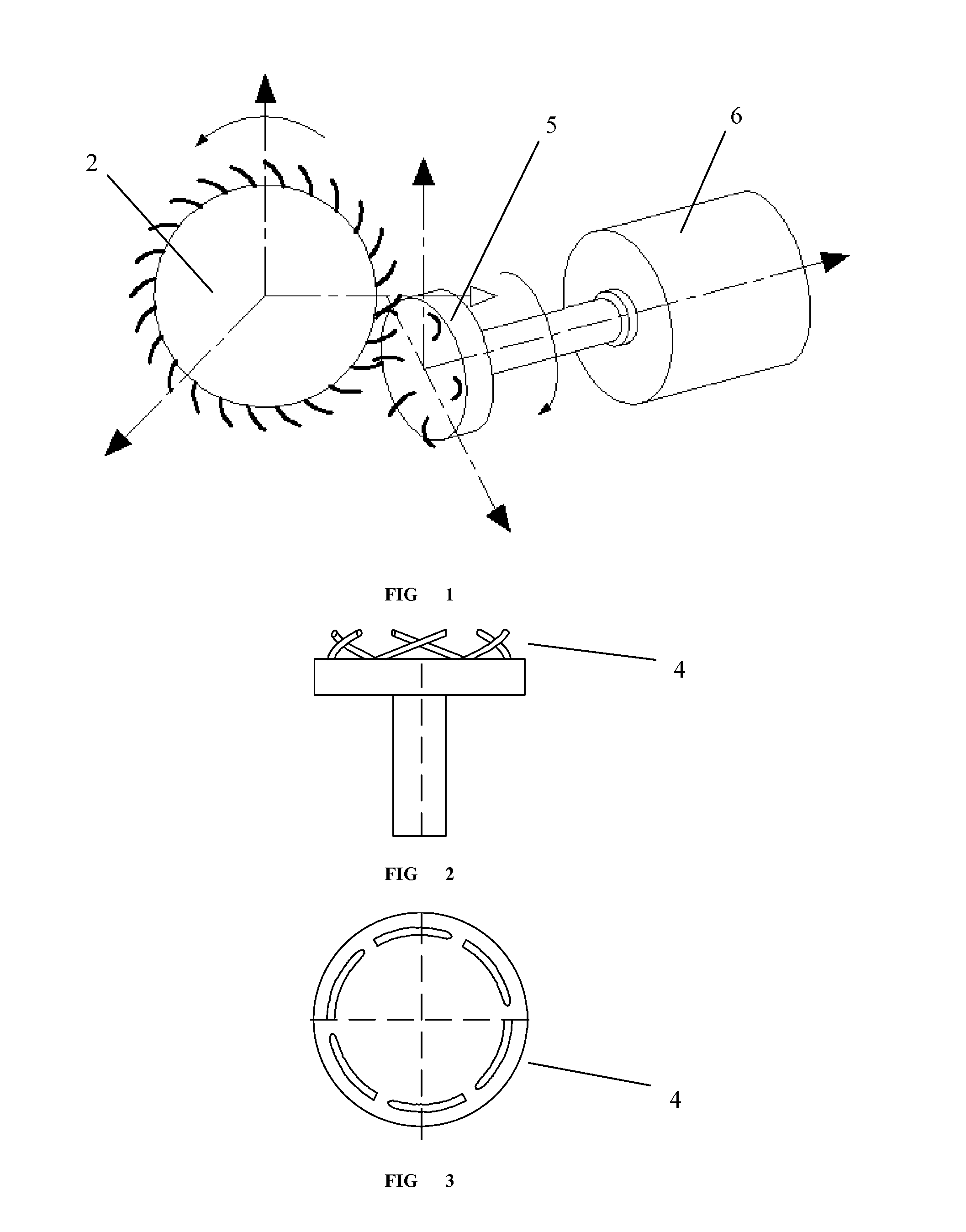

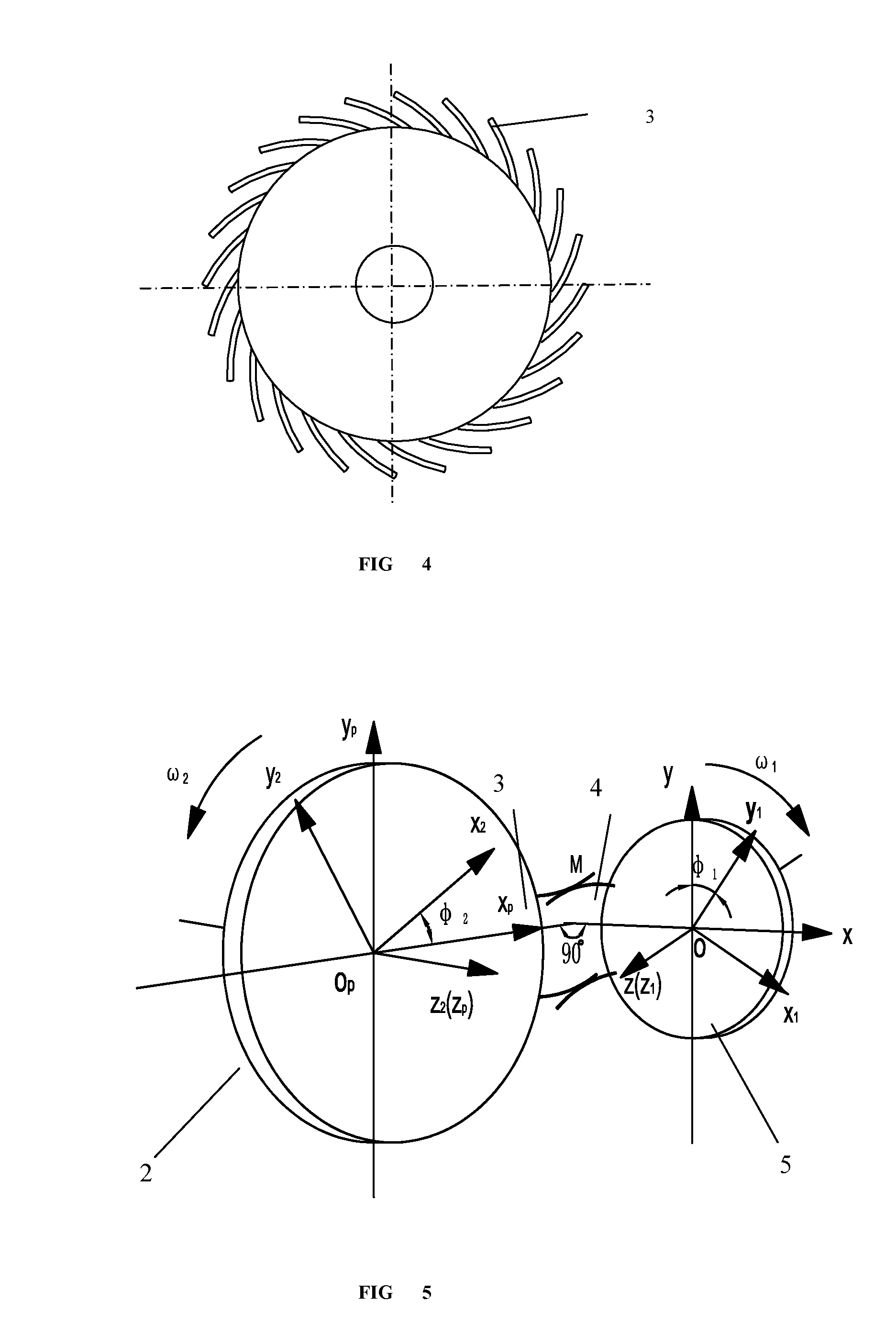

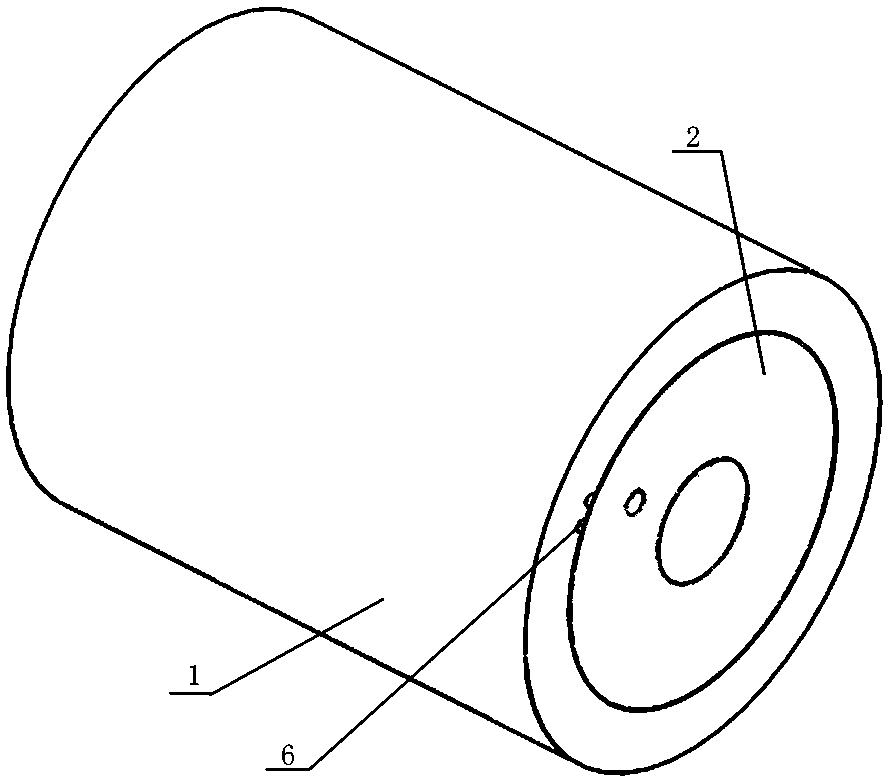

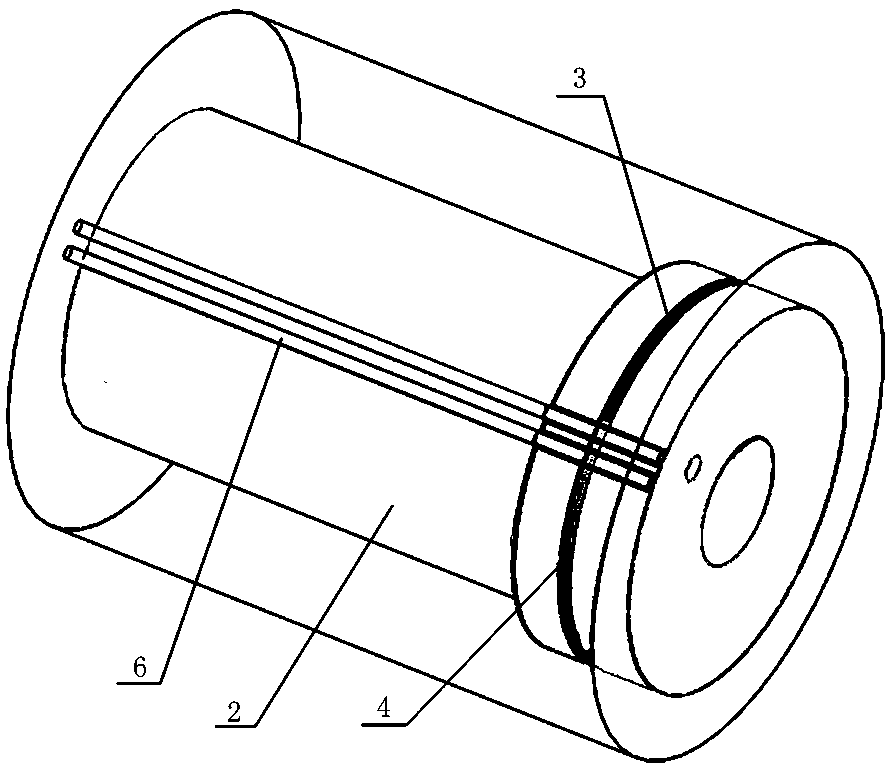

Space curve mesh driving pair and polyhedral space curve mesh transmission

ActiveUS20130145876A1Improve efficiencyImprove manufacturabilityToothed gearingsMovable microstructural devicesDrive wheelEngineering

A space curve mesh driving pair and a polyhedral space curve mesh transmission are disclosed. Said space curve mesh driving pair consists of a driving wheel and a driven wheel. Axes of the driving wheel and the driven wheel are intersected at an angle of 0°˜180°, and power transmission is realized by continuous mesh between the driving tines and the driven tines; a number of driving tines are provided on said driving wheel, and a number of driven tines are provided on the driven wheel; the driving tines are uniformly arranged on an end face of a cylinder of the driving wheel, and the driven tines are uniformly arranged on the circumference of a cylindrical surface of the driven wheel. Said polyhedral space curve mesh transmission consists of an above-mentioned space curve mesh driving pair. Motion is input from an input end, and is passed through a number of pace curve mesh driving pairs to realize the speed change, then is output from one or more output ends. Wherein, the space curve mesh driving pair is the core of the transmission. The invention has the advantages of compact structure, small size, light weight, stable transmission and flexible operation, and can be widely used in micro-mechanism field.

Owner:SOUTH CHINA UNIV OF TECH

A micro rotating mechanism based on shape memory alloy

PendingCN109217733ARealize rotary driveNo working noiseThermal electric motorShape-memory alloyAlloy

The invention discloses a micro rotating mechanism based on shape memory alloy, consisting mainly of a fixed sleeve and a rotating shaft, characterized in that: A first wire and a second wire are respectively arranged on the outer surface of the rotating shaft along the circumferential direction, The first end of the first wire material and the first end of the second wire material are fixed on the rotating shaft respectively and the distance between the two fixing points is less than 5% of the circumference of the rotating shaft. The first wire material and the second wire material are respectively rotated around the rotating shaft backward and led out and fixed through a fixing sleeve so that the first wire material and the second wire material are in a pulled state. The first wire is ashape memory alloy wire working in a shape memory state, and the second wire is a shape memory alloy wire in a superelastic state; A constant current power supply is connected between the two ends ofthe first wire. The invention is suitable for completing small-range rotation in narrow space, and can be applied to medical operation, micro-mechanism control and the like. Easy to control the specific position of the rotation, and no operating noise.

