MEMS in-plane displacement measurement method correlated with mixed fractal interpolation and frequency-domain digital speckle

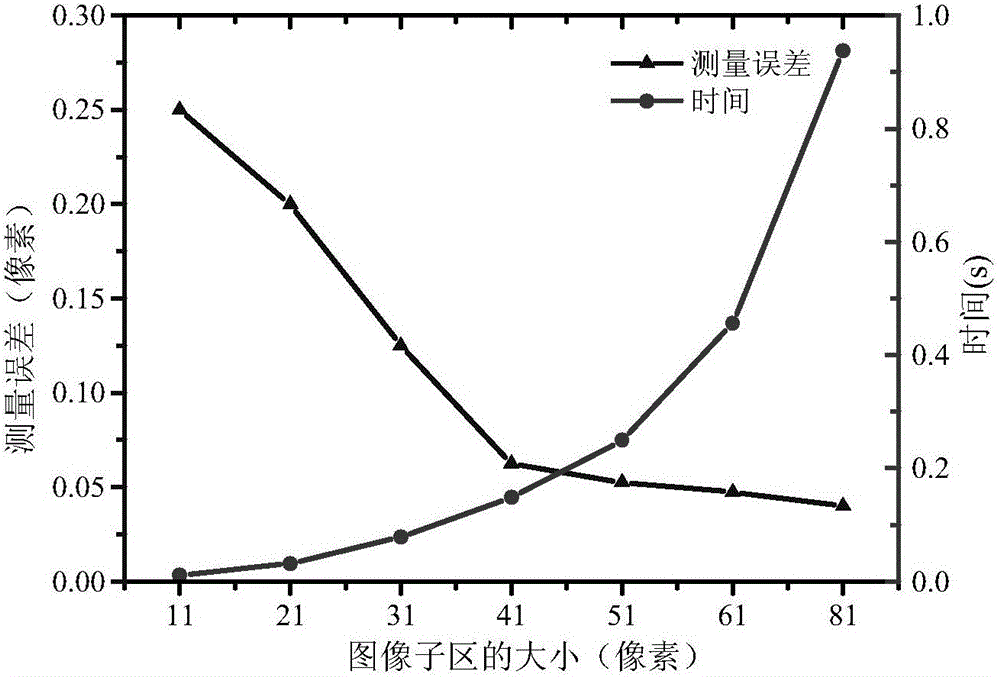

A frequency-domain digital speckle and fractal interpolation technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of large measurement errors, large calculations, and low calculation efficiency, so as to improve test accuracy and repeated search. , the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

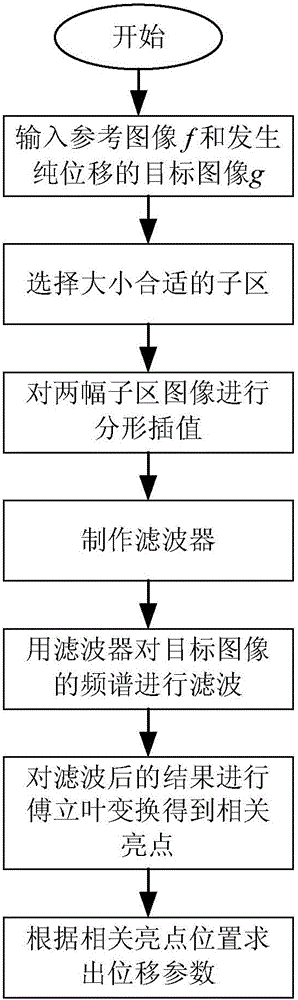

[0041] Below in conjunction with accompanying drawing, the present invention will be further described:

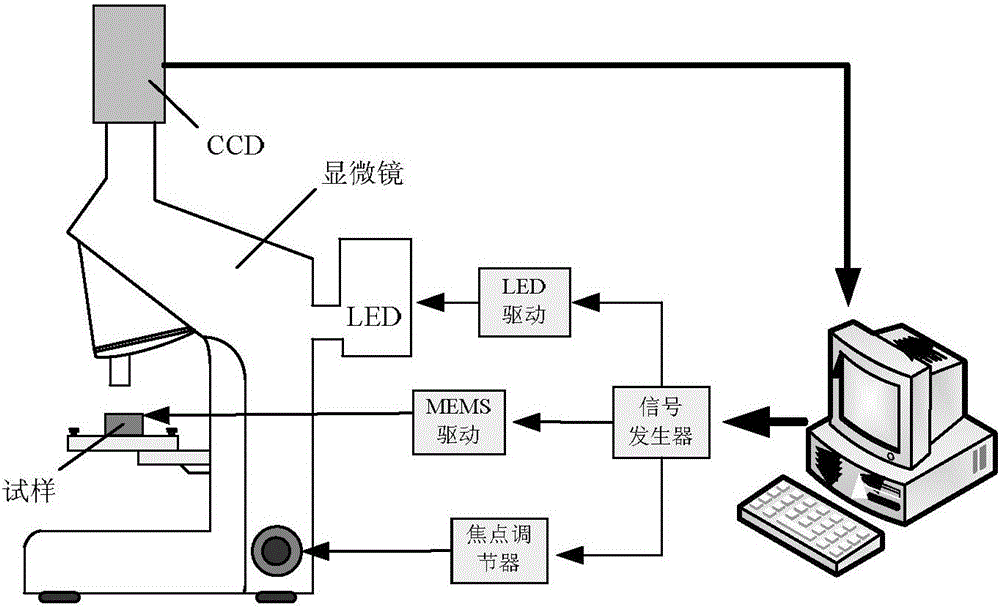

[0042] First, based on the micro-visual stroboscopic system, artificial spraying speckle is used to obtain the moving image of the MEMS microstructure, and its sub-regions f (MEMS microstructure image at zero phase time) and g (MEMS microstructure moving image at a certain phase), and There is only a simple pure translation relationship between them, namely

[0043] g(x,y)=f(x+u,y+v)(1)

[0044] The relative translation size between images f and g is denoted by (u, v).

[0045] Then, the fractal interpolation processing based on the random midpoint is performed on the two sub-region images, and the random midpoint displacement method can use a simple formula to represent the interpolation point (x mi ,y mi )

[0046] x mi =(x i +x i+1 ) / 2+s w rand() (2)

[0047] the y mi =(y i +y i+1 ) / 2+s w rand()

[0048] In formula (2), s and w are parameters controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com