Owner:苏州微加测试仪器有限公司

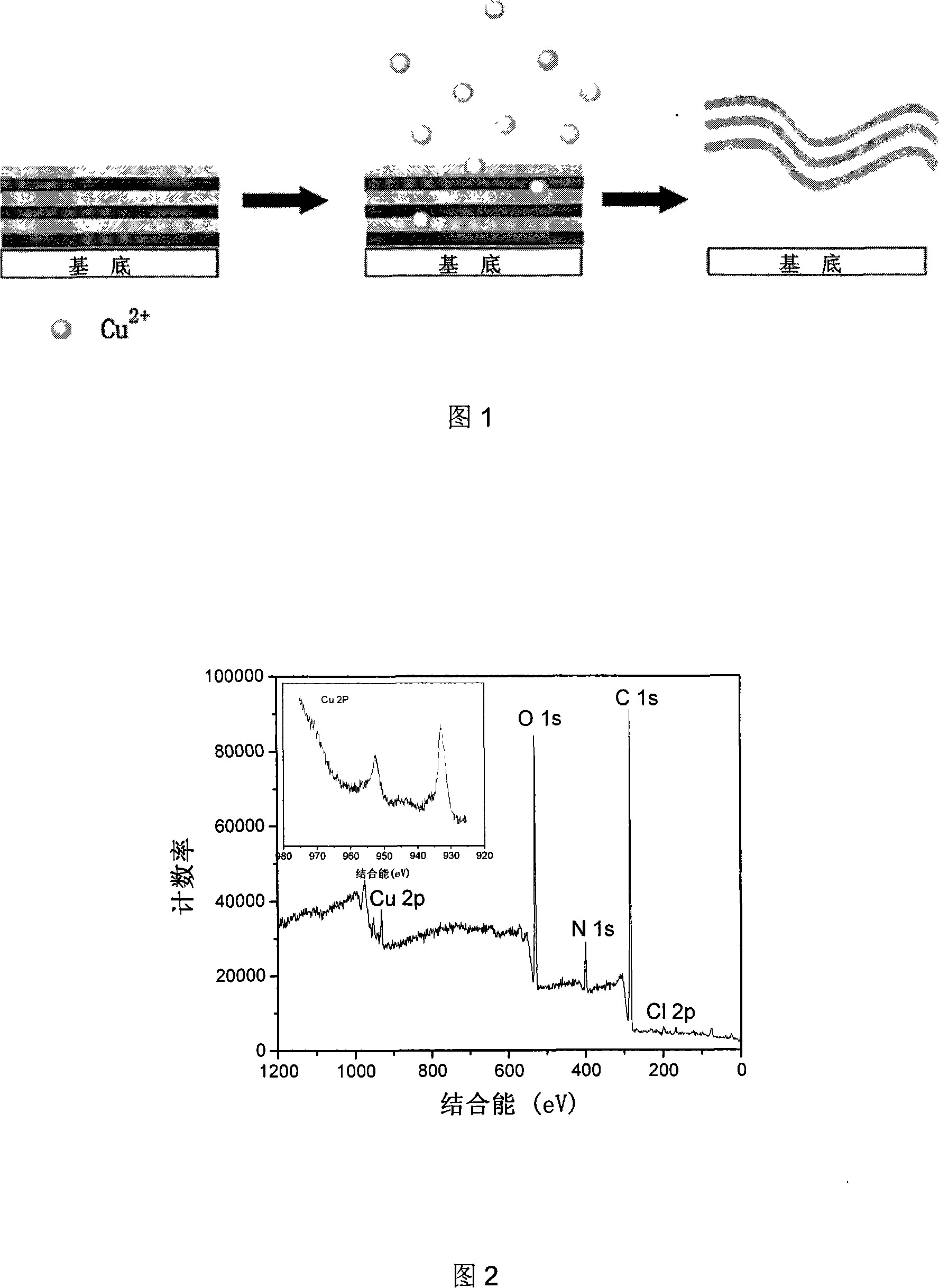

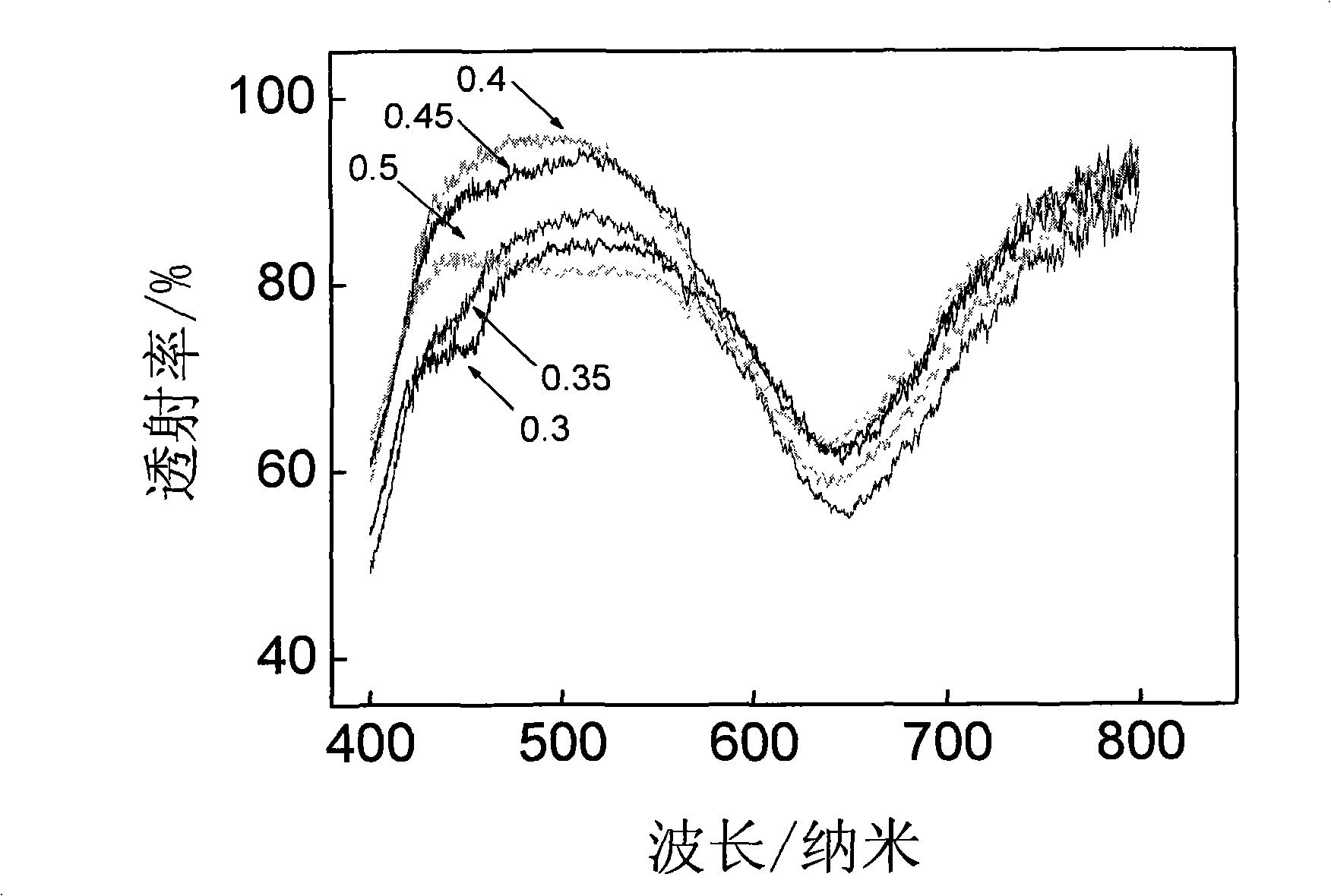

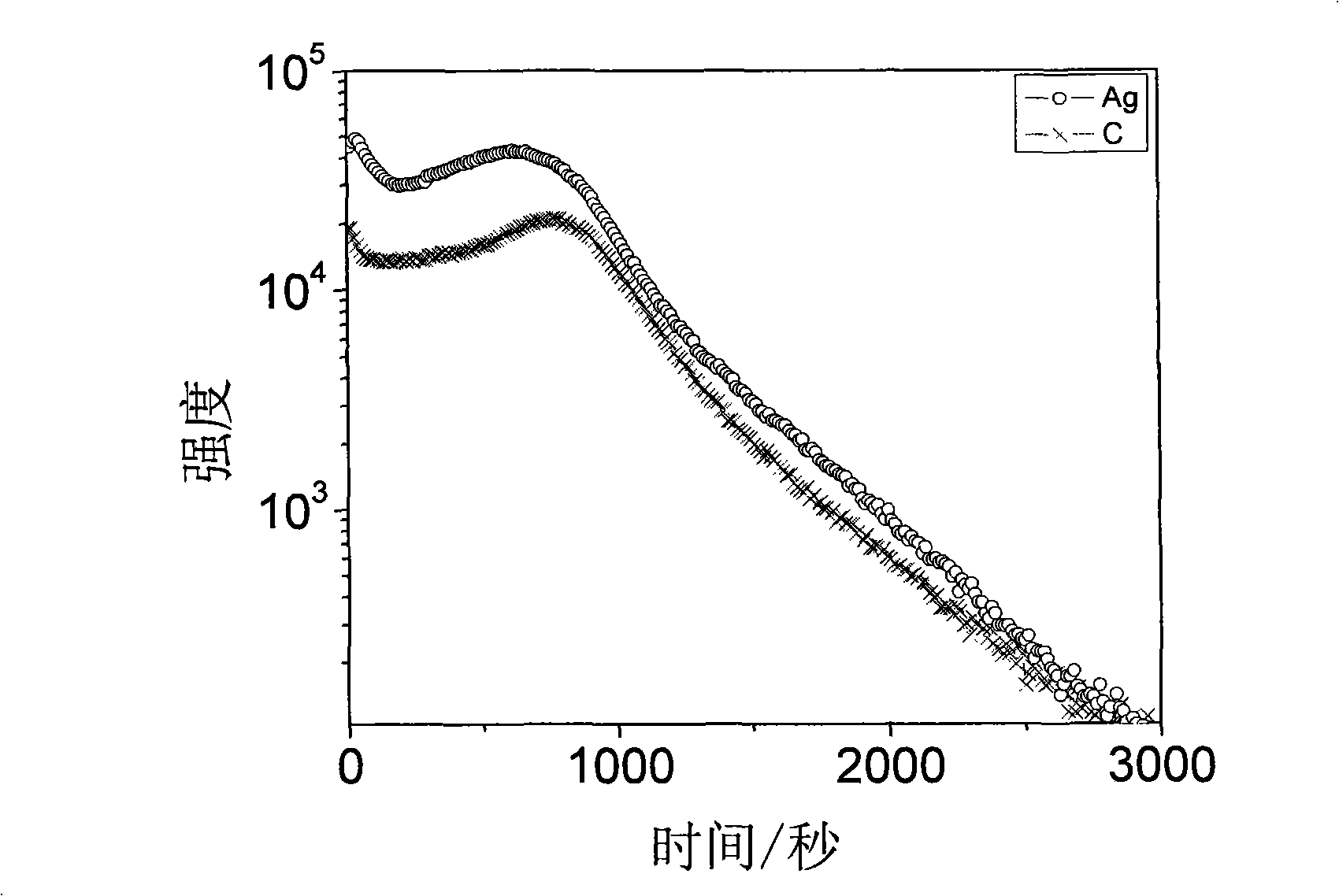

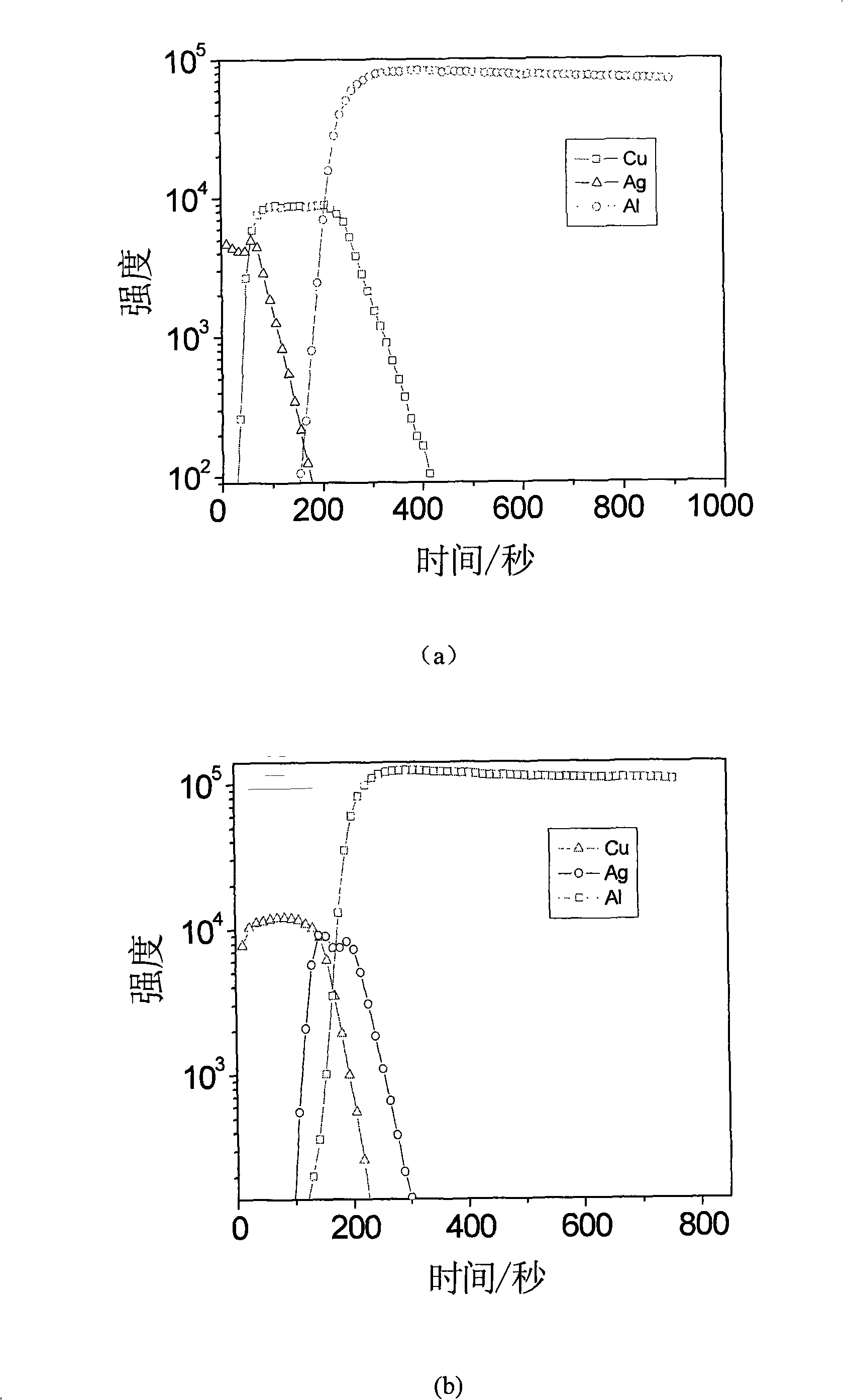

Method for characterizing metal organic double layer thin film mass transfer microcosmic mechanism

InactiveCN101261239AAccurate representationSimple processParticle separator tubesMaterial analysis by electric/magnetic meansMicro mechanismMass transfer

The invention belongs to the technical field of film mass transferring characterization, particularly relating to a method for characterizing the micro mechanism of the mass transferring of a metal organic double-layer film, which is characterized in that the micro mechanism of the metal organic multi-layer film system is obtained by using a heterogeneous element as a mark and analyzing the element distribution of the metal organic multi-layer film system by SMS after the mass transformation is finished. The method can effectively research the micro mechanism of the mass transformation in the process of complexation of metal organics, thus having important scientific values.

Owner:FUDAN UNIV

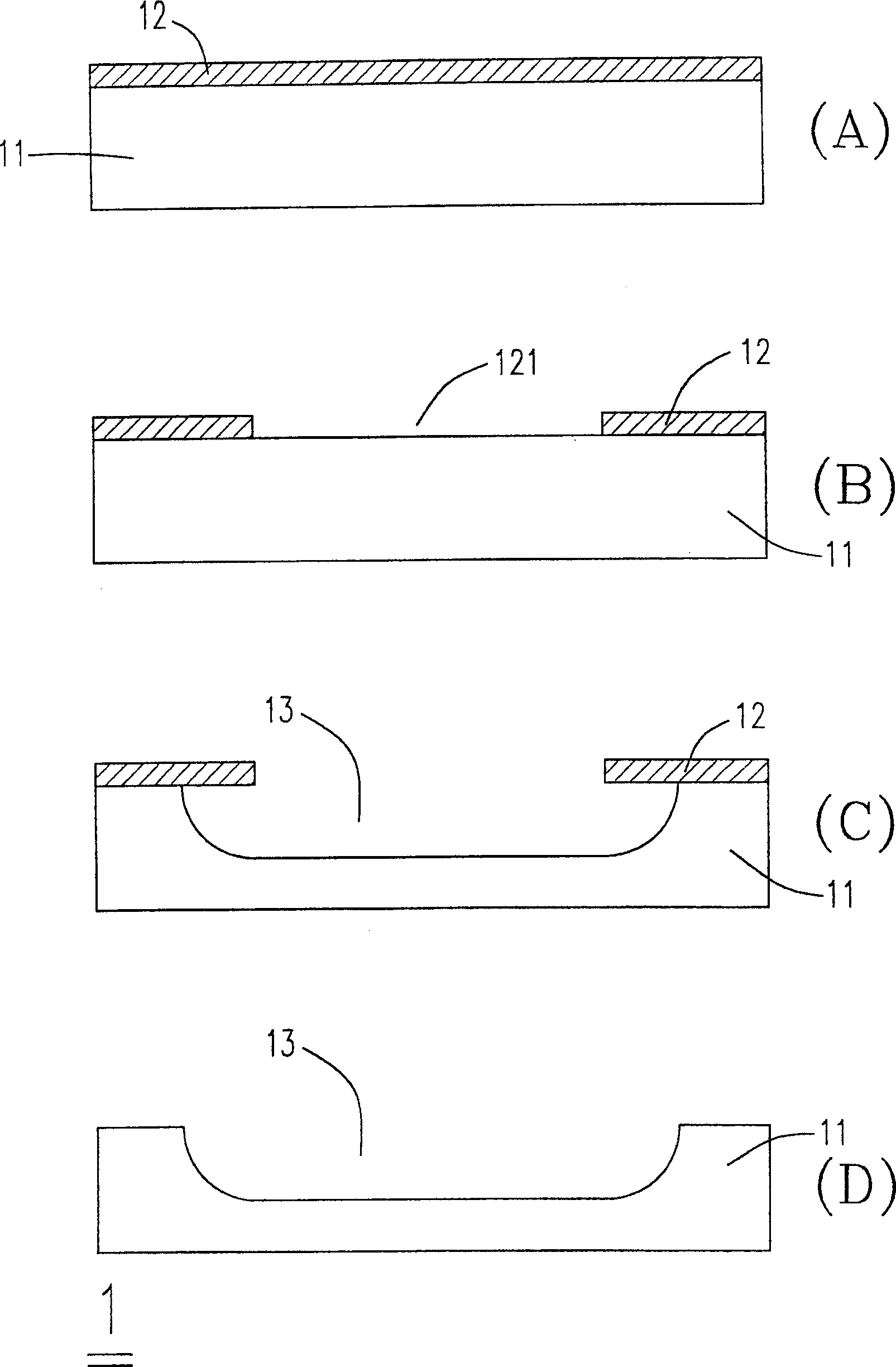

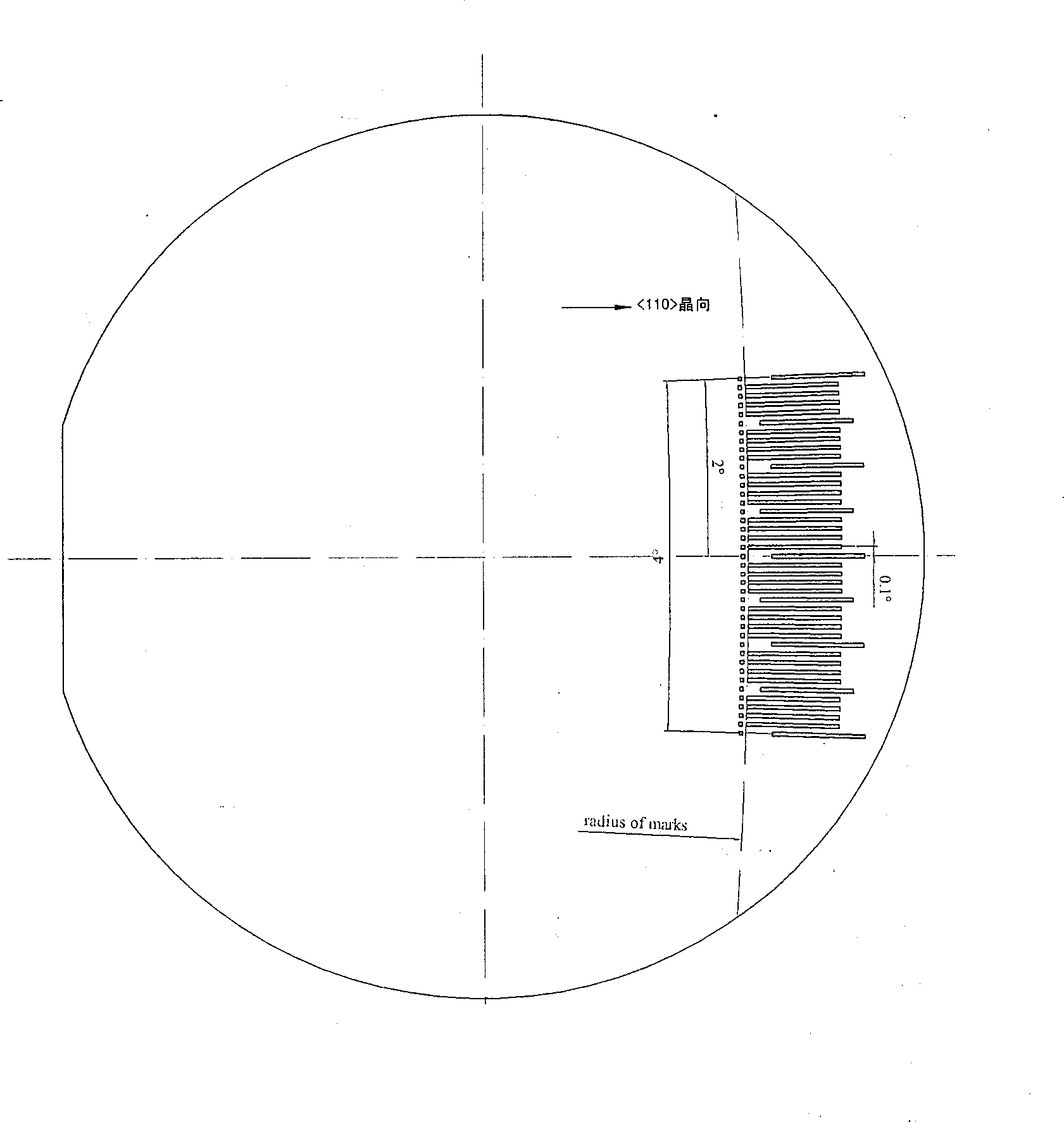

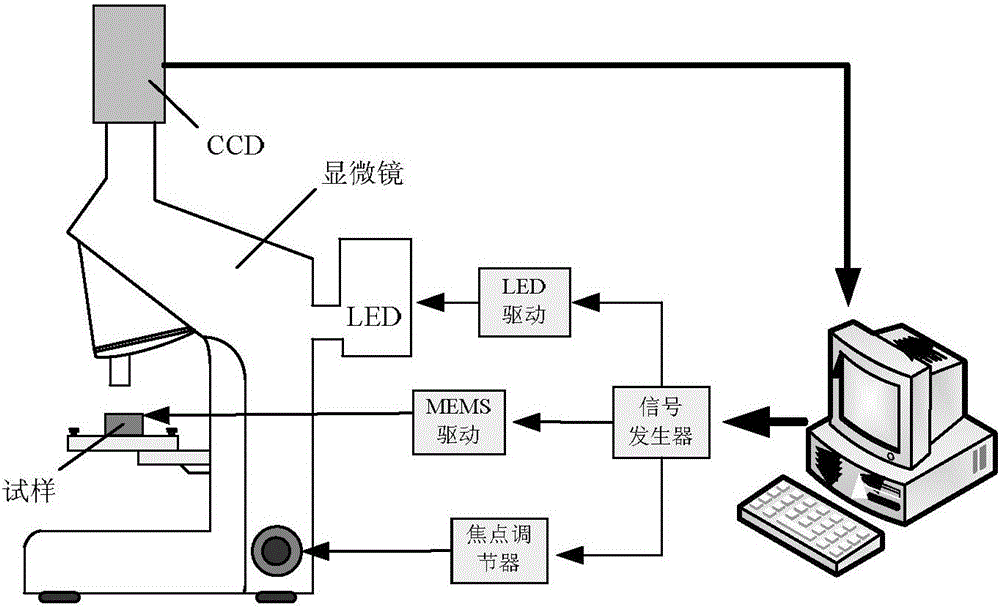

Monocrystalline silicon wafer crystal orientation calibrating method

InactiveCN1345085AMeet processing requirementsImprove machining accuracySemiconductor/solid-state device testing/measurementPhotomechanical apparatusCrystal orientationReference patterns

The invention relates to a method to calibrate crystal orientation of mono-crystalline silicon wafer used in area of micro mechanism and microelectronics. The crystal orientation of wafer is clearly exposed by means of claborate reference patterns and following pre-etching process. The error calibrating the crystal orientation of wafer is controlled within plus or minus 0.1 degree, by observing the etching results formed from different reference patterns. With the etching results being processed further by using digital image processing technique, the calibrating accuracy can be improved to plus or minus 0.05 degree or even higher.

Owner:XI AN JIAOTONG UNIV

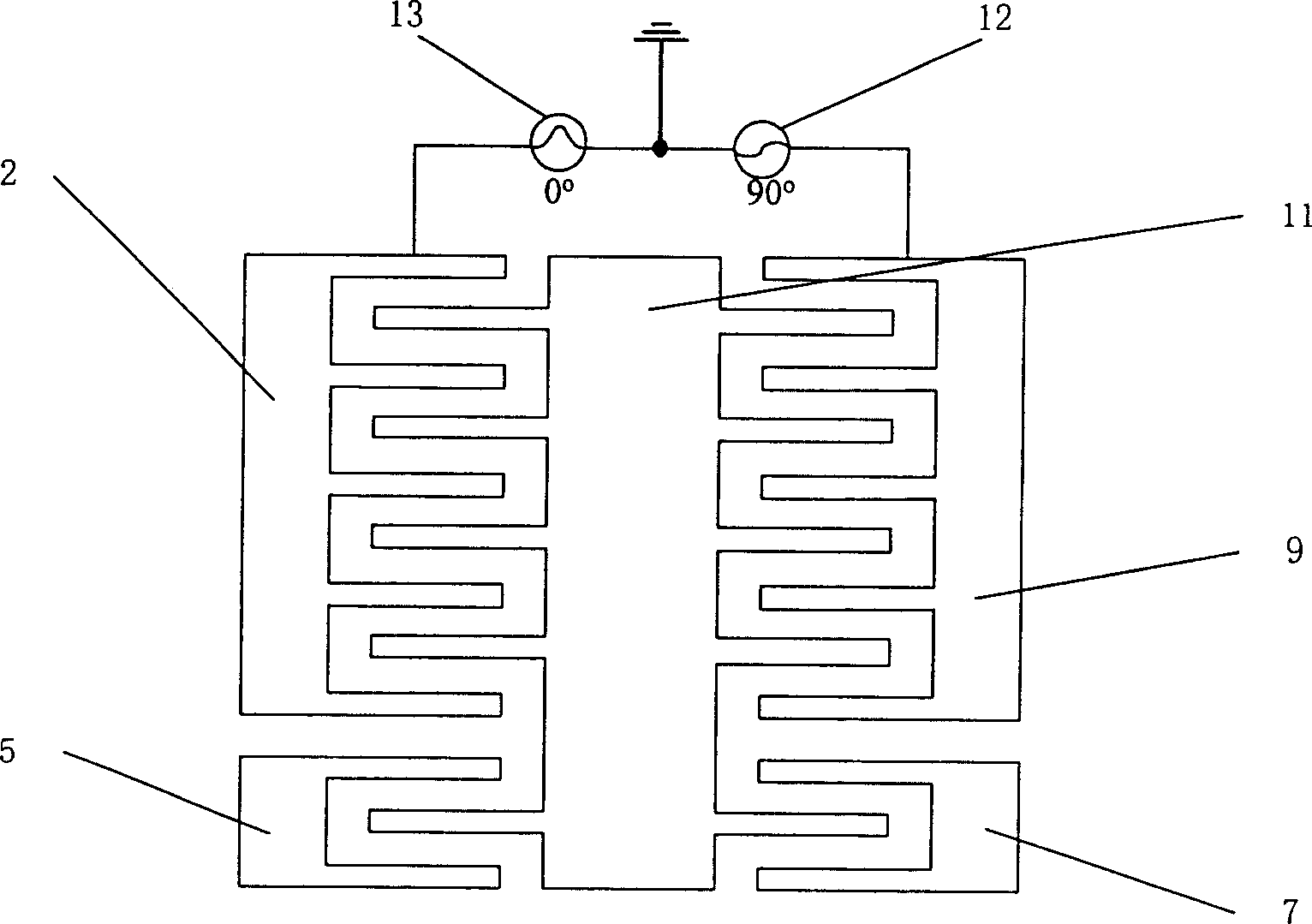

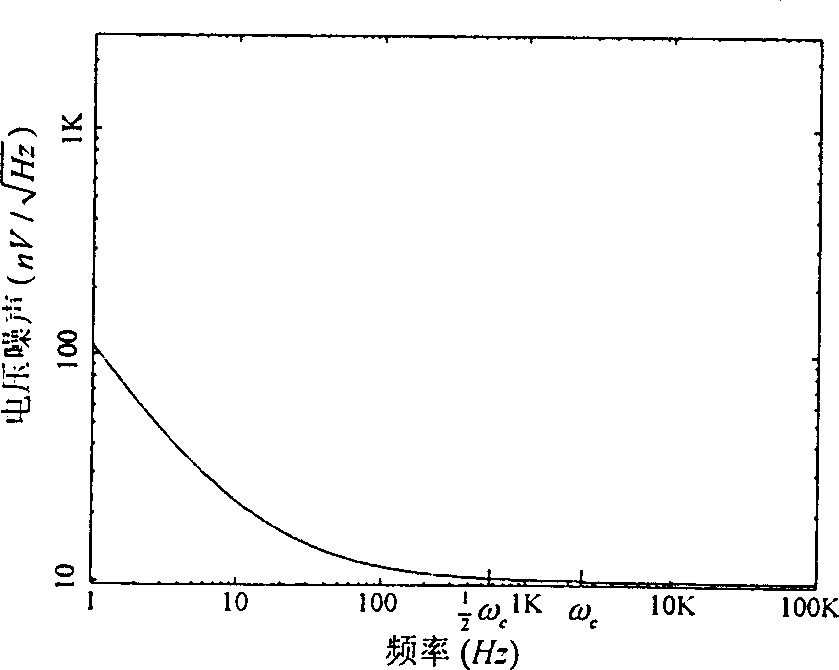

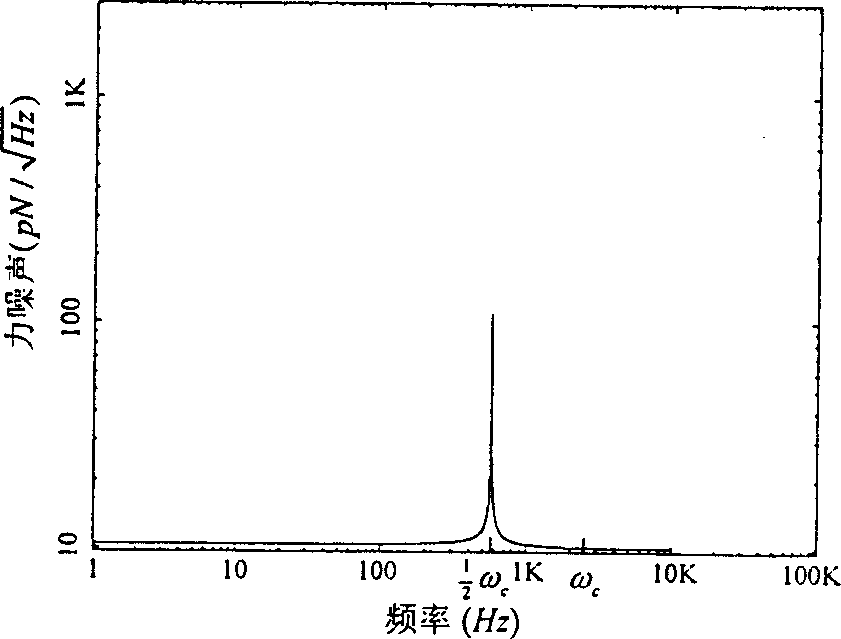

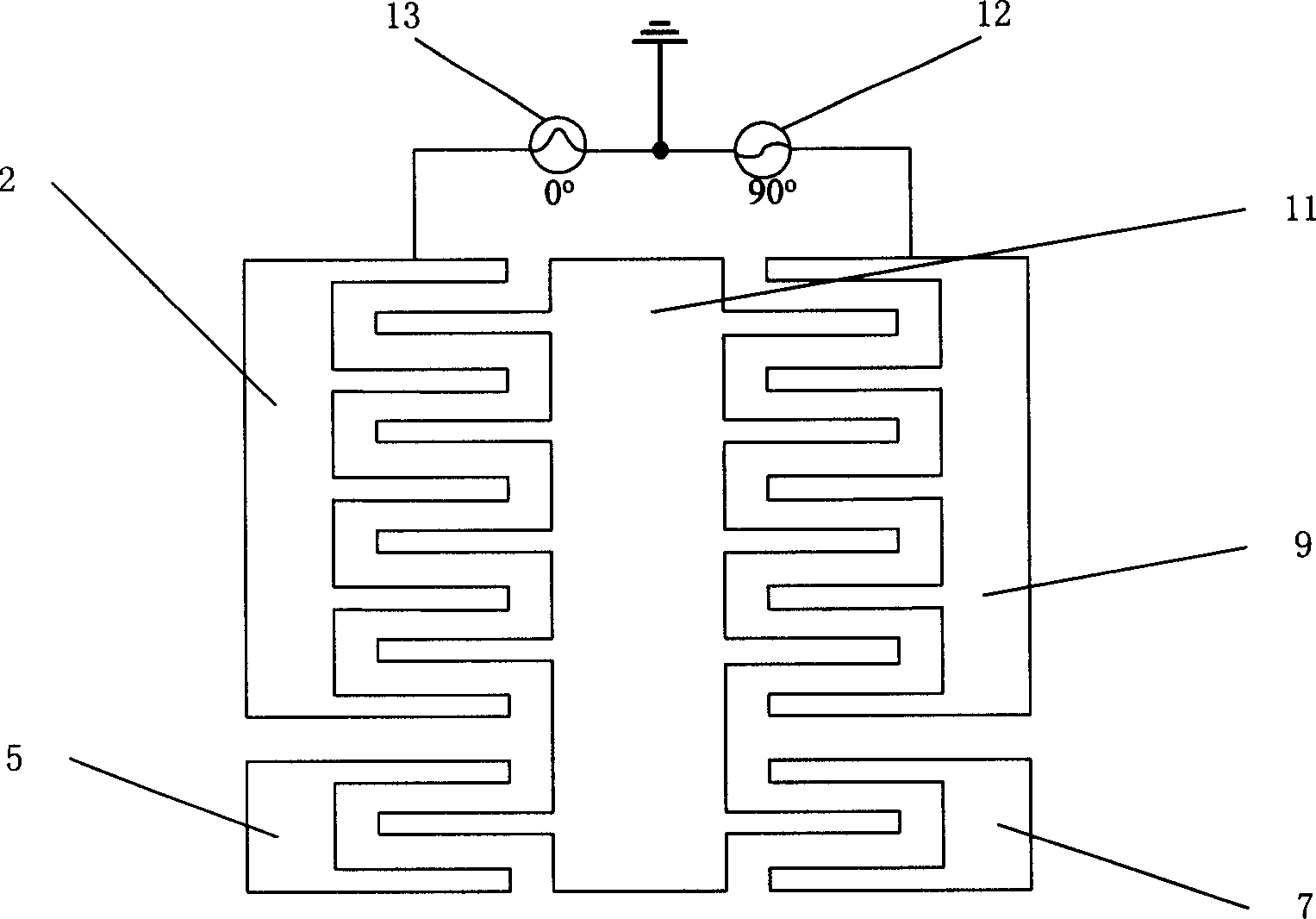

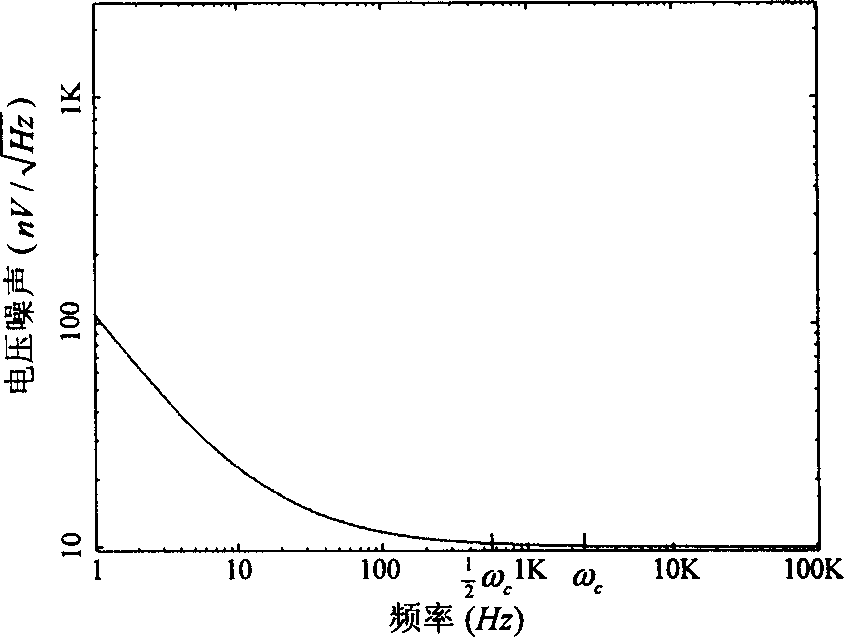

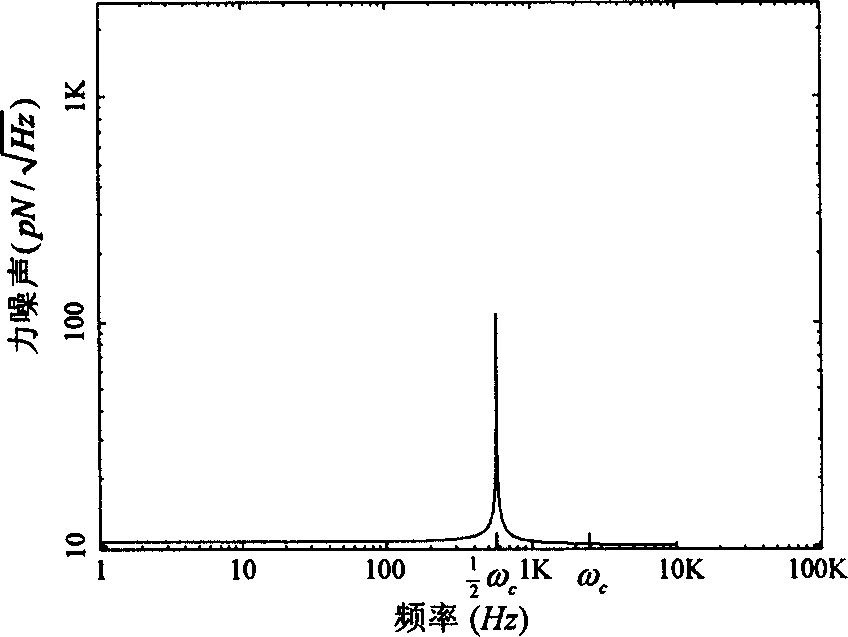

Semi-frequency driving and loop closing method for micro mechanic sensor

InactiveCN1299427CImprove driving precisionReduce noiseElectrostatic generators/motorsElectricityLoop control

The half-band driving and closed loop method for micro mechanism sensor. For overcoming the effects of electrical coupling and 1 / f noise, this invention opens the half-band driving method for micro mechanism sensor, the feature is: at the two drive pole of static differential diver, adds two way pure alternating voltage to dive it, and the above statement two way voltage have 90 degree discrepancy, its frequency is the half of the mover vibration frequency. This method can eliminate the electrical coupling from the driving voltage to the sensor, can reduce effects of 1 / f noise introduce from driving voltage, and for this method utilizes approximate way in small scale to eliminate the effects of non-linear from voltage to electrical static force, implements closed loop control.

Owner:TSINGHUA UNIV

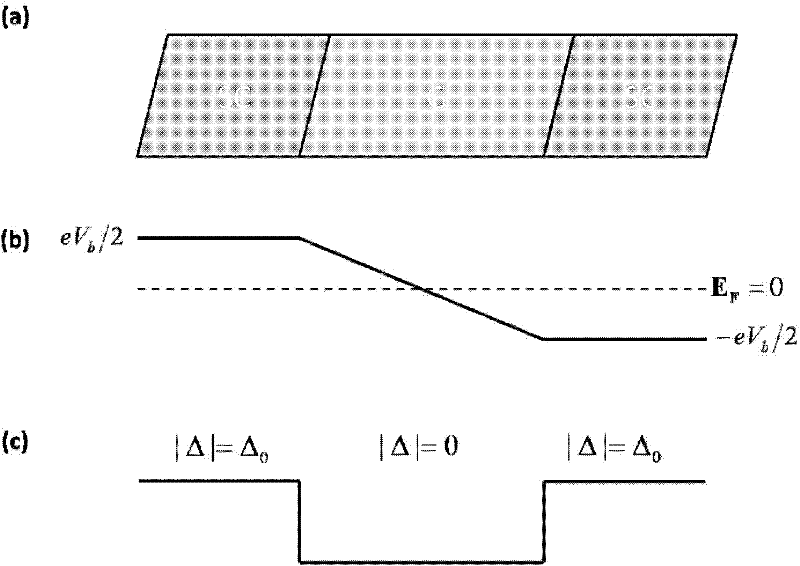

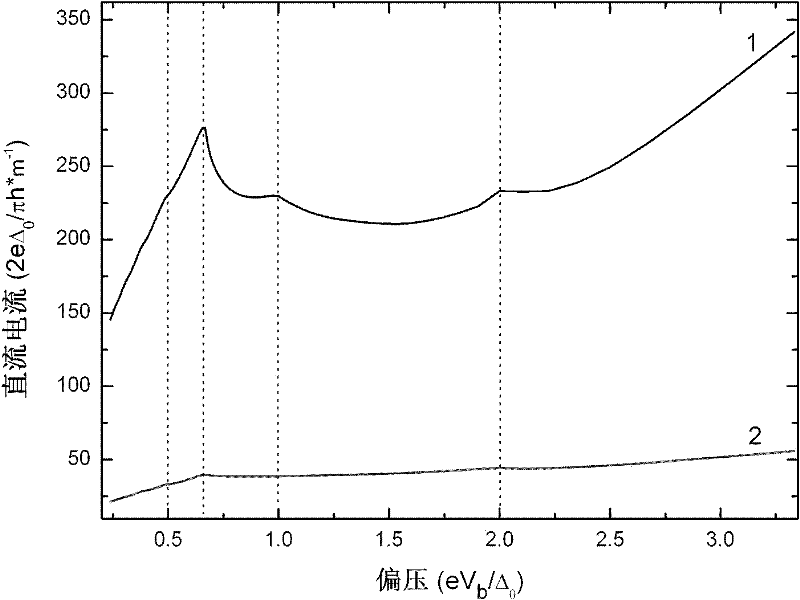

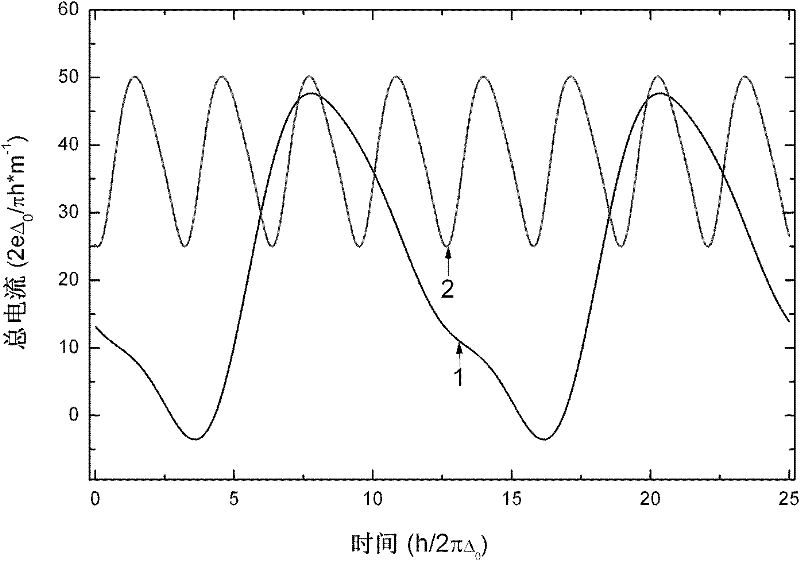

Method for optimizing negative differential conduction phenomenon in superconductor-graphene heterojunction

InactiveCN102393862AEasy to calculateImprove current characteristicsSuperconductor device manufacture/treatmentSpecial data processing applicationsHeterojunctionAlternating current

The invention discloses a method for optimizing a negative differential conduction phenomenon in a superconductor-graphene heterojunction. The method comprises the following steps: firstly, drawing up a dirac equation in a Josephson junction and discretizing a Hamiltonian along a spreading direction; utilizing a Floquet theorem to unfold an alternating current effect generated by a bias in the junction in a form of a non-equilibrium Green function; utilizing self-energy items at two ends to solve Green functions at the two ends, thereby solving the Green function in a transmission area; respectively solving a direct current item and an alternating current item according to a current formula; and finally, adjusting grid voltage distribution according to requirements and optimizing the negative differential conduction phenomenon and current amplitude. The Green function has an advantage in treating a micro mechanism, so that interactions between electrons and phonons and between electrons and electrons are easily considered.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Building wall coating layer additive grinding equipment

ActiveCN113042165AWell mixedImprove filtering effectTransportation and packagingRotary stirring mixersStructural engineeringMicro mechanism

The invention discloses building wall coating layer additive grinding equipment. The building wall coating layer additive grinding equipment comprises a base, a vertical plate is fixedly arranged at the right end of the top of the base, and a top plate is fixedly arranged at the top of the vertical plate. According to the building wall coating layer additive grinding equipment, in the additive grinding process, large block-shaped additives and small block-shaped additives can be mixed together to be smashed and evenly mixed at the same time, in this way, after the large block-shaped additives are smashed, follow-up grinding is easier, and therefore the overall grinding efficiency of the additives can be improved; a micro mechanism is arranged, so that a mixture is conveniently discharged and ground downwards during grinding, the grinding efficiency is further ensured, and a grinding gap at the grinding body is easier to discharge and grind downwards during grinding; and meanwhile, various additives can be conveniently and uniformly mixed in the smashing process, and finally, the working efficiency during overall grinding is greatly improved.

Owner:德伊福颜料科技(泰兴)有限公司

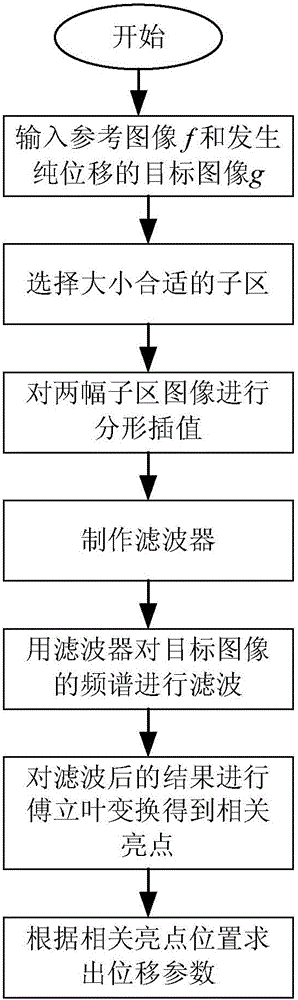

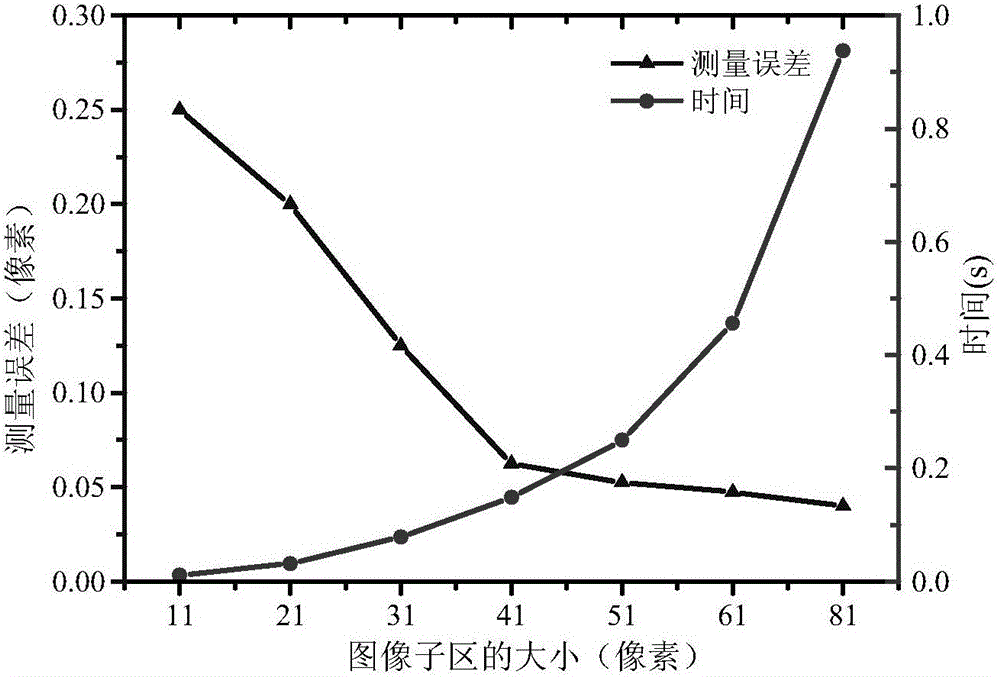

MEMS in-plane displacement measurement method correlated with mixed fractal interpolation and frequency-domain digital speckle

InactiveCN105043270AHigh precisionReduce measurement impactUsing optical meansFrequency spectrumPhase time

The invention provides an MEMS microstructure plane displacement measurement method based on correlated technologies of mixed fractal interpolation and frequency-domain digital speckle, and relates to the field of image frequency-domain correlated technologies and MEMS dynamic measurement. The method comprises the steps that MEMS microstructure motion speckle image f (zero-phase time) and g (a phase time) are acquired; appropriate sizes of a reference sub-region and a target sub-region are selected; fractal interpolation processing is carried out on two sub-region images; reference sub-region image Fourier conversion adjoint is used as a matching filter; an acquired filter is used to filter the frequency spectrum of the target sub-region; Fourier conversion is carried out on a result acquired through filtering again, so as to acquire a correlated highlight; and a displacement parameter is acquired according to the position of the correlated highlight. The defects of large calculating quantity and insufficient measurement resolution of a traditional method are overcome. Fast and high-precision measurement of MEMS micro mechanism plane motion displacement can be realized.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Semi-frequency driving and loop closing method for micro mechanic sensor

InactiveCN1490926AImprove driving precisionReduce noiseElectrostatic generators/motorsElectricityLoop closing

The half-band driving and closed loop method for micro mechanism sensor. For overcoming the effects of electrical coupling and 1 / f noise, this invention opens the half-band driving method for micro mechanism sensor, the feature is: at the two drive pole of static differential diver, adds two way pure alternating voltage to dive it, and the above statement two way voltage have 90íÒdiscrepancy, its frequency is the half of the mover vibration frequency. This method can eliminate the electrical coupling from the driving voltage to the sensor, can reduce effects of 1 / f noise introduce from driving voltage, and for this method utilizes approximate way in small scale to eliminate the effects of non-linear from voltage to electrical static force, implements closed loop control.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